Patents

Literature

1573 results about "Pervious concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pervious concrete (also called porous concrete, permeable concrete, no fines concrete and porous pavement) is a special type of concrete with a high porosity used for concrete flatwork applications that allows water from precipitation and other sources to pass directly through, thereby reducing the runoff from a site and allowing groundwater recharge.

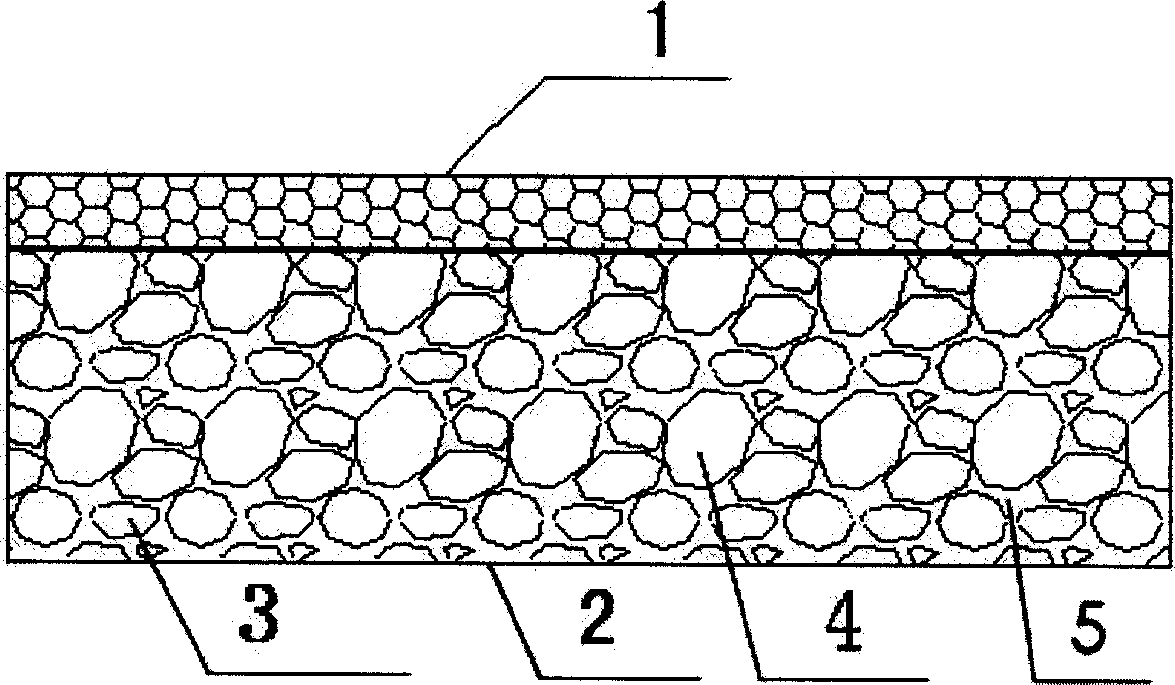

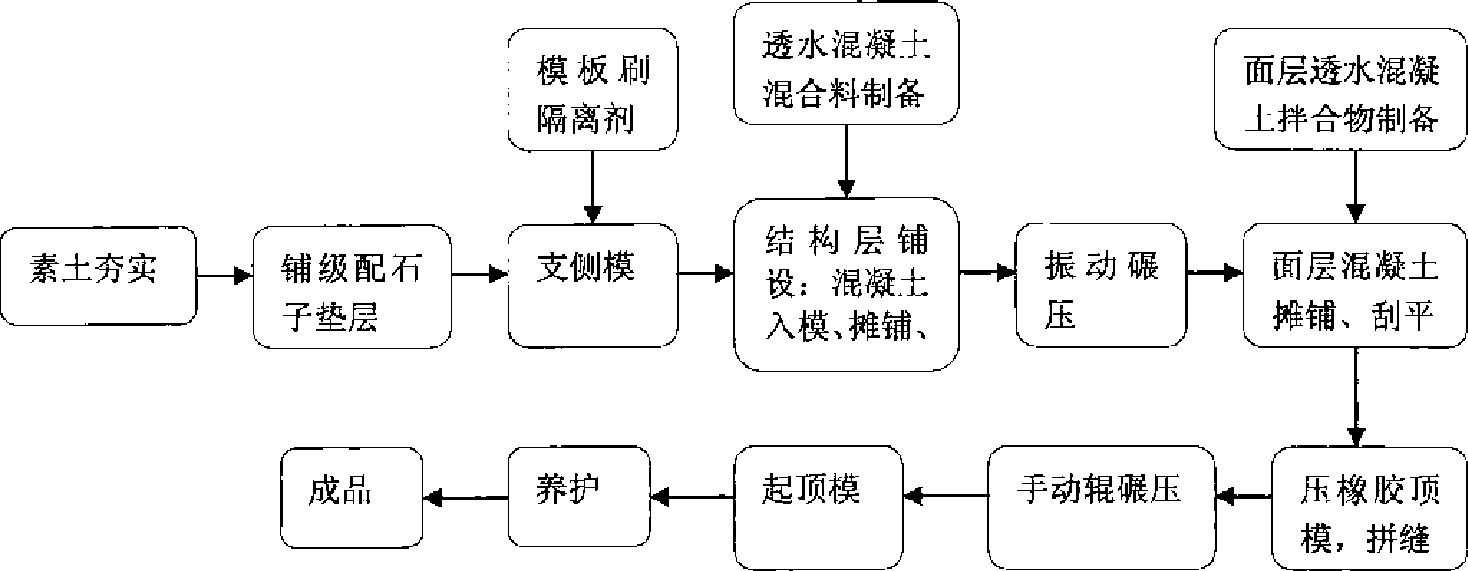

High-strength water-permeable concrete floor brick and its production method

The production process of permeable high-strength concrete paver includes the steps of: the first making base layer via mixing cement 18-21 wt%, small rubble of 3-5 mm size 50-55 wt%, large rubble of 7-10 mm size 18-21 wt%, admixture 0.1-6 wt% and water in 0.2-0.23 weight of cement, molding and vibrating to form; and the subsequent making facing layer via mixing cement 15-22 wt%, quartzite 76-85 wt%, admixture 0.1-6 wt%, dispersible latex powder 0.2-0.6 wt% and water in 0.24-0.26 weight of cement, pouring the mixture onto freshly formed base layer, and vibrating to form; demolding; and curing to obtain the finished product. The permeable high-strength concrete paver has high strength, high water permeability and no need of baking, and may be used widely.

Owner:潘英豪

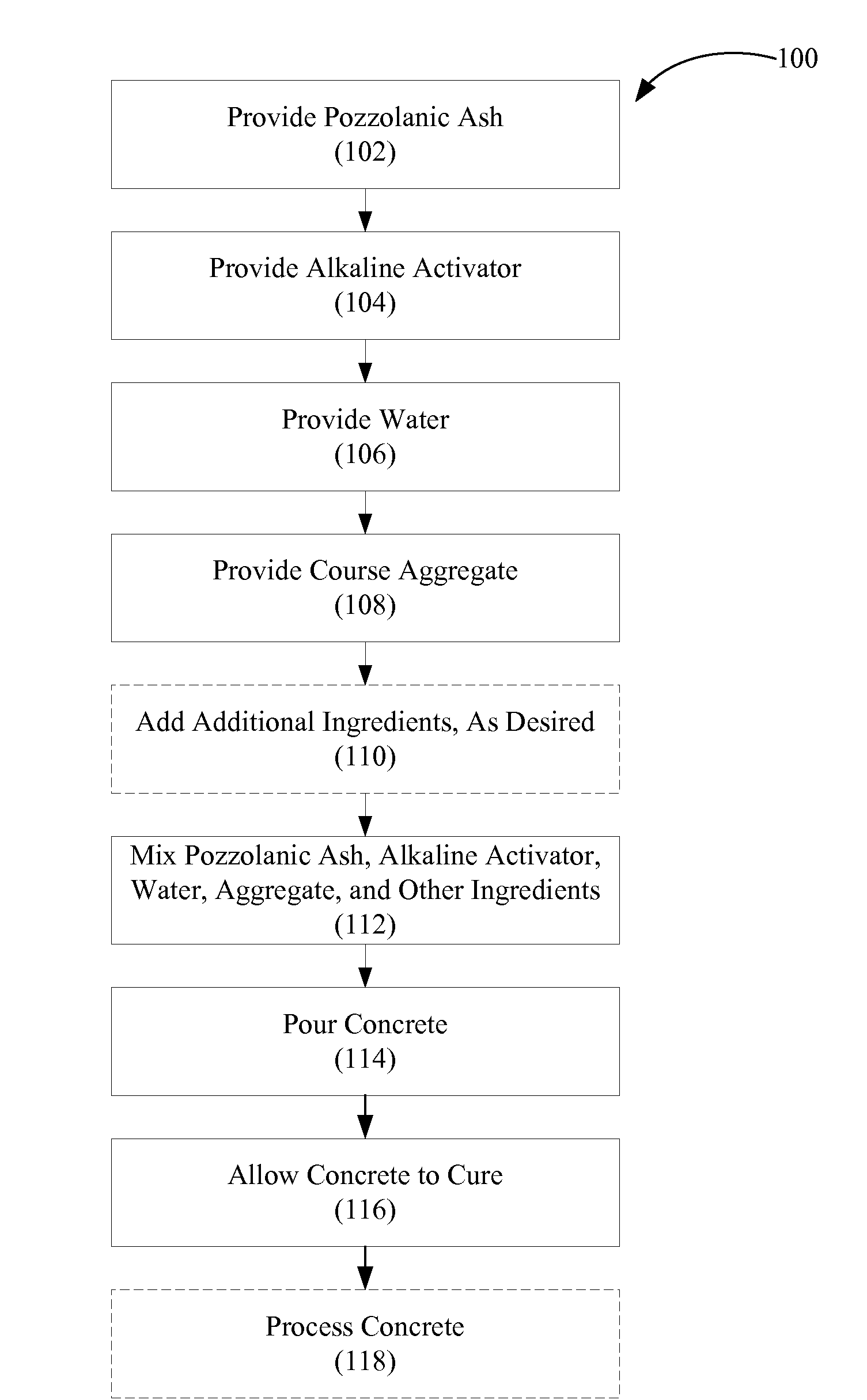

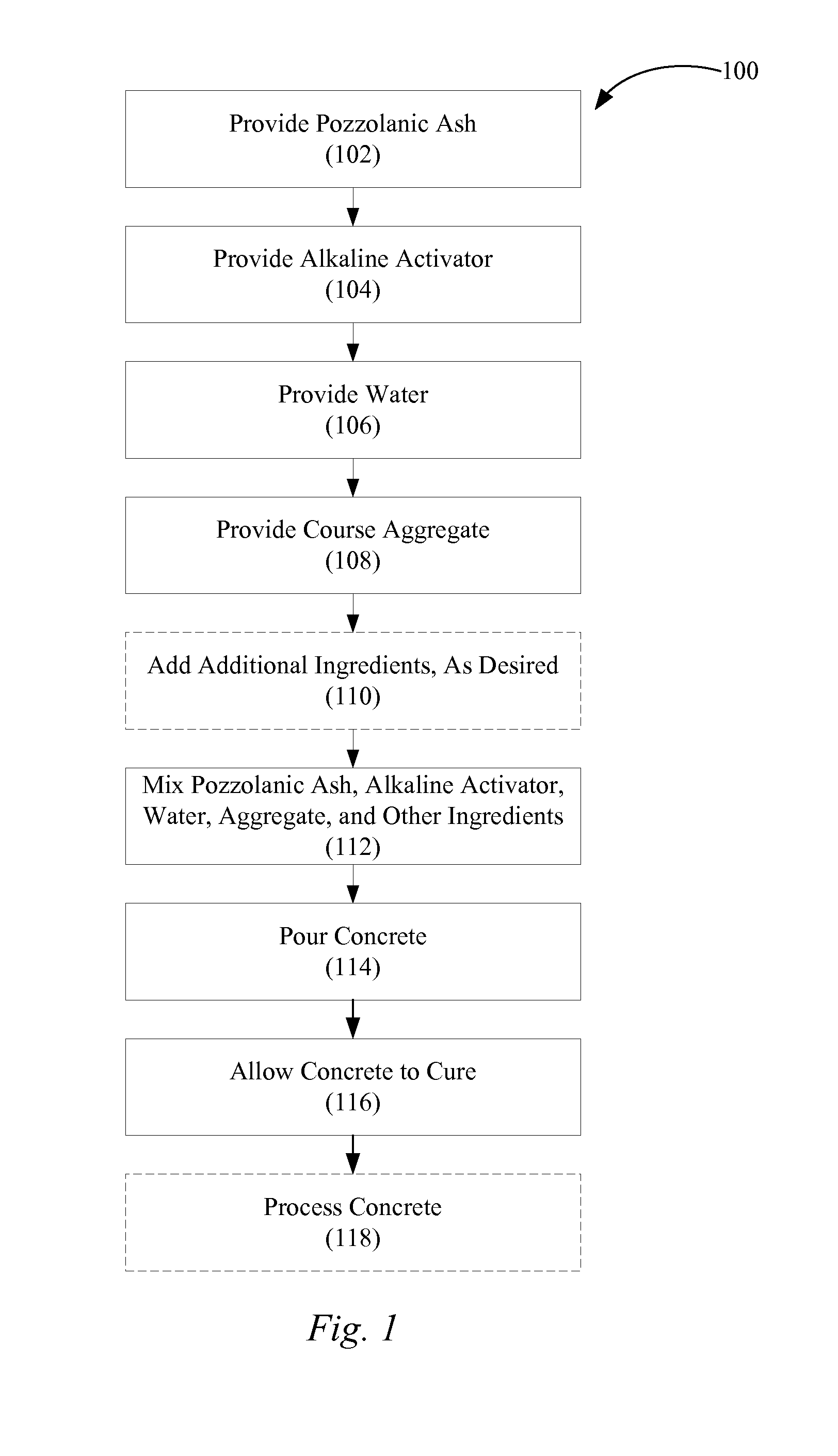

Previous concrete comprising a geopolymerized pozzolanic ash binder

ActiveUS20100058957A1Low costImprove performanceSolid waste managementCement productionAluminateCombustion

A process for making a pervious concrete comprising a geopolymerized pozzolanic ash. Generally, the process includes mixing a solid aggregate and a geopolymerized pozzolanic ash binder together to form a pervious concrete mixture. Some examples of suitable aggregates comprise recycled carpet, recycled cement, and aggregates of coal-combustion byproducts. The geopolymerized pozzolanic ash binder is made by combining a pozzolanic ash, such as fly ash, with a sufficient amount of an alkaline activator and water to initiate a geopolymerization reaction. The activator solution may contain an alkali metal hydroxide, carbonate, silicate, aluminate, or mixtures thereof. In some aspects, the final concrete forms a solid mass in the form of pavement or a pre-cast concrete shape. The solid mass of concrete may have a void content of between about 5% and about 35%.

Owner:CERAMTEC

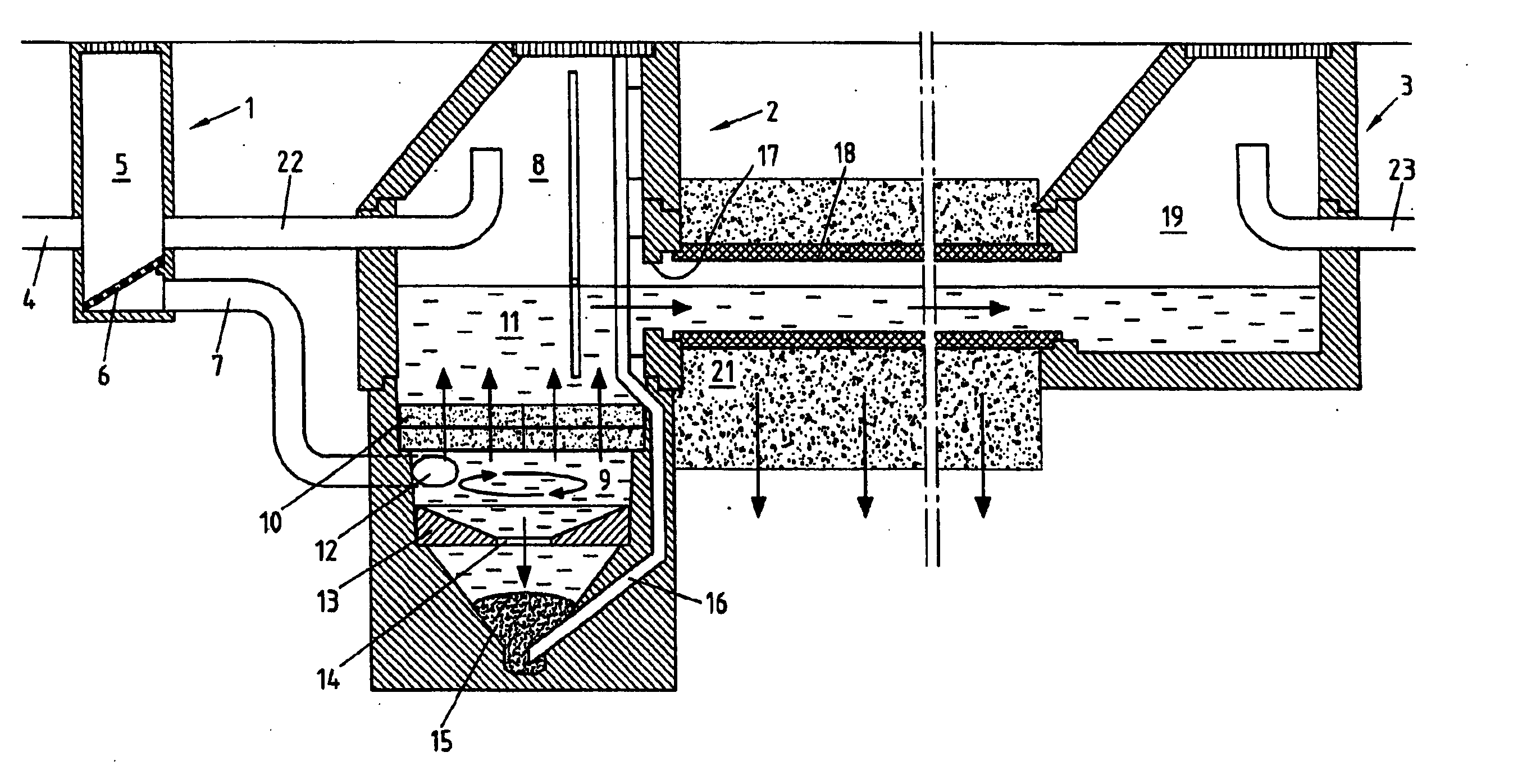

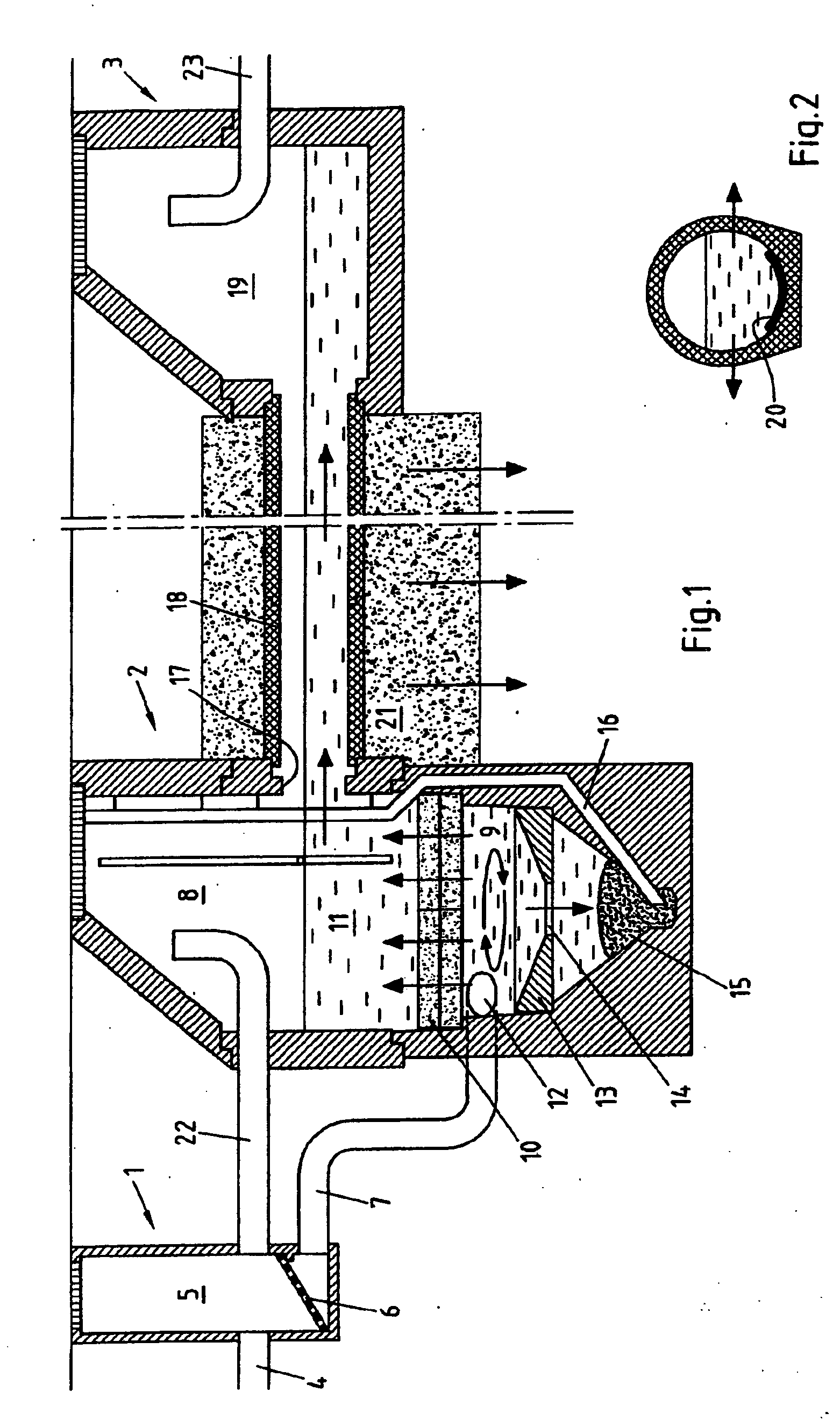

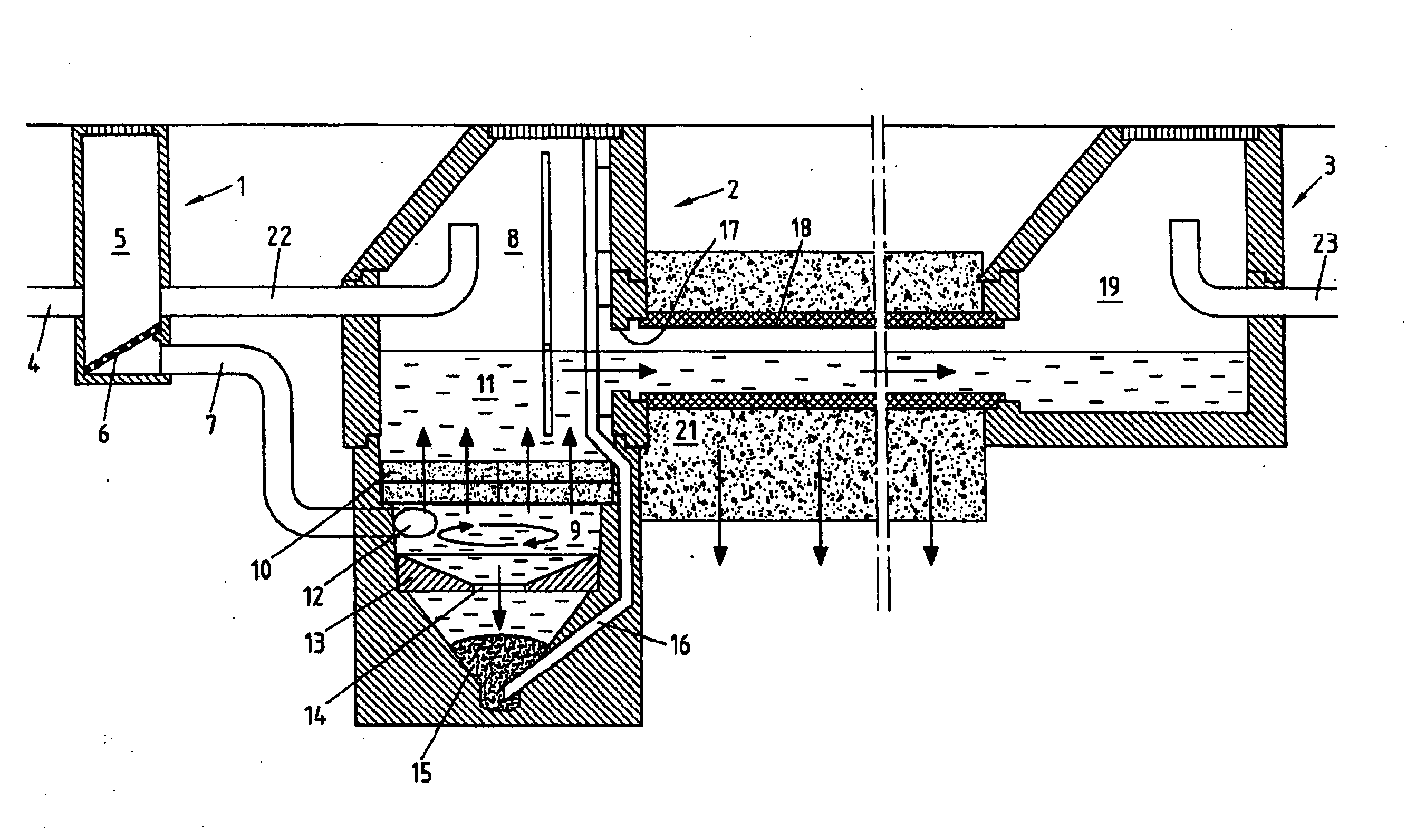

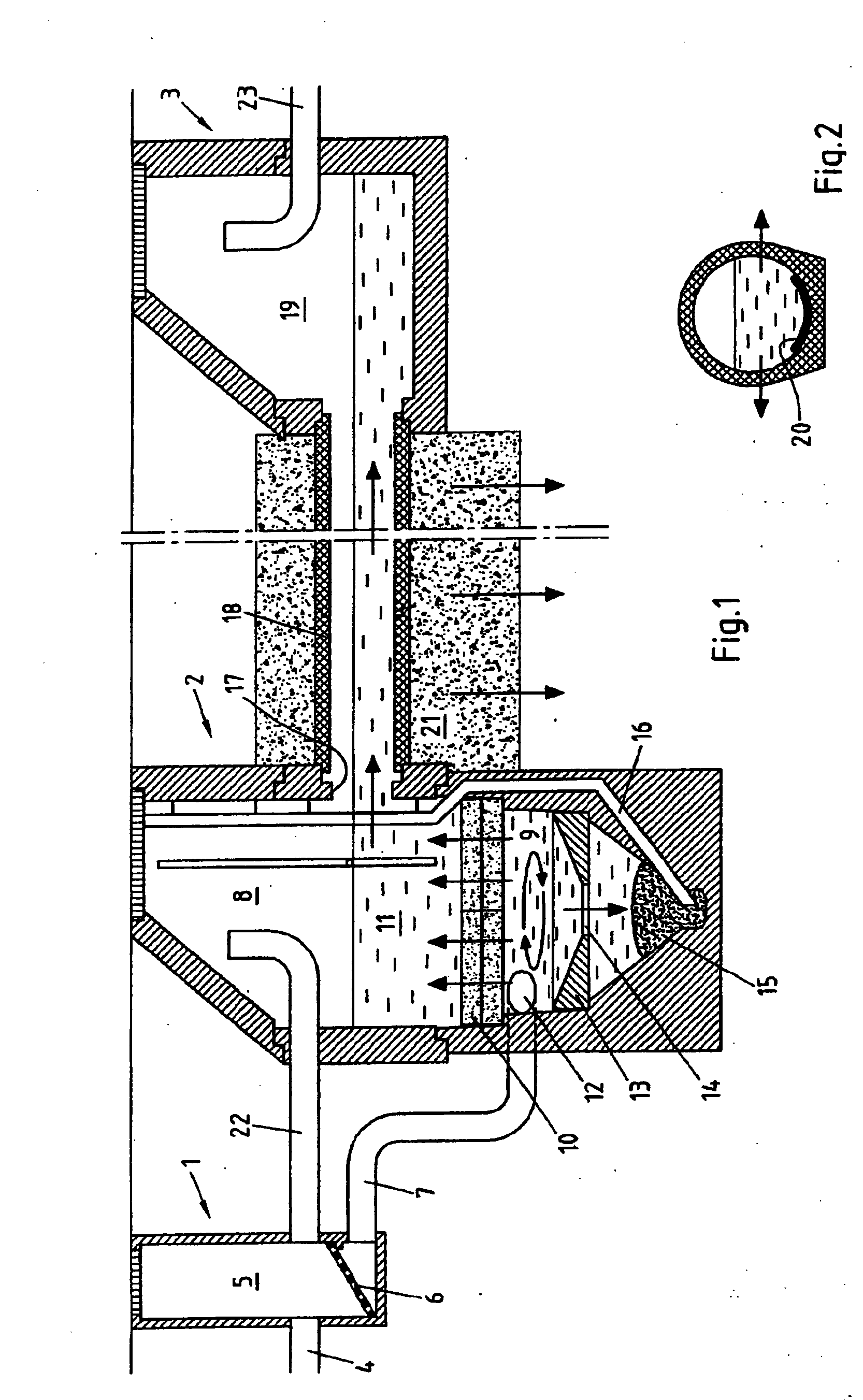

Filter element for water loaded with solid particles and dissolved toxic substances and purification system equipped with said filter element

InactiveUS20060163147A1Enhance adsorption action of filterHigh pH-valueSewerage structuresTreatment involving filtrationWater flowEnvironmental engineering

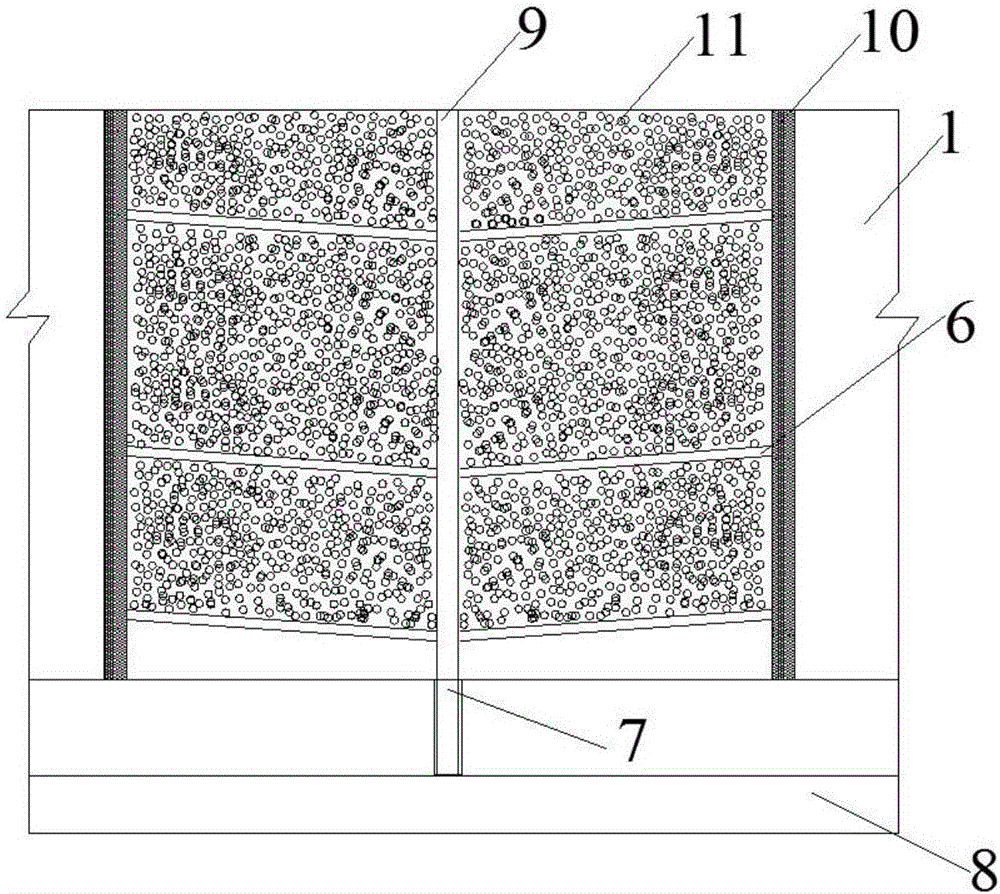

The invention relates to a filter element consisting of a molded body of porous concrete, which element is arranged in the water stream of a purification system. In particular, the filter element (10) is a molded pervious concrete layer arranged as a partition between a lower compartment (9) and an upper compartment (11) of a treatment chamber (8), wherein the water inlet (12) opens into the lower compartment (9) and a water outlet (17) issues from the upper compartment (11). The pervious concrete filter layer may contain one or more additives to enhance adsorption of pollutants, such as heavy metal ions, phosphorous, hydrocarbons or other target soluble pollutants.

Owner:ROYAL ENVIRONMENTAL SYST +1

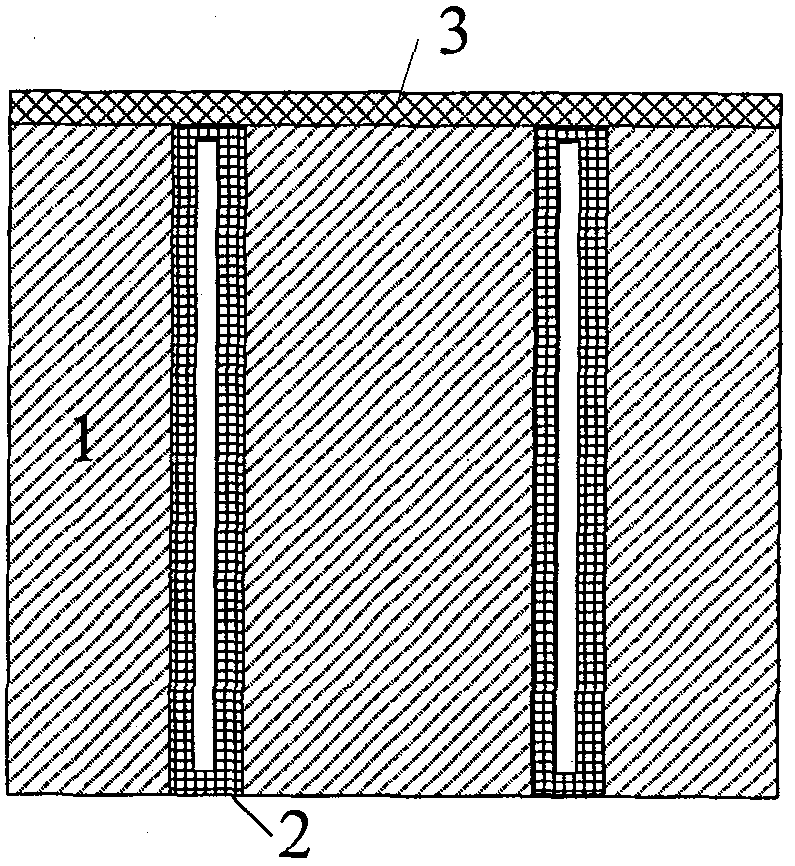

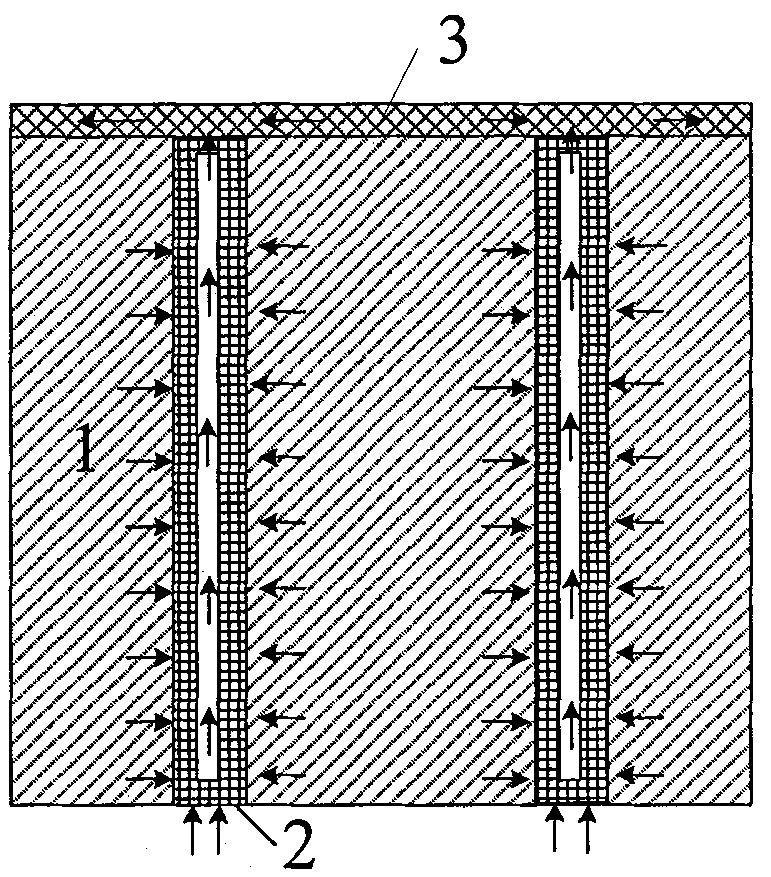

Pervious concrete and construction method thereof

ActiveCN104402339AImprove workabilityIncreased intensityIn situ pavingsRoad surfaceUltimate tensile strength

The invention discloses pervious concrete and a construction method thereof. The pervious concrete comprises the following raw materials in percentage by weight: 13.1-15.9% of cement, 12.7-15.6% of river sand, 59.6-66.0% of stones, 3.7-3.9% of water and 4.5-5.0% of admixtures, wherein the admixtures comprise the following raw materials in percentage by weight: 45-50% of ultrafine mineral powder, 15-20% of heavy calcium carbonate, 15-20% of gypsum powder, 3-5% of polypropylene fiber, 5-10% of a polycarboxylate water reducing agent, 4.2-8.4% of adhesive powder and 2-5% of a pigment. The pervious concrete provided by the invention has relatively high water permeability, strength and durability; after the pervious concrete is applied to a practical engineering, the pervious concrete can greatly improve the problem of poor drainage of a hardened road surface, so that the development of the pervious concrete can be promoted.

Owner:TIANYUAN CONSTR GROUP

Water permeable concrete and manufacturing method thereof

InactiveCN101190833AQuality improvementHigh strengthSolid waste managementWater storageWeather resistance

The invention discloses a pervious concrete and is characterized in that the pervious concrete is made by mixing cement, aggregate, water, water reducer agent and adhesive evenly; and the cement, the aggregate, the water, the water reducer agent and the adhesive are mixed in different weight proportions of 1-1.2 to 5.5-8.5 to 0.2-0.5 to 0.01-0.2 to 0.01-0.2. The invention can solve the natural ecology problems of hardened ground in cities, atmospheric circulation as well as soil and water moisture retention, thereby forming a high-quality natural ecology environment and maintaining urban ecological balance. The pervious concrete consists of two pervious surface courses and two macadam bases in different particles so as to provide a water storage structure which can store the water until the water penetrates into the soil; meanwhile, the invention can be made into building block, which can be provided with different decorative patterns and colors on the surface, and has the advantages of artistic quality, water permeability, good water retention, skid resistance, high strength, cold resistance and weather resistance, etc.

Owner:上海恒方防腐工程有限公司

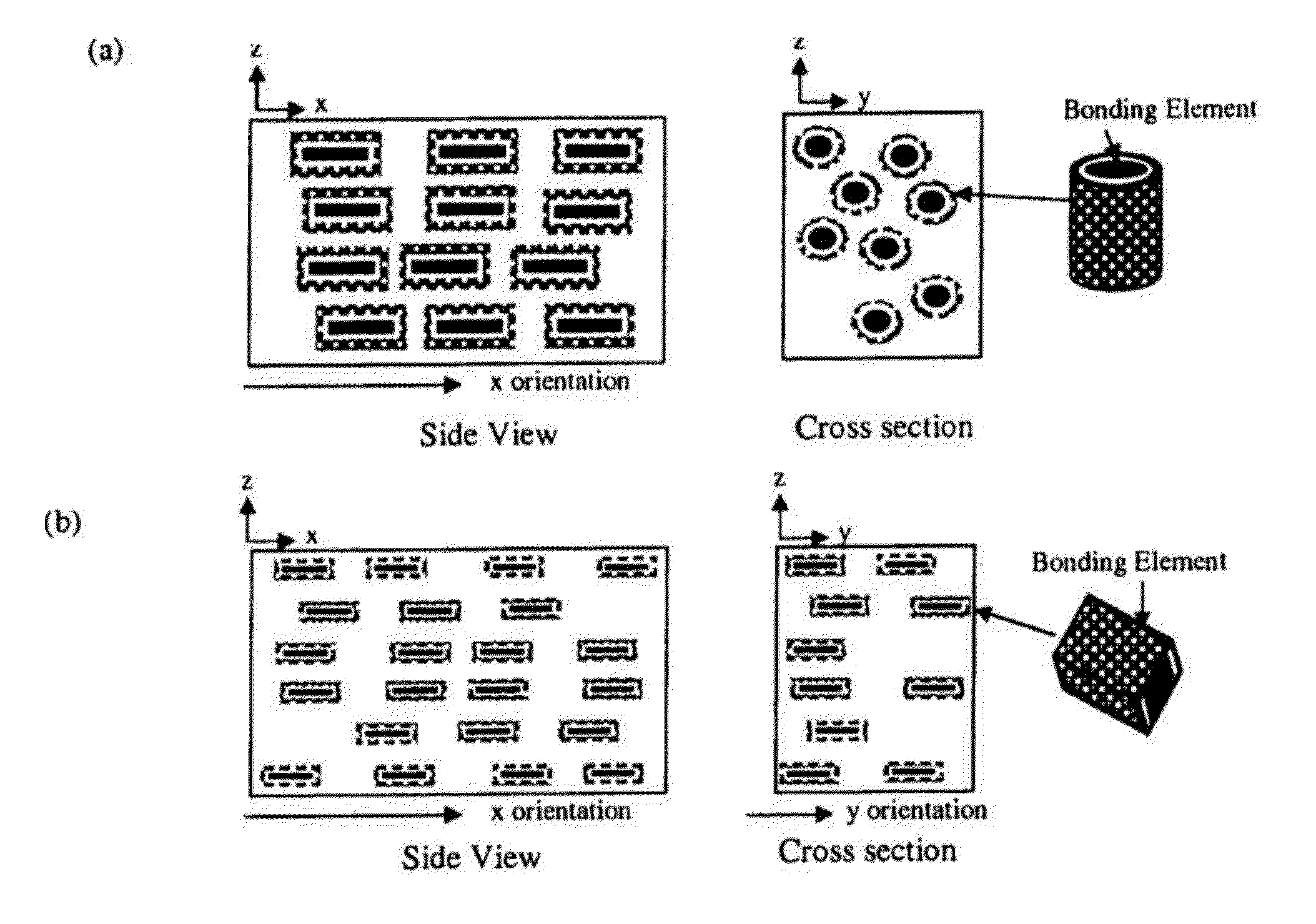

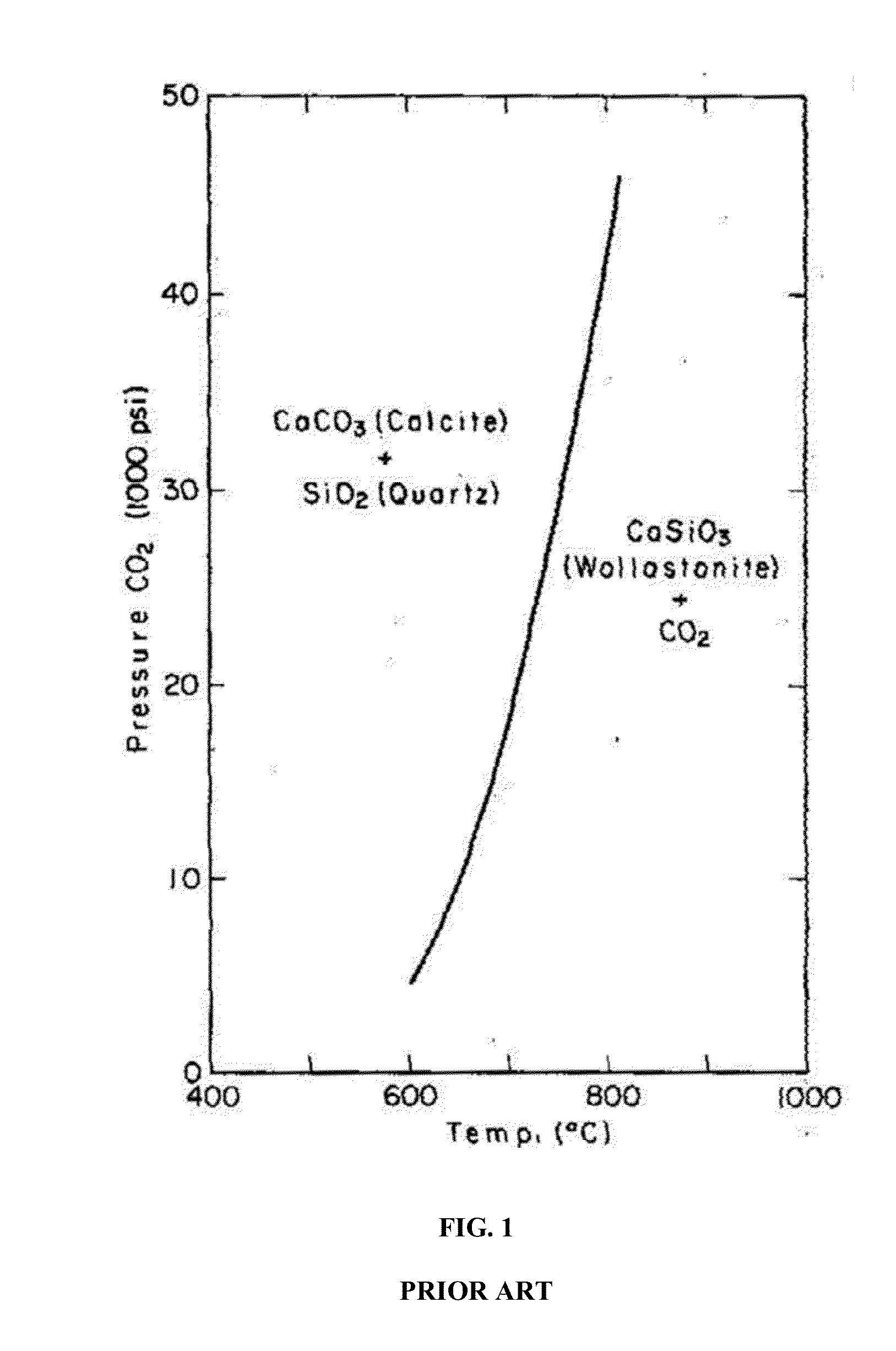

Pervious composite materials, methods of production and uses thereof

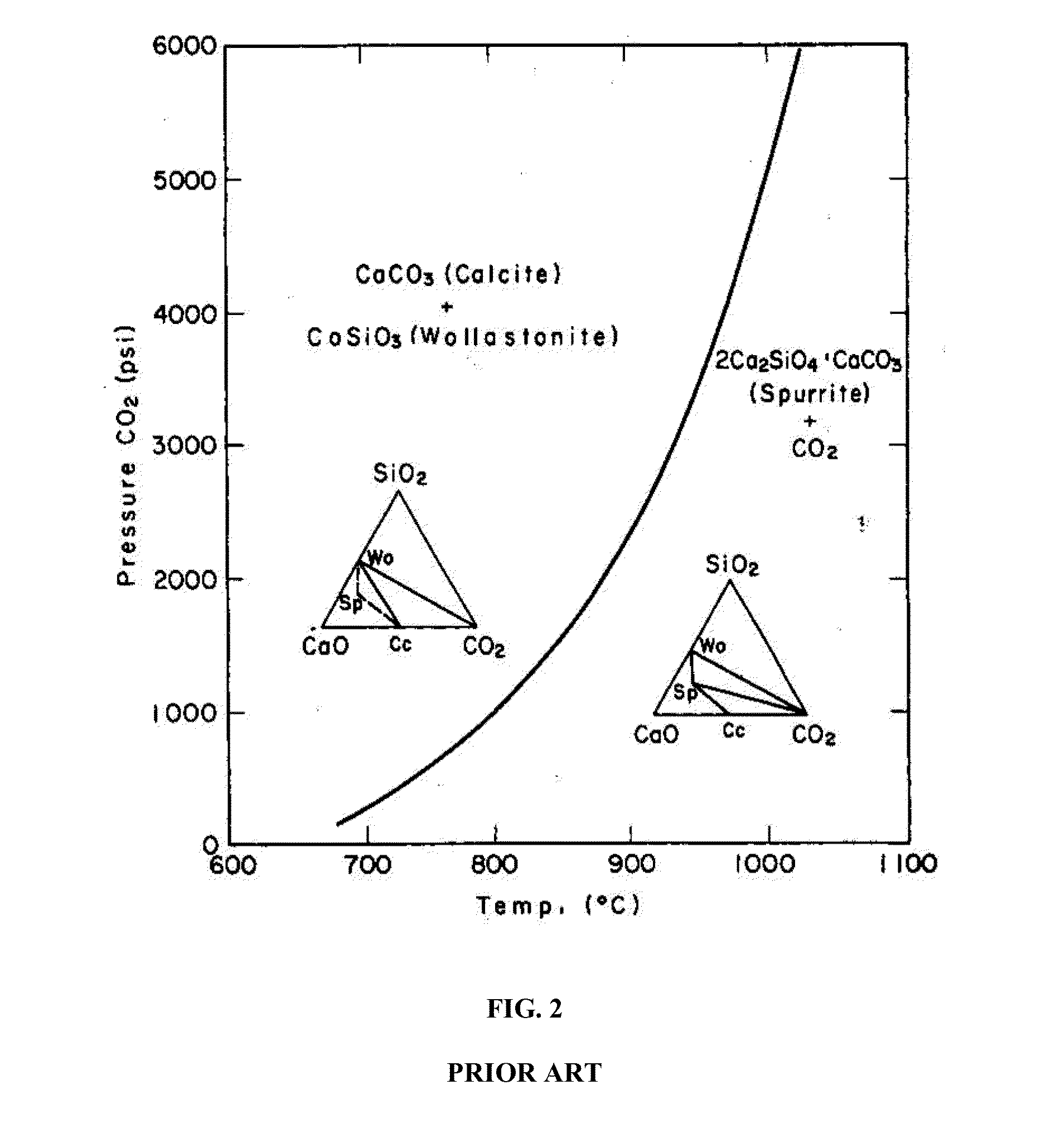

ActiveUS20140363665A1Excellent physical and performance characteristicEasy to produceRecord information storageCeramic shaping apparatusEnvironmental effectCarbon footprint

The invention provides novel pervious composite materials that possess excellent physical and performance characteristics of conventional pervious concretes, and methods of production and uses thereof. These composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production with improved energy consumption, desirable carbon footprint and minimal environmental impact.

Owner:SOLIDIA TECH

Nano photocatalysis porous concrete product and preparation method thereof

The invention provides a nano photocatalysis porous concrete product and a preparation method thereof. The nano photocatalysis porous concrete product is prepared by the method comprising the following steps: curing press formed porous concrete for 1 to 7 days, then soaking the porous concrete in nano TiO2 dispersion liquid of which the mass concentration is between 2 and 10 percent for 1 to 5 minutes, and taking out the cured porous concrete to obtain the nano photocatalysis porous concrete product. The nano photocatalysis porous concrete product has the following main advantages: (1) compared with dense concrete, the nano photocatalysis porous concrete product has a larger contact area between the nano photocatalysis porous concrete product and polluted gas or liquid, has high photocatalysis efficiency, and can be applied to air purification treatment or water treatment; and (2) compared with P25, the nano photocatalysis porous concrete product adopts the P25 doped with nano titanium dioxide powder to have higher photocatalysis Nox degradation efficiency.

Owner:ZHEJIANG UNIV OF TECH +1

Pervious concrete additive and preparation method thereof

ActiveCN103641374AGuaranteed StrengthGuaranteed wear resistanceStructural engineeringPervious concrete

The invention provides a pervious concrete additive, which is characterized by comprising the following components by weight: 50-70 parts of micro porous material, 20-30 parts of a slow-dissolving agent, 3-5 parts of hydrosol and 2-3 parts of other additives. The concrete additive employs fine porous material as a main body, and the slow-dissolving material is stored in the pores of the porous materials in advance through vacuum adsorption. The additive is used for the preparation of porous concrete, can eliminate or reduce the usage of coarse aggregate; after formation of a firm integrity by the fine porous material and the concrete, slow-dissolving material in the pores gradually degrades and dissolves along with time; and completely-through micro permeable pores formed in the concrete not only guarantee the strength and abrasion resistance of the concrete but also have complete permeability, so that the additive can be added to high load road concrete for municipal roads and highways.

Owner:厦门市西联恒业建筑工程有限公司

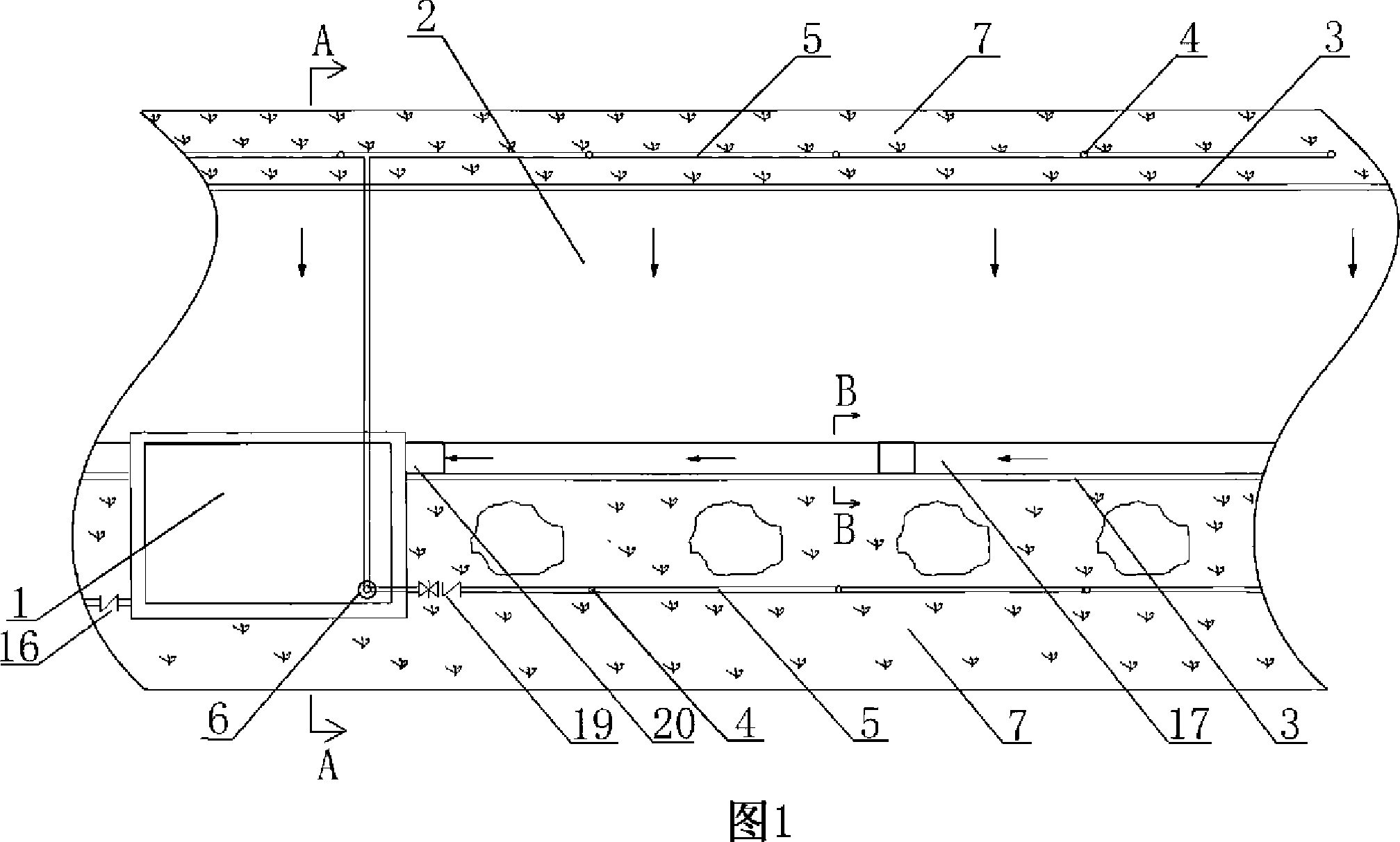

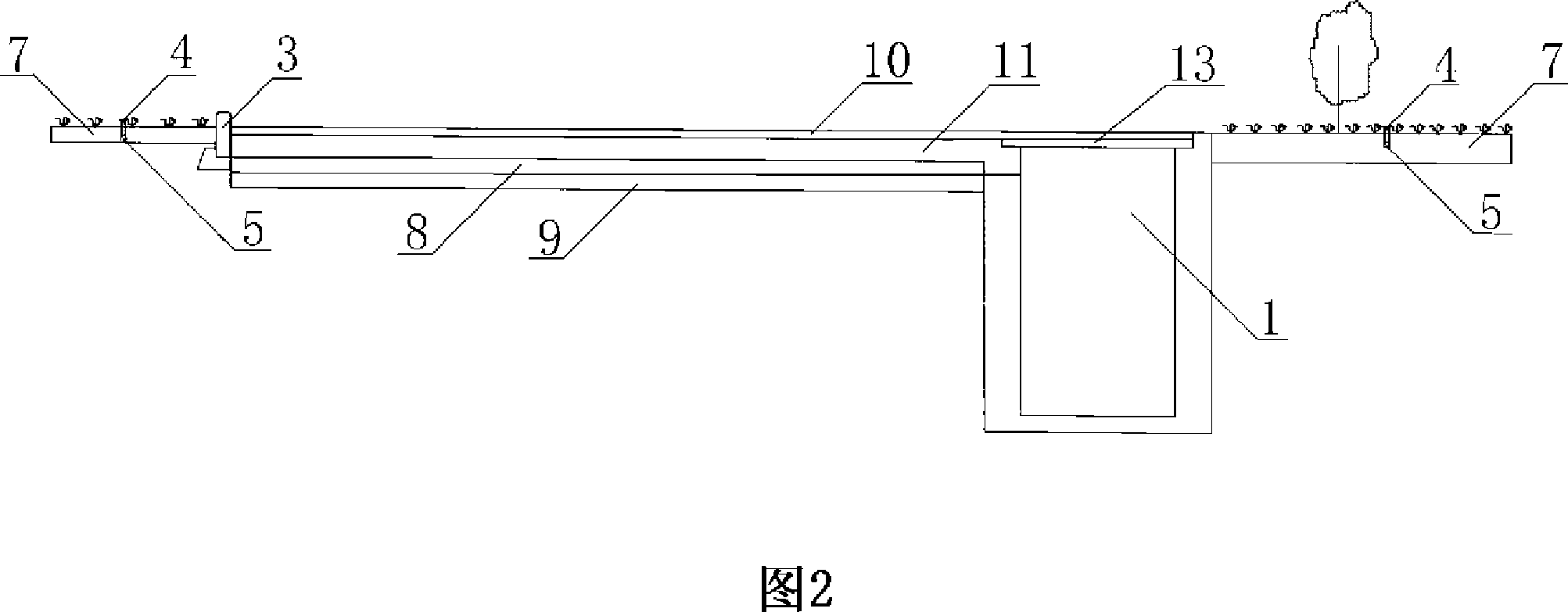

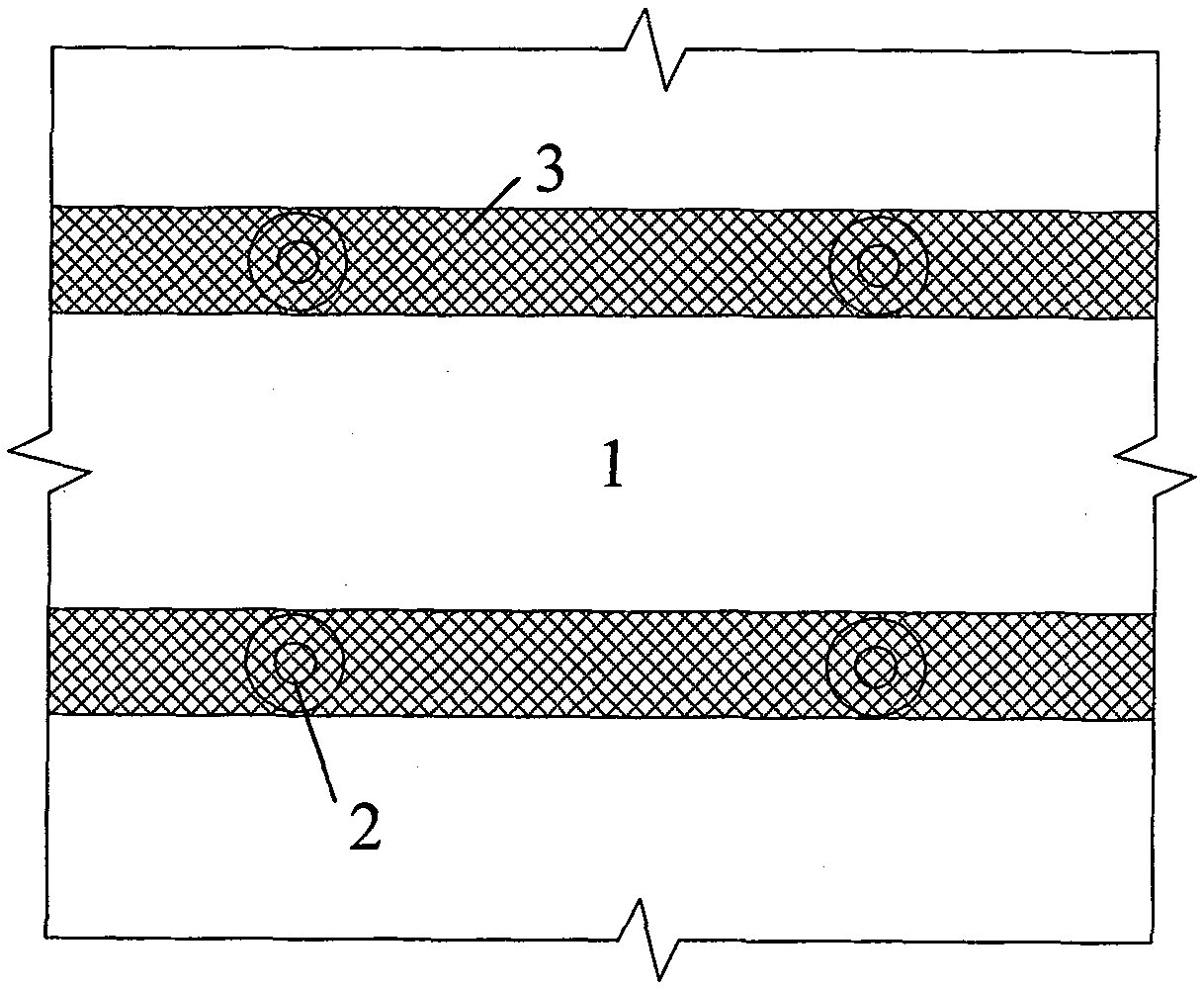

Pervious concrete pavement system capable of collecting rainwater

InactiveCN101003962AReduce negative impactMeet the load-bearing strength requirementsIn situ pavingsSewerage structuresRainwater harvestingRoad surface

The present invention relates to a rainwater-collecting permeable concrete pavement system. It is characterized by that said pavement structure includes rammed earth layer whose thickness is greater than 10mm, general concrete base layer whose thickness is 80-100 mm, permeable concrete structure layer whose thickness is 100-150 mm and permeable concrete face layer whose thickness is 40-60mm from bottom to top. Said pavement system is adjacent to green belt, under the green belt a rainwater-collecting pool is set, and the bottom portion of said rainwater-collecting pool is equipped with a submersible pump. Along the length direction of said pavement structure two sides of said pavement system are respectively equipped with a rainwater-collecting channel, the outlet of said submersible pump is connected with pipe network, and said pipe network is distributed in the green belt.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

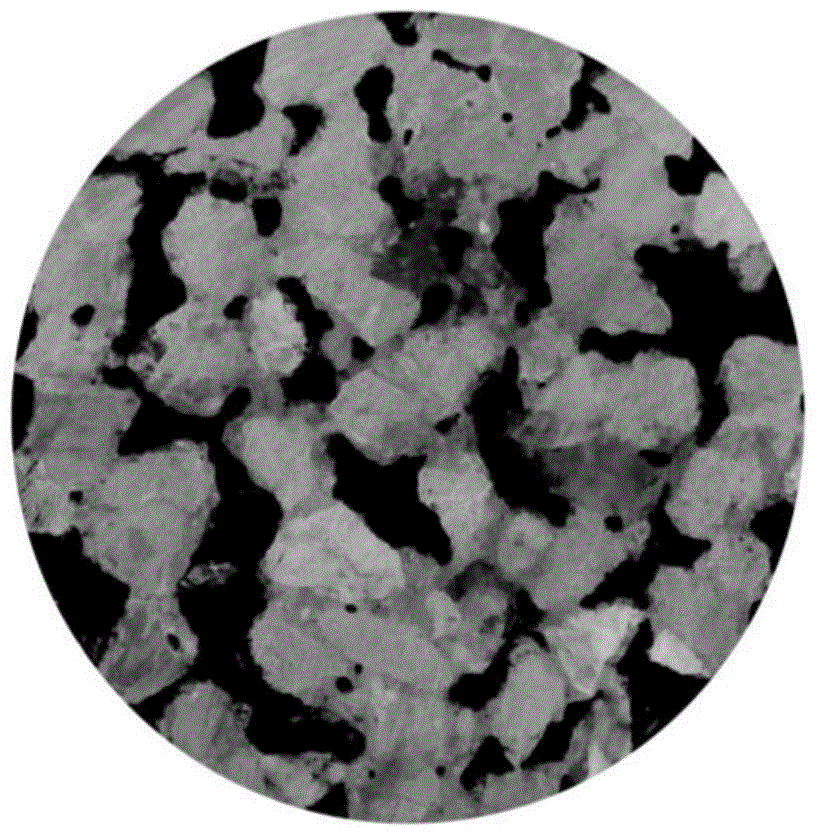

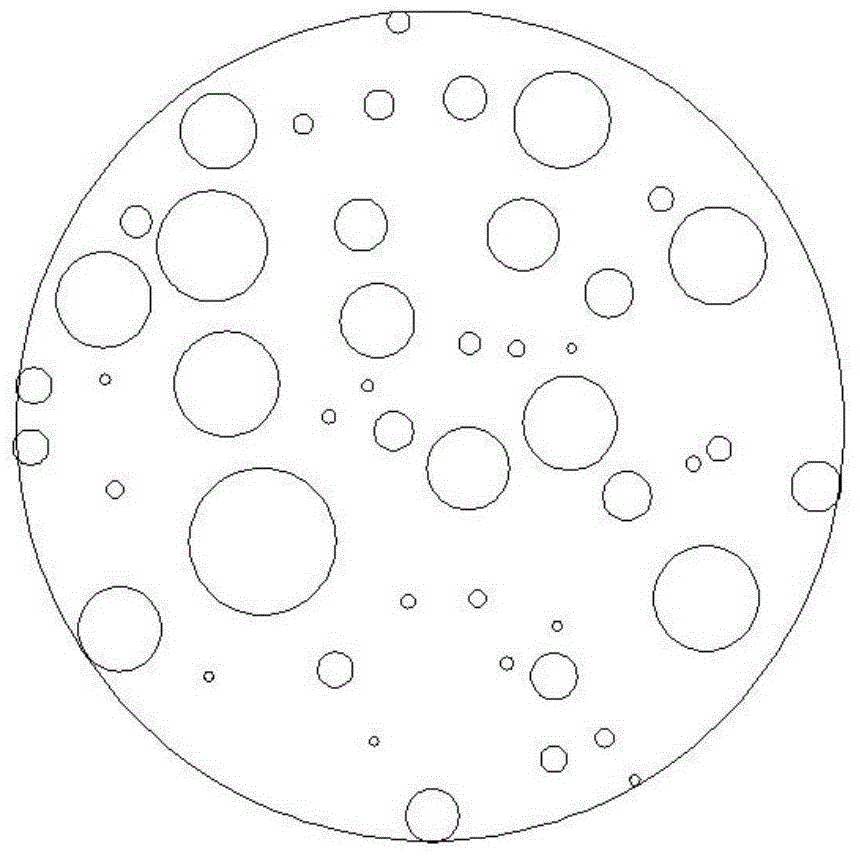

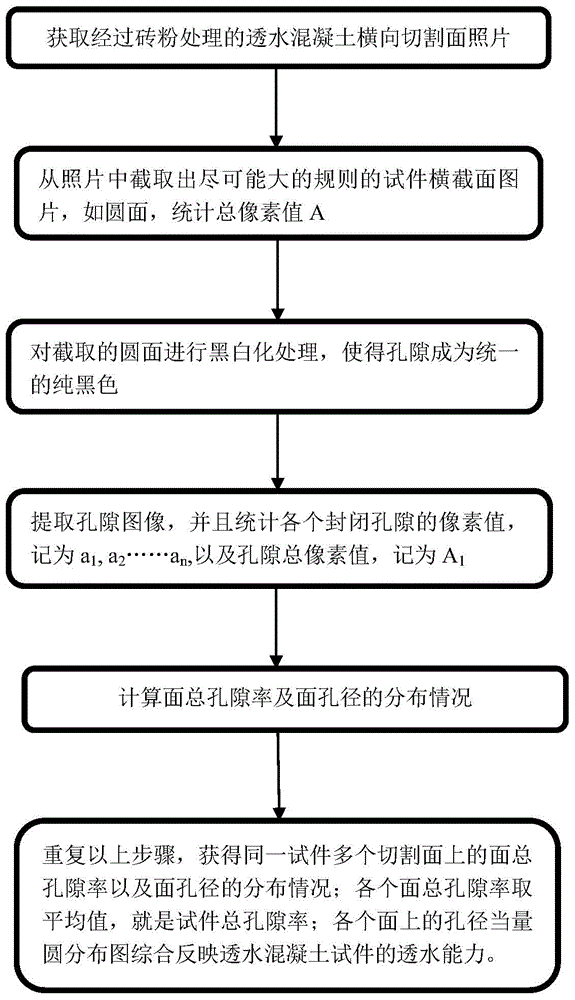

Method for detecting character of pores of pervious concrete by processing images

InactiveCN104596911AEasy to handleReduce processing timePermeability/surface area analysisBrickPore diameter

The invention provides a method for detecting the character of pores of pervious concrete by processing images. The method comprises the following steps: cutting a pervious concrete sample transversely to expose an intact and smooth cutting plane which serves as an experimental surface; obtaining the images of the obverse side of the experimental surface of the brick-powder processed pervious concrete; selecting the largest regular section image of the sample from the obtained images of the obverse side, and calculating the total pixel value of the largest regular section image; blacking and whitening the selected image; extracting the pore image of the blacked and whitened image, and calculating the pixel value of each pore; calculating the total pixel value of the pores; calculating the total porosity and the distribution situation of internal pore diameters according to the obtained pixel values of the pores and the obtained total pixel value of the pores; repeating the steps, obtaining the total porosity of a plurality of cutting surfaces of the same pervious concrete sample and the distribution situation of pore diameters, and calculating the average value of the total porosity of the cutting surfaces of the same pervious concrete sample to obtain the total porosity of the pervious concrete sample and further the character of the pores of the pervious concrete.

Owner:SHANDONG UNIV

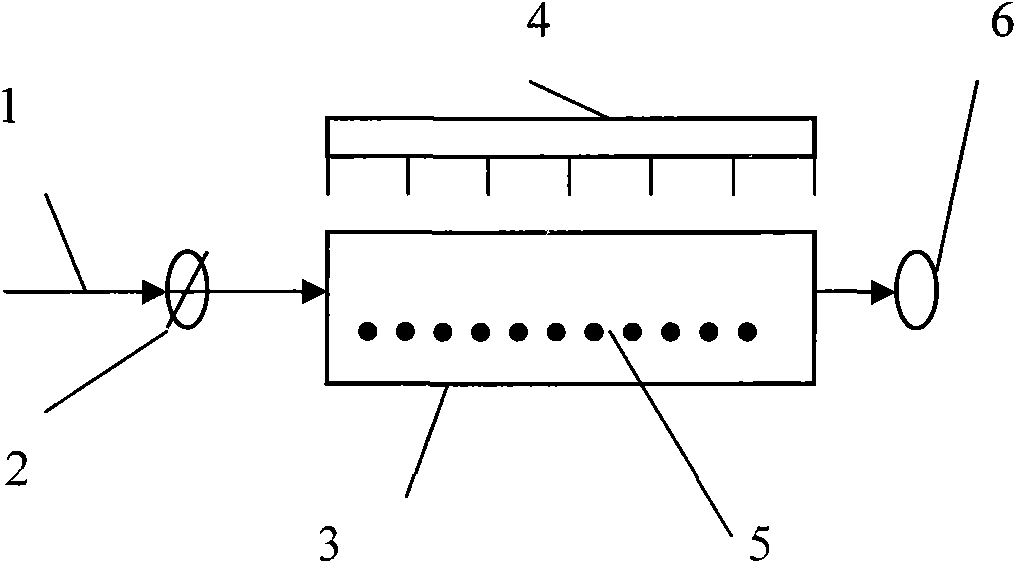

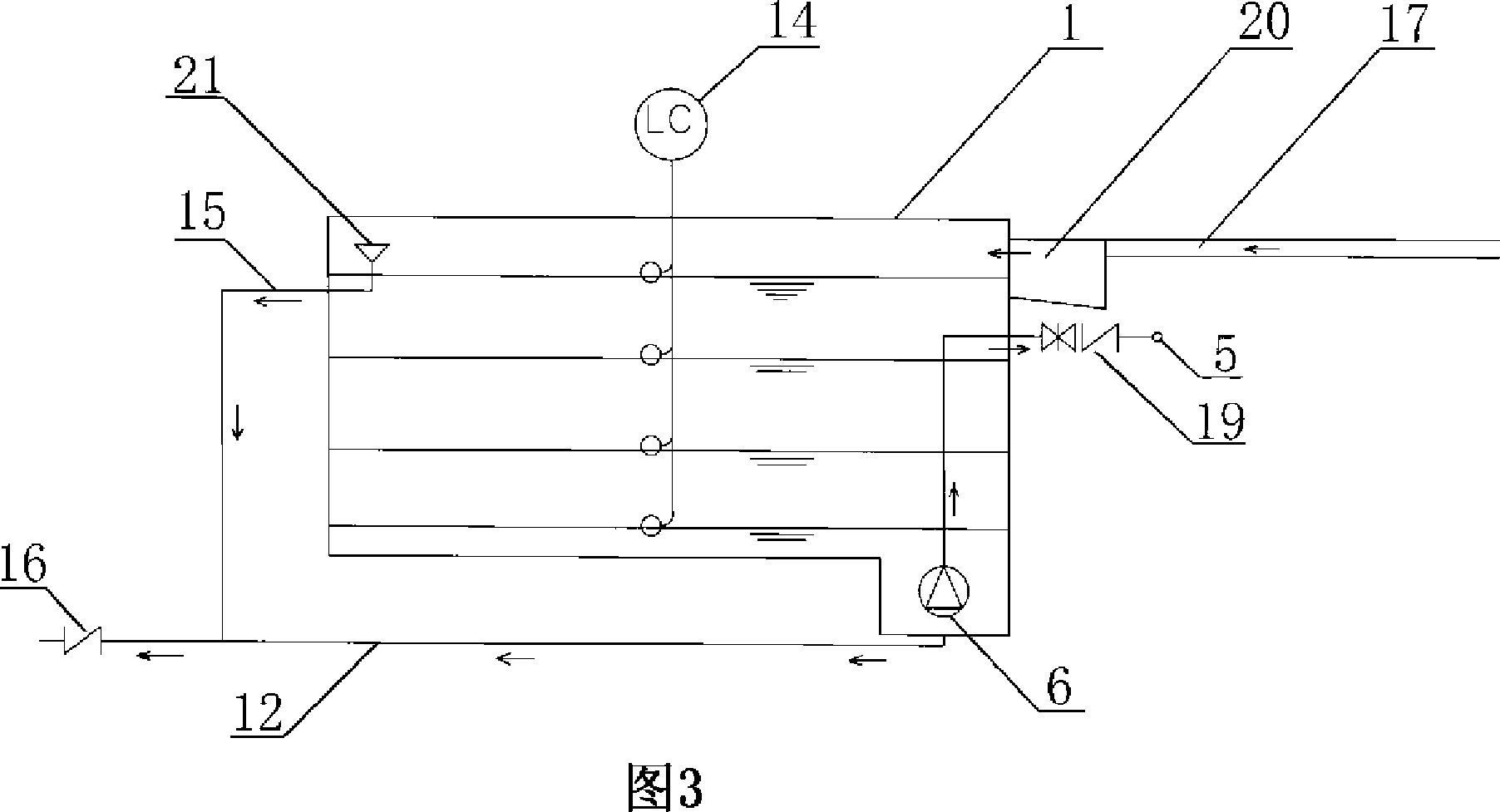

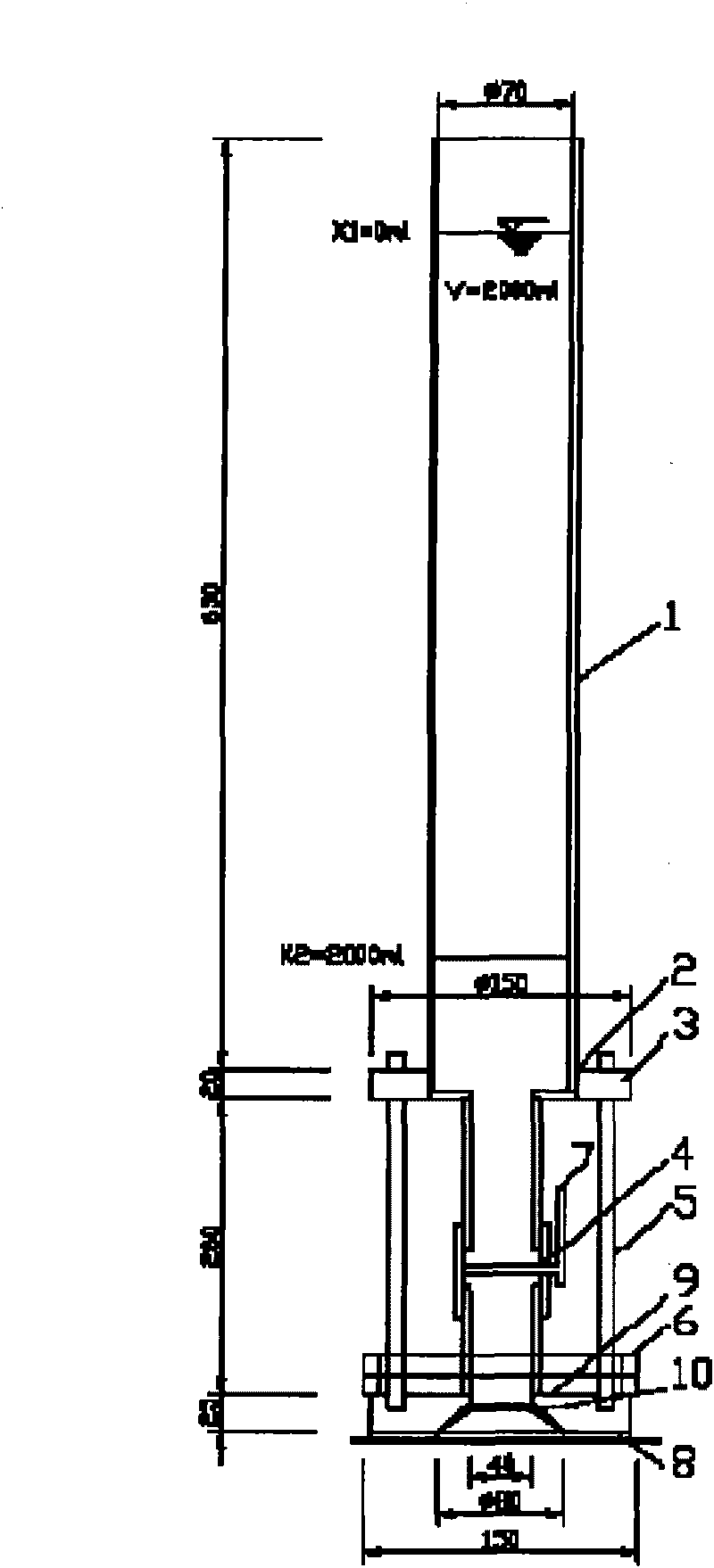

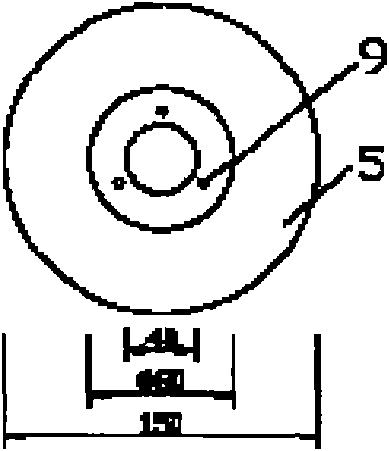

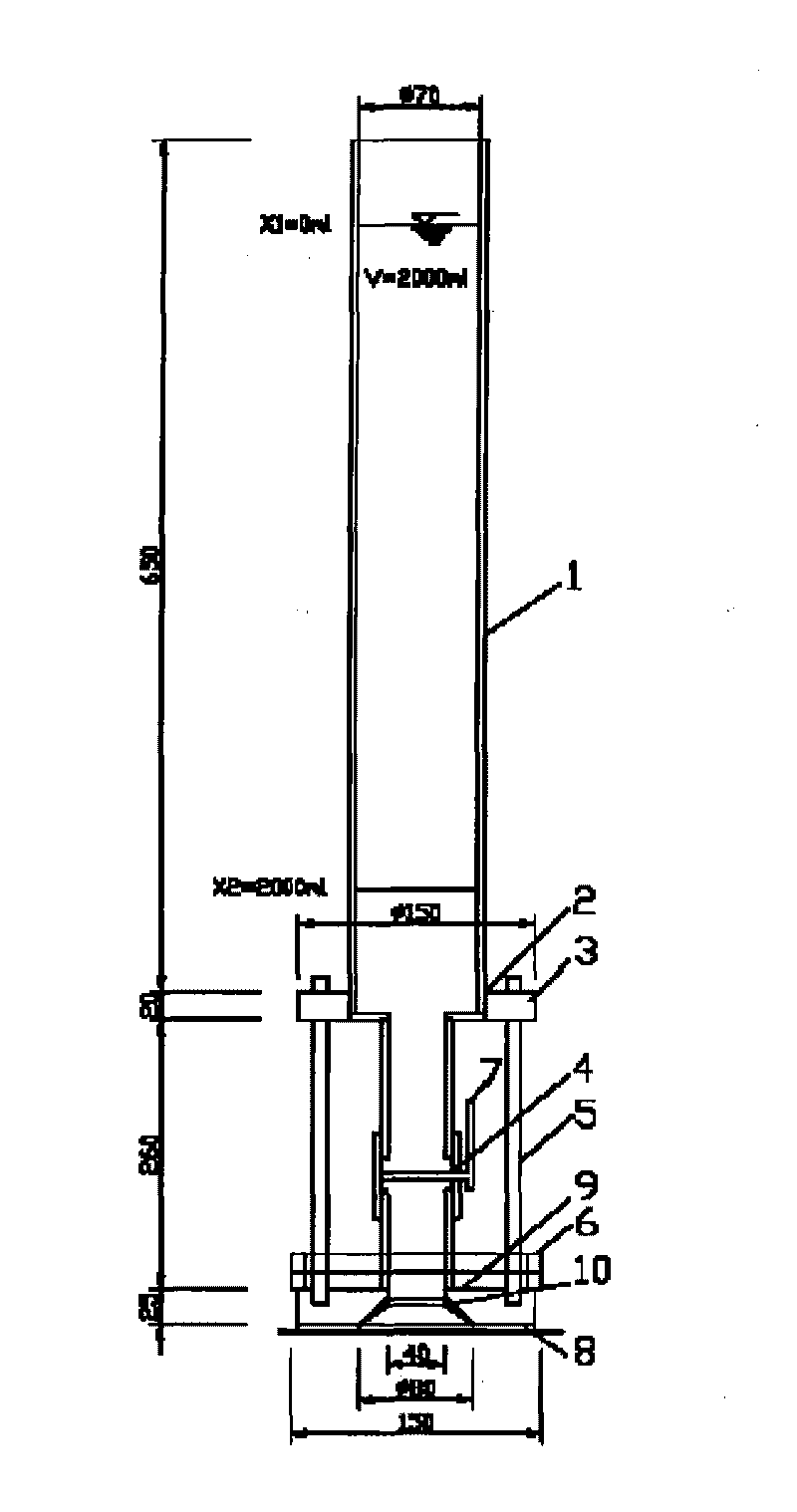

Instrument and method for testing permeability coefficient

ActiveCN101738363AComparableVersatilitySurface/boundary effectPermeability/surface area analysisTester deviceRoad surface

The invention relates to an instrument special for the field test or the nondestructive test of the permeability coefficient for ecological permeable roadways and permeable test blocks and a test method thereof. The instrument for testing the permeability coefficient of the invention comprises a measuring cylinder, a top plate, a base, an upright post bracket, a valve and a timing device, and can intuitively and fast test the permeability coefficient of the permeable roadways and permeable concrete test blocks without sampling drilled cores of the roadways. The instrument and the method for testing the permeability coefficient simulate the calculation of natural rainfall per unit area so that the test and calculation of the permeability coefficient of the permeable roadways are more practical and operable.

Owner:上海砼仁环保技术发展有限公司

Colorful regeneration permeable concrete for road and preparation method thereof

InactiveCN103011735ALow resolutionSolving Recycling ProblemsSolid waste managementAcid waterChipseal

The invention discloses a colorful regeneration permeable concrete for road and a preparation method thereof. The colorful regeneration permeable concrete consists of aggregate, a cementing material, polypropylene fiber, a water reducing agent, pigment and water; the cementing material consists of silicate cement and mineral waste residue; the ratio of water to glue is 0.27-0.33; the mass ratio of the aggregate to the cementing material is 2.82-3.80; the aggregate consists of coarse aggregate and fine aggregate; the coarse aggregate consists of natural broken stone and regeneration broken stone prepared from waste concrete; the fine aggregate is common water-washing medium sand; the mass of the fine aggregate is 5-20% of the mass of coarse aggregate; the mass of the polypropylene fiber is 0.1-0.3% of the mass of the cementing material; the mass of the polycarboxylic acid water reducing agent is 0.5-1.5% of the mass of the cementing material; and the mass of the pigment is 2.5-7.5% of the mass of the cementing material. Through the combination of recycled aggregate and common aggregate, the invention can recycle the waste resources and solve the problem of low strength.

Owner:CHANGZHOU UNIV

Porous cement concrete using regenerative concrete aggregate

InactiveCN101407390AReduce the amount of miningEasy to useSolid waste managementPerformance indexWater circulation

The invention relates to water permeable cement concrete using recycled concrete as the aggregate, which has the raw material compositions with the weight parts of 250-400 parts of cement, 1500-2000 parts of recycled concrete aggregate, 25-40 parts of inorganic plastering agent and 2.5-5 parts of synthetic fiber, wherein, the recycled concrete aggregate has 5-12mm of unitary size fraction and 25 percent or smaller of crushing value. The ecological water permeable concrete has the advantages of increasing the service means of the high added value of waste concrete, reducing the mining quantityof natural aggregates, lowering the cost for confecting water permeable materials, improving the traffic safety factors of the road, improving the water circulation function of the environment and having the performance indexes meeting the requirements of the set mechanical performance and other technical indexes.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

High-porosity epoxy resin pervious concrete

The invention provides high-porosity epoxy resin pervious concrete, which comprises the following components in part by mass: 100 parts of epoxy resin, 0-50 parts of reactive diluent, 20-80 parts of curing agent, 2,000-10,000 parts of aggregate and 0-30 parts of dye. The invention has the beneficial effects that (1) the pervious concrete with porosity of greater than 40% is prepared by using the epoxy resin as gel material; (2) the pervious concrete the maximum breaking strength of which is 12 MPa can be prepared, which can bear relatively large impact load and prevent the aggregate from falling compared with the cement-based pervious concrete; (3) when the steel slag is used as the aggregate, the steel slag can be used without special treatment; and (4) the pervious concrete with variouscolors can be prepared by adding the dye.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

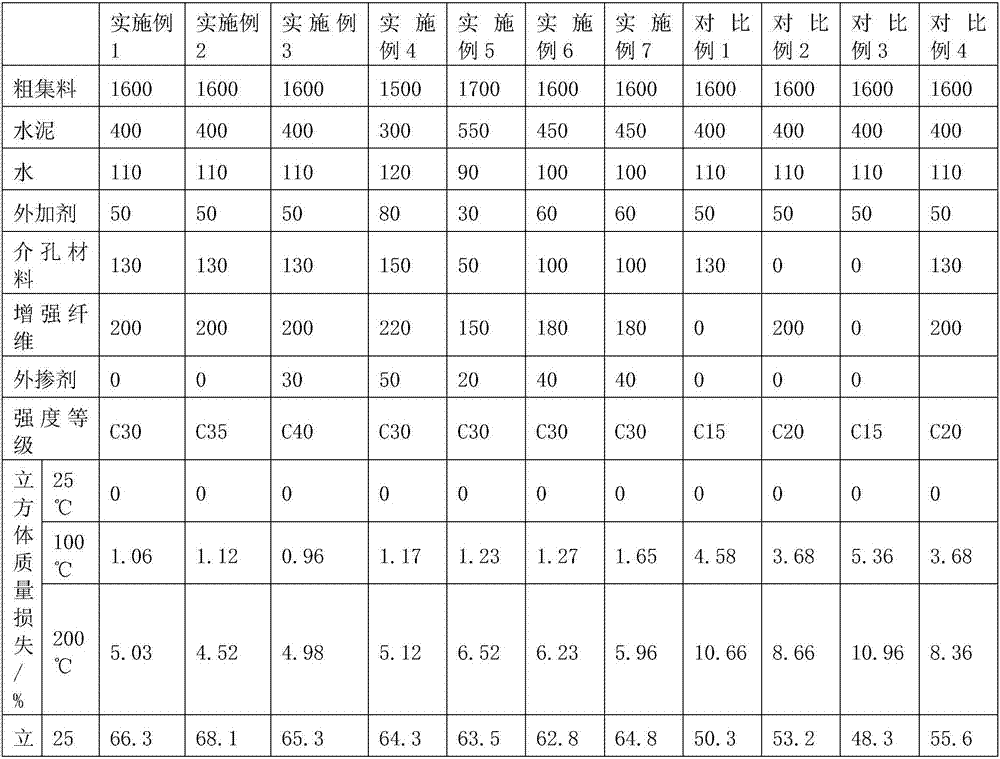

Permeable concrete

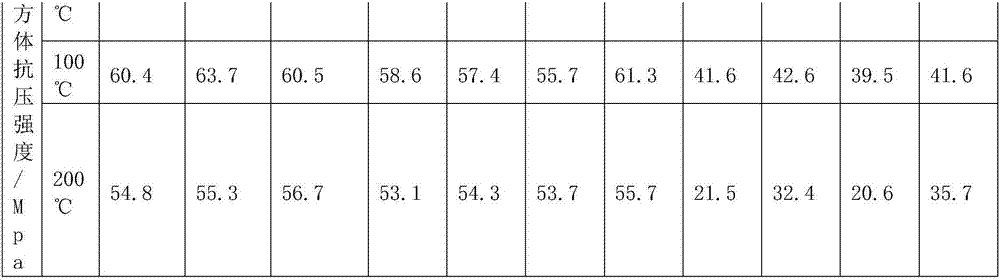

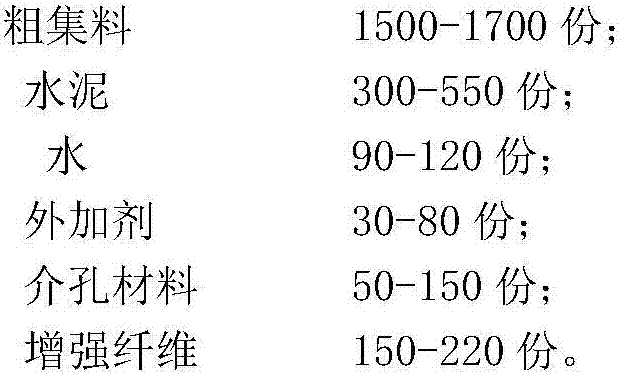

Theinvention discloses a permeable concrete. The permeable concrete is prepared from the following components in parts by weight: 1500-1700 parts of coarse aggregate, 300-550 parts of cement, 90-120 parts of water, 30-80 parts of admixture, 50-150 parts of mesoporous material, and 150-220 parts of reinforced fiber. The permeable concrete has the following advantages and effects: first, the mesoporous material, reinforced fiber and cement in the permeable concrete are mixed and then form an adhesive layer in the coarse aggregate particles, the reinforced fiber in the adhesive layer is connected through the mesoporous material so as to form a mesh structure, so that the strength of the permeable concrete is improved; second, due to the mesh structure in the adhesive layer on the surface of the coarse aggregate particle, the permeable concrete has higher mechanical property at high temperature, and the high temperature resistance of the permeable concrete is improved; and third, the coarse aggregate is of a single grain level, so that the permeable concrete has excellent permeability, has ecological functions of discharging water, reducing noise and adjusting ground temperature and humidity, protects the environment, and achieves the effect of good permeability, environment protection, high strength, high temperature resistance, and wide application range.

Owner:广东信强混凝土有限公司

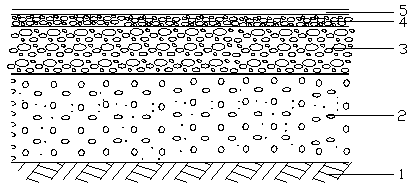

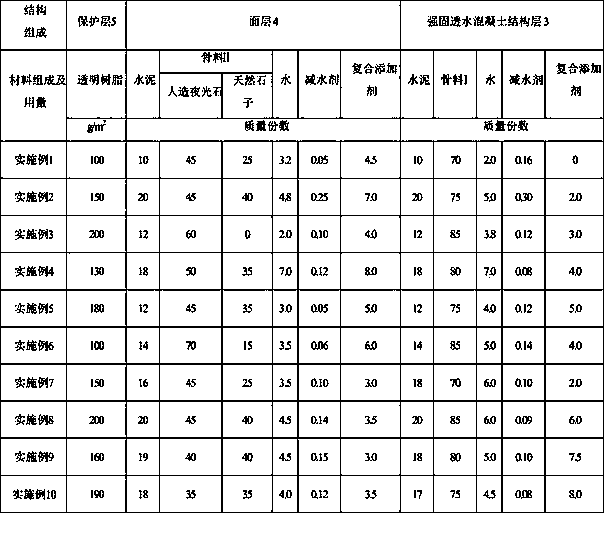

Non-radioactive environment-friendly energy-accumulation luminous pervious concrete pavement and construction method thereof

ActiveCN103437259AEasy to viewPlay the role of lighting instructionsIn situ pavingsPavement lightsSurface layerLight energy

The invention relates to a non-radioactive environment-friendly energy-accumulation luminous pervious concrete pavement which structurally comprises a soil matrix, a base layer, a reinforced pervious concrete structure layer, a luminous pervious concrete surface layer and a protection layer from bottom to top. The pavement disclosed by the invention has a good ornamental value in daytime, can absorb and storage light energy, can emit light at night to play a role in illumination and indication, has a favorable decoration property and a good energy saving effect and can be widely applied to sidewalks on two sides of courtyards, public areas, scenic spots and driving roads.

Owner:中建西部建设西南有限公司

Pervious concrete and preparation method thereof

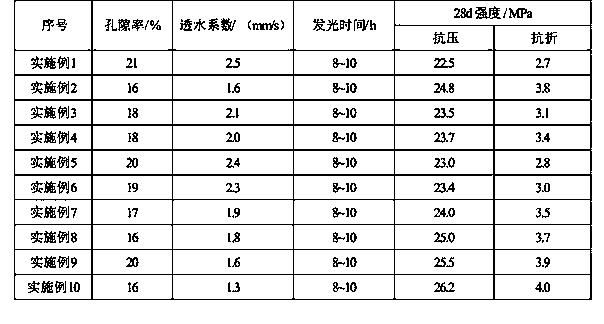

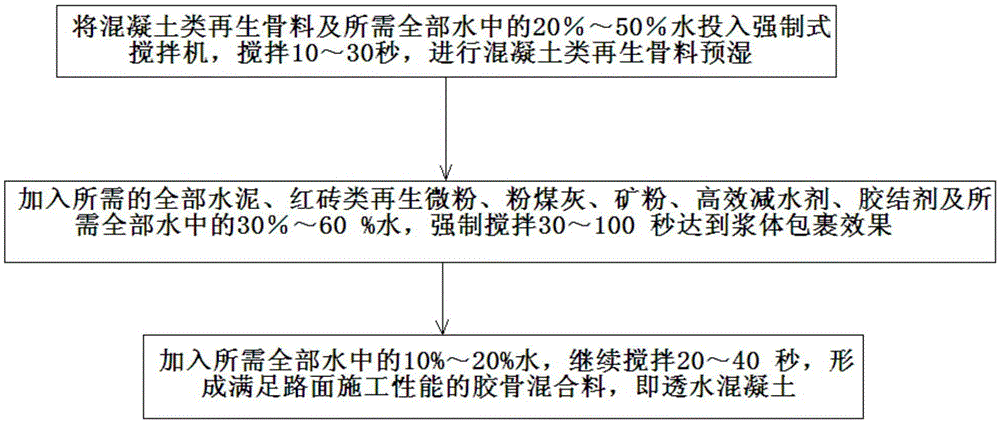

InactiveCN105461262AFully tap the potential valueRealize classification and efficient recyclingSolid waste managementBrickSuperplasticizer

The invention discloses a pervious concrete and a preparation method thereof, and belongs to the technical field of resource reutilization. The concrete comprises the following components: 1400-1600kg / m<3> of concrete recycled aggregate, 120-225 kg / m<3> of water, 300-450 kg / m<3> of cement, 30-135 kg / m<3> of red brick powder regenerated micropowder, 0-22.5 kg / m<3> of fly ash, 0-22.5 kg / m<3> of ore powder, 0-7.5 kg / m<3> of a superplasticizer, and 0-15 kg / m<3> of cement. The pervious concrete and preparation method thereof waste can fully exploit the potential value of construction waste to achieve classification and efficient recycling of construction waste resource to the greatest degree.

Owner:SHOUGANG ENVIRONMENTAL IND

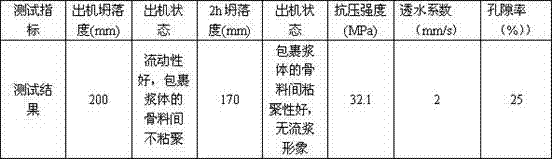

Specialadmixture for pervious concrete and application ofspecialadmixture

The invention discloses a specialadmixture for pervious concrete and application of the specialadmixture. Thespecial admixture comprises the following materials in weight percent: 5 to 15 percent (solid content) of a water reducing agent; 0.1 to 1 percent of a retarder; 0.1 to 1 percent of a thickener; 15 to 25 percent of an early strength agent; 25 to 50 percent of a water-repellent agent; 25 to 50 percent of rubber powder. The admixture overcomes the problem that the existing pervious concrete is not easy to transport bya tanker, and ensures that the phenomenon of blocking cannot occur when the pervious concrete is put into a tanker after the admixture is used, has excellent service behavior after the pervious concrete is discharged from the tanker, and has excellent cohesiveness, without phenomena of bottom sealing and hole blocking.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

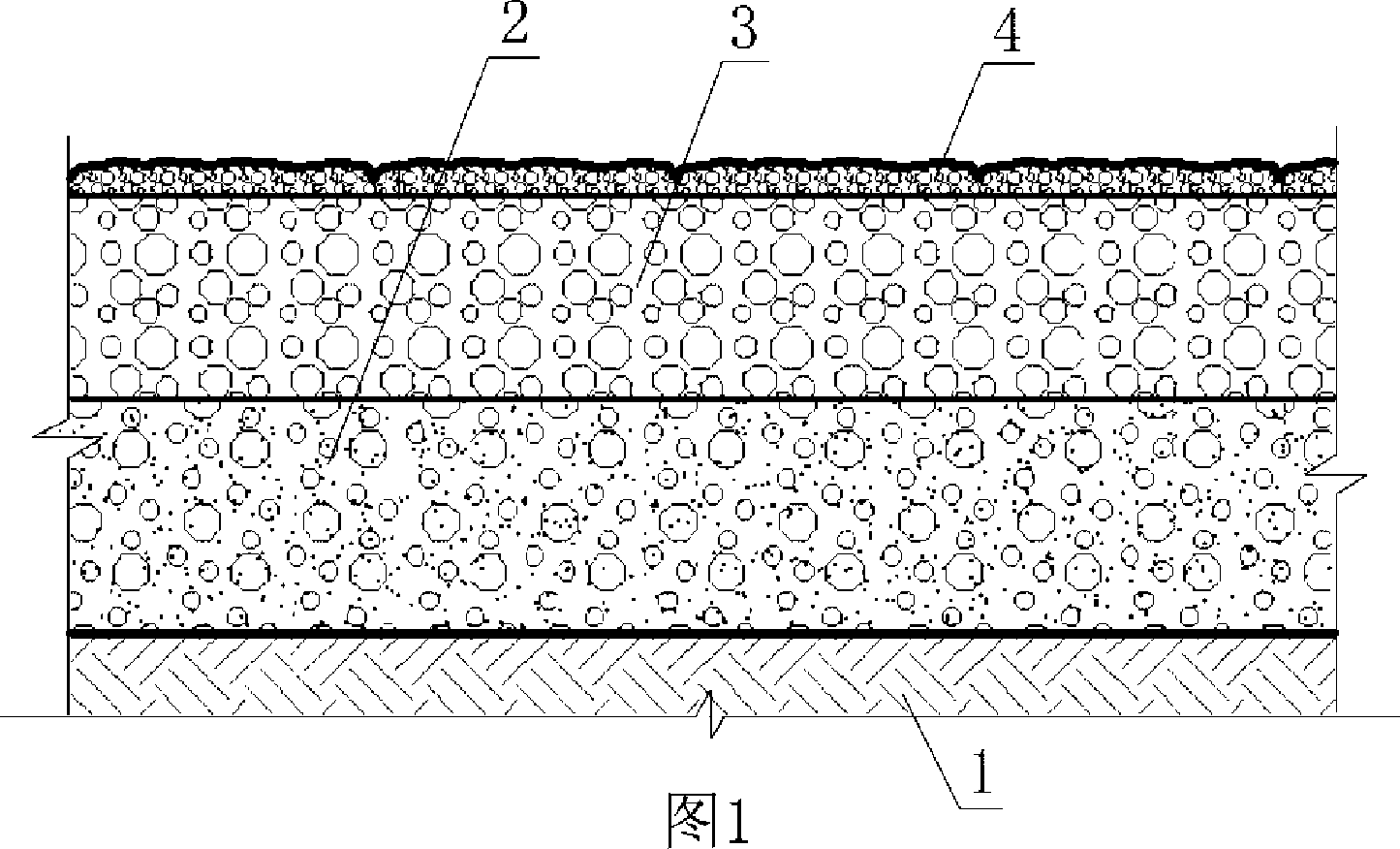

Stone texture-like permeable concrete ground and construction method thereof

InactiveCN101392484AGood water permeabilityMeet the use requirementsIn situ pavingsSolid waste managementSurface layerCrushed stone

The invention relates to a stone-simulating pervious concrete floor and a construction method thereof. The concrete floor includes a tamped foundation, a crushed stone layer, a pervious concrete structural layer and a pervious concrete surface layer from bottom to top; the pervious concrete surface layer is a stone-simulating pervious concrete surface layer, which adopts the following materials and weight ratio: 2100-2300kg / m<3> of river sand; 325-335kg / m<3> of cement; 39-41kg / m<3> of silicon power; 24-26kg / m<3> of Grade I coal ash; 3.4-3.6kg / m<3> of water reducer and 78-80kg / m<3> of tap water. The invention leads the pervious concrete road surface to have water permeability and decoration simultaneously, and improves the water-permeable and air-permeable effect of the concrete road surface on the premise of ensuring the strength of the road surface and having the texture of the concrete road surface.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +3

Colorful water permeable concrete pavement and construction technique

InactiveCN101293760AReduce intensitySolve the problem of defects with low strengthSolid waste managementRoad surfaceToxic industrial waste

The invention relates to a chromatic pervious concrete pavement material and a construction process thereof, which is characterized in that the formulation of a special concrete binding agent comprises 85 to 92 percents of cement (weight), 5 to 10 percents of silicon ash, and rubber powder, early strength admixture, water reducing agent and paint. The ash collection ratio is 4.0 to 6.0; the water cement ratio is 0.30 to 0.40; dry power shaped binding agent, aggregate and water are added in a concrete agitator according to the blending ratio so as to be churned into a mixture with uniform and proper dryness and humidity, which is then is used for paving and construction after being flattened; a low frequency flat oscillator is used for vibrating, compacting and leveling on the surface; the water is poured for maintenance; oily crylic acid resin is taken as mat coat agent to ensure that the color of the pavement is fresh. The chromatic pervious concrete pavement material and the construction process thereof have the advantages that steel-making industrial waste residue is adopted as the aggregate to change waste into valuables; the problem of low strength of the non-sand water permeability concrete material with a plurality of holes is solved by lower cost; compared with the high molecule permeable material, the cost is low, the strength is high, and the ageing resistance is good; compared with the sintering ceramics permeable material, the cost is low, the energy consumption is reduced, and the permeability effect is strong.

Owner:上海固华墙体环保科技有限公司 +1

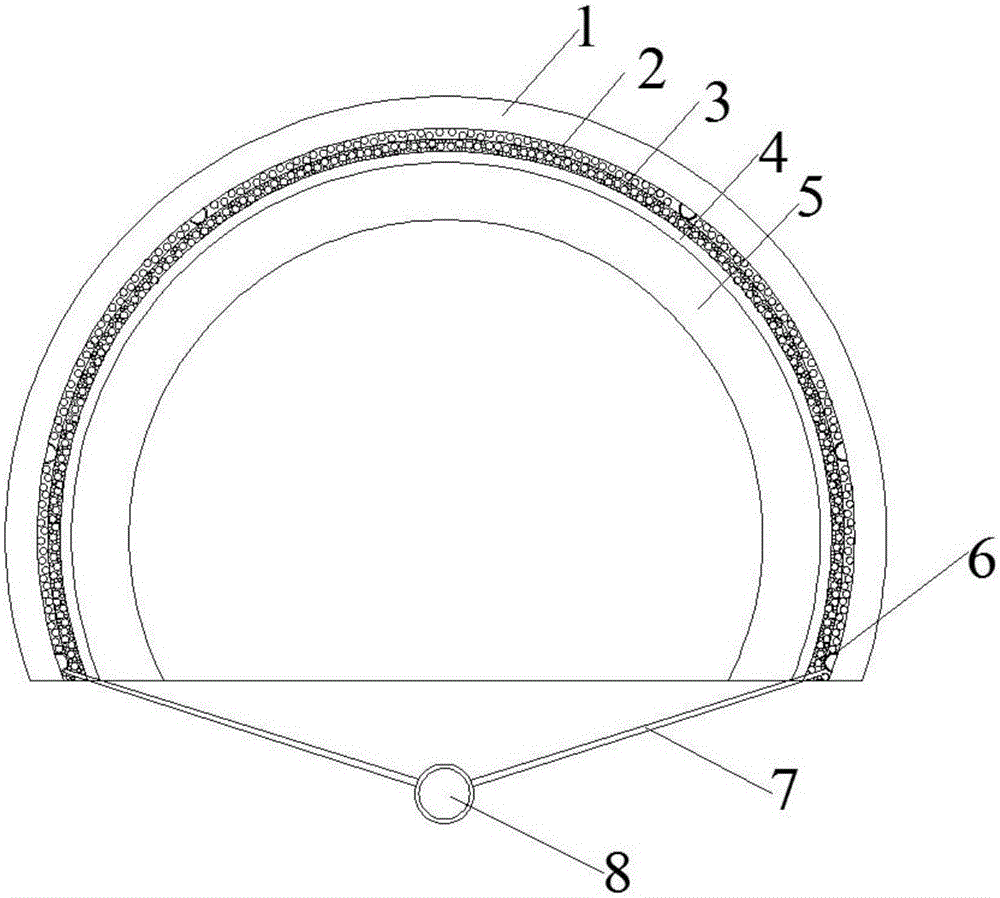

Tunnel waterproof and water-draining system and construction method thereof

ActiveCN106194255AEliminate frost heaving forceEasy to findUnderground chambersDrainageShotcreteDraining tube

The invention discloses a tunnel waterproof and water-draining system and a construction method thereof. The tunnel waterproof and water-draining system comprises a water draining layer, a transition layer, a waterproof layer, a transverse water draining pipe, a central water draining pipe and the like, and the water draining layer, the transition layer and the waterproof layer are located between a tunnel primary support and a secondary lining. The water draining layer comprises water-permeable shotcrete, a longitudinal water draining pipe, an annular water draining pipe and a waterstop strip, the longitudinal water draining pipe, the annular water draining pipe and the waterstop strip are fixed to the outer surface of the primary support to carry out water draining partitioning on the primary support, and the water-permeable shotcrete is sprayed in each water draining area. The annular water draining pipe and the central water draining pipe are connected through the transverse water draining pipe, and finally the tunnel water draining system is formed. The transition layer and the waterproof layer are formed by shotcrete with different grades and used for waterproofness of a tunnel. According to the tunnel waterproof and water-draining system and the construction method thereof, the water draining pipes and the water-permeable shotcrete form a tunnel stereoscopic water draining passage, the water draining effect of the tunnel is good, the tunnel waterproof and water-draining system and the structure of the tunnel are integrated, and the long-term service performance is good.

Owner:SOUTHEAST UNIV

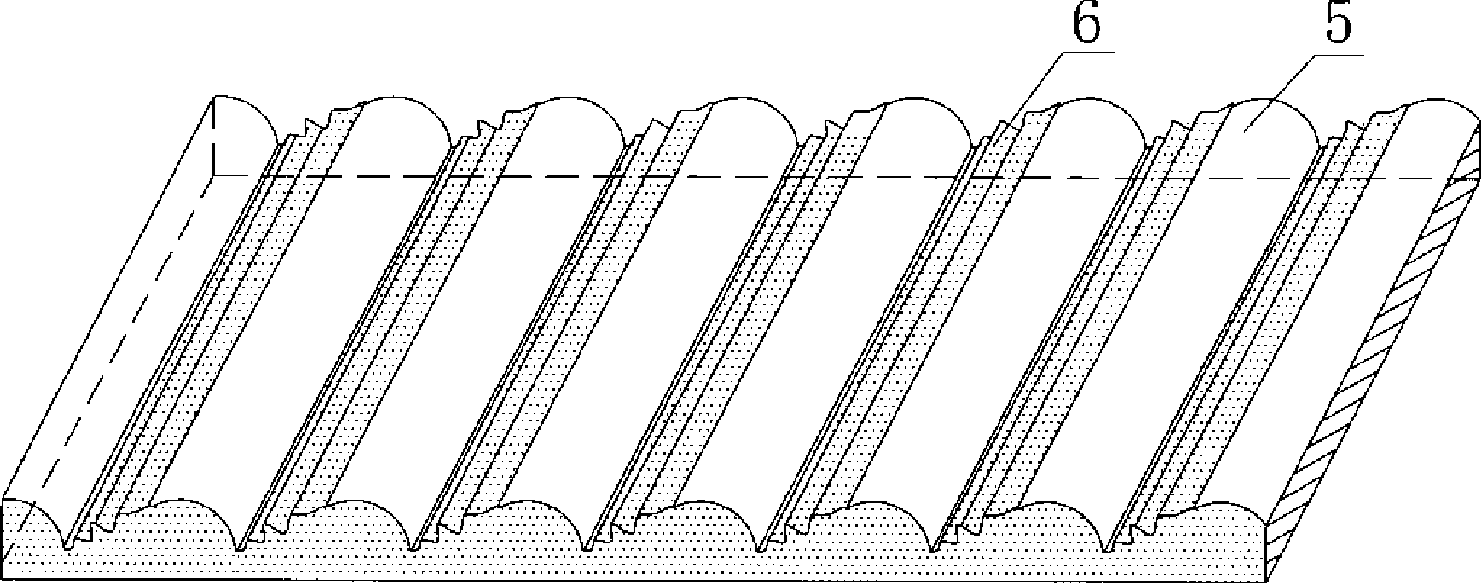

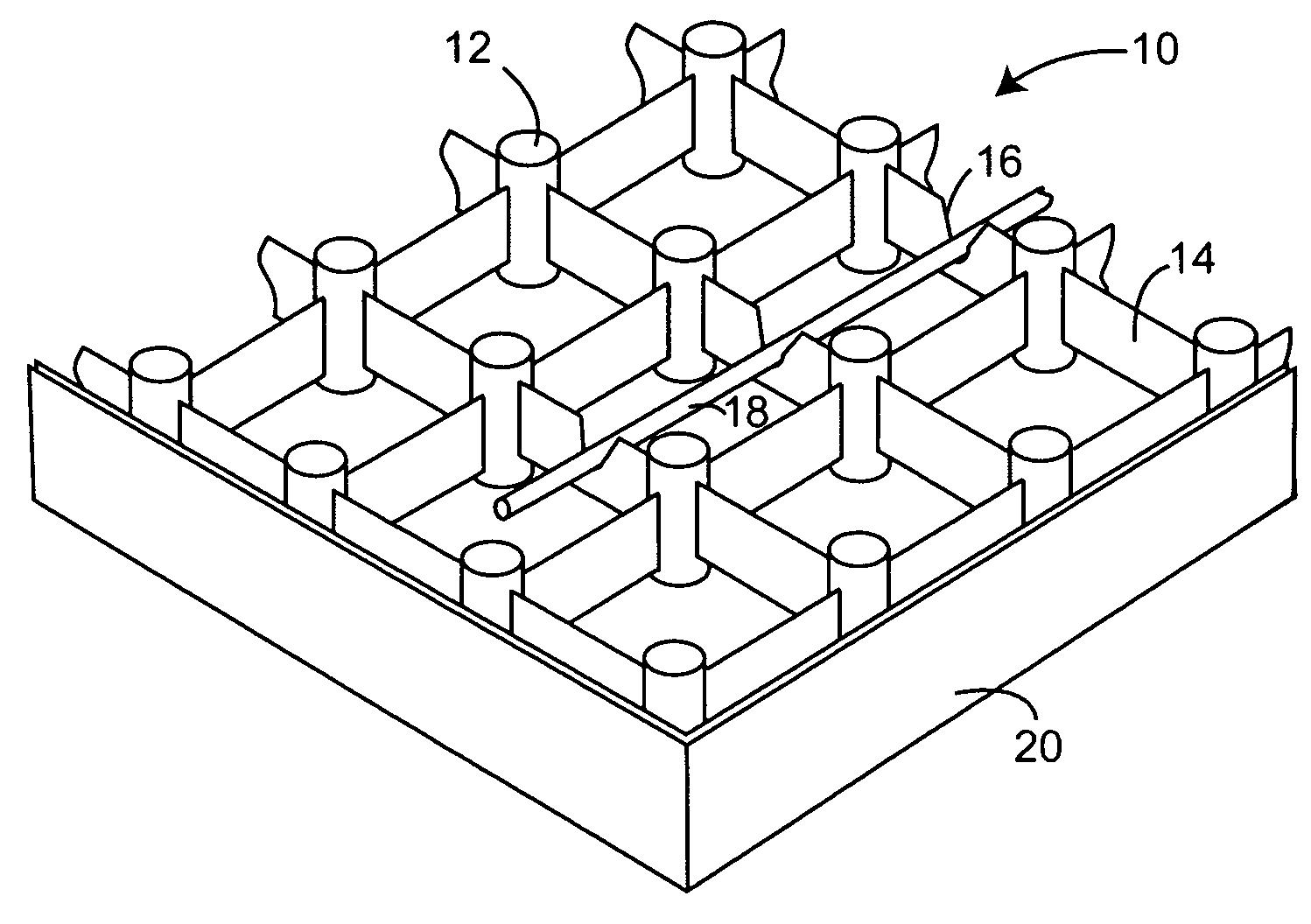

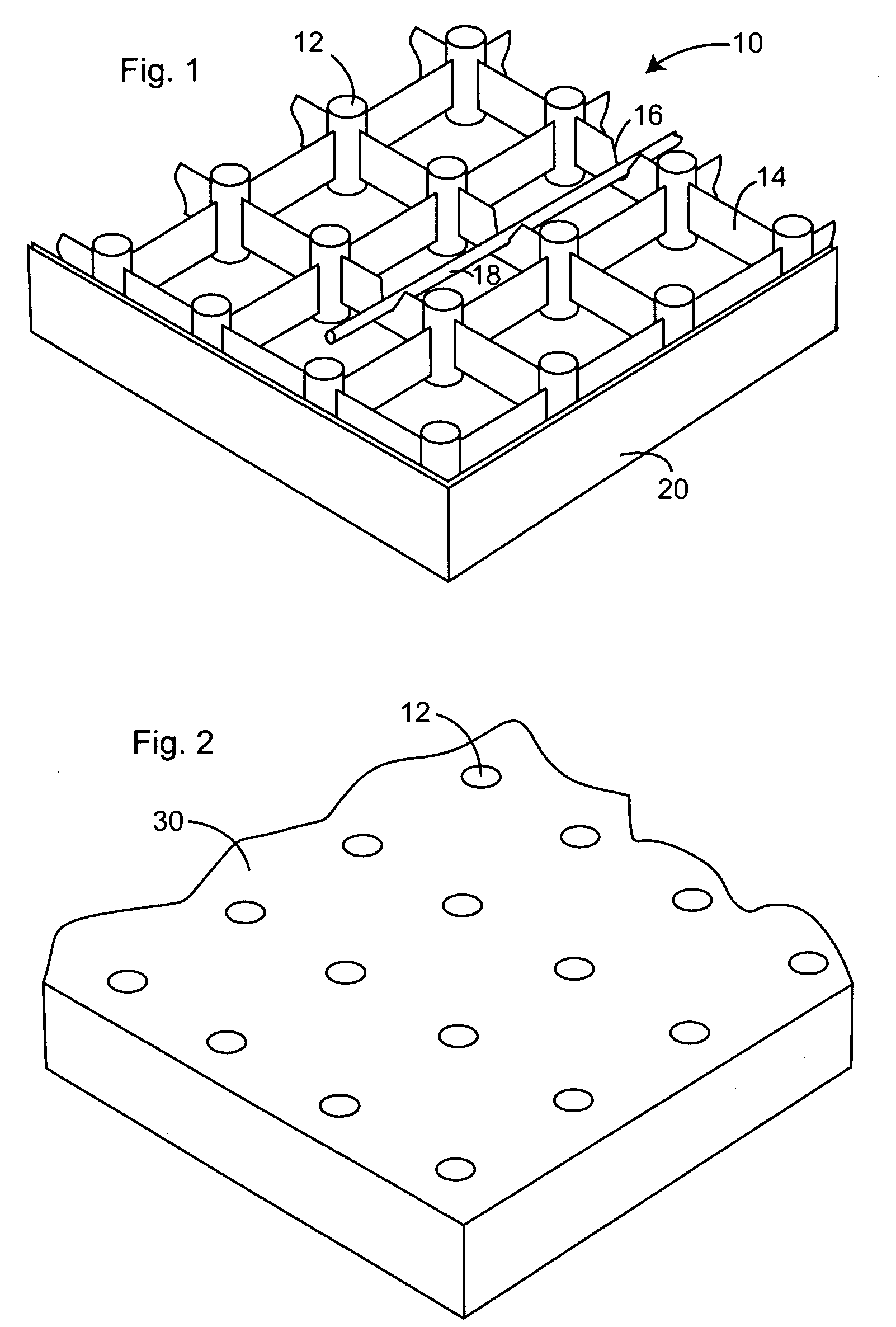

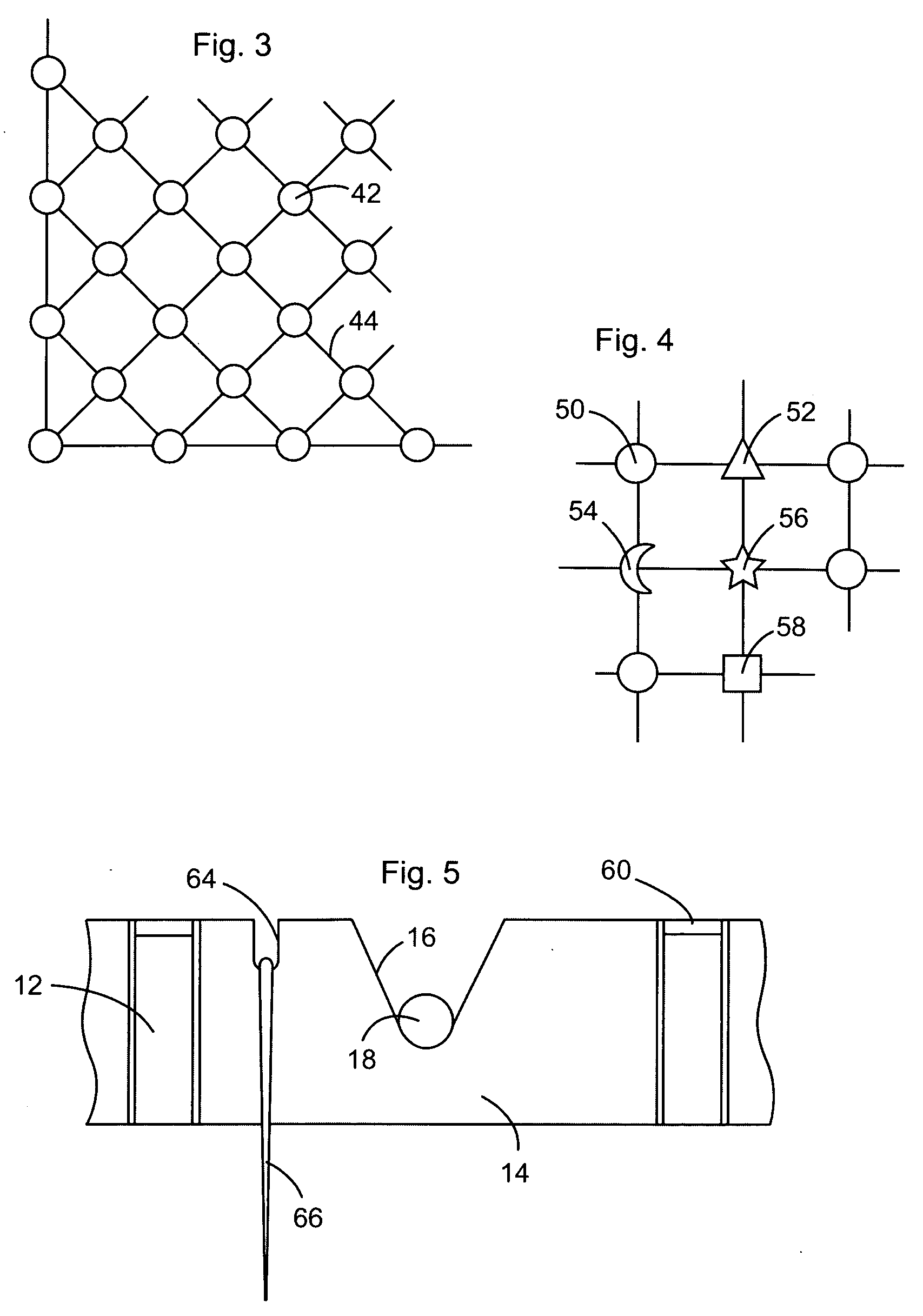

Water-permeable concrete pad and form

InactiveUS20050224690A1Permit useIn situ pavingsSingle unit pavingsStructural engineeringPervious concrete

Owner:HOBBS GEORGE J

Water-permeable agent for water-permeable bricks or water permeable concrete and application of water-permeable agent

The invention discloses a water-permeable agent for water-permeable bricks or water permeable concrete and application of the water-permeable agent. The water-permeable agent comprises, by weight, 75-110 parts of water reducing agent, 150-300 parts of retarder, 100-150 parts of binder, 55-70 parts of air entraining agent and 55-100 parts of water. The water-permeable agent has the advantages that the water-permeable agent can increase the workability of a water-permeable layer, increase water permeability and increase the durability and later strength of the water-permeable bricks and is low in adding amount and low in cost. The water-permeable bricks have the advatnages that the bricks use haycite and regenerated porous coarse aggregate as the aggregate of the water-permeable layer and use the water-permeable agent, the features of porosity, good water absorption performance and high strength of the aggregate and the good performance of the water-permeable agent are utilized to increase the strength and water permeability of the water-permeable bricks, and the bricks are lightweight and convenient to carry.

Owner:SHANDONG JINYI GARDEN SHARES CO LTD

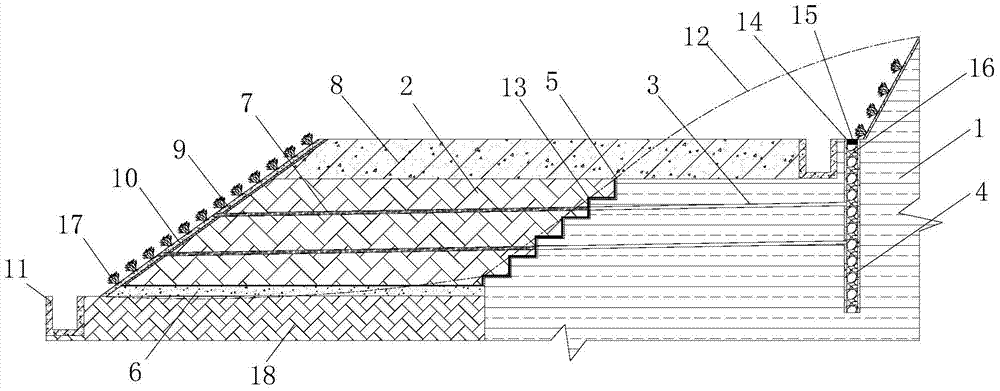

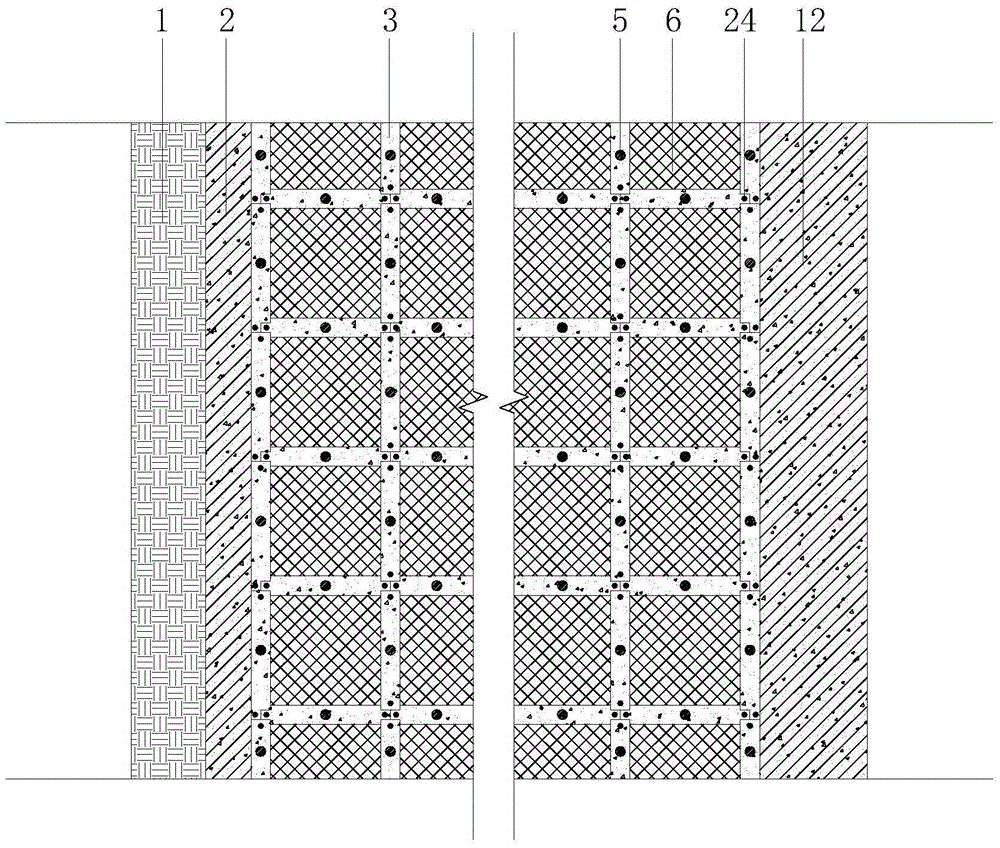

Semi-filling and semi-excavating ecological subgrade structure and construction method

InactiveCN104264557AAvoid enteringAccelerate evaporationRoadwaysExcavationsEnvironmental resource managementUnderwater

The invention relates to a semi-filling and semi-excavating ecological subgrade structure. The semi-filling and semi-excavating ecological subgrade structure is characterized in that a junction face of a fill subgrade and an excavating subgrade is paved with waterproof geotextile and a step type integral connection net; a change fill layer, a pervious concrete isolation layer and waterproof geotextile are sequentially arranged at the bottom of the fill subgrade; through long transverse drainage ventilating pipes are arranged in the excavating subgrade and are communicated with a vertical ventilating channel close to a side slope; the fill subgrade is provided with a three-dimensional composite water drainage ventilation net which is in lap joint with the transverse drainage ventilating pipes; the side face of the fill subgrade is paved with waterproof geotextile and planting concrete; and side ditches are dug in the bottom of the side slope. According to the semi-filling and semi-excavating ecological subgrade structure, water in the subgrade can be effectively drained; underwater can be prevented from migrating to the subgrade and a road surface; frost heaving, thaw collapsing and frost boiling are effectively prevented; the defect that a longitudinal crack appears in a junction of the filling position and the excavating position of the subgrade due to uneven frost heaving can be effectively overcome; the good technical and economic benefits are achieved. The invention further discloses a construction method of the semi-filling and semi-excavating ecological subgrade structure.

Owner:神州建设集团有限公司

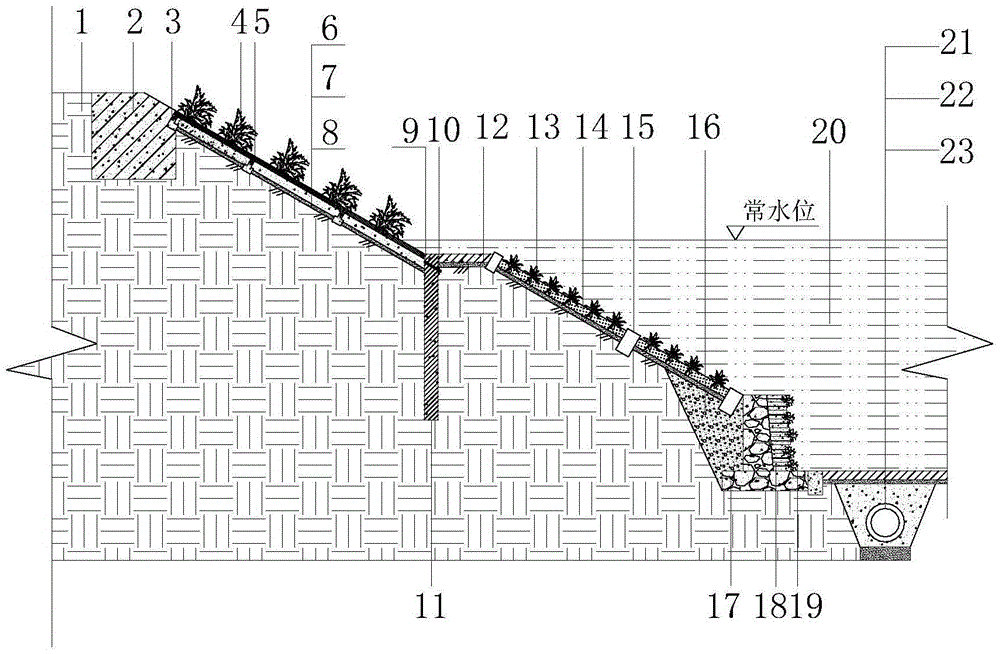

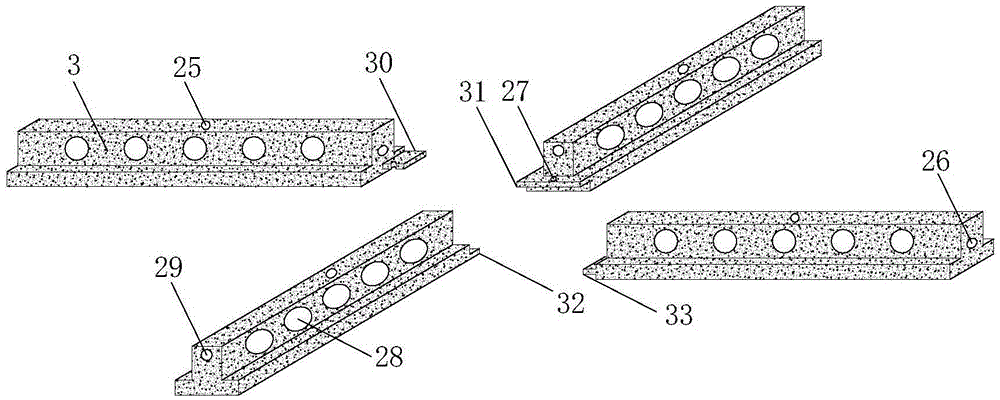

Construction method of cast-in-situ planting type ecological concrete slope protection

ActiveCN105544460AMeet stability and securityAchieve harmonyCoastlines protectionEngineeringRetaining wall

The invention relates to a construction method of a cast-in-situ planting type ecological concrete slope protection, which mainly comprises the steps of construction preparation, cast-in-situ construction of a concrete bottom protection, construction of a rubble concrete retaining wall, cast-in-situ construction of a grid, mounting of an erosion-resistant biological blanket, construction of a waterborne platform, construction of a permeable concrete slope protection wall, assembling of frame beams, pouring of planting concrete into the frame beams, mounting of coiled planting material and pouring of a concrete top protection. According to the invention, a slope protection structure is constructed quickly, and the surface of the slope protection is completely ecological from top to bottom.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

High strength permeable concrete additive and permeable concrete

The invention relates to a high strength permeable concrete additive and permeable concrete. The invention aims to overcome the problem of low strength of permeable concrete. The high strength permeable concrete additive comprises the following raw materials by weight: 50 to 100 of a water reducer, 100 to 120 of rubber powder, 180 to 300 of pigments, 80 to 100 of asbestos wool, 150 to 200 of gypsum powder and 100 of heavy calcium powder. The prepared permeable concrete is characterized in that: the weight ratio of the additive to cement in the concrete is 30 to 35%, and there is 15 to 18 wt %of iron ore slag in the concrete. The balance in the concrete is gravel and water. The prepared concrete has the following advantages: good water penetration and good permeability are obtained; when it is raining, no water is accumulated on the concrete, splashing of rainwater is mitigated, and occurrence of the phenomenon that shoes, wheelchairs and the like are wetted is reduced; high load-bearing capability and superior environment-friendliness are achieved; good security and a beautiful visual effect are realized, and car accidents caused by reflection of headlights at night in a rainy day are reduced; when the concrete is used for an antiskid track, occurrence of the phenomenon of water mist is reduced, and traffic accidents are prevented; the advantage of reutilization of waste resources is achieved.

Owner:北京利坚美保温材料有限公司

Method for performing foundation treatment by using permeable concrete pipe piles

The invention discloses a method for performing foundation treatment by using permeable concrete pipe piles, which comprises the following steps of: selecting a soft soil foundation or a liquefiable foundation for the arrangement of the permeable concrete pipe piles, wherein the permeable concrete pipe pile is a closed pipe pile of which two ends are closed and a pile body is made of permeable concrete; and arranging the piles along narrow sides in a site, connecting the centers of each row of permeable concrete pipe piles into a straight line and paving a cushion along the straight line, wherein the cushion is made of sands or gravels; and the cushion has a width equal to the diameter of the pipe pile and is 20 to 40cm thick. The permeable concrete pipe piles not only function as reinforcement bodies of composite foundations, but also are good drainage channels per se. As the advantages of the composite foundations treated by a drainage consolidation method and a composite foundation method are integrated, the method has the advantages of improving foundation treatment effect, shortening a construction period and saving the engineering construction cost.

Owner:SOUTHEAST UNIV

Filter Element for Water Loaded with Solid Particles and Dissolved Toxic Substances and Purification System Equipped with Said Filter Element Test System for Portable Analyzer

InactiveUS20080121594A1Enhance adsorption action of filterHigh pH-valueReversed direction vortexTreatment involving filtrationWater flowSolid particle

The invention relates to a filter element consisting of a molded body of porous concrete, which element is arranged in the water stream of a purification system. In particular, the filter element (10) is a molded pervious concrete layer arranged as a partition between a lower compartment (9) and an upper compartment (11) of a treatment chamber (8), wherein the water inlet (12) opens into the lower compartment (9) and a water outlet (17) issues from the upper compartment (11). The pervious concrete filter layer may contain one or more additives to enhance adsorption of pollutants, such as heavy metal ions, phosphorous, hydrocarbons or other target soluble pollutants.

Owner:FORTERRA CONCRETE PROD INC +1

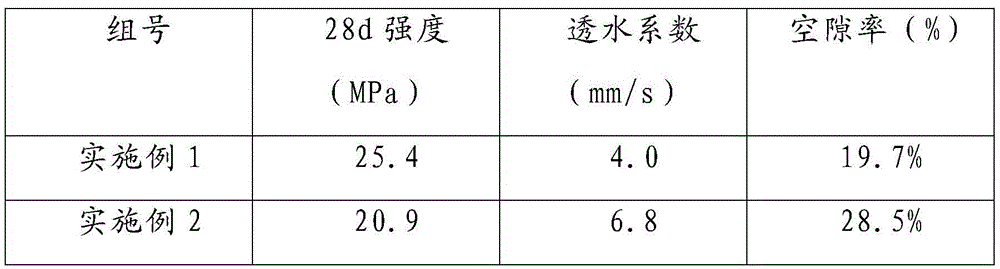

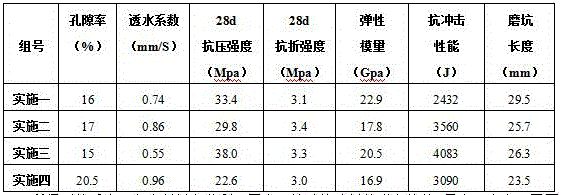

Glue-powder pervious concrete and preparation method thereof

The invention discloses glue-powder pervious concrete and a preparation method thereof. The glue-powder pervious concrete contains the following ingredients in parts by mass: 300-450 parts of cement, 1,300-1,800 parts of coarse aggregates, 2-15 parts of additives, 20-50 parts of mineral admixture, 6-50 parts of waste / used tire rubber powder, 6-12 parts of cementing agent, 0.2-1.0 part of humectant and 100-150 parts of water. According to the glue-powder pervious concrete, the compressive strength, folding strength, porosity, coefficient of water permeability, wear resistance and the like are in line with technical regulations for pervious concrete pavements CJJ / T135-2009; meanwhile, the glue-powder pervious concrete also has the advantages of high toughness, high shock resistance, low elastic modulus, and the like, thereby playing a very good role in promoting the development of high-performance concrete technologies in the construction of sponge cities. The preparation method provided by the invention comprises three steps, i.e., carrying out mortar preparation, carrying out mortar coating treatment and carrying out stirring, thereby obtaining the finished product, and novel equipment is not required to be increased, so that the method is easy and feasible.

Owner:重庆绿恒环保科技有限公司

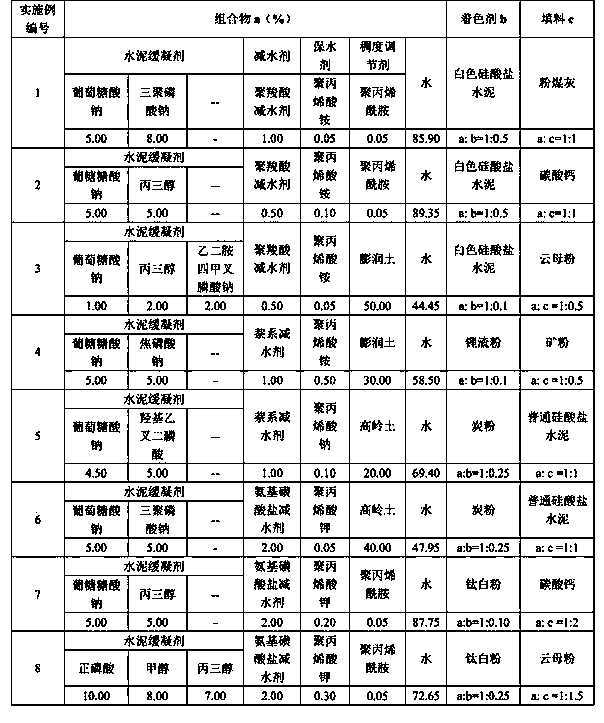

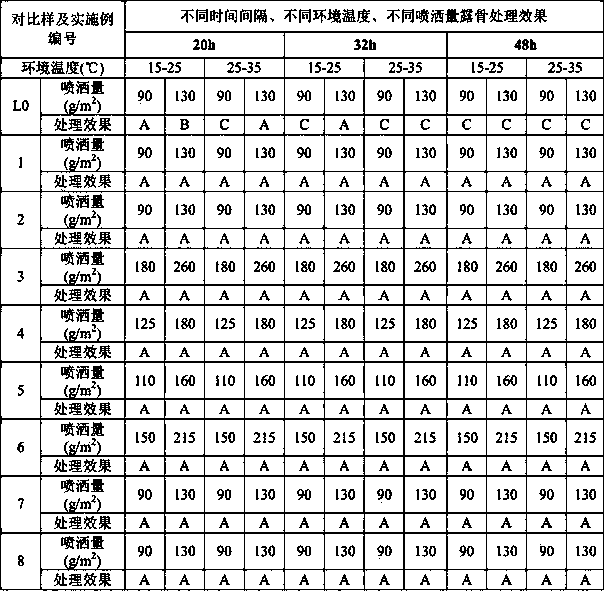

Surface cleaning agent dedicated to exposed pervious concrete and preparation and application methods thereof

The invention discloses a surface cleaning agent dedicated to exposed pervious concrete, which comprises a composition a, a coloring agent b and a filling material c, wherein the composition a comprises the following raw materials by weight: 5 to 25 % of a cement retarder, 0.5 to 2 % of a water reducer, 0.05 to 50 % of a consistence modifier, 0.05 to 0.5% of a water-retaining agent and 44 to 90 % of water; the mass of the coloring agent b is 10 to 50 % of that of the composition a; the mass of the filling material c is 50 to 200 % of that of the composition a. The surface cleaning agent is stable in property, the spray quantity is fluctuated in a certain range, the effect influence by the environmental temperature change is small, sound washing effect can be realized in 20 to 48 h after the spraying, the penetration depth is appropriate, the condition that the surface cleaning agent penetrates into root parts of stones can be prevented, the normal development of the cement paste strength at the root parts of the stones cannot be influenced, and the condition that the surface layer stones of the exposed pervious concrete fall off is avoided.

Owner:广西中建西部建设有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com