Assembly type frame-core tube structural system adopting all-steel-encased stress component

A force-bearing component and assembled technology, which is applied in the direction of building structure and construction, can solve the problems of high maintenance requirements and maintenance costs, slow construction speed, deformation of steel box shear walls, etc., and achieve significant economic and social benefits , reduce the amount of on-site labor, and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

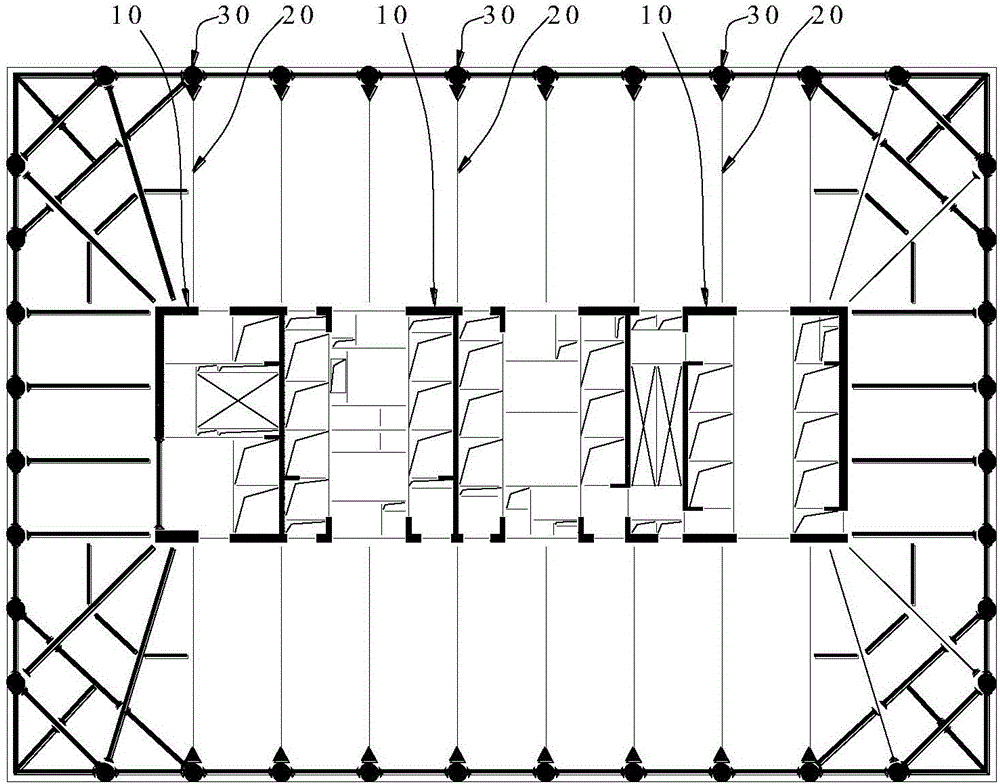

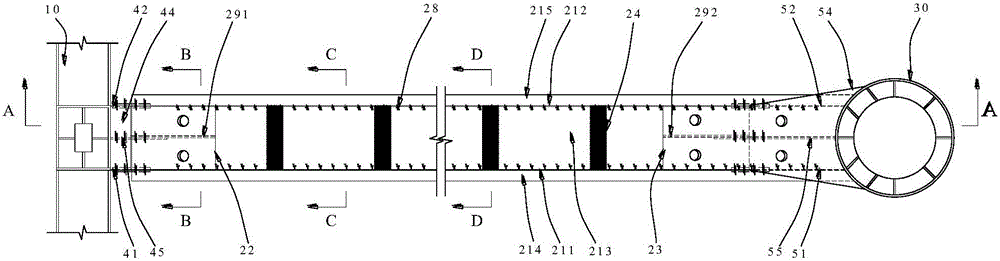

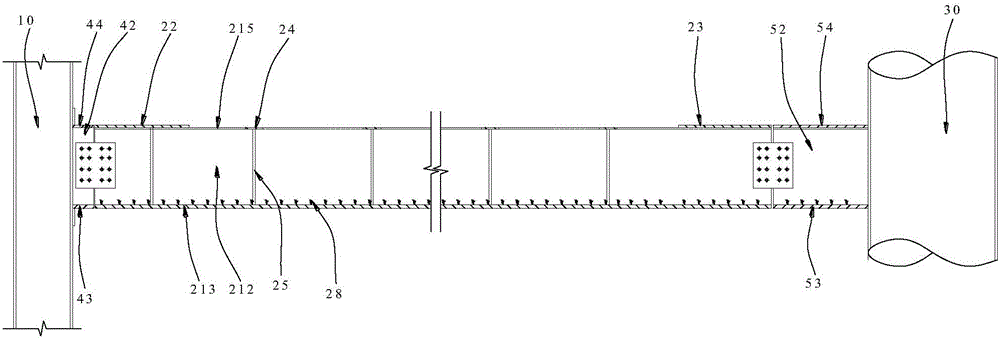

[0056] Such as Figure 1 to Figure 4 As shown, the present invention adopts the assembled frame-core tube structure system of all-clad steel stress members, which is the same as the conventional frame-core tube structure system, which is composed of a core tube with a shear wall and a frame column and a frame The outer frame of the beam is connected, and, in the fabricated frame-core tube structural system of the present invention, the shear wall is the external steel box 11 as the outer wall of the shear wall and cast-in-situ concrete is poured inside the external steel box 11 12 of the steel box concrete shear wall 10, the frame column is a steel tube concrete column 30 with the outsourcing steel pipe 31 as the outer wall of the column and the cast-in-situ concrete 32 is poured inside the outsourcing steel pipe 31, and the concealed column connected to the steel box concrete shear wall 10 The frame beam between the position and the steel tube concrete column 30 is a steel con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com