Patents

Literature

257 results about "Slip line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

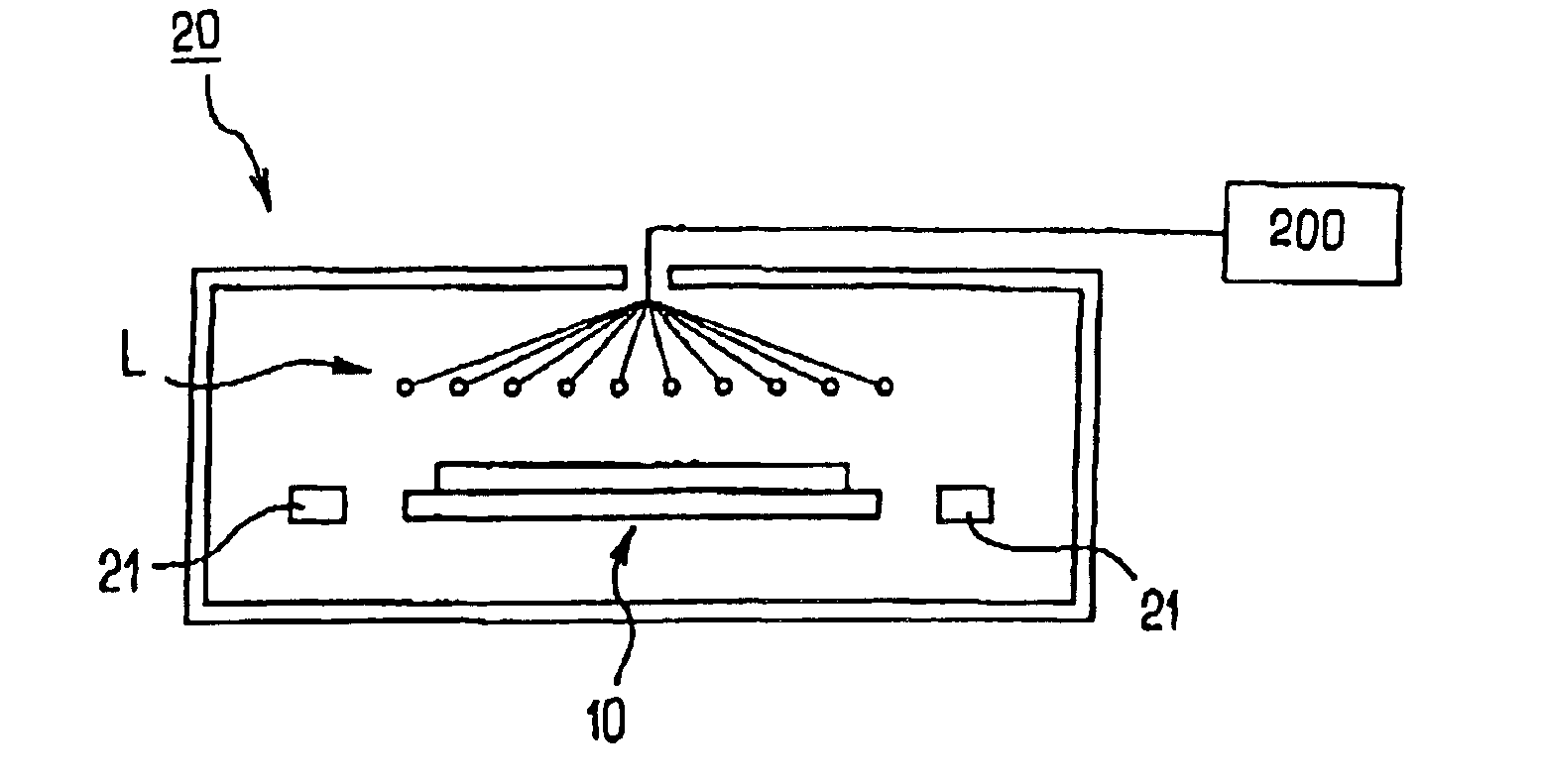

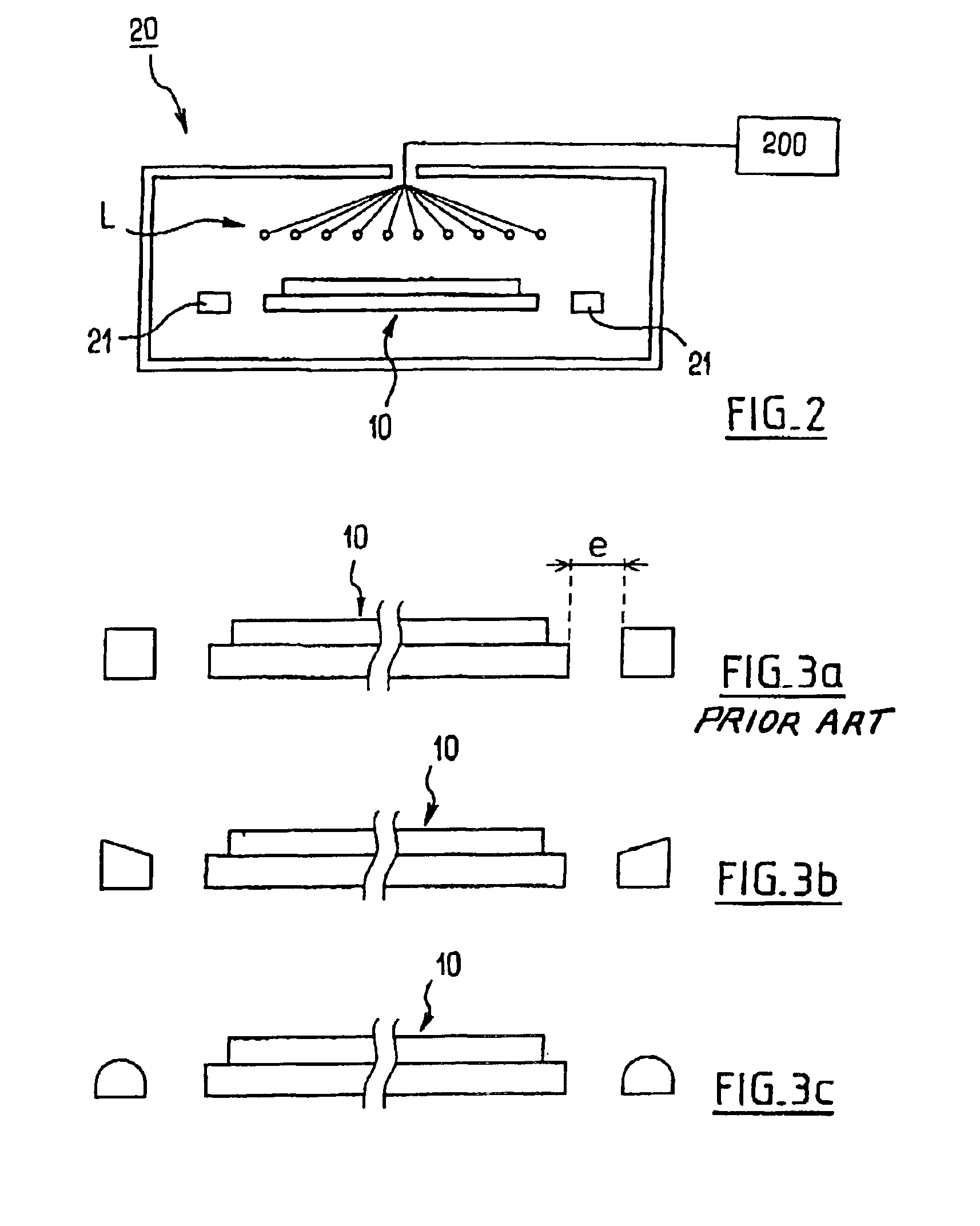

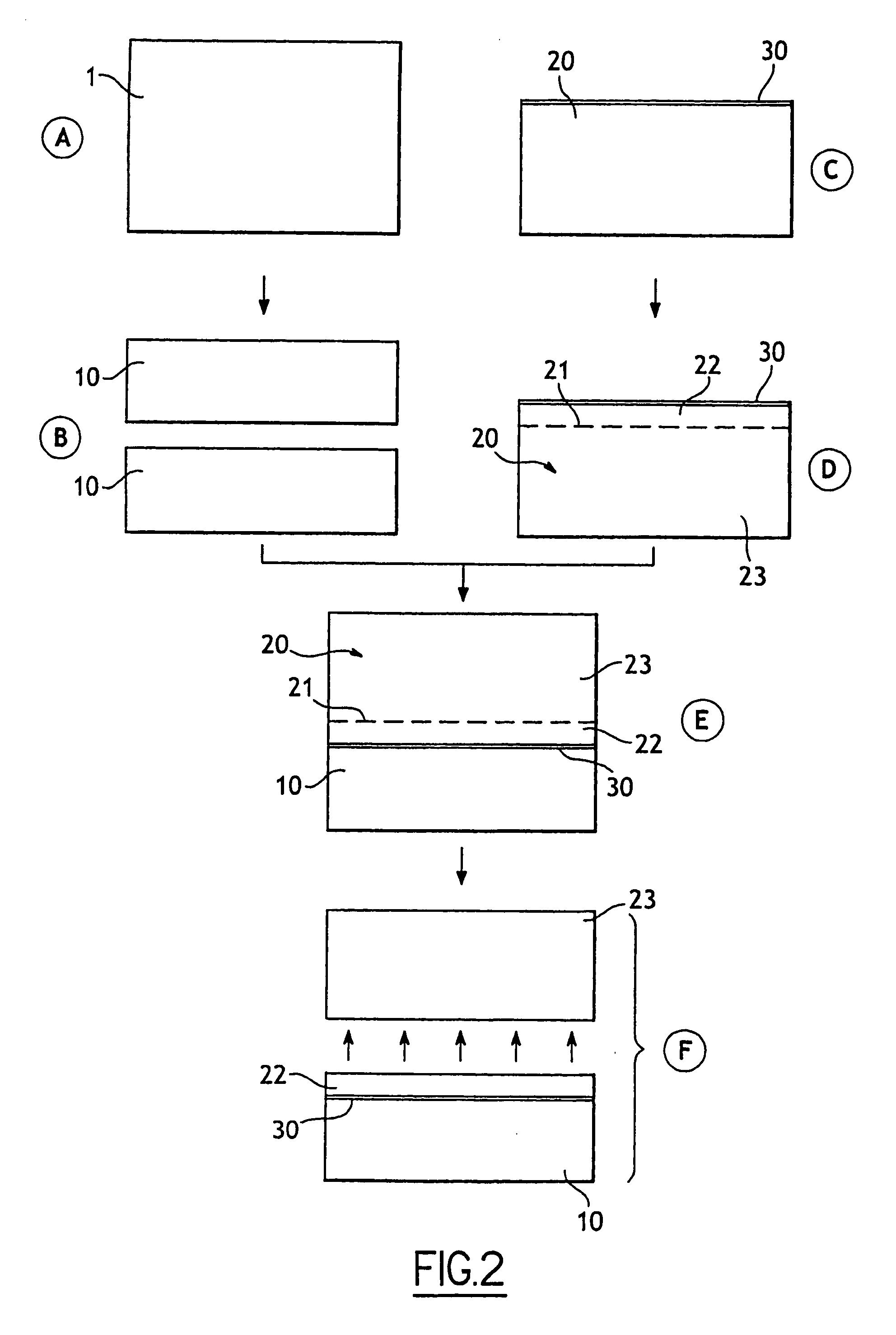

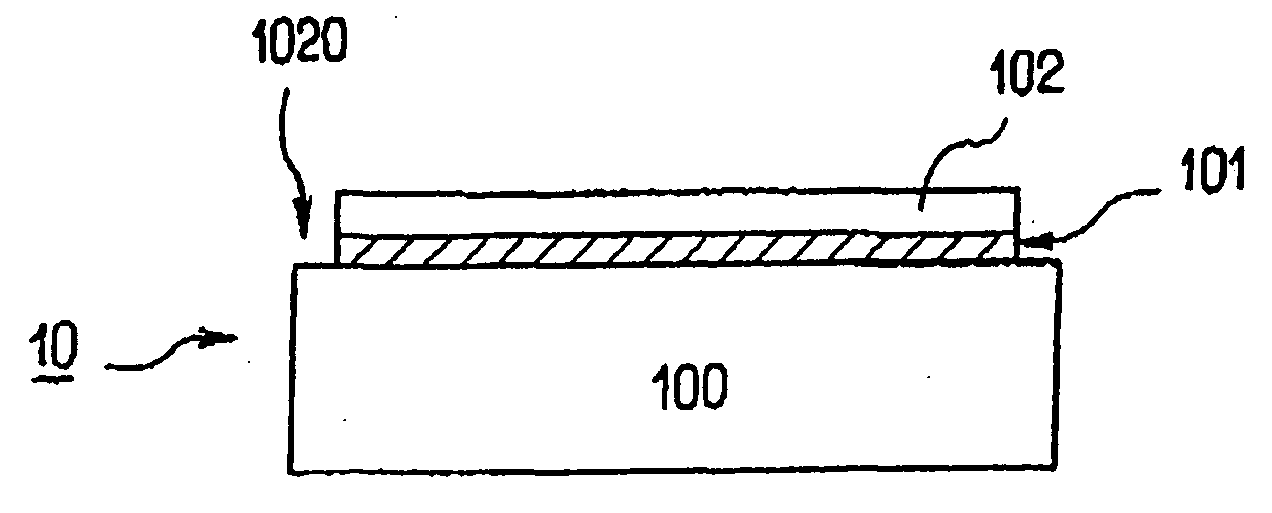

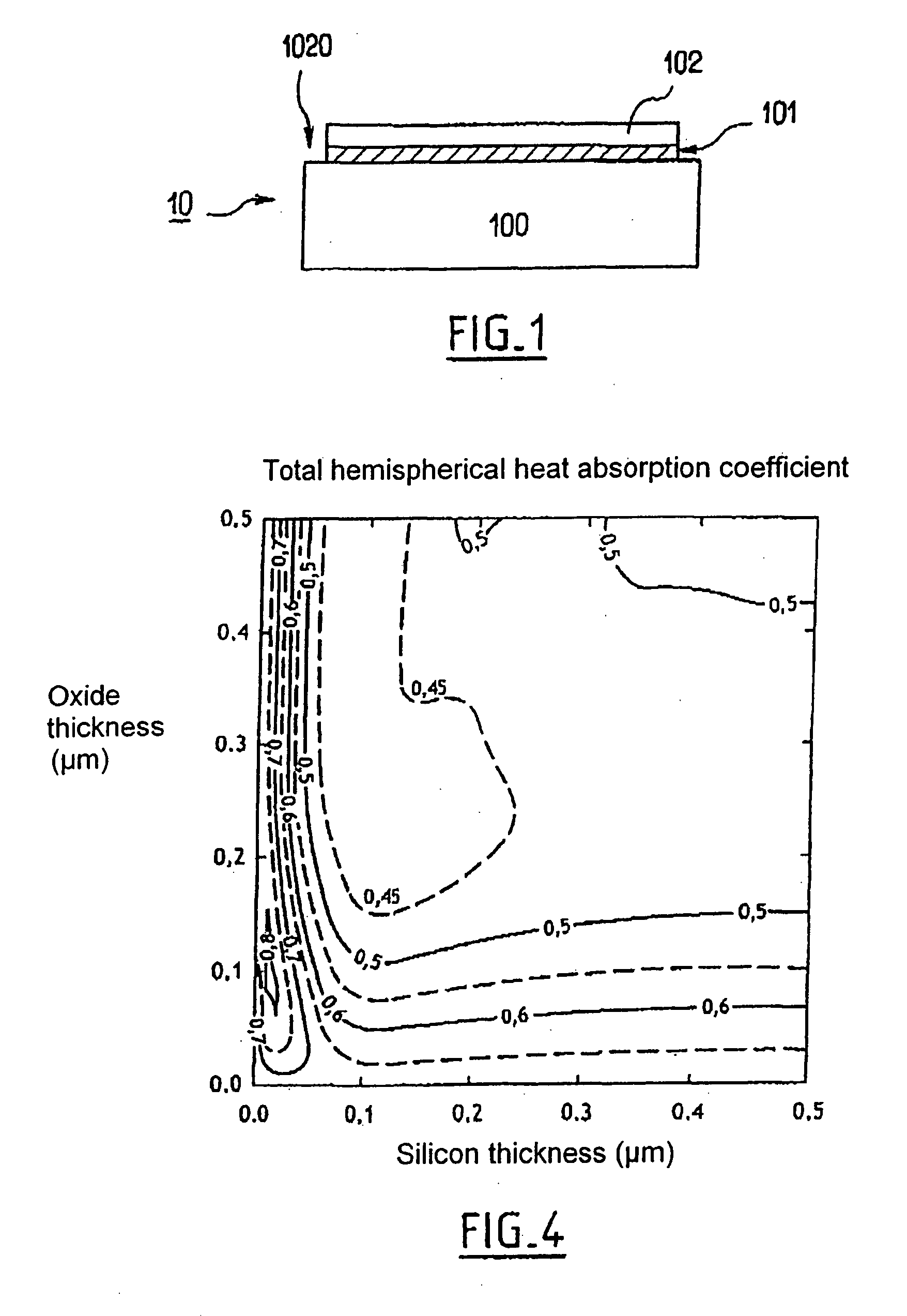

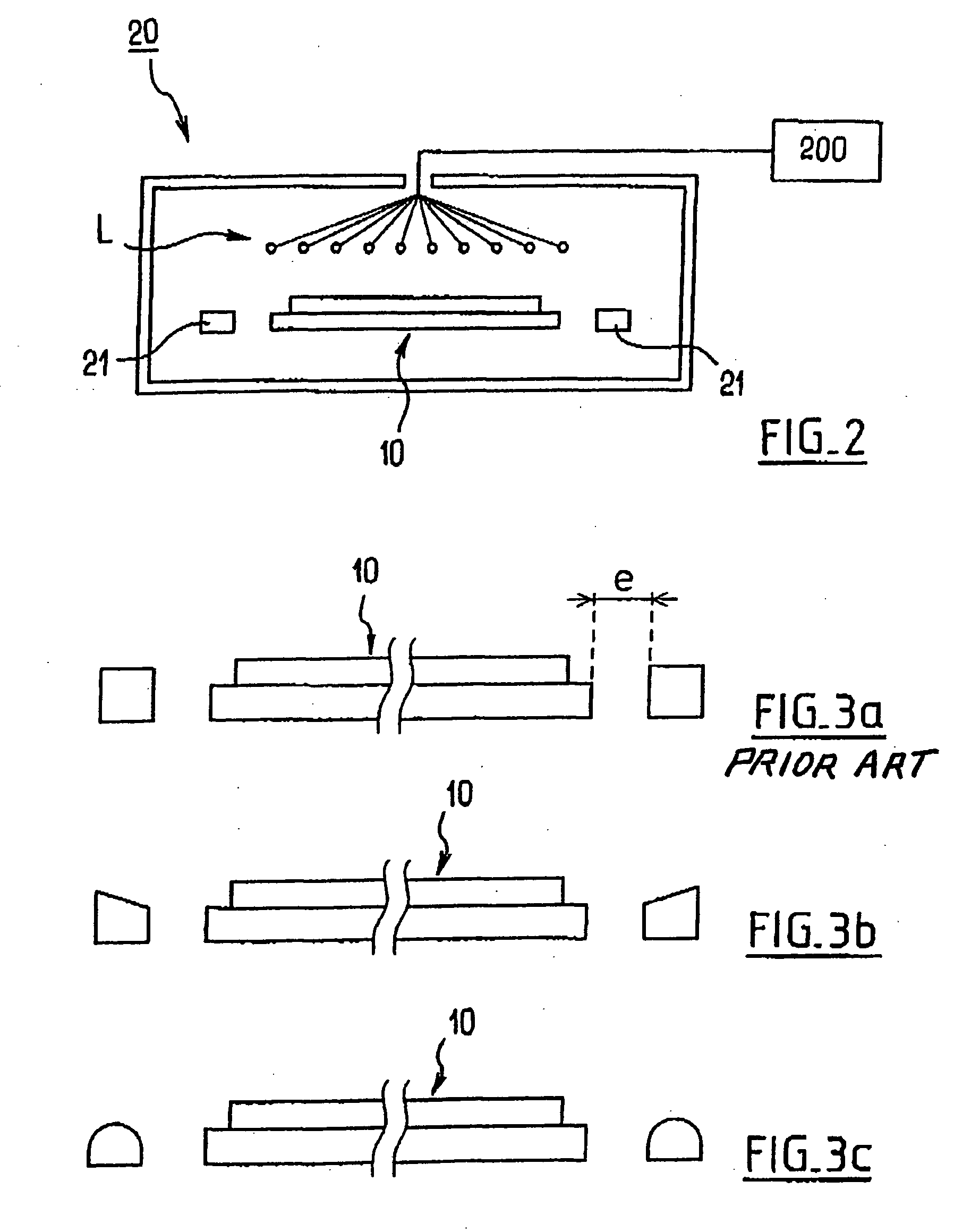

Heat treatment for edges of multilayer semiconductor wafers

A method for heat treating a multilayer semiconductor wafer having a central region and a peripheral edge each having a surface. The method includes thermally treating selected portions of the peripheral edge to compensate for local differences in heat absorption. This establishes a substantially equivalent temperature over both the surface of the central region and the surface of the peripheral edge to prevent the appearance of slip lines on those surfaces.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

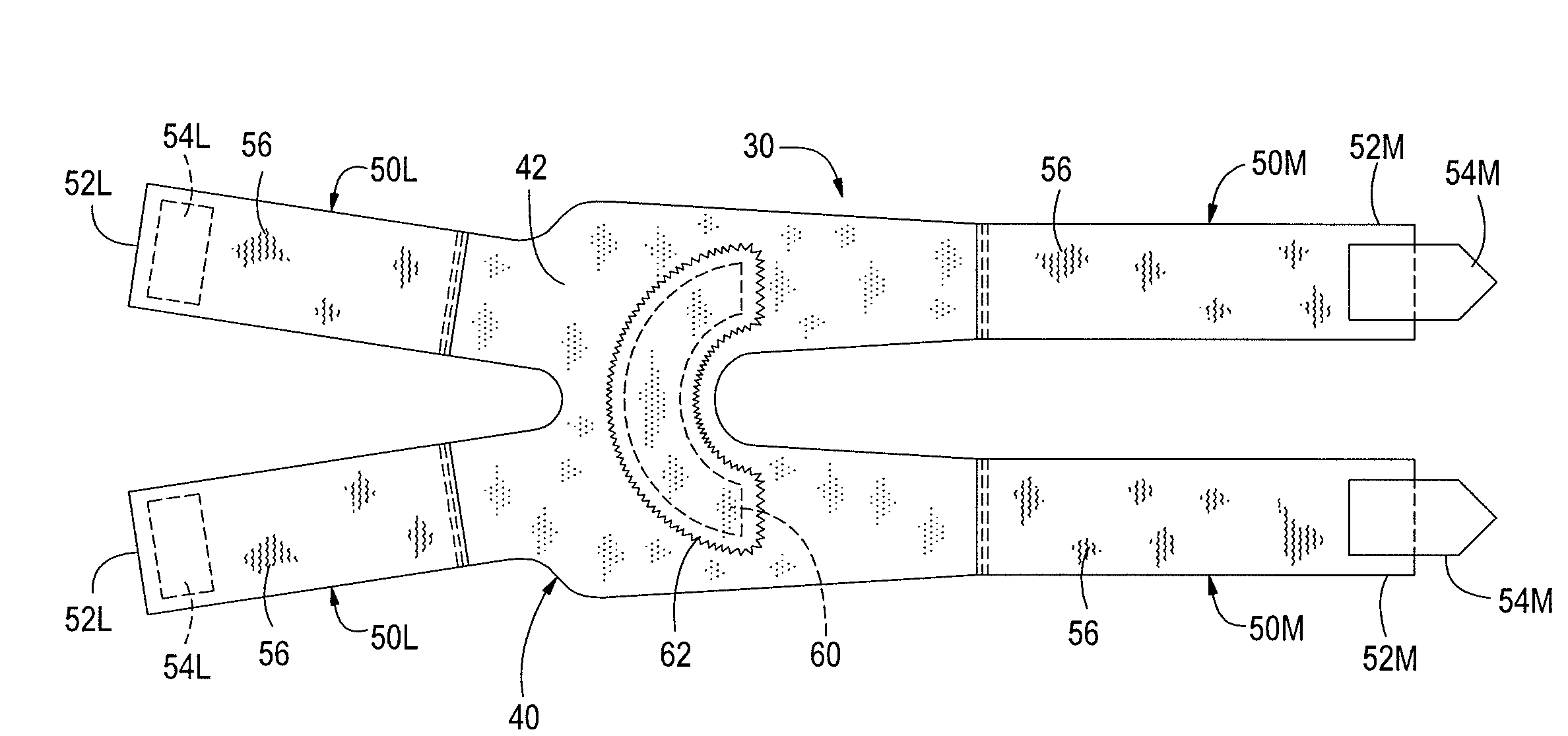

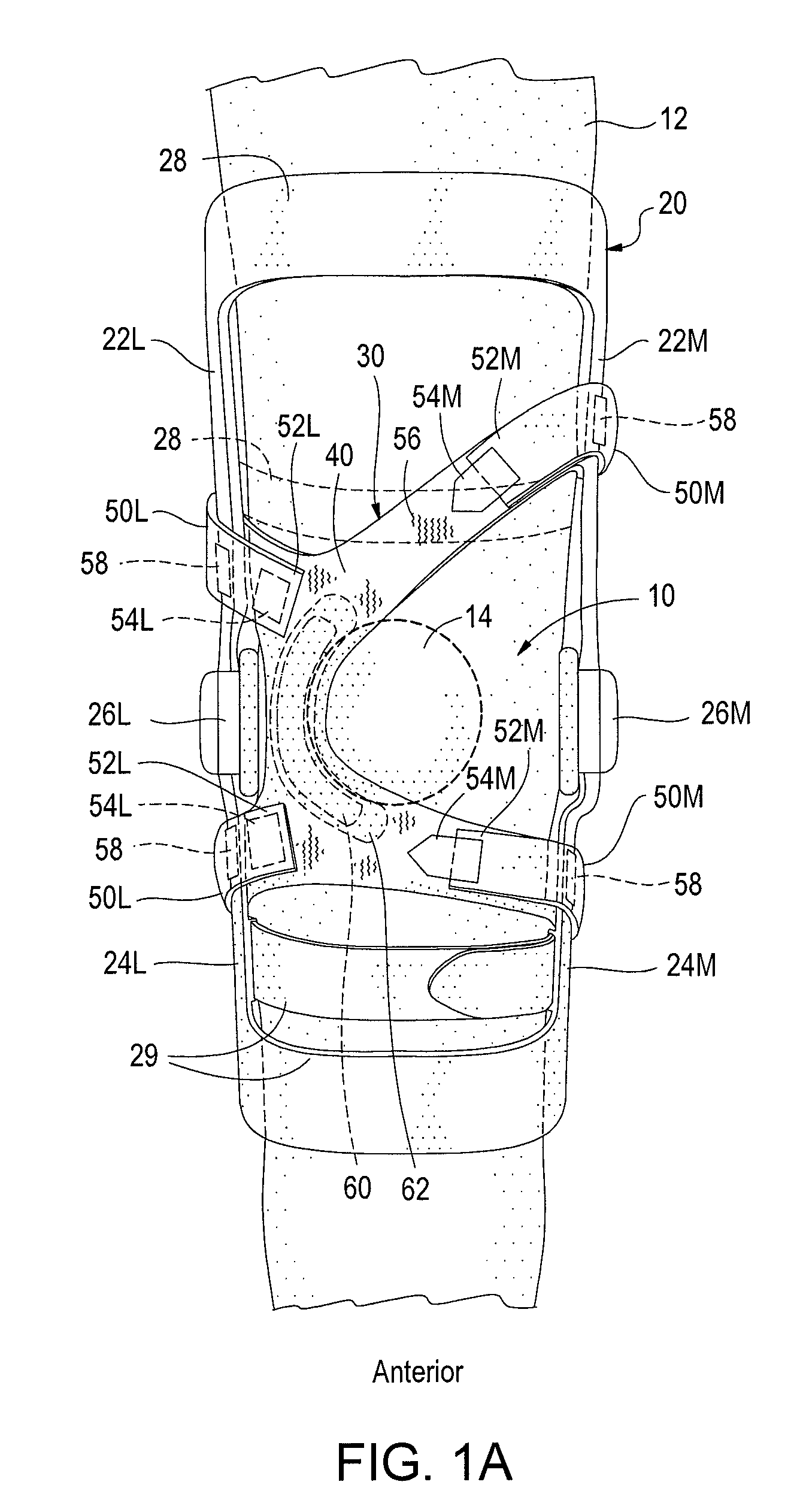

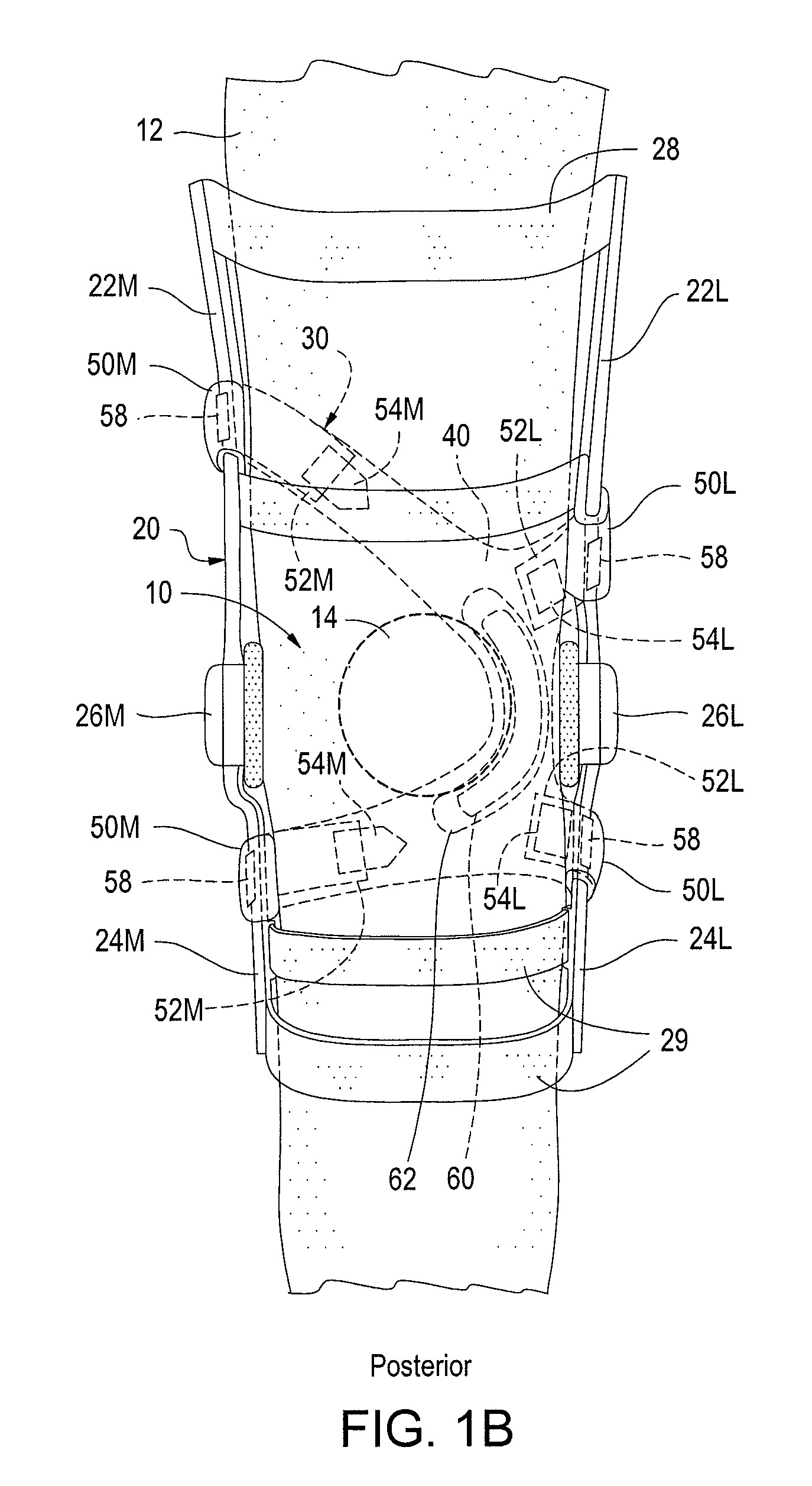

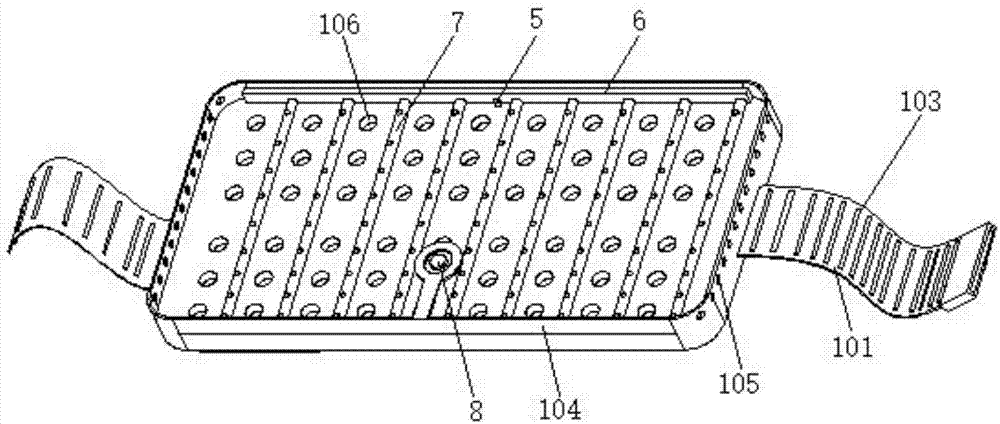

Tension Strap for Migration Prevention and Patellar Stabilization for Use With Knee Braces

InactiveUS20090131844A1Improve efficiencyEliminate distractionsNon-surgical orthopedic devicesSlip lineButtress

A tension strap to be used with any brand of ACL or OA functional knee bracing. The position, elasticity and versatility of the strap allow it to be used for patella support and to prevent vertical migration of the brace. The strap is placed over the anterior side of the face of the knee joint with the support buttress lying adjacent to the anterior edge of the patella and the support straps extended posteriorly to the upper arms and lower arms of the brace. The support straps are then pulled around the outside of the upper arms and lower arms of the brace and adhered back to themselves using hook and loop fastener material. Additional support tension can be applied to the patella through the buttress support by increasing tension through the support straps. The prevention of vertical migration of the knee brace is also achieved through the use of non-slip lining on the face of the tension strap that is in contact with the skin covering the knee joint and patella.

Owner:DEAN JOHN HARVEY +1

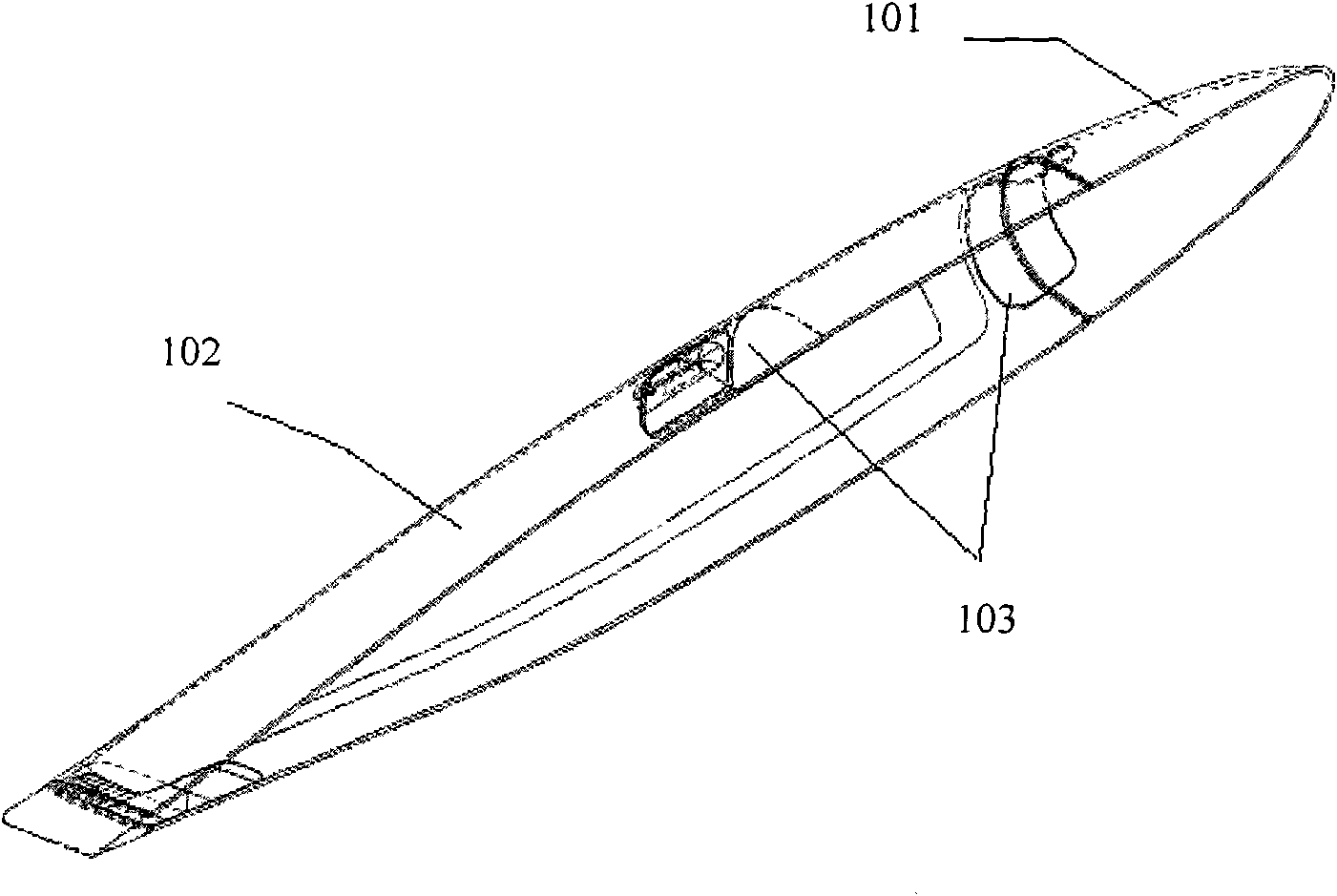

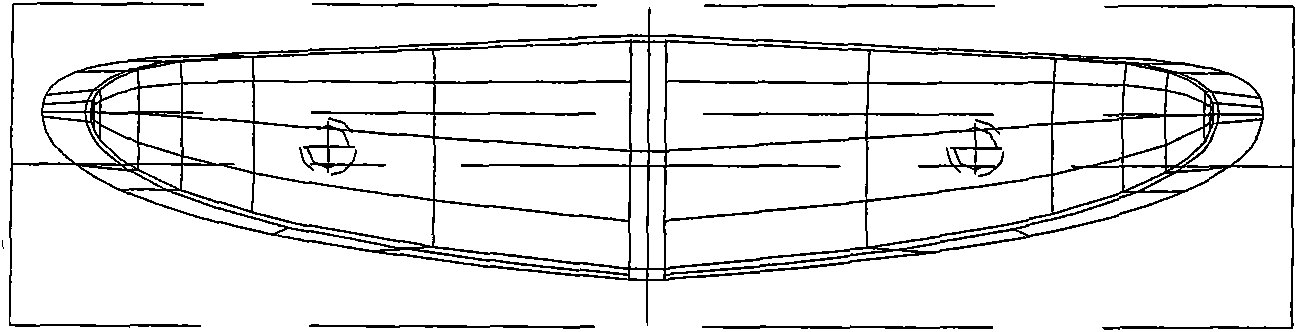

Wingtip cover mirror face part drawing processing method

The invention discloses a wingtip cover mirror face part drawing processing method, which comprises the following steps: according to a size, which is obtained after the contour line of the opening of a female die is deflected outwards at a preset value, of the drawing die, making blank materials in irregular elliptic shapes by using a mechanically polished skin material; uniformly applying lubricating oil on the round corner parts of the female die as well as the inside and outside surfaces of an upper molding cavity in a pressing face of the drawing die consisting of the female die and a male die, and the surfaces, which are contacted with the round corner parts and the inside and outside surfaces, of the blank materials; placing the blank materials in a drawing die with the fiber direction of the blank materials consistent with the length direction of the blank materials; covering a layer of rubber skin between the female die and the blank materials; drawing under a drawing pressure of 3 to 5Mpa and an edge pressure of 3 to 5Mpa; keeping for 5 to 10 seconds after drawing; and relieving pressure, and taking part out. The surface of the mirror face part thus obtained does not have slip lines and coarse grains and is smooth without scraps, so the mirror face part meets the quality requirements for mirror parts and defect products are avoided basically.

Owner:COMAC +1

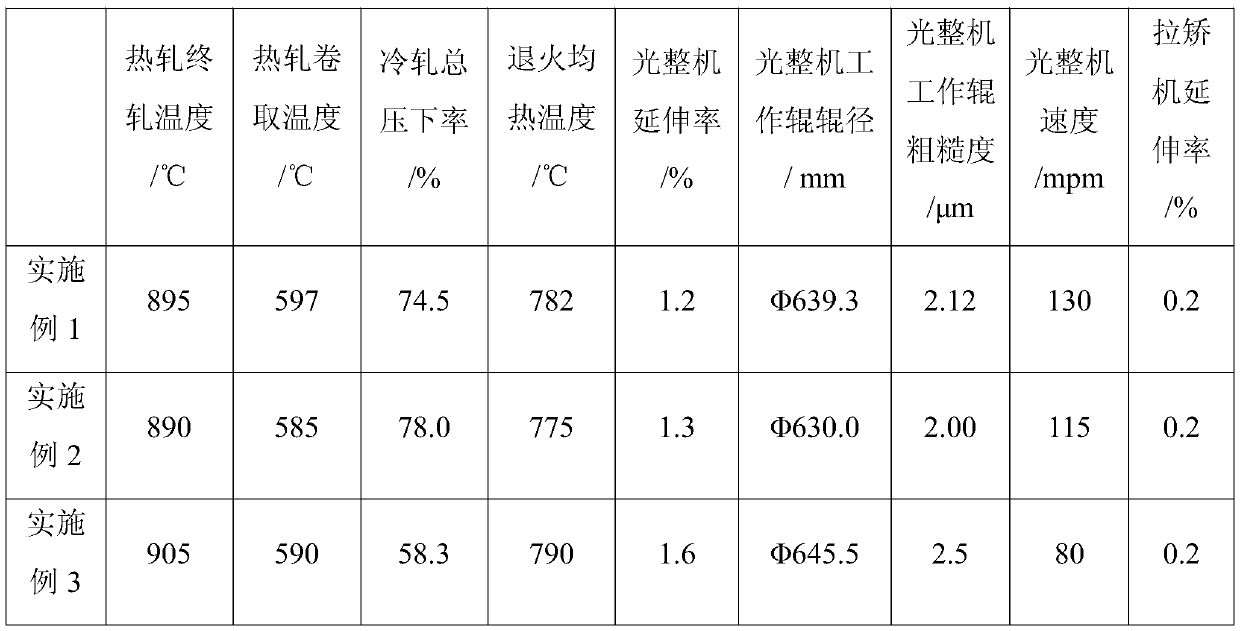

Production method of anti-aging tinning black plate

InactiveCN101643828AUniform mechanical propertiesImprove corrosion resistanceManufacturing convertersSlip lineChemical composition

The invention relates to a production method of an anti-aging tinning black plate with hardness HR30Tm of 55+ / -4 and discloses a production method of an anti-aging tinning black plate. The method comprises the following steps: smelting: adopting KR desulfurization, smelting in a converter, RH vacuum treatment and continuous casting; hot rolling: carrying out the hot rolling of a continuous castingblank comprising the following chemical components in percentage by weight: C: 0.02-0.06, Si: smaller than or equal to 0.025, Mn: smaller than or equal to 0.50, P: smaller than or equal to 0.020, S:smaller than or equal to 0.030, Als: 0.005-0.040, Ti: 0.005-0.020, N: smaller than or equal to 0.005, the balance of Fe and inevitable impurities; and carrying out pickling, cold rolling, electrolyticdegreasing, full-hydrogen bell furnace annealing and leveling of a tinning black plate with hardness HR30Tm of 51-59. The invention has the advantages of small production control difficulty and low cost and hardness value, is beneficial for users to use the anti-aging tinning black plate to manufacture deep drawing cans and can lids with complicated deformation, lessens the canning defects of cracks, crazing slip lines or corded bent surfaces, and the like and improves the canning yield rate and the canning qualified rate.

Owner:WUHAN IRON & STEEL (GROUP) CORP

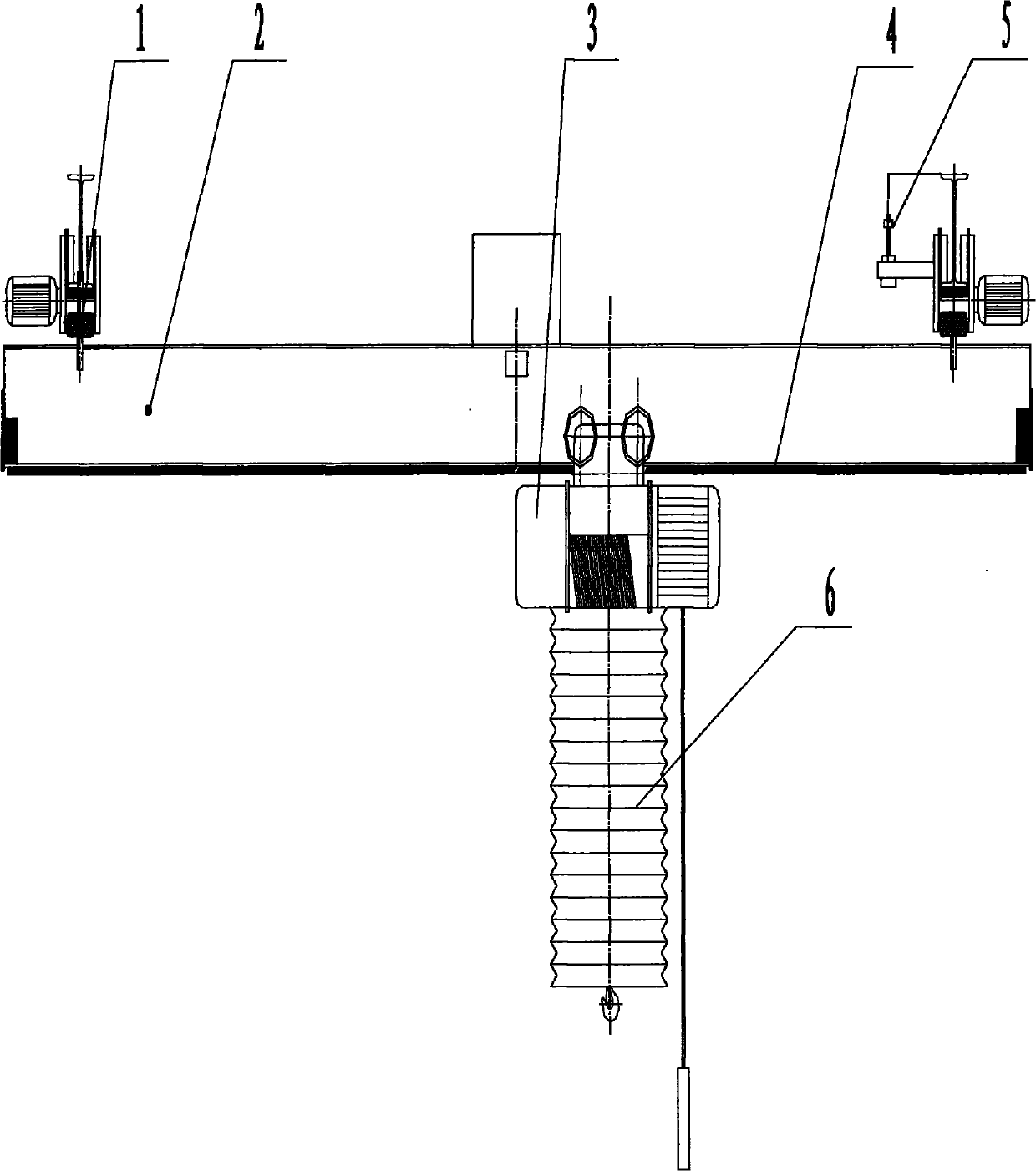

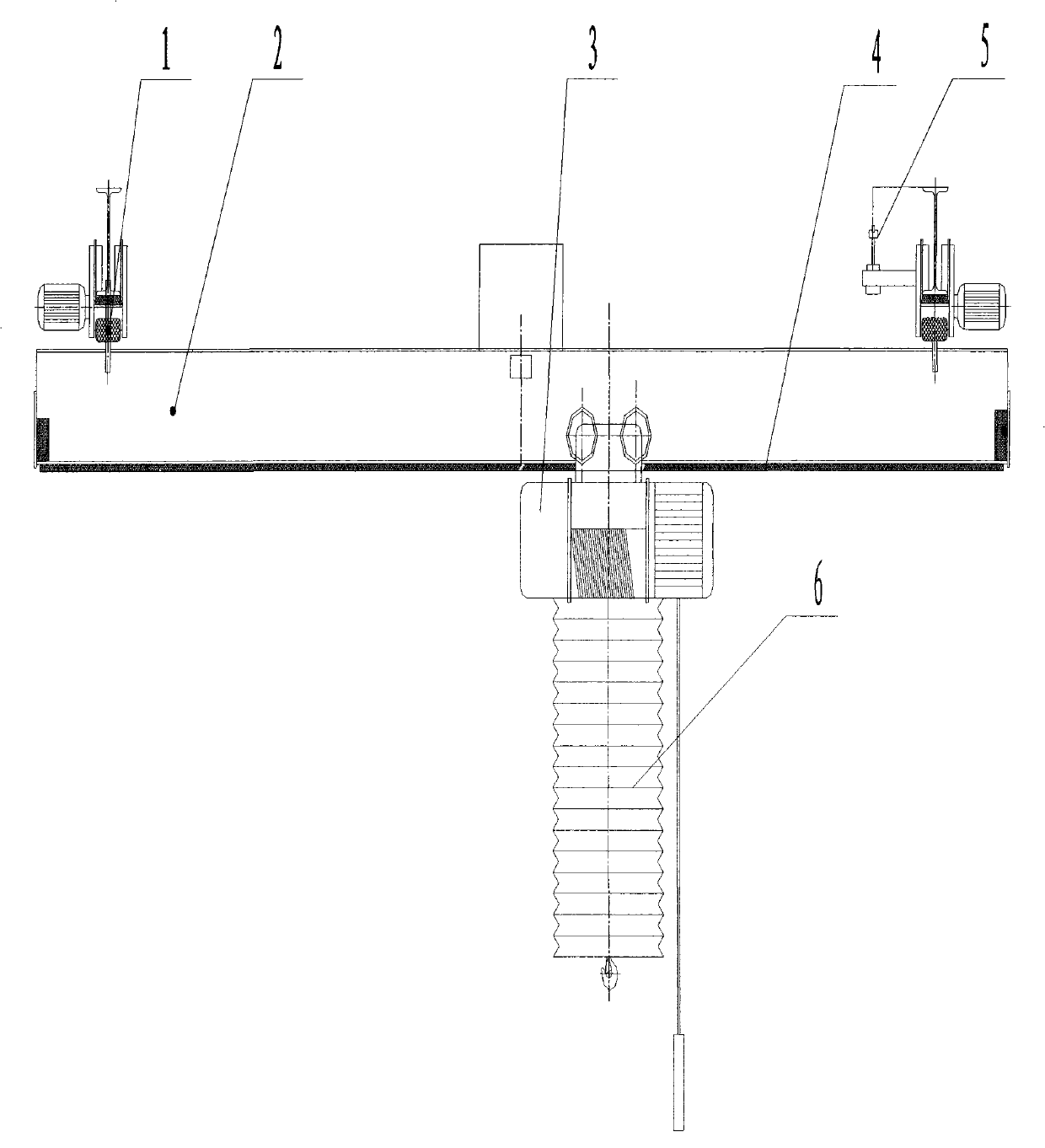

Clean and dust-proof crane

InactiveCN102020205AImprove dustproof effectImprove efficiencyCombination devicesTravelling cranesCycloneSlip line

The invention discloses a clean and dust-proof crane which comprises a crane and a dust remover. The crane comprises a crane cart end beam structure, a main beam, and a trolley; exsertion gears and wheels are both made of dust-free materials such as nylon or hard plastic; the cart end beam structure and the main beam are both made of stainless steel material; wheels of the cart and wheels of the trolley respectively have a dust-proof difference; the lifting steel wire rope is formed of stainless steel wires and the lifting steel wire rope and the pulley are all sealed in a dust-proof cover; a dust-proof safety slip line with a dust-proof device disposed at the lower part is adopted; the turbine fan of the wind-guiding wheel of the dust remover is fixed on the shaft of a motor, and the motor is fixed on a rectangular body by mounting feet; a dust collecting filter is disposed at the lower part of the turbine fan; the whirlwind dust collector includes a multi cyclone unit having a first cyclone and a secondary cyclone disposed outside the first cyclone. The crane has the advantages of excellent dust-proof effect and high efficiency, and is convenient to use.

Owner:CHENGDU WEST TAILI INTELLIGENT EQUIP CO LTD

Method for growing high-resistance thick layer silicon epitaxy on 6-inch heavily As-doped silicon substrate

ActiveCN104851784AInactive doping effect suppressionImprove uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesSlip lineHigh resistance

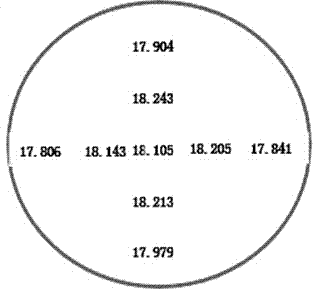

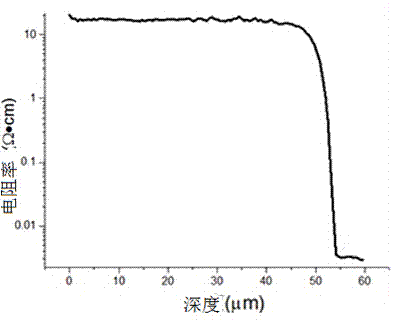

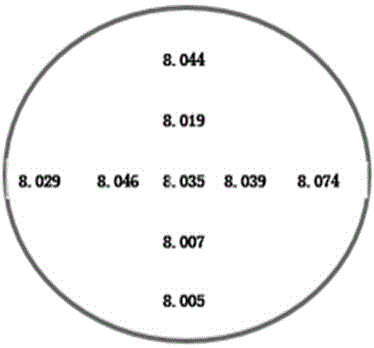

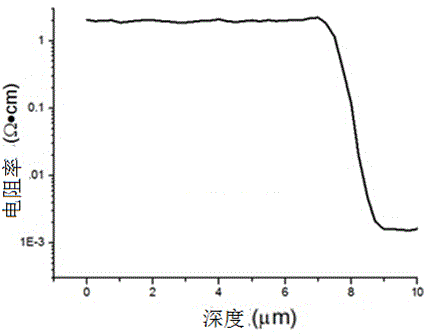

The invention relates to a method for growing a high-resistance thick layer silicon epitaxy on a 6-inch heavily As-doped silicon substrate. In the method, a normal-pressure flat plate type epitaxial furnace is adopted. The method comprises the following steps: (1) corroding an epitaxial furnace base by using hydrogen chloride with the purity of not less than 99.99 percent at a high temperature; (2) loading a silicon substrate sheet in the epitaxial furnace, purging a cavity of the epitaxial furnace for 8-10min by sequentially using nitrogen and hydrogen with purities of not less than 99.99 percent; (3) performing in-situ corrosion on the surface of the silicon substrate sheet by using hydrogen chloride gas; (4) purging the surface of the silicon substrate sheet by large-flow hydrogen; (5) growing an intrinsic epitaxial layer on the substrate by using non-doped trichlorosilane; (6) growing a doped epitaxial layer; and (7) cooling after the epitaxial layer reaches a preset temperature during growing. The method has the beneficial effects of being used for successfully preparing a high-resistance thick layer silicon epitaxy structure with thickness non-uniformity of less than 1 percent and specific resistance non-uniformity of less than 1 percent, without defects of a stacking fault, dislocation, a slip line and fog, with an optimal transition region width of less than 4 micrometers, good uniformity and a narrow transition region, and capable of completely meeting a requirement of a power MOS device on a silicon epitaxial material in an aspect of a parameter.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST +1

Production method of heavily phosphorus-doped thin substrate silicon epitaxial layer for Schottky devices

ActiveCN104947183AInactive doping effect suppressionImprove uniformitySemiconductor/solid-state device manufacturingFrom chemically reactive gasesSlip lineHydrogen

The invention relates to a production method of a heavily phosphorus-doped thin substrate silicon epitaxial layer for Schottky devices. The method adopts a normal-pressure flat plate type epitaxial furnace, and comprises the following steps: 1, polishing the pedestal of the epitaxial furnace at a high temperature by using hydrogen chloride with the purity being not lower than 99.99%; 2, filling the epitaxial furnace with a phosphorus-doped silicon substrate slice, and sequentially purging the cavity of the epitaxial furnace by nitrogen and hydrogen, wherein the purities of nitrogen and hydrogen are not lower than 99.999% respectively; 3, polishing the surface of the silicon substrate slice by using a hydrogen chloride gas; 4, purging the surface of the silicon substrate slice by using a bulk flow of hydrogen; 5, growing an intrinsic epitaxial layer; 6, carrying out variable flow purging on the reaction cavity of the epitaxial furnace; and 7, growing a doped epitaxial layer. The thickness inhomogeneity of the epitaxial layer is smaller than 1%, the resistivity inhomogeneity of the epitaxial layer is smaller than 1%, the surface of the epitaxial layer has no stacking fault, dislocation, slip lines, mist or other defects, the width of a transition region under optimum conditions can be smaller than 1[mu]m, and requirements of the silicon epitaxial layer by the Schottky devices can be completely met, so the performances and the yield of the Schottky devices are improved.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST +1

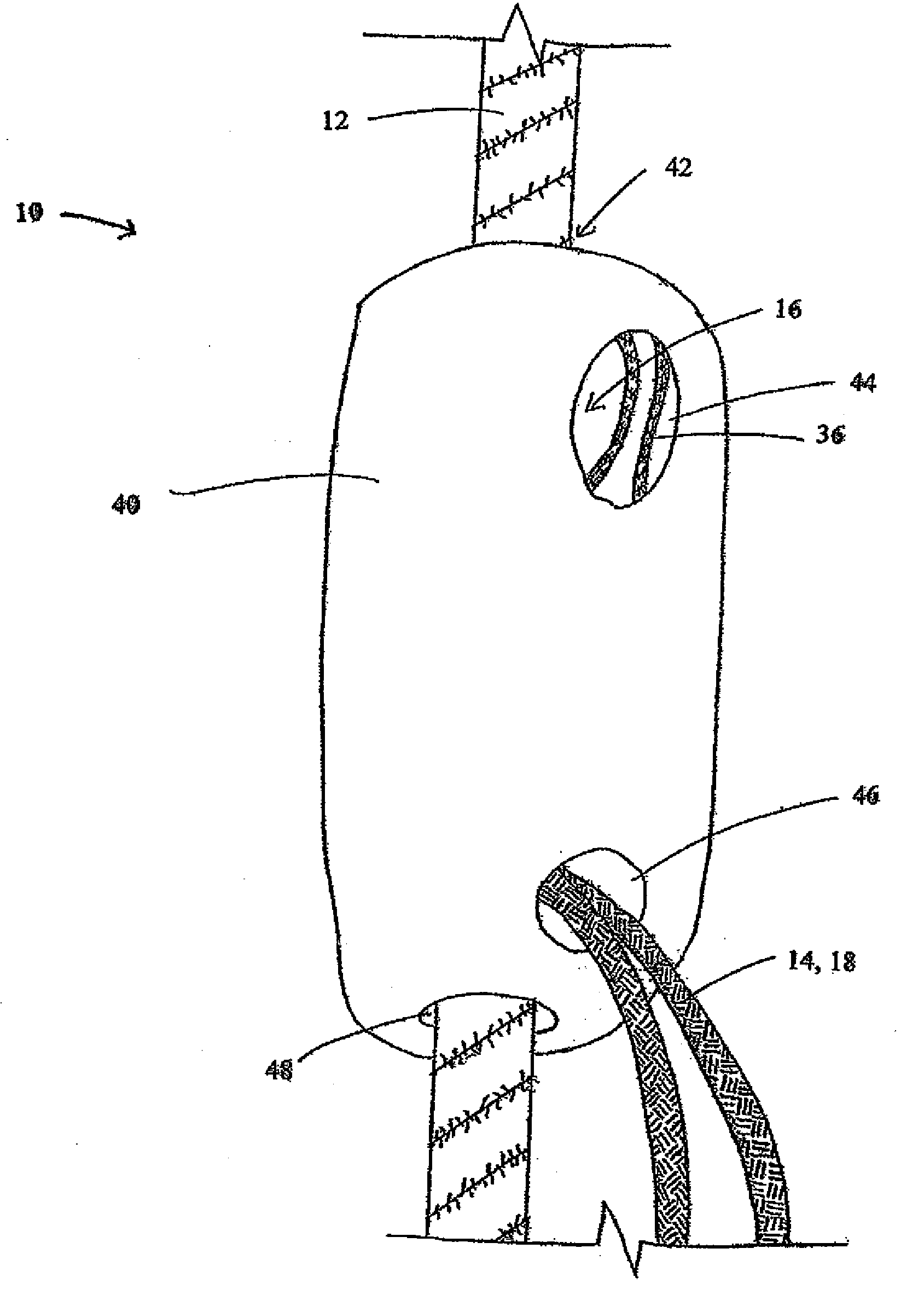

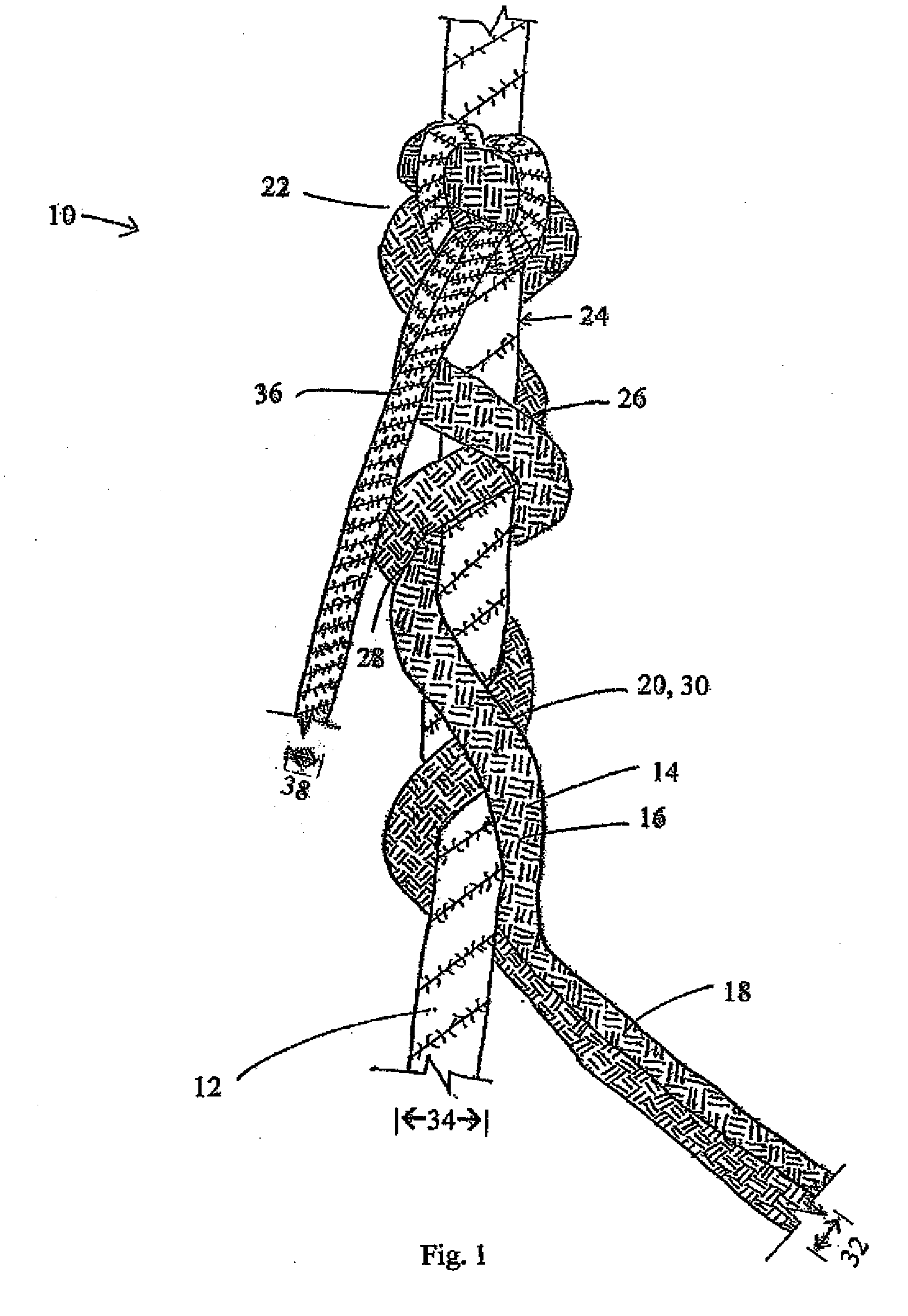

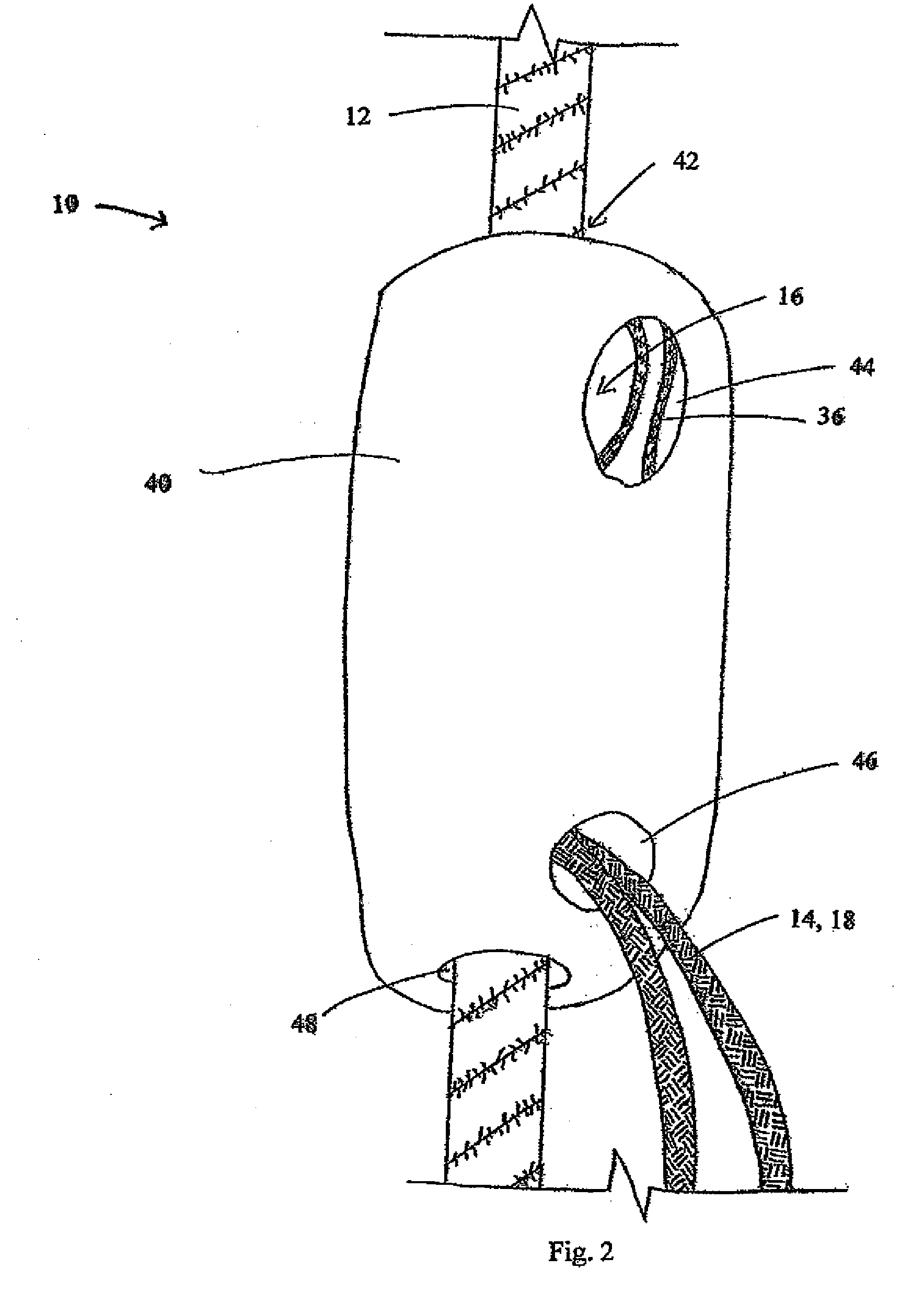

Fall Protection Apparatus with Controlled Descent

A fall protection apparatus is described which allows for a user to effectuate a controlled descent after a fall has been arrested. The apparatus includes a tether line secured above a protected position of the user and a cinch line which frictionally engages the tether. The cinch line is attached to the user, and when the user falls, the frictional engagement of the cinch line and the tether line increase and arrests the fall. The user then pulls on a slip line attached to the cinch line to descend. Pulling on the slip line decreases the frictional engagement of the cinch line and the tether line so the user can control their descent rate based on how hard they pull on the slip line.

Owner:THE HUNTER SAFETY SYST

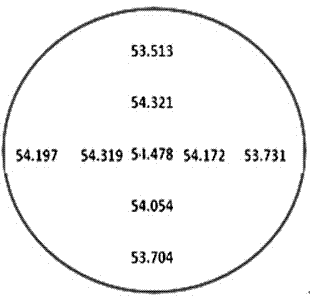

Method for preparing thick epitaxial layer on thin sb substrate for VDMOS device

ActiveCN106128938AImprove processing yieldPromotes epitaxial growthSemiconductor/solid-state device manufacturingSlip lineHydrogen

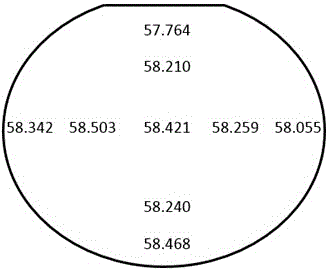

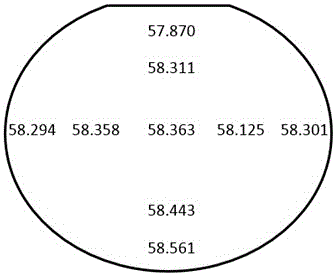

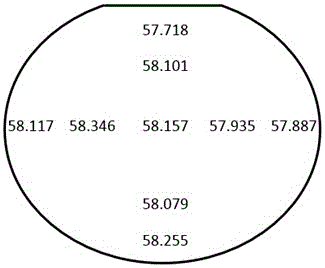

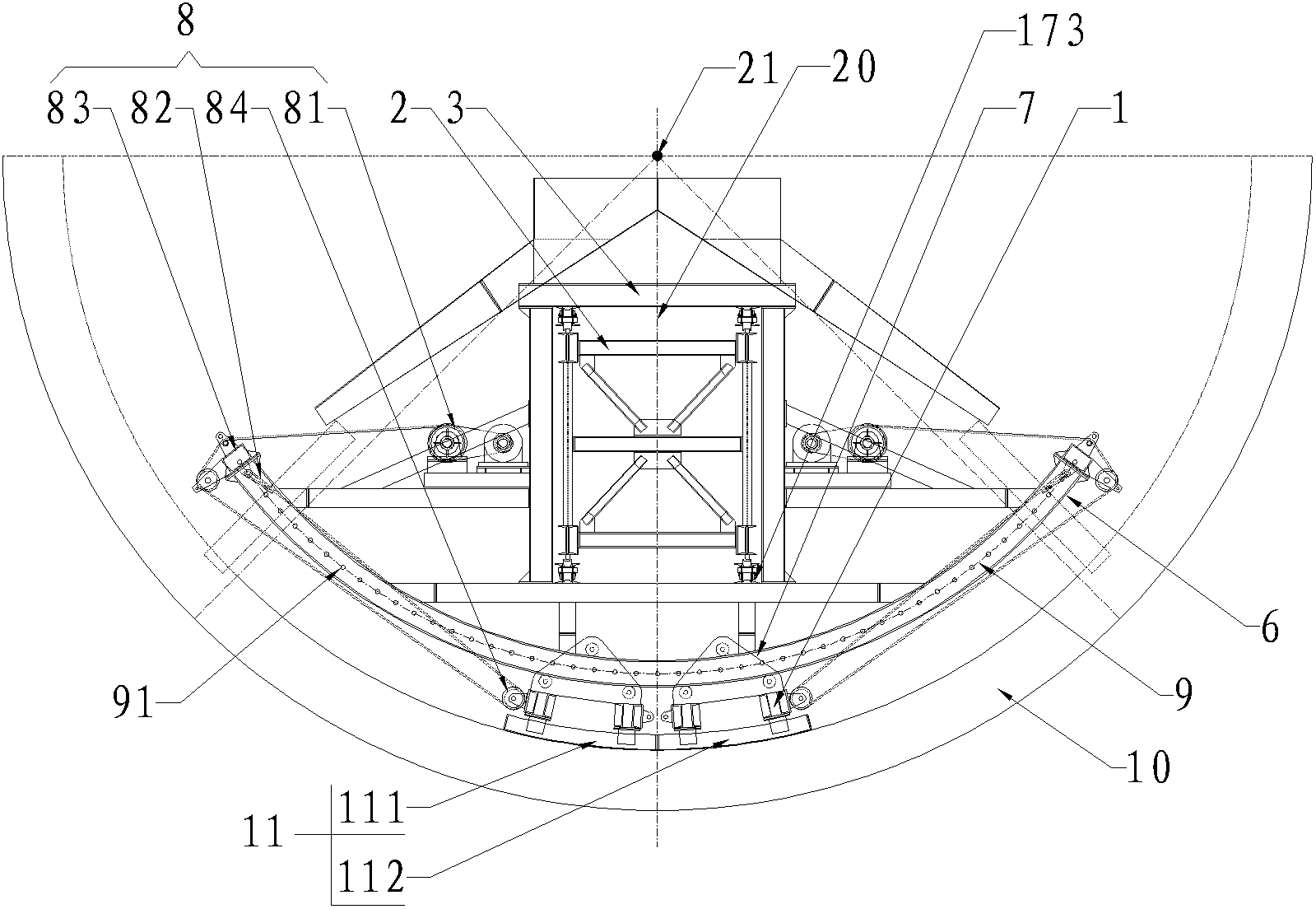

The invention relates to a method for preparing a thick epitaxial layer on a thin sb substrate for a VDMOS device. The method comprises: scale values of nine groups of adjusting rods arranged below a graphite pedestal of an epitaxial furnace are set respectively; the epitaxial furnace pedestal is processed by etching and polishing by using hydrogen chloride HC1 gas under a high temperature; a silicon substrate sheet is installed in a pit of the epitaxial furnace pedestal and the surface of the silicon substrate is polished by using the HC1 gas; sweeping is carried out on the surface of the silicon substrate sheet by using high-flow hydrogen; a thin intrinsic epitaxial layer grows on the silicon substrate sheet; a doped epitaxial layer grows; after the thickens of the doped epitaxial layer reaches a predetermined thickness, cooling is carried out; and then thicknesses of nine testing points of the epitaxial wafer are measured, thereby obtaining an average thickness value and a uniformity value of a silicon epitaxial wafer. Therefore, good control of epitaxial growth of the thin 400-micron sb substrate is realized; the nonuniformity of the thickness is less than 0.5%; defects of slip line, edge breakage, and damage existence at the edge are overcome; and the requirements on the silicon epitaxial layer of the VDMOS device are met; and the processing yield of the device is improved.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST +1

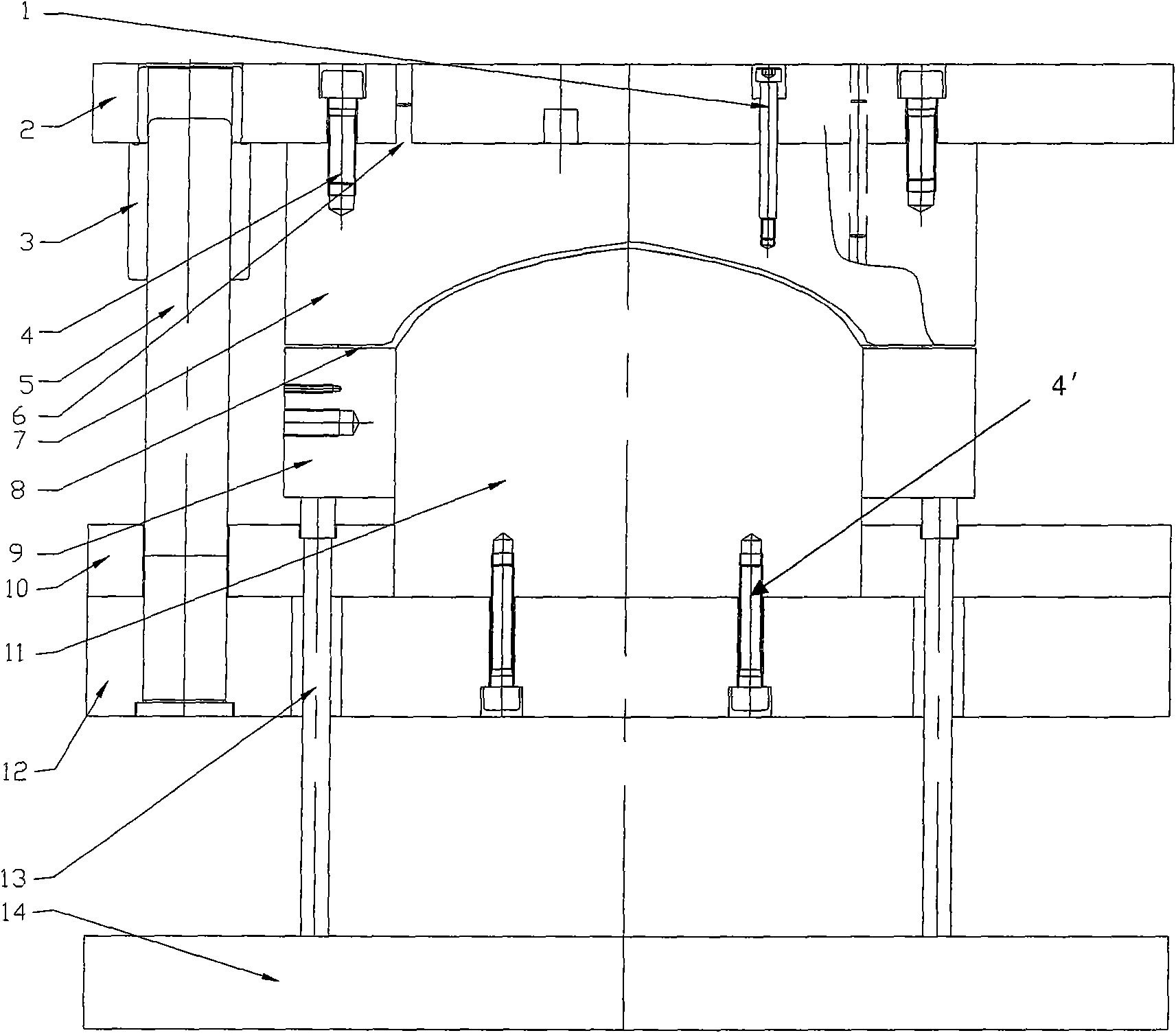

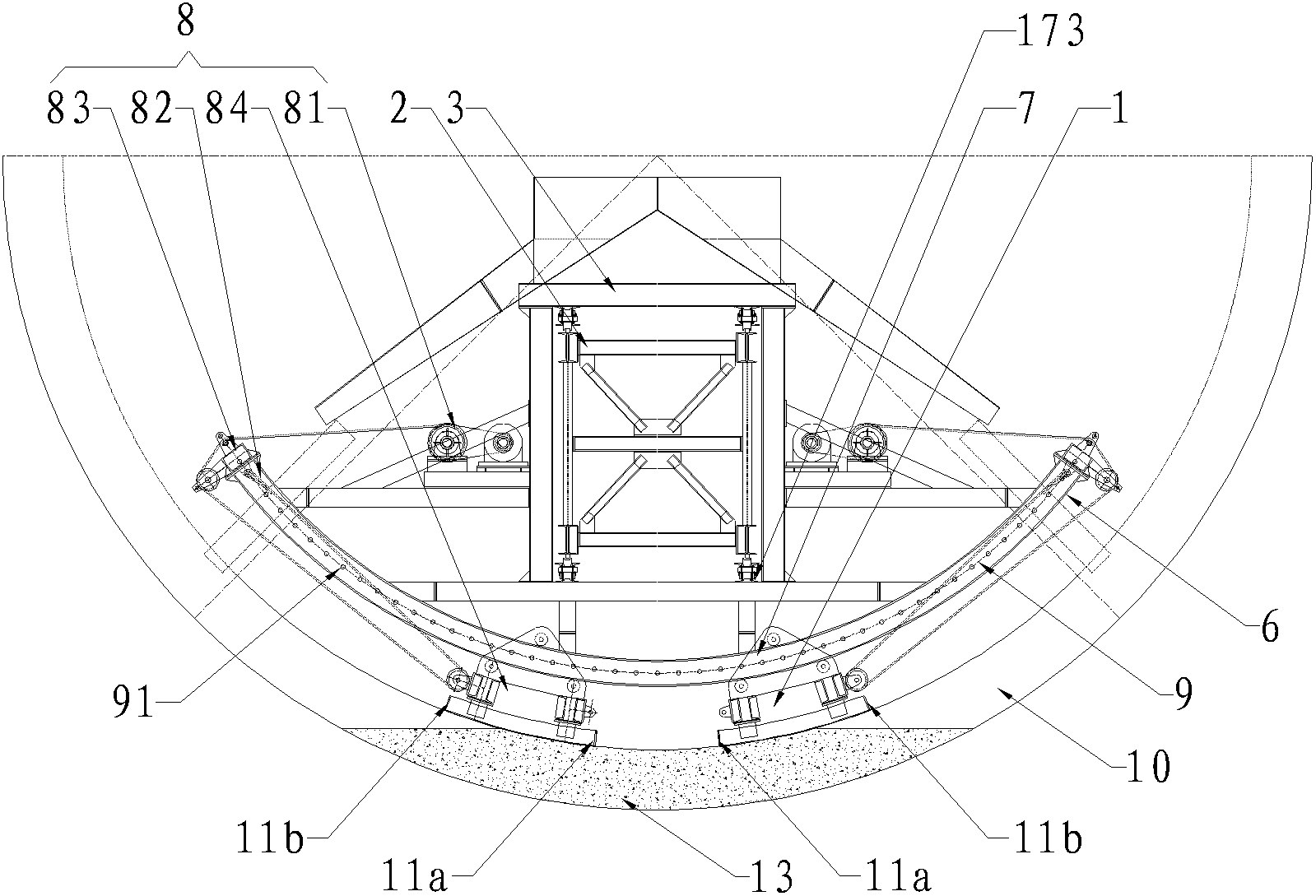

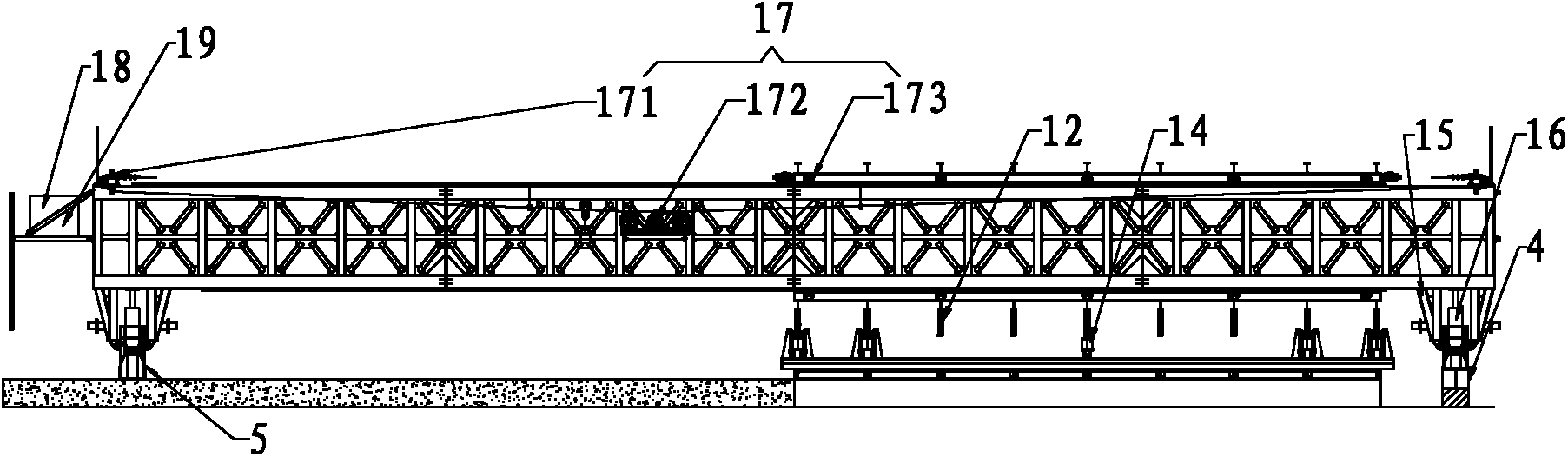

Tunnel bottom concrete side-slipping lining construction method and side-slipping needle beam bottom board trolley

InactiveCN102434171AEasy dischargeImprove construction conditionsUnderground chambersTunnel liningSlip lineTraction system

The invention discloses a tunnel bottom concrete side-slipping lining construction method capable of overcoming the bubble defect and a side-slipping needle beam bottom board trolley. The method sequentially comprises construction steps of in-position of a formwork group, side-slipping pouring of concrete and longitudinal movement of the trolley. Guiding tracks matched with designed linear dimension of a tunnel construction face are respectively and fixedly connected in front of and on the back of the lower portion of a beam frame assembly of the side-slipping needle beam bottom board trolley. The formwork group consists of a pair of slide formworks, the pair of slide formworks is symmetrical with a vertical face where the central line of a beam frame is located and is respectively connected with the guiding tracks through a sliding guide mechanism, and the sliding guide mechanism is connected with the beam frame assembly through a side-slipping traction system. The tunnel bottom concrete side-slipping lining construction method is capable of overcoming the defects of bubbles on the surface of concrete, overlap-joint slab staggering of new and old concrete, temperature cracking and the like, has the advantages of being reliable in structure, quick in lining speed, good in construction quality and safe in construction, reducing interference of construction conditions and the like, and is mainly used for side-slipping lining construction of tunnel bottom concrete.

Owner:广汉金达隧道机械有限公司

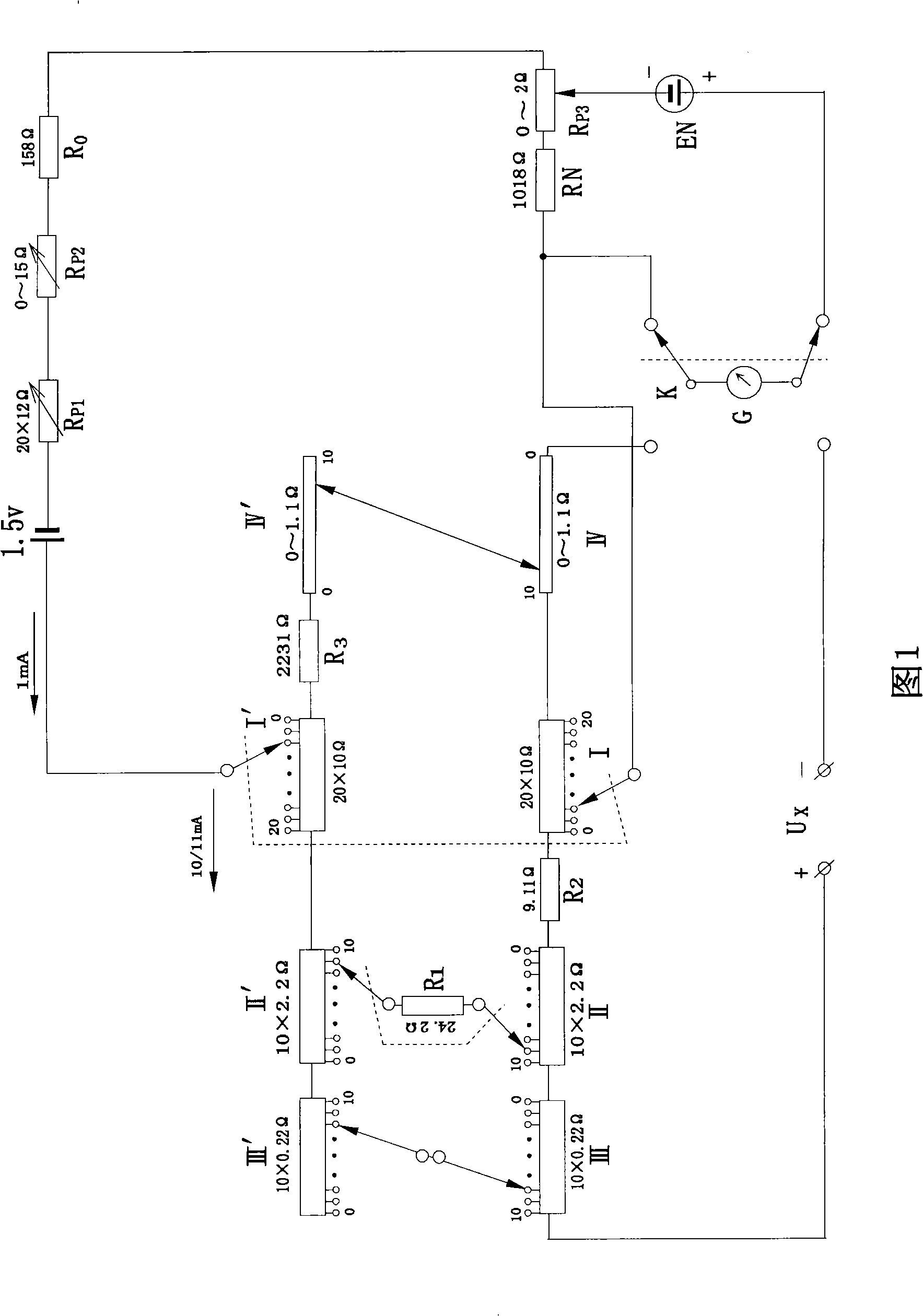

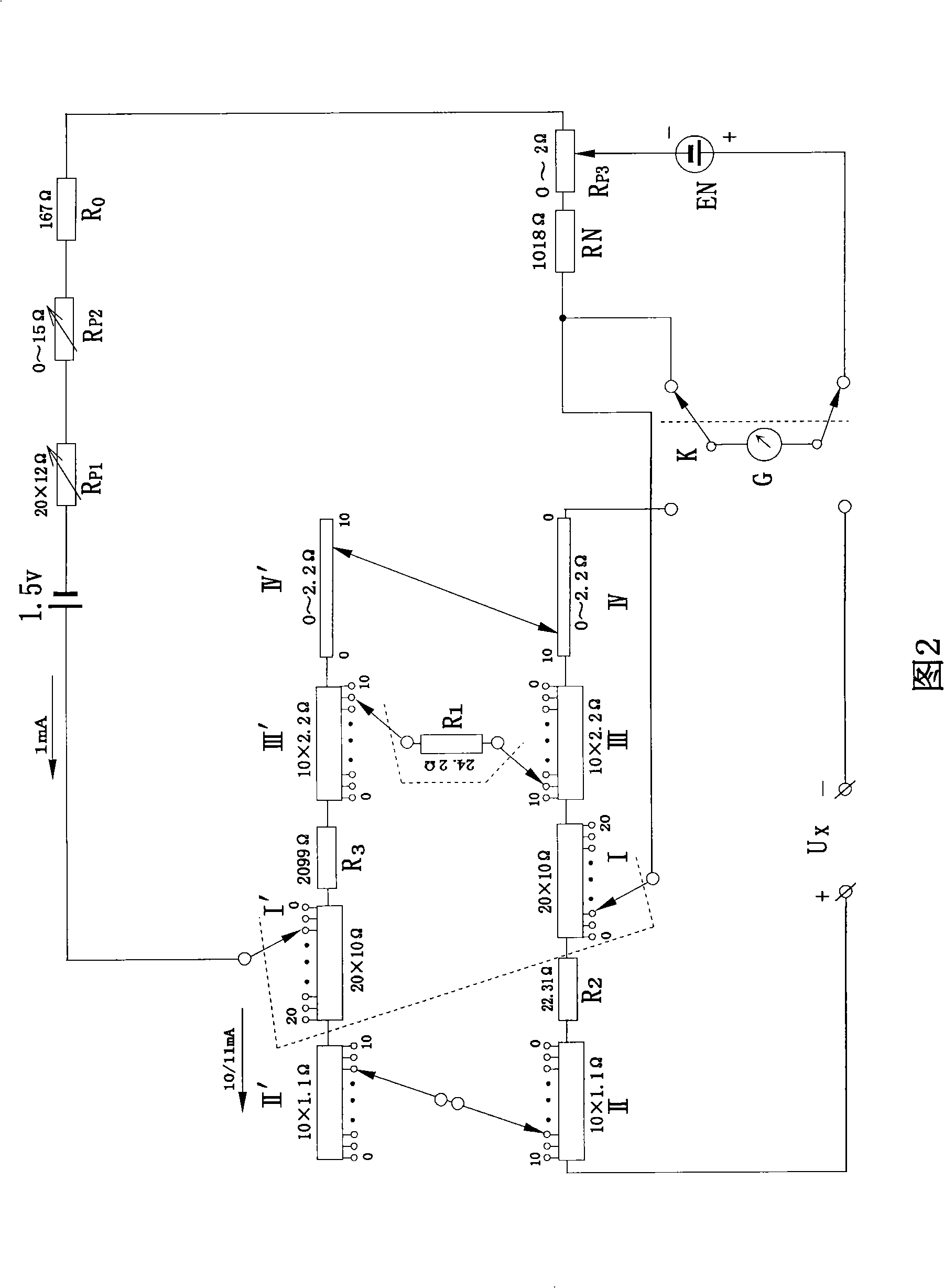

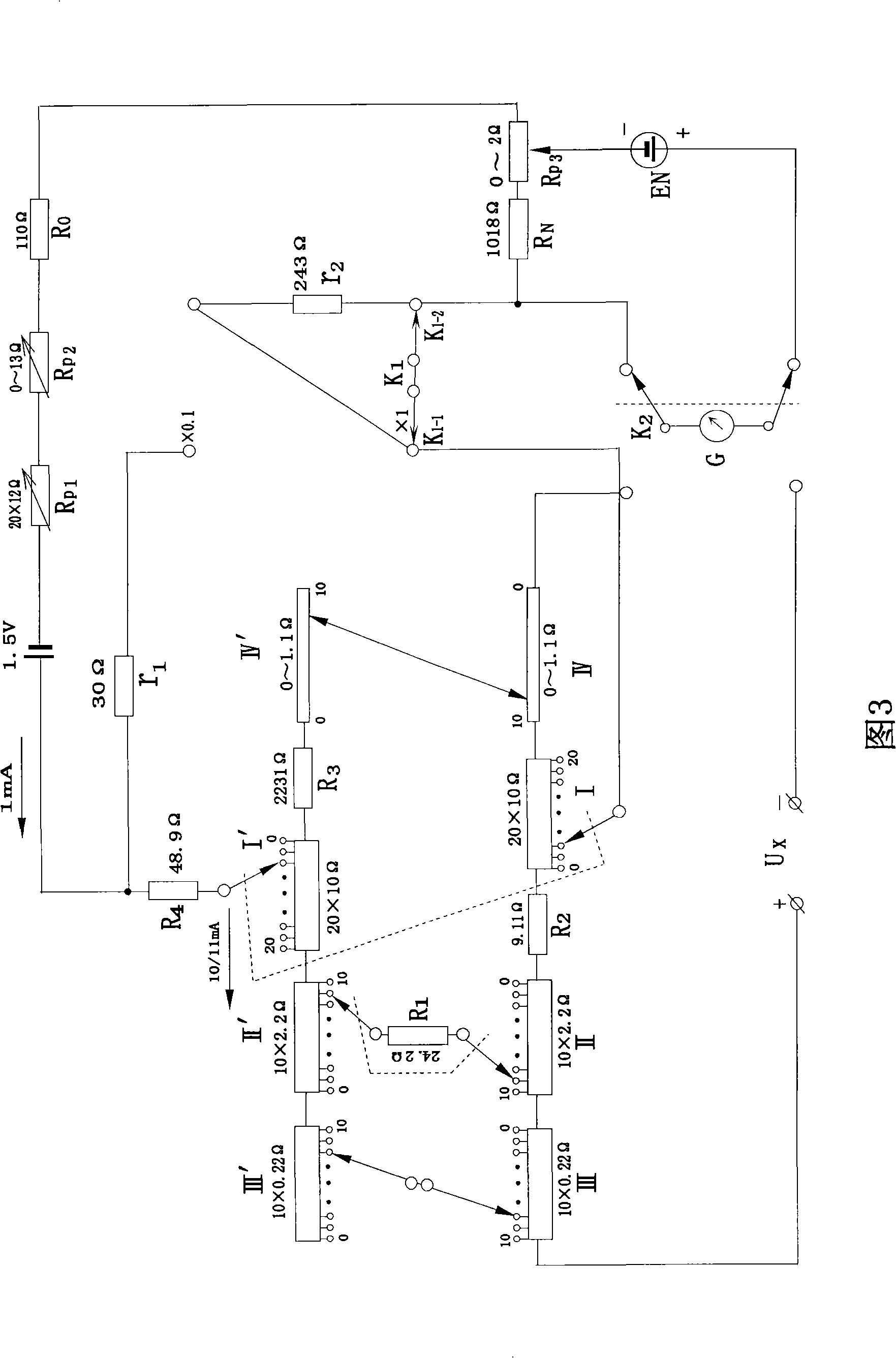

Potential difference meter using sliding disk

InactiveCN101359002ASimple structureReduce volumeCurrent/voltage measurementAc/dc potentiometric measuring arrangementsSlip lineElectrical resistance and conductance

The present invention relates to a potentiometer, which is used for measuring the DC voltage and adopts the slip-line disc. The potentiometer consists of three stepping discs and a double-slip-line disc; the four discs all consist of a measuring disc and a replacing disc, which have the same resistance value; the working current is divided into two branches of 10 to 1 between two electrical brushes of the first stepping disc; two branches of the same current are formed in the branch with two parallel discs; the electrical brushes of the other measuring discs except the first stepping disc are connected with the electrical disc of the replacing disc through resistances or wires; each stepping disc or the double-slip-line disc has no auxiliary disc; therefore, the volume of the device is reduced, the manufacturing cost of the device is reduced, simultaneously the four measuring discs are connected through wires, and the influence of the variation and the thermoemf is eliminated.

Owner:程军

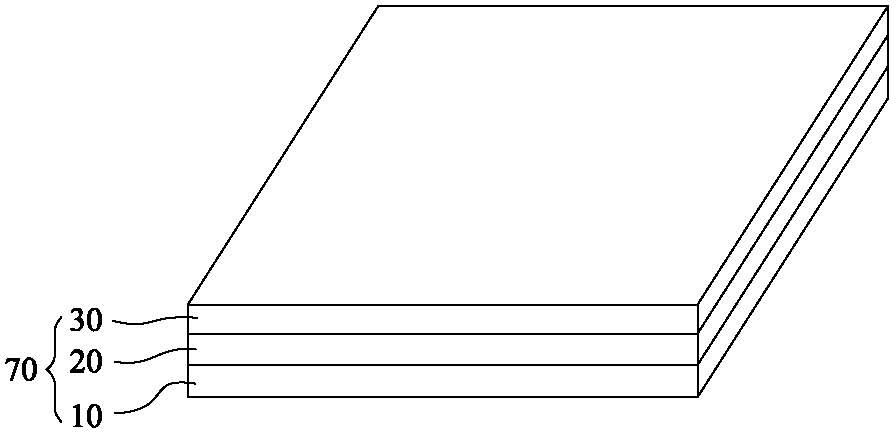

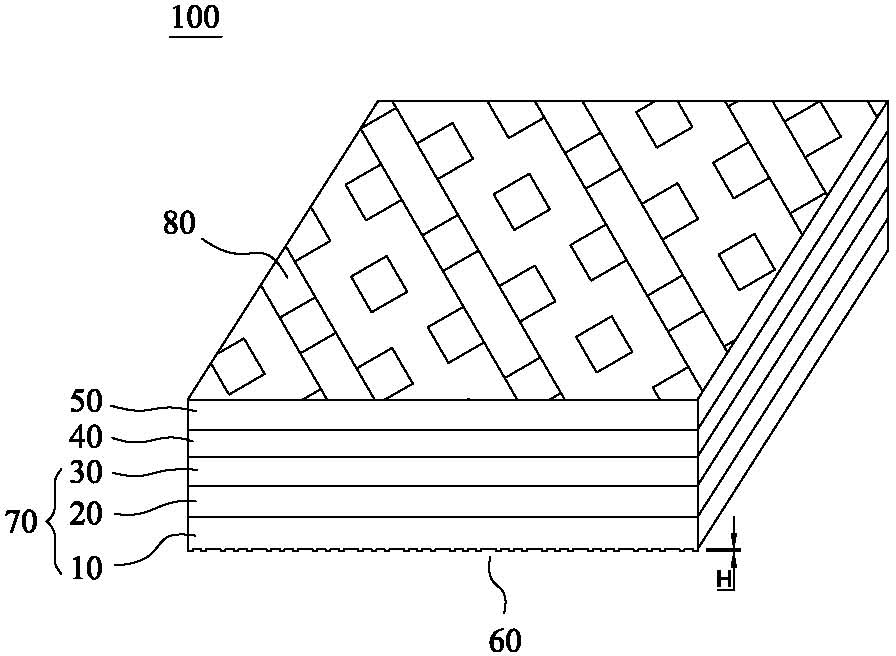

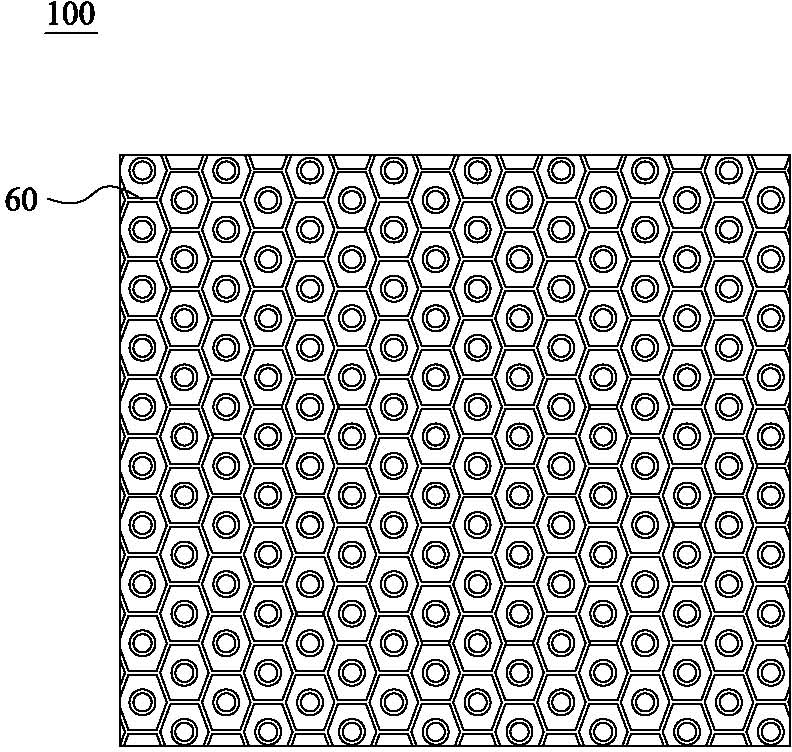

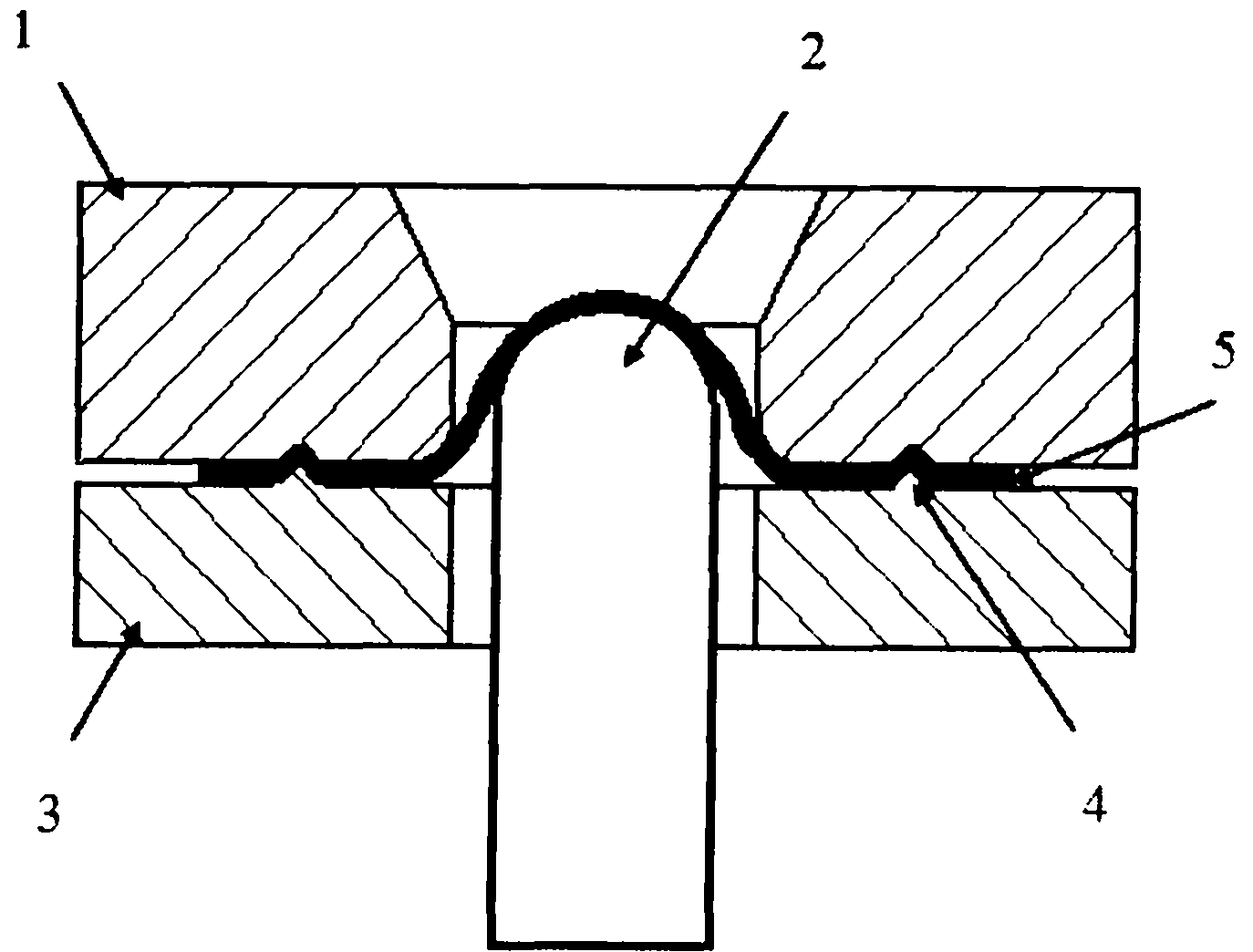

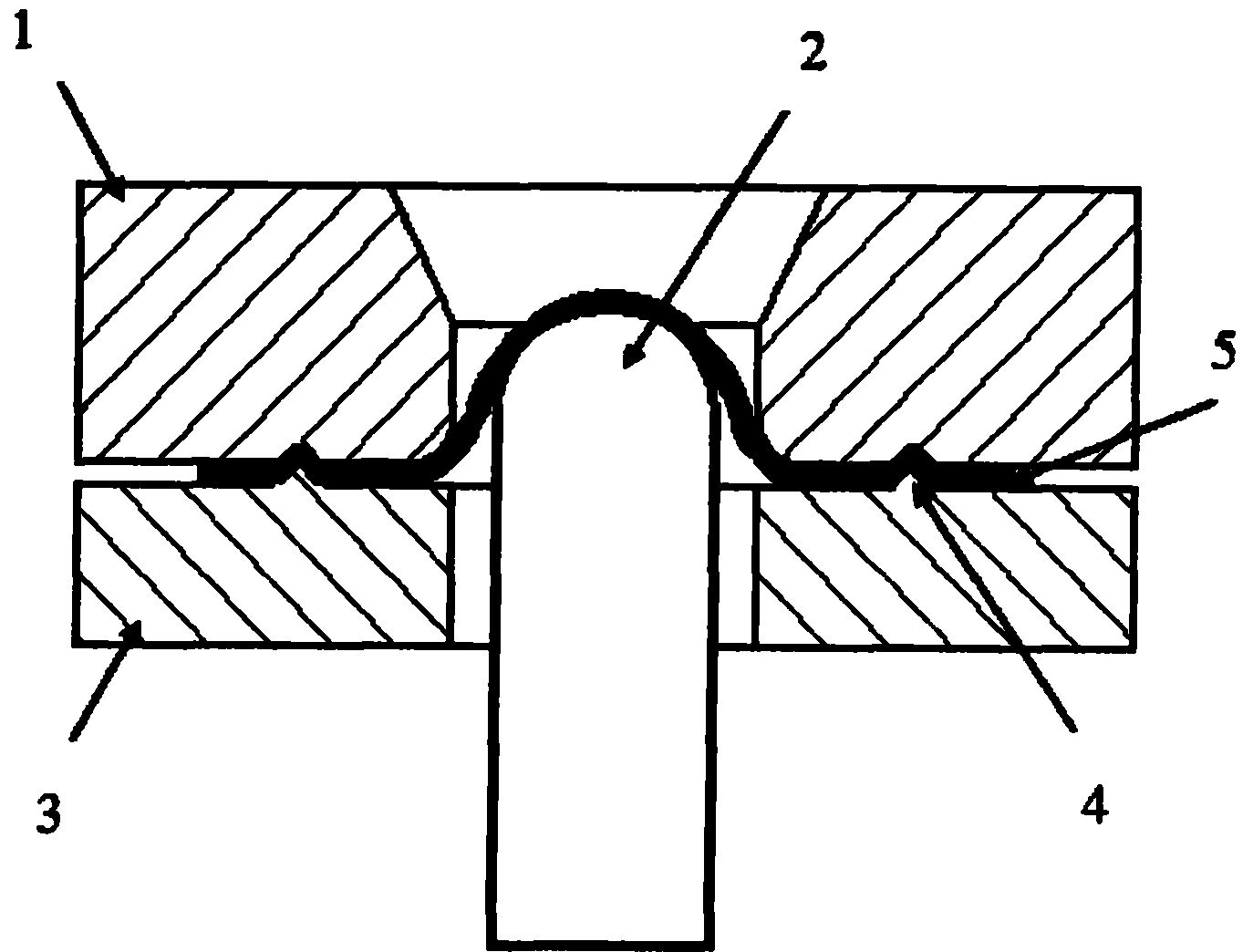

Glue-free PVC (polyvinyl chloride) limited slip floor tile of ring structure and preparation method thereof

ActiveCN102561657AImprove anti-slip performanceRemove security concernsFlooringSlip lineSlip coefficient

The invention discloses a glue-free PVC (polyvinyl chloride) limited slip floor tile of a ring structure and a preparation method thereof. as for the limited slip floor tile, a flexible thermocompression line is formed on the bottom surface of a PVC limited slip layer in a thermocompression manner; the thermocompression line comprises a plurality of seal hexagon protruding ribs which are continuously and repetitively connected and seal round protruding ribs which are positioned in each hexagon protruding rib; the material formulation of the PVC limited slip layer comprises the following components by weight: 58.5%-63.5% of PVC with polymerization degree of 1000, 34.9-39% of plasticizing agent, 0.95%-2.1% of stabilizing agent, 0.5%-0.69% of toner, and 0.06%-0.08% of calcium carbonate of 800 molybdenum; and the required softness obtained by using particular formulation dosage of the limited slip layer is combined with the limited slip line which is composed of non-hexagon of particular size and shape and the round protruding ribs to enable the limited slip coefficient to be more than 1.5, thereby overcoming the bottle neck of improving the limited slip performance in the industry of plastic floor tiles.

Owner:DONGGUAN PULONG PLASTIC PRODS

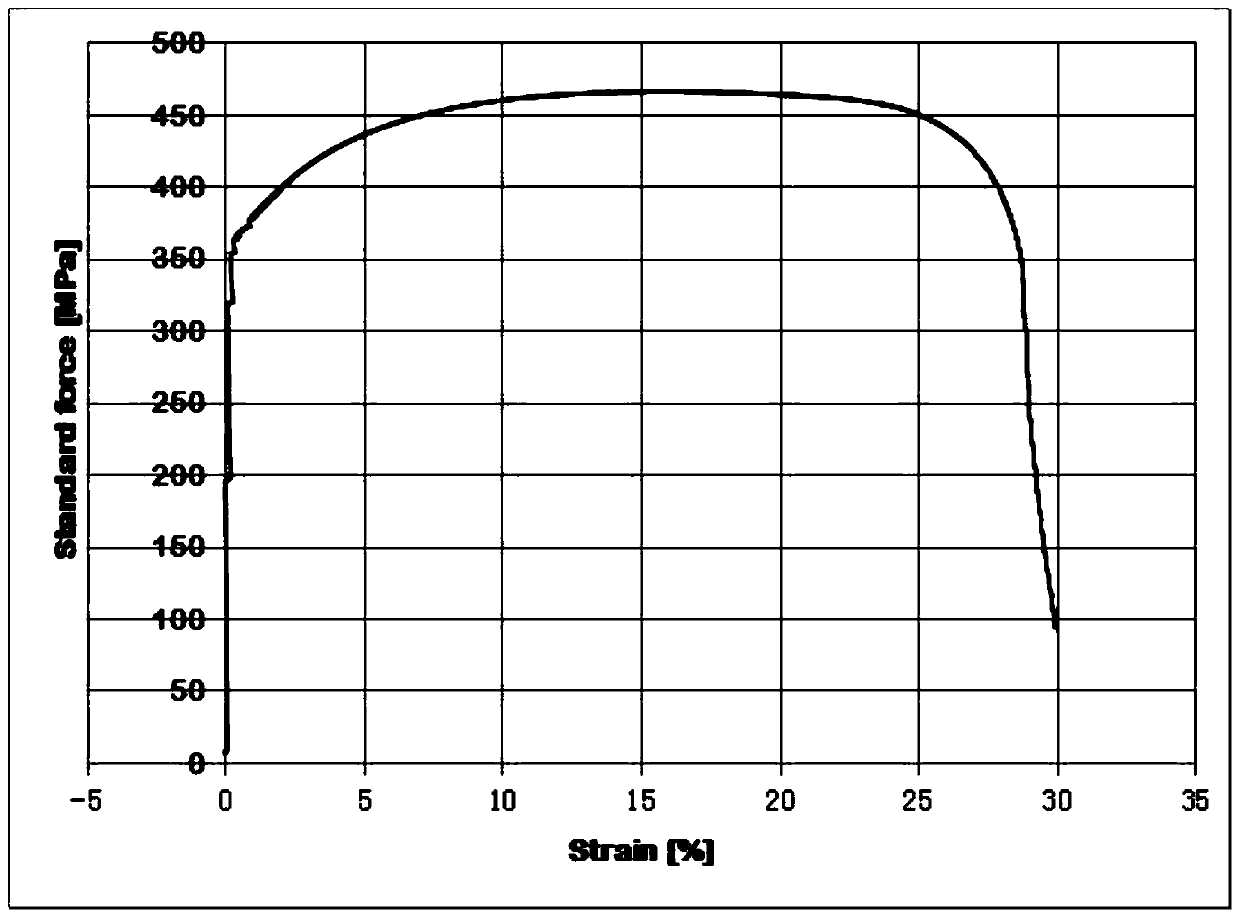

Production method of hot-galvanized low-alloy high strength steel having no yield point elongation and used for automobile sheets

The invention relates to a production method of hot-galvanized low-alloy high strength steel having no yield point elongation and used for automobile sheets. The production method comprises smelting,continuous casting, hot rolling, acid continuous rolling and hot galvanizing procedures. The steel comprises chemical components in percentage by mass as follows: 0.060%-0.090% of C, smaller than or equal to 0.05% of Si, 0.65%-0.75% of Mn, 0.015%-0.025% of P, smaller than or equal to 0.010% of S, 0.025%-0.06% of Als, 0.025%-0.035% of Nb, smaller than or equal to 0.0040% of N and the balance Fe andinevitable impurities. By reasonable component design and control on key process parameters such as hot rolling coiling temperature and finishing elongation, dislocation gets rid of the effect of solute atom (Cottrell) anchoring, the yield point elongation can be completely eliminated, slip line defects in the re-machining forming process are avoided, the final surface quality of the product is improved, and the steel has excellent mechanical properties.

Owner:SD STEEL RIZHAO CO LTD

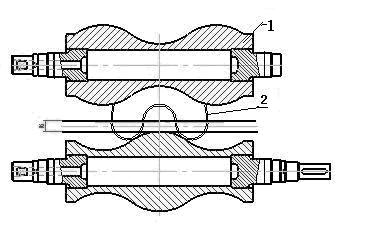

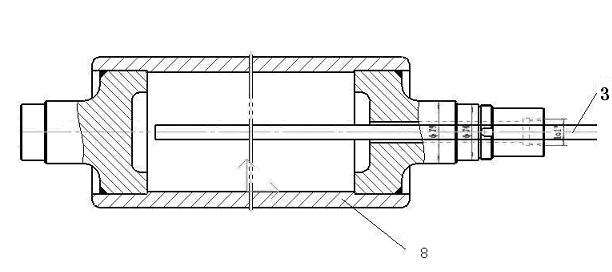

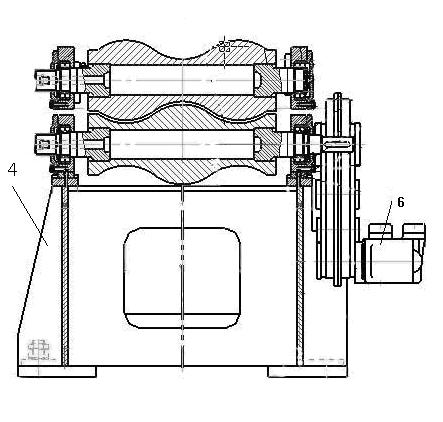

Process and device for flattening W-like arc-shaped magnesium alloy blank plate

InactiveCN102430575AFlattened implementationLess investmentRollsMetal rolling arrangementsSlip lineNonferrous metal

The invention relates to the technical field of processing of novel nonferrous metal materials and discloses a process and device for flattening a W-like arc-shaped magnesium alloy blank plate. The process comprises the following step of: successively flattening the W-like arc-shaped plate for three times: (1) carrying out broadening by adopting a W-like gap constituted by two corresponding concave and convex arc-shaped rollers of an arc roller flattening machine; (2) obtaining a smooth magnesium alloy plate by adopting a five-roller flattening machine; and (3) carrying out smoothing and warm rolling with 5% of rolling reduction by adopting a finishing flattening machine to eliminate an extrusion slip line and obtaining a magnesium alloy plate surface with the thickness of 2mm-4mm and the broad width of 620mm by flattening. The device comprises a preliminary flattening machine, a flat plate flattening machine, the finishing flattening machine and a synchronous control system which are arranged along a discharge axial line of the magnesium alloy plate at an outlet of an extruding machine. According to the process and the device disclosed by the invention, a semi-finished product, namely the W-like arc-shaped magnesium alloy blank plate which is produced by a small-tonnage extruding machine, can be flattened, the purpose of increasing the breadth can be achieved by flattening the curved surface, and the flattening of the W-like arc-shaped magnesium alloy blank plate is realized. The process and the device disclosed by the invention have the characteristics of optimized process, reasonable equipment and low investment.

Owner:李跃华

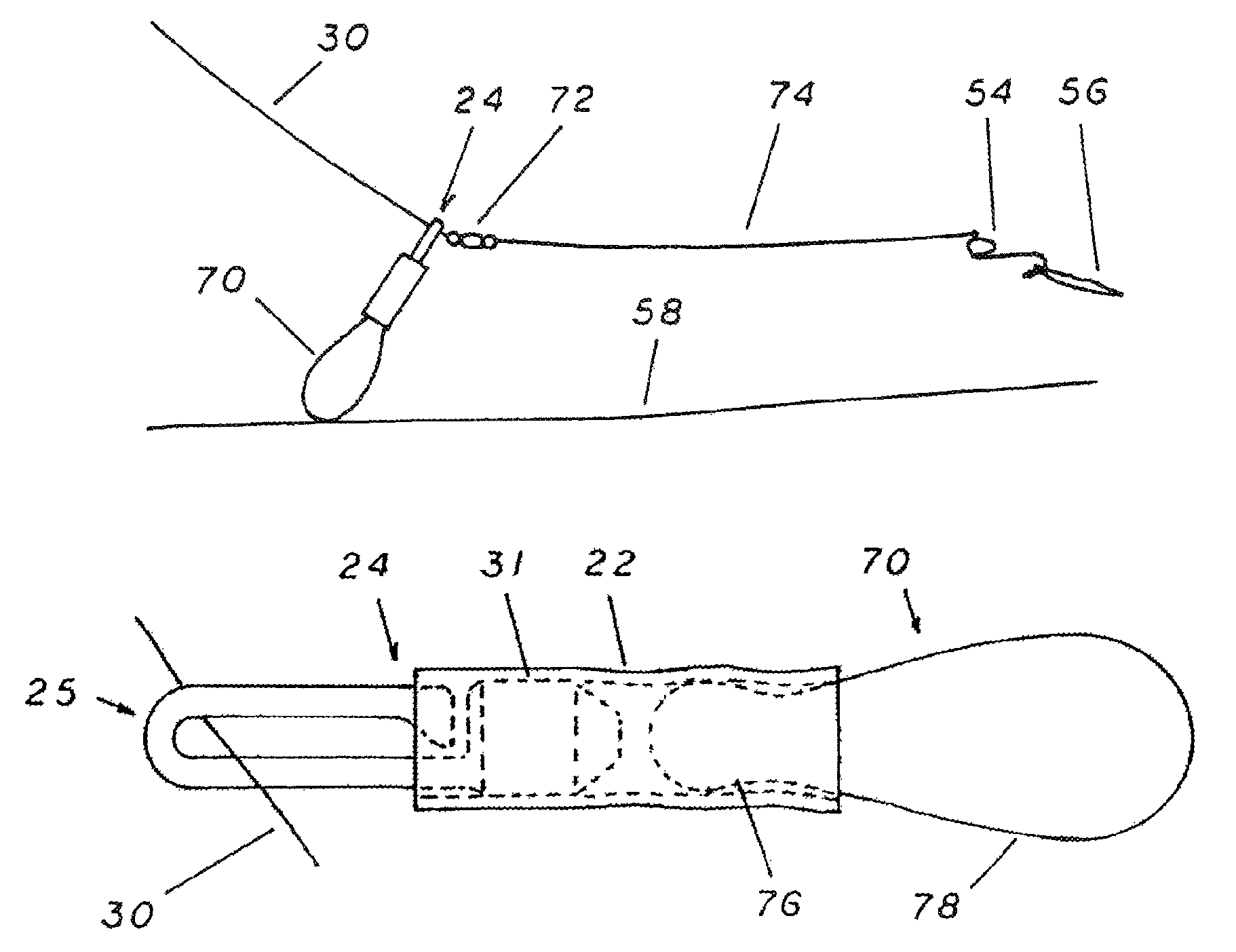

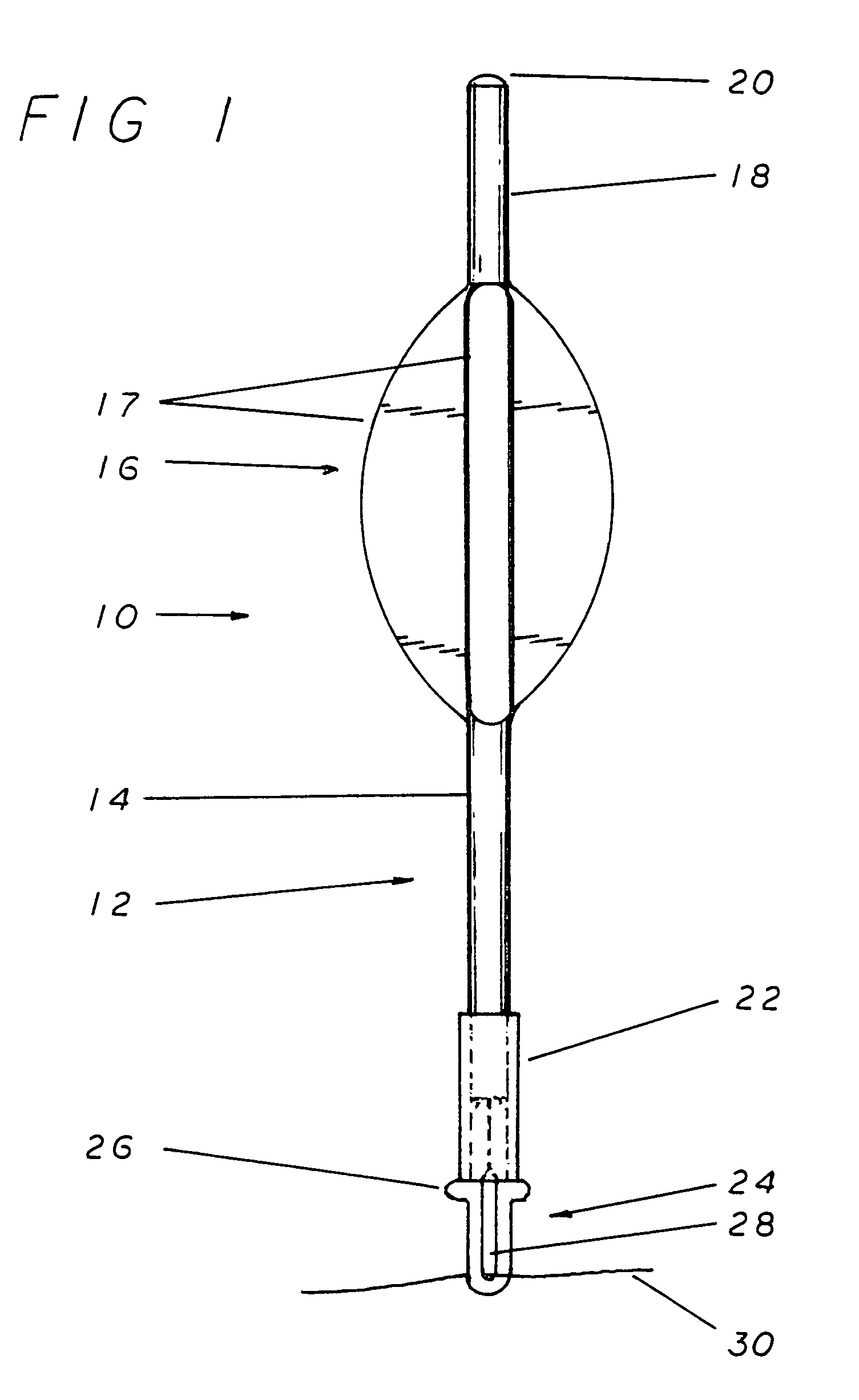

Slip line apparatus for fishing float

InactiveUS7832139B1Easily and quickly attachedEasy to removeLinesOther angling devicesSlip lineEngineering

A slip clip line apparatus designed for use with fishing floats and sinkers to aid in their attachment to a fishing line. The slip clip has a slip body which engages the fishing line and allows the slip clip to slide freely along a predetermined length of fishing line. The slip body is a U-shaped apparatus having an open and centrally located line slip which is substantially closed. The slip clip further has a lower insertion body which may be connected to a piece of tubing that in turn may be connected to a float or a sinker.

Owner:CHRISTENSEN EVERETT B

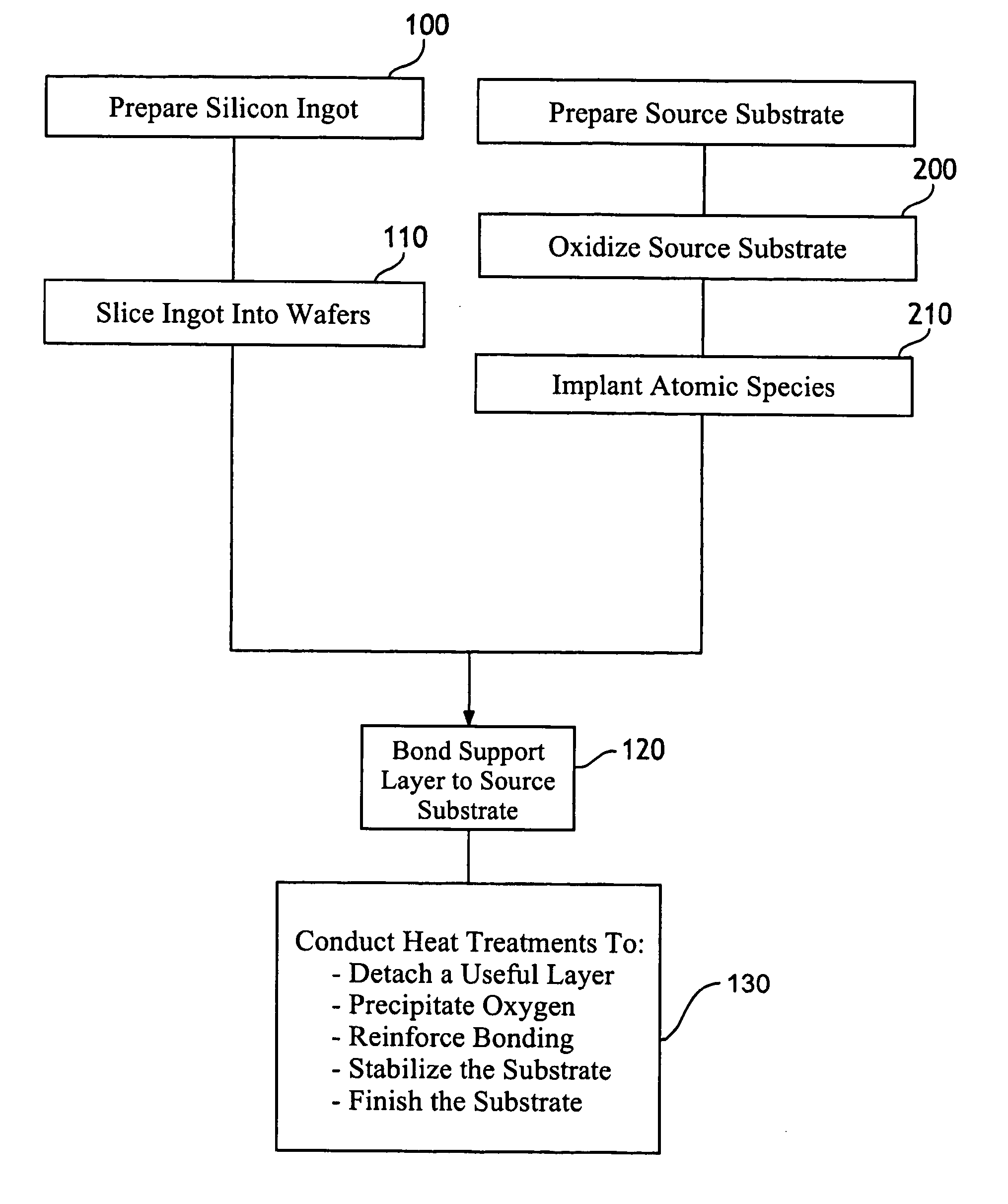

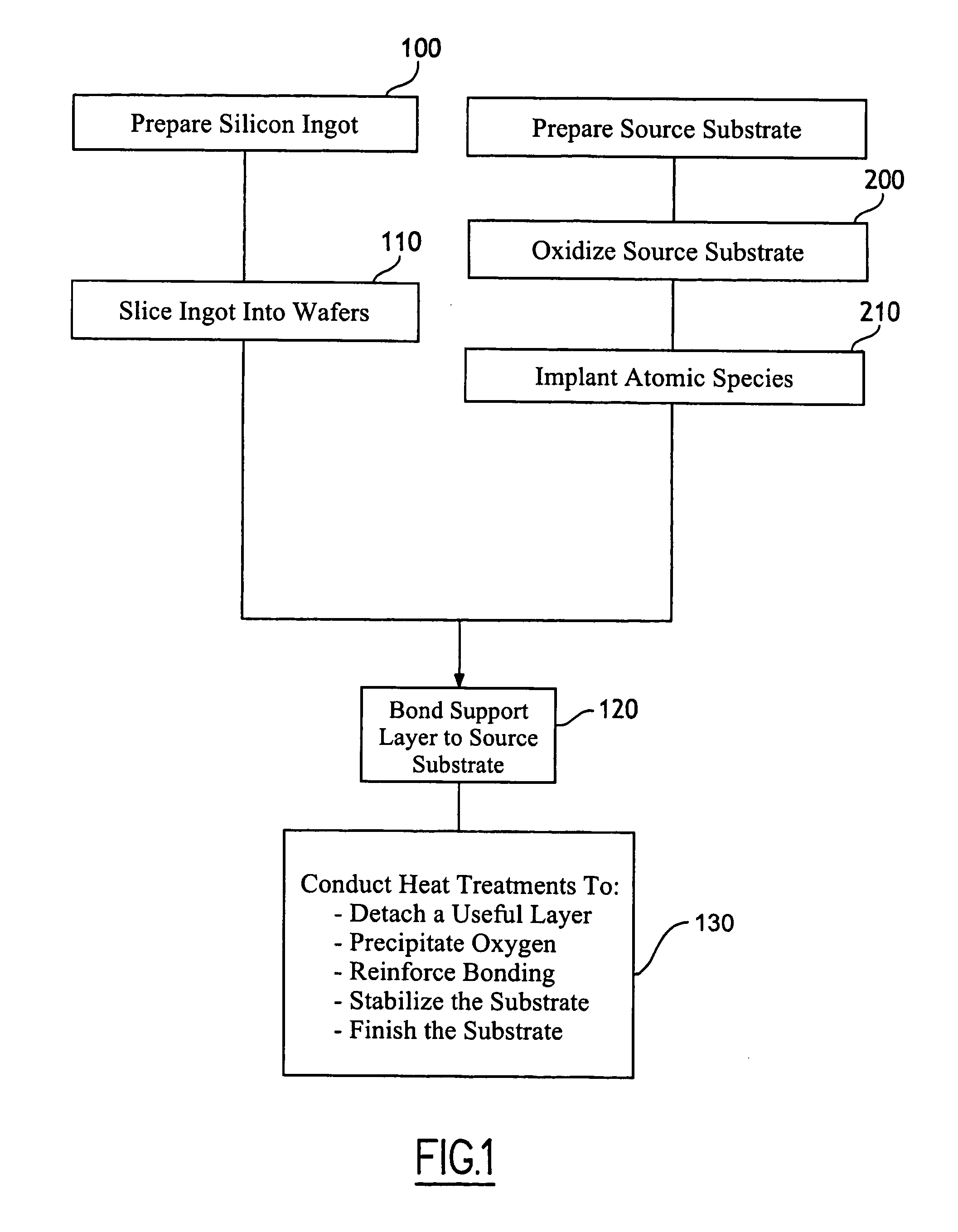

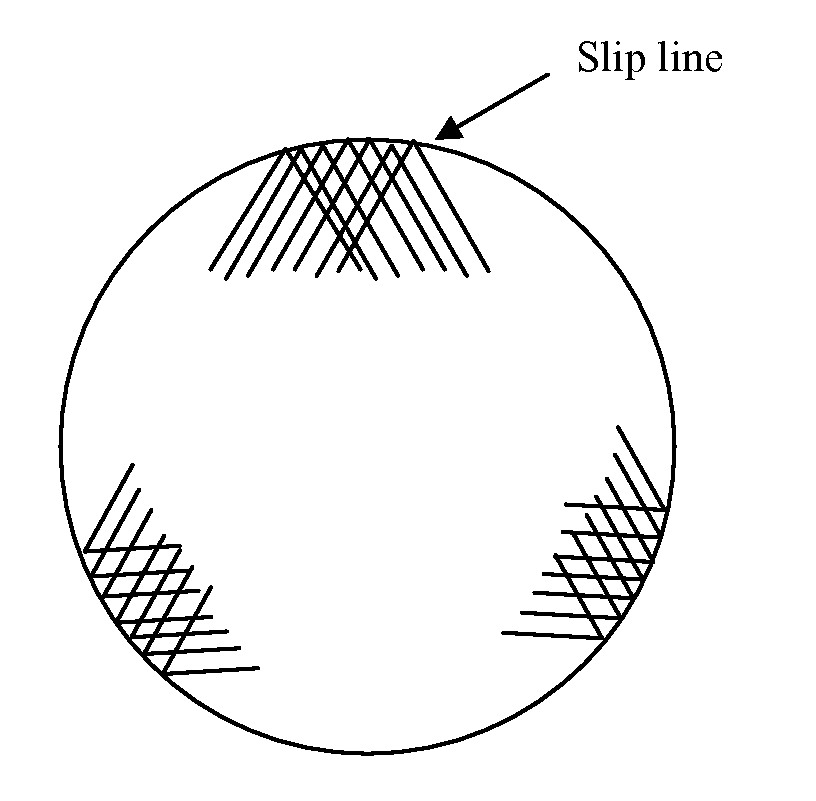

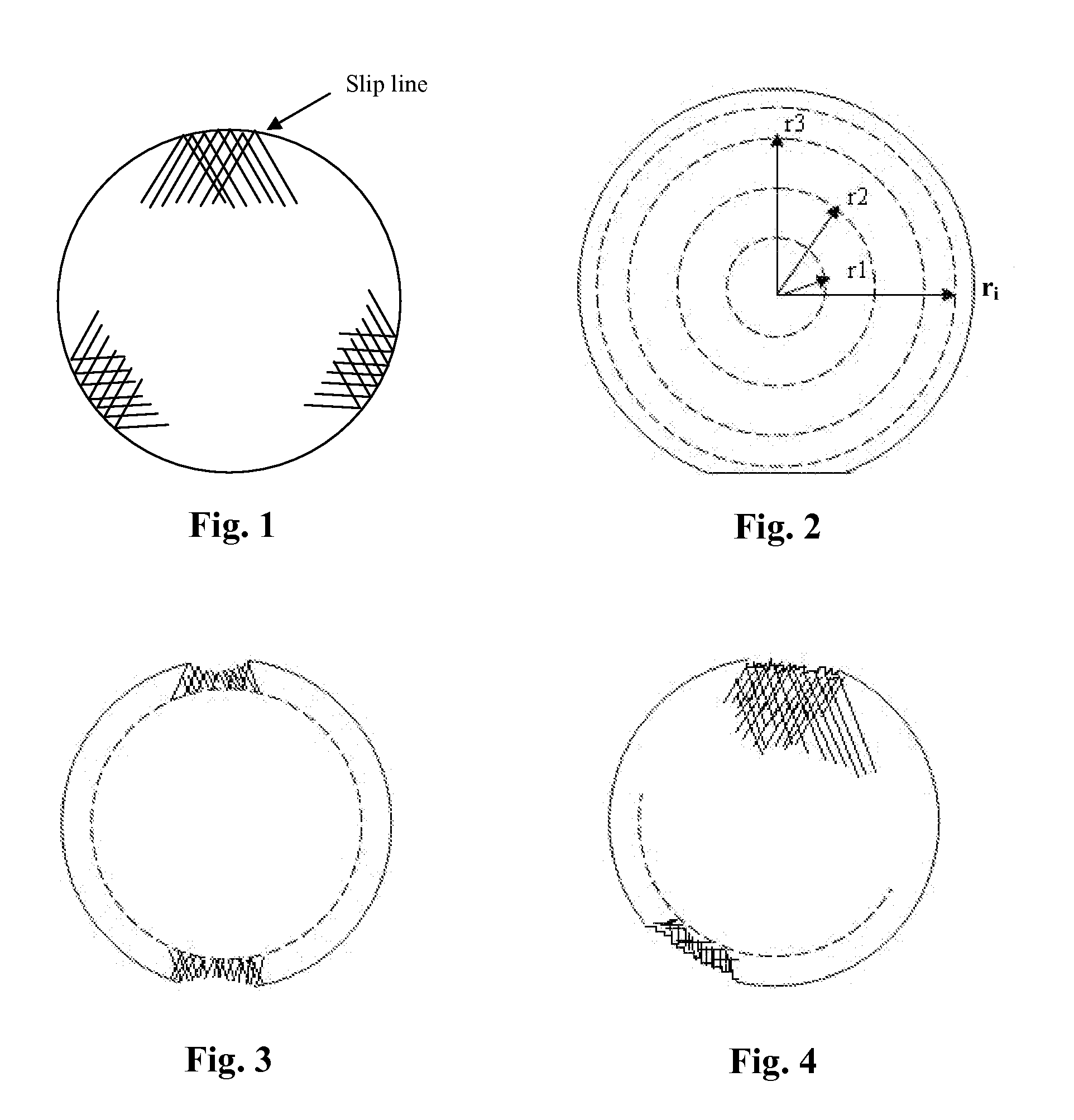

Method for limiting slip lines in a semiconductor substrate

ActiveUS20050202658A1Reduce generationImprove bonding interfaceSemiconductor/solid-state device manufacturingSlip lineEngineering

A method for limiting slip lines in a semiconductor substrate including a support layer and a useful semiconductor layer that is transferred to the support layer. The method includes precipitating at least a portion of interstitial oxygen in the support layer by a series of heat treatments conducted after bonding of the useful semiconductor layer to the support layer. The heat treatments occur at a temperature and a time sufficient to reduce the generation of slip lines therein.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

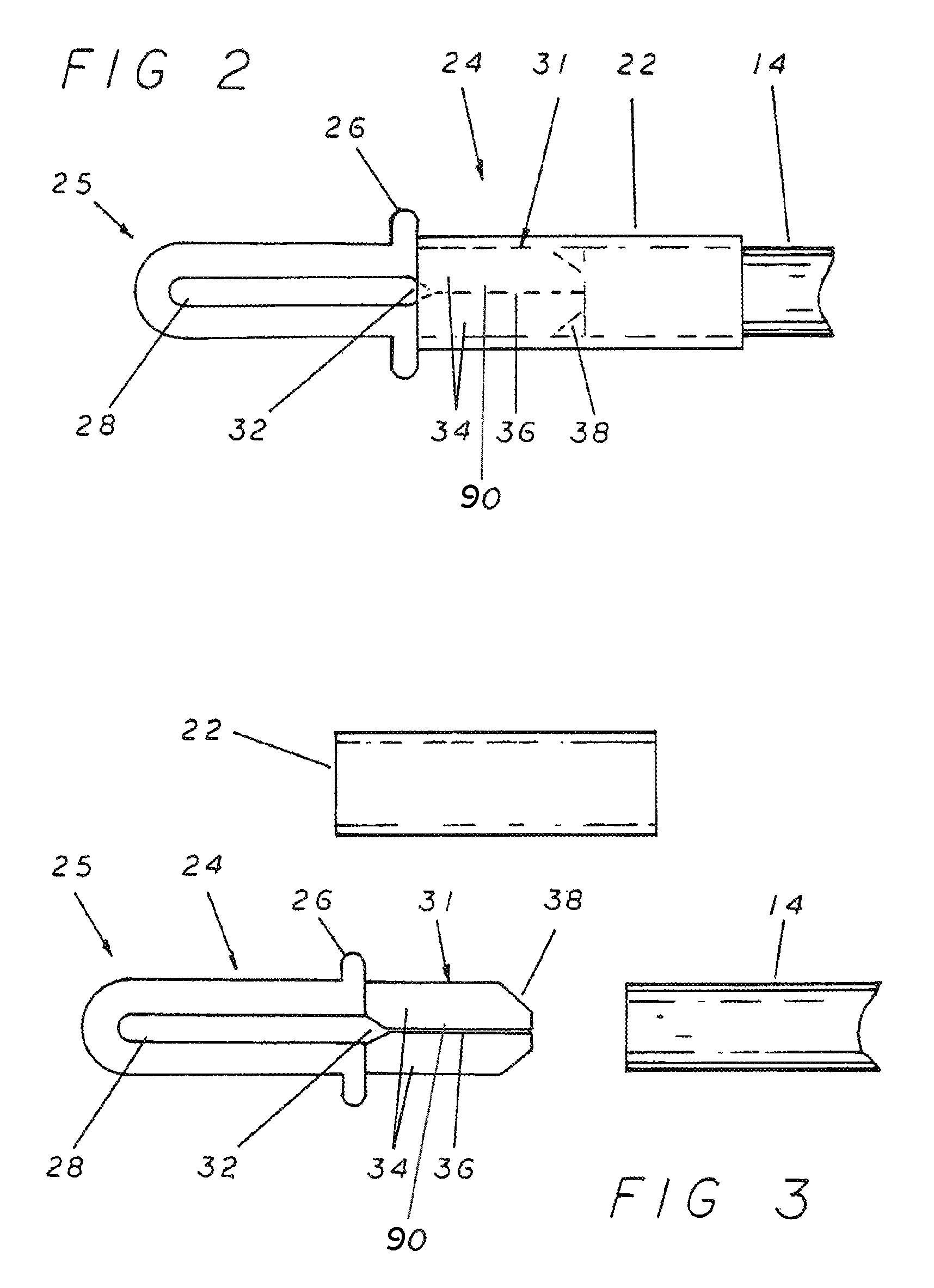

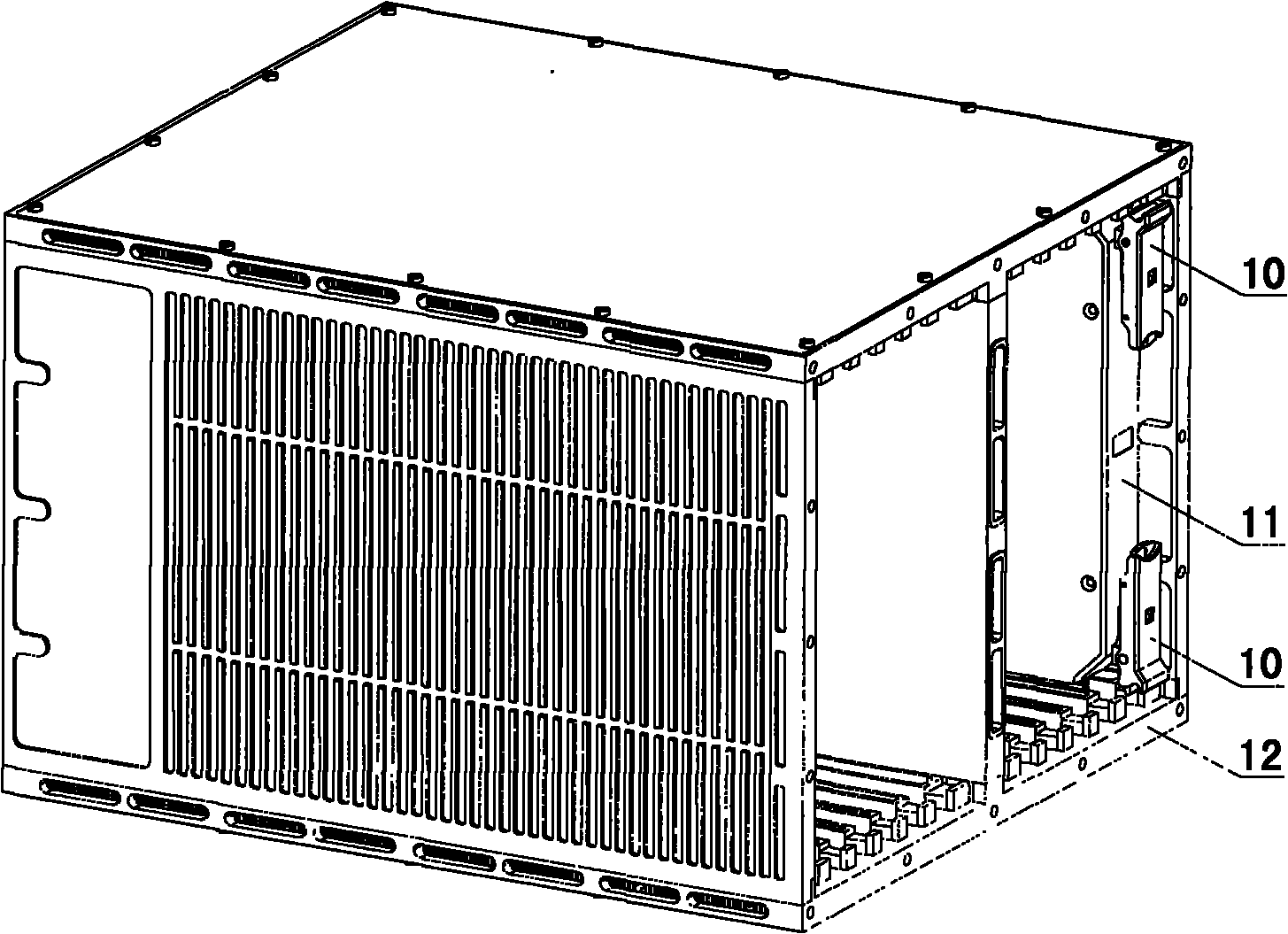

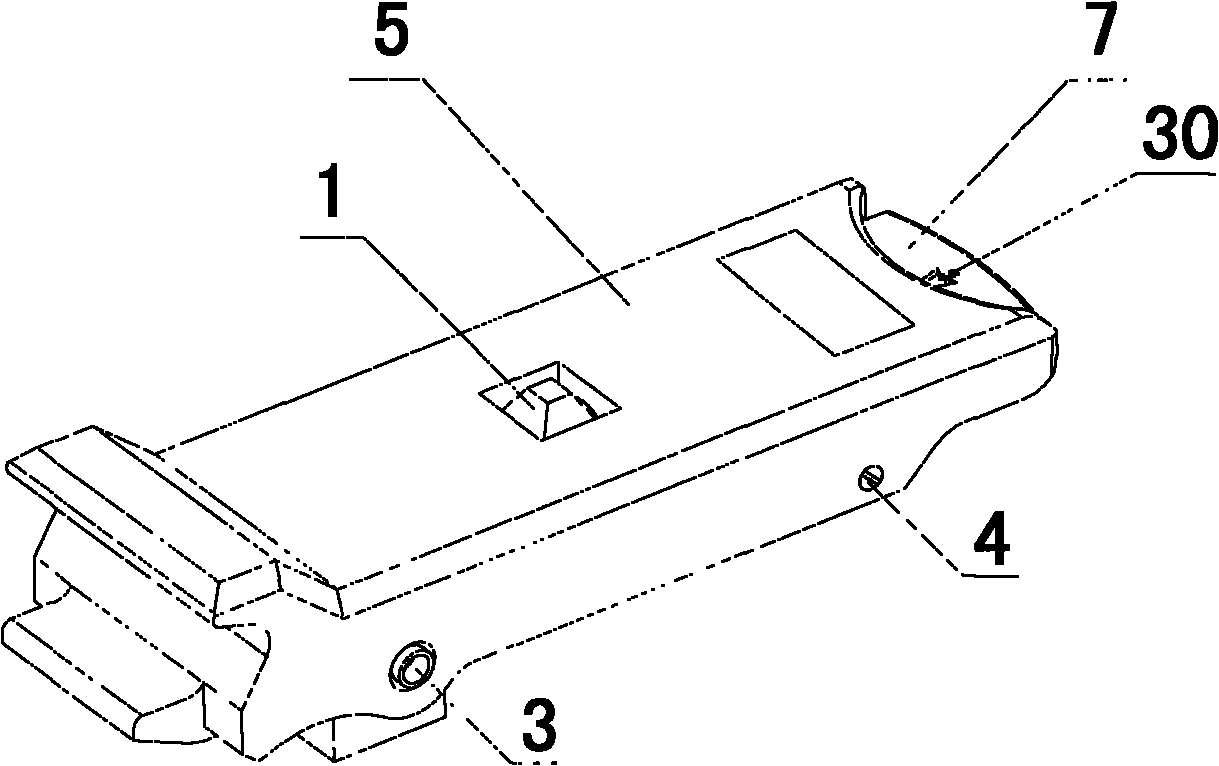

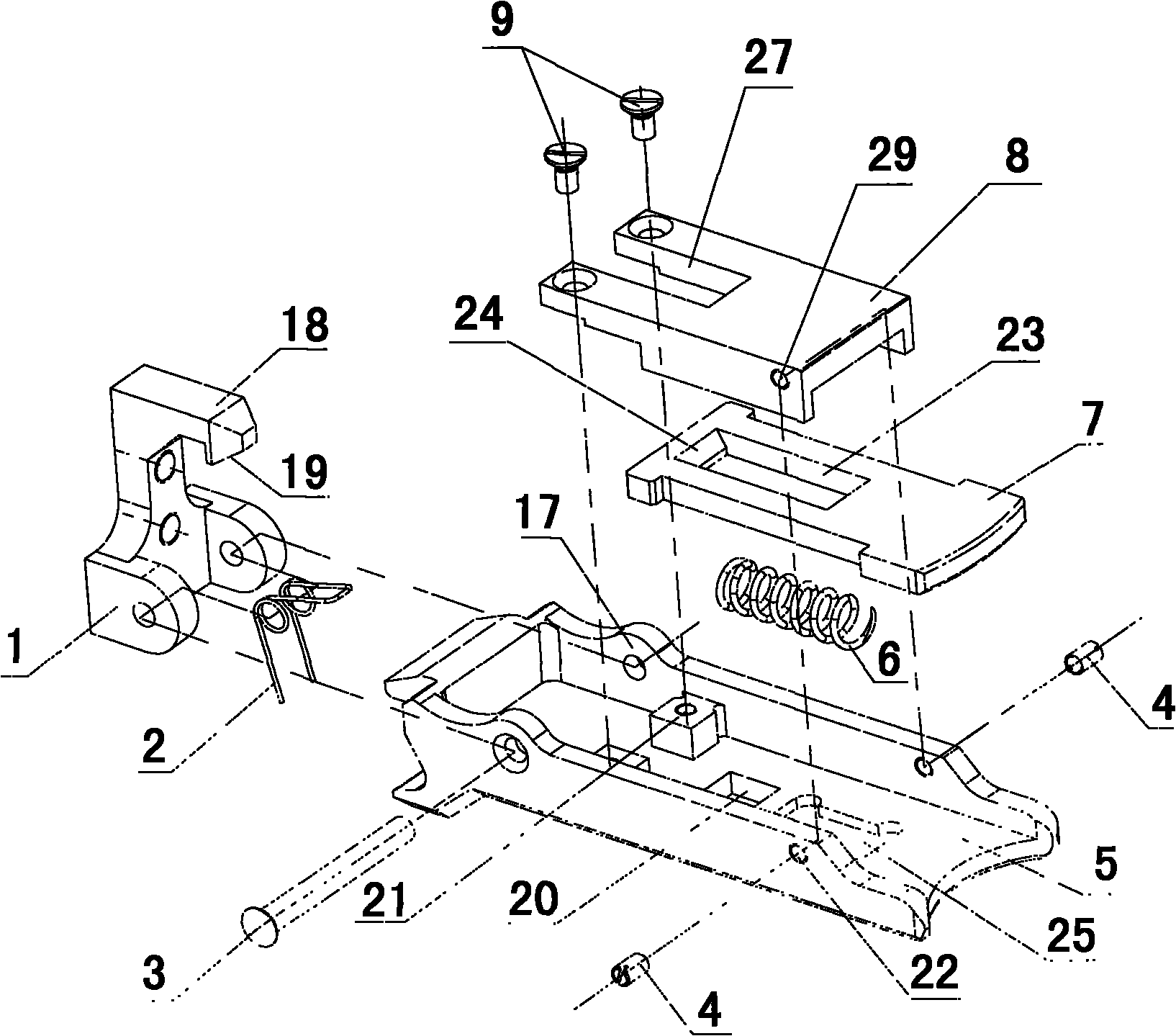

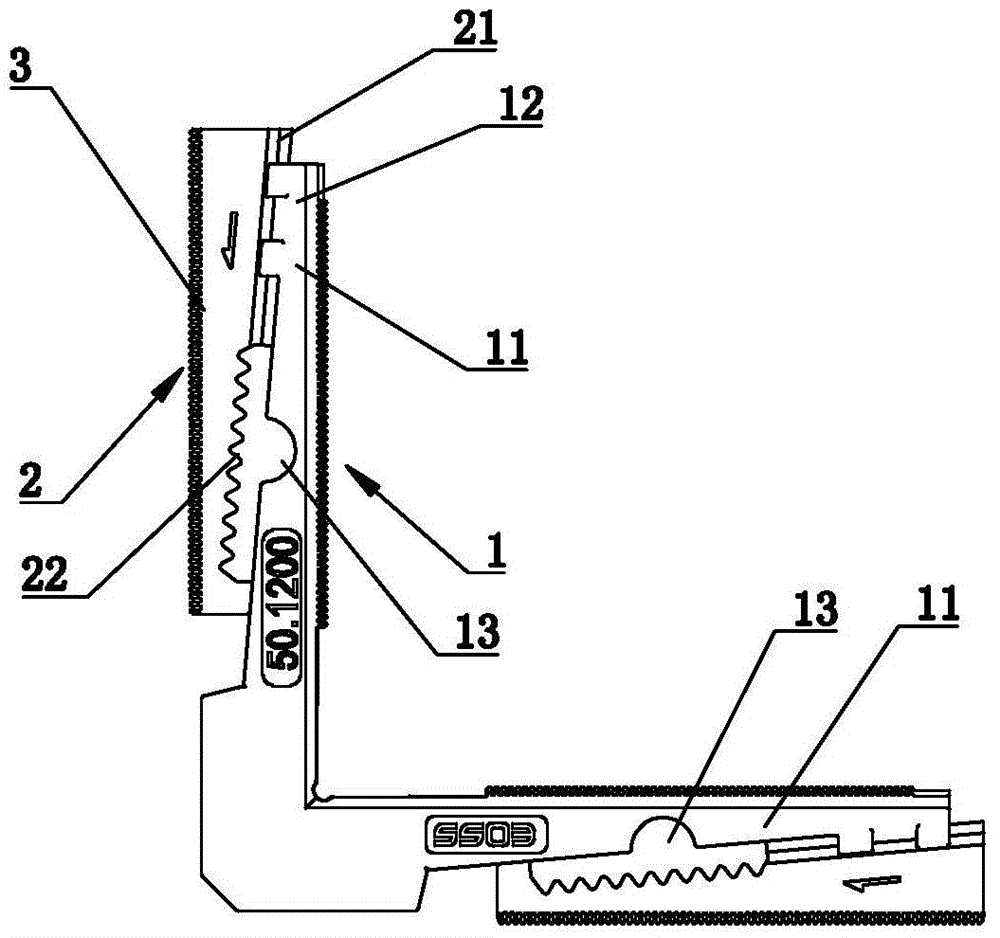

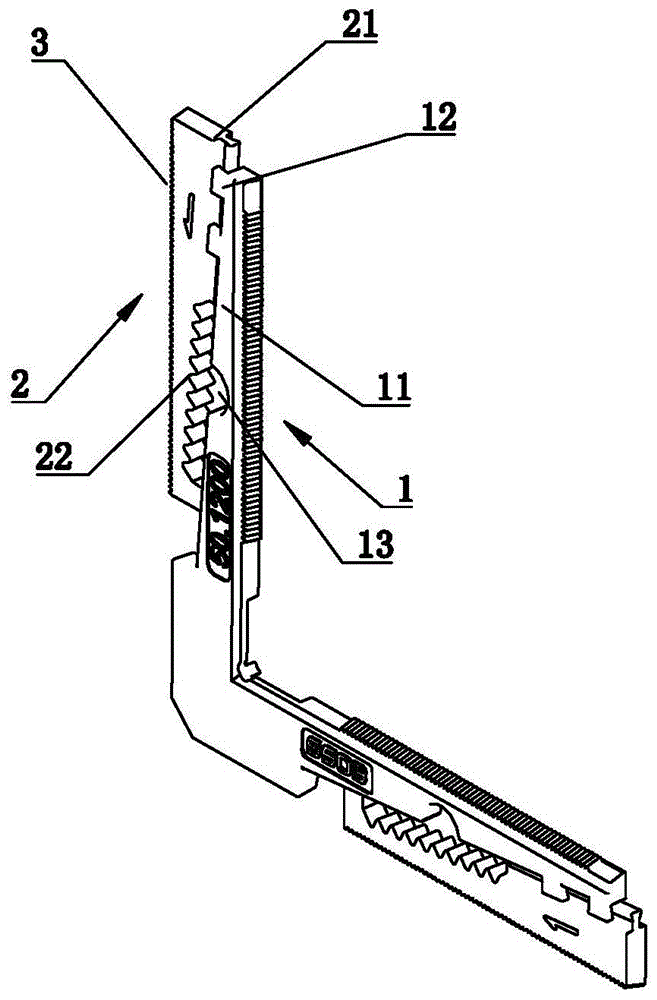

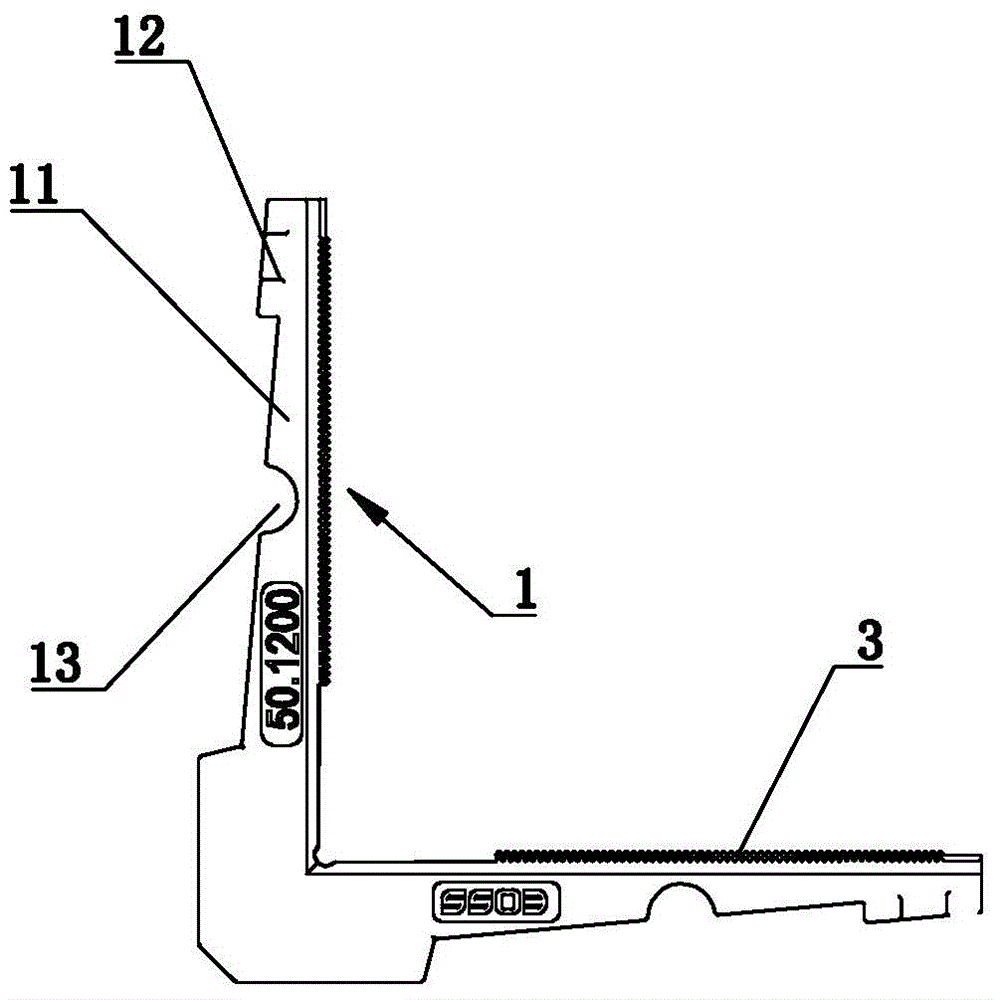

Plug-pull locking device for external replaceable module

ActiveCN101901990AOvercoming insertion forceSignal transmission is normalIncorrect coupling preventionElectricitySlip line

The invention belongs to a fastener technology, and in particular relates to a plug-pull locking device for an external replaceable module of airborne electronic equipment. The plug-pull locking device comprises a lock hook, a torsion spring, a pin shaft, a locking screw, a handle, a compression spring, a lock tongue, a pressure plate and a countersunk screw. The device is a mechanical device for inserting, pulling out and locking the external replaceable module of the airborne electronic equipment and is mainly used for overcoming the plug-pull force of an electric connector when the module is pushed in or pulled out, ensuring that the module in loading or unloading has a movement locus in a slip line, enabling the electric connector to keep full engaged when the module is impacted or vibrates, ensuring the normal transmission of signals and ensuring that the external force of the module can not be transferred to electric connector terminals to cause mechanical damage or electric performance failure. The device of the invention has the triple functions of inserting, pulling out and locking the module to a case.

Owner:XIAN FLIGHT AUTOMATIC CONTROL RES INST

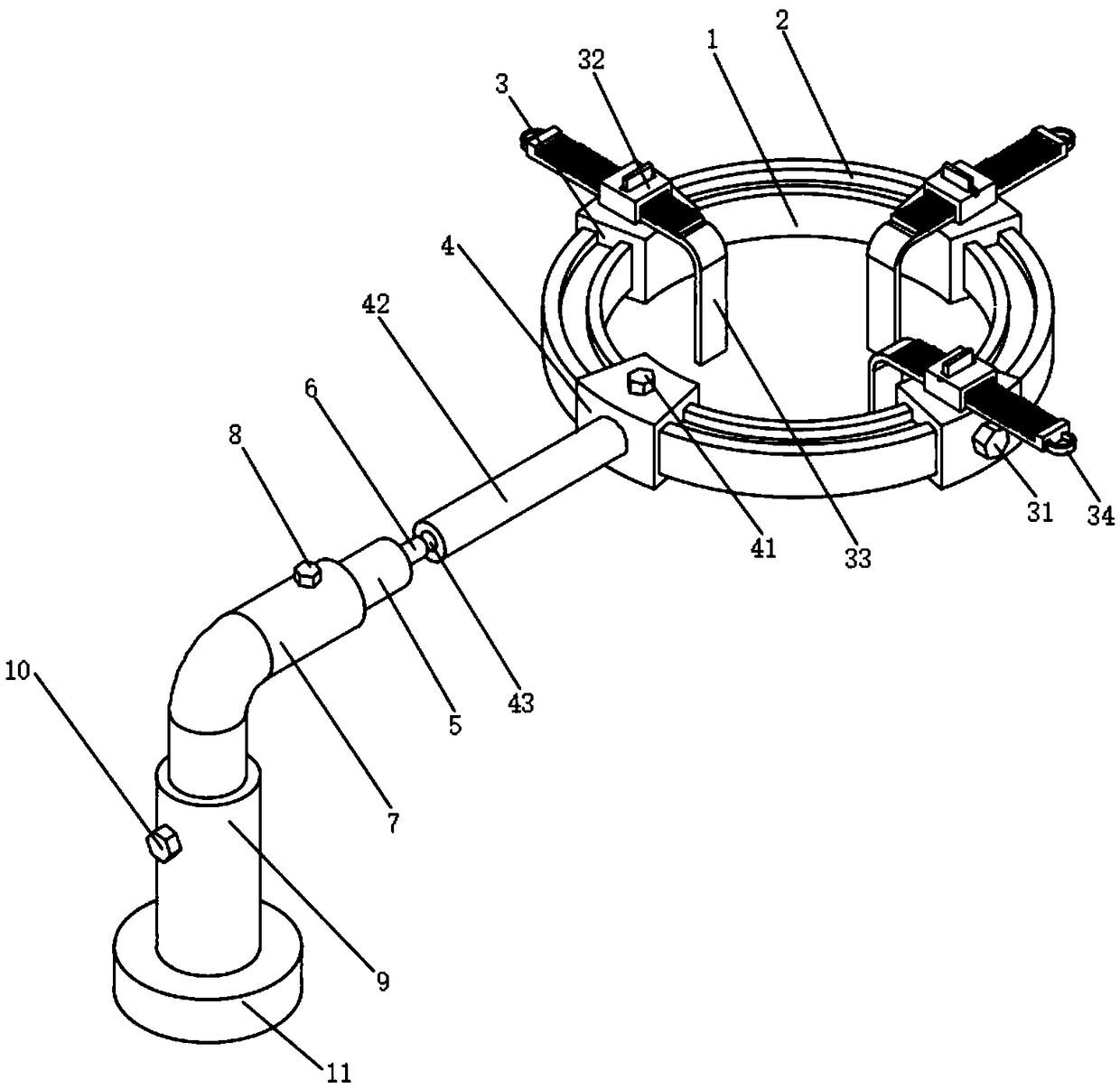

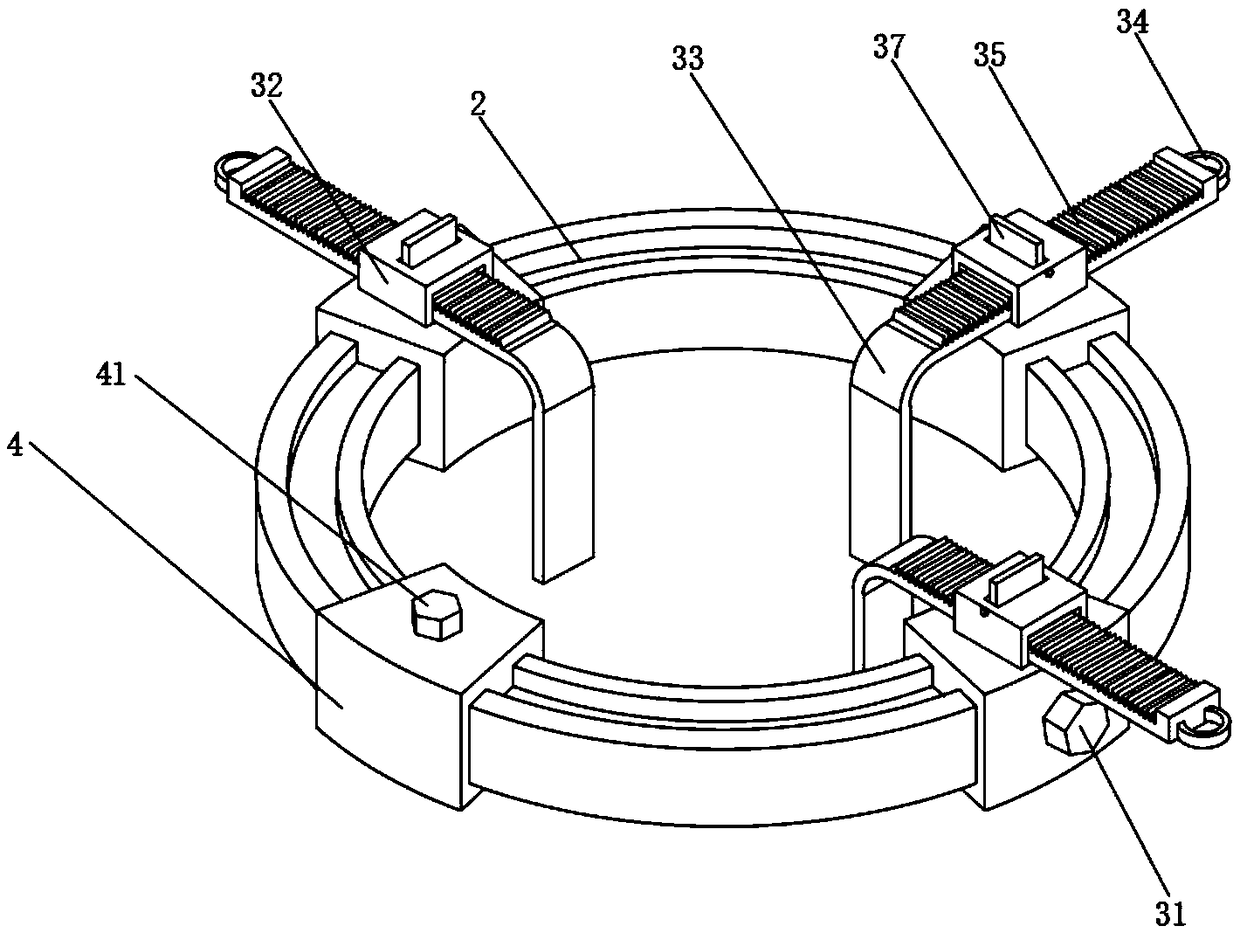

Wound expanding device for general surgery

The invention discloses a wound expanding device for general surgery, including a mounting ring, wherein the upper surface and the lower surface of the mounting ring are provided with sliding grooves;a first sliding block is slidably connected in the sliding groove; the side surface of the first sliding block is provided with a screw hole; the screw hole is internally threaded with a first fixingbolt, the upper surface of the first sliding block is provided with a mounting block, an expansion plate is slidably connected with a through groove opened on the side surface of the mounting block,a pull ring is arranged at the end of the expansion plate, the side surface of the pull ring is provided with anti-slip lines, and the upper surface of the expansion plate is uniformly provided with oblique teeth. A surgical wound expand device for general surgery clinically can expand wounds in different direction according to operating needs, can expose operating position without multiple operating, alleviates pain degree of patient, is simple to operate, convenient to use, easy to fix at the same time, does not require long-time hand-held operating, lightens work burden, and improves work efficiency.

Owner:邵永波

Method for rapidly detecting surface formation defect of thin sheet

ActiveCN102095683AEasy to measureHigh speedUsing mechanical meansMaterial analysisSlip lineCommon cold

The invention relates to a method for rapidly detecting the surface formation defect of a thin sheet, belonging to the technical field of steel plate surface detection. The detection steps comprises the following steps: processing the thin sheet to be measured to sheet-like samples with a thickness identical to the shin sheet and a size meeting the requirement for a bulging test; cleaning the surface of the samples and drying; carrying out a rigid convex die bulging test to detect the surface formation defect, wherein different surface formation defects can be detected according to the different bulging depths because different bulging depths result in different deformation amount and different strain state of the thin sheet. The method has the advantages that the method not only can detect the surface formation defects of common cold plate, such as slip line, surface roughening and impurities, but also can detect the formation defects of Zn-plated plate, such as scaling and powderingof the surface Zn layer. In addition, the method is simple, and has high speed and high accuracy.

Owner:SHOUGANG CORPORATION

Production method of tin plate

The invention relates to a production method of a tin plate. The tin plate comprises the following chemical components by percent: 0.0010%-0.0040% of C, 0.4%-0.7% of Mn, 0.03%-0.08% of Al, not more than 0.03% of Si, 0.015%-0.04% of Ti, 0.003%-0.005% of B, not more than 0.015% of P, not more than 0.015% of S, not more than 0.003% of N and the balance of Fe and some inevitable impurity elements. The production method of the tin plate sequentially comprises the following steps of: steel-making, continuous casting, hot-rolling, pickling, cold continuous rolling, continuous annealing, leveling and tinning. Compared with the prior art, the tin plate produced by the method is easy for subsequent processing, is unlikely to have defects of cracking, slip line cobwebbing or creasing and barring of a curved surface, is capable of meeting the needs of a user, and is low in cost and convenient for large-scale popularization.

Owner:李晓昭

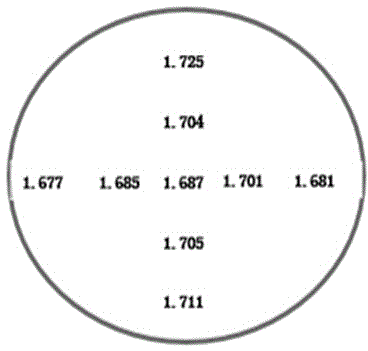

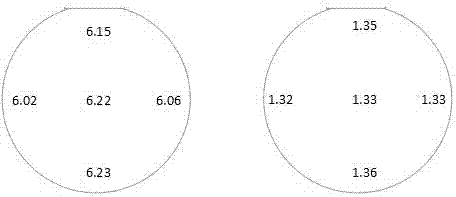

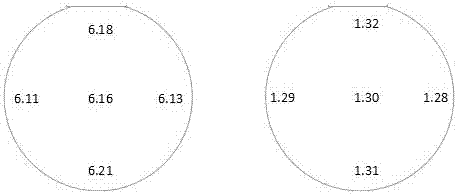

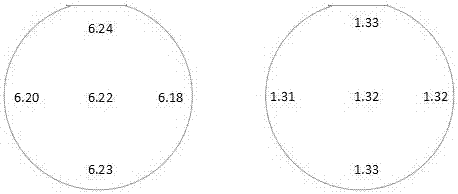

Preparation method for silicon epitaxy sheet for transient voltage restraining diode

ActiveCN107099840AMeet the use requirementsImprove uniformityPolycrystalline material growthSemiconductor/solid-state device manufacturingSlip lineSelf-diffusion

The invention discloses a preparation method for a silicon epitaxy sheet for a transient voltage restraining diode. According to the preparation method, a gas flow field and a base temperature field are adjusted and an epitaxy technology is optimized, for solving the problem of uniformity control on thickness and resistivity of a present technology for a silicon epitaxy sheet for a transient voltage restraining diode. The control on a self-diffusion process of substrate impurities is realized through the optimization for the epitaxy technology; the high uniformity of the thickness and resistivity of the silicon epitaxy sheet is guaranteed; the surface is free from the defects of stacking fault, dislocation, slip line, fog, and the like; the nonuniformity of the thickness and resistivity of the silicon epitaxy sheet prepared according to the method is below 2%; the scope of average thickness of the silicon epitaxy sheet is 6.10-6.25 micrometers and the scope of average resistivity is 1.25-1.35 ohms.cm, so that the use requirement for the transient voltage restraining diode is met.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

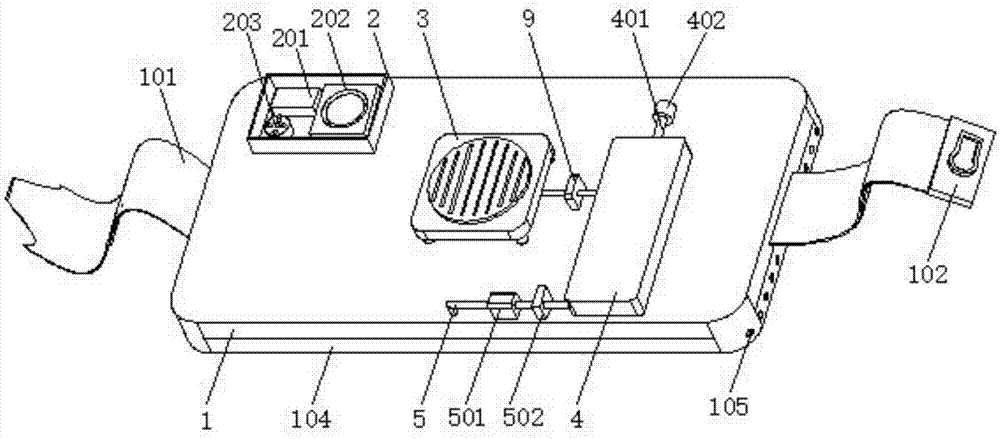

Rapid cooling apparatus applied to general nursing

ActiveCN107260391APrevent rotationEffect fitTherapeutic coolingTherapeutic heatingSlip lineSkin surface

The invention discloses a rapid cooling device applied to general nursing. The rapid cooling device comprises a sticking plate, wherein the sticking plate is a hollow elastic plate body; air vents are uniformly distributed in the lower surface of the sticking plate; a control box is fixed to the left side of the upper surface of the sticking plate; and a fan is arranged on an air intake tube in the middle of the upper surface of the sticking plate. The rapid cooling device applied to general nursing, which is fixed by virtue of straps in coordination with latches, is simple to fix; by virtue of non-slip lines, the sticking plate is prevented from rotating; through the fan, controllable fluid can be provided, so that skin surface can be cooled; under pressure caused by the fan, water in a water bag is sprayed out by a trace amount; heat energy is taken away with evaporation of the water, and in coordination with air-cooling, a better effect is guaranteed; meanwhile, the fan can be used for controlling a cooling speed; by arranging a temperature sensor, feedback parameters can be provided for control of the fan timely; an alarm can be triggered as the temperature sensor is separated away from the skin or the water in the water bag runs out; therefore, the rapid cooling device is convenient to control, high in cooling speed and good in effect; and the rapid cooling device is applicable to patient cooling in general nursing.

Owner:崔晓霞

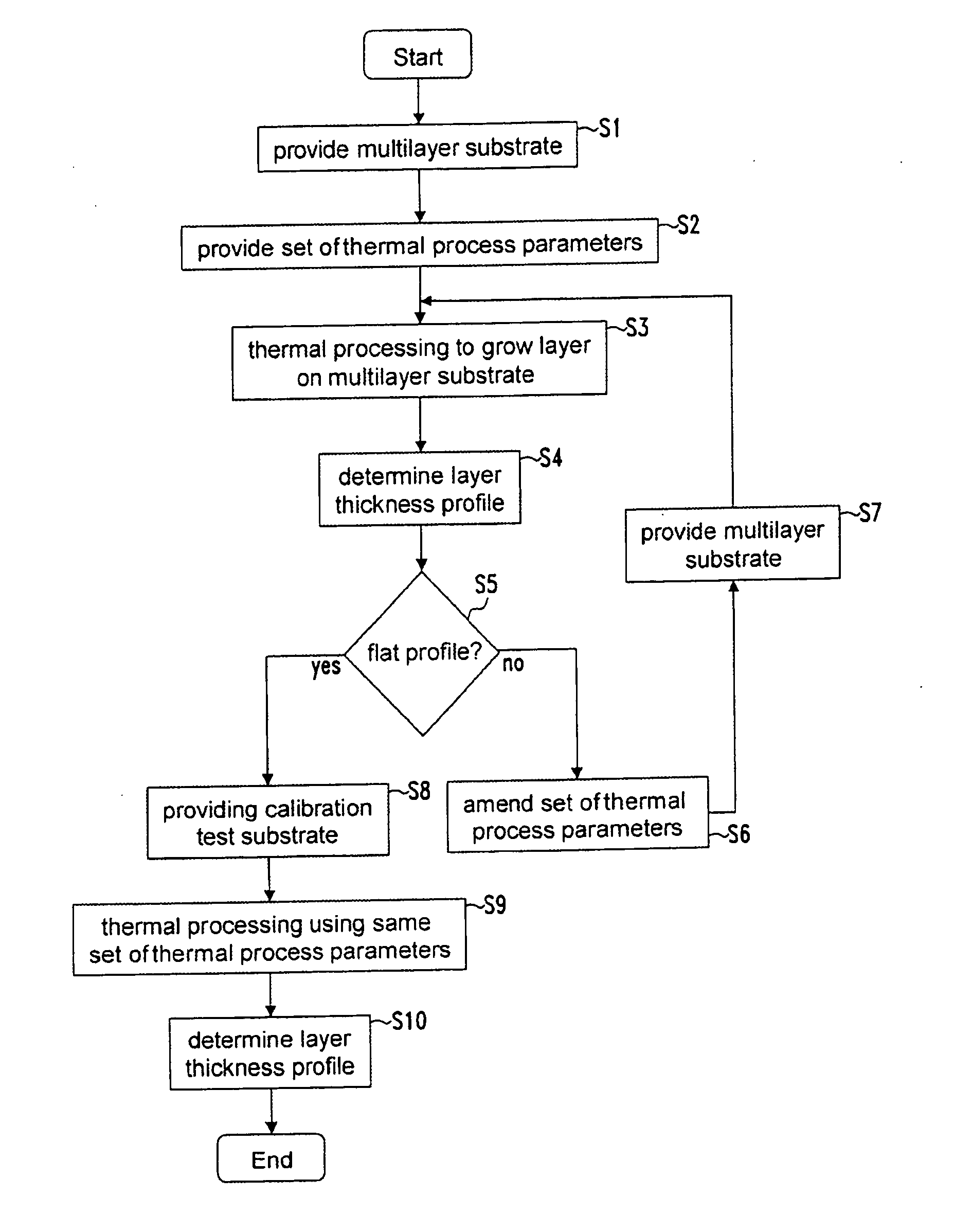

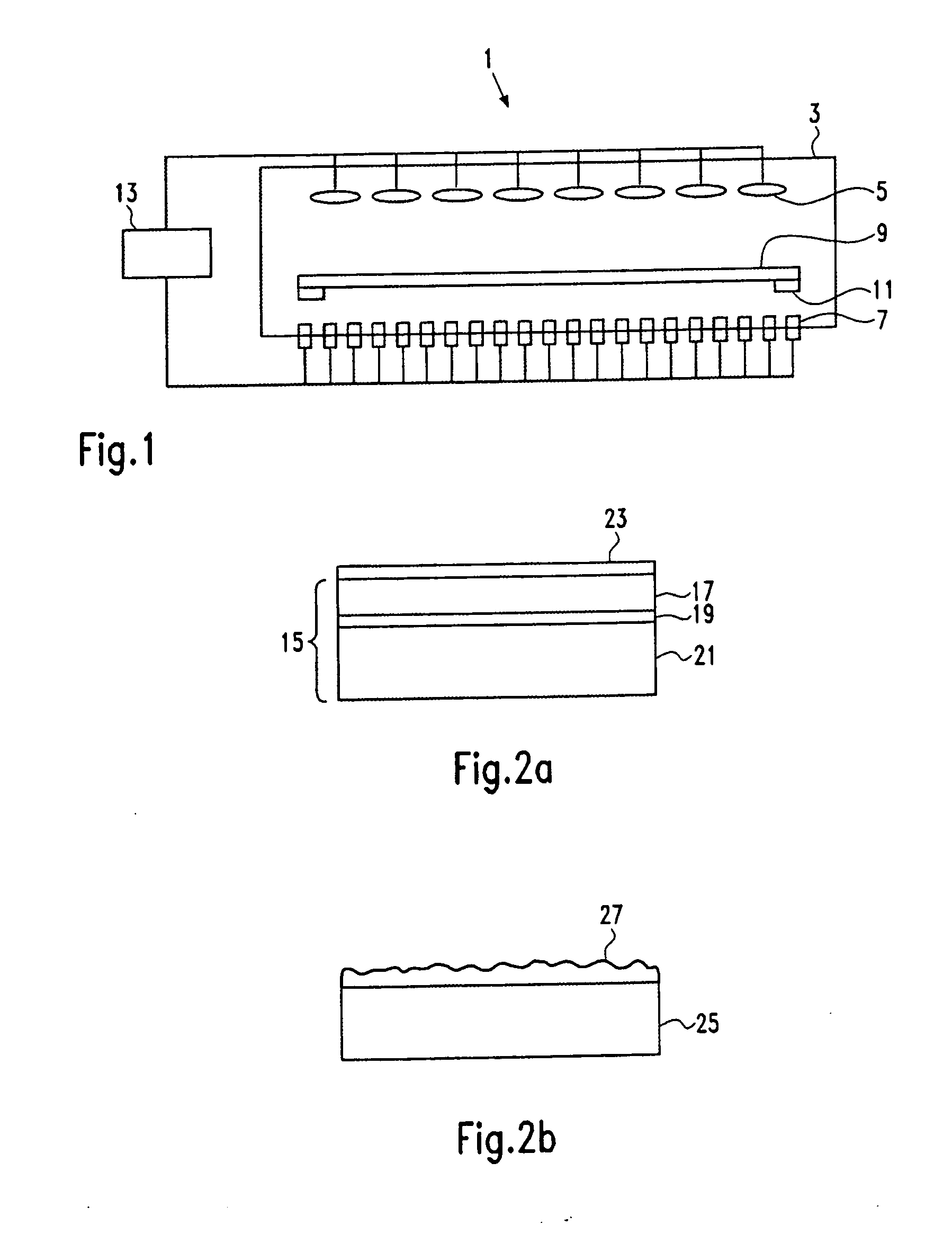

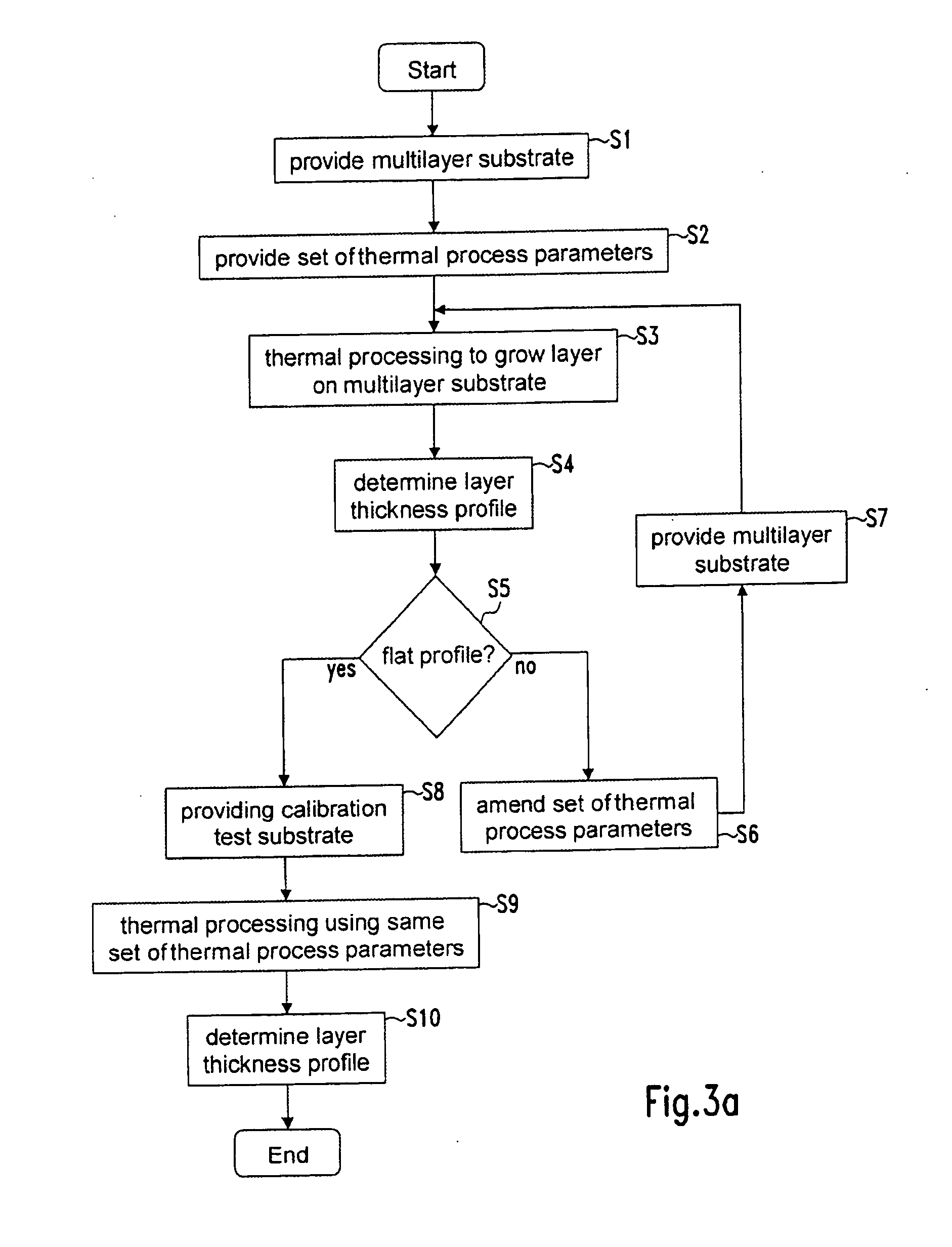

Thermal processing equipment calibration method

ActiveUS20060284720A1Reduce distortionEasy to carrySemiconductor/solid-state device testing/measurementSolid-state devicesSlip lineEngineering

The invention relates to a method for calibrating thermal processing equipment used for heat treatment of a multilayer substrate, in particular a multilayer semiconductor substrate. A calibration test profile is determined by processing a calibration test substrate according to thermal process parameters that produce multilayer substrates having an even thickness profile, and / or having reduced slip lines and / or reduced wafer deformation, and / or having other desired and predetermined properties. Then a particular thermal processing equipment is calibrated by determining thermal process parameters for that equipment so that a test substrate processed with these parameters will have the determined calibration test profile.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

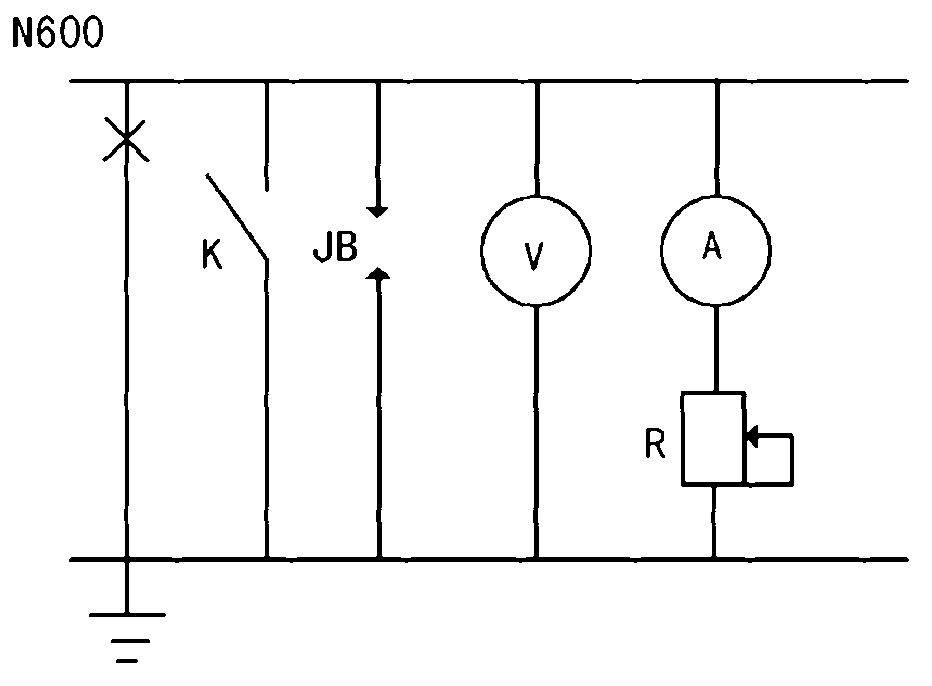

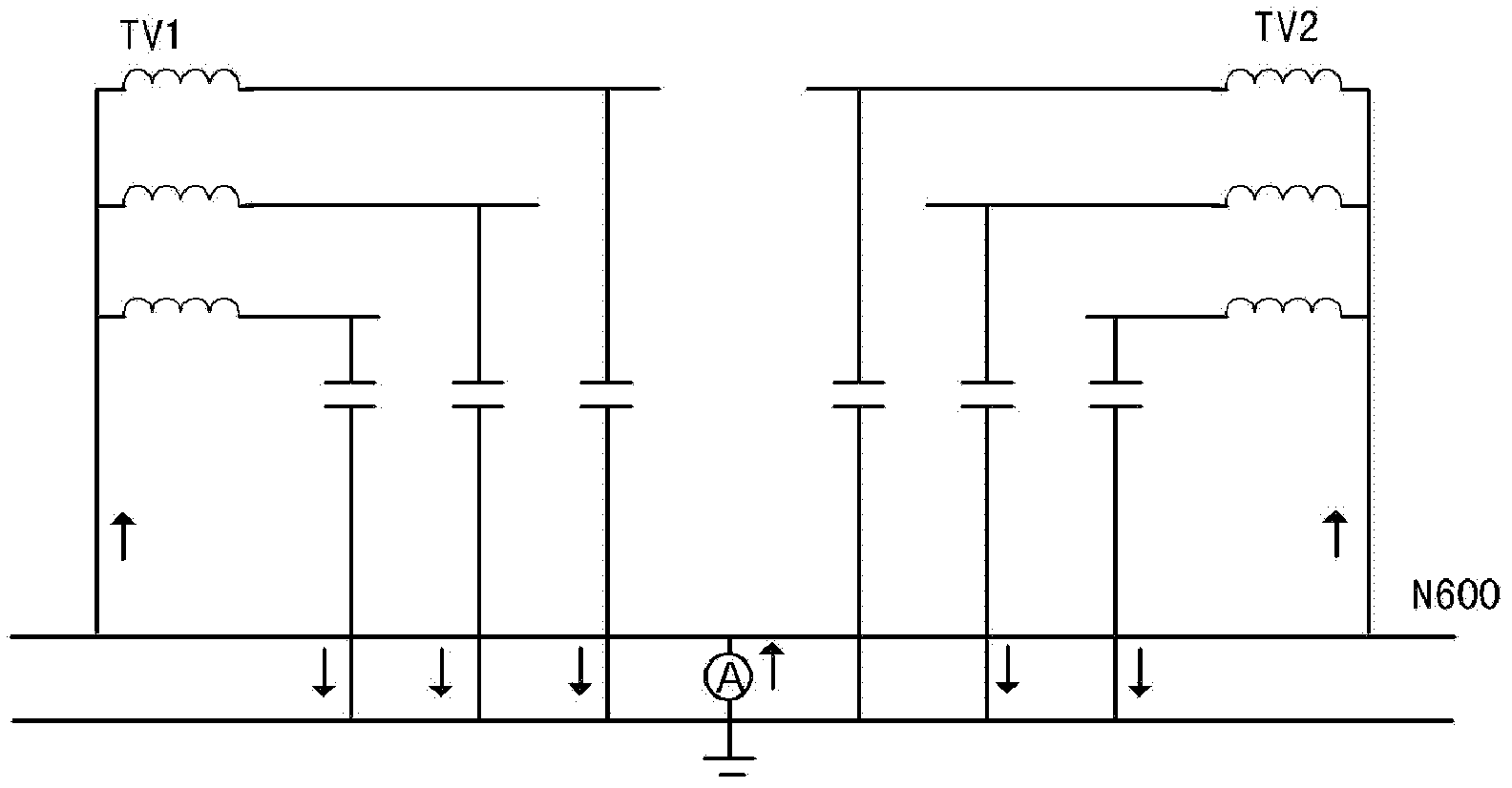

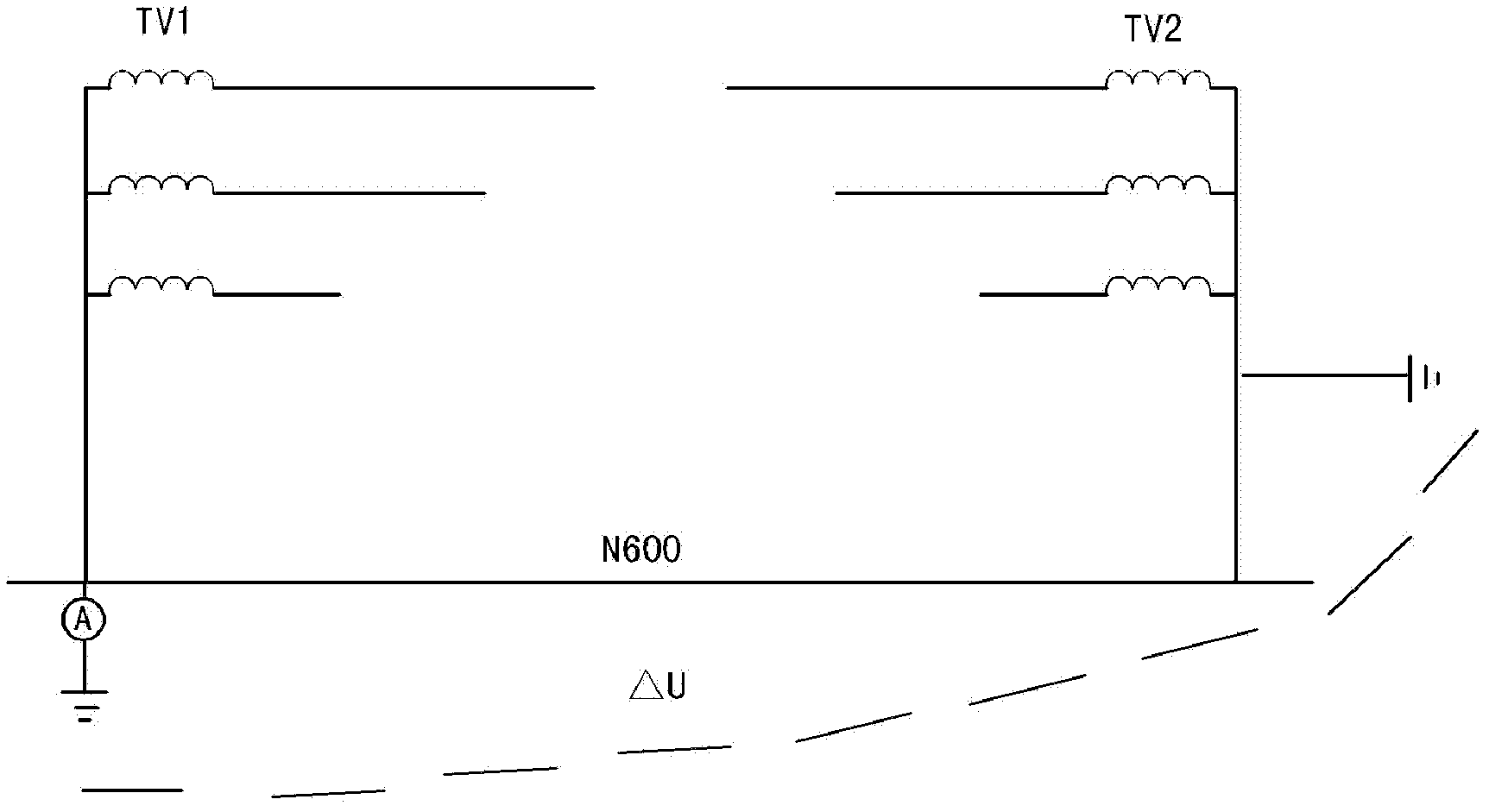

One-point grounding detection device and detection method for neutral line of secondary coil of voltage transformer

InactiveCN102288868ADoes not affect normal workDoes not affect the metering circuitElectrical testingSlip lineOvervoltage

The invention discloses a detection device and a detection method for one-point grounding of the neutral line of the secondary coil of a voltage transformer. Between; adjust the resistance value of the sliding wire rheostat to obtain the corresponding current reading in the ammeter; connect the voltmeter between the neutral line of the secondary coil of the voltage transformer and the equipotential ground network; use the voltmeter to detect the sliding wire The variation of the resistance value of the varistor; the discharge gap and the knife switch are respectively connected between the neutral line of the secondary coil of the voltage transformer and the equipotential ground network, the discharge gap is used for overvoltage protection, and the knife switch is used to control the connection in the test On and off of the location. The invention is suitable for detecting the reliability of the grounding of the secondary circuit of the voltage transformer during operation, improves the correct rate of relay protection actions in the substation, and ensures safety.

Owner:HUAINAN POWER SUPPLY CO OF STATE GRID ANHUI ELECTRIC POWER CORPORATIO +1

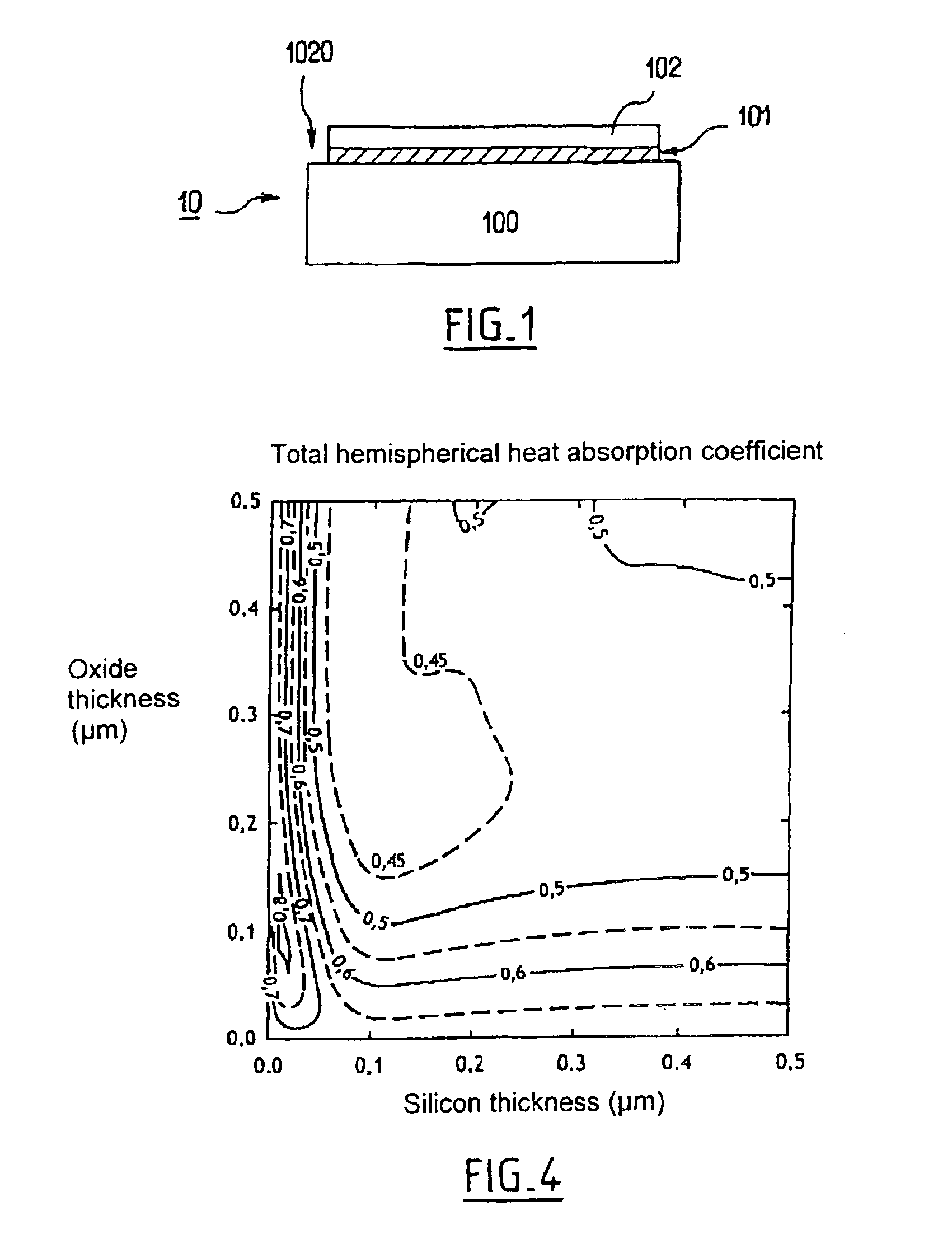

Heat treatment for edges of multilayer semiconductor wafers

InactiveUS20050094990A1Avoid deformationAvoid problemsSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingSlip lineEngineering

A method for heat treating a multilayer semiconductor wafer having a central region and a peripheral edge each having a surface. The method includes selecting thickness values for the layers of the wafer to provide substantially equivalent heat absorption coefficients both in the central region and the edge of the wafer. This results in a substantially equivalent temperature being attained over the surface of the central region and the peripheral edge during thermal treatment. In turn, that prevents the appearance of slip lines on those surfaces while also preventing deformation of the wafer due to the thermal treatment. To achieve the desired thickness, layers or portions of layers can be selectively added or otherwise provided upon the central region or peripheral edge of the wafer, or on both, to modify the heat absorption coefficient of the wafer.

Owner:SOITEC SA

Method of eliminating surface stress of silicon wafer

InactiveUS20070298690A1Eliminate surface stressReduce and eliminate surface stressSemiconductor/solid-state device manufacturingFine working devicesAnti stressSurface stress

This invention provides a method for eliminating the surface stress of a silicon wafer comprising forming one or more anti-stress groove(s) on the surface of the silicon wafer. These anti-stress grooves can reduce or eliminate the surface stress of silicon wafer effectively to avoid the formation of slip lines and dislocation arrangements, which may induce the p-n junction to conduct or the leakage current to increase. The process is highly efficient and low in cost. It is simple to manage and does not require additional equipment beyond that already used for processing of silicon wafers.

Owner:LIU YULING +5

Profile angle assembling device

The invention discloses a profile angle assembling device which comprises an L-shaped first member and two second members. The first member comprises two supporting arms connected vertically mutually; the two second members are respectively arranged at outer ends of the two supporting arms. Contact surfaces between the second members and the supporting arms are bevel surfaces with uniform inclination angle, and side surfaces, opposite to the bevel surfaces, of the second members are parallel to side surfaces, opposite to the bevel surfaces, of the supporting arms. Rails and slots matched mutually are respectively arranged on the contact surfaces between the second members and the supporting arms and at the positions near the outer ends of the supporting arms. Regulating threads are formed on the contact surfaces between the second members and the supporting arms and at the positions near the vertical joints, and through slots are formed, corresponding to the threads, in the contact surfaces between the supporting arms and the second members. Anti-slip lines are respectively formed on the side surfaces, opposite to the bevel surfaces, of the second members and the side surfaces, opposite to the bevel surfaces, of the supporting arms. The profile angle assembling device is convenient to use and mount and capable of improving evenness and strength of assembled profile angles.

Owner:SHANDONG HUAJIAN ALUMINUM GRP +1

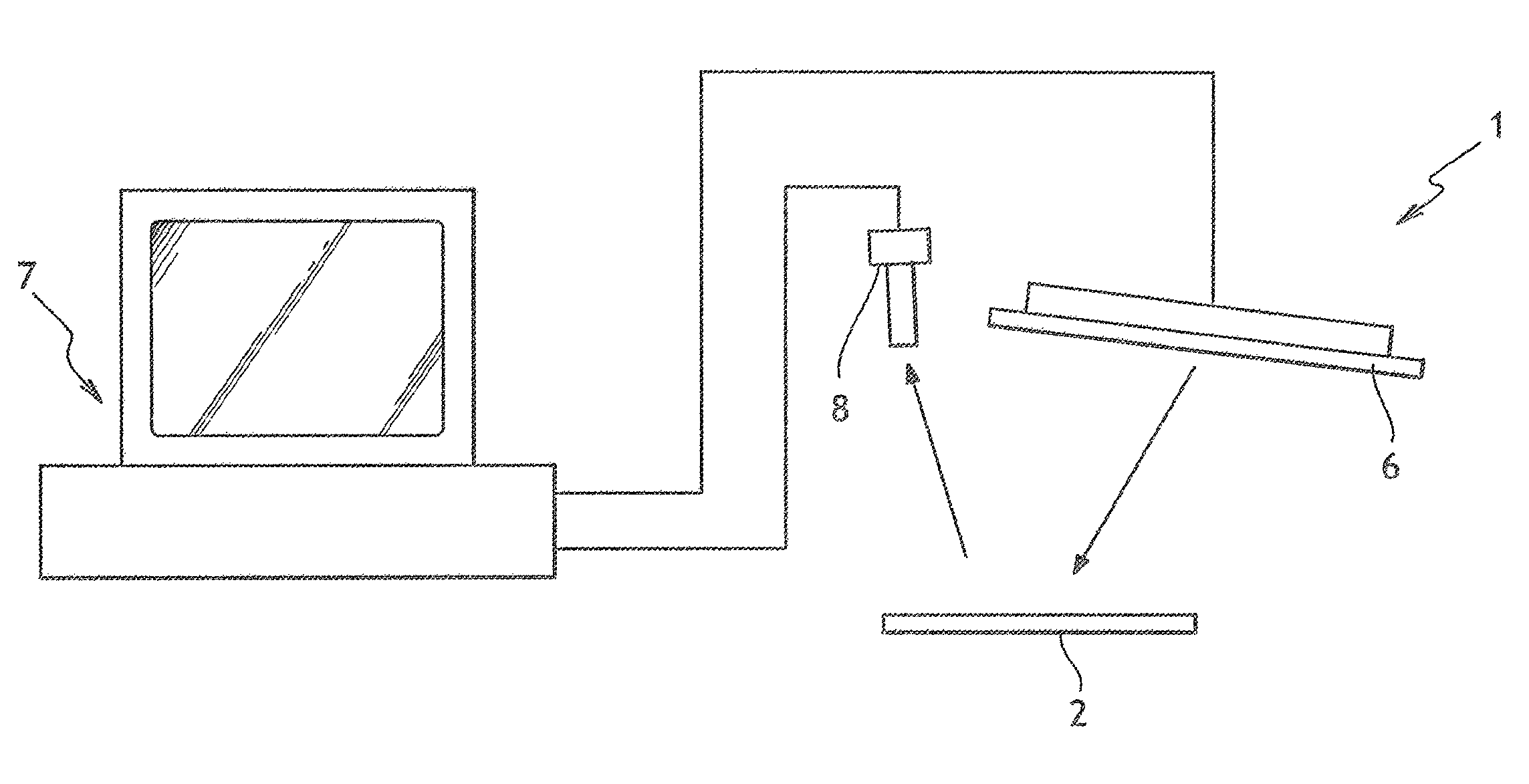

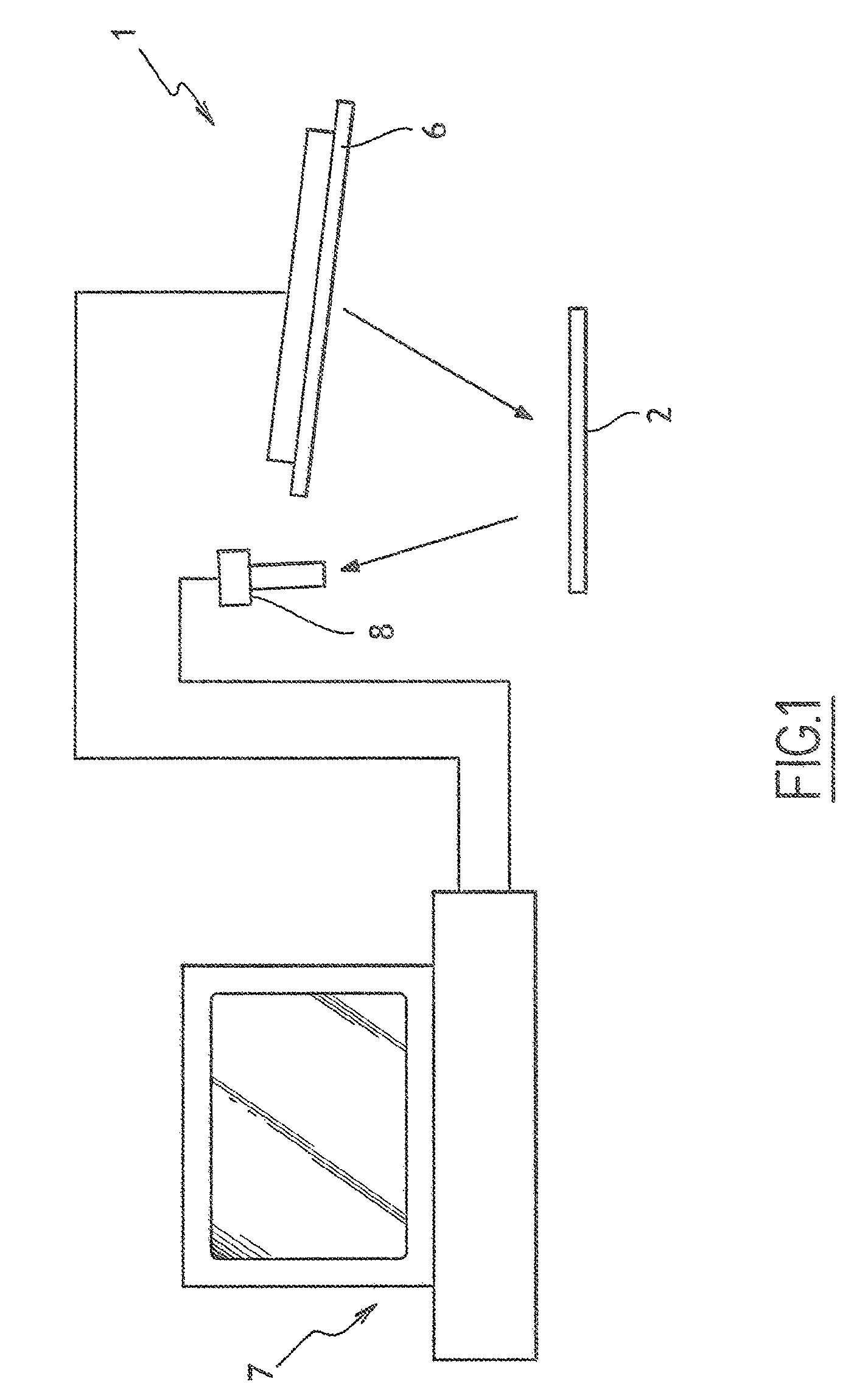

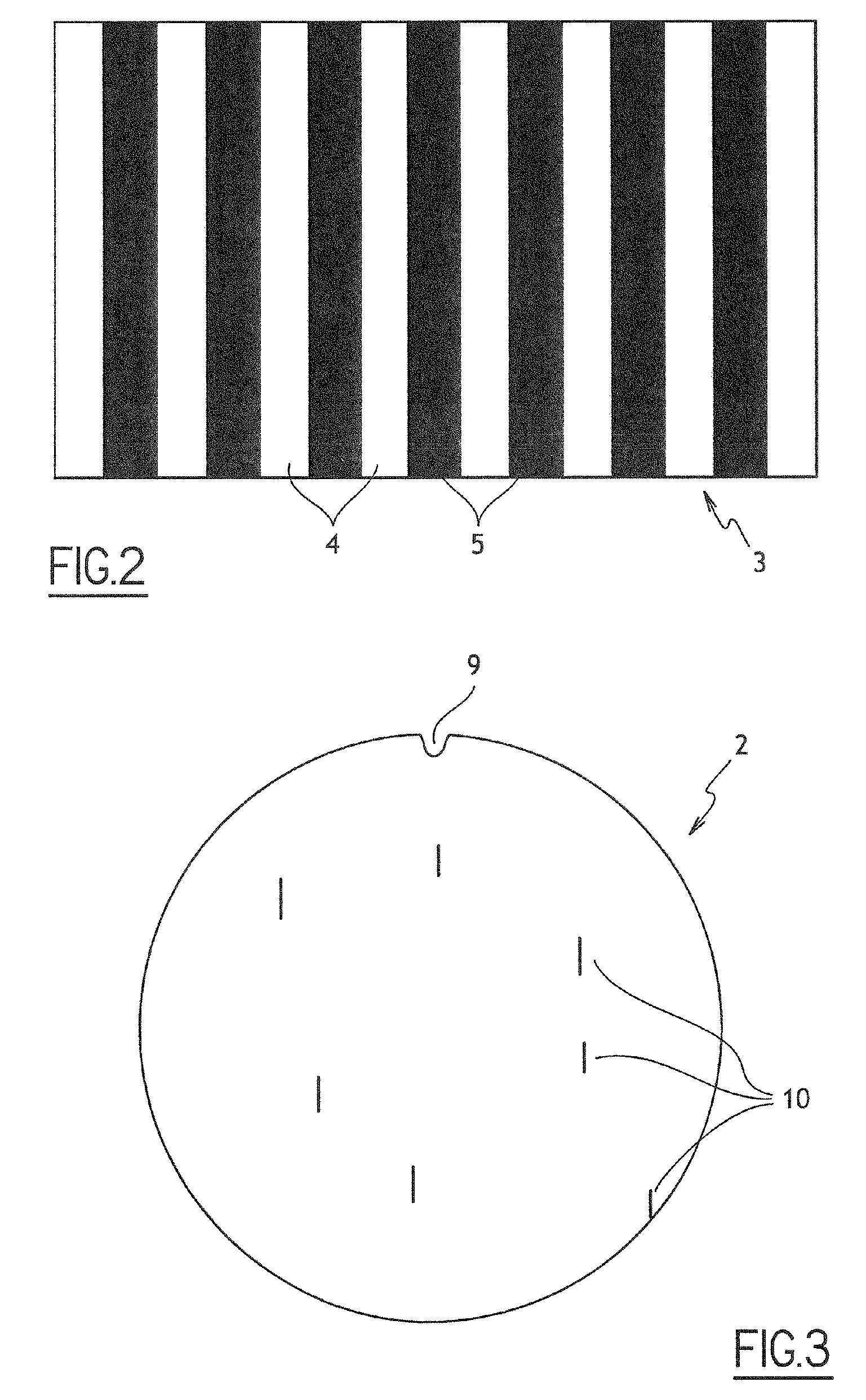

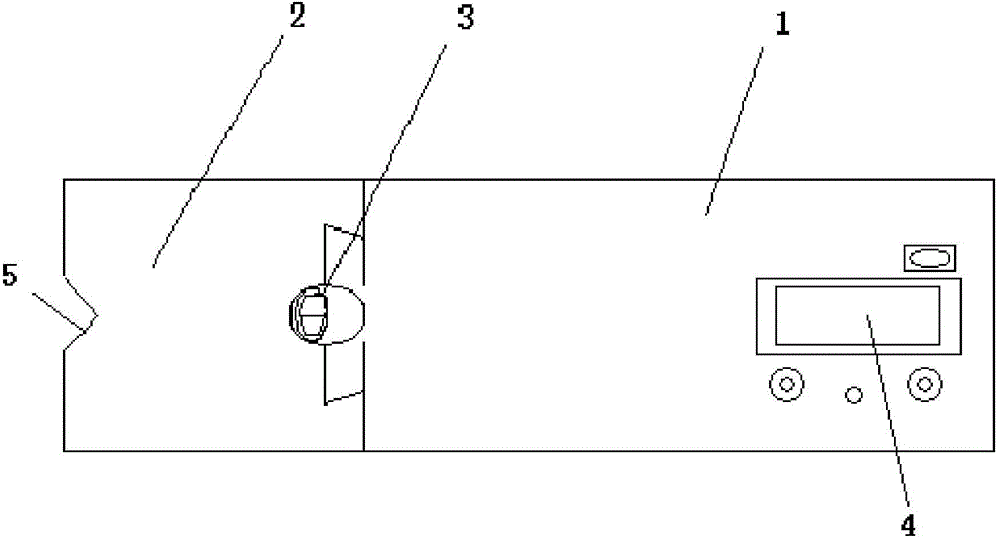

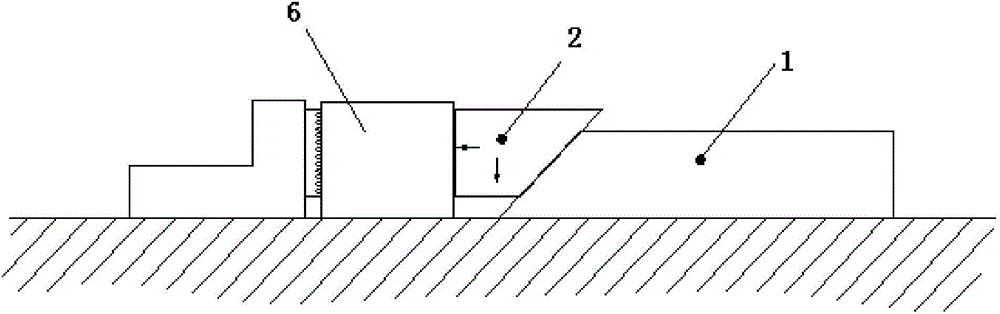

Method for detecting surface defects on a substrate and device using said method

ActiveUS7812942B2Quick checkAvoid depositionSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationRelative displacementSlip line

Owner:ALCATECH SEMICON +1

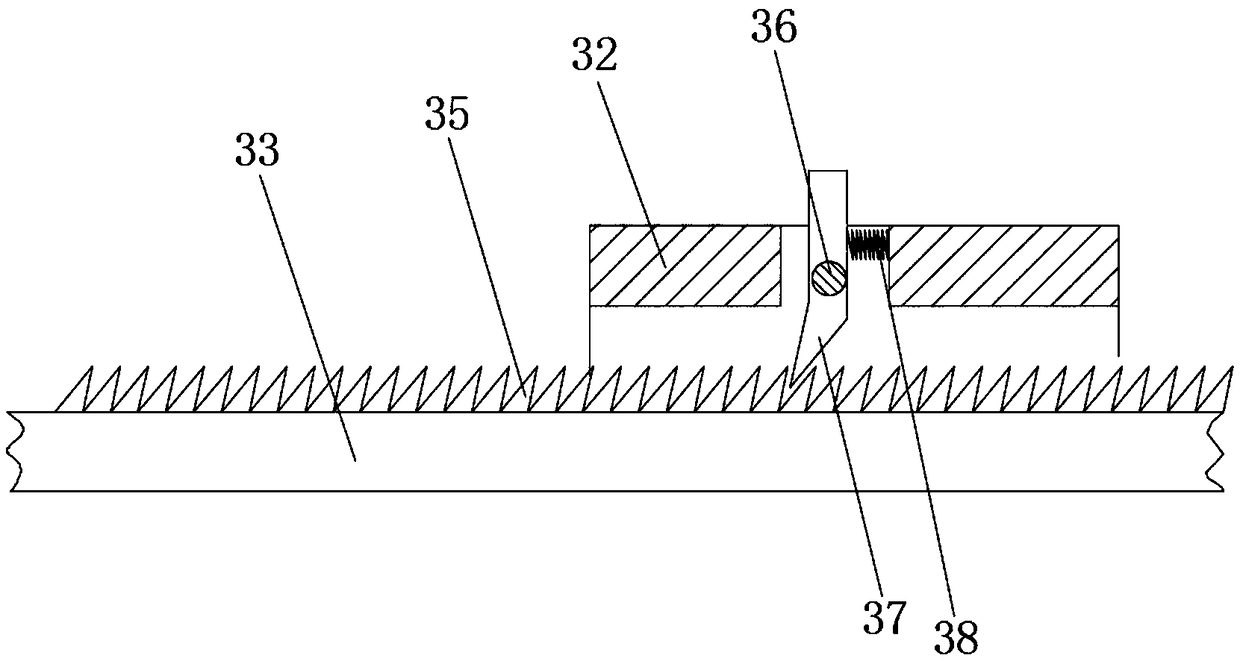

Lateral compression device used for compressing side face of workpiece

InactiveCN105619103AEasy to navigateStable supportPositioning apparatusMetal-working holdersSlip lineLateral compression

The invention relates to a lateral compression device used for compressing the side face of a workpiece. The device comprises a positioning block, a compressing block and a transmission bolt, wherein an inclined face is arranged on one side of the positioning block and provided with a dovetail convex groove; one side face of the compressing block is matched with the inclined face of the positioning block and provided with a dovetail concave groove; the other side face of the compressing block is provided with zigzag anti-slip lines; the compressing block is in sliding connection with the positioning block through the transmission bolt; the upper surface and the inclined face of the positioning block are provided with a digital display mainboard and a pressure sensor correspondingly; the pressure sensor communicates with the digital display mainboard through a circuit. Compared with the prior art, the lateral compression device used for compressing the side face of the workpiece is simple in structure, high in practicability, capable of accurately controlling the amplitude of compressing force, convenient to operate, safe, reliable and wide in use range.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

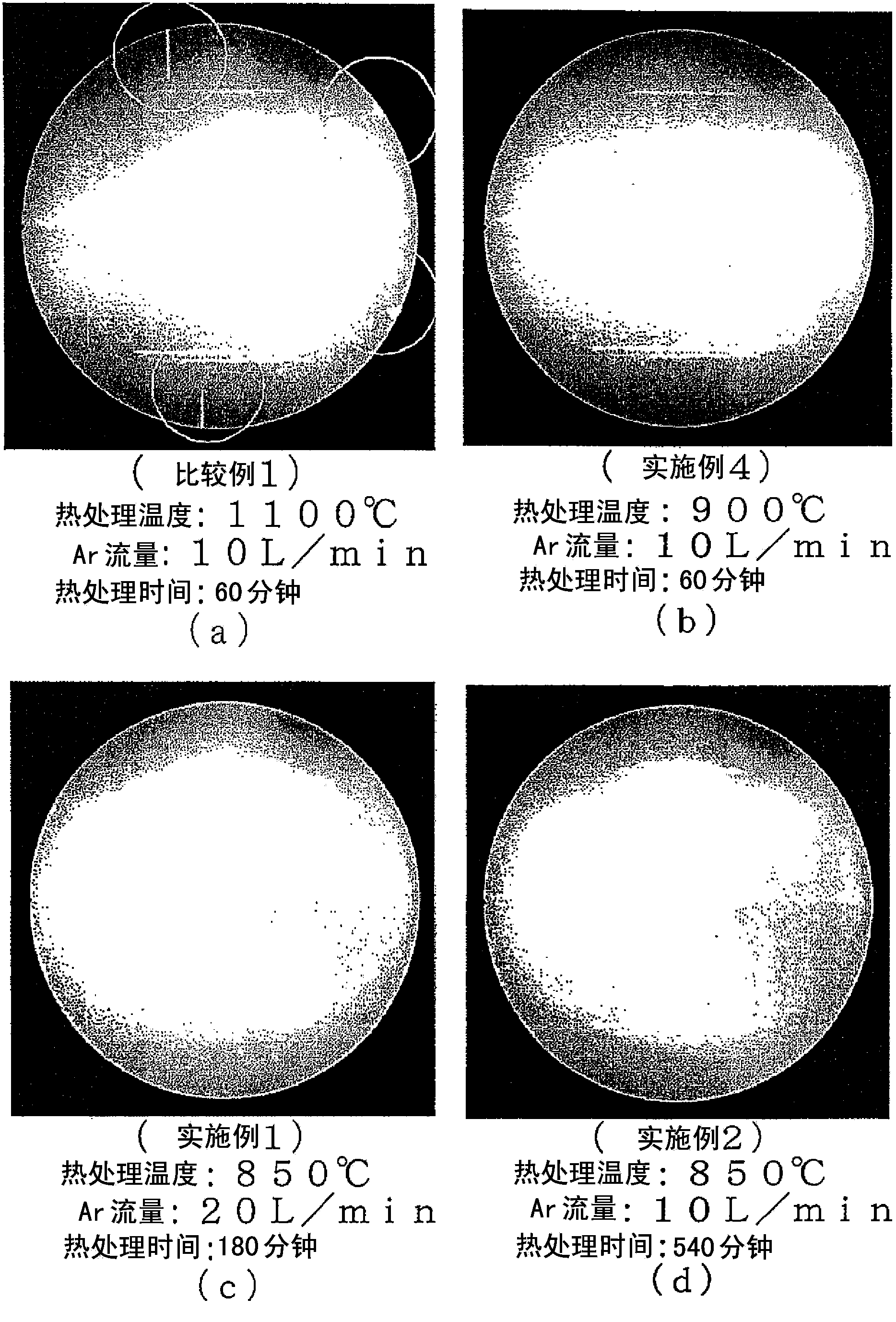

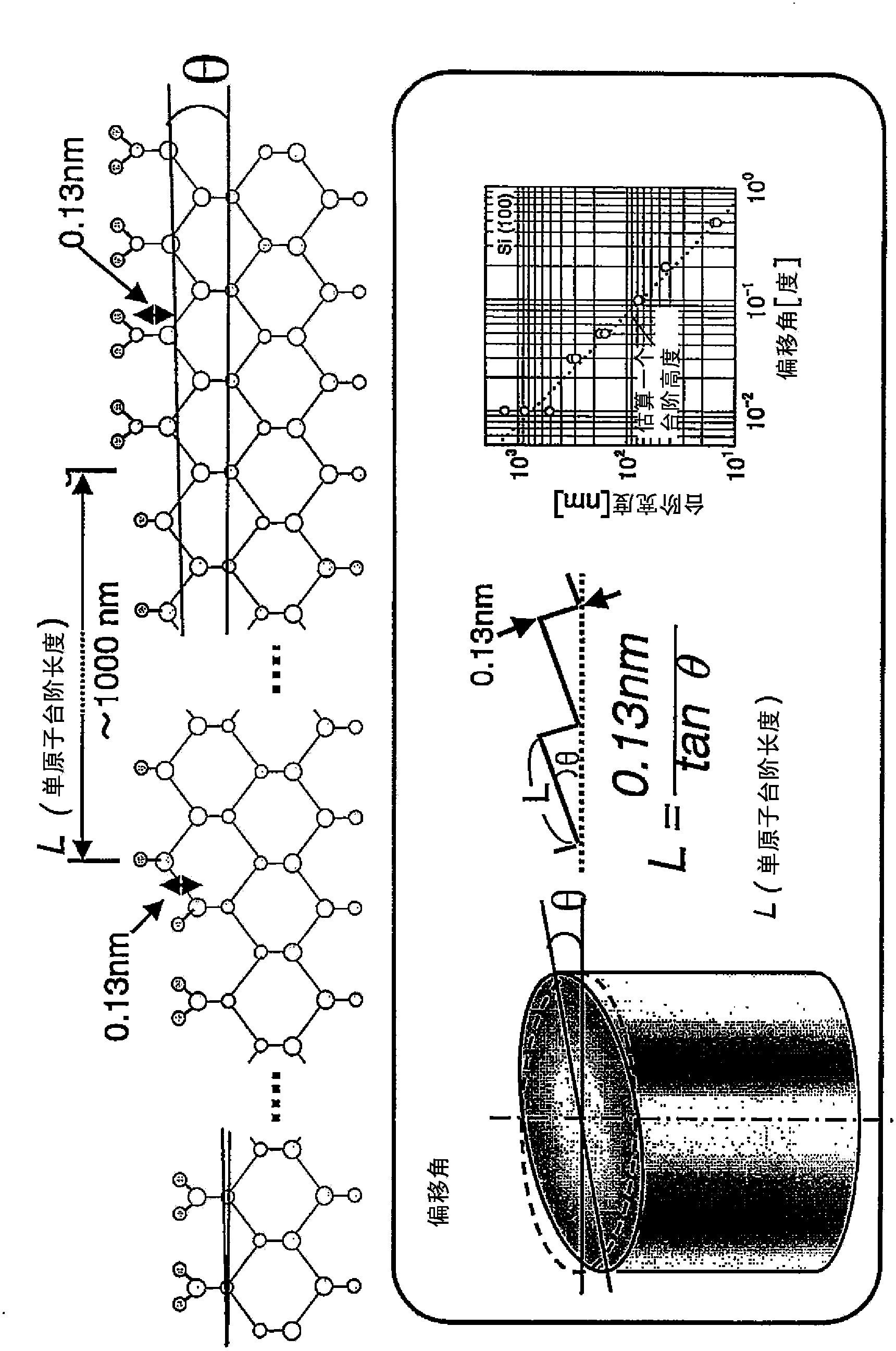

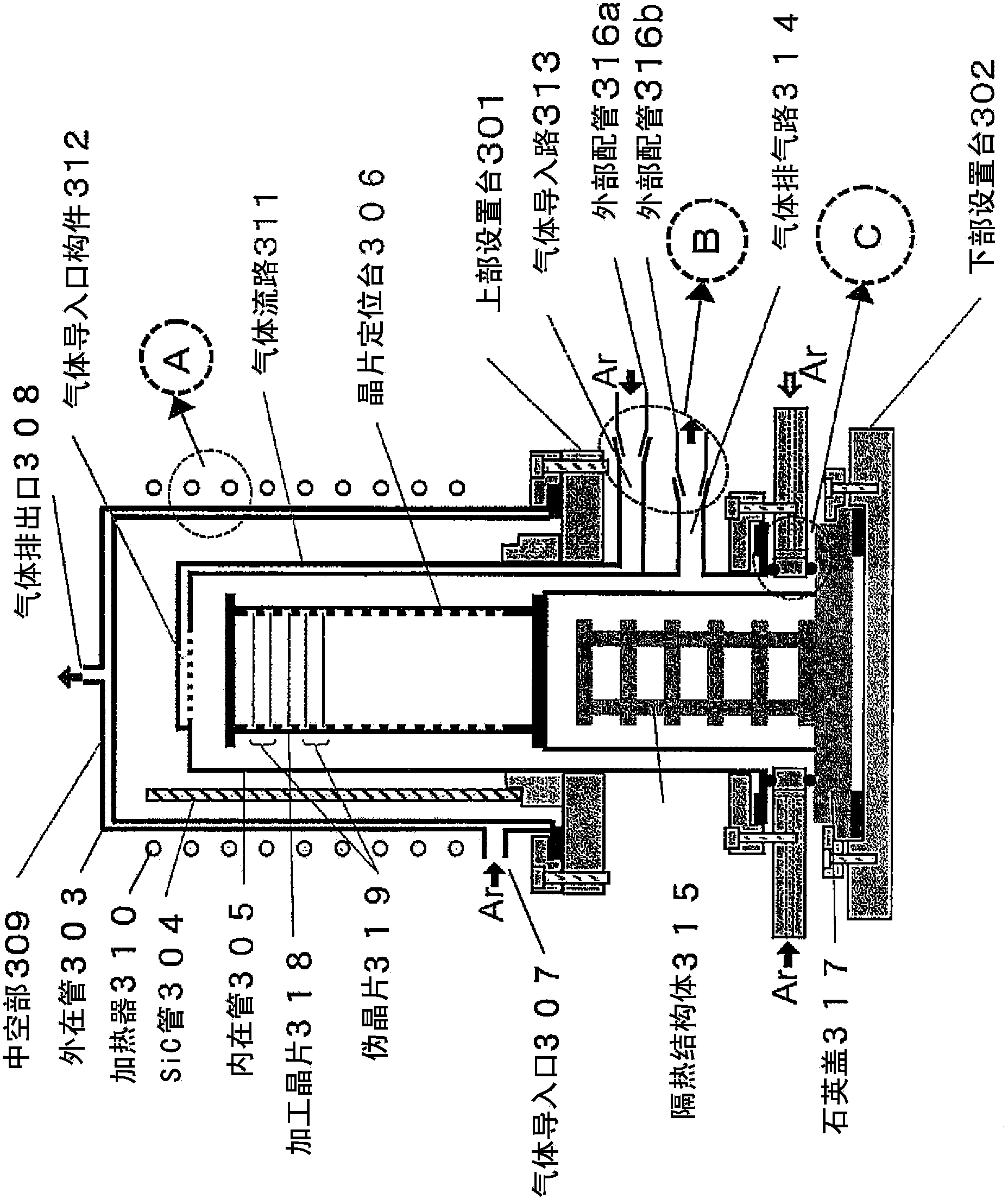

Atomic-order flat surface treatment method of silicon wafer, and heat treatment device

InactiveCN103443910AHas a flat surfaceReduce usageSemiconductor/solid-state device manufacturingSemiconductor devicesAtomic orderSlip line

Owner:TOHOKU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com