Pile-forming device and method for vortex pressing extruding and expanding concrete layering expanding uplift pile

A technology of concrete and uplift piles, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of unguaranteed uplift quality, unsatisfactory bearing capacity, low efficiency, etc. The effect of improving the pull-out bearing capacity and improving the longitudinal and lateral strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

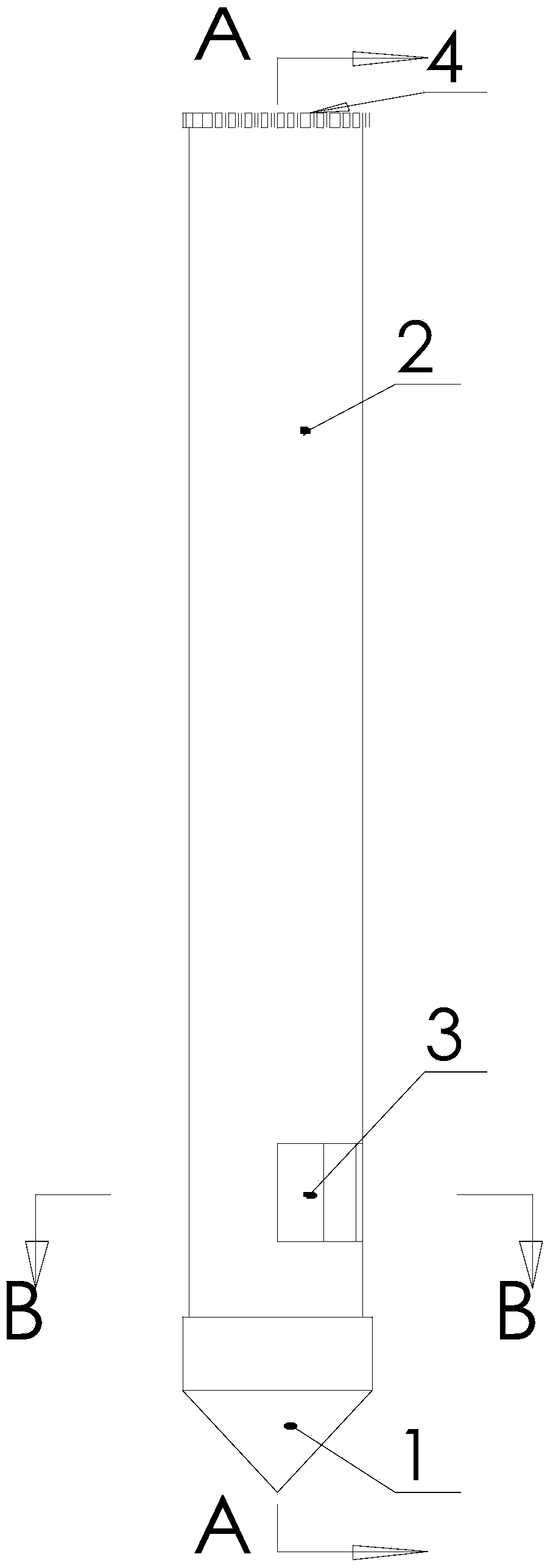

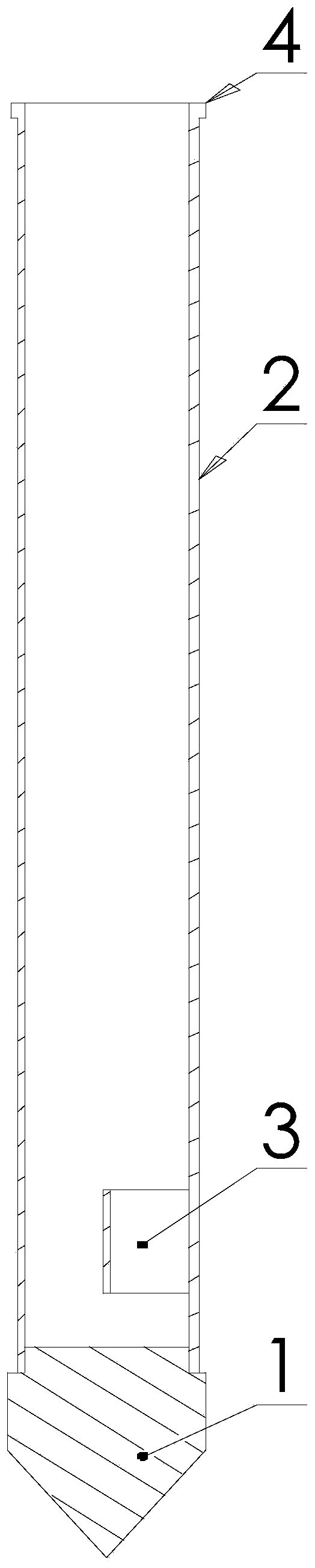

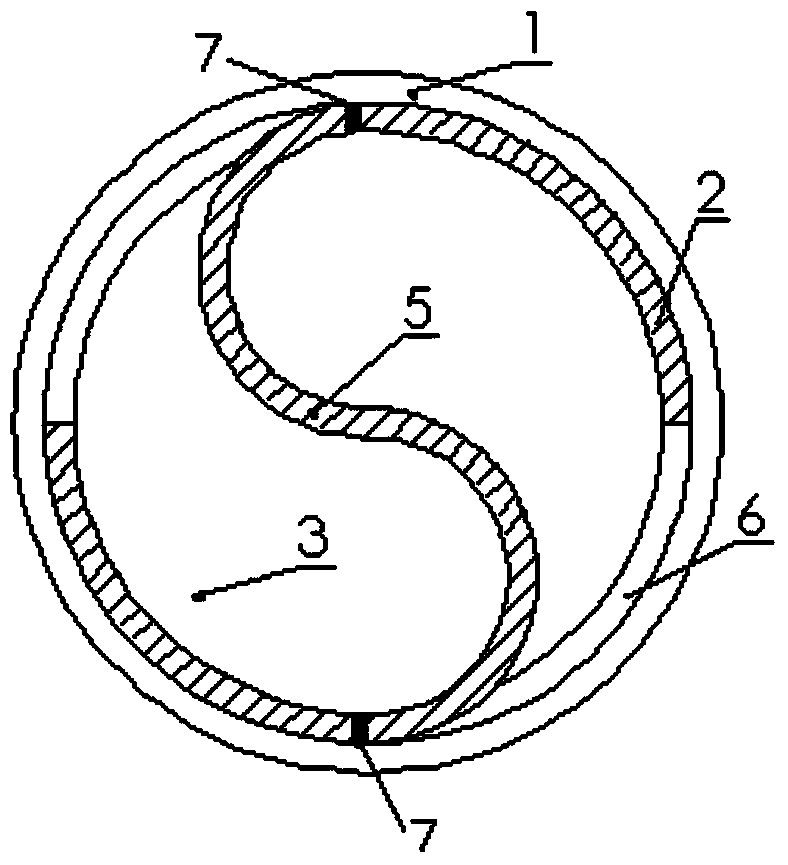

[0029] Such as Figure 1 to Figure 2 As shown, the pile-forming equipment of vortex squeezed and expanded concrete layered diameter-expanded uplift piles includes: prefabricated concrete pile head 1, steel casing 2, rotating gear 4, vortex blade 5, H-shaped steel 8 with anchor 9 The precast concrete pile head 1 is arranged at the bottom of the steel casing, the rotating gear 4 is installed on the top of the precast concrete pile head 1, and the vortex pressure blade 5 is installed at the opening of the steel casing; wherein:

[0030] The prefabricated concrete pile head 1 has a cone at the bottom and a cylinder at the top, and a cylindrical boss is formed at the top of the cylinder.

[0031] The steel casing 2 is a metal round pipe, and the inner diameter of the steel casing 2 is slightly larger than the outer diameter of the cylindrical boss of the precast concrete pile head 1, so as to ensure that the top of the precast concrete pile head 1 can just be embedded in the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com