Patents

Literature

347 results about "Voids in mineral aggregate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Voids in Mineral Aggregate or VMA is the intergranular space occupied by asphalt and air in a compacted asphalt mixture. In a component diagram, it is the sum of the volume of air and the volume of effective asphalt. The volume of absorbed asphalt is not considered to be a part of VMA because it is part of the pore structure of the mineral aggregate.

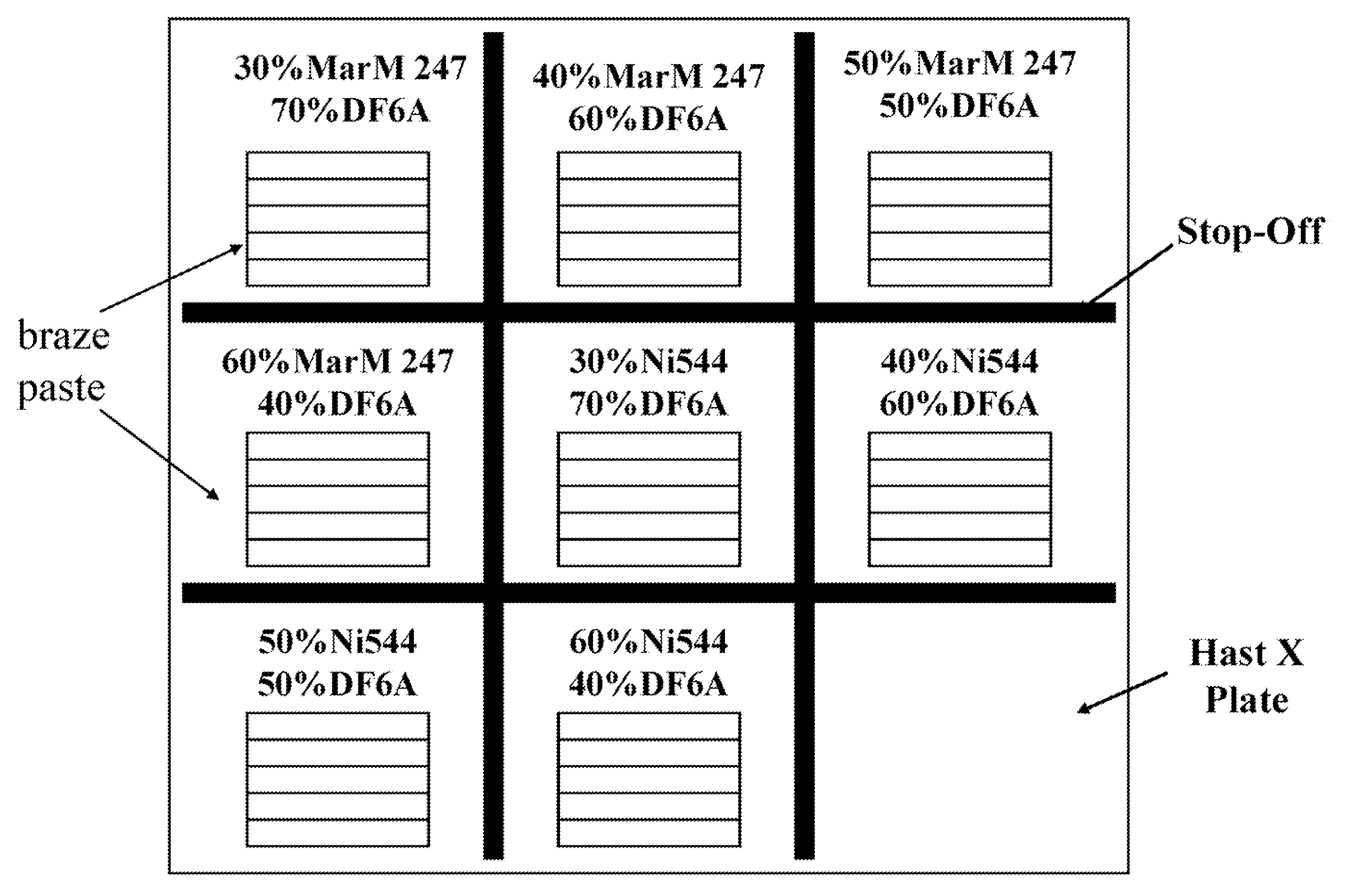

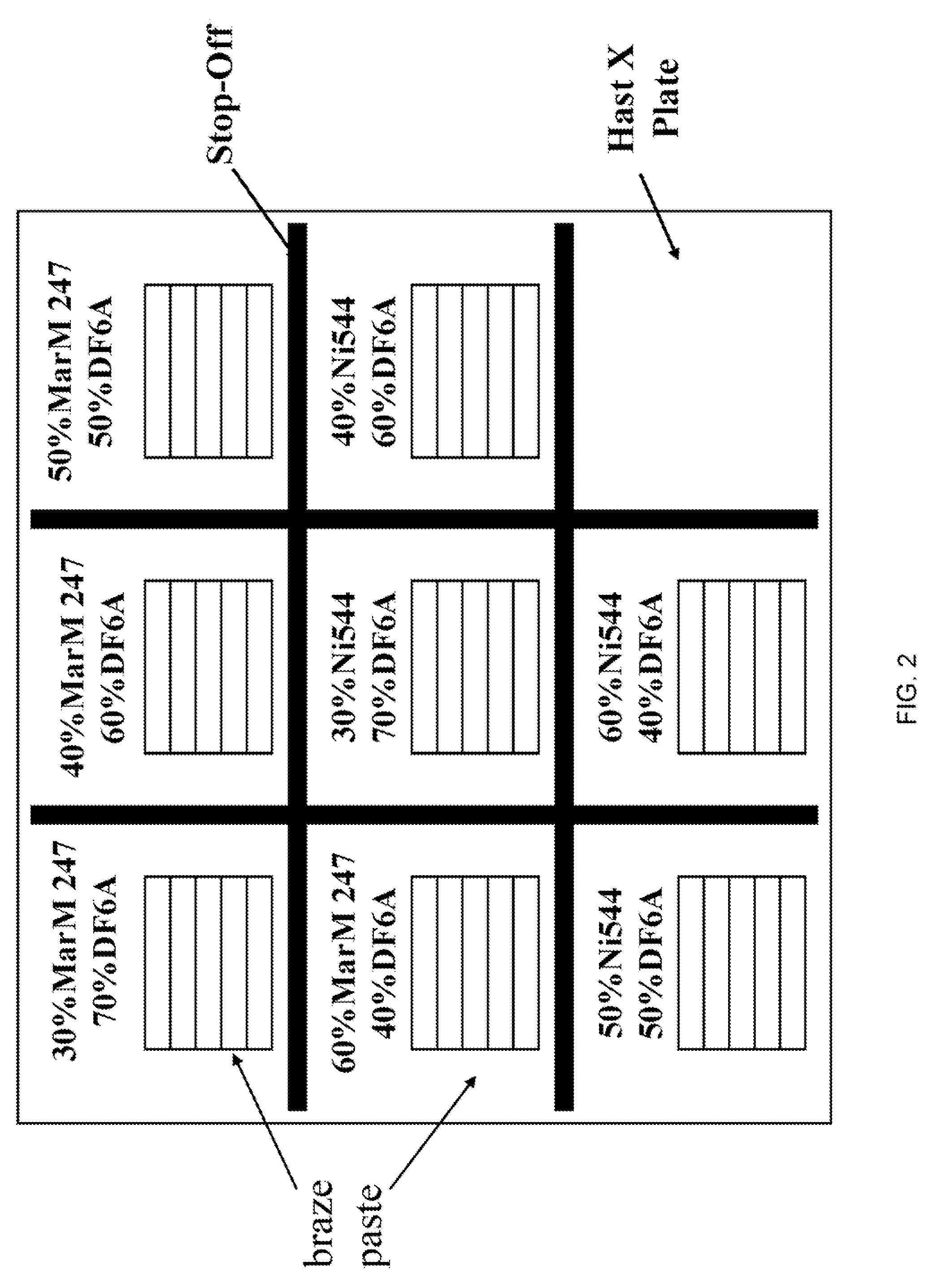

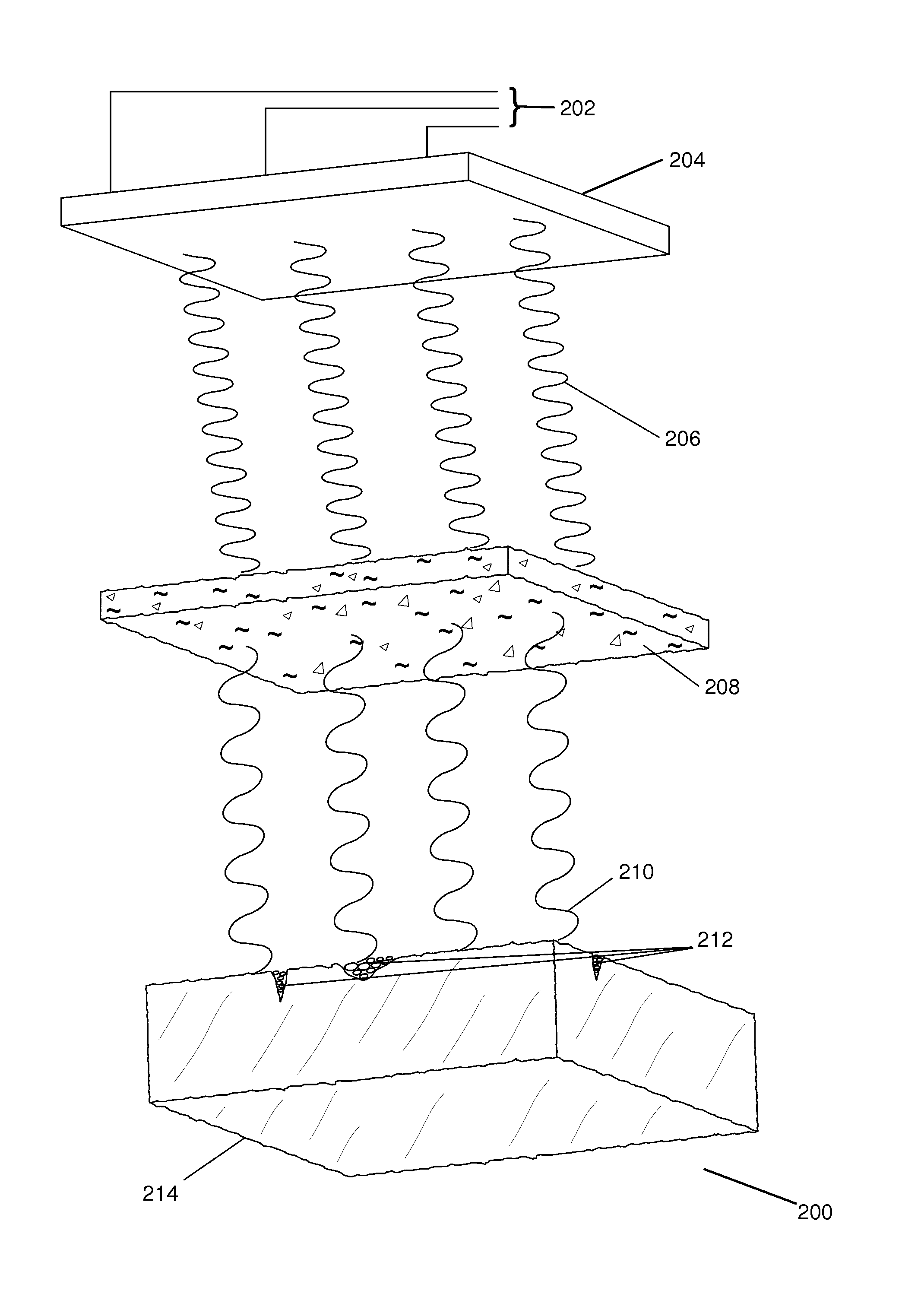

Brazing process and material for repairing a component

A process and braze paste suitable for filling and closing voids in relatively thin wall sections of high temperature components, such as an impingement plate of a combustor of a gas turbine engine. The process entails applying at least a first braze paste to the crack to form a braze paste patch comprising powders of first and second alloys and an organic binder. The first alloy has a higher melting temperature than the second alloy, and the powders of the first and second alloys are present in the braze paste patch at a weight ratio of about 30:70 to about 70:30 weight percent. The braze paste patch is then heated to burn off the binder and melt at least the powder of the second alloy to form a brazement within the crack that contains particles of the first alloy dispersed in a matrix formed by the second alloy.

Owner:GENERAL ELECTRIC CO

Pavement repair system utilizing solid phase autoregenerative cohesion

ActiveUS8992118B2Long and longer useful lifePaving propertyPaving reinforcementsIn situ pavingsOligomerEmulsion

A method for repairing an aged or damaged asphalt pavement is provided. The method involves preparing a surface of the aged or damaged asphalt pavement by filling in deviations from a uniform surface plane with dry aggregate and compacting the dry aggregate; applying a reactive asphalt emulsion to the prepared surface; and passing an emitter over the prepared pavement, wherein the emitter generates electromagnetic radiation having a wavelength of from 2-5 mm that penetrates into the pavement to a depth of at least 2 inches. The asphalt pavement is repaired by disturbing voids and interstices in the damaged pavement without dehydrogenation of the asphalt, such that oligomers present in the aged asphalt are linked together into longer polymer chains to improve ductility of the aged asphalt.

Owner:COE WILLIAM B

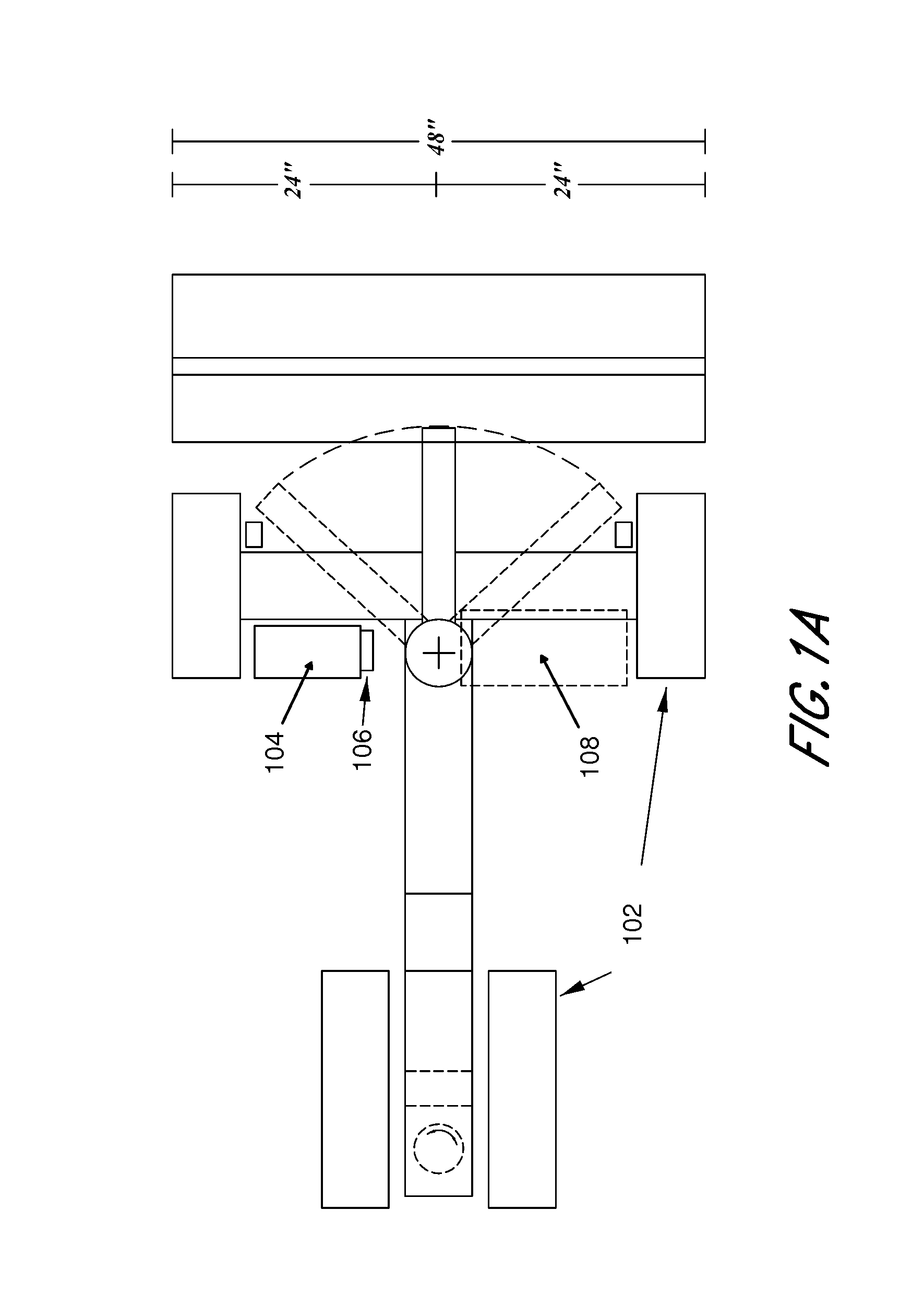

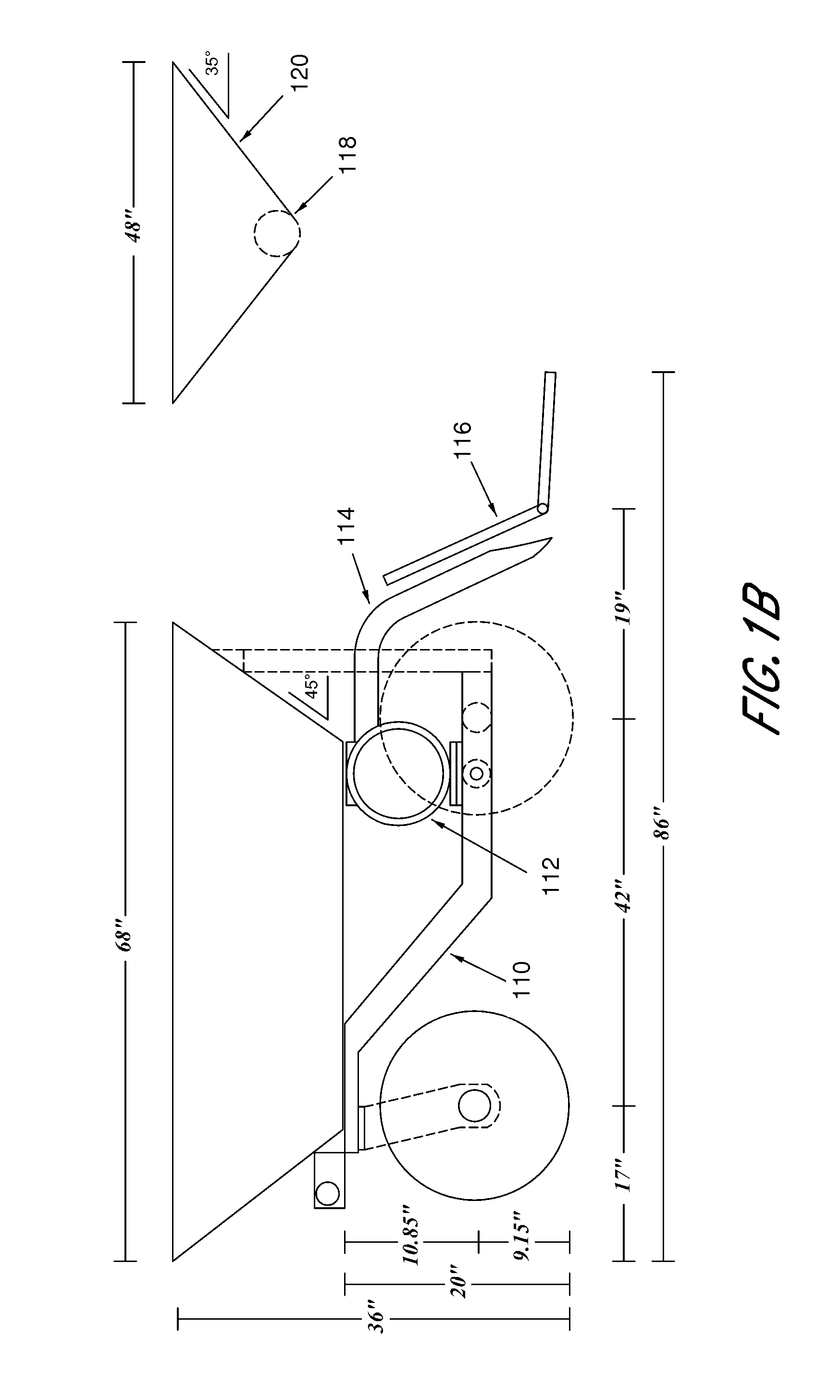

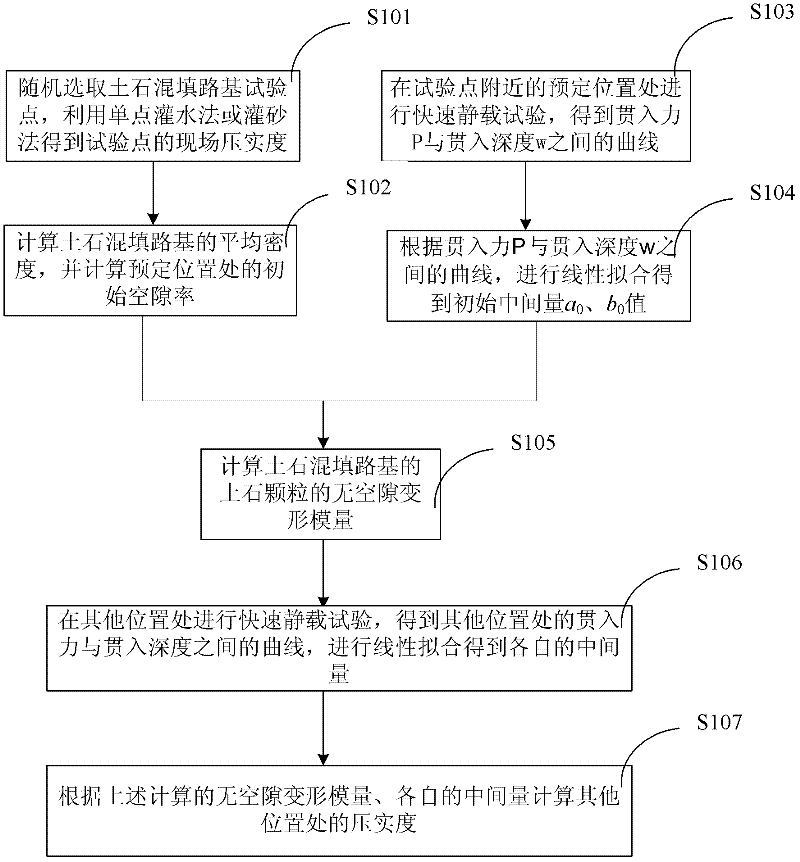

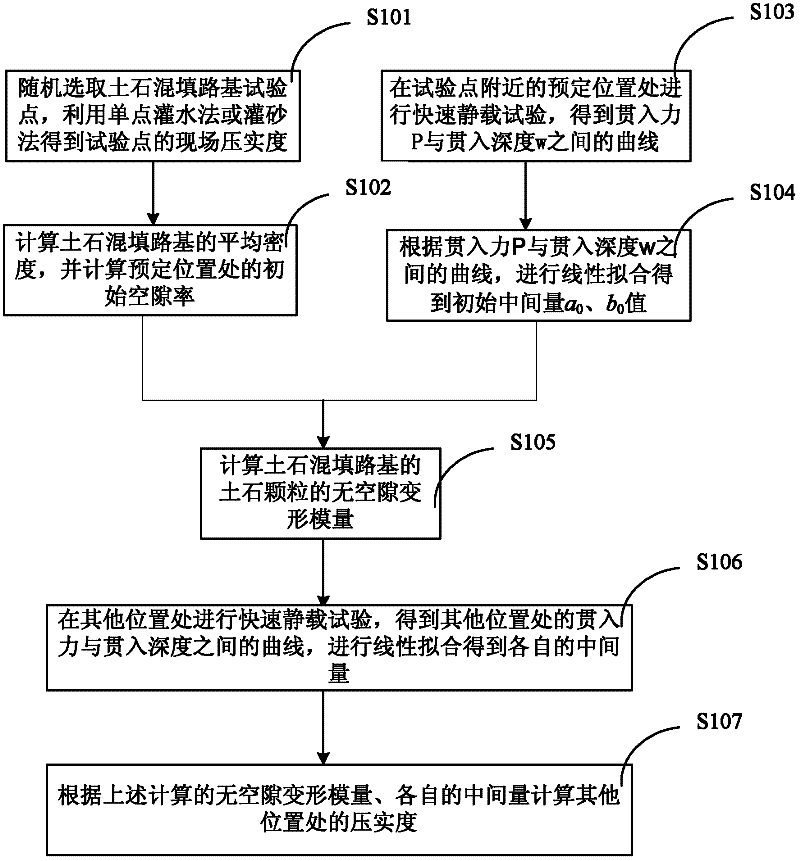

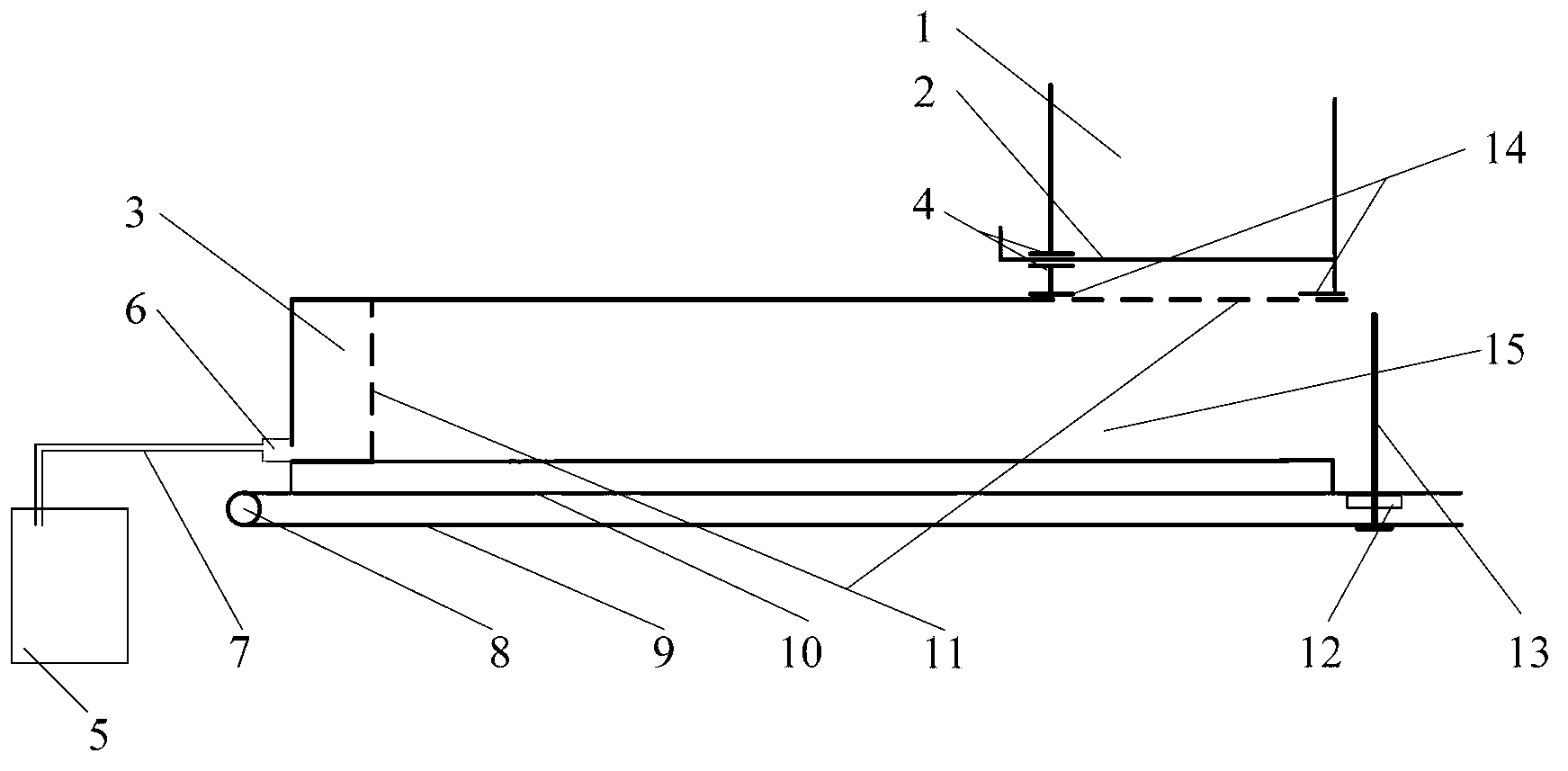

Soil and stone mixed filling roadbed compaction degree detecting method

The invention discloses a soil and stone mixed filling roadbed compaction degree detecting method, which comprises the steps of: randomly selecting a soil and stone mixed filling roadbed test site, and obtaining the site compaction degree by a single-point douche or a sand cone method; carrying out fast static test in a preset position near the test site and obtaining a curve between the penetration power P and the penetration depth w; calculating the average density Rhom of the soil and stone mixed filling roadbed and calculating the initial void ratio n0 in the preset position; carrying out linear fitting according to the curve between the penetration power P and the penetration depth w and obtaining the value of the initial intermediate quantity a0 and b0; calculating the void-free deformation modulus E0 of stone particles of the soil and stone mixed filling roadbed; and calculating the compaction degree of other positions, i.e. the compaction degree in the ordinary positions. The method can be used for fast, stably and accurately detecting the compaction degree of the soil and stone mixed filling roadbed and is suitable for any compaction process and roadbeds compacted by compaction machinery.

Owner:HUNAN UNIV

Cold-regenerated emulsified asphalt mixture and method of cold-regenerated emulsified asphalt mixture for road surface reconstruction

ActiveCN101748677AThe damage is correct and reasonableCorrect and reasonable damageRoads maintainenceSpecial data processing applicationsRoad surfaceMaterials science

The invention provides a cold-regenerated emulsified asphalt mixture and a method of the cold-regenerated emulsified asphalt mixture for road surface reconstruction. In the method, the damage condition of a structural layer below a surface layer is measured on the spot, and then quantitative evaluation is carried out on the bearing capacity so as to obtain actual mechanics and structural parameters; the production of the regenerated asphalt mixture is carried out in a cold mixing factory after milling materials on the asphalt surface layer of an old road, cement, emulsified asphalt and water mixed together; the regenerated asphalt mixture passes the forming test piece detection; the mixture obtained by the above steps is used for a to-be-reconstructed road surface structure, including the laying of a roadbed, a base layer and the surface layer. Moreover, the cold-regenerated asphalt mixture used for the above method has the following characteristics: mineral materials which are mainly composed of the milling materials of the asphalt surface layer of the old road, asphalt cementing materials and residual gaps form a multi-phase disperse system structure with a space network structure; the material property is granular; and the mechanics strength is reached by the cohesive force and the inner frictional resistance of the asphalt mixture.

Owner:JIANGXI GANYUE EXPRESSWAY

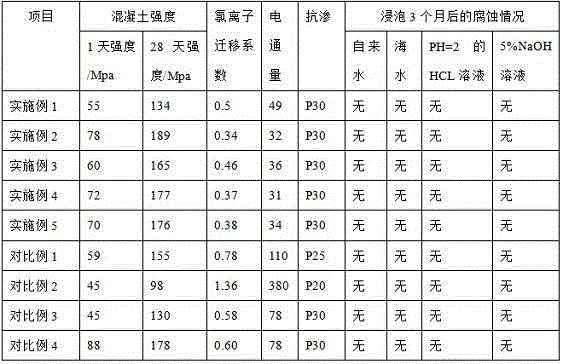

Sea sand powder concrete

ActiveCN105084837AEasy to fillImprove mechanical propertiesSolid waste managementFiberCopper plating

The invention relates to sea sand powder concrete. The sea sand powder concrete comprises, by weight, 450-750 parts of cement, 250-450 parts of active mineral admixture, 50-150 parts of inert admixture, 850-1400 parts of sea sand, 24-32 parts of high efficiency slushing agents, 145-220 parts of seawater, 2-4 parts of organic fiber and 78-250 parts of copper-bearing steel fiber with the thickness ranging from 0.08 mm to 0.35 mm. According to the sea sand powder concrete, a compact stacking structure principle is adopted, the interior of the concrete is almost seamless in communication channel through optimization of particle size gradation, and a channel of internal ion medium migration is further eliminated through secondary hydration of the active mineral additive, so that the powder concrete obtained by stirring the raw materials through the seawater and the sea sand is ultra-high performance concrete with high durability, corrosion resistance and high mechanic property.

Owner:黄贺明

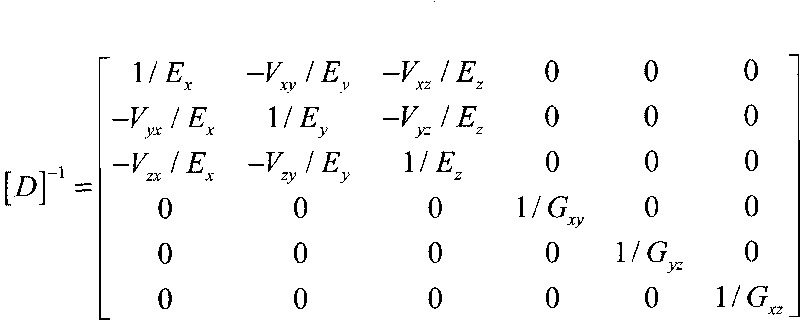

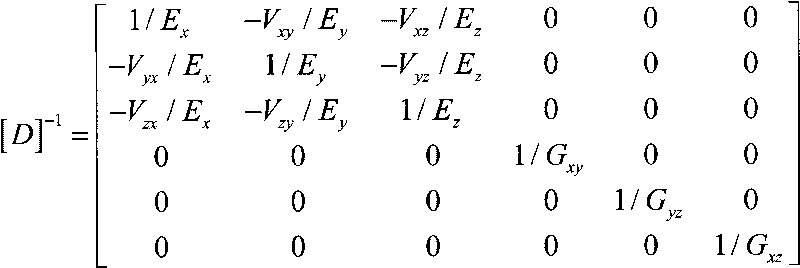

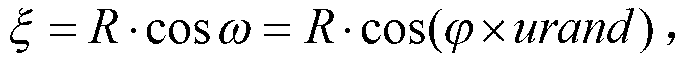

Method for randomly building bituminous mixture multilayered structure simulation model

ActiveCN103218480AReduce complexityLow costSpecial data processing applicationsImaging processingSimulation

The invention discloses a method for randomly building a bituminous mixture multilayered structure simulation model. The method comprises the following steps of: generating units with different sizes and different size distribution features in different preset spaces by defining; mutually combining the units in each preset space and processing; and finally, building the bituminous mixture multilayered structure simulation model. According to the method for randomly building the bituminous mixture multilayered structure simulation model, the buildup of the bituminous mixture microstructure simulation model can get rid of constraints of conditions of testing equipment, the image processing technology and the like, and meanwhile, and gap capture can also be realized, so that the testing complexity is lowered, and the testing cost is also reduced.

Owner:SOUTHEAST UNIV

Water-borne epoxy resin modified cement grouting material

The invention provides a water-borne epoxy resin modified cement grouting material. The material is prepared by the following raw materials in parts by weight: 5-10 parts of water-borne epoxy resin, 30-50 parts of cement, 5-30 parts of quartz powder, 0-40 parts of quartz sand, 5-10 parts of calcium carbonate powder, 5-10 parts of a composite expanding agent, 0.01-0.03 parts of low-viscosity cellulose, 0.5-1 parts of asphalt powder, 0.2-0.6 parts of a water reducer, and 0.001-0.03 parts of a retarder. The material overcomes the deficiency in prior art, the composite expanding agent is used for compensating shrinkage in plastic stage, density of grouting is increased, and interspace structure is effectively filled; at the same time, fluidity is good, and settlement phenomenon disappears; the material is suitable for common cement grouting, and is suitable for repairing and strengthening, duct grouting, crack repairing, and other engineering occasions; furtherly, the materials has the advantages of good fluidity, adhesive property, shrinkage compensation performance and corrosion resistance.

Owner:天津天盈新型建材有限公司

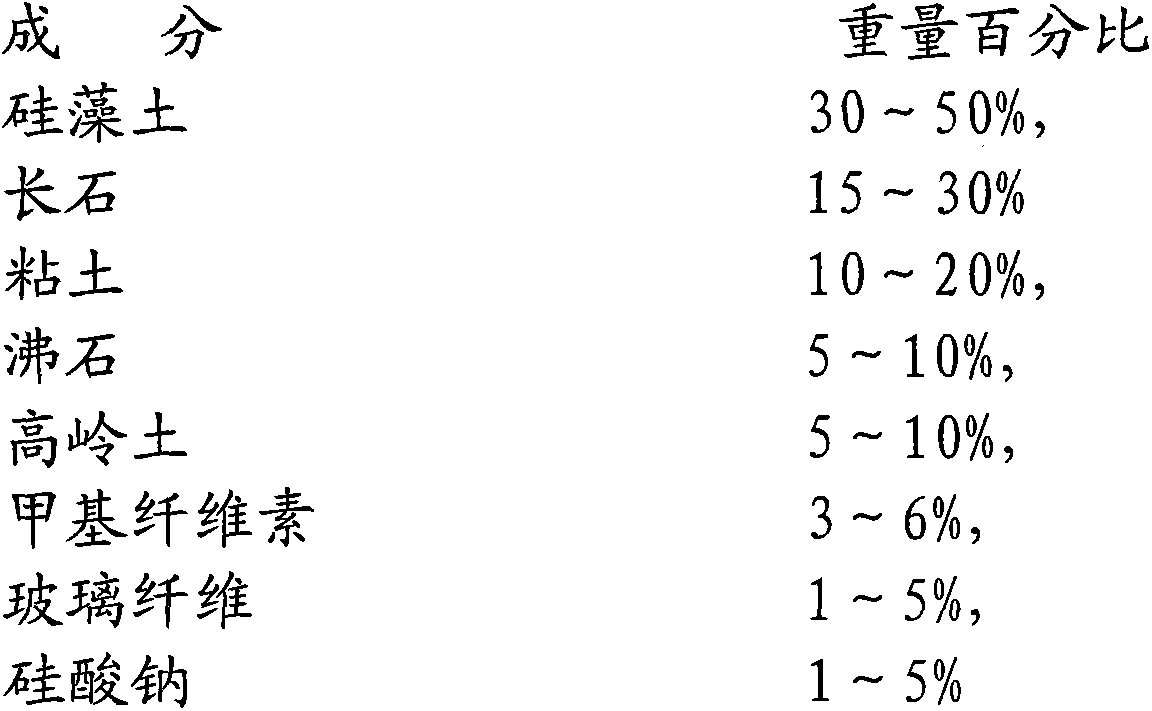

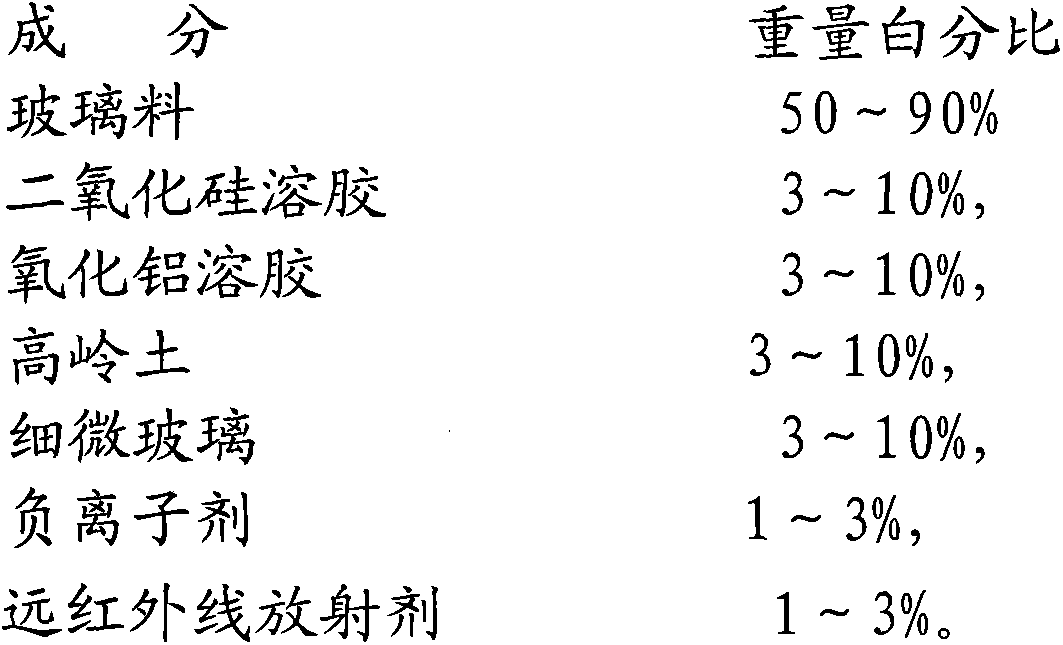

Method for producing ceramic tiles with absorption and release functions by using kieselguhr as main component

The invention provides a method for producing ceramic tiles with absorption and release functions by using kieselguhr as a main component, relates to a ceramic tile production method and particularly relates to a method for producing tiny porous ceramic tiles by using the kieselguhr as the main component in combination with materials such as kaolin, feldspar and clay. The kieselguhr is characterized by multiple tiny pores and is a light natural mineral. The kieselguhr is used as the main raw material for producing indoor decorating ceramic tiles by using the characteristics of lots of tiny gaps of the kieselguhr and can automatically adjust the indoor dryness and humidity; and when the indoor vapor quantity is large, moisture can be absorbed into ceramic tile bodies by the kieselguhr through the pores, when the indoor air is dry, the moisture in the ceramic tile bodies can be released by the kieselguhr, so that the temperature and humidity adjustment is realized. In addition, as the ceramic tiles contain an infrared ray generating agent and a negative ion generating agent, far infrared rays and negative ions can be released at ordinary times and have a health care effect on human bodies, and therefore, the ceramic tiles are ideal indoor decorating ceramic tiles.

Owner:营口盼盼硅藻材料集团有限公司

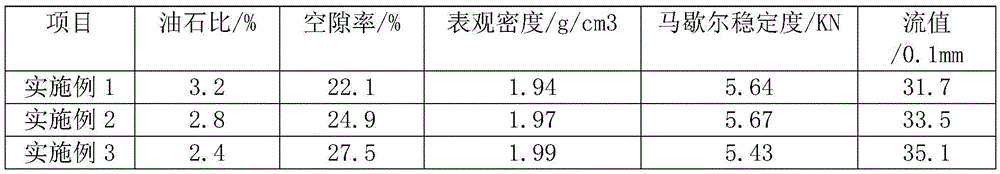

Semi-flexible pavement material and pavement construction method thereof

ActiveCN107915427AFlexibleExtended service lifeIn situ pavingsCeramicwarePolyvinyl alcoholRoad surface

The invention discloses a semi-flexible pavement material and a pavement construction method thereof. According to key points of the technical scheme, components of the semi-flexible pavement materialinclude an asphalt mixture serving as a large-pore matrix and cement slurry serving as a filler, wherein a weight percentage of the asphalt mixture is 70-80%; a weight percentage of the cement slurryis 20-30%; the asphalt mixture contains the following components in parts by weight: 1-2 parts of SBS modified asphalt, 4-5 parts of coarse aggregate, 0.5-0.8 part of fine aggregate, 0.2-0.3 part ofwater, 0.4-0.5 part of limestone dust and 0-0.005 part of a lithium salt composite early strength agent; the coarse aggregate is natural sand with a particle size of 13.2-16mm; the fine aggregate is natural sand with a particle size of 4.5-9mm; and the cement slurry contains the following components in parts by weight: 0.5-1.5 parts of Portland cement, 0.2-0.3 part of super-fine sand, 0.05-0.2 part of fly ash, 0.4-0.9 part of water, 0.05-0.09 part of a UEA expanding agent, 0.2-0.6 part of a water reducing agent, 0.01-0.05 part of polyvinyl alcohol and 0-0.5 part of BD emulsion. The aim of prolonging the service life of the semi-flexible pavement is achieved.

Owner:苏州三创路面工程有限公司

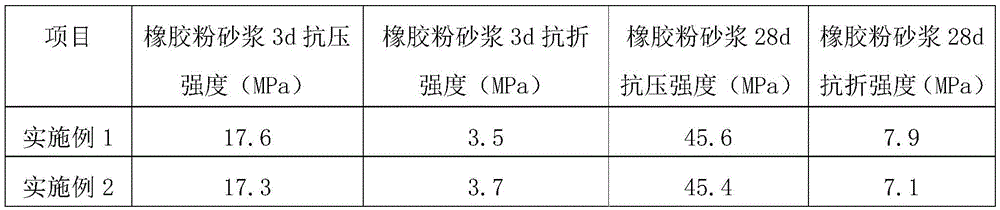

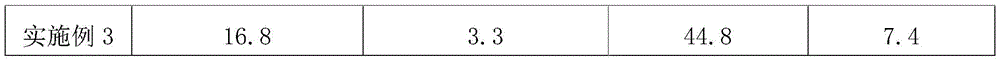

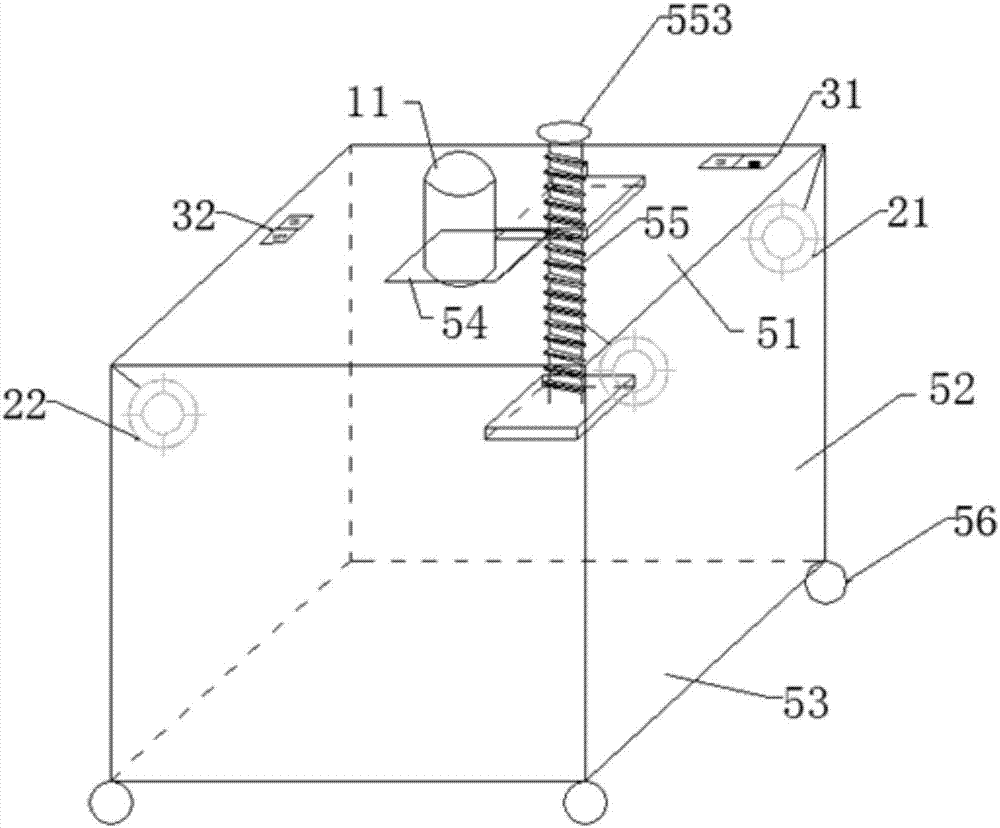

Semi-flexible composite pavement structure and preparation method thereof

The invention provides a semi-flexible composite pavement structure and a preparation method thereof. The semi-flexible composite pavement structure comprises components in percentage by weight as follows: 70%-80% of a macro-porous asphalt mixture matrix and 20%-30% of rubber powder cement mortar; the macro-porous asphalt mixture matrix is prepared firstly, then the rubber powder cement mortar is prepared, the rubber powder cement mortar is poured into a mixture gap of the macro-porous asphalt mixture matrix finally, and a product can be utilized after maintenance. According to the semi-flexible composite pavement structure, the defects of asphalt pavements and cement concrete pavements in China at present are overcome, rigidity of the cement concrete pavements and the flexibility of the asphalt pavements are integrated, the respective advantages of rigid and flexible pavement structures can be sufficiently played, the respective defects of the rigid and flexible pavement structures are overcome, and the semi-flexible composite pavement structure is a novel pavement structure with better pavement performance and higher cost performance.

Owner:广西交通职业技术学院

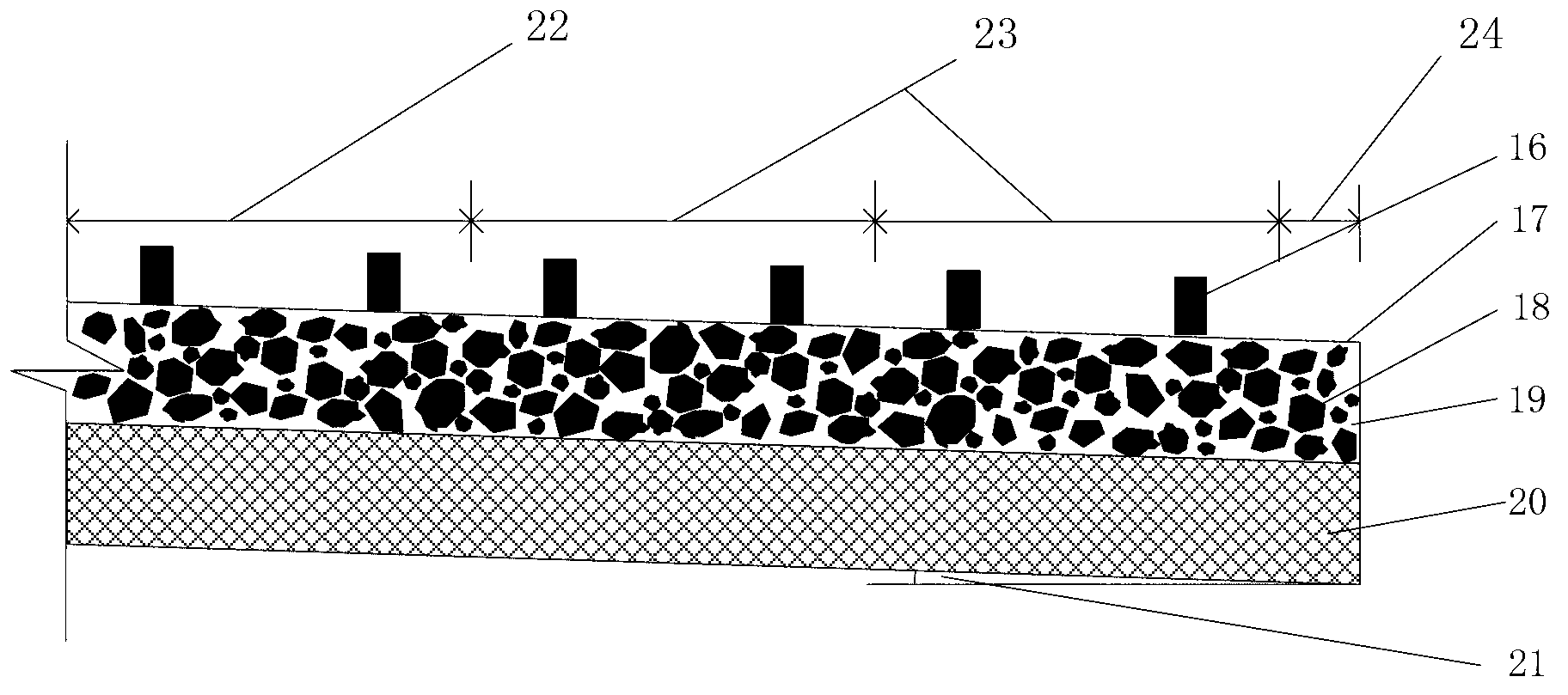

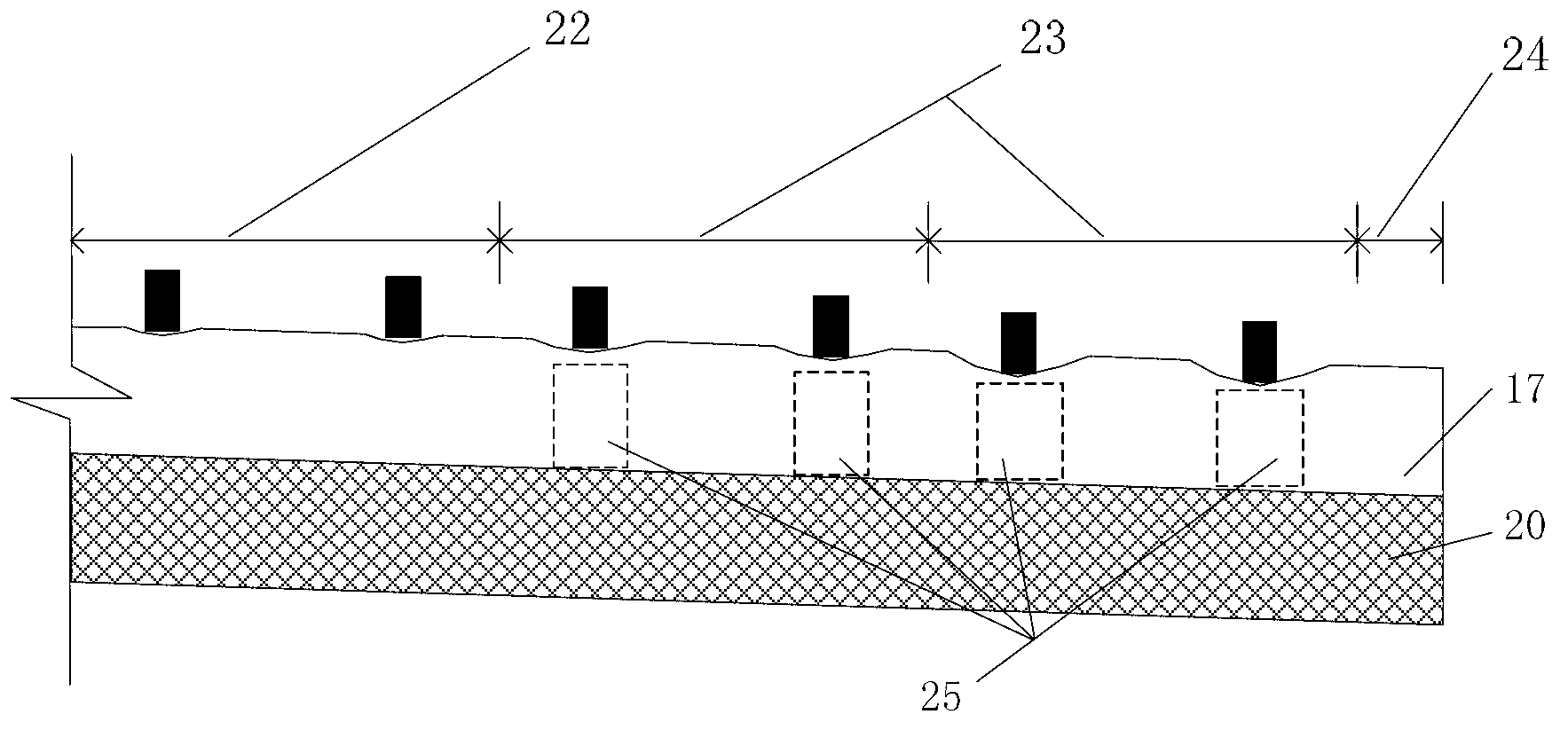

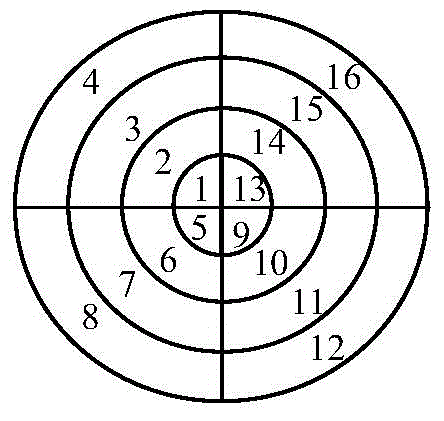

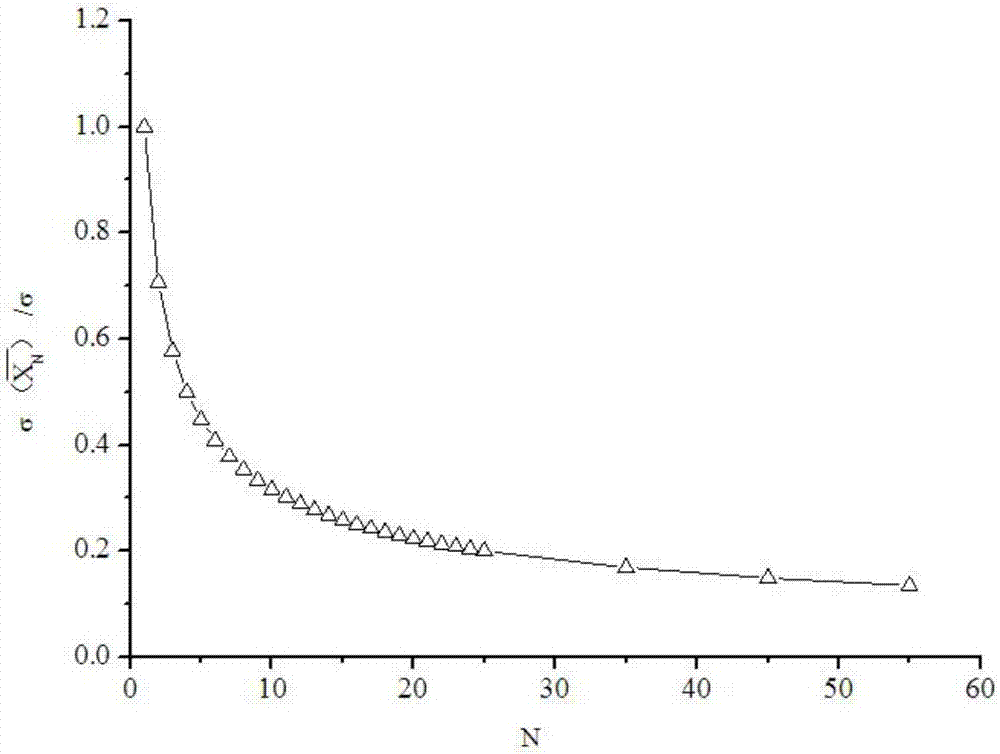

Construction quality uniformity detection and evaluation method of asphalt pavement

InactiveCN107024411AEffective segmentationEffective evaluation of construction qualityImage enhancementImage analysisPorosityRoad surface

The invention relates to a construction quality uniformity detection and evaluation method of an asphalt pavement. The construction quality uniformity detection and evaluation method comprises the following steps: acquiring a texture image of a surface of a detected road section by adopting an image acquisition device and drilling a density representative core sample; processing the image on the surface of a road and a CT (Computerized Tomography) image of the core sample so as to calculate a pavement macrostructure width index K, a coarse aggregate horizontal non-uniform coefficient DH and vertical non-uniform coefficients DV1 and DV2; evaluating aggregate distribution uniformity of the pavement from the pavement and the inner part of a structure; then, testing densities of different regions of the pavement by adopting a non-nuclear density gauge PQI; calculating density repeatability standard deviations Sr and SR in detection channels and between the detection channels, and density consistency statistic values k and h in the detection channels and between the detection channels; calculating a cross section gap quantity uniformity coefficient UCN and a cross section gap porosity uniformity coefficient UCR of the CT image of the core sample; evaluating compaction quality distribution uniformity of the asphalt pavement from density and porosity distribution conditions. By adopting the method provided by the invention, the problem that a detection index for the construction quality uniformity of the asphalt pavement is lacked in a pavement construction inspection and acceptance process at present is solved.

Owner:CHANGAN UNIV +2

Method for evaluating attenuation degree of porous asphalt mixture void

InactiveCN103323381ASimplify the test operation processIn line with the actual situationPermeability/surface area analysisUltrasound attenuationTester device

The invention discloses a method for evaluating attenuation degree of porous asphalt mixture void. The method is characterized by comprising the following steps: molding a plate test piece by rolling according to the grade of a porous asphalt mixture to be evaluated; coating a sealing material on three side faces and a bottom surface of the test piece to seal the surface voids, putting the test piece on a drainage coefficient tester, and taking a side face where the sealing material is not coated as a drainage channel; setting the testing slope of the drainage coefficient tester according to cross slope of the pavement, and testing to obtain an initial value of the drainage coefficient of the test piece; performing a wheel tracking test on the test piece, wherein the wheelmark track is required to be parallel to the drainage side face of the test piece during test; and after the wheel tracking test, testing the final drainage coefficient of the test piece by employing the drainage coefficient tester; comparing the final drainage coefficient with the initial value, and evaluating the attenuation degree of the porous asphalt mixture voids. The method can evaluate the attenuation degree of the porous asphalt pavement pore structure under the repetitive vehicle action and is used for selecting proper aggregate grading in the process of designing the porous asphalt mixture.

Owner:HOHAI UNIV

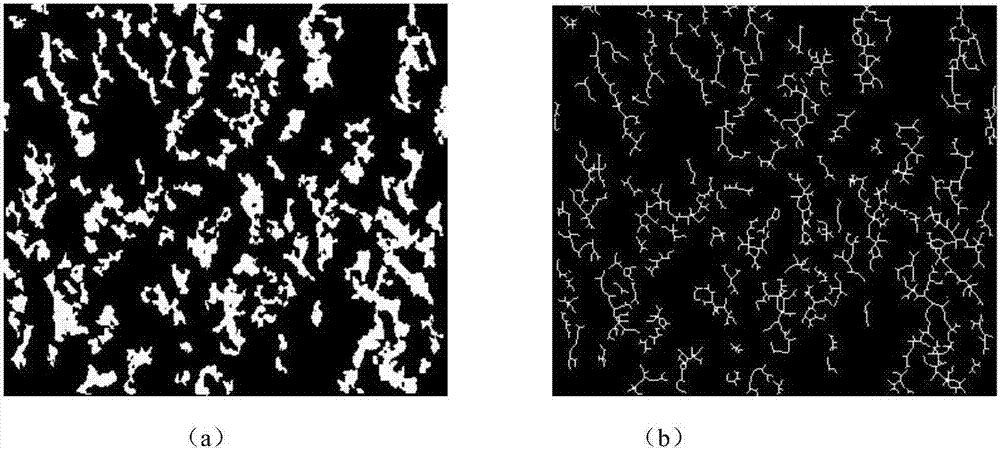

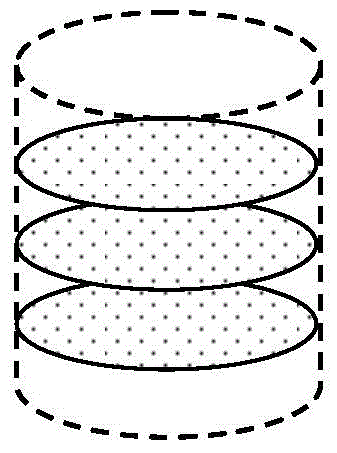

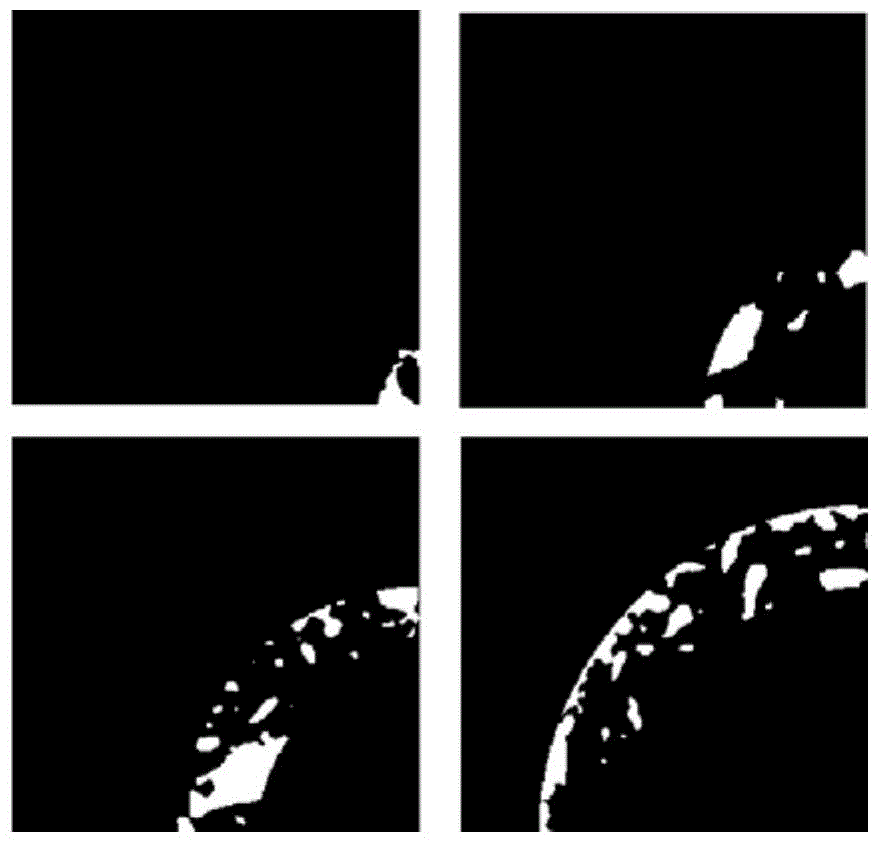

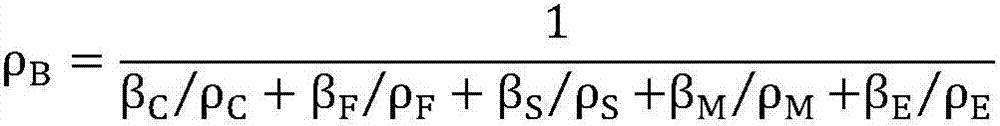

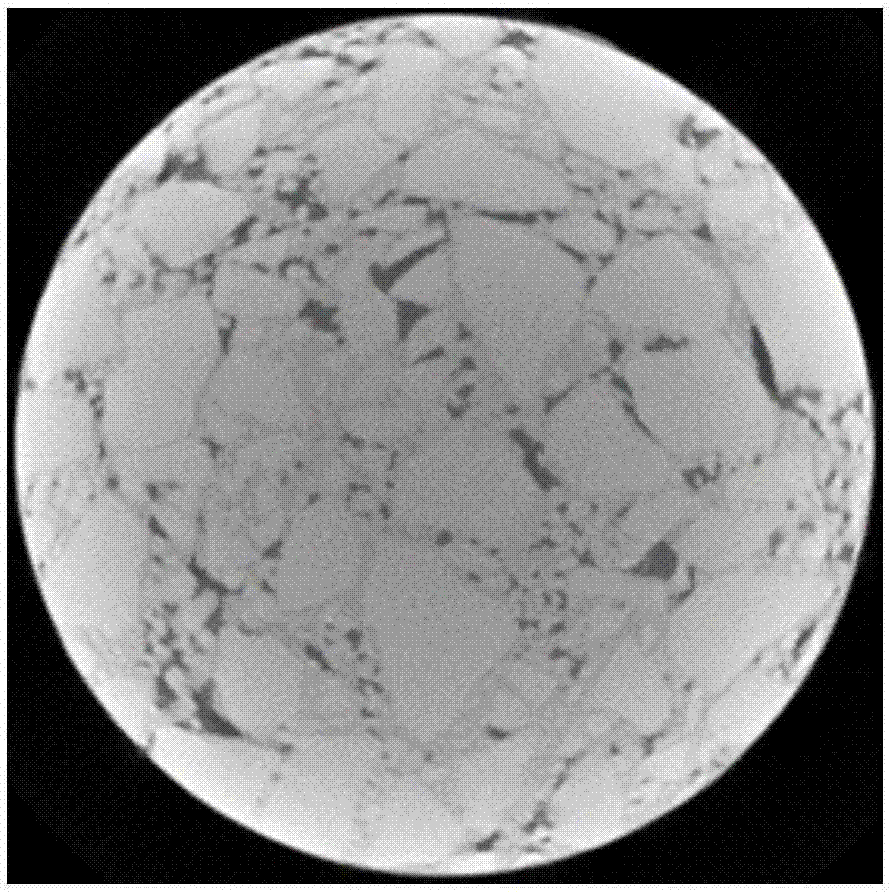

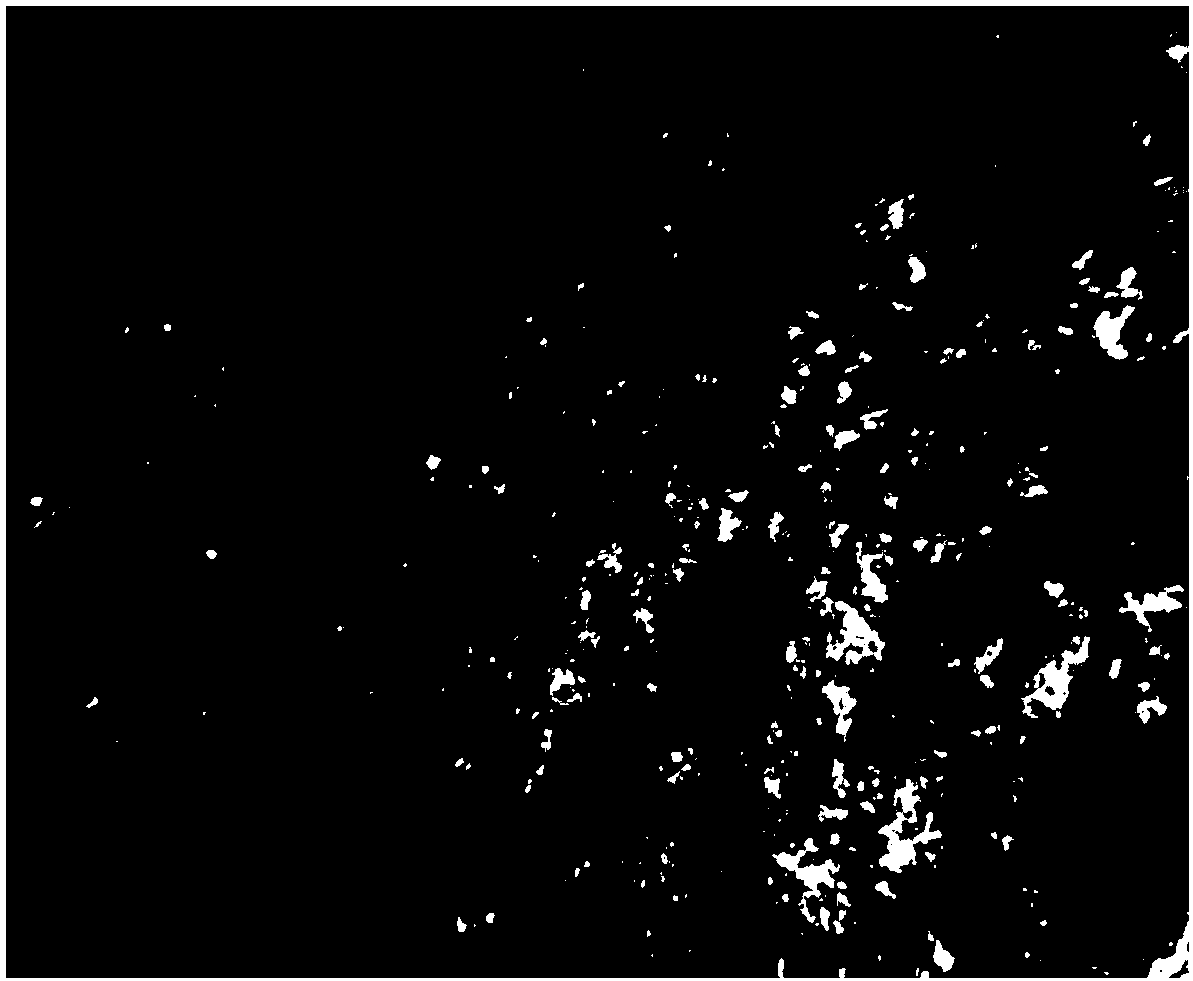

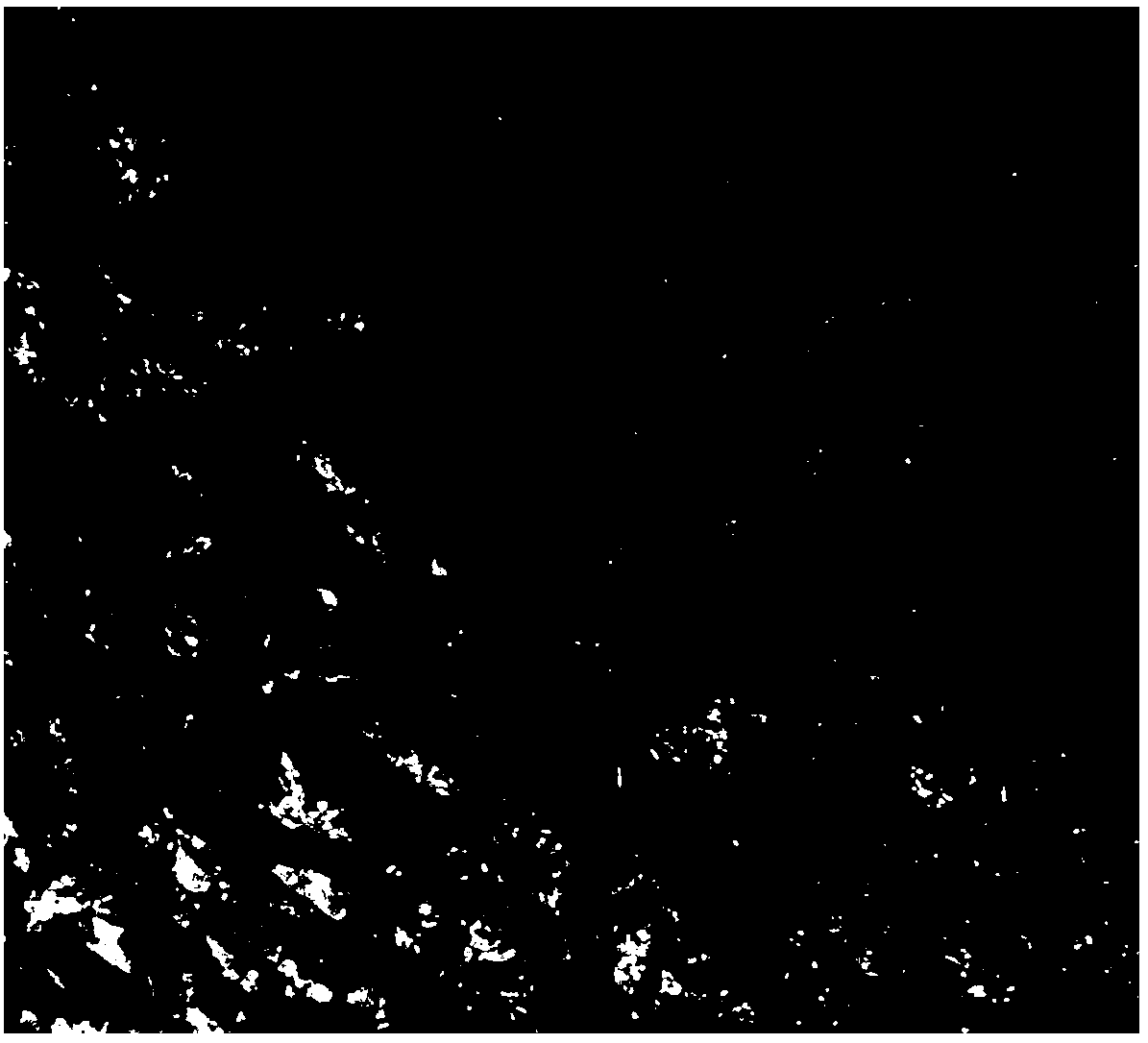

Interior uniformity recognition method based on relative density of all components of bituminous mixture

InactiveCN104931515AEigenvalue avoidanceImprove computing efficiencyMaterial analysis by transmitting radiationPattern recognitionFractography

The invention discloses an interior uniformity recognition method based on the relative density of all components of a bituminous mixture. The interior uniformity recognition method comprises the following steps: firstly, performing tomography in the axial direction of a bituminous mixture test piece to form a plurality of sections of which the effective areas are the same; secondly, dividing each section into a plurality of regular small areas, and establishing a digital image set of the interior structure of the bituminous mixture test piece; thirdly, performing compiled image segmentation and threshold selection; meanwhile, calculating the relative density of all the components in an image according to actual density values and the area ratio of coarse aggregates, gaps and mortar in each small area of the digital image, directly evaluating the interior structure uniformity of the bituminous mixture according to data, and quantitatively judging the damage position of the interior structure of the bituminous mixture.

Owner:DALIAN MARITIME UNIVERSITY

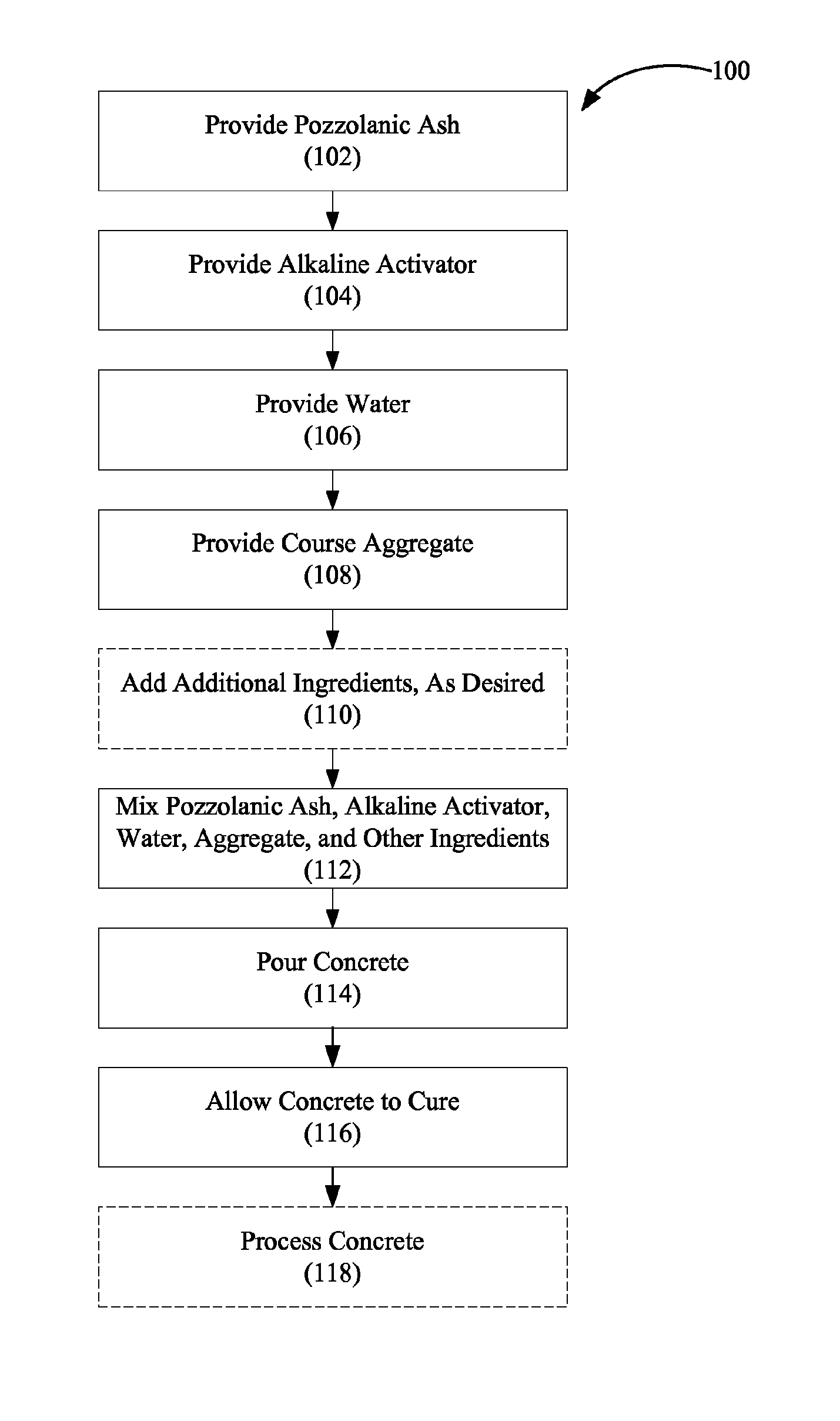

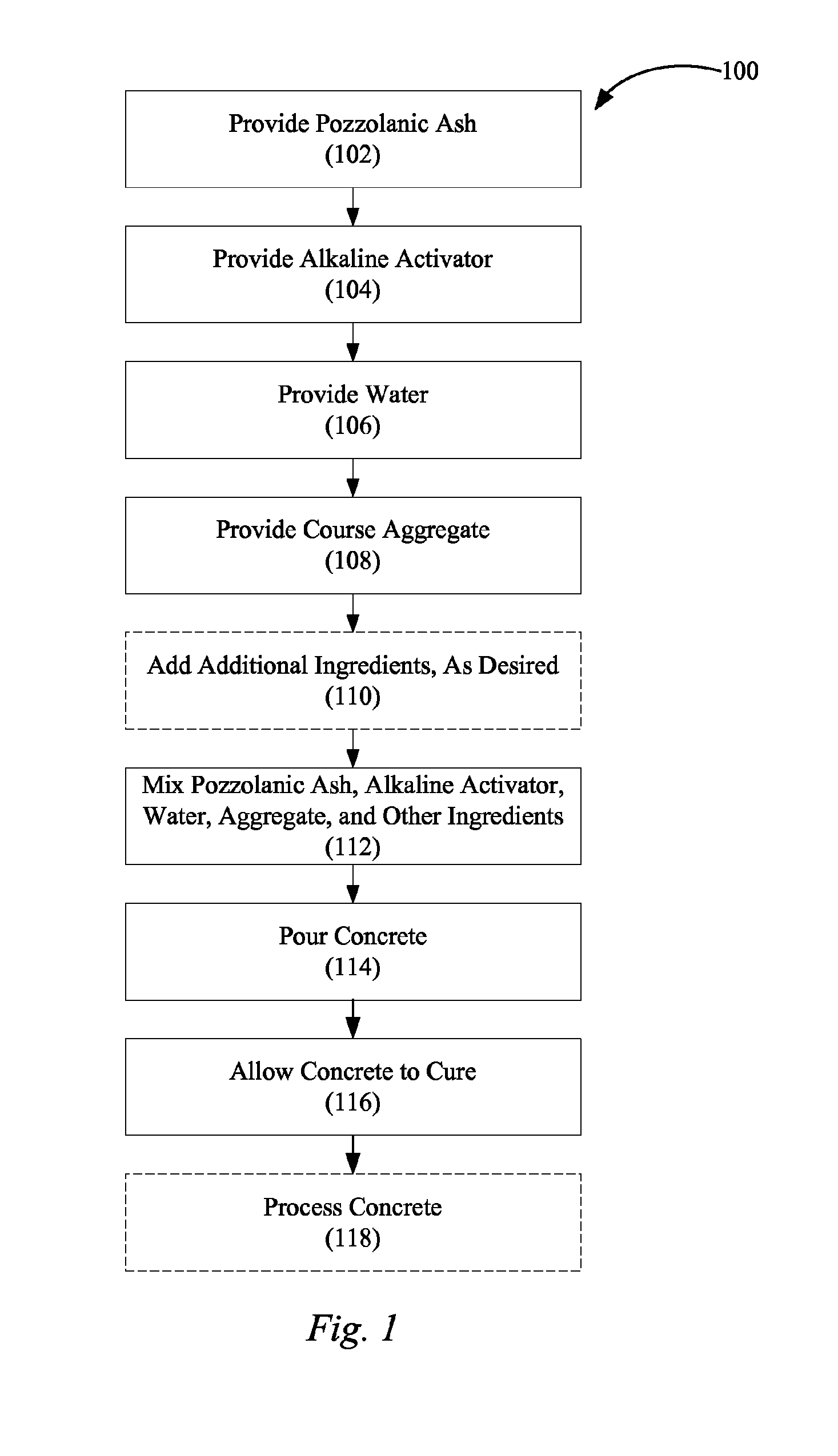

Pervious concrete comprising a geopolymerized pozzolanic ash binder

InactiveUS8038789B2Low costImprove performanceSolid waste managementCement productionAluminateRoad surface

Owner:CERAMTEC

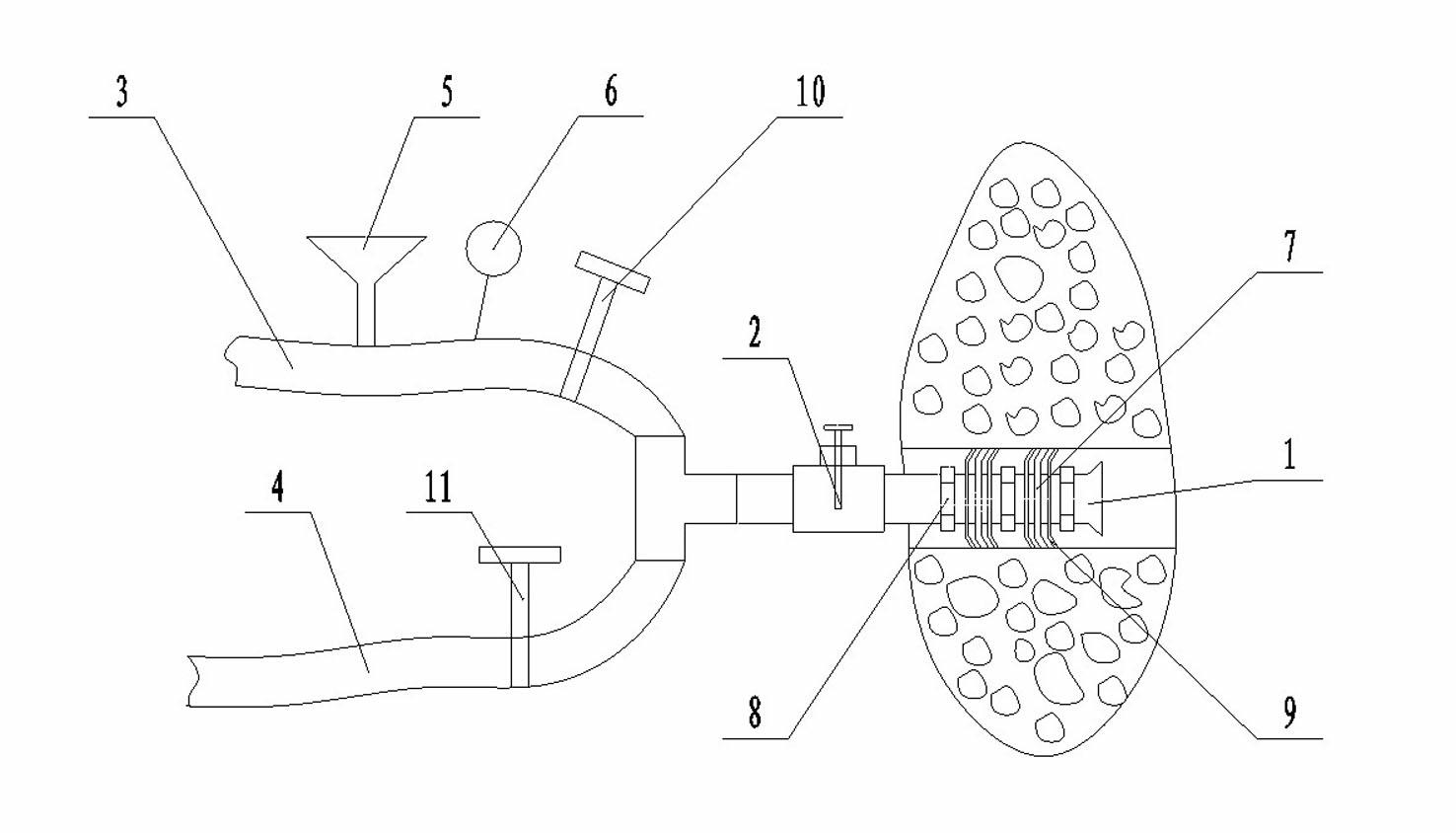

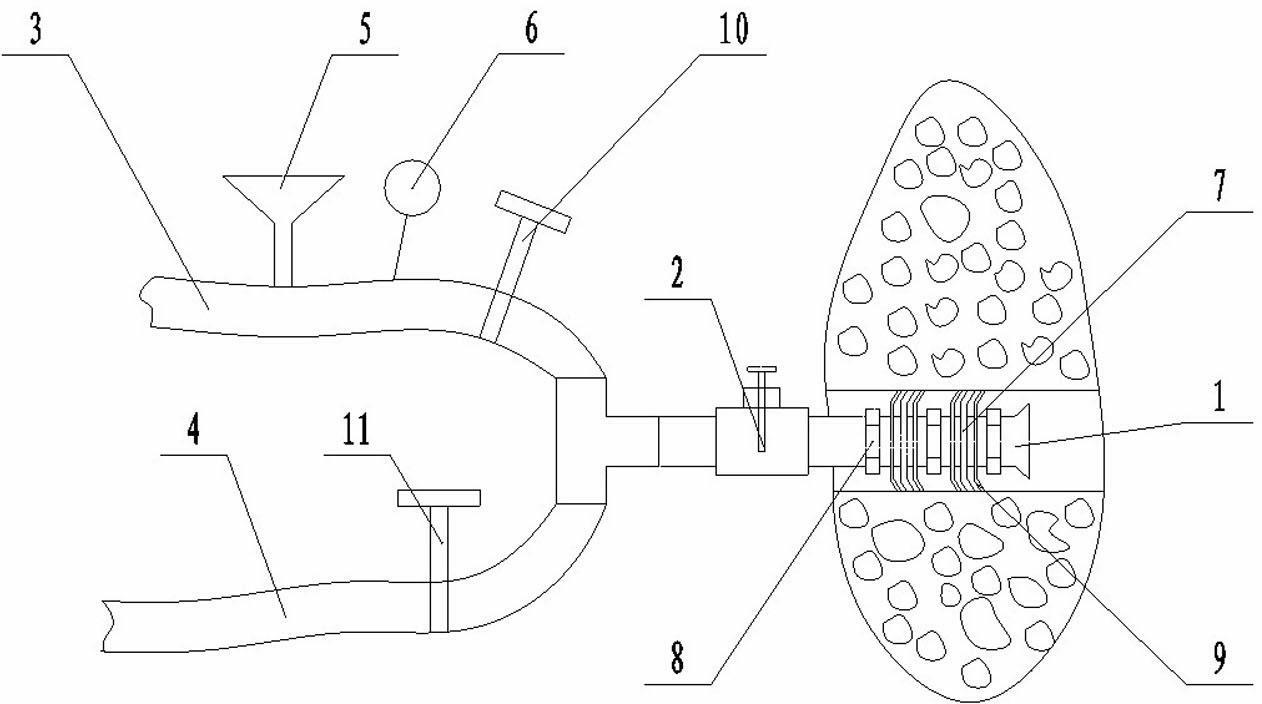

Method and device for solidifying water-filling cracking surrounding rocks of tunnel by adopting high-pressure air water-dispelling grouting

ActiveCN102182468AOvercome costsOvercoming Process ComplexityUnderground chambersTunnel liningEngineeringCement slurry

The invention particularly relates to a method and a device for solidifying water-filling cracking surrounding rocks of a tunnel by adopting high-pressure air water-dispelling grouting, solving the problems of high cost and complex process during the solidification of the water-filling cracking surrounding rocks of the tunnel in the prior art. The method adopts the following processes: a. drilling horizontal geology after ascertaining the range and the water filling condition of the water-filling cracking surrounding rocks, and then inserting a pressure-withstand pipe and sealing the periphery of the pressure-withstand pipe; b. sealing an excavation working surface to form a pump stop wall; c. guiding high-pressure air into the pressure-withstand pipe to replace and drain water filled in clearances among the cranking surrounding rocks; and d. after the pressure of the air is kept balanced, guiding cement slurry into the pressure-withstand pipe to fill the cracking surrounding rocks with the water filled in the clearance being replaced by the air. In the invention, by pressing the high-pressure air into the water-filling cracking surrounding rocks, pressing and delivering sealing material which has light weight and expanses when meeting water, quickly condensing the slurry to drain water by pressurizing, and sealing a clearance water supplement passage of the surrounding rocks,the original water-filling cracking belt grouting is changed into the water-free cracking belt grouting, thereby realizing the comprehensive effects of improving the process, simplifying the construction, improving the work efficiency and reducing the cost.

Owner:中铁十七局集团第三工程有限公司

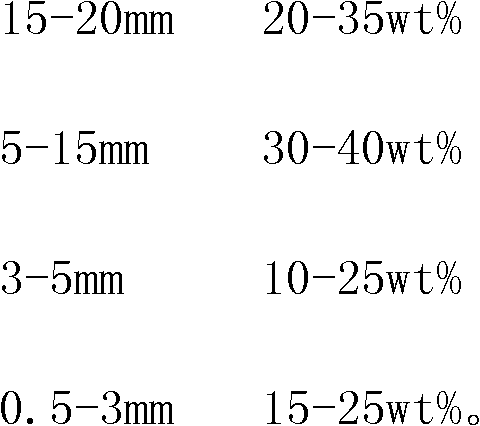

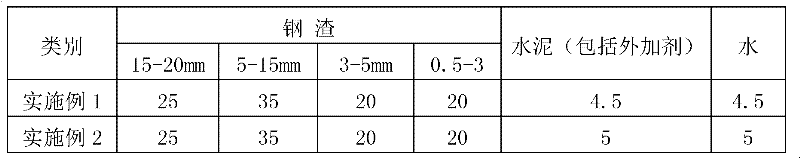

Steel slag and cement stabilized base material

The invention provides a steel slag and cement stabilized base material comprising components of steel, cement, water, and an additive. The weight ratio of steel to cement to water is 100:4-6:4-6; and the weight of the additive is 0.6-6% of the weight of cement. According to the invention, graded steel slag serves as an aggregate, and is used for replacing crushed stones. The voids of the aggregate are filled by using a certain amount of a cementing material and the volume of enough mortar. The materials are paved and compacted according to an interlocking principle. The strength of the base is high. With increasing age periods, the base rapidly turns into a board body. Therefore, the material has high strength, high water permeability and high freezing resistance. The material can be used in road base constructions.

Owner:MCC BAOSTEEL TECH SERVICE

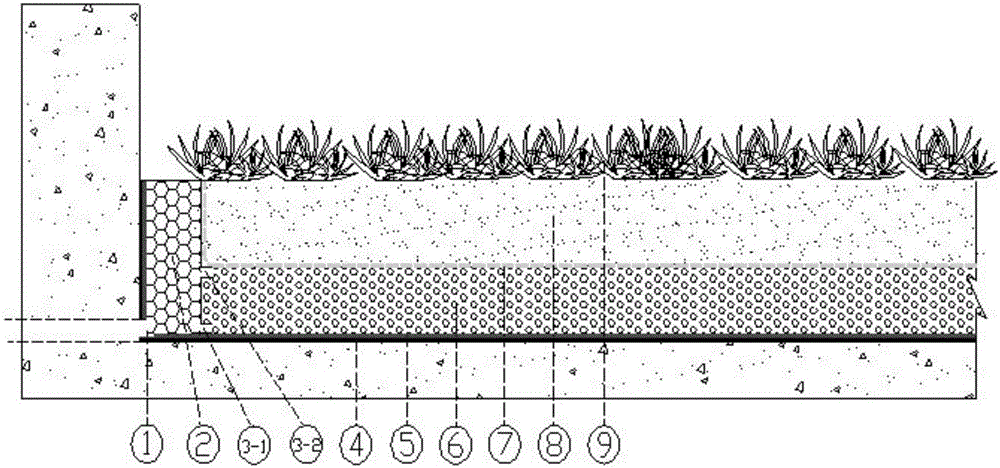

Roof greening structure and greening method

ActiveCN106065692AStrong penetrating powerReduce flood peakRoof improvementGeneral water supply conservationPlant rootsEngineering

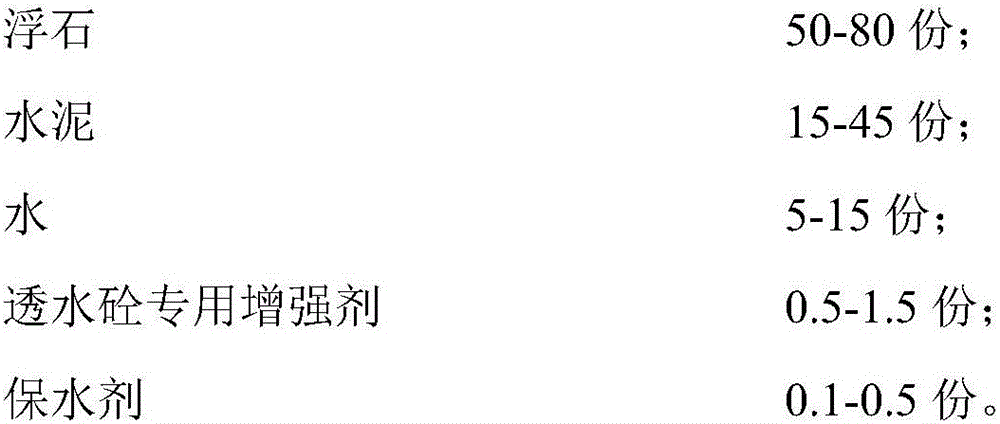

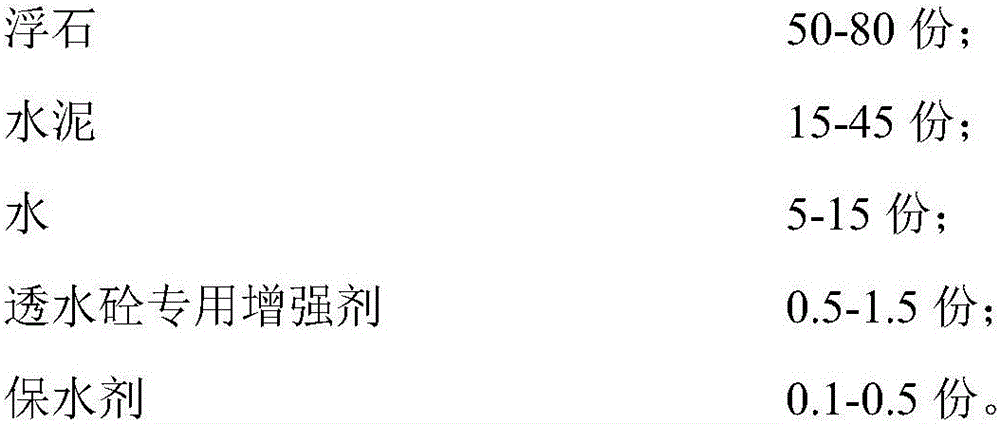

The invention provides a roof greening structure and a greening method. The roof greening structure comprises a main structure and an auxiliary structure, wherein the main structure comprises a water-proof root-blocking layer, a protection layer, a light-weight aggregate pervious concrete water storage layer, a filter layer, a light nutrient soil layer and a vegetation layer which are paved on the main structure in sequence; the auxiliary structure comprises a water drainage opening, an inspection well, a spare drain opening and an overflow opening; the material, namely light-weight aggregate pervious concrete, of the light-weight aggregate pervious concrete water storage layer is prepared from the following materials by weight: 50 to 80 parts of pumice, 15 to 45 parts of cement, 5 to 15 parts of water, 0.5 to 1.5 parts of a special strengthening agent for pervious concrete, and 0.1 to 0.5 part of a water-retaining agent. The void ratio of the light-weight aggregate pervious concrete water storage layer is equal to or larger than 20 %, can store rainwater of concentrated rainfall, and has the functions of flood detention, storage regulation, flood peak reduction, and initial rainwater purification in a regional scale; due to the large void structure, plant roots can penetrate easily, so that the roof greening structure and the greening method are suitable for planting low shrubs and dwarf trees, and have a good root fixing effect.

Owner:上海砼仁环保技术发展有限公司

Metakaolin concrete for oversized structure and mixing proportion designing method

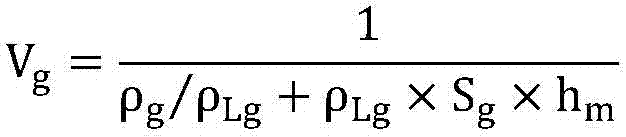

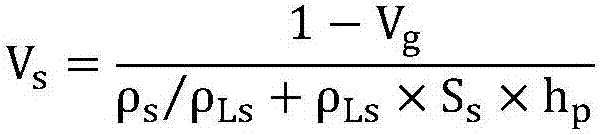

The invention discloses metakaolin concrete for oversized structure and a mixing proportion designing method. The metakaolin concrete is prepared by mixing 1016-1072kg of gravel, 825-848kg of refined machine-made sand, 213-282kg of P.O42.5 cement, 37-43kg of II-grade coal ash, 51-80kg of S75 slag powder, 22-26kg of metakaolin, 22-26kg of I-type UEA expanding agent, 0.6-1.5kg of polypropylene fiber, 6.26-8.13kg of coagulation-delaying polycarboxylate superplasticizer and 163-176kg of water. An aggregate close packing model is adopted, and a designing method based on wrapping and filling gravel gaps through mortar and wrapping and filling refined machine-made sand gaps through binding material slurry is adopted, so that close packing of components of the concrete is realized, improvement on strength and fluidity of the concrete is facilitated, and binding material consumption and system hydration heat can be reduced.

Owner:云南建投绿色高性能混凝土股份有限公司

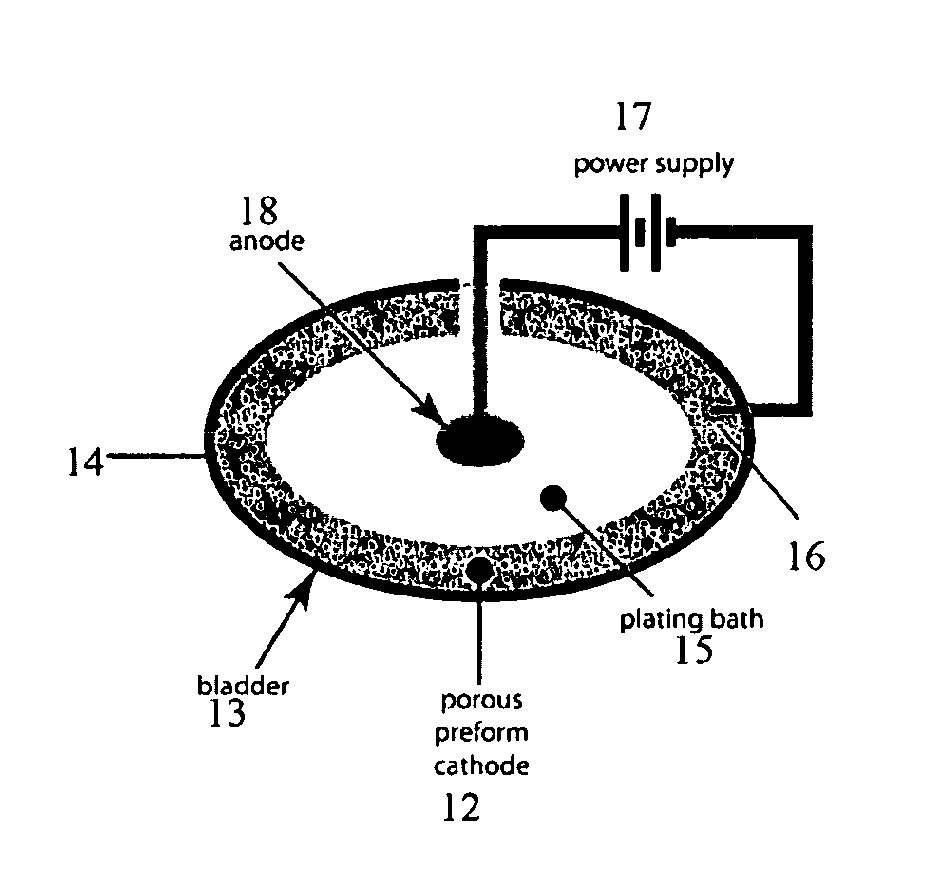

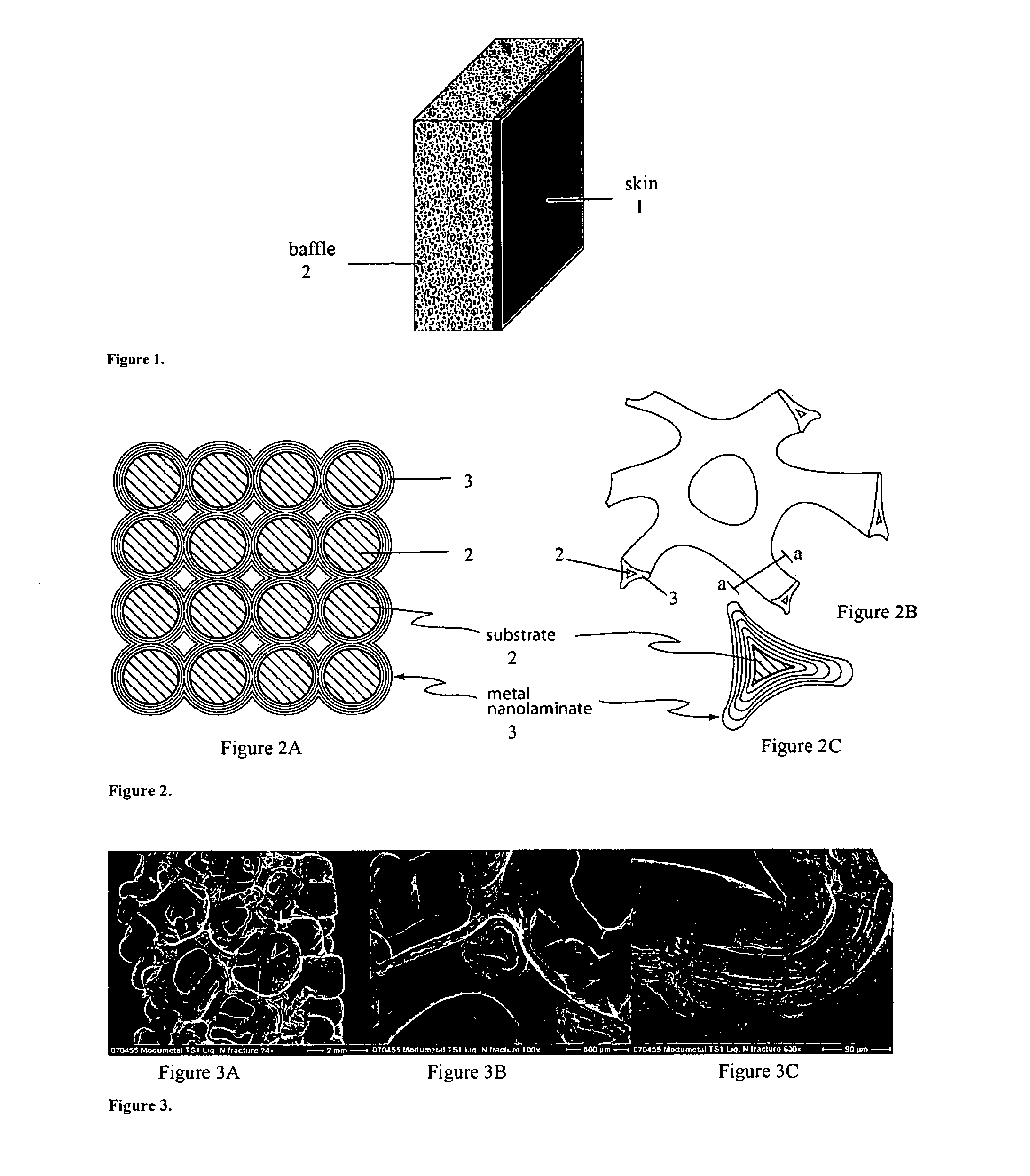

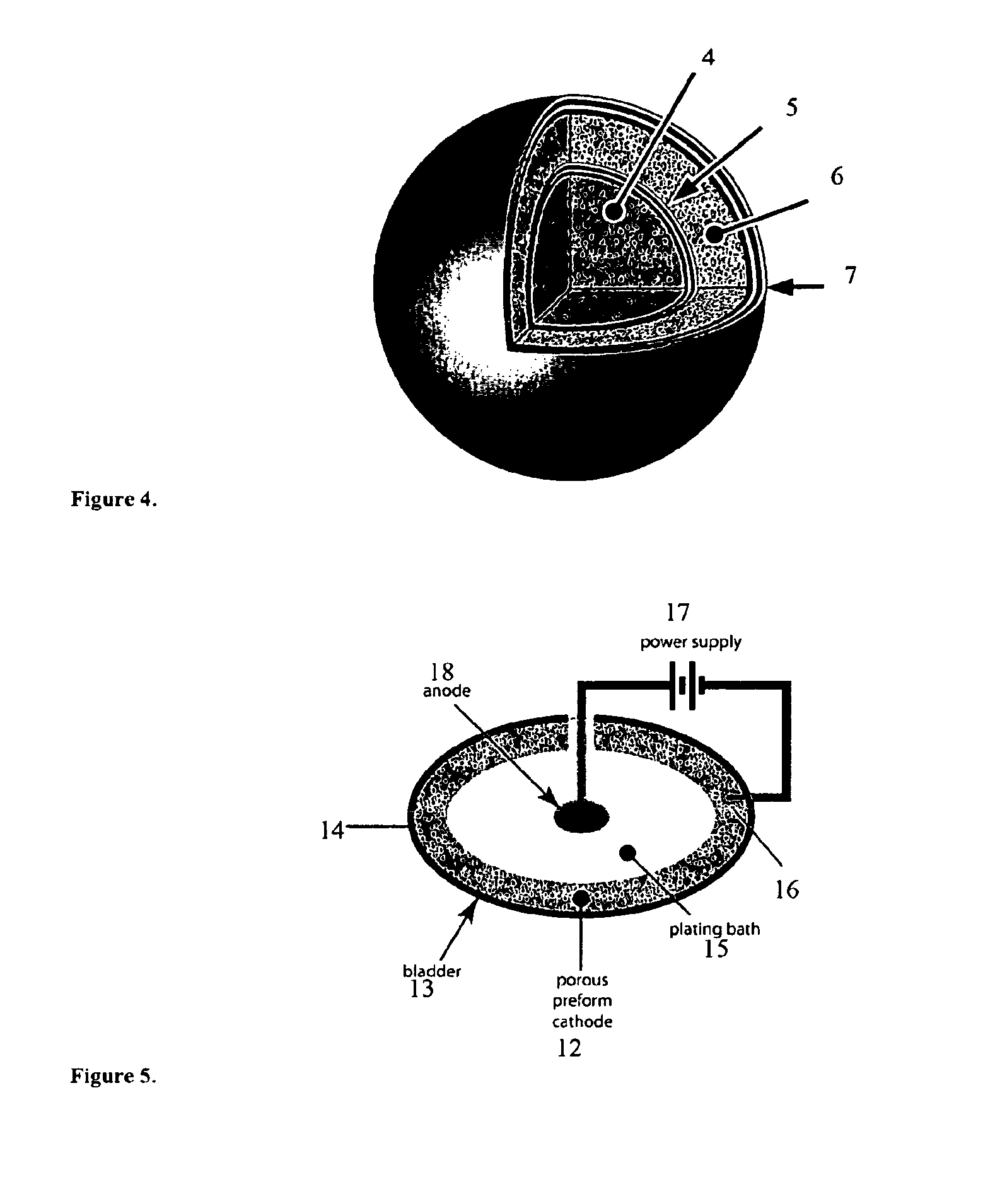

Nanolaminate-reinforced metal composite tank material and design for storage of flammable and combustible fluids

ActiveUS9108506B2Raise the ratioIncrease energy densityElectrolytic coatingsLarge containersFuel tankMetal foam

An improved fuel tank and method of forming a fuel tank utilize reinforced porous metal composite materials. In one embodiment, the composite material includes a fully dense, fluid-impermeable skin combined with a porous metal baffle. The skin and baffle may be formed as a single monolithic system via electrodeposition of a nanolaminate material into at least a portion of open, accessible void space within a porous preform (e.g., a metal foam preform) and on the exterior surface of the preform to form the fluid-impermeable skin.

Owner:MODUMETAL LLC

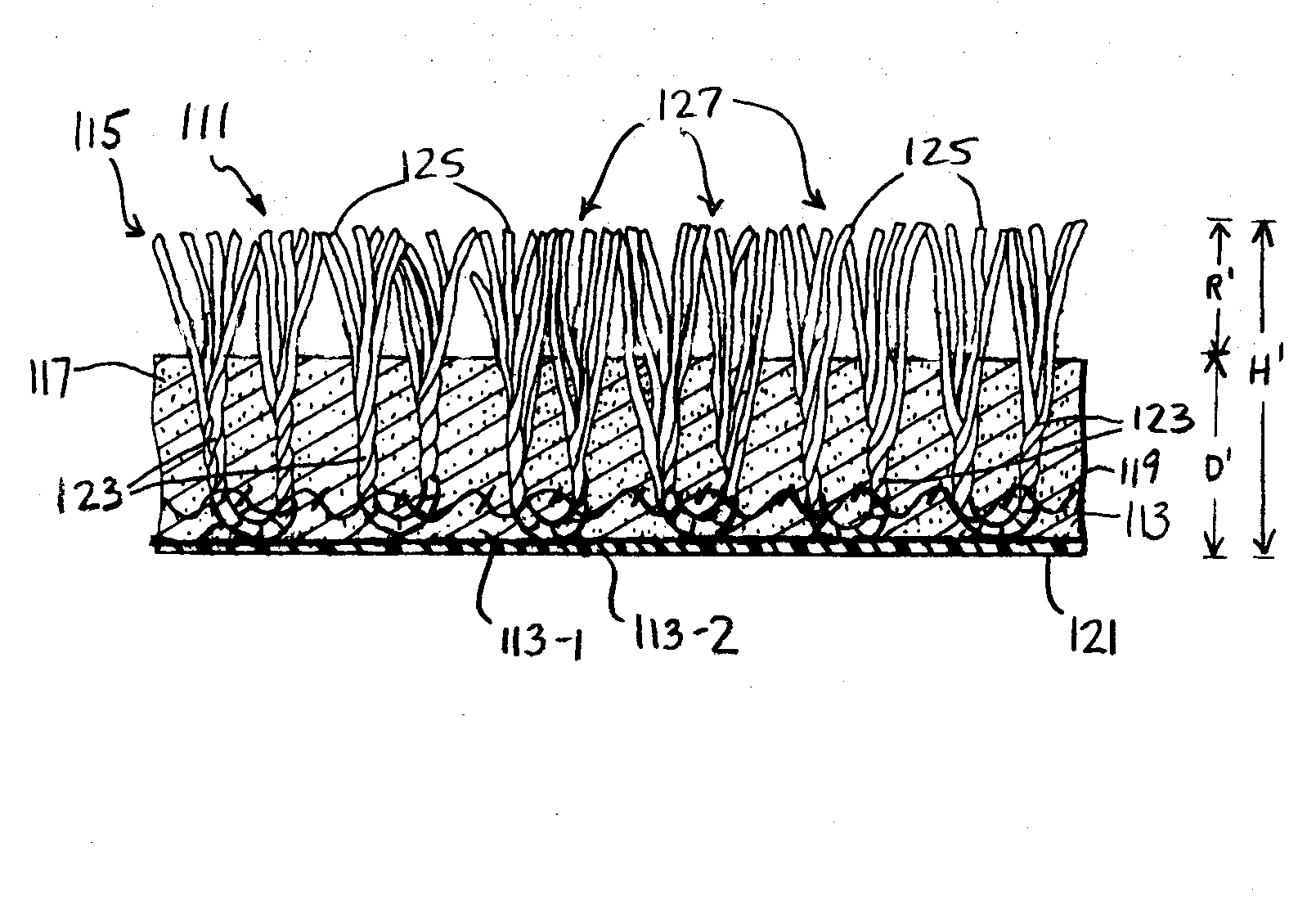

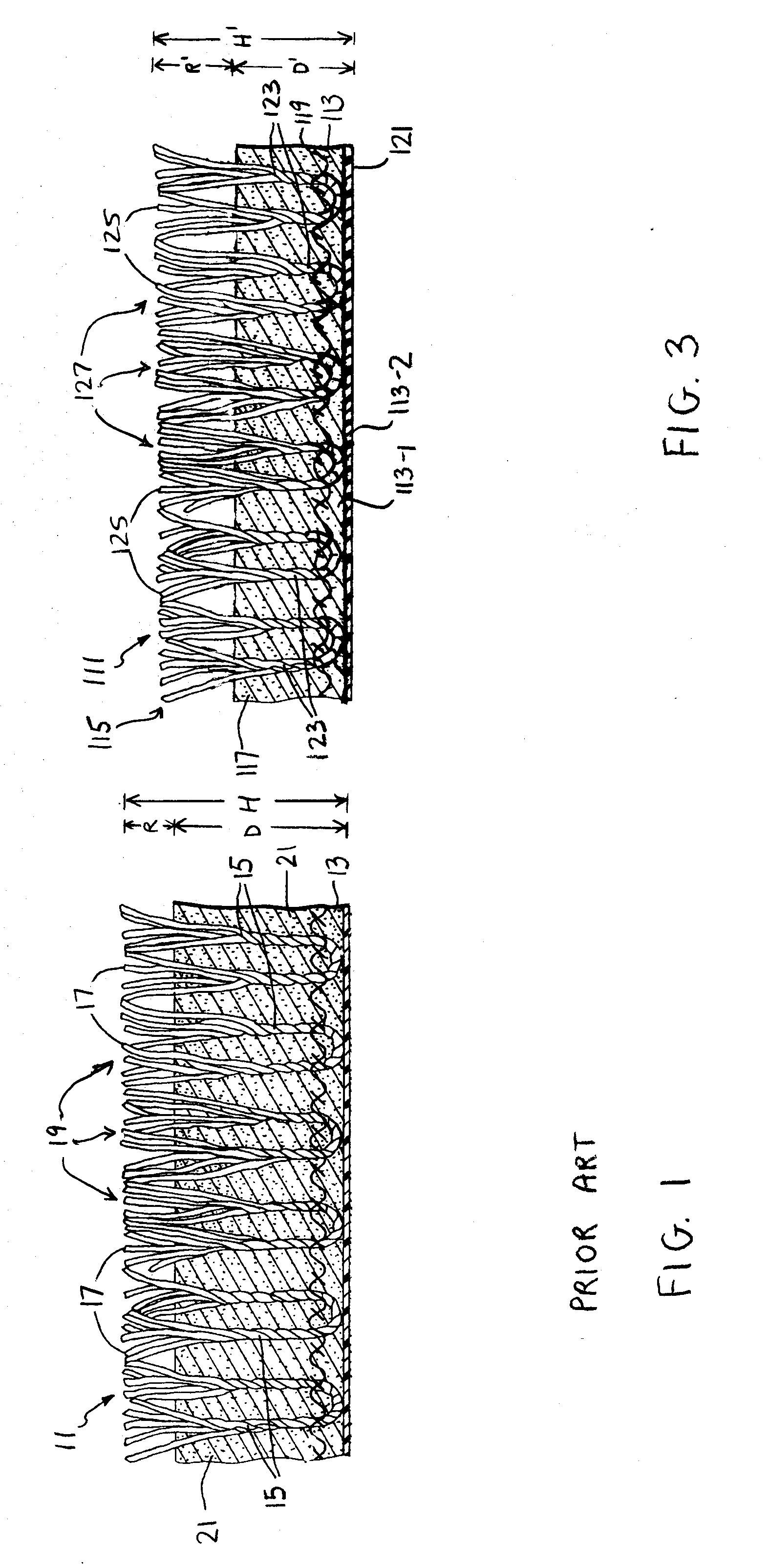

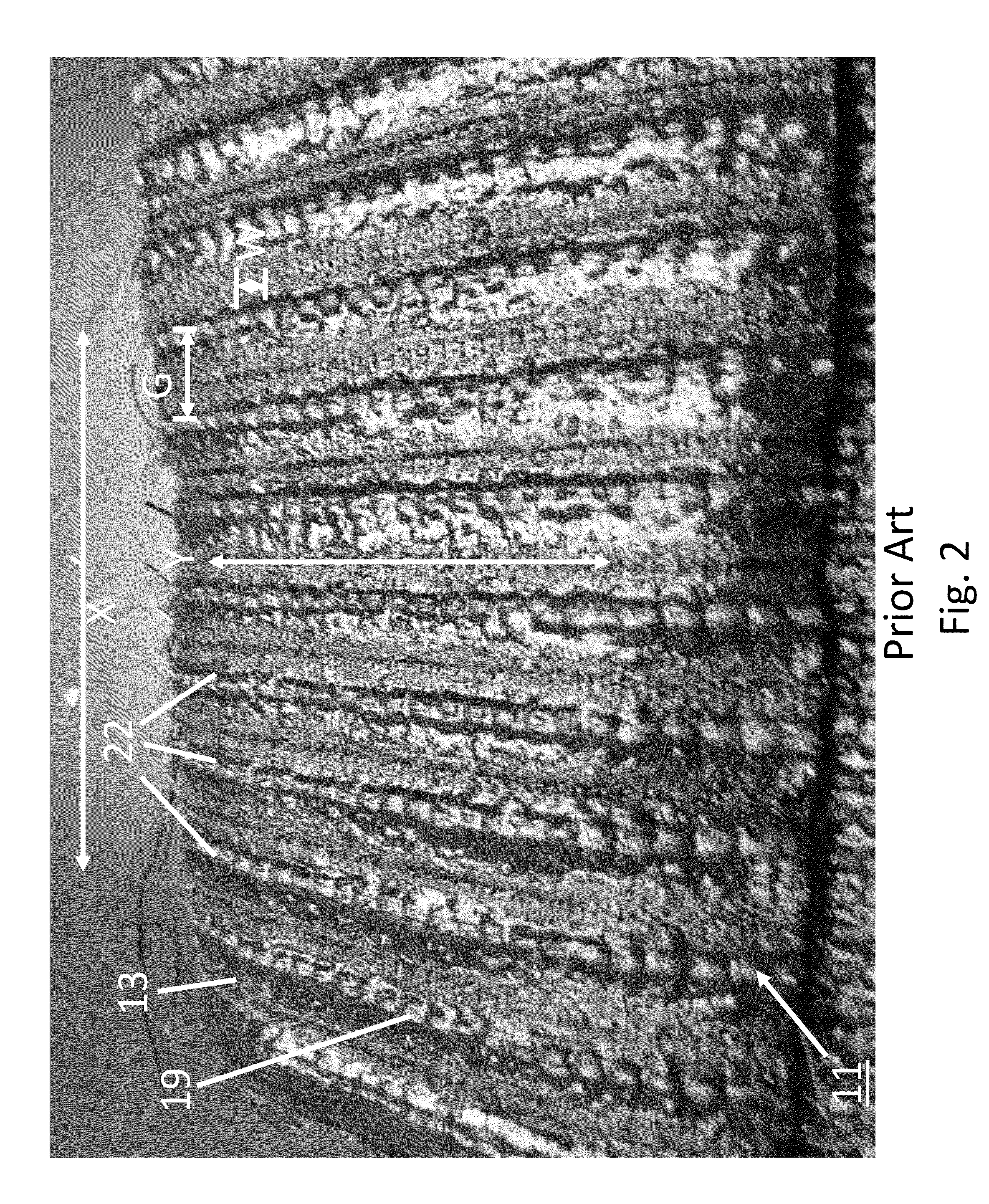

Artificial turf

InactiveUS20140193593A1Optimal performance characteristicMinimize retention of heatDead plant preservationArtificial flowers and garlandsInfillEnvironmental standard

An artificial turf for a synthetic field system includes a flexible, water-permeable backing, a pile fabric woven into the backing, and a limited layer of water-absorbent, eco-friendly and light reflective infill deposited within voids formed in the pile fabric. The pile fabric is constructed with a plurality of separate, upwardly standing, reduced height tufts, each tuft including a plurality of synthetic filaments that resemble individual blades of natural grass. The tufts are arranged into parallel rows, with the spacing between rows being fixed and equal to the spacing between successive tufts in each row so as to yield an artificial field surface with an increased density of filaments. The dimensional aspects and high filament density of the artificial turf introduces a number of notable advantages over conventional artificial turfs including better performance, less surface heat retention, improved aesthetics, reduced infill maintenance requirements, and greater compliance with environmental standards.

Owner:SPORTS FIELD HLDG

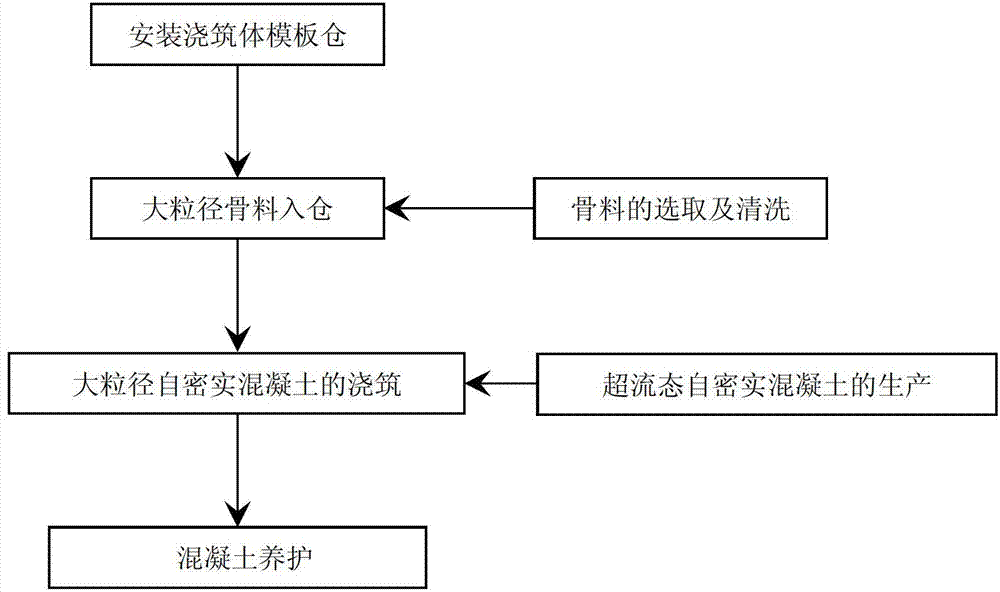

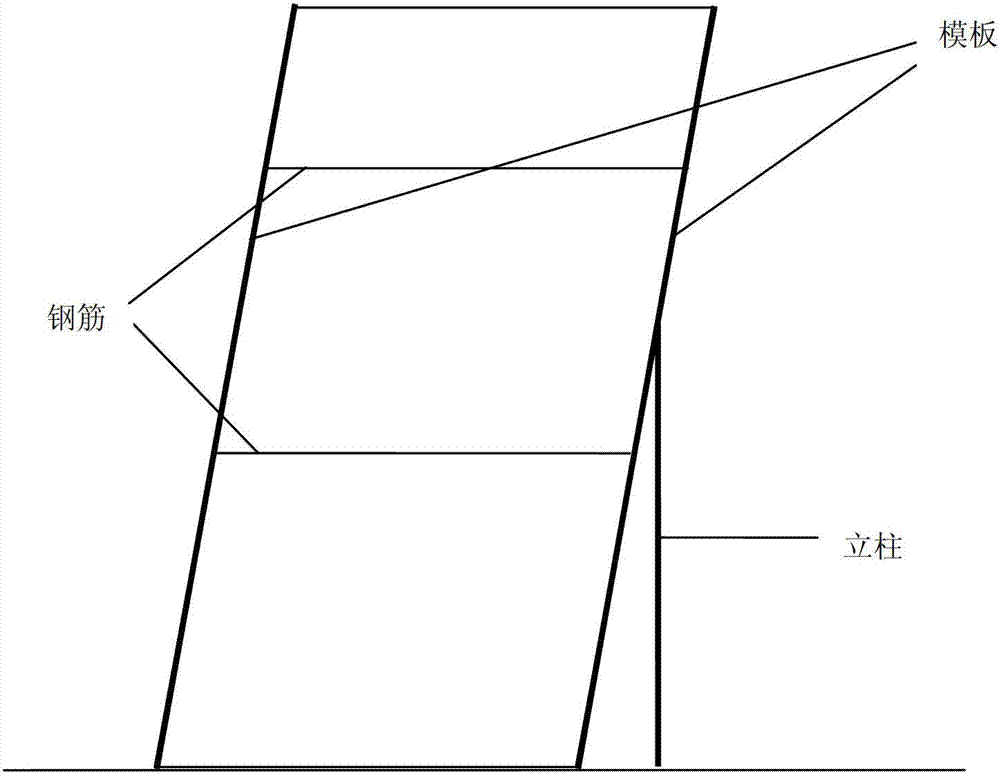

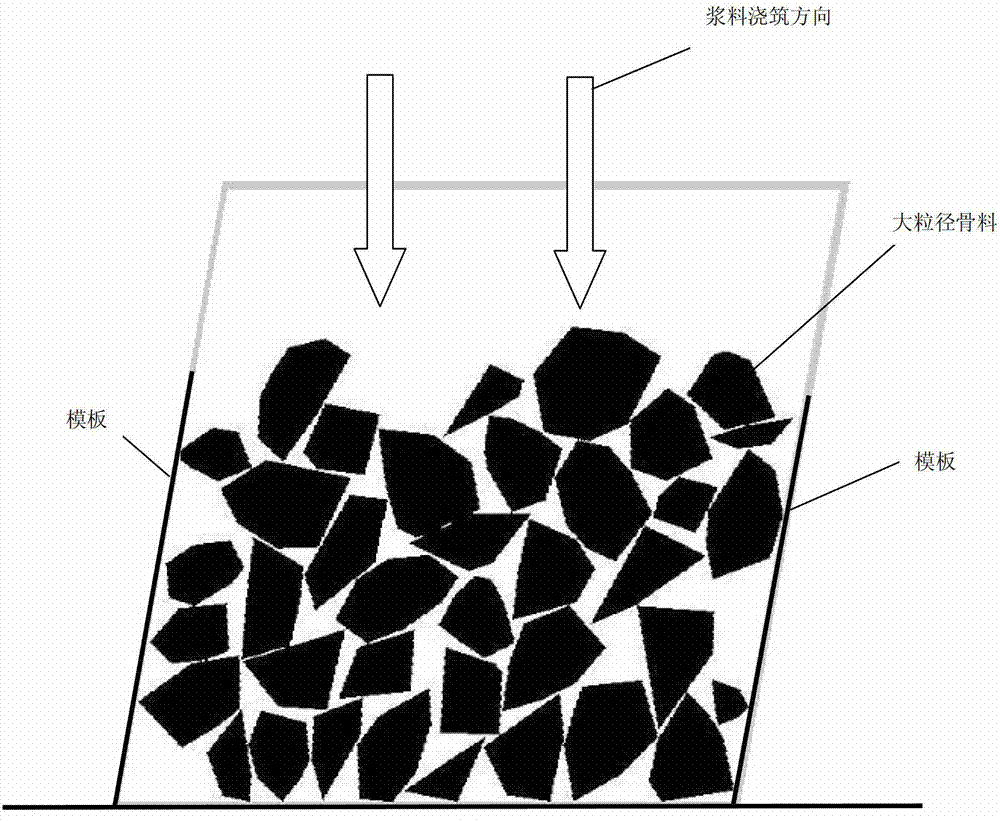

Self-compact concrete with oversized-particle aggregate and construction technology thereof

The invention relates to a self-compact concrete with oversized-particle aggregate. The self-compact concrete is prepared by pouring large-particle-size aggregate with particle size of 100mm-1500mm and superfluid self-compact concrete slurry, wherein the superfluid self-compact concrete slurry is prepared by adding water into cement, pulverized coal ash, silica fume, dedicated superfluid additive, sand, stones and other mineral admixtures and mixing. The construction technology comprises the steps of directly placing the oversized-particle aggregate into a construction bin to form large-particle-size aggregate accumulation body with certain natural clearances, then pouring the superfluid self-compact concrete slurry on the surface of the large-particle-size aggregate, filling the clearances of the large-particle-size aggregate by means of self gravity, forming a complete, compact and low-hydration-heat concrete structure together with the large-particle-size aggregate after the superfluid self-compact concrete slurry is hardened, wherein the strength grade of the concrete can meet different design demands. The self-compact concrete with oversized-particle aggregate is not only applicable to mass concrete construction, but also applicable to reinforcing bar system engineering.

Owner:GUIZHOU HIGHWAY ENG GRP +1

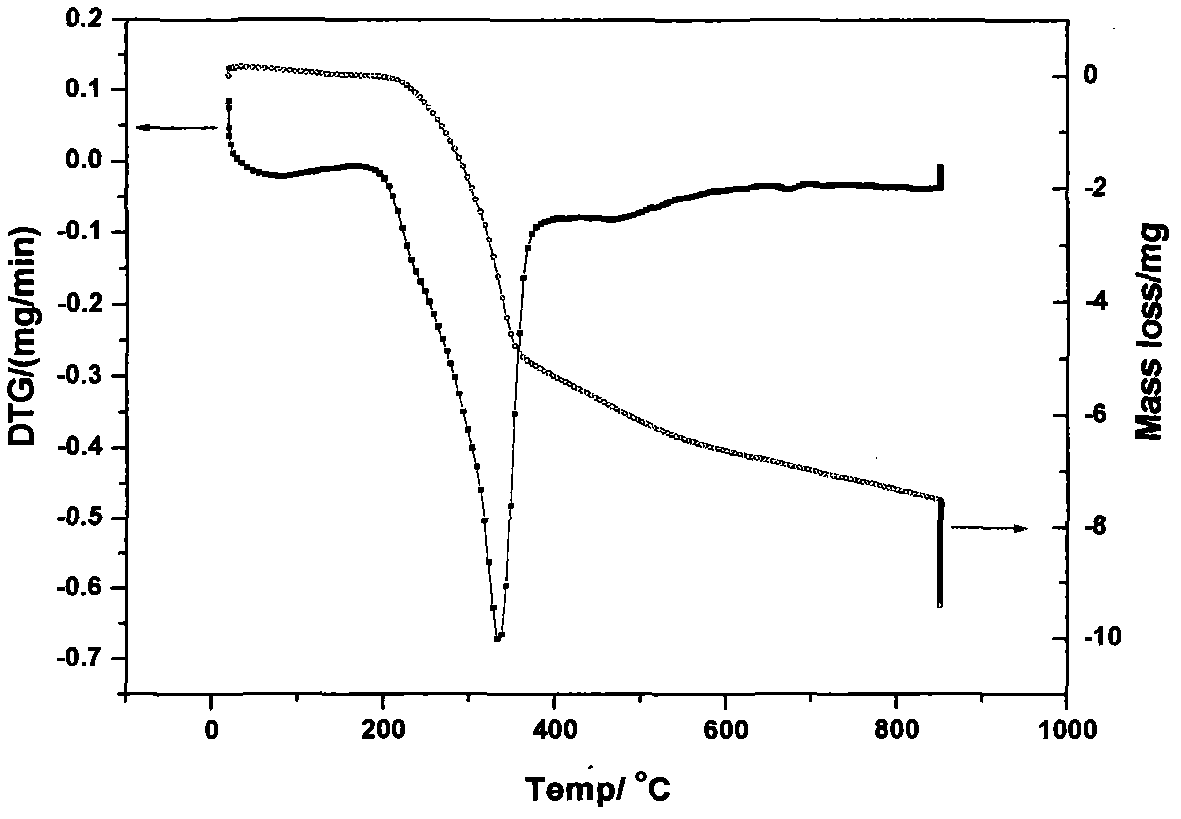

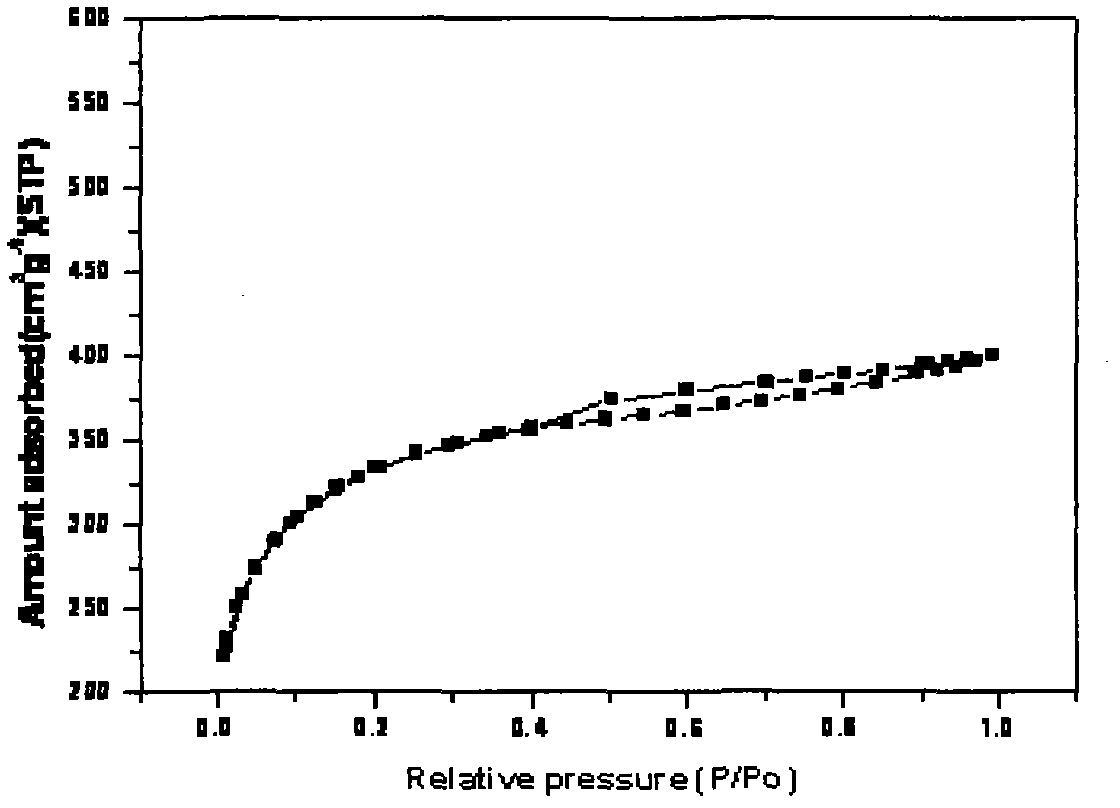

Method for preparing active carbon from lotus seed hulls

The invention discloses a method for preparing active carbon from lotus seed hulls, which relates to a method for preparing high-performance granular active carbon with a chemical activation method. The method comprises the following steps of: performing impurity removing, air drying, smashing, soaking, drying, carbonizing and activating on lotus seed hulls; and performing procedures such as recycling, acid cooking, rinsing, drying and the like to obtain finished granular active carbon. The active carbon has the advantages of uniform texture, firmness, developed air gap, controllable pore diameter, large specific surface area, and the like. The lotus seed hulls adopted in the method refer to crop waste which is not utilized effectively and has a sufficient source, so that environmentally-friendly granular active carbon is prepared by effectively utilizing the lotus seed hulls, the problem of environmental pollution caused by burning is solved, preparation cost of active carbon is reduced greatly, and industrial production is available.

Owner:JIANGXI NORMAL UNIVERSITY

Lightweight panel

ActiveUS20070054102A1Improve sag resistanceSolid waste managementPaper/cardboard layered productsWater basedAdhesive

A composite board comprising a core and a paper facer sheet adhesively laminated to one face of the core, the core including a mixture of perlite, binder, and cellulose fiber, the core being formed as a water slurry with said perlite, binder and cellulose fiber being uniformly distributed therein, the perlite being in an expanded state such that its particles include internal voids and exhibit a density of about 5 to about 15 pounds per cubic foot and being present in sufficient quantity to occupy in bulk at least 50% of the volume of the core, on a weight basis, the perlite and cellulose fiber combined forming at least 25% of the weight of the core. The paper facer being laminated to the core with a water-based adhesive applied across substantially the full area of the facer, both the compressive strength of the perlite and tensile strength of the cellulose fiber being utilized by operation of the binder such that a relatively high nail-pull capacity in comparison to the weight of the composite board is achieved and sag resistance is imparted to the composite board when it is used for ceiling tile.

Owner:USG INTERIORS INC

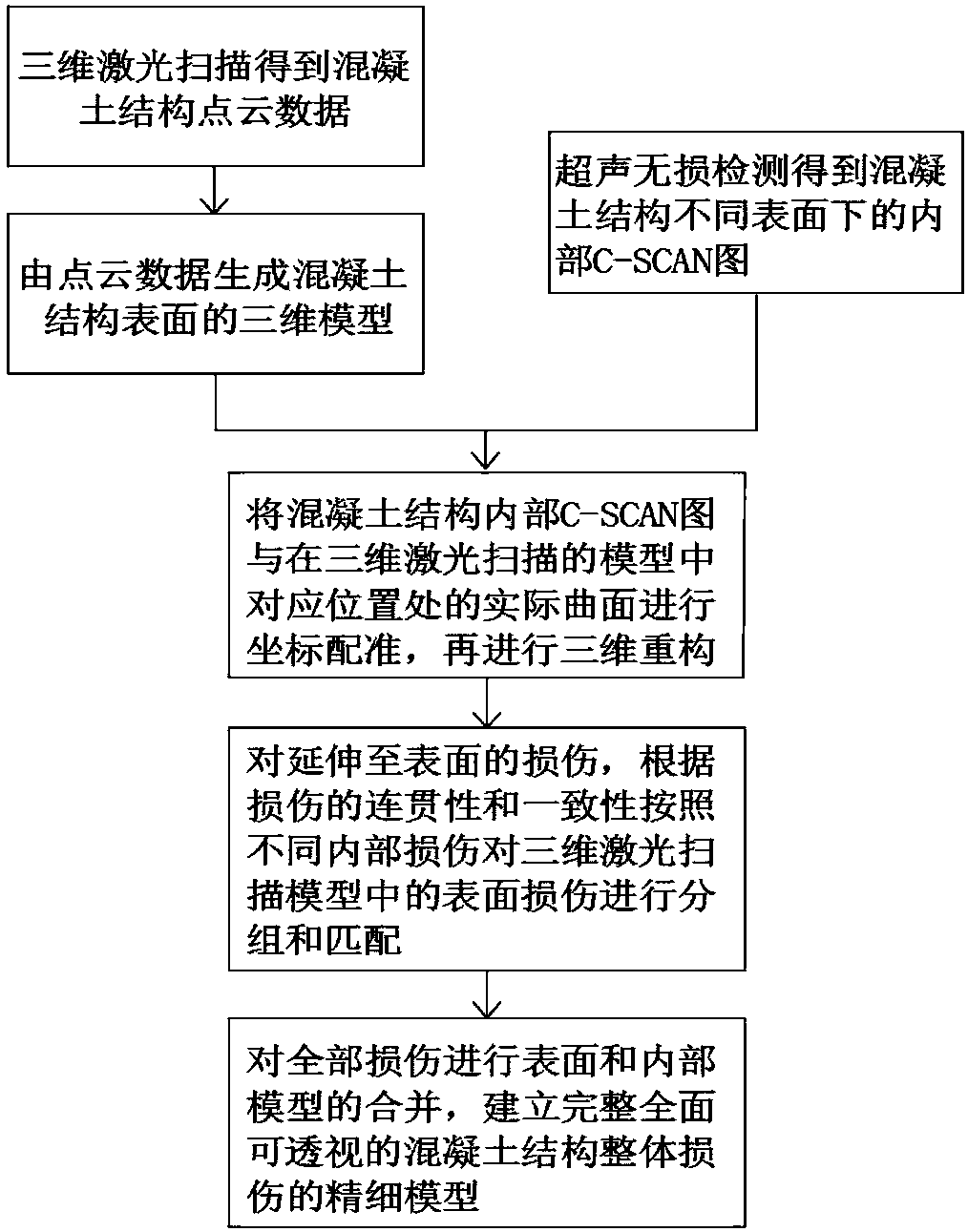

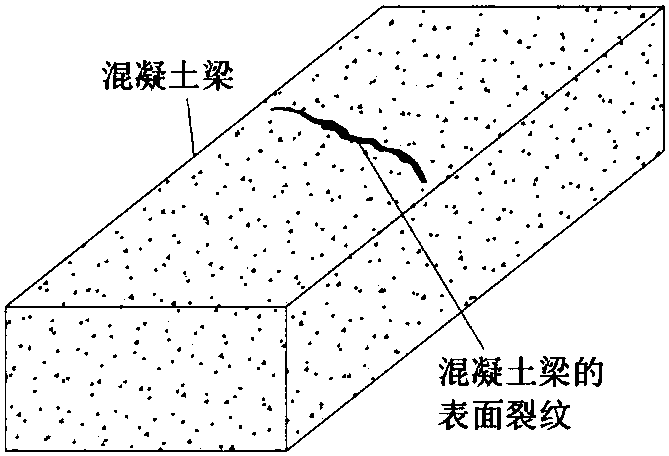

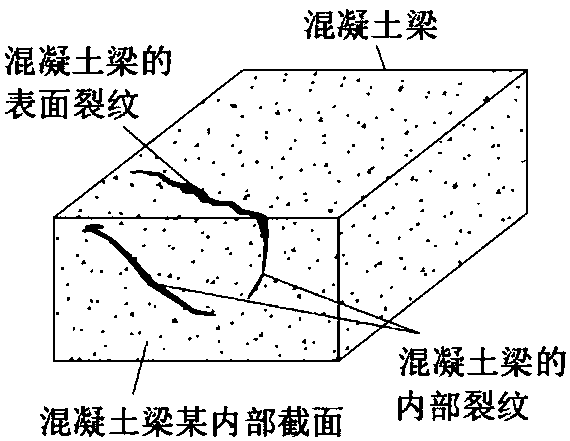

Refined modeling method of damages at concrete structure surface and inner part

InactiveCN107655971AQuickly acquire 3D point cloud dataRealize three-dimensional restorationAnalysing solids using sonic/ultrasonic/infrasonic wavesOptically investigating flaws/contaminationPoint cloudStructure of the Earth

The invention discloses a refined modeling method of damages at concrete structure surface and inner part, which mainly includes steps of scanning a damaged concrete structure surface by a three-dimensional laser, and acquiring three-dimensional point cloud data; building a three-dimensional model and its coordinate system; scanning and detecting the inner part of the concrete structure without damage face by face, and acquiring a C-SCAN cross section of the inner structures in relative to different depths of the scanning face; matching the C-SCAN cross section with the actual corresponding curve face in a three-dimensional model according to the calibrated coordinate and the three-dimensional model; restructuring the concrete structure three-dimensionally; scanning the concrete structuresurface before damage according to above steps; building a concrete three-dimensional structure before damage; comparatively analyzing the concrete three-dimensional structures before and after damage; accurately positioning and measuring the damage, gap, crack and deformation at the surface and the inner part of the concrete structure. The detecting result forms the C-SCAN cross section drawing in relative to different depths of the scanning face, the inner damage condition is displayed more intuitively.

Owner:TIANJIN UNIV

Semi-flexible pavement injection grout

InactiveCN101693611AImprove road performanceExtended service lifeIn situ pavingsRoad surfaceUltimate tensile strength

A semi-flexible pavement injection grout is characterized in that the semi-flexible pavement injection grout comprises the following raw materials by mass percentage: 54.0064-65.6958 percent of common silicate cement, 33.1-37.3 percent of water, 0.001-0.662 percent of water reducing agents, 0-7.944 percent of plumping agents and 0-0.8028 percent of air entraining agents. By employing the semi-flexible pavement injection grout for construction, the grout can be easily poured into the clearances of asphalt mixtures and well combined with the asphalt mixtures. The semi-flexible pavement injection grout of the invention has small dress shrinkage and strong intensity, which can improve the road performance of semi-flexible pavement and prolong the life time of the semi-flexible pavement.

Owner:CHANGAN UNIV

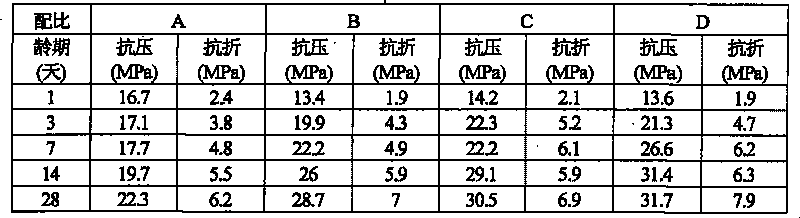

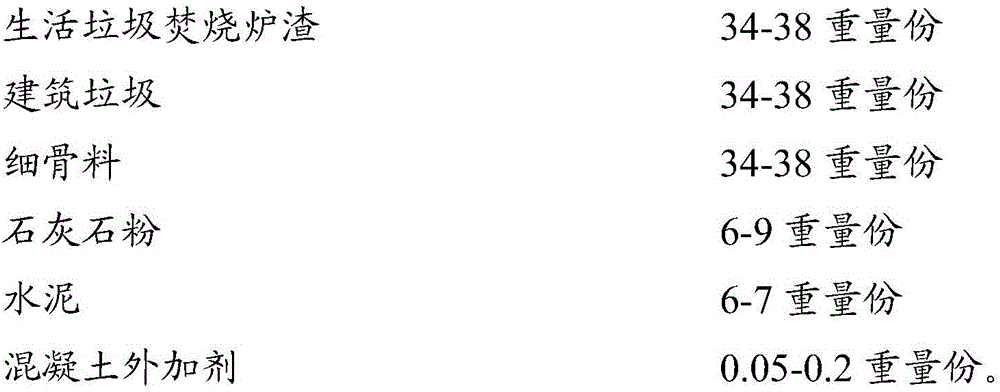

Regenerated backfill concrete prepared from domestic garbage incineration residues and application of regenerated backfill concrete

ActiveCN106830777AHigh solid waste contentHigh compressive strengthLand resourcesCompressive strength

The invention discloses regenerated backfill concrete prepared from domestic garbage incineration residues and application of the regenerated backfill concrete and belongs to the field of preparation of the regenerated backfill concrete. The regenerated backfill concrete is prepared from the following components in parts by weight: 30 to 40 parts of the domestic garbage incineration residue, 30 to 40 parts of construction waste, 30 to 40 parts of fine aggregate, 5 to 10 parts of limestone powder, 5 to 10 parts of cement and 0.03 to 1 part of a concrete additive. The optimal grading is realized by utilizing substances with different grain diameters; in a preparation process, the substances with relatively small grain diameters are filled into gaps among the substances with last-grade grain diameters in a mixing process through selection of specific grain diameters of all components, so that the adhesion between all grades of the grain diameters is enhanced; the gaps in the concrete are reduced and the compressive strength and durability of the concrete are greatly improved. To sum up, the regenerated backfill concrete with high solid waste content is successfully prepared and has the advantages of high solid waste utilization rate, high compressive strength and the like; meanwhile, the occupied area of solid wastes is also reduced and land resources are saved.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Bituminous paving compacting uniformity refinement detection and evaluation method

InactiveCN107036933ASolve the problem of lack of detection index of asphalt pavement compaction uniformityEffective evaluationPermeability/surface area analysisSpecific gravity measurementStatistical analysisRoad surface

Owner:FUYANG NORMAL UNIVERSITY +1

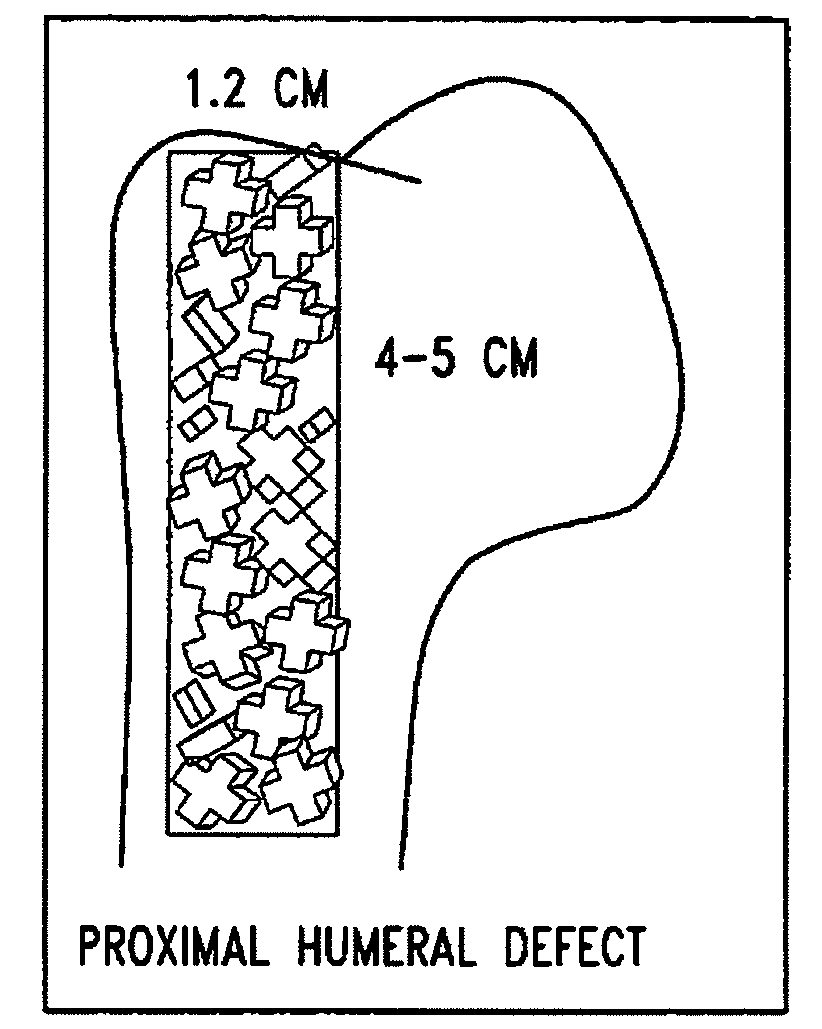

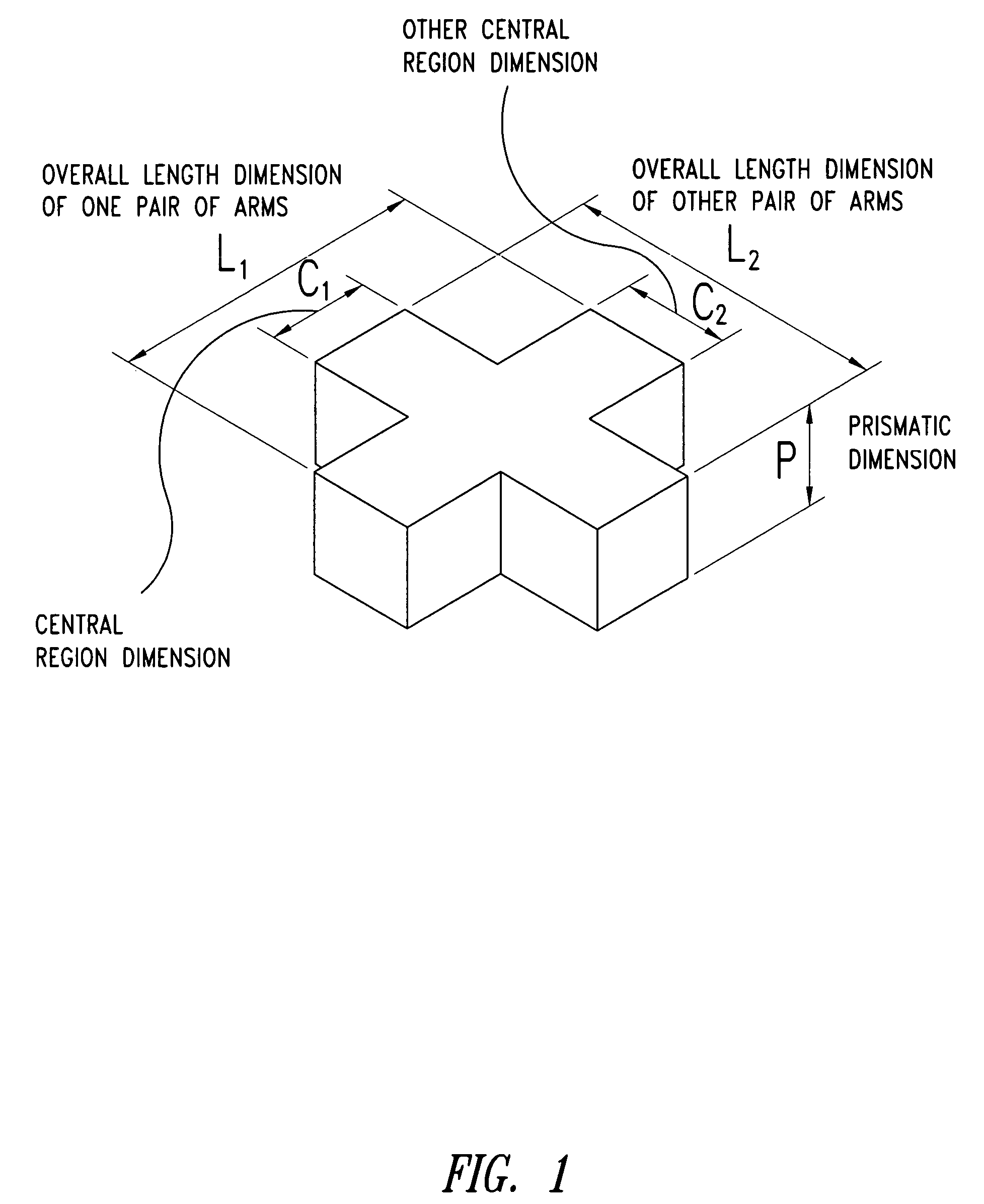

Bone void filler and method of manufacture

Bone void filler pieces that are conducive to packing or nesting when a plurality of pieces are located in a cavity in random orientation. The bone void filler of the present invention includes a higher bulk packing density and a porosity of less than 80% to provide a better match native bone ingrowth rate. Further, the bone void filler includes a bi-modal pore distribution with a high frequency of smaller pores to enhance the density characteristic of the bone void filler pieces. A method of manufacturing the bone void filler pieces includes a precursor powder composition suitable to form a ceramic matrix; the preform is converted by chemical reaction to a final composition. The preform further includes the use of a porogen that decomposes to gaseous decomposition products upon heating.

Owner:THEKEN SURGICAL LLC

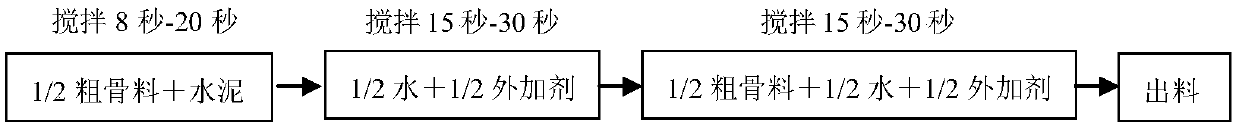

Preparation method for coal gangue aggregate no-sand porous plant-growing concrete

InactiveCN107857528ARealize comprehensive utilizationWide range of raw materialsPorosityPlant growth

The invention discloses a preparation method for coal gangue aggregate no-sand porous plant-growing concrete. The method comprises the following steps: taking coal gangue coarse aggregate as a skeleton structure, taking cement and fly ash as cementing materials, adding an admixture which is a water reducing agent, performing stirring step by step, performing vibration molding to obtain porous concrete, covering the concrete with a transparent plastic film, performing wet curing for 28 days, spraying an acetic acid aqueous solution at the surface of the porous concrete for alkali reducing treatment, detecting the pH value of the surface of the porous concrete, when the pH value is less than or equal to 9, stopping to spray the acetic acid aqueous solution, and performing natural drying to obtain the coal gangue aggregate no-sand porous plant-growing concrete. The concrete provided by the invention has the advantages of higher compressive strength, a large communicating porosity, good water permeability, and good air permeability; and the alkaline environment in gaps of the coal gangue aggregate no-sand porous plant-growing concrete after the pH value alkali reducing treatment is performed in a later period can be better improved to meet the environmental requirements of plant growth.

Owner:LIAONING TECHNICAL UNIVERSITY

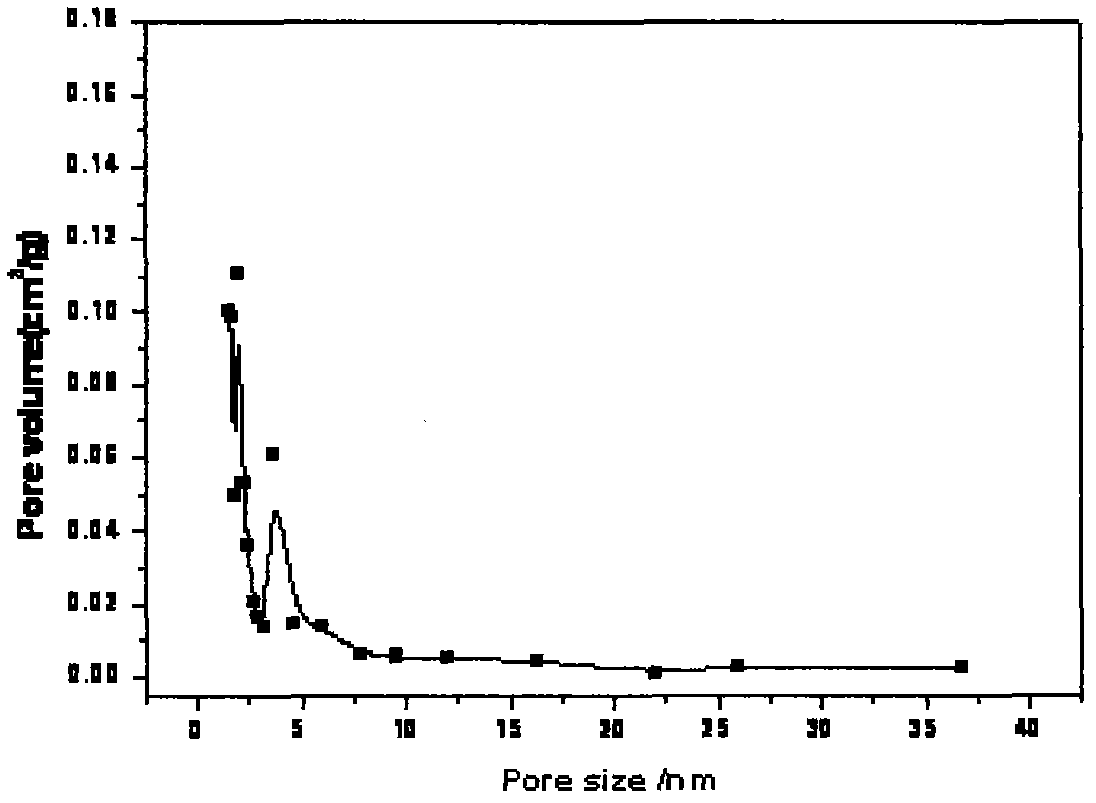

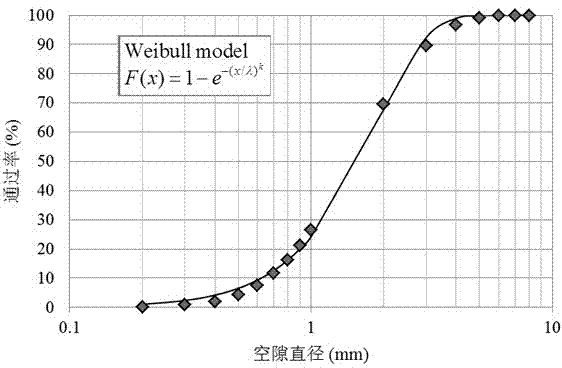

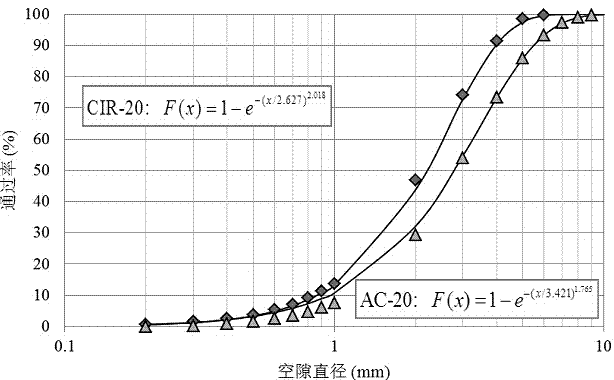

Void characteristic of asphalt mixture and extraction method of void characteristic

ActiveCN105445160AAccurate dataImprove processing efficiencyPermeability/surface area analysisVoid ratioScale space

The invention discloses a void characteristic of an asphalt mixture and belongs to the technical field of a civil engineering material. The void characteristic is a two-dimensional characteristic vector composed of a scale parameter and a shape parameter; the scale parameter and the shape parameter are obtained by fitting a void grading curve of the asphalt mixture by using a double-parameter Weibull distribution model; a logarithm transverse coordinate of the void grading curve is a size scale value of a void; and a vertical coordinate of the void grading curve is a quantity occupied ratio of the void smaller than the size scale value. The invention further discloses an extraction method of the void characteristic. With the adoption of the void characteristic of the asphalt mixture and the extraction method of the void characteristic, scale space distribution information of the void in the material can be relatively comprehensively and accurately reflected, and the distinguishing degree on the different materials is high; the formal structure is simple and subsequent simulation modeling is convenient to carry out; and the void characteristic can be used for replacing an existing void ratio to be used as a material parameter for characterizing the properties of the asphalt mixture.

Owner:南京路通检测有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com