Process and device for flattening W-like arc-shaped magnesium alloy blank plate

A magnesium alloy and arc-shaped technology is applied in the field of technology and device for flattening W-shaped arc-shaped magnesium alloy billets, and can solve the problems of high investment, low-efficiency production, and unsuitable continuous production of coils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

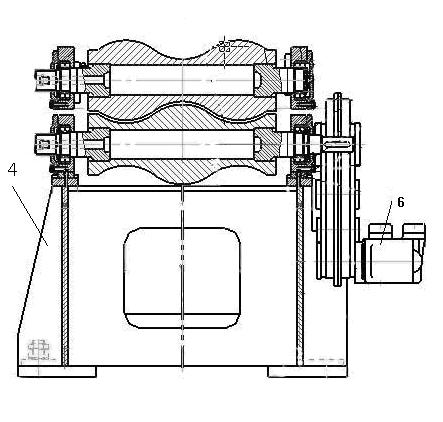

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

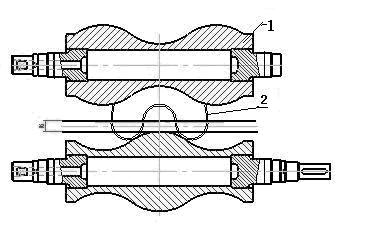

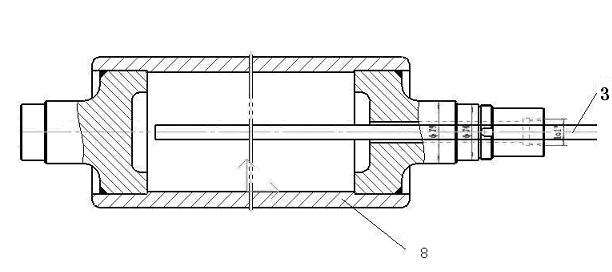

[0031] Such as figure 1 , 2 , 3, 4, 5, 6, and 7 show: a kind of technology of flattening arc-shaped magnesium alloy slab, and its steps are as follows:

[0032] a. The first preliminary flattening, using two corresponding concave and convex arc-shaped rolls to form a W-shaped gap similar to the W-shaped arc-shaped slab, and apply the W-shaped arc-shaped slab passing through the gap between them. Pressing and stretching to obtain a wide magnesium alloy arc-shaped slab; the temperature of the W-shaped arc-shaped slab during the stretching process is controlled at 230°C-280°C by two corresponding electric heating concave and convex arc-shaped rolls;

[0033] b. The second flat plate is flattened, using a wide flat plate-shaped gap formed by two upper flattening rollers and three lower flattening rollers, and widening the wide-width magnesium alloy arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com