Semi-filling and semi-excavating ecological subgrade structure and construction method

A half-fill, half-dug, subgrade technology, which is applied in the field of highway engineering, can solve problems such as soil damage, collection, and unsatisfactory drainage effects, and achieve the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

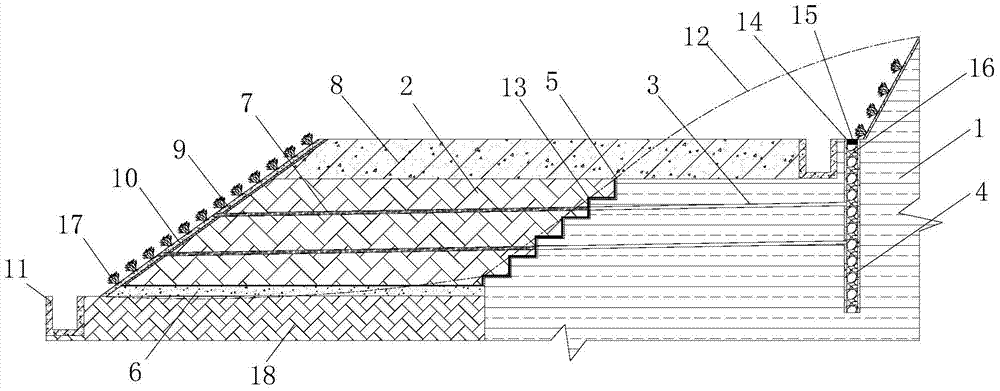

[0030] figure 1 It is a cross-sectional view of the invented half-filled and half-dug ecological subgrade structure. refer to figure 1 As shown, the half-fill and half-cut ecological subgrade structure is composed of excavated subgrade 1, filled subgrade 2, pavement structure layer 8 and other parts.

[0031] According to the design requirements, excavate and level the excess soil layer of the original soil layer in hills or mountainous areas to form excavated subgrade 1, excavate excavated subgrade 1 near the filled subgrade 2 into a stepped shape, and roll compactly, and the excavated subgrade near the edge corresponds Excavate the vertical ventilation channel 4 at the position of the horizontal drainage ventilation pipe 3, and backfill the gravel filling material 16 after the vertical ventilation channel 4 is drilled. . A cover plate 14 is covered on the top of the vertical ventilation channel 4, and the center of the cover plate 14 is hollow. The upper surface of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com