UHPC prefabricated special-shaped pile and preparation method thereof

A prefabricated pile body technology, applied in sheet pile walls, manufacturing tools, ceramic forming machines, etc., can solve the problems of pile body deformation, falling off, high cost, increase mechanical occlusal force and friction resistance, and reduce settlement deformation. , the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

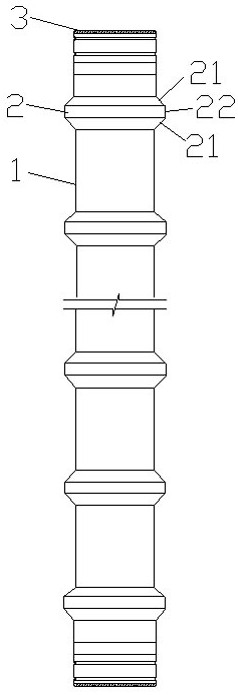

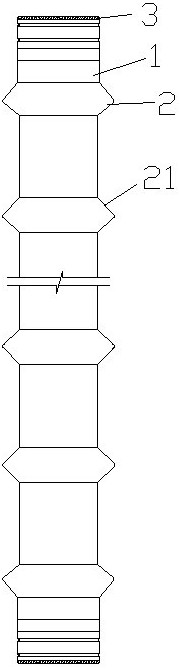

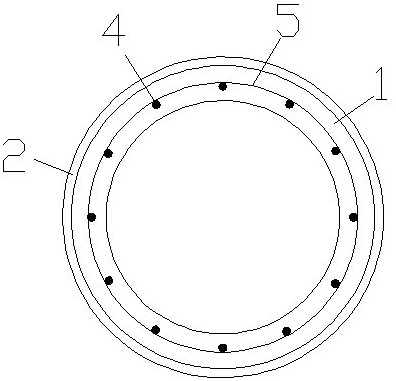

[0028] Figures 1 to 6 It is a schematic diagram of the structure of the present invention and its use in pile sinking.

[0029] The reference signs therein are: arc chamfer R, pile body 1 , bearing plate 2 , load-bearing slope 21 , friction surface 22 , pile end plate 3 , non-prestressed reinforcement 4 , and stirrup 5 .

[0030] The invention discloses a UHPC prefabricated special-shaped pile. The pile has extremely strong mechanical occlusal force and frictional resistance, so it has a very high resistance to settlement of the pile foundation in soft soil areas. It includes a hollow cylindrical pile body 1. The pile body 1 of the present invention is a non-prestressed reinforced concrete pile, which does not need a special formwork with a tensioning system in the manufacturing process, so there is no tensioning process when the traditional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com