Steel-plastic meshed composite pipe with detachment preventive function

A composite pipe and functional technology, applied in the direction of pipes, rigid pipes, pipe components, etc., can solve the problems of steel-plastic composite pipe body losing anticorrosion performance, plastic coating or pipe body rupture, plastic pipe and steel pipe flow away, etc., to achieve mechanical Improvement of properties, improvement of inner hole adhesion, and prevention of degumming and peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

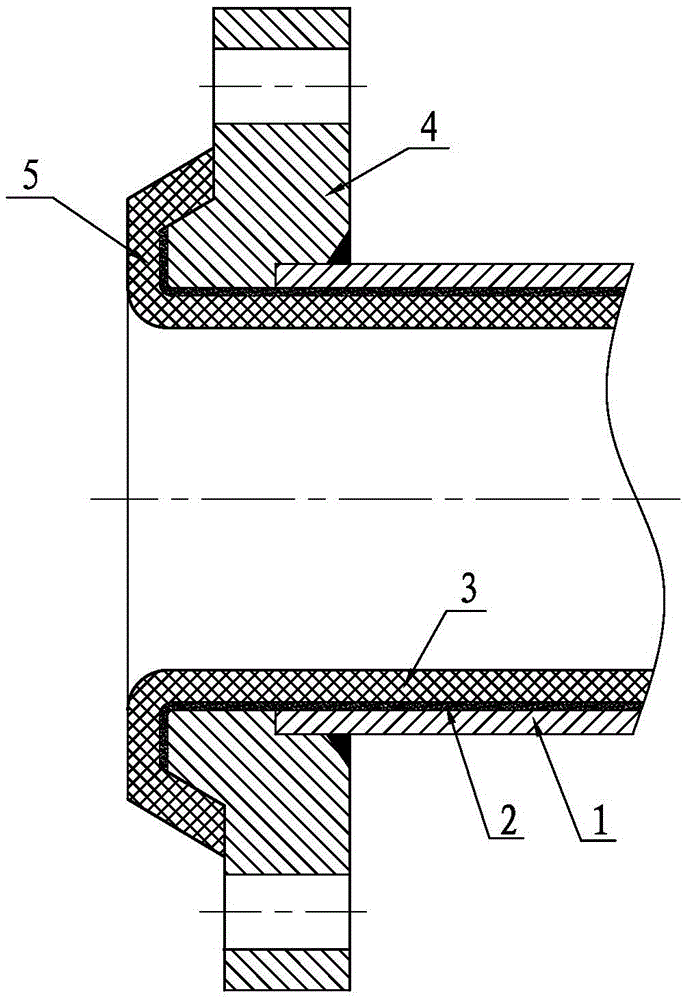

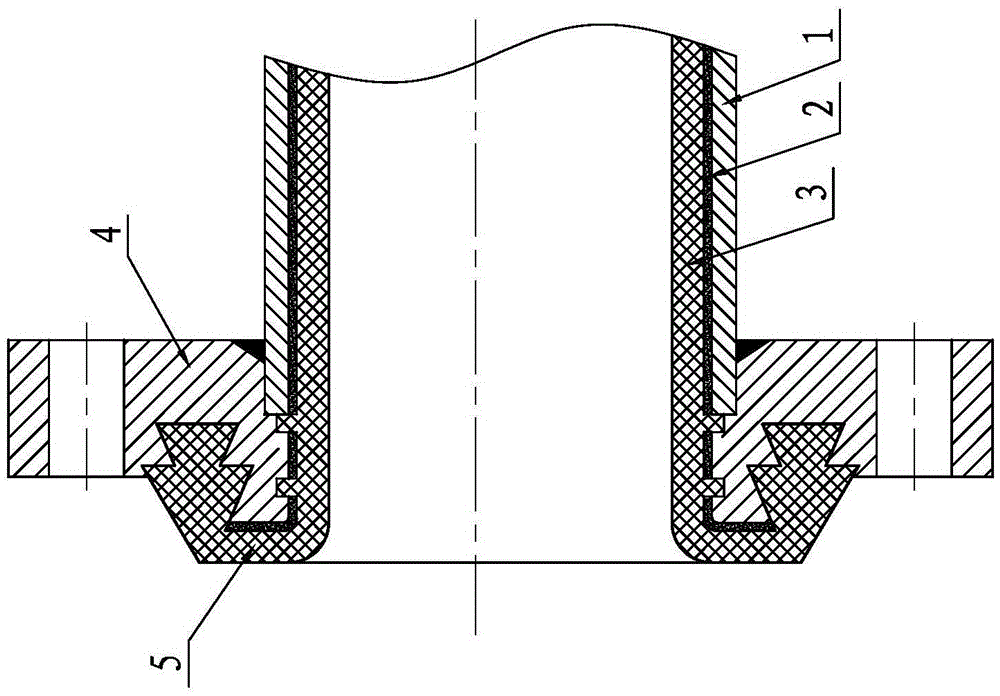

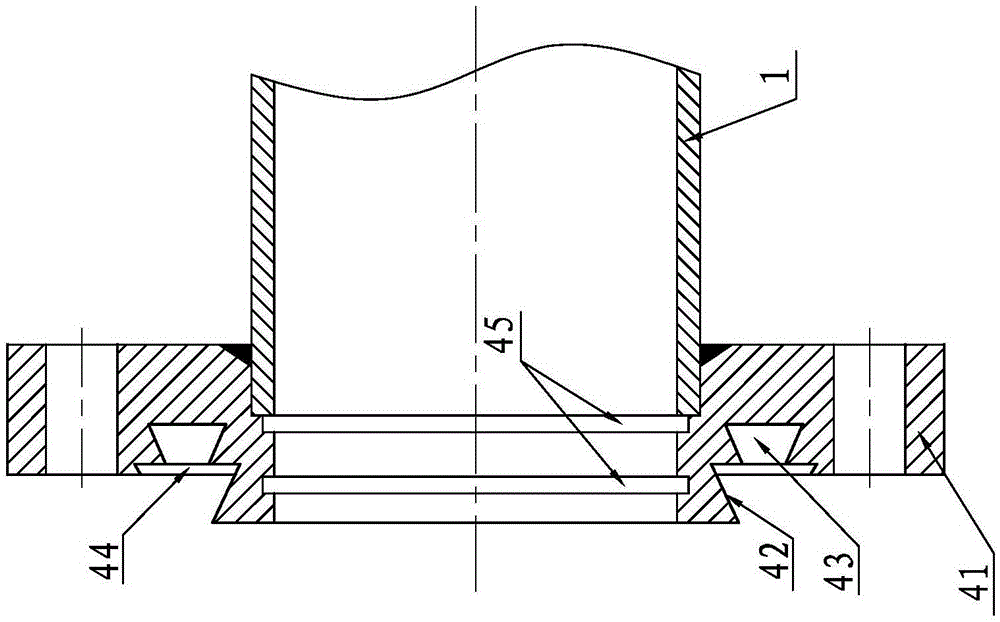

[0025] Embodiment 1: A steel-plastic jointed composite pipe with anti-barge function, such as figure 2 and image 3 As shown, it includes a steel outer tube 1, an adhesive layer 2, an anti-corrosion inner tube 3, a connecting flange 4 and an end flange 5, and the anti-corrosion inner tube 3 is bonded to the steel outer tube 1 through the adhesive layer 2 On the inner wall of the steel outer pipe 1, connecting flanges 4 are fixedly connected at both ends, and the two ends of the anti-corrosion inner layer pipe 3 form end face flanging 5 on the butt joint surface of the connecting flange 4 through thermal melting deformation. , between the end flange 5 and the connecting flange 4 is provided with an anti-barge axial separation structure, that is, on the butt joint surface 41 of the connecting flange 4 is provided with a occlusal inverted cone surface positioning boss 42 .

Embodiment 2

[0026] Embodiment 2: On the basis of Embodiment 1, a dovetail groove 43 is provided on the mating surface 41 , and the dovetail groove 43 is located outside the positioning boss 42 of the occlusal inverted cone surface.

Embodiment 3

[0027] Embodiment 3: In Embodiment 2, the dovetail groove 43 is a double-layer superimposed dovetail groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com