Controllable air exhausting device for constructing precast pile in gas-containing soil layer and construction method of device

A technology of exhaust device and construction method, which is applied in protection devices, sheet pile walls, infrastructure engineering and other directions to achieve the effects of reducing personnel and property losses, preventing foundation instability and facilitating exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

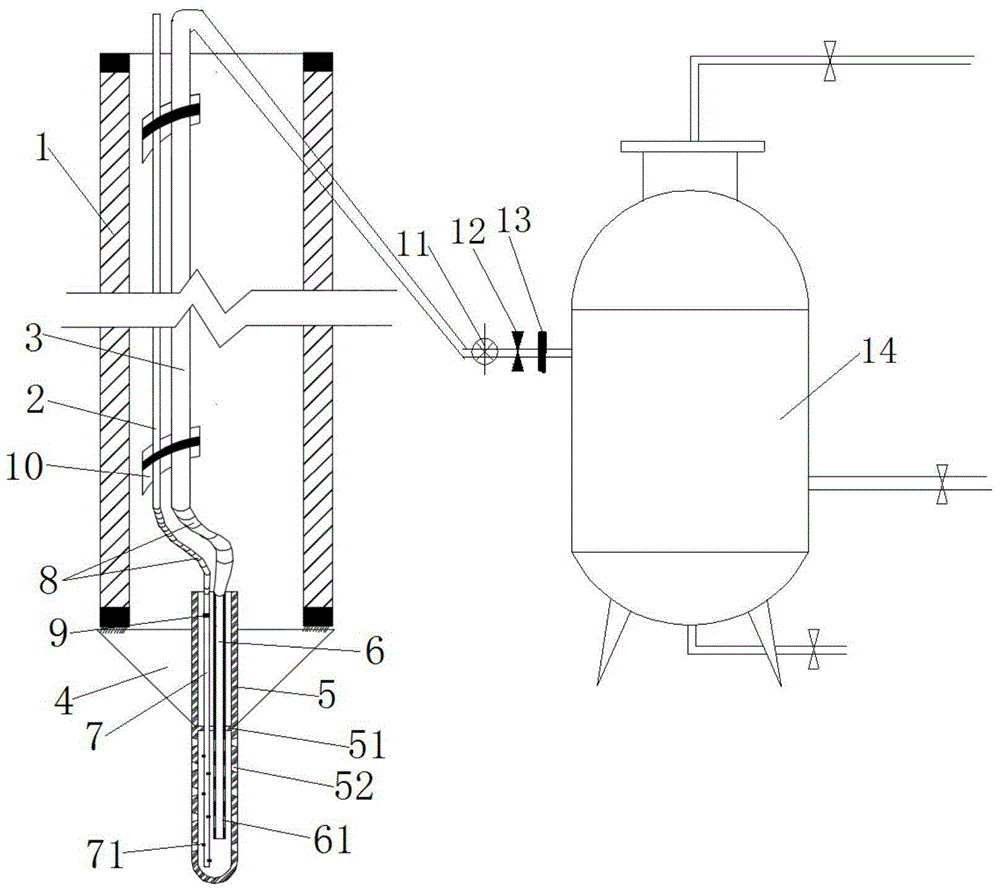

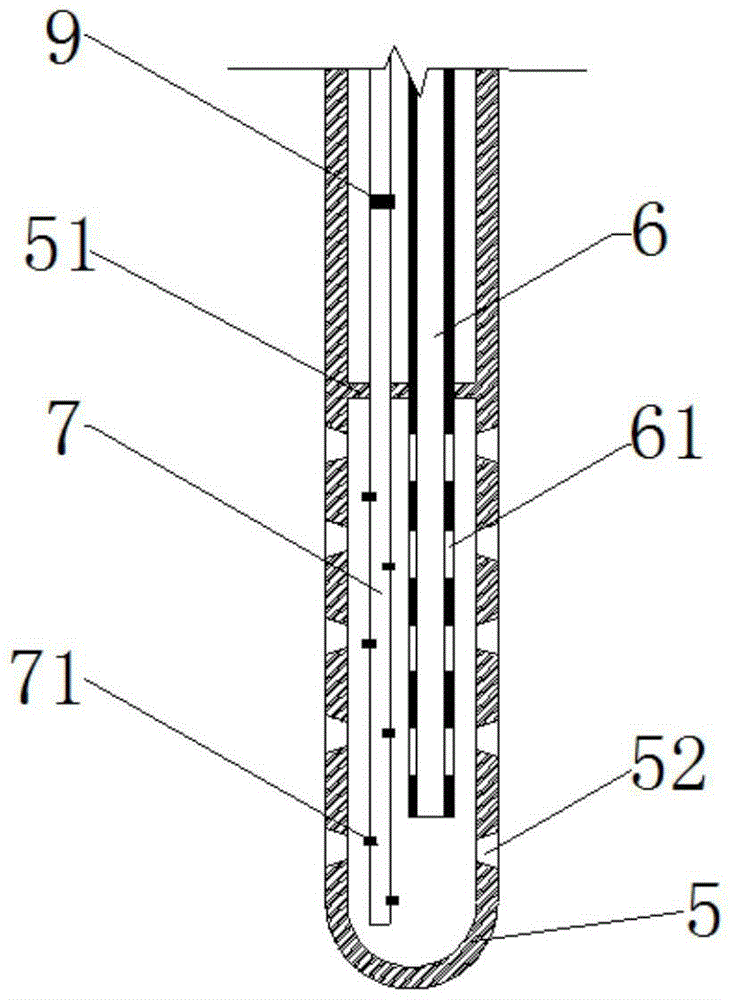

[0037] combine figure 1 and figure 2 , a controllable exhaust device for the construction of prefabricated piles in air-bearing soil layers in this embodiment, including a prefabricated hollow pile 1, the prefabricated hollow pile 1 is a prefabricated concrete pipe pile or a prefabricated concrete hollow square pile or a prefabricated hollow steel pile Both are available; the bottom of the prefabricated hollow pile 1 is provided with a closed pile tip 4 made of steel or concrete, and the prefabricated hollow pile 1 and the closed pile tip 4 are connected by welding or bonding; the front end of the closed pile tip 4 is provided with an exhaust device , the layout form is simple and flexible, so that the gas in the air-bearing soil layer is discharged through the exhaust device, and the exhaust effect is good, which can prevent engineering disasters caused by gas eruption in the air-bearing soil layer, reduce personnel and property losses, and can also enhance the gas-containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com