Double roller crusher

A technology of roller crusher and roller, which is used in the preparation of test samples, grain processing, etc., can solve the problems of easy sticking, difficult to clean, affecting the crushing efficiency, etc., so as to increase the driving force and crushing force, and improve the overall Service life, the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

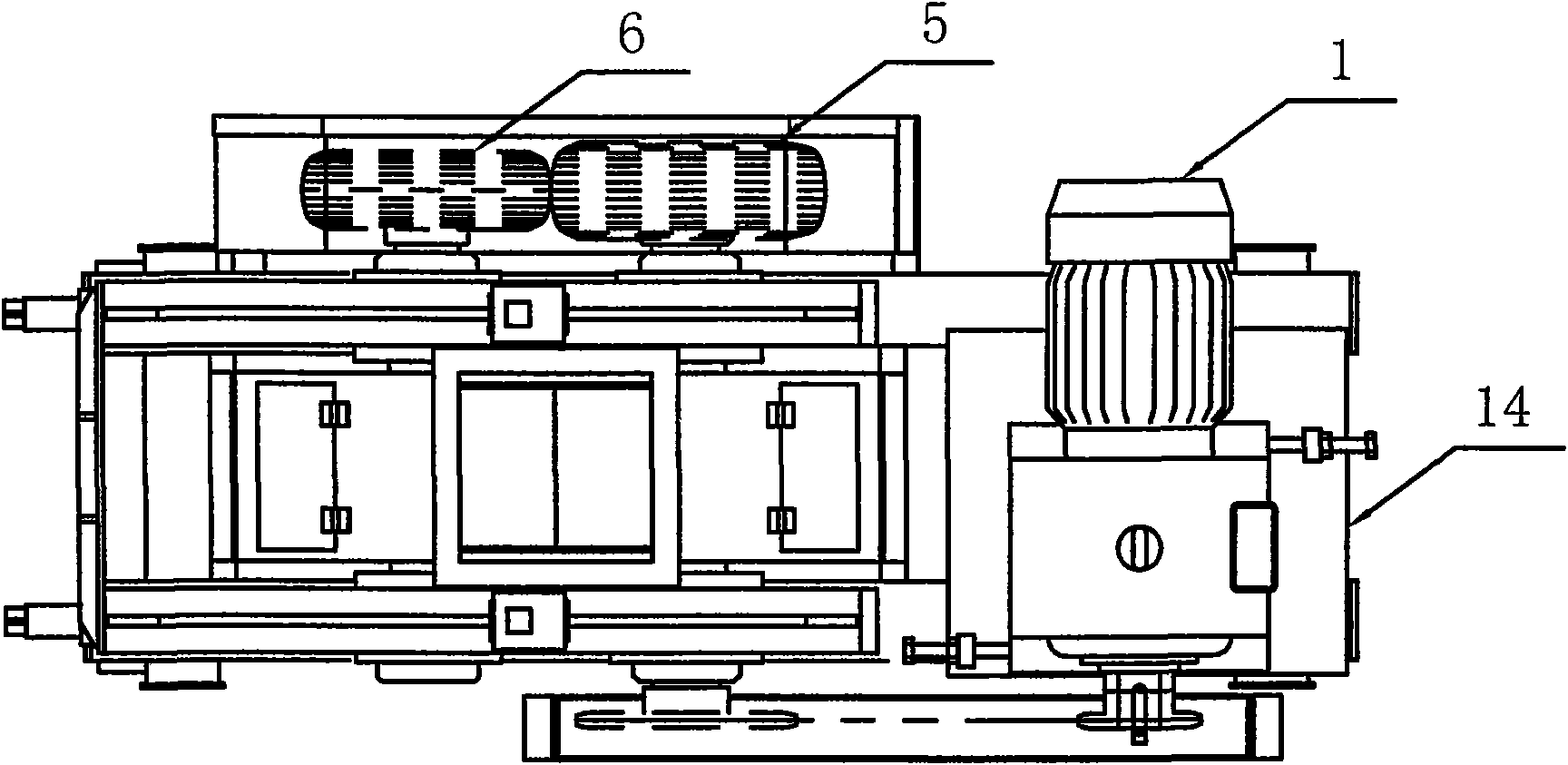

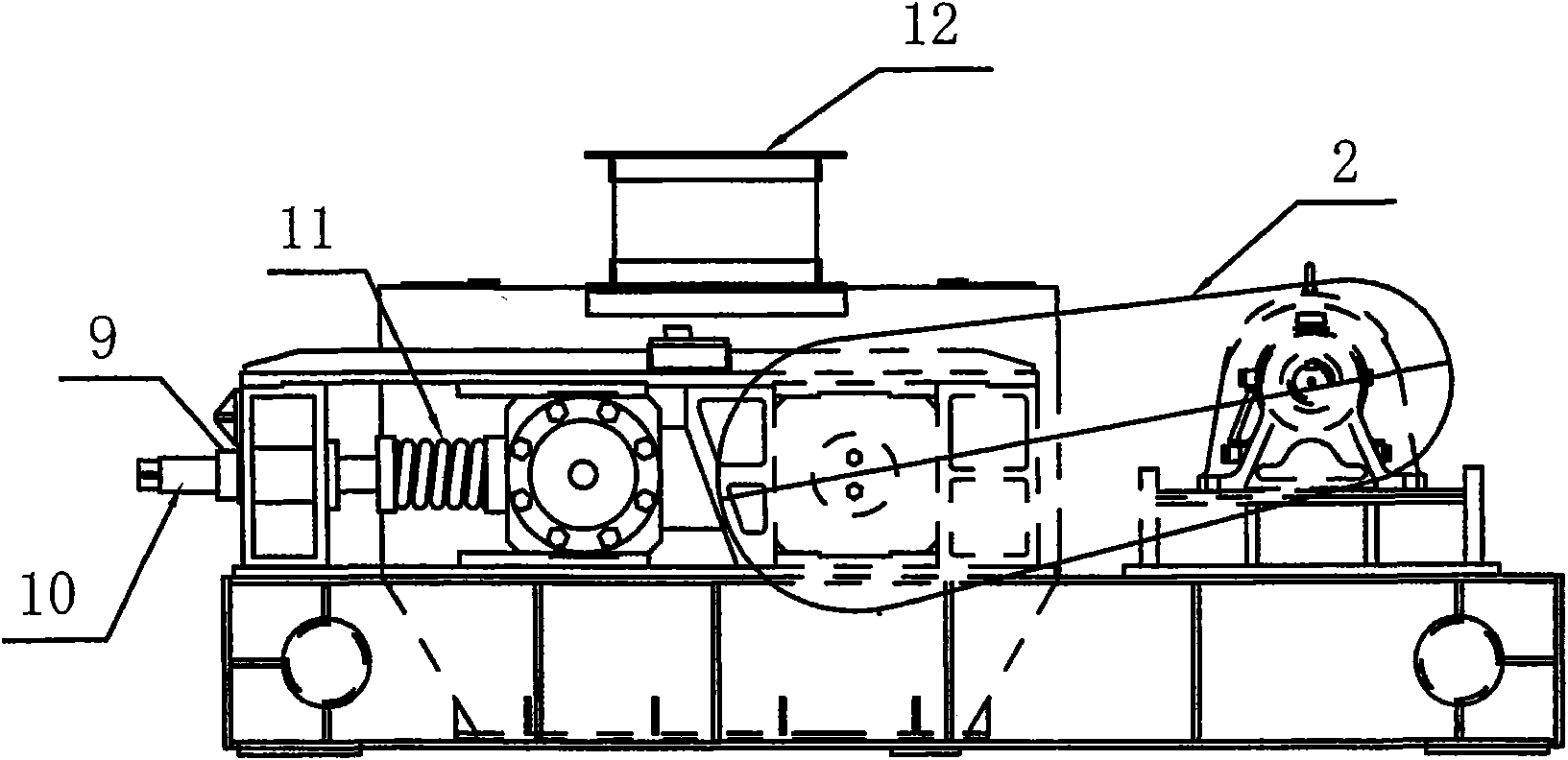

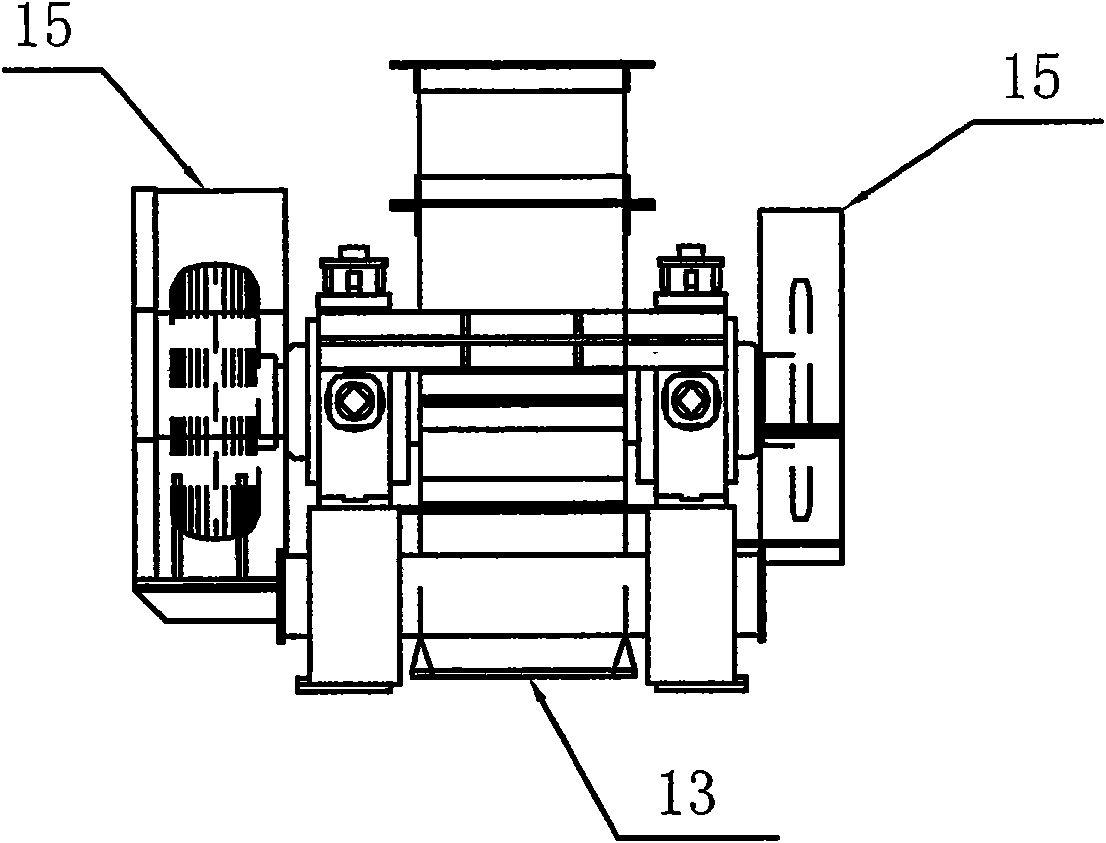

[0024] Refer to attached figure 1 to attach Figure 5 , the embodiment of the present invention will be described.

[0025] The roller crusher of the present invention is mainly composed of a drive reduction motor 1, a chain transmission mechanism 2, a driving shaft 3, a driven shaft 4, a driving tire 5, a driven tire 6, a material inlet 12, a material outlet 13, and a support 14; one end of the driving shaft 3 is connected to the driving reduction motor 1 through the chain transmission mechanism 2, the other end is connected to the driving tire 5, and the driven shaft 4 is connected to the driven tire 6, so that the driving tire 5 and the driven tire 6 are closely matched to each other , the driving shaft 3 and the driven shaft 4 are respectively tightly sleeved with a roller 7, and four in-line teeth 8 are evenly welded on the roller 7 along the circumferential direction, as Figure 5 As shown; the roller crusher also includes a roller spacing adjustment device, which is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com