Patents

Literature

70results about How to "Easy edge banding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

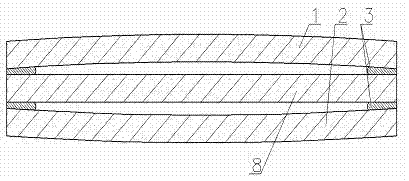

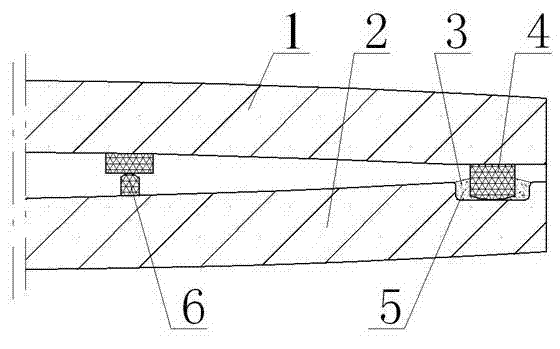

Convex low-altitude glass welded by metal solders and subjected to edge sealing by strip frame and groove, and manufacturing method of glass

InactiveCN102951814AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionConvex sideAlloy

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding peripheries of the upper glass and the lower glass are respectively provided with an edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a high-temperature edge sealing furnace, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

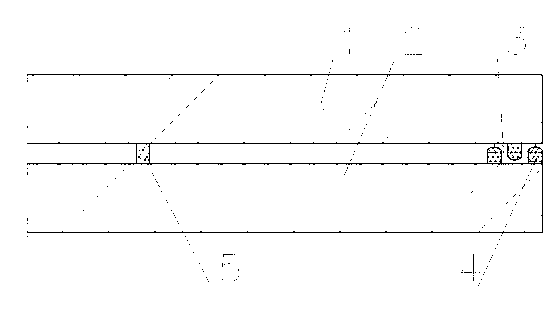

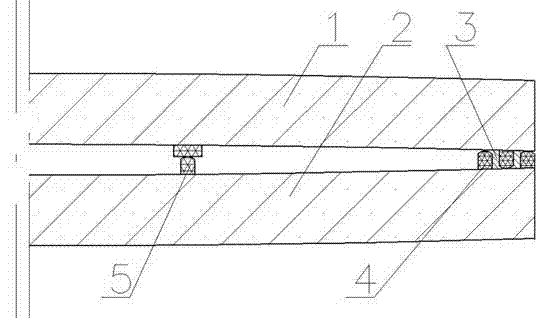

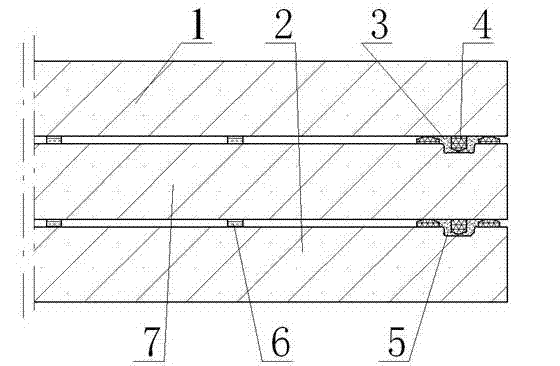

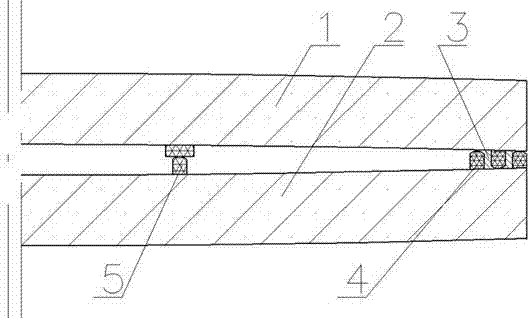

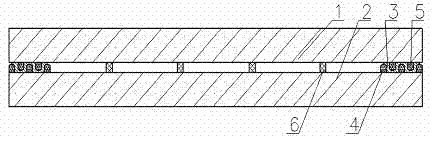

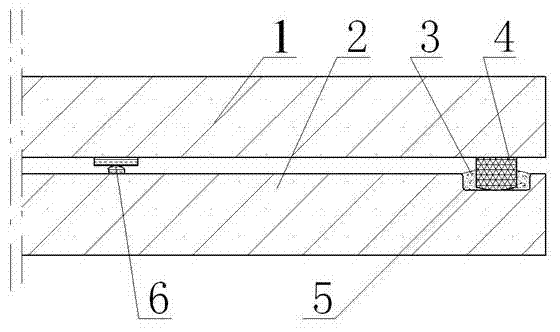

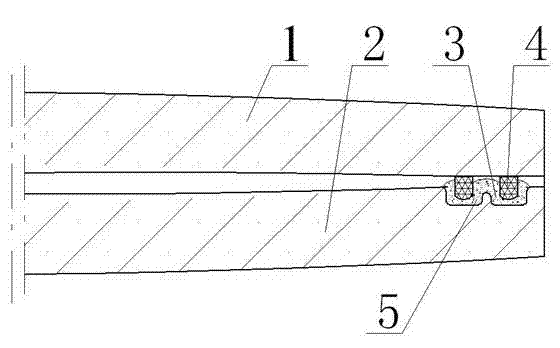

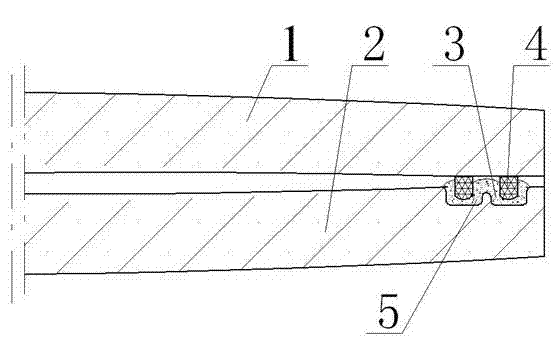

Flat vacuum glass welded by using metal welding material and provided with strip frame edge sealing, and manufacturing method thereof

InactiveCN102976592AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionAlloyGlass manufacturing

The present invention relates to a vacuum glass, which is characterized in that peripheries of an upper glass and a lower glass of the vacuum glass comprise edge sealing strip frames, and a metal welding material or an alloy welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the upper edge sealing strip frame and the lower edge sealing strip frame. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

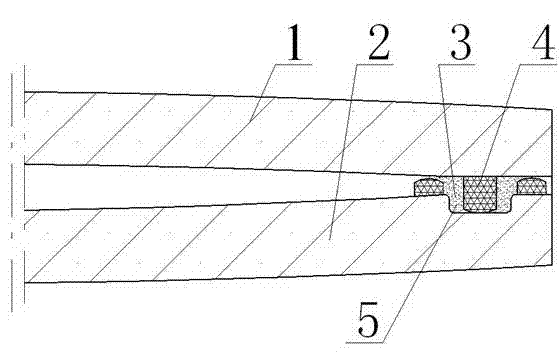

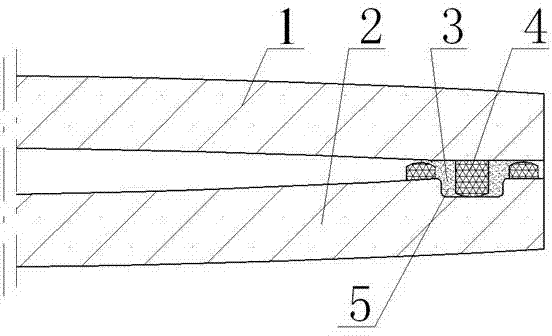

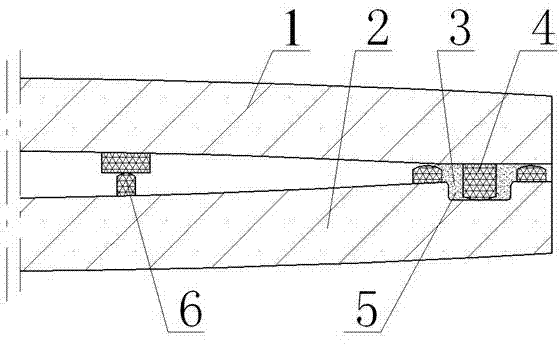

Metal solder-welded and strip frame-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951826AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMetalEdge banding

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex surface glass, edge sealing strip frames are arranged at the welded peripheries of the upper glass and the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the upper and the lower edge sealing strip frames can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

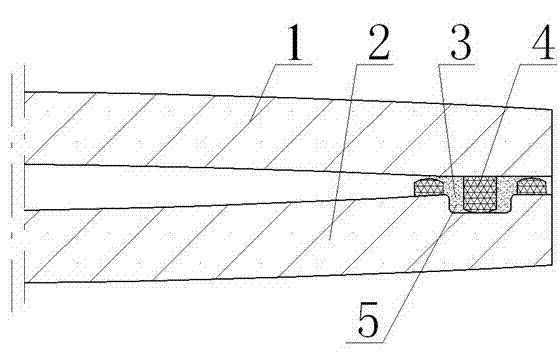

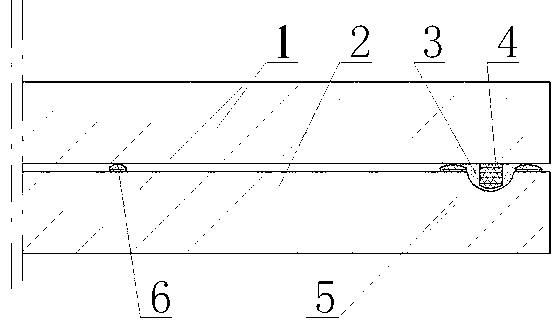

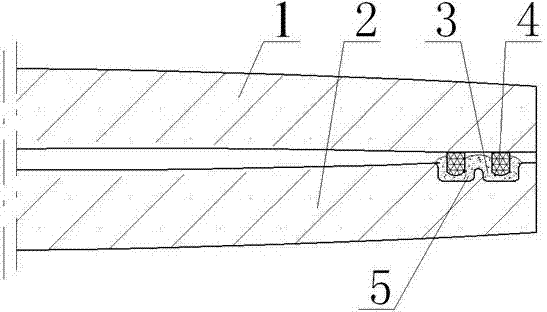

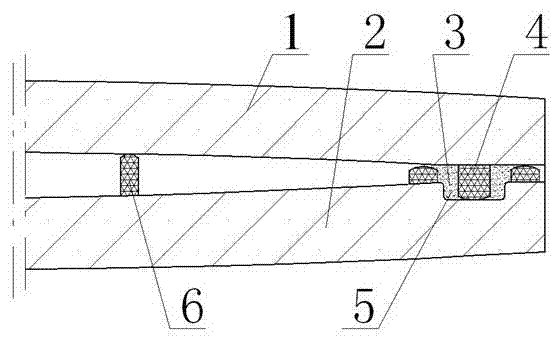

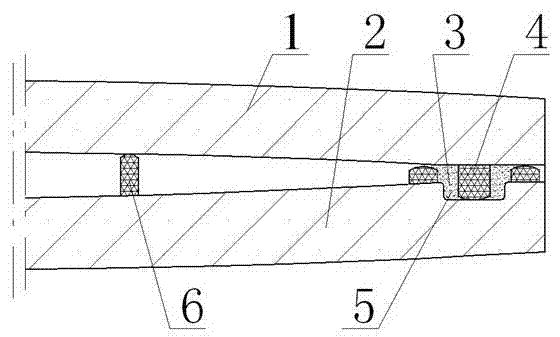

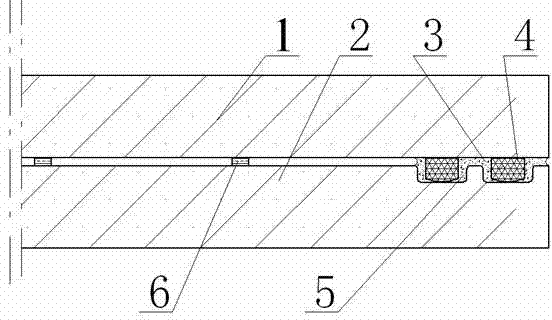

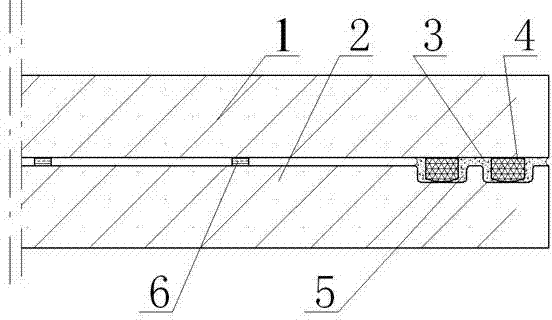

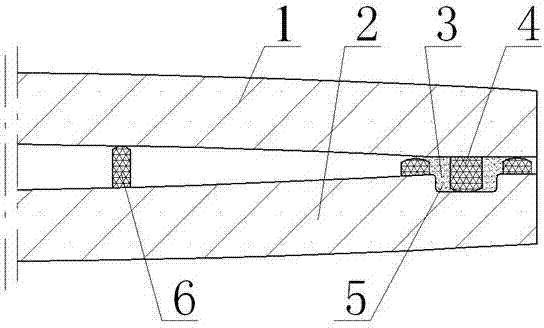

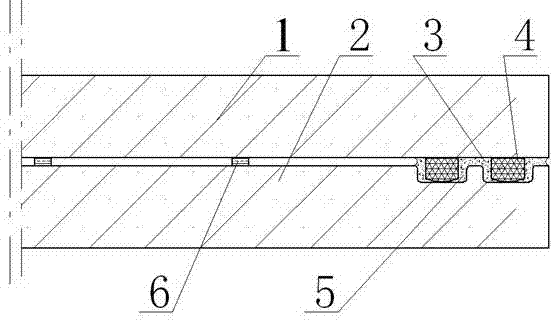

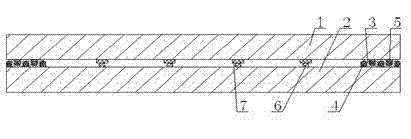

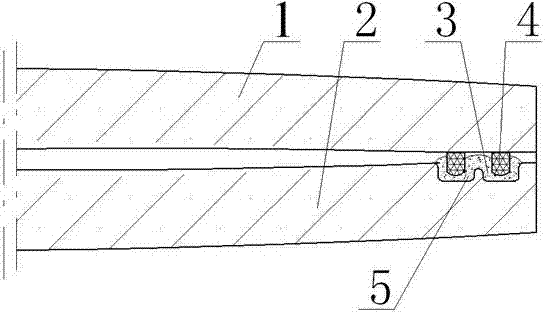

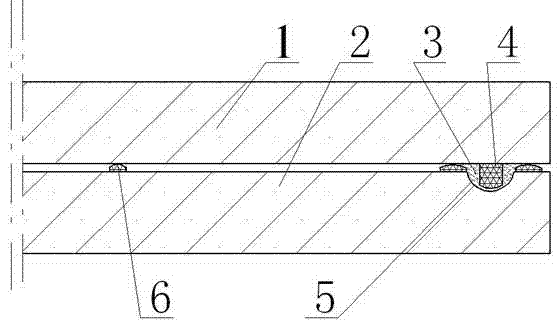

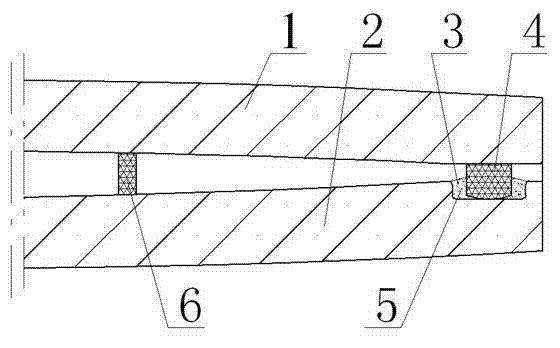

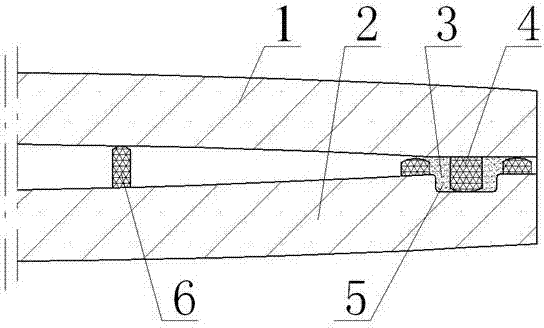

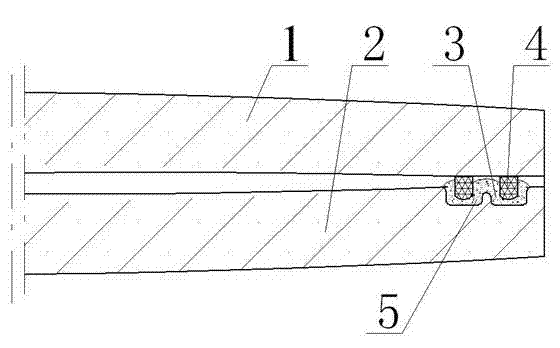

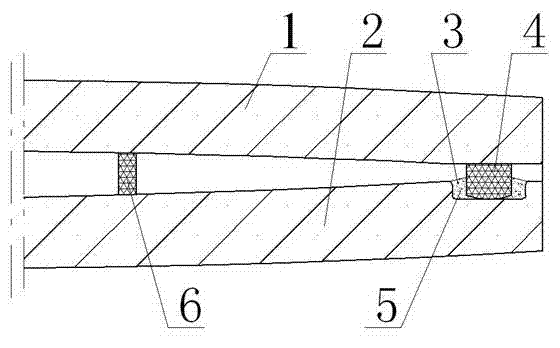

Flat vacuum glass welded by using glass welding material and provided with strip frame edge sealing and ditch groove edge sealing, and manufacturing method thereof

InactiveCN102976595AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionEngineeringGlass manufacturing

The invention relates to a vacuum glass, which comprises an upper glass and a lower glass, and is characterized in that the welding periphery of the upper glass is provided with an edge sealing strip frame, the welding periphery of the lower glass is provided with an edge sealing strip frame and an edge sealing ditch groove, and a glass welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the edge sealing strip frame and the edge sealing ditch groove. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

Convex vacuum glass welded by glass solders and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951803AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionConvex sideEngineering

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by glass solders in a vacuum edge sealing furnace, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and not only can be used for manufacturing common vacuum glass, but also is particularly suitable for manufacturing of tempered vacuum glass; and the vacuum glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

Convex low-altitude glass welded by glass solders and subjected to edge sealing by strip frame and groove, and manufacturing method of glass

InactiveCN102951813AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionGlass manufactureLow altitude

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding peripheries of the upper and lower glass are provided with an edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by glass solders in a high-temperature edge sealing furnace, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

Glass solder-microwave welded and strip frame-groove-edge-sealed planar vacuum glass and manufacturing method thereof

InactiveCN102951828AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention relates to vacuum glass. The vacuum glass comprises upper glass and lower glass and is characterized in that an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing glass solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology; and the method can be used for manufacturing both the ordinary vacuum glass and tempered vacuum glass.

Owner:戴长虹

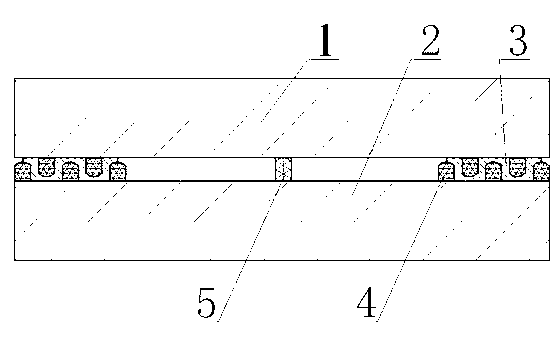

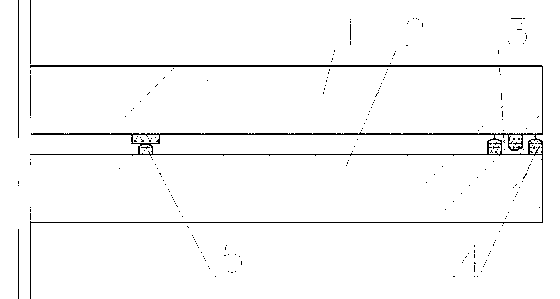

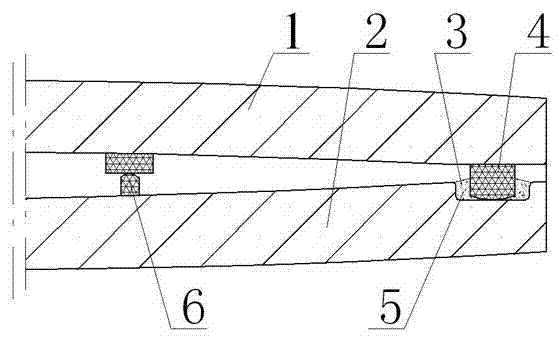

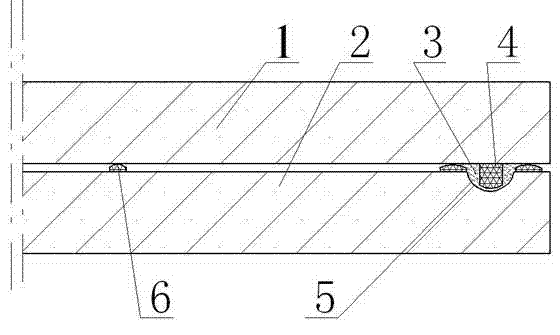

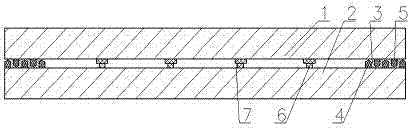

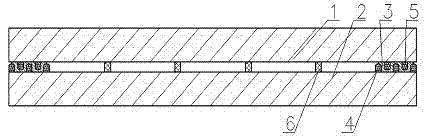

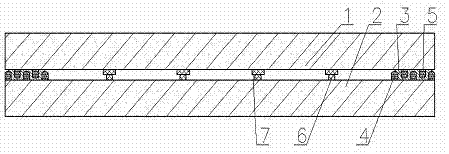

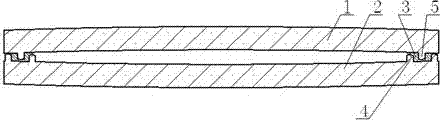

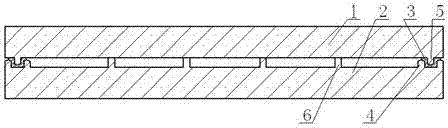

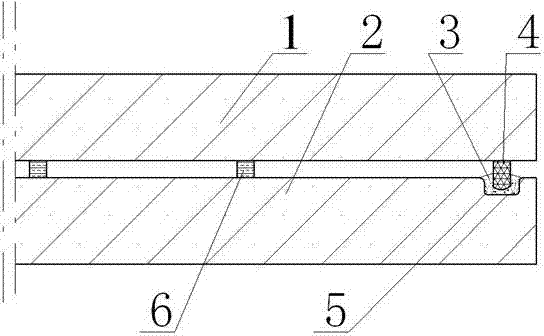

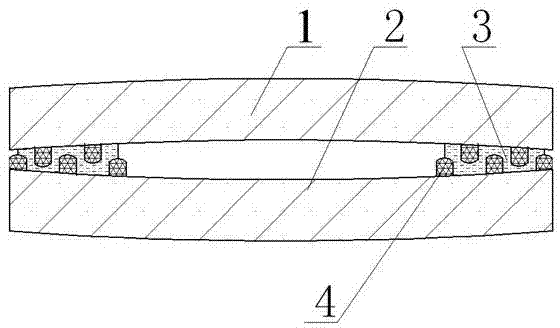

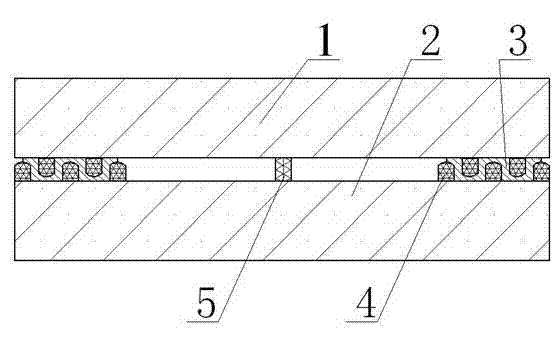

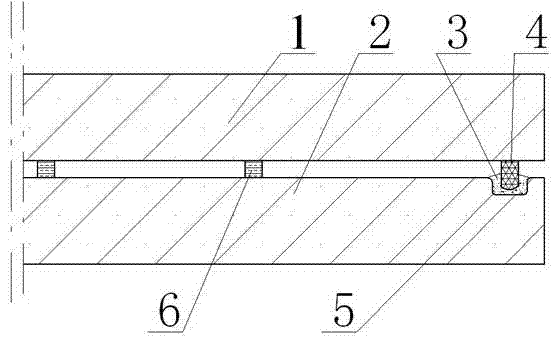

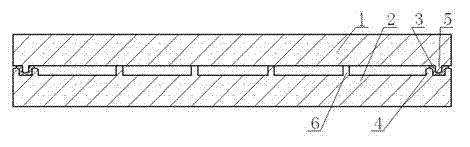

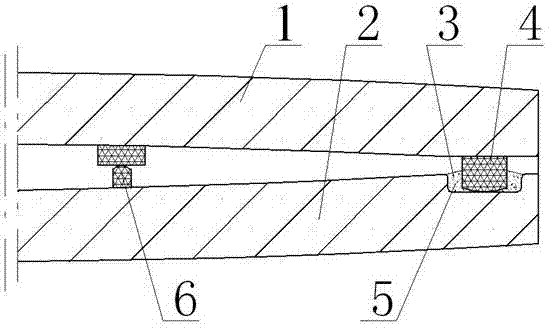

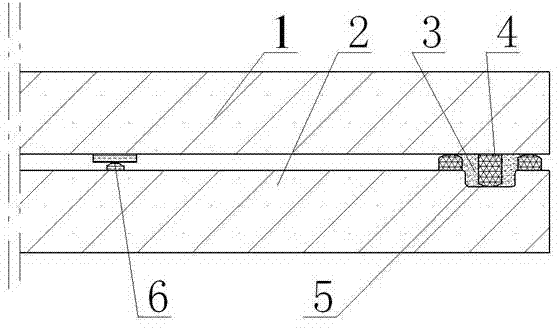

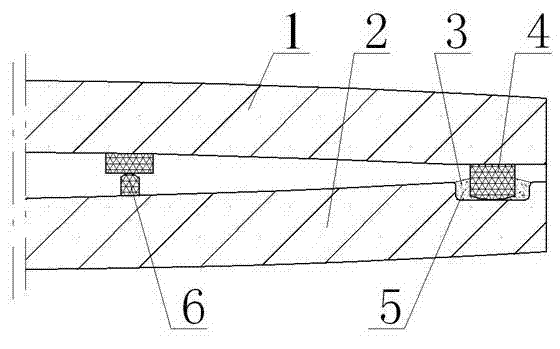

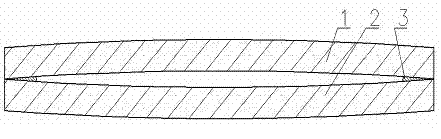

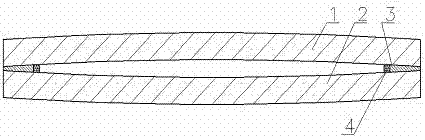

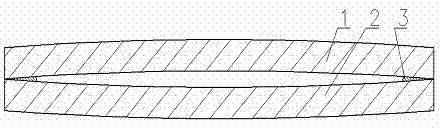

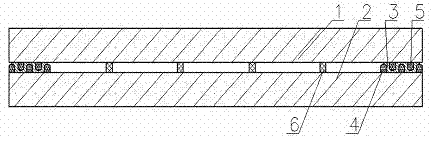

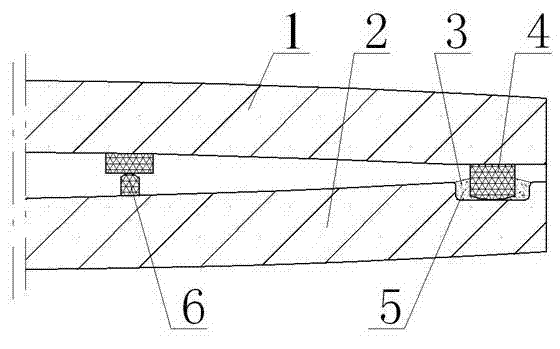

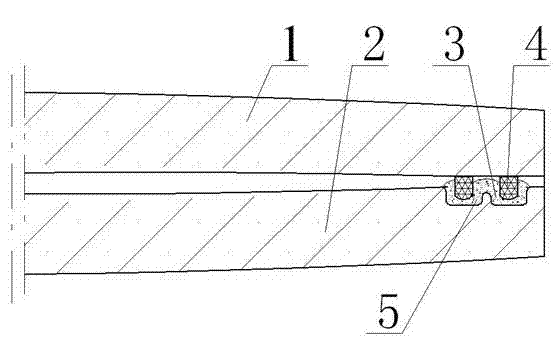

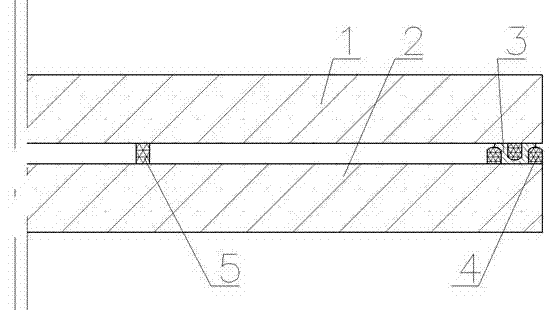

Flat tempered vacuum glass with glass welding and manufacturing method of glass

ActiveCN102951790AEasy edge bandingGuaranteed tightnessGlass reforming apparatusGlass productionEngineeringWelding

The invention provides flat tempered vacuum glass. The glass comprises upper glass and lower glass, which are flat tempered glass, wherein edge sealing strip frames are arranged on the peripheries of the welding surfaces of the upper and lower glass; the peripheries of the upper and lower glass are welded together through low-temperature glass solders; and a closed vacuum layer is formed between the upper glass and the lower glass and is internally provided with supports which are arranged in a lattice manner. A manufacturing method of the vacuum glass provided by the invention is simple in process; and the manufactured tempered vacuum glass can overcome defects in the prior art and can be subjected to mass production.

Owner:戴长虹

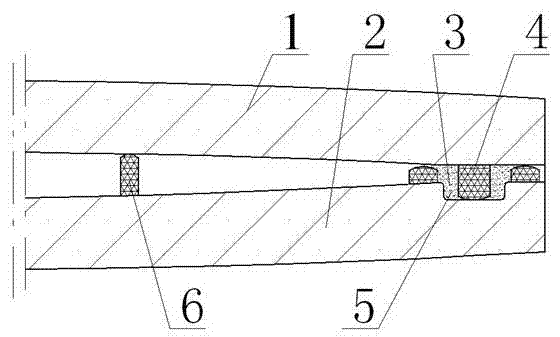

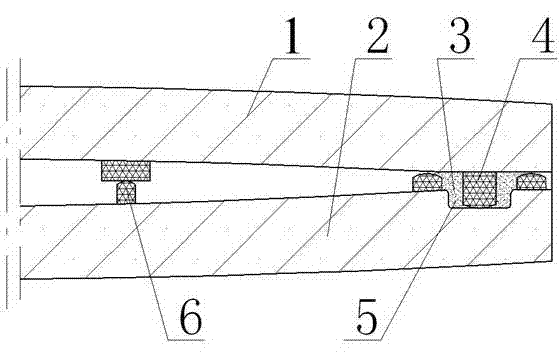

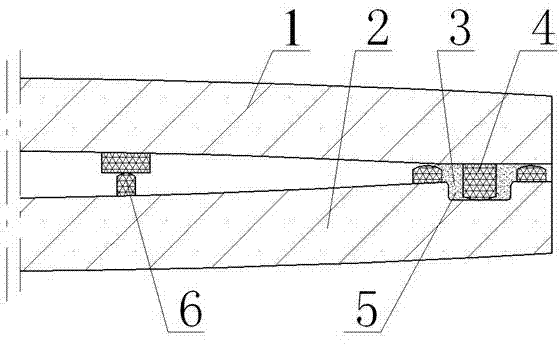

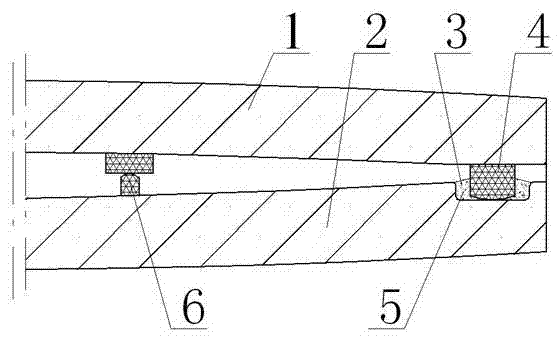

Metal solder-welded and strip frame-groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951829AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionAlloyMetal

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

Vacuum ceramic thermal baffle welded by metal solders and manufacturing method of thermal baffle

InactiveCN102953509AGood heat insulationGood sound insulationCovering/liningsLaminationUltimate tensile strengthAir tightness

The invention provides a vacuum ceramic thermal baffle. The thermal baffle comprises an upper thermal baffle and a lower thermal baffle, wherein the peripheries of the upper and lower thermal baffles are welded together by metal or alloy solders; a closed vacuum layer is formed between the upper thermal baffle and the lower thermal baffle; and the upper and lower thermal baffles can be flat, flat externally and concave internally, or convex. A manufacturing method of the vacuum ceramic thermal baffle is simple in process. According to the invention, the manufactured vacuum ceramic thermal baffle can overcome defects of the conventional thermal baffle, the air tightness of the vacuum layer of the thermal baffle can be effectively ensured, the service life of the thermal baffle can be prolonged, the strength, sound insulation and fireproof performance of the thermal baffle can be improved, and the thermal baffle also can achieve a good decoration effect.

Owner:戴长虹

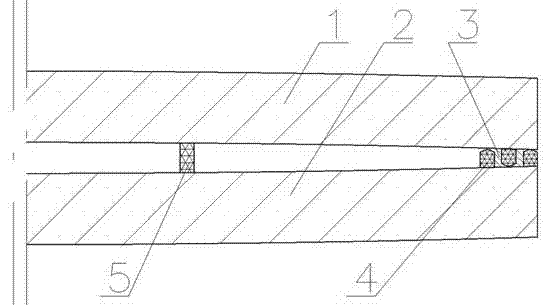

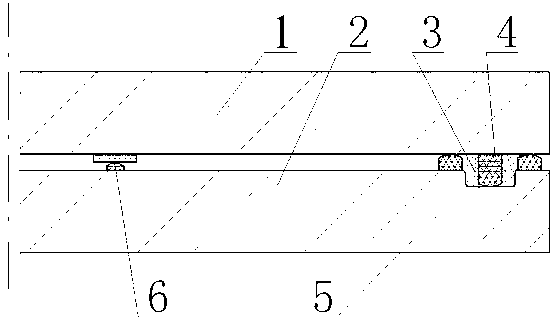

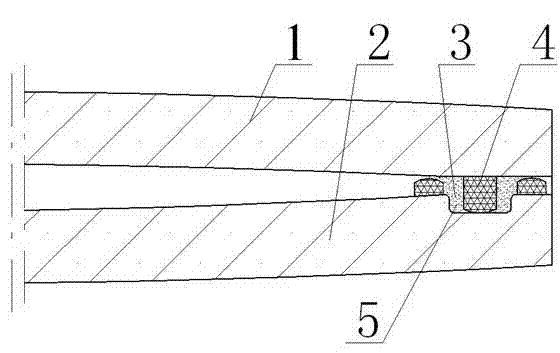

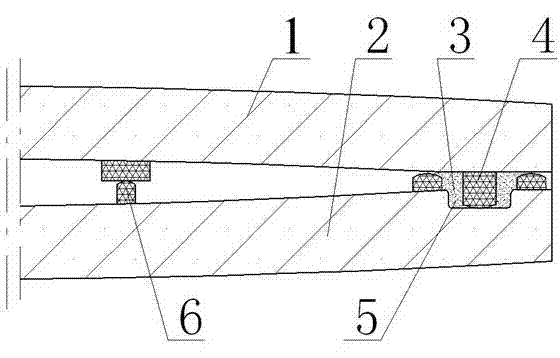

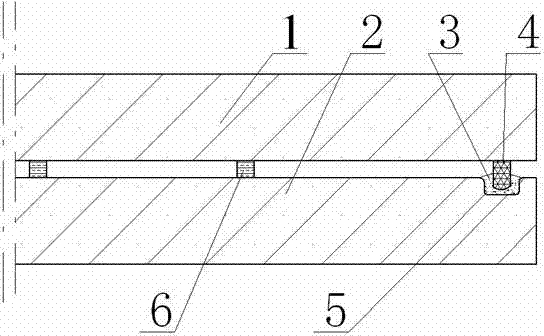

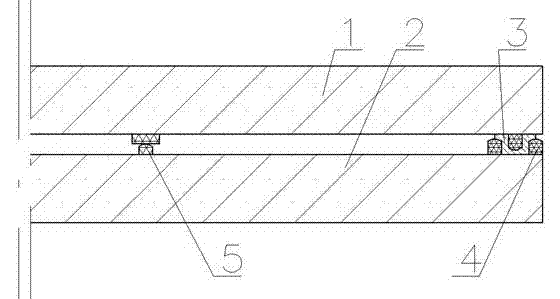

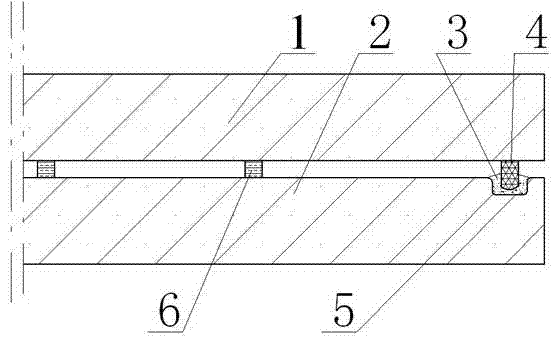

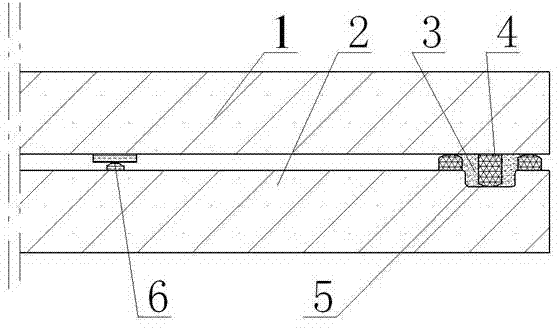

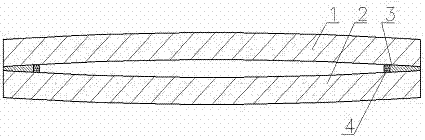

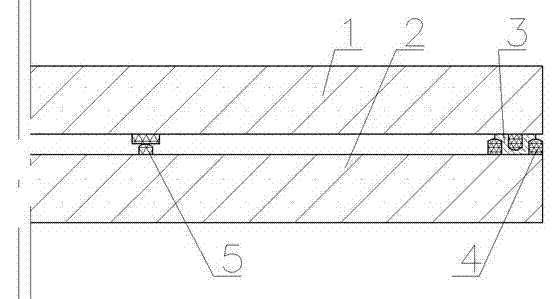

Metal solder-welded and groove-edge-sealed planar vacuum glass and manufacturing method thereof

InactiveCN102951825AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionAlloyMetal

The invention relates to vacuum glass. The vacuum glass comprises upper glass and lower glass and is characterized in that an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing groove is arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frame and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology; and the method can be used for manufacturing both the ordinary vacuum glass and tempered vacuum glass.

Owner:戴长虹

Planar vacuum glass welded by metal solders in microwave manner and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951809AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetal

The invention discloses vacuum glass. The vacuum glass consists of upper glass and lower glass and is characterized in that the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing not only common vacuum glass but also tempered vacuum glass.

Owner:戴长虹

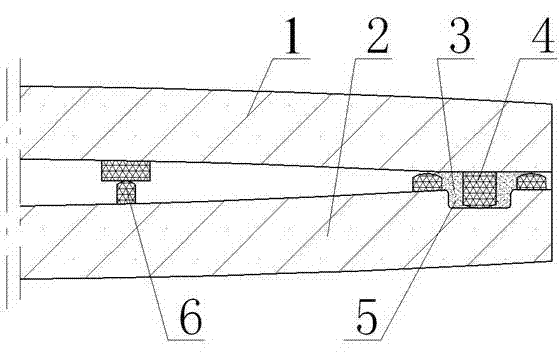

Glass solder-welded and strip frame-groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951821AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionEngineeringEdge banding

Owner:戴长虹

Convex vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951806AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by low-temperature glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing common vacuum glass and tempered vacuum glass.

Owner:戴长虹

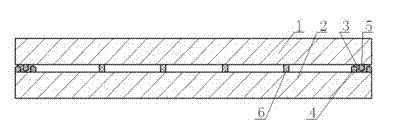

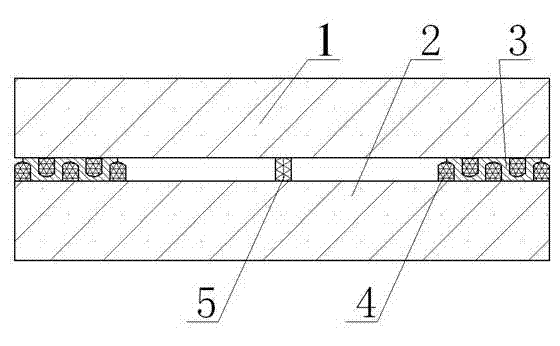

Planar vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951817AEasy edge bandingExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention discloses vacuum glass. The vacuum glass is characterized in that the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by low-temperature glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without special extraction openings in mass by virtue of a one-step method, and can be used for manufacturing common vacuum glass and tempered vacuum glass.

Owner:戴长虹

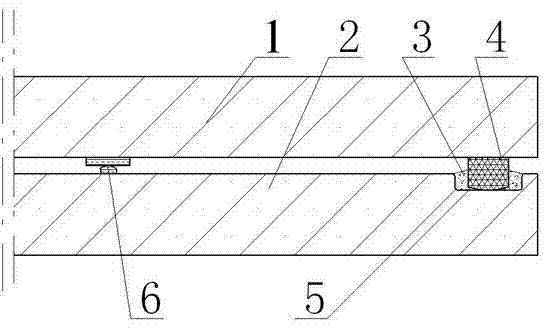

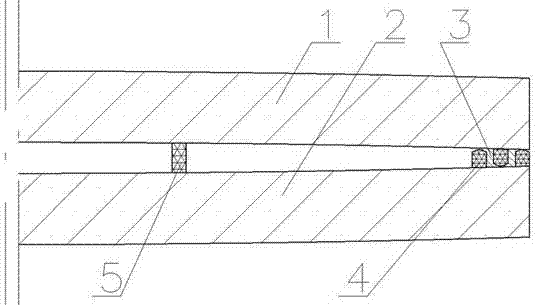

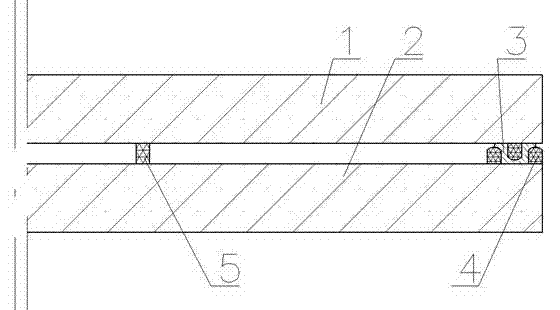

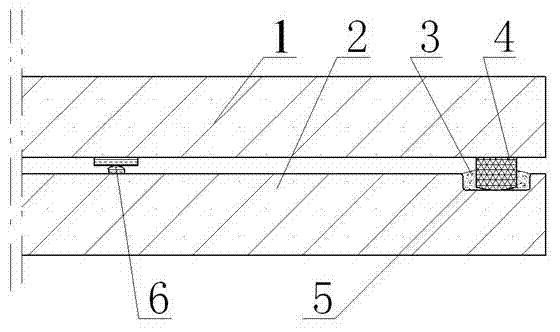

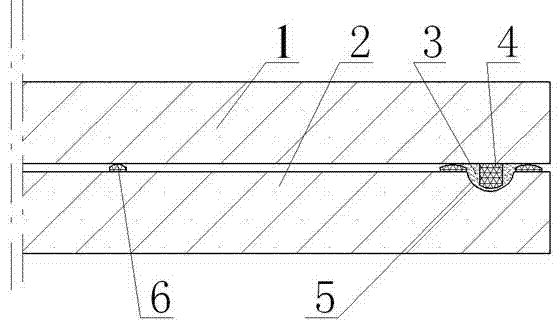

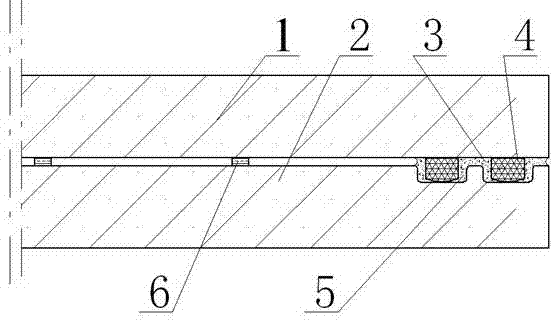

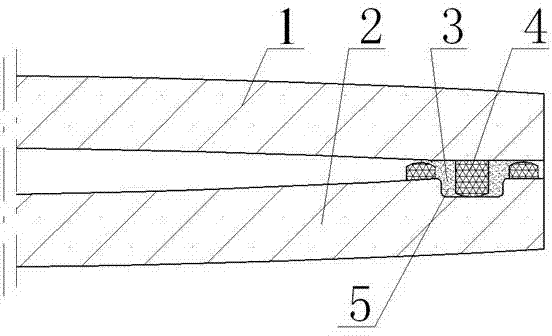

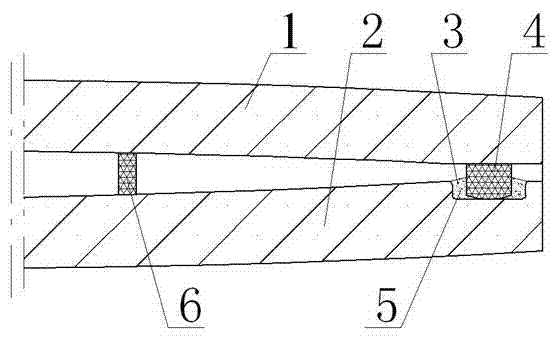

Planar vacuum glass welded by glass solders and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951802AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMetallurgyEdge banding

The invention discloses vacuum glass consisting of upper glass and lower glass. The vacuum glass is characterized in that the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by glass solders in a vacuum edge sealing furnace, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing not only common vacuum glass but also tempered vacuum glass.

Owner:戴长虹

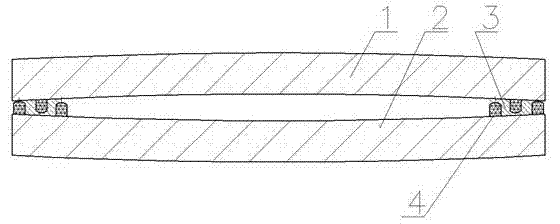

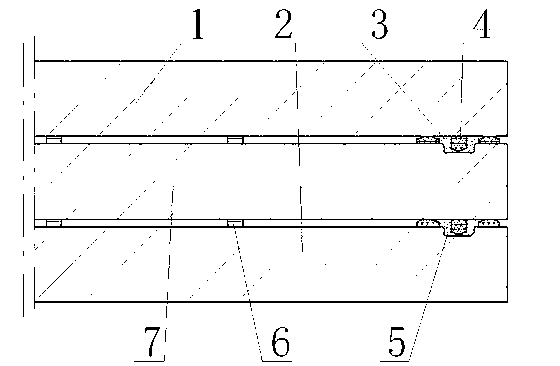

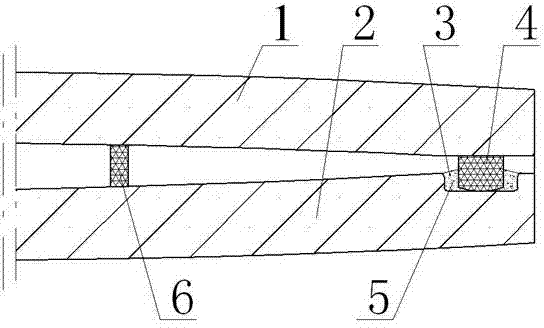

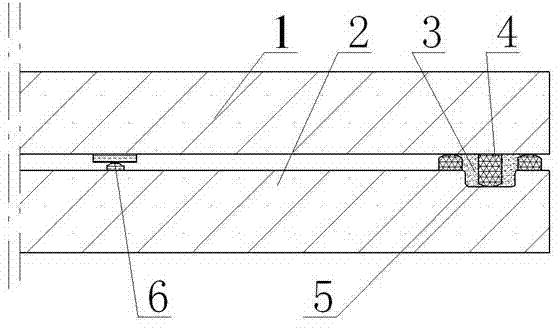

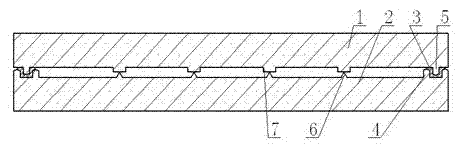

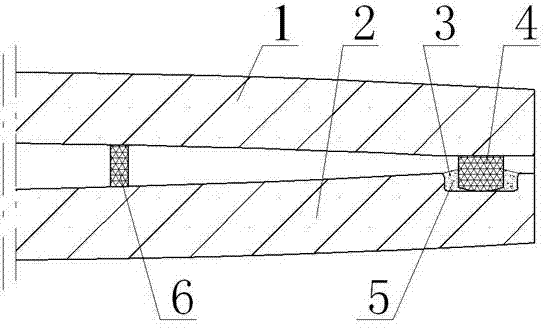

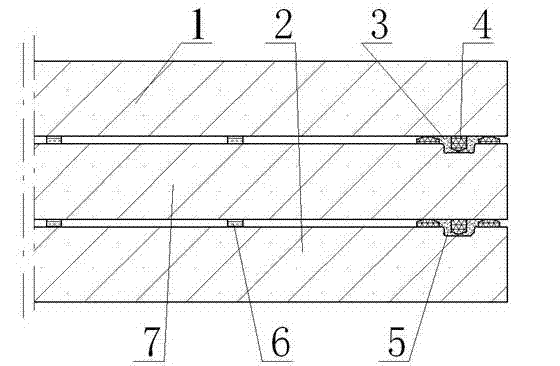

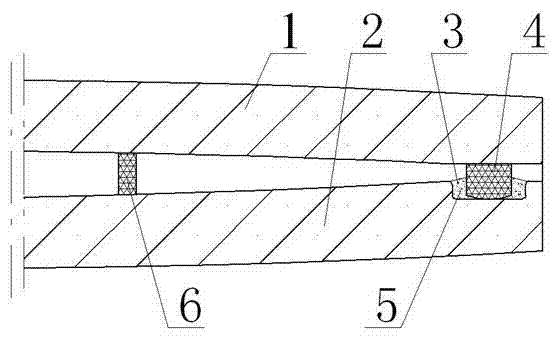

Flat tempered vacuum glass welded by metal and manufacturing method thereof

InactiveCN102951789AEasy edge bandingGuaranteed tightnessGlass reforming apparatusGlass productionMaterials scienceMetal

The invention provides flat tempered vacuum glass. The glass comprises upper glass and lower glass, wherein the upper and lower glass are flat tempered glass; edge sealing strip frames are arranged on the peripheries of the welding surfaces of the upper and lower glass; the peripheries of the upper and lower glass are welded together through low-temperature solders which are low-melting-point metal or alloy solders; and a closed vacuum layer is formed between the upper glass and the lower glass and is internally provided with supports which are arranged in a lattice manner. A manufacturing method of the vacuum glass provided by the invention is simple in process; and the manufactured tempered vacuum glass can overcome the defects in the prior art and can be subjected to mass production.

Owner:戴长虹

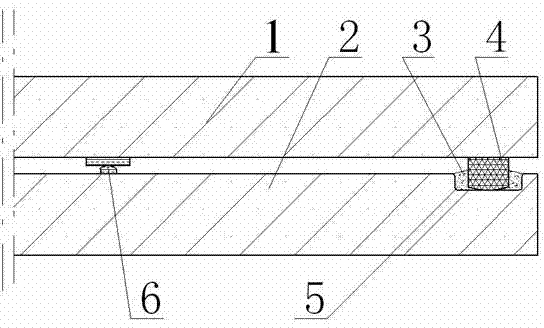

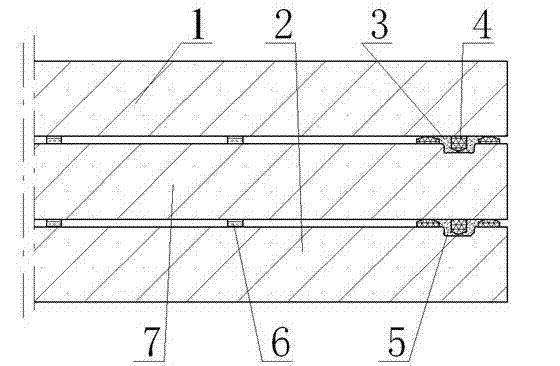

Vacuum ceramic thermal baffle and manufacturing method of vacuum ceramic thermal baffle

ActiveCN102953444AEasy edge bandingExtend your lifeClimate change adaptationInsulation improvementThermal insulationAir tightness

The invention provides a vacuum ceramic thermal baffle comprising an upper thermal baffle and a lower thermal baffle which are of flat plates, wherein the peripheries of the upper thermal baffle and the lower thermal baffle are welded together by welding fluxes, a closed vacuum layer is formed between the upper thermal plate and the lower thermal plate, and supports are arranged in the vacuum layer in a dot matrix manner. According to a manufacturing method of the vacuum ceramic thermal baffle, the process is simple, the manufactured vacuum ceramic thermal baffle overcomes the defects of the existing thermal baffle, the air tightness of the vacuum layer of the vacuum ceramic thermal baffle can be effectively ensured, the service life of the vacuum ceramic thermal baffle is prolonged, the strength, the thermal insulation, sound insulation and fire resistance of the vacuum ceramic thermal baffle are enhanced, and simultaneously, the vacuum ceramic thermal baffle has an excellent decorative effect.

Owner:海宁市袁花镇工业投资有限公司

Metal solder-welded and groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951819AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMetalAlloy

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing groove is arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frame and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

Planar vacuum glass welded by metal solders in microwave manner and subjected to edge sealing by strip frames and groove, and manufacturing method of glass

InactiveCN102951815AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenAlloy

The invention discloses vacuum glass consisting of upper glass and lower glass. The vacuum glass is characterized in that the periphery of the welding surface of the upper glass is provided with an edge sealing strip frame, and the periphery of the welding surface of the lower glass is provided with en edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing not only common vacuum glass but also tempered vacuum glass.

Owner:戴长虹

Glass solder-microwave welded and groove-edge-sealed planar vacuum glass and manufacturing method thereof

InactiveCN102951824AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention relates to vacuum glass. The vacuum glass comprises upper glass and lower glass and is characterized in that an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing groove is arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing glass solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frame and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology; and the method can be used for manufacturing both the ordinary vacuum glass and tempered vacuum glass.

Owner:戴长虹

Metal solder-welded and strip frame-groove-edge-sealed planar vacuum glass and manufacturing method thereof

InactiveCN102951822AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionAlloyMetal

The invention relates to vacuum glass. The vacuum glass comprises upper glass and lower glass and is characterized in that an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology; and the method can be used for manufacturing both the ordinary vacuum glass and tempered vacuum glass.

Owner:戴长虹

Convex vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951805AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenConvex side

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and not only can be used for manufacturing common vacuum glass, but also is particularly suitable for manufacturing of tempered vacuum glass; and the vacuum glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

Metal solder-microwave welded and strip frame-groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951830AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenConvex side

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simple manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

Convex vacuum thermal baffle and manufacturing method thereof

InactiveCN102953439ASimple manufacturing processReduce manufacturing costClimate change adaptationInsulation improvementThermal insulationConvex side

The invention provides a vacuum thermal baffle plate comprising an upper thermal baffle and a lower thermal baffle, wherein the peripheries of the upper thermal baffle and the lower thermal baffle are welded together by welding fluxes, a closed vacuum layer is formed between the upper thermal baffle and the lower thermal baffle, the upper thermal baffle and the lower thermal baffle are both convex, and the convex sides of the convex thermal plates face to the outer side. According to a manufacturing method of the vacuum thermal baffle provided by the invention, the process is simple, the manufactured vacuum thermal baffle overcomes the defects of the existing thermal baffle, the air tightness of the vacuum layer of the vacuum thermal baffle can be effectively ensured, the service life of the vacuum thermal baffle is prolonged, the strength, the thermal insulation, the sound insulation and the fire resistance of the vacuum thermal baffle are enhanced, and meanwhile, the vacuum thermal baffle has an excellent decorative effect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Convex-sided low-altitude heat-insulating board, flattened low-altitude heat-insulating board and preparation methods thereof

The invention provides a low-altitude heat-insulating board which comprises an upper heat-insulating board and a lower heat-insulating board, wherein the peripheries of the upper heat-insulating board and the lower heat-insulating board are welded together through using a welding flux, a closed low-altitude layer is formed between the upper heat-insulating board and the lower heat-insulating board, the upper heat-insulating board and the lower heat-insulating board are flattened heat-insulating boards or convex-sided heat-insulating boards, and the convex side of each convex-sided heat-insulating board faces outwards. The production method of the low-altitude heat-insulating board provided by the invention is simple in process, and the prepared low-altitude heat-insulating board overcomes the defects of the existing heat-insulating board, so that the tightness of a low-altitude layer of the low-altitude heat-insulating board can be effectively guaranteed, the service life of the low-altitude heat-insulating board is prolonged, and the strength and heat insulation, sound insulation and fire prevention properties of the low-altitude heat-insulating board can be increased.

Owner:戴长虹

Metal solder-microwave welded and groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951827AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenAlloy

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing groove is arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frame and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

Glass solder-welded and groove-edge-sealed convex low vacuum glass and manufacturing method thereof

InactiveCN102951823AIncrease contact areaReduce tensile stressGlass reforming apparatusGlass productionEdge bandingLow vacuum

The invention relates to low vacuum glass. The low vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing groove is formed at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing glass solder in a high-temperature edge sealing furnace; and the manufacturing of the low vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frame and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the low vacuum glass can be realized by utilizing the technology, and the manufactured low vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary low vacuum glass and is particularly suitable for manufacturing tempered low vacuum glass.

Owner:戴长虹

Convex low-altitude glass welded by metal solders in microwave manner and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951808AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenAlloy

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

Planar vacuum glass welded by metal solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951811AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionMicrowave ovenAlloy

The invention discloses vacuum glass. The vacuum glass is characterized in that the peripheries of upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing not only common vacuum glass but also tempered vacuum glass.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com