Preparation method for coal gangue aggregate no-sand porous plant-growing concrete

A technology of planting concrete and porous concrete, which is applied in the field of preparation of coal gangue aggregate sand-free porous planting concrete, can solve the problem that the comprehensive utilization rate is less than 10%, and achieve the effects of improving the alkali environment, wide sources, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

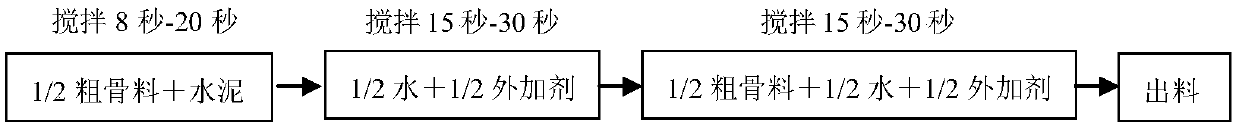

Method used

Image

Examples

Embodiment 1

[0035] The cement in this example is PO.42.5 ordinary portland cement produced in Fuxin. The main chemical composition and technical parameters of cement are shown in Table 1 and Table 2.

[0036] The main chemical composition (%) of table 1 cement

[0037]

[0038] Table 2 Main Technical Parameters of Cement

[0039]

[0040] Coarse aggregate is unburned coal gangue that has not been sorted for a long time. It is crushed by a crusher and then screened to form a continuously graded coarse aggregate with a particle size range of 4.75-31.5mm. The main chemical composition and basic physical and mechanical properties of unburned coal gangue are shown in Table 3 and Table 4 below.

[0041] The main chemical composition (%) of table 3 unburned coal gangue

[0042]

[0043] Table 4 Basic physical and mechanical properties of unburned coal gangue

[0044]

[0045] The external admixture is selected from Class 2 fly ash from Fuxin Power Plant. The main chemical compon...

Embodiment 2

[0061] The cement in this example is PO.42.5 ordinary portland cement produced in Fuxin. The main chemical composition and technical parameters of the cement are the same as in Example 1; the coarse aggregate is the unburned coal gangue that has not been sorted for a long time, which is crushed with a crusher, and then sieved to form a continuously graded coarse aggregate with a particle size range of 4.75-31.5mm. aggregate. The main chemical components and basic physical and mechanical properties of unburned coal gangue are the same as in Example 1;

[0062] The admixture is a naphthalene-based high-efficiency water reducer; ordinary tap water is used for mixing and curing of coal gangue aggregate sand-free porous plant-growing concrete.

[0063] The preparation method of coal gangue aggregate sand-free porous planting concrete is carried out according to the following steps:

[0064] (1) Crushing solid waste unburned coal gangue with a jaw crusher, and then sieving and dis...

Embodiment 3

[0075] The cement in this example is PO.42.5 ordinary portland cement produced in Fuxin. The main chemical composition and technical parameters of the cement are the same as in Example 1; the coarse aggregate is the unburned coal gangue that has not been sorted for a long time, which is crushed with a crusher, and then sieved to form a continuously graded coarse aggregate with a particle size range of 4.75-31.5mm. aggregate. The main chemical components and basic physical and mechanical properties of unburned coal gangue are the same as in Example 1;

[0076] The admixture is a naphthalene-based high-efficiency water reducer; ordinary tap water is used for mixing and curing of coal gangue aggregate sand-free porous plant-growing concrete.

[0077] The preparation method of coal gangue aggregate sand-free porous planting concrete is carried out according to the following steps:

[0078] (1) Crushing solid waste unburned coal gangue with a jaw crusher, and then sieving and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com