Soil and stone mixed filling roadbed compaction degree detecting method

A detection method and compaction technology, which can be used in the field of foundation soil survey, infrastructure engineering, construction, etc., and can solve problems such as subgrade damage, lack of universal adaptability, and difficulty in excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

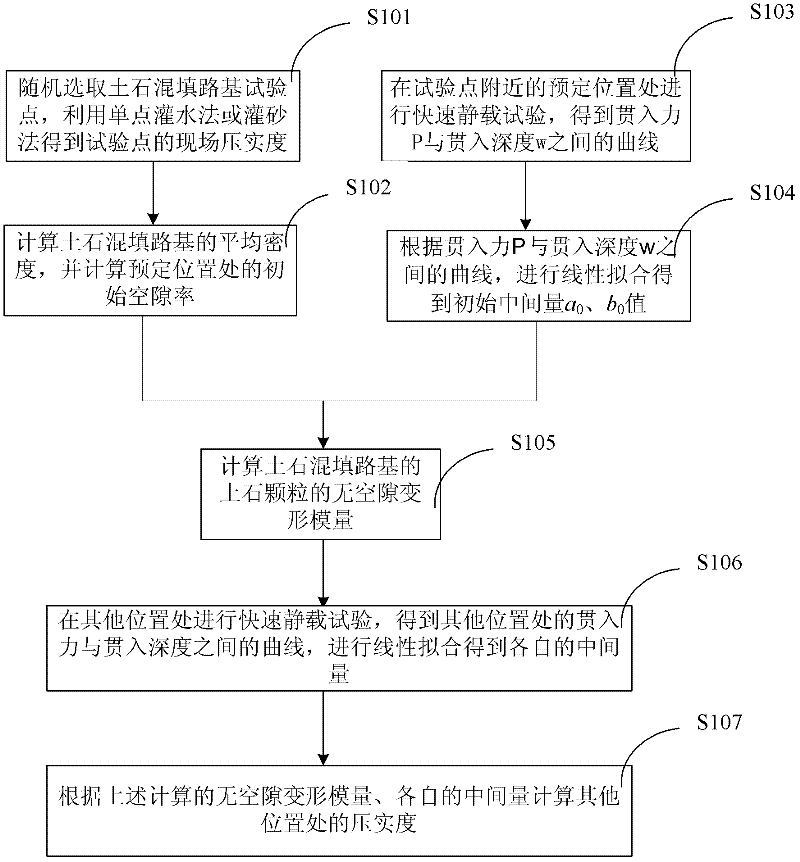

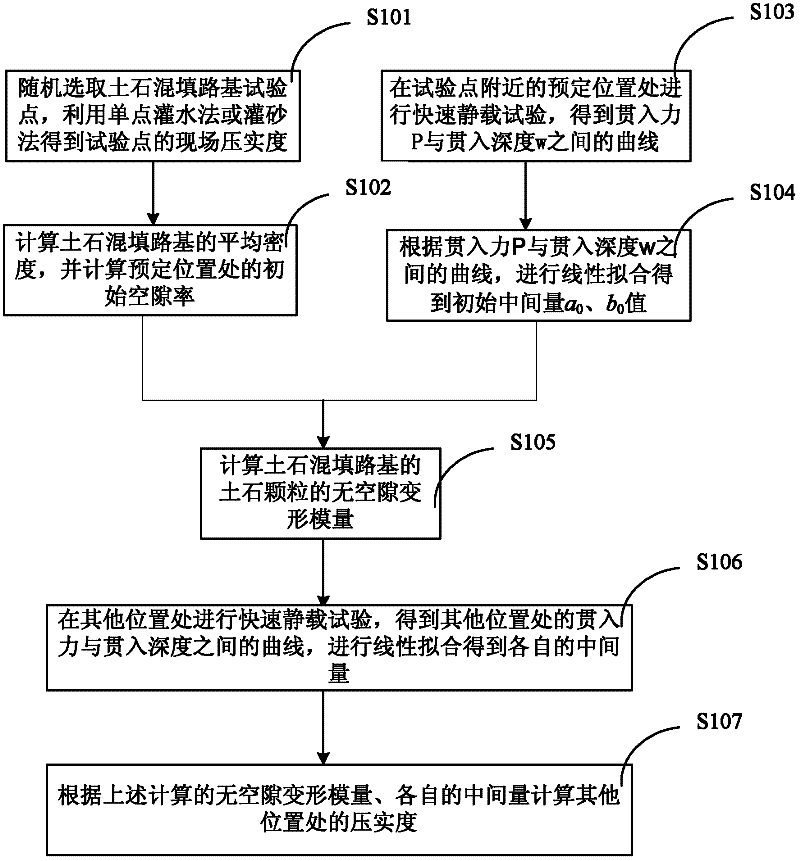

[0015] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] The method for detecting the degree of compaction of soil-rock mixed filling subgrades of the present invention is mainly used for detecting the degree of compaction of soil-rock mixed filling roadbeds, and according to the characteristics of soil-rock mixed fillings, the relationship between force, displacement and compaction degree in rapid static load tests is established Model, through the degree of influence of the degree of compaction on the force-displacement curve, inversion of some parameters and degree of compaction of soil-rock mixed filler; figure 1 , including steps:

[0017] S101. Randomly select soil-rock mixed subgrade test points, and use the single-point irrigation method or sand irrigation method to obtain the on-site compaction degree K of the test points 0 ;

[0018] The on-site compaction degree K of the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com