3D printing wire feeding, clamping and guiding device

A guiding device and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of weak clamping, interrupted feeding, poor feeding, etc., to solve the problem of slippage and deviation, improve service life, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

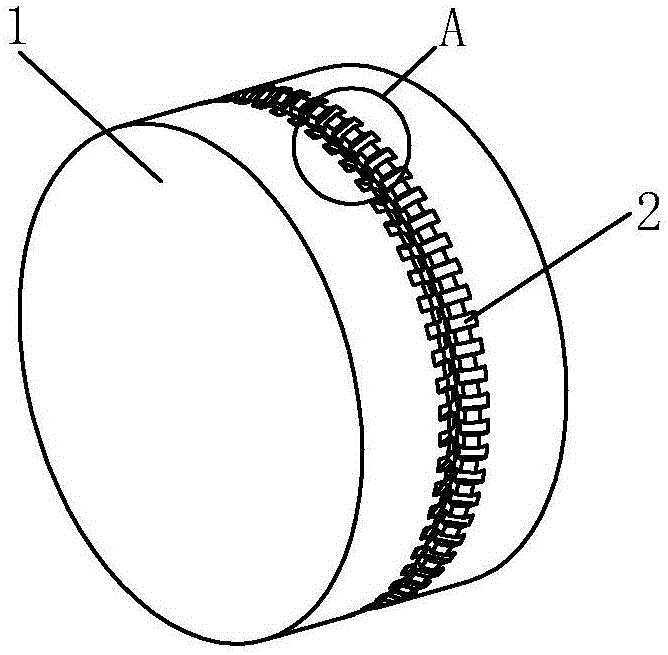

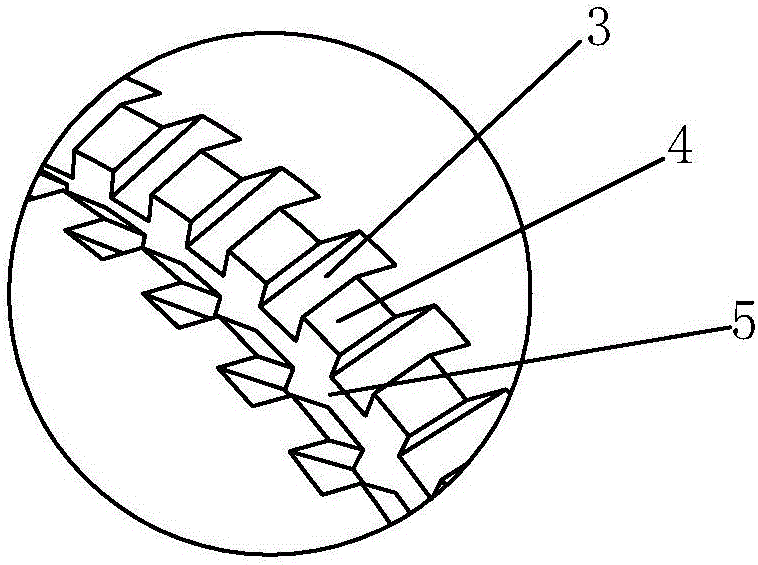

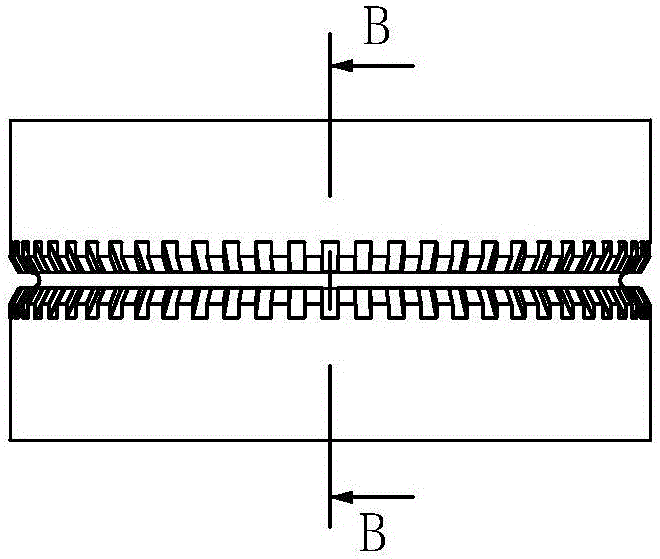

[0025] Such as Figure 1 to Figure 8 As shown, the 3D printing material filament feeding and clamping guide device of the present invention includes guide wheel I1 and guide wheel II8 for clamping the material wire, guide wheel I1 and guide wheel II8 are arranged side by side, and the circumferential surface of guide wheel I1 is provided with an inward A circle of V-shaped cogging Ⅰ2 is sunken, and a circle of V-shaped cogging Ⅱ14 sunken inward is provided on the circumferential surface of the guide wheel Ⅱ8. The V-shaped cogging Ⅰ2 on the guide wheel Ⅰ1 and the V-shaped cogging Ⅱ14 on the guide wheel Ⅱ8 The positions are corresponding. When the guide wheel I1 and the guide wheel II8 are arranged side by side, the V-shaped tooth groove I2 and the V-shaped tooth groove II14 enclose the guide groove 9 for clamping the guide wire. The waste material groove I5 connected with the V-shaped tooth groove I2 is inwardly recessed on the inner side of the V-shaped tooth groove II14 and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com