Multifunctional concrete surface forming machine

A concrete surface and molding machine technology, which is applied in ceramic molding machines, manufacturing tools, coastline protection, etc., can solve the problems of inability to extract pulp, poor light forming effect, difficult pulp extraction, etc., and achieve fast construction speed, dense pulp extraction, The effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

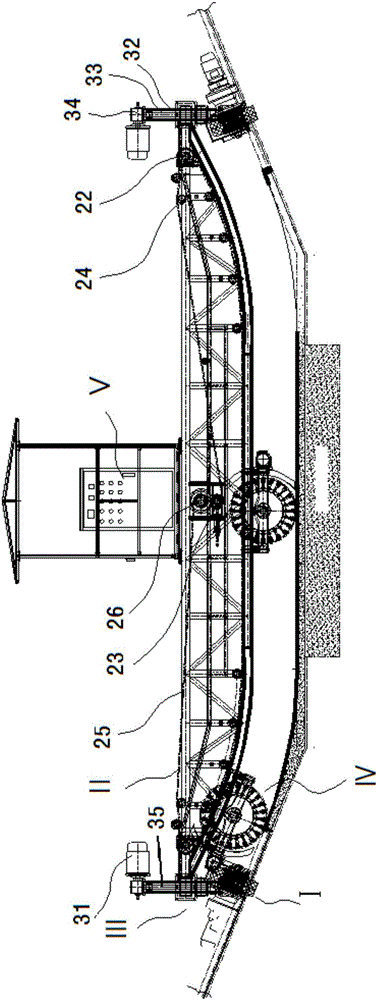

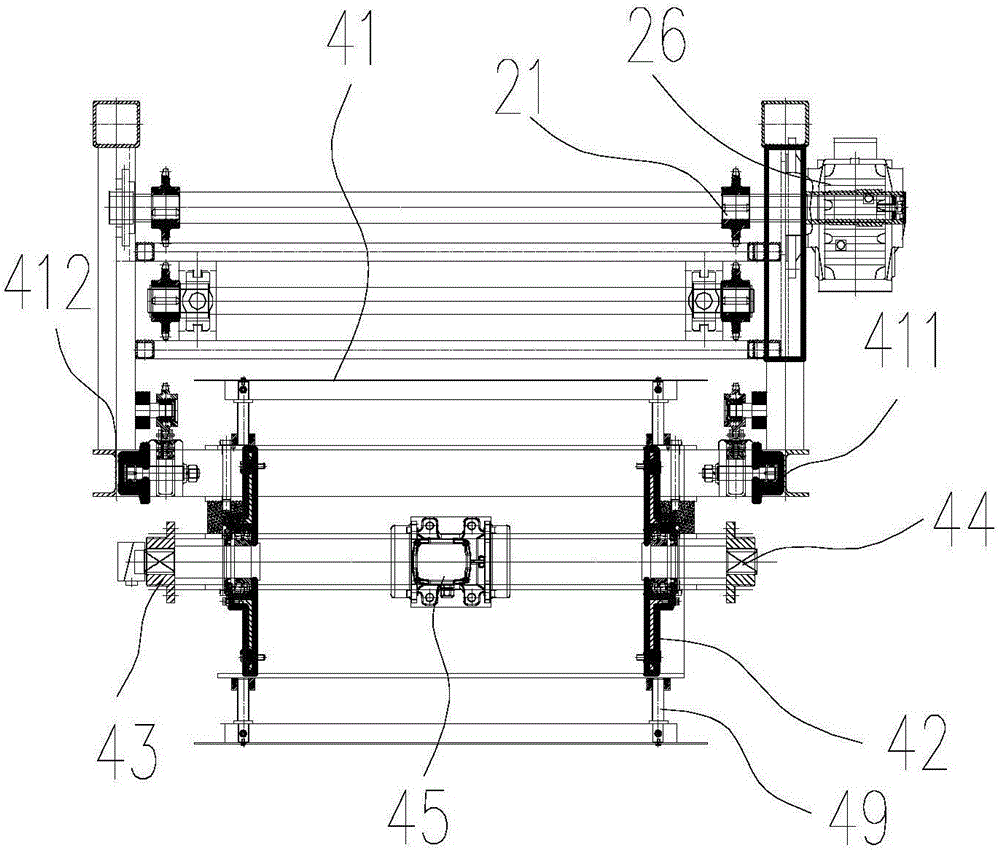

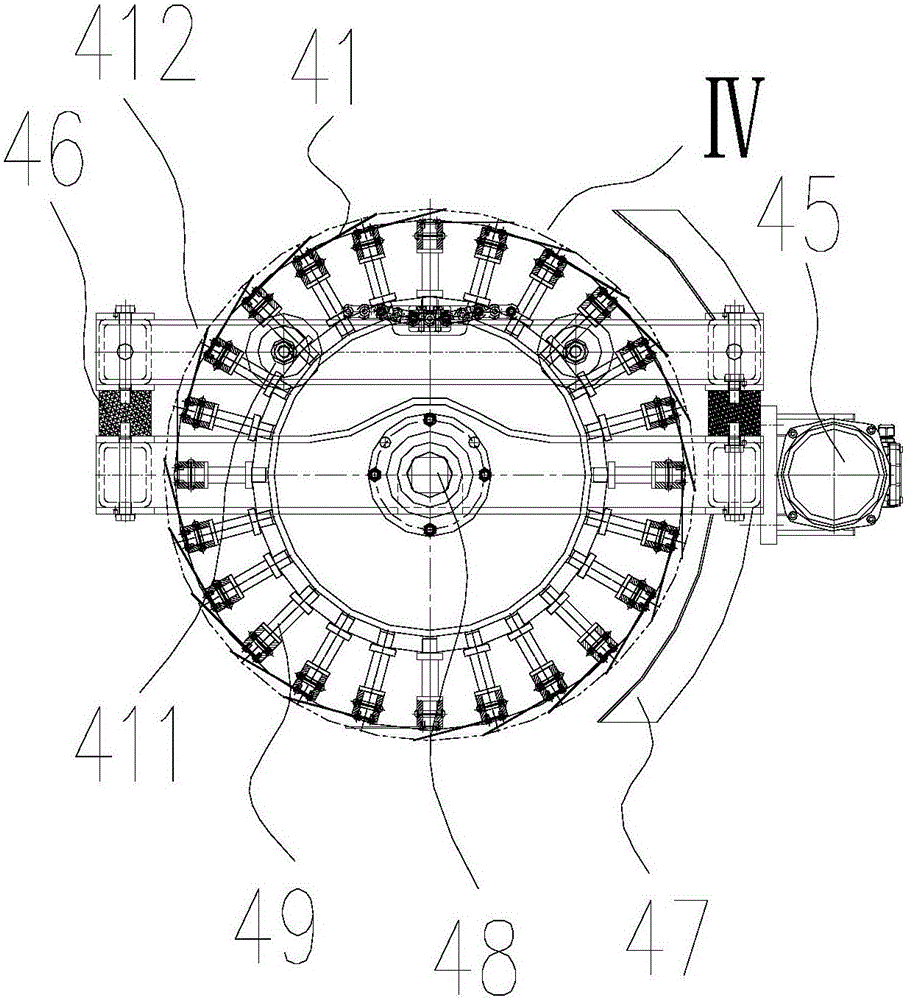

[0017] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a concrete surface multifunctional forming machine, which comprises a supporting frame assembly; a walking device I of the frame assembly; adjusting the height of both ends of the frame assembly to adapt to the inclination of the slope The frame assembly supports the lifting device III; the vibrating roller forming vehicle IV for shaping, lifting and finishing the concrete surface; the forming vehicle traction device II that drives the vibrating roller forming vehicle IV to reciprocate along the frame assembly ; Control and lighting system Ⅴ.

[0018] The main functions of this concrete surface multifunctional molding machine are: it can realize mechanized operation on the surface of plane and curved surface lining concrete; it can simulate all the functions of manual finishing and calendering on the concrete surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com