Patents

Literature

166results about How to "Avoid squishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

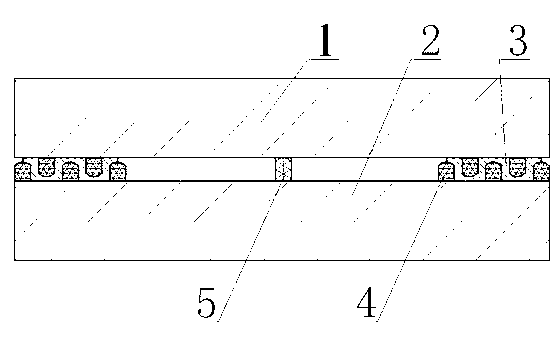

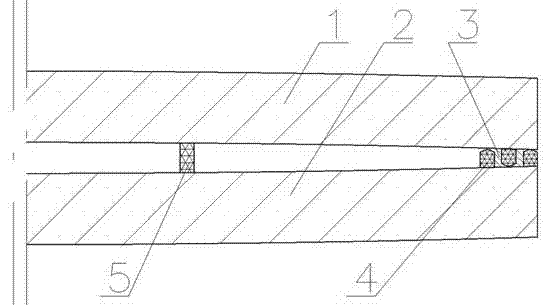

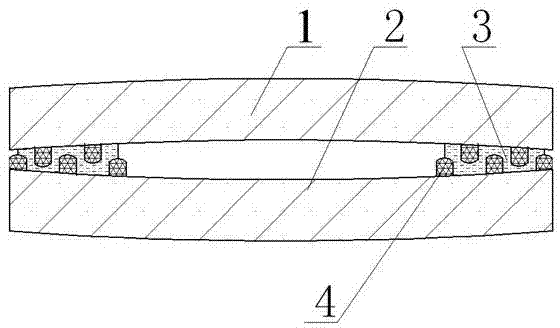

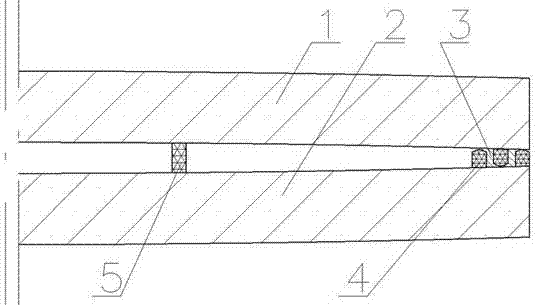

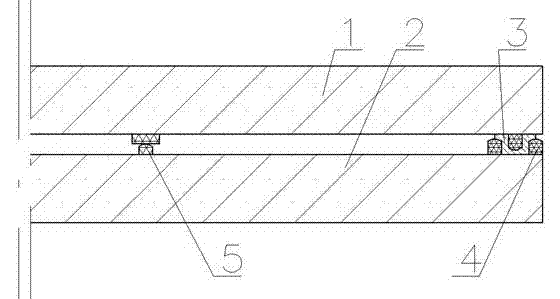

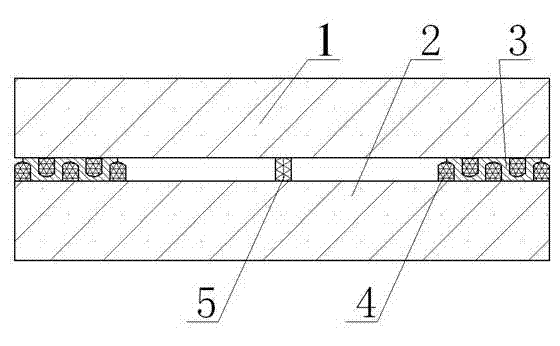

Flat vacuum glass welded by using metal welding material and provided with strip frame edge sealing, and manufacturing method thereof

InactiveCN102976592AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionAlloyGlass manufacturing

The present invention relates to a vacuum glass, which is characterized in that peripheries of an upper glass and a lower glass of the vacuum glass comprise edge sealing strip frames, and a metal welding material or an alloy welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the upper edge sealing strip frame and the lower edge sealing strip frame. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

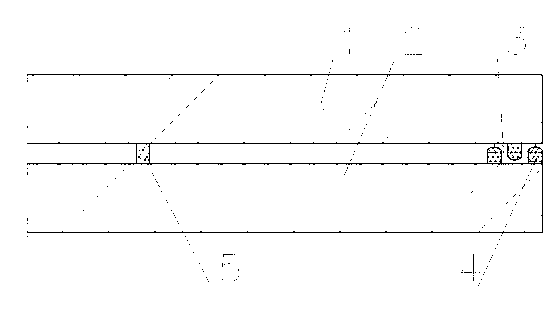

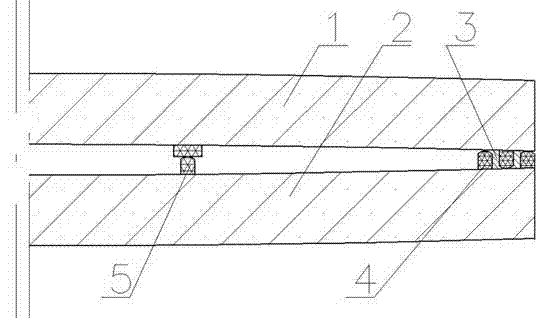

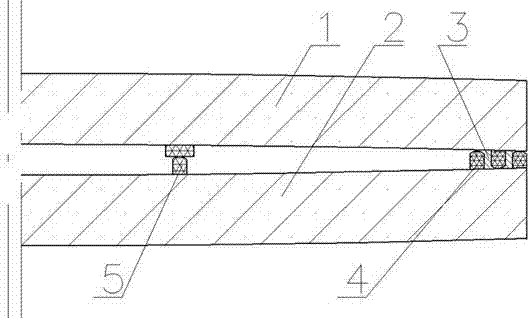

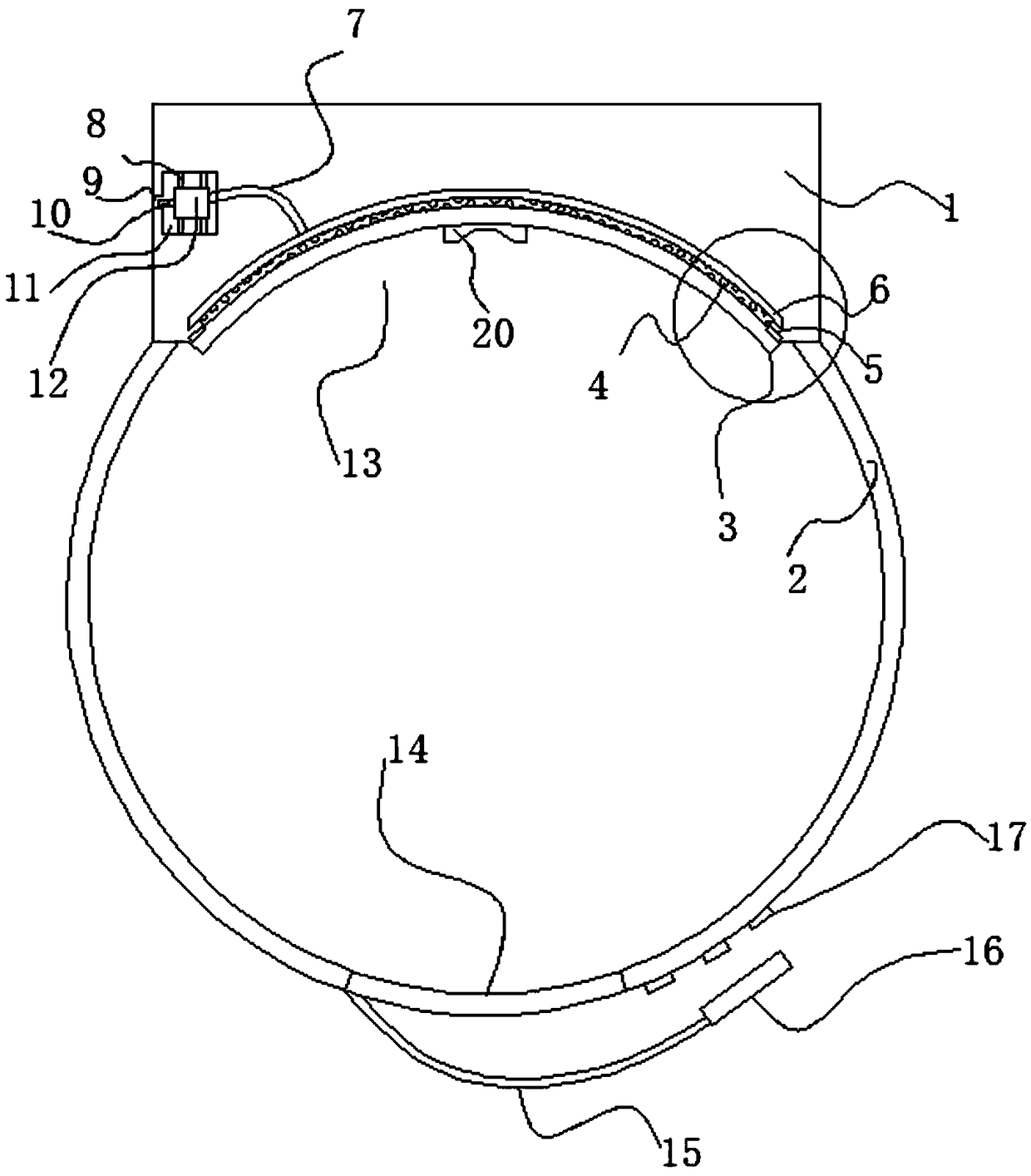

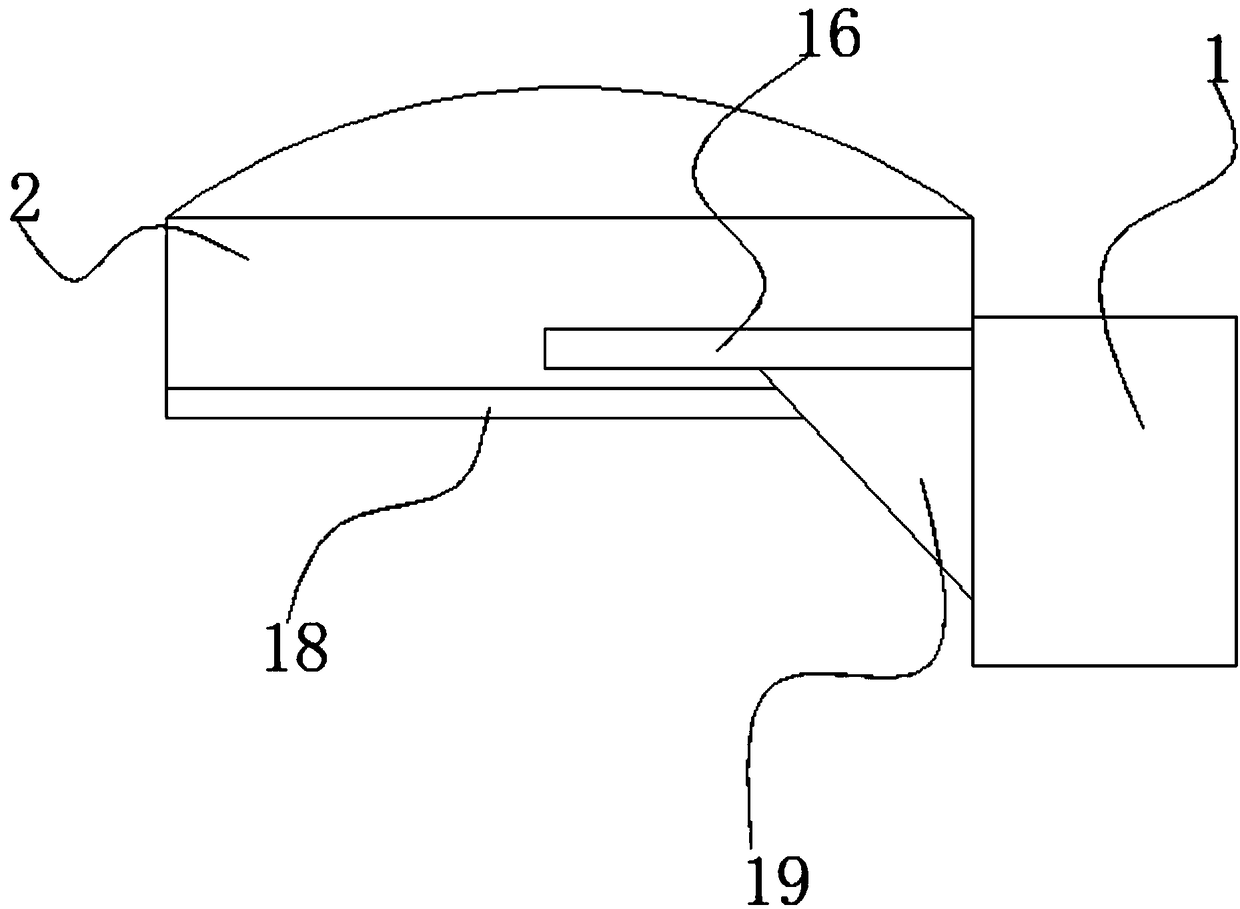

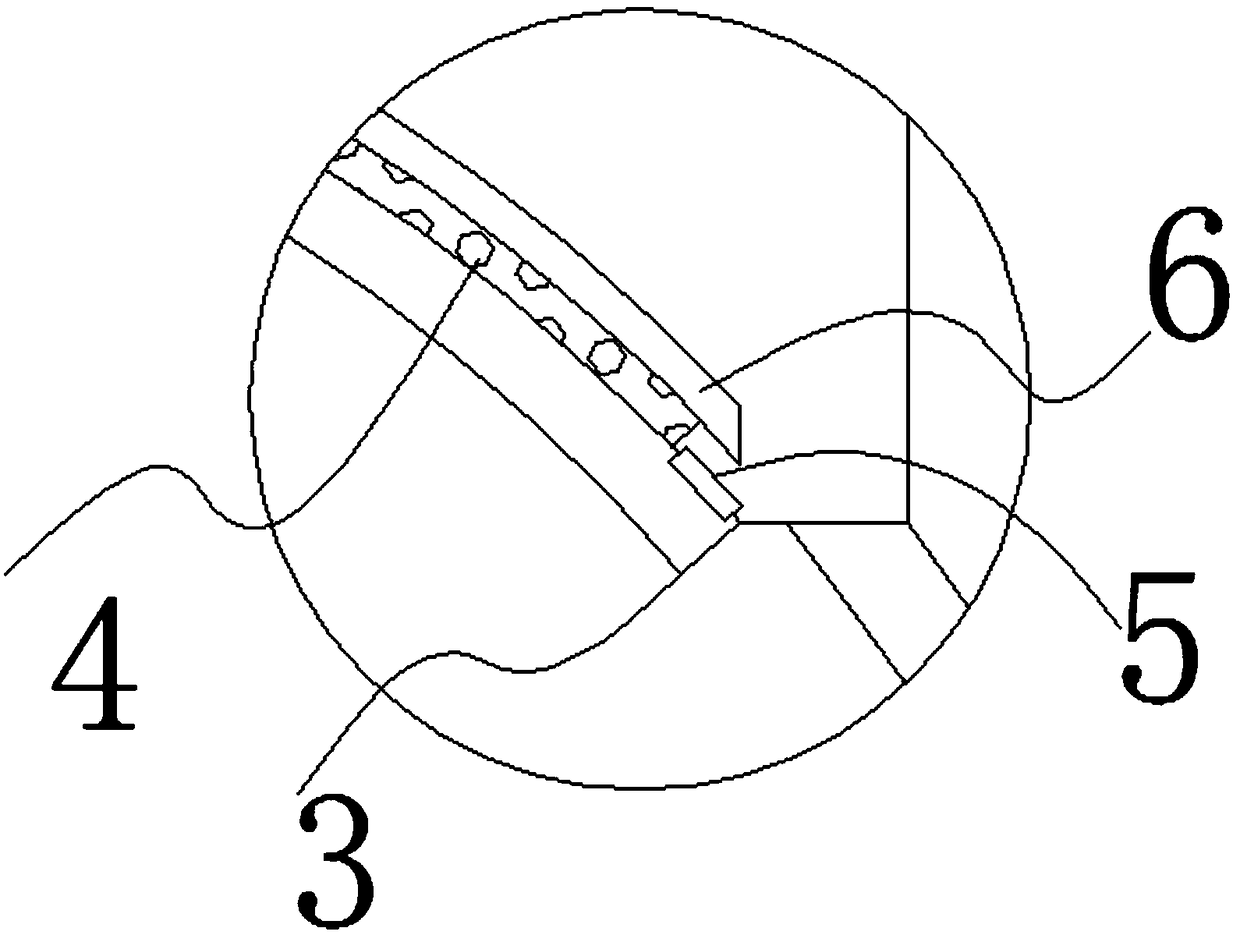

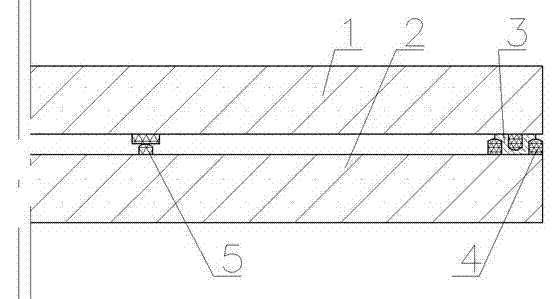

Metal solder-welded and strip frame-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951826AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMetalEdge banding

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex surface glass, edge sealing strip frames are arranged at the welded peripheries of the upper glass and the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the upper and the lower edge sealing strip frames can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

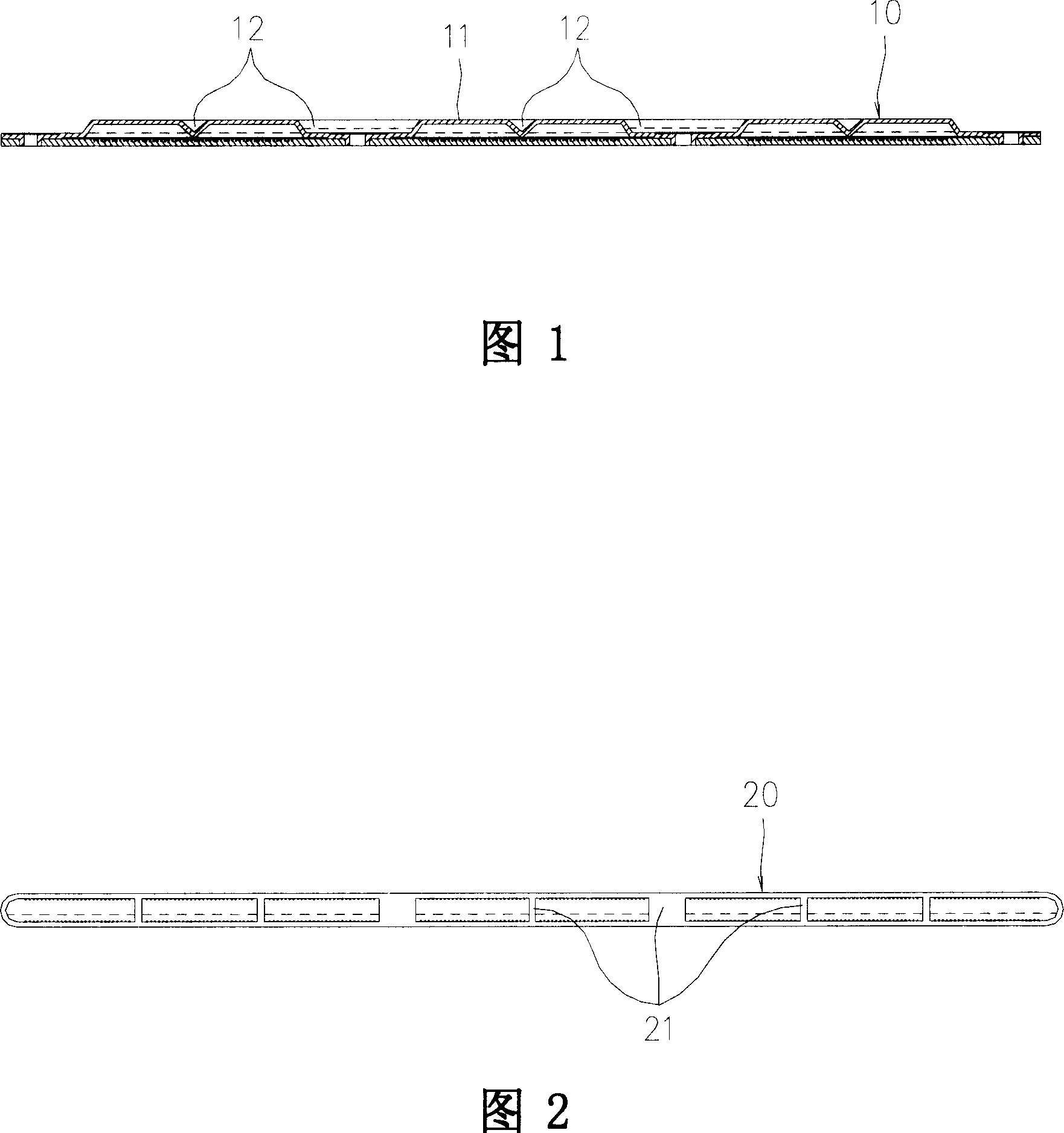

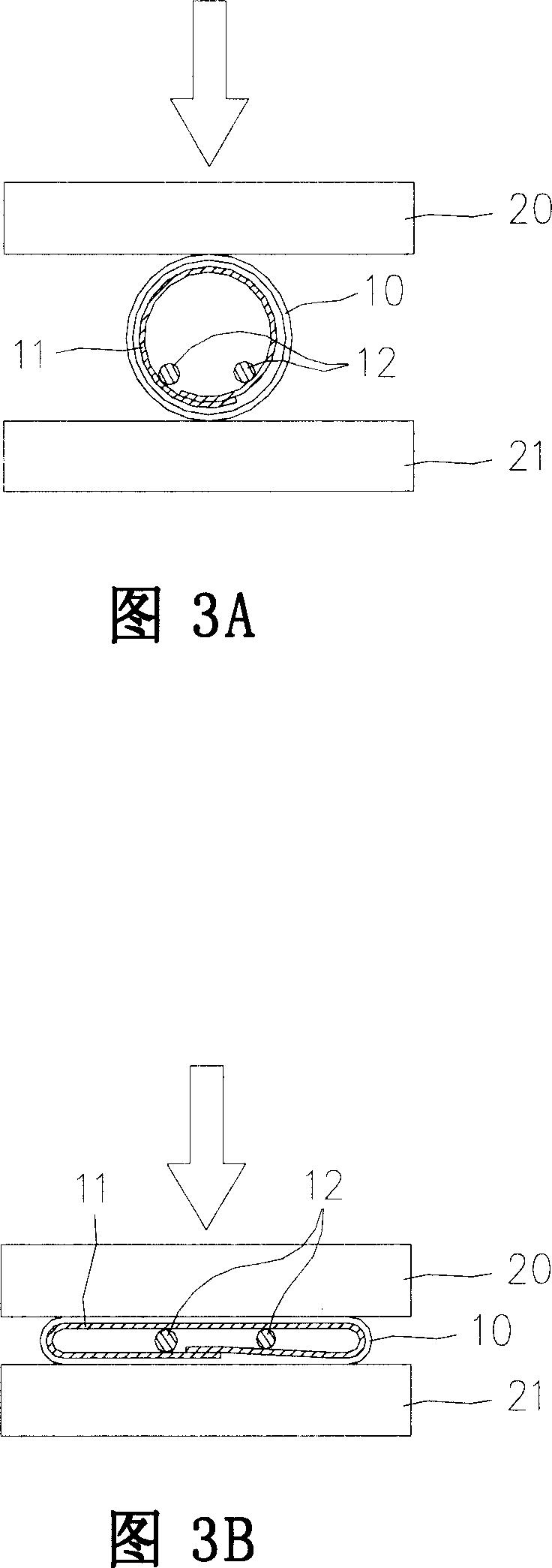

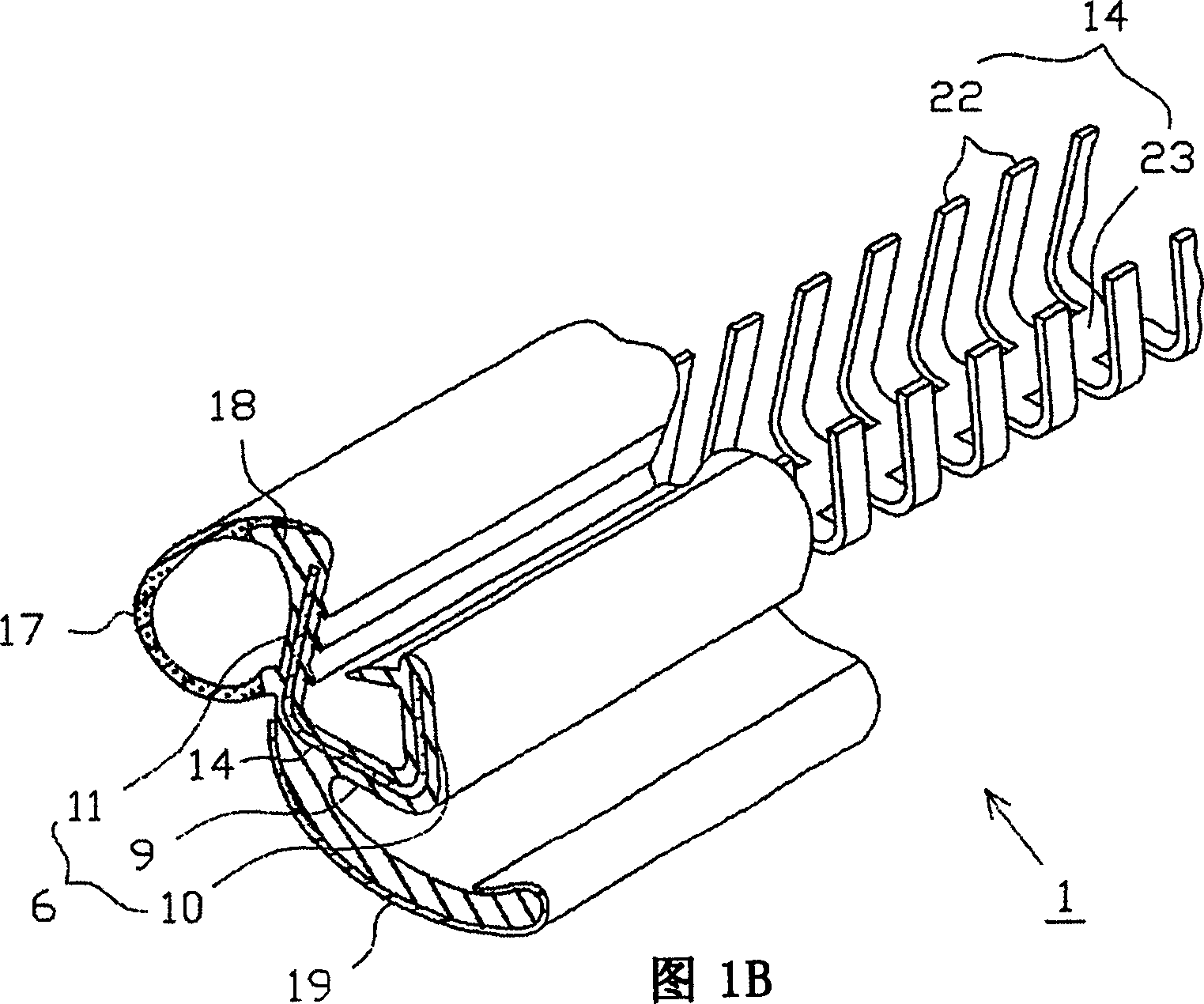

Penetrating support structure and its production

The inventive structural support is made of the braided wire or is made of sheet or block material to form a sheet-shaped concave-convex structure with several throughholes by punching, etching, electroplating or electroforming processes. The structural support is combined in the cavity of liquid-vapour two phases cooling assembly and is fit with a capillary structural layer.

Owner:奇科技股份有限公司

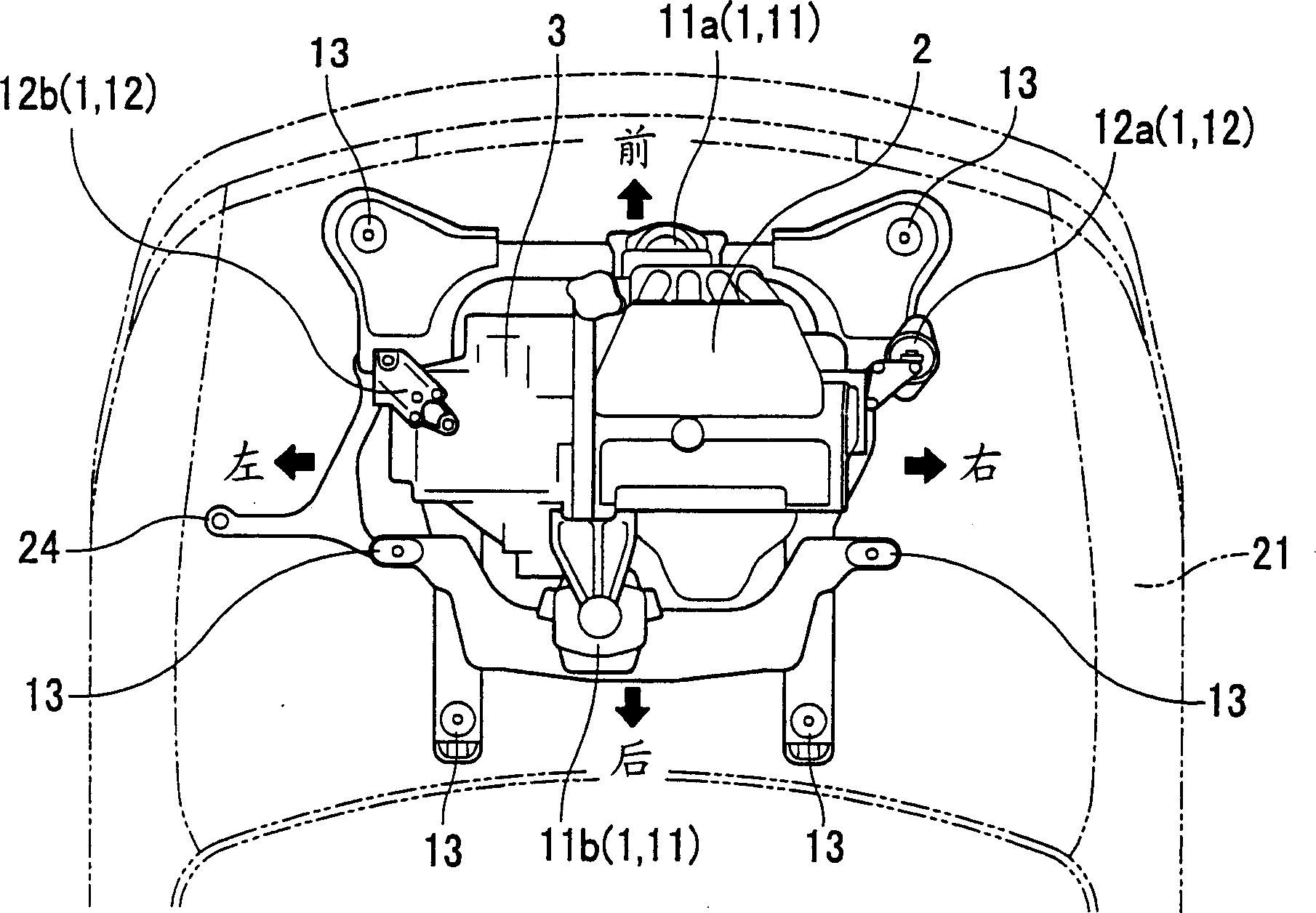

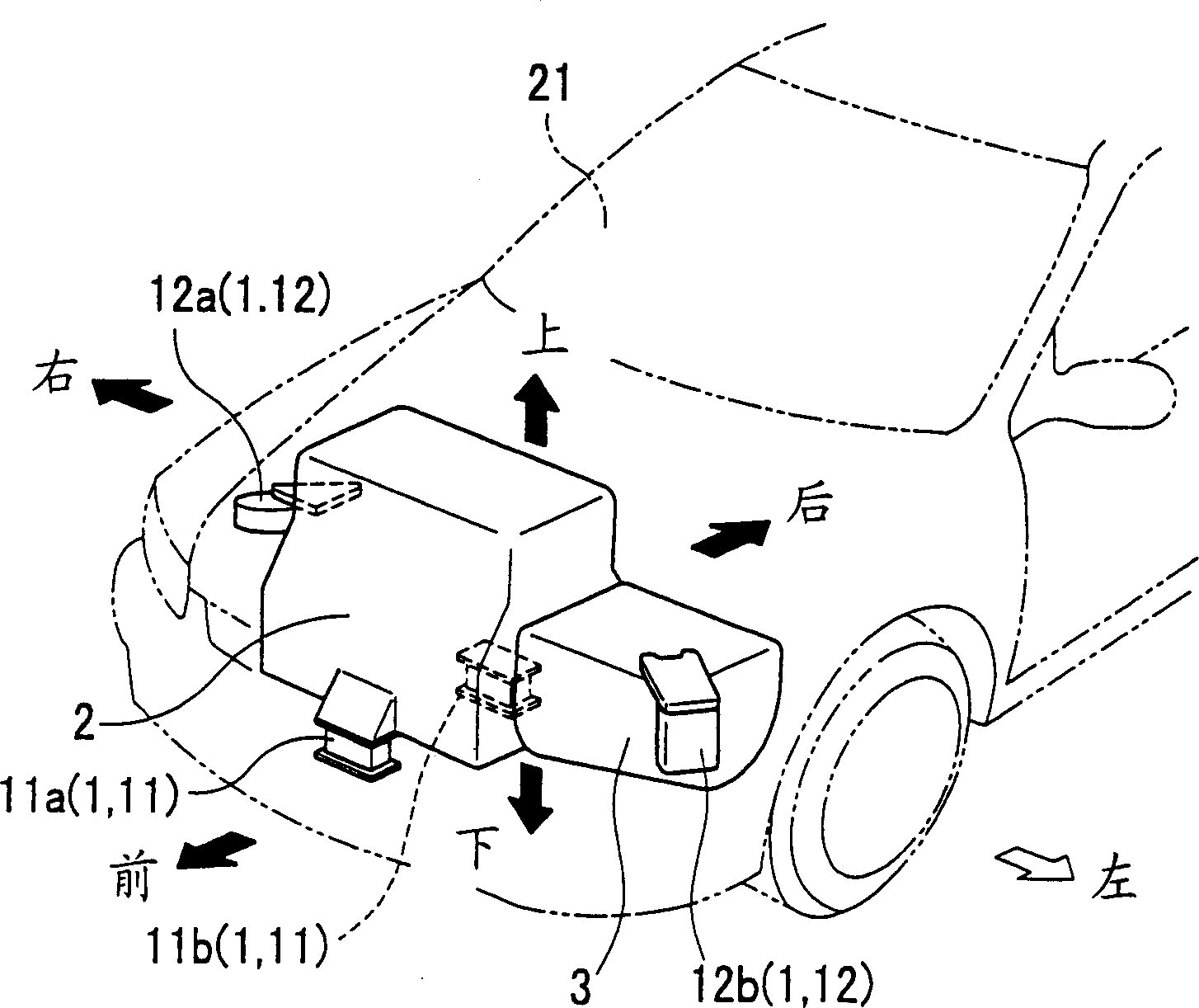

Supporting structure for vehicle power source

InactiveCN1490187AAvoid squishingJet propulsion mountingInternal combustion mountingGravity centerAutomotive engineering

A supporting structure of a vehicle power source consists of a plurality of mount members with elasticity through which a power source is mounted on a vehicle body; first mount members for primarily sharing the weight of the power source and at least one of the first mount members, which is supported by the vehicle body at a first height lower than the height of gravity center of the power source, is attached to a sub-frame; and second mount members for secondarily sharing the weight of the power source and the second mount members, which have a spring effect in at least one of longitudinal and lateral directions of the vehicle body, are attached to the vehicle body at a second height higher than the gravity center of the power source. In the supporting structure, the height of elasticity center of the structure defined by the first and second mount members is set to be higher than the gravity center of the power source.

Owner:HONDA MOTOR CO LTD

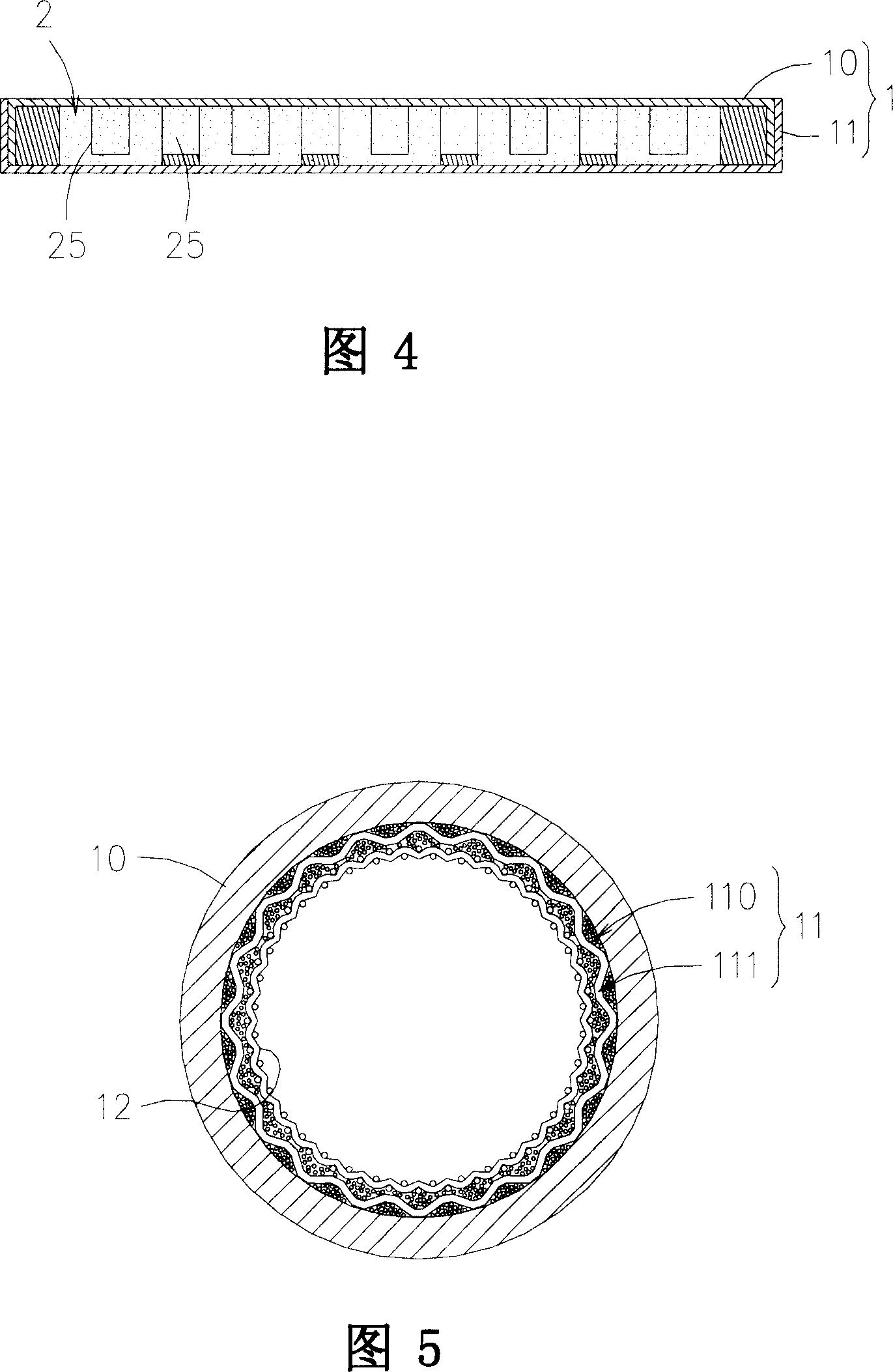

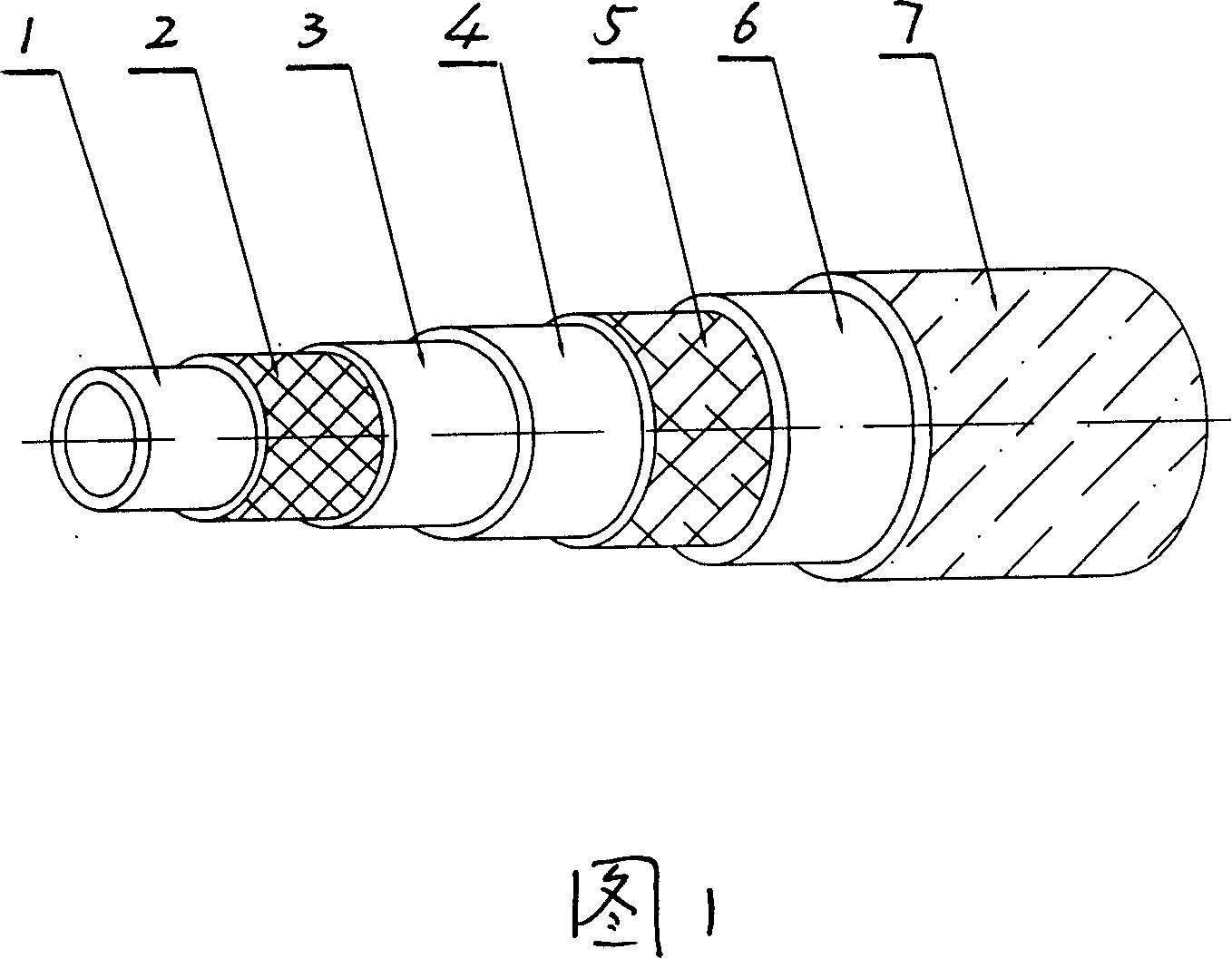

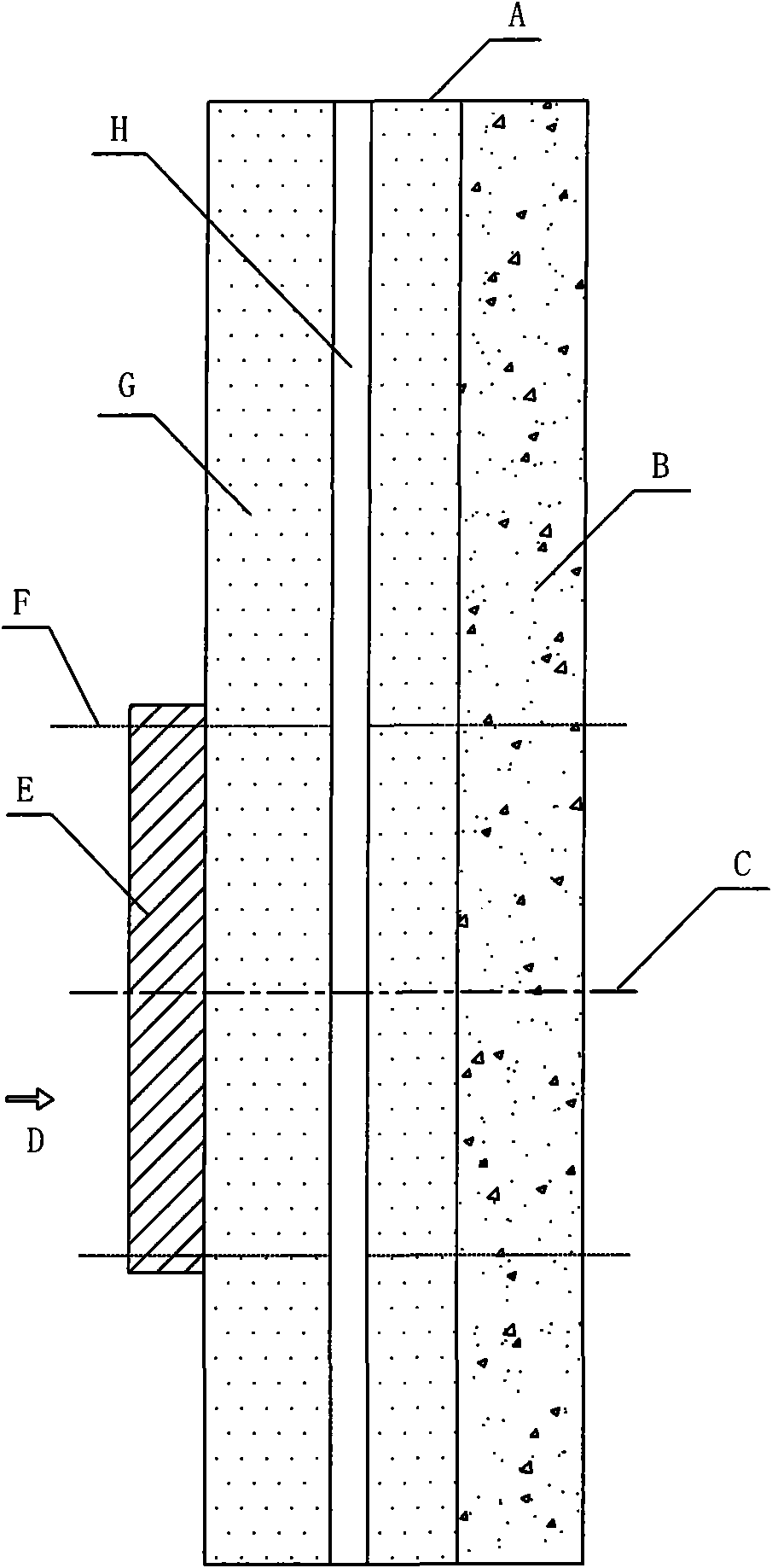

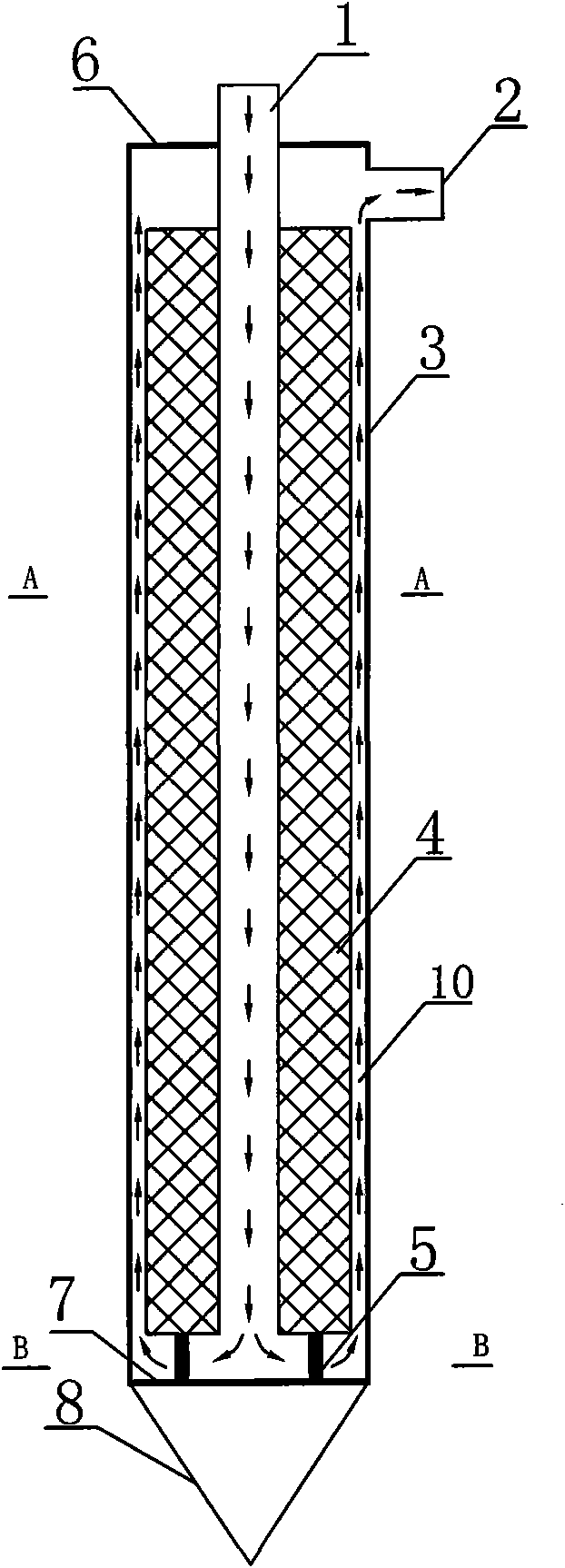

Continuously reinforced plastic heat-preserving composite pipeline used for oil field ground and its manufacturing technique

InactiveCN101153674AMemoryImprove insulation effectRigid pipesTubular articlesCross-linked polyethyleneSealant

The present invention discloses a continuous reinforced plastic composite pipe and the production technique for buried heat insulation of oil field; the continuous reinforced plastic composite pipe consists of an anticorrosive coating, a reinforced layer and a coating layer; crosslinked polyethylene foamed material is continuously rolled on the continuous reinforced plastic composite pipe to form a continuous insulating course, and fluid sealant layers are respectively coated between the coating layer and the insulating layer, the insulating layer and the protective layer. The reinforced layer is weaved by metal steel wires; the anticorrosive coating and the coating layer are made of crosslinked polyethylene material; the protective layer is made of polyethylene; the insulating course is made of crosslinked polyethylene foam. The pipe of the present invention is a long-distance flexible continuous pipe; the insulating course is made of crosslinked polyethylene flexible material; the continuous reinforced plastic composite pipe has good memory, rebound resilience and concentricity inside and outside the pipeline and ensures that the continuous heat insulation pipeline prevents being squashed after being coiled and buried; thereby the thickness of the insulating course is consistent and achieving better heat insulation effect. The pipeline paved by the invention, even if the local part is damaged, water can be effectively prevented to seep into the insulating course in order to ensure the heat insulation effect.

Owner:长春高祥特种管道有限公司

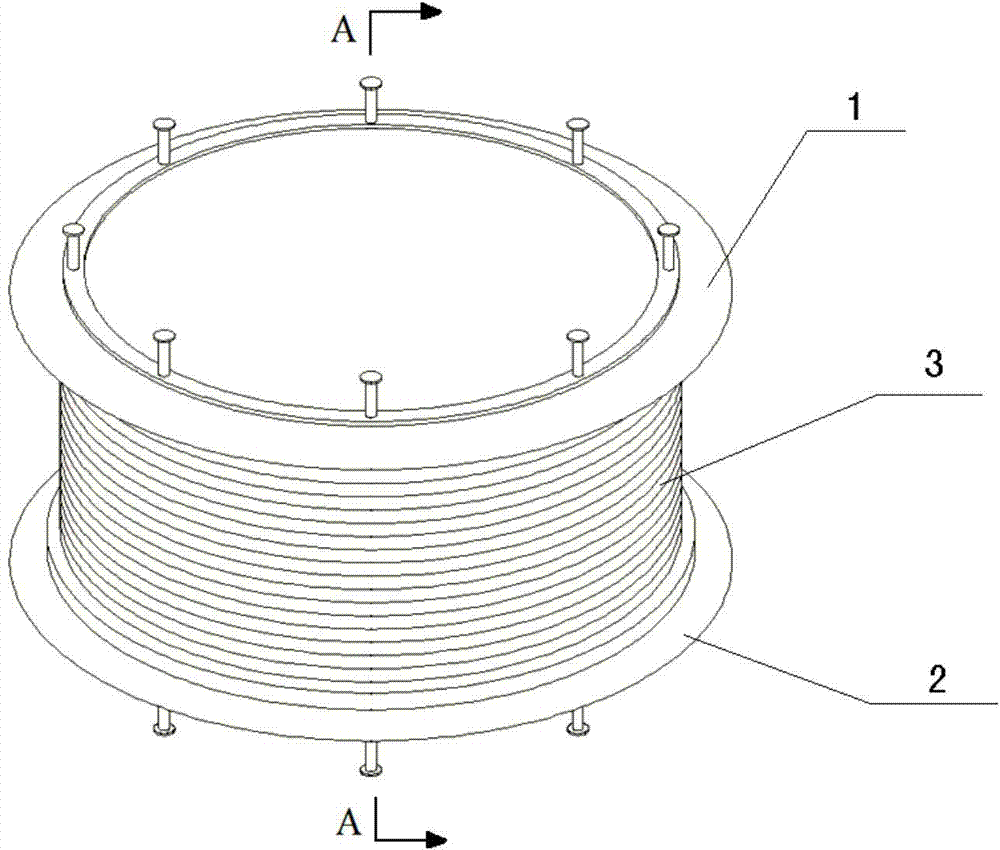

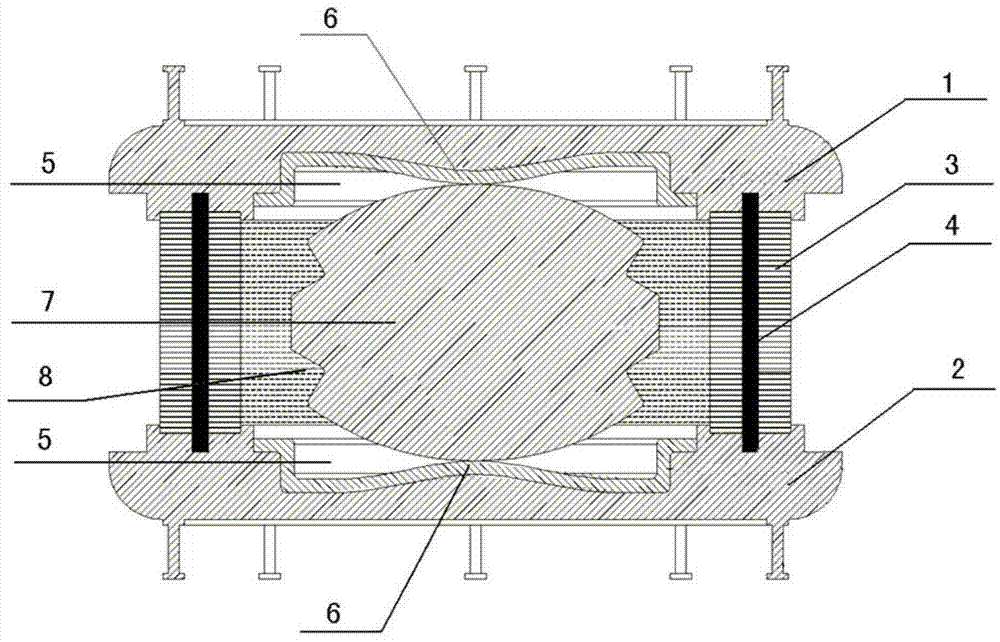

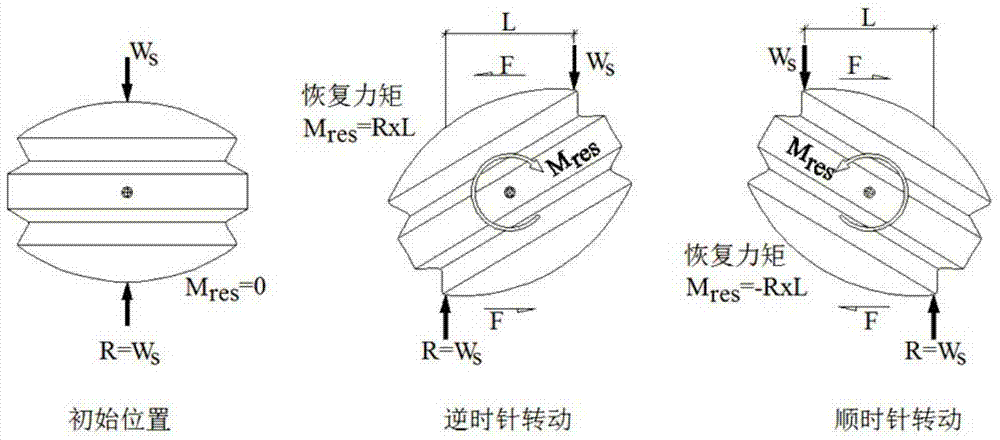

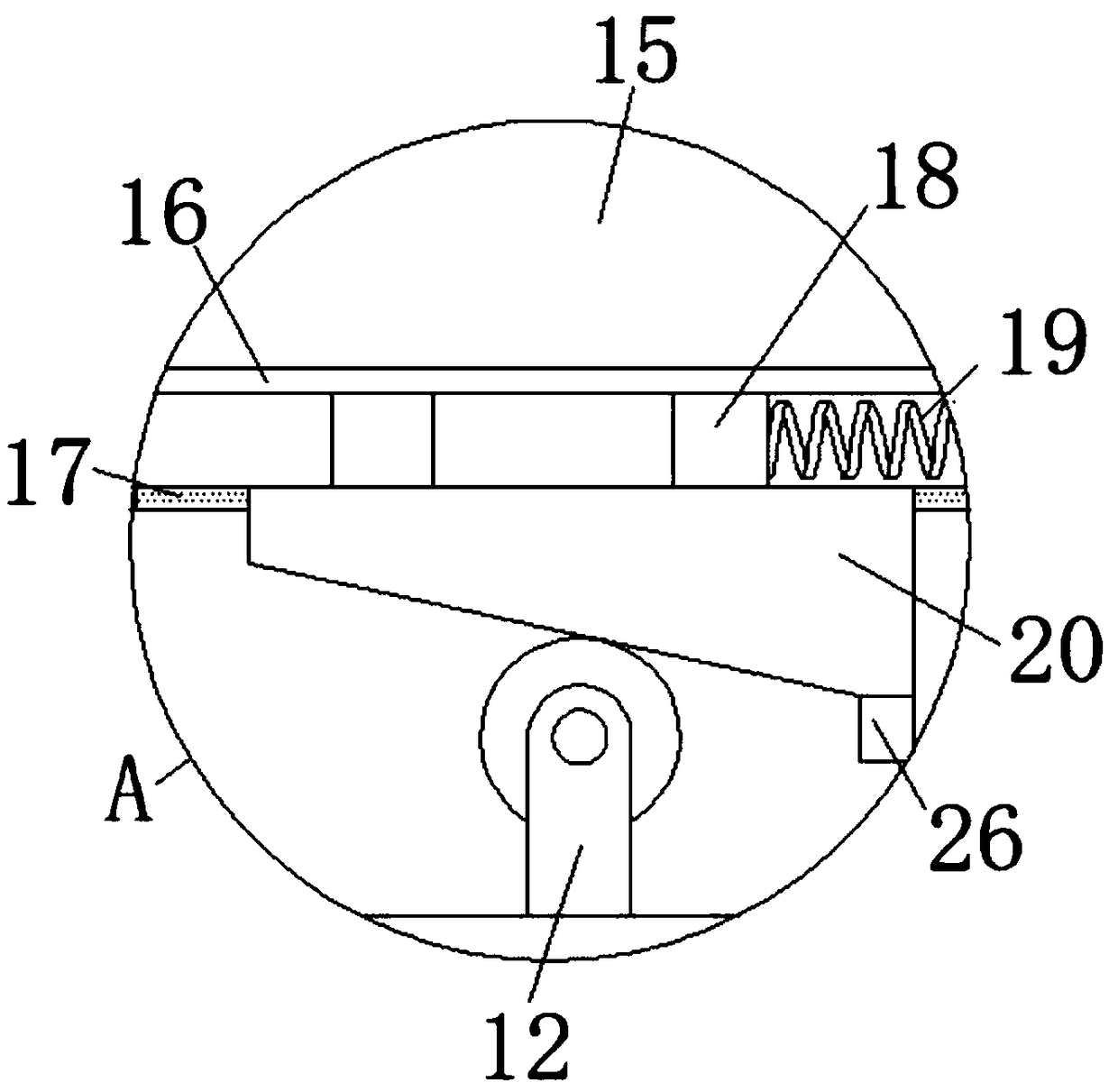

Novel self reset shock insulation support seat

ActiveCN104775358ASelf-resetting function guaranteeReduce overdependenceBridge structural detailsShock proofingSelf recoveryEngineering

The invention discloses a novel self reset shock insulation support seat, comprising an upper connection plate and a lower connection plate. The novel self reset shock insulation support seat is characterized in that corresponding grooves are formed in middles of the upper connection plate and the lower connection plate; bulges are correspondingly formed at the middles of the grooves; elastic cushion layers are cemented at the surfaces of the grooves; an oval rolling body is movably connected between the elastic cushion layers; two trenches are symmetrically formed in the spherical surface of the rolling body; a steel plate laminating rubber drum connected with the upper connection plate and the lower connection plate is arranged at the outside of the rolling body; a clearance is reserved between the rolling body and the steel plate laminating rubber drum; lead cores are arranged at the inner peripheral direction of the steel plate laminating rubber drum at equal intervals. The support seat can absorb high vibration energy, is high in self recovery capacity, and has the advantages of simple structure, convenience in use, high safety and the like, and excessive lateral displacement of the support seat is avoided without lifting a structure body.

Owner:TIANJIN UNIV

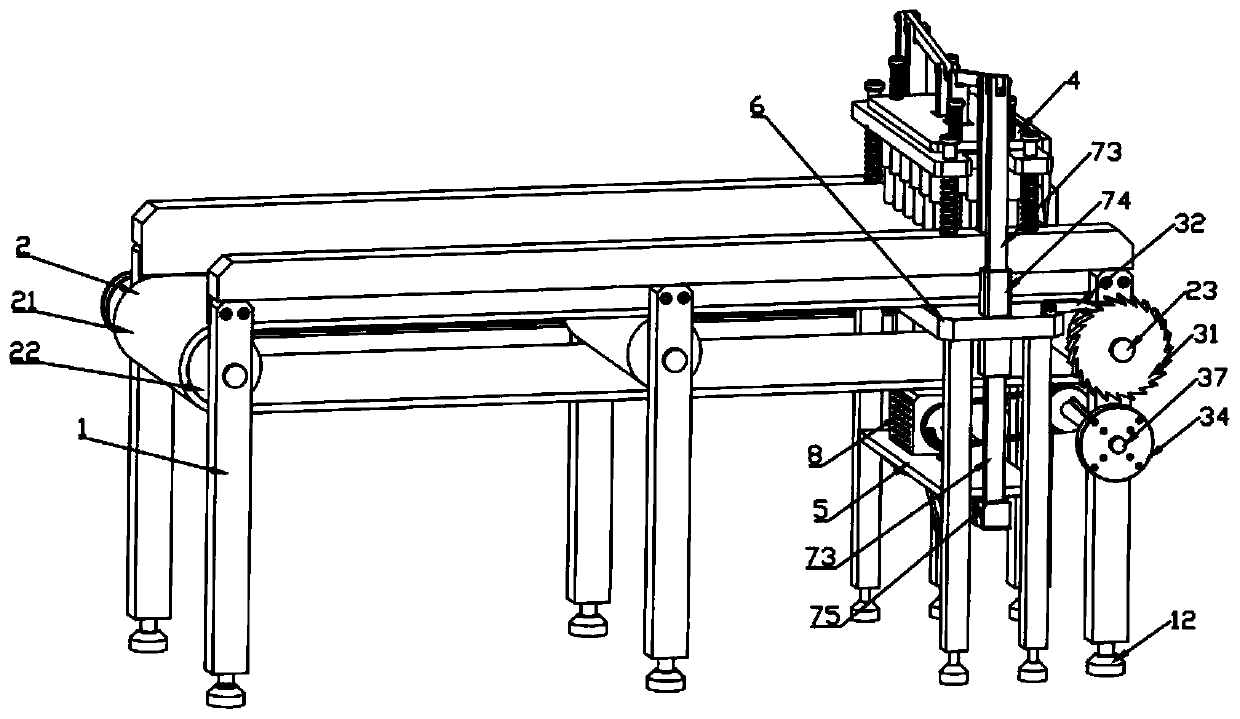

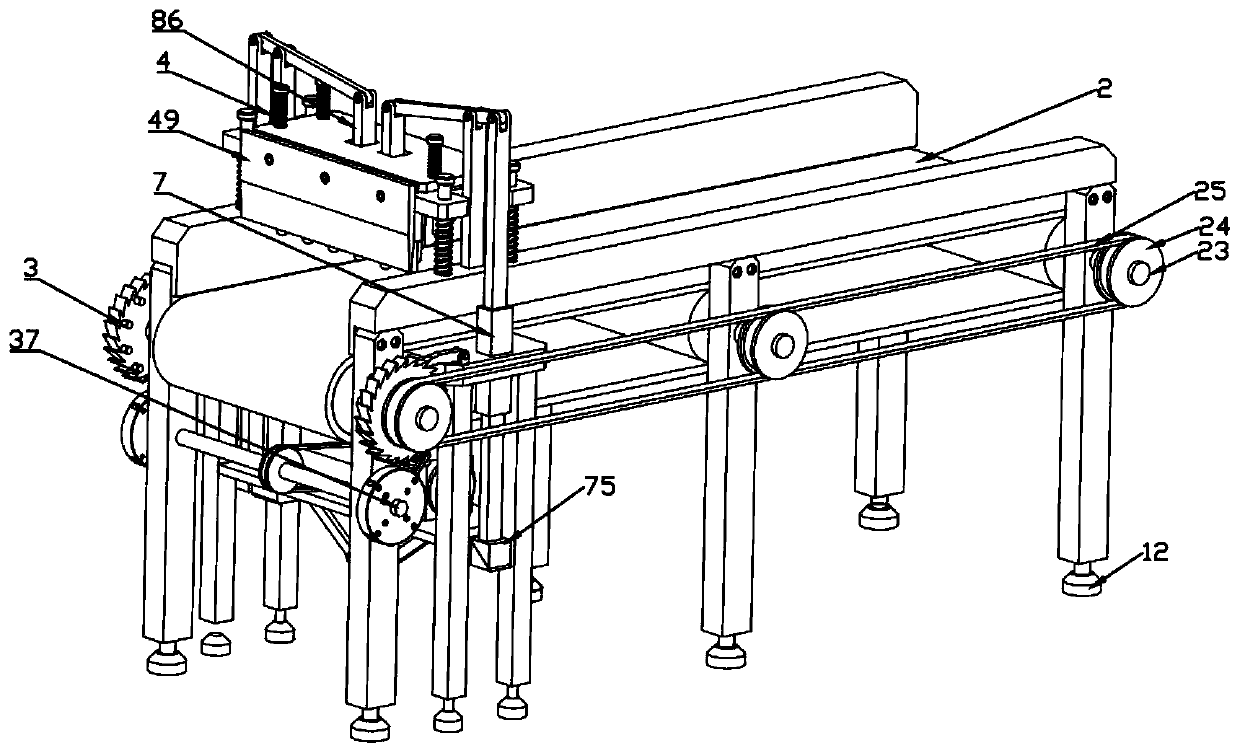

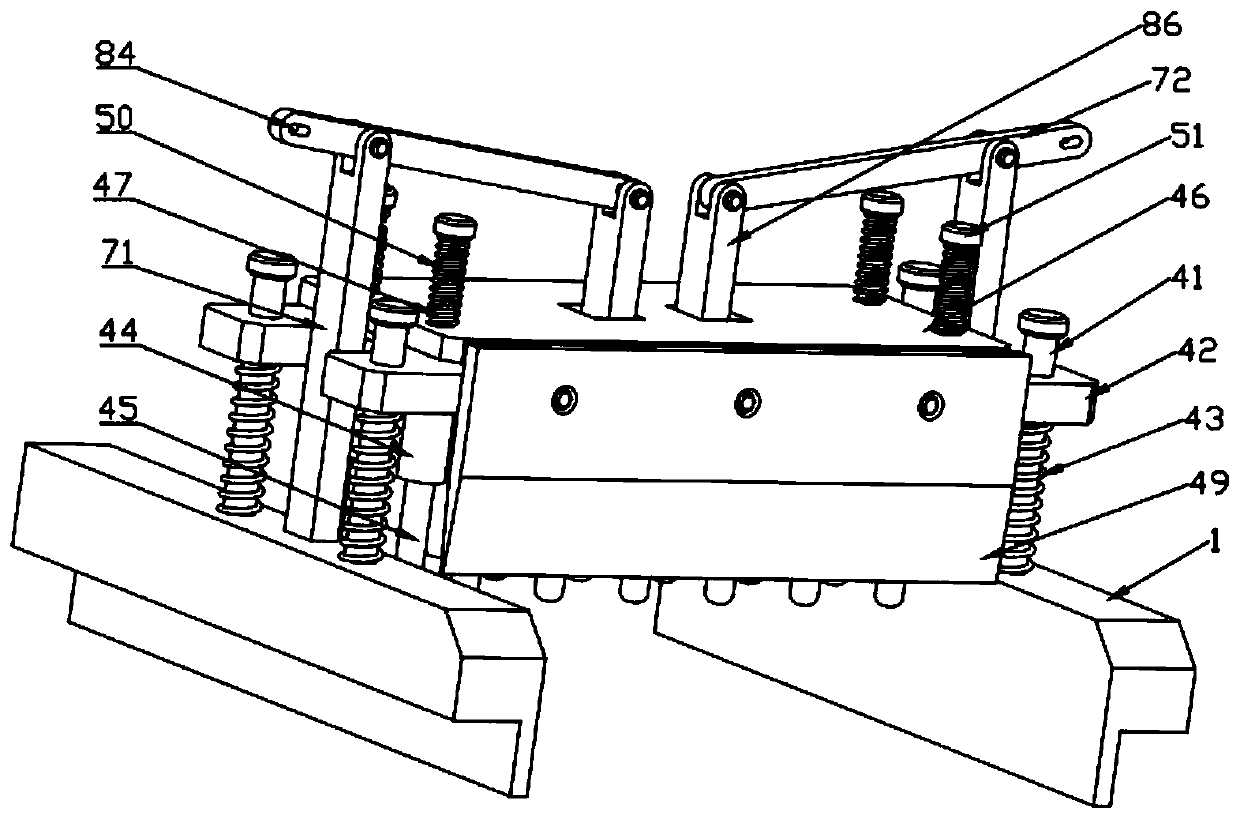

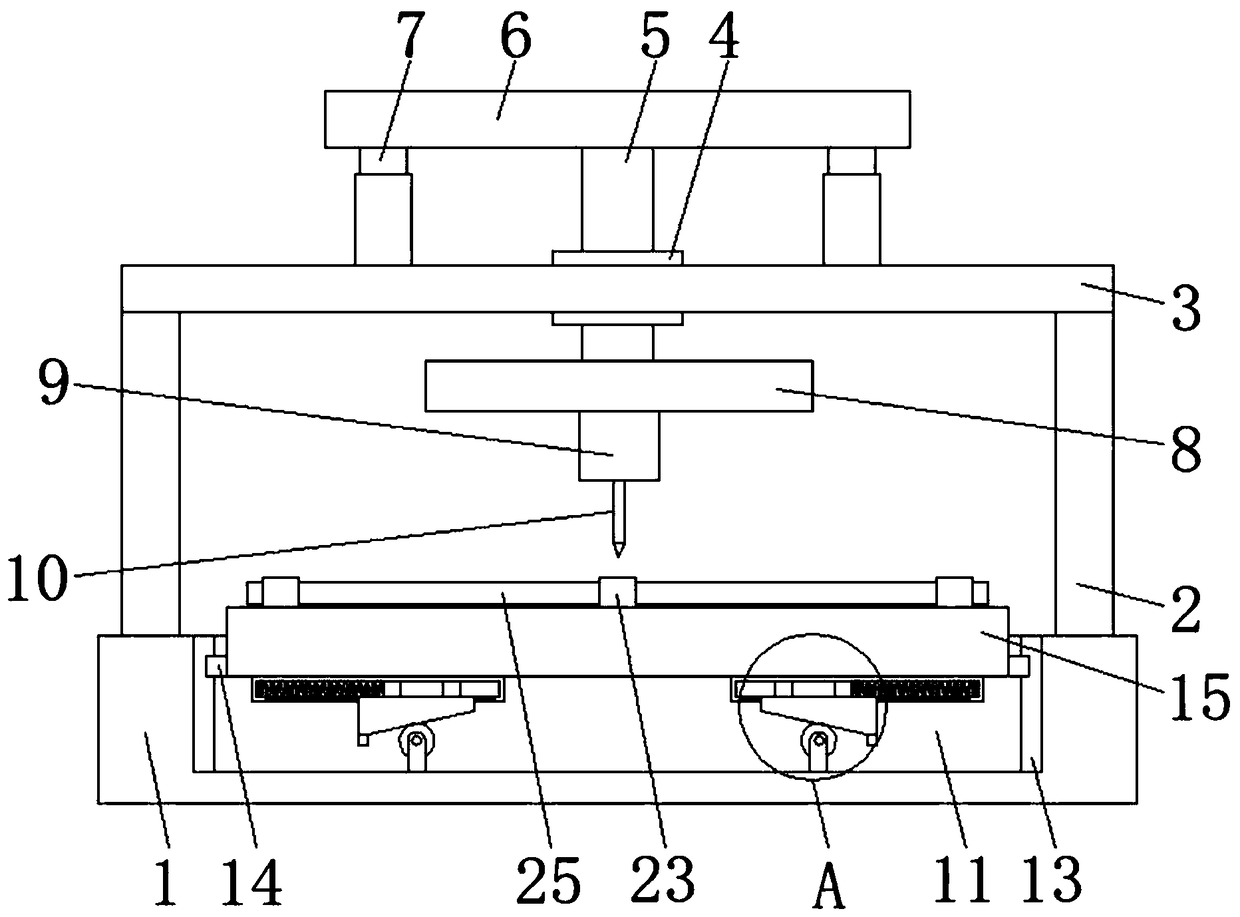

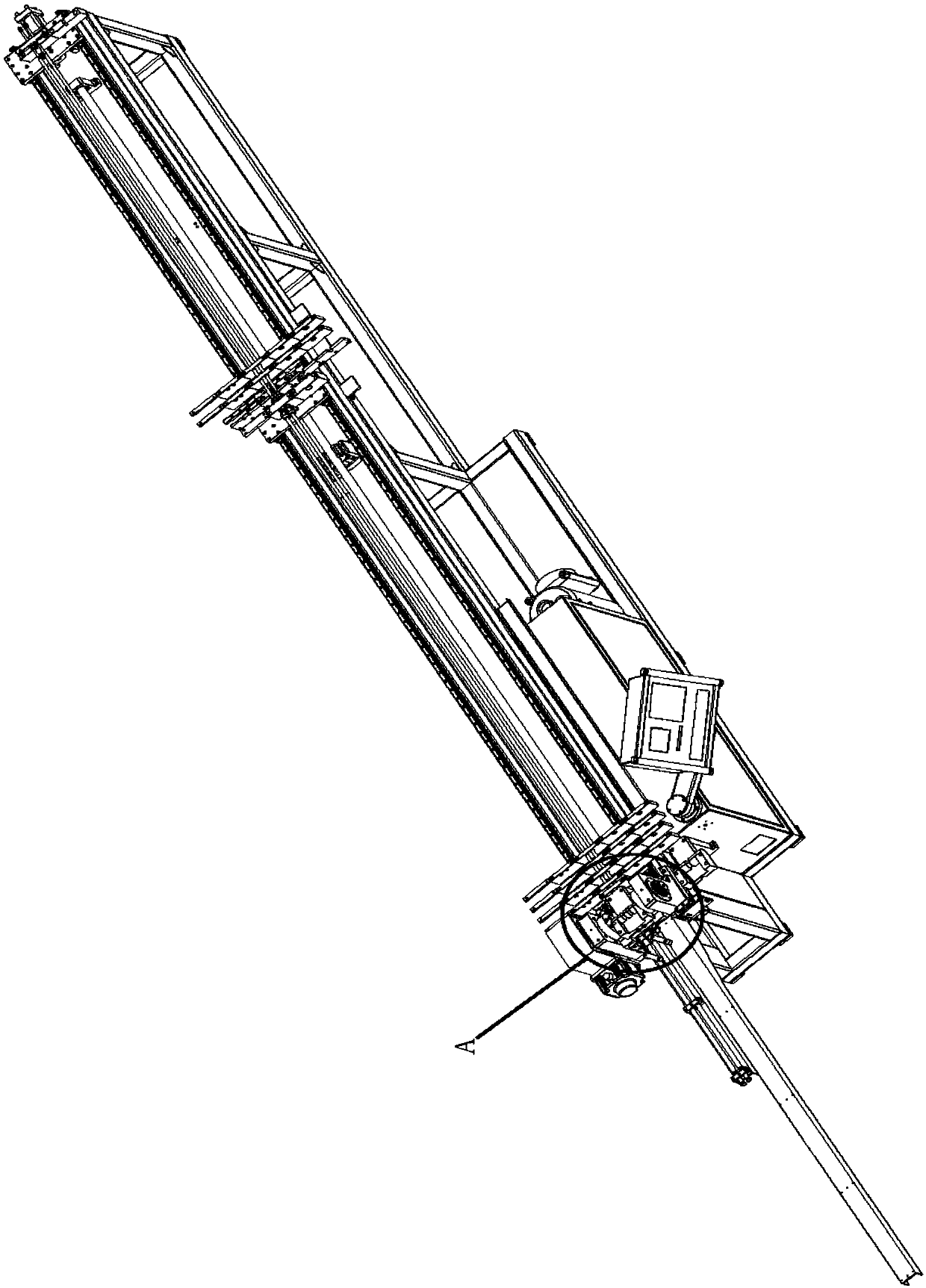

Dried beef cutting equipment

The invention discloses dried beef cutting equipment, and relates to the technical field of cutting equipment. The dried beef cutting equipment comprises an installing frame, an intermittent rotatingassembly and a conveying assembly, wherein a cutting assembly is arranged above the conveying assembly; a support plate corresponding to the cutting assembly is arranged in a conveying belt of the conveying assembly; and a motor and connecting rod assemblies are arranged under the conveying assembly. The dried beef cutting equipment has the advantages that the structure is simple; the operation isconvenient and fast; through the arrangement of the intermittent rotating assembly, the intermittent material feeding of dried beef can be realized; in the period that the conveying assembly stops the material feeding, the dried beef is cut and segmented; one driving mechanism is used, so that the cost is reduced; meanwhile, a cutting device in the dried beef cutting equipment can adapt to the cutting of the dried beef with different heights, different sizes and uneven surface shapes; the manual regulation is not needed; the dried beef flattening caused by too great stress can be avoided; thepracticability is high; and the production efficiency is high.

Owner:马鞍山市春晖食品有限责任公司

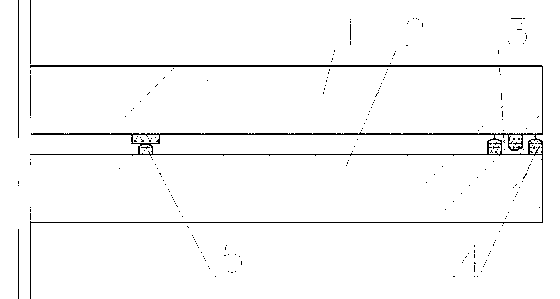

Convex vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951806AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by low-temperature glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing common vacuum glass and tempered vacuum glass.

Owner:戴长虹

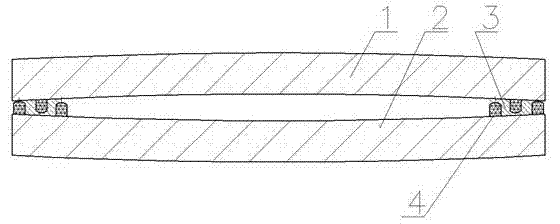

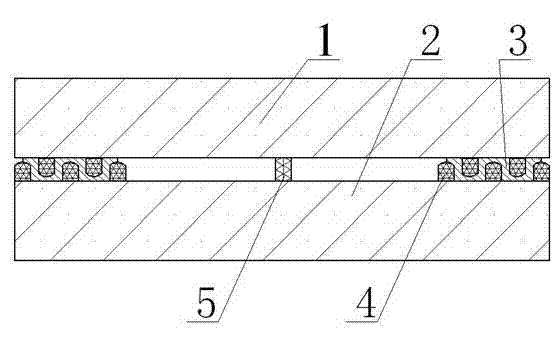

Planar vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951817AEasy edge bandingExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention discloses vacuum glass. The vacuum glass is characterized in that the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by low-temperature glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without special extraction openings in mass by virtue of a one-step method, and can be used for manufacturing common vacuum glass and tempered vacuum glass.

Owner:戴长虹

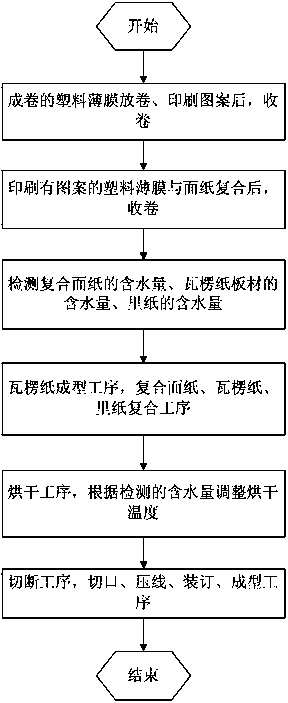

Paper-plastic package box and manufacturing method thereof

InactiveCN103612417ANo pressureAvoid squishingMechanical working/deformationBox making operationsCardboardMolded pulp

The invention provides a paper-plastic package box and a manufacturing method thereof. The manufacturing method of the paper-plastic package box comprises the following steps that a volumed thin film is unwound, and after patterns are printed, the thin film is wound; the thin film printed with the patterns and surface paper are wound after being combined; a forming procedure of corrugated paper is conducted, and a composition procedure of the composite surface paper, the corrugated paper and inner paper is conducted; a cutting-off procedure is conducted, and cutting, line folding, binding and forming procedures are conducted. According to the manufacturing method of the paper-plastic package box, technological processes are simplified, working efficiency is improved, and production cost is reduced. By heating rollers through which the corrugated paper, the compote surface paper and the inner paper pass, bonding firmness of the corrugated paper, the compote surface paper and the inner paper is enhanced. The gap between second compression roller is equal to the sum of the thickness of the composite surface paper, the thickness of the corrugated paper and the thickness of the inner paper, so that the second compression rollers have non compacting force on composite paper boards and only play a traction and composite role, and it is avoided that strength of the composite paper boards is reduced because the corrugated paper is flattened during composition.

Owner:龙口锦昇包装有限公司

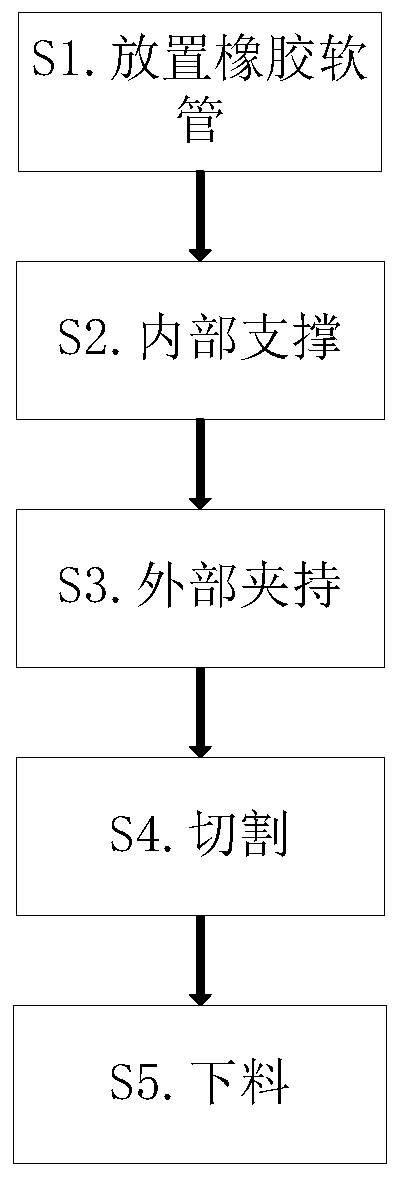

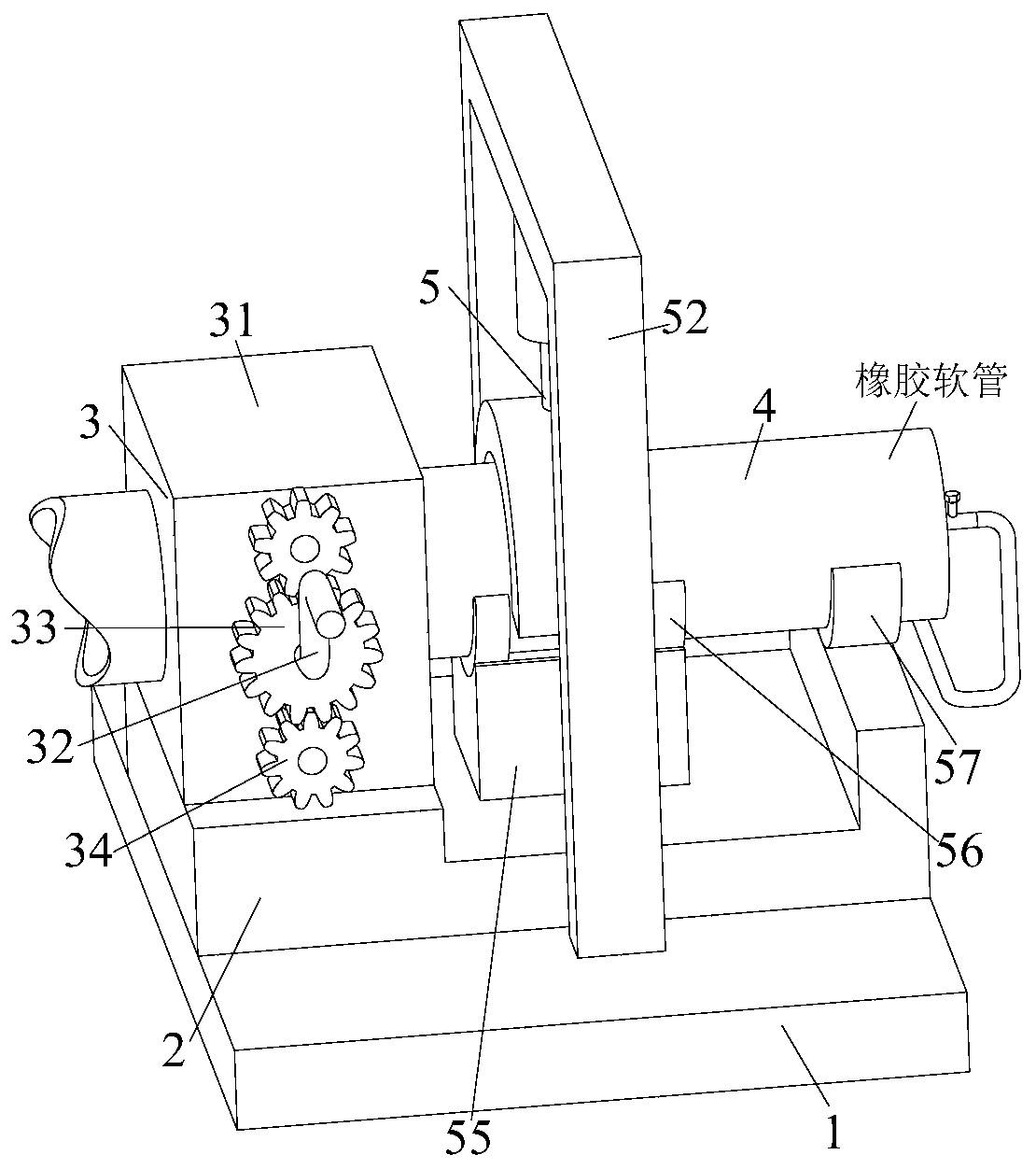

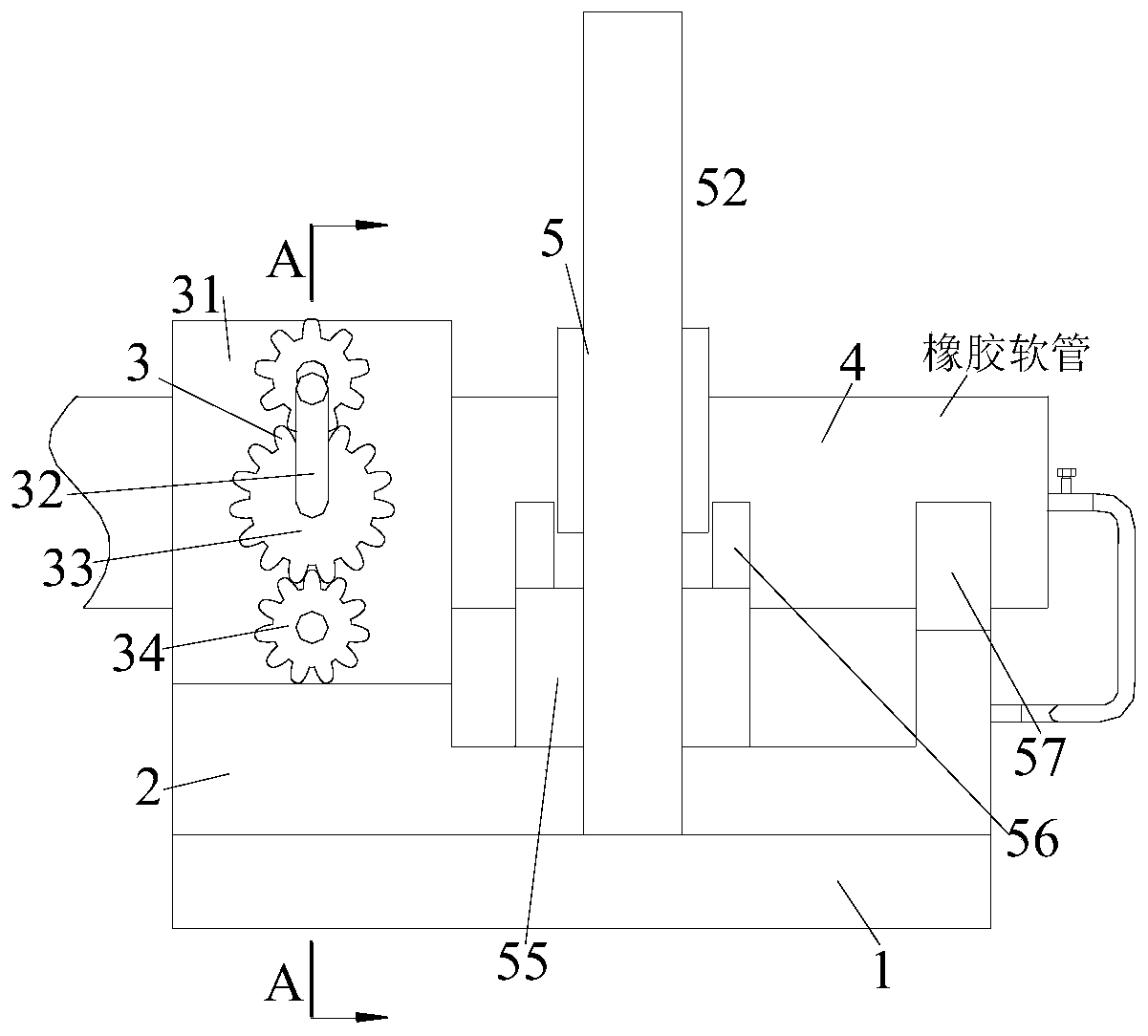

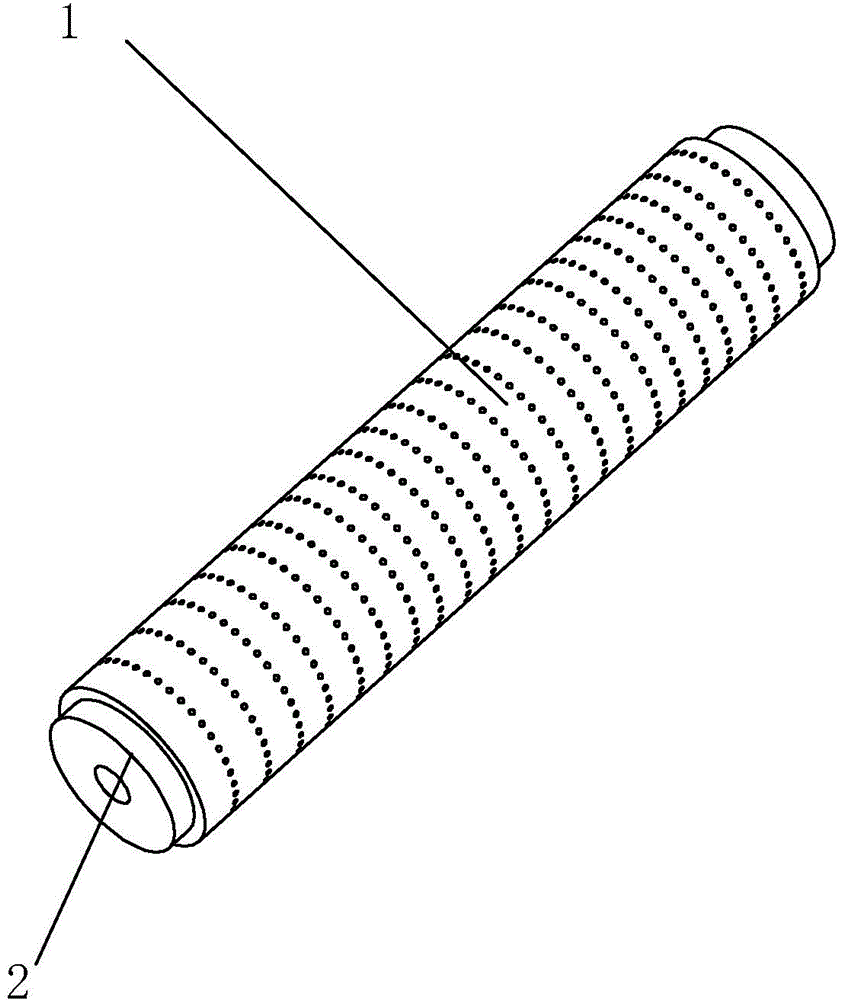

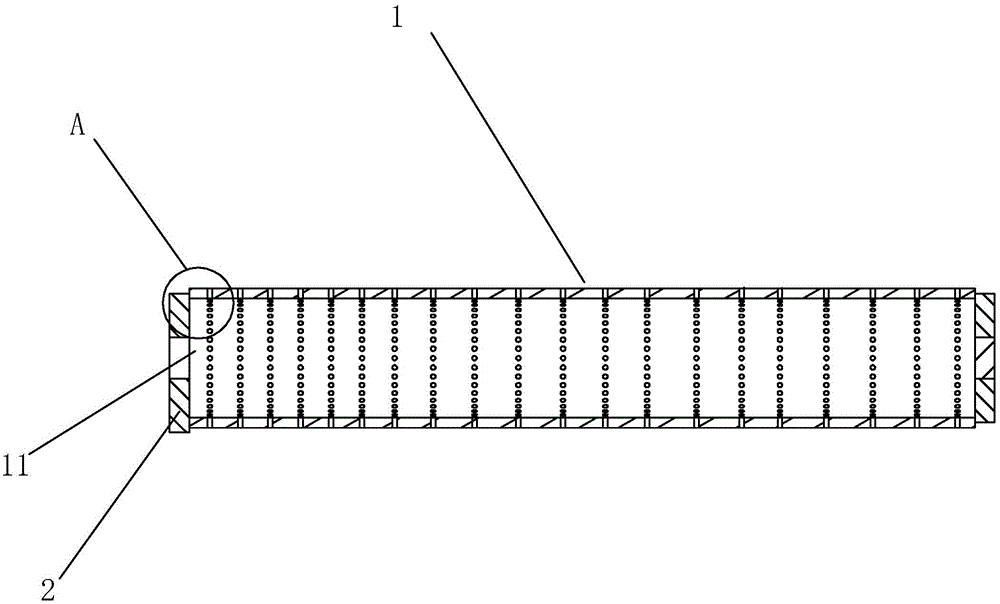

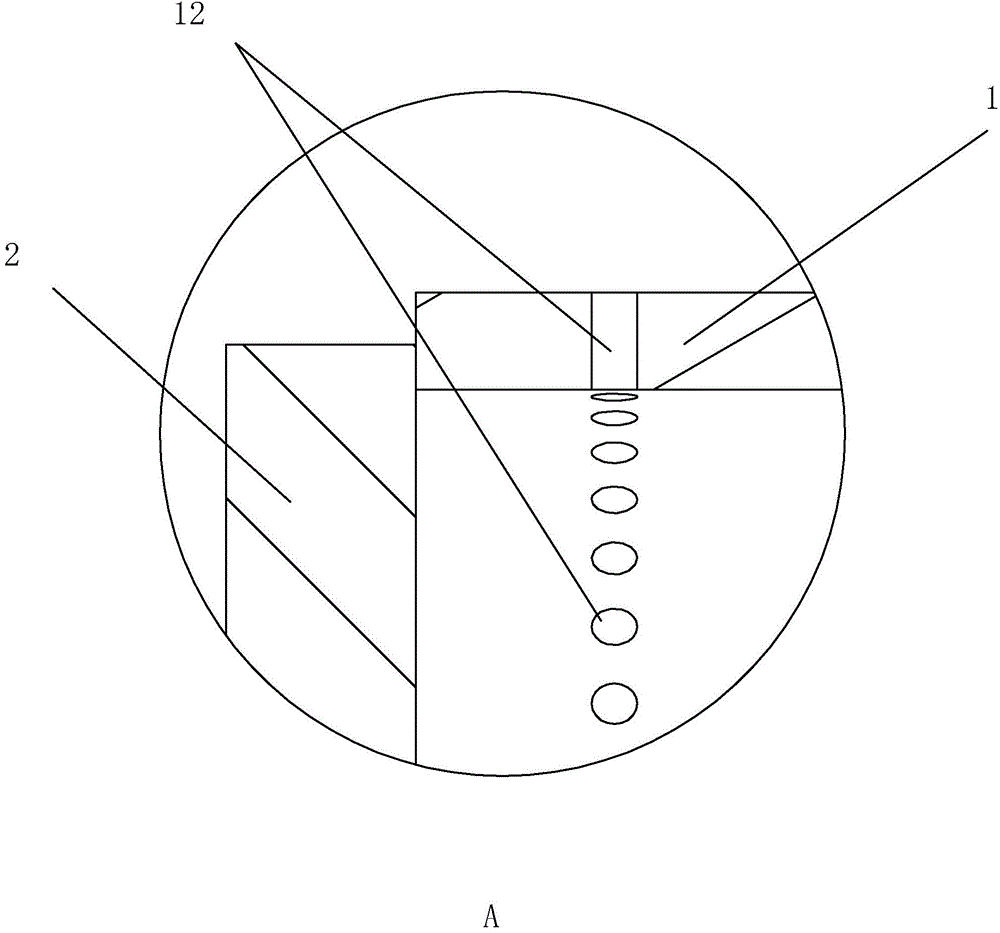

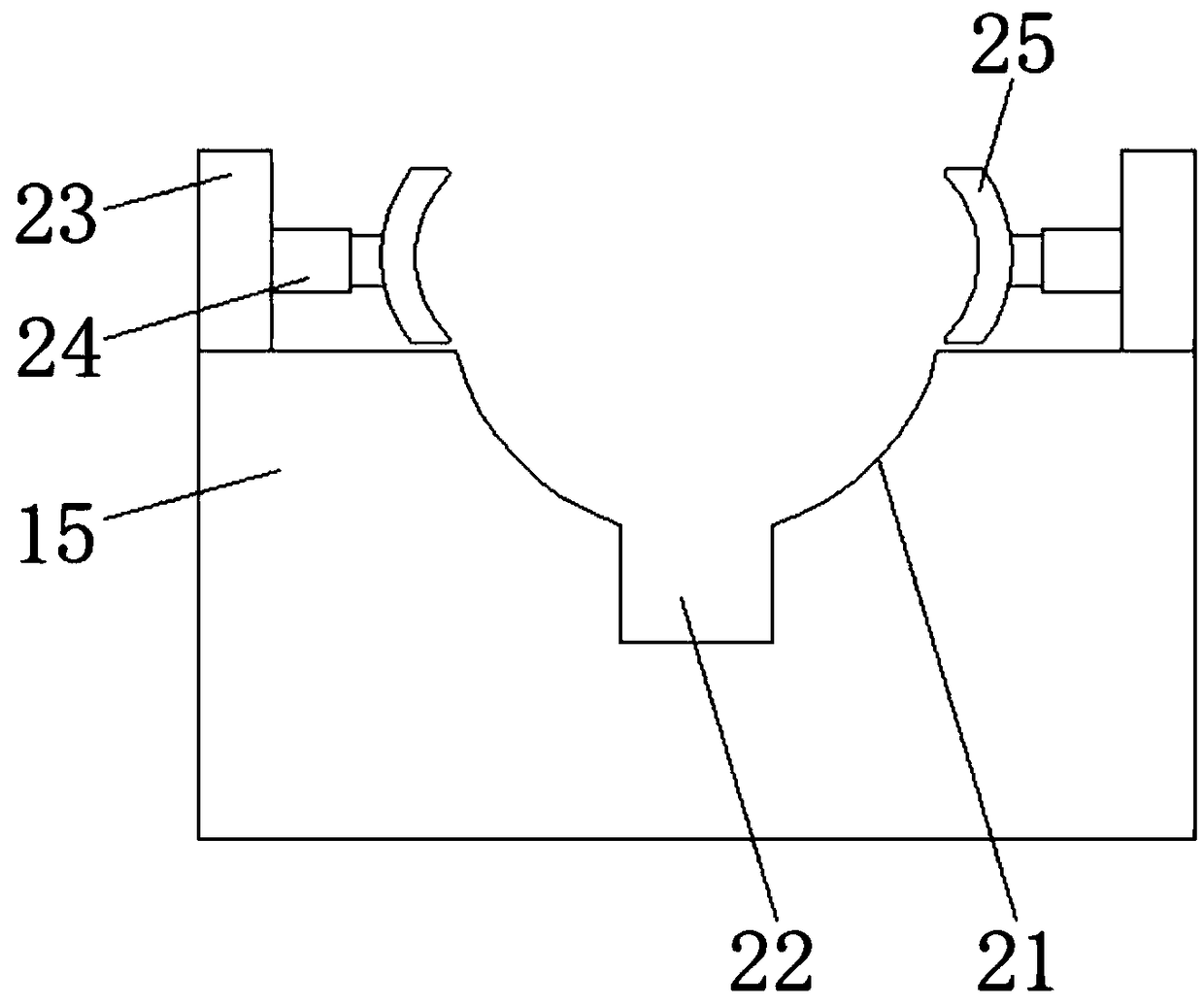

Manufacturing and machining method of rubber hose

ActiveCN111390998AImprove processing efficiencyReduce manual laborMetal working apparatusMachiningWorkbench

The invention relates to a manufacturing and machining method of a rubber hose. A mounting plate, a workbench, an outer clamping device, an inner supporting device and a cutting device are included. The workbench is mounted in the middle of the upper end of the mounting plate, the outer clamping device is mounted on the left side of the upper end of the workbench, the inner supporting device is arranged in the outer clamping device, and the cutting device is mounted in the middle of the upper end of the workbench. According to the manufacturing and machining method of the rubber hose, the problems that when the rubber hose is manually manufactured, firstly, the flat position of the rubber hose is pressed to be round, then the rubber hose is locked and fixed and cut, the process of manuallypressing the rubber hose to be round is tedious, during existing manufacturing and machining of the rubber hose, existing rubber hose manufacturing equipment usually directly locks and fixes the exterior of the rubber hose, the rubber hose is cut apart through a tool, then the flat position of the rubber hose is pressed to be round after the rubber hose is cut apart, and the manufacturing efficiency is low due to the cooperation of mechanical and manual operation can be solved.

Owner:JINGJIANG YONGHE POLYMOLECULAR TECH

Rubber rod for secondary processing of plastic pipe and secondary processing process of plastic pipe

The invention discloses a rubber rod for secondary processing of plastic pipes and secondary processing process of plastic pipes. The rubber rod includes a rubber rod body; one end of the rubber rod body is provided with an air inlet channel; the side wall of the rubber rod body is provided with a plurality of air outlets communicated with the air inlet channel. The processing process using the rubber bar comprises the steps of: 1, selecting a pipe to be bent; 2, heating the part to be bent of the pipe; 3, stuffing the rubber rod body into the pipe; 4, placing the pipe to be bent between a fixed mold and a movable mold, and assembling a fixed mold and the movable mold, thereby bending the pipe; 5, inflating the inside of the rubber rod body through the air inlet channel, and fitting the side wall of the bent part of the pipe with a cavity by the expanded rubber rod body; 6, discharging gas in the rubber rod body to restore the original size of the rubber rod body, so as to remove the rubber rod body from the pipe inside of the pipe; and 7, removing the pipe and cooling.

Owner:ZHEJIANG LIUTONG PLASTIC

3D printing wire feeding, clamping and guiding device

InactiveCN105690771AImprove clamping bite forceIncrease frictionAdditive manufacturing apparatusEngineeringGuide wires

The invention discloses a 3D printing wire feeding, clamping and guiding device, and relates to the technical field of quick molding of 3D printing. The 3D printing wire feeding, clamping and guiding device comprises a guide wheel I and a guide wheel II; the guide wheel I and the guide wheel II are arranged side by side; a lap of V-shaped tooth grooves I, inwards recessed, is formed in the peripheral surface of the guide wheel I; a lap of V-shaped tooth grooves II, inwards recessed, is formed in the peripheral surface of the guide wheel II; the V-shaped tooth grooves I in the guide wheel I and the V-shaped tooth grooves II in the guide wheel II are opposite in position; when the guide wheel I and the guide wheel II are arranged side by side, the V-shaped tooth grooves I and the V-shaped tooth grooves II surround guide grooves for clamping and guiding wires; waste grooves I communicated with the V-shaped tooth grooves I are inwards recessed in the inner sides of the V-shaped tooth grooves I; and waste grooves II communicated with the V-shaped tooth grooves II are inwards recessed in the inner sides of the V-shaped tooth grooves II. The 3D printing wire feeding, clamping and guiding device can improve the wire surface clamping engagement force and friction force to prevent the wire slip or deviation in the feeding process.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

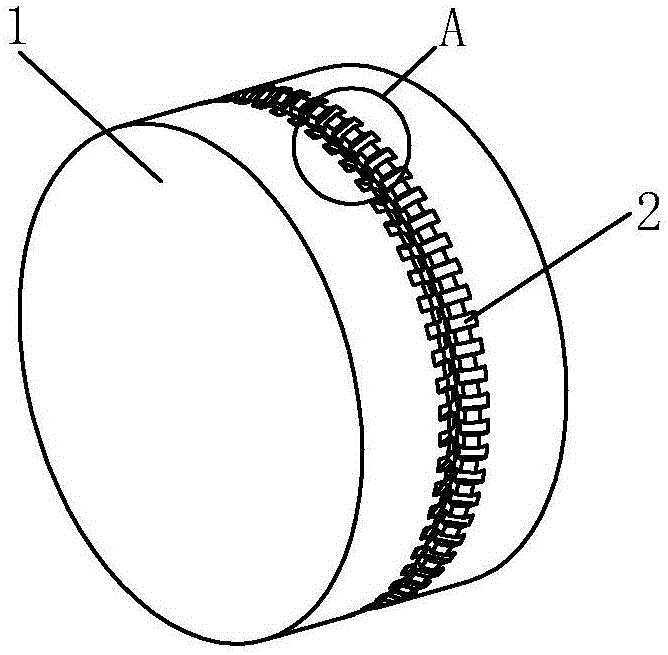

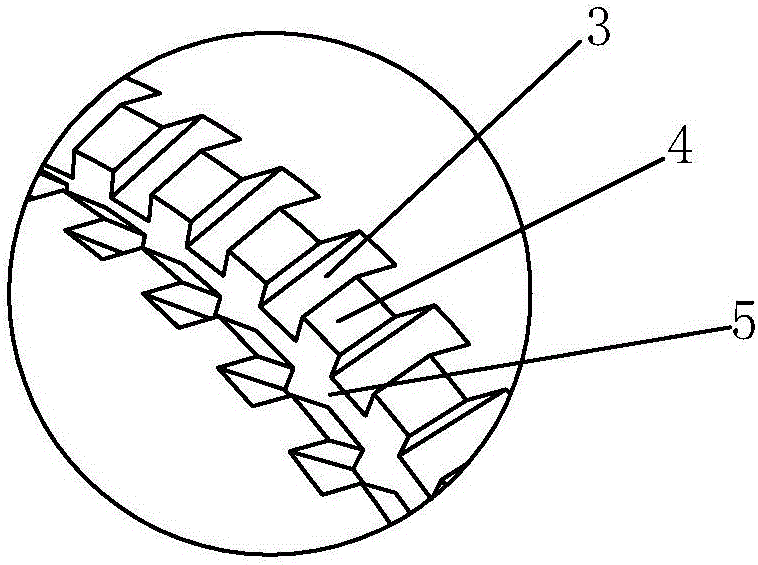

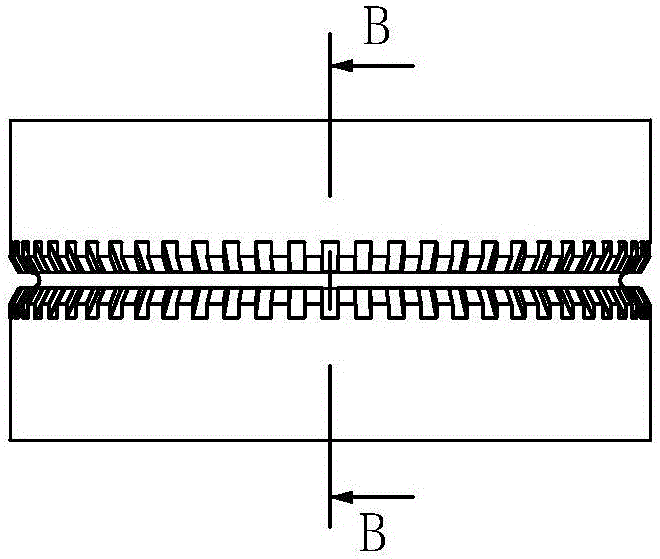

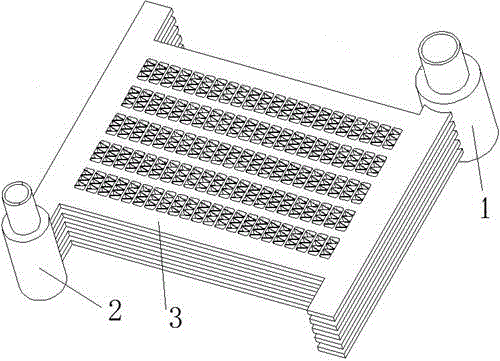

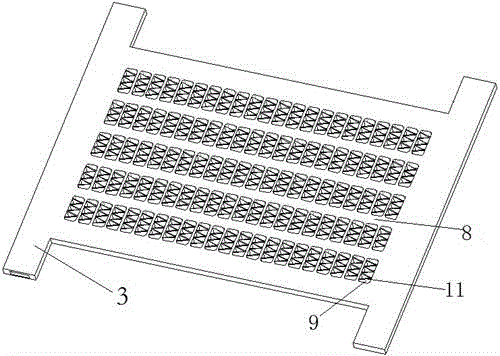

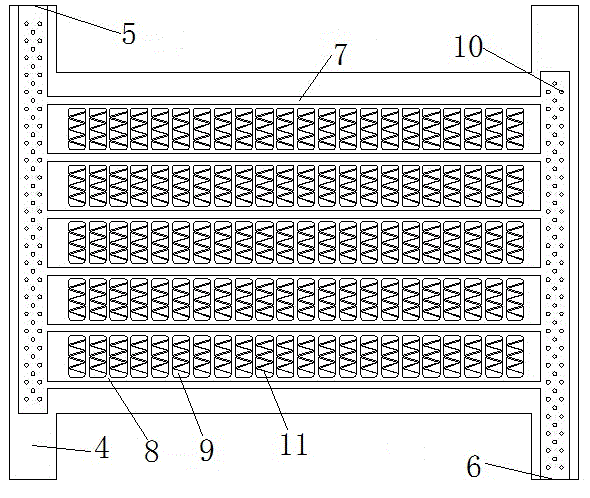

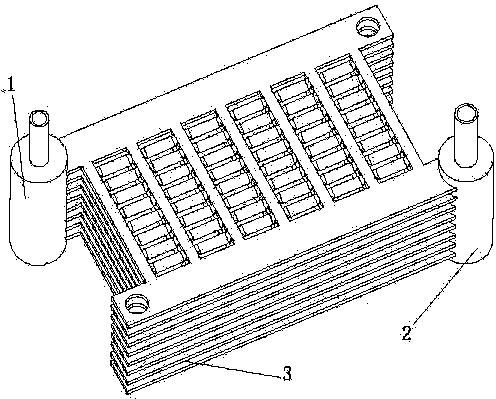

Novel micro-channel heat exchanger

ActiveCN104089498ASimple structureEasy to shapeStationary conduit assembliesHeat exchanger casingsEngineeringButt joint

The invention discloses a novel micro-channel heat exchanger which comprises a first header pipe, a second header pipe and a heat exchange assembly communicated with the first header pipe and the second header pipe. The heat exchange assembly comprises a plurality of heat exchange units. Each heat exchange unit comprises two heat exchange pieces which are in butt joint to form a whole, wherein concave grooves are formed in butt joint faces of the two heat exchange pieces, and after the butt joint faces of the two heat exchange pieces are in butt joint, the butt joint concave grooves form a fluid channel. Each fluid channel comprises an inlet channel, an outlet channel and multiple middle channels enabling the inlet channel to be communicated with the outlet channel. Each heat exchange piece is further provided with multiple fins formed between two adjacent middle channels and formed by multiple ventilating slots distributed in columns in the length direction of the middle channels, and auxiliary fins are further arranged in the ventilating slots. The fins and circulating channels are arranged on the same level, gas needing heat exchange is fed in perpendicular to the heat exchange pieces, heat exchange is carried out on gas and fluid in the middle channels through the ventilating slots in a multidirectional mode, and therefore sufficient heat exchange is achieved. The heat exchange efficiency of the heat exchanger is high.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

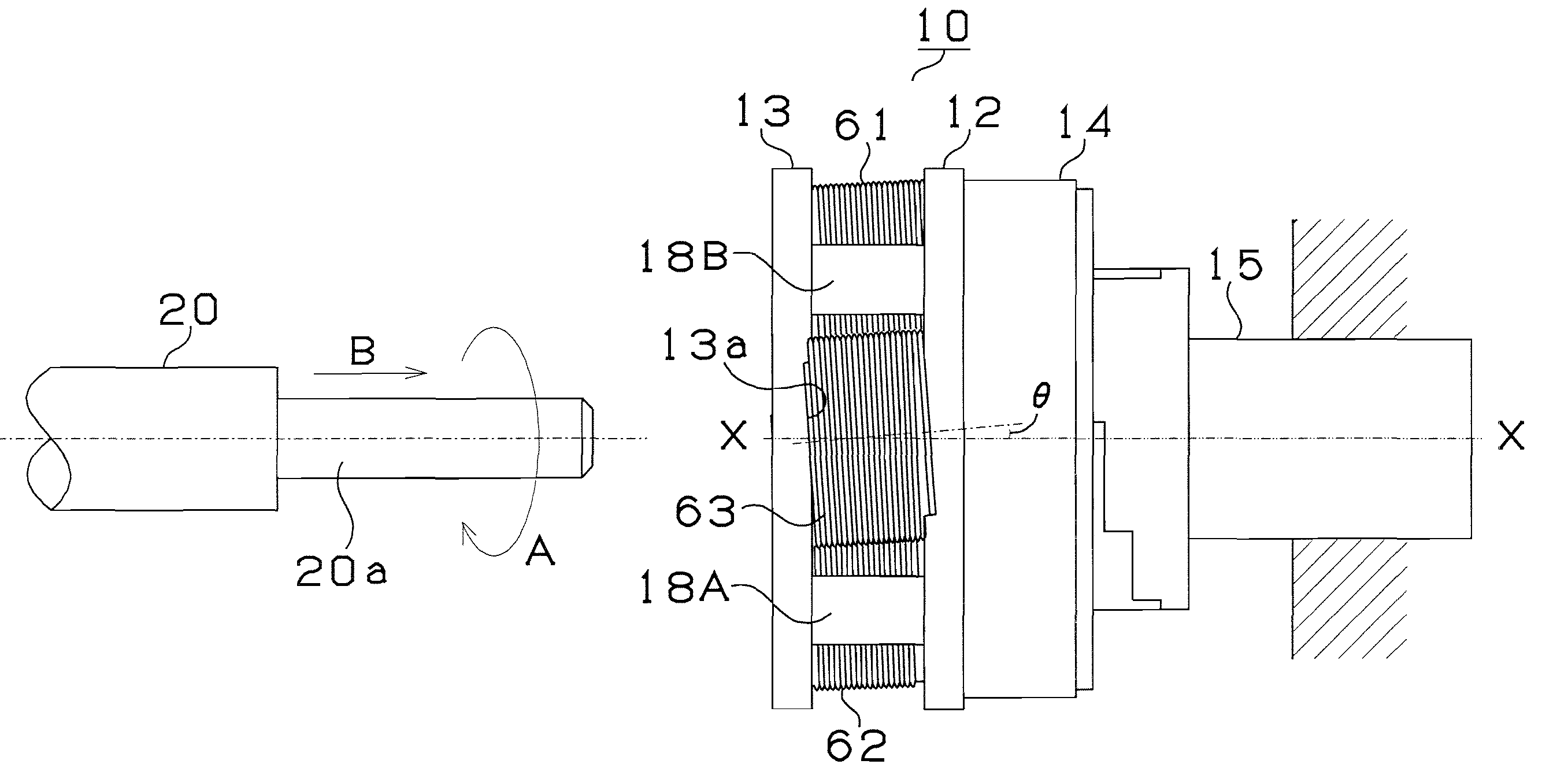

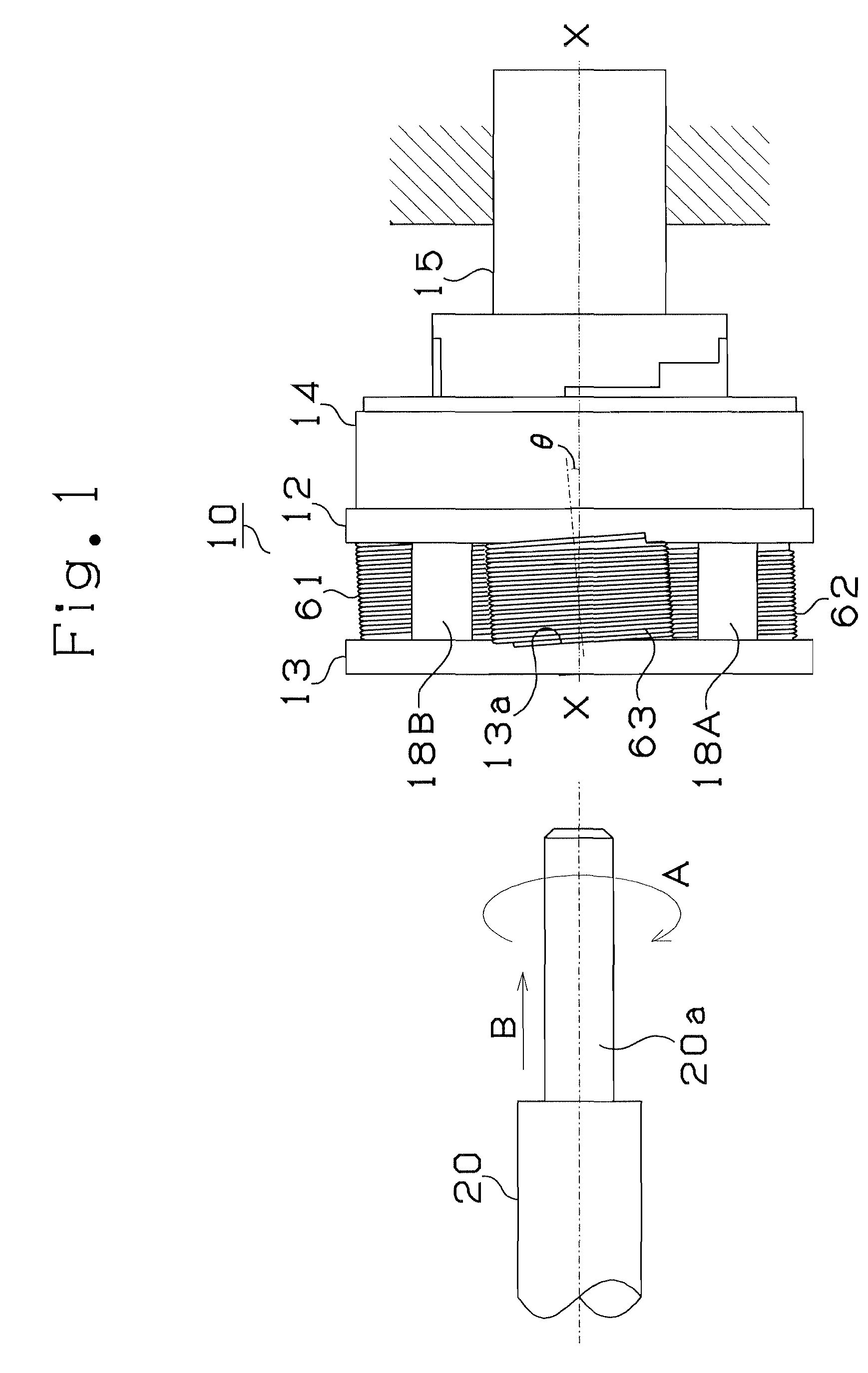

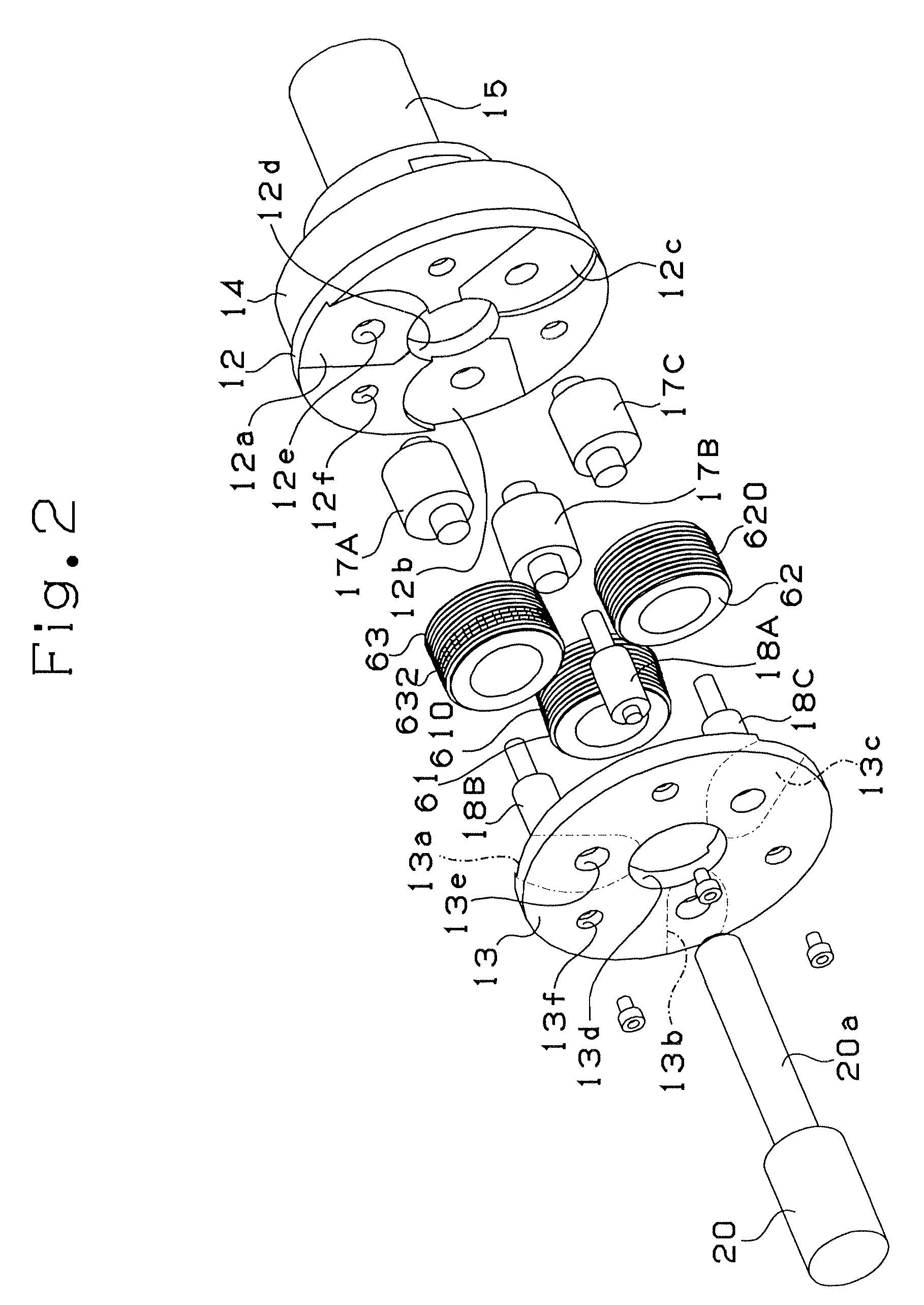

Multi-Pitch Screw, And Manufacturing Method And Manufacturing Apparatus Of Multi-Pitch Screw

InactiveUS20080010807A1Difficult to manufactureRolled easily and efficientlyAutomatic/semiautomatic turning machinesNutsScrew threadHelix

The invention presents a method of manufacturing a multi-pitch screw having desired threads and pitches by rolling. A trace of general (even lead angle) spiral screw is formed by even pitch protrusions 610 and 620 of an existing rotating dies 61 and 62, and it is combined with a trace of stair step screw formed by stair step protrusions 632 of a rotating die 63 of uneven lead angle, and multi-pitch screw threads are formed efficiently. Herein, only one rotating die 61 of uneven lead angle is used, and screw threads are not flattened out by stair step protrusions of the plurality of rotating dies of uneven lead angles.

Owner:NAGOYA INDUSTRIAL SCIENCE RESEARCH INST

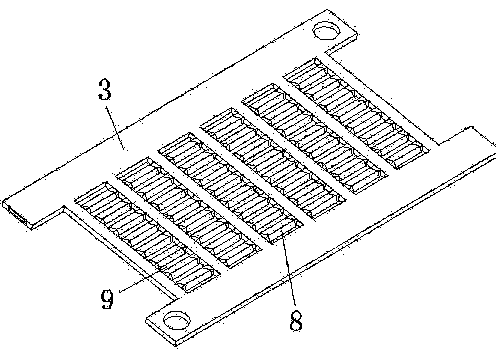

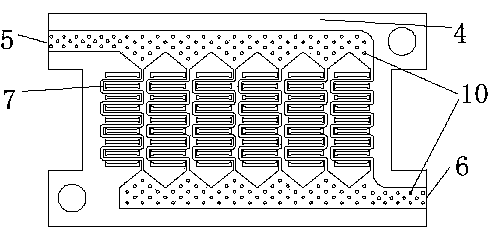

Micro-channel heat exchanger

ActiveCN103776285AImprove heat transfer efficiencyImprove heat transfer performanceEvaporators/condensersLaminated elementsEngineeringInlet channel

The invention discloses a micro-channel heat exchanger. The micro-channel heat exchanger comprises a first fluid collecting pipe, a second fluid collecting pipe and a heat exchange assembly, wherein the heat exchange assembly is communicated with the first fluid collecting pipe and the second fluid collecting pipe; the heat exchange assembly comprises a plurality of heat exchange units; the heat exchange units comprise two heat exchange fins which are butted integrally; sunken grooves are formed in butted surfaces of the heat exchange fins; after the butted surfaces of the two heat exchange fins are butted, the butted sunken grooves form fluid channels; circulation channels comprise an inlet channel, an outlet channel and a plurality of middle channels; the middle channels are communicated with the inlet channel and the outlet channel; a plurality of semi-encircled fins are also arranged on the heat exchange fins; ventilating slots are formed between paired fins; and the middle channels are formed in semi-encircled spaces of the fins. According to the micro-channel heat exchanger, the fins and the circulation channels are formed in the same layer; fluid required to exchange heat is fed perpendicular to the exchange fins; the fluid flows through the ventilating slots and can exchange heat with the fluids in the middle channels in a multi-directional manner, so that the heat is fully exchanged; and the heat exchanger is high in heat exchange efficiency.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

VR device worn in exercise

The invention discloses a VR device worn in exercise. The VR device comprises a VR device body which is provided with a curved groove matched with a face, the VR device body where the curved groove islocated is provided with a ventilating structure, the outer side of the curved groove is detachably provided with a sweat absorbing pad, the sweat absorbing pad is matched with the surface of the curved groove, and the surface of the sweat absorbing pad is provided with honeycomb sweat absorbing holes, so that the gas generated by the ventilating structure is blown out from a side of the sweat absorbing pad. The sweat absorbing pad and the curved groove surface are connected and fixed by Velcro, a nose bridge block is arranged at the intermediate position of the curved groove and is matched with the shape of a nose, and the surface of the nose bridge block is provided with a silica gel layer. By setting the silica gel layer, the comfort of wearing the device can be improved, and the lowerside of the curved groove is provided with an auxiliary fixing mechanism for generating upward pulling force on the VR device body. The structure of the device is simple and reasonable, the disadvantages of an existing device are eliminated, the comfort of wearing is improved, and the VR device is practical.

Owner:CHONGQING INST OF ENG

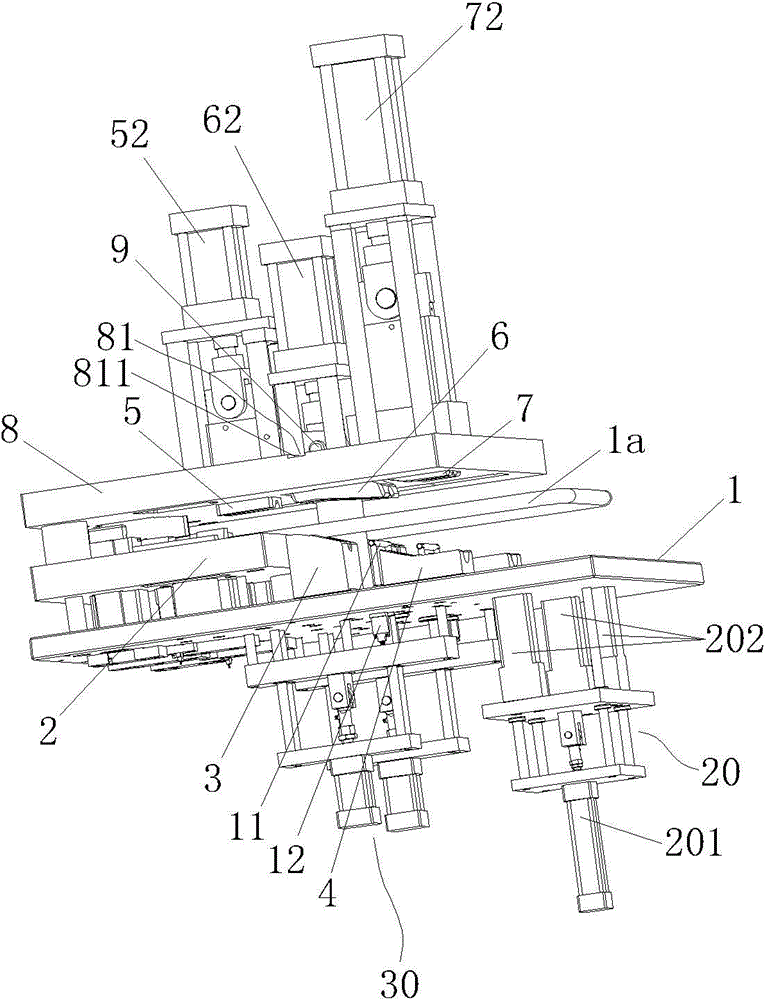

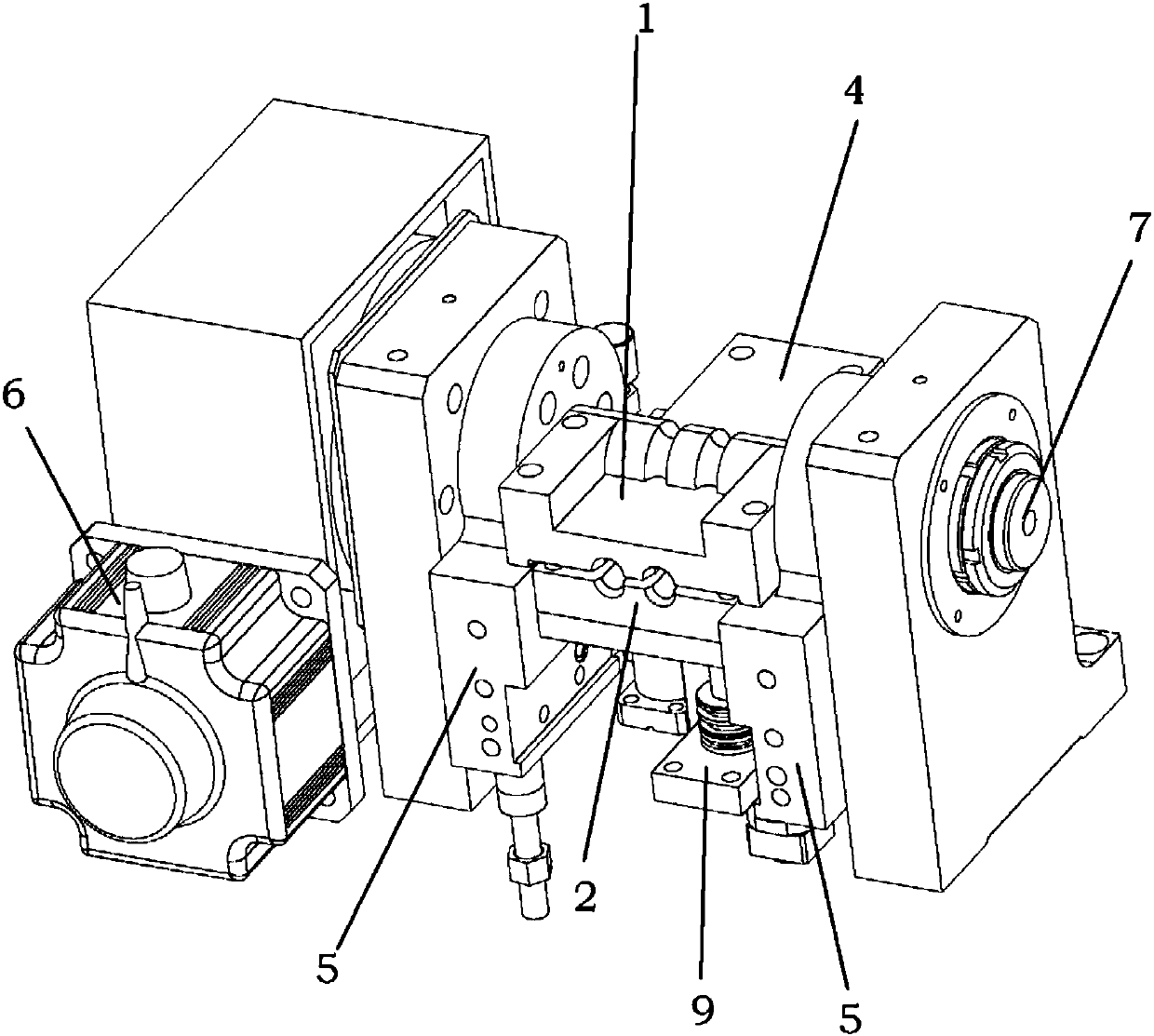

Secondary bending mechanism for pipe fitting

InactiveCN104607509AImprove processing efficiencyPrevents crushing of fittingsMetal-working feeding devicesPositioning devicesEngineeringPipe fitting

The invention discloses a secondary bending mechanism for a pipe fitting. The mechanism comprises a working table, wherein a pipe fitting supporting base, a primary bending supporting base and a secondary bending supporting base are sequentially arranged on the working table, a clamping press block, a primary bending pressing block and a secondary bending press block driven by a first driving part, a second driving part and a third driving part respectively to move up and down are arranged on the pipe fitting supporting base, the primary bending supporting base and the secondary bending supporting base respectively, the upper portion of the primary bending press block is hinged to the second driving part through a pin shaft, a pin shaft downward movement limiting surface is arranged on the lower side of the pin shaft, the second driving part drives the primary bending press block to move downwards to a pin shaft touch limiting surface to conduct primary pre-bending on the pipe fitting, the third driving part drives the secondary bending press block to move downwards, the secondary bending press block drives the primary bending press block to rotate around the pin shaft to achieve primary bending of the pipe fitting firstly, and then the secondary bending press block disengages from the primary bending press block to continue to move downwards to achieve secondary bending of the pipe fitting. The mechanism is high in machining efficiency, low in rejection rate and high in stability of machined product quality.

Owner:XIAMEN EGRET PRECISION MACHINERY

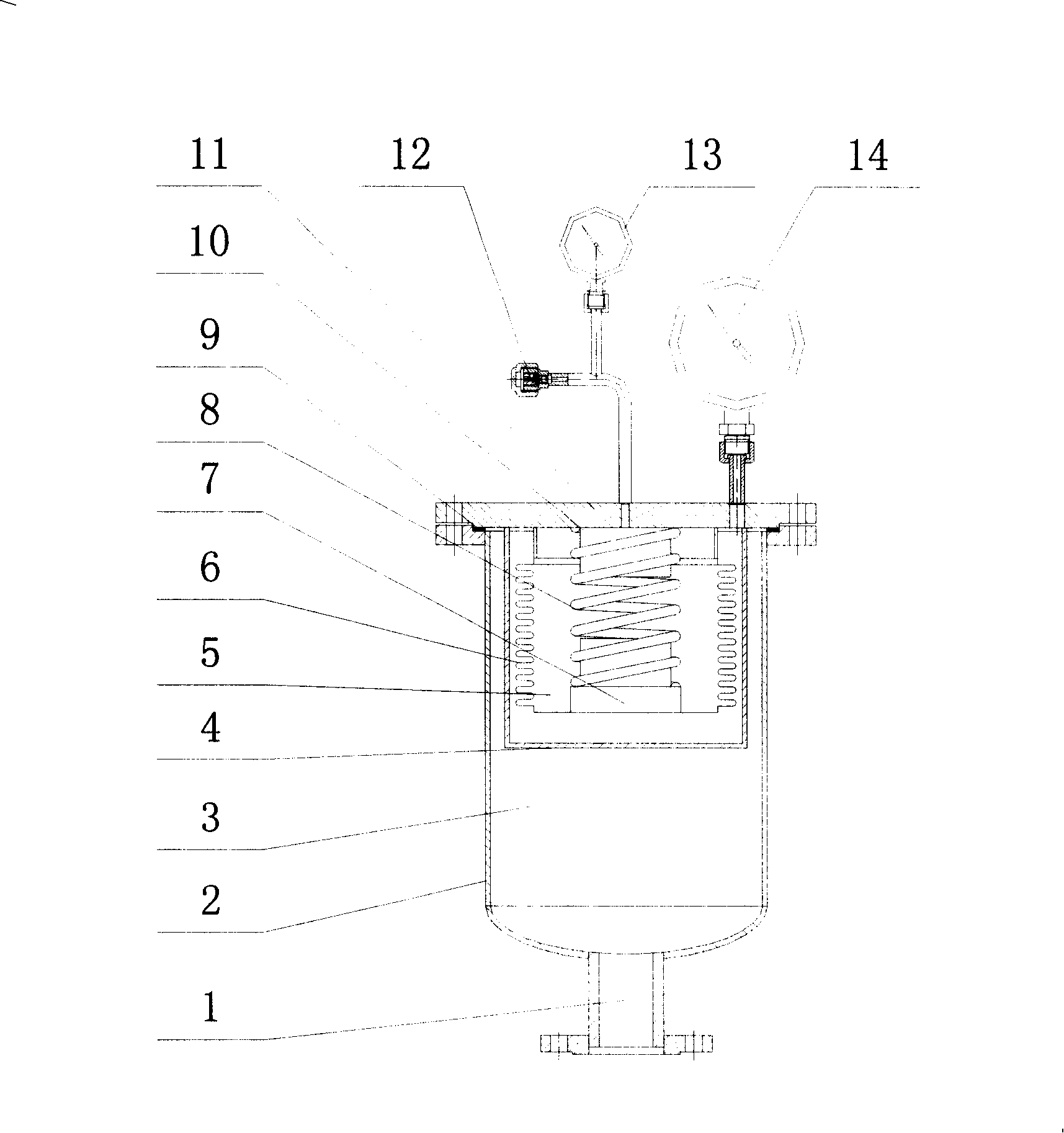

Corrugated pipe buffers

ActiveCN101236119AImprove pressure resistanceAdjust gas pressureFluid pressure measurementElastomerBuffer tank

The invention relates to a novel buffer of a corrugated pipe, which mainly comprises a buffer tank body, a corrugated pipe elastic body and an air charging device, wherein the buffer tank body comprises a pipe connection, a buffer chamber rounded by a tank and a corrugated pipe, a cover of the buffer tank and a pressure gage in buffer chamber, the corrugated pipe elastic body comprises a lift limiter, a corrugated pipe, a spring, a spring holder, an air chamber formed by the corrugated pipe and the buffer tank cover, the air charging device comprises a charging valve, a pressure gage in air chamber. The mouthpiece of the pipe connection is connected with a lower end of the tank, the corrugated pipe elastic body is disposed at upper end of the tank with a buffer tank cover, and the air charging device and the pressure gage of the buffer chamber are disposed on the cover of the buffer tank. Comparing with prior art, the novel buffer of a corrugated pipe has the advantages of wide appliance, reliability and safety, good sealing property, convenient maintenance and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Polyethylene water supply pipe for trenchless construction

The invention relates to a polyethylene water supply pipe for trenchless construction. The pipe which is formed by blending and extrusion molding of a special high-density polyethylene pipe material and co-polypropylene mixture which are used as base materials, a glass fiber and a proper number of auxiliary agent comprises more than 70 percent of polyethylene, 10-20 percent of co-polypropylene, 5-15 percent of boron and alkali-free (E-CR) glass fiber, an antioxidant, an activating agent and a compatilizer. Compared with the traditional PE100 water supply polyethylene pipe, the polyethylene water supply pipe prepared by the raw materials through methods of high-speed kneading, mixed granulation and extrusion molding has higher ring stiffness and tensile strength, improves the ring stiffness by more than 25 percent and improves the tensile yield strength by more than 30 percent. The pipe disclosed by the invention can be prevented from being flattened or broken during trenchless construction, the dragging and ejecting length of the pipe is greatly reduced, the pipe cost is reduced and the construction cost is also reduced.

Owner:浙江经纬集团环保工程有限公司

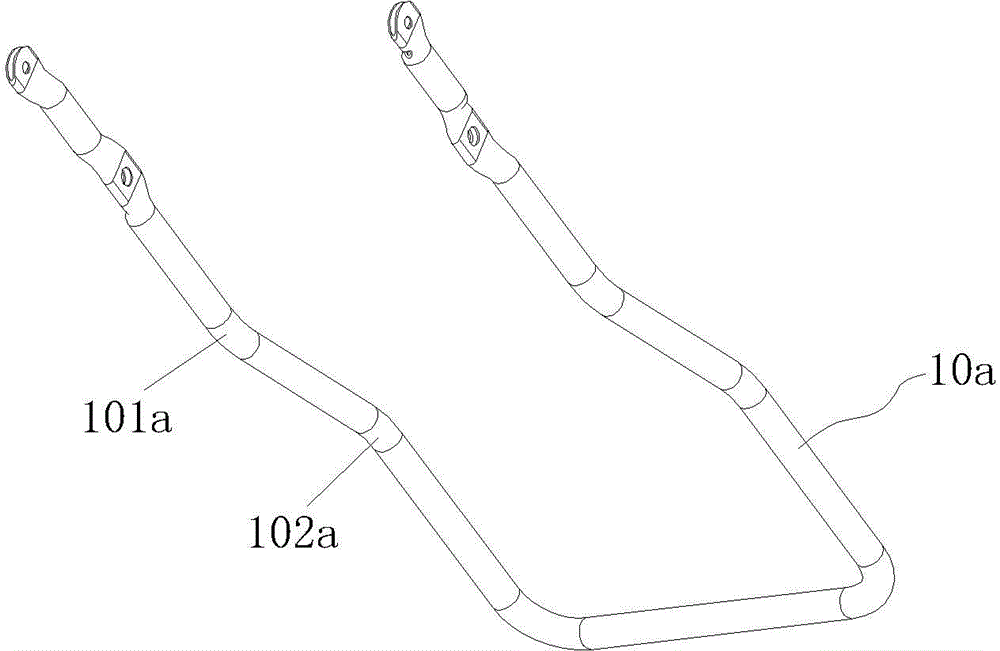

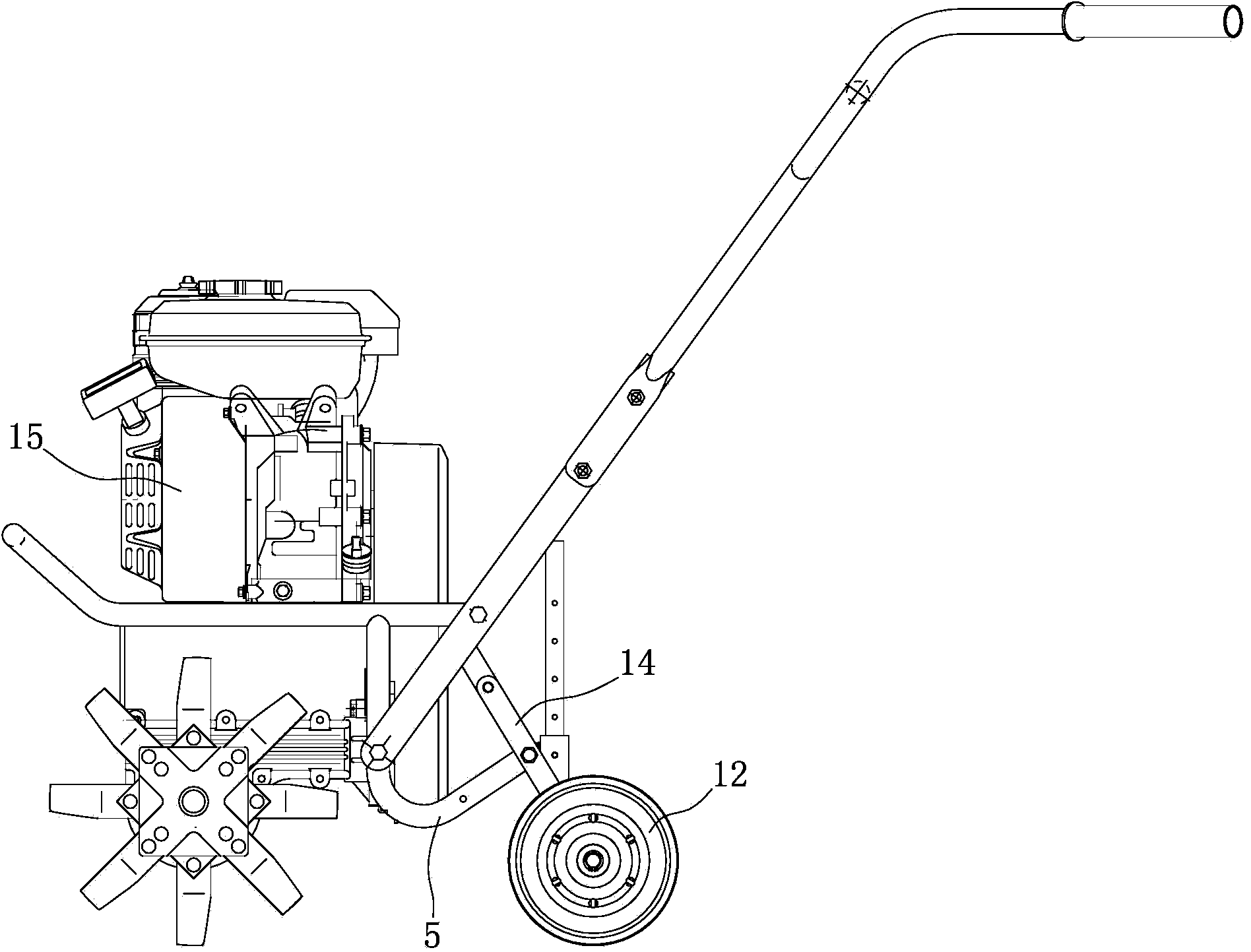

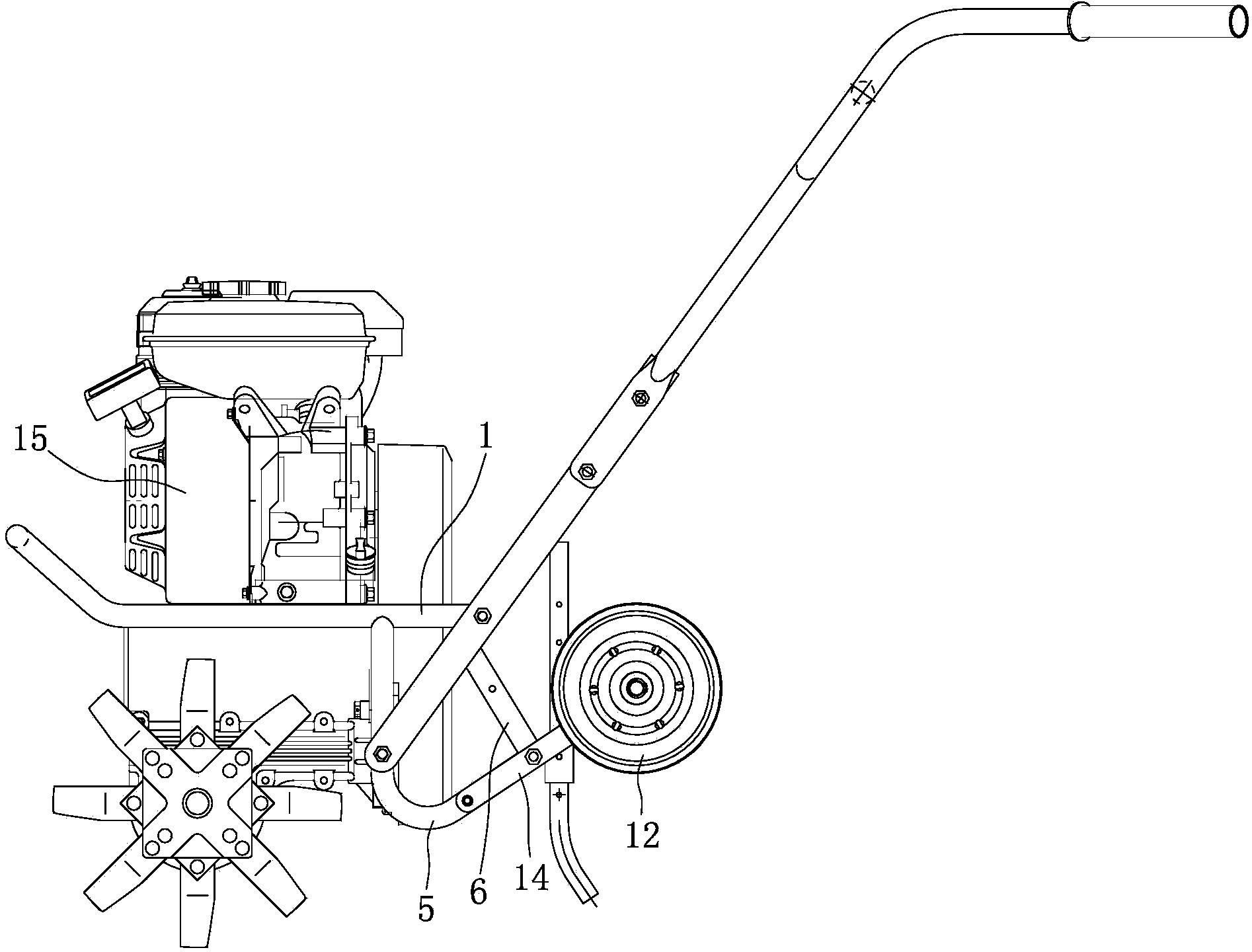

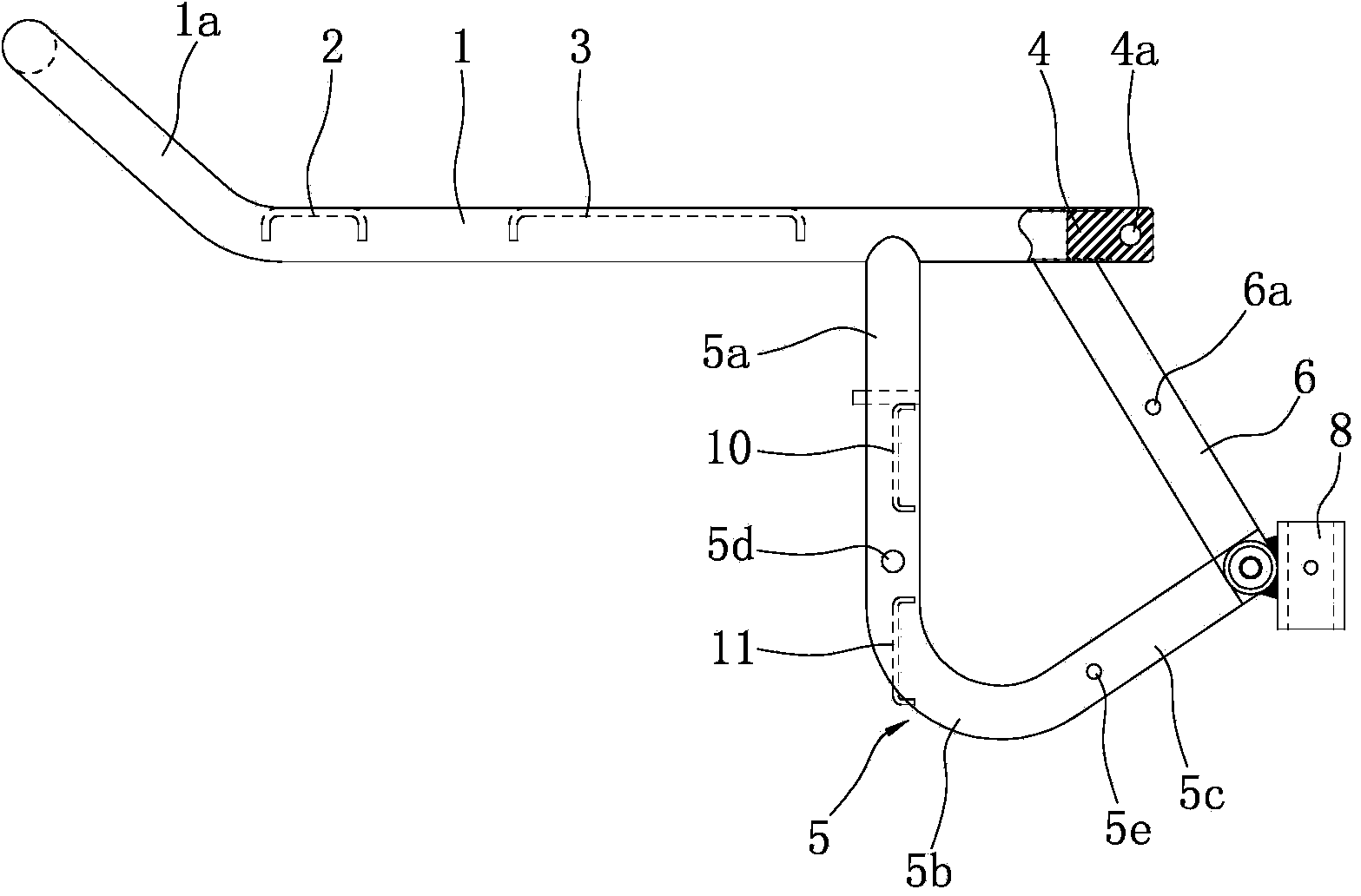

Portable mini tiller rear wheel assembly and engine arrangement structure

ActiveCN104067717AEasy to shapeCompact structureAgricultural machinesTilling equipmentsGear wheelWheel and axle

The invention discloses a portable mini tiller rear wheel assembly and engine arrangement structure. An engine (15) is supported on a support plate (3), an output shaft of the engine (15) stretches out backwards horizontally, and the bottom of the engine (15) is fixed on the support plate (3) through four bolts distributed in a rectangle. Rear wheels (12) are symmetrically arranged on the left side and the right side below the rear portion of a transverse pipe (7), the rear wheels (12) sleeve the end portions of an axle (13) in a rotating mode, a left long strip block (14) and a right long strip block (14) are symmetrically arranged on the axle (13), and the long strip blocks (14) are connected with a first rear wheel installation hole (6a) formed in an inclined pipe (6) on the corresponding side or a second rear wheel installation hole (5e) formed in a bend (5) on the corresponding side through bolts. The rear wheels can be put away or put down according to requirements, the putting away and putting down operation is simple and quick, and the working efficiency of the mini tiller can be effectively improved. The engine is a horizontal engine, a user has many choices, and the mini tiller size can be further reduced.

Owner:CHONGQING JIAMU MACHINERY

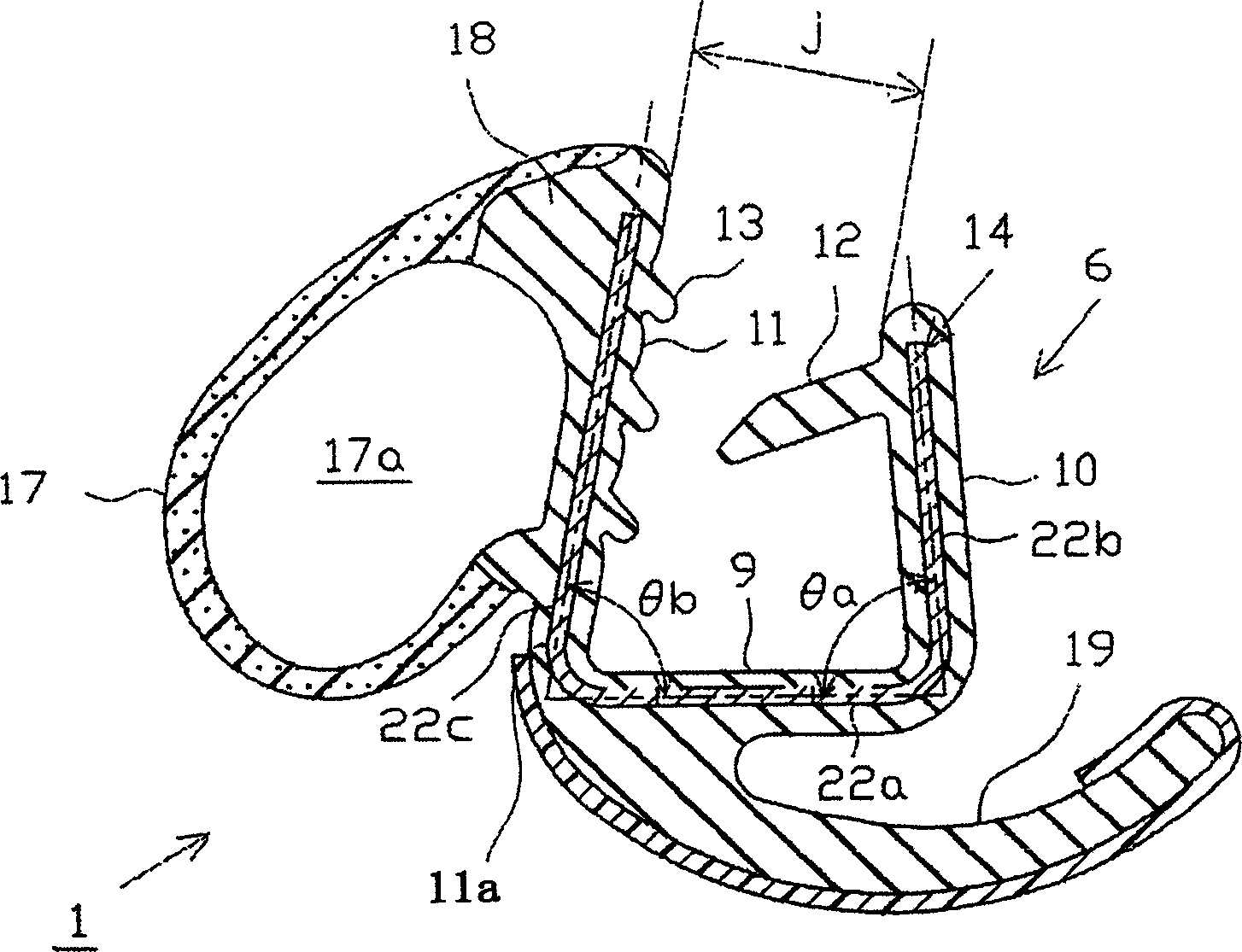

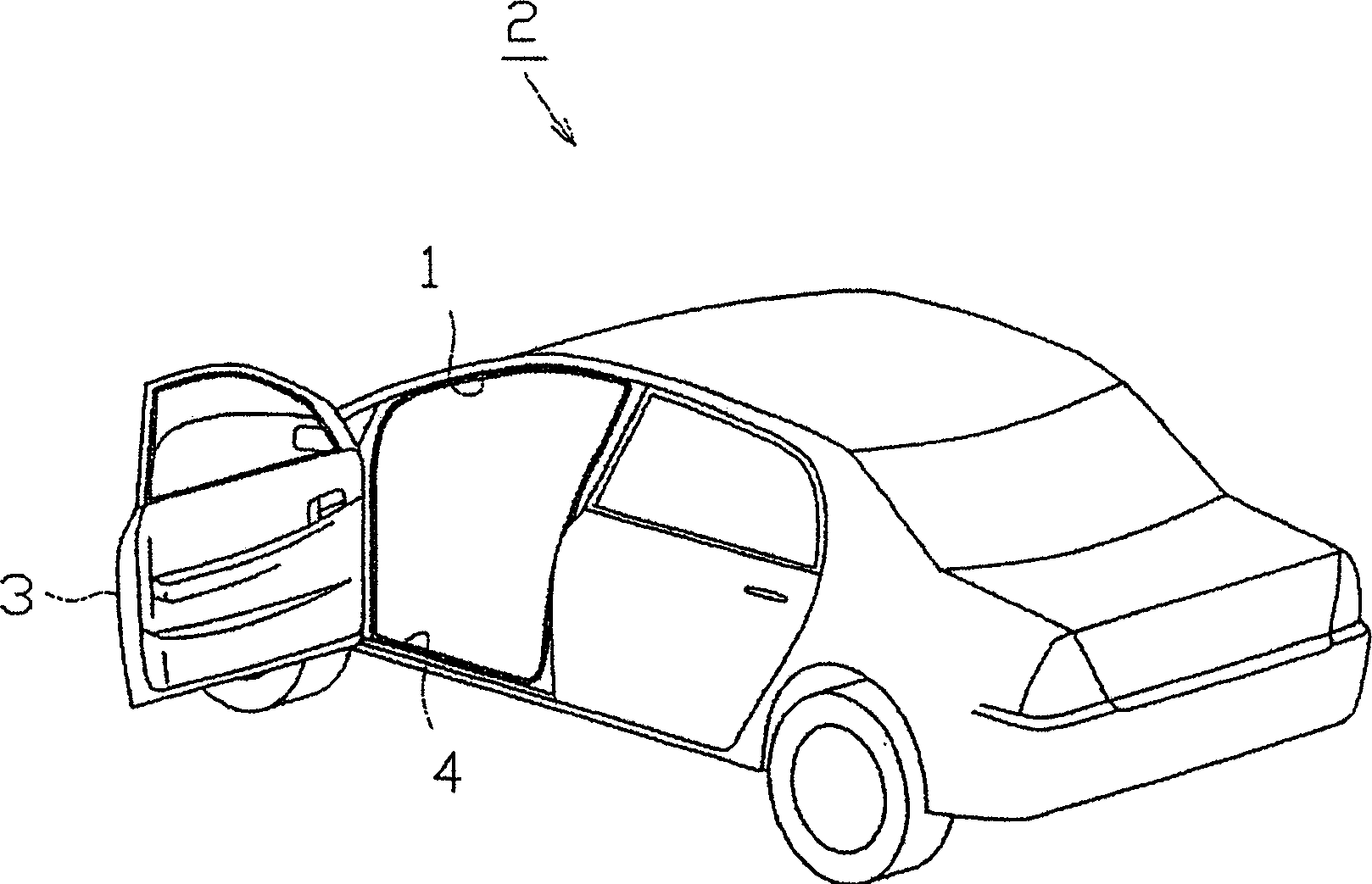

Weather strip

A sealing strip includes a beading portion adjusted to fit onto a flange, a sealing member having a hollow portion, and a cover lip. The hemming portion includes: a bottom wall portion; an inner side wall portion and an outer side wall portion which constitute a pair of side wall portions and are formed to have a substantially U-shaped cross section as a whole; within the blank holder portion of the construction. In the bone piece of the core, an angle θa is formed by the bottom wall member pre-embedded in the bottom wall portion and the inner member pre-embedded in the inner side wall portion, and the angle θa is formed by the bottom wall member and the outer member pre-embedded in the outer side wall portion θb, both the angle θa and the angle θb are made acute.

Owner:TOYODA GOSEI CO LTD

Punching equipment with buffer effect

ActiveCN108687371AHas a buffering effectAvoid squishingAdverse effect compensationBoring/drilling machinesPunchingArchitectural engineering

The invention relates to the technical field of punching devices, and discloses punching equipment with a buffer effect. The punching equipment comprises a base. The top of the base is fixedly connected with two mutually-symmetrical supporting columns. A supporting plate is fixedly connected between the tops of the two supporting columns. A sleeve is fixedly connected to the protected middle of the top of the supporting plate. The bottom of the sleeve penetrates through and extends to the bottom of the supporting plate. A supporting rod is movably connected into the sleeve in a sleeved mode. The top end of the supporting rod is fixedly connected with a fixing plate. Two mutually-symmetrical first electric pushing rods are fixedly connected between the bottom of the fixing plate and the topof the supporting plate. The bottom end of the supporting rod is fixedly connected with a connecting plate. The bottom of the connecting plate is fixedly connected with a motor. According to the punching equipment, the problems that existing punching equipment does not has the buffer function, consequently, the machining error is large, the quality is low, penetration machining cannot be effectively conducted on a workpiece during machining, and the machining time is long are solved, and the effects of high machining precision, good buffer effect, avoiding of material waste, convenient operation and saving of trouble and labor are achieved.

Owner:安徽锴模装备模具股份有限公司

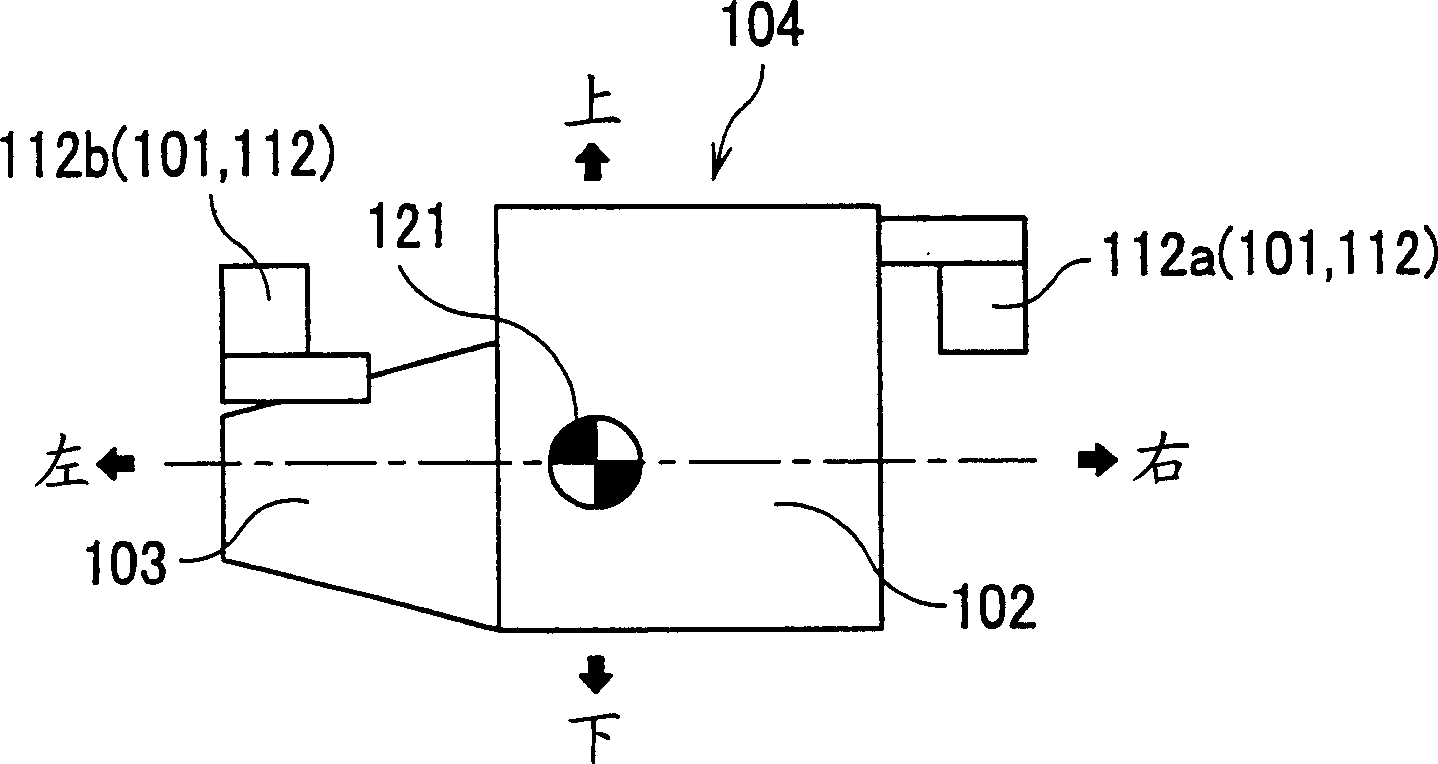

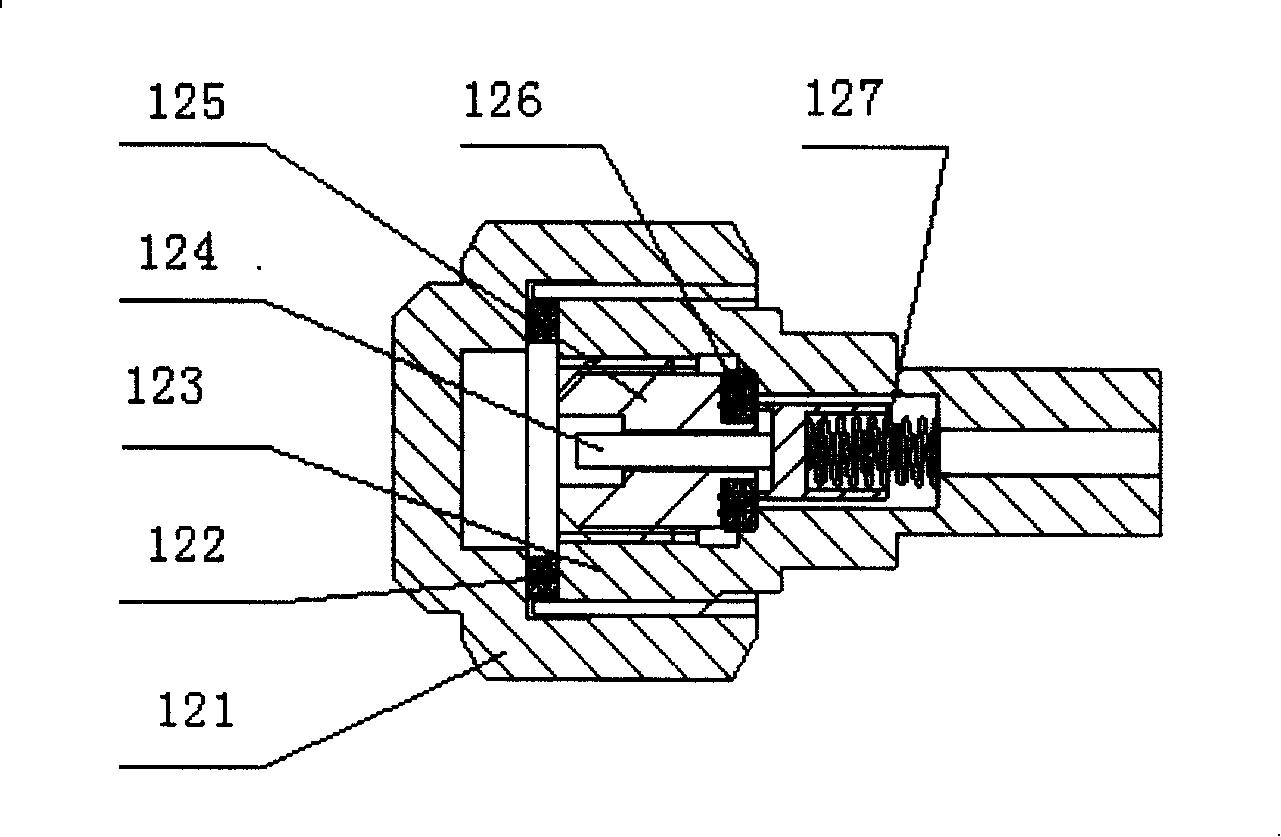

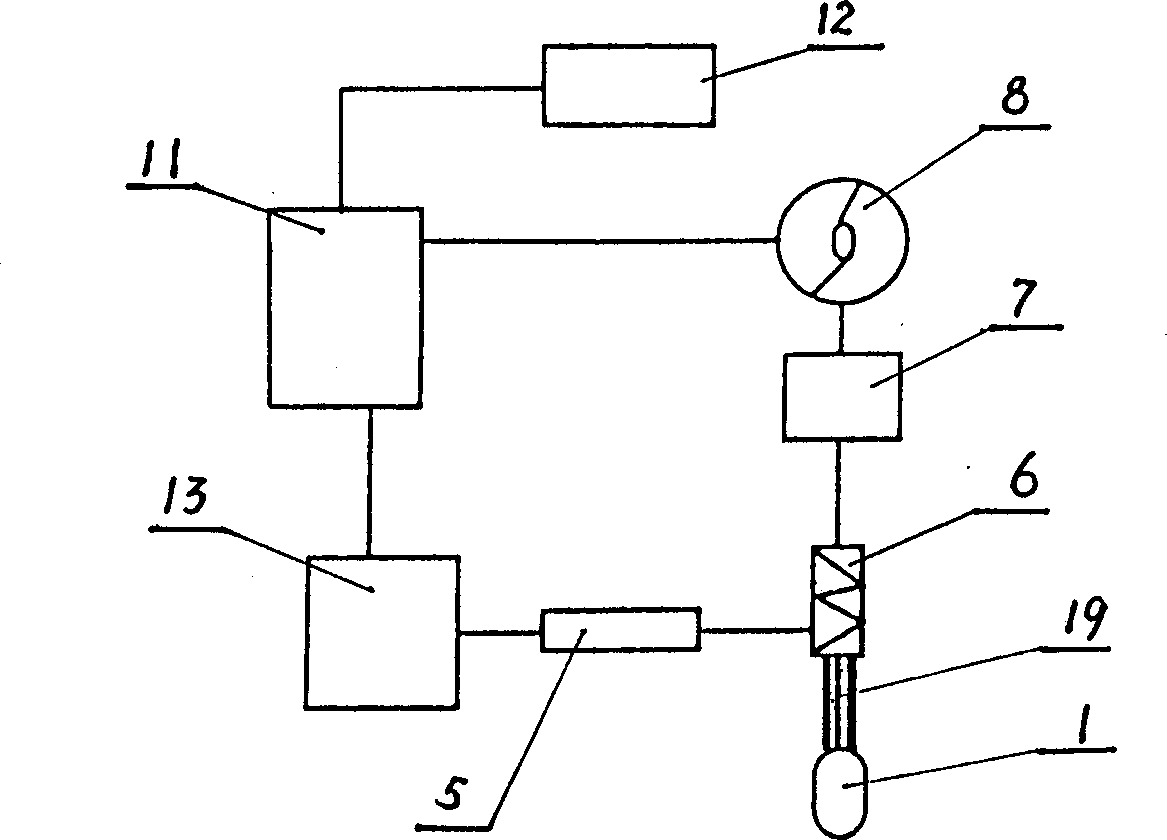

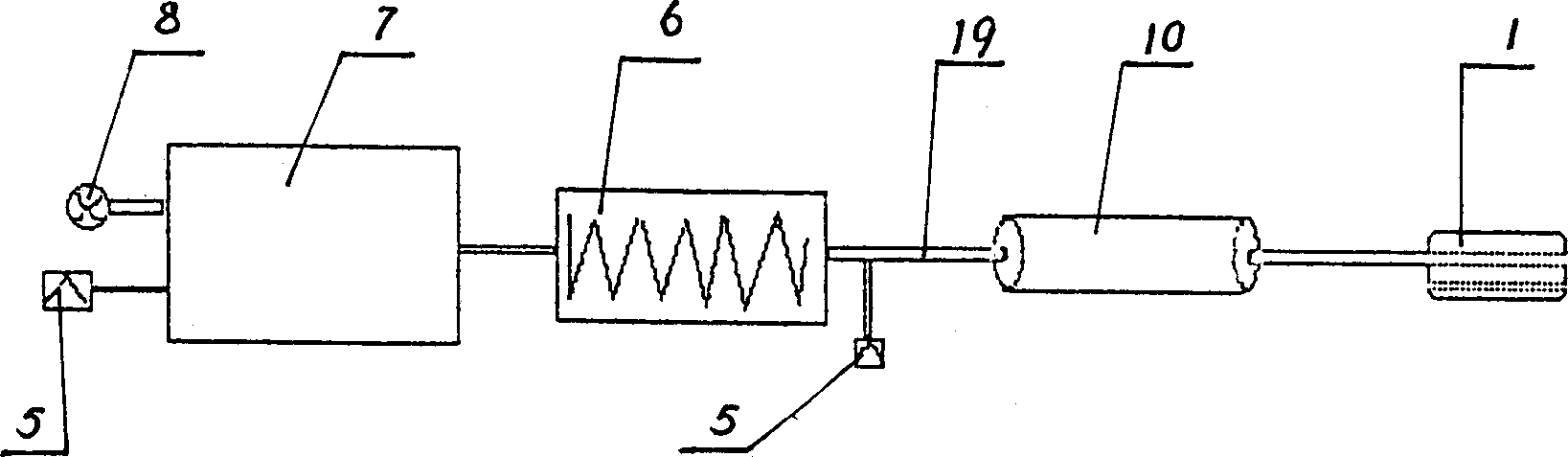

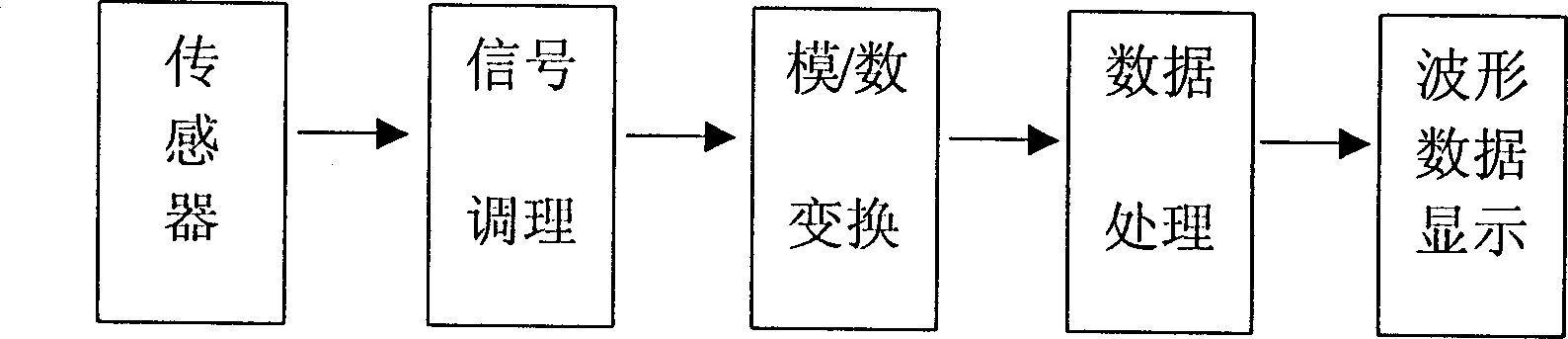

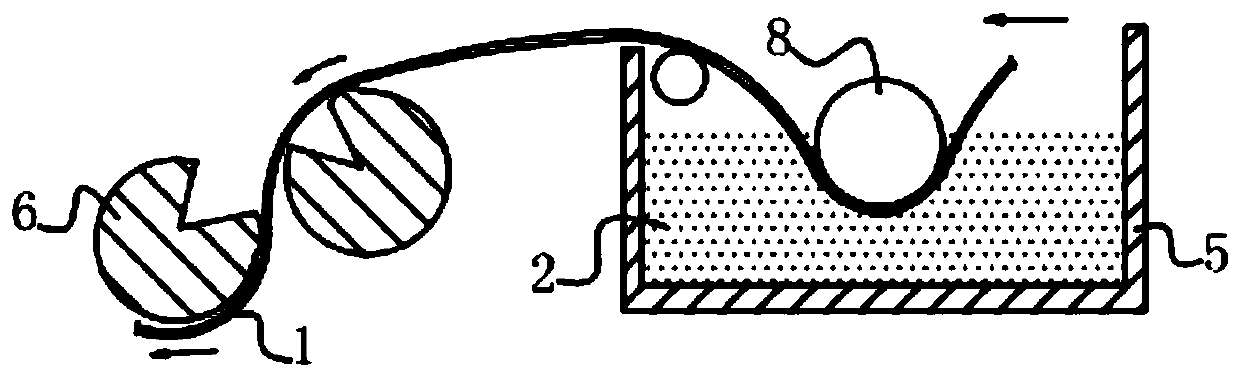

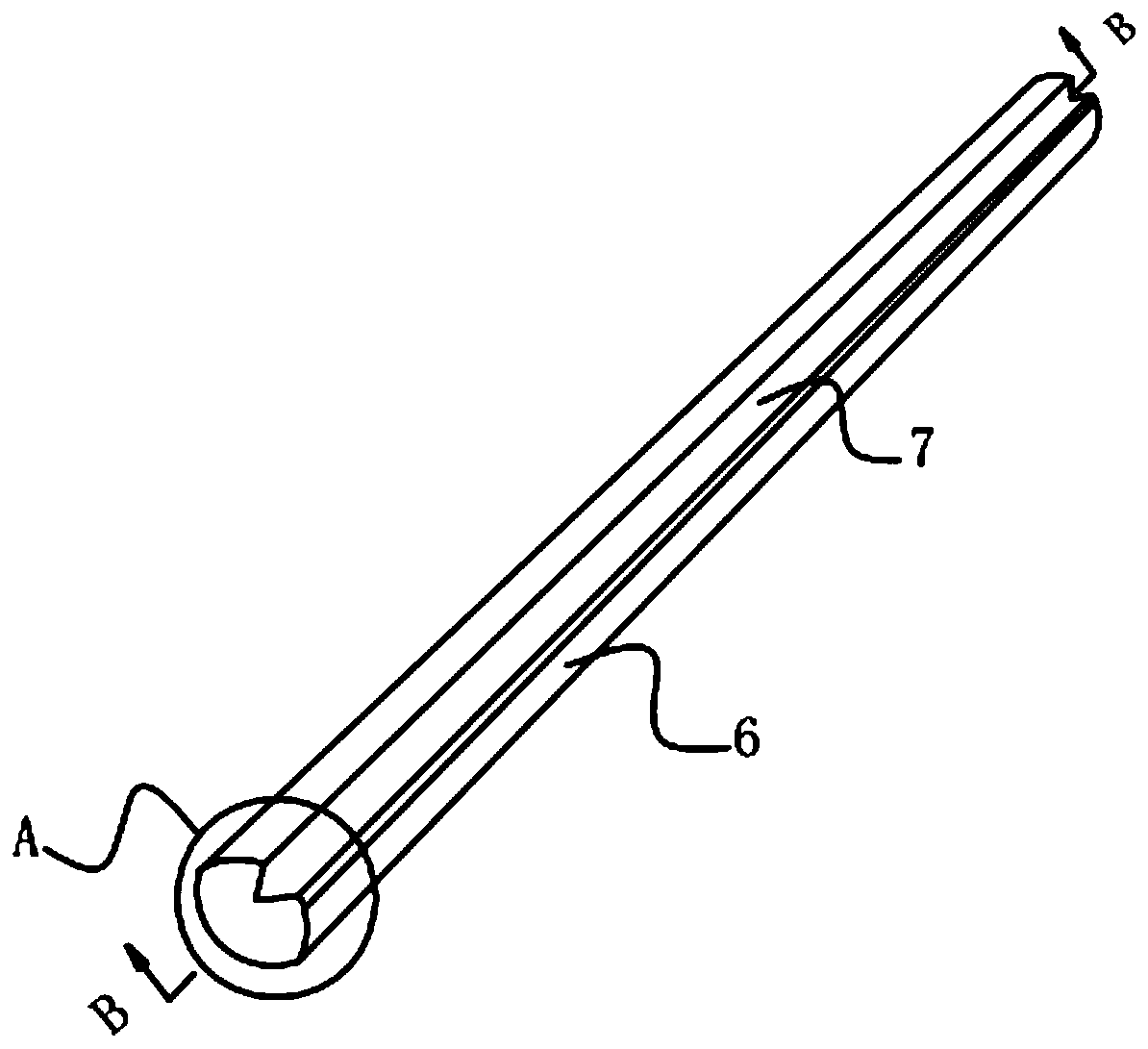

Method and device for measuring esophageal varicose vein pressure without wound

InactiveCN1390524AAccurate pressure measurementAccurate measurementEvaluation of blood vesselsAngiographyVenous vesselAir pump

A method and equipment for measuring the esophageal varicose vein pressure without wound is disclosed. Said equipment is composed of air channel including air pump, air sensitive probe connected to capillary tube via guide tube, circuit unit consisting of amplifier and A / D converter, and data processing unit consisting of computer and display. Said method features that the vein pressure is sensed by air sensitive probe and then transmitted via sensor to amplifier, A / D converter and computer sequentially. The result is displayed in waveform and numerals modes. Its advantages are simple method and high correctness.

Owner:湖南省肝硬化门脉高压症治疗研究中心

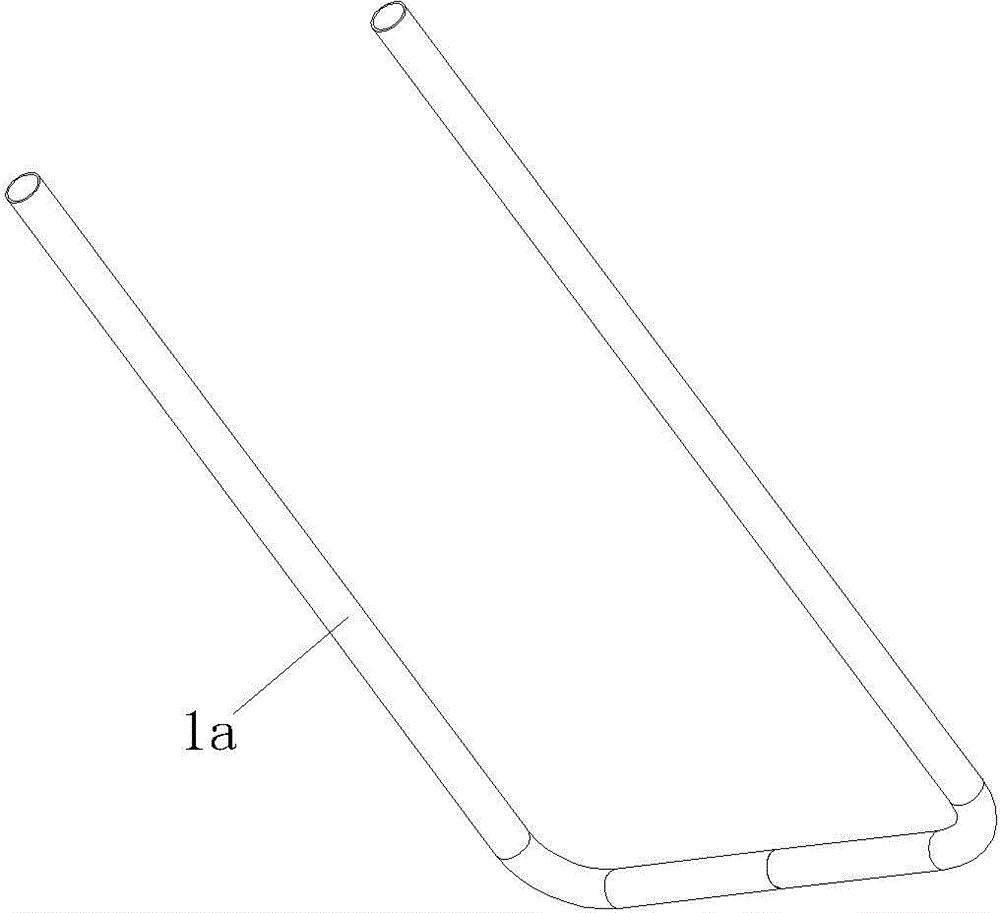

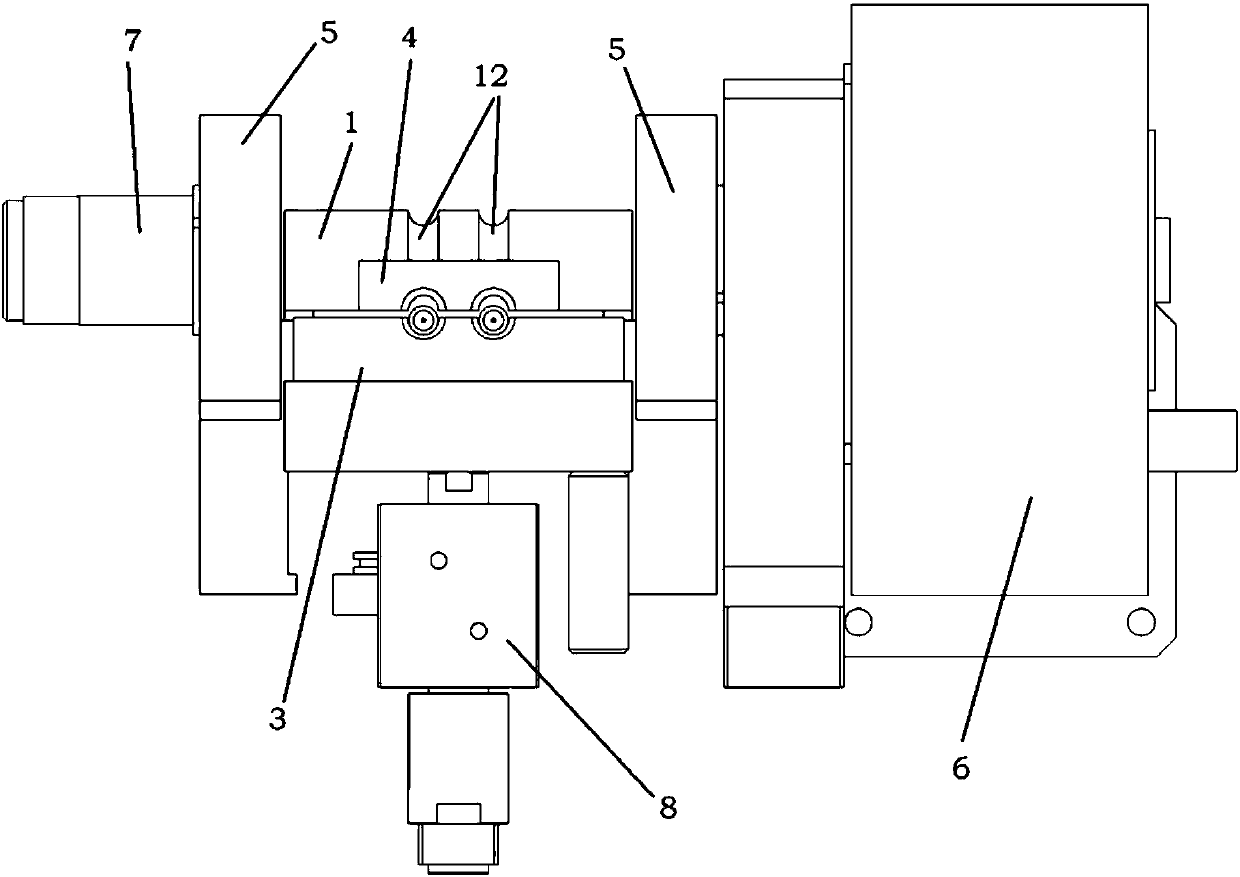

U-shaped pipe bending mechanism

The invention discloses a U-shaped pipe bending mechanism which comprises a bending die, a clamping die and a back die. A pipe penetrates the part between the bending die and the clamping die. The back die is arranged on the side, the same with the clamping die, of the pipe. The inner side of the bending die is an arc bending die face. A crease-resisting back die is further arranged on the side, the same with the bending die, of the pipe. The crease-resisting back die corresponds to the back die. The pipe penetrates the part between the crease-resisting back die and the back die, and the crease-resisting back die abuts against the face of the bending die. The face, making contact with the face of the bending die, of the crease-resisting back die is an arc face, the arc face is matched withthe bending die, and the top end of the side, making contact with the pipe, of the arc face stretches in the side, close to the clamping die, of the bending die. By means of the U-shaped pipe bendingmechanism adopting the above technical scheme, the pipe can be flattened, in addition, the pipe cannot be wrinkled due to stress during bending, and the U-shaped pipe bending mechanism is particularly suitable for machining pipes with thin walls or soft pipes.

Owner:ZHONGSHAN JINGDA TEKE MACHINERY CO LTD

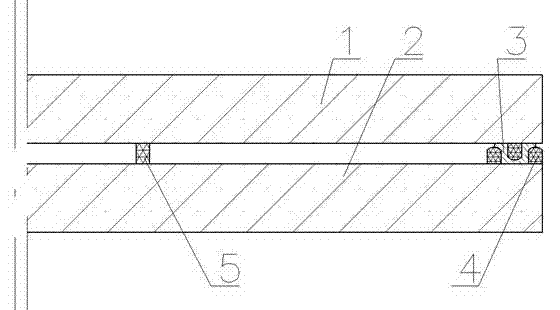

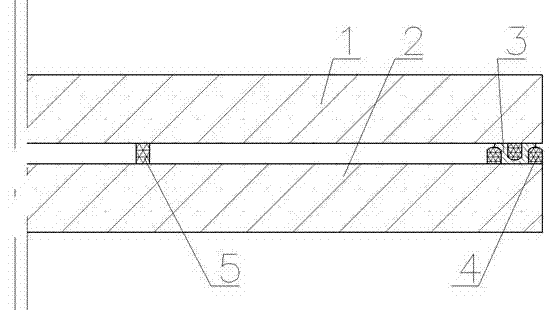

Planar vacuum glass welded by metal solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951811AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionMicrowave ovenAlloy

The invention discloses vacuum glass. The vacuum glass is characterized in that the peripheries of upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing not only common vacuum glass but also tempered vacuum glass.

Owner:戴长虹

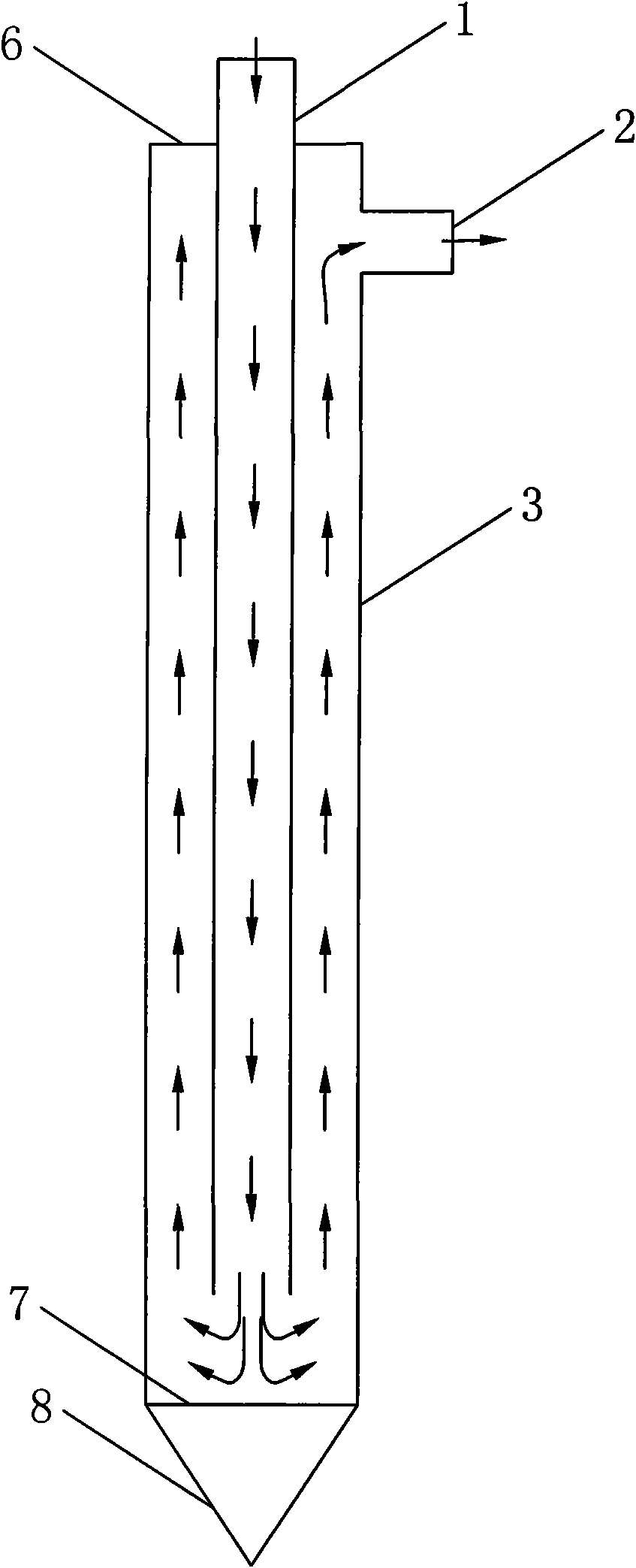

Unplugging-free freezer

The invention discloses an unplugging-free freezer used in tunnel construction, which mainly solves the problems of easily damaged cutter head, long time-consuming construction and high cost of the conventional freezer during the advance of a shield. The unplugging-free freezer is characterized in that: a freezing pipe (3) and upper and lower blanking plates (6,7) are all made of thin-walled aluminum or copper materials; a thick-walled plastic pipe (4) is arranged in the freezing pipe (3), wherein grooves (9) are formed at the outer periphery of the thick-walled plastic pipe (4) and central holes communicated with a feed pipe (1) are formed in the thick-walled plastic pipe (4); and strutting pieces (5) are arranged between the thick-walled plastic pipe (4) and the lower blanking plate (7). The freezer can be left in a frozen soil wall without being unplugged after the frozen soil wall reaches a designed thickness; the front end cutter head of the shield can easily cut the freezer distributed in the frozen soil wall without damaging the cutter head in construction, so the project cost of a project can be effectively reduced, the project period can be shortened, and the project risk can be reduced.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

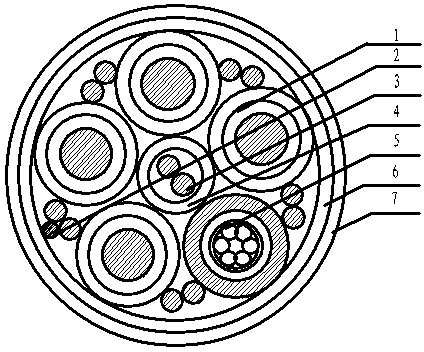

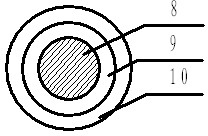

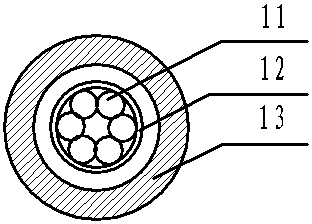

Field operation anti-bending and anti-interference photoelectric mixed cable and preparation method thereof

ActiveCN103811129AAvoid interferenceAvoid crosstalkInsulated cablesCable/conductor manufactureInterference resistanceStructural engineering

The invention discloses a field operation anti-bending and anti-interference photoelectric mixed cable which comprises a shielding insulating cable core, a drainage wire, a force-bearing fiber, an optical unit, a total shielding layer and an outer sheath layer. The shielding insulating cable core, the drainage wire, the force-bearing fiber and the optical unit are distributed in the outer sheath layer, and the total shielding layer wraps the outside of the shielding insulating cable core and the optical unit. The invention further discloses a preparation method for the field operation anti-bending and anti-interference photoelectric mixed cable. An aluminum plastic composite belt is applied to serve as the shielding layer, so that the anti-interference effect of insulating wires is achieved besides prevention of interference and crosstalk between the insulating wires; the drainage wire is adopted to effectively guide signals, and the tensile strength of the cable is greatly improved by adopting an aramid fiber; a loose sleeve spiral steel tape armoring layer is adopted to effectively protect the optical unit, the cable is prevented from being flattened and broken, and the bending capability of the optical cable is improved. The laying requirements are remarkably met, the anti-bending and anti-interference capability is improved, and the field operation anti-bending and anti-interference photoelectric mixed cable is suitable for meeting the use requirements in the field operation environment.

Owner:江苏通光电子线缆股份有限公司

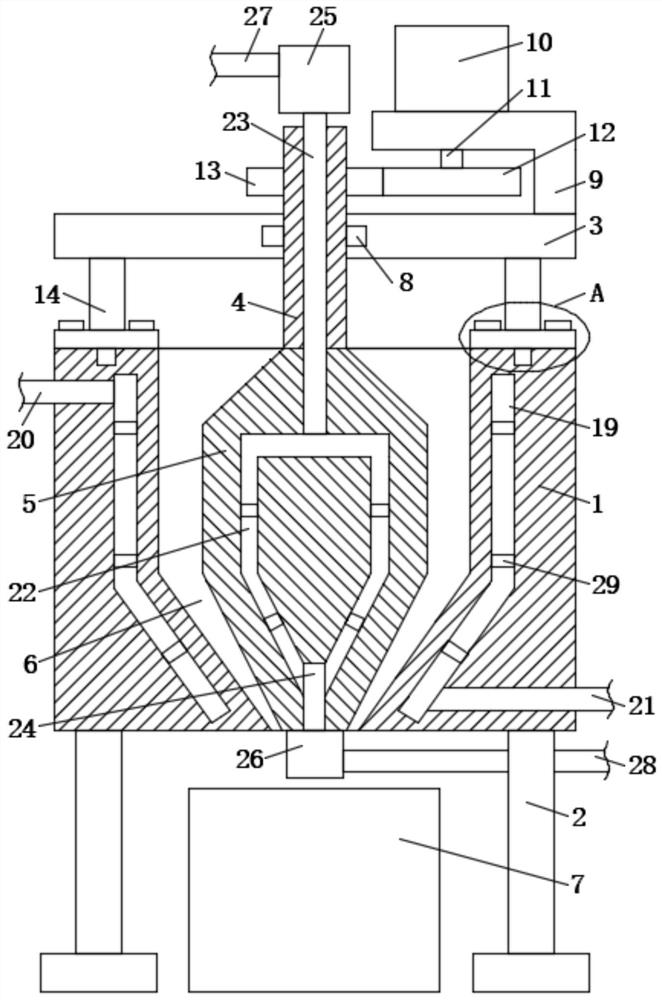

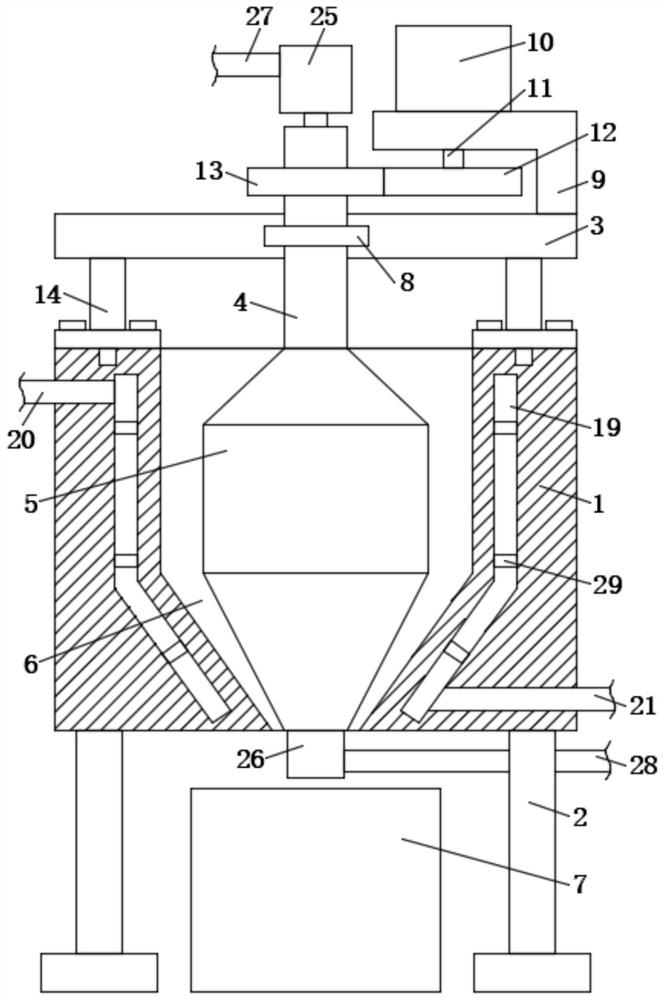

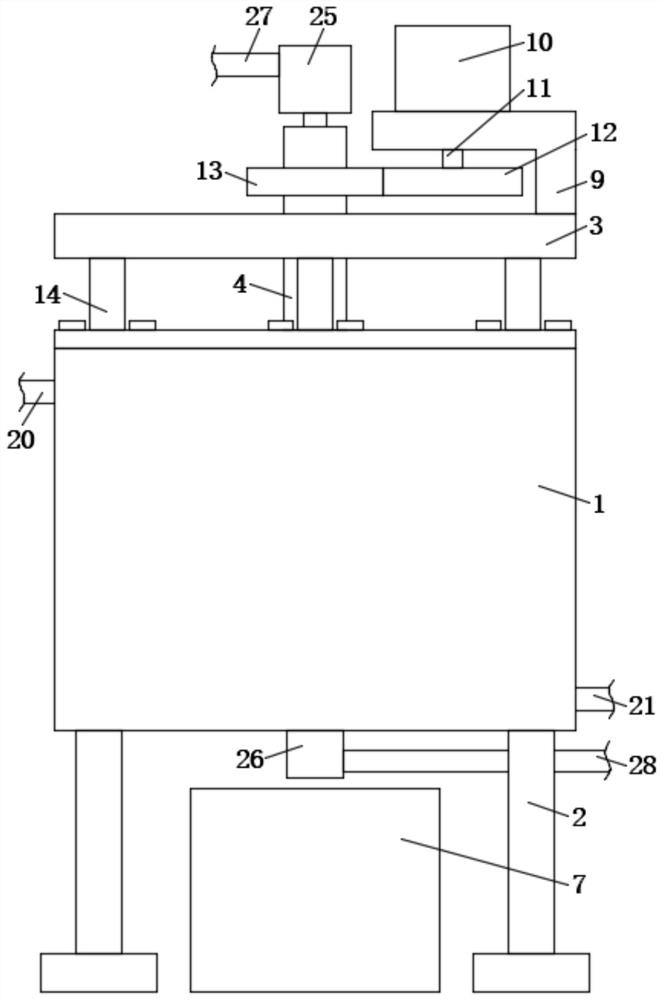

Medicinal material grinding equipment for daily life

PendingCN112473965AReduce manual labor intensityEasy to operateGrain treatmentsDaily livingMedicinal herbs

The invention discloses medicinal material grinding equipment for daily life. The medicinal material grinding equipment for daily life comprises a mounting base, wherein a plurality of supporting legsare evenly mounted at the bottom end of the mounting base; a top plate is detachably mounted at the top end of the mounting base; a rotating rod is rotatably mounted on the top wall of the top plate;the bottom end of the rotating rod penetrates through the top plate and extends to the lower side of the top plate; a grinding block is fixedly mounted at the bottom end of the rotating rod; the grinding block is inserted into the mounting base; a grinding groove matched with the grinding block is formed in the mounting base; the bottom end of the grinding groove extends to the lower side of themounting base; and the outer side wall of the bottom end of the grinding block and the inner side wall of the bottom end of the grinding groove are obliquely arranged. According to the medicinal material grinding equipment for daily life provided by the invention, a driving motor drives the grinding block to rotate so as to grind and crush medicinal materials, and a gap between the grinding blockand the grinding groove is gradually reduced from top to bottom, so that only the completely ground and crushed medicinal materials can flow out of the bottom end of the grinding groove, the convenience in operation is realized, the labor intensity of workers is low, the occurrence of the phenomenon of incomplete crushing can be avoided, the design is reasonable and the practical effect is good.

Owner:刘士云

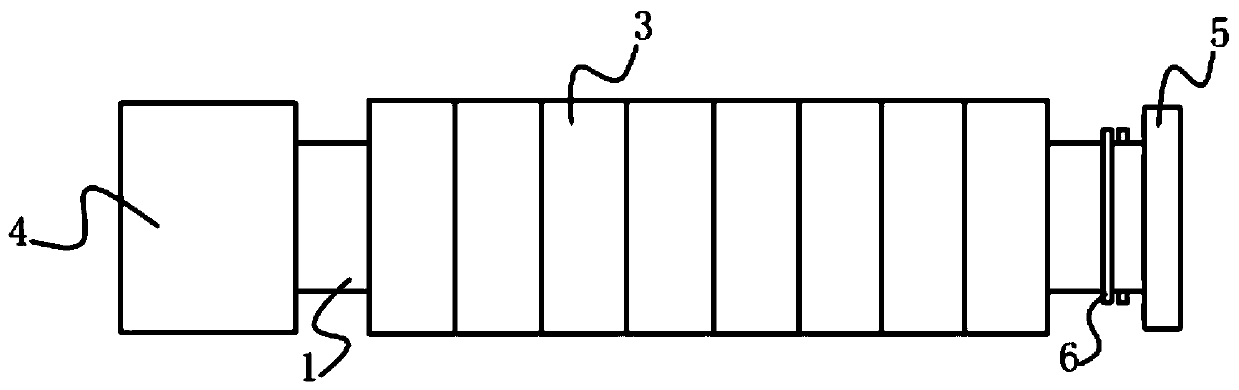

Glass fiber flame-retardant cloth foamed coating one-time forming production line and production process

ActiveCN109759275AControl the amount of glueReduce manufacturing costPretreated surfacesCoatingsWinding machineDyeing

The invention relates to the technical field of flame retardant cloths, and particularly relates to a glass fiber flame-retardant cloth foamed coating one-time forming production line and a productionprocess. The production line comprises a glue coating device, a drying device and a winding machine, wherein the drying device is composed of eight drying boxes, the glue coating device comprises a glue coating groove and a glue amount control device arranged on one side of the discharge direction of the glue coating groove, the glue amount control device comprises a glue scraping roller and an adjusting mechanism, a glue scraping mechanism is arranged on the glue scraping roller, the glue scraping mechanism comprises a glue scraping groove which are arranged along the axis direction of the glue scraping roller in a penetrating mode. The invention further discloses a glass fiber flame-retardant cloth foamed coating one-time forming production process. The production process comprises thefollowing production steps of (1) preparing; (2) dipping the dyeing glue; (3) carrying out glue scraping and spreading; (4) drying; and (5) rolling. The glass fiber flame-retardant cloth produced by the process is good in air permeability, excellent in sound-absorbing effect and soft in fabric hand feeling, dyeing glue dipped on the two surfaces of the glass fiber flame-retardant cloth can be simultaneously spread, the gluing amount is controlled, the coating is uniform, the application range is wide, and the working efficiency is high.

Owner:青岛博时阻燃织物有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com