Plasma chemical vapor deposition and magnetron sputtering or ion plating compounded plating method

A chemical vapor deposition, magnetron sputtering technology, applied in sputtering coating, ion implantation coating, gaseous chemical coating and other directions, can solve the problem that the surface technology can not meet the needs and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

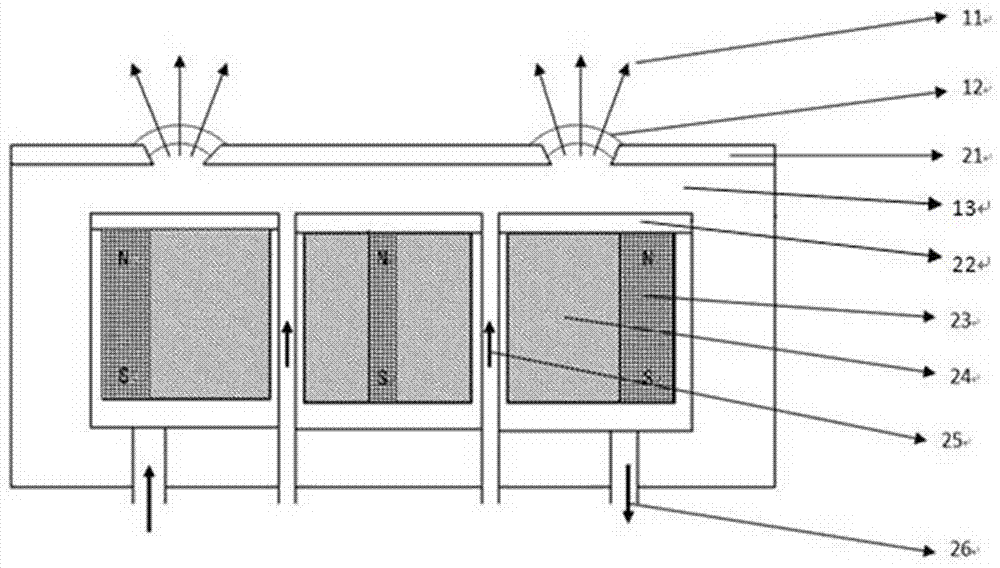

[0018] Taking the process of coating hydrogen-containing DLC on YT15 cemented carbide tools as an example, the specific implementation and effect of a composite surface technology of plasma chemical vapor deposition and intermediate frequency twin target magnetron sputtering are illustrated.

[0019] YT15 means tungsten-cobalt-titanium cemented carbide containing 15% TiC, and the others are WC and Co.

[0020] The process flow is: pretreatment of workpiece → preparation before coating → vacuuming → heating and bombardment cleaning → preparation of intermediate transition layer → coating of DLC film → cooling and removal of workpiece.

[0021] The pretreatment of the workpiece includes the following four processes: (1) Ultrasonic cleaning, that is, degreasing and cleaning with ultrasonic waves in the prepared metal cleaning solution; (2) Pickling, to neutralize the residual lye during ultrasonic cleaning and play a role The role of activation treatment; (3) rinsing, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com