Gradient color aluminum honeycomb mirror board module and preparation process thereof

A preparation process, aluminum honeycomb technology, applied in the field of gradient color aluminum honeycomb mirror panel module and its preparation process, to achieve the effect of good visual effect, light weight, advanced and reasonable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

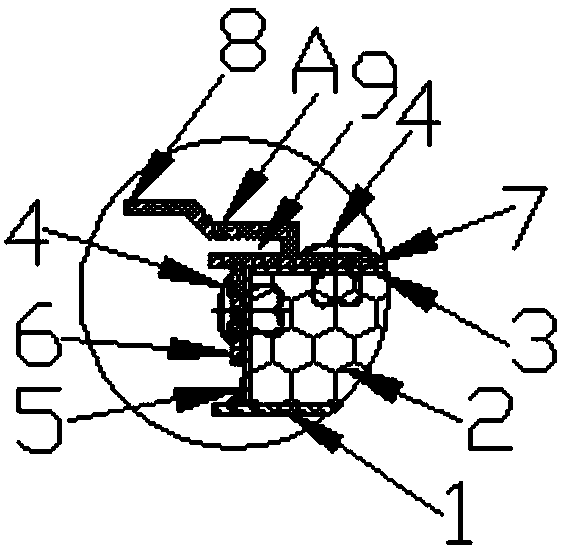

[0048] Such as Figure 1-9 As shown, a gradient color aluminum honeycomb mirror panel module provided by the present invention includes an aluminum honeycomb panel 2, a stainless steel mirror panel 1 is provided on the front side of the aluminum honeycomb panel 2, and a gradient film is covered on the surface of the stainless steel mirror panel 1, and the aluminum honeycomb panel The other surfaces of the honeycomb panel 2 are wrapped with an aluminum plate 3, and the aluminum plate 3 is integrally formed. The upper and lower sides of the aluminum honeycomb panel 2 are respectively provided with profile one A and profile two B, and the left and right sides of the aluminum honeycomb panel 2 are respectively provided with profile one A and profile two B; Outrigger one 6 connected to the side of the panel 2, outrigger two 7 used to connect with the back of the aluminum honeycomb panel 2, outrigger three 8 and groove 9 used to connect with the wall surface, and the cross section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com