Tunnel bottom concrete side-slipping lining construction method and side-slipping needle beam bottom board trolley

A construction method and concrete technology, which are applied in tunnel lining, wellbore lining, earth-moving drilling, etc., can solve problems such as defects in the appearance of air bubbles, inability to discharge air bubbles in time, and temperature cracks when new and old concrete are overlapped on different platforms. Social benefits, the effect of reducing bubble defects and improving construction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

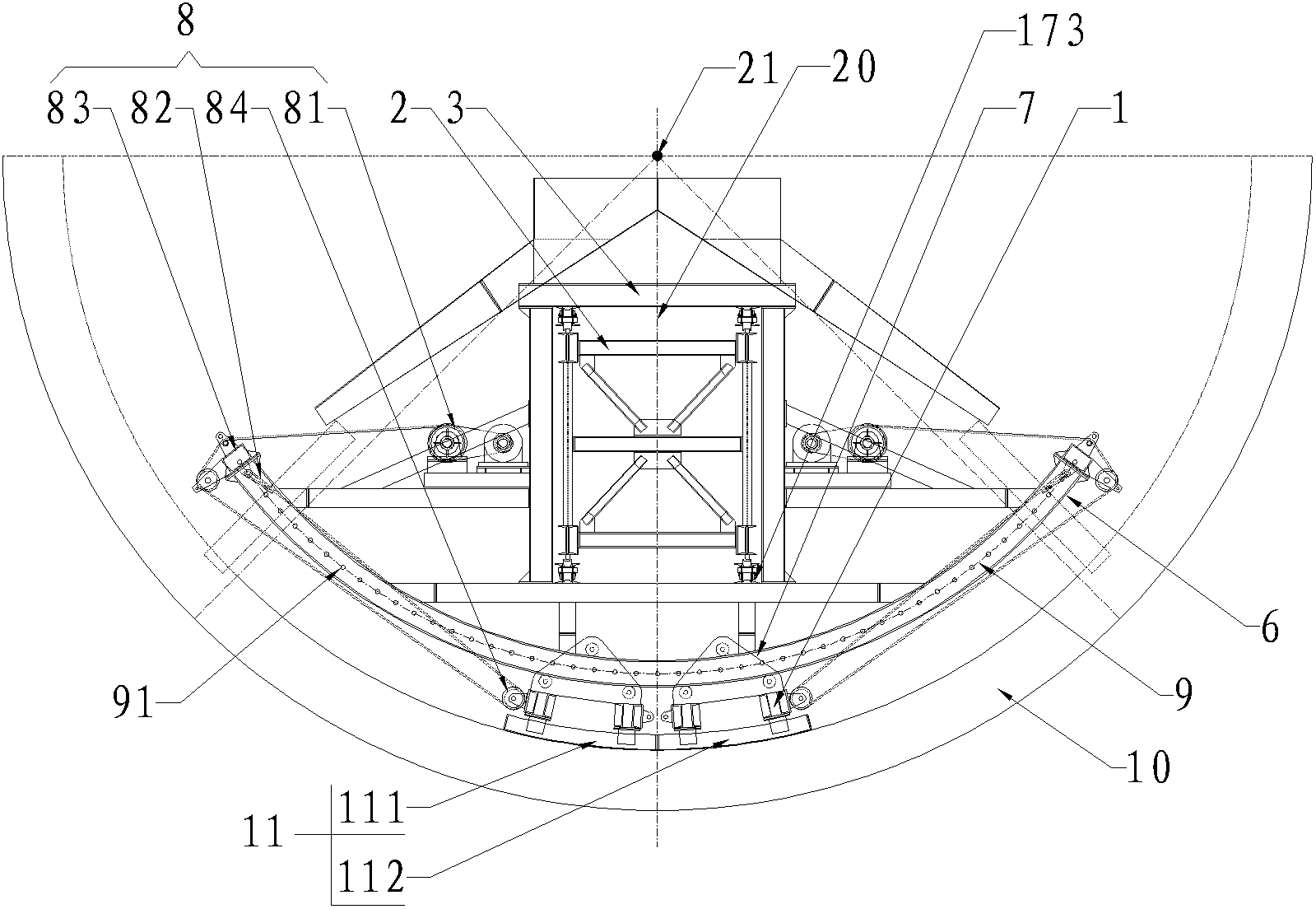

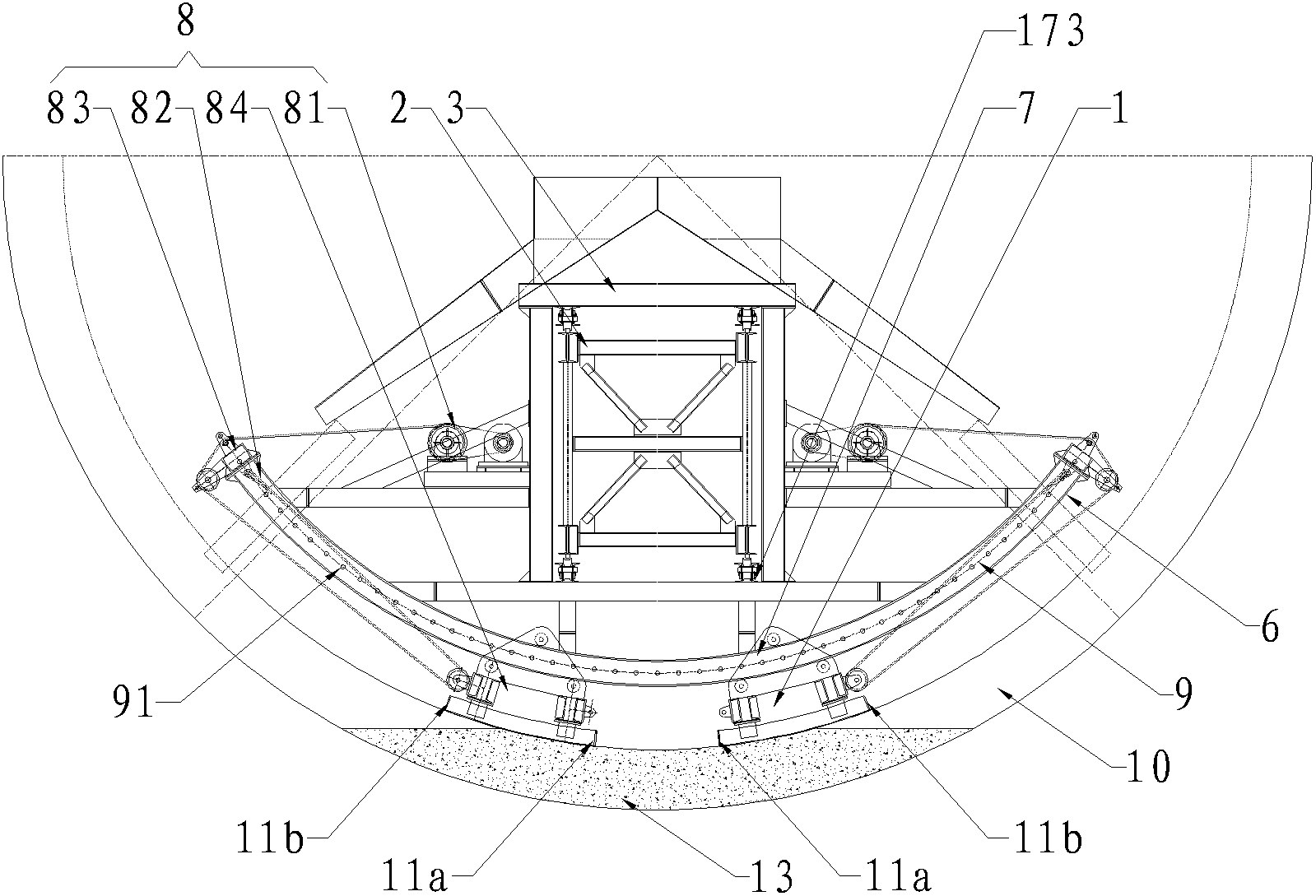

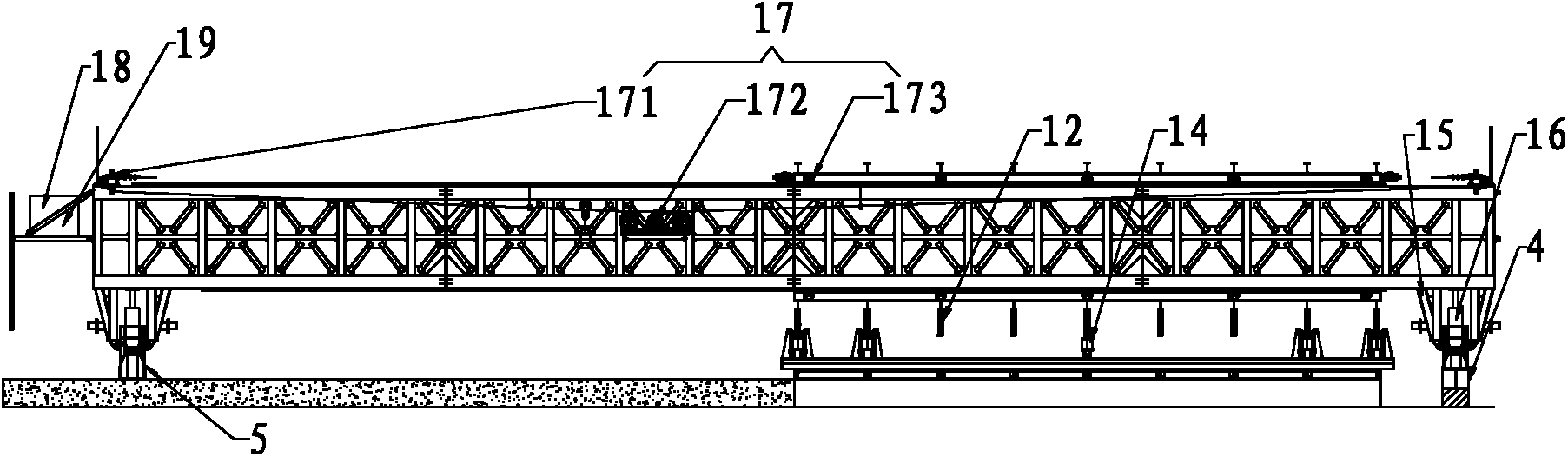

[0054] A side-sliding needle beam bottom mold trolley is mainly composed of formwork assembly 1, guide rail 6, side-slip traction system 8, beam frame assembly 3, needle beam assembly 2, walking system 17, guide slide mechanism 7, centering Adjusting device 16, hydraulic system 18, electrical system 19 and other components.

[0055] Its every cover template comprises left and right two slide templates 11. The outer contour size of the formwork is designed according to the tunnel forming radius. The width of each sliding formwork 11 is generally designed to be 1-1.5 meters, and the longitudinal length of the two sliding formworks 11 is designed according to the tunnel construction requirements. The single-sided sliding formwork 111 and 112 are connected by two double-channel steel combined steel beams to ensure that the entire formwork has sufficient rigidity and straightness. Considering the convenience of transportation and hoisting, the shaped steel beams and formwork are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com