Patents

Literature

88results about How to "Good wind pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

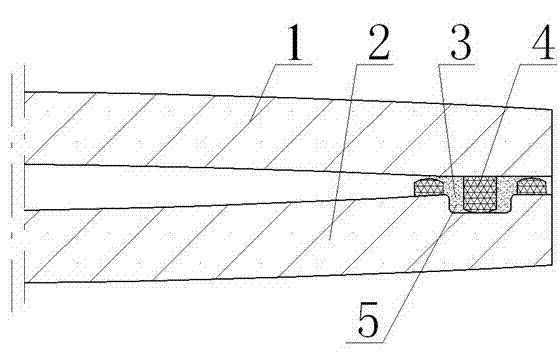

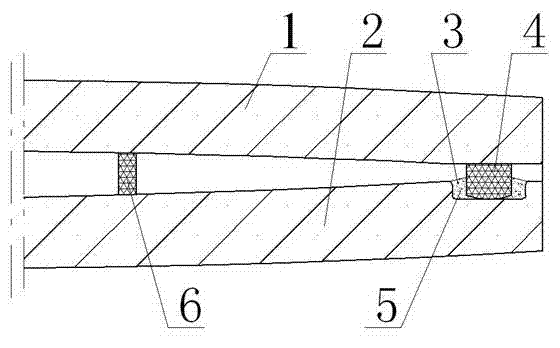

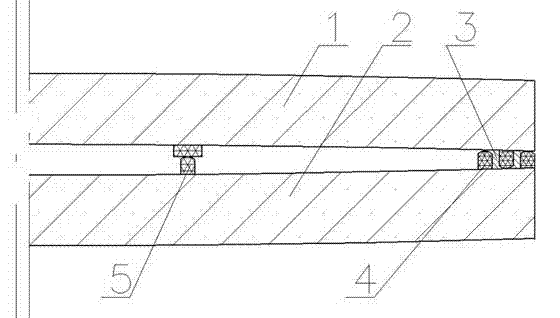

Convex low-altitude glass welded by metal solders and subjected to edge sealing by strip frame and groove, and manufacturing method of glass

InactiveCN102951814AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionConvex sideAlloy

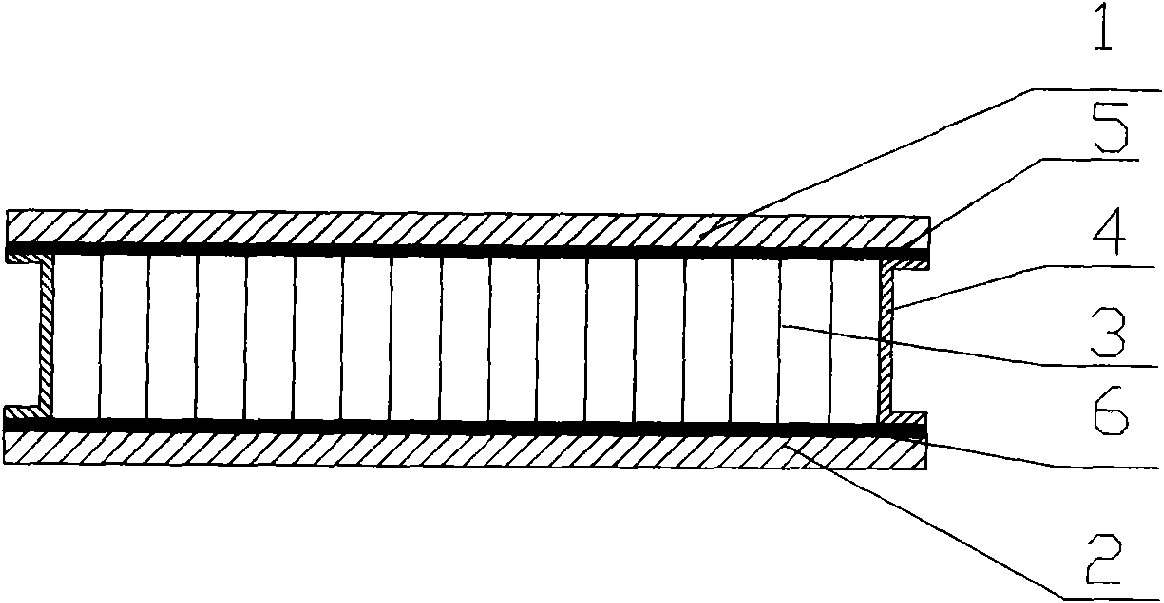

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding peripheries of the upper glass and the lower glass are respectively provided with an edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a high-temperature edge sealing furnace, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

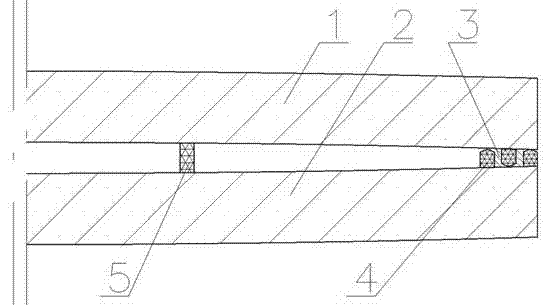

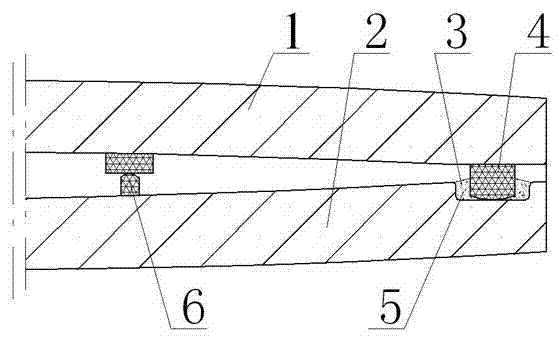

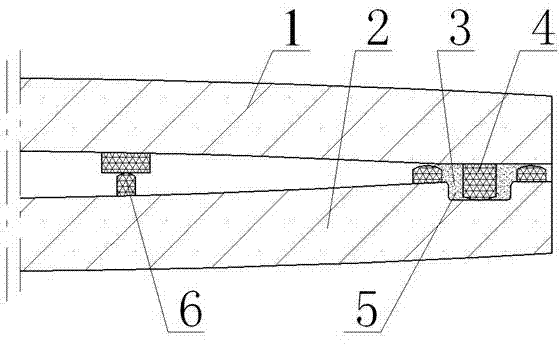

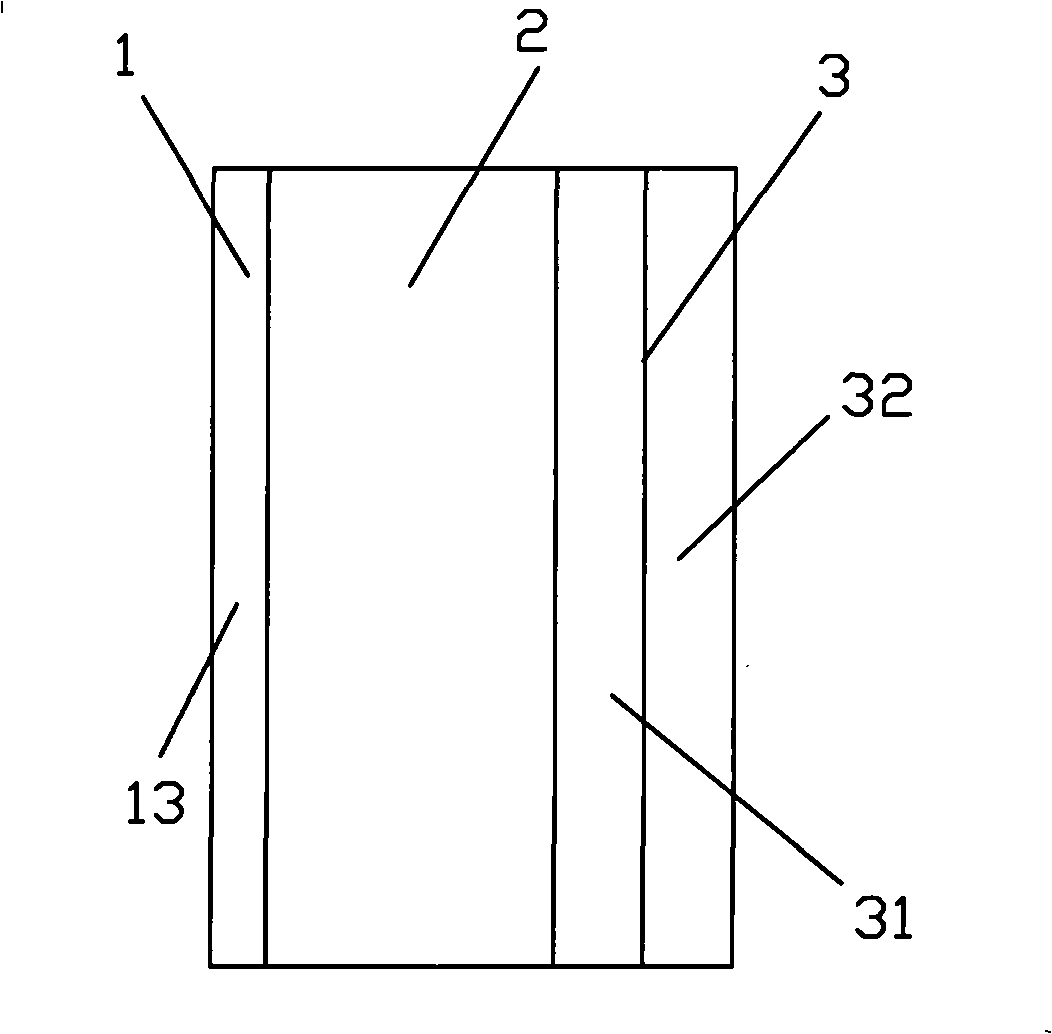

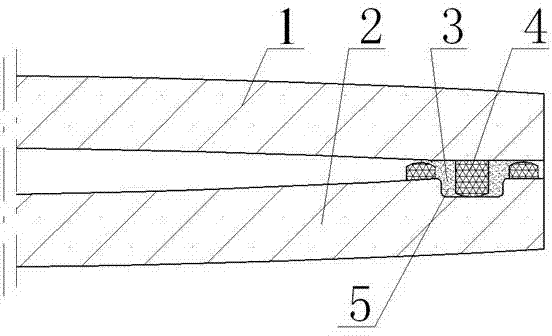

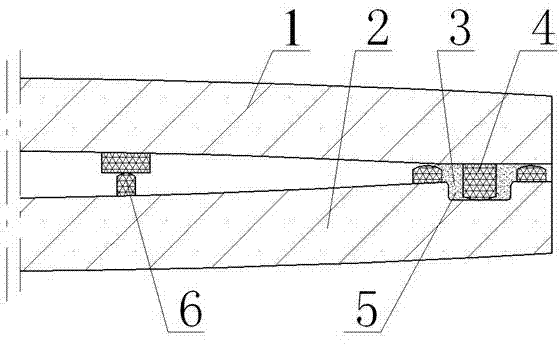

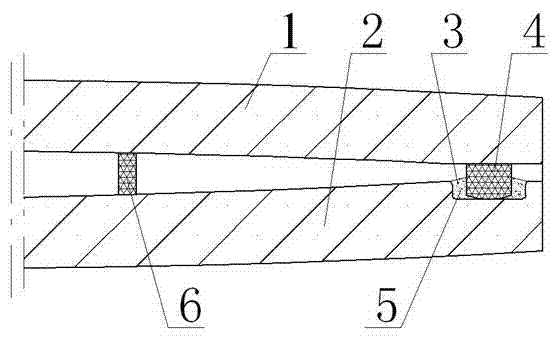

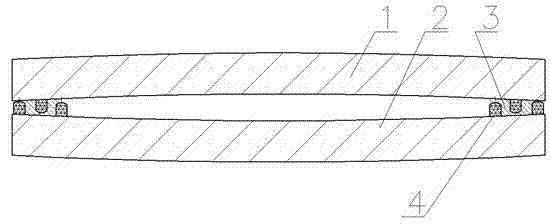

Metal solder-welded and strip frame-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951826AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMetalEdge banding

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex surface glass, edge sealing strip frames are arranged at the welded peripheries of the upper glass and the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the upper and the lower edge sealing strip frames can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

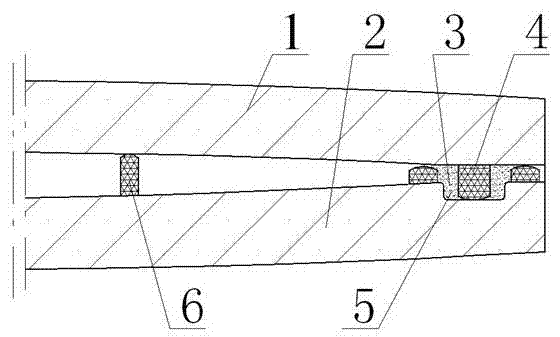

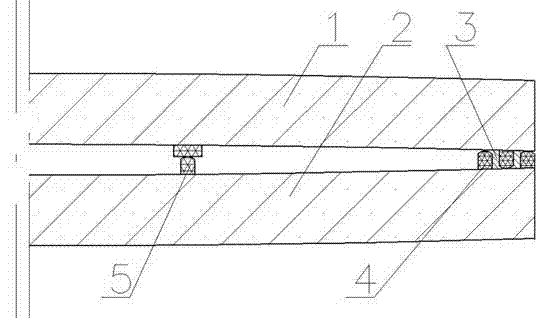

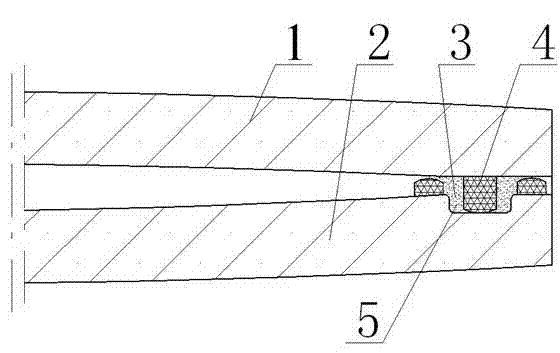

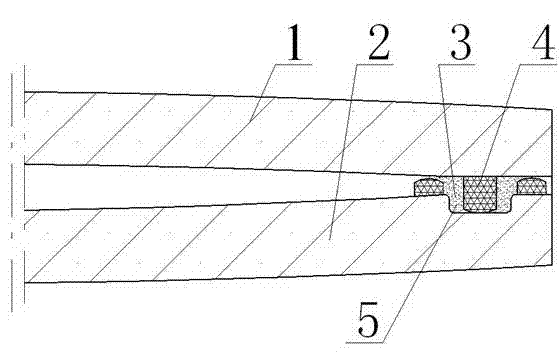

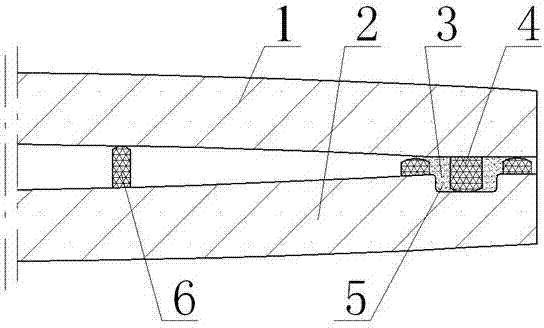

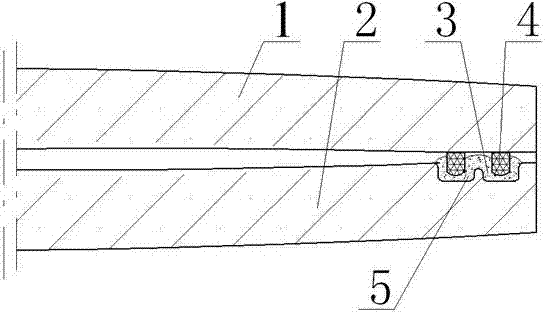

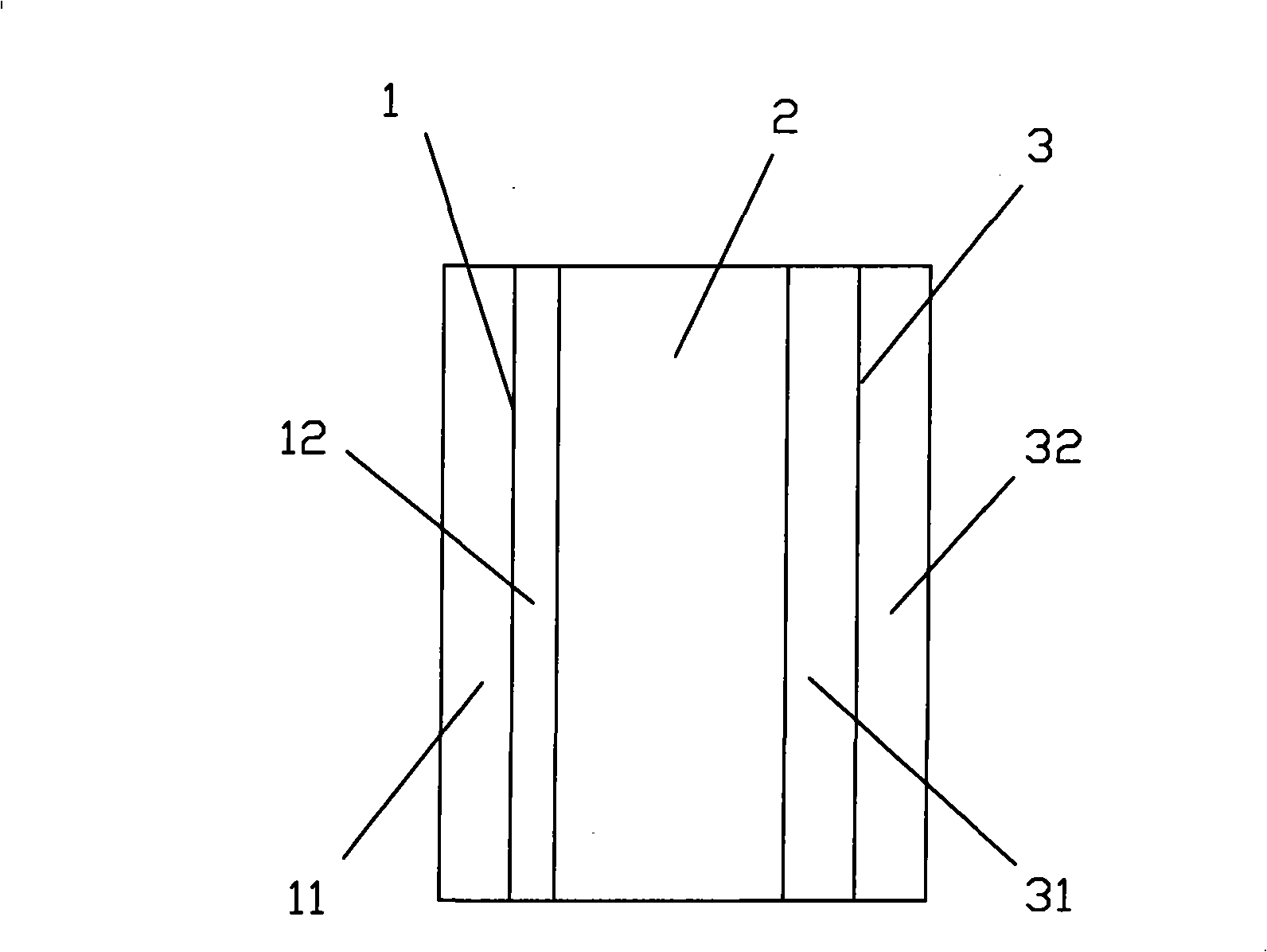

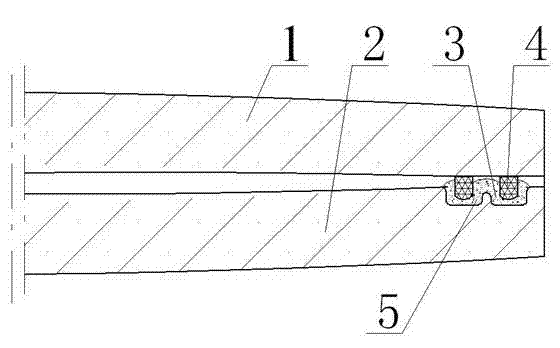

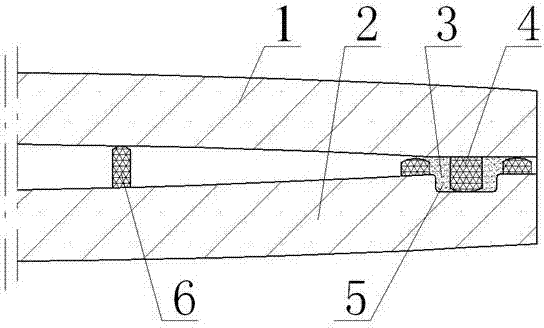

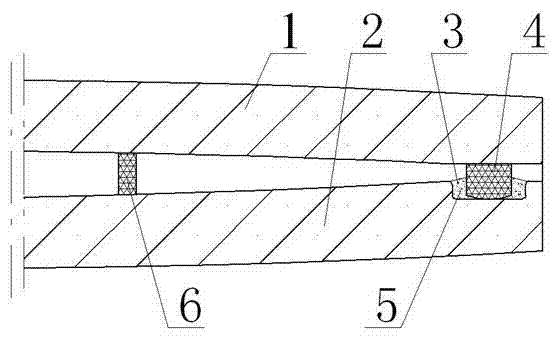

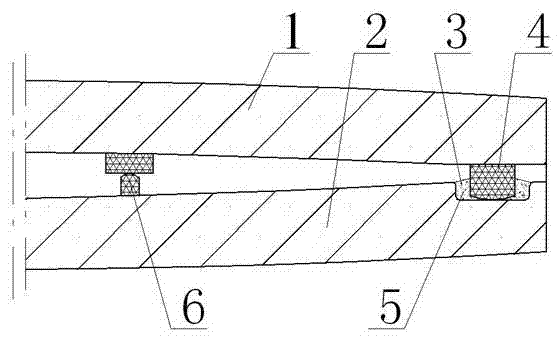

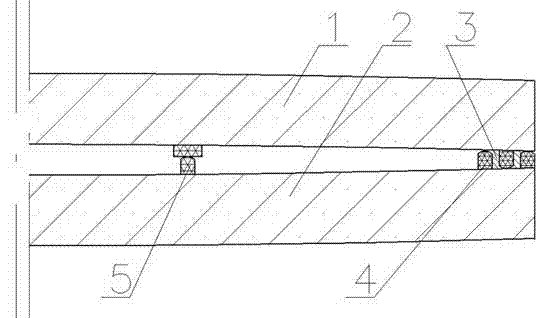

Convex vacuum glass welded by glass solders and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951803AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionConvex sideEngineering

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by glass solders in a vacuum edge sealing furnace, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and not only can be used for manufacturing common vacuum glass, but also is particularly suitable for manufacturing of tempered vacuum glass; and the vacuum glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

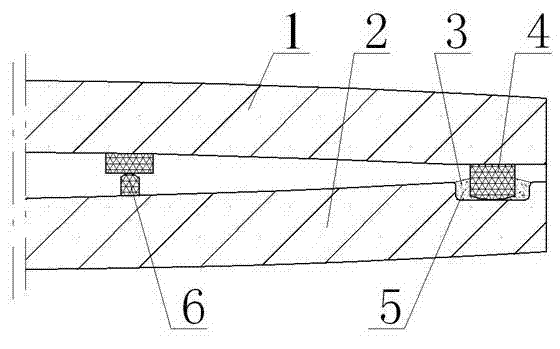

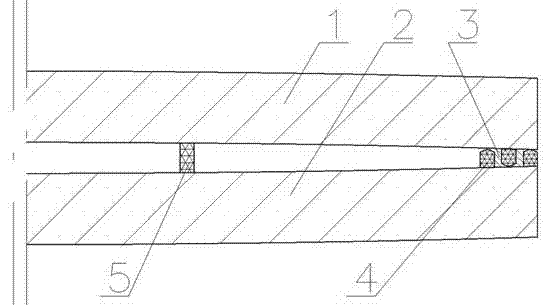

Convex low-altitude glass welded by glass solders and subjected to edge sealing by strip frame and groove, and manufacturing method of glass

InactiveCN102951813AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionGlass manufactureLow altitude

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding peripheries of the upper and lower glass are provided with an edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by glass solders in a high-temperature edge sealing furnace, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

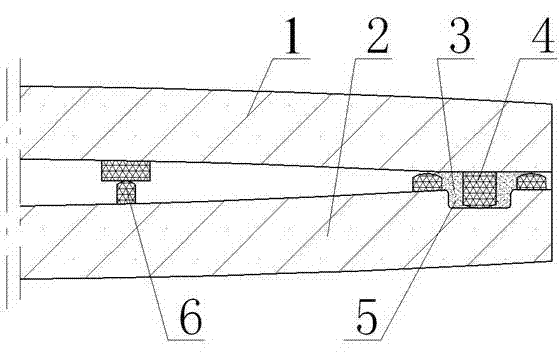

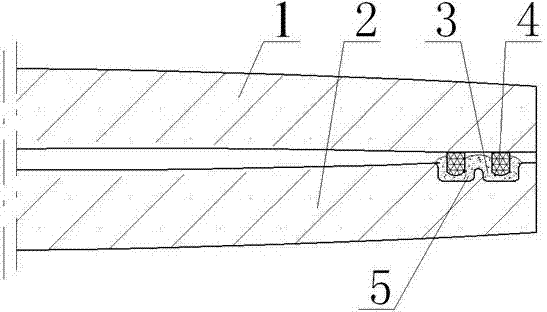

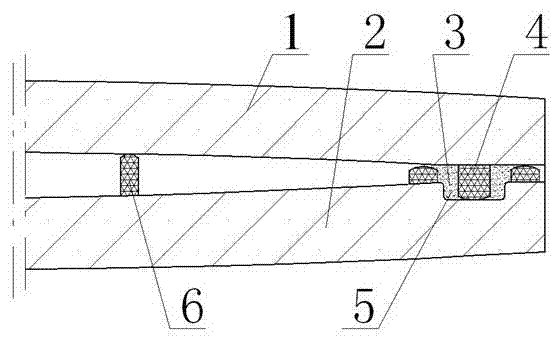

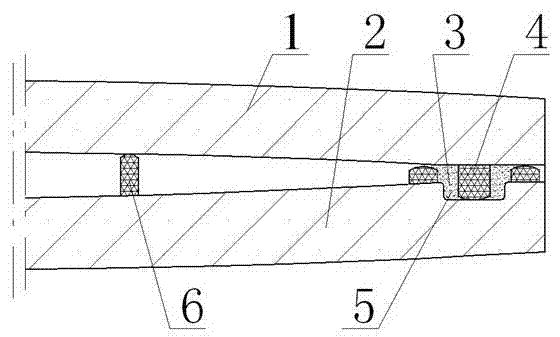

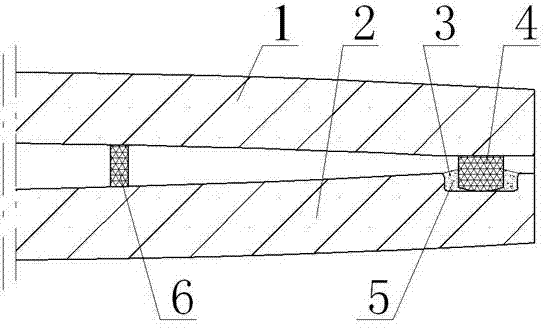

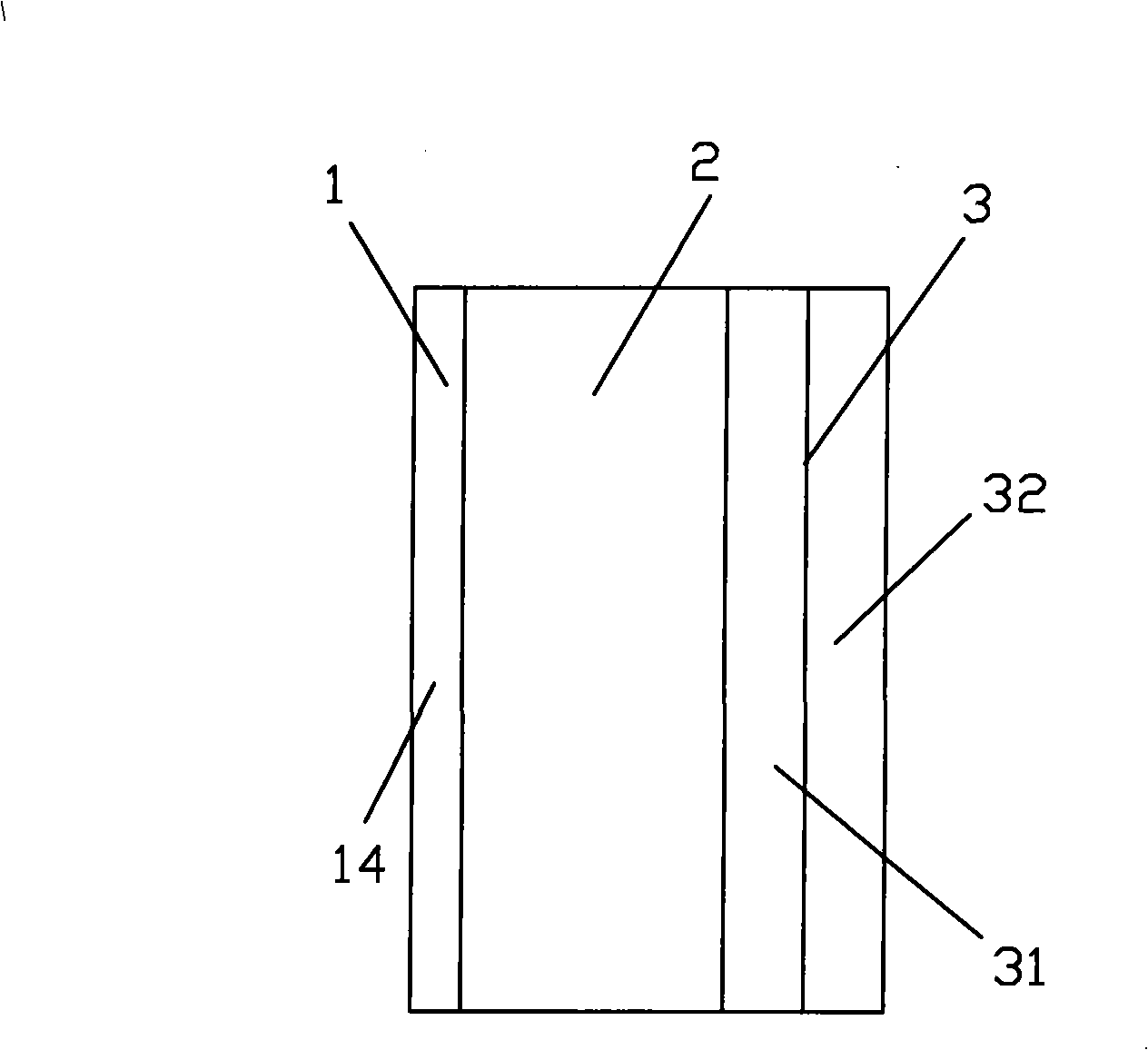

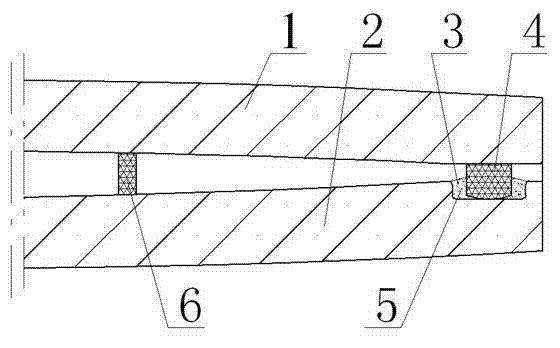

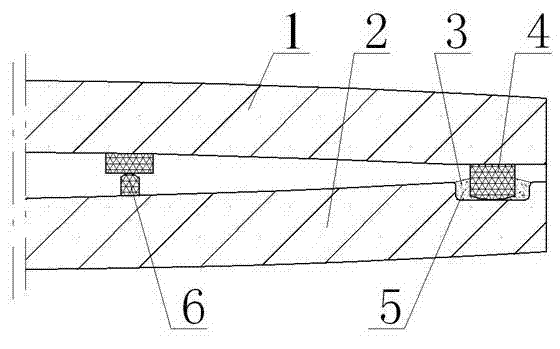

Metal solder-welded and strip frame-groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951829AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionAlloyMetal

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

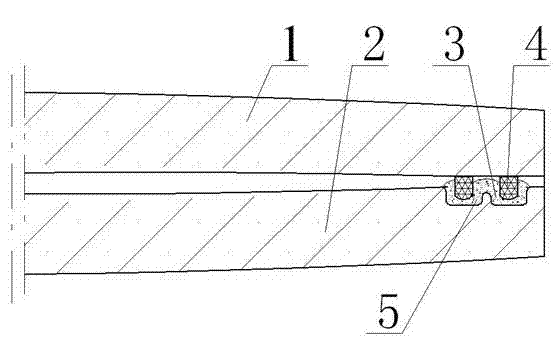

Glass solder-welded and strip frame-groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951821AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionEngineeringEdge banding

Owner:戴长虹

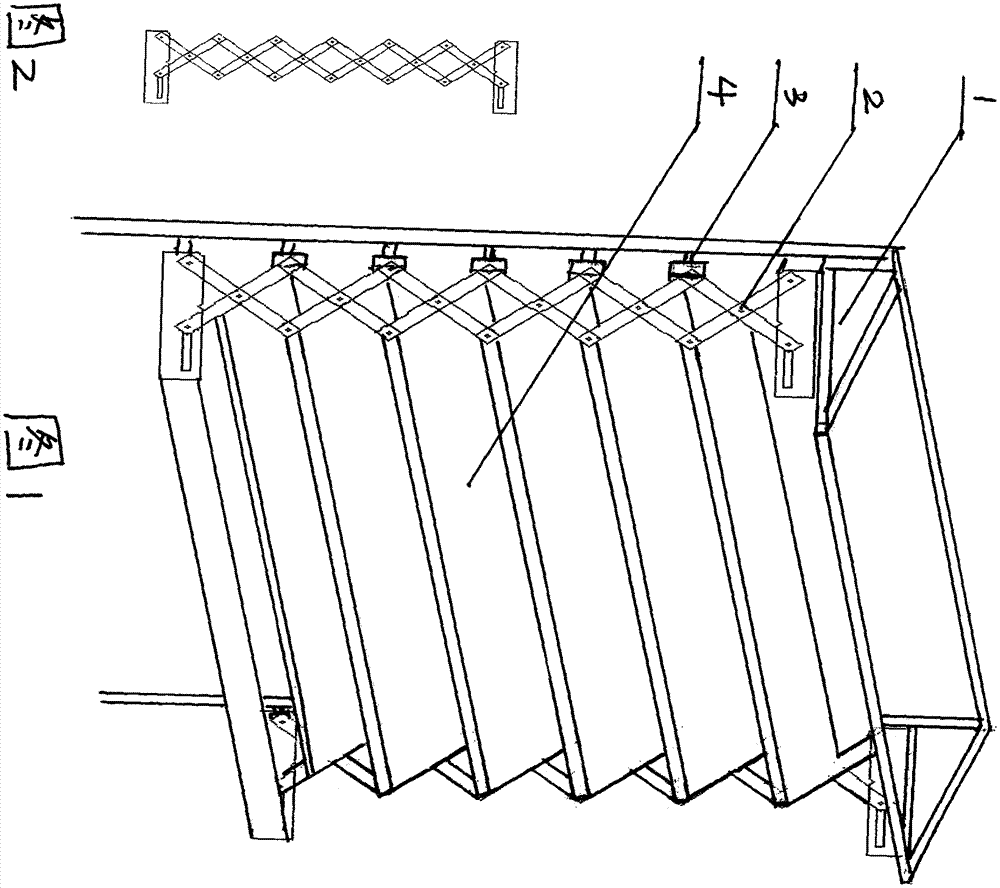

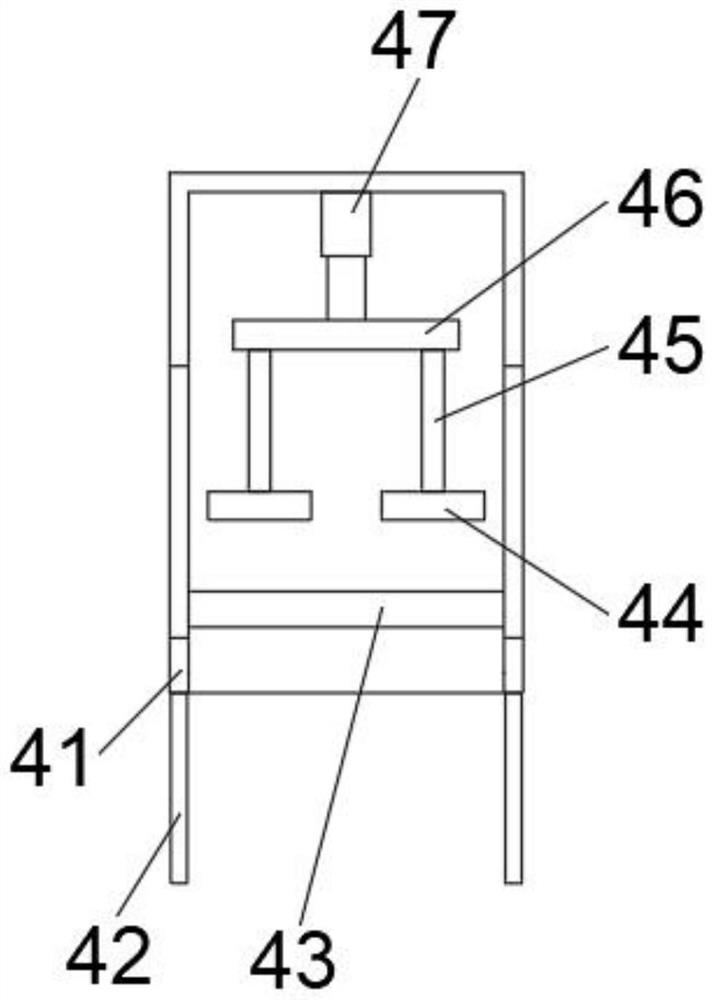

Manufacturing method for supporting type retractable and foldable outer sun shading shutter system

InactiveCN106948739AUnfold stableGuaranteed unityDoor/window protective devicesGratingBuilding energy

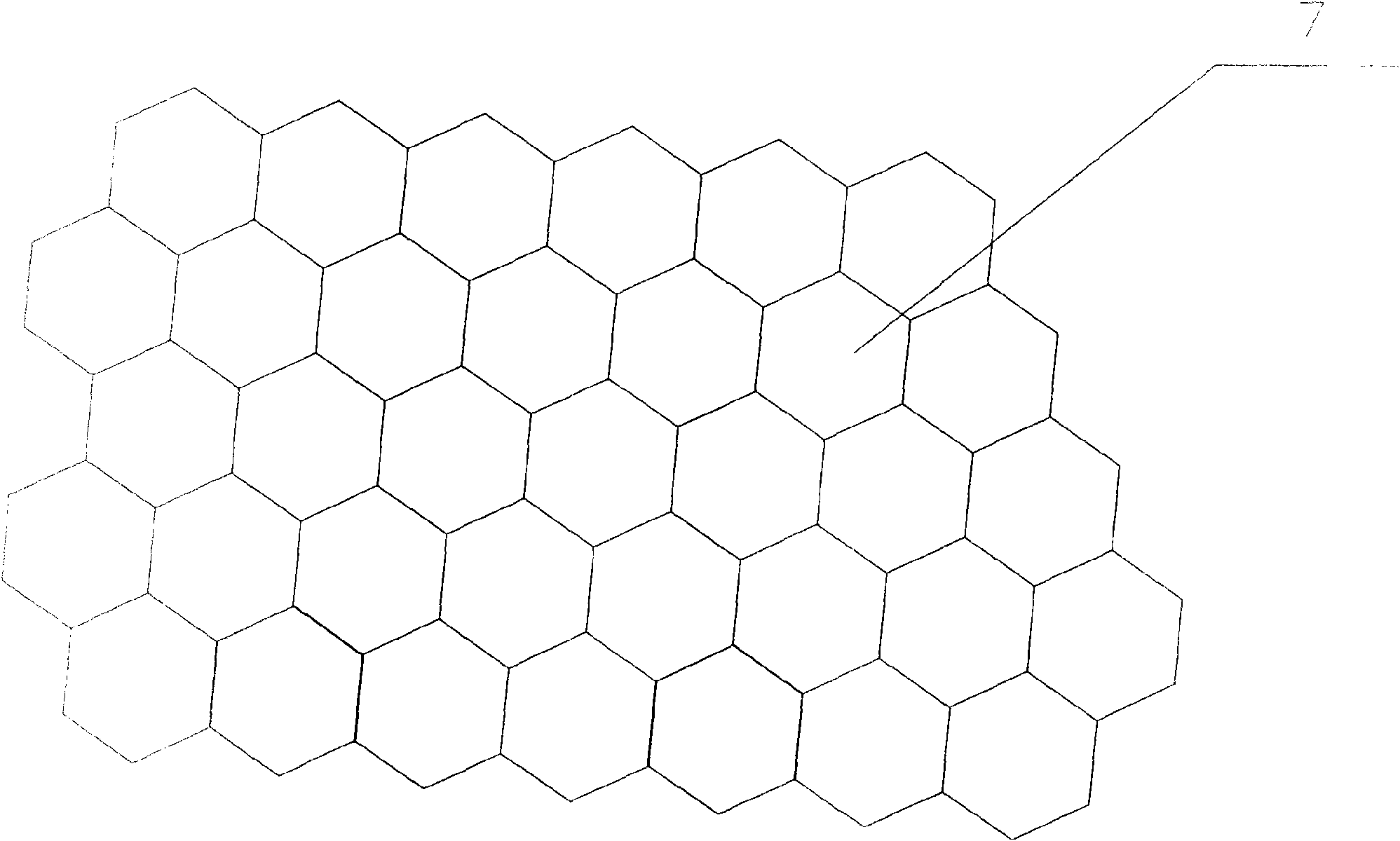

Building sun shading products are indispensable rigid demands of building energy saving. Outer sun shading facilities comprise outer shutter sun shading facilities, roller blind sun shading facilities, sailboard sun shading facilities, fixed sun shading facilities and the like. The outer sun shading facilities and equipment have more or less defects of sight shielding, small adjustable range, heaviness, large mounting difficulty, difficult later maintenance, limited heat insulation effect, poor wind pressure resistant capacity and the like. A supporting type retractable and foldable outer sun shading shutter system can be unfolded fully and folded up; a sun shading shutter base plate can be made into types of plane sun shading, plane punched sun shading, stereo grating type sun shading and honeycomb type sun shading; the outer sun shading shutter system is light in design, and different mounting positions also can be selected according to the sun shading requirement of different orientation; a certain ventilation gap exists between the sun shading shutter base plate and the sun shading face, so that the heat dissipation effect is good; and the unicity and defect that an existing sun shading product shades sun but not insulates heat are overcome completely, the overall appearance of a building is made to be attractive through the outer sun shading shutter system, and the external facade of the building is attractive while sun shading is achieved.

Owner:广西海汇节能科技有限公司

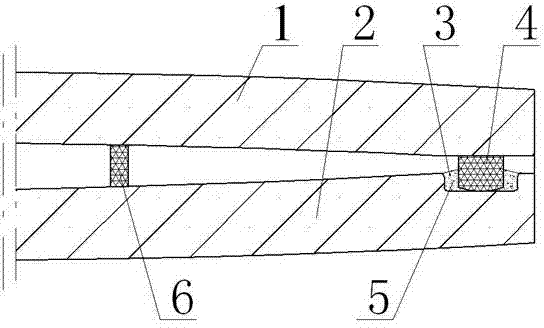

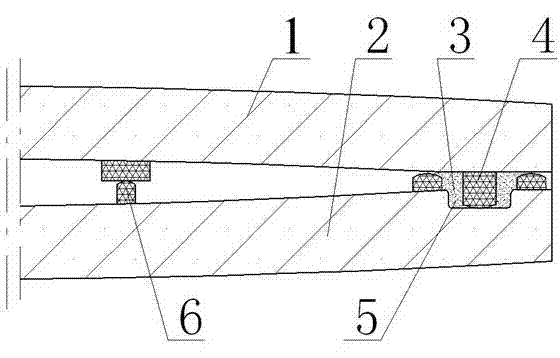

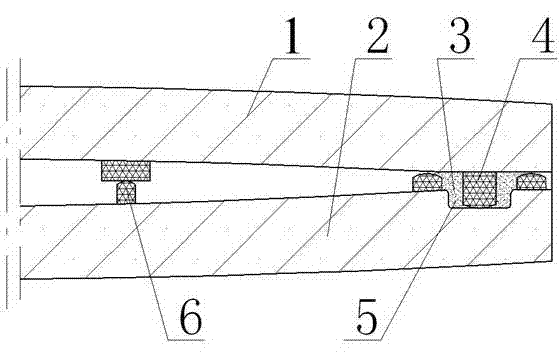

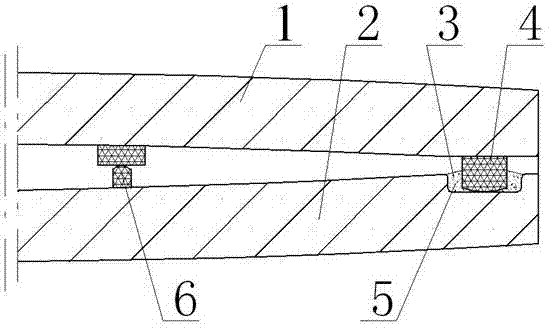

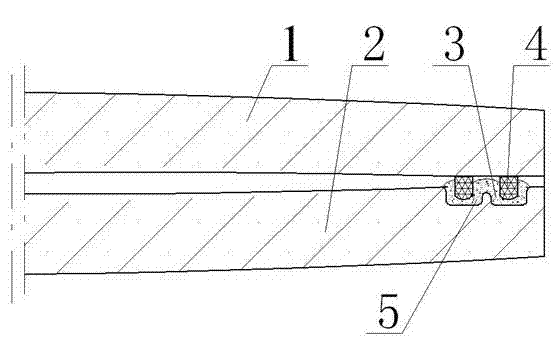

Metal solder-welded and groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951819AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMetalAlloy

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing groove is arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frame and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

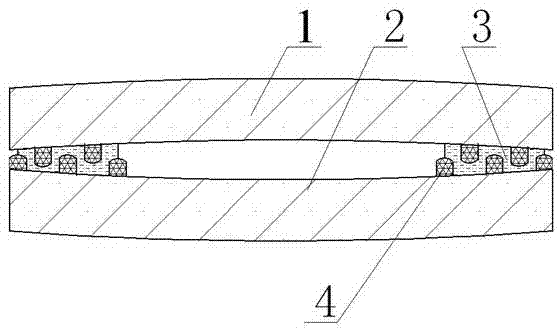

Honeycomb composite clean wall plate

The invention discloses a honeycomb composite clean wall plate, comprising a panel and a soleplate, wherein at least one layer of honeycomb core layer is arranged between the panel and the soleplate; the external edge of the honeycomb layer between the panel and the soleplate is provided with a circle of metal keel. The honeycomb composite clean wall plate has light specific weight, high strength, large rigidity, stable structure and good wind load resistance performance. The honeycomb composite clean wall plate has clean surface and is pressurized and combined to complete by an environment-protective adhesive and by totally sealed dustless operation and the honeycomb plate composite equipment at high temperature, has no smell, no toxicity and no three wastes during the production and application process, leads the honeycomb plate to be firmer, more rigid, more straight, fireproof, waterproof and electrostatic-proof, and is a green environment-protective wall material which has high quality, light weight, high strength and luxurious surface.

Owner:北京中玉仁技术有限公司

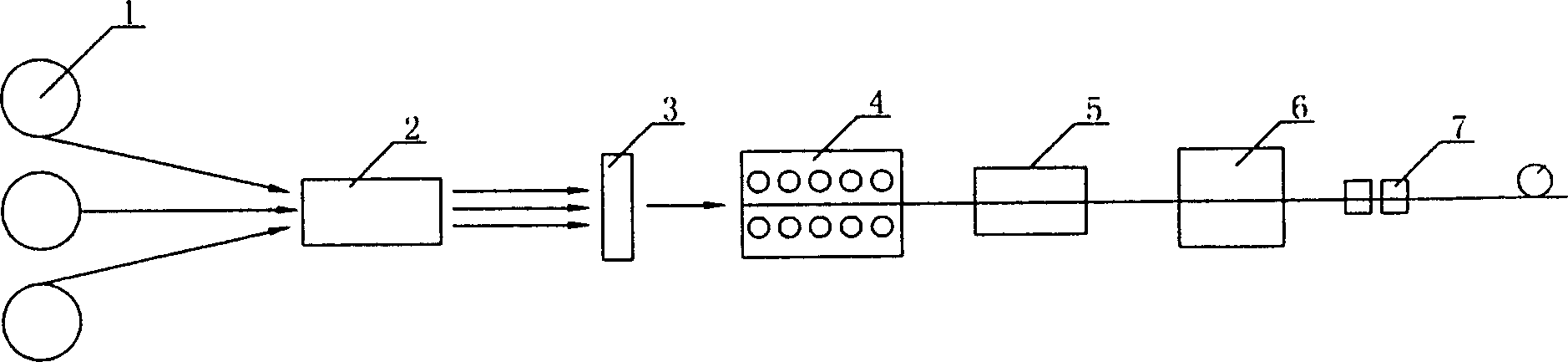

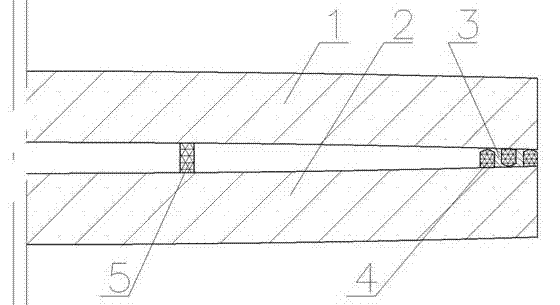

Combined glue composite aluminum honeycomb plate production equipment and process

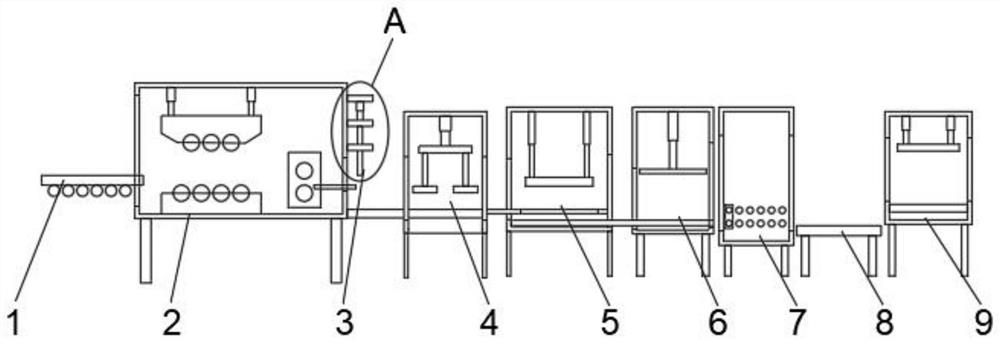

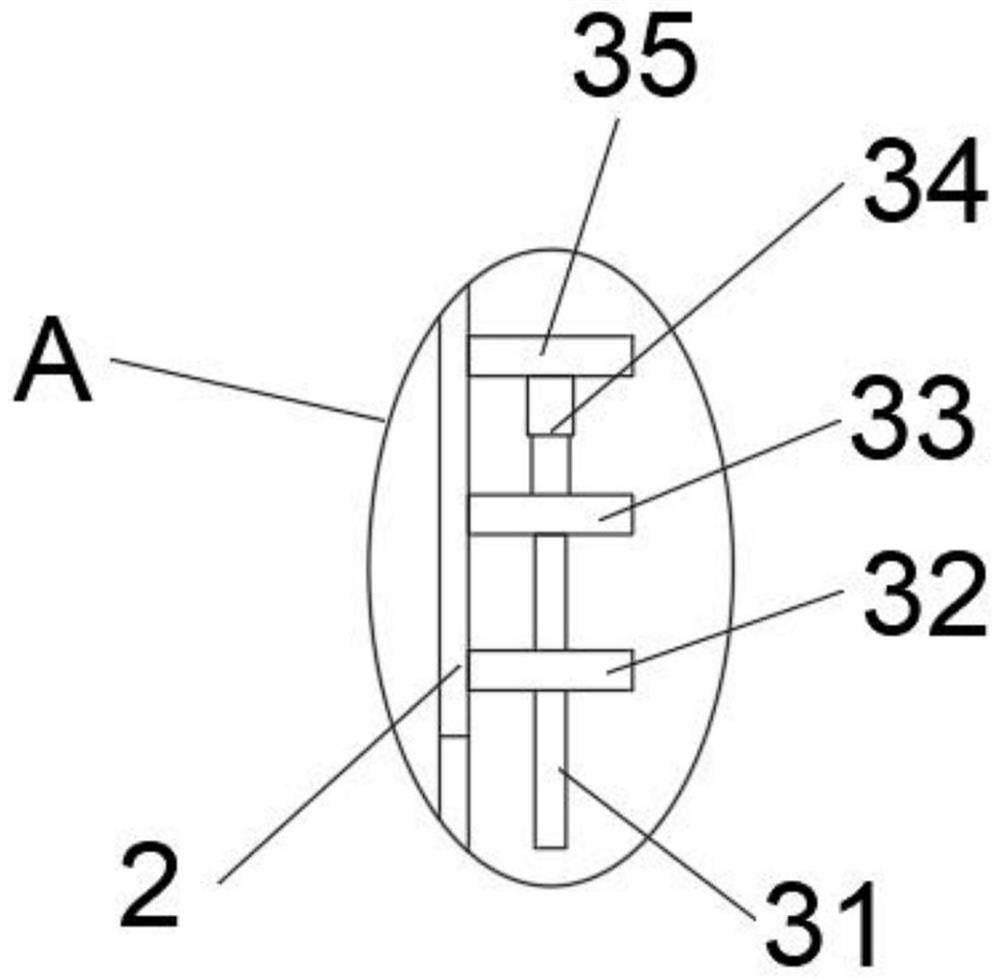

PendingCN112171187AEfficient and simple production processReduce weightLiquid surface applicatorsLamination ancillary operationsAluminum honeycombAdhesive glue

The invention discloses combined glue composite aluminum honeycomb plate production equipment and process, and relates to the technical field of aluminum honeycomb plate production. The combined gluecomposite aluminum honeycomb plate production equipment specifically comprises a feeding machine and a decoiler, wherein a cutting device is arranged at a discharging port of the decoiler; the lower portion of the discharging port of the decoiler is connected with a feeding port of an angle shearing machine; a discharging port of the angle shearing machine is connected with a feeding port of a bending machine; a discharging port of the bending machine is fixedly connected with a feeding port of a grinding machine; a discharging port of the grinding machine is connected with a feeding port of agluing machine; a discharging port of the gluing machine is connected with a workbench used for the laying of the composite aluminum honeycomb plate; and a hot press is arranged on the side face of the workbench. According to the aluminum honeycomb plate produced by the production equipment and process, high-strength alloy aluminum plates are used as a panel and a bottom plate, a hexagonal aluminum foil honeycomb core is adhered in the middle by using an aviation adhesive, hot-pressing compounding is carried out, and a decorative and anti-corrosion coating is applied to the surface of the aluminum plate, so that the defects of low brittleness, low tear resistance and low impact resistance of a honeycomb plate bonding layer produced by the conventional process are overcome.

Owner:湖北航飞蜂窝复合材料有限公司

Multifunctional furring brick

InactiveCN101294440ASimple processQuick operationFireproof paintsCovering/liningsPrepolymerLower face

The invention discloses a multifunctional furring brick which consists of a finishing coat, a multifunctional layer, and a bonding layer. The multifunctional layer is manufactured and molded at a time with multifunctional liquid and foaming equipment. The finishing coat and the bonding layer are manufactured on the upper face and the lower face of the multifunctional layer respectively. The multifunctional liquid adopts polyfunctionality polyether glycol, polyester polyol prepolymer, vegetable oil polyhydric alcohol and hydramine as initiators, and polyether glycol, a fire retardant, a foam uniformizing agent, a foaming agent, postassium acetate, triethylenediamine, acetal mixture, a delaying catalyst, an ultraviolet absorbent and isocyanate as raw materials. The finishing coat can be an ordinary finishing coat, a fashionable finishing coat, a luxurious finishing coat or a fireproof finishing coat as required. The multifunctional furring brick has the characteristics of energy conservation, water resistance, decoration and portability. Wet land construction with the multifunctional furring brick can be carried out as the construction with ceramic mosaic and porcelain facing bricks, and the multifunctional furring brick can also be cast with concrete in a molding board. In addition, the multifunctional furring brick can also be bonded with an adhesive. The process is simple and operation is quick. The multifunctional furring brick integrates a plurality of functions, such as decoration, thermal insulation, water resistance and imperviousness, antisepsis, sound insulation, light weight, hardness and so on.

Owner:刘建永

Convex vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951805AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenConvex side

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and not only can be used for manufacturing common vacuum glass, but also is particularly suitable for manufacturing of tempered vacuum glass; and the vacuum glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

Metal solder-microwave welded and strip frame-groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951830AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenConvex side

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simple manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

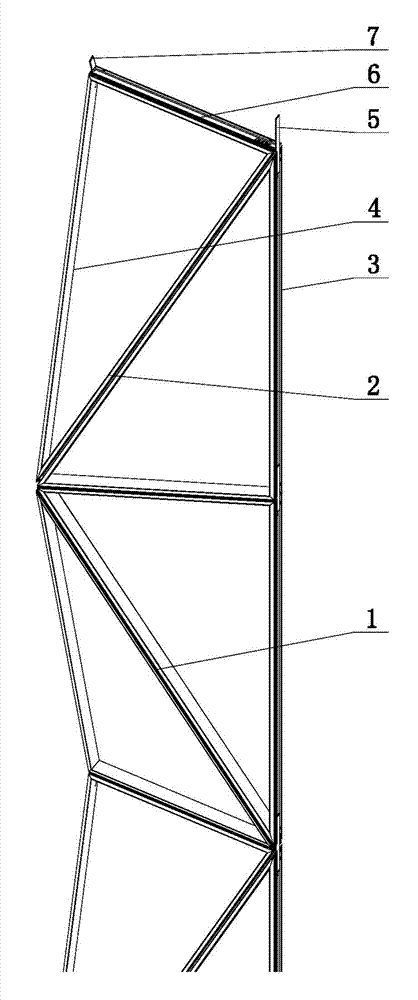

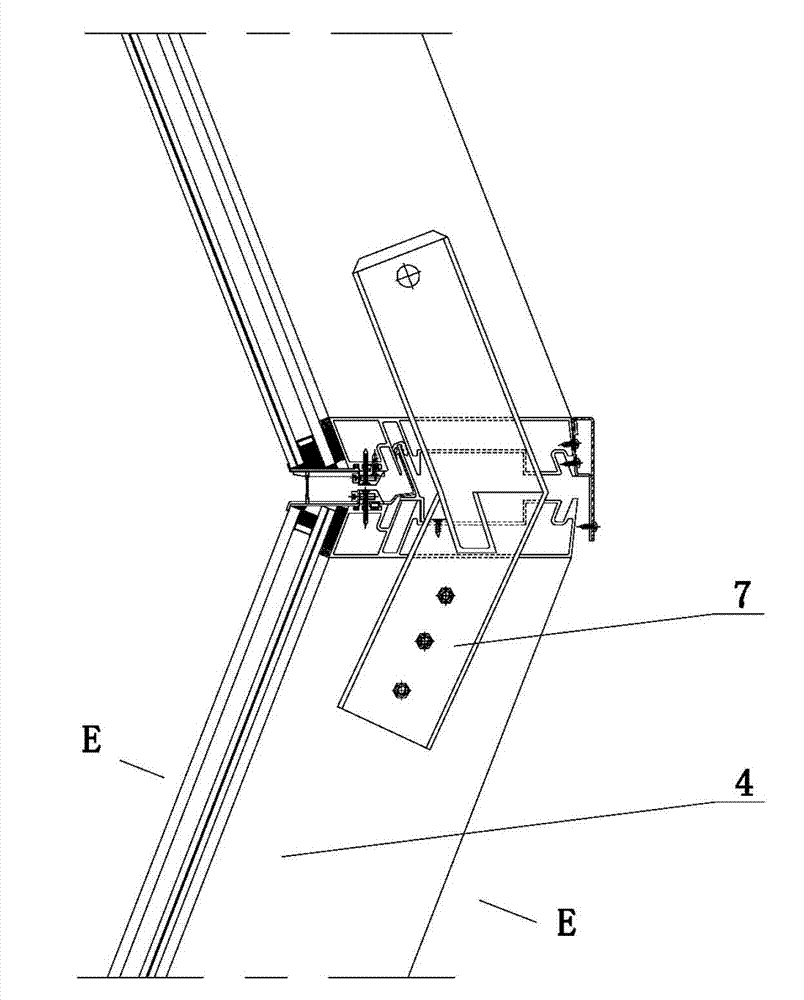

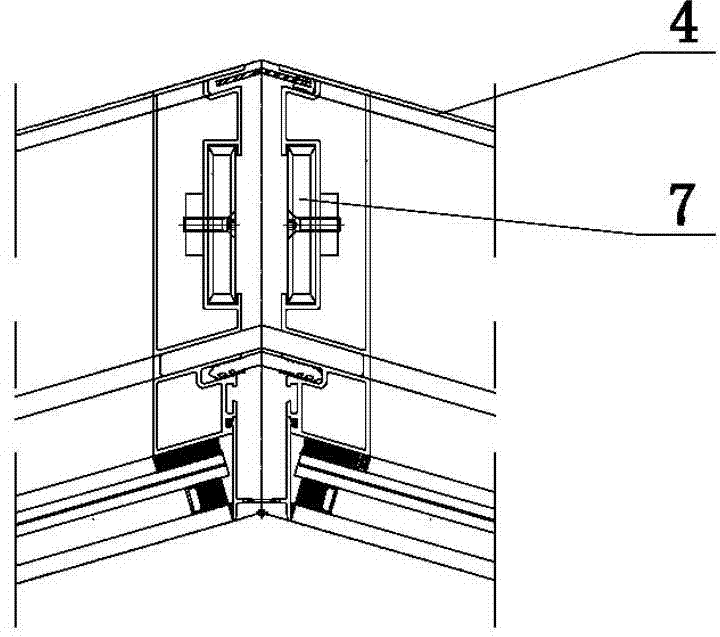

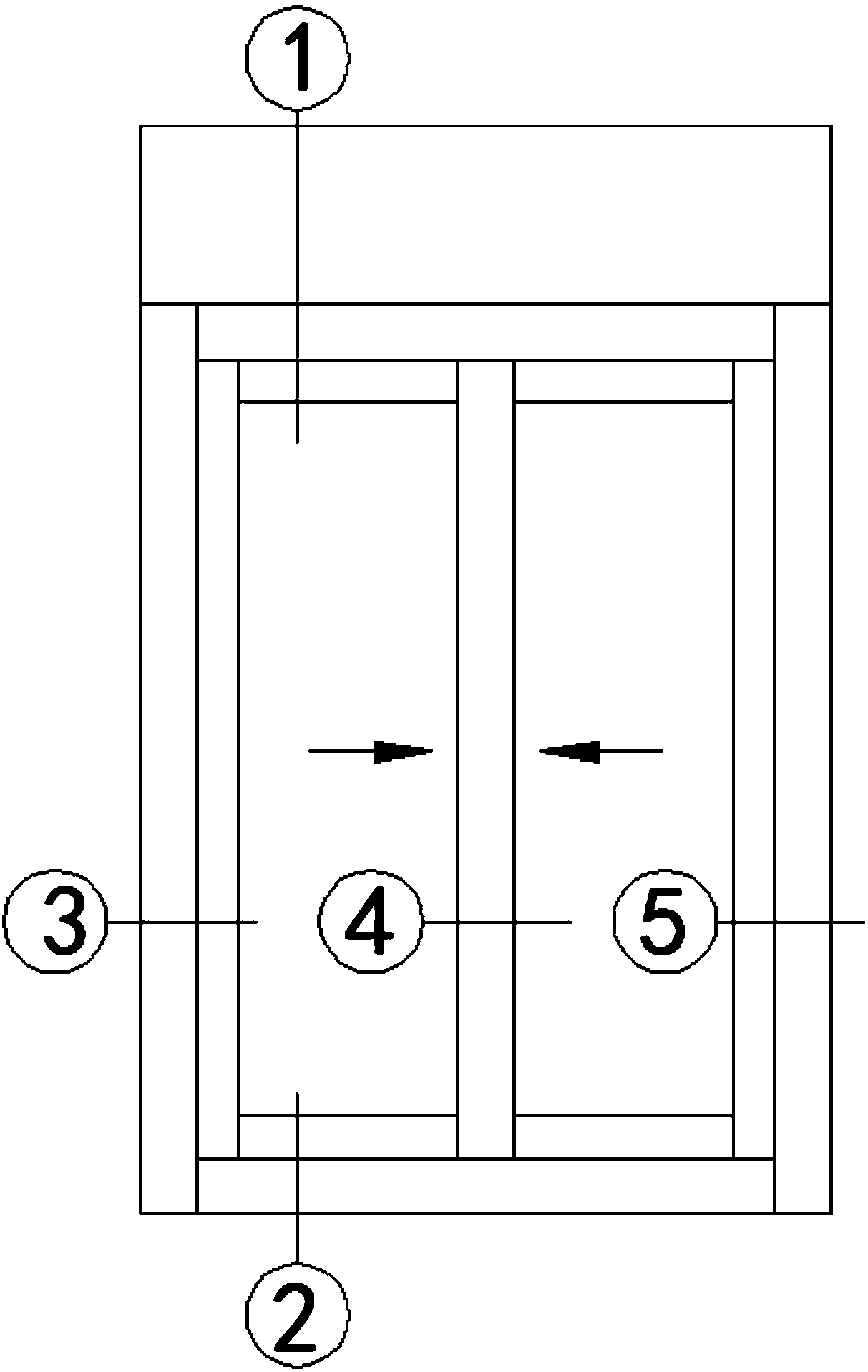

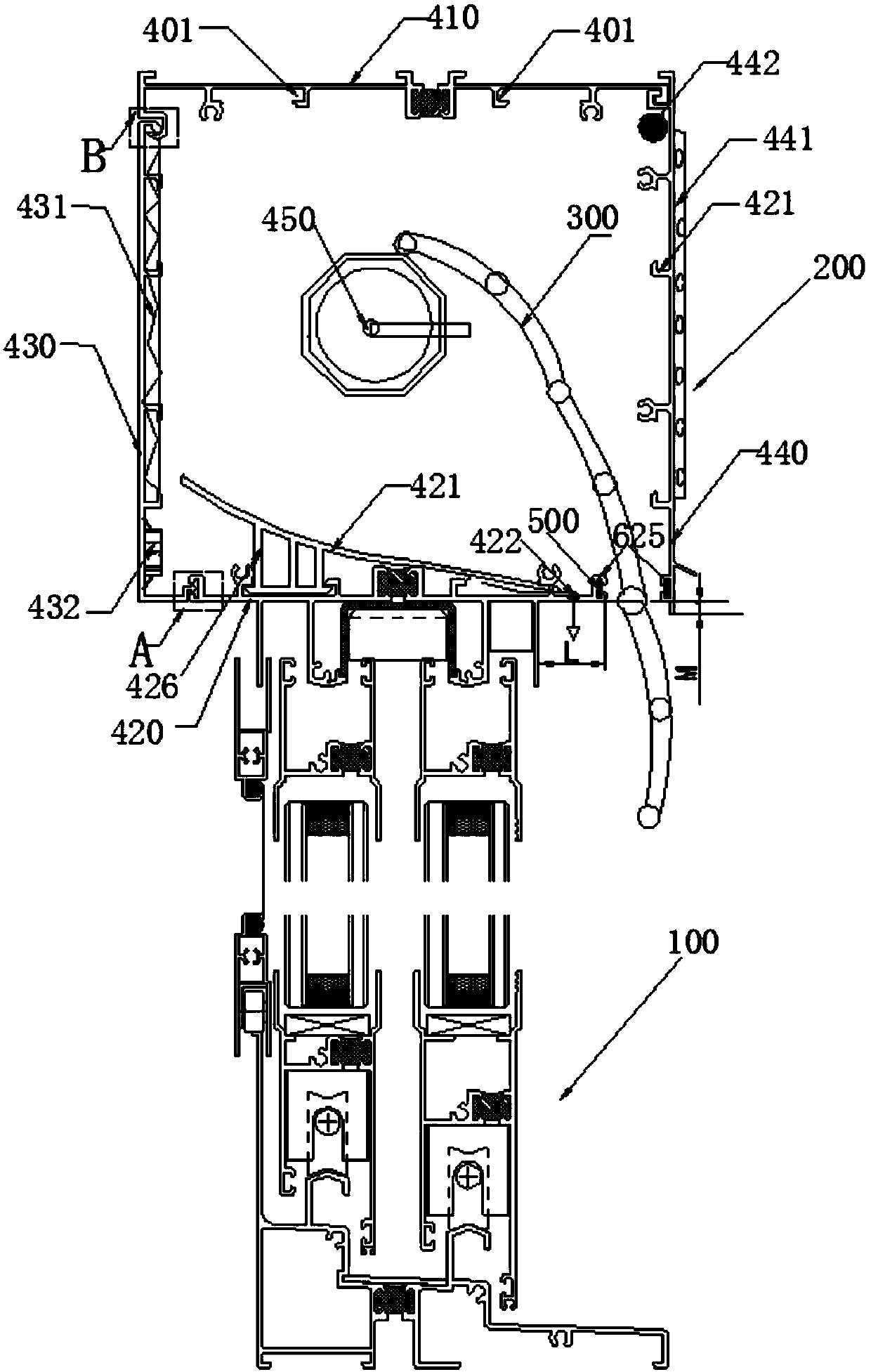

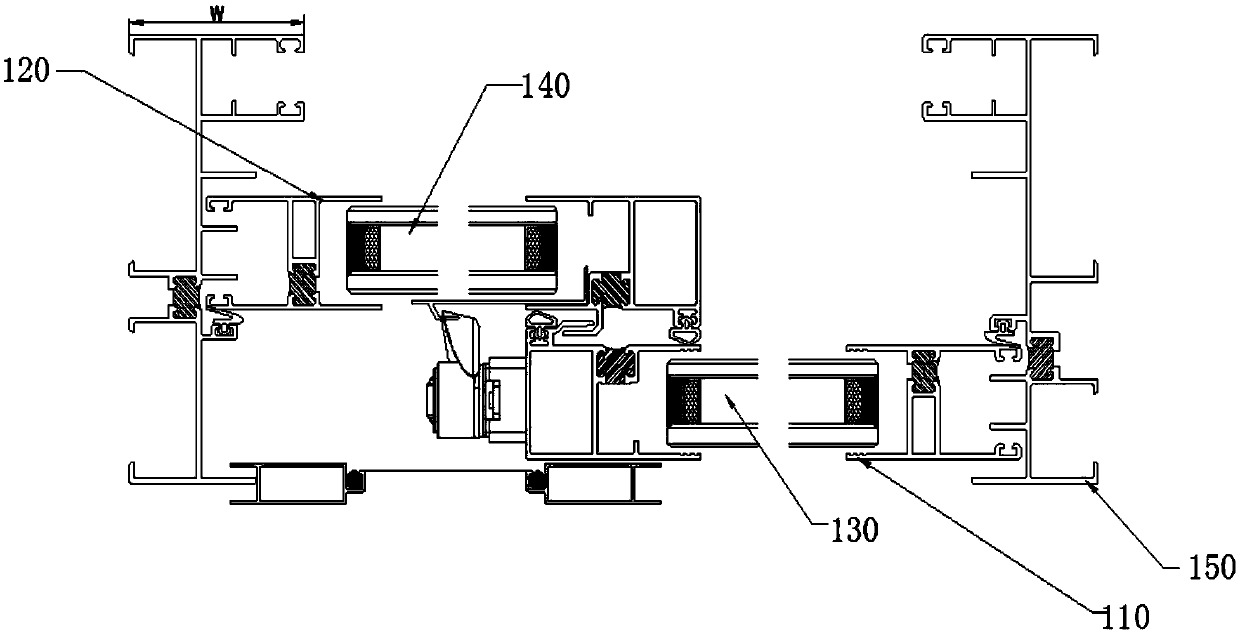

Non-coplanar inclined unit curtain wall system

InactiveCN103485456AAchieve vertical connectionGood wind pressure resistanceWallsUnit systemEngineering

The invention discloses a non-coplanar inclined unit curtain wall system and belongs to the technical field of unit curtain walls. The invention particularly relates to the non-coplanar inclined unit (including triangular units) curtain wall. The invention provides the non-coplanar inclined unit curtain wall system which is simple in structure, convenient to install, few in profile type and low in cost. The non-coplanar inclined unit curtain wall system provided by the invention comprises a unit system, and is characterized in that the unit system comprises a vertical mullion and inclined mullions. The vertical mullion and the inclined mullions are non-coplanar; the vertical mullion is connected with end parts of the inclined mullions by unit cross frames; the upper end of each inclined mullion is provided with an inclined bolt forming an included angle with the inclined mullion; the lower end of each inclined mullion is provided with an inclined rabbet which can be matched with the corresponding inclined bolt; the lower end of the vertical mullion is provided with a chute; a sliding bolt is arranged in the chute; the upper end of the vertical mullion is provided with a vertical rabbet which can be matched with the sliding bolt.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

Composite silicate external-wall thermal-insulation material and preparation method thereof

The invention provides a composite silicate external-wall thermal-insulation material and a preparation method thereof. The composite silicate external-wall thermal-insulation material is prepared from the following raw materials in parts by weight: 30-40 parts of cement, 30-50 parts of modified open-cell expanded perlite, 30-40 parts of mineral slag, 20-30 parts of meerschaum, 10-15 parts of composite fiber, 4-8 parts of crack-resistant fiber, 2-4 parts of dispersing agent, 3-5 parts of high efficiency water reducing agent, 1-5 parts of foaming agent and 2-4 parts of ceramic adhesive. The preparation method comprises the following steps: stirring and mixing the raw materials, and curing. The thermal-insulation material has the advantages of favorable thermal-insulation property, favorable crack resistance, favorable fire resistance, favorable water resistance and environment friendliness.

Owner:合肥广能新材料科技有限公司

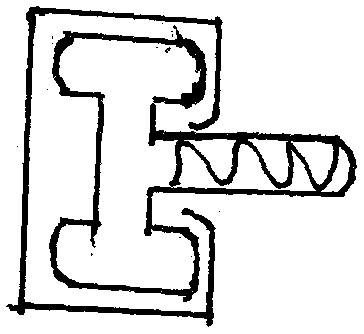

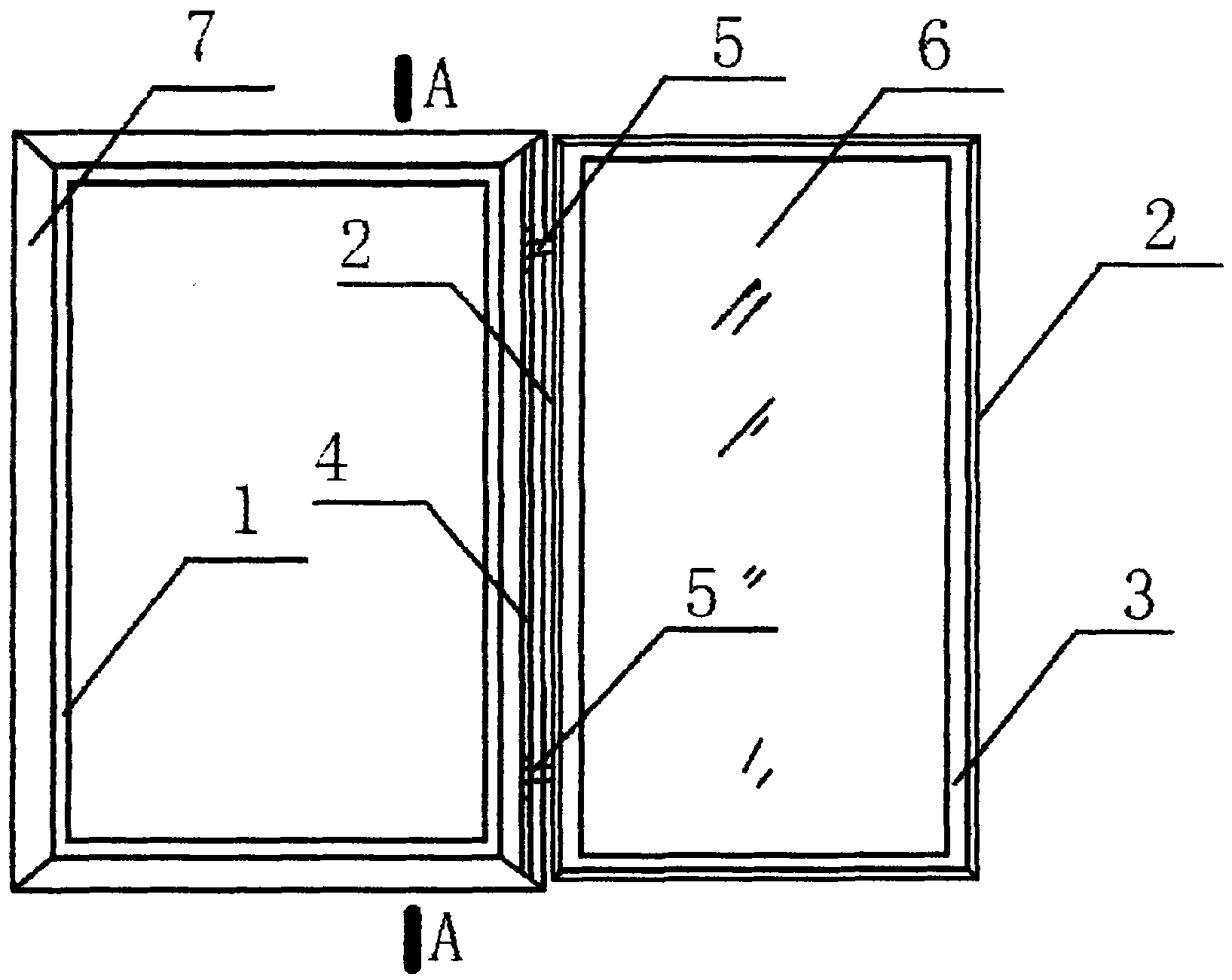

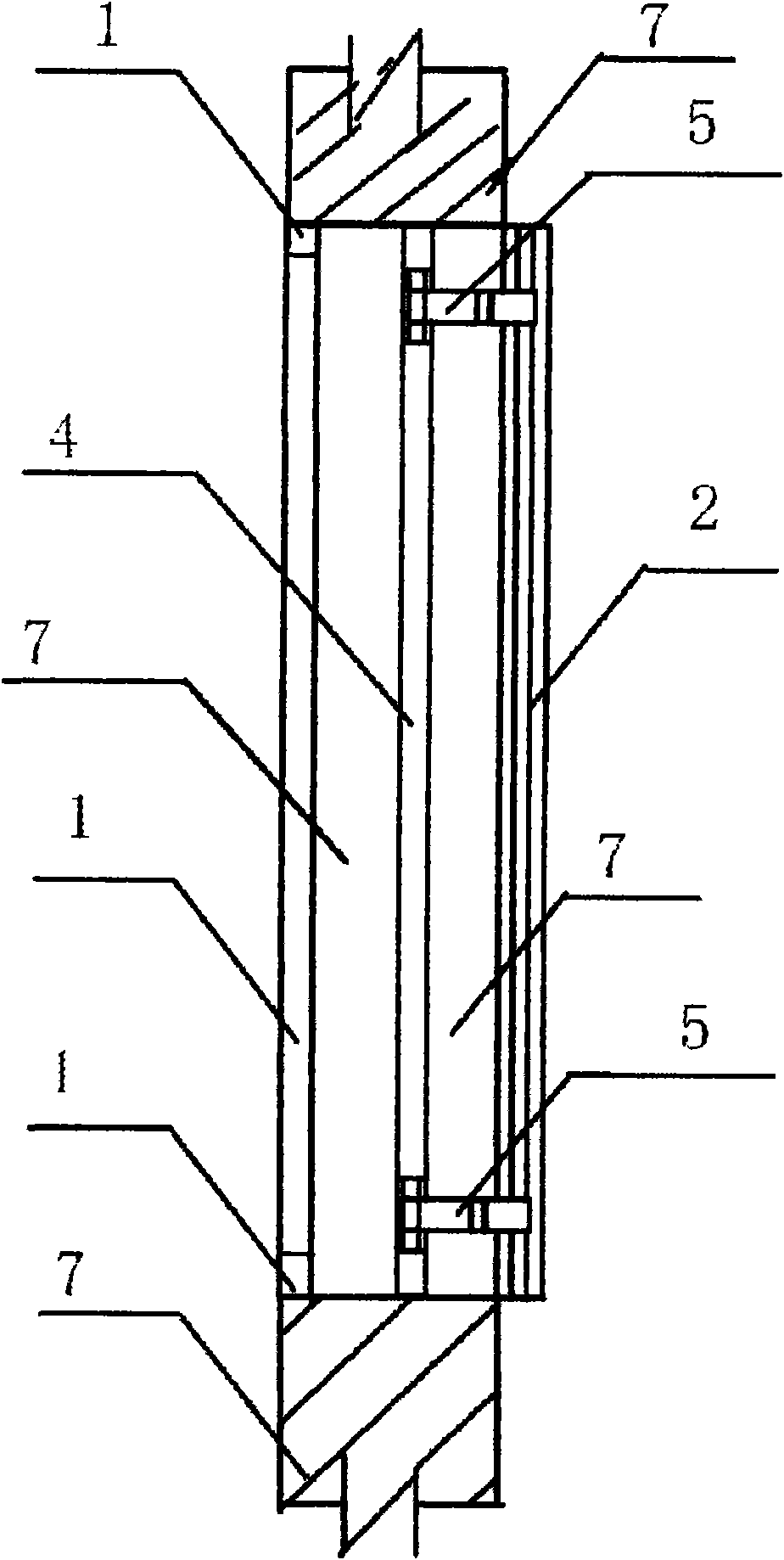

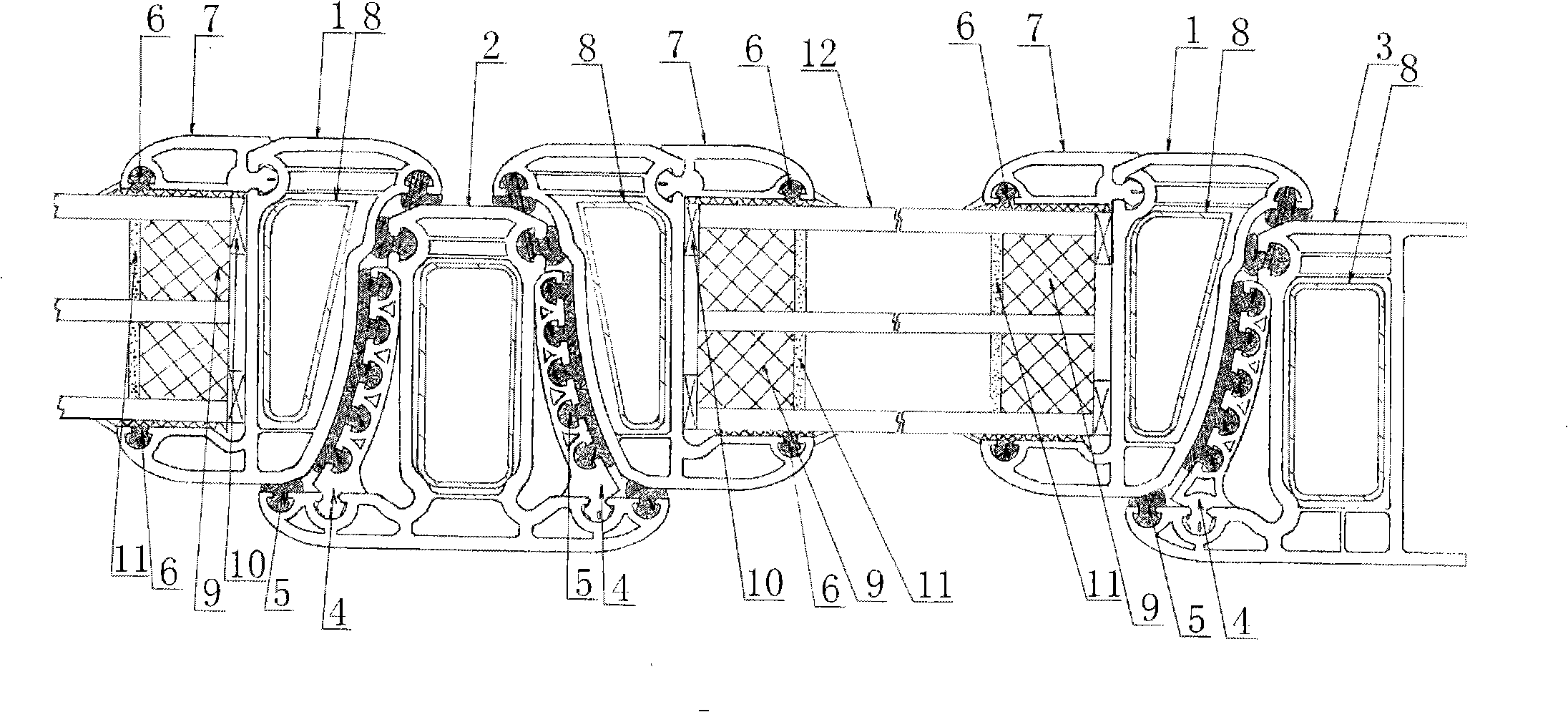

Flush door

InactiveCN103643858ASimple structureImprove sealingDoors/windowsLoad resistanceElectrical and Electronics engineering

The invention relates to a flush door. The flush door comprises an outward-opening door frame, outward-opening door leaves, glass panes, and door mullions, wherein heat insulation strips are arranged at the positions of connection between the outward-opening door frame and the outward-opening door leaves, the upper left glass panes are installed on the outward-opening door leaves respectively through battens, inner heat insulation rubber strips are arranged between the upper left glass panes and the battens, outer heat insulation strips are arranged between the outward-opening door leaves and the upper left glass panes, the other end of each upper left glass pane is installed on the corresponding door mullion, the door mullions are connected with the lower left glass panes, the other end of each lower left glass pane is installed on the corresponding outward-opening door leaf, the other end of each upper left glass pane is installed on the corresponding outward-opening door leaf through battens, the outward-opening door leaves are connected with Z-shaped door leaves through the heat insulation strips, the upper right glass panes are installed on the Z-shaped door leaves respectively through battens, and the other end of each upper right glass pane is installed on the outward-opening door frame through battens. The flush door is simple in structure; due to the fact that a swallow-tail-shaped groove structure of the outward-opening door leaves and the Z-shaped door leaves are arranged, sealing performance, energy saving performance and water prevention performance are improved, heat insulation performance and wind load resistance performance are good, firmness is achieved, and the operating requirements are met.

Owner:TIANJIN SHENGFA IND & TRADE

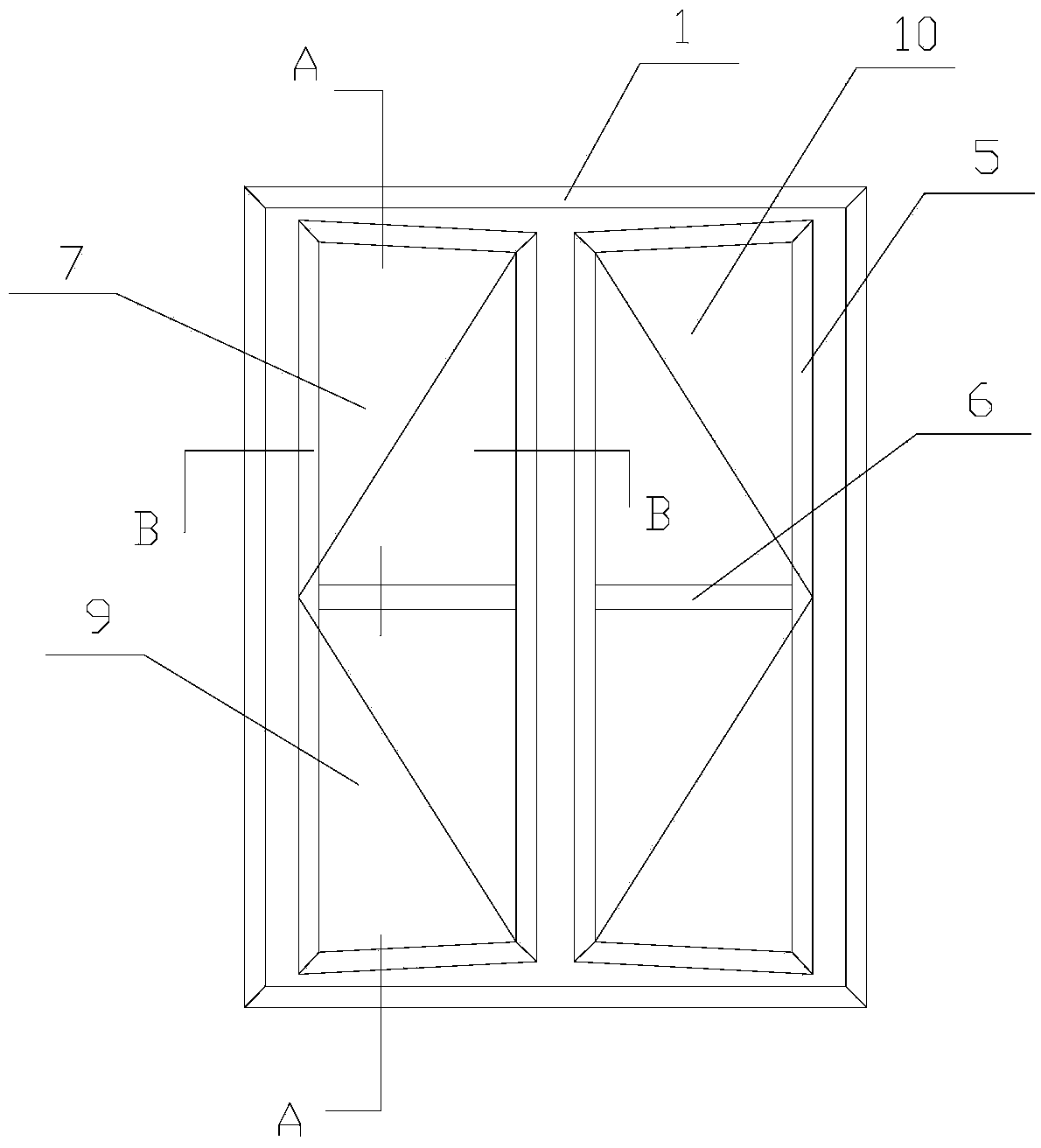

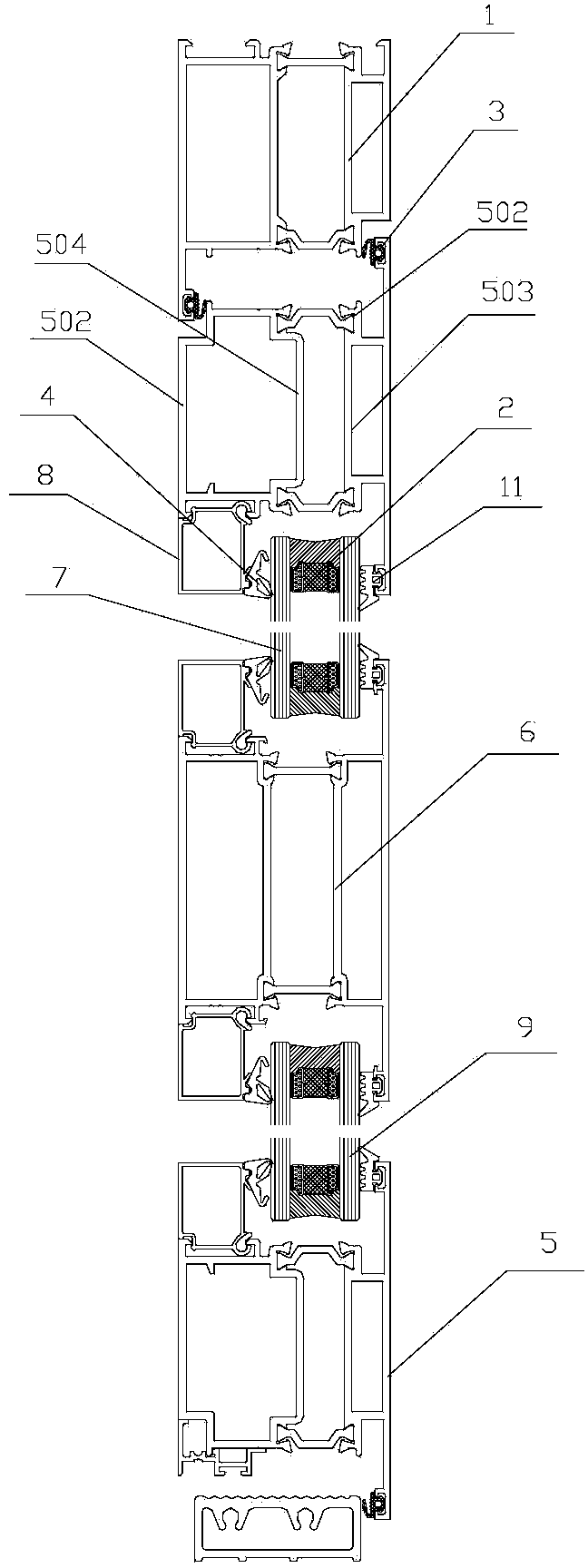

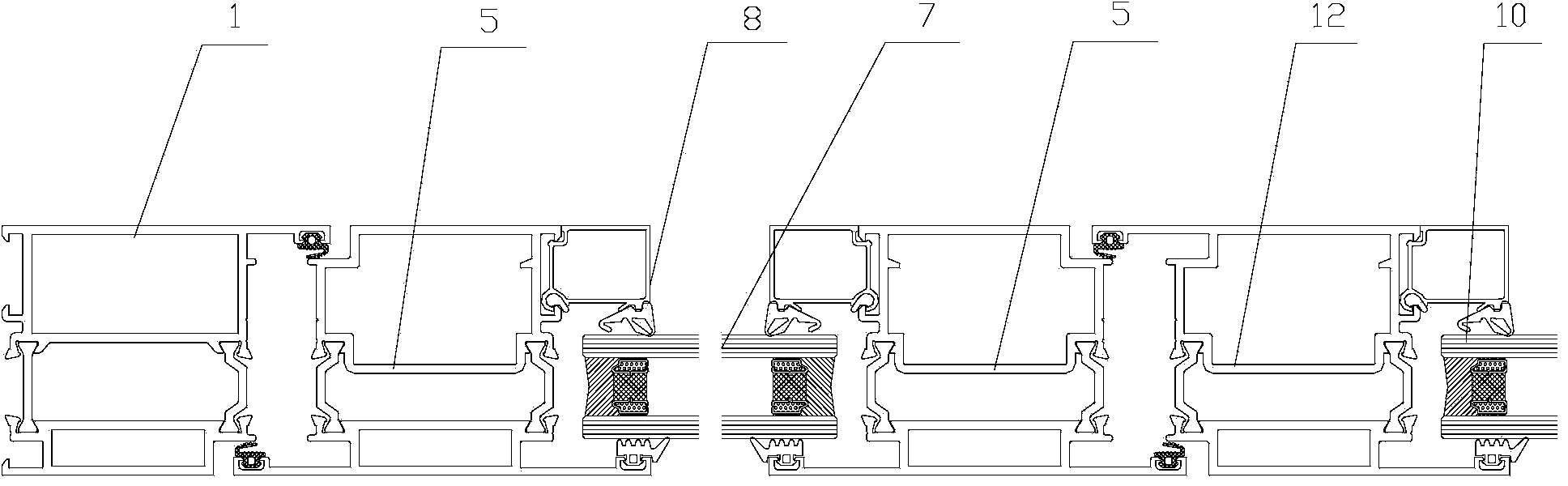

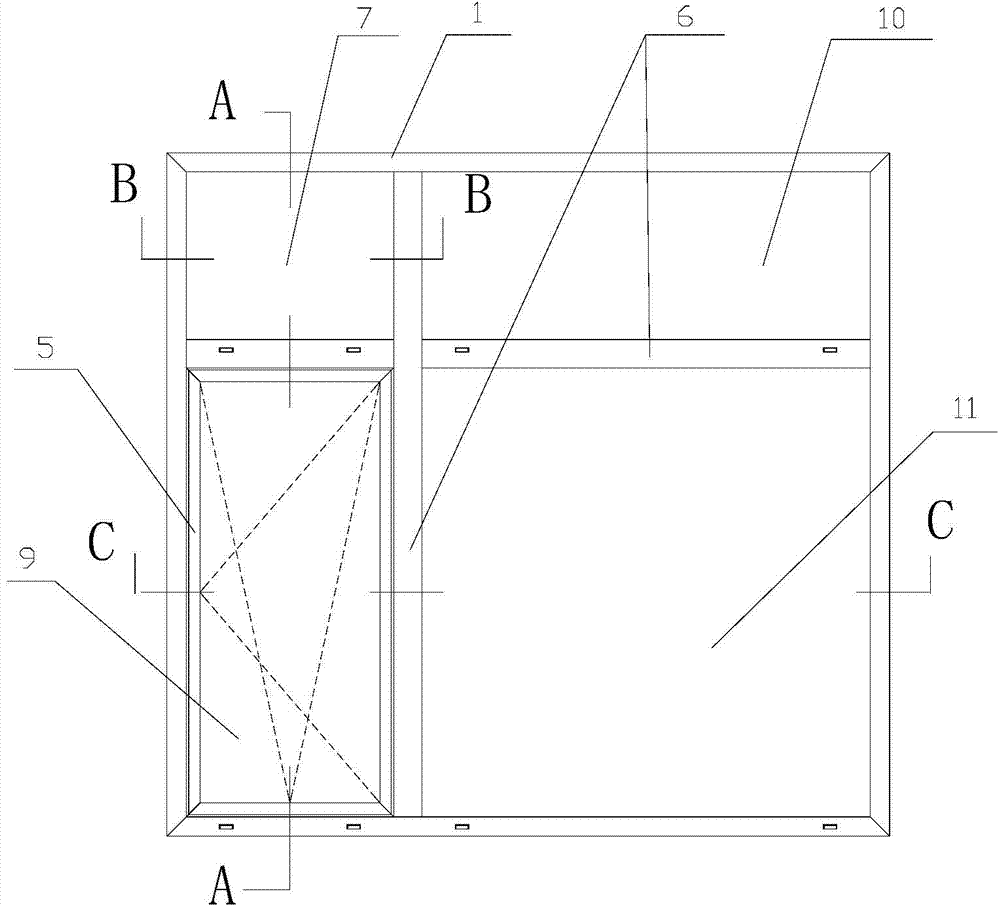

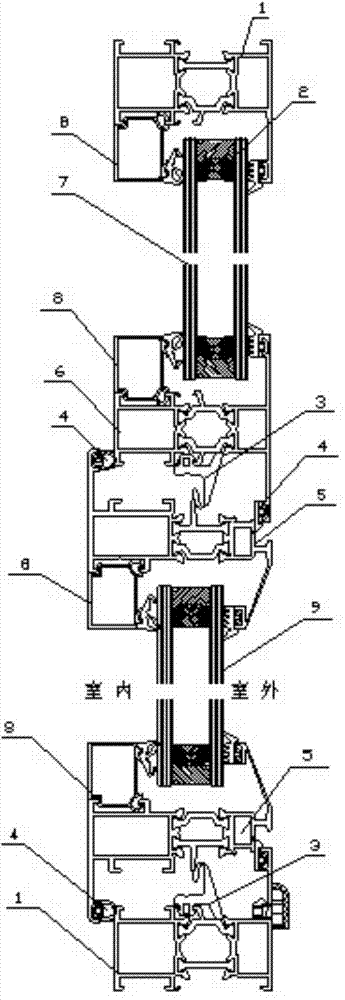

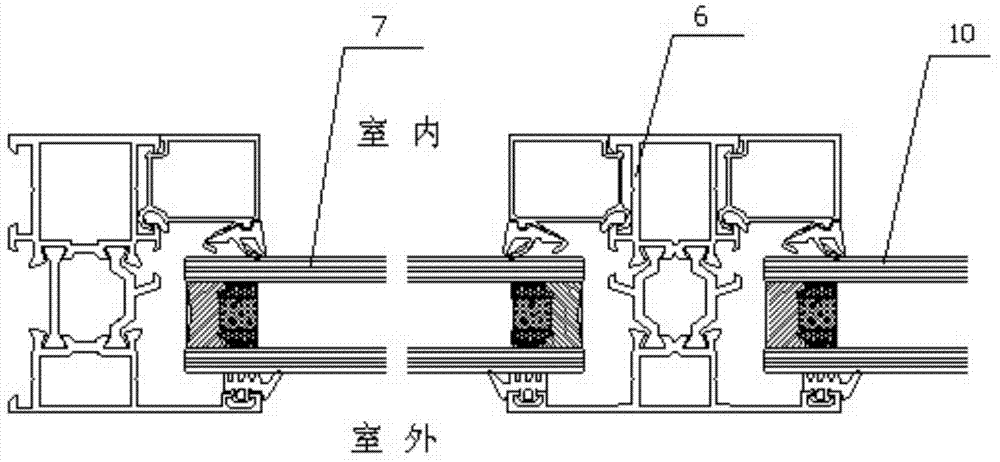

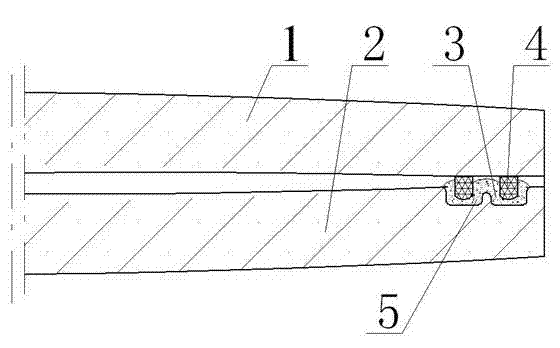

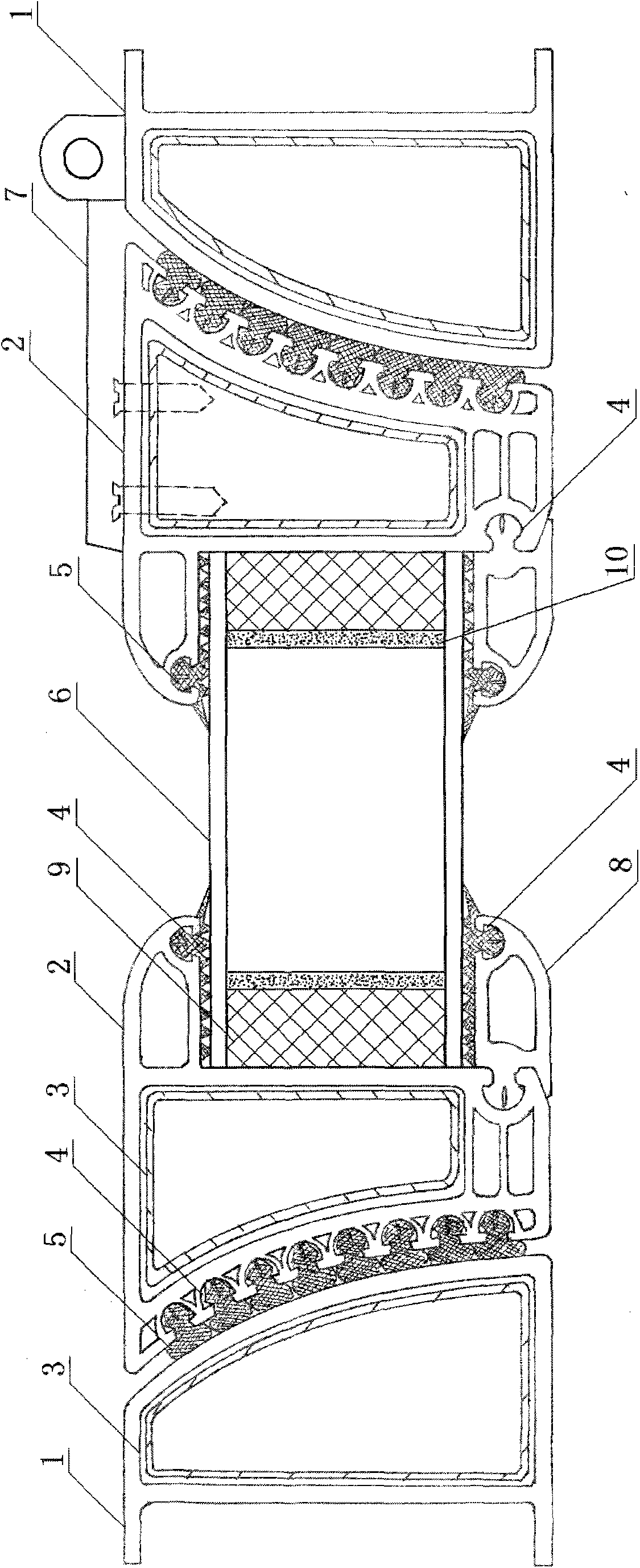

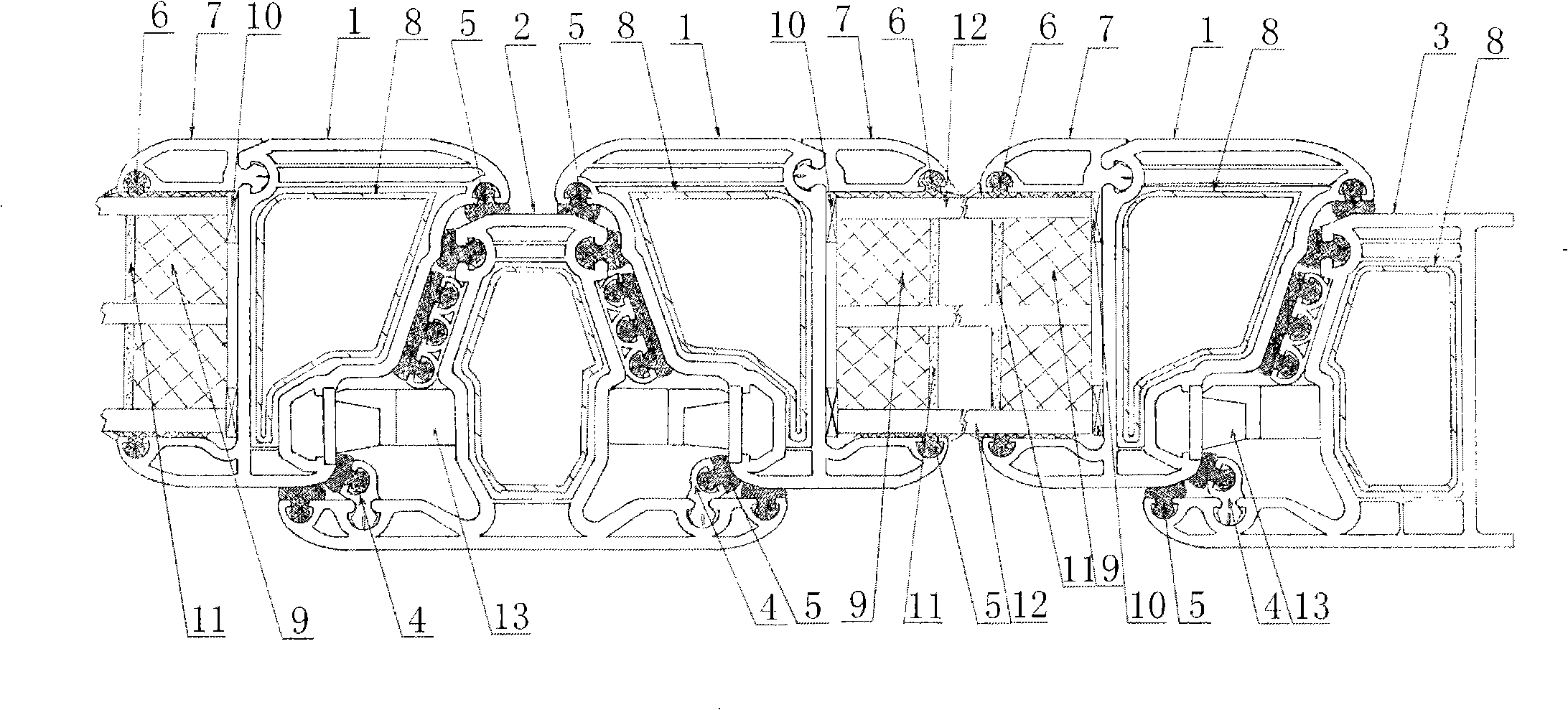

In-swinging tilt-turn window

InactiveCN103590704ASimple structureImprove energy saving performance and waterproof performanceSealing arrangementsEngineeringPressure resistance

The invention relates to an in-swinging tilt-turn window comprising a frame, an in-swinging sash, glass sheets and an in-swinging stile. The frame is connected with the upper left glass sheet through a glazing bar, the other end of the upper left glass sheet is connected to the in-swinging stile, the in-swinging sash is connected with the lower left glass sheet, the other end of the lower left glass is connected to the in-swinging sash, the other end of the left upper glass is connected to the in-swinging stile, the in-swinging stile is connected with the upper right glass sheet, the other end of the upper right glass sheet is connected to the frame, the in-swinging sash is connected with the lower left glass sheet, the other end of the lower left glass sheet is connected to the in-swinging sash, the in-swinging stile is connected with the right lower glass sheet, and the other end of the right lower glass sheet is connected to the sash. Sealed cavities are respectively formed between the in-swinging stile and the in-swinging sash and between the in-swinging sash and the frame through heat-insulated adhesive tapes, and each of the sealed cavities is divided into two parts by an insulated strip inside. The in-swinging tilt-turn window is simple in structure, high in energy-saving and water-proofing performance, low in production cost, good in heat insulation and wind-pressure resistance and high in firmness, and meets service requirements.

Owner:TIANJIN SHENGFA IND & TRADE

Metal solder-microwave welded and groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951827AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenAlloy

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing groove is arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frame and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

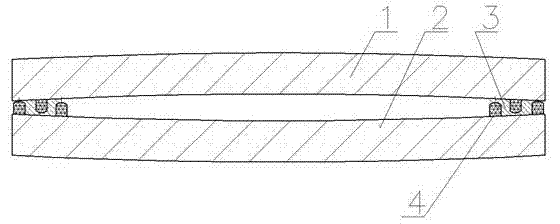

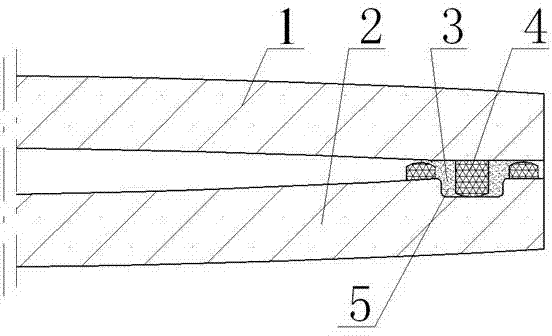

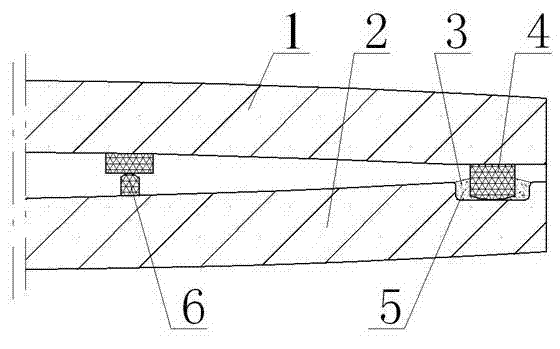

Glass solder-welded and groove-edge-sealed convex low vacuum glass and manufacturing method thereof

InactiveCN102951823AIncrease contact areaReduce tensile stressGlass reforming apparatusGlass productionEdge bandingLow vacuum

The invention relates to low vacuum glass. The low vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing groove is formed at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing glass solder in a high-temperature edge sealing furnace; and the manufacturing of the low vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frame and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the low vacuum glass can be realized by utilizing the technology, and the manufactured low vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary low vacuum glass and is particularly suitable for manufacturing tempered low vacuum glass.

Owner:戴长虹

Convex low-altitude glass welded by metal solders in microwave manner and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951808AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenAlloy

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

Method of making plastic section bar for door and window by glass fiber reinforced thermoplastic composite material

This invention relates to a method for making a plastic door and widow section bar by glass fiber heat plasticity composite material, which uses PVC, PP plastic as basic material, and uses glass fiber untwisted yarn and its textile as reinforced material, making section bar through extrusion forming method, then makes the finished product widow. Said invention can meet market requirement for architecture widow, and the widow is lightening and has high-strength; in addition, it is insulated and energy saving, and can be recovered.

Owner:山东伟佳玻璃钢制品有限公司

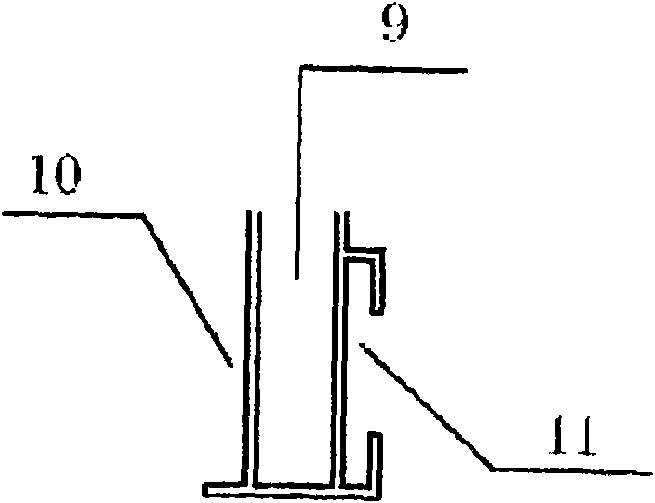

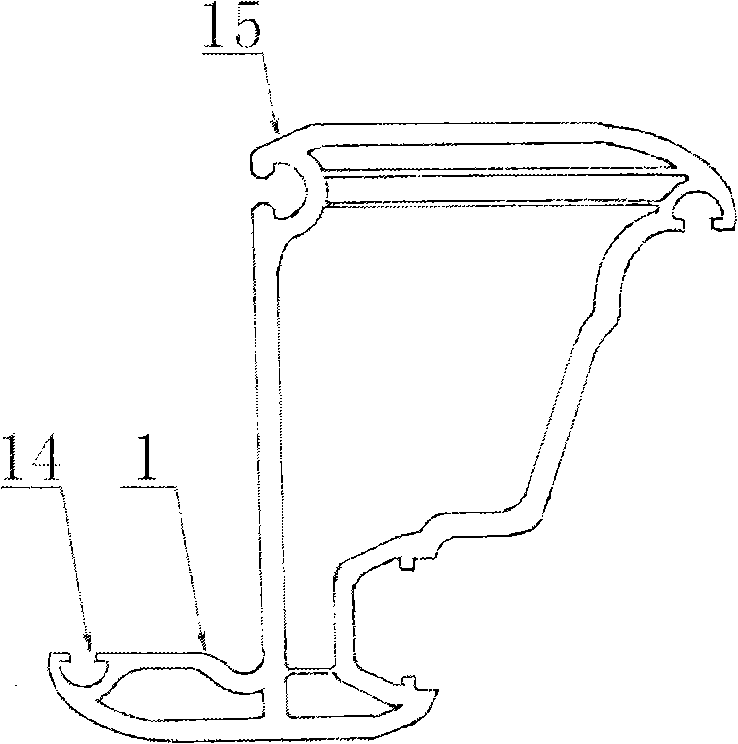

Section bar for multifunctional inward-outward casement window and window contexture

InactiveCN102071863AReduce dosageEasy to useSealing arrangementsWing arrangementsEngineeringCasement window

The invention discloses a section bar for a multifunctional inward-outward casement window and a window contexture. The section bar comprises a window frame, an inward-outward casement window frame, a sash, a special sash frame section bar, a vertical frame section bar, a hinge and a positioning and supporting piece and is characterized in that a window hole required to be installed with the inward-outward casement window is respectively provided with the window frame, the inward-outward casement window frame and the sash, wherein the window frame is fixed in the window hole; the inward-outward casement window frame is assembled in the hinge mounting slot of the positioning and supporting piece fixed on the proper position of the wall of the side surface of the window hole by an assembly hinge; the inward-outward casement window frame is not only the sash of the window frame but also the window frame of the sash; and the sash is installed in the inward-outward casement window frame by a hinge. When rotating and operating to the window frame direction by taking the central shaft of the hinge as the center of a circle, the inward-outward casement window frame can be locked in the window frame, the sash installed in the inward-outward casement window frame can be outwards opened to realize the purpose of outwards opening the window horizontally; and when the inward-outward casement window frame rotates and operates to the inner wall surface, the window can be inwards opened horizontally.

Owner:谭远志

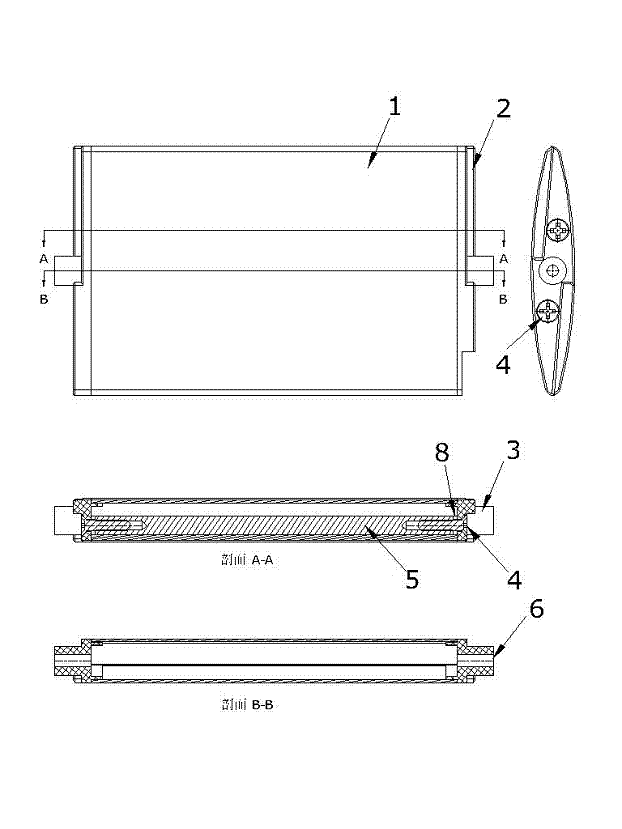

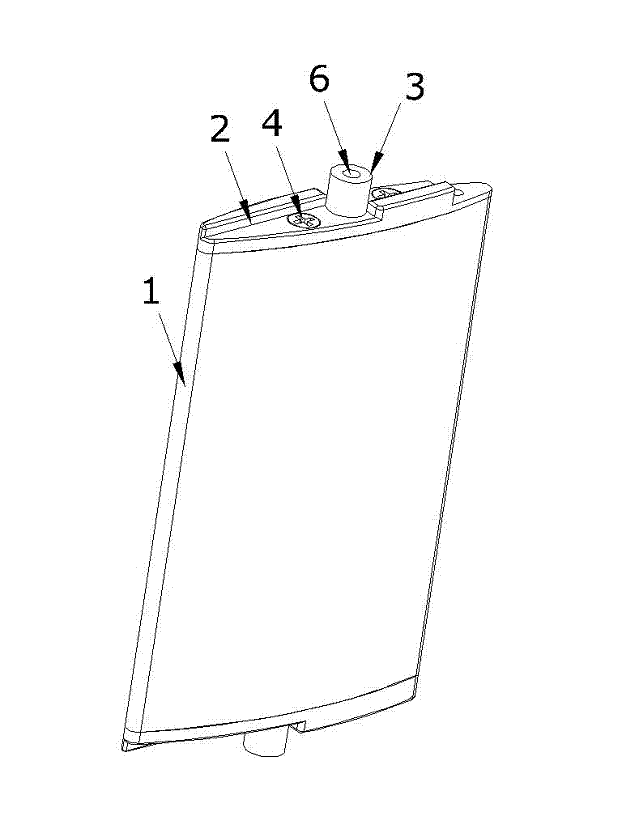

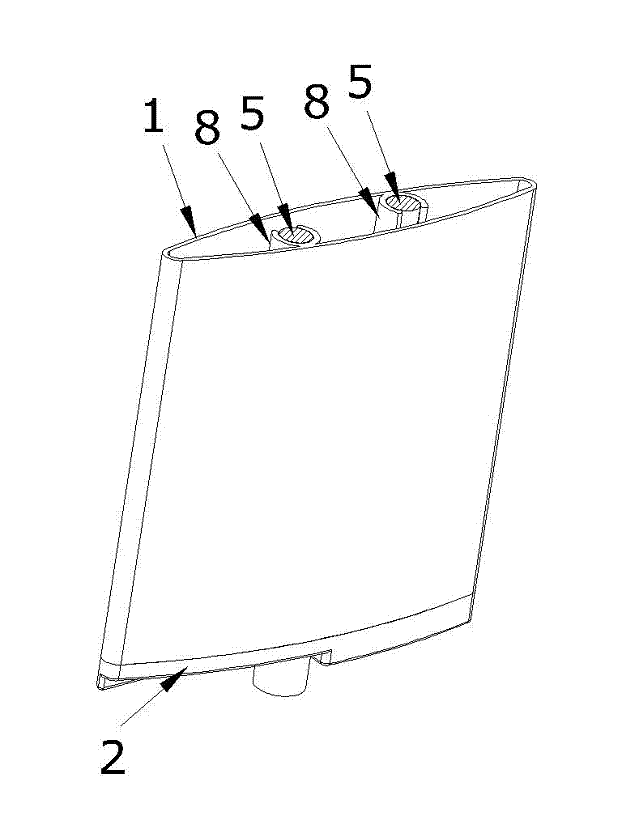

High-strength louver blade component

InactiveCN102953662ASimple structureHigh strengthShutters/ movable grillesSpecial door/window arrangementsLoad resistanceWindow shutter

The invention provides a high-strength louver blade component which mainly comprises a louver blade, a blade cover, a protruding rotary shaft, screws, a metal part, threaded holes, a circular step, semicircular clamping ribs and the like. The high-strength louver blade component has the advantages of simple structure, high strength, high burglary proofing, high wind load resistance and the like, and is applicable to various structures of louver doors, louver widows and louver curtain walls.

Owner:韦尚进

Full-sealing energy-saving chamber indoor/outdoor vertical-hinged door

InactiveCN101538976AGood wind pressure resistanceImprove insulation effectSealing arrangementsWing arrangementsEngineeringAir tightness

The invention provides a full-sealing energy-saving indoor / outdoor vertical-hinged door, belonging to the field of fixed or movable closing device technology used for the opening of a building. The vertical-hinged door solves the problem that the vertical-hinged door has bad sealing performance and large heat dissipation amount and comprises a door leaf and a doorframe; a door leaf invisible surface is a concave arc surface and a doorframe invisible surface is a convex arc surface; the door leaf invisible surface is provided with 6-8 concave troughs which are internally provided with sealing strips; the door leaf comprises a glass and a leaf material; the glass is fixedly buckled by the sealing strip and a glass pressing strip; the glass has two or three layers; a hollow sealing strip and a fixed square pipe are arranged between the two glass layers; and the indoor / outdoor vertical-hinged door has excellent rainwater permeability resistance and excellent air tightness, not only shortens the section of the profile material, enlarges the daylighting surface, saves the raw material, but also improves the wind pressure resistance, the heat-preservation performance and the sound insulation performance of the door, reduces the energy consumption and the cost, and has the advantages of good sealing effect and easy installation.

Owner:陈凯 +1

Hard PVC plate

The invention relates to a hard PVC plate which comprises the following components in parts by weight: 100 parts of PVC, 8 parts of a stabilizer, 5 parts of silica flour, 12 parts of bamboo fiber, 12 parts of glass fiber, 10 parts of nano calcium carbonate, 6 parts of light activated calcium carbonate, 5 parts of calcium chloride, 2 parts of titanium dioxide, 2 parts of glycoprotein and 2 parts of a processing agent. According to the invention, the PVC plate is high in hardness, high in transparency and good in wind pressure resistant performance, and can be used for the field of doors and windows of buildings.

Owner:QINGDAO KECHUANG PLASTIC MACHINERY

Gradient color aluminum honeycomb mirror board module and preparation process thereof

ActiveCN108952000AHas a flat surfaceEnvironmentally friendlyConstruction materialWallsColor effectPolyurethane adhesive

The invention discloses a gradient color aluminum honeycomb mirror board module and a preparation process thereof. The module comprises an aluminum honeycomb plate, wherein a stainless steel mirror board is arranged on the front side of the aluminum honeycomb plate; other surfaces of the aluminum honeycomb plate are wrapped with aluminum plates; sections I / sections II and sections II / sections I are respectively arranged on the upper and lower sides and left and right sides of the aluminum honeycomb plate; and when two or more modules are connected, the section I and section II between adjacentmodules are matched with each other. The preparation process comprises the following steps: uniformly applying polyurethane adhesives to the inner sides of the stainless steel mirror board and the aluminum plates; putting the aluminum honeycomb plate into the aluminum plates coated with the polyurethane adhesives, and laminating the stainless steel mirror board to form modules; performing cold pressing on the modules, laminating gradient films, drying, and finally mounting the sections. The gradient color aluminum honeycomb mirror board module disclosed by the invention is clear in sense of line and beautiful in style, the sense of depth of the gradient color effect of the whole wall space is prominent, the product uniqueness of customers is ensured, and the visual effect is excellent.

Owner:SHANGHAI KONGBO IND

Metal solder-microwave welded and strip frame-edge-sealed convex low vacuum glass and manufacturing method thereof

InactiveCN102951818AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention relates to low vacuum glass. The low vacuum glass is characterized in that each of upper glass and lower glass is convex glass, edge sealing strip frames are arranged on the welded peripheries of the upper glass and the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a microwave oven; and the manufacturing of the low vacuum glass is simpler and more convenient, and the matching of the upper and the lower edge sealing strip frames can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the low vacuum glass can be realized by utilizing the technology, and the manufactured low vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary low vacuum glass and is particularly suitable for manufacturing tempered low vacuum glass.

Owner:戴长虹

Convex vacuum glass welded by metal solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

PendingCN102951810AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenConvex side

The invention discloses vacuum glass. The vacuum glass is characterized in that upper and lower glass are convex; the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and not only can be used for manufacturing common vacuum glass, but also is particularly suitable for manufacturing of tempered vacuum glass; and the vacuum glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

Flat-open complete seal plastic steel window

InactiveCN101280658ASolve the sealing problemSolve the cooling problemSealing arrangementsWing arrangementsDecreased energyThermal insulation

The invention discloses a flat-opening whole sealing plastic steel window which pertains to the technical field of fixed or movable closure devices applied to the openings of buildings and solves the problems of poor sealing performance and large heat release of plastic steel windows. The flat-opening whole sealing plastic steel window comprises glass, a glass stop, sealant tapes, a sash material, a bearing material and a frame material. The non-visual surface of the sash material is composed of an arc shaped surface and an inclined plane and is in lap joint with the bearing material or the edge of the non-visual surface of the frame material; the support of sealant tapes is arranged between the sash material and the bearing material or the non-visual surface of the frame material; grooves are positioned at the support of the sealant tapes and / or sash material or the bearing material or the non-visual surface of the frame material and the sealant tapes are positioned in the grooves; angle iron is arranged at the inner side and the outer side of the connecting parts of the frame material at the four corners of the window frame. The flat-opening whole sealing plastic steel window of the invention reduces the cross section of section materials, enlarges the lighting surface of the windows, increases the exit window ratio of section materials, improves the resisting wind press capacity, thermal insulation performance and sound insulation property of windows, decreases energy consumption and cost and has the advantages of good sealing performance and easy installation.

Owner:陈凯 +1

Sunshade integrated door window structure

PendingCN107893610AGood weather resistanceStrong wind pressure resistanceLight protection screensCondensed water drain-offSlide plateSolar power

The invention relates to the technical field of building machinery, in particular to a sunshade integrated door window structure. The sunshade integrated door window structure comprises a door windowand an external sunshade roller shutter device. The door window comprises an inner frame, an outer frame, an inner leaf material, an outer leaf material and a side frame. A roller shutter box comprises an upper frame plate, an up-sliding integrated bottom plate, an overhaul plate, an outer stopping plate, an reinforcing end plate, a rotary shaft and an outer sunshade roller shutter wound on the rotary shaft. The roller shutter box is mounted on the upper portion of the door window. A heat insulation device, a solar energy power supply device and an air purifying device and arranged on the roller shutter box, and a flow guiding plate and a permeating hole structure are further arranged. Through the integrated up-slipping integrated bottom plate structure, the problem that a traditional integrated door window structure leaks water is solved, and the sunshade door window has better water tightness, air tightness, safety and energy-saving performance, and is one of most effective measuresto effectively reduce the energy consumption of buildings.

Owner:无锡日兆节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com