Patents

Literature

315results about How to "Increase bite force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

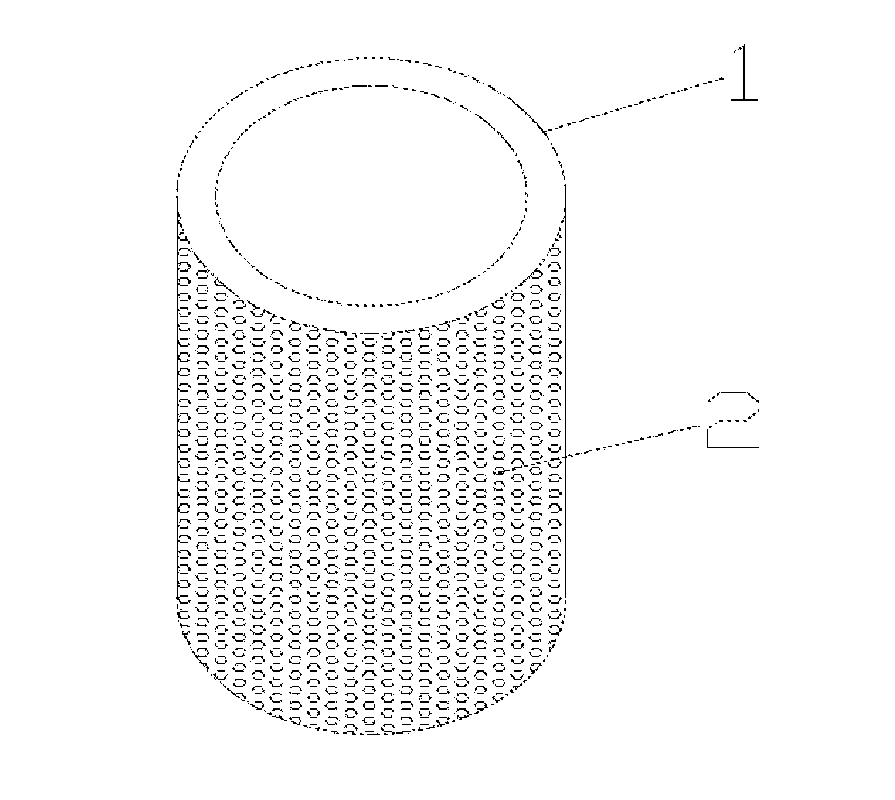

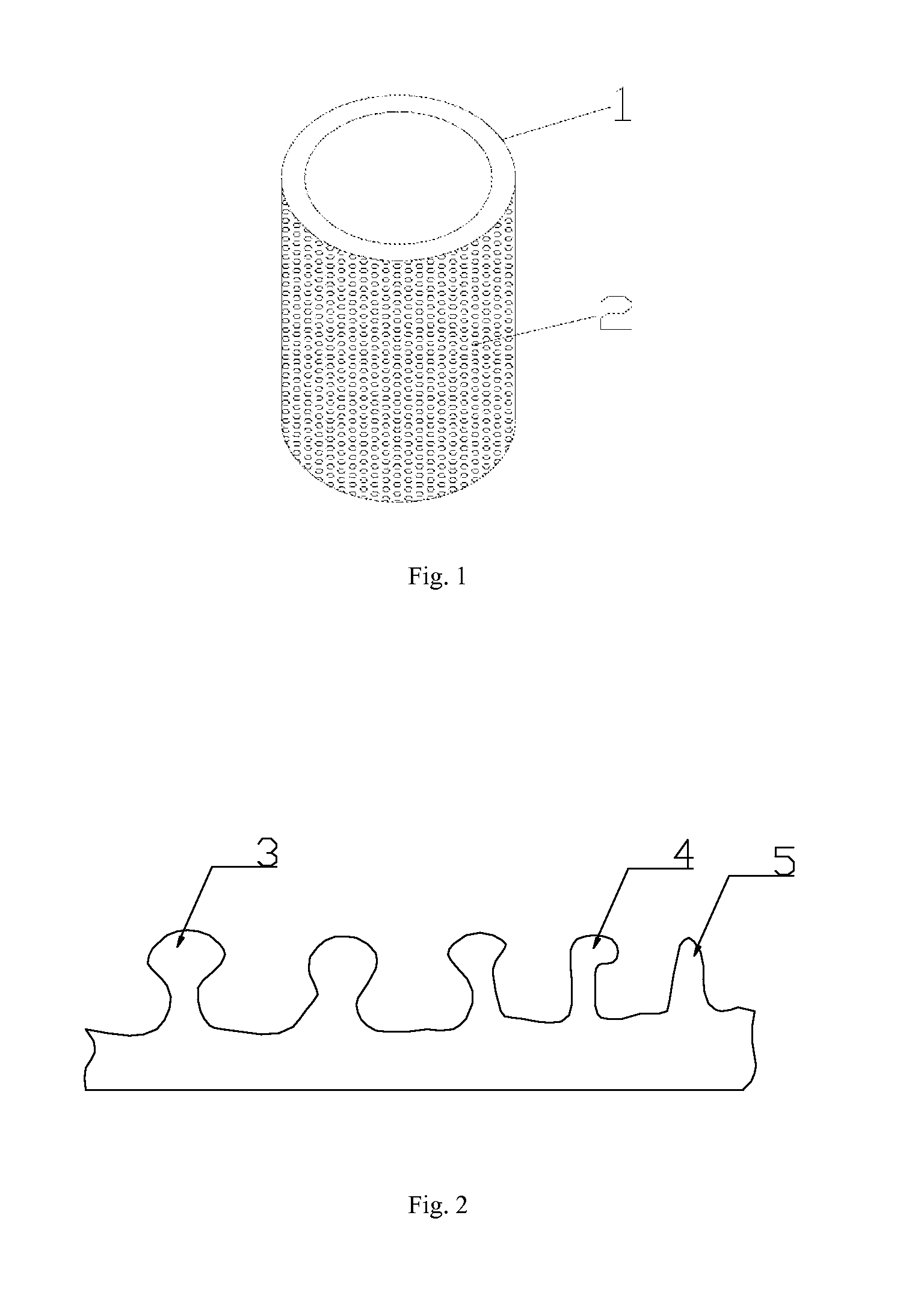

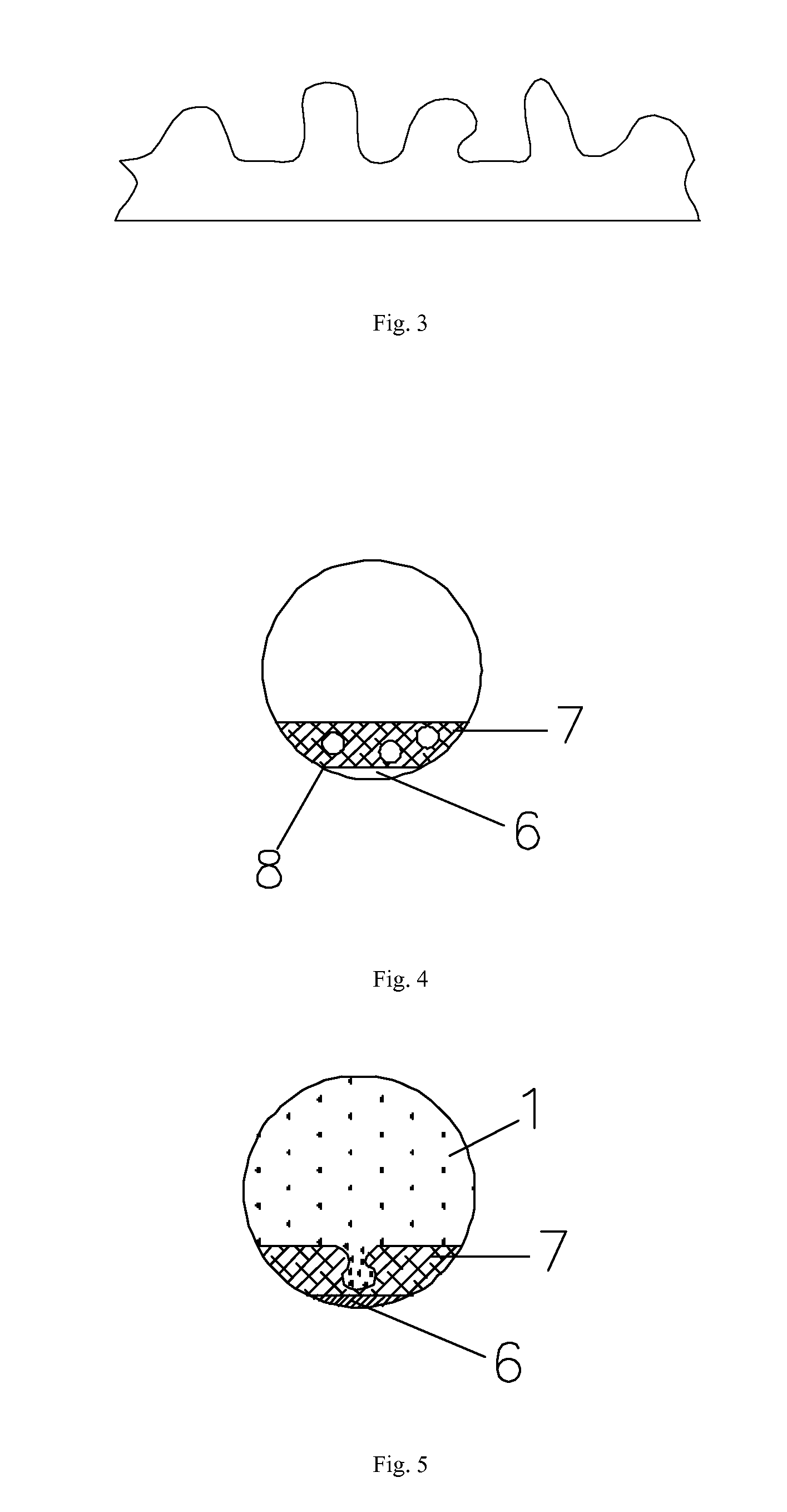

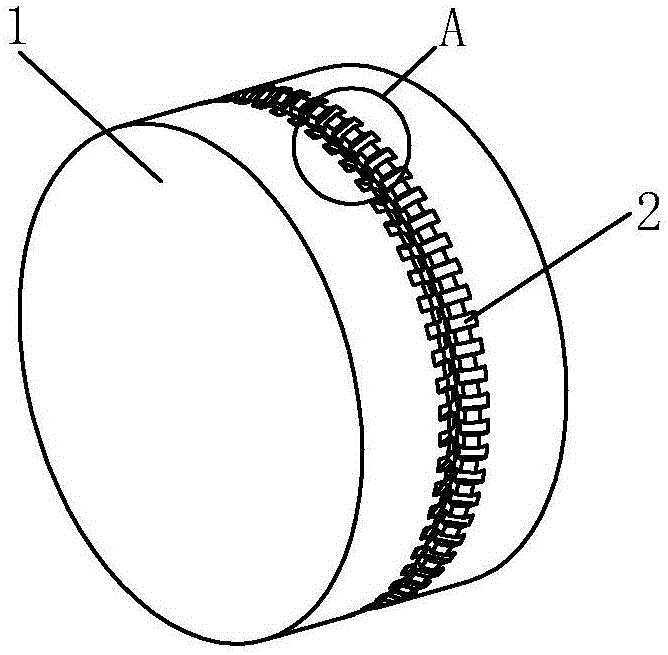

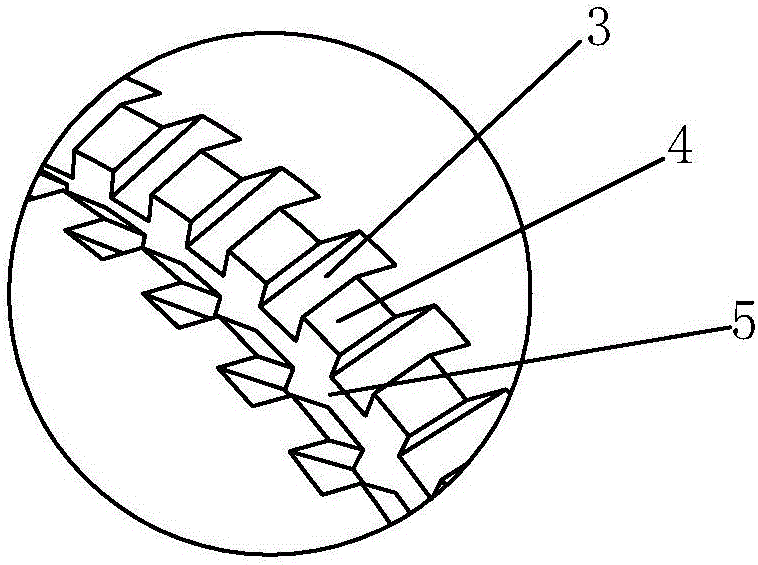

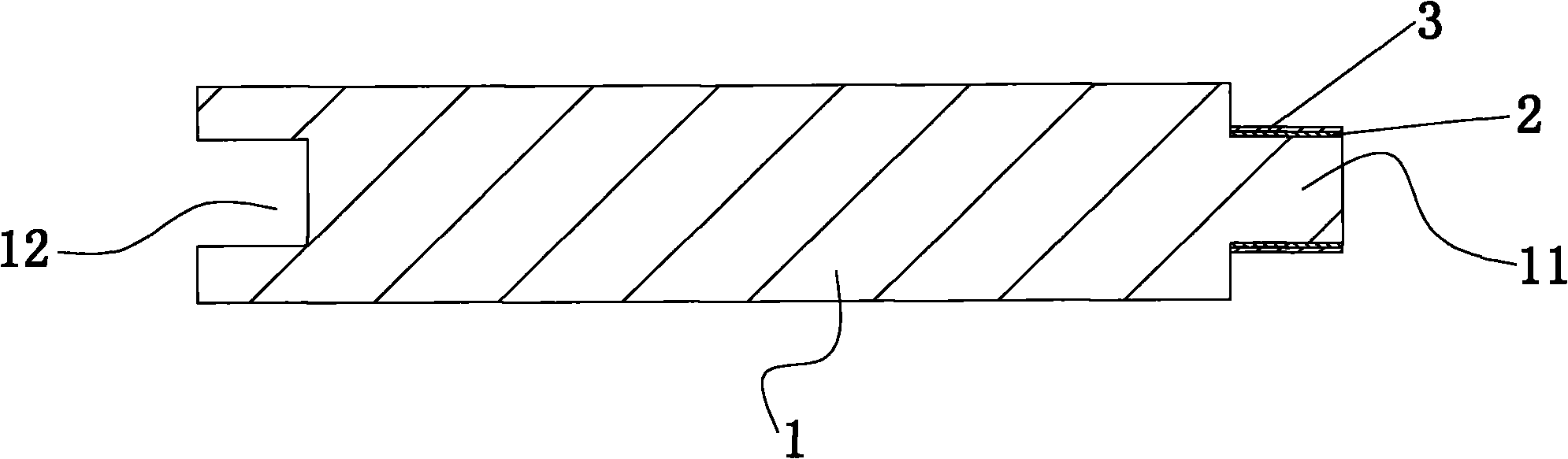

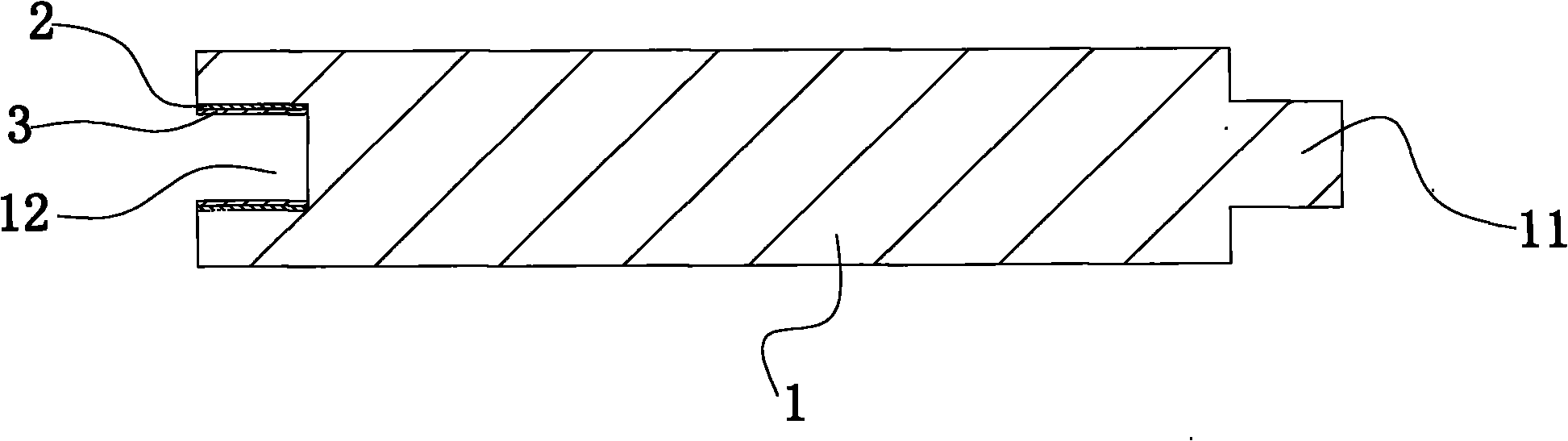

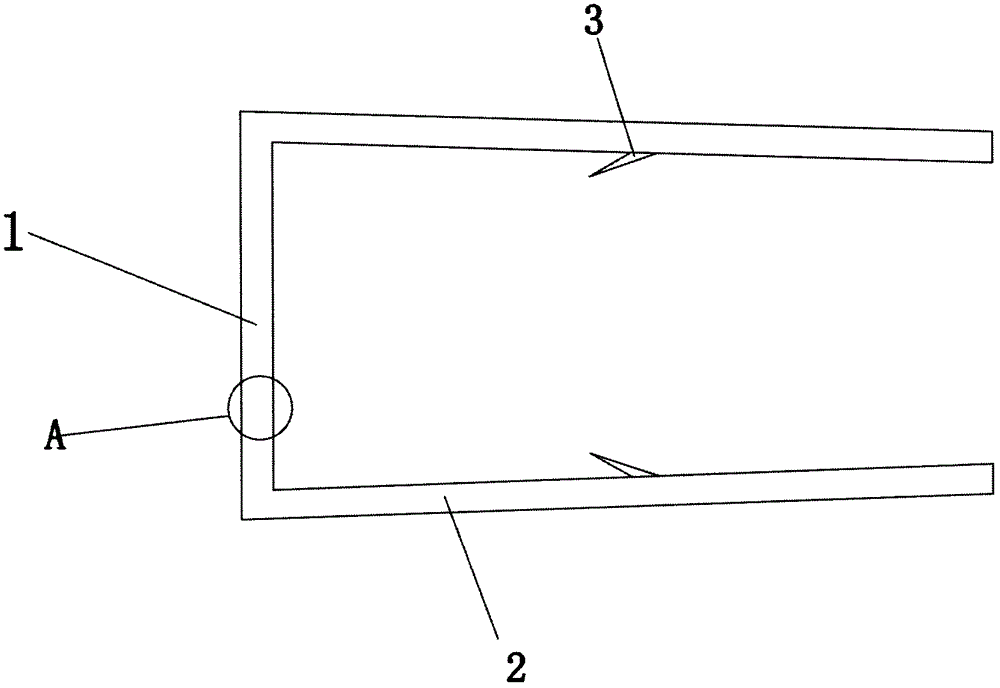

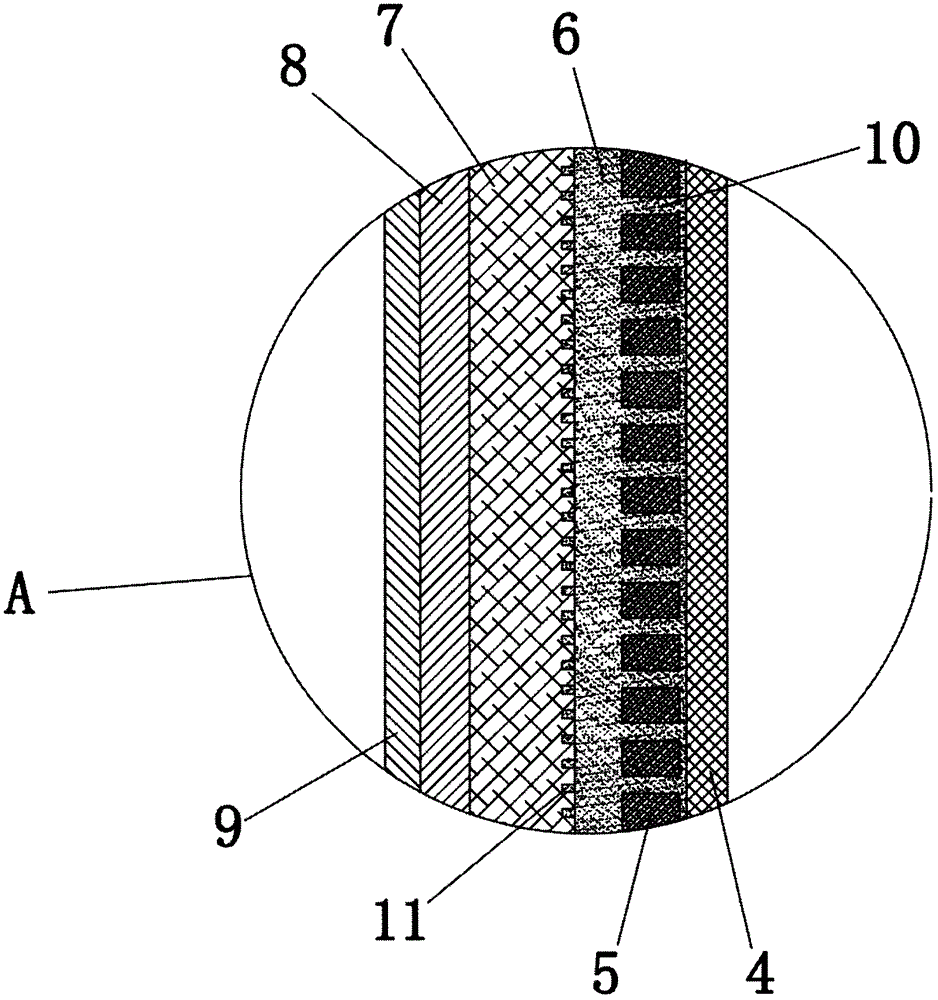

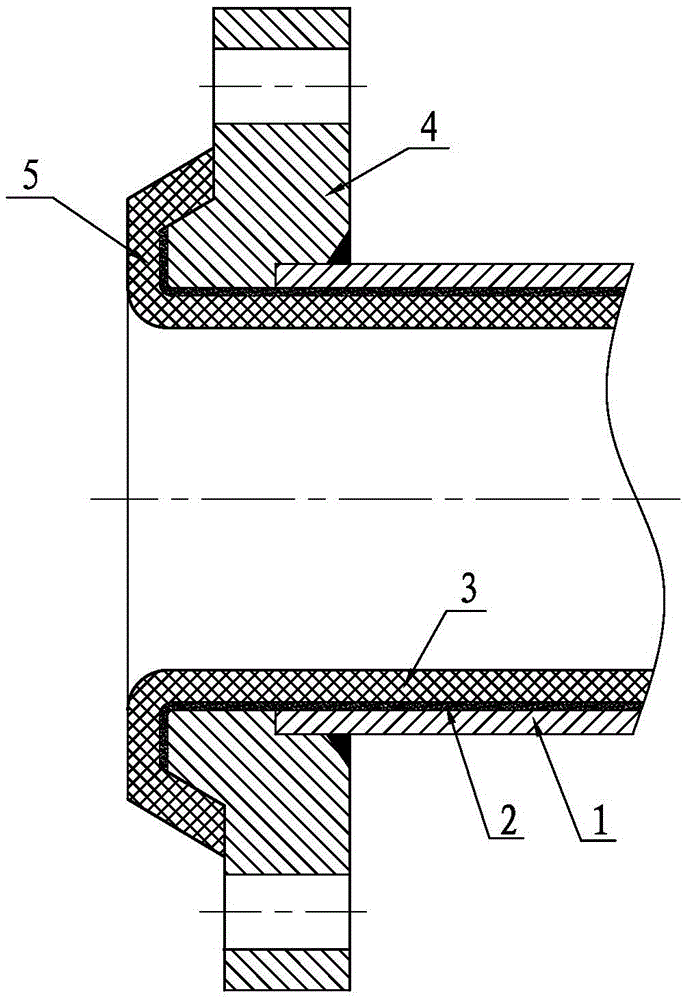

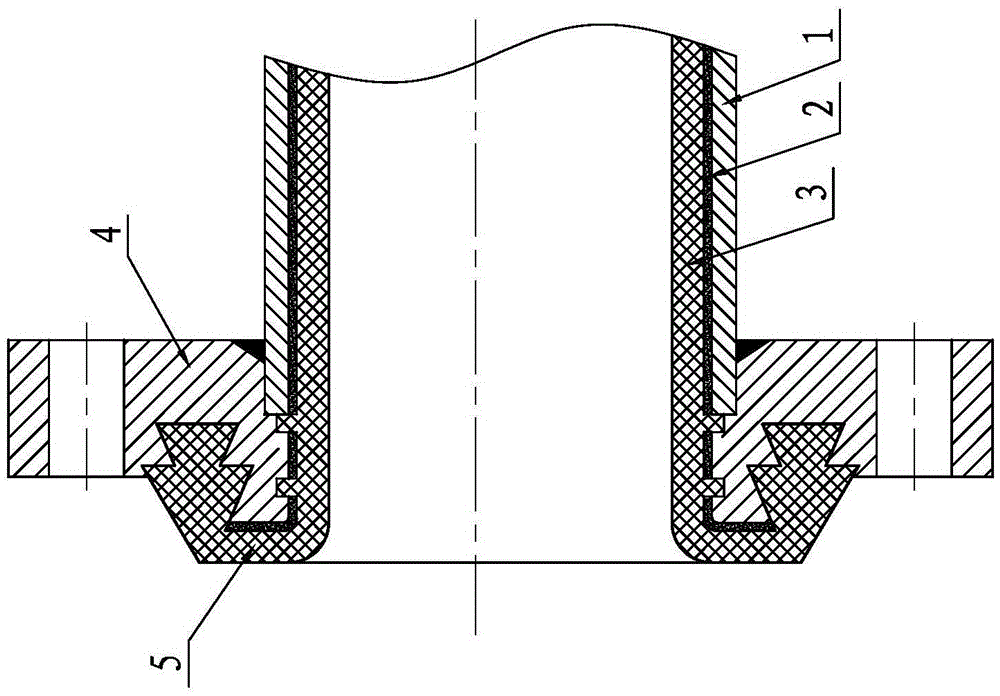

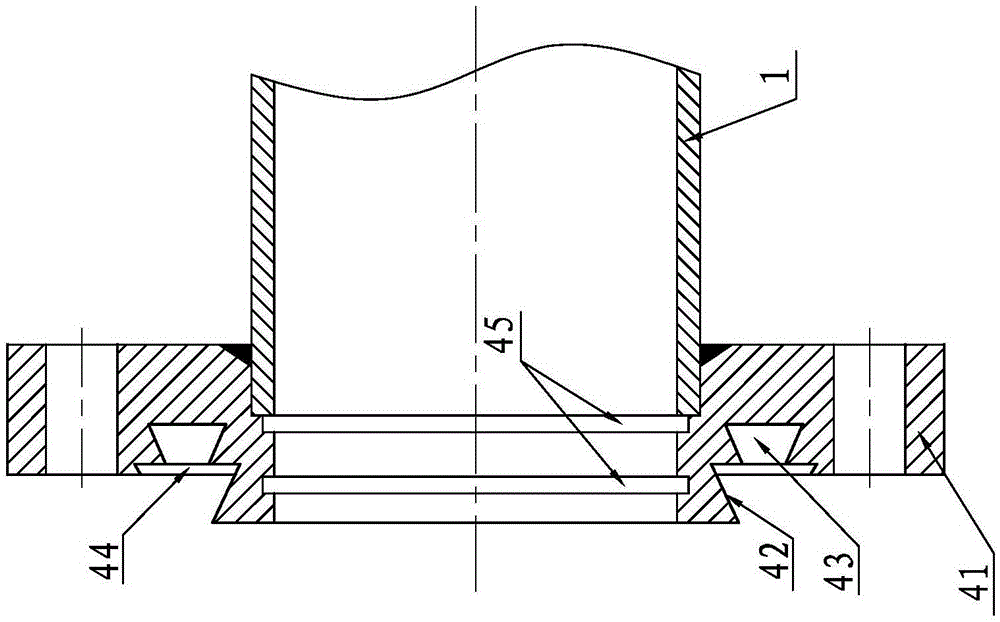

Cylinder liner and preparation method thereof

ActiveUS20150122118A1Improve radial load capacityIncrease bite forceMolten spray coatingCylinder headsCylinder blockMechanical engineering

A cylinder liner with a plurality of protrusions on its outside surface and the manufacturing method thereof are disclosed. The protrusions are Ω-shaped, P-shaped or taper-shaped, and the Ω-shaped, P-shaped and taper-shaped protrusions are accounted for 50-99.5%, 0.5-30% and 0-20% of the total number of protrusions, respectively. The density of the protrusions on the outside surface of the cylinder liner is 15-65 per square centimeter. The outer surface of the protrusions of the cylinder liner is curved, and has a large contact area and a concave which can be filled by an aluminum sheath to improve the radial bearing capacity, so as to effectively improve the bite force between the cylinder liner and the outside aluminum sheath and prevent the cylinder liner from breaking away from the cylinder body.

Owner:GUANGDONG ZHAOQING POWER ACCESSORIES

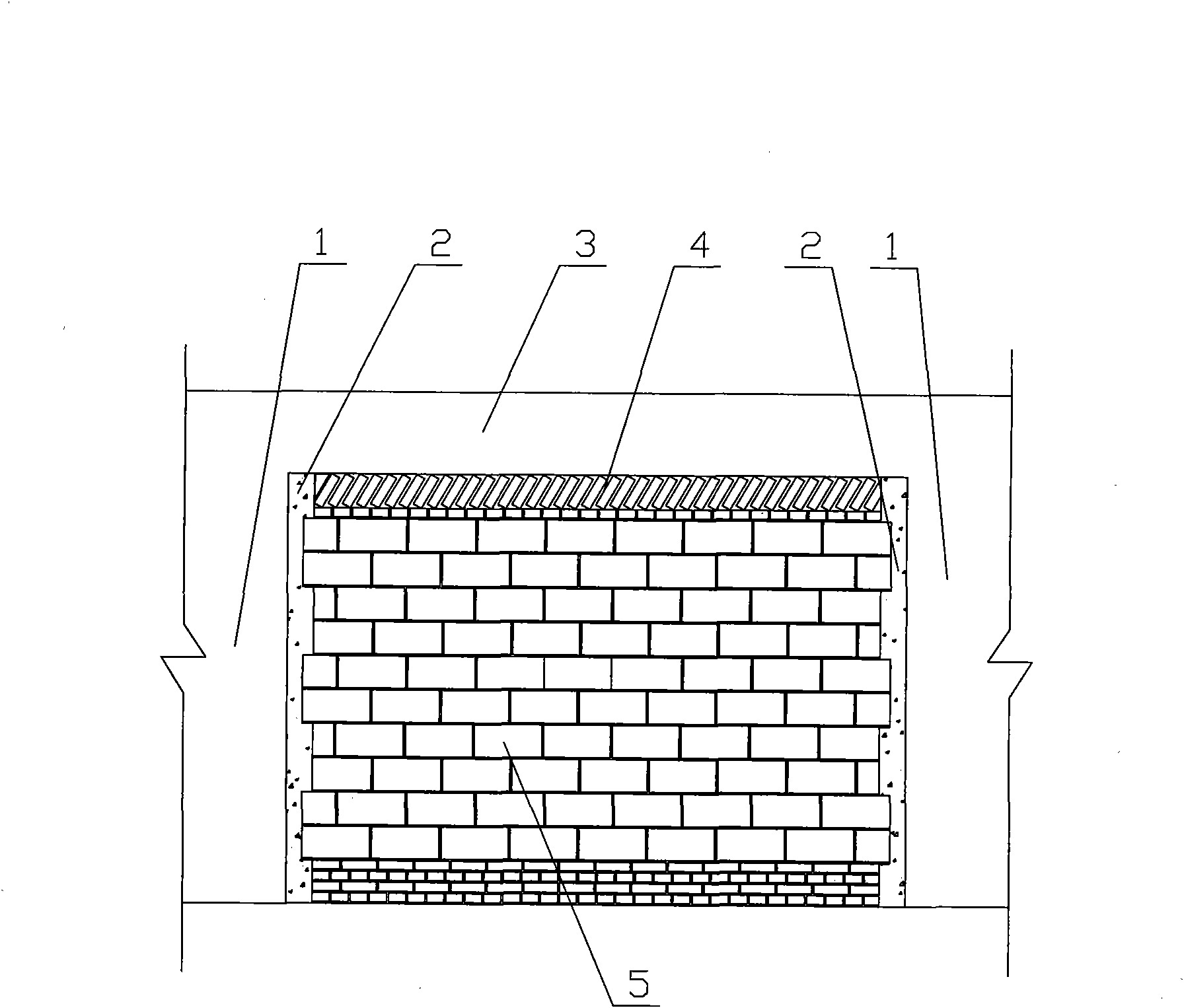

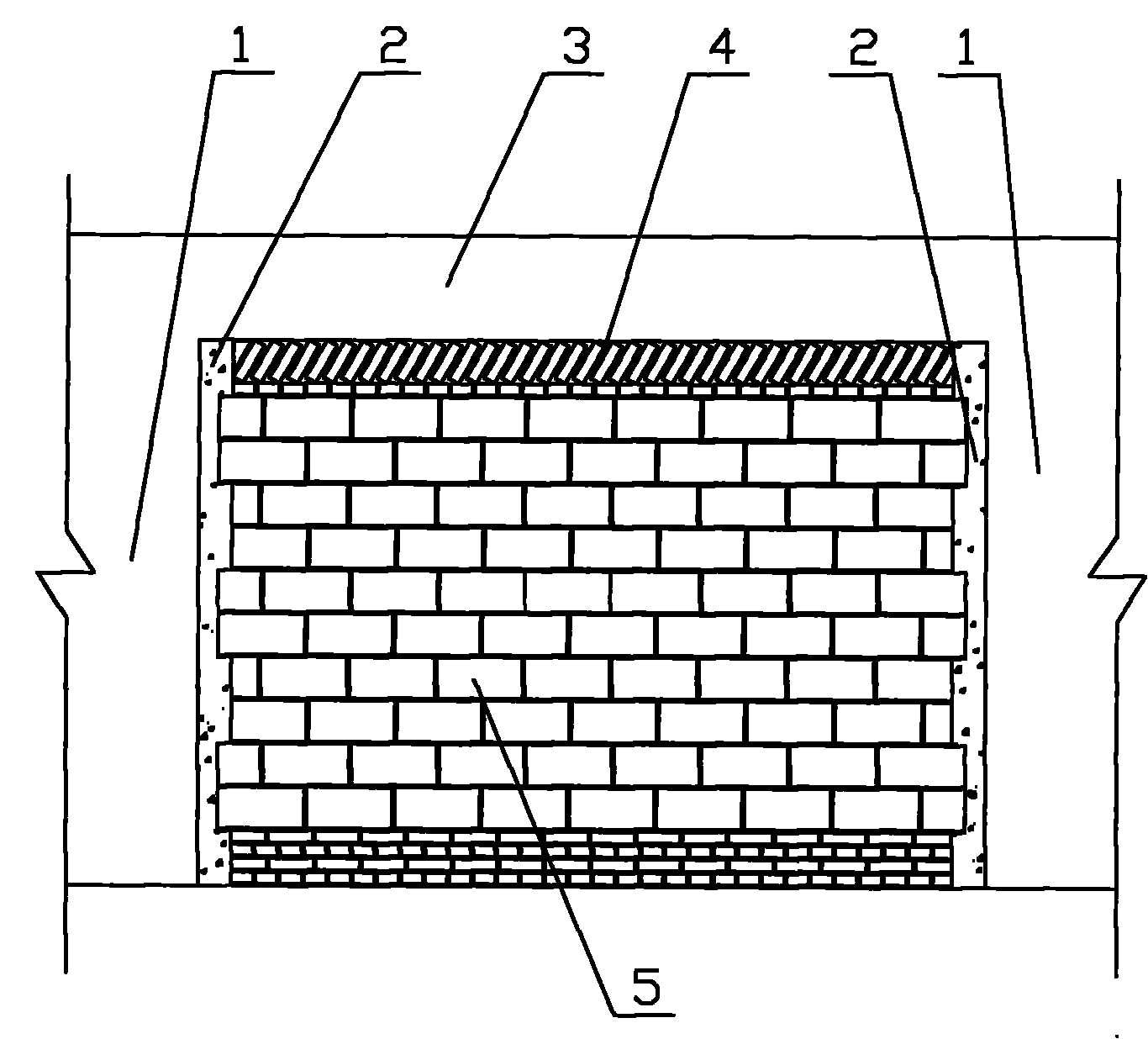

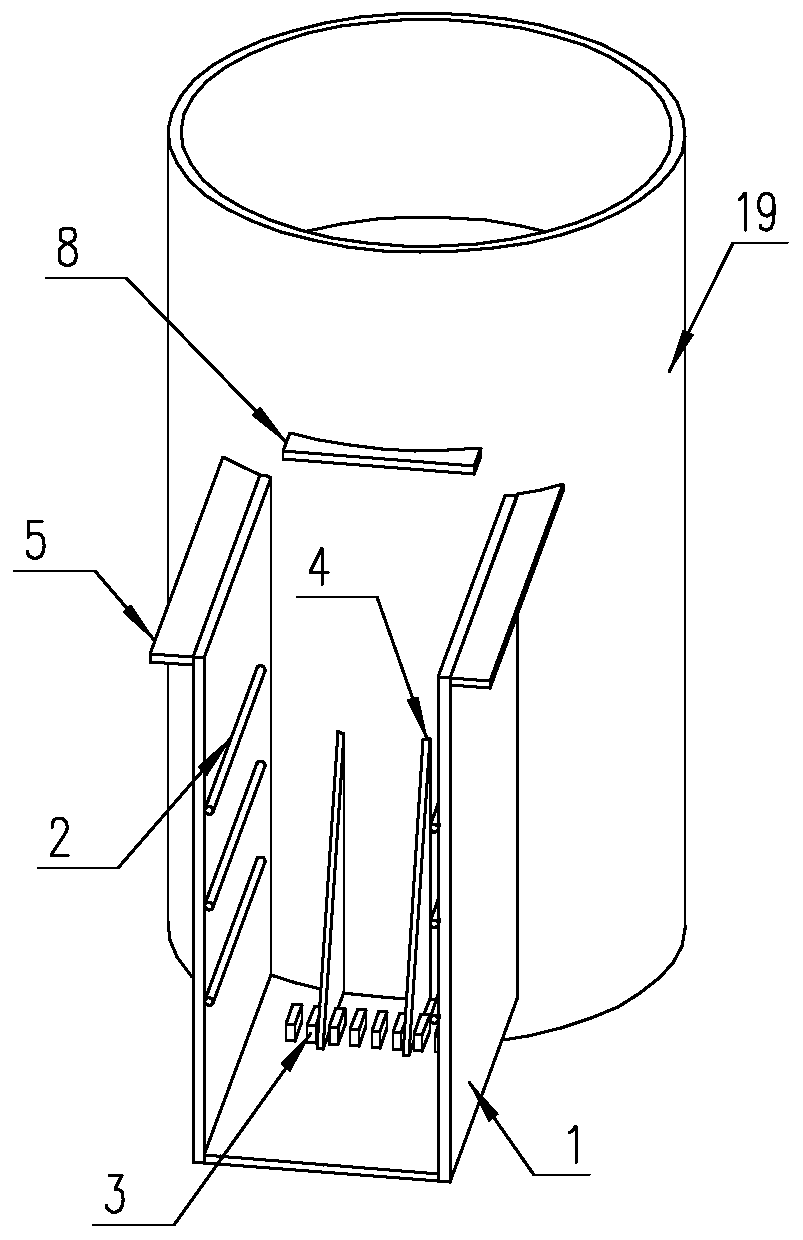

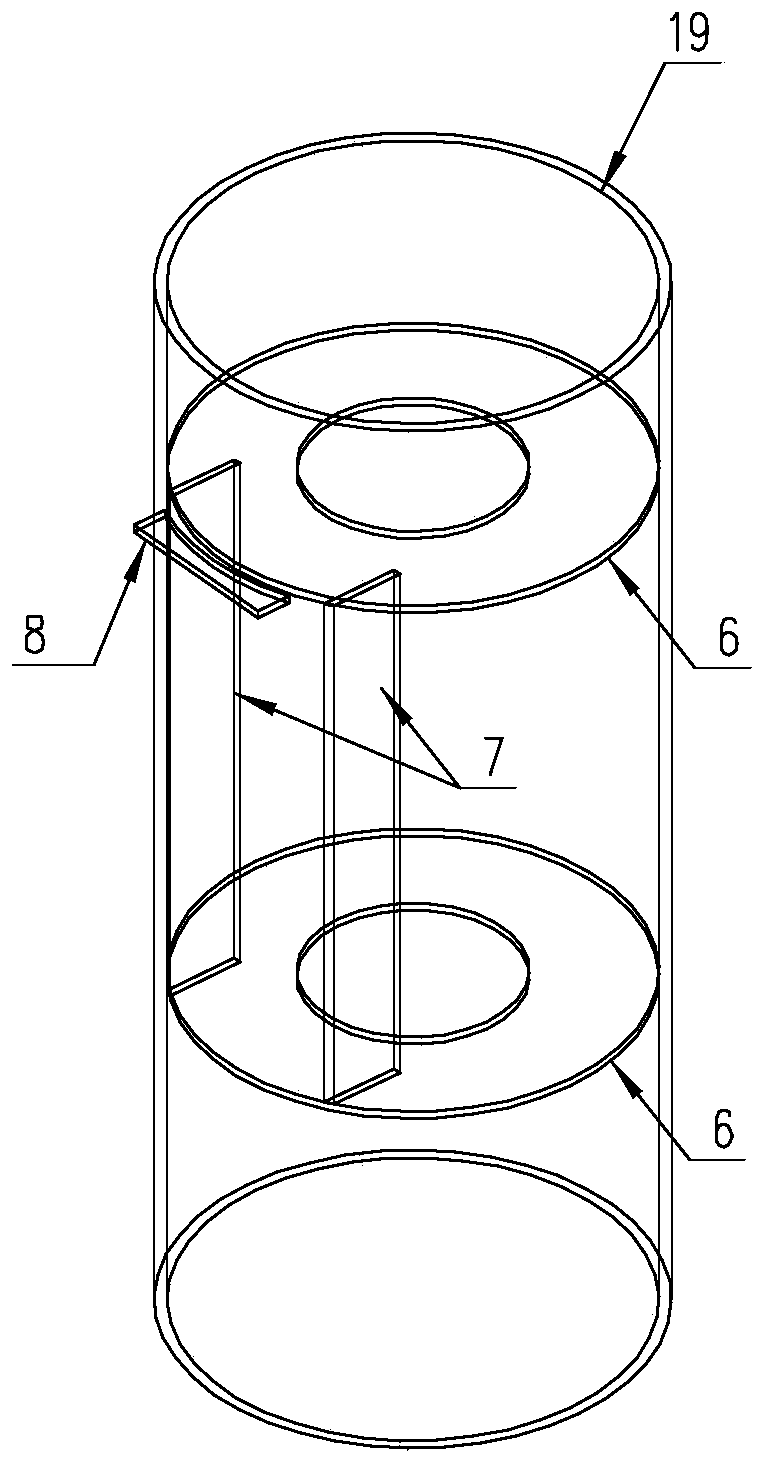

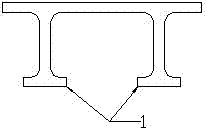

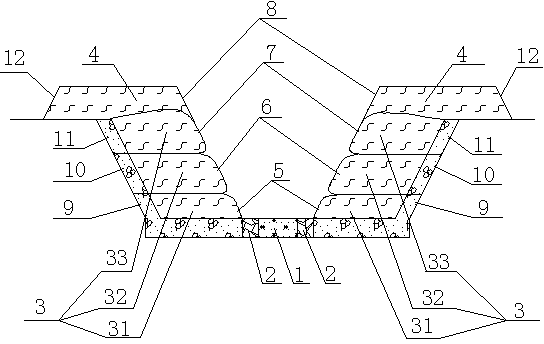

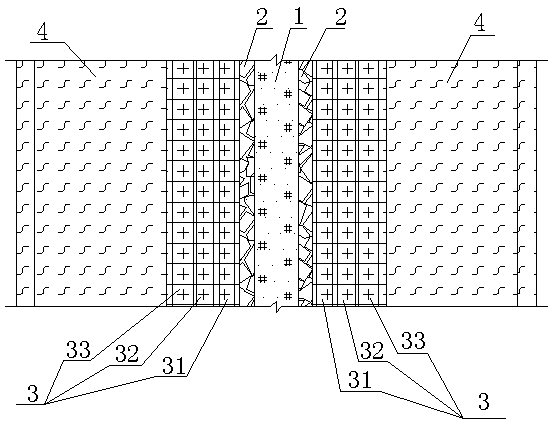

Construction method for preventing vertical cracking between main structure and filled wall

InactiveCN101858142AIncrease bite forceReduce crackingWallsBuilding material handlingEngineeringColumn space

The invention discloses a construction method for preventing vertical cracking between a main structure and a filled wall. After the construction of the main structure is finished, the construction of the filled wall is implemented; when the filled wall is constructed, the side surface of the filled wall in connection with the main structure is made into a zigzag structure; a tension rib in the filled wall penetrates a reserved combination column space to be connected with the main structure at the side surface; a combination column template is supported at the reserved combination column space, and plain concrete is poured and vibrated tightly to form a combination column; and the filled wall and the main structure are connected as a whole through the combination column. The plain concrete combination column is poured between the side surface of the filled wall and the main structure, and the combination column is connected with the main structure through the same material and engaged with the filled wall through the zigzag structure, therefore, the problem of cracking caused by insufficient engaging force between the main concrete structure and the filled wall and the shrinkage of the dissimilar materials of the wall is successfully solved; meanwhile, the combination column can effectively adjust the line snapping size and reduce the loss rate of the building blocks.

Owner:ZHONGTIAN CONSTR GROUP

Flexible electric conductive fabric and its producing method

InactiveCN1715473AImprove shielding effectIncrease bite forceMagnetic/electric field screeningFibre treatmentMetal alloyCotton fibre

The present invention features that the flexible electrically conductive fabric has base fabric woven with metal fiber in 35-45 % and cotton fiber in 55-65 %, surface metal or alloy coating including one priming layer and one outer layer. The present invention can shield high strength electromagnetic field effectively and has resistance of as low as 1 micro-ohm / cm, shield effect up to 90-120 dB on electromagnetic wave in the frequency range of 0.15 MHz to 20 GHz and magnetic field shielding effect up to 40-50 dB. The present invention has the advantages of being light, ventilating, transparent, non-toxic, fireproof, etc. and is especially suitable for use in fields needing shield on strong electromagnetic wave.

Owner:上海利昂高科技有限公司

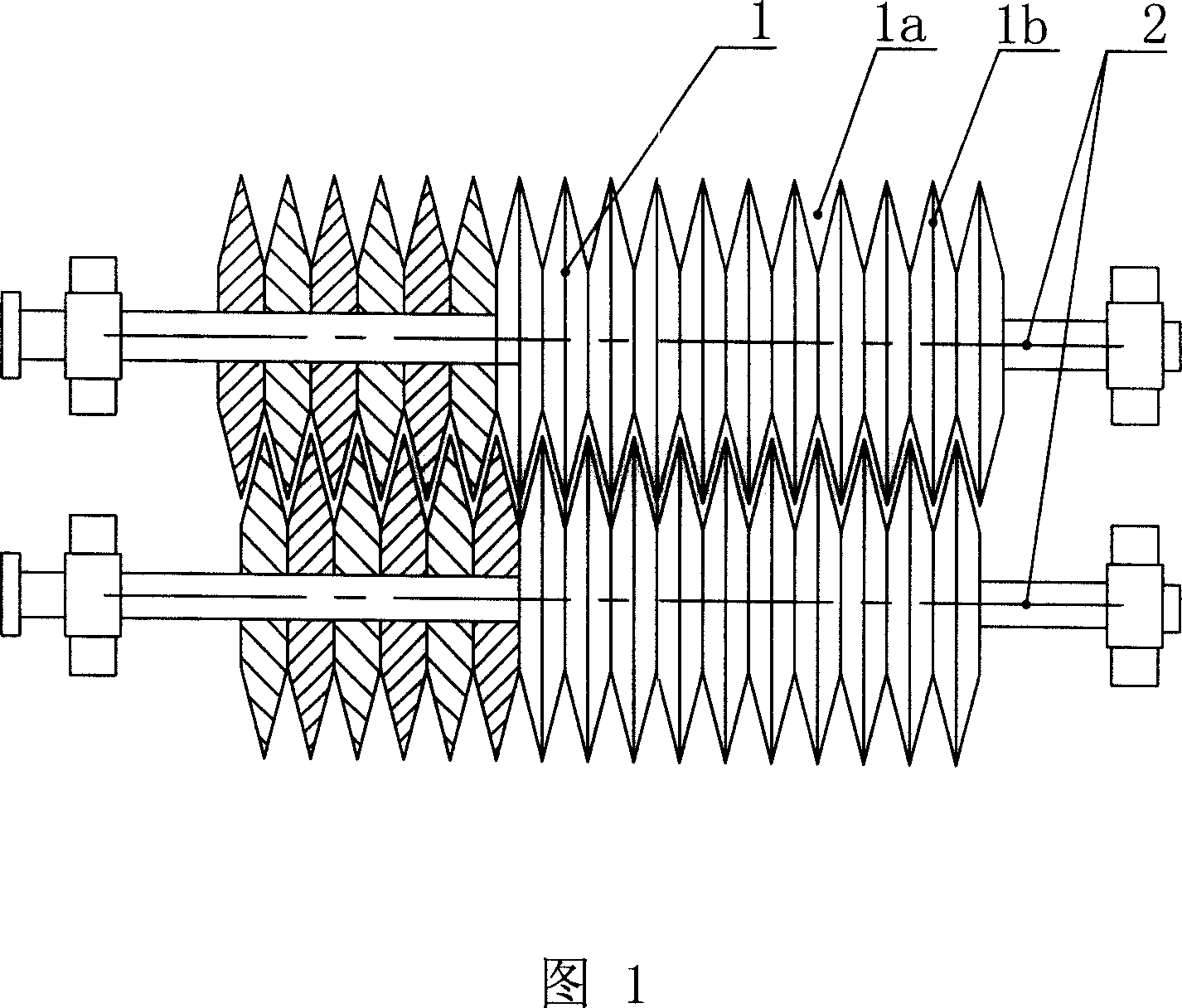

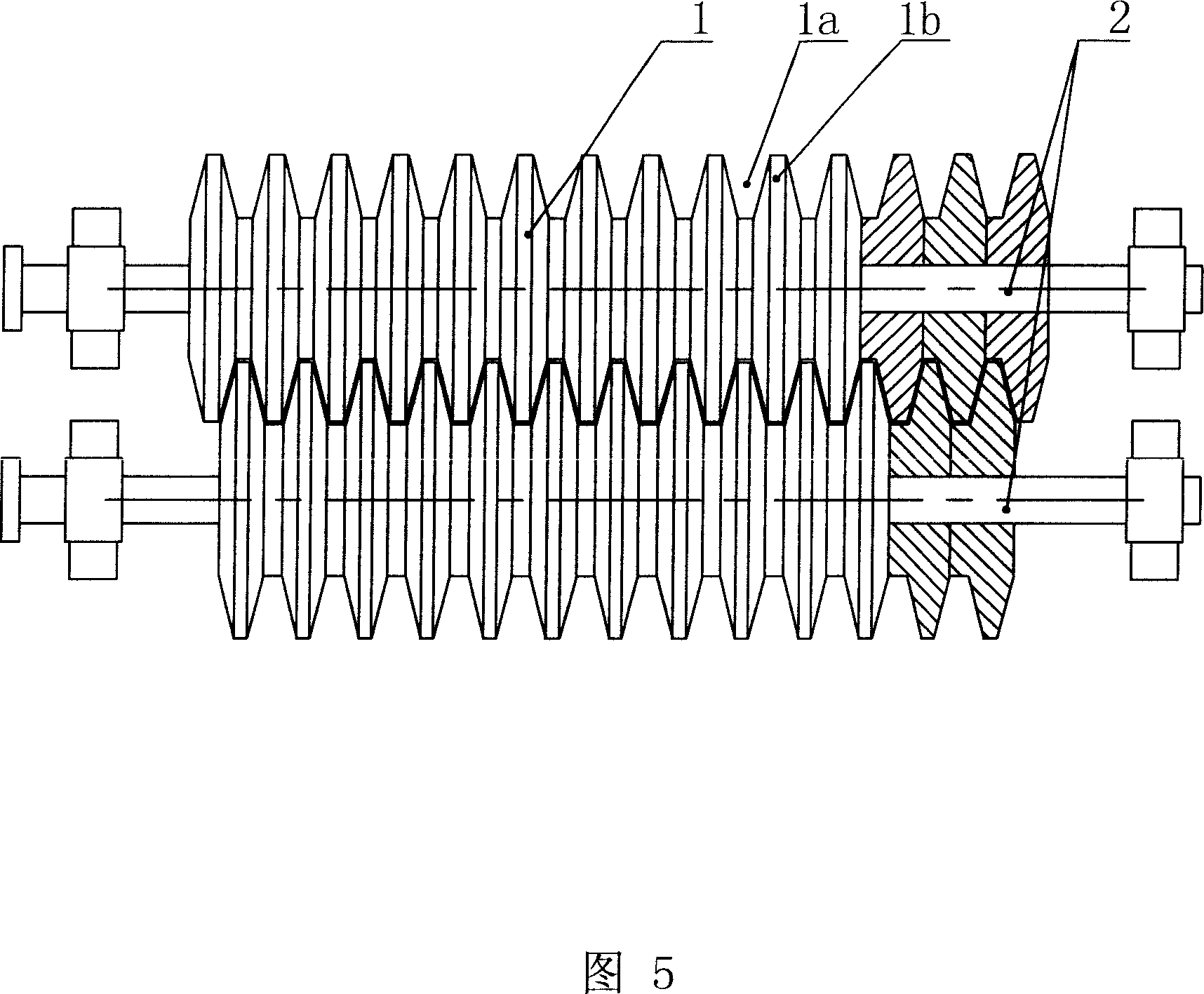

Roller type crushing device

InactiveCN101011673AIncrease contact areaReduce energy consumptionGrain treatmentsEngineeringEnergy consumption

The rolling crusher comprises at least a set of main shaft, each comprising at least two main shafts in parallel position, crushing roll on the main shaft with several convexes and concaves in wave like distribution, with the adjacent convex and concave of two crushing roller matching with each other with gaps between them. The crushed material goes through the gap between the crushing rollers with pressing and tearing. It has low noise, high output, low energy consumption, feasible for the crushing of food and forage.

Owner:JIANGSU MUYANG GRP CO LTD

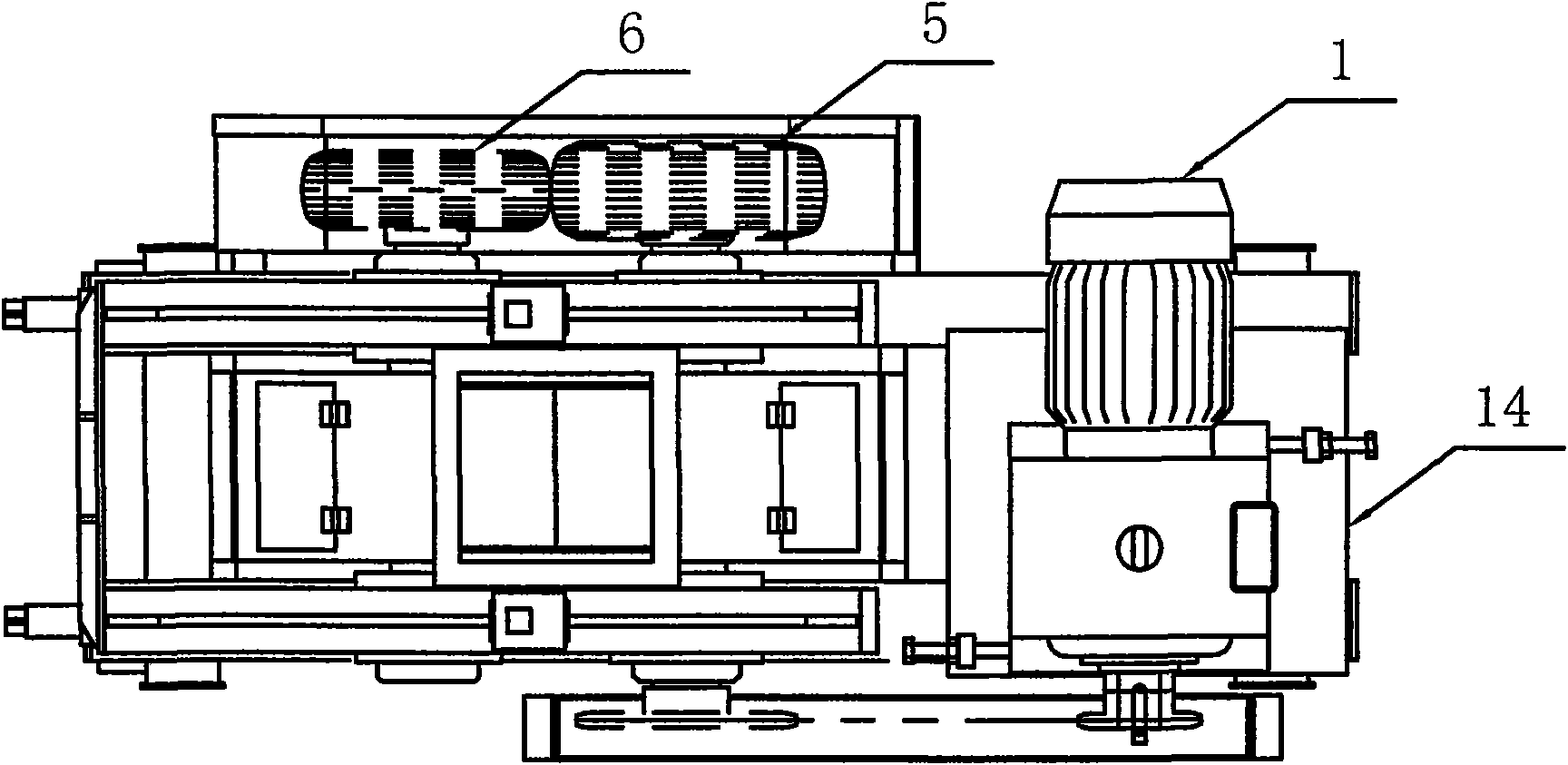

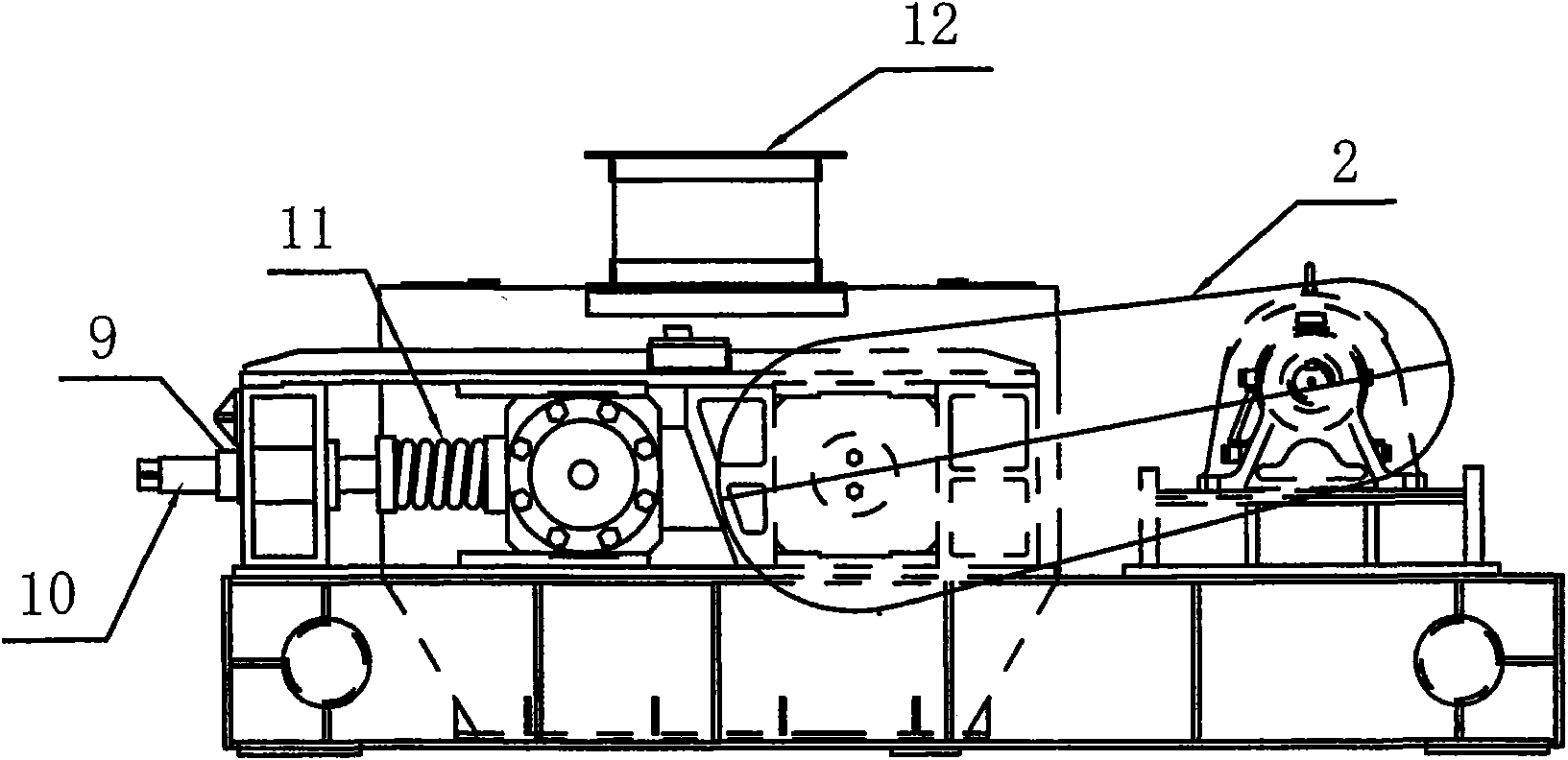

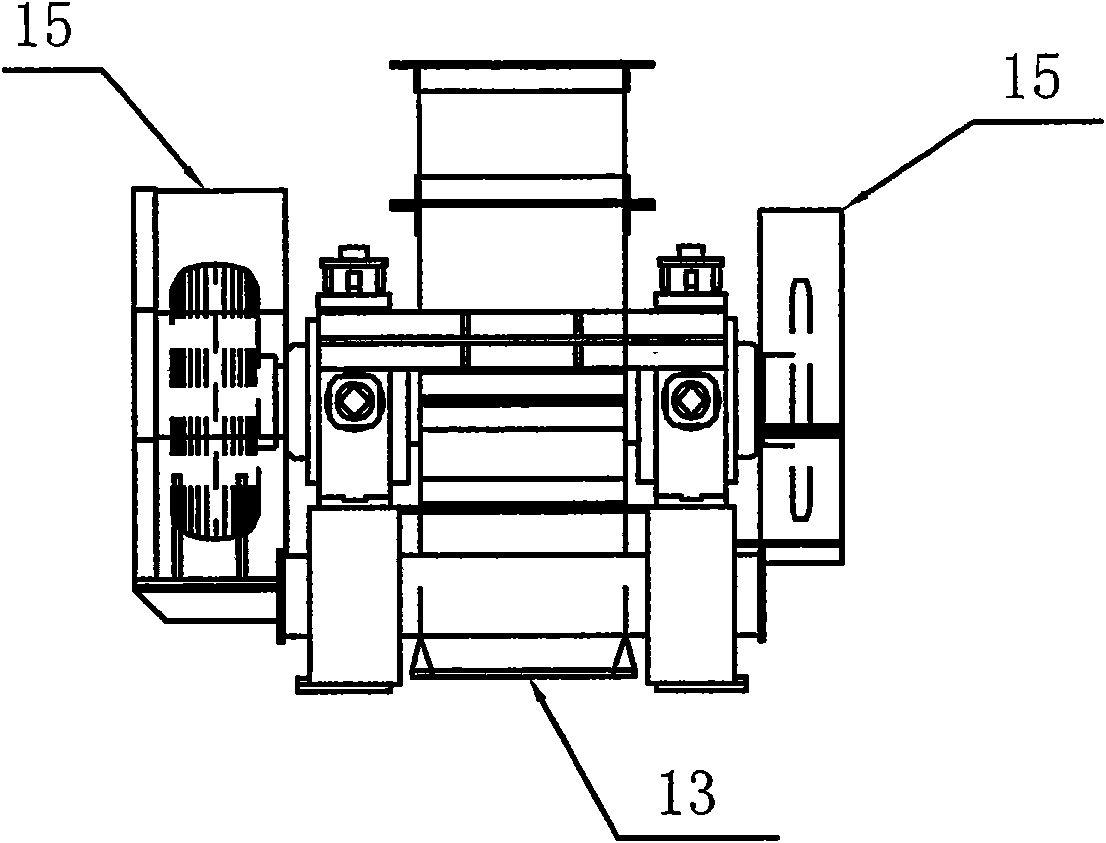

Double roller crusher

InactiveCN101992138AReduce vibration and shockIncrease driving force and crushing forcePreparing sample for investigationGrain treatmentsCrusherLow noise

The invention relates to a crusher which comprises a drive device, a driving shaft, a driven shaft, a transmission mechanism, rollers, a feed inlet, a feed outlet and a bracket, wherein the transmission mechanism comprises a driving tire and a driven tire; one end of the driving shaft is connected with the drive device, and the other end of the driving shaft is connected with the driving tire; the driven shaft is connected with the driven tire; the driving tire and the driven tire are mutually matched tightly; the rollers are respectively sleeved on the driving shaft and the driven shaft tightly; and straight teeth are fixed on the rollers. When the two rollers move relative to each other, materials entering the crusher are extruded, so that material particles are smaller, and the material particles smoothly enter an equipment body. The crusher has the advantages of large and adjustable transmission force, little damage to the equipment, smooth and safe operation, low noise, easy cleaning and no material residues.

Owner:霍春生

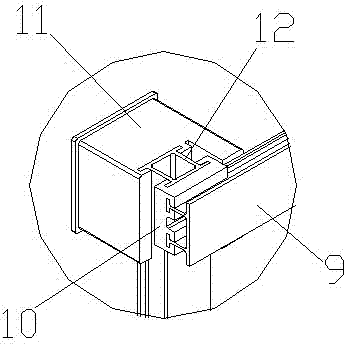

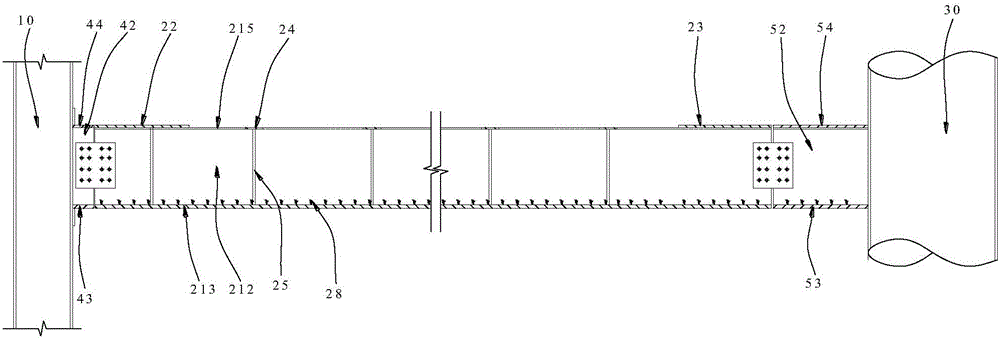

Steel pipe concrete column-precast concrete superposed beam assembly type building connection node

The invention discloses a steel pipe concrete column-precast concrete superposed beam assembly type building connection node. The steel pipe concrete column-precast concrete superposed beam assembly type building connection node comprises a steel pipe concrete column and a precast concrete superposed beam, wherein the outer wall of the steel pipe concrete column is provided with a U-shaped steel tank and a prewelded outer ring steel plate in a welded manner, the prewelded outer ring steel plate is horizontally arranged and located above the U-shaped steel tank, the U-shaped steel tank is provided with a bottom plate and side plates, the bottom plate is provided with bottom steel bar clamping buckle devices, and the tops of the side plates are provided with upper flanges being folded outwards; and the precast concrete superposed beam is installed inside the U-shaped steel tank in an inserted manner, the bottom of the precast concrete superposed beam is connected with the bottom steel bar clamping buckle devices in a clamped manner, the top of the precast concrete superposed beam is welded to the prewelded outer ring steel plate, a mutual plug-in mounting area of the precast concretesuperposed beam and the U-shaped steel tank is a superposed area, and concrete is poured into the superposed area after lap joint and assembly of the precast concrete superposed beam. The steel pipeconcrete column-precast concrete superposed beam assembly type building connection node is convenient and fast to install without bolts and mold supporting, and the production and construction efficiency can be effectively improved.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

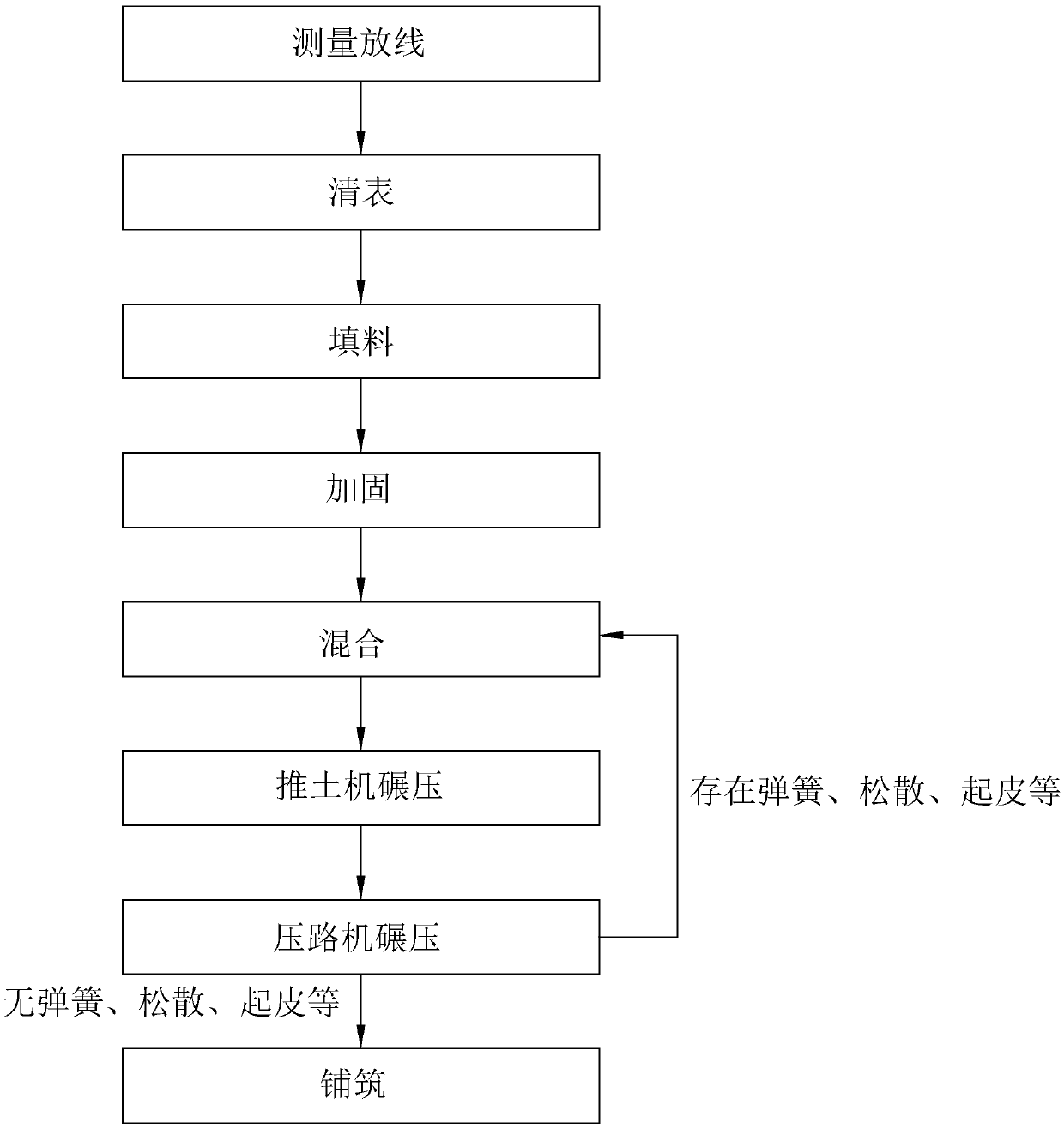

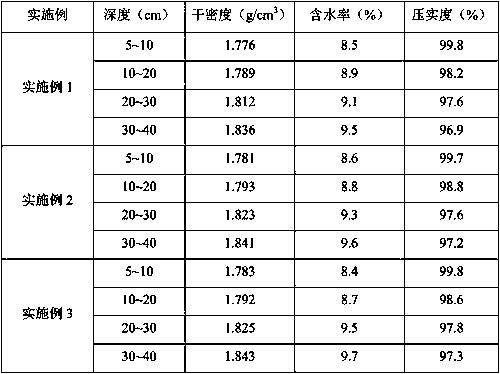

Method for constructing roadbed

InactiveCN109629361AImprove reinforcementImprove corrosion resistanceRoadwaysEngineeringRoad construction

The invention discloses a method for constructing a roadbed through sand filling, and belongs to the field of traffic construction. In the technical scheme, the method is characterized by including the steps of surveying and setting out, surface clearing, filling, reinforcing, mixing, rolling compaction of a bulldozer, rolling compaction of a road roller and paving. The method solves the technicalproblem that in the prior art, the roadbed is prone to losing stability and deforming, and is applied to road construction to enhance the effect of roadbed stability.

Owner:鼎固建安集团有限公司

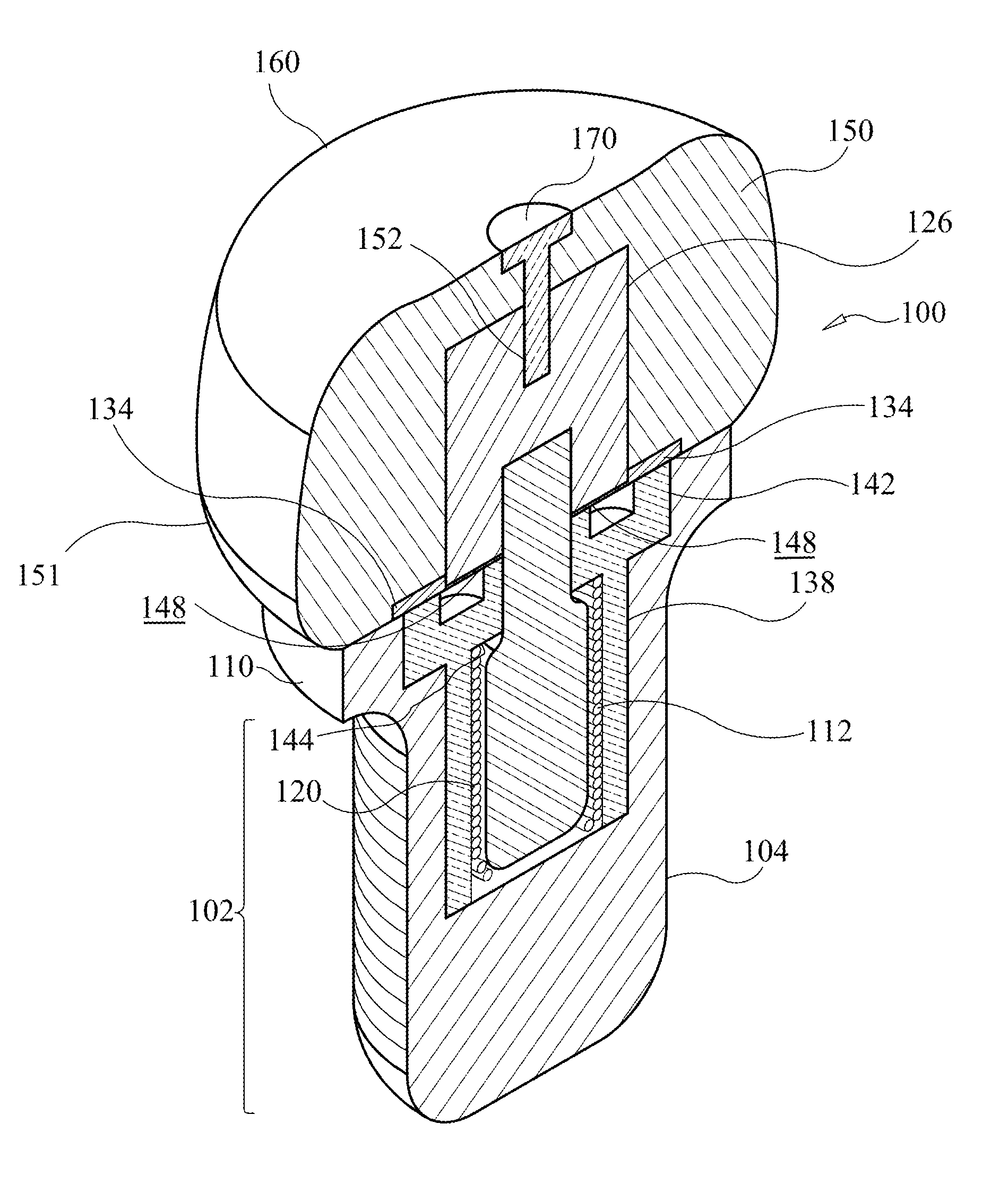

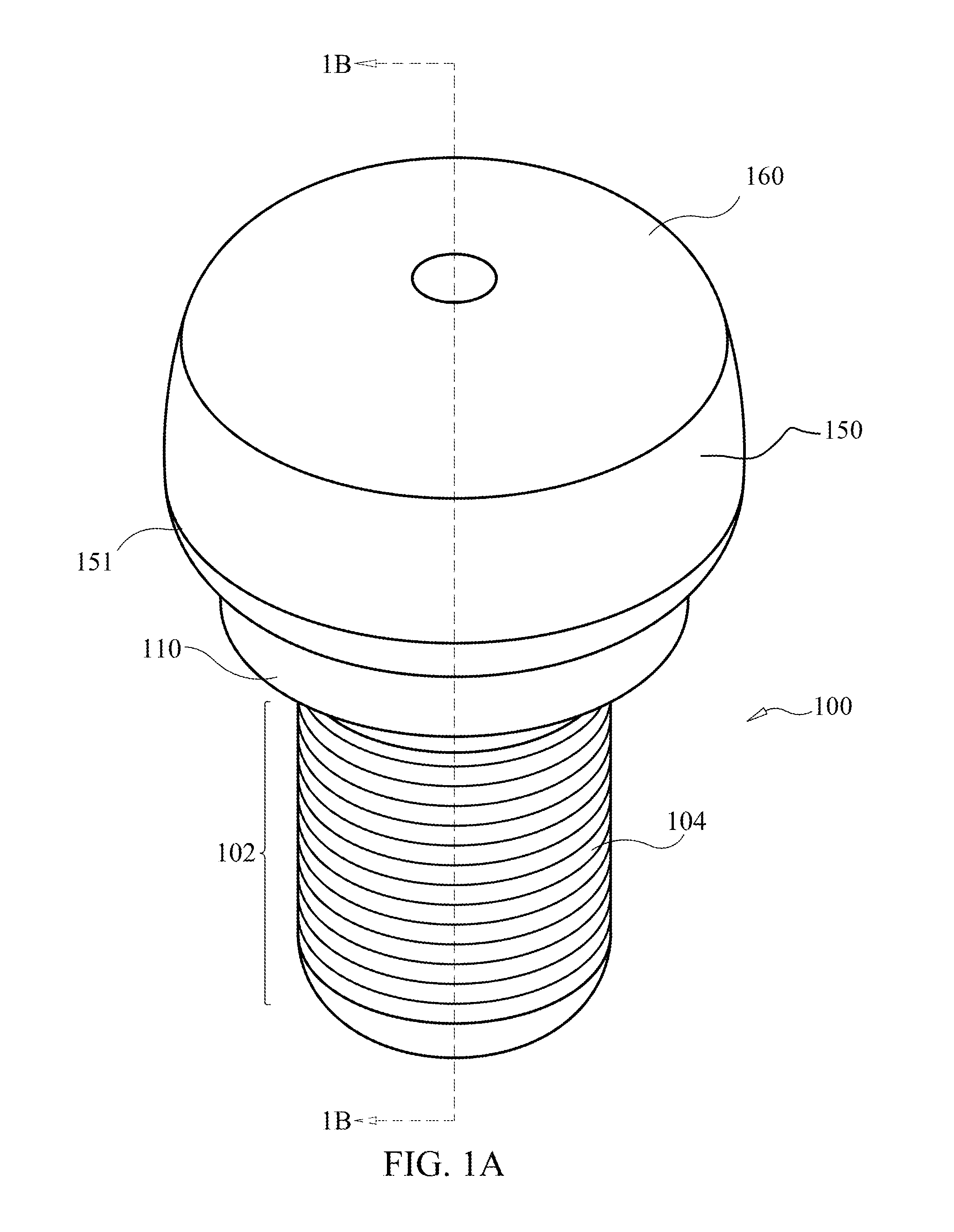

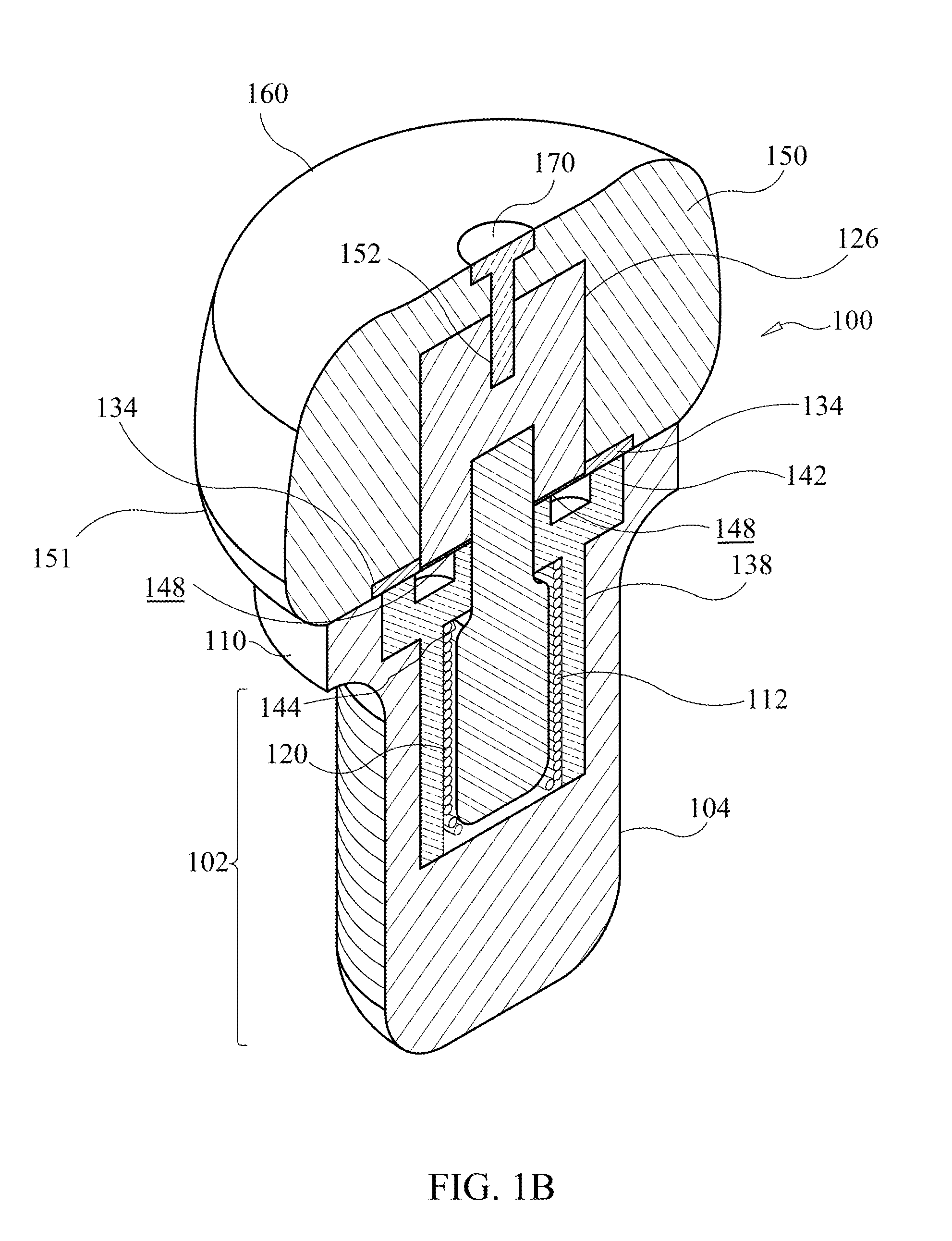

Dental Implant Assembly for Uniform Distribution Of Occlusal Forces

ActiveUS20160302893A1Reduce deleterious forceMaintain microvascularity and viable structural supportDental implantsDental alveolusMicro motion

A dental implant abutment assembly imitates a micro-motion mechanism to direct occlusal forces internally, and uniformly distribute the occlusal forces into the body of an ossoeintegrated dental implant. The micro-motion mechanism is configured to imitate the biomechanical behavior of the periodontal ligament through a compressive action that dampens vertical, horizontal, and angular forces. A compressive ring provides a dampening effect to supportive components of the assembly. A compressive coil redirects vertical forces along a longitudinal axis of the assembly. An implant body osseointegrates into the dental alveolus. A central mobile element seats in the dental body. The compressive coil extends along the central mobile element to absorb vertical forces. The compressive ring seats on the collar of the dental implant. A threaded cannulated housing securely holds the central mobile element and the compressive coil to form a single unit. A restorative abutment portion threadably seats on the central mobile element.

Owner:VUKAS STEVEN

Preparation method for cast iron cylinder liner based on inner surface coating

ActiveCN107619990AImprove yieldImprove wear resistanceCylinder headsFoundry mouldsHydrogenSand blasting

The invention discloses a preparation method for a cast iron cylinder liner based on an inner surface coating. The coating is formed by coating the inner wall of a mold with a paint with an optimizedformula, a casting is cast through a centrifugal casting mode and then subjected to ultrasonic treatment through a hydrogen ethanol solution, then the inner wall of the casting is subjected to roughening through a high-speed sand blasting mode, and finally a co-diffusion coating is formed through co-diffusion with a co-diffusion agent. The yield of the cast iron cylinder liner is up to 96.3-97.2%,compared with traditional cylinder liners of the type on the market, the abrasion resistance of the cast iron cylinder liner is improved by 33.9-35.1%, and thus the service life of the cast iron cylinder liner can be effectively prolonged.

Owner:ZYNP GRP ANHUI CO LTD

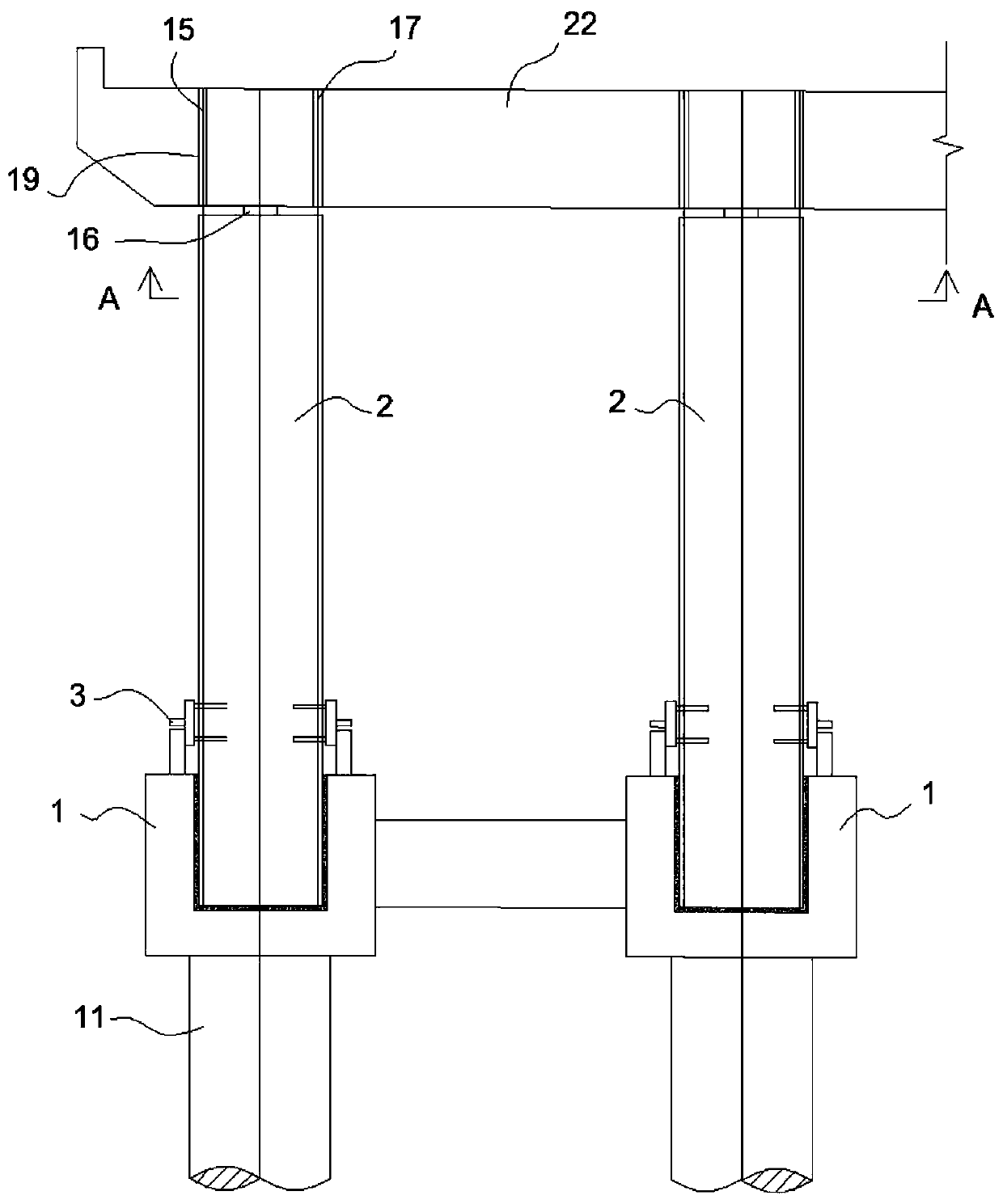

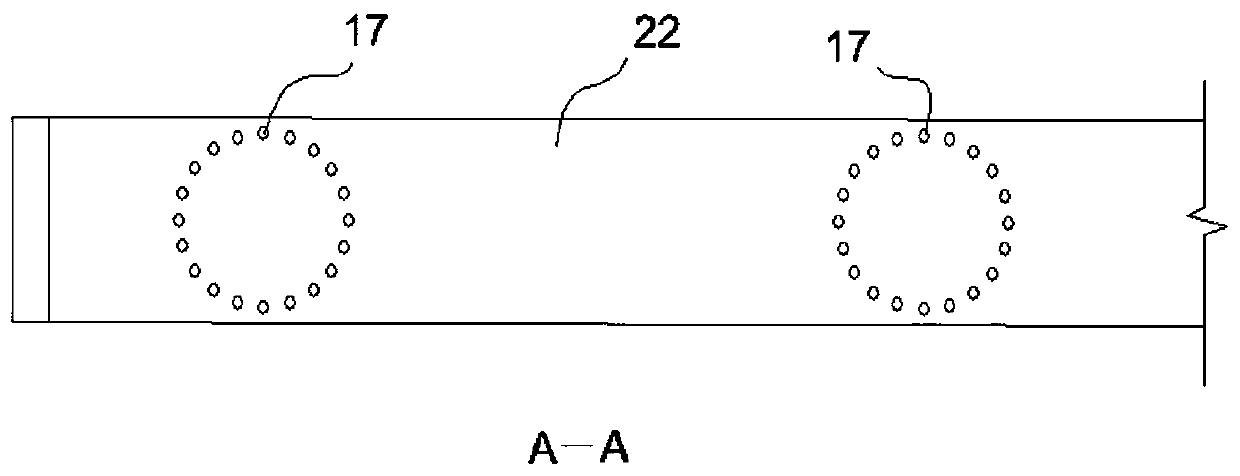

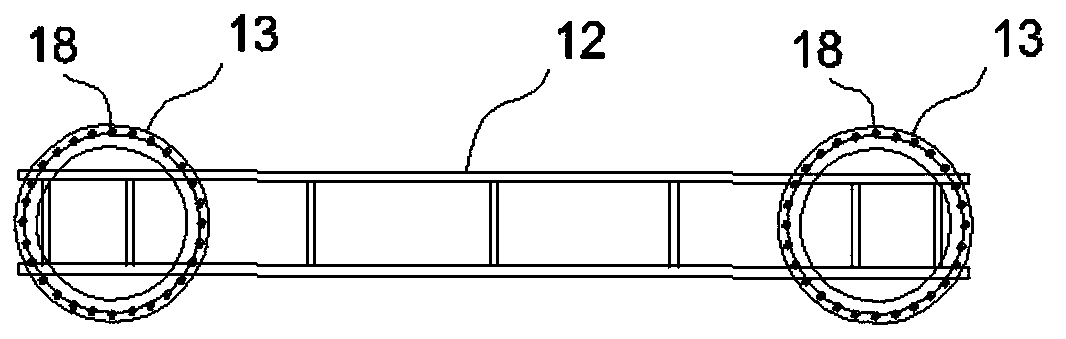

Capping beam mounting method for mutual constraint of adjacent pier columns in prefabricated bridge

ActiveCN111305082AAvoid the situation that cannot be installed in placeImprove construction efficiencyBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses a capping beam mounting method for mutual constraint of adjacent pier columns in a prefabricated bridge. The capping beam mounting method comprises steps of arranging a cappingbeam formwork according to a capping beam form, respectively and fixedly arranging limiting steel rings at two ends of a rectangular frame, and vertically arranging steel bar sleeves in the limitingsteel rings; in the installation process, hoisting a bent cap formwork at the tops of every two adjacent prefabricated pier columns, and inserting pier column embedded steel bars protruding out of tops of the two prefabricated pier columns into the steel bar sleeves at two ends of the bent cap formwork in a one-to-one correspondence mode; limiting the two adjacent prefabricated pier columns in thebent cap formwork; The method is advantaged in that construction efficiency of bent cap installation can be remarkably improved, and the engineering quality is guaranteed.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

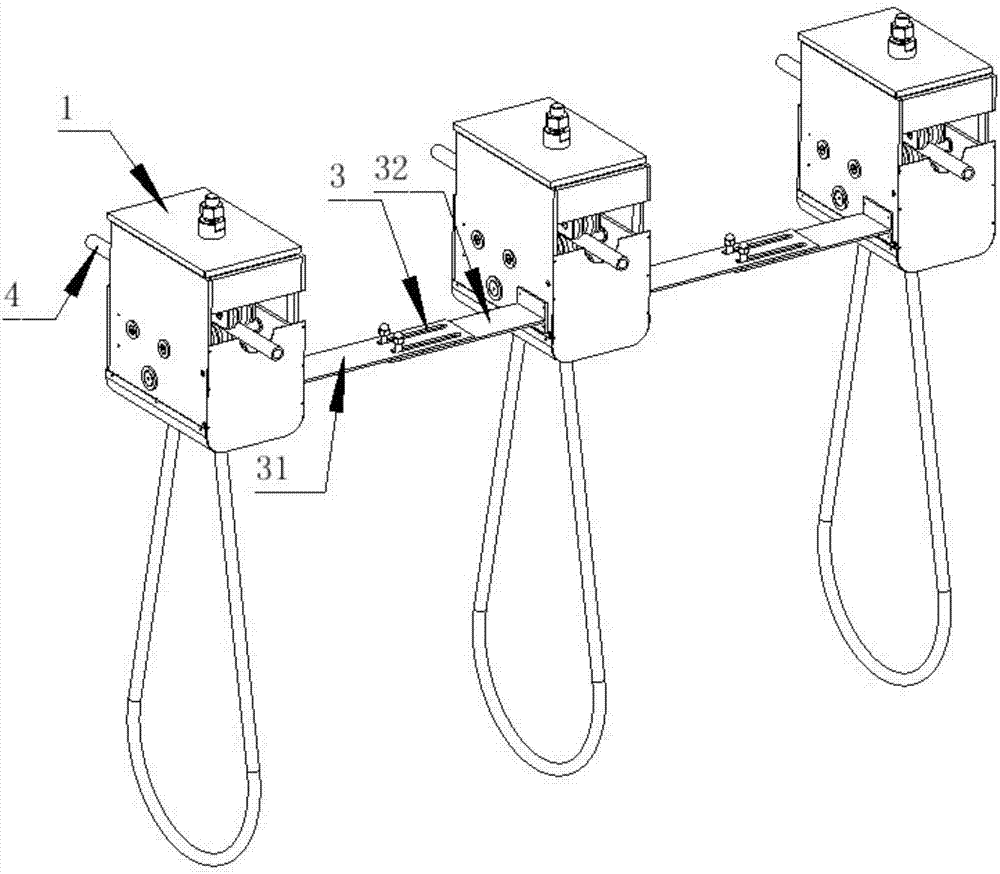

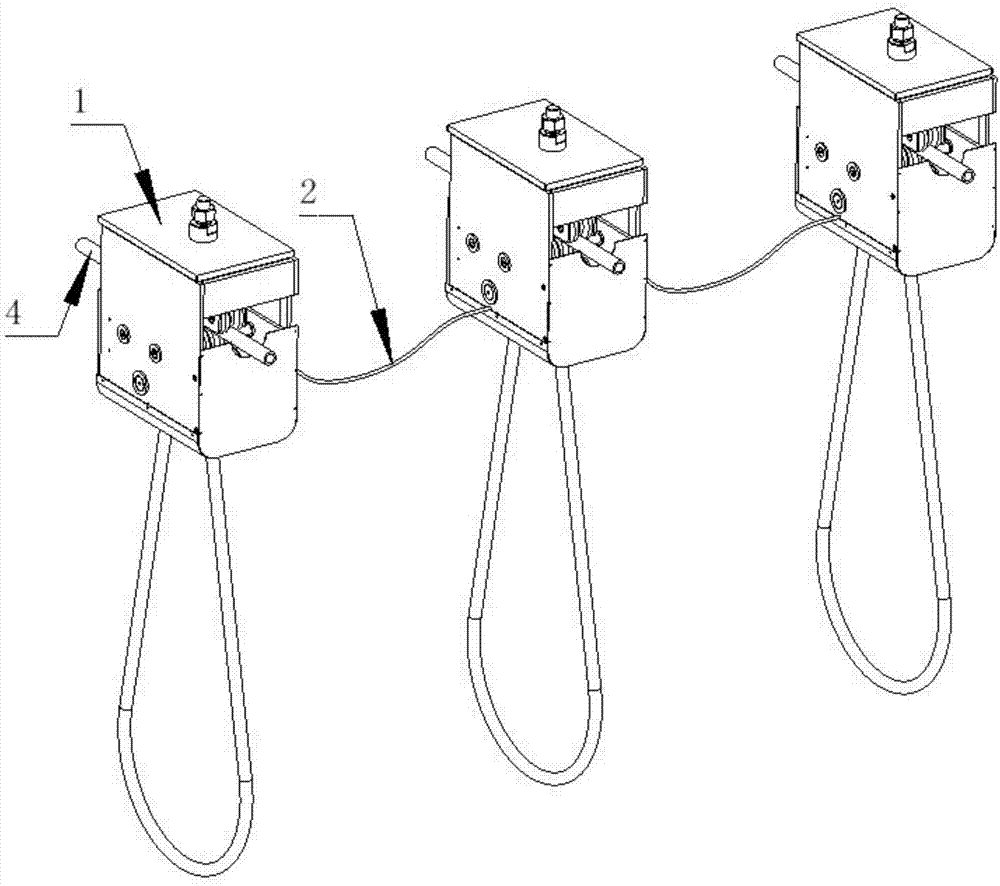

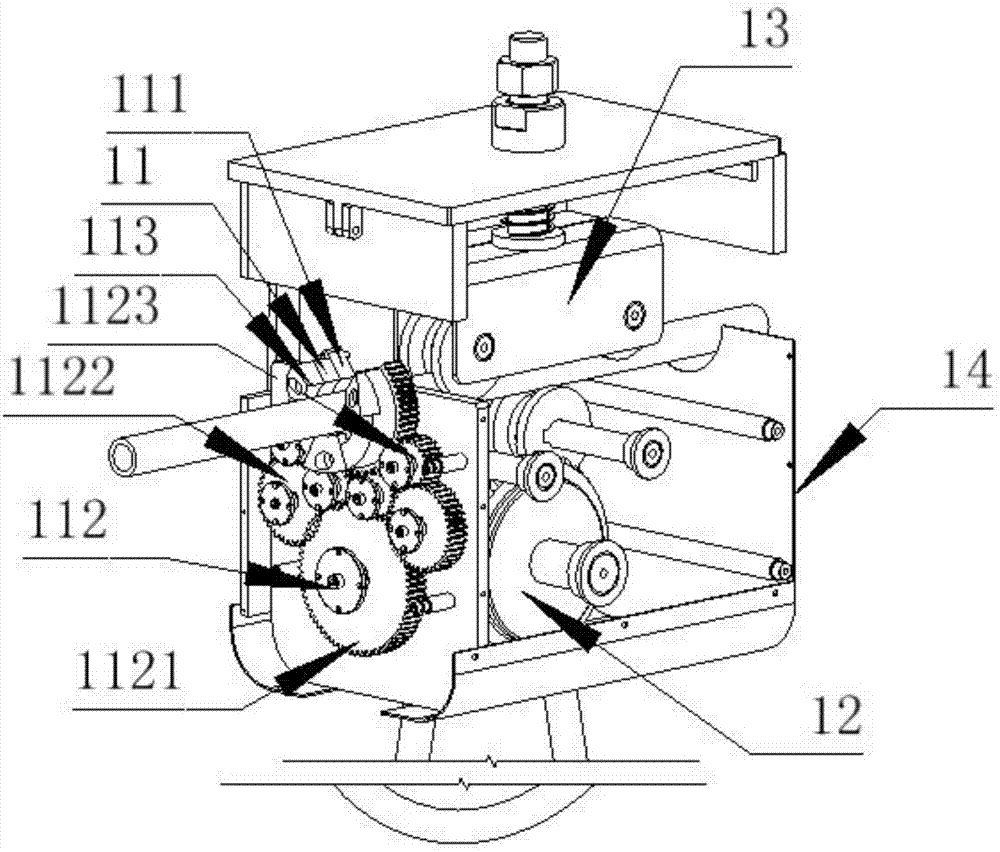

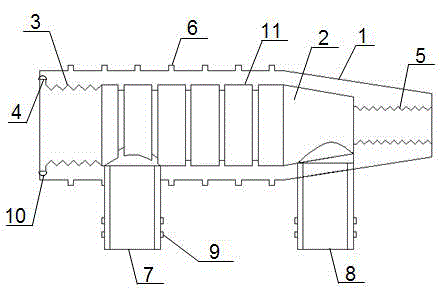

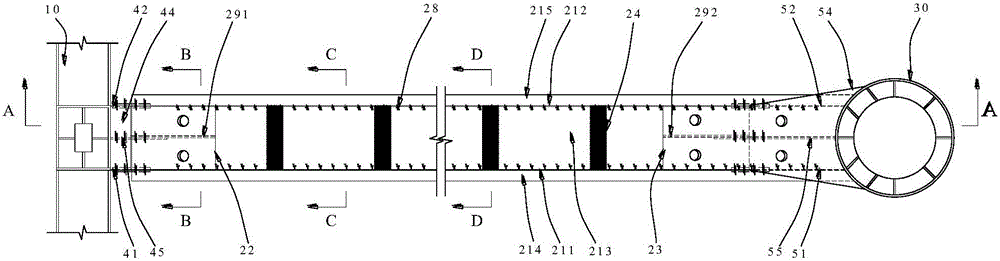

Electric transmission line deicer

InactiveCN107516865AGuaranteed uptimeRemove completelyOverhead installationMinimum distanceTransmission cable

The invention discloses an electric transmission line deicer. The electric transmission line deicer comprises at least two deicing machines arranged on an electric transmission cable, and each two adjacent deicing machines are connected with each other through a rope or a connecting plate. Every deicing machine comprises a deicing mechanism, a power mechanism, a feeding mechanism and a shell, the deicing mechanism and the feeding mechanism are connected with the power mechanism, the deicing mechanism comprises a deicing wheel and a deicing drive mechanism, the deicing wheel is in the shape of a ring less than 360 degrees, a minimum distance at a notch of the deicing wheel is greater than a diameter of the electric transmission cable, and a deicing knife is arranged on the deicing wheel. Every deicing drive mechanism comprises a power wheel A, two intermediate wheels and four planet wheels, wherein the four planet wheels mesh with the deicing wheel, each intermediate wheel meshes with two of the four planet wheels, the power wheel A meshes with the two intermediate wheels and is connected with the power mechanism, and a meshing area of the deicing wheel and the planet wheels is greater than 180 degrees. The notches of the deicing wheels can allow the electric transmission cables to pass through, and the electric transmission line deicer can clamp the external portions of the electric transmission cables.

Owner:吴桐

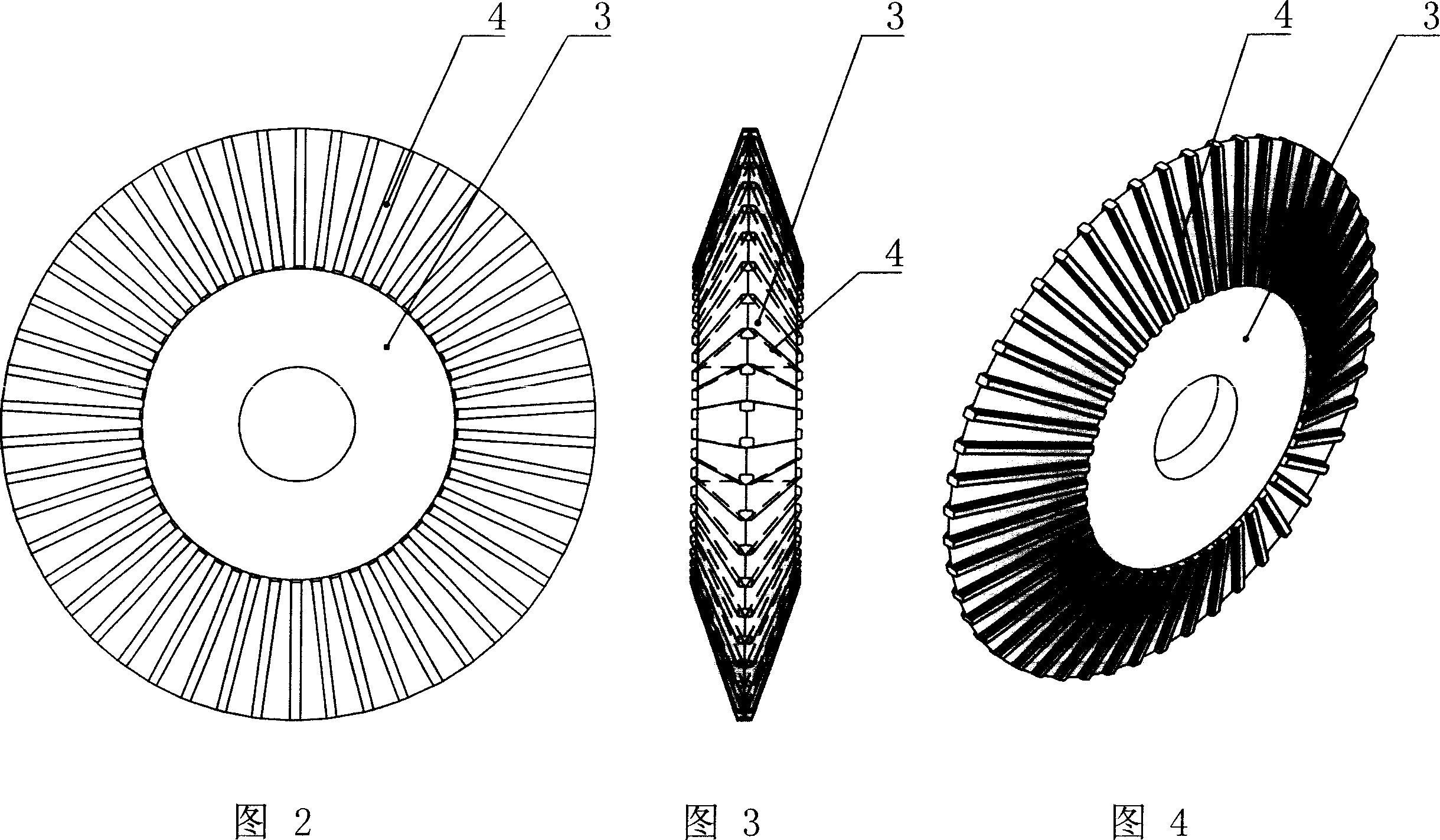

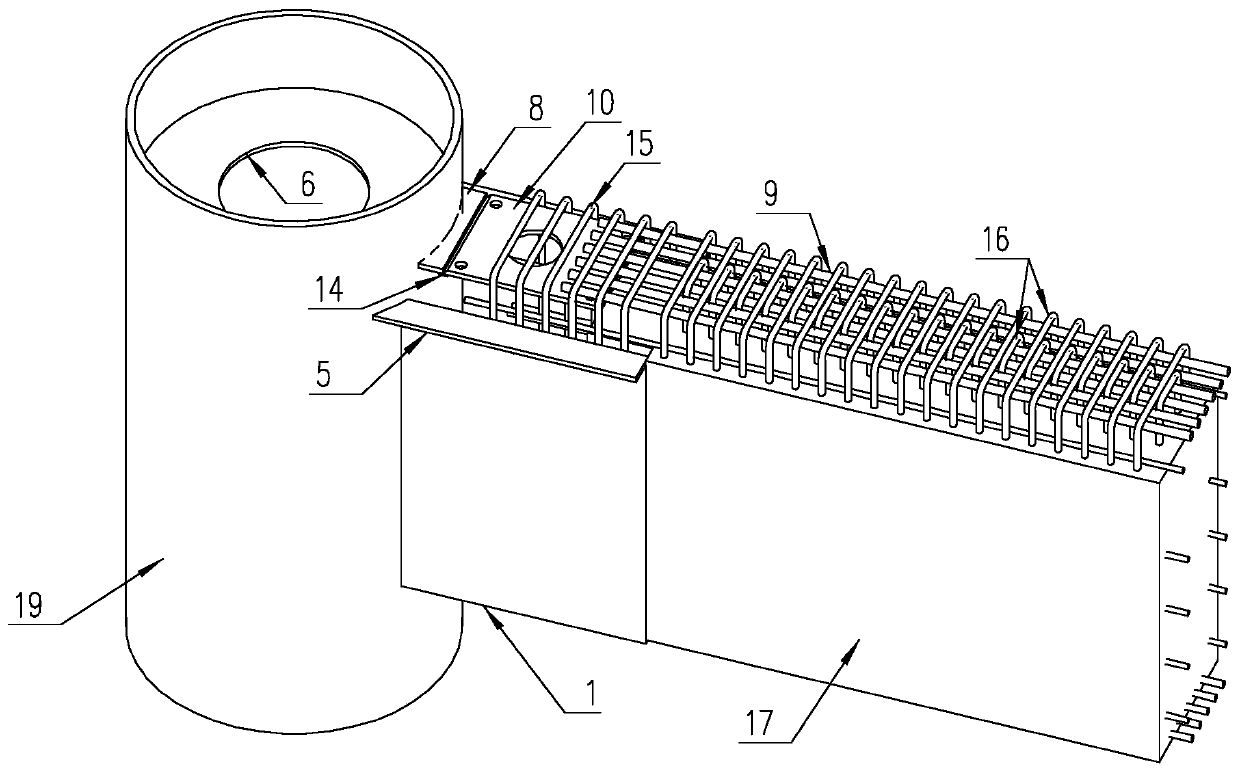

3D printing wire feeding, clamping and guiding device

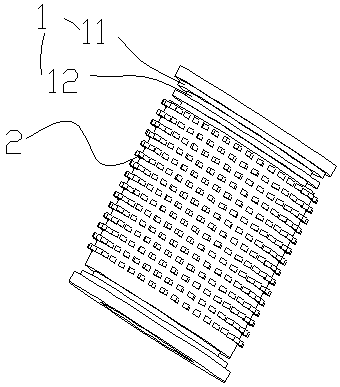

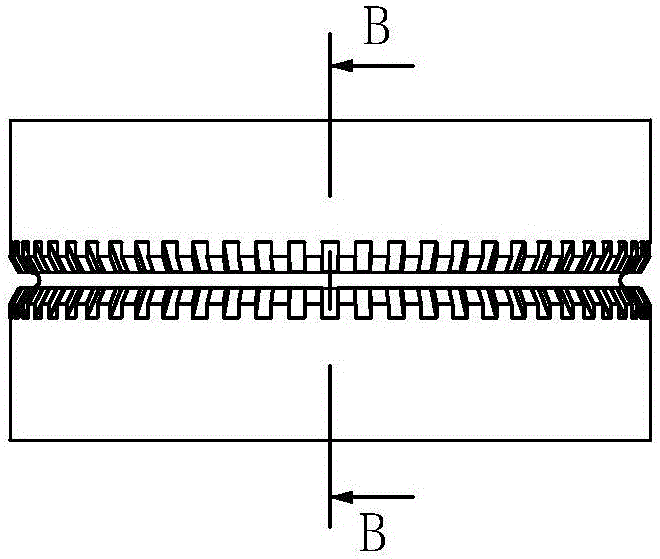

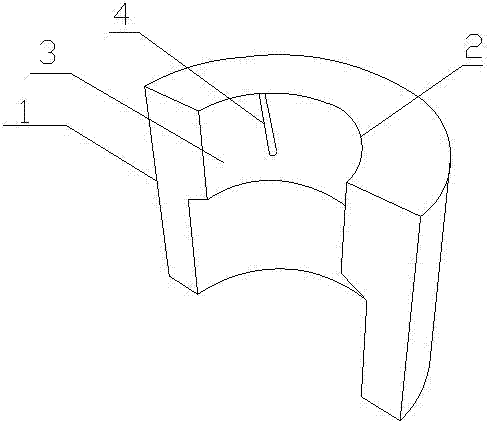

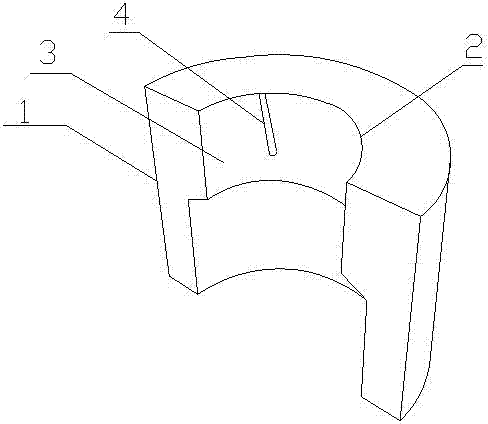

InactiveCN105690771AImprove clamping bite forceIncrease frictionAdditive manufacturing apparatusEngineeringGuide wires

The invention discloses a 3D printing wire feeding, clamping and guiding device, and relates to the technical field of quick molding of 3D printing. The 3D printing wire feeding, clamping and guiding device comprises a guide wheel I and a guide wheel II; the guide wheel I and the guide wheel II are arranged side by side; a lap of V-shaped tooth grooves I, inwards recessed, is formed in the peripheral surface of the guide wheel I; a lap of V-shaped tooth grooves II, inwards recessed, is formed in the peripheral surface of the guide wheel II; the V-shaped tooth grooves I in the guide wheel I and the V-shaped tooth grooves II in the guide wheel II are opposite in position; when the guide wheel I and the guide wheel II are arranged side by side, the V-shaped tooth grooves I and the V-shaped tooth grooves II surround guide grooves for clamping and guiding wires; waste grooves I communicated with the V-shaped tooth grooves I are inwards recessed in the inner sides of the V-shaped tooth grooves I; and waste grooves II communicated with the V-shaped tooth grooves II are inwards recessed in the inner sides of the V-shaped tooth grooves II. The 3D printing wire feeding, clamping and guiding device can improve the wire surface clamping engagement force and friction force to prevent the wire slip or deviation in the feeding process.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Anti-scrap-bounding female die for high-speed progressive die

The invention discloses an anti-scrap-bounding female die for a high-speed progressive die. The anti-scrap-bounding female die comprises a female die body and a female die cutter point arranged on the female die body and is characterized in that: the female die cutter point is circular; the upper section of the female die cutter point is a cutting edge incision section having a cutting edge incision depth; a plurality of uniformly distributed inclined grooves inclined to the central line of the female die cutter point are formed on the inner wall of the cutting edge incision section; and the uniform depth of each inclined groove is 0.1 to 0.2 millimeters. In the anti-scrap-bounding female die for the high-speed progressive die, the inclined grooves are formed below the cutting edge incision depth of the female die cutter point; at the initial stage of a blanking working procedure, blanked wastes can form small protrusions corresponding to the inclined grooves of the female die; the protrusions can be compressed (a flattening function) by the side face of the female die, the holding-on force of scraps is enhanced and the friction is increased, so that the wastes are prevented from bounding, the production efficiency of finished products is improved and the defective rate and the production cost are reduced.

Owner:JOUDER PRECISION INDAL KUSN

Glued groove-and-tongue floor

InactiveCN102080438AImproving the gluing installation processStable splicingFlooringEngineeringTongue and groove

The invention discloses a glued groove-and-tongue floor, which comprises a floor body, wherein the floor body is provided with a joint tongue and a joint groove. The glued groove-and-tongue floor is characterized in that: a pressure sensitive glue layer is coated on the joint tongue and / or the joint groove. The glued groove-and-tongue floor has the advantages that: 1, the pressure sensitive glue layer is pre-coated on the joint tongue and / or the joint groove, namely the tongued and grooved positions, of the floor so as to greatly improve a floor gluing mounting process and the mounting efficiency, save time, avoid the surface of the floor being polluted and achieve higher environmental friendliness; 2, adjacent floor blocks can be separated without any damage after being glued and spliced by pressure sensitive glue, so the floor is convenient to disassemble and rearrange after faults are produced in arrangement and pavement, and the after-service cost of the product is reduced; and 3, the adhesive power of the pressure sensitive glue can greatly strengthen an interlocking force between tongues and grooves of the floors and make securer and more stable the splicing of the floor, thereby greatly reducing the problem of contraction joint deformation of the paved floor as well as noises caused by friction between the tongues and grooves of the floors and greatly improving the mounting quality of the floor.

Owner:GUANGDONG YINGRAN WOOD IND

Edge banding strip for waterproof board

InactiveCN104441789AImprove the isolation effectImprove isolationCovering/liningsSynthetic resin layered productsIsolation effectUltimate tensile strength

The invention discloses an edge banding strip for a waterproof board. The edge banding strip comprises a bottom edge and side edges, which are molded into a whole, wherein the two side edges are available, and a U shape is formed by the side edges and the bottom edge; a multi-layer structure which is molded into a whole is formed by the bottom edge and the side edges; an adhesion layer, a carbon fiber layer, a hot melt adhesive layer, a base material layer, a printing layer and a surface waterproof layer are sequentially arranged from inside to outside from the end surface contacted with the waterproof board; a reversed hanging side which is arranged towards the bottom edge is positioned at the inner side of each side edge. The edge banding strip is in the U shape formed by the two side edges and the bottom edge, and the external wrapping structure is better jointed with the cross section of the waterproof board, so that the effect of isolating air from water is improved; the reversed hanging sides which are arranged towards the bottom edge are positioned at the inner sides of the side edges, so that the edge banding strip is good in an isolation effect; the multi-layer structure comprises the carbon fiber layer, and the carbon fiber layer can be used for effectively improving the structural strength of the edge banding strip, so that the mechanical damage to the edge banding strip can be avoided to a certain extent in the using process.

Owner:常熟市中海塑胶制品有限公司

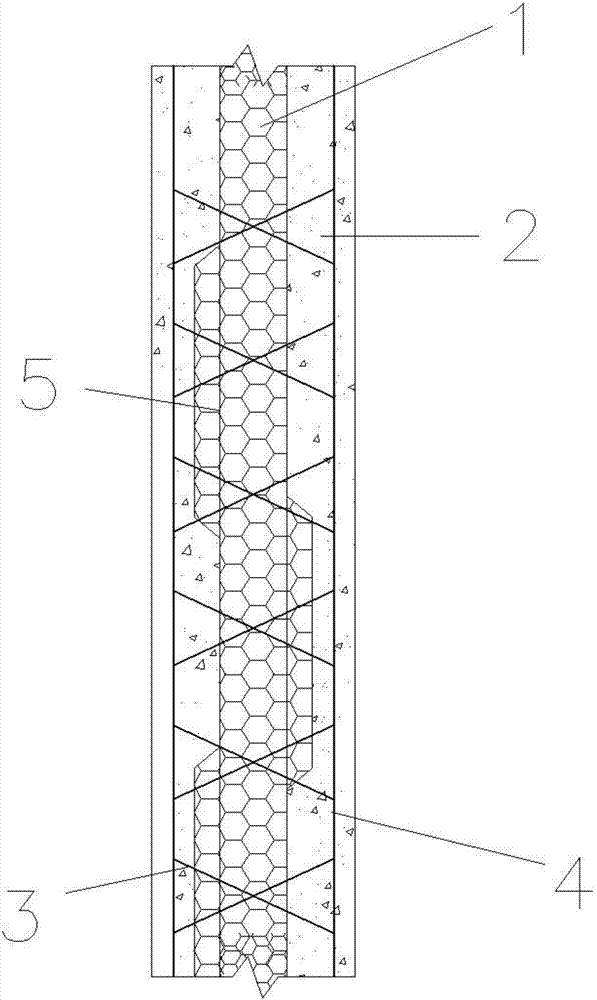

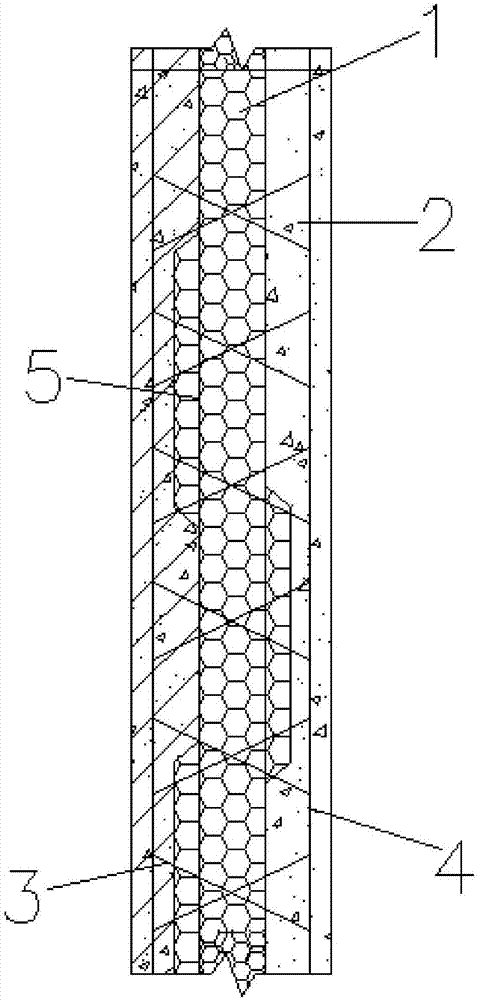

Steel wire net frame type composite interlayer wallboard internally installed with three layers of insulation boards and construction method of composite interlayer wallboard

ActiveCN106978877AAvoid problemsImprove insulation effectBuilding componentsThermal insulationAdhesive

The invention relates to a steel wire net frame type composite interlayer wallboard internally installed with three layers of insulation boards and a construction method of the composite interlayer wallboard, belonging to the technical field of energy conservation and thermal insulation of buildings. The composite interlayer wallboard comprises a steel wire net frame, three layers of the insulation boards and concrete layers, wherein the steel wire net frame is formed by two parallel steel wire net pieces and multiple cold-drawing oblique-inserting steel wires for connecting the two steel wire net pieces, the insulation boards are clamped between the two steel wire net pieces, and the concrete layers are arranged on two sides of the insulation boards; the steel wire net pieces are formed by welding steel wires in a vertical and horizontal crossing manner; three layers of the insulation boards include relatively-thick main insulation boards on a middle layer, and relatively-thin insulation boards are respectively distributed on two sides of the relatively-thick main insulation boards at intervals in a 'combed joint' manner, and the insulation boards on any side can cover abutted seam positions of the main insulation boards; and abutted seams of three layers of the insulation boards are adhered through an adhesive. According to the steel wire net frame type composite interlayer wallboard, the thermal insulation property of a wall body is well improved, and the structural stiffness and integrality of the wall body are increased.

Owner:保定市冀创建筑工程有限公司 +3

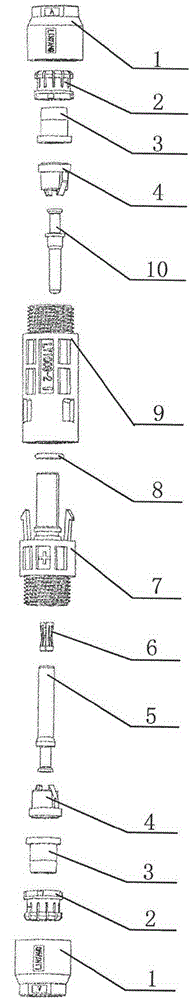

Recyclable blanking plug in oil tubing

ActiveCN105484696ACompact and reasonable structureEasy to useSealing/packingGrip forceMechanical engineering

The invention relates to the technical field of a blanking plug device in an oil tube and provides a recyclable blanking plug in the oil tube. The recyclable blanking plug comprises a back off sub, a fishing head, an unsetting mandrel, an upper slips barrel, a rubber packer mandrel, a lower slips seat, a lower joint, a lower mandrel and a locking pawl, wherein an upper mounting shaft cavity opening downwards is formed in the back off sub; the fishing head is arranged in the upper mounting shaft cavity in a sleeving manner, and the inner wall of the lower part of the fishing head is fixedly mounted together with the outer wall of the upper part of the unsetting mandrel; long shaft holes are formed uniformly in the circumference of the upper part of the unsetting mandrel. The blanking plug is reasonable and compact in structure and convenient to use, a steel wire running tool is used during setting and unsetting, and setting and unsetting operation is simple and feasible, larger gripping force can be provided under the condition that good plugging is guaranteed, the plug does not move after plugging, and sealing is guaranteed; meanwhile, the plug can be recycled after unsetting, can perform setting in any position in the oil tube, the plugging pressure is high, various working condition requirements are met, and the cost is reduced effectively.

Owner:XINJIANG SINOGASOLINEEUM ENG

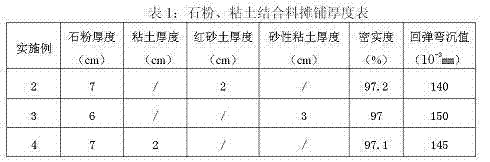

Construction method for subbase layer of natural graded pebble road surface

The invention discloses a construction method for a subbase layer of a natural graded pebble road surface, comprising the following processing steps of: 1, lower bearing layer preparation: performing testing, measuring and lofting on a road bed and dividing distributing grids; 2, natural graded pebble paving: paving natural graded pebbles according to the design thickness and the coefficient of a loose paving material, and performing primary leveling and static press; 3, binder paving: paving 5-7 cm of rock powder in thickness and 2-3 cm of clay in thickness on the surface of a pebble layer; 4, blending: blending clay, rock dust and the natural graded pebbles together 2-3 times; 5, rolling: performing fine leveling by using a land leveler, performing static press 1-2 times by using a road roller and performing vibrational rolling 6-8 times; and 6, testing: testing compactness and a rebound deflection value. By mixing of the binder of rock dust and clay in the invention, the biting force, stability and hardening property of the natural graded pebbles are increased without performing crashing, plant mixing or site mixing on the natural graded pebbles nor performing secondary carrying, and the construction cost is reduced.

Owner:CHINA MCC17 GRP

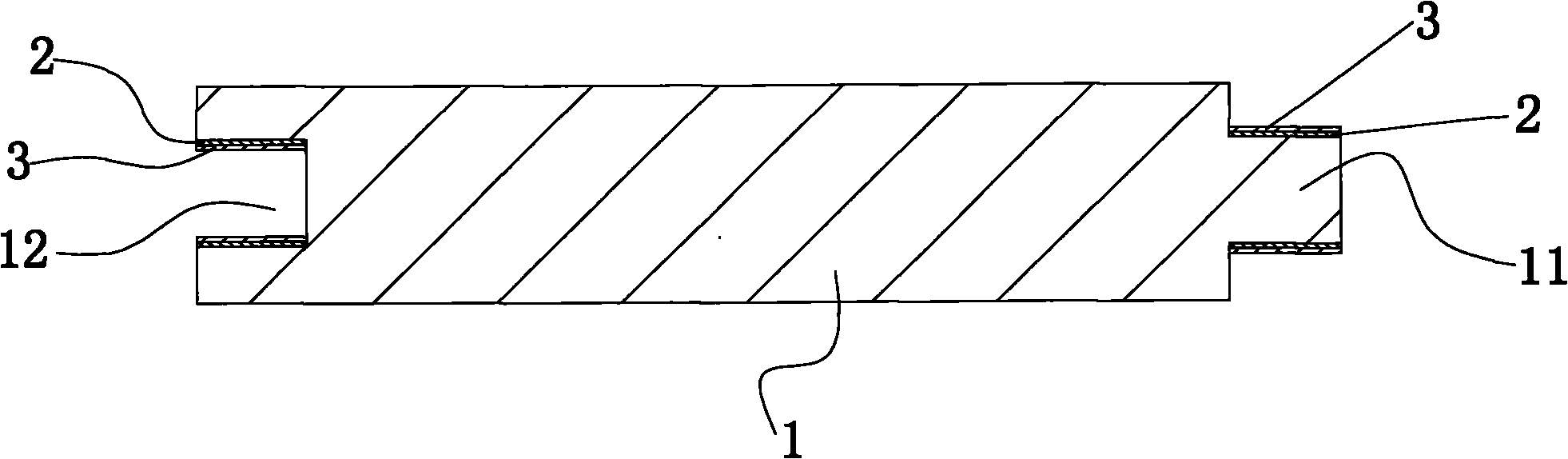

Grouting sleeve for rebar connection

The invention discloses a grouting sleeve for rebar connection. The grouting sleeve comprises a grouting sleeve body, a grouting cavity is arranged inside the grouting sleeve body, a thread with a first rebar inserted is arranged at one end of the grouting sleeve body and communicated with the cavity, a notch which extends out is formed in the tail end of the screw, a sleeve thread connected with a second rebar is arranged at the other end of the grouting sleeve body, a shear force ring is arranged on the outer surface of the grouting sleeve body, a grouting port is arranged at one end, close to the thread, of the grouting sleeve body, a grout outlet is arranged at one end, close to the sleeve thread, of the grouting sleeve body, and a thread is arranged on the outer surface of each of the grouting port and the grout outlet. The grouting sleeve is reasonable in design, and occlusive force of the sleeve and concrete is increased; more easiness in operation is realized in the process of production due to integral design, an externally-connected grouting pipe is enabled to be less prone to falling, an outer side die is enabled to be easier to position, and axial positioning is more accurate, so that construction quality is improved.

Owner:山东明达建筑科技有限公司

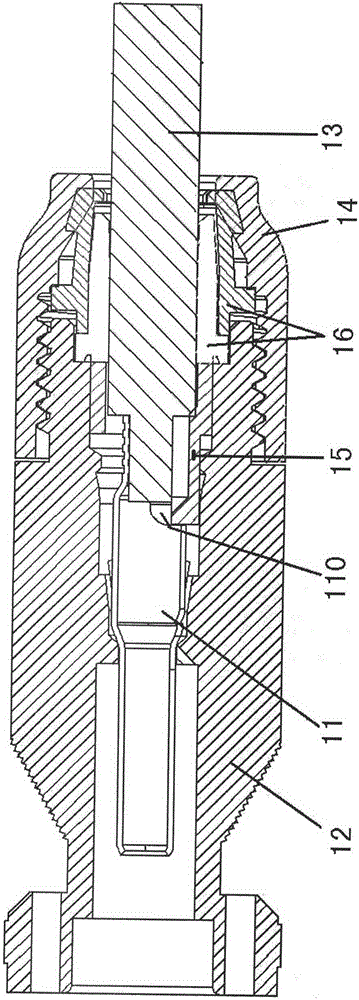

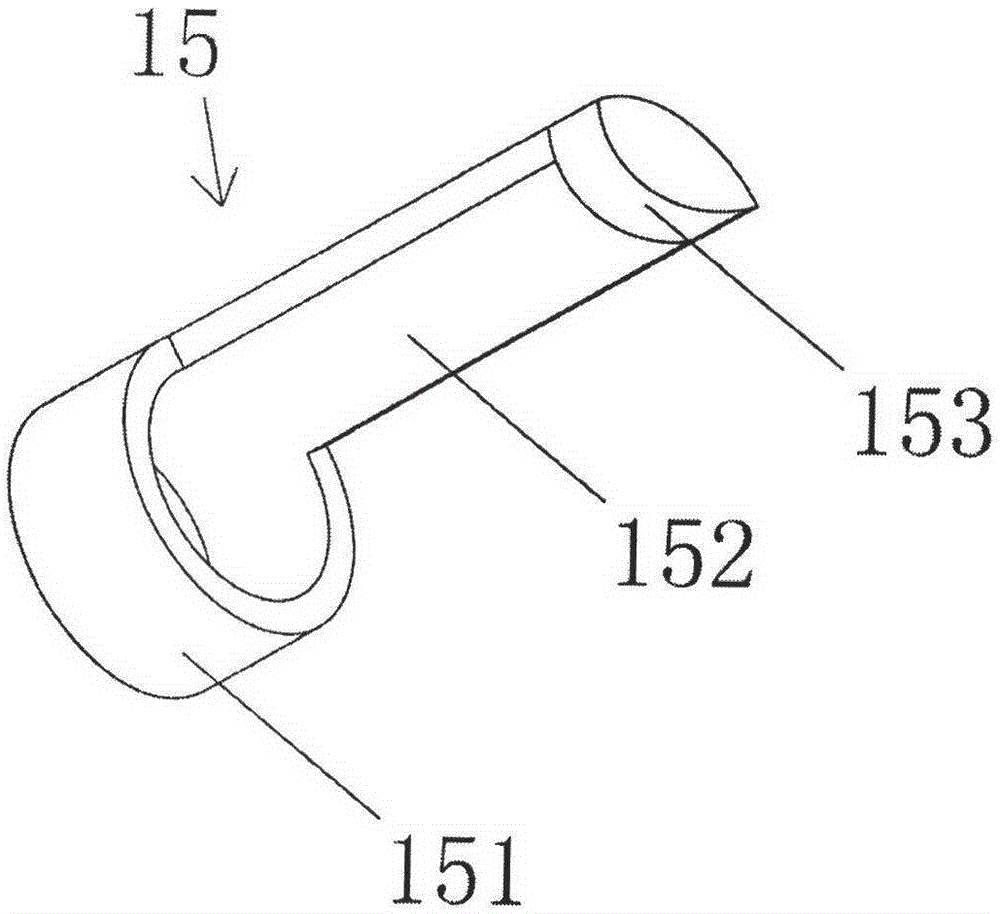

Photovoltaic junction box connector provided with limiting sleeve

ActiveCN104659519AImprove pullout forceImprove securityRelieving strain on wire connectionCouplings bases/casesMetal electrodesJunction box

The invention relates to a photovoltaic junction box connector. A limiting sleeve is supported between a metal electrode and a lock nut to prevent the metal electrode from being pulled out of a connector main body. The limiting sleeve comprises an annular sleeve and an upright axially stretching out of a side wall of the annular sleeve, wherein a reinforcing block radially stretching is arranged at the front end of the upright; and the reinforcing block is embedded into a notch at the rear end of the metal electrode. The limiting sleeve is mounted between the tail of the metal electrode of the connector and a cable sheath straining ring component, the upright pushes against the notch of the metal electrode, and the head of the annular sleeve pushes against the cable sheath straining ring component, so that a metal electrode terminal and the lock nut form overall support by the limiting sleeve of a cable in the connector. A drawing force of the cable for mounting the connector is above 400N.m, so that the drawing force is basically greater than a snap-in force of a cable core and the metal electrode terminal, and cable looseness and extraction caused by limiting can be permanently avoided.

Owner:启东市防爆电器仪表有限责任公司

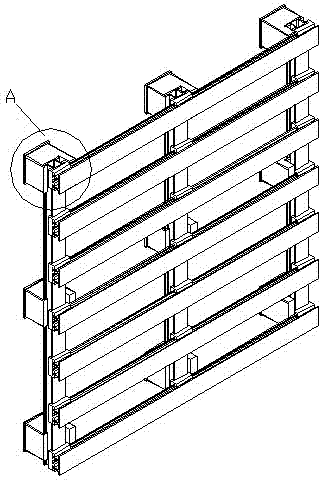

Splicing-insertion type glass fiber reinforced plastic tray

The invention relates to a splicing-insertion type glass fiber reinforced plastic tray, in particular to a tray which is suitable for different dimensional specifications and bearing capacities and capable of being reused for a long time. The splicing-insertion type glass fiber reinforced plastic tray is composed of long-strip panels, beams and supporters of supporting beams, wherein the upper side of each long-strip panel is a plane; the beams are crosswise placed under the panel and clamped to the panel in parallel; the supporters of the supporting beams are fixedly clamped to the beams; and the panels, the beams and the supporters are all produced from glass fiber reinforced plastic. The splicing-insertion type glass fiber reinforced plastic tray disclosed by the invention has the advantages of high bearing capacity, long repetitive use life, high strength, water resistance, corrosion resistance, large range of applicable sizes, large range of applicable bearing capacities, easy maintenance and simplicity for installation.

Owner:ZHENSHI GRP HUAMEI NEW MATERIALS

Reinforced soil composite structure drainage ditch

InactiveCN103243694AImprove permeabilitySolve wasteful technical problemsConstructionsSoil drainageWater resourcesEngineering

The invention discloses a reinforced soil composite structure drainage ditch. Reinforced soil composite structure bottom layers, reinforced soil composite structure middle layers and reinforced soil composite structure upper layers are arranged on ditch walls on the two sides of a drainage ditch from the bottom up sequentially, wherein capping layers are arranged on the top surfaces of the upper layers; a ditch bottom original soil layer is arranged in the middle of a ditch bottom in a length direction of the drainage ditch; water-permeable bottom angle protection layers are arranged on the two sides of the ditch bottom original soil layer respectively; macadam and coarse sand layers are arranged on the outer sides of the bottom layers, the middle layers and the upper layers and at the bottoms of the bottom layers; clay layers are arranged beside the macadam and coarse sand layers; and the external surfaces of the bottom, the top, and the inner side of each bottom layer are coated with geotextile. The drainage ditch is high in stability, and the permeability of the ditch walls is high, so that the drainage ditch effectively solves the technical problems that the interior of a ditch body of the field drainage ditch is completely isolated from soil outside, water in the middle layer and the lower layer of the field soil cannot be drained, the soil is waterlogged for a long term, the soil aeration and the water permeability become poor, the water in the ditch body in a dry season cannot re-infiltrate into the field soil, and a water resource is wasted.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +1

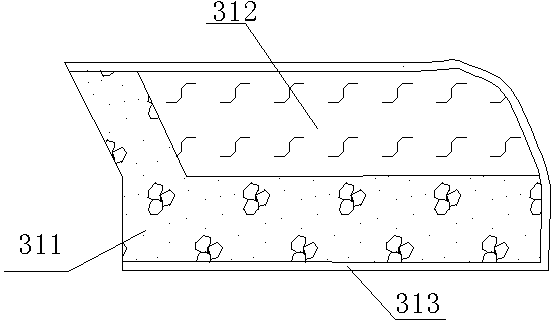

Structure enhanced synthetic fiber for concrete and preparation thereof

InactiveCN101348342AHigh compressive strengthHigh tensile strengthMelt spinning methodsSevering fibresRough surfacePolyamide

The invention relates to a structurally reinforced synthetic fiber for concrete. The synthetic fiber is prepared by processes of fusion, spinning, dispersion and fixing, and the synthetic fiber comprises the following components: 20 to 70 percent of polypropylene, 25 to 75 percent of polyethylene, 0 to 25 percent of polyamide, 0.05 to 0.5 percent of nucleating agent and 0.1 to 0.5 percent of antioxidant. The synthetic fiber of the invention has rough surface and clear contour, and has good dispersibility and cement basal body with excellent cementing property; the product has not only the functions of steel fibers, but also advantages of synthetic fibers, so that the synthetic fibers of the invention is mainly used to replace weld metal screens and steel fibers in the concrete panel structure for improving the bending resistant, shock resistant and fatigue resistant performance of concrete.

Owner:南京派尼尔科技实业有限公司

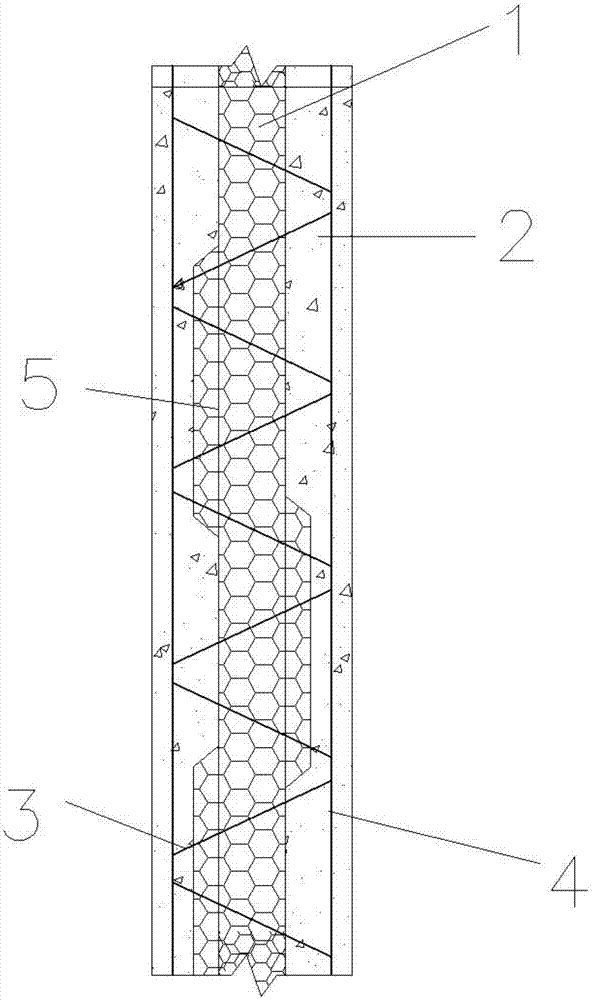

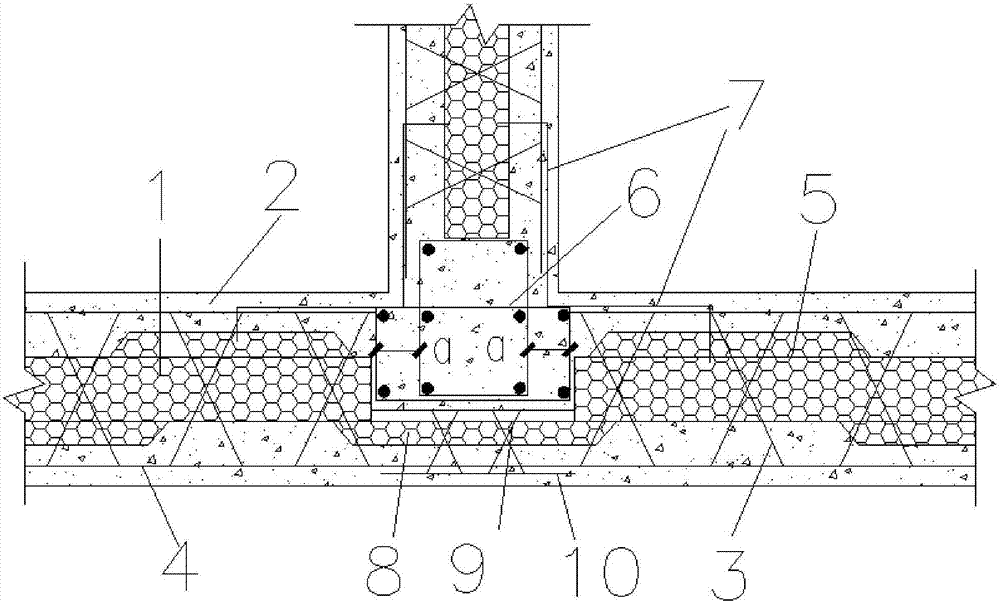

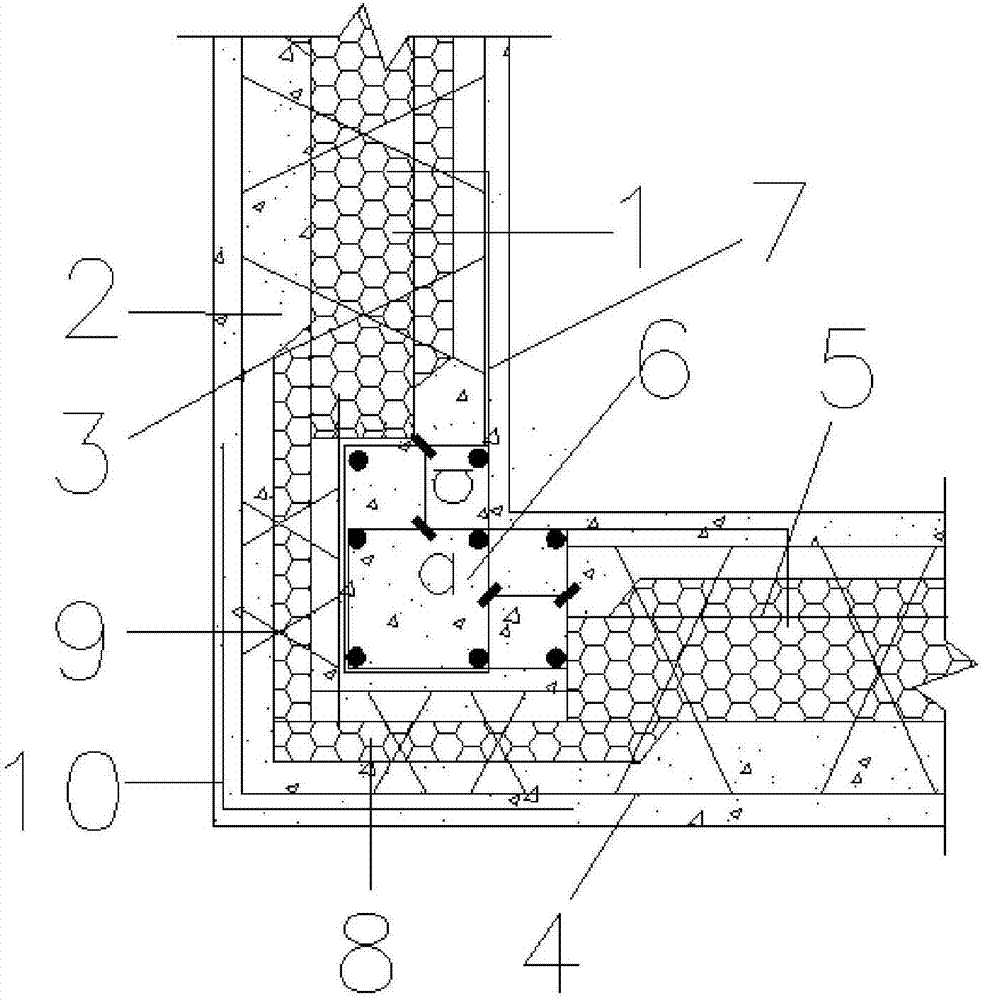

Steel wire net frame composite heat-insulation sandwich wall board node and construction method thereof

ActiveCN106968362AAvoid problemsSolve the real problemWallsClimate change adaptationBuilding energyMechanical engineering

The invention relates to a steel wire net frame composite heat-insulation sandwich wall board node and a construction method thereof and belongs to the technical field of building energy-saving heat insulation. The steel wire net frame composite heat-insulation sandwich wall board node is of a T-shaped, L-shaped or Z-shaped node structure formed by mutually connecting steel wire net frame composite heat-insulation sandwich wall boards. The connecting position of the wall boards is a column body, each steel wire net frame composite heat-insulation sandwich wall board comprises a steel wire net frame formed by two steel wire net pieces which are mutually parallel and a plurality of cold-drawing obliquely-inserting steel wires for being connected with the two corresponding steel wire net pieces, a three-layer heat insulation board sandwiched between the two corresponding steel wire net pieces and concrete layers arranged on the two sides of the corresponding heat insulation board; the steel wire net pieces are formed through longitudinally and transversely intersection of steel wires in a welding mode; and each three-layer heat insulation board comprises a middle-layer thick main heat insulation board body and thin heat insulation board bodies which are arranged on the two sides of the corresponding main heat insulation board body in a spaced mode, every two corresponding heat insulation board bodies on the two sides are distributed in a horse-tooth-stubble shape on the two sides of the corresponding middle main heat insulation board body, and the heat insulation board bodies on any side can cover the abutted seam positions of the middle main heat insulation board bodies.

Owner:保定市冀创建筑工程有限公司 +3

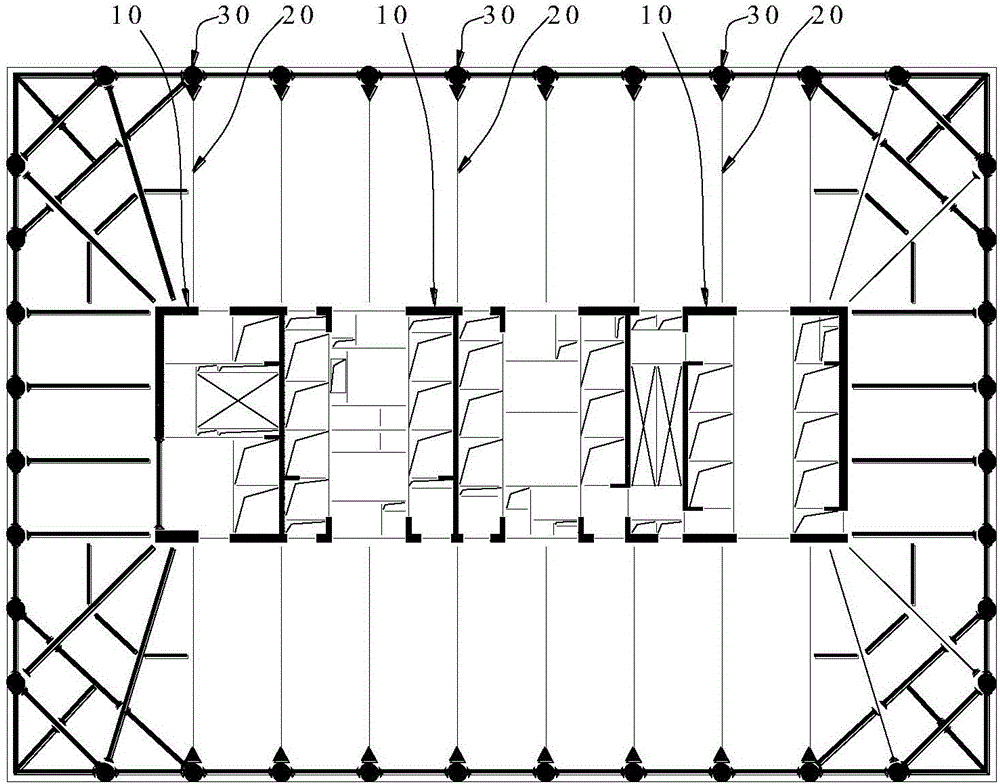

Assembly type frame-core tube structural system adopting all-steel-encased stress component

ActiveCN105756189AEfficient deliveryIncrease stiffnessBuilding constructionsShear capacityUltimate tensile strength

The invention discloses an assembly type frame-core tube structural system adopting an all-steel-encased stress component. A core tube shear wall is a steel box concrete shear wall, a frame column is a steel pipe concrete column, and a frame beam connected between the embedded column position of the steel box concrete shear wall and the steel pipe concrete column is a steel-concrete combined beam which can coordinate a peripheral frame and a core tube of the assembly type frame-core tube structural system to bear earthquake force together. A steel-encased box of the steel box concrete shear wall is formed by assembling multiple sections of finished steel boxes on site, and every two adjacent sections of finished steel boxes are connected through multiple son buckle connecting pieces welded to the first section of finished steel box and mother buckle connecting pieces welded to the second section of finished steel box. The flatness of the steel box concrete shear wall in the large-length core tube can be ensured, and it can be ensured that the strength and shear capacity of the steel box concrete shear wall met construction standard requirements.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

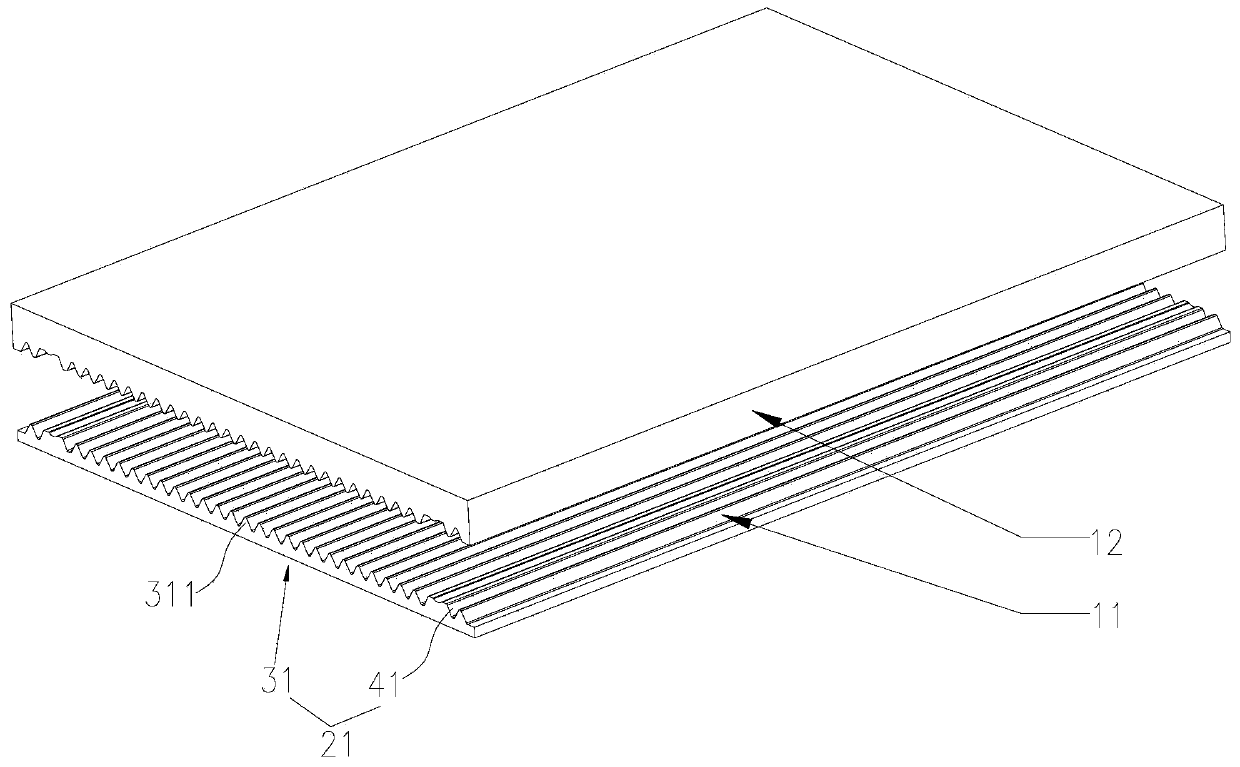

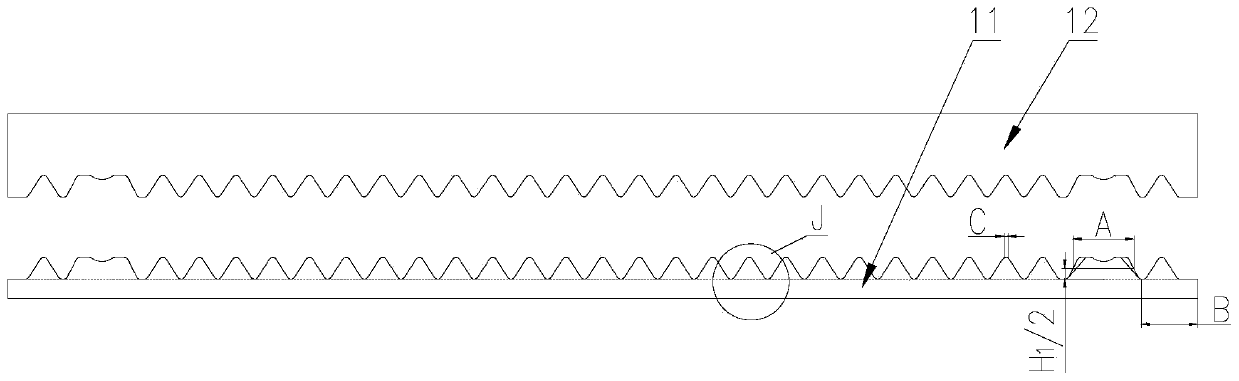

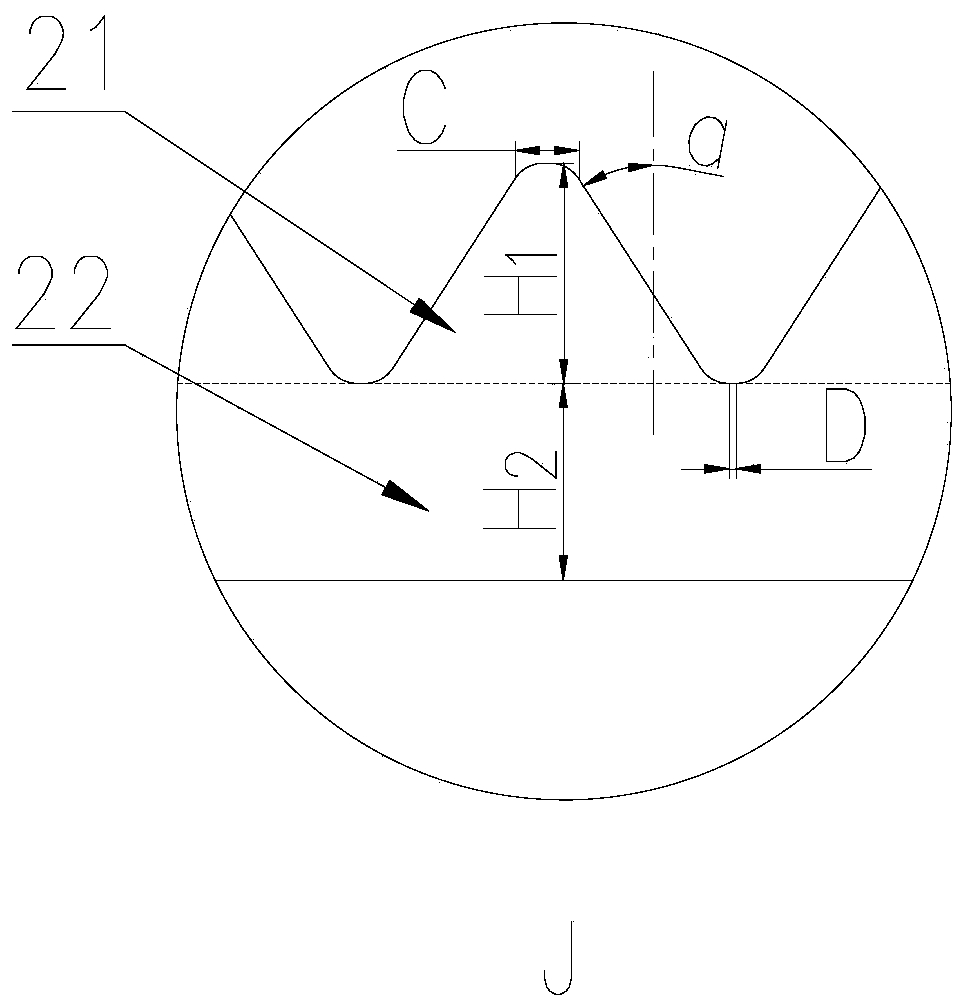

Porcelain plate formed by one-time dry pressing of prefabricated mold and manufacturing method

PendingCN111421652ASafer and stronger dry hangingHigh densityWallsMouldsMechanical engineeringCurtain wall

The invention discloses a porcelain plate formed by one-time dry pressing of a prefabricated mold and a manufacturing method. The porcelain plate comprises a flat blank layer and a prefabricated protrusion, the flat blank layer and the prefabricated protrusion are integrally formed by porcelain raw materials in a dry pressing mode, the height H1 of the prefabricated protrusion ranges from 8 mm to20 mm, and the thickness H2 of the flat blank layer ranges from 6 mm to 15 mm. According to the porcelain plate formed by one-time dry pressing of the prefabricated mold and the manufacturing method,safer curtain wall dry hanging application of the porcelain plate can be carried out through hanging pieces, the fact that the flat blank layer and the prefabricated protrusion are integrally formed in a dry pressing mode is adopted, the porcelain plate has the characteristic of being high in strength and good in integrality; and therefore, a curtain wall material with better physical and chemicalproperties and safer dry hanging is provided for dry hanging application of a building curtain wall.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +2

Steel-plastic meshed composite pipe with detachment preventive function

InactiveCN105526432AIncrease internal stressLimited axial elongationPipe elementsRigid pipesEngineeringThermal expansion

The invention discloses a steel-plastic meshed composite pipe with a detachment preventive function. The steel-plastic meshed composite pipe comprises a steel outer pipe, an anti-corrosion inner-layer pipe and a connecting flange, two ends of the anti-corrosion inner-layer pipe form end face turnups on a docking face of the connecting flange by means of hot melting deformation, axial meshing structures are arranged between the end face turnups and the connecting flange, and a radial meshing structure is arranged between the anti-corrosion inner-layer pipe and an inner hole of the connecting flange. When environment temperature changes greatly, although a plastic inner pipe deforms greatly due to heat expansion and cold contraction, two ends of the anti-corrosion inner-layer pipe are limited by the axial meshing structures of the connecting flange and cannot extend outwards, deformation due to heat expansion and cold contraction of the anti-corrosion inner-layer pipe is converted into internal stress, and compactness of the anti-corrosion inner-layer pipe and improvement on mechanical performance of the same are facilitated, so that displacement, degumming and detachment defects between the anti-corrosion inner-layer pipe and the steel outer pipe are eliminated structurally.

Owner:JIANGSU KAIXING PIPELINE CO LTD

Medical forceps

ActiveCN108969026AAvoiding problems near "dead spots"Push flexibleVaccination/ovulation diagnosticsSurgical forcepsPush pullBiopsy forceps

The invention relates to medical forceps. The medical forceps comprise a handle, a traction rope, a spring hose, a forceps holder, a push-pull rod, connecting pieces and forceps claws; the spring hoseis connected with the cup holder, the traction rope penetrates through the spring hose and the forceps holder, one end of the traction rope is connected with the handle, and the other end of the traction rope is connected with the push-pull rod; the middles of the two forceps claws are hinged through a hinge shaft, the hinge shaft is installed on the forceps holder, the lower portion of each forceps claw is hinged to one end of the corresponding connecting piece, the other end of each connecting piece is hinged to the push-pull rod, the push-pull rod is provided with two hinge centers for being hinged to the two connecting pieces respectively, and the two connecting pieces are crossed. According to the medical forceps, the push-pull rod adopts a double-hinge central structure, a staggeredfive-connecting-rod mechanism is formed by the forceps claws, the connecting pieces and the push-pull rod, the meshing force of the forceps is improved while it is ensured that the forceps are flexibly pushed, and the efficiency and accuracy of clamping tissue by the biopsy forceps are improved.

Owner:ANREI MEDICAL HZ

Light porous artificial stone board and preparation method thereof

ActiveCN106316445ALight in massLow densityCeramic materials productionCeramicwareOn boardArtificial stone

The invention relates to the technical field of building materials and particularly discloses a light porous artificial stone board and a preparation method thereof. The density of the artificial stone board is below 2.0 g / cm<3>, and 500 or more holes are formed in every cubic centime of the artificial stone board. The artificial stone board is prepared from tile waste, kaolin, a foamer, ore sand and glaze. The stone board is low in mass, low in density and high in strength, and has good heat preservation and insulation functions, the waste recovery ratio is larger than 40%, and the stone board belongs to environment-friendly products. The surface texture of the stone board is closer to that of natural stone. The back face of the stone board is porous and is used for outer wall wet combining, a binder can permeate into gaps, engaging force is higher, and the stone board can be firmly attached to an outer wall. In addition, the stone board is calcined at high temperature, has stable physical and chemical performance, and is not prone to weather.

Owner:广州米伽新材料科技有限公司

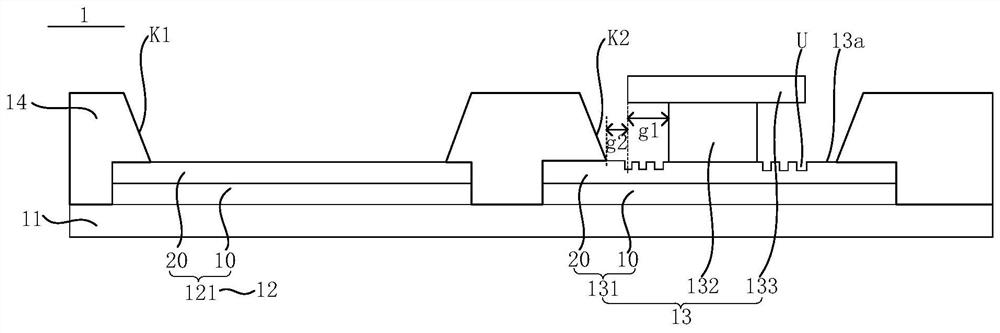

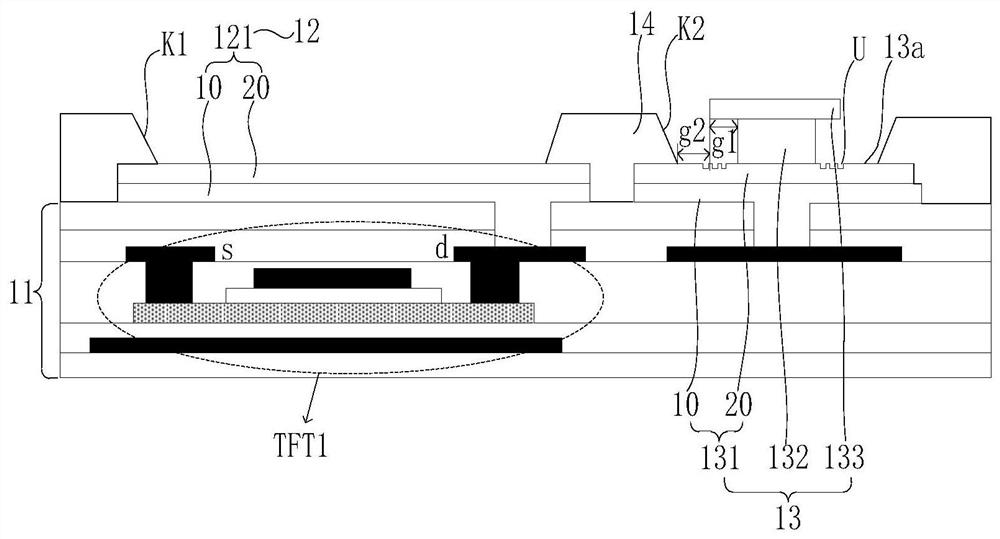

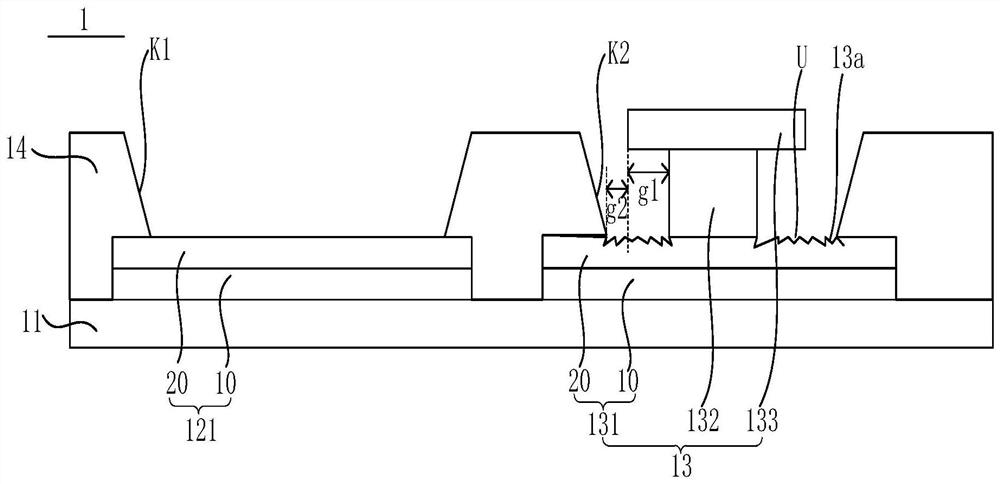

Display panel, preparation method thereof and display device

PendingCN112331801AImprove diffusion abilityIncrease contact areaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePhysics

The invention relates to the technical field of display, in particular to a display panel, a preparation method thereof and a display device. The technical scheme is used for solving the problems of small contact area and poor lapping stability during lapping of a cathode layer and an auxiliary cathode layer in the prior art. The embodiment of the invention provides a display panel. The display panel comprises a substrate; the at least one second opening is formed in the first conductive pattern layer, the second conductive pattern layer, the third conductive pattern layer and the fourth conductive pattern layer of the substrate, and in the at least one second opening, a first gap is formed between the edge of the orthographic projection of the third conductive pattern layer on the substrate and the edge of the orthographic projection of the fourth conductive pattern layer on the substrate; a second gap is formed between the fourth conductive pattern layer and the bottom edge of the second opening; the surface, away from the substrate, of the part, not covered with the third conductive pattern layer, of the at least one second conductive pattern layer is a first surface, and each first surface is at least provided with a groove in the first gap position.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com