Patents

Literature

32results about How to "Improve soil strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

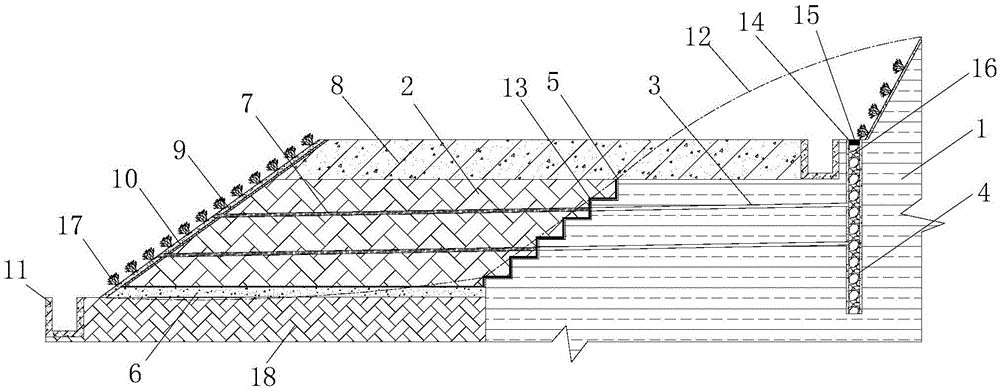

Semi-filling and semi-excavating ecological subgrade structure and construction method

InactiveCN104264557AAvoid enteringAccelerate evaporationRoadwaysExcavationsEnvironmental resource managementUnderwater

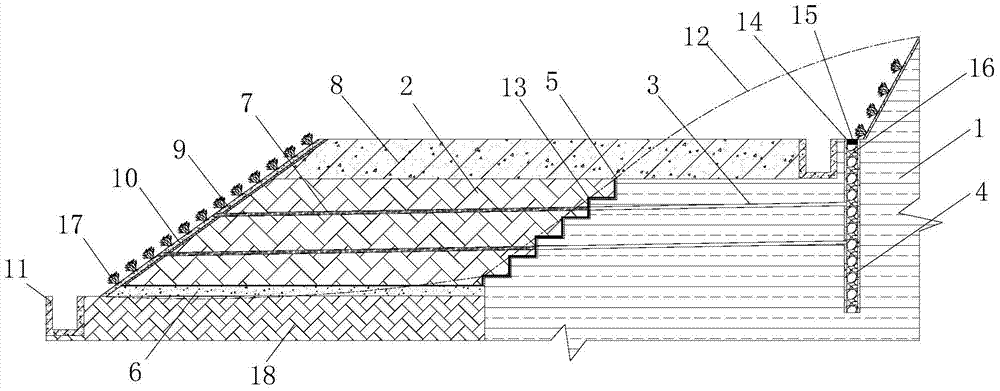

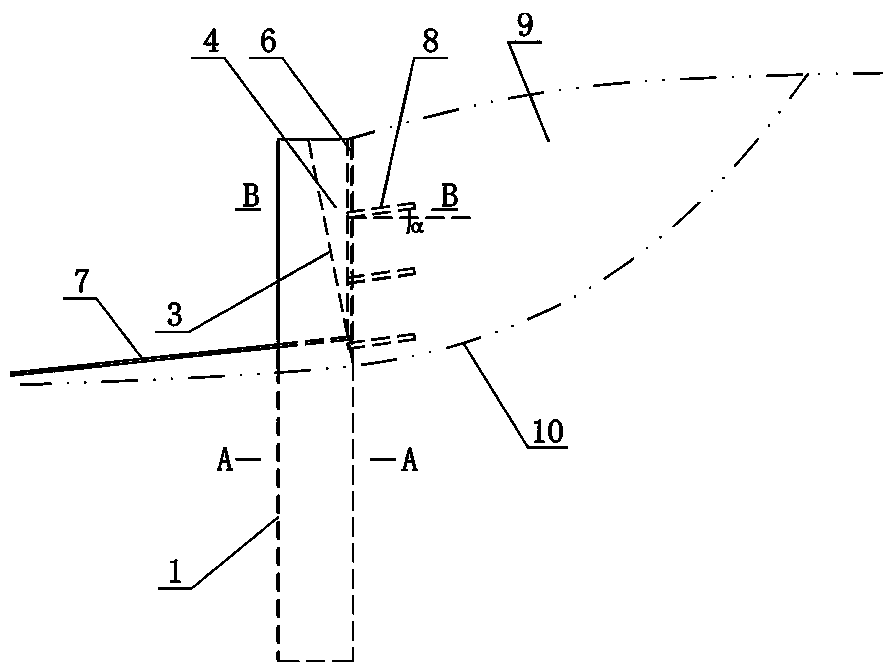

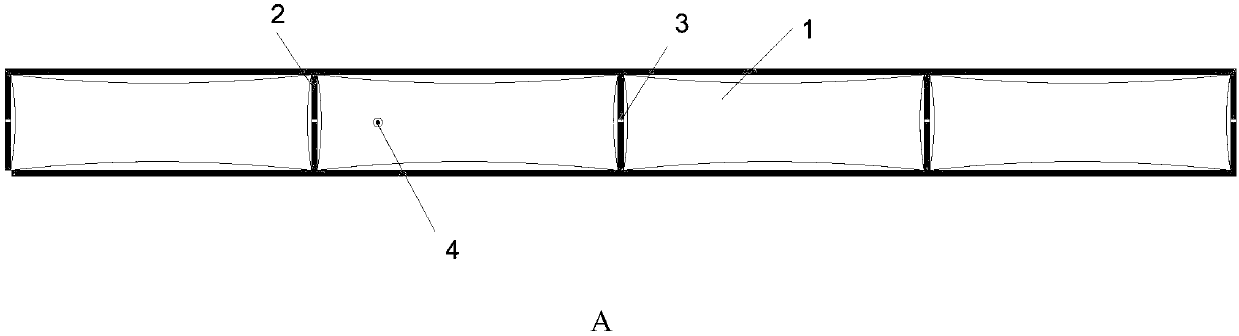

The invention relates to a semi-filling and semi-excavating ecological subgrade structure. The semi-filling and semi-excavating ecological subgrade structure is characterized in that a junction face of a fill subgrade and an excavating subgrade is paved with waterproof geotextile and a step type integral connection net; a change fill layer, a pervious concrete isolation layer and waterproof geotextile are sequentially arranged at the bottom of the fill subgrade; through long transverse drainage ventilating pipes are arranged in the excavating subgrade and are communicated with a vertical ventilating channel close to a side slope; the fill subgrade is provided with a three-dimensional composite water drainage ventilation net which is in lap joint with the transverse drainage ventilating pipes; the side face of the fill subgrade is paved with waterproof geotextile and planting concrete; and side ditches are dug in the bottom of the side slope. According to the semi-filling and semi-excavating ecological subgrade structure, water in the subgrade can be effectively drained; underwater can be prevented from migrating to the subgrade and a road surface; frost heaving, thaw collapsing and frost boiling are effectively prevented; the defect that a longitudinal crack appears in a junction of the filling position and the excavating position of the subgrade due to uneven frost heaving can be effectively overcome; the good technical and economic benefits are achieved. The invention further discloses a construction method of the semi-filling and semi-excavating ecological subgrade structure.

Owner:神州建设集团有限公司

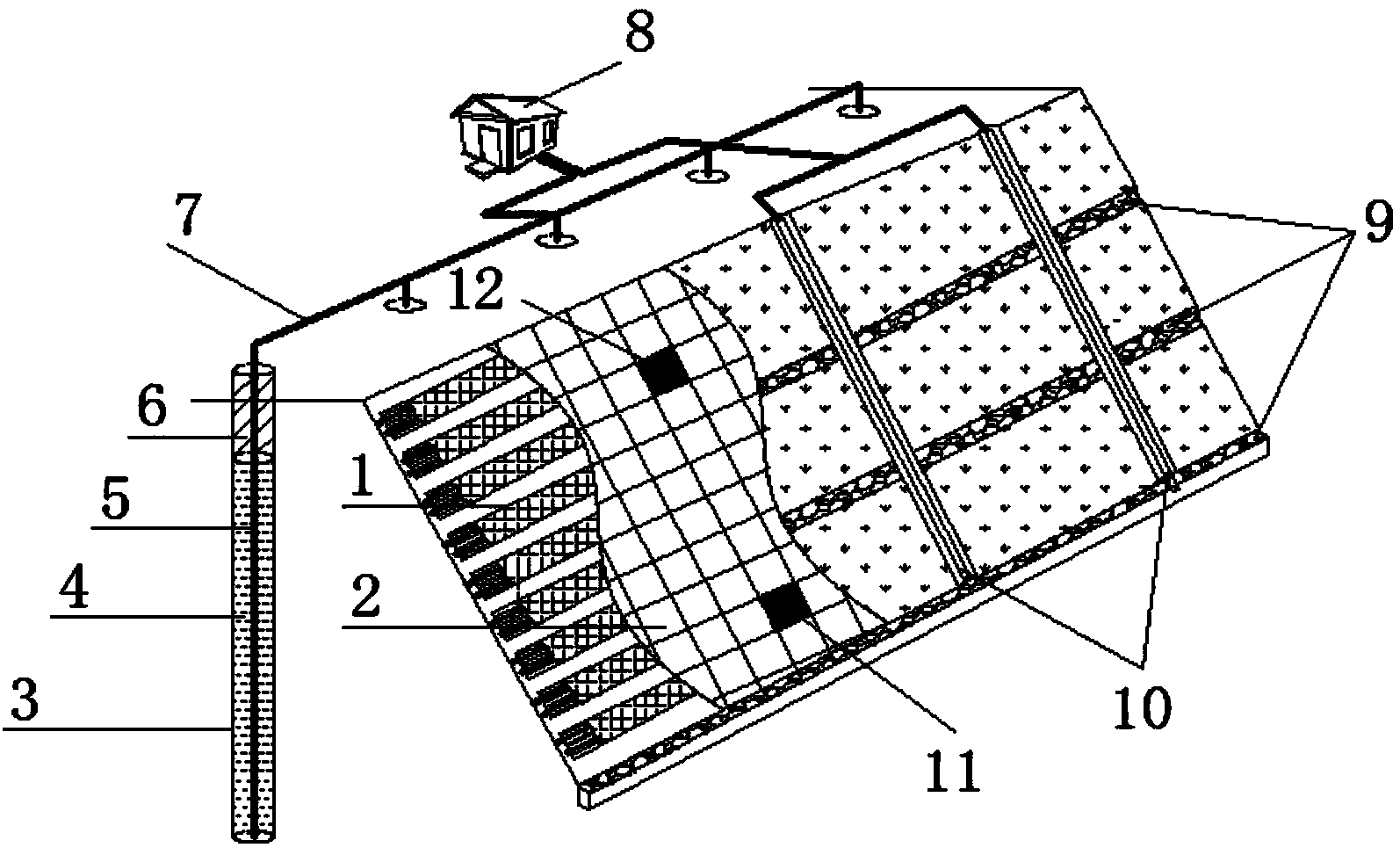

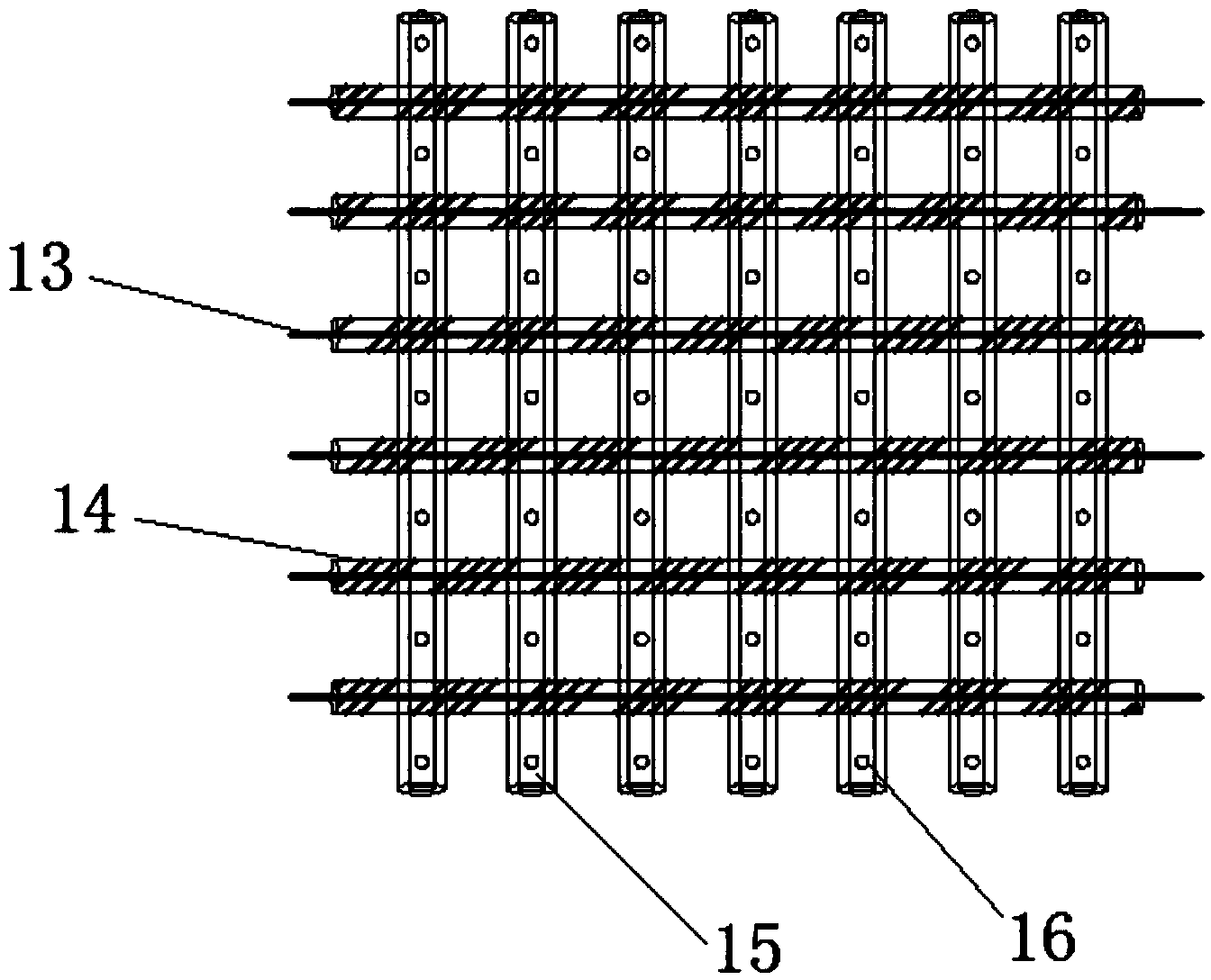

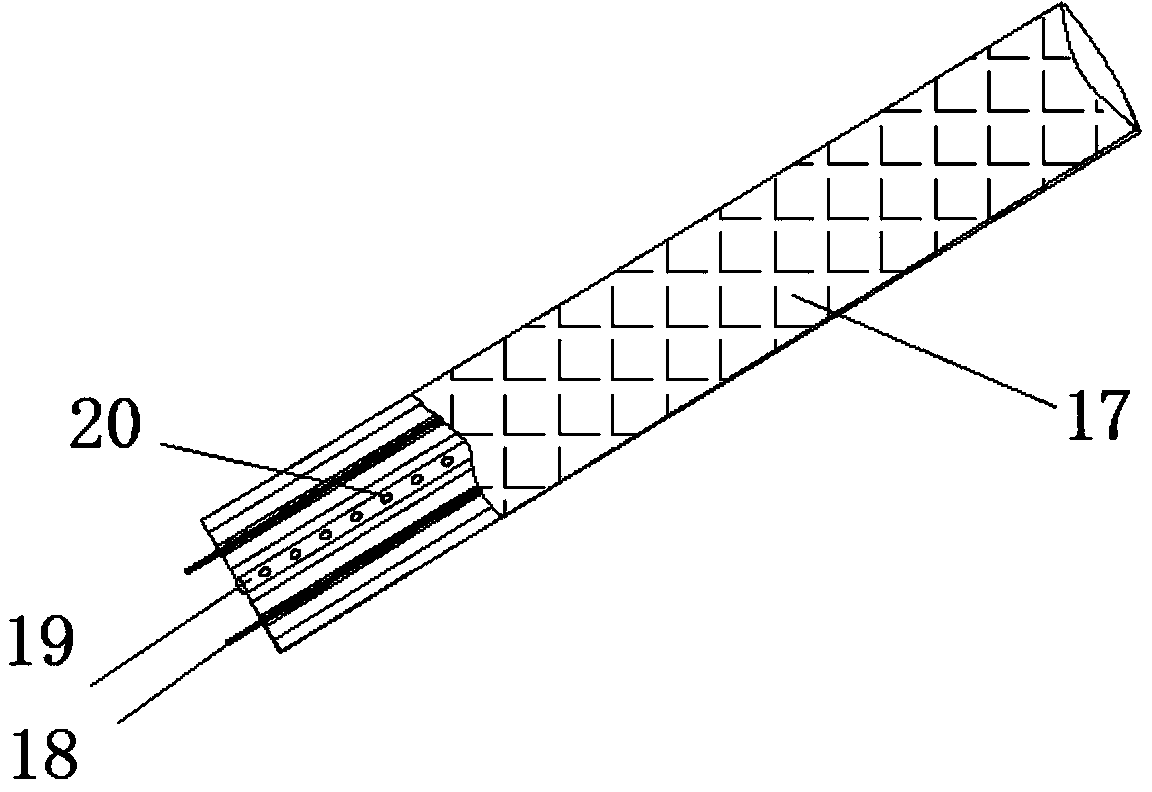

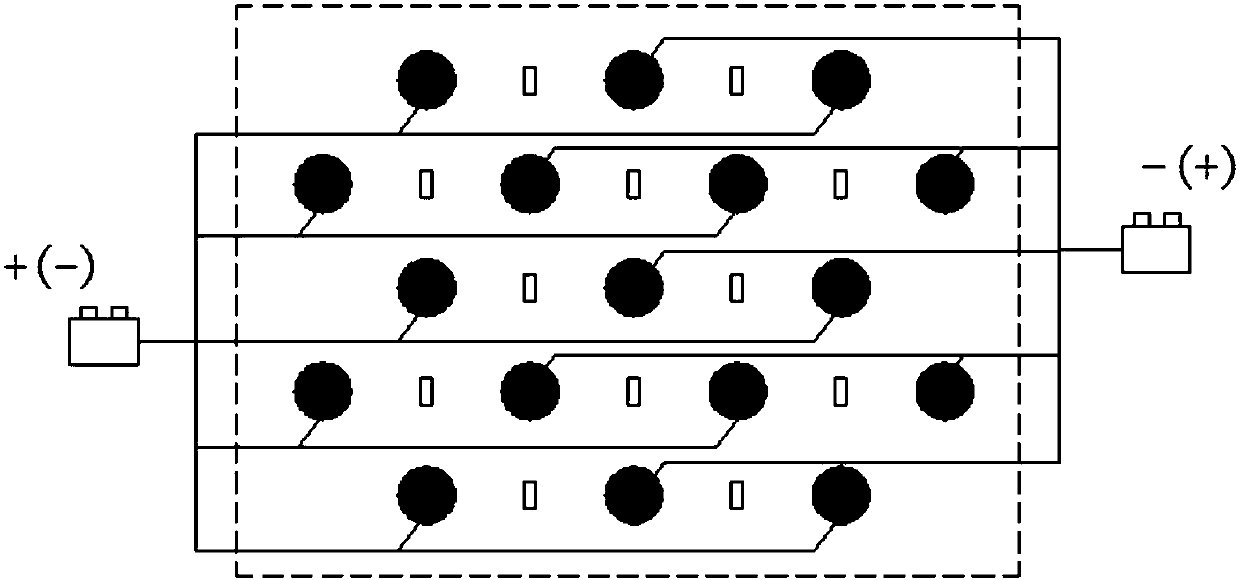

Electroosmotic ecological slope protection maintenance system and technology

ActiveCN104343126AImprove reliabilityImprove soil strengthExcavationsSoil preservationWater contentFertilizer

The invention discloses an electroosmotic ecological slope protection maintenance system and a technology. Devices such as a novel conductive plastic water diversion body, a water content sensor and a soil EC (effective concentration) meter are buried in a soil body, so that intelligent control of water supply under a drought condition and drainage in a rainy season for an ecological side slope are realized, disadvantages in manual maintenance are eliminated, the water, fertilizer, time and labor are saved, and the reliability of the side slope is improved. In addition, the problem of poor durability of electroosmotic treatment in the former project is saved, a novel corrosion resistant material is used, a scheme of adding supply liquid is provided, and the electroosmotic efficiency is kept. The method is simple in construction technology and strong in operability, facilitates quality control, has the characteristic of life-long benefit after single construction, and has significant economic benefits and a certain popularization value.

Owner:HOHAI UNIV

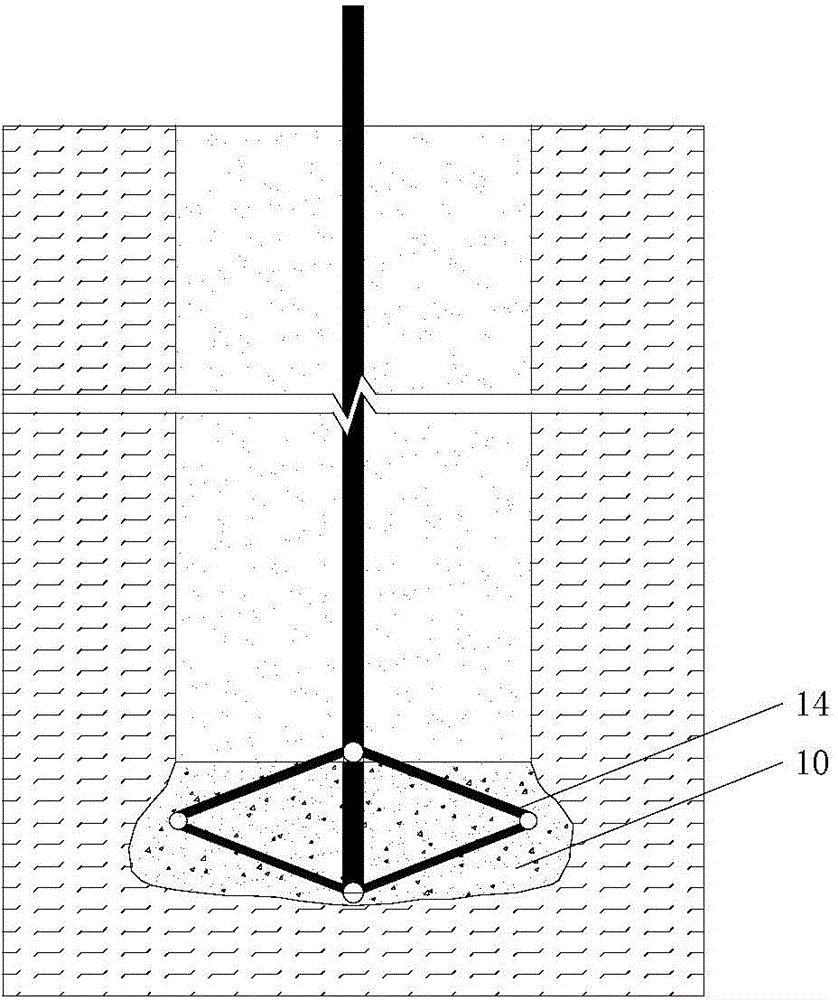

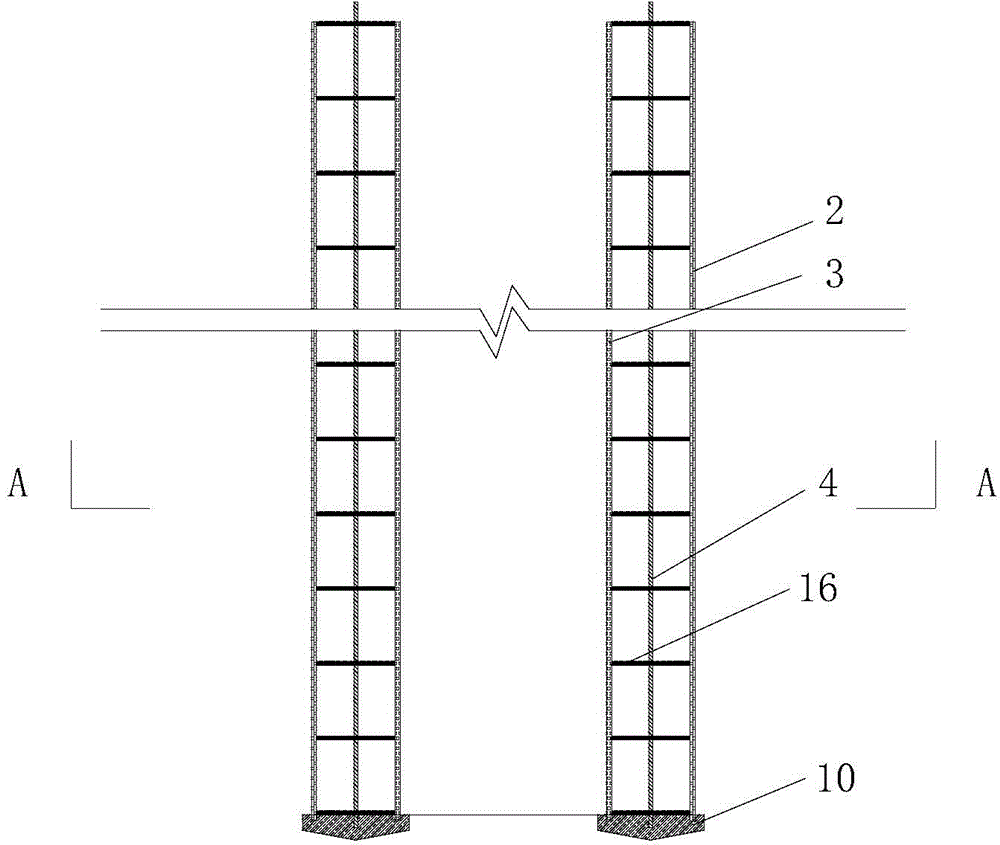

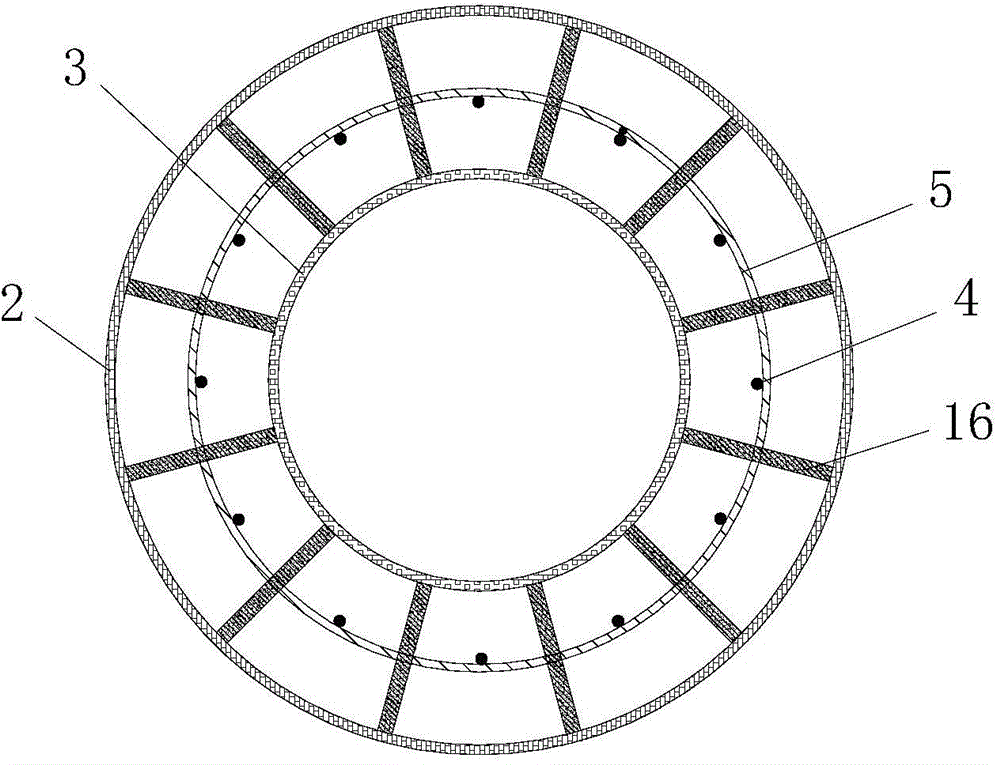

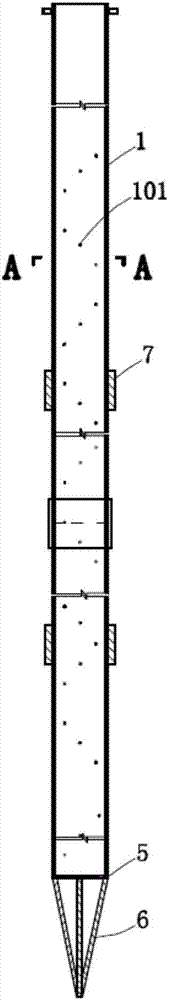

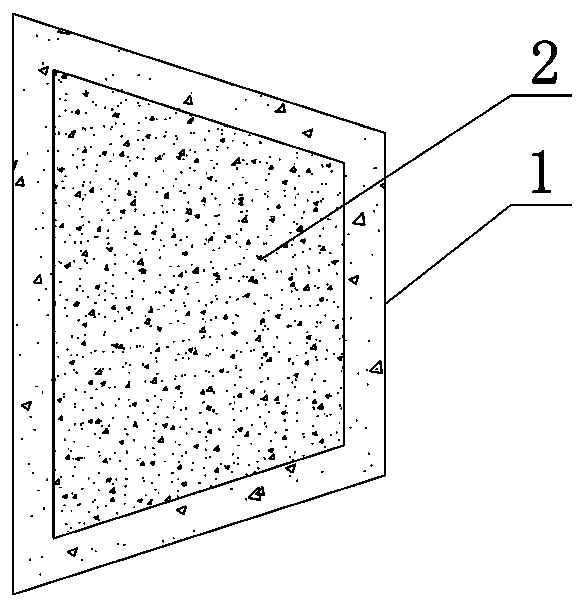

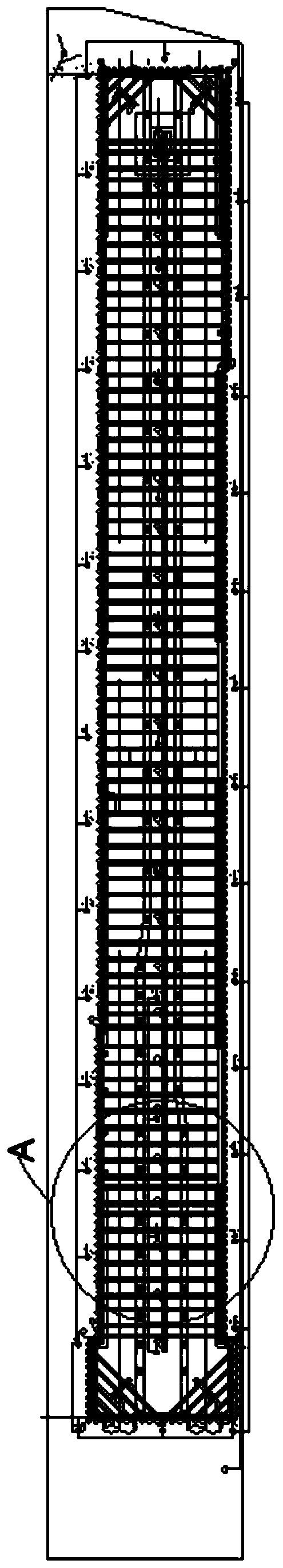

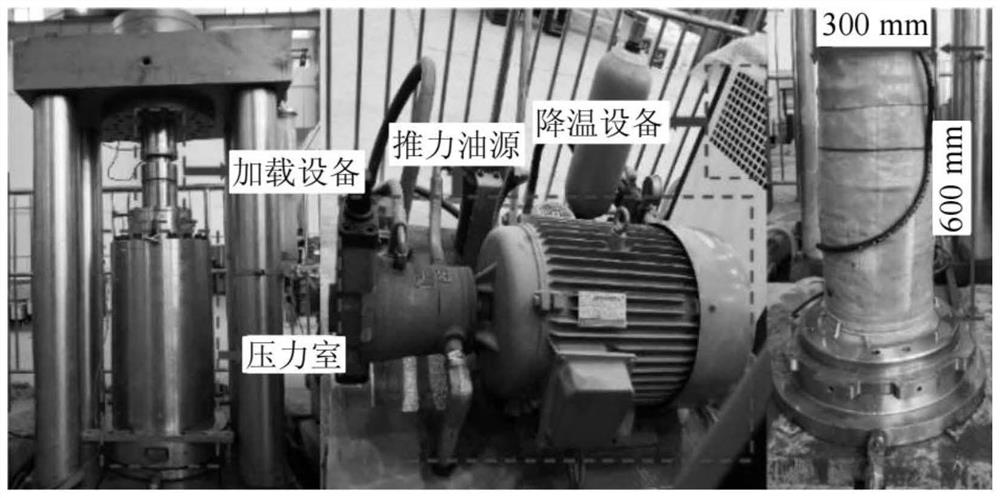

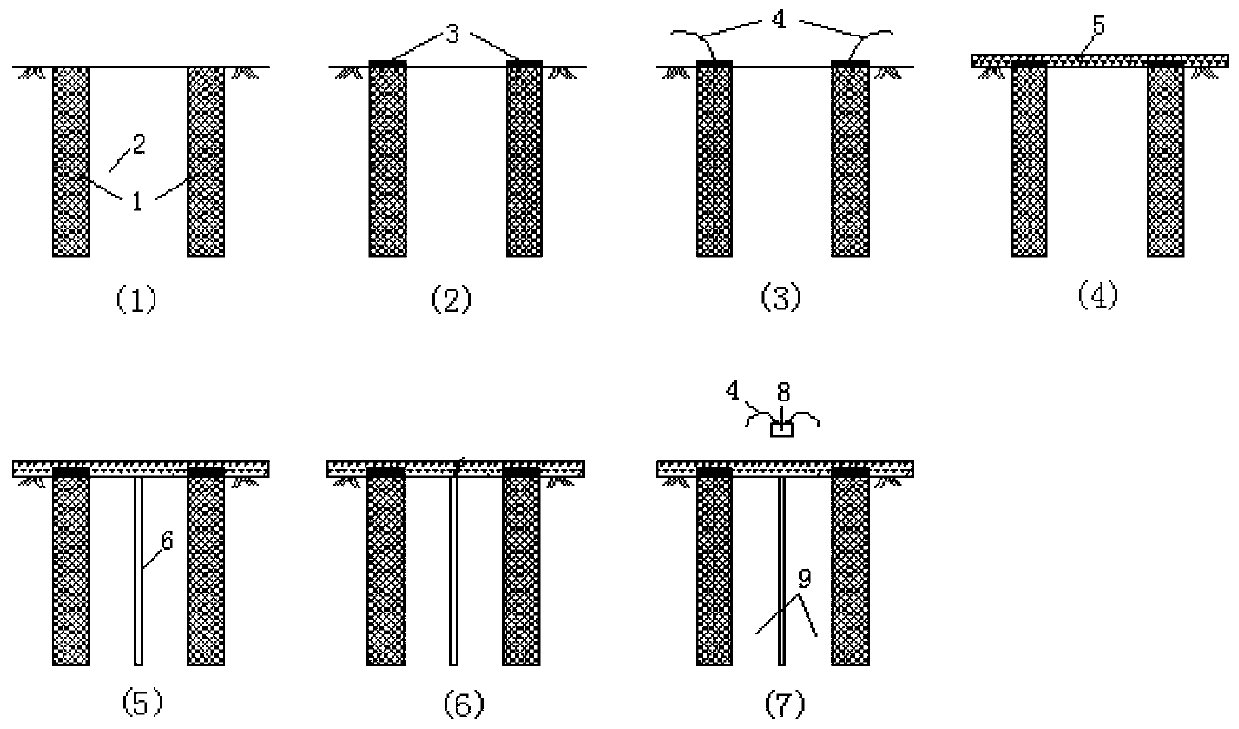

Construction method of reinforced concrete current-poured pile

ActiveCN104452749AImprove carrying capacityEasy constructionBulkheads/pilesSocial benefitsReinforced concrete

The invention relates to a construction method of a reinforced concrete current-poured pile. The method mainly comprises the steps that (1), a slurry protecting wall is drilled for hole forming, a drilling machine is used for drilling a hole in the hole forming process, and then the hole bottom is chambered through a branch tray forming machine; (2), the expanding end at the bottom of the pile is poured in an underwater concrete pouring mode; (3), a reinforcing cage is manufactured, stirrups are provided with reinforced protection cushion blocks at intervals, and a positioning support is formed; (4), inner side mould bags and outer side mould bags are attached to the inner side and the outer side of the positioning support respectively, and end boards are installed at the bottom of the positioning support; (5), the positioning support and the mould bags are pressed into the hole together; (6), micro-expansion concrete is poured in the space of the inner side mould bags and the outer side mould bags; (7), after the concrete of a pile body reaches the intensity, a pile top closing body and a cover board are constructed. The reinforcing cage is arranged in the reinforced concrete current-poured pile, the pile bearing capacity is improved, influence on the quality of the finished pile from foundation soil is reduced, the construction speed is high, quality is convenient to ensure, and good economic benefits and social benefits are obtained.

Owner:山东恒祥城市建设发展集团有限公司

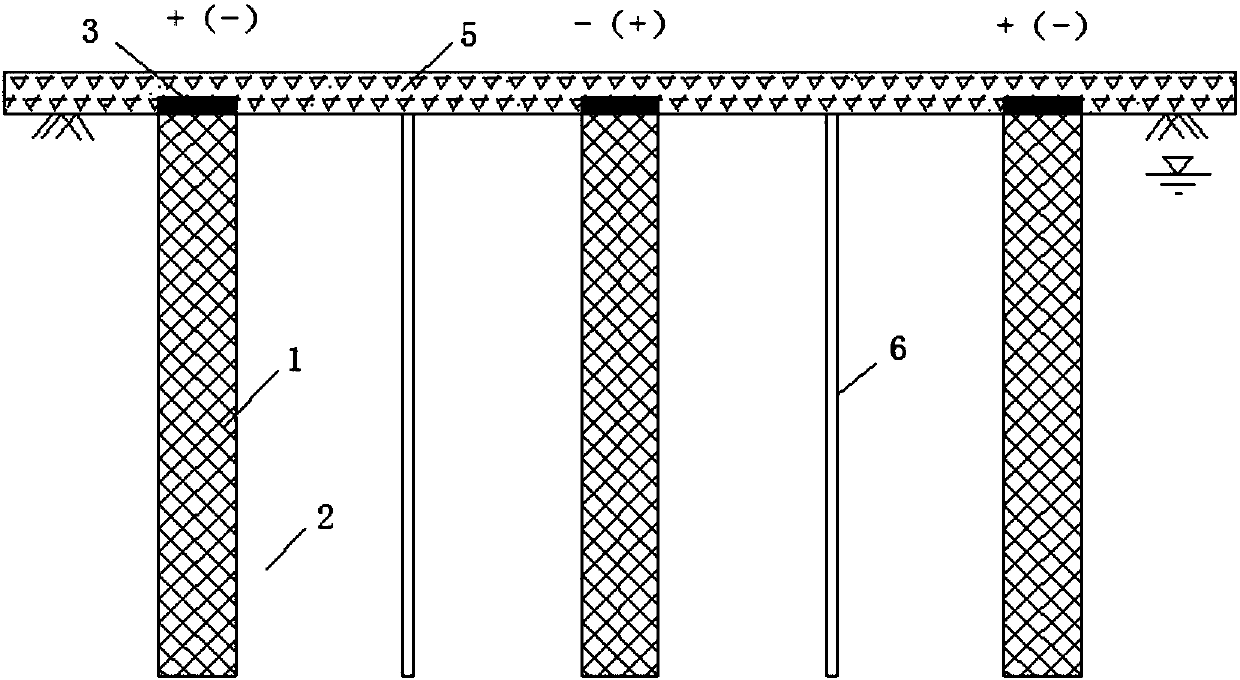

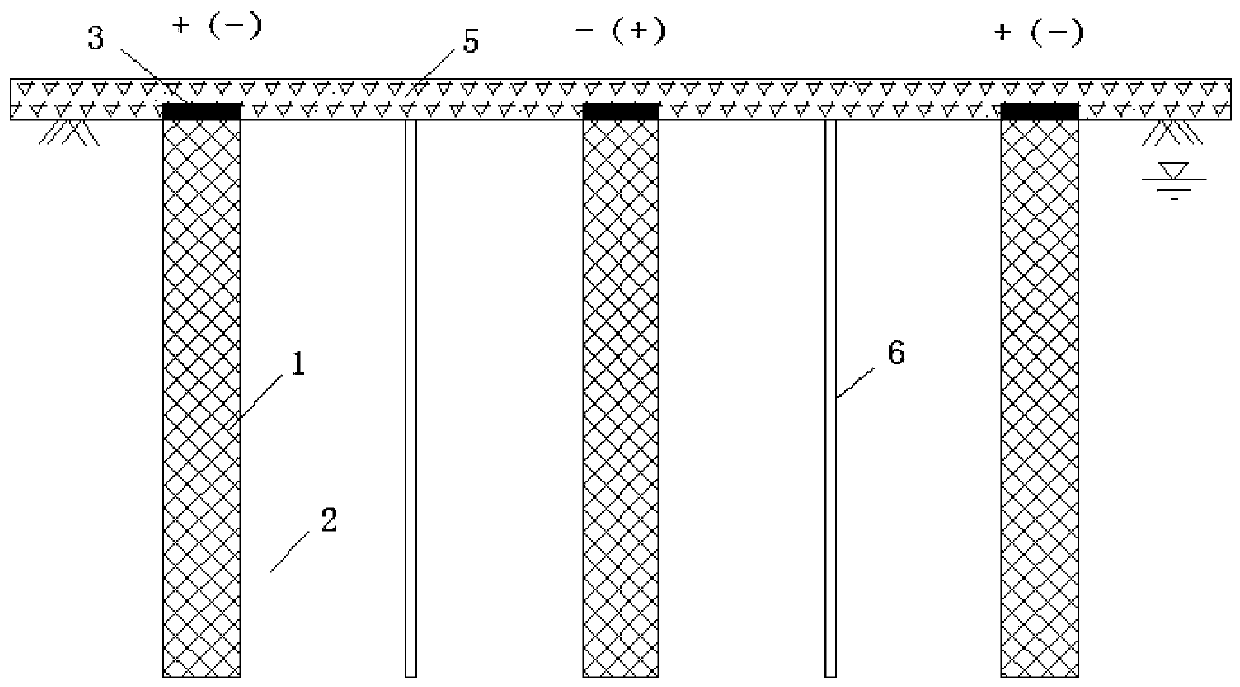

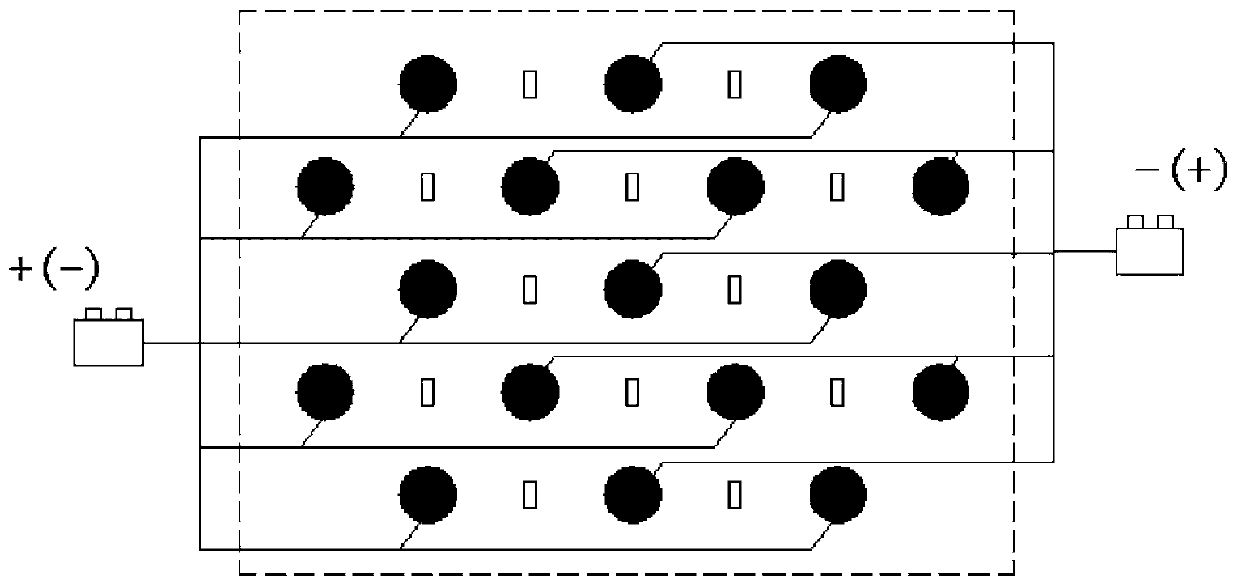

Construction method for soft foundation consolidation by utilizing carbon fiber cement mixing piles combined with electroosmosis method

ActiveCN107630450ASolve corrosiveSolve the problem of bubble accumulation and accumulationBulkheads/pilesSoil preservationFiberCarbon fibers

The invention discloses a construction method for soft foundation consolidation by utilizing carbon fiber cement mixing piles combined with the electroosmosis method. The construction method is characterized in that conductive carbon fibers are added into the conventional cement mixing piles, and conductive blocks are arranged at the tops of the piles to form electrodes; and besides, a horizontalsand cushion layer and vertical plastic drainage plates are laid to serve as drainage channels, and a calcium chloride solution or sodium silicate solution is injected into the soil among the piles during different periods of time from the top ends of the plastic drainage plates, so as to shorten the electroosmosis period and improve the strength of the soil among the piles. With the adoption of the construction method for soft foundation consolidation by utilizing carbon fiber cement mixing piles combined with the electroosmosis method, the problems of electrode erosion of the electroosmosismethod and gathering and accumulating of gas bubbles are effectively solved, and the advantages as follows are achieved: the construction time is short, the strength of the foundation after treatmentis high, and the post-construction settlement is little

Owner:HOHAI UNIV

A construction method for reinforced concrete cast-in-place pipe piles

ActiveCN104452749BImprove carrying capacityEasy constructionBulkheads/pilesSocial benefitsReinforced concrete

The invention relates to a construction method of a reinforced concrete current-poured pile. The method mainly comprises the steps that (1), a slurry protecting wall is drilled for hole forming, a drilling machine is used for drilling a hole in the hole forming process, and then the hole bottom is chambered through a branch tray forming machine; (2), the expanding end at the bottom of the pile is poured in an underwater concrete pouring mode; (3), a reinforcing cage is manufactured, stirrups are provided with reinforced protection cushion blocks at intervals, and a positioning support is formed; (4), inner side mould bags and outer side mould bags are attached to the inner side and the outer side of the positioning support respectively, and end boards are installed at the bottom of the positioning support; (5), the positioning support and the mould bags are pressed into the hole together; (6), micro-expansion concrete is poured in the space of the inner side mould bags and the outer side mould bags; (7), after the concrete of a pile body reaches the intensity, a pile top closing body and a cover board are constructed. The reinforcing cage is arranged in the reinforced concrete current-poured pile, the pile bearing capacity is improved, influence on the quality of the finished pile from foundation soil is reduced, the construction speed is high, quality is convenient to ensure, and good economic benefits and social benefits are obtained.

Owner:山东恒祥城市建设发展集团有限公司

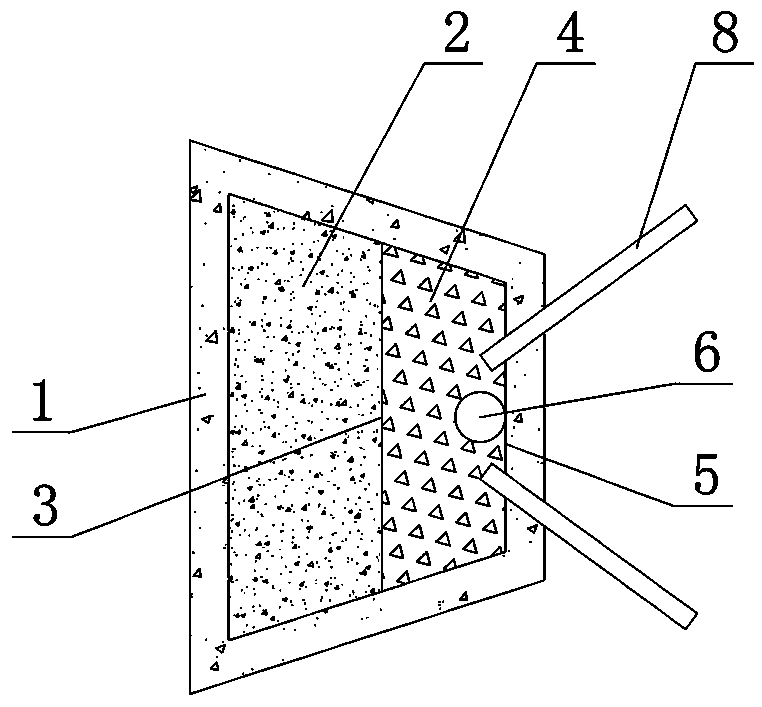

Vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure and construction method thereof

The invention relates to a vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure and a construction method thereof and belongs to the technical field of capital construction. The vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure comprises a steel perforated pipe drill hole formed in a slope, the steel perforated pipe drill hole is internally provided with a steel perforated pipe, and the steel perforated pipe is spirally provided with a plurality of secondary grouting holes; the bottom of the steel perforated pipe is provided with a blocking plate, and the side, away from the steel perforated pipe, of the blocking plate is fixedly connected with a triangular supporting frame; the steel perforated pipe drill hole is internally provided with a grouting body, a pipe opening of the steel perforated pipe is provided with a sealing cover, the position of the pipe opening of the steel perforated pipe is provided with a concrete supporting beam, the concrete supporting beam is internally provided with a steel bar structure, the steel bar structure is welded to the steel perforated pipe, and the concrete supporting beam is provided with a retaining wall. By means of the vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure, the technical problems that a traditional pile foundation technology is high in construction condition requirement, low in manual hole digging speed and high in comprehensive cost are solved, and the vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure is widely applied to slope reinforcement engineering, such as roads, railways, mines and municipal administration.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Special-shaped drainage anti-skidding pile and construction method thereof

The invention discloses a special-shaped drainage anti-skidding pile and a construction method thereof. The special-shaped drainage anti-skidding pile comprises a pile body coated with an outer protective wall. The cross section of the pile body is of a trapezoidal structure, the long side of the trapezoidal structure is a pile body soil-facing layer, the short side of the trapezoidal structure isa pile body soil-opposite face, a formwork obliquely stretching to the pile body soil-facing face is arranged from the top of the soil-opposite face of a pile body cantilever section to the pile top,a wedge-shaped cavity between the formwork and the soil-opposite face of the outer protective wall is filled with gravel, a water collecting pipe is vertically arranged in the wedge-shaped cavity, adrainage pipe at the bottom of the water collecting pipe obliquely penetrates out of the pile body soil-facing face downwards. A water drainage hole is formed in the soil-opposite face of the outer protective wall, and a water drainage shock pipe is inserted into the water drainage hole. The long side of the trapezoidal structure of the pile body is the soil-facing face, the acting width of the pile body is increased, ,the deformation resisting capacity of the anti-skidding pile is improved, and the safety of a slope is guaranteed; the cross section of the cantilever section is linearly reduced from bottom to top, the construction cost is reduced, a vertical water drainage system is integrated on the pile body cantilever section, the water drainage effect is good, and the safety of the anti-skidding pile is guaranteed.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

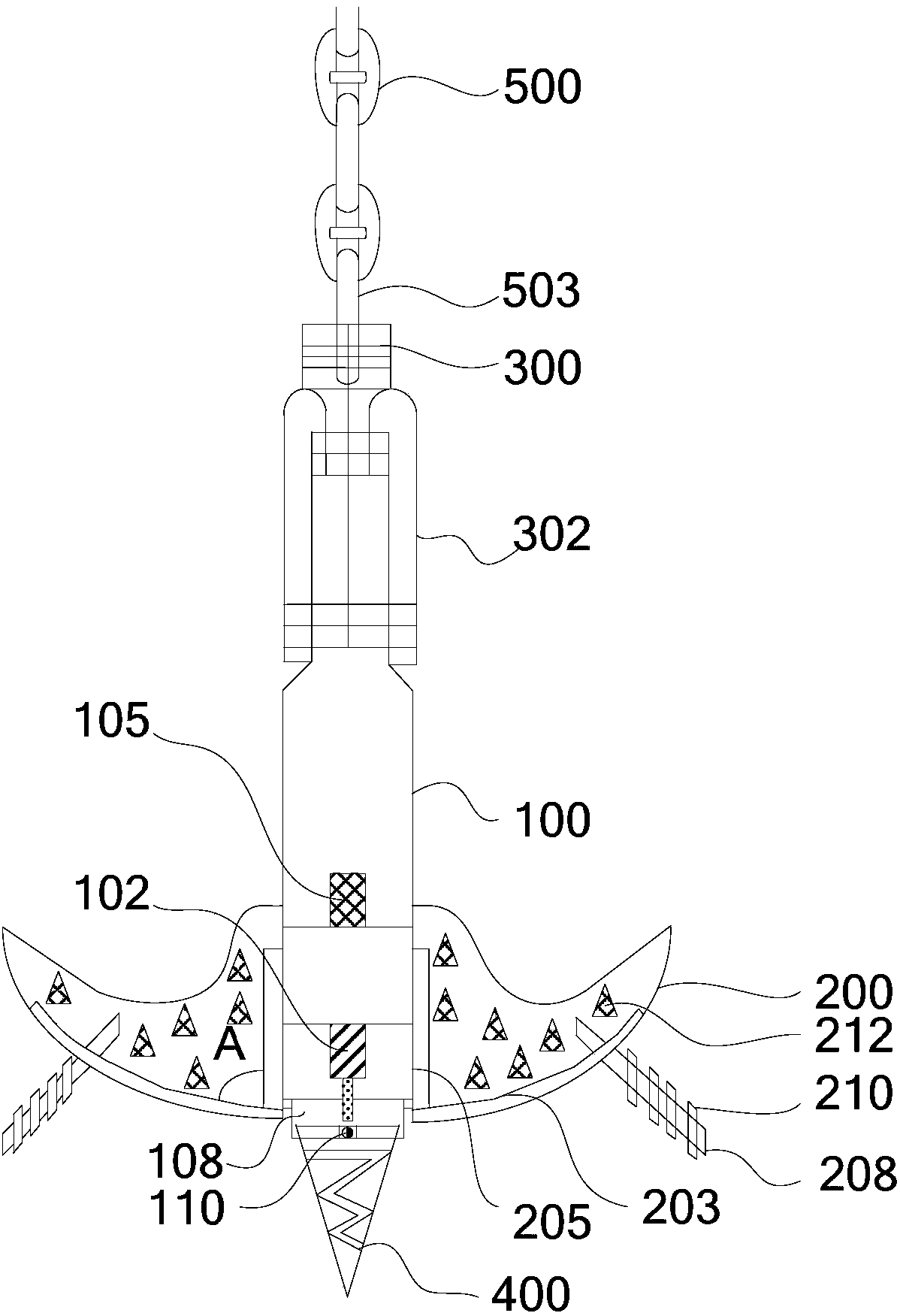

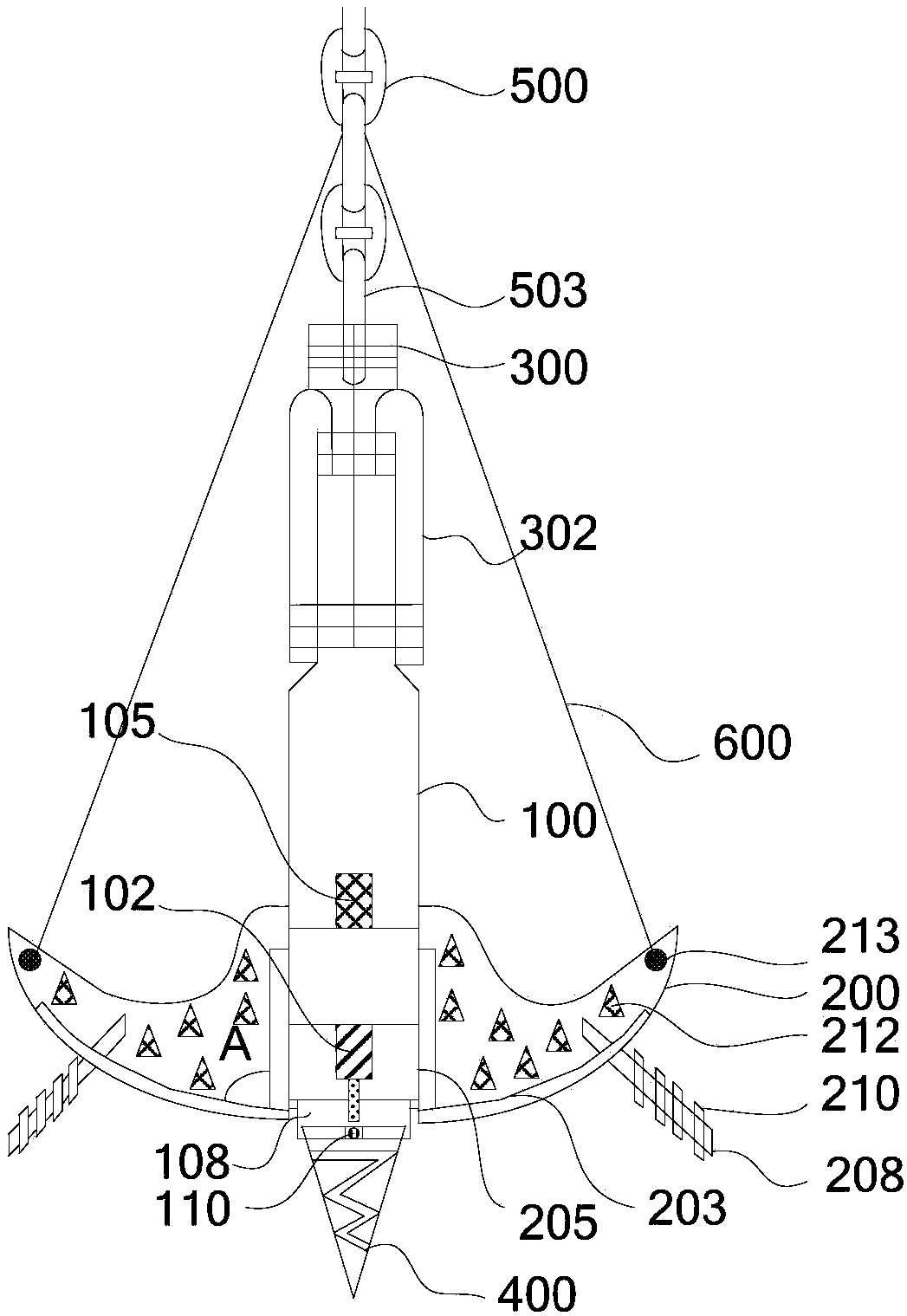

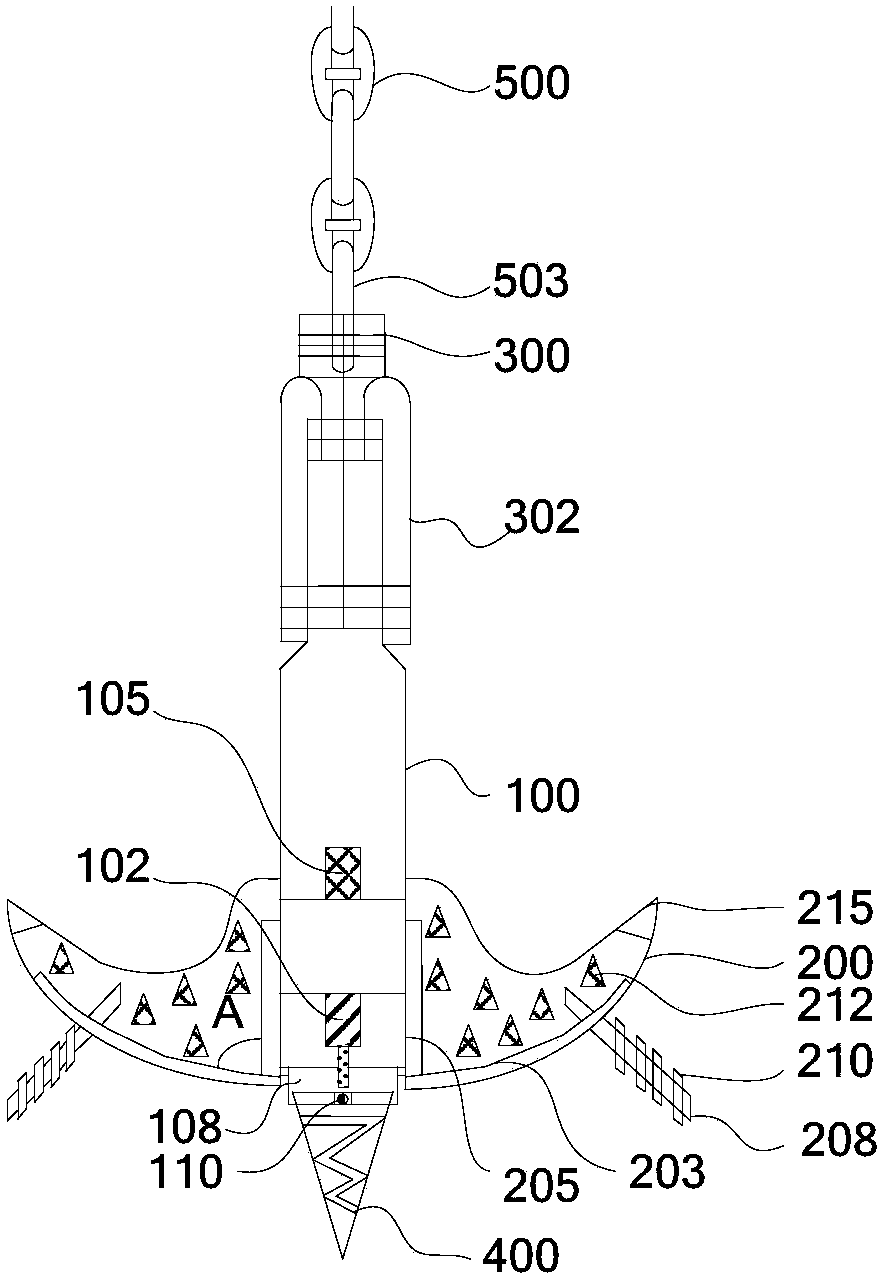

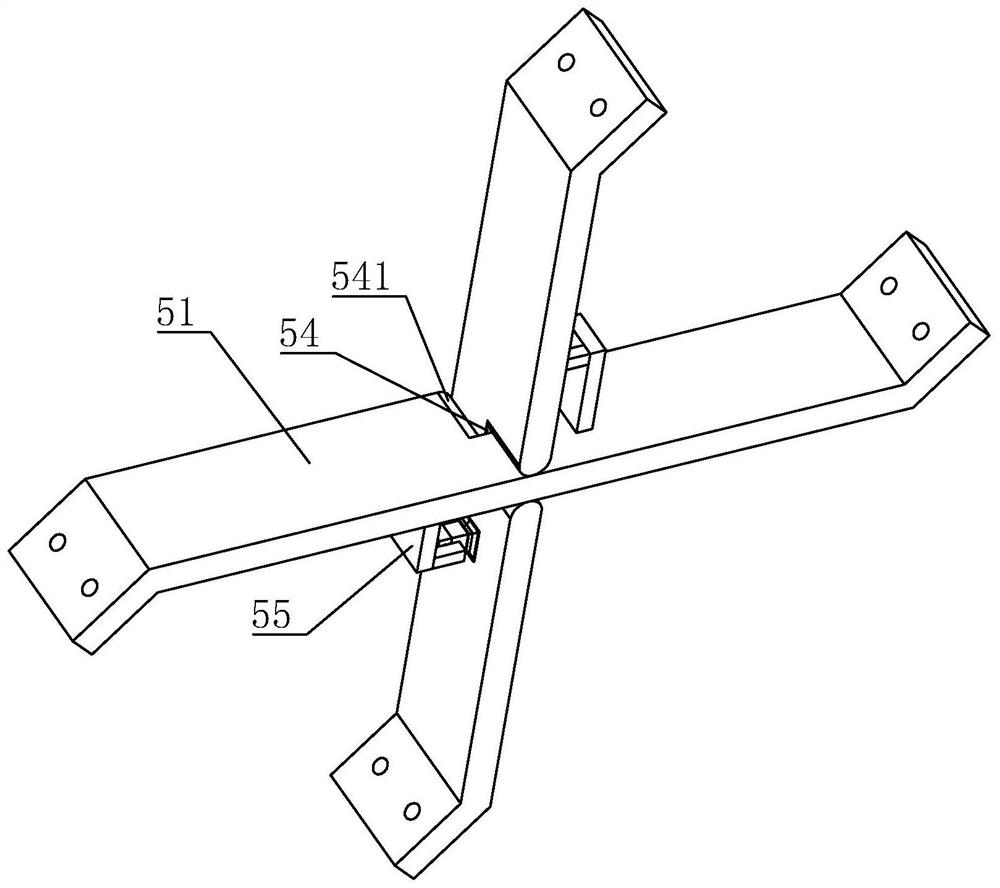

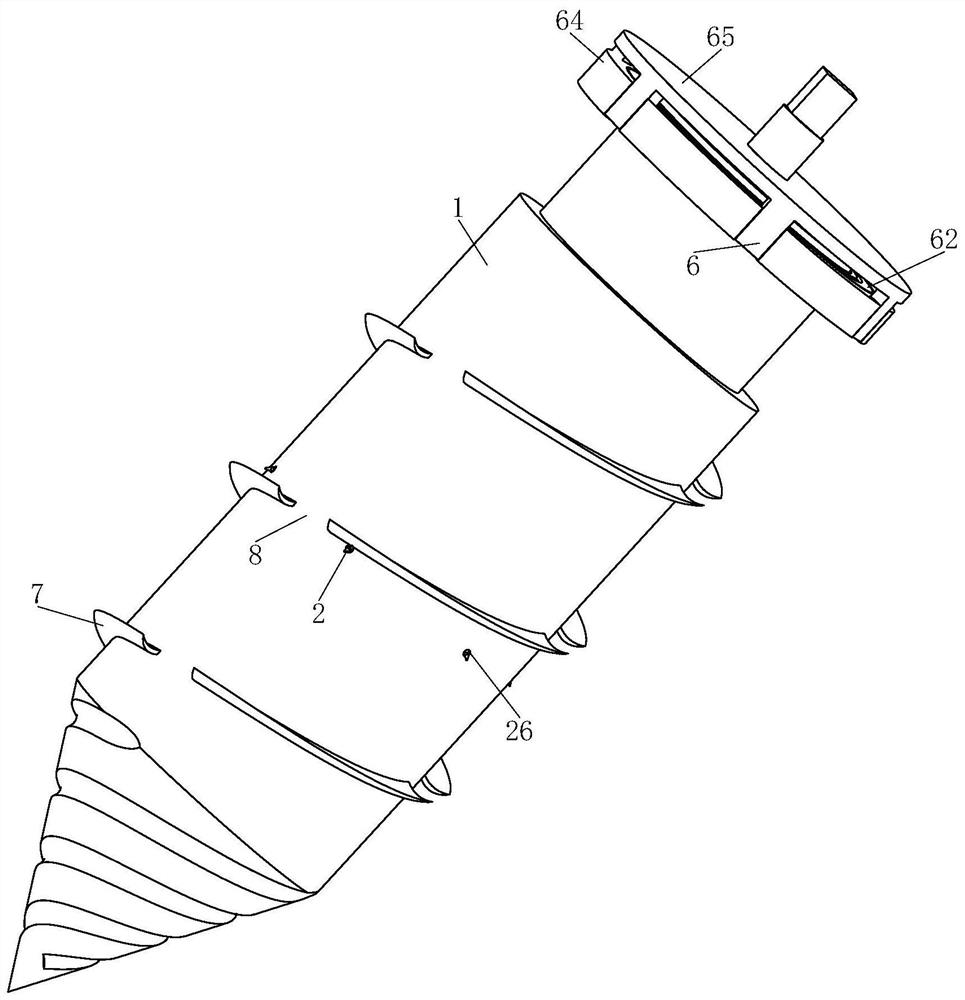

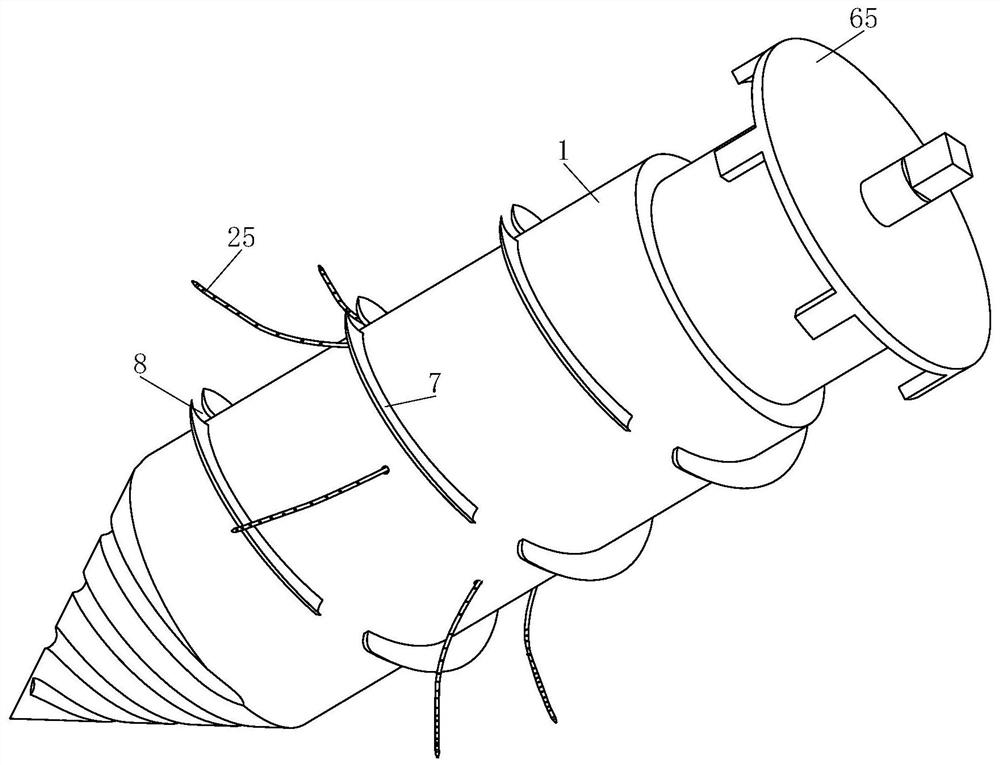

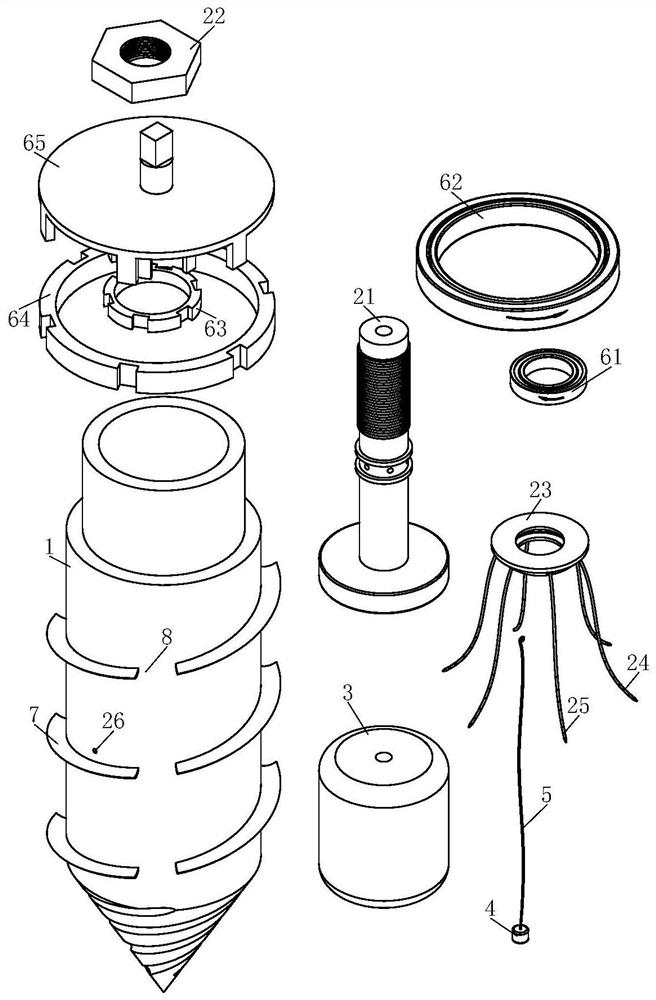

High-holding-power ship anchor and ship

InactiveCN107745784AImprove soil strengthAdd depthAnchor handling/lashingAnchorsManufacturing technologyEngineering

The invention relates to the technical field of ships and marine engineering manufacturing technology and especially relates to a high-holding-power ship anchor and a ship. The high-holding-power shipanchor comprises an anchor handle, anchor flukes are symmetrically installed at a bottom side edge of the anchor handle, a rotating ring installed on a top of the anchor handle and an anchor cone which is installed at a bottom of the anchor handle; and an anchor chain which is connected with the rotating ring; the end part connecting the anchor chain and the rotating ring is an anchor end chain;the rotating ring is connected with the anchor handle through an anchor shackle; a rotating motor which is connected with the anchor cone is installed above the anchor cone in the anchor handle innerchamber and the anchor cone is driven by the rotating motor to drill downward; the anchor handle inner chamber is also provided with a vibrator; reinforcement plates are vertically installed at two sides of the bottom of the anchor flukes; two sides of the anchor handle are provided with a fixing board vertically connected with the anchor flukes; one end of the fixing board is connected with one end of the reinforcement board; a balancing rod is installed at one side, away from the anchor handle, on the anchor fluke.

Owner:ZHEJIANG OCEAN UNIV

Shield head structure for effectively controlling ground surface settlement

InactiveCN111350515AImprove soil strengthPrevent subsidenceUnderground chambersHydraulic/pneumatic force measurementShield machineGeotechnical engineering

The invention discloses a shield head structure for effectively controlling the ground surface settlement. The shield head structure comprises a cutter head assembly, a shield shell I, a shield shellII, a shell outside injection pipe, a pressure detecting device and a conveying main pipe. The cutter head assembly is arranged at the front end of the shield shell I. The rear end of the shield shellI and the front end of the shield shell II are coaxially and fixedly connected. During tunneling, the ground stress in front of a shield head is detected in real time through the pressure detecting device, the thrust power of a shield tunneling machine is adjusted in real time according to a detection value, and the shield tunneling machine keeps at a stable thrust speed; in the tunneling process, waterproof slurry is discharged to the joint of the shield shell I and the shield shell II through an injection hole, at the moment, muck and the waterproof slurry make contact and are mixed to forma muck waterproof mixture, the muck waterproof mixture is extruded by the exterior of the shield shell II, and the muck waterproof mixture is compacted and fixed to a tunnel goaf surface formed aftertunneling of the shield tunneling machine; and thus, the soil body strength and waterproof treatment of the tunnel goaf surface are improved, the effect of preventing the ground surface settlement isrealized, a slope face is leveled, and the water seepage route is reduced.

Owner:XUZHOU UNIV OF TECH

Special fertilizer for water grass for rice-fish complex planting and breeding

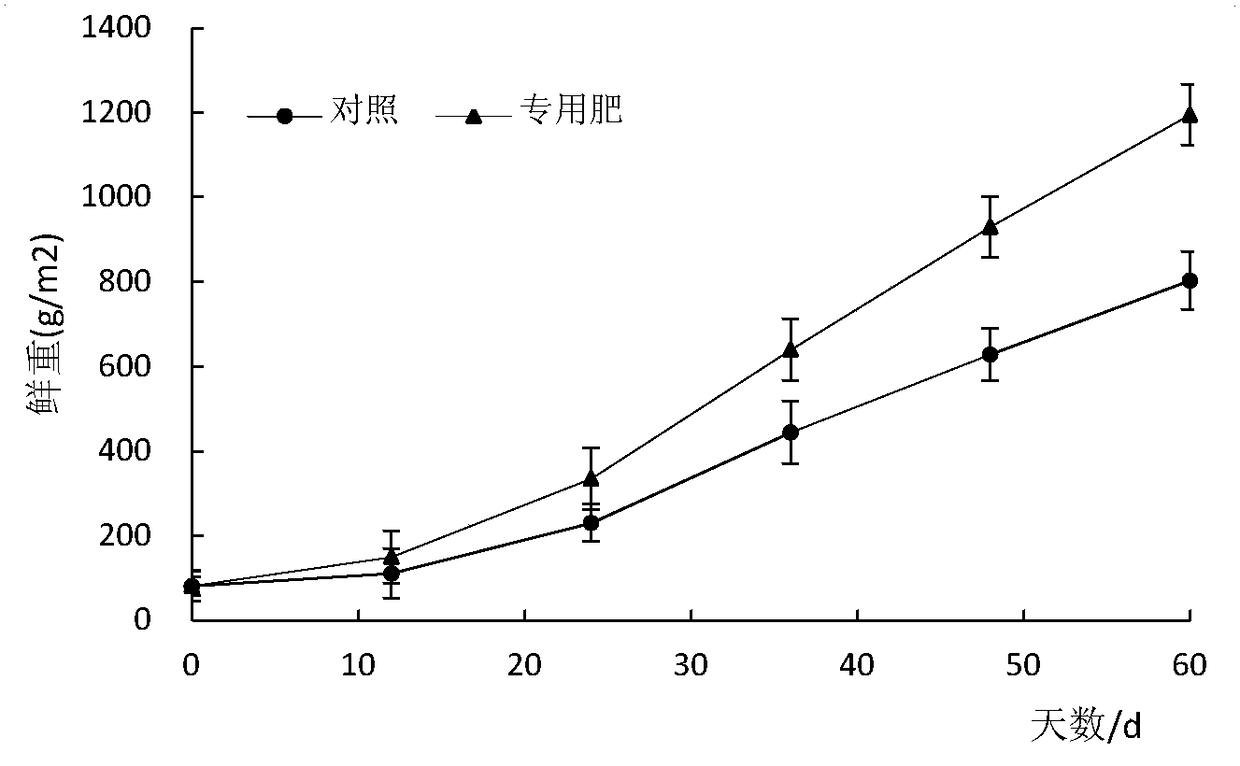

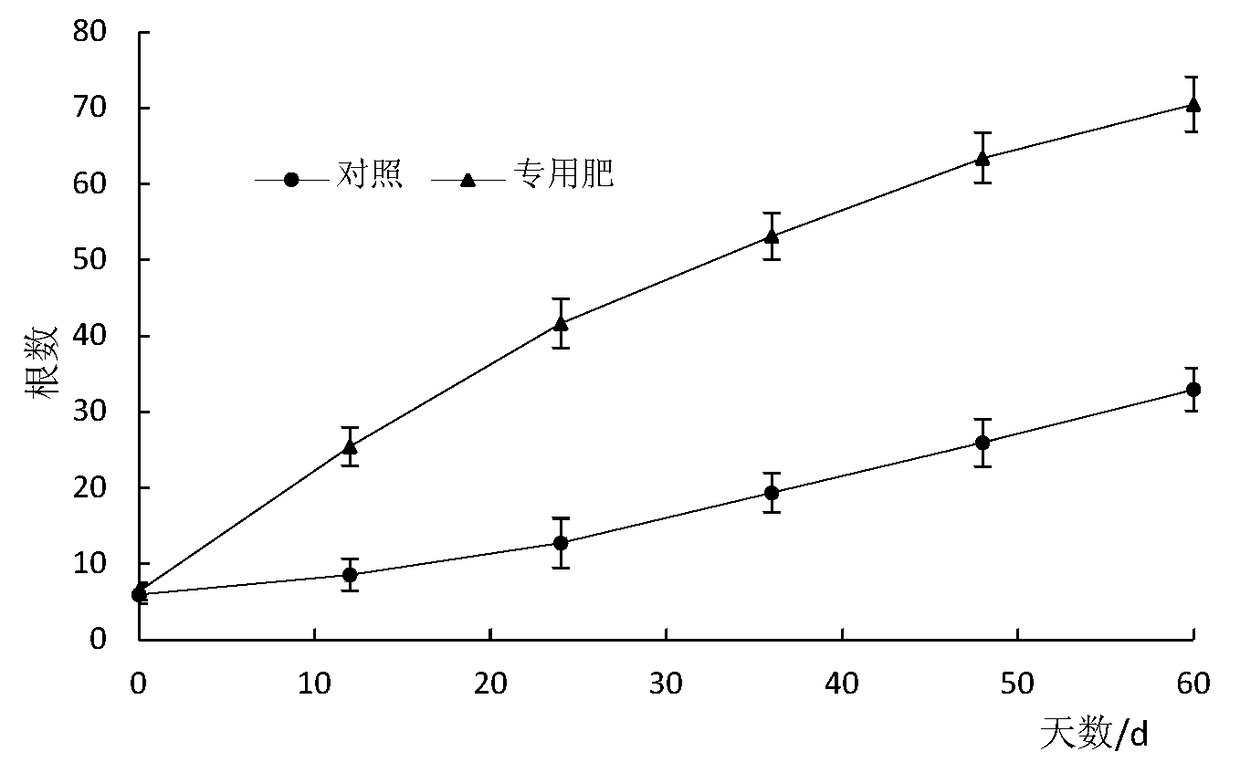

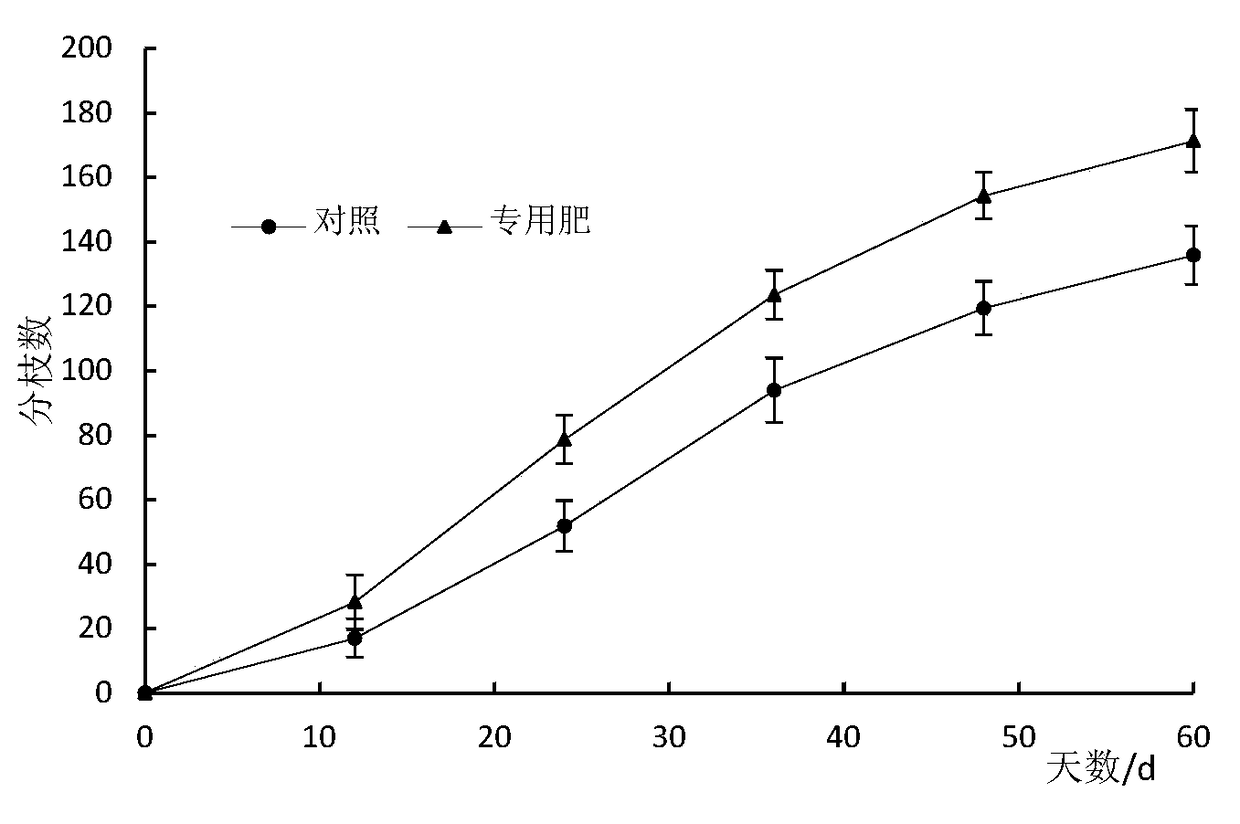

InactiveCN108101627APromote wound repairFast rootingAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersRoot growthPaddy field

The invention discloses special fertilizer for water grass for rice-fish complex planting and breeding. The special fertilizer is prepared from the following raw material components in parts by weight: 20 to 30 parts of potassium sulfate type slow release fertilizer, 8 to 24 parts of humic acid, 18 to 25 parts of ammonium sulfate, 15 to 20 parts of calcium magnesium phosphate fertilizer, 4 to 8 parts of diaminoferric xanthohumate, 6 to 12 parts of attapulgite, and 6 to 10 parts of composite root growth promoting agent. According to the special fertilizer for the water grass for rice-fish complex planting and breeding provided by the invention, growth characteristics and fertilizer requirement laws of the water grass for rice-fish complex planting and breeding are combined, so that accuratenutrition is provided for the water grass, the water grass can quickly grow roots and grow continuously and are promoted to grow new roots and grow new buds, the water grass is developed in root systems and robust in stems, a soil holding force of the water grass is improved, the root amount is increased, the root taking vitality of the water grass is improved, the resistance of the water grass can be also improved, and the requirements of a rice-fish industry on the water grass are met.

Owner:NANJING AGRICULTURAL UNIVERSITY

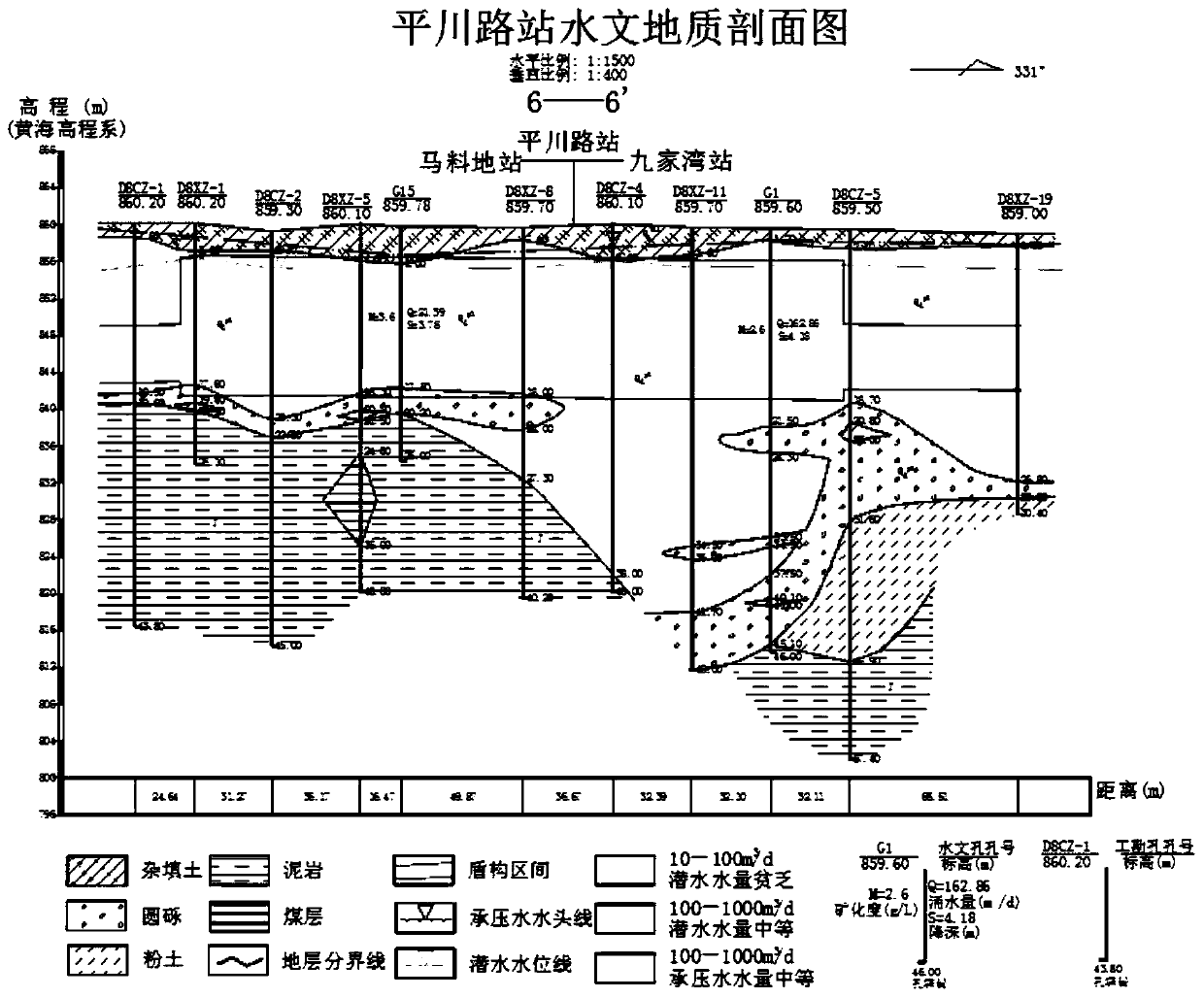

Deep foundation pit floury soil stratum deep-well well point rainfall construction method and application

InactiveCN110424430AReduce moisture contentImprove soil strengthFoundation engineeringPrecipitationBuilding construction

The embodiment of the invention provides a deep foundation pit floury soil stratum deep-well well point rainfall construction method and application, and relates to the field of traffic building and construction. The construction method comprises the steps of drilling a plurality of out-of-pit precipitation wells outside a foundation pit, and drilling a plurality of in-pit precipitation wells in the foundation pit; and lowering a plurality of well pipes to the corresponding out-of-pit precipitation wells and the corresponding in-pit precipitation wells to form corresponding in-pit well pipes and out-of-pit well pipes. By means of the deep foundation pit floury soil stratum deep-well well point rainfall construction method and the application, the out-of-pit precipitation wells and the in-pit precipitation wells are combined for precipitation, and the conditions that when light well points cannot meet the precipitation requirement, the number of the light well points are gradually increased, consequently the number of the well points is increased, and the excavation amount is increased are effectively avoided; and in-pit precipitation and out-of-pit precipitation are combined, the groundwater in soil within the foundation pit excavation scope is effectively drained, and construction work of construction machinery and workers in the pit are facilitated.

Owner:XINJIANG COMM CONSTR GRP

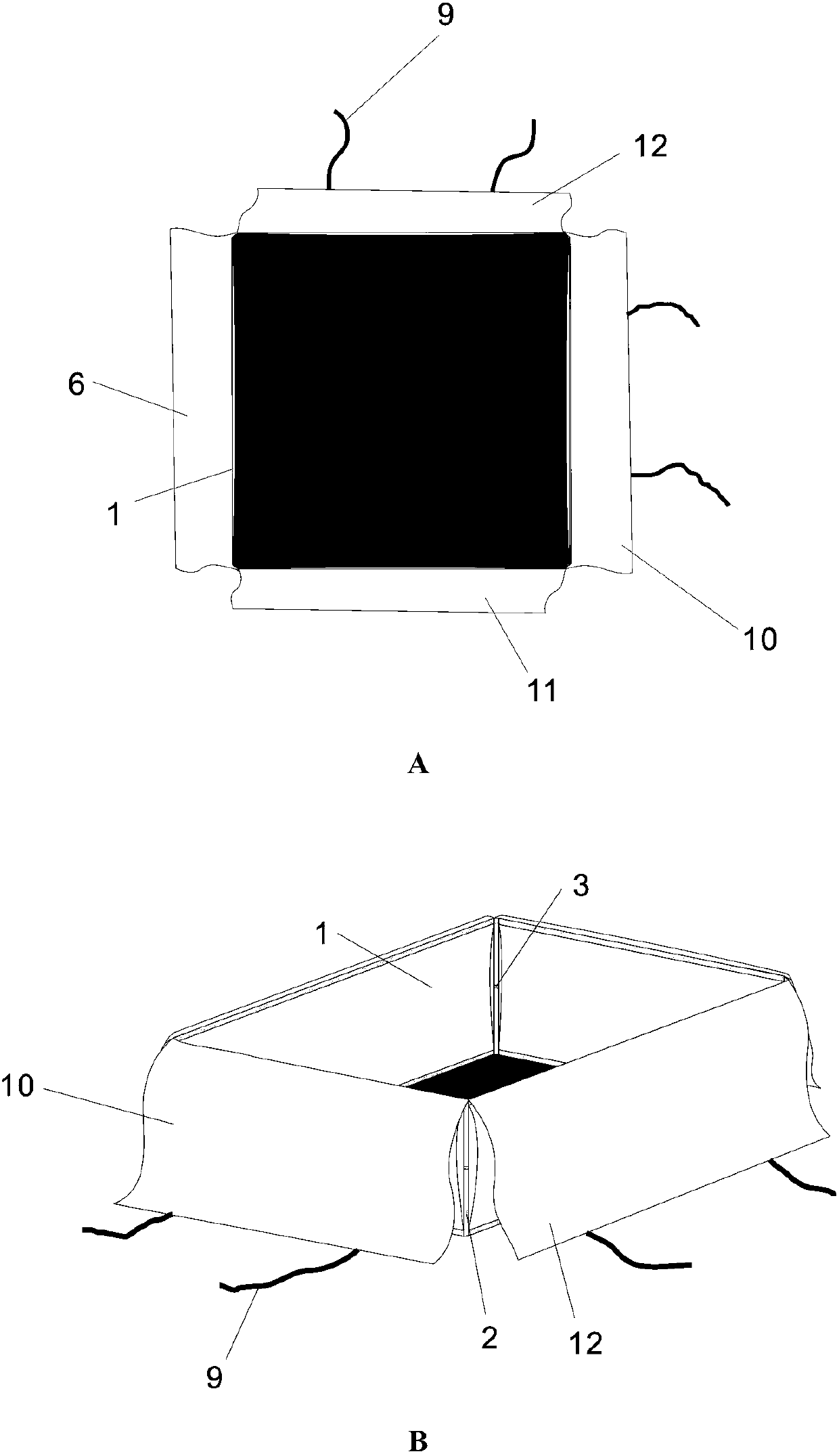

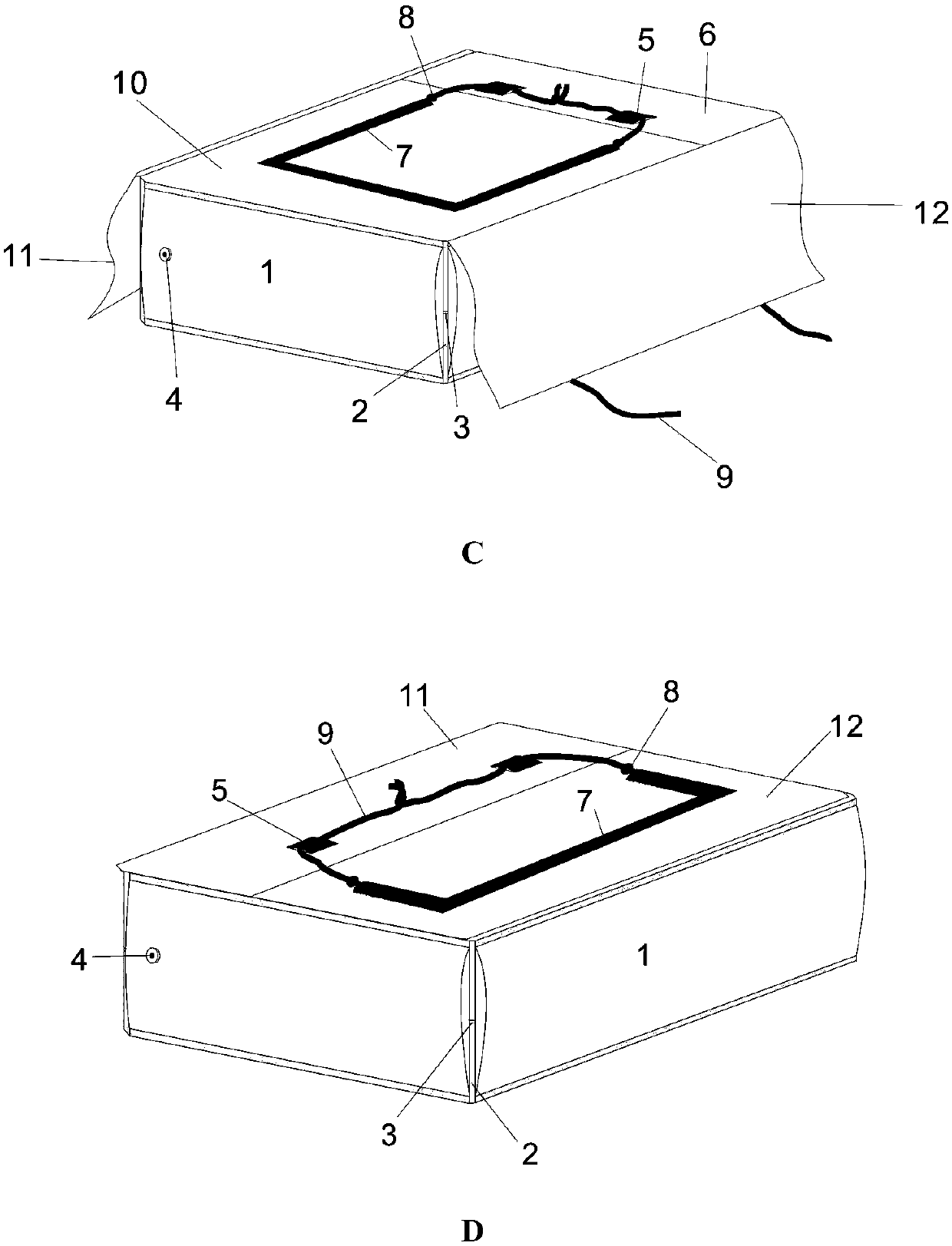

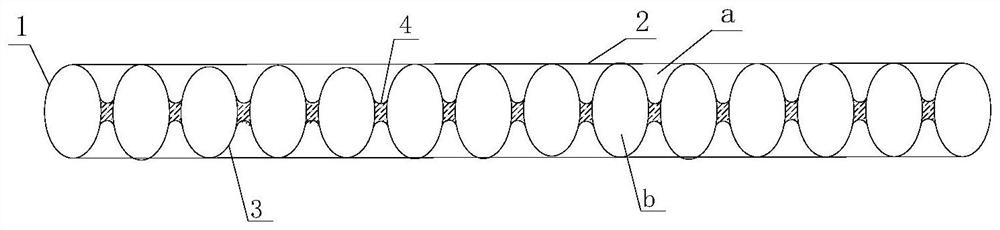

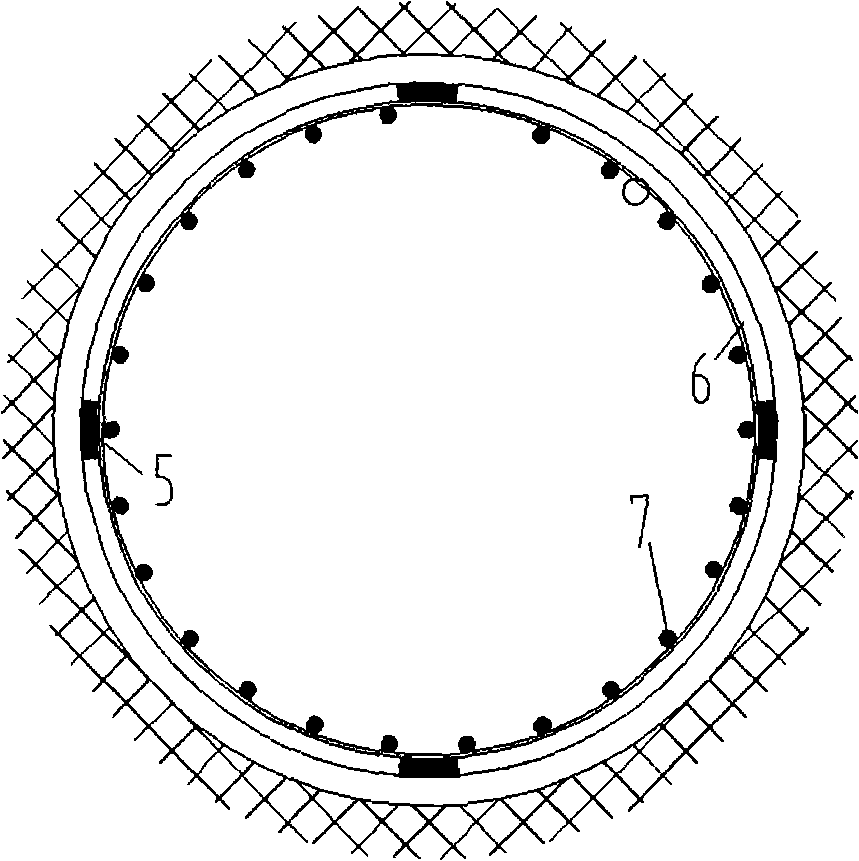

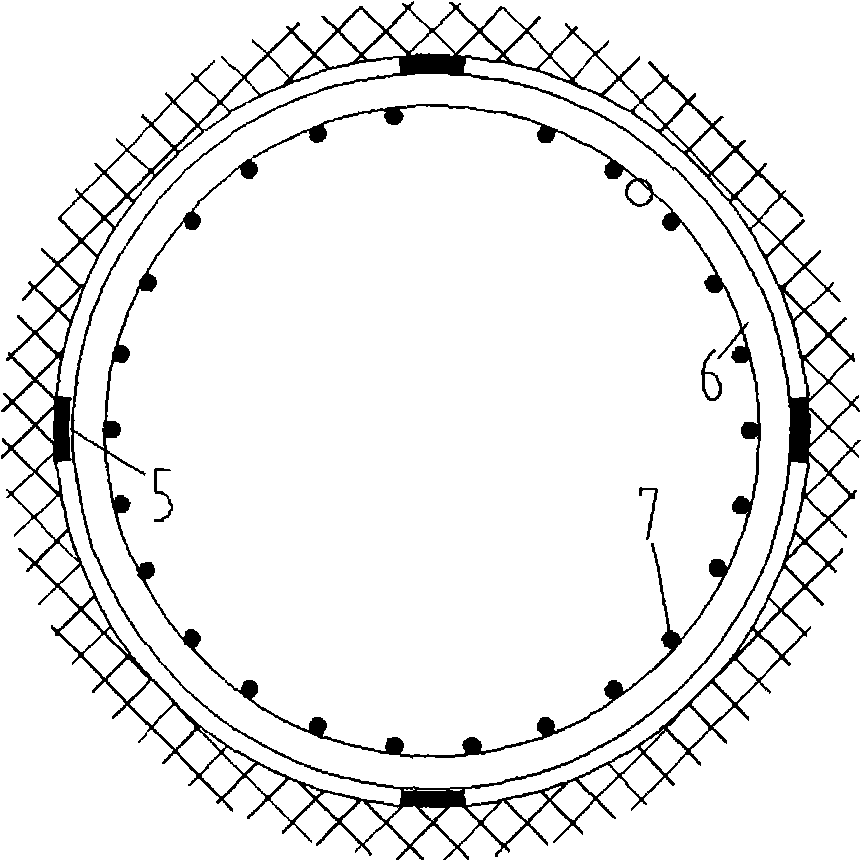

Inflatable geobag and construction method thereof

PendingCN107938644AImprove construction efficiencyImprove soil strengthArtificial islandsBagsSoil strengthRevegetation

The invention discloses an inflatable geobag and a construction method thereof. The geobag is composed of at least one geobag units. Each geobag unit is of a semi-closed structure which is composed ofa top closing material, a bottom closing material and an annular double-layer geomembrane. The bottom closing material and the annular double-layer geomembrane are closed in a side pressing mode. Theadjacent edges of the annular double-layer geomembrane are subjected to side pressing treatment. Vent holes are formed in the pressed edges. The annular double-layer geomembrane and the top closing material are closed in a side pressing mode. An inflation port is formed in the annular double-layer geomembrane. The geobag is high in construction efficiency and can be automatically unfolded by inflating the annular double-layer geomembrane, and the geobag can be directly filled without mechanical or manual supporting. When soil is filled with the geobag, a powerful restraint function can be achieved on the soil by the annular double-layer geomembrane, and the soil strength is improved. The geobag is wide in application range, and suitable for the fields of foundation reinforcement, dyke slope protection, retaining wall construction, slope protection and revegetation and the like.

Owner:NANJING HYDRAULIC RES INST

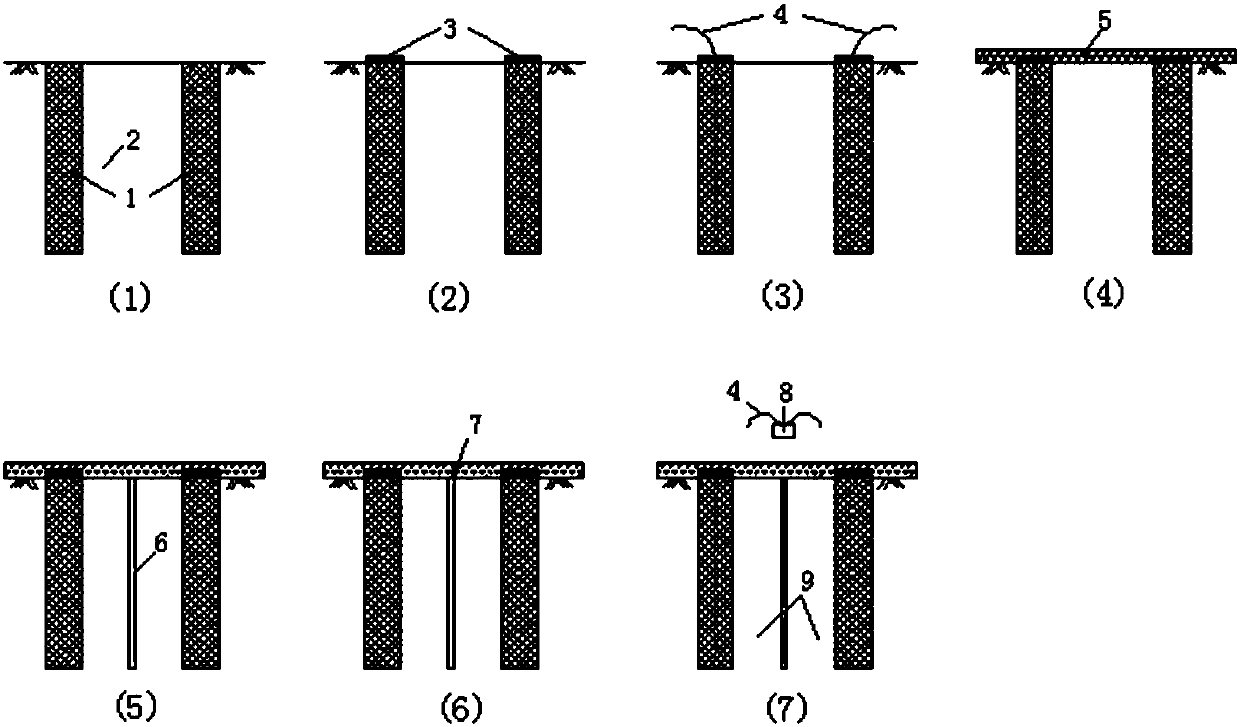

Anchor rod structure for heating curing soil body and using method thereof

PendingCN110080220AImprove bearing capacityHigh strengthBulkheads/pilesSoil preservationStructure of the EarthEngineering

The invention relates to an anchor rod structure for heating curing soil body. The anchor rod structure comprises an anchor rod, the anchor rod comprises an anchoring section and a free section, the anchoring section is provided with an electric heating pipe, the anchor rod is inserted into a drilled hole and abuts against the inner wall of the drilled hole, and the two ends of the electric heating pipe are connected with an external power source through wires. Soil around the anchoring section in the drilled hole is heated through the heating pipe, water in the surrounding soil is gasified and transported, a soil body structure is physically and chemically changed, the bearing capacity of the soil body is increased, the surrounding soil body and the anchor rod body form an anchoring lumpwith a larger diameter, and therefore the bearing capacity effect of the anchor rod is improved; and the anchor rod structure has the advantages that the soil body strength of an anchoring section isimproved, the bearing capacity of the anchor rod is improved, and the length of the anchor rod is reduced.

Owner:北京爱地地质工程技术有限公司

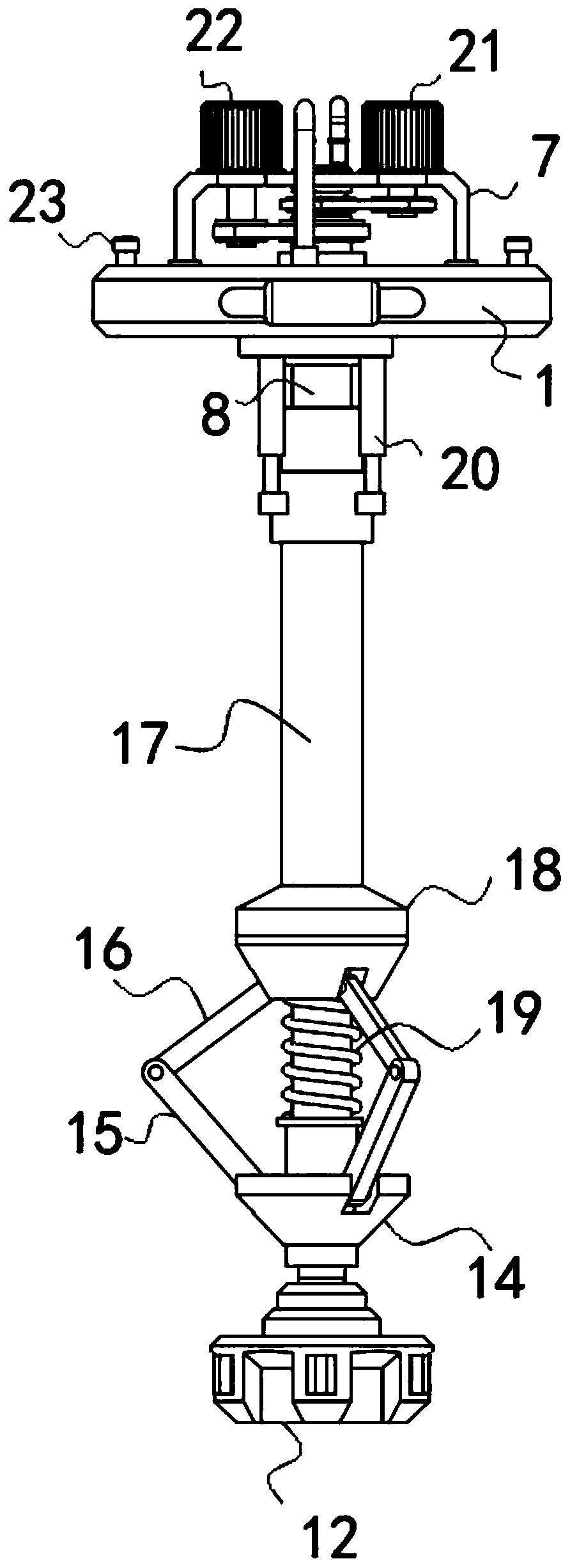

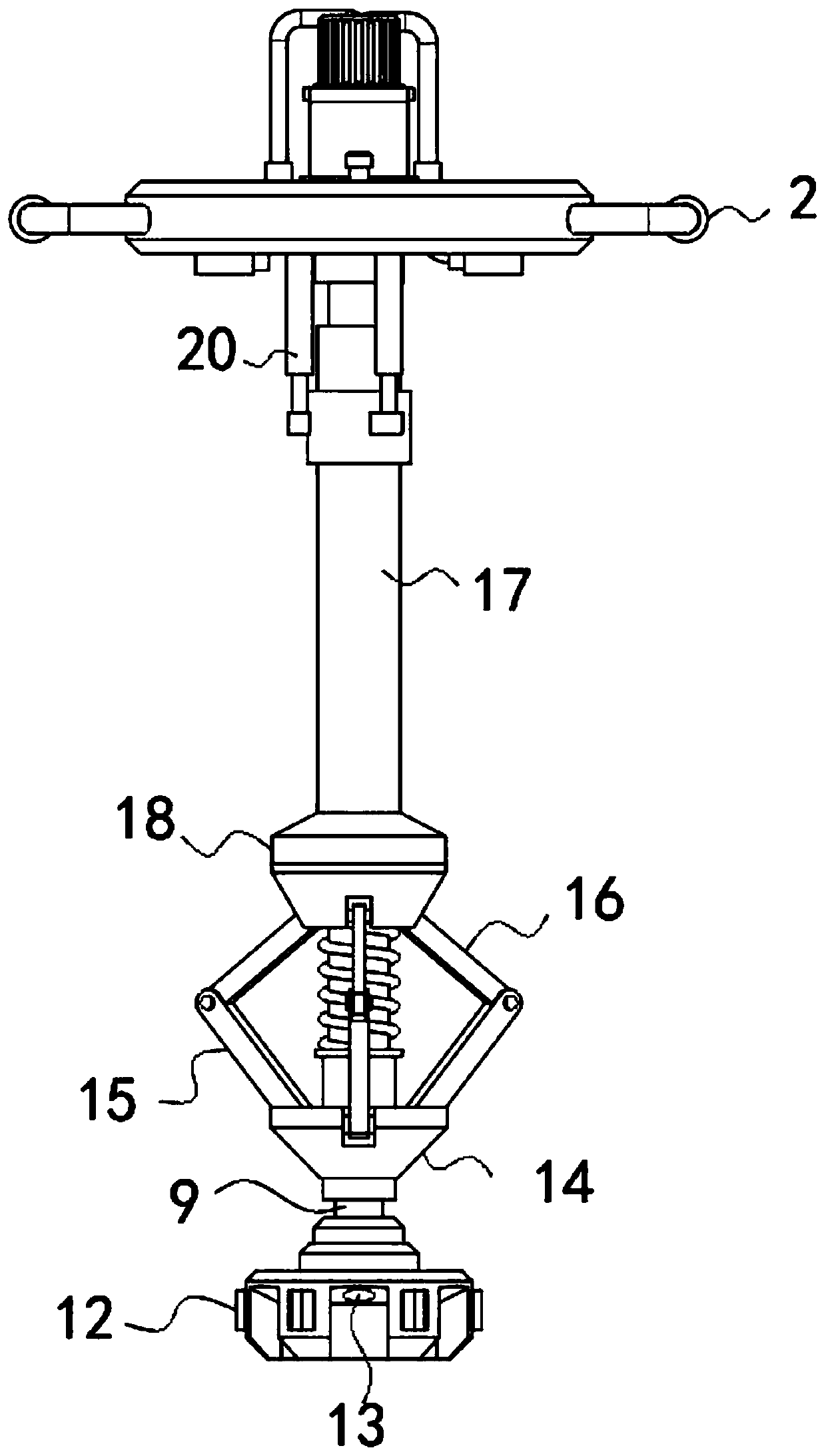

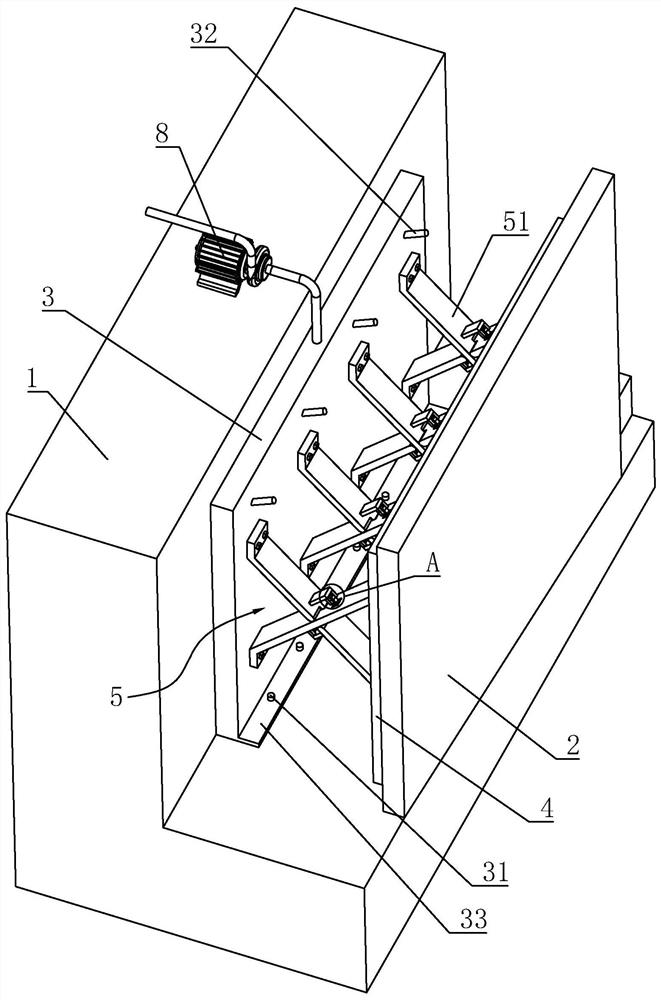

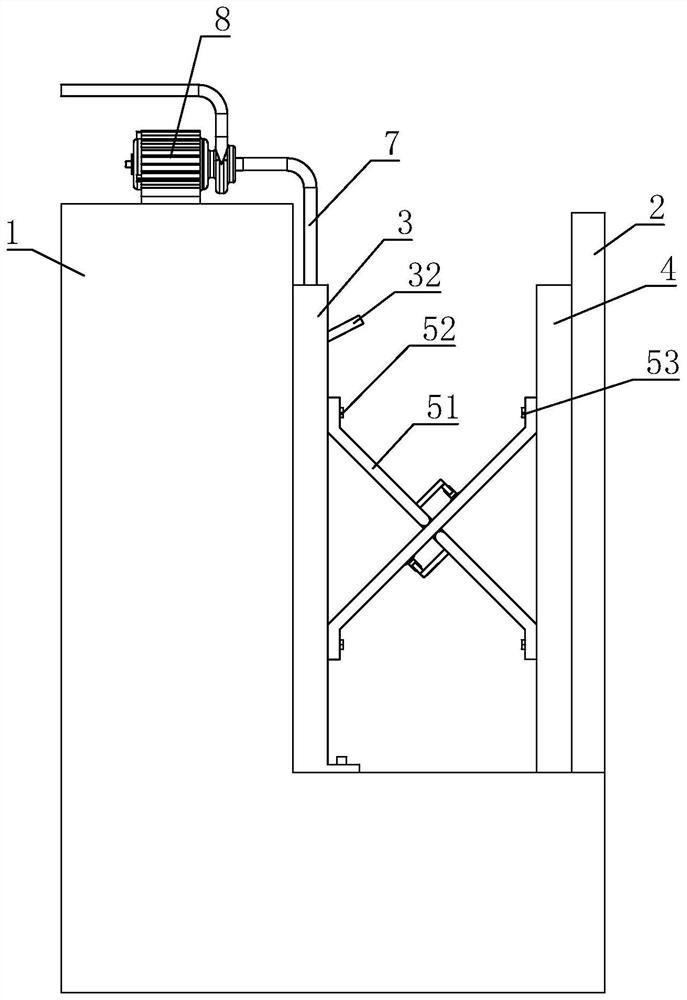

Improvement device and improvement method for collapsible loess roadbed

ActiveCN111235993AImprove soil strengthIncrease the degree of mixingRoads maintainenceSoil preservationSoil scienceGeotechnical engineering

The invention discloses an improvement device and an improvement method for a collapsible loess roadbed, and relates to the technical field of building construction equipment. The device comprises a machine table, handles are arranged on the two side faces of the machine table, and a first liquid storage tank and a second liquid storage tank are fixedly connected to the bottom face of the machinetable; one surface of each of the first liquid storage tank and the second liquid storage tank is fixedly connected with a micro high-pressure pump; one ends of water inlets of the two miniature high-pressure pumps are respectively communicated with the first liquid storage tank and the second liquid storage tank; and the top face of the machine table is fixedly connected with a mounting frame. The collapsible loess subgrade is reinforced by adopting a chemical reinforcement principle, a chemical reagent is injected into foundation soil by the two liquid outlets in a high-pressure and high-speed rotating state during working, a gelling substance is generated or the surfaces of soil particles are activated through a chemical reaction, and the soil particles are combined, so that the soil body strength of the collapsible loess subgrade is effectively improved.

Owner:吴桥县交通运输局

Controllable air exhausting device for constructing precast pile in gas-containing soil layer and construction method of device

ActiveCN105672252ASmall settlement deformationImprove carrying capacityProtective foundationBulkheads/pilesCarrying capacitySoil horizon

The invention discloses a controllable air exhausting device for constructing a precast pile in a gas-containing soil layer and a construction method of the device. The device comprises the precast hollow pile, and a closed-opening pile tip is arranged at the bottom of the precast hollow pile; the air exhausting device is arranged at the front end of the closed-opening pile tip and can prevent engineering disasters caused by gas eruption in the gas-containing soil layer, and therefore personal and property losses are reduced; and pile end and pile side soil bearing carrying capacity within the gas-containing soil layer range can be improved, and settlement deformation of a pile foundation obtained after construction is reduced. The construction method of the device is easy and convenient to operate.

Owner:常州东吉路国际贸易有限公司

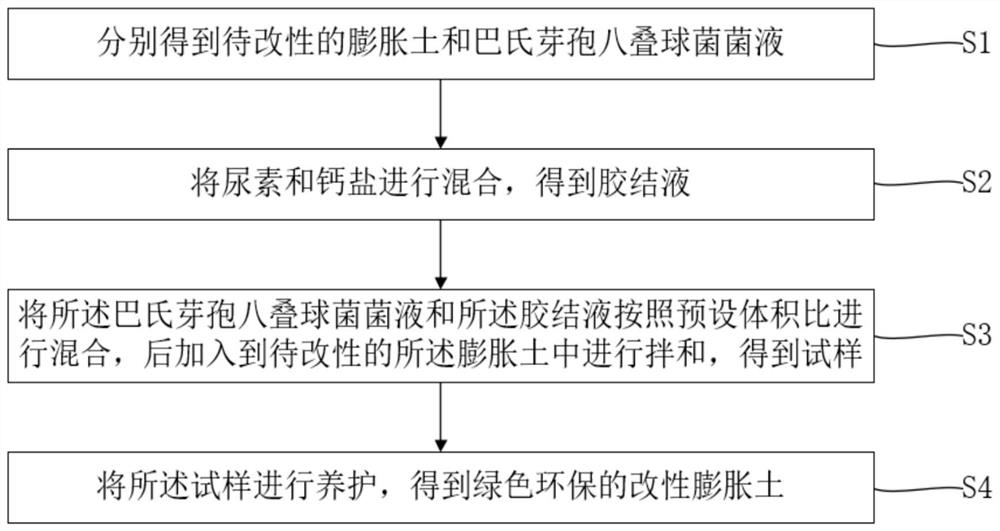

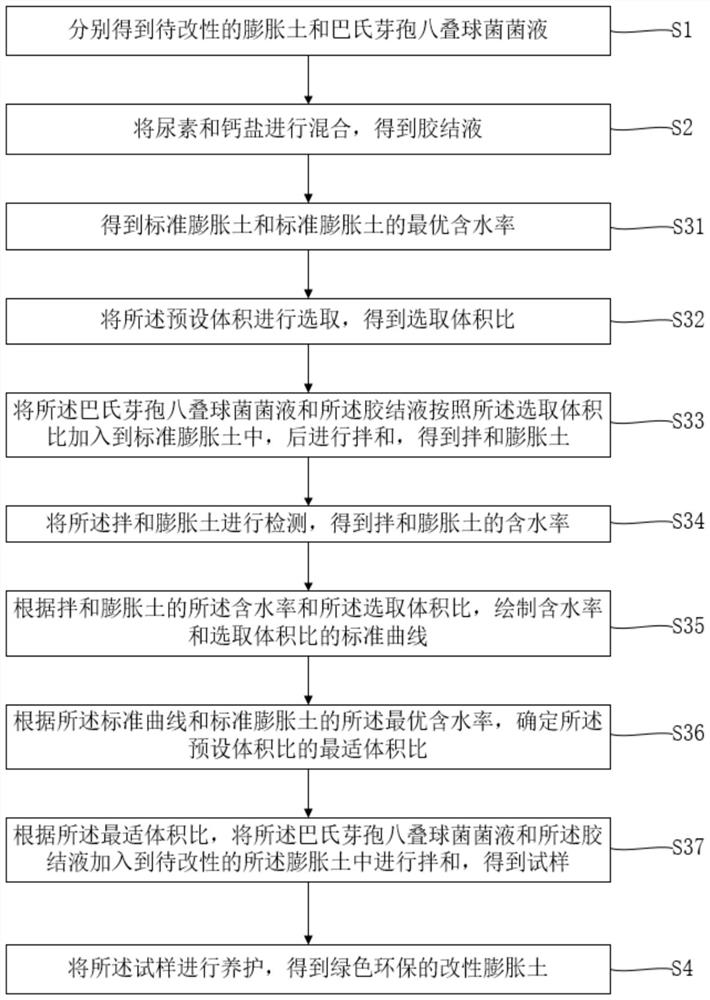

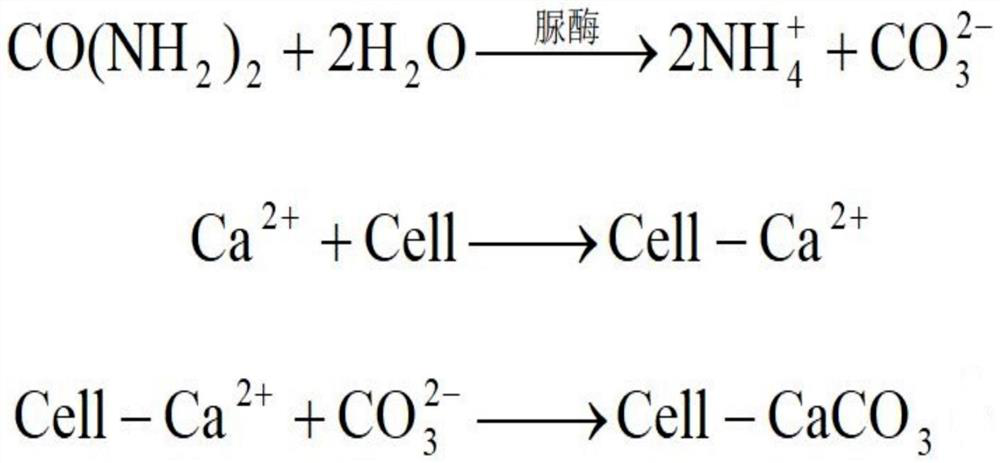

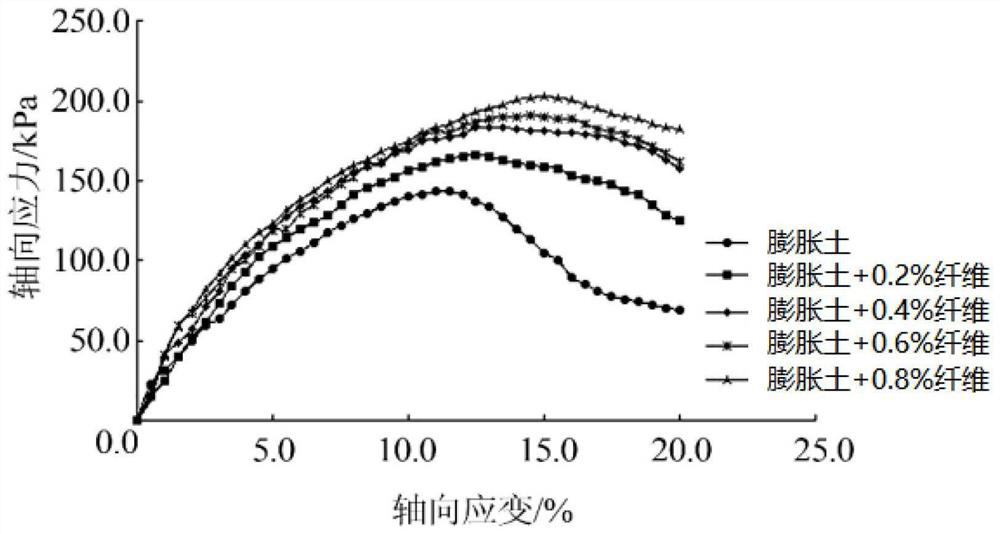

Microbial ecological modification method for expansive soil

ActiveCN114737557ALow expansibilityReduce rejectionBuilding constructionsOrganic fertilisersCalcium crystalsMicroorganism

The invention relates to the field of environmental geotechnical engineering, in particular to a microbial ecological modification method for expansive soil. The method comprises the following steps: respectively obtaining to-be-modified expansive soil and a sporosarcina pasteurii bacterial solution; mixing urea and calcium salt to obtain a cementing liquid; mixing the sporosarcina pasteurii bacterial liquid and the cementing liquid according to a preset volume ratio, and then adding the mixture into to-be-modified expansive soil for mixing to obtain a sample; maintaining the sample to obtain the green and environment-friendly modified expansive soil. By adopting sporosarcina pasteurii, urea can be continuously hydrolyzed into NH4 < + > and CO3 < 2->, meanwhile, Ca < 2 + > in expansive soil and added CaCl2 is continuously attracted to the surfaces of thalli, and Ca < 2 + > and CO3 < 2-> are combined on the surfaces of the thalli to form calcium carbonate crystals, so that the soil body strength of the expansive soil is enhanced; meanwhile, residual NH4 < + > and Ca < 2 + > in the reaction system can reduce the expansibility of the expansive soil through the effects of neutralizing negative charges and replacing cations respectively.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

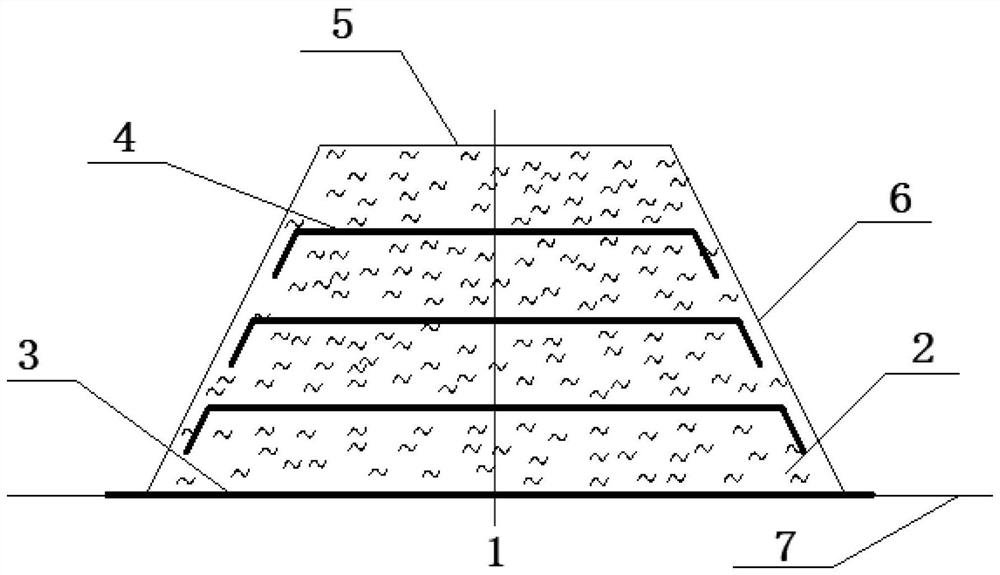

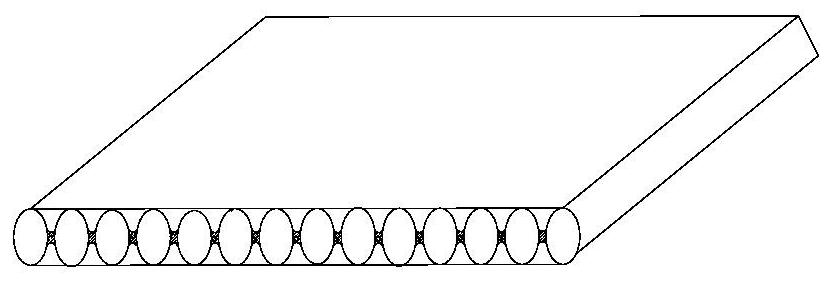

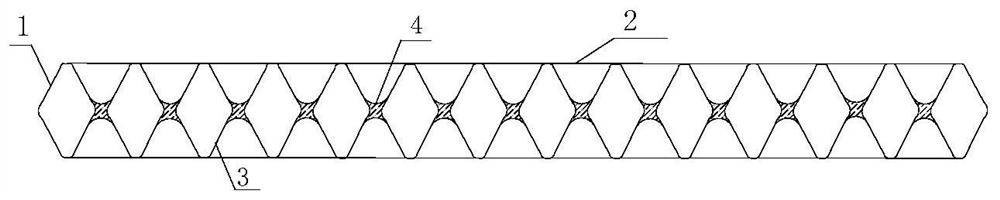

Coconut fiber and coconut geotextile composite reinforced expansive soil roadbed and construction method thereof

PendingCN114753201AStrong toughnessHigh strengthPaving reinforcementsOpen work fabricsSoil scienceRoad surface

The invention discloses a coconut fiber and coconut geotextile composite reinforced expansive soil roadbed and a construction method thereof. The coconut fiber and coconut geotextile composite reinforced expansive soil roadbed comprises a foundation layer, a roadbed layer laid on the top surface of the foundation layer and a pavement layer laid on the top surface of the roadbed layer, wherein the roadbed layer comprises a roadbed base body and a plurality of reinforced structure layers; the roadbed base body is formed by mixing and compacting coconut shell fibers and expansive soil, and the reinforced structure layer is mainly composed of coconut shell geotechnical cloth. The expansive soil roadbed mainly solves the problems of poor permeability, water swelling, water loss shrinkage, multiple cracks, humidification and the like of a current expansive soil roadbed, the coconut shell fibers and the coconut shell geotextile are used, the coconut shell fibers and the coconut shell geotextile serve as rib materials, the strength of a soil body is greatly improved, the coconut shell geotextile and the coconut shell fibers are environment-friendly materials, and therefore the expansive soil roadbed is environmentally friendly. And the method plays an important role in protecting the environment and saving resources.

Owner:HUBEI UNIV OF TECH

A half-filled and half-dug ecological subgrade structure and construction method

InactiveCN104264557BAvoid enteringAccelerate evaporationRoadwaysExcavationsVentilation tubeEnvironmental resource management

The invention relates to a half-filled and half-dug ecological subgrade structure, which is characterized in that a waterproof geotextile and a step-type integral connection network are laid on the interface between the filled subgrade and the excavated subgrade; layer and waterproof geotextile; the excavated subgrade is provided with a long horizontal drainage and ventilation pipe, and the horizontal drainage and ventilation pipe is connected with the vertical ventilation channel near the slope; Lap the side of the fill subgrade with waterproof geotextiles and planting concrete, and excavate side ditches at the bottom of the slope. The invention can effectively discharge the water in the foundation, prevent groundwater from migrating to the roadbed and road surface, effectively prevent frost heaving, thawing and muddying, and can effectively overcome the occurrence of longitudinal cracks at the junction of filling and excavation of the roadbed caused by uneven frost heaving. It has good technical and economic benefits. The invention also discloses a construction method for the half-filled and half-dug ecological subgrade structure.

Owner:神州建设集团有限公司

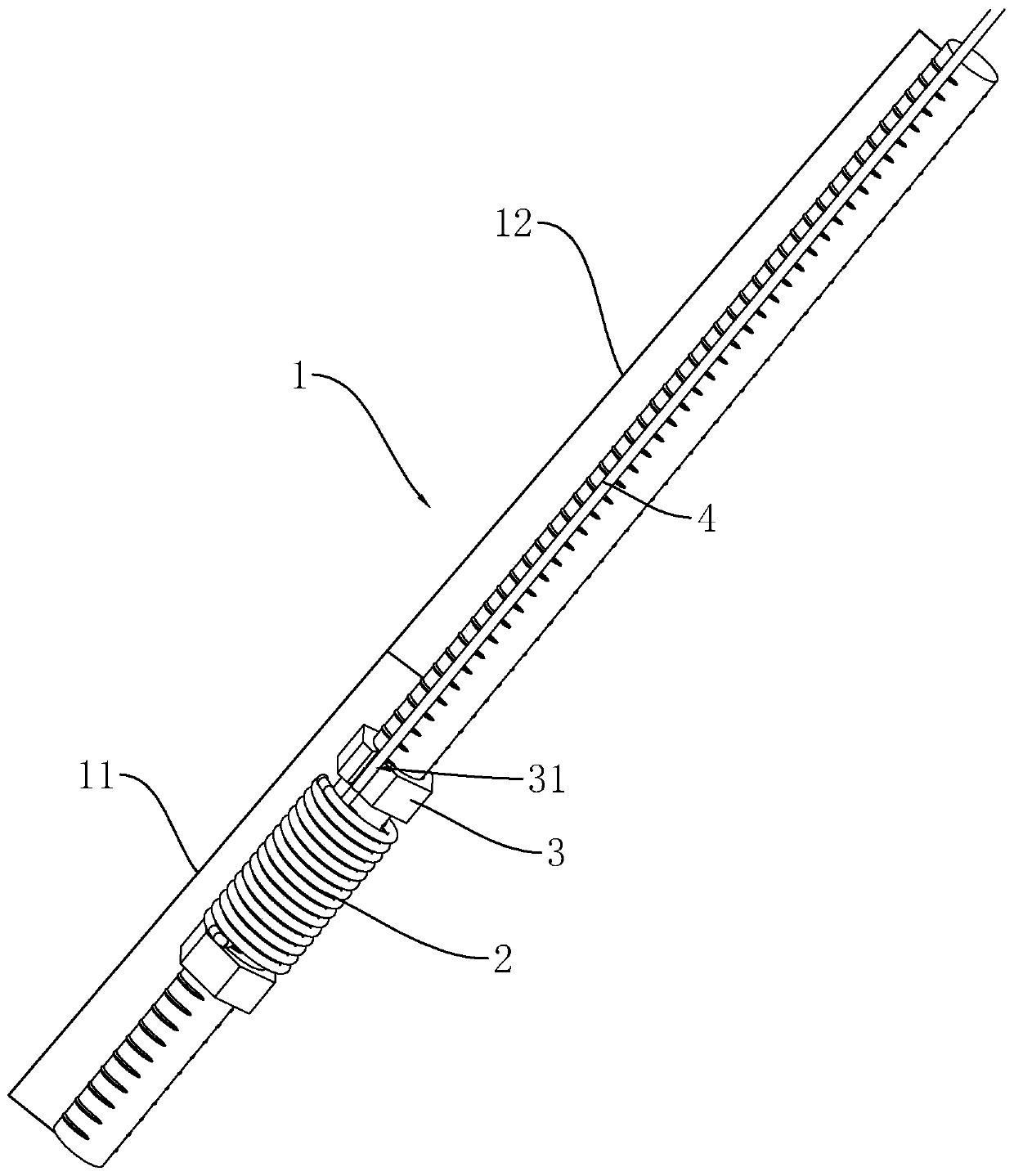

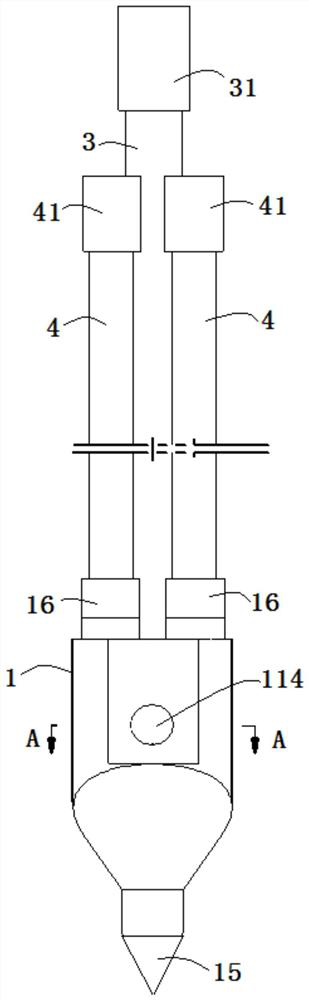

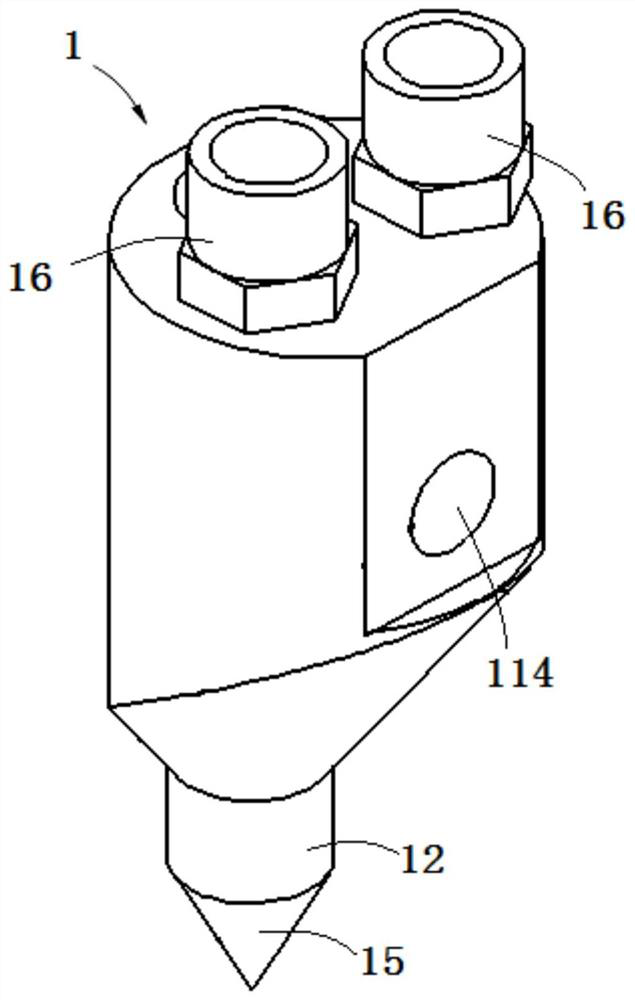

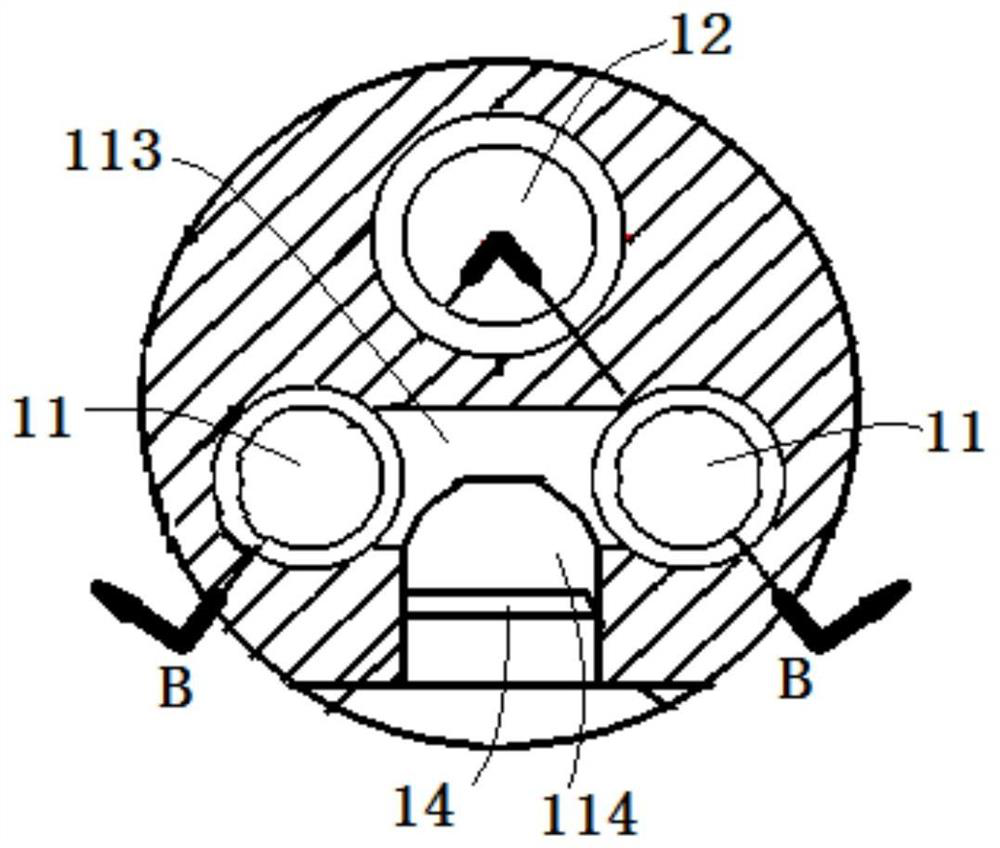

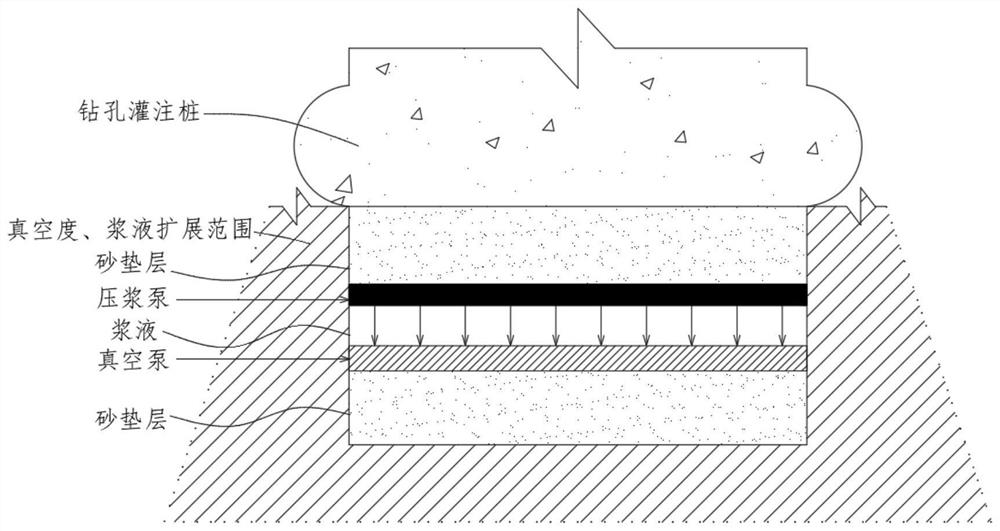

Same-hole multi-slurry injection machine tool and same-hole multi-slurry injection plugging method

PendingCN111877379AImprove soil strengthEnhance water and leak pluggingProtective foundationFoundation repairGeotechnical engineeringMachine tool

The invention provides a same-hole multi-slurry injection machine tool and a same-hole multi-slurry injection plugging method. The machine tool comprises a grouting head body, a grouting hard pipe andgrouting hoses; the grouting head body comprises two first grouting cylinder parts which are arranged side by side and a second grouting cylinder part, and one-way valve elements are arranged in thefirst grouting cylinder parts; a first transverse channel and a second transverse channel communicating the first transverse channel with the outside are communicated between the two first grouting cylinder parts, and a first temporary plug is arranged at the end, communicating with the outside, of the second transverse channel; a second temporary plug is arranged at the bottom of the second grouting cylinder part; the grouting hard pipe is communicated with the top of the second grouting cylinder part, and the grouting hard pipe is communicated with a hard pipe outer joint; and the grouting hoses are communicated with the tops of the first grouting cylinder parts, and hose outer joints are communicated with the grouting hoses. According to the same-hole multi-slurry injection machine tooland the same-hole multi-slurry injection plugging method, water stopping and leaking stoppage can be achieved rapidly, the soil body strength of a water stopping and leaking stoppage position can beimproved, the double-liquid grouting setting time is easy to master, and the grouting effect is good.

Owner:城盾隧安地下工程有限公司

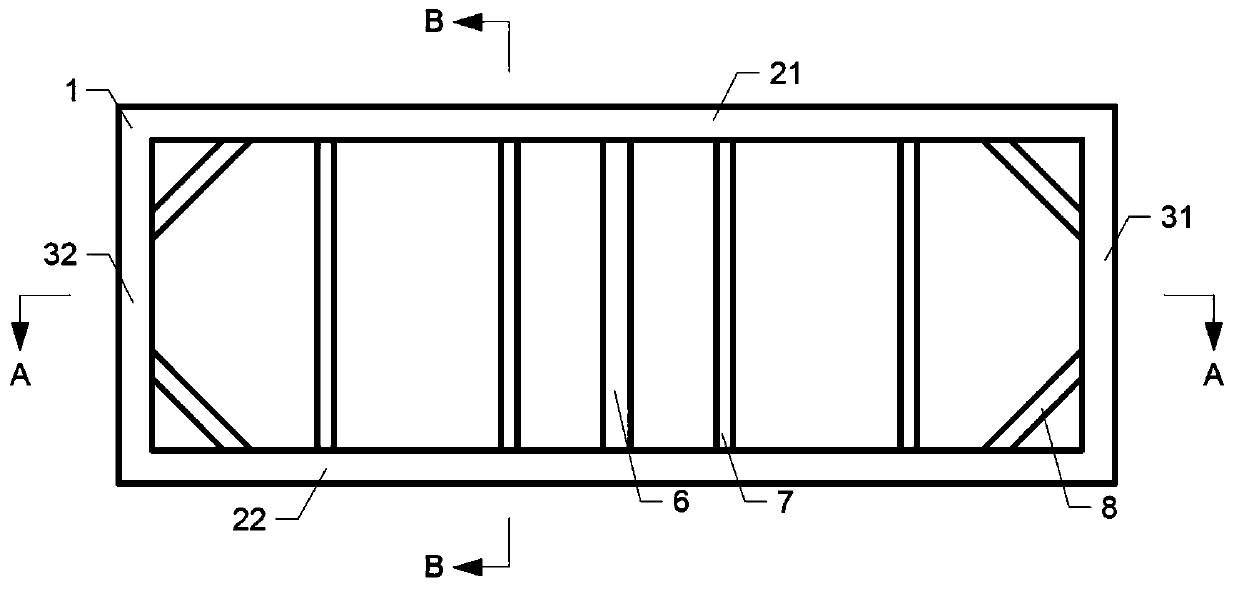

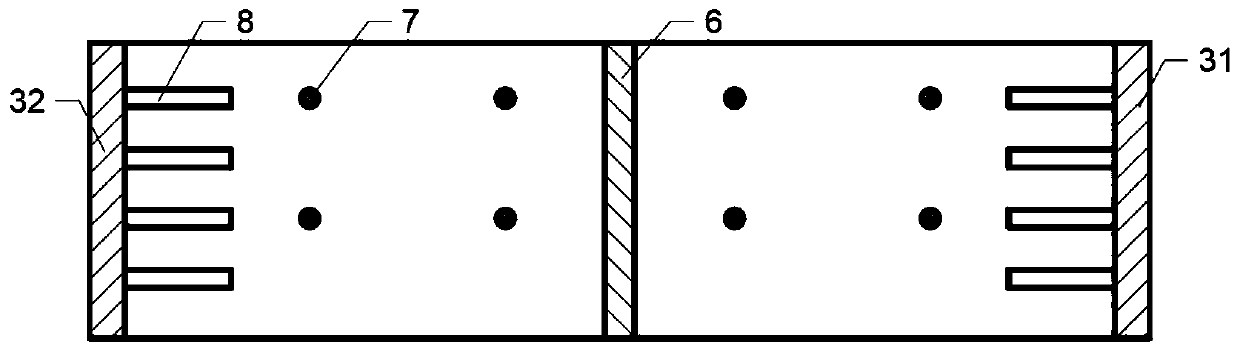

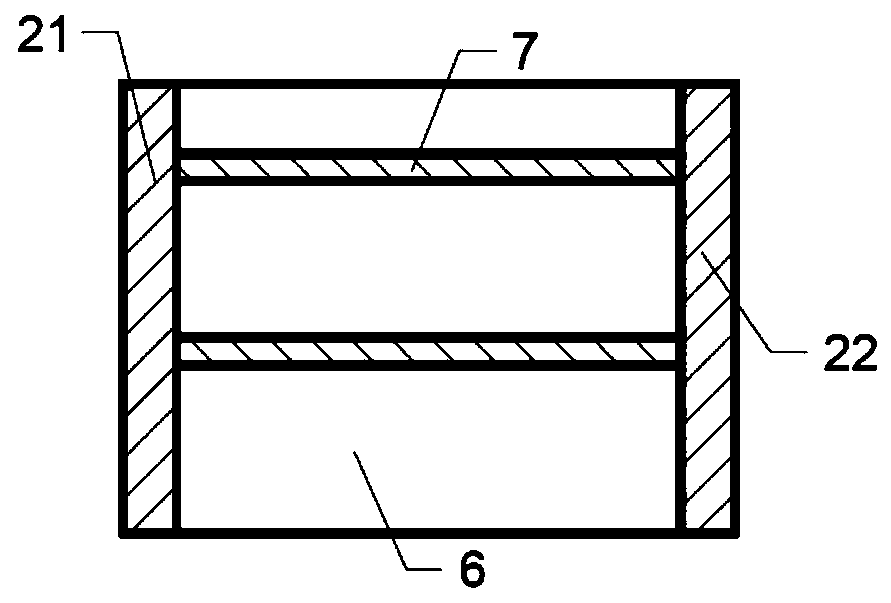

Foundation pit enclosure support plate structure

ActiveCN110904976BGuaranteed supportImprove monitoring accuracyFoundation testingExcavationsContact pressureArchitectural engineering

Owner:南京市第二建筑设计院有限公司

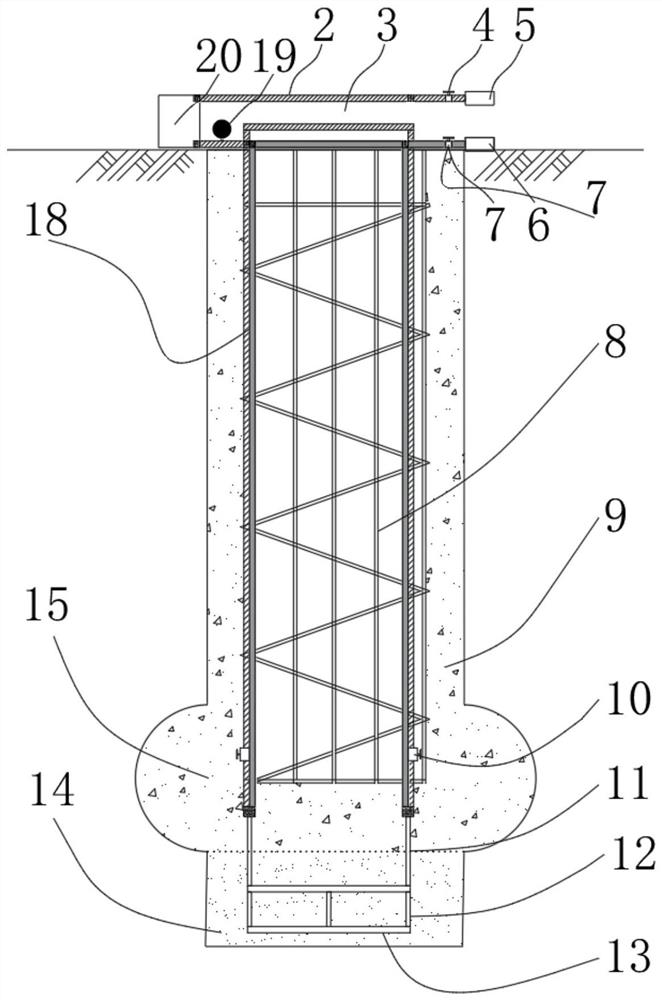

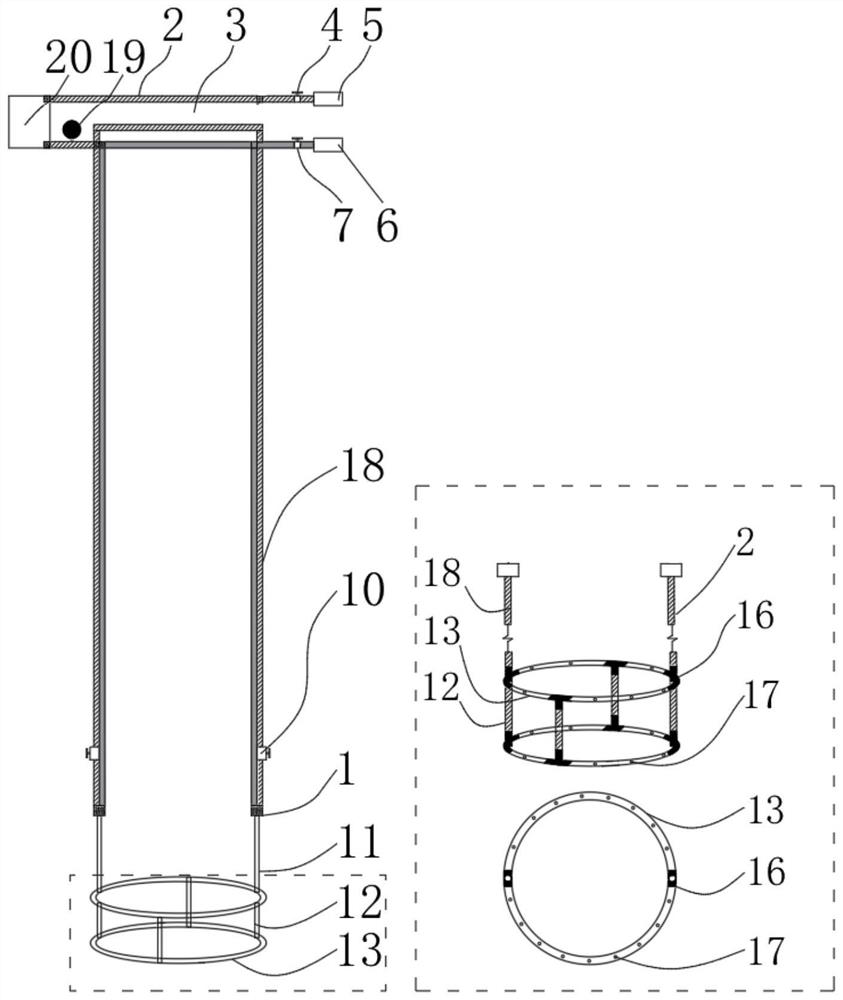

Narrow and long open caisson of thick soft soil layer and construction method thereof

InactiveCN110952559AImprove soil strengthImprove lateral resistanceCaissonsBulkheads/pilesSoil horizonWater pressure

The invention provides a narrow and long open caisson of a thick soft soil layer and a construction method thereof and relates to the technical field of open caisson construction. The open caisson isformed by splicing a plurality of segments. The method comprises the following steps of S1, setting the position of the open caisson, and arranging a cement mixing pile on a soil layer at the open caisson to reinforce the soil layer; S2, manufacturing the first segment above the soil layer; S3, draining away water in an in-well area and cutting earth till the segment descends to a position which is a preset distance from the ground; S4, manufacturing the next segment contrapuntally on the manufactured segment S5, draining away water in an in-well area and cutting earth till the next segment descends to a position which is a preset distance from the ground; S6, repeating the steps 4-5 till all segments are manufactured; and S7, carrying out grouting to the bottom of the open caisson and sealing the bottom. Phenomena such as bottom heave and sedimentation of soil layers around the open caisson due to a too large water pressure in the open caisson in the sinking process can be prevented.

Owner:广州市第三市政工程有限公司

Soil anticorrosive fertilizer-conservation preparation and preparation method thereof

PendingCN107721714AEasy to useEasy to manufactureNitrogenous fertilisersOrganic fertilisersAlcoholSoil surface

The invention discloses a soil anticorrosion fertilizer-conservation preparation, ad relates to the field of water and soil conservation. The preparation is prepared from the following components in parts by weight: 0.1-5 parts of alginate, 0.1-5 parts of soy isolate protein, 0.01-1 part of alcohol additives, 0.01-2 parts of viscosity modifier, 0.01-1 part of surfactant and the balance of deionized water. The preparation can react with soil to form a relatively thin protective layer on the soil surface, and has the advantages of improving the strength of surface oil, improving corrosion resistance of soil and preventing fertility loss of soil. The invention further discloses a method for preparing the soil anticorrosive fertilizer-conservation preparation.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

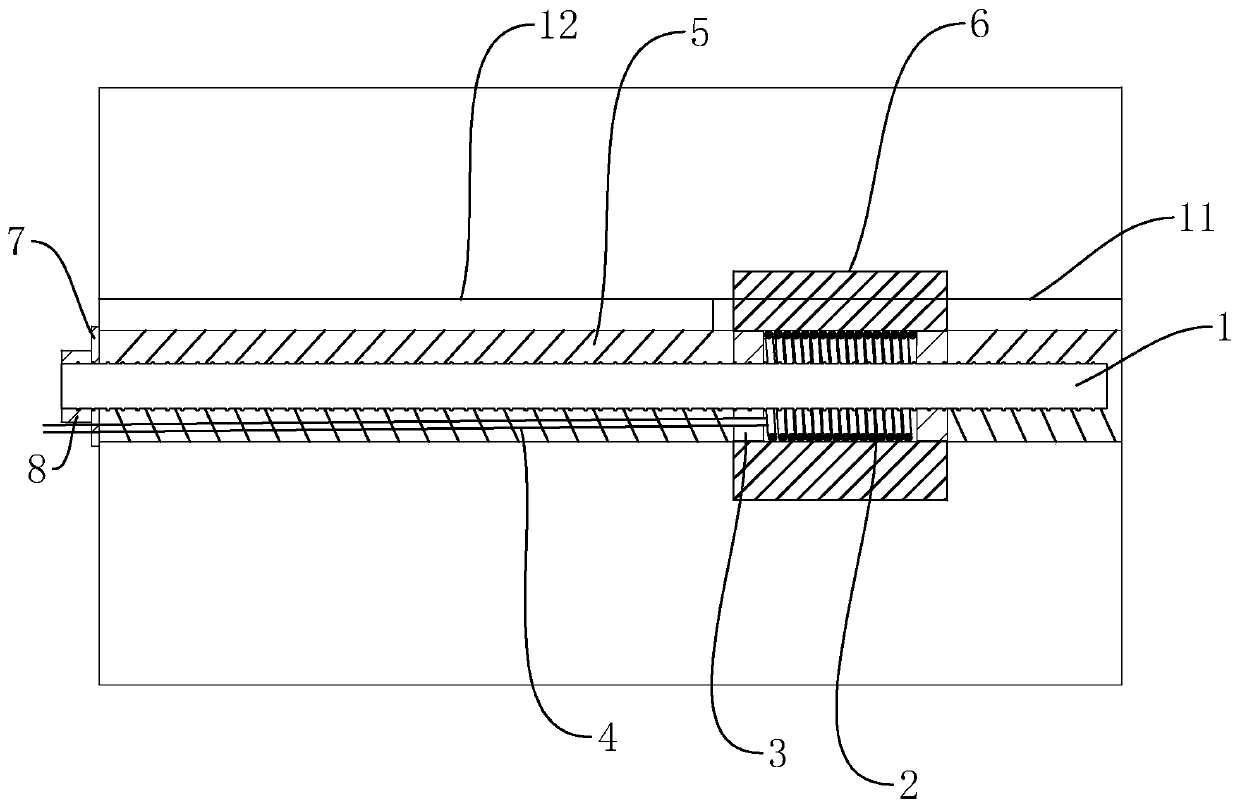

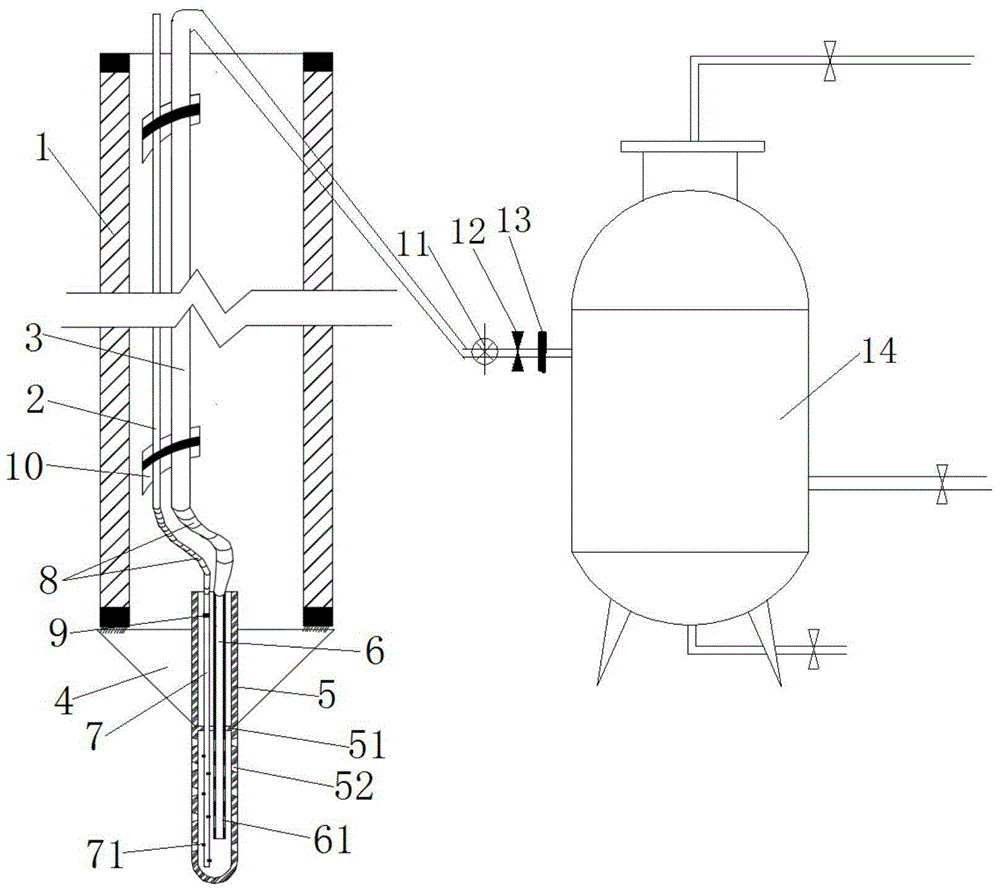

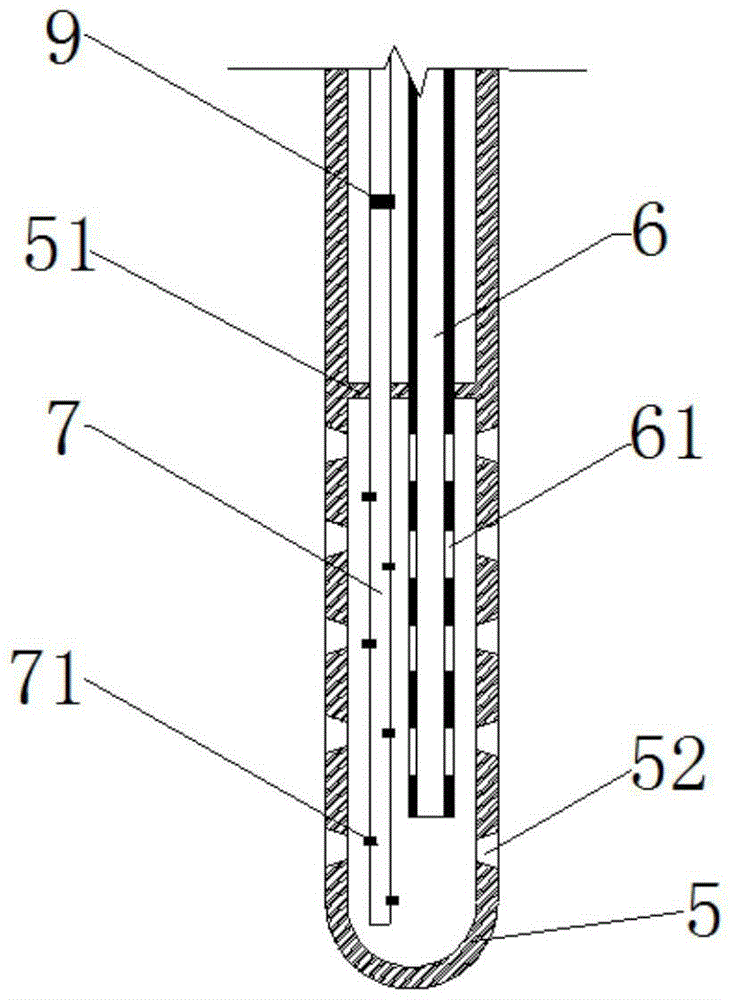

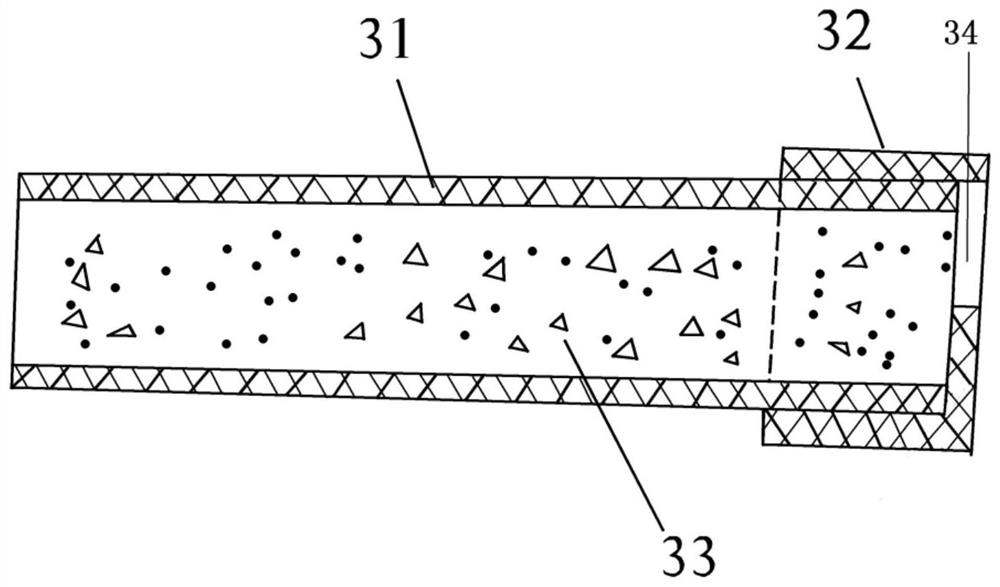

Vacuum preloading and foundation heating combined foundation treatment system

PendingCN112627165AReduce dynamic viscosityWith vacuum preloadSoil preservationWater filterStructural engineering

The invention discloses a vacuum preloading and foundation heating combined foundation treatment system. The foundation treatment system is characterized in that a plastic drainage plate is vertically arranged in a to-be-treated soft soil foundation, the plastic drainage plate comprises a core plate and a filter membrane coating the core plate, the core plate is formed by connecting a plurality of relatively independent channel pipes side by side, drainage channels are formed in the spaces between the filter membrane and the outer walls of the channel pipes of the core plate, internal channels are formed by internal channels of the channel pipes, the top end of the channel pipe of each plastic drainage plate is connected with a top end joint, and the bottom end is connected with a top end joint, so that each plastic drainage plate has a hot water circulation channel; a sand cushion layer is laid on the soft soil foundation, a transversely-arranged water filtering pipe is buried in the sand cushion layer, a sealing film is laid on the sand cushion layer, and a closed vacuum preloading system is formed; and circulating water inlets and circulating water outlets of the top end joints at the top ends of all the plastic drainage plates are connected with circulating heating equipment through pipelines to form a water circulating heating system capable of heating the soft soil foundation.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +2

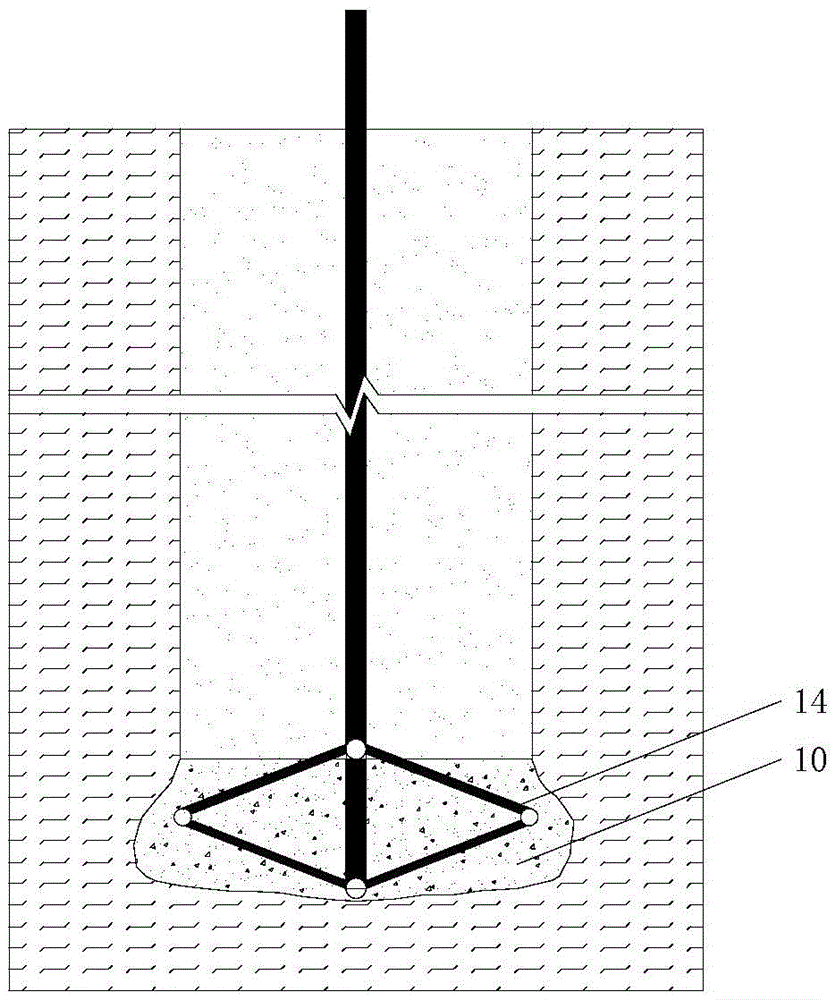

A vacuum grouting device and construction method for bored piles

The invention discloses a vacuum grouting device and a construction method for bored cast-in-situ piles. In the device, a vacuum pump and a grouting pump are arranged on the vacuum grouting device, a vacuum pipe valve is connected to the vacuum pump, and the vacuum pump passes through the vacuum pipe valve and the top of the vacuum pipe. connected; the grouting pump is connected with a grouting valve, and the grouting pump is connected with the top of the grouting pipe through the grouting valve; the bottom of the vacuum grouting pipe is connected with a pile-end grout connecting pipe, a vertical connecting pipe at the pile end, and a horizontal The connecting pipe is provided with a plurality of pipe holes on the horizontal connecting pipe at the pile end. The method includes drilling the cast-in-situ pile to form a hole; expanding the pile end and the pile bottom; cleaning the hole for the first time; making a steel cage and installing a vacuum grouting device; cleaning the hole for the second time; pouring the cast-in-situ pile; maintaining the pile body; Carry out vacuuming to remove water vapor at the pile tip; reinforce the pile tip with grouting; stop grouting; test and accept. The invention improves the effect of grouting at the pile end; makes the grout fully spread around the pile end, increases the bearing area of the pile end, and improves the strength of the soil body at the pile end and the bearing capacity of the pile body.

Owner:CHINA FIRST METALLURGICAL GROUP

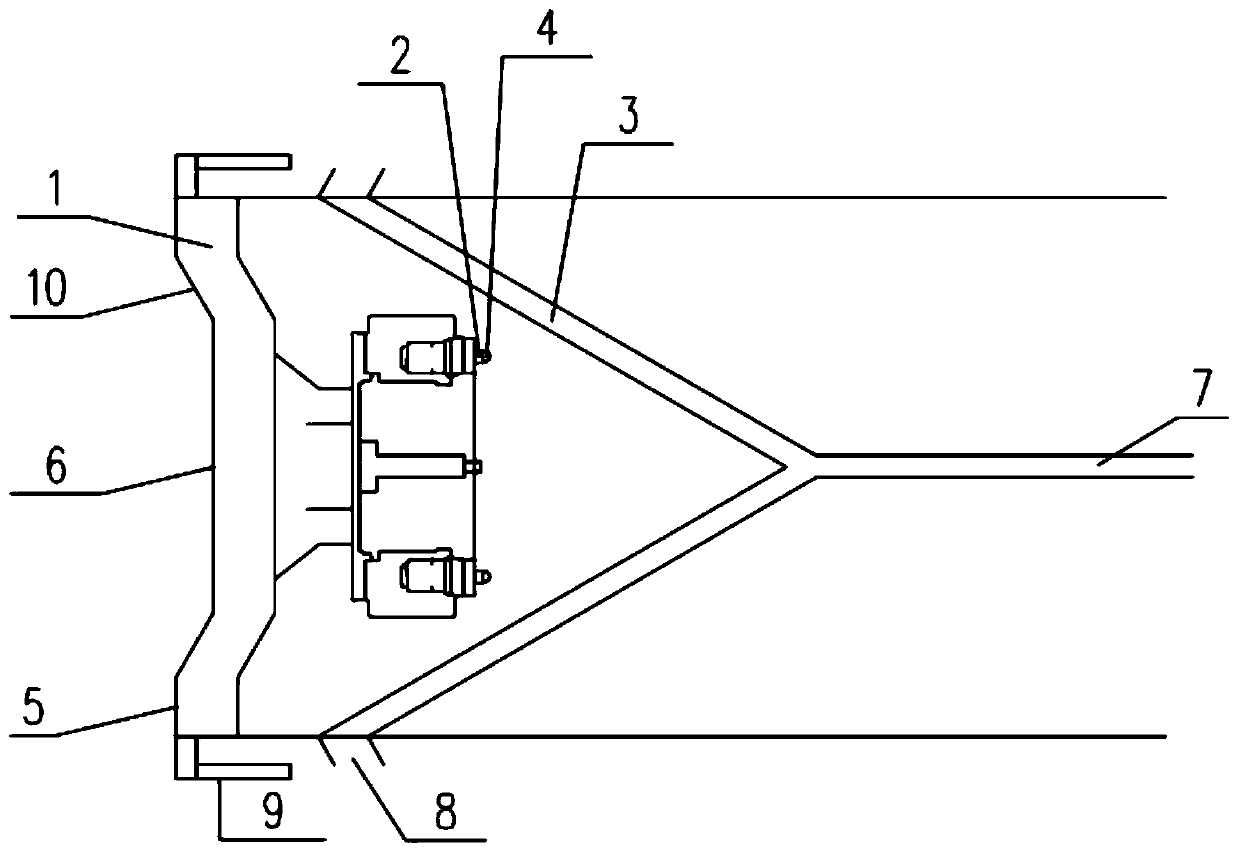

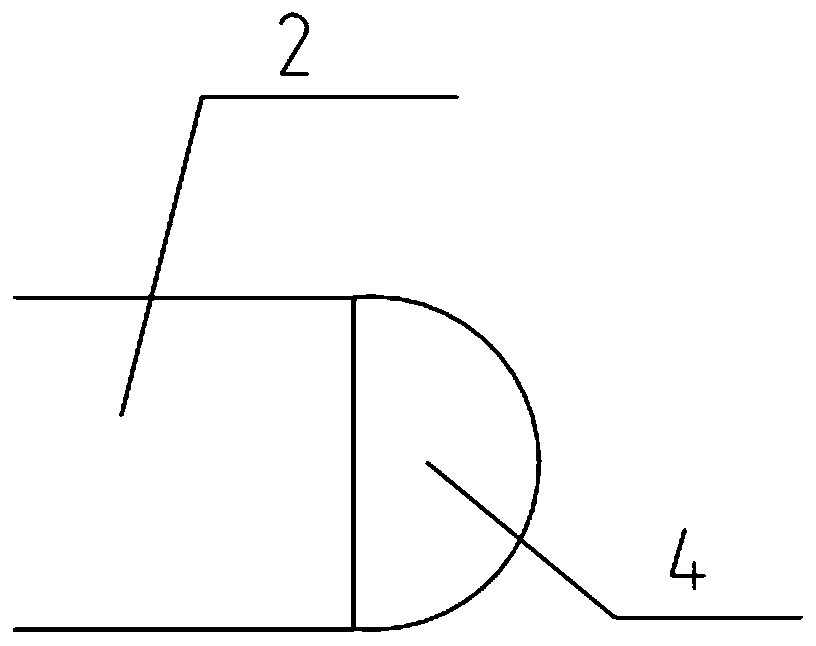

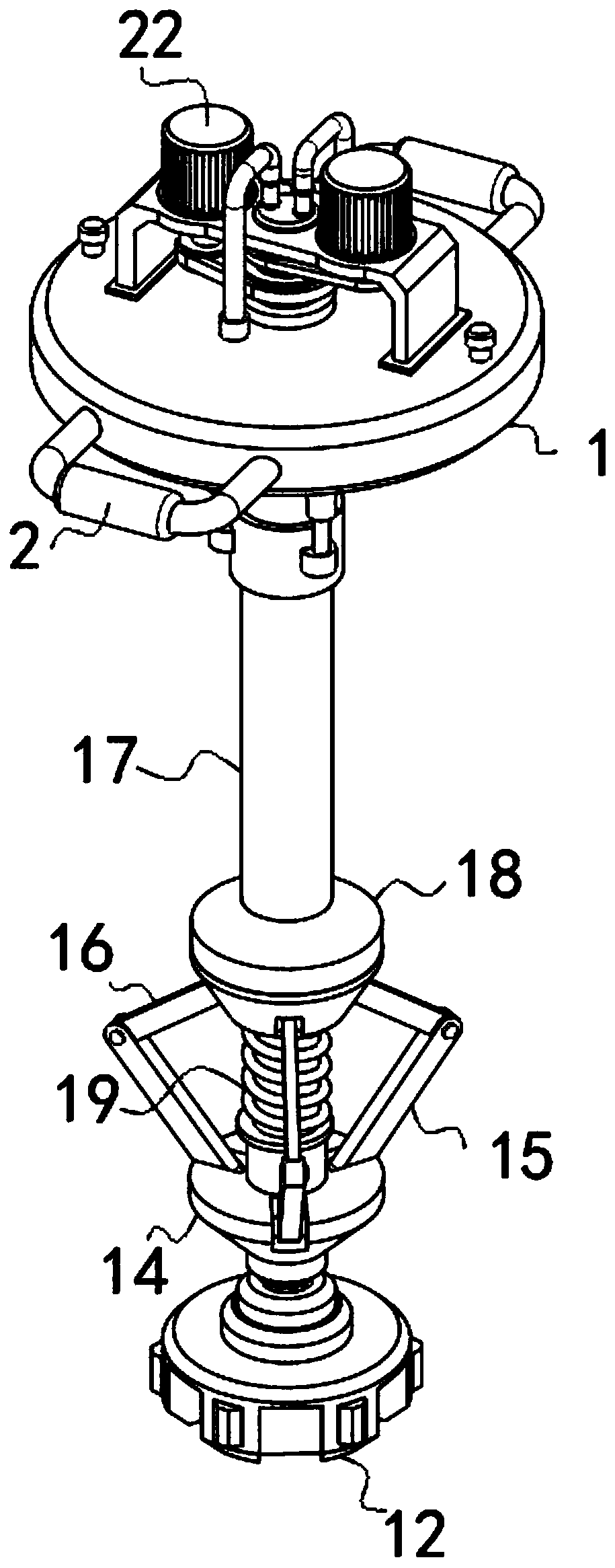

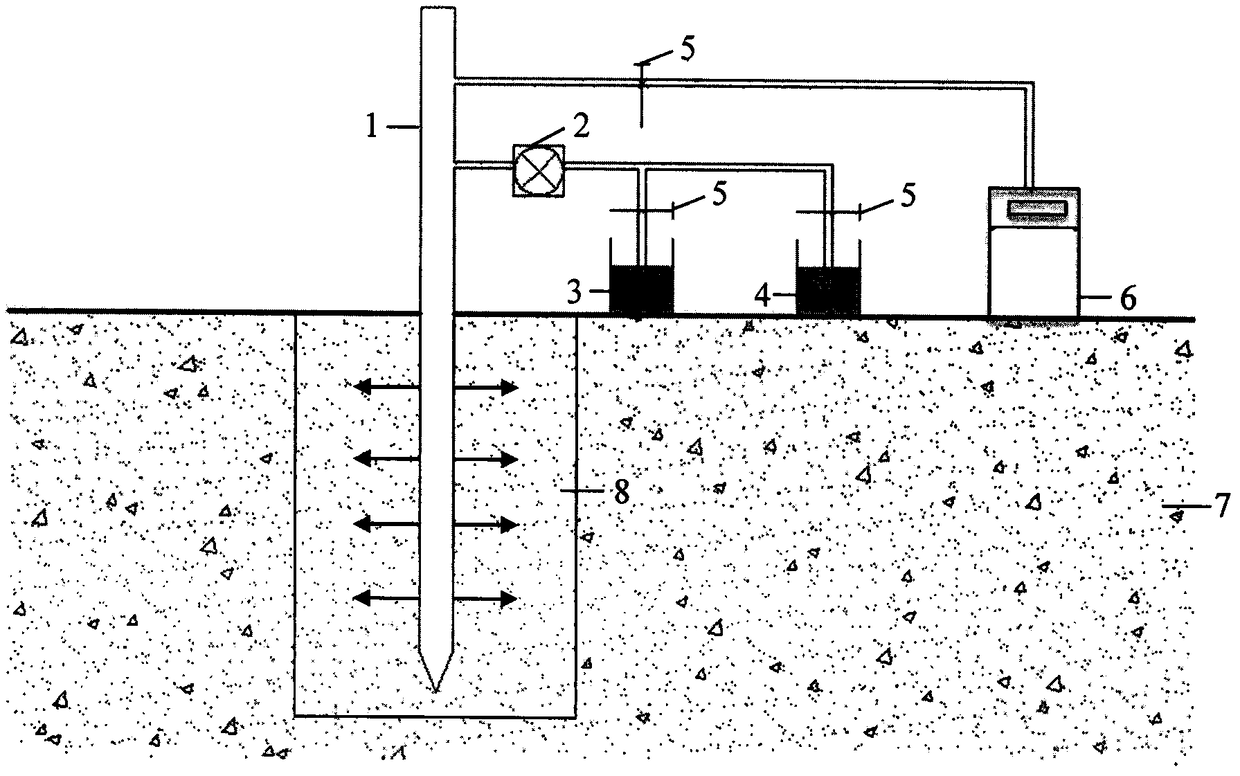

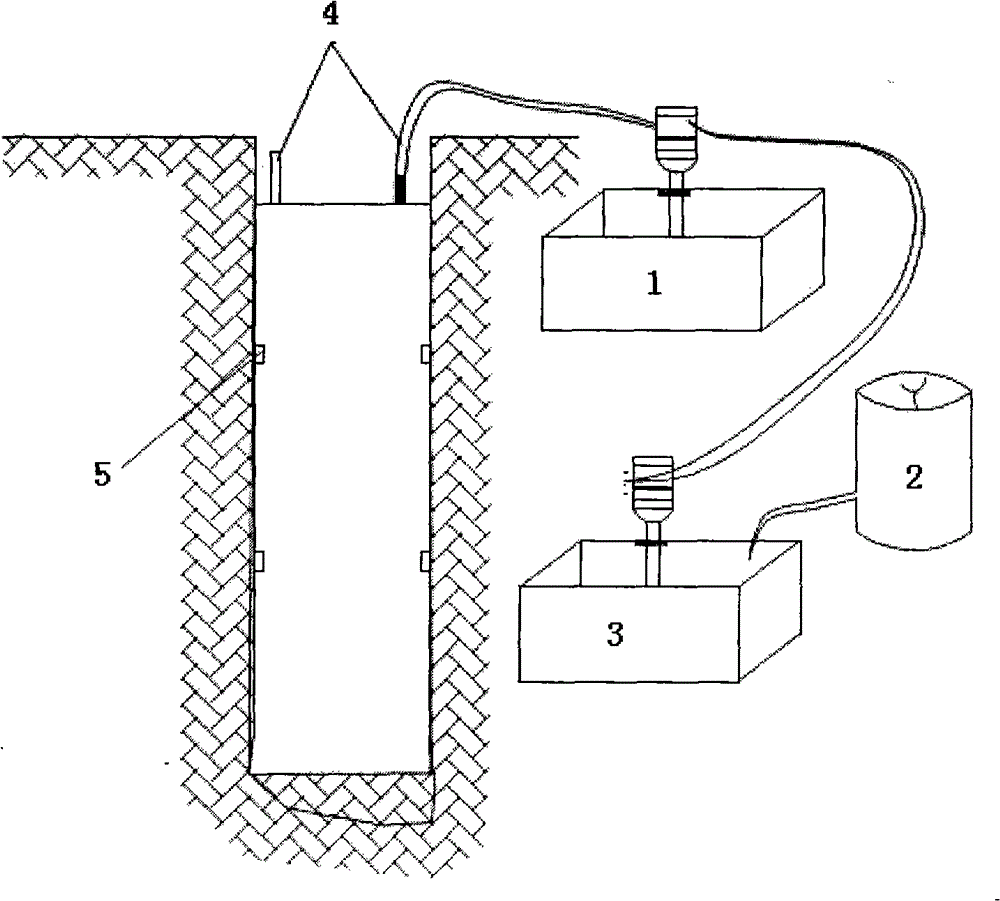

A method for soil consolidation by microbial gas-liquid circulation grouting

A microbial gas-liquid circulation grouting method for soil consolidation, the steps comprising: a. vertically driving the grouting flower tube 1 into the foundation 7; b. injecting the soil body 8 to be consolidated into the soil body 8 to be consolidated through the grouting flower tube 1 OD of 1.5 times the pore volume 600 = 1.2 of the bacterial solution 3, then inject urea and CaCl with a concentration equal to the volume of the bacterial solution 3 of 0.5mol / L to 1.0mol / L 2 The mixed cementing liquid 4; c. Utilize the air compressor 6 to inject compressed air with a pressure of 100KPa~200KPa and a volume of 1.5 times the pore volume of the soil to be consolidated into the soil to be consolidated 8, and place the soil to be consolidated in the soil 8 The pore liquid is ejected, so that the soil body 8 to be consolidated is in an unsaturated state, and left to stand for 12 hours; d. Inject the cementing fluid 4 of 1.5 times the pore volume of the soil to be consolidated 8 into the soil to be consolidated 8, and stand for 12 hours; e. . Repeat operation d once; f. Repeat operations b, c, d, and e until the strength of the soil body 8 to be consolidated reaches the requirement or the grouting liquid (bacteria liquid 3 or cementation liquid 4) cannot be injected into the soil body 8 to be consolidated , stop grouting.

Owner:NANJING FORESTRY UNIV

A construction method for strengthening soft foundation with carbon fiber cement mixing pile combined with electroosmotic method

ActiveCN107630450BStrong bearing capacity of foundation after high treatmentImprove bearing capacityBulkheads/pilesSoil preservationFiberElectrode erosion

The invention discloses a construction method for soft foundation consolidation by utilizing carbon fiber cement mixing piles combined with the electroosmosis method. The construction method is characterized in that conductive carbon fibers are added into the conventional cement mixing piles, and conductive blocks are arranged at the tops of the piles to form electrodes; and besides, a horizontalsand cushion layer and vertical plastic drainage plates are laid to serve as drainage channels, and a calcium chloride solution or sodium silicate solution is injected into the soil among the piles during different periods of time from the top ends of the plastic drainage plates, so as to shorten the electroosmosis period and improve the strength of the soil among the piles. With the adoption of the construction method for soft foundation consolidation by utilizing carbon fiber cement mixing piles combined with the electroosmosis method, the problems of electrode erosion of the electroosmosismethod and gathering and accumulating of gas bubbles are effectively solved, and the advantages as follows are achieved: the construction time is short, the strength of the foundation after treatmentis high, and the post-construction settlement is little

Owner:HOHAI UNIV

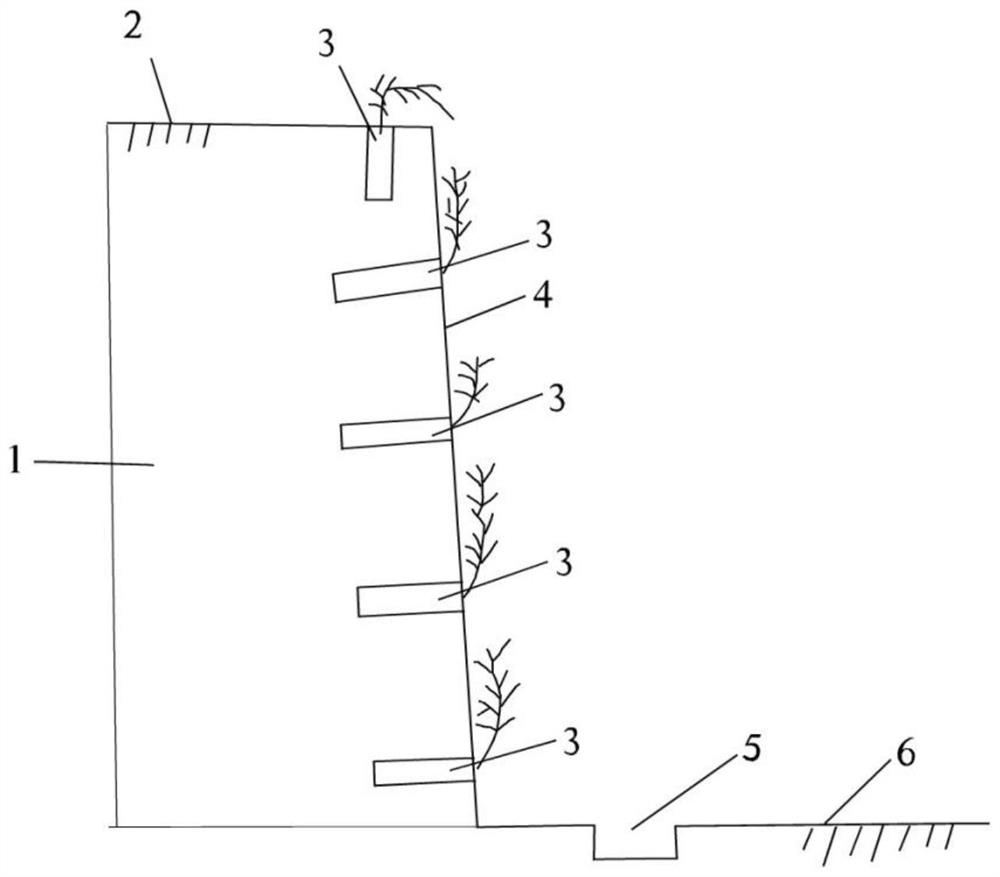

Ecological slope protection method for steep cliff slope and ecological pile thereof

PendingCN114687367AImprove water retentionImprove fat retentionGrowth substratesCulture mediaLandslideEnvironmental engineering

The invention relates to a slope protection technology, in particular to an ecological slope protection method for a steep cliff slope and an ecological pile thereof. According to the method, holes are drilled in the slope top of the slope and the slope surface of the steep cliff, the ecological piles are placed in the holes, the ecological planting bags are arranged in the ecological piles, the seedlings of the climbing plants and the seeds of the grass are arranged in the ecological planting bags, and the seedlings of the climbing plants climb the whole slope surface of the steep cliff after growing to achieve the effects of greening the slope surface of the steep cliff and stabilizing the slope. After grass seeds grow, the steep cliff slope surface can be greened to stabilize the ecological pile, meanwhile, rock and soil bodies of the steep cliff slope surface can be prevented from being weathered, drainage ditches are dug in the slope bottom, and the slope stability is improved. The method is simple in construction, short in construction period and low in cost, landslide disasters can be prevented, the slope is greened while the stability of the slope is improved, and the good ecological slope protection effect is achieved.

Owner:JIANGXI UNIV OF SCI & TECH

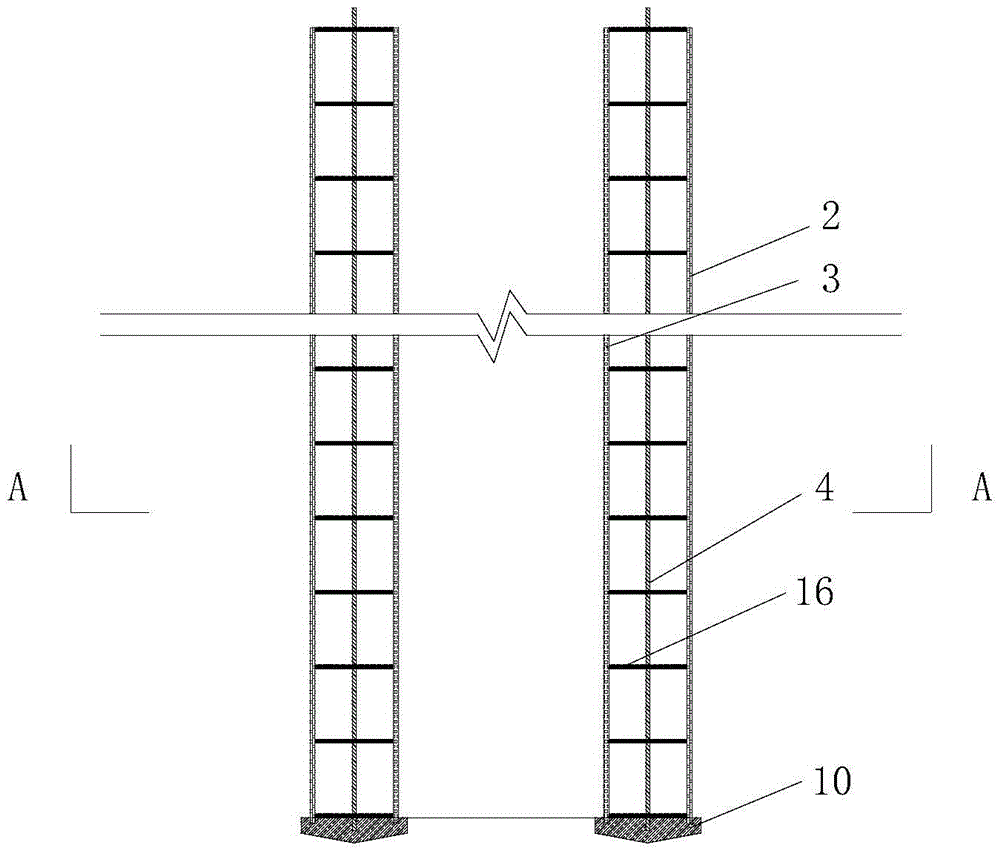

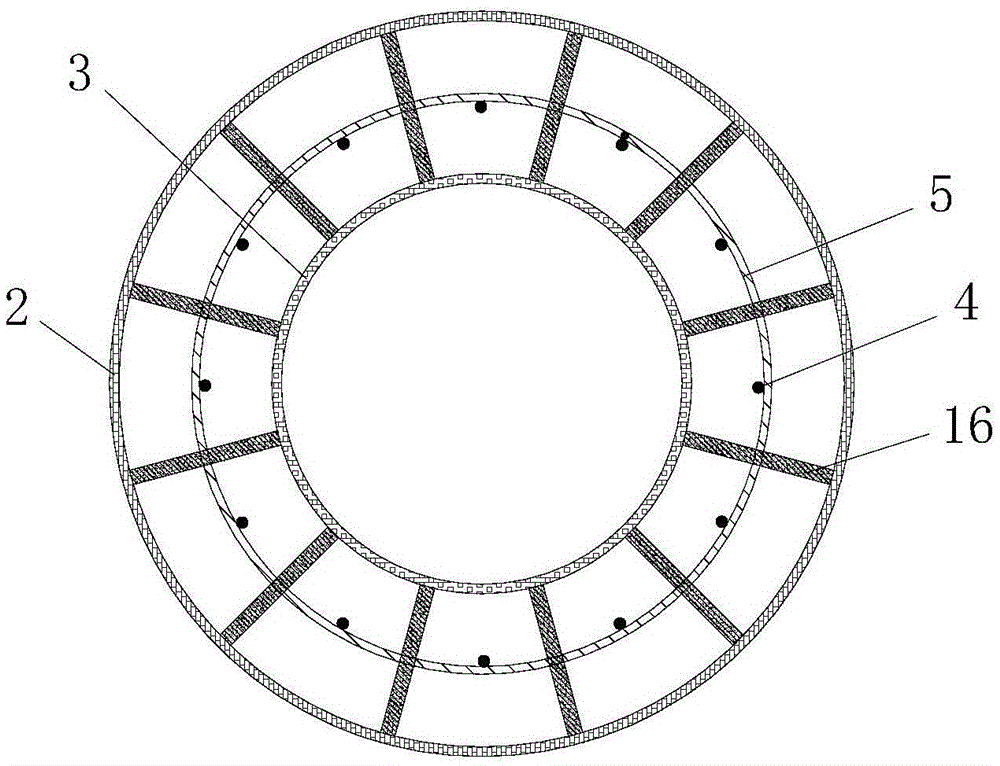

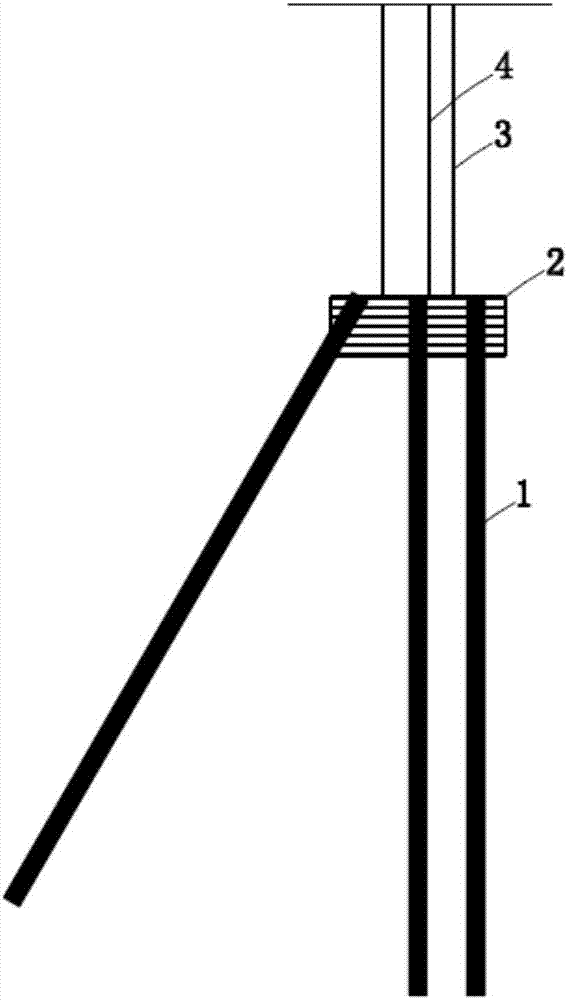

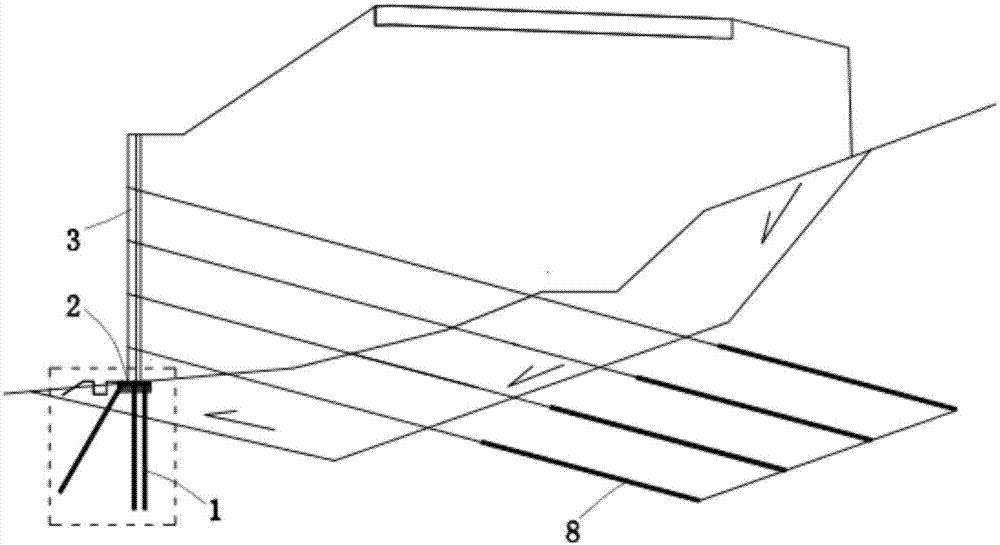

Grouter for back side grouting and its construction method

The invention relates to a pile side post-grouting grouting device and the construction method thereof, including a ground grouting device and an underground grouting device; the underground grouting device is composed of a pile body grouting guide pipe and an inner pile grouting device; both ends of the pile body grouting guide pipe are connected with the ground conveying pipe and the pile side grouting device; the pile body grouting guide pipe is distributed along the grouting section, fixedly bound with the main rib of the steel reinforcement cage and is arranged in a drilled hole togetherwith the steel reinforcement cage; the pile side grouting device is composed of an annular high-pressure hose and a grouting device; the annular high-pressure hose is communicated with the pile body grouting guide pipe and is fixedly connected with the bored pile steel reinforcement cage. During the pile forming process of the bored pile, the pile side post-grouting grouting device and the construction method prearrange the grouting pipelines on a plurality of positions on the pile body, distribute the annular high-pressure hose outside the grouting section and mount the grouting device; a high-pressure grouting pump is adopted when pile body concrete reaches certain strength; the cement grout is injected into the pile lateral through the grouting pipelines to improve the pile lateral mudcover; the pile lateral soil mass intensity is improved at the same time, so as to improve the bearing capacity of the pile and reduce the skirt pile settlement.

Owner:SHANGHAI FOUND ENG GRP

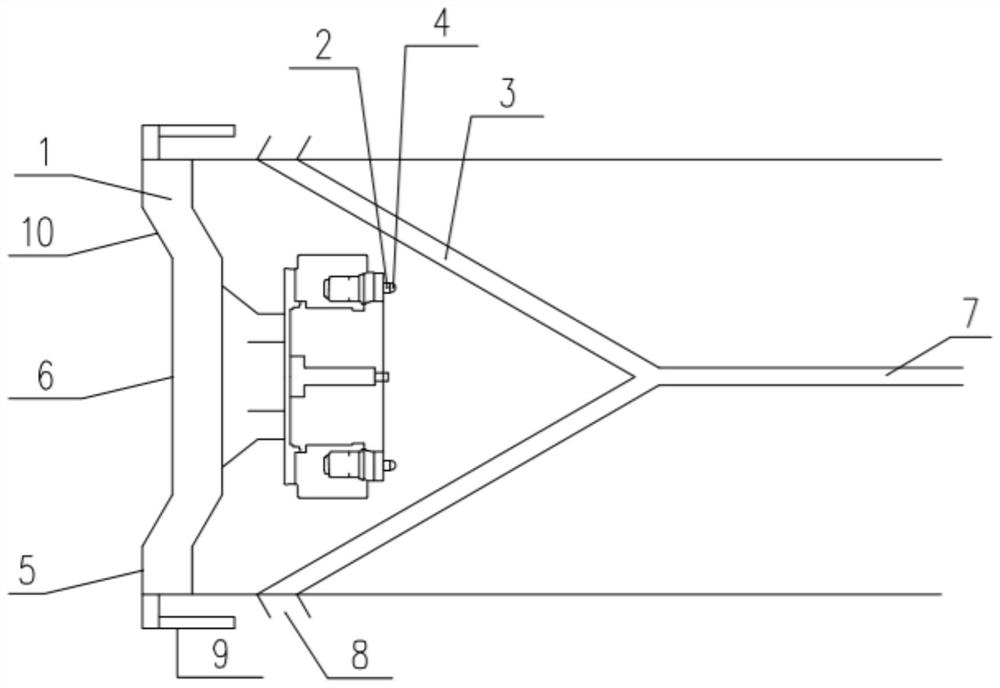

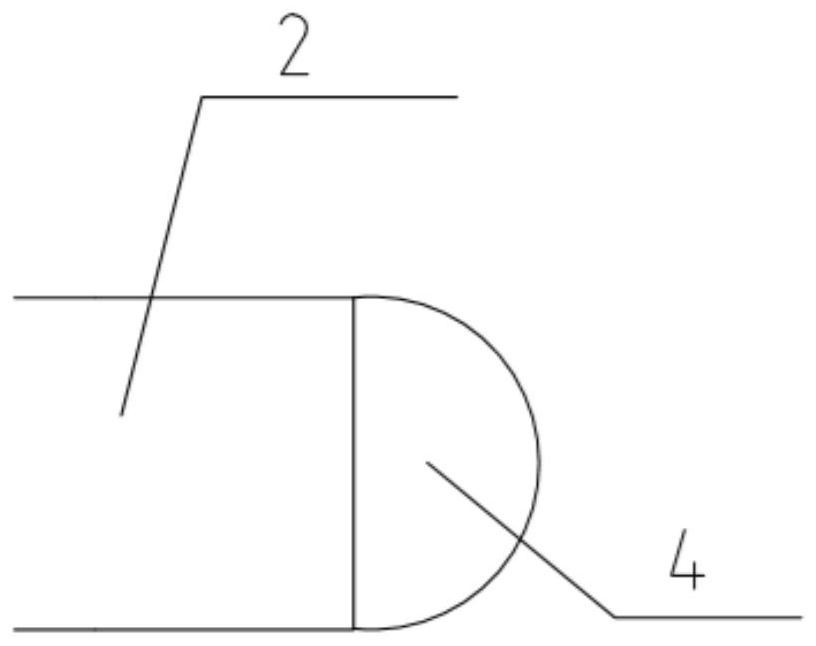

Shield head system capable of effectively reducing surrounding rock disturbance

ActiveCN111648779AStable propulsion speedImprove soil strengthUnderground chambersHydraulic/pneumatic force measurementControl systemSlurry

The invention discloses a shield head system capable of effectively reducing surrounding rock disturbance. During tunneling, a pressure detection device is used for feeding ground stress detected in real time back to a ground control system, meanwhile, a GIS positioning system positions the real-time position of a shield tunneling machine, and positioning data are fed back to the ground control system. The ground control system combines the real-time positioning data and the real-time ground stress data to conduct calibration and adjustment on two air bags, then, the two air bags are used foradjusting the pushing power of the shield tunneling machine in real time, and the shield tunneling machine is kept with the stable pushing speed. In addition, waterproof slurry is discharged to the connected position of a shield shell I and a shield shell II through grouting holes, then muck and the waterproof slurry are in contact and are mixed, a muck waterproof mixture is formed and extruded through the exterior of the shield shell II, and the muck waterproof mixture is compacted and fixed to the tunnel goaf surface formed after shield tunneling machine tunneling; and accordingly, the soilbody strength and waterproof treatment of the tunnel goaf surface are improved, the effect of preventing ground surface settling is achieved, the side face is flattened, and the water seepage path isreduced.

Owner:XUZHOU UNIV OF TECH

Rapid emergency pile for building foundation pit

InactiveCN113718781AIncrease contact areaExpand the scope of actionProtective foundationExcavationsWater seepageEnvironmental geology

The invention belongs to the technical field of building tools, and particularly relates to a rapid emergency pile for a building foundation pit. The rapid emergency pile comprises a main body, a grouting component, a cooling bin, a plug, a pull rope and a connecting component. The emergency pile is rapidly connected with an external tool through the connecting component; the main body is arranged in a soil body of a water seepage area, then the grouting component is pushed into the soil body, after the emergency pile is arranged and the grouting component enters the soil body, a user pulls the pull rope, so that the plug is separated from the cooling bin, cooling liquid in the cooling bin enters the soil body, water in the soil body is frozen, a frozen area with a certain area is formed in the soil body around the emergency pile, then a water outlet passage is blocked, then water in the foundation pit is prevented from seeping into the foundation pit, the foundation pit is temporarily stabilized, then the collapse time of the foundation pit is delayed, then enough safety time is bought for evacuation of personnel in the foundation pit and evacuation of equipment in the foundation pit, and then life and property losses caused by collapse of the foundation pit are prevented.

Owner:王超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com