Roof greening structure and greening method

A roof greening and main structure technology, applied in roof decoration, building roofs, botanical equipment and methods, etc., can solve the problems of rainwater accumulation, heavy weight of the structure layer, and failure to meet the use requirements of water storage and regulation, etc. Achieve the effect of reducing flood peaks, good root fixation, and favorable penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

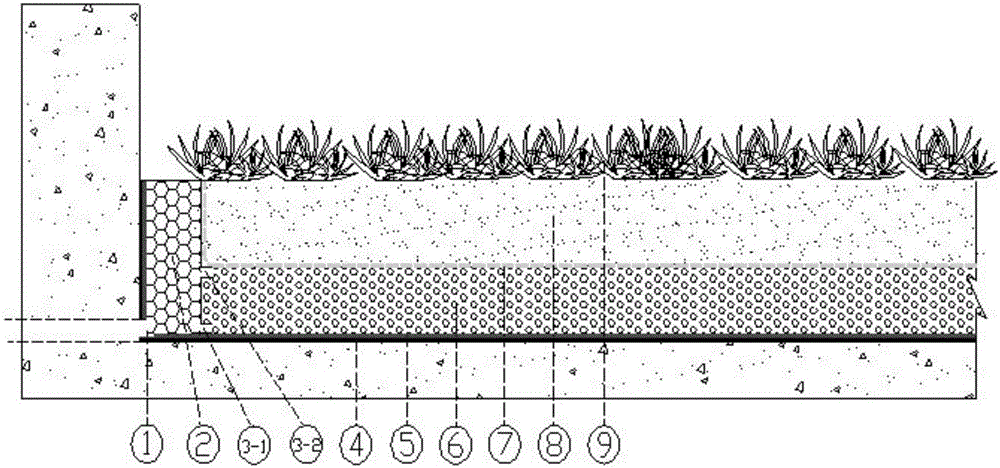

[0047] 1) Set up an inspection well (2) with a width of 20 cm along the roof edge, and set a drain outlet (1) at the lower part of the contact surface between the inspection well and the roof, and set a spare drain at the upper and lower parts of the contact surface between the inspection well and the aquifer. Water port (3-1) and overflow port (3-2);

[0048] 2) Cleaning the roof, laying a layer of SBS modified asphalt root puncture-resistant waterproof membrane with a thickness of 5mm on its surface as the waterproof root layer (4), and performing a closed water test;

[0049] 3) Lay a protective layer with a thickness of 1mm on the surface of the waterproof root layer (5) HDPE anti-seepage film, and the lap width of the HDPE anti-seepage film is 10cm;

[0050] 4) On-site mixing of lightweight aggregate permeable concrete, first mix cement and pumice evenly according to the proportion, then add water, a special reinforcing agent for permeable concrete, and a water-retaining ...

Embodiment 2

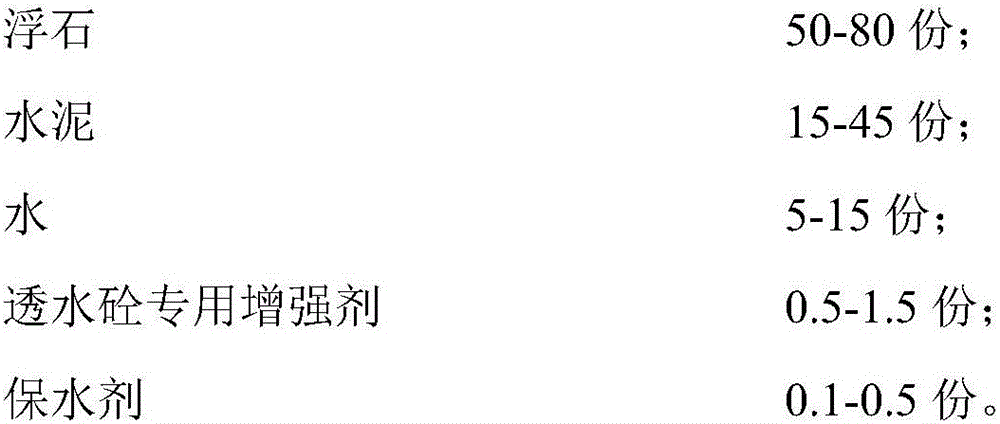

[0058] Omit the same part as in Example 1, the difference is that the thickness of the lightweight aggregate permeable concrete water storage layer is 10cm, and the specific ratio is as follows:

[0059]

[0060]

[0061] Among them, the weight ratio components of the special reinforcing agent for permeable concrete are as follows: 15.8% deionized water; 80% Japanese Showa AD-10 emulsion; 2% Kaiyuan chemical powder polyvinyl alcohol 2488; 1% Sika Polycarboxylate superplasticizer 325C; 0.2% of Dow Corning Dimethicone OFX-0193.

Embodiment 3

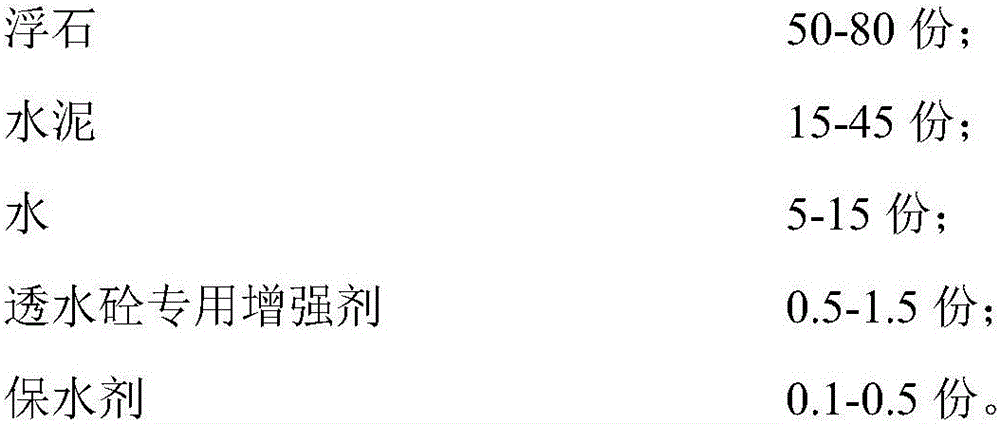

[0063] Omit the same part as in Example 1, the difference is that the specific proportion of lightweight aggregate permeable concrete is as follows:

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com