Patents

Literature

368results about How to "Achieve horizontal movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

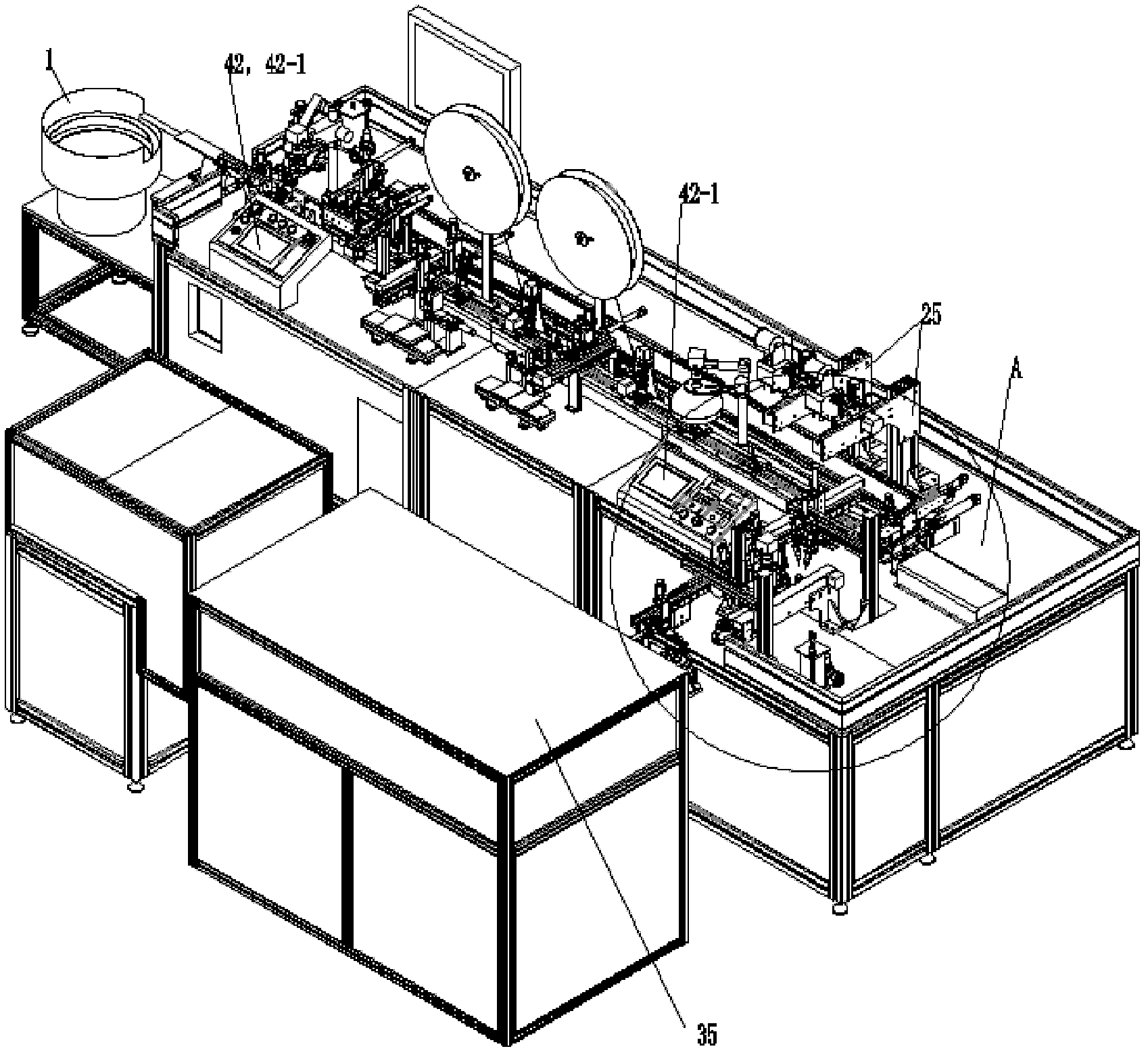

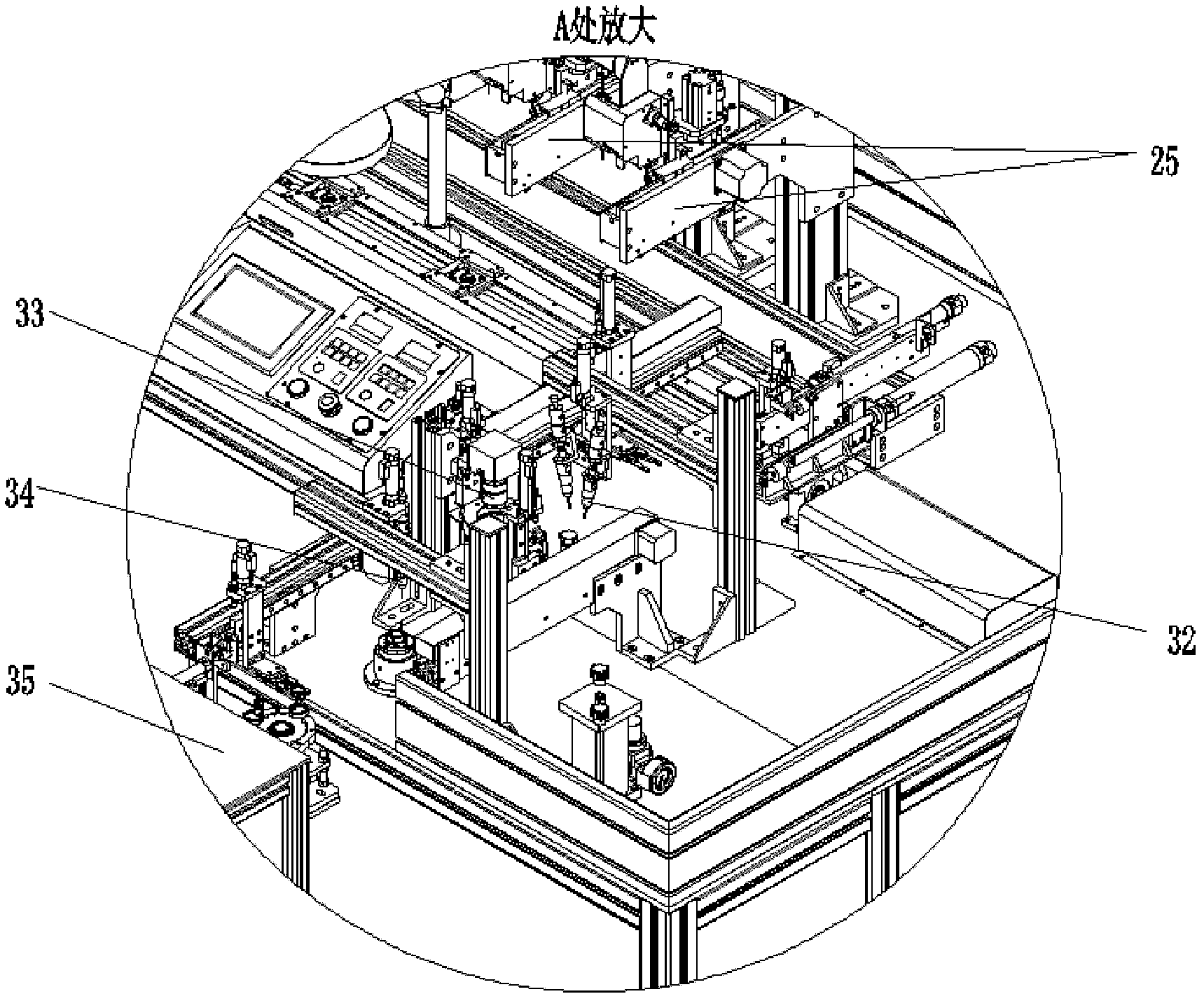

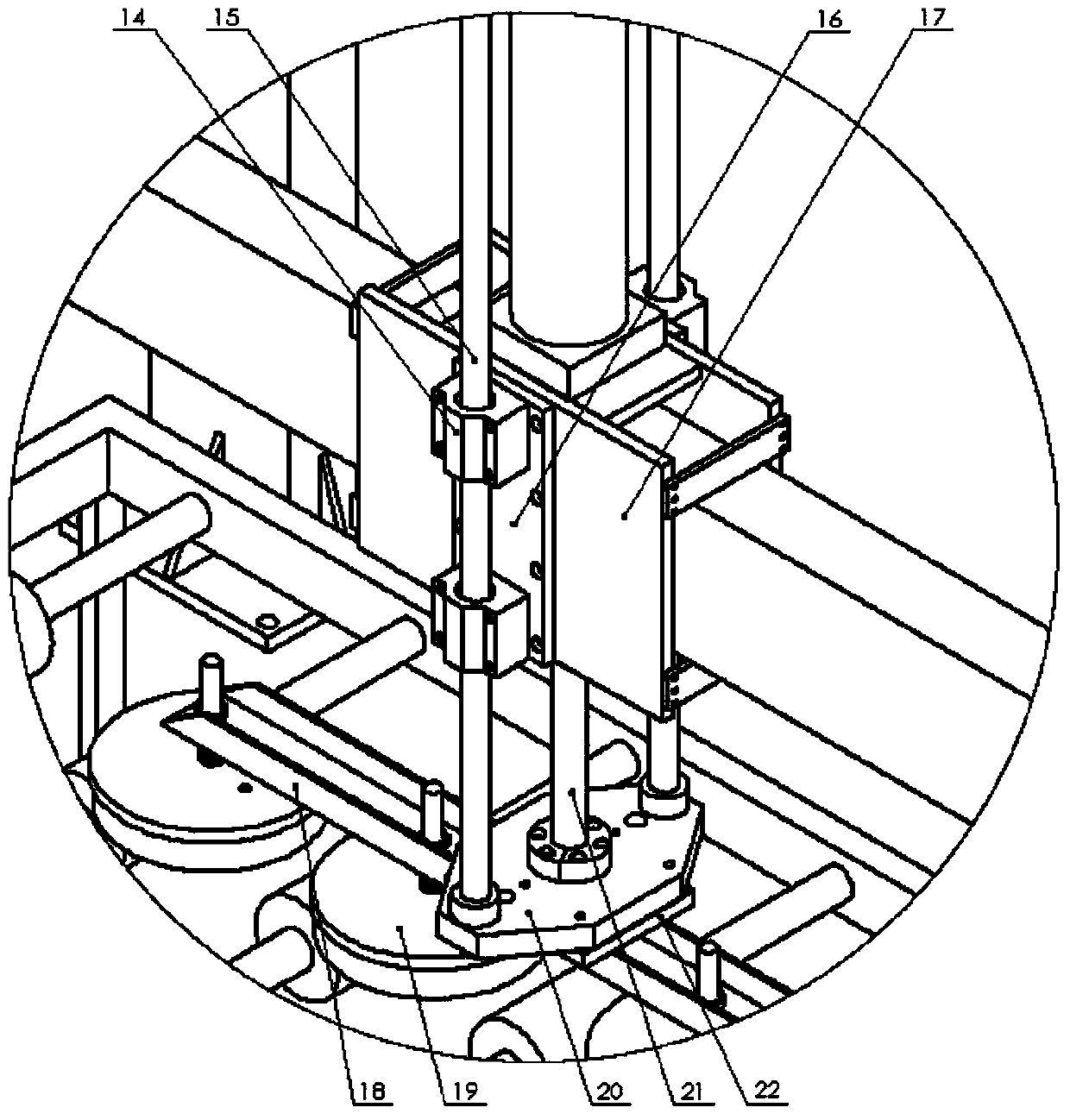

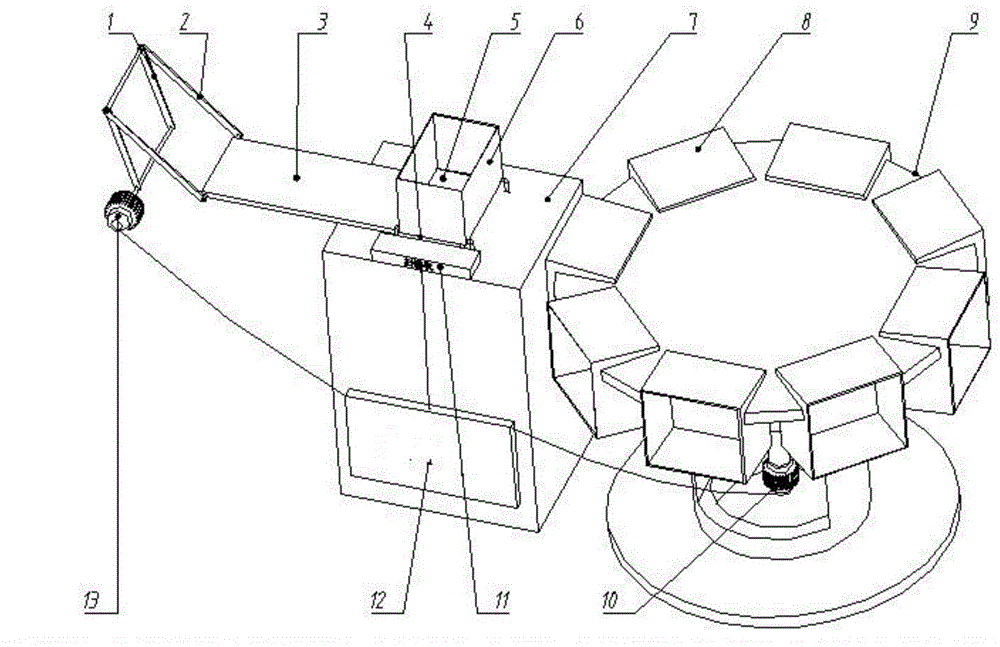

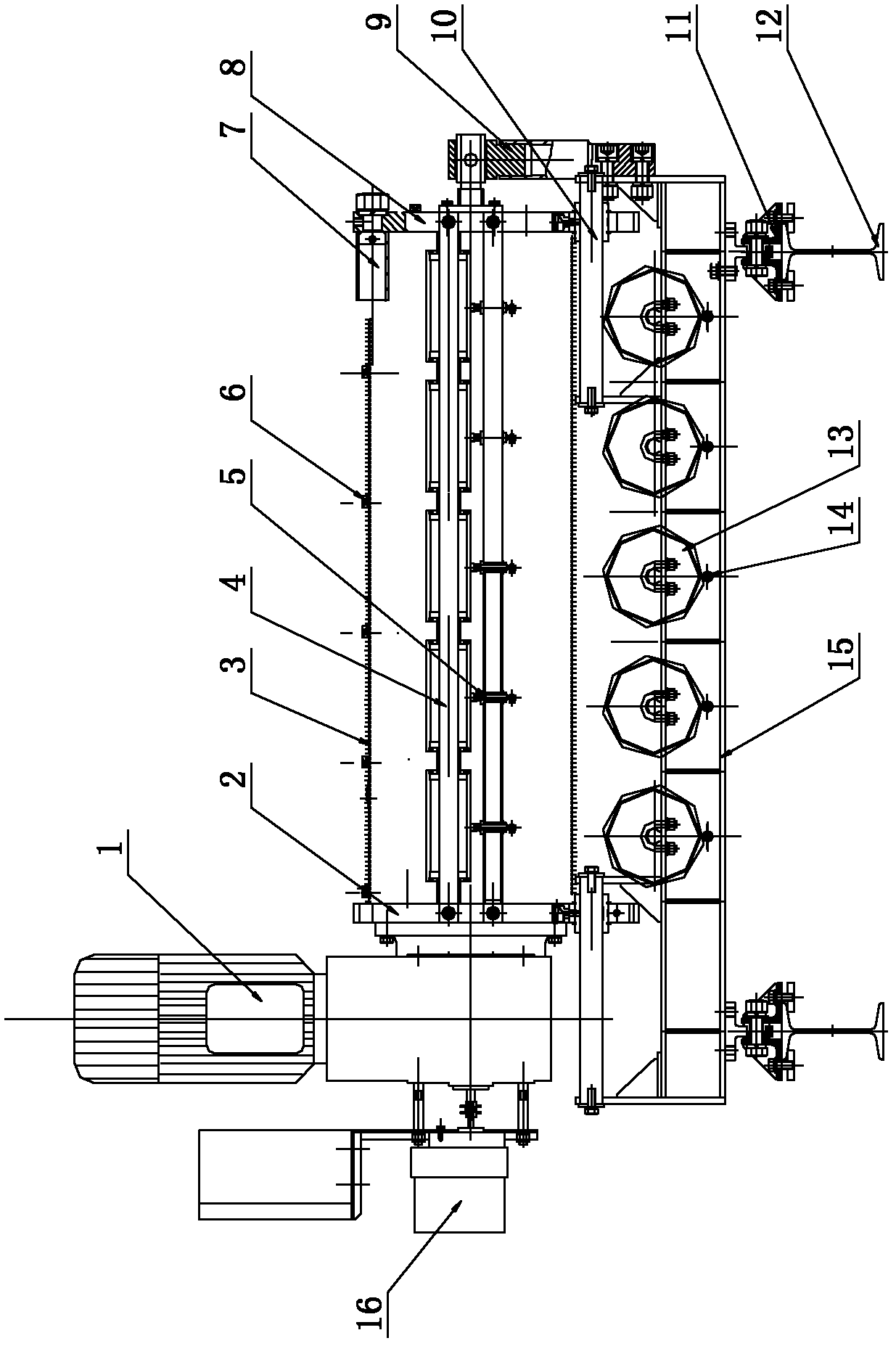

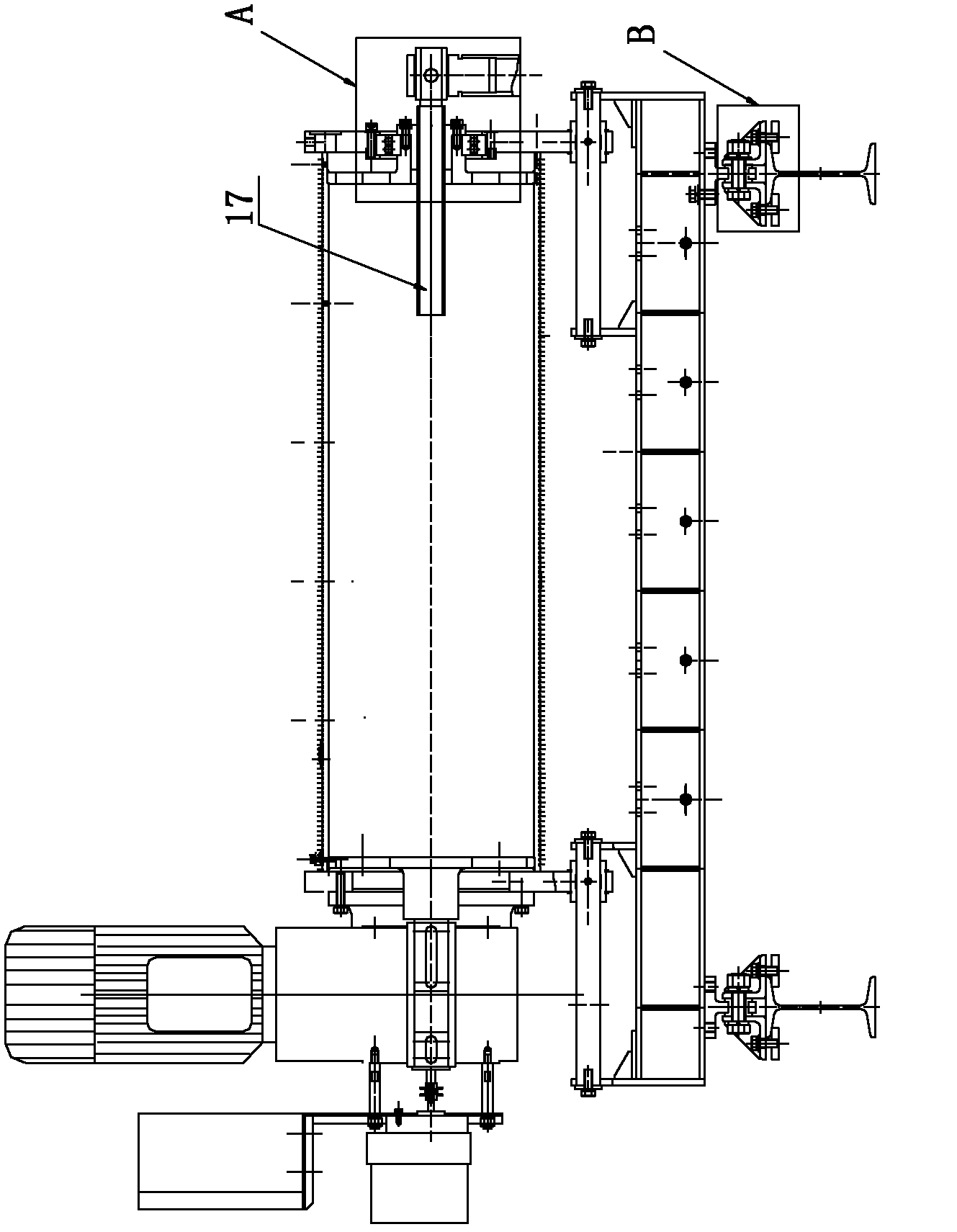

Automatic assembly production line of buzzers

ActiveCN102848187AGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

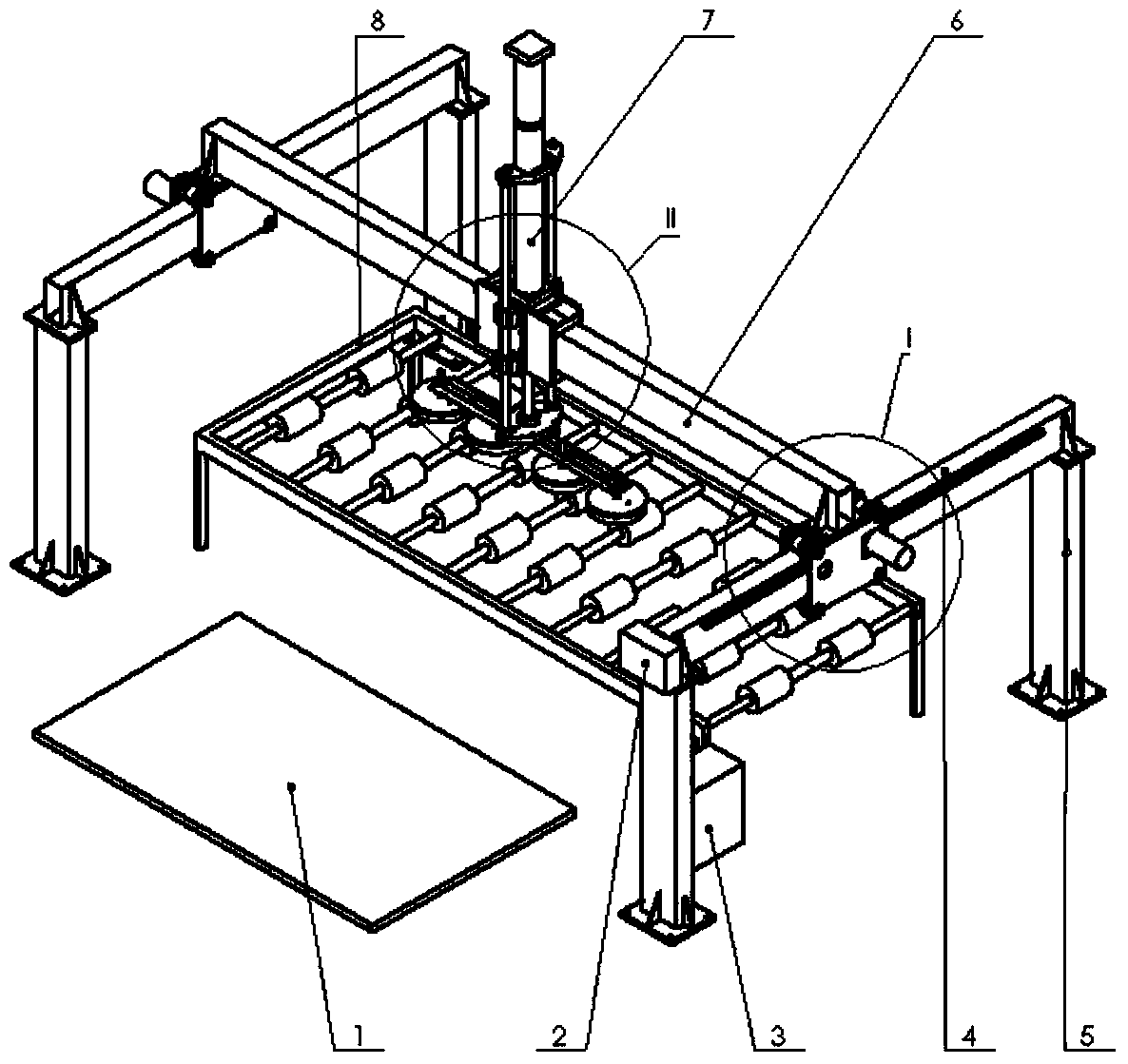

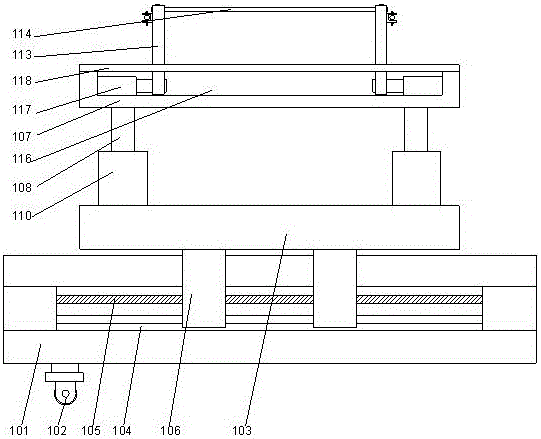

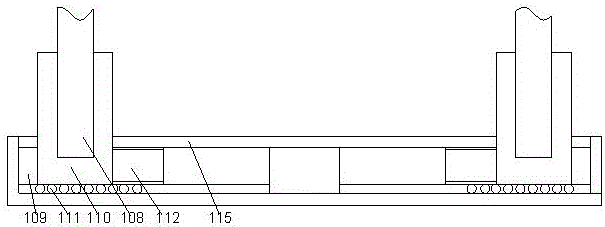

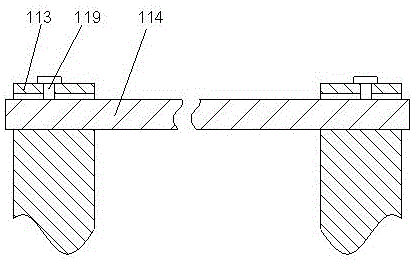

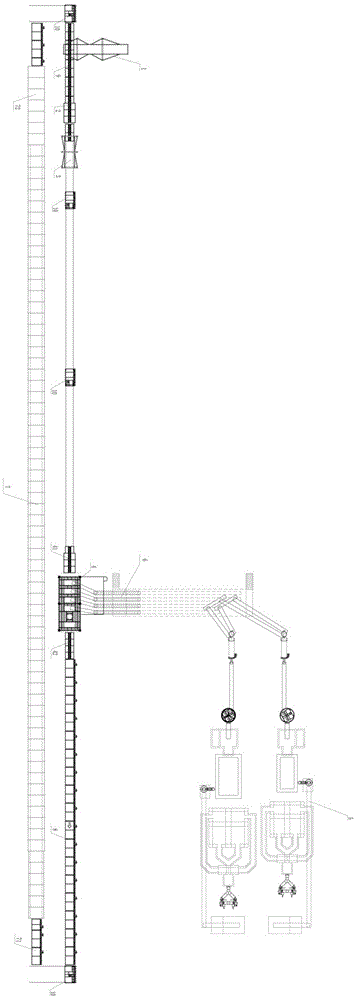

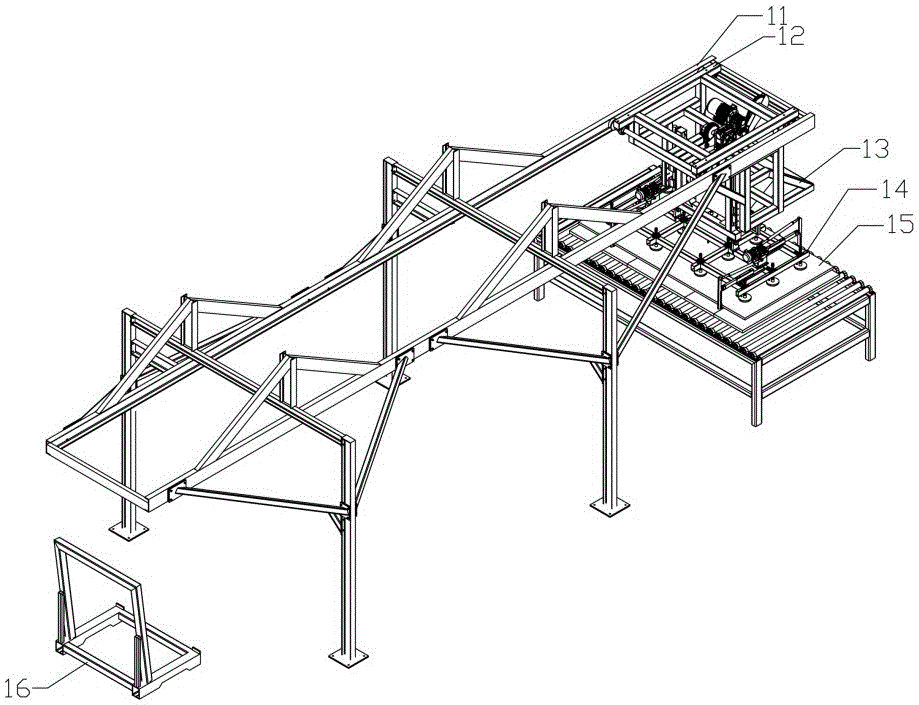

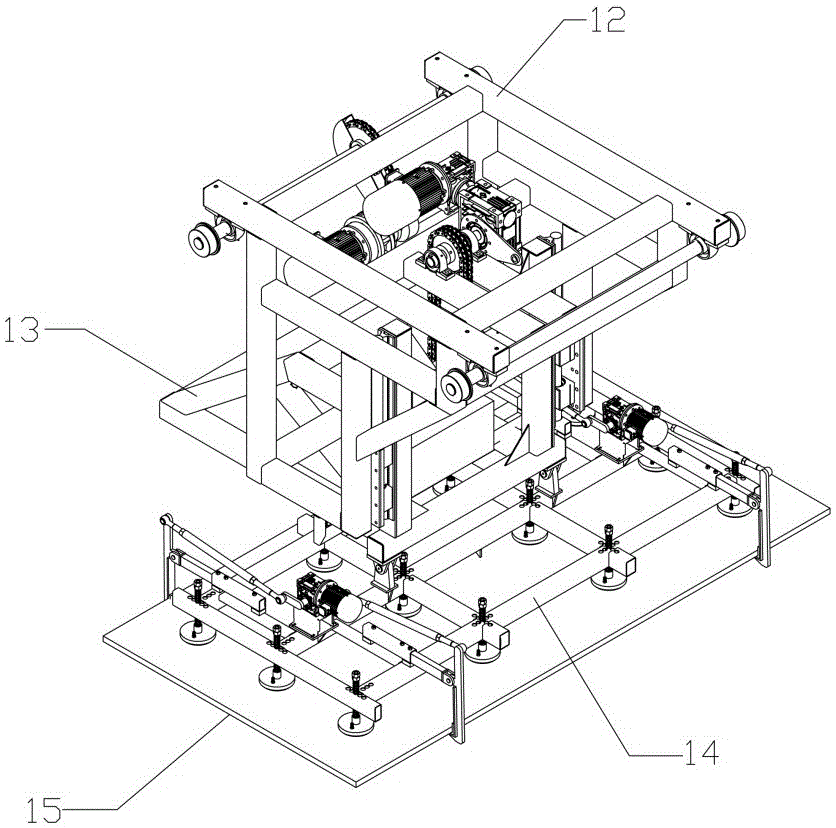

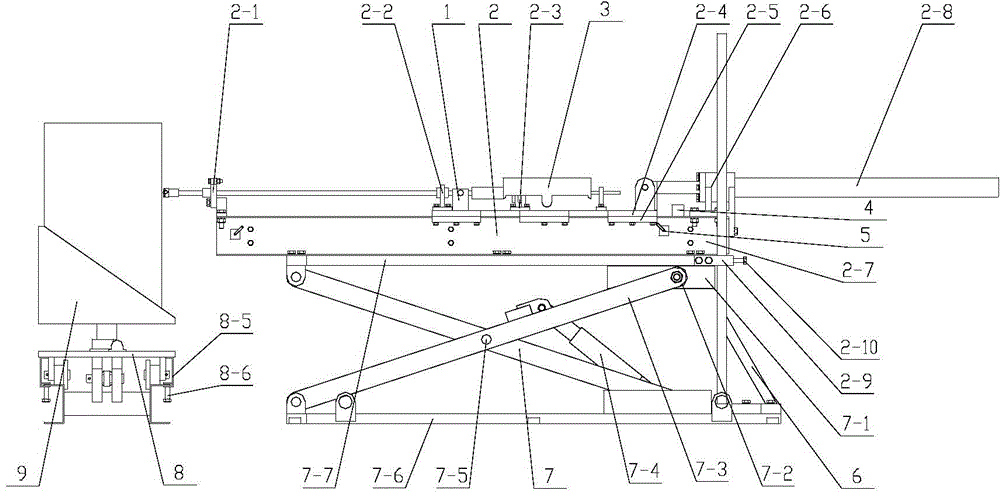

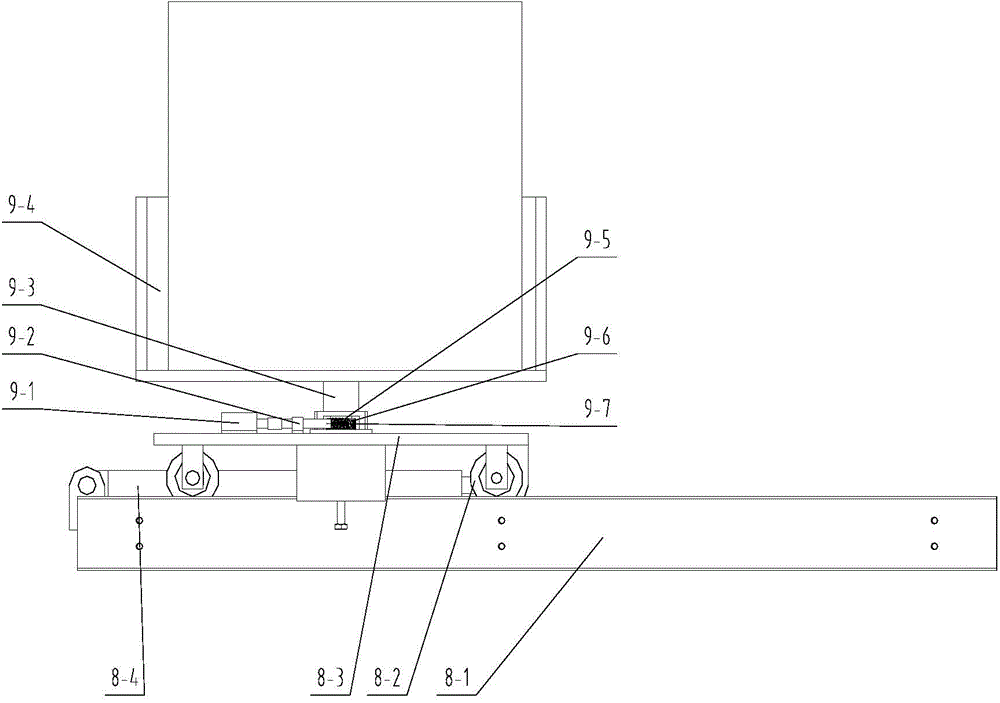

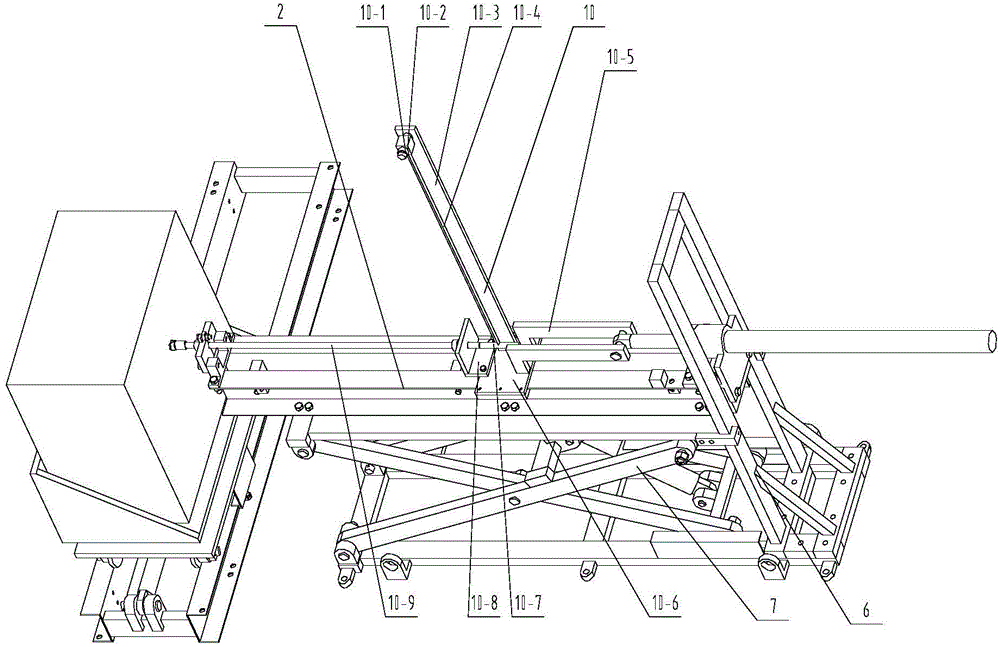

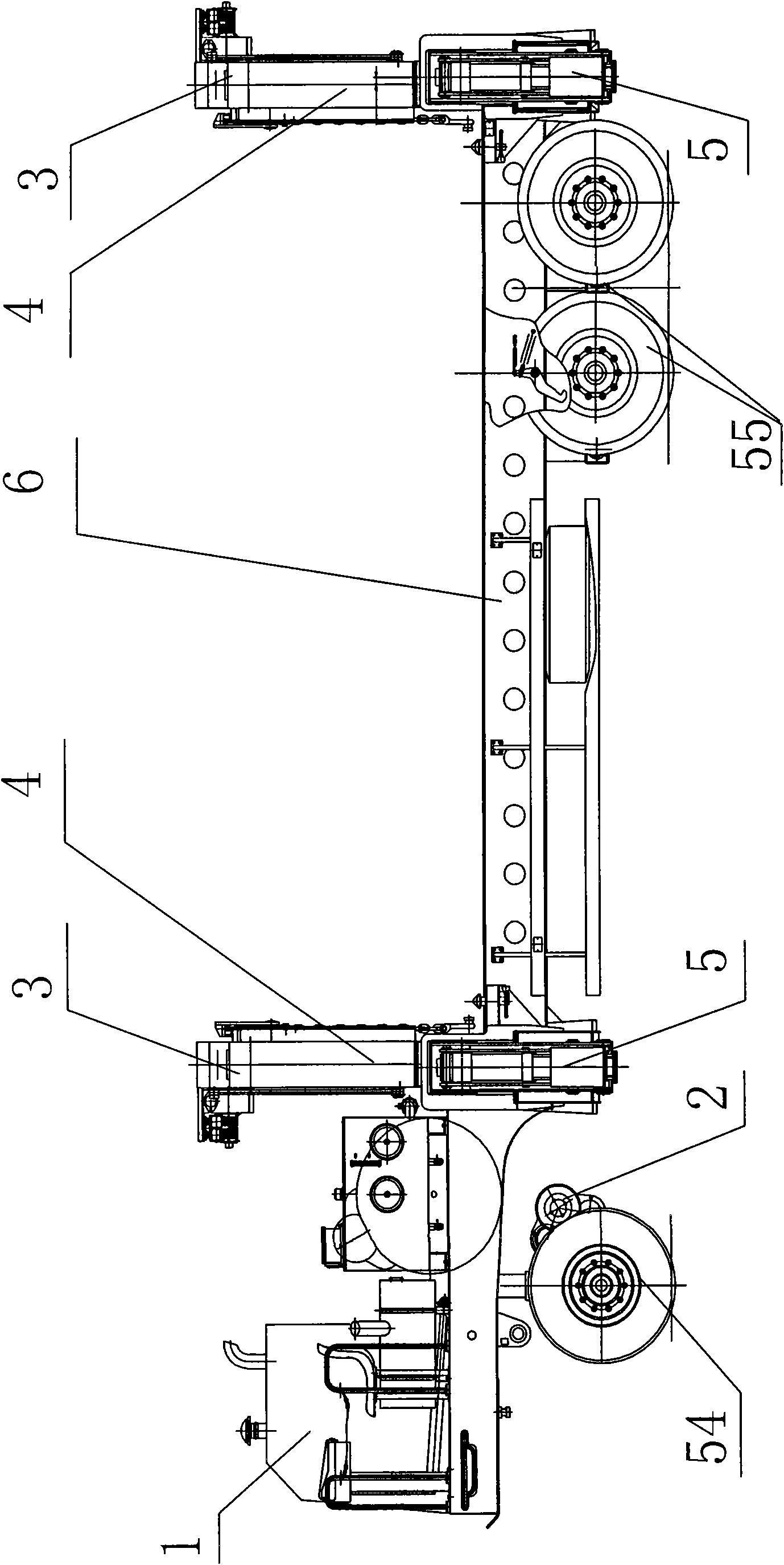

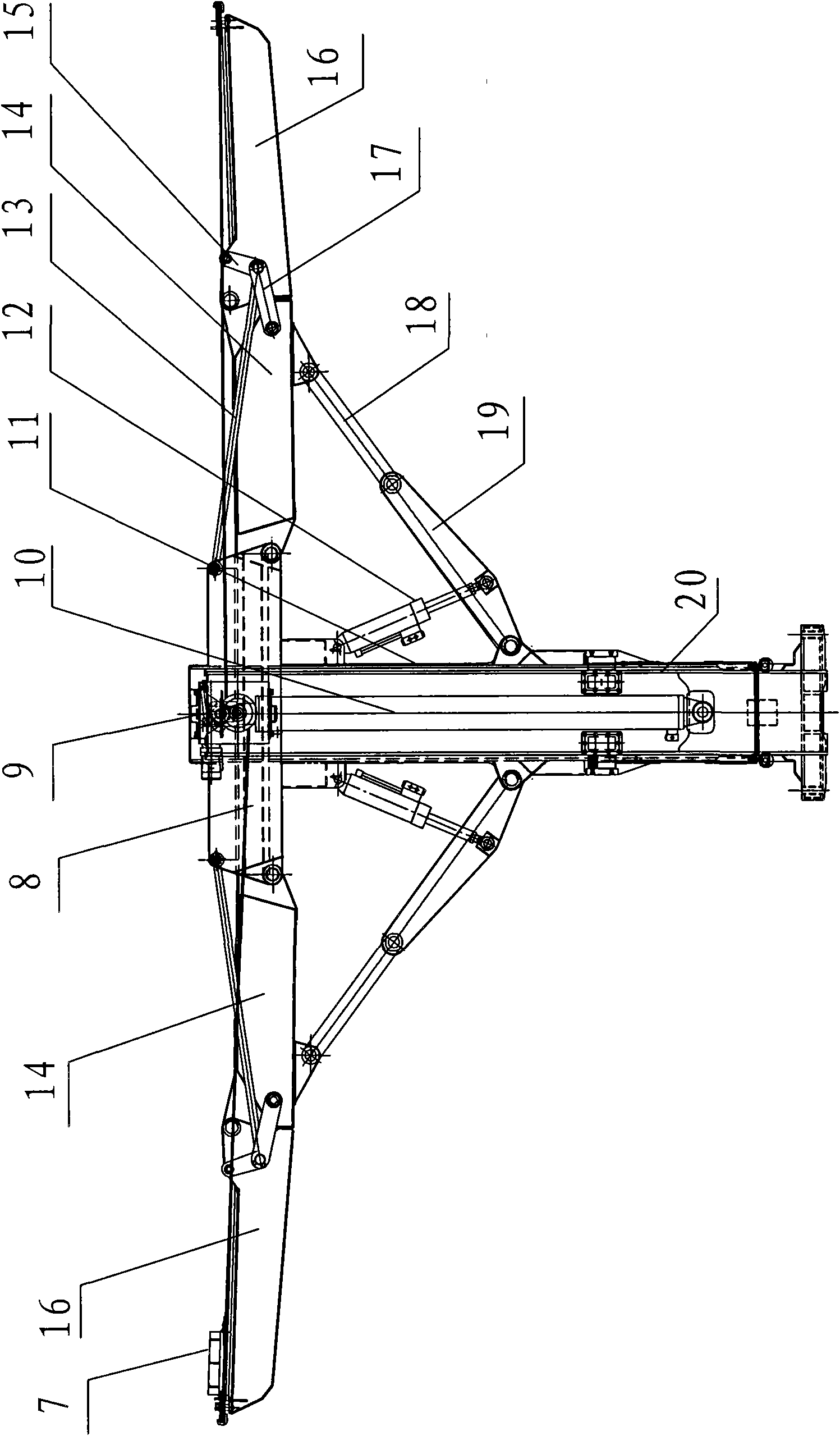

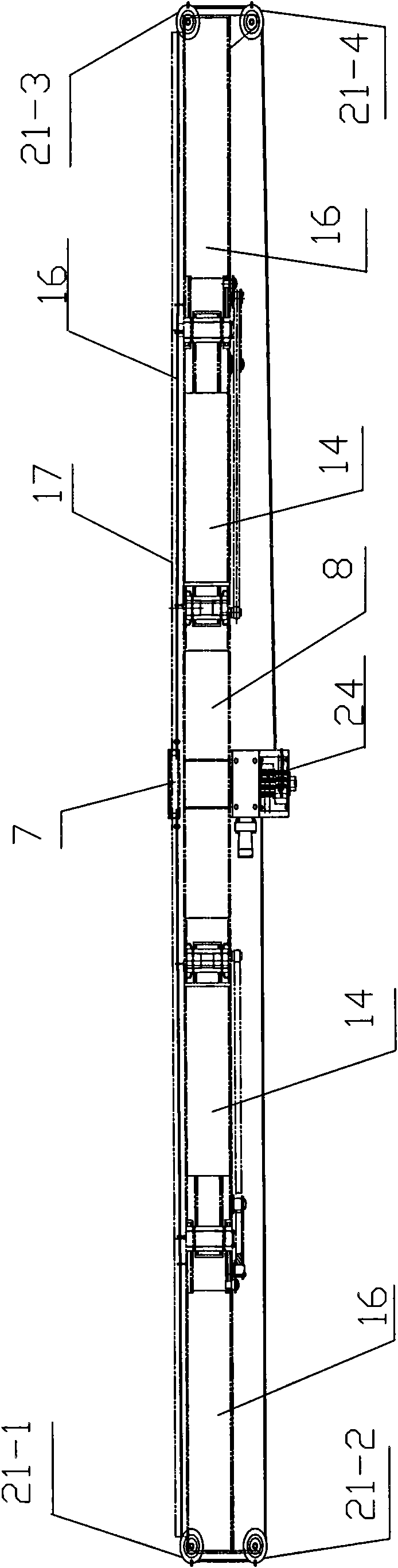

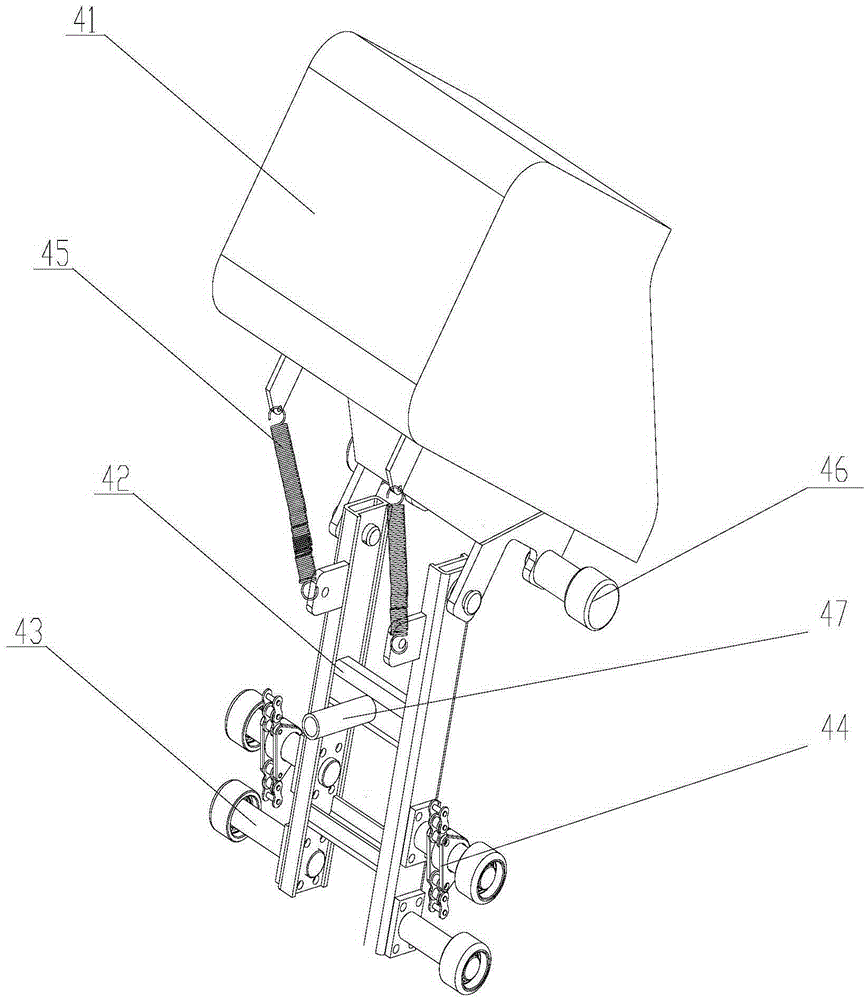

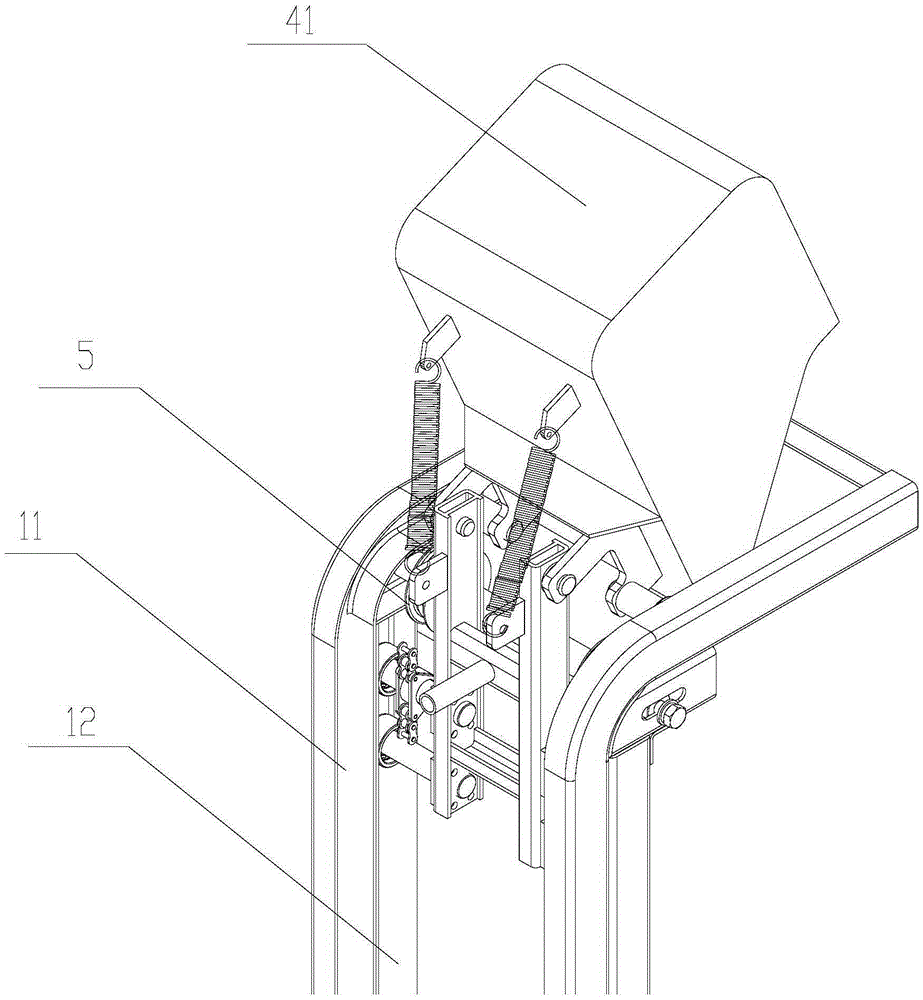

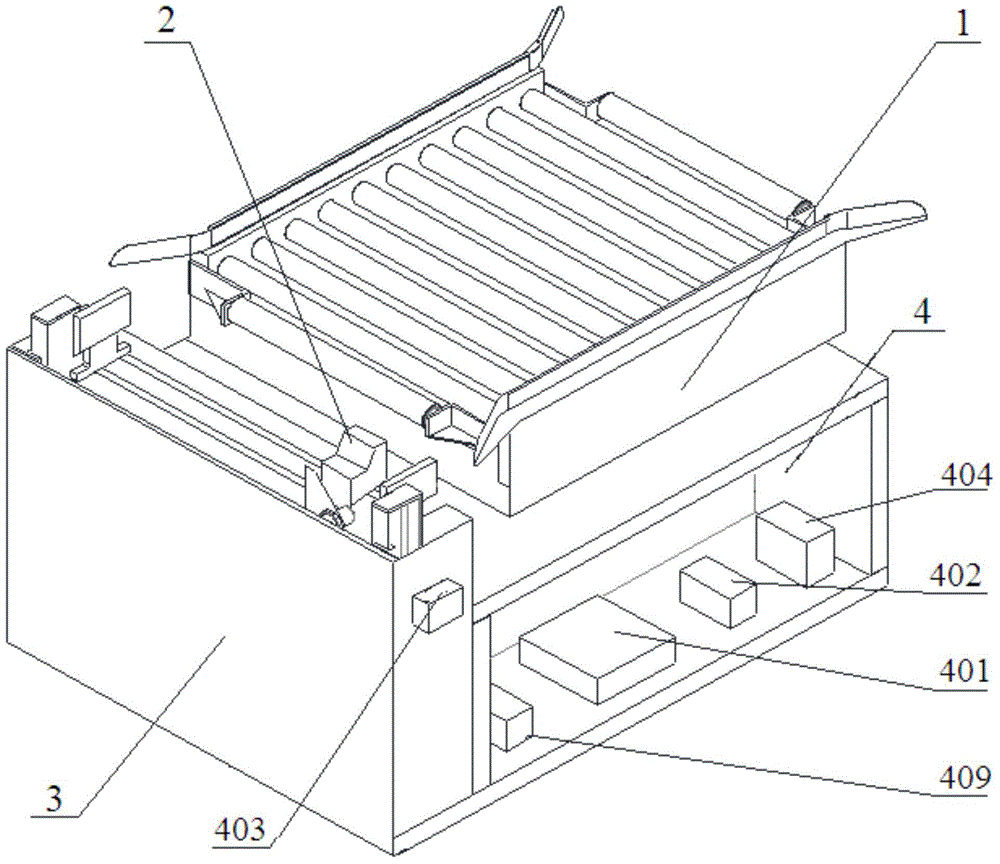

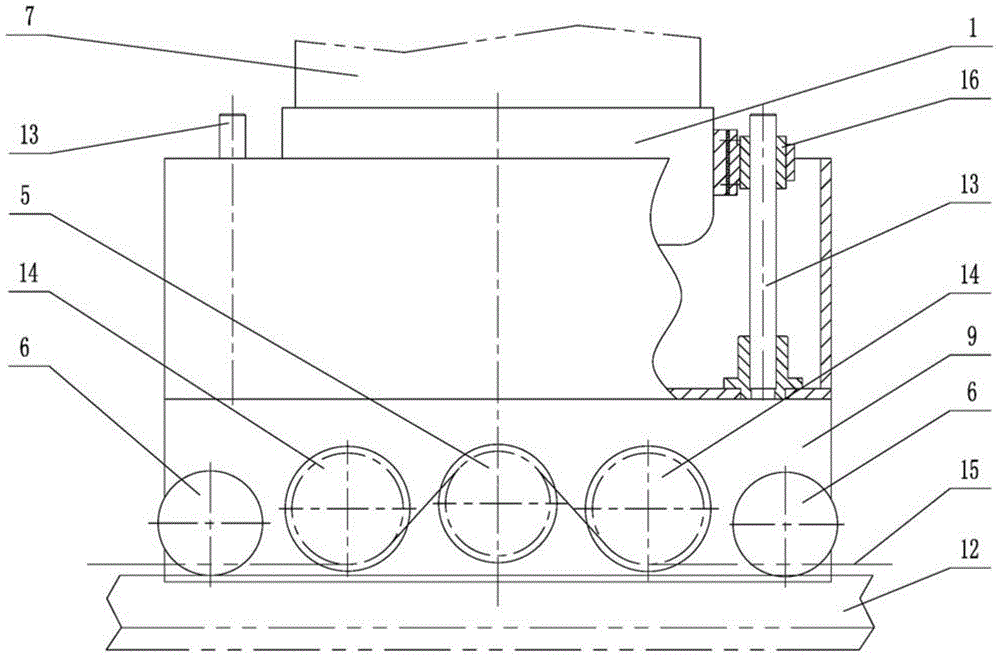

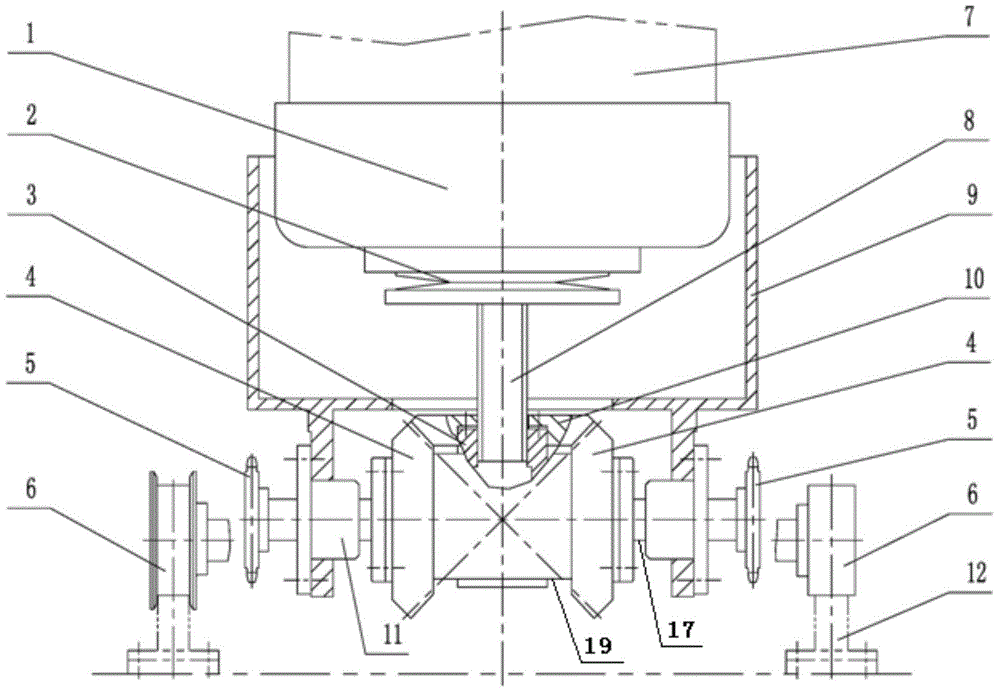

Device and method for automatic feeding and discharging of stone slabs

ActiveCN104176498ARealize automatic crawlingAchieve horizontal movementGrinding machine componentsConveyor partsMechanical engineeringTransverse beam

Owner:RIZHAO HEIN SAW

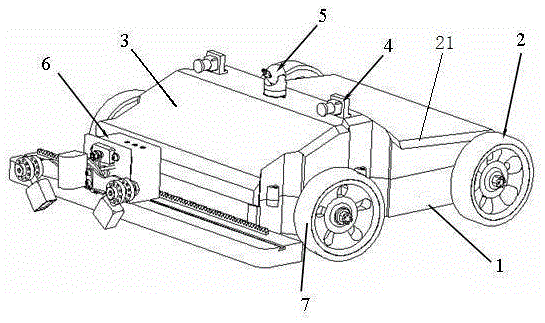

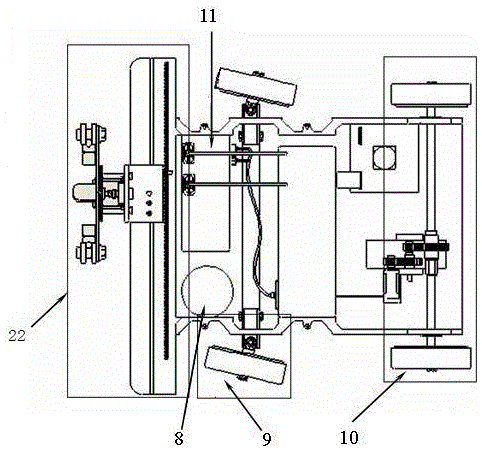

Automatic detector for welding line of storage tank bottom plate based on wireless transmission

ActiveCN105158337ARealize non-destructive testingAchieve horizontal movementAnalysing solids using sonic/ultrasonic/infrasonic wavesWireless transmissionComputer module

The invention relates to an automatic detector for a welding line of a storage tank bottom plate based on wireless transmission. The automatic detector comprises a machine body, a synchronous positioning and map construction module, a wireless data communication module and a control mechanism, wherein front wheels capable of controlling steering are mounted on the two sides of the machine body; driving rear wheels are mounted on the two sides of the rack; a bottom plate is arranged at the front end of the machine body in a manner of stretching frontwards; a lossless detection mechanism is mounted on the bottom plate; the lossless detection mechanism is provided with two air coupling ultrasonic probes with adjustable positions; the two air coupling ultrasonic probes are obliquely arranged in a V shape; a laser welding line tracking device is arranged between the two probes; an infrared camera and an infrared sensor are mounted at the top of the machine body; the control mechanism is connected with the front wheels and the driving rear wheels respectively; and the synchronous positioning and map construction module, the wireless data communication module, the laser welding line tracking device, the infrared camera and the infrared sensor are connected with the control mechanism respectively. With the adoption of the automatic detector, intelligent detection and evaluation of the welding line of the bottom plate are realized, and the manual detection cost is greatly reduced.

Owner:桐乡金橙云智科技有限公司

Lifting platform for electric power overhauling

InactiveCN105819378AEven by forceAchieve horizontal movementLifting devicesMechanical engineeringClassical mechanics

The invention discloses a lifting platform for electric power overhauling. The lifting platform for electric power overhauling comprises a base and universal wheels which are arranged under the base. A horizontal movement platform is arranged above the base. Sliding grooves are formed in the side walls of the two sides of the base correspondingly. Lead screws are arranged in the sliding grooves. Lead screw bases are arranged on the two sides of each sliding groove correspondingly. Motors used for driving the lead screws are arranged on the inner sides of the lead screw bases. Sliding blocks are arranged on the two sides of the horizontal movement platform correspondingly. The sliding blocks are arranged on the lead screws in a sleeving mode and can move in the axis direction of the lead screws. A vertical movement platform is arranged above the horizontal movement platform. Four lifting devices are arranged between the vertical movement platform and the horizontal movement platform. According to the lifting platform for electric power overhauling, three-direction movement of the lifting platform in the horizontal direction and the vertical direction can be achieved.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LONGKOU POWER SUPPLY CO

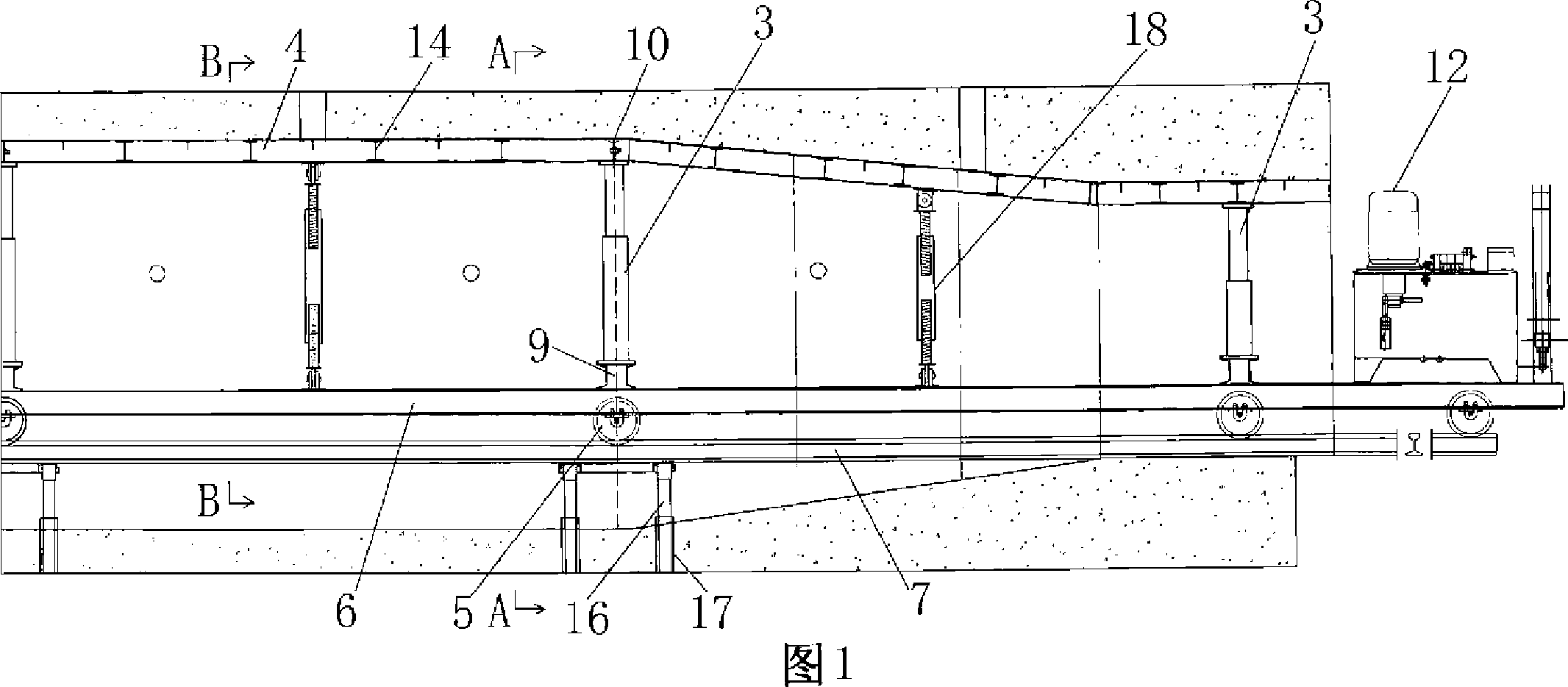

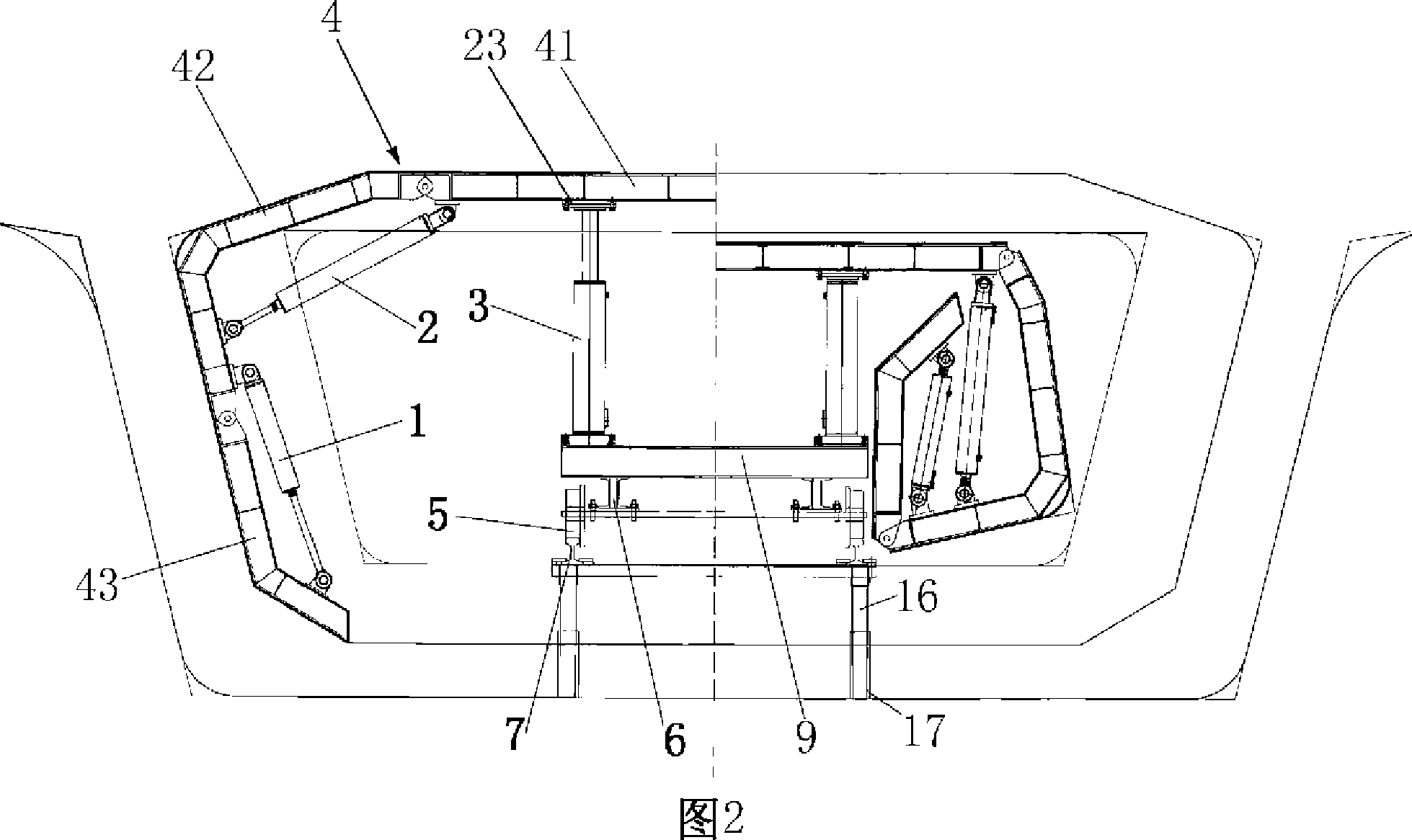

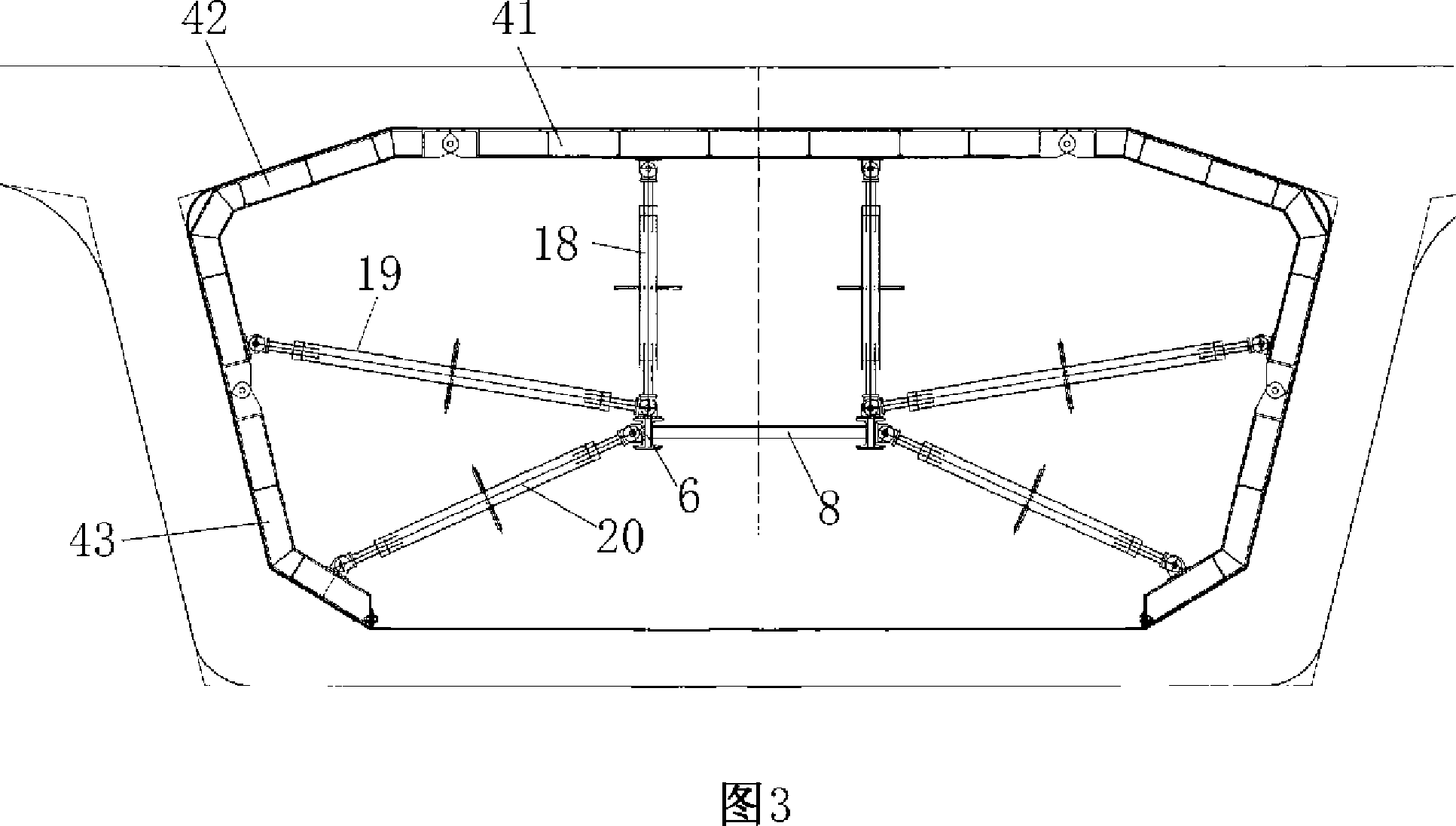

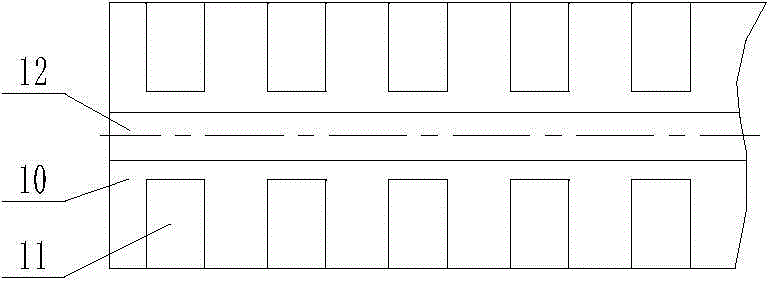

Full-automatic hydraulic prefabricated box girder inner formwork system

InactiveCN1970264ASimple structureLess consumablesMouldsCeramic shaping mandrelsInterior spaceVehicle frame

The automatic hydraulic premade box beam inner formwork system has the inner mold hinging with a pair of up corner mold and a lower corner mold, oil tank slanting upward connected between the top mold and the up corner mold, oil tank slanting downward connected between the top corner mold and the lower corner mold, bracket barricaded along the box beam at the center of the cavity bottom surrounded by inner molds supporting up steel track that has translation cart along it with the cart composed of walking wheel, frame, supporting base beam fastened on the frame, frame of the cart extending outside of the inner mold plate with hydraulic pump station and operation platform. It is simple, steel consumption effective, low in cost, improving inner space 25% than the traditional one.

Owner:杨秋利

Automatic library book sorting method

The invention discloses an automatic library book sorting method, which comprises a book recycling device, a scanning device, a sorting device, an output device and the like. At present, bar codes are mounted on books in a library; sorting information of the books is stored in the bar codes; the books are placed on an apparatus manufactured according to the method; the sorting information of the books is read by a bar code scanning device which is mounted on the apparatus, and then the books are transferred to sorting openings of corresponding classifications through system judgment so as to be classified.

Owner:CHANGZHOU UNIV

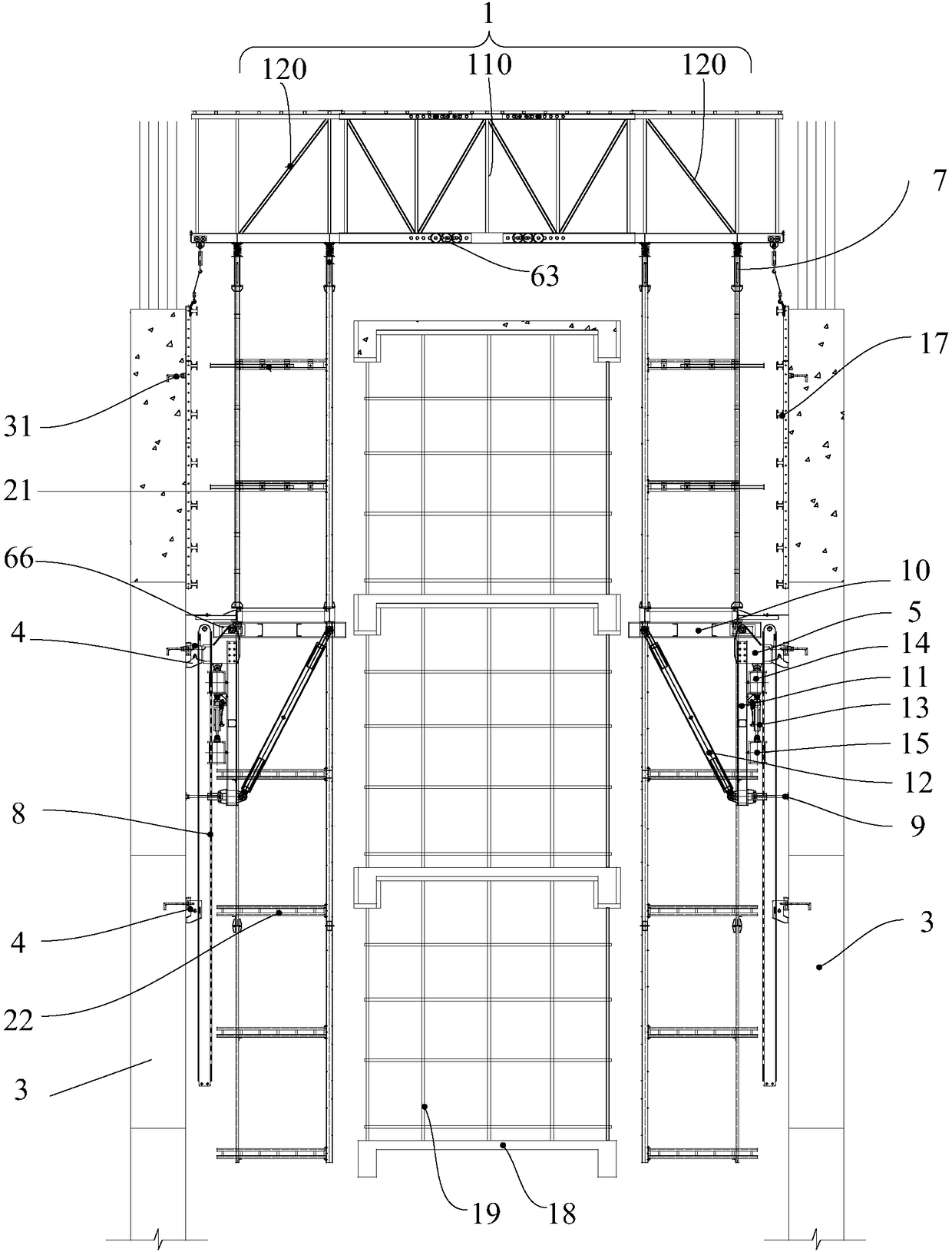

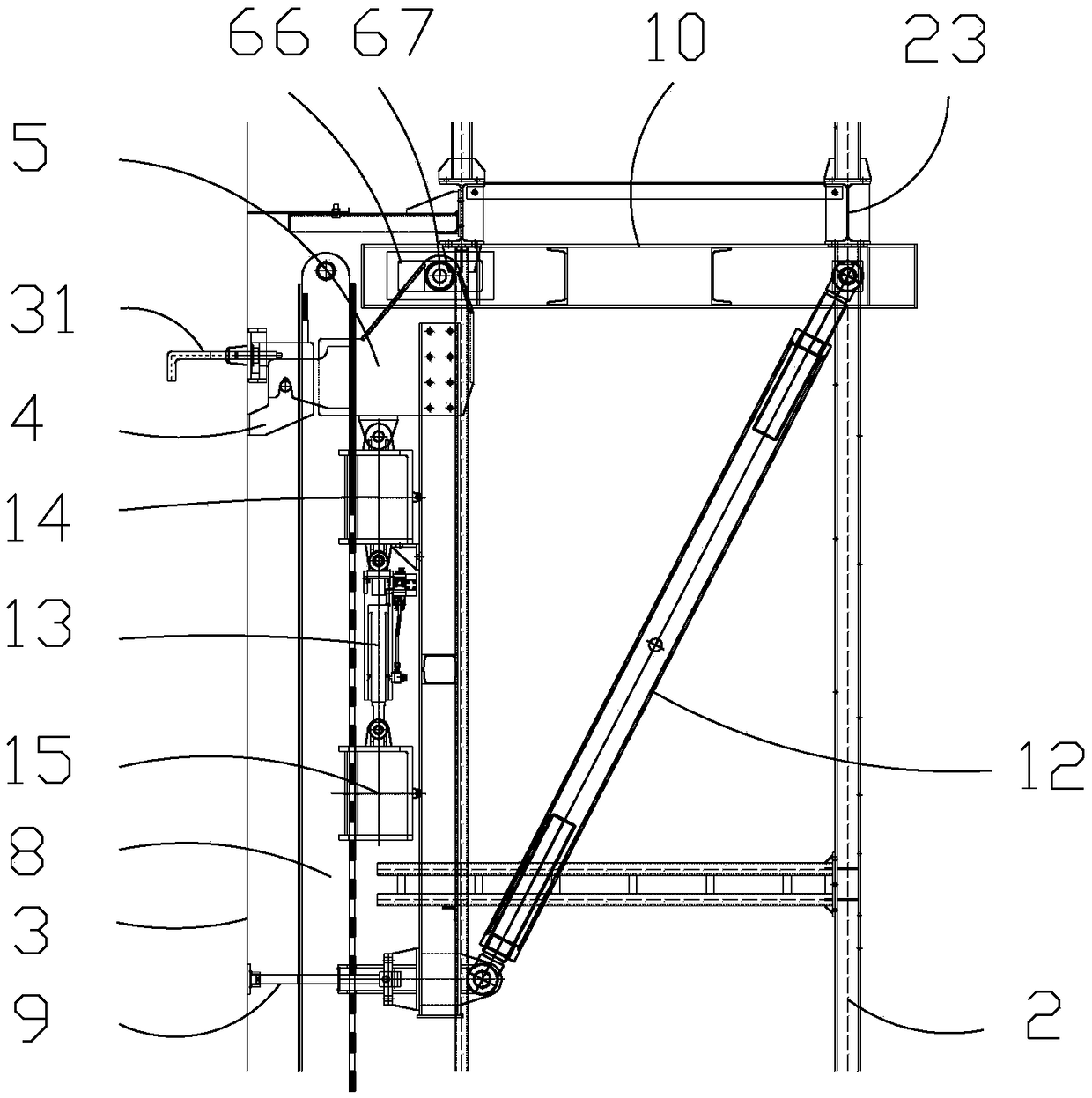

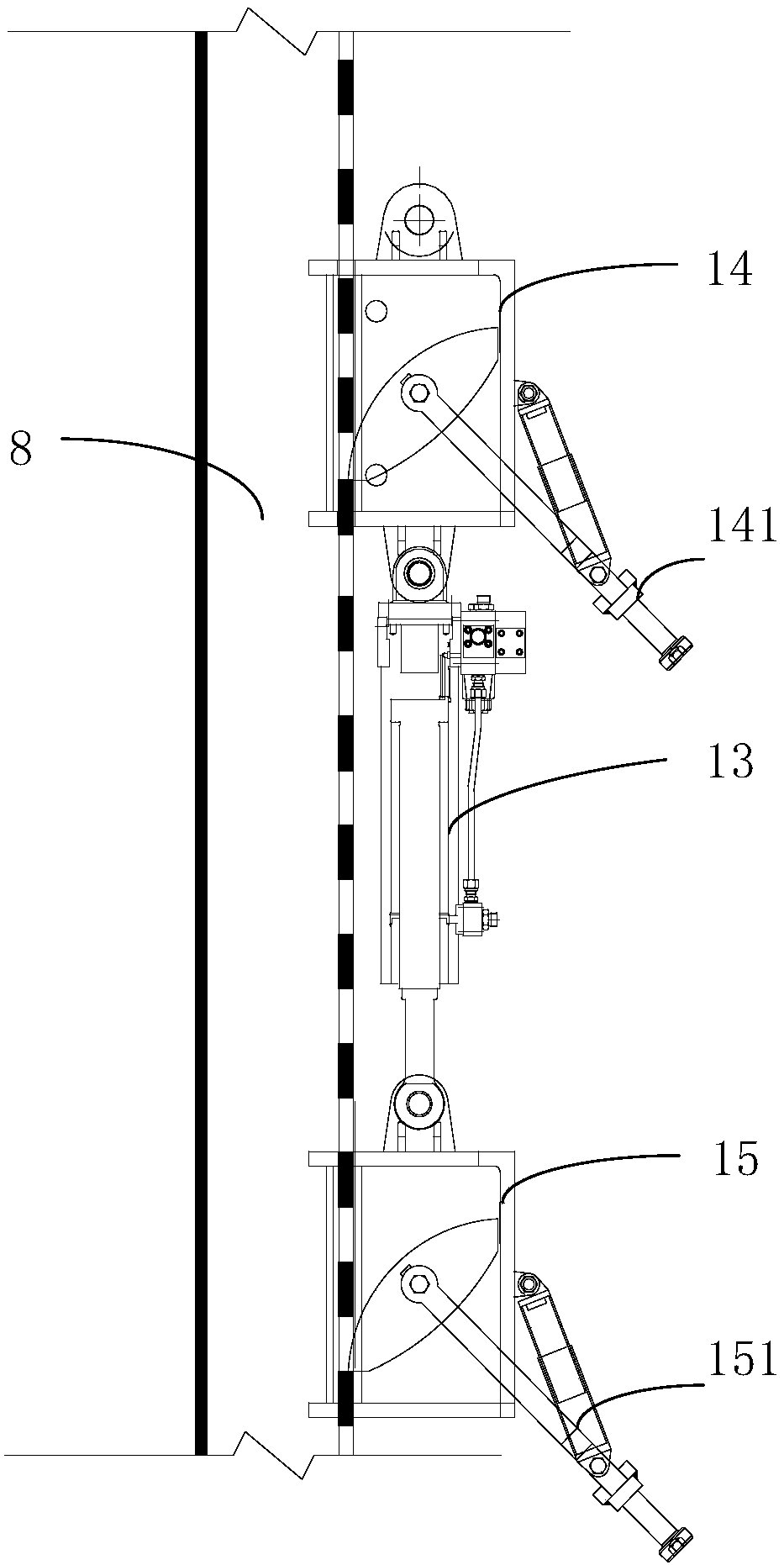

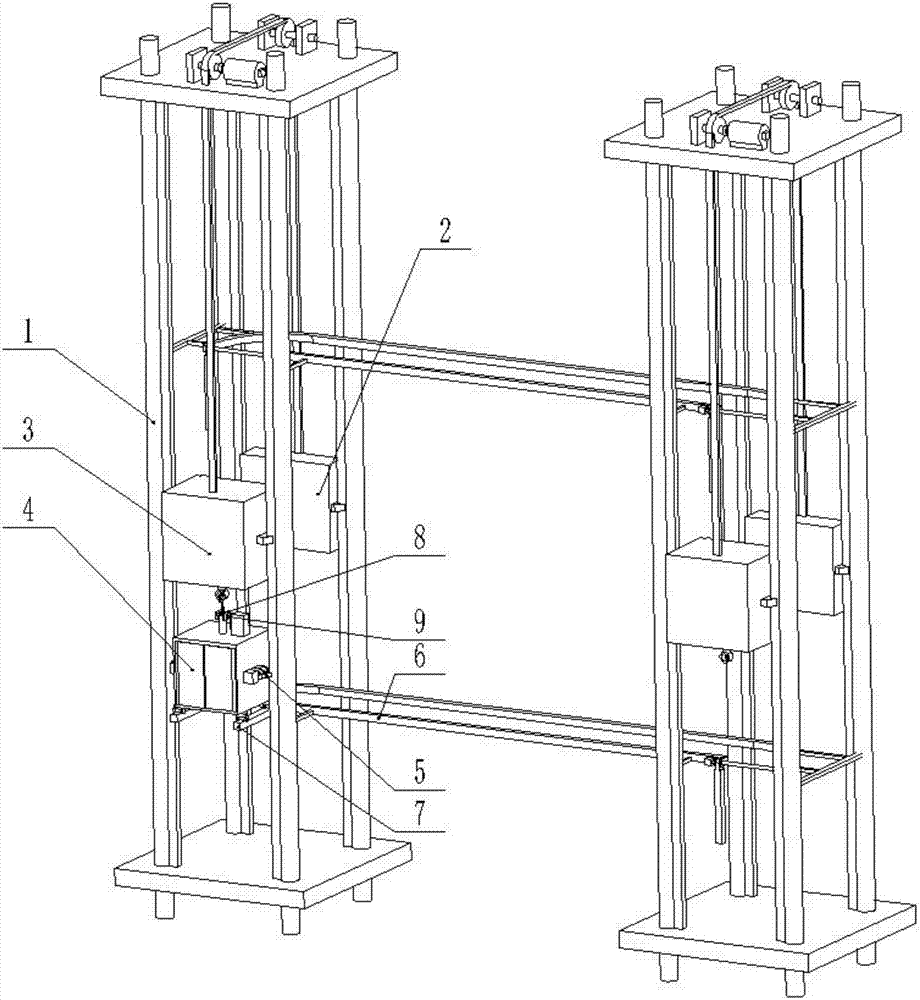

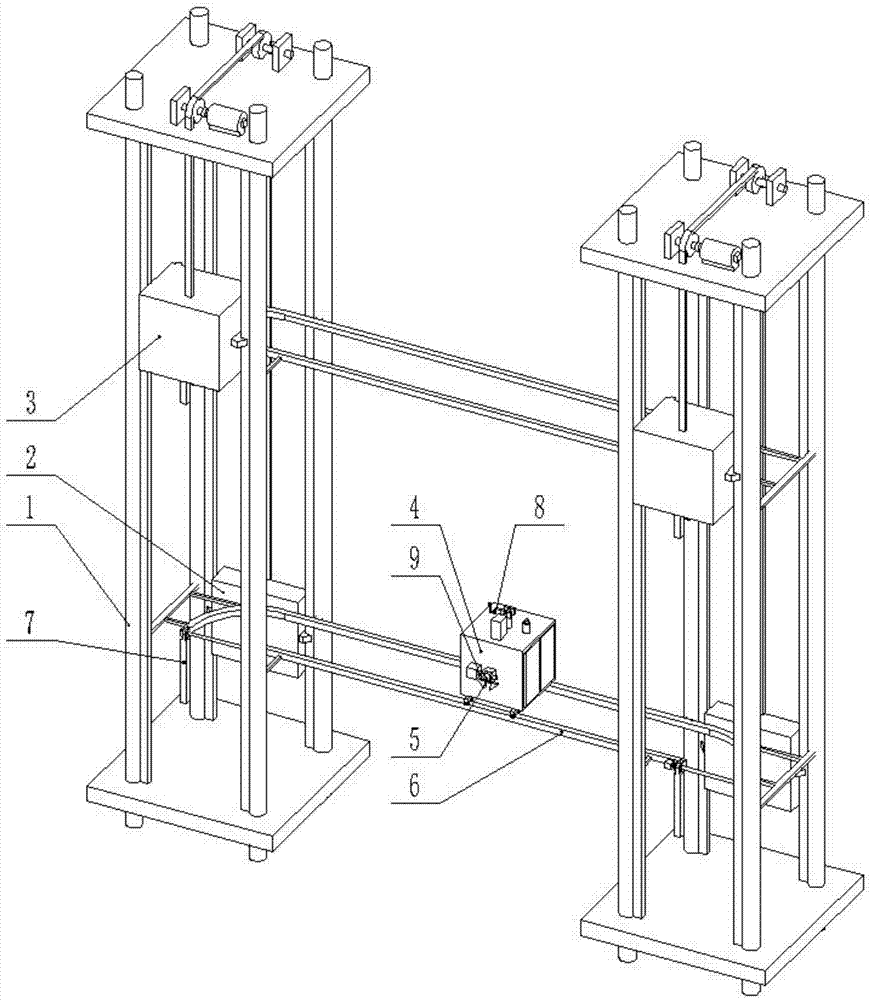

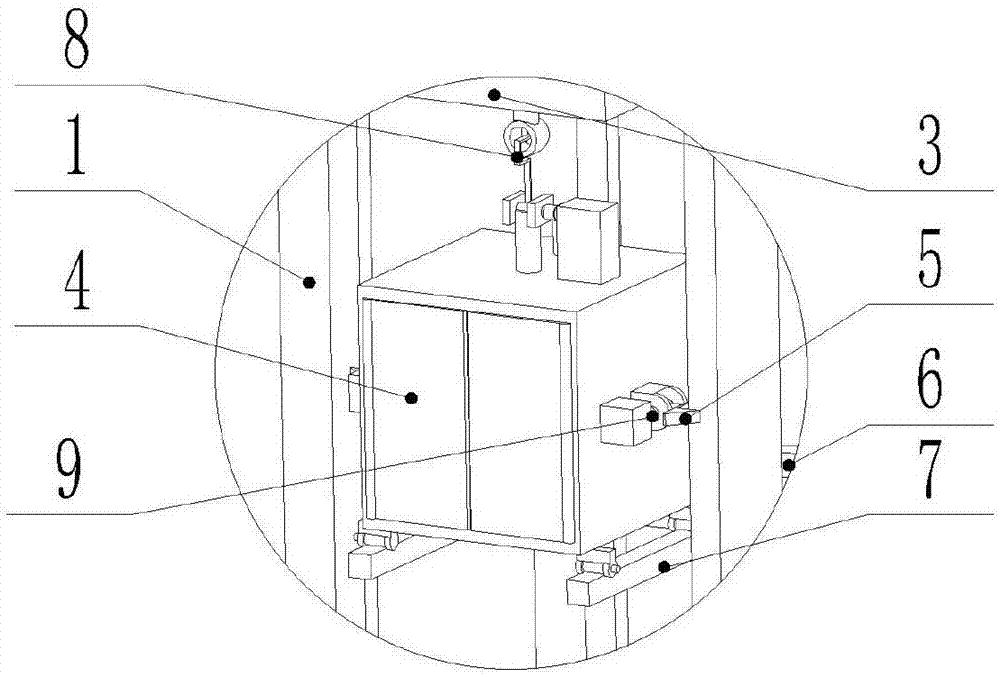

Door-type self-adaptive telescopic hydraulic climbing platform system and climbing method thereof

ActiveCN108222482ASolve construction problemsClimb achievedBuilding support scaffoldsSelf adaptiveMechanical system

The invention discloses a door-type self-adaptive telescopic hydraulic climbing platform system and a climbing method thereof. The platform system comprises a top frame platform, two vertical frame bodies and a plurality of climbing mechanical systems; the two vertical frame bodies are oppositely arranged on the inner wall of a wall body of a core cylinder through the at least two climbing mechanical systems correspondingly; the upper ends of the two vertical frame bodies are connected with the two ends of the top frame platform correspondingly to form a door-type frame body; each climbing mechanical system comprises a plurality of wall-attached devices, load-bearing hooks and mechanical climbing devices; the load-bearing hooks are connected with the vertical frame bodies and the mechanical climbing devices correspondingly; and the door-type self-adaptive telescopic hydraulic climbing platform system further comprises an adjusting mechanism which can make the climbing mechanical systems to be capable of climbing at the position where spaces of the inner wall of the wall body of the core cylinder are changed by adjusting the horizontal position of the load-bearing hooks. According to the door-type self-adaptive telescopic hydraulic climbing platform system and the climbing method thereof, the concrete core cylinder inner construction problem that an existing hydraulic climbing platform cannot be used for contraction of the wall body to which a machine position is attached can be solved.

Owner:SHANGHAI CONSTRUCTION GROUP

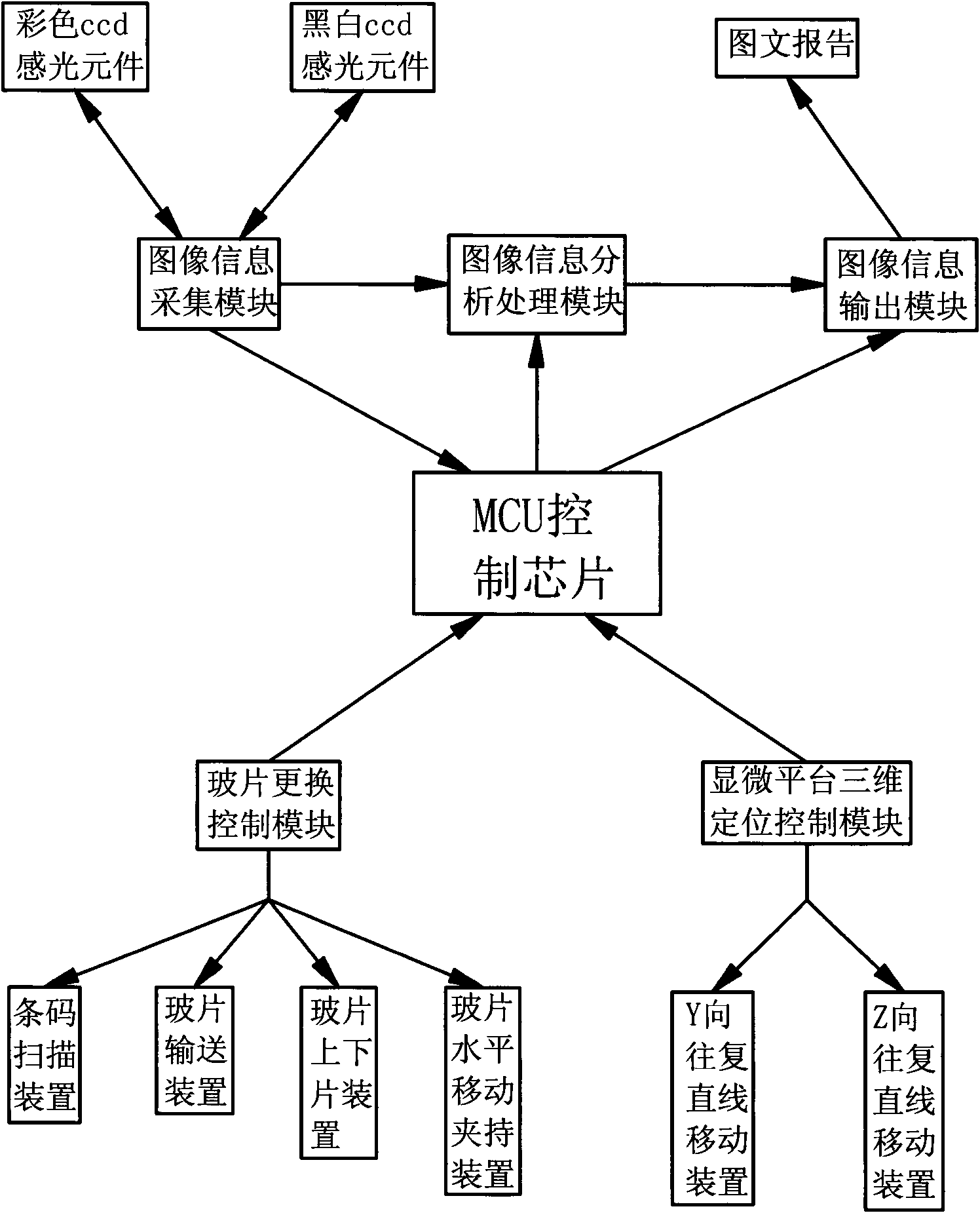

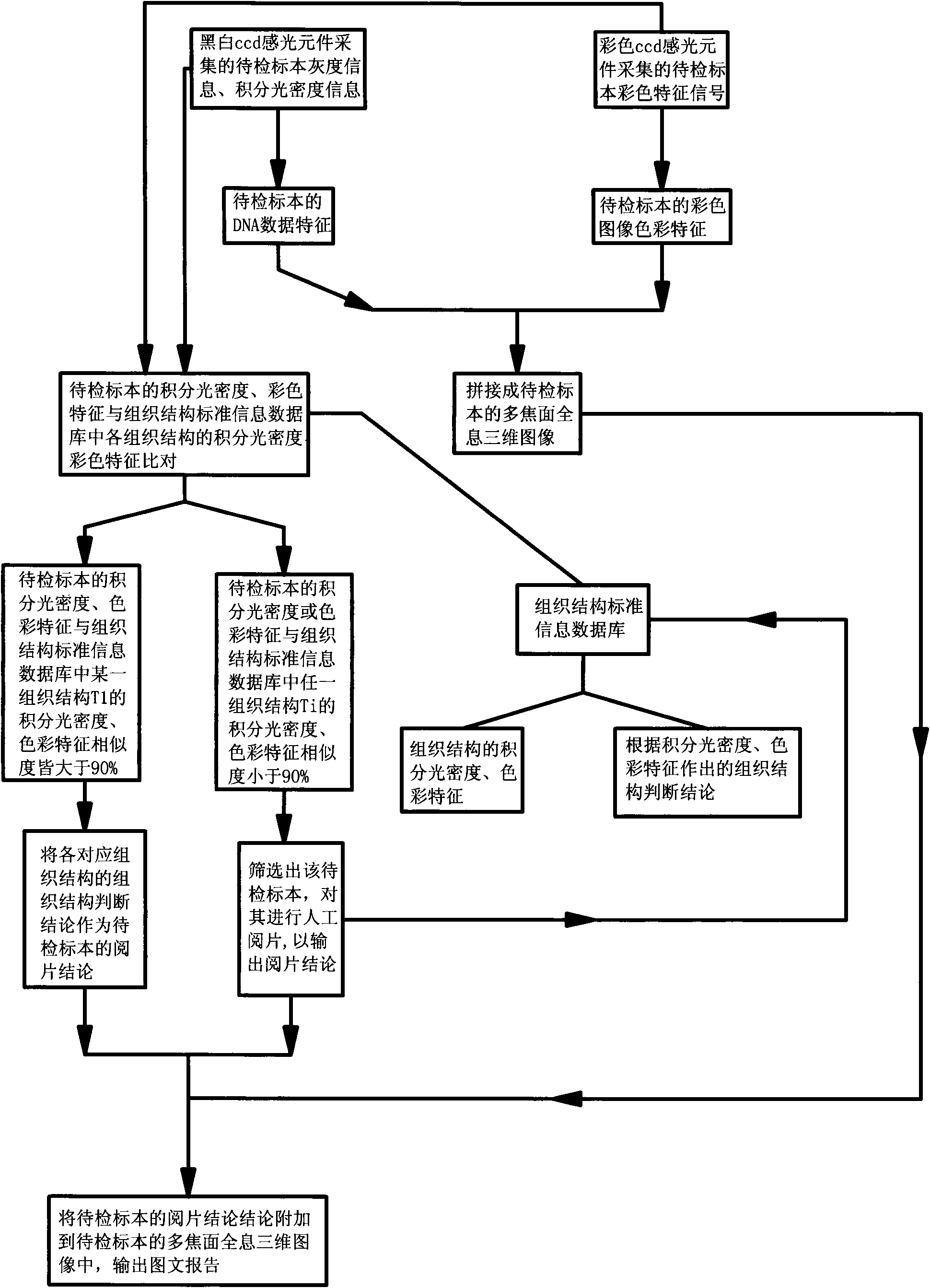

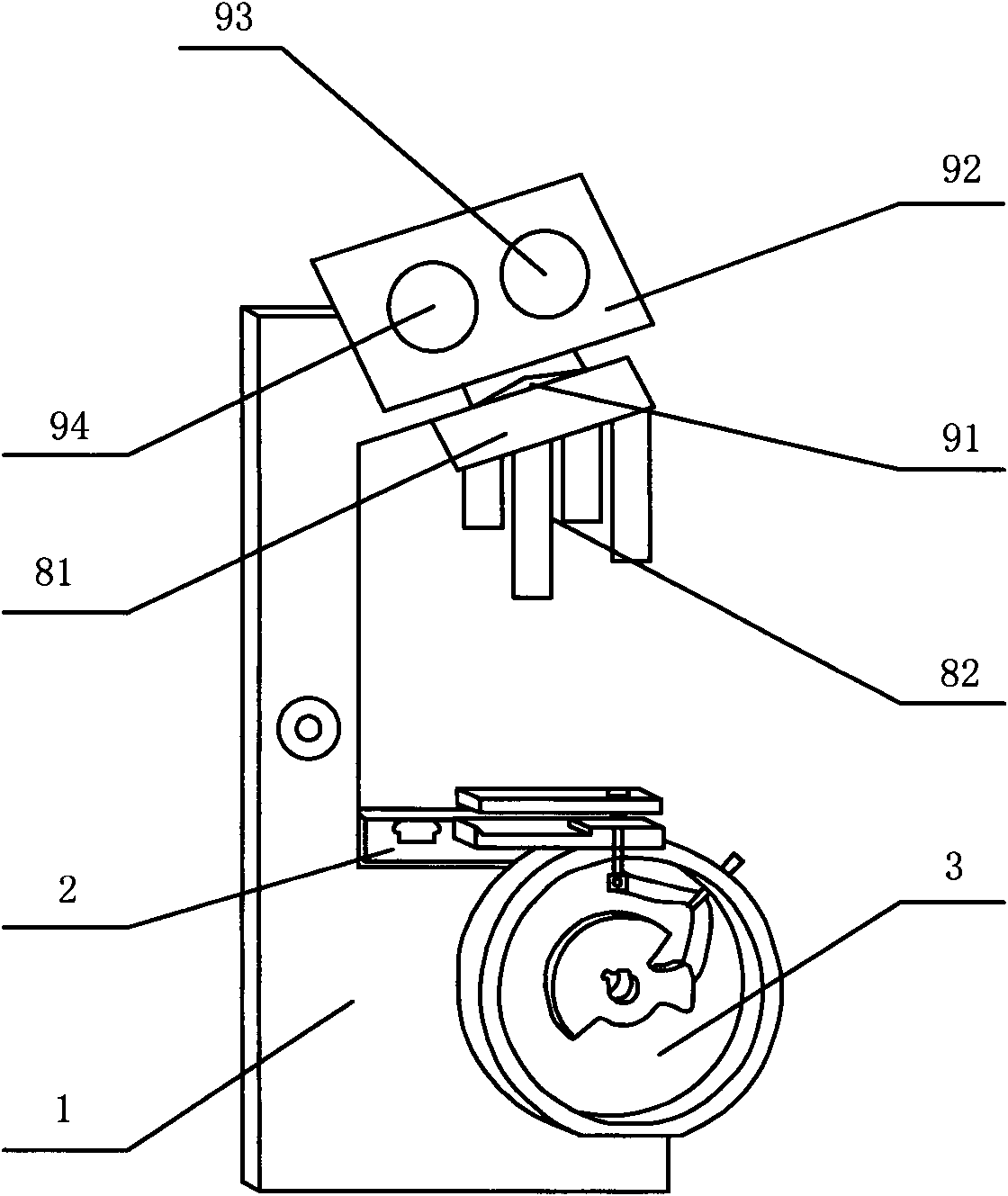

Full-automatic double-ccd photosensitive element digital microscope

ActiveCN102122066ATo achieve the purpose of intelligent screeningGuaranteed effectMicroscopesDigital imageOptical density

The invention discloses a full-automatic double-ccd (charge-coupled device) photosensitive element digital microscope, which is used for acquiring specimen image information by synchronously using a colored ccd photosensitive element and a black-and-white ccd photosensitive element so as to obtain a multifocal plane holographic three-dimensional image, synchronously outputting a specimen reading result according to nucleus integral optical density acquired by the black-and-white ccd photosensitive element, and finally outputting a specimen picture and text report. Additionally, the full-automatic double-ccd photosensitive element digital microscope comprises a slide uploading and unloading device and a horizontal migration clamping device for automatically changing the specimen slide, and then, the slide is located in three dimensions through a three-dimensional frame, so that the colored ccd photosensitive element and the black-and-white ccd photosensitive element can conveniently acquire the image information of the specimen. Thus, the full-automatic double-ccd photosensitive element digital microscope can be used for not only performing morphological observation on the specimen, but also taking digital images for a dyed tissue section so as to form the multi-focal plane holographic three-dimensional image, so that all the information of the cell can be observed in multiple layers and multiple focal planes, and accuracy of early diagnosis is greatly improved.

Owner:湖南港湾科学仪器有限公司

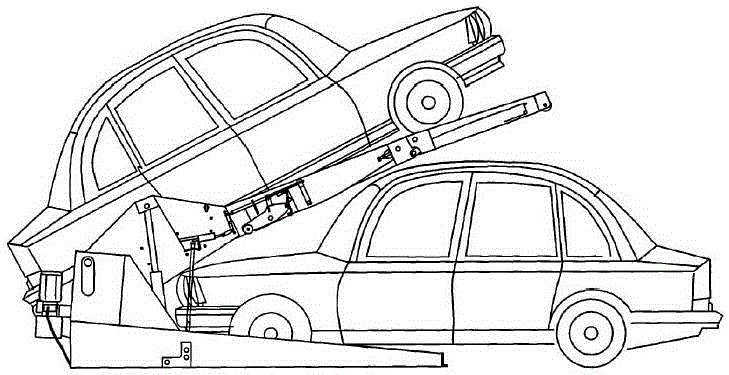

Side movement type parking system

The invention belongs to the technical field of vehicle parking, and particularly discloses a side movement type parking system. The system comprises a supporting frame and a bracket used for supporting a vehicle, wherein the supporting frame is pivoted to the bracket, the supporting frame is located below the bracket, and a supporting hydraulic cylinder is arranged between the supporting frame and the bracket; a cylinder tube of the supporting hydraulic cylinder is hinged to the supporting frame, a piston rod of the supporting hydraulic cylinder is hinged to the bracket, and a hydraulic station is arranged on the supporting frame and connected with the supporting hydraulic cylinder through a first hydraulic pipe. The system further comprises a telescopic mechanism, wherein the telescopic mechanism comprises a power part, a telescopic part and a fixed block fixed to the ground, the power part, the telescopic part and the fixed block are sequentially connected, the power part is fixed in the supporting frame, and the supporting frame is located within the projected area of the bracket in the horizontal plane. The system has the advantages of being high in adaptability in a parking lot, and capable of improving the parking rate of the parking lot.

Owner:杨自忠

Cab elevator capable of being connected in series and moving horizontally

The invention provides a cab elevator capable of being connected in series and moving horizontally, and belongs to the field of industrial machinery. The cab elevator capable of being connected in series and moving horizontally is composed of a liftshaft, a balance weight, a vertical cab, a horizontal cab, a rotating guide shoe, a horizontal track, a revolving transverse rail, a U-shaped hook and a fastening ring; the liftshaft is composed of a supporting plate, a vertical column, a vertical rail, a traction rope, a first vertical frame, a first gear, a first gear shaft, a motor shaft, a motor, a second vertical frame, a third vertical frame, a second gear shaft and a second gear; the balance weight is composed of a balance body and a balance weight guide shoe; the vertical cab is composed of a vertical cab body, a first door shaft, a first cab door, a vertical cab guide shoe and an upper pulling ring; and the horizontal cab is composed of a horizontal cab body, a second door shaft, a second cab door, a first cabinet-type steering engine, a first power output shaft, a U-type hook seat, an ultrasonic wave sensor, a second cabinet-type steering engine, a second power output shaft, a rotating guide shoe seat, a wheel frame, a micro motor, a cylindrical wheel and a photoelectric sensor. The cab elevator capable of being connected in series and moving horizontally has the beneficial effect that through erection of the rotating transverse rail, running of the cab in the horizontal direction and the vertical direction is achieved.

Owner:济南振宏机械有限公司

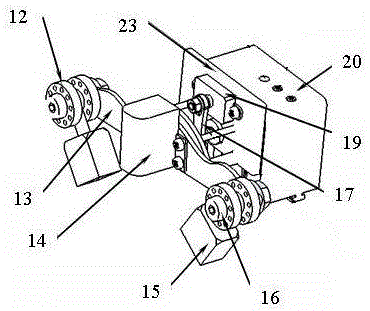

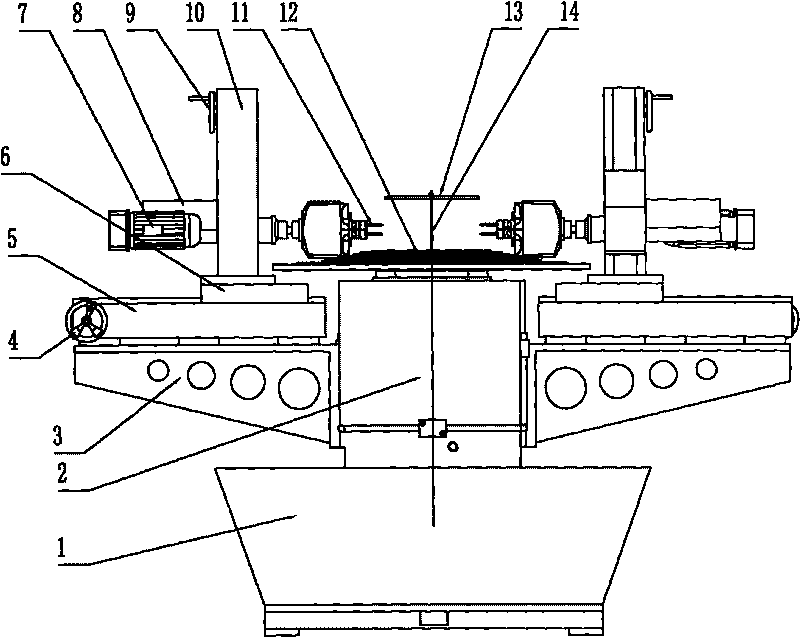

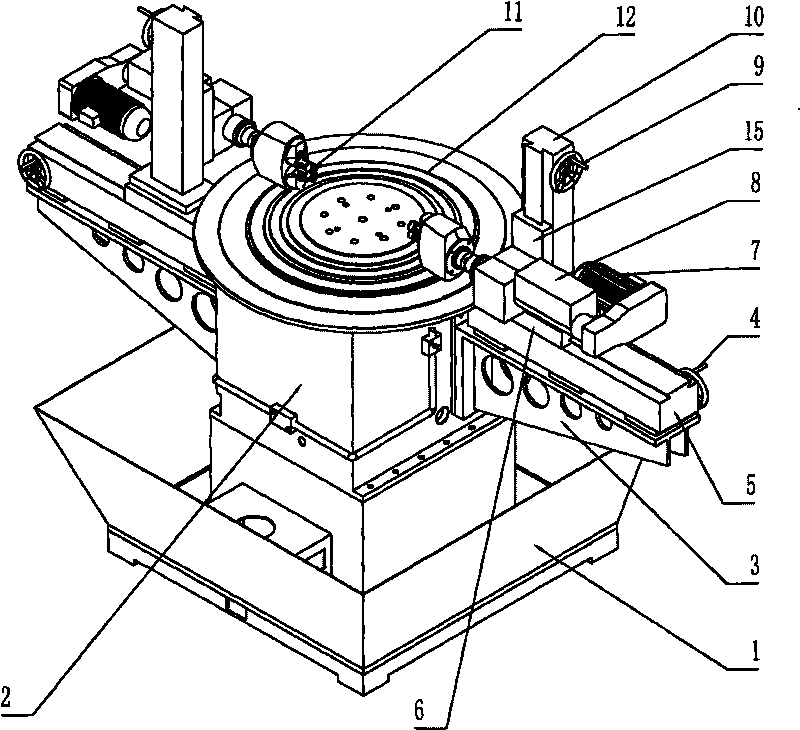

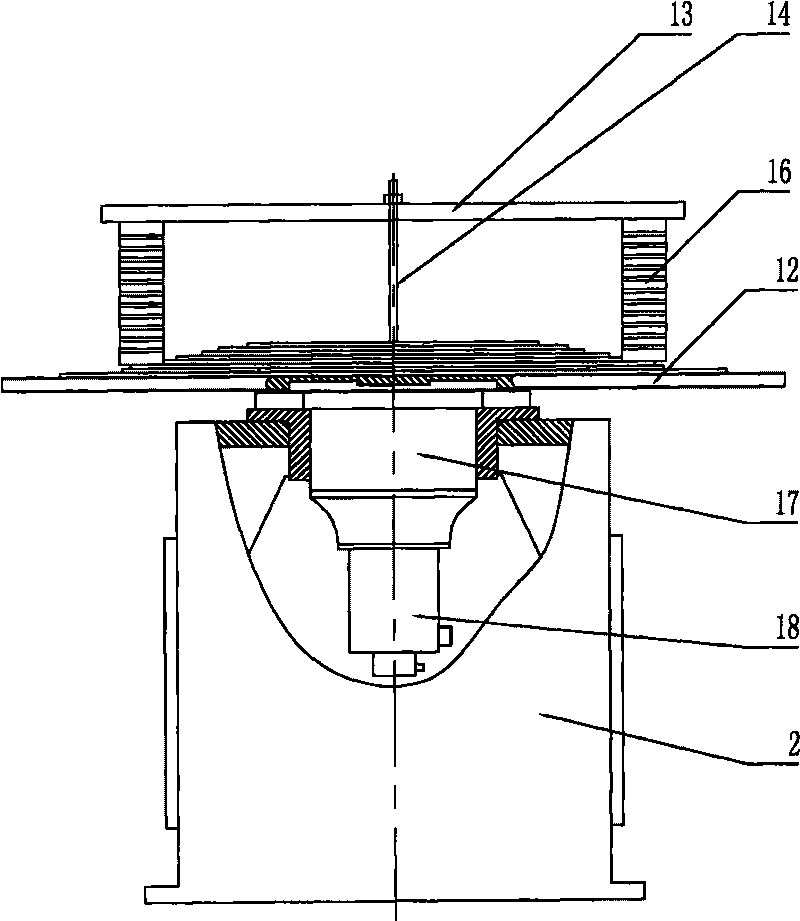

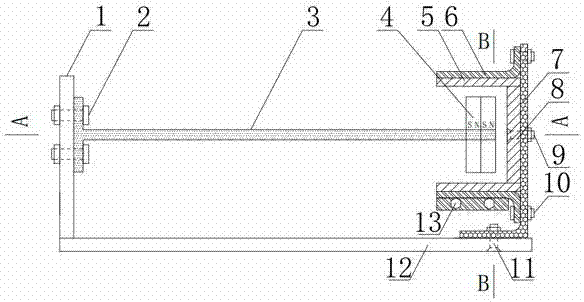

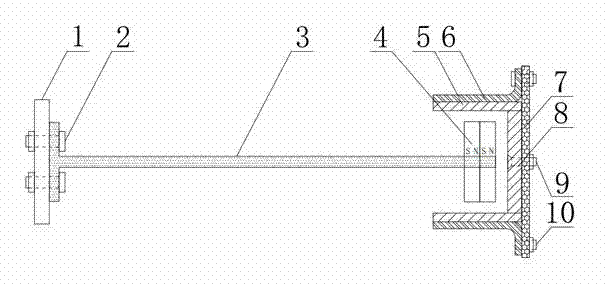

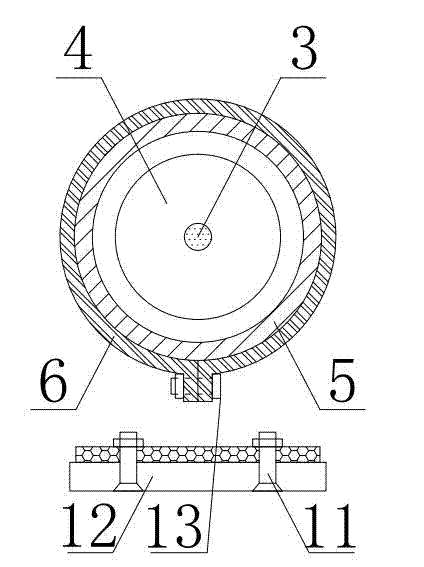

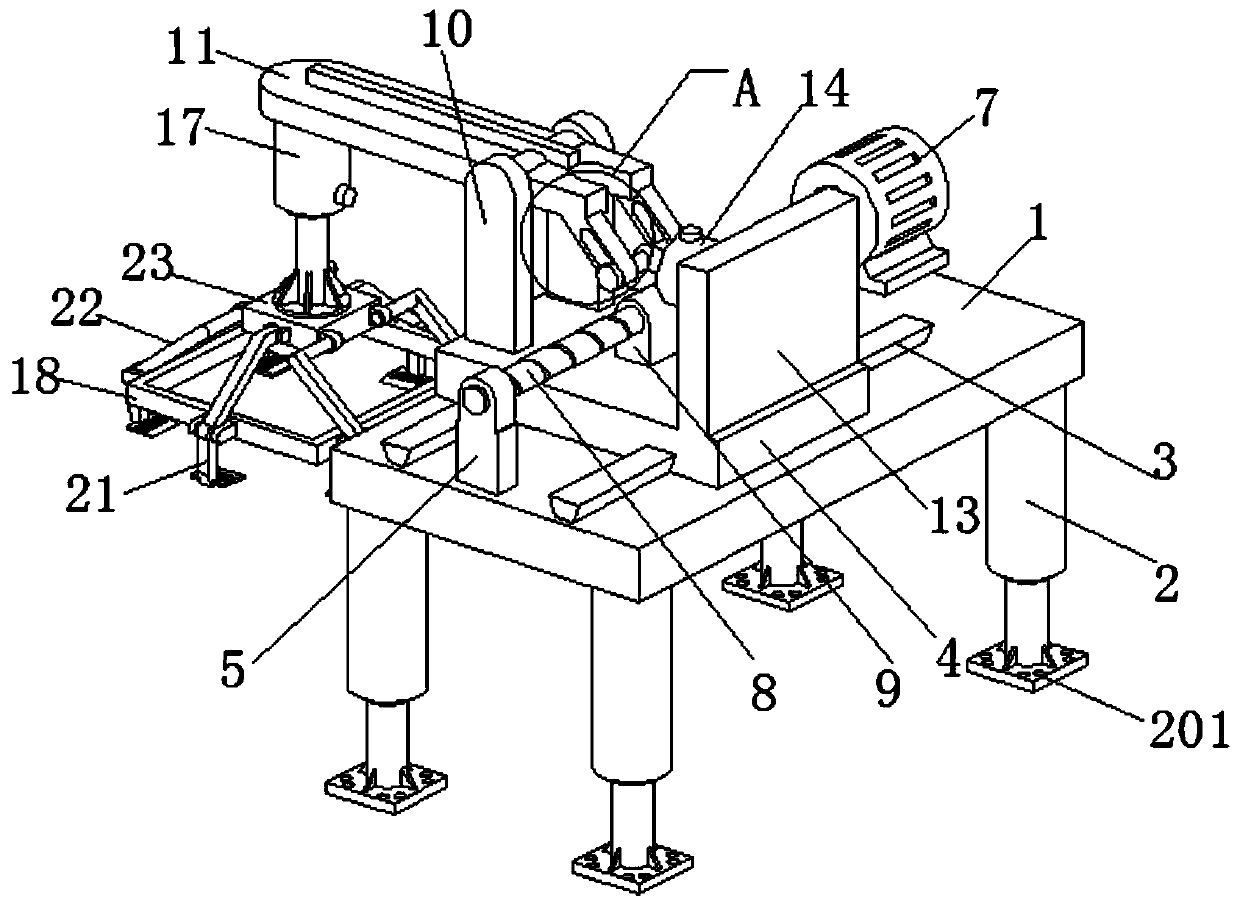

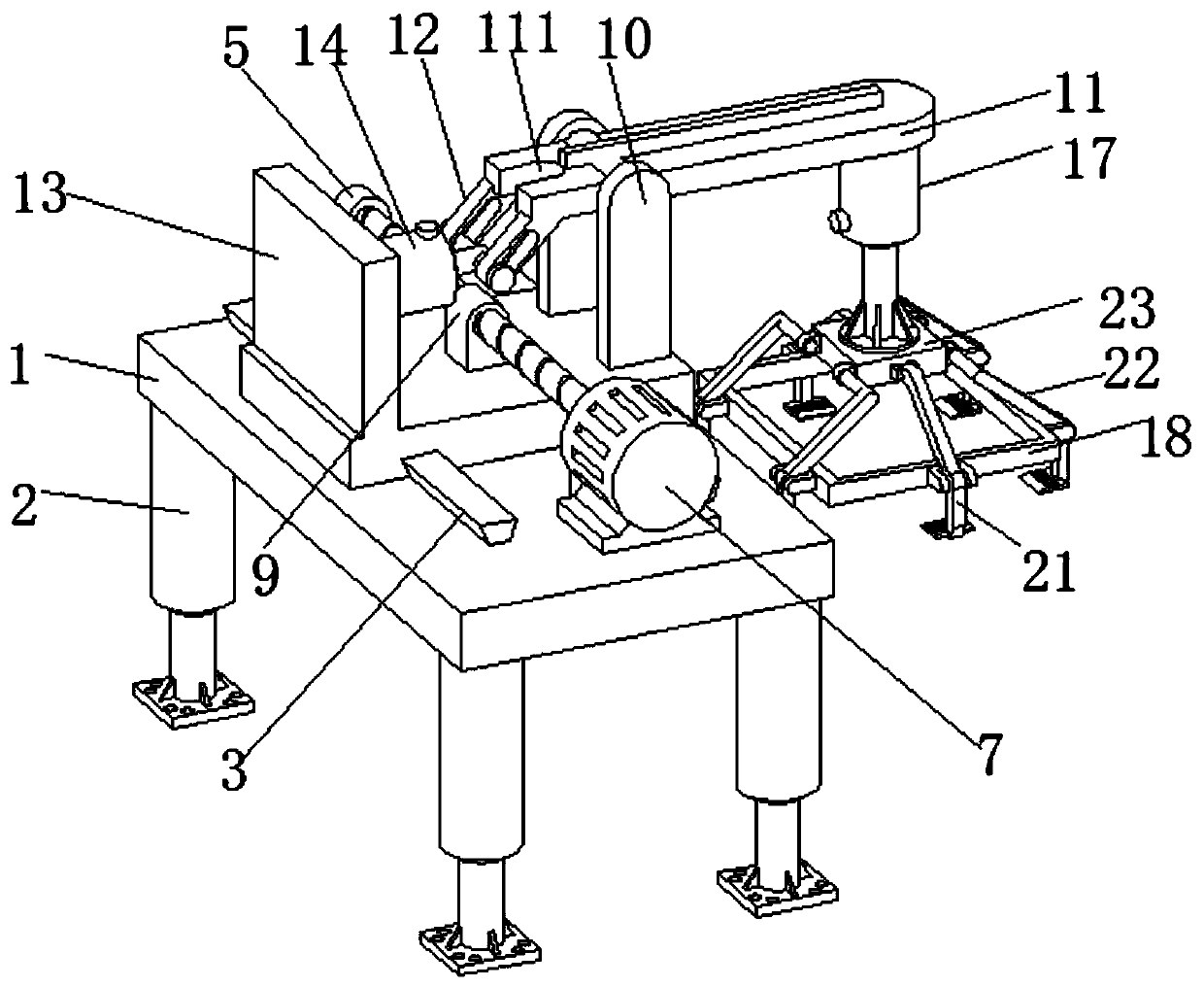

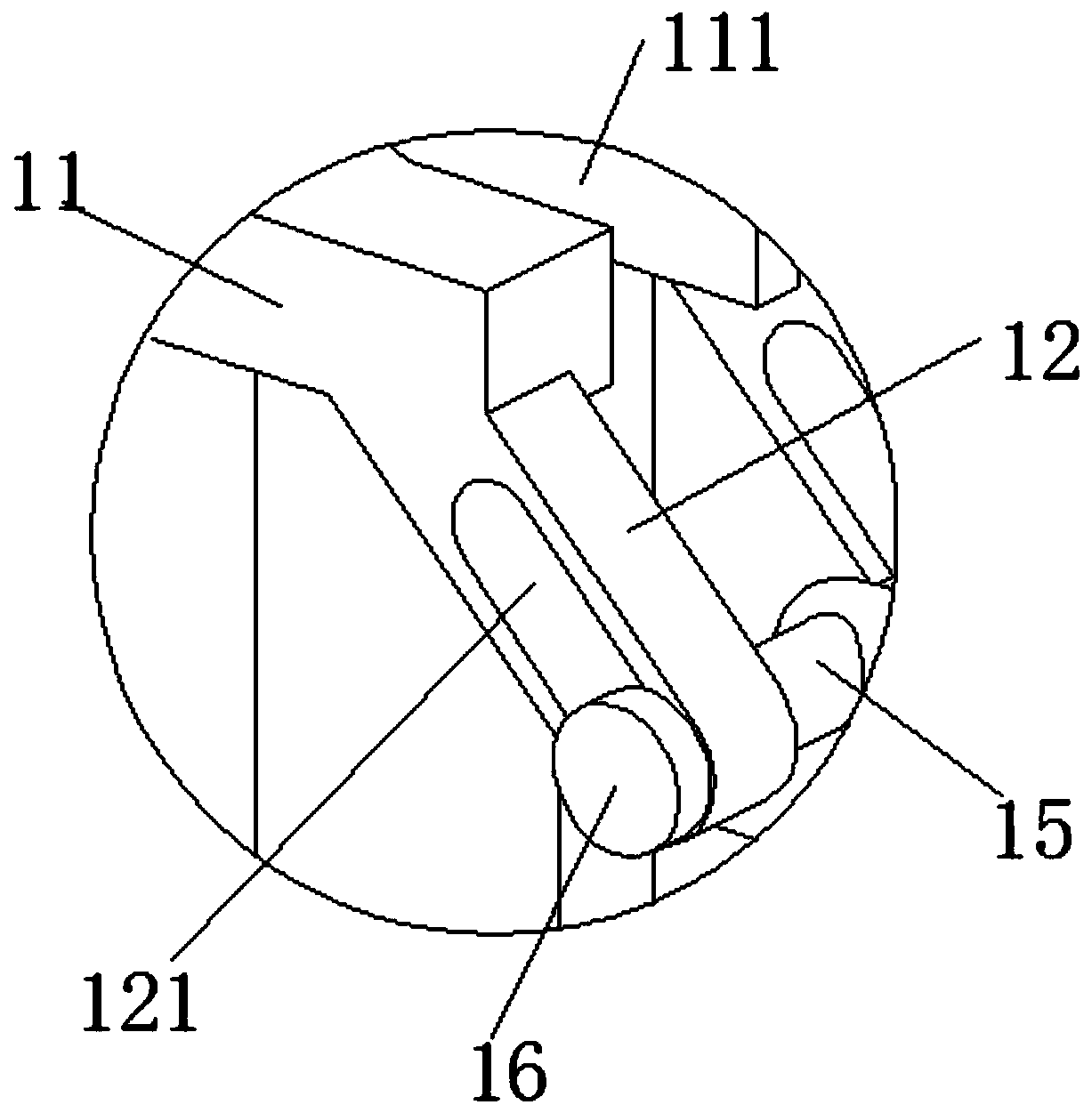

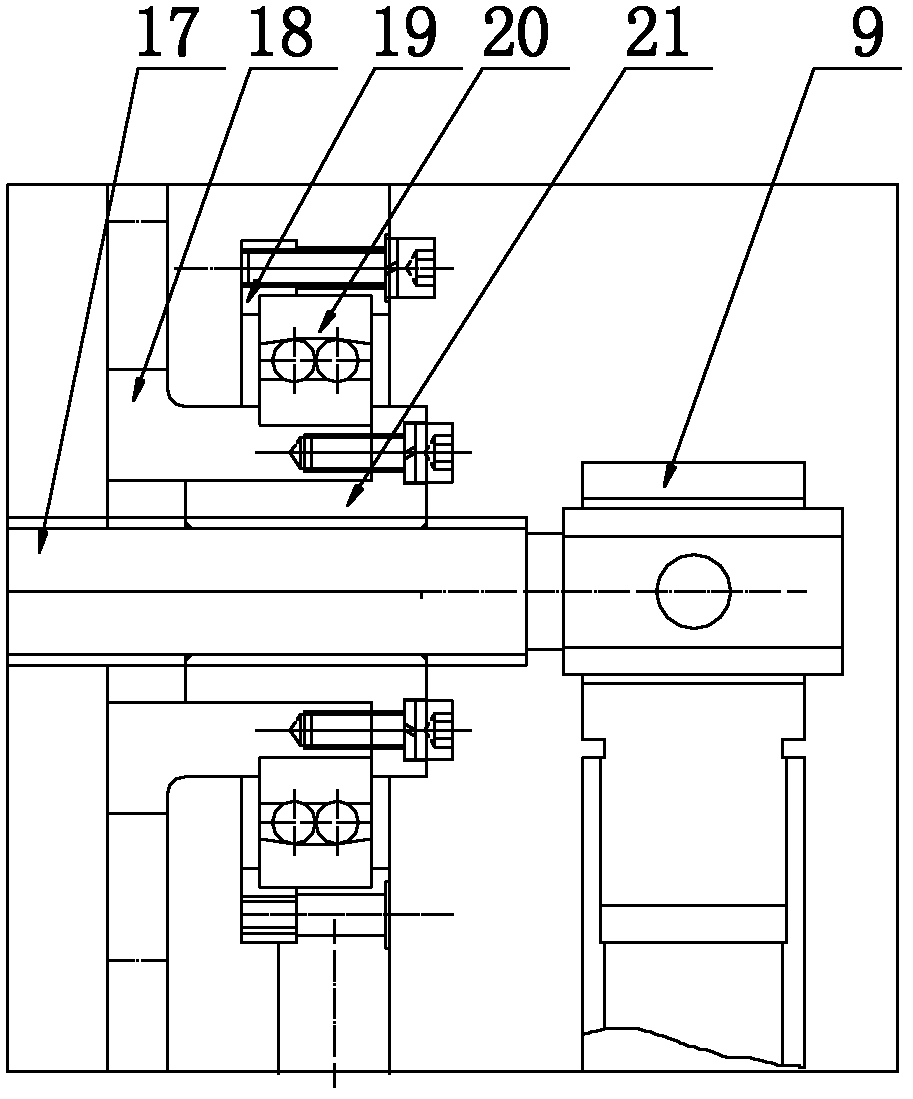

Borehole and counterbore machine for annular mold

InactiveCN101733445AAchieve horizontal movementAchieve positioningBoring/drilling componentsBoring/drilling machinesDrill bitEngineering

The invention discloses a borehole and counterbore machine for an annular mold in the field of bore machining tools, which comprises a main spindle box body. At least one side of the main spindle box body is provided with a supporting beam, a horizontal guide rail is arranged on the supporting beam, and a horizontal slide block is arranged on the horizontal guide rail in a matching mode. The horizontal slide block and the horizontal guide rail are in transmission connection through a lead screw nut pair. A vertical guide rail is fixedly arranged on the horizontal slide block, and a vertical slide block is arranged on the vertical guide rail in a matching mode. The vertical slide block and the vertical guide rail are in transmission connection through another lead screw nut pair. A bit component is fixed on the vertical slide block, and a speed-reducing mechanism is fixed in the main spindle box body. An input shaft of the speed-reducing mechanism is connected with an end of an output shaft of a servo motor. An output shaft of the speed-reducing mechanism extends upwards, an upper end of which is connected with a rotating table. A plurality of rotating steps in step-shaped distribution are arranged on the rotating table, wherein the rotating steps and the rotating table are arranged coaxially. The borehole and counterbore machine for the annular mold has the advantages of accurate positioning of a workpiece and convenient processing, and can be applied to machining the annular mold or radial multi-hole parts.

Owner:JIANGSU MUYANG GRP CO LTD

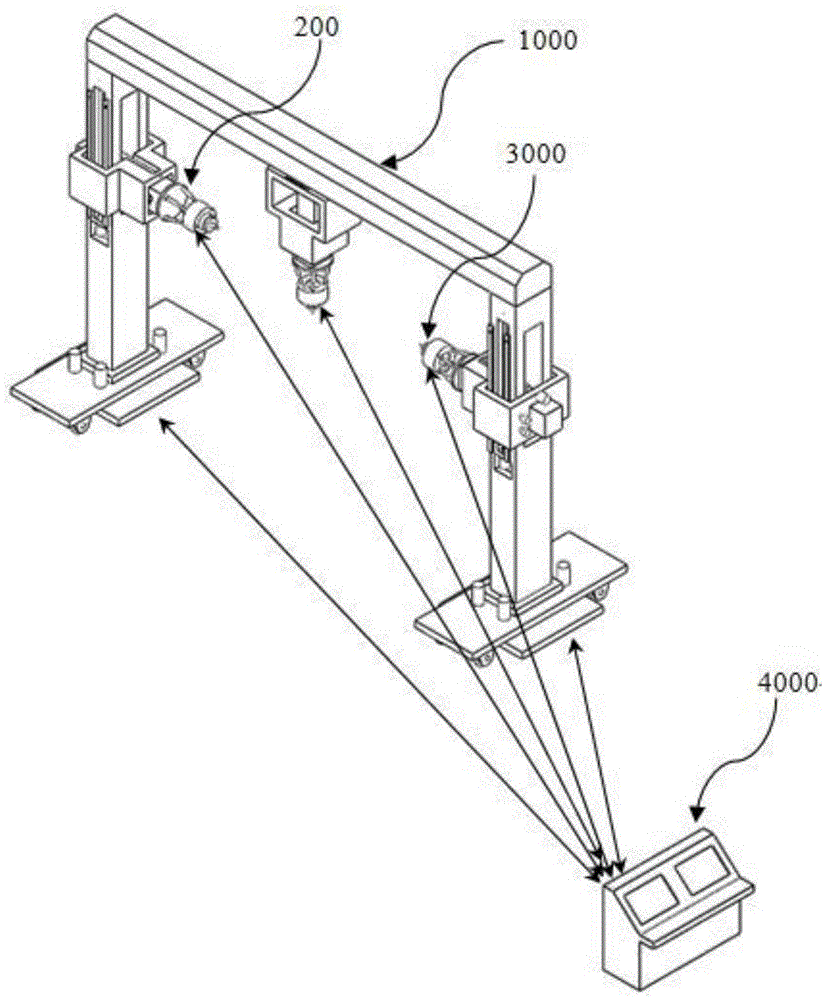

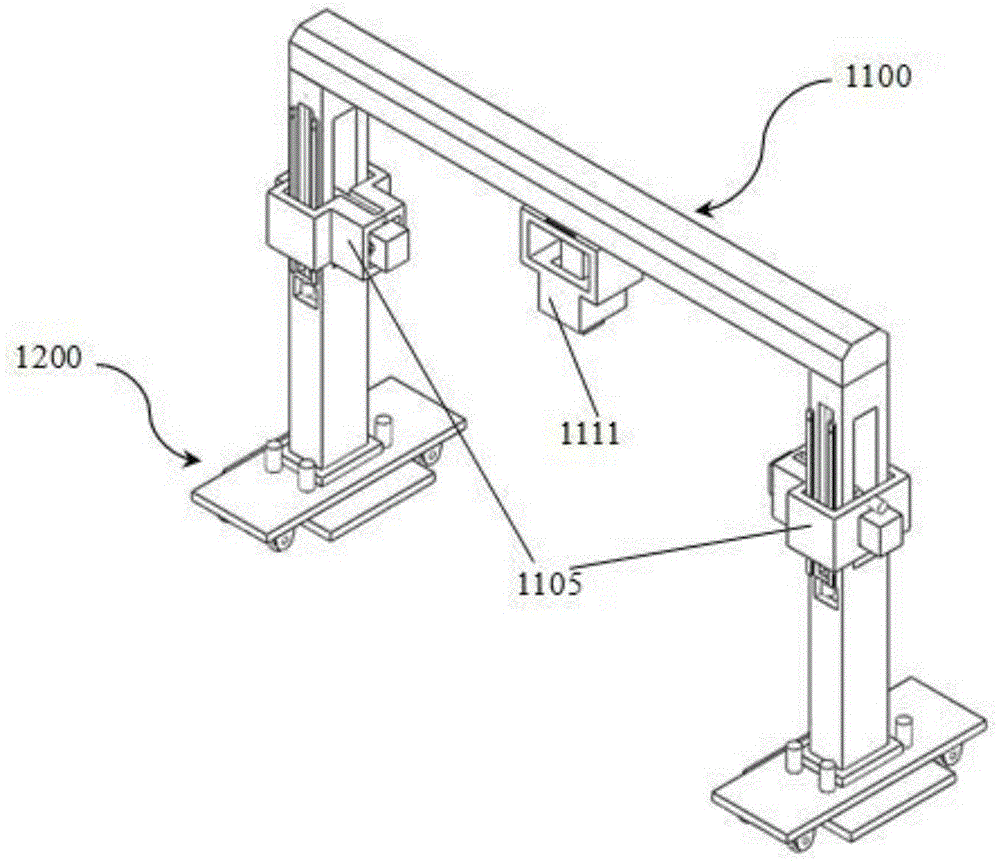

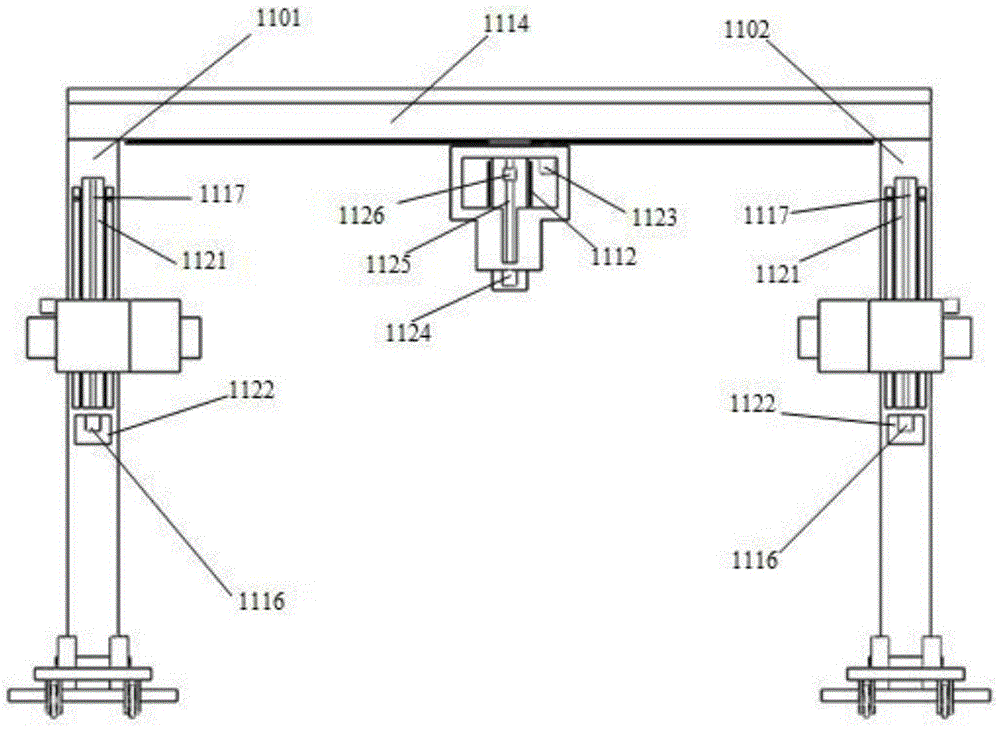

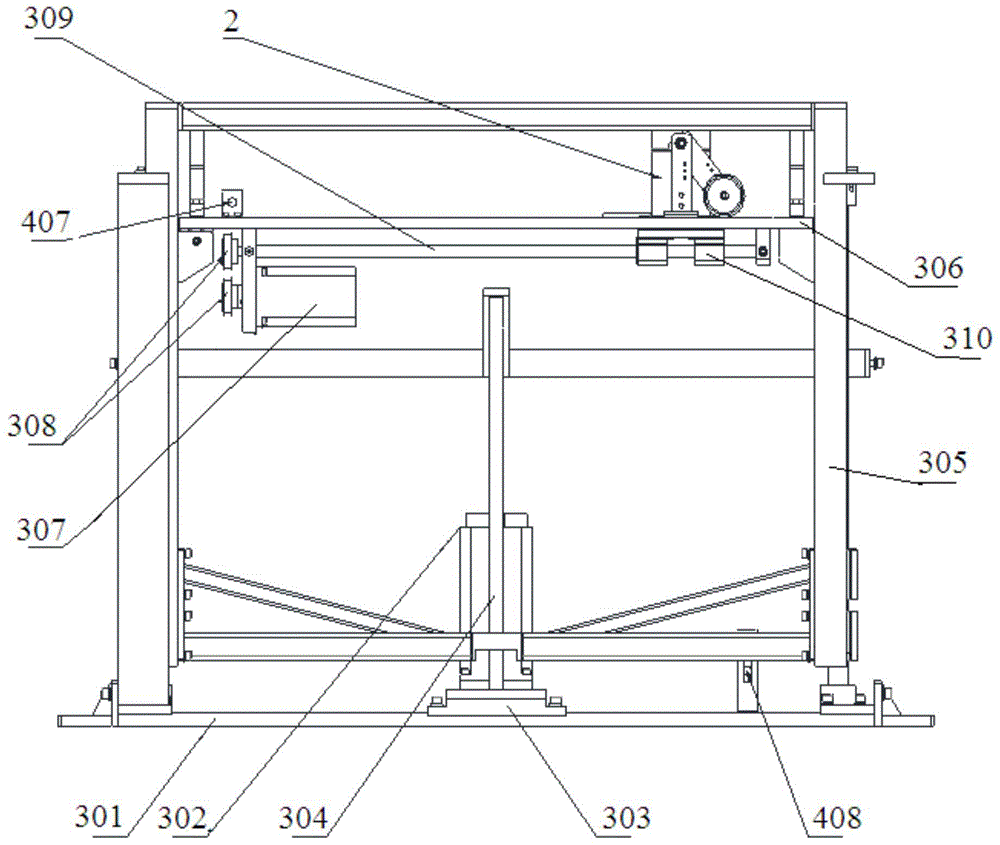

Gantry type numerical control hole manufacturing system used for airplane wing body abutting joint

ActiveCN105618809AAchieve horizontal movementRealize normal attitude adjustmentLarge fixed membersBoring/drilling machinesNumerical controlJet aeroplane

The invention provides a gantry type numerical control hole manufacturing system used for airplane wing body abutting joint. The gantry type numerical control hole manufacturing system comprises a gantry bracket assembly, three four-rod pose adjusting mechanisms and three terminal hole manufacturing units. The gantry bracket assembly comprises a door shaped bracket, two perpendicular lifting devices and a horizontal sliding device. Each four-rod pose adjusting mechanism comprises a movable platform, a fixed platform, a first electric telescopic rod, a second electric telescopic rod, a third electric telescopic rod and a fourth electric telescopic rod. Each terminal hole manufacturing unit comprises a T-shaped feed supporting shell body, a T-shaped revolution supporting shell body, a U-shaped revolution shell body, a U-shaped rotation supporting shell body and a rotation driving device. The gantry type numerical control hole manufacturing system is capable of remarkably improving the efficiency and the quality of hole manufacturing of wing body abutting joint and assembly and especially suitable for hole manufacturing of large-size airplane wing body abutting joint and assembly.

Owner:NANJING COLLEGE OF INFORMATION TECH

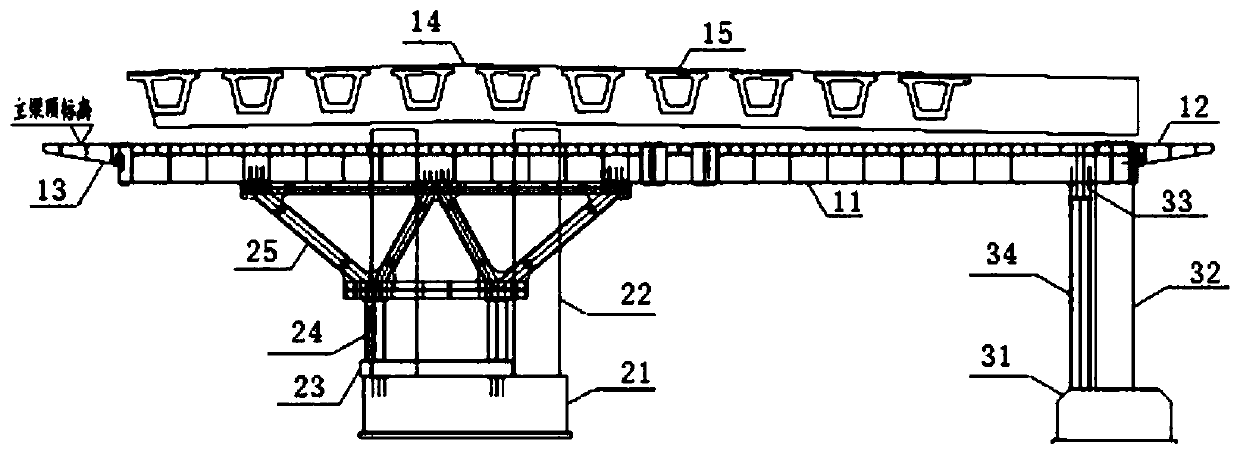

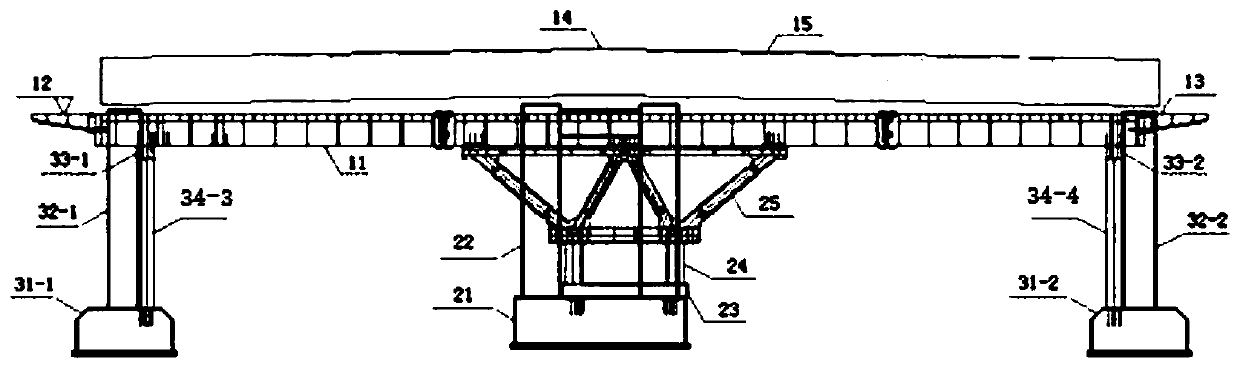

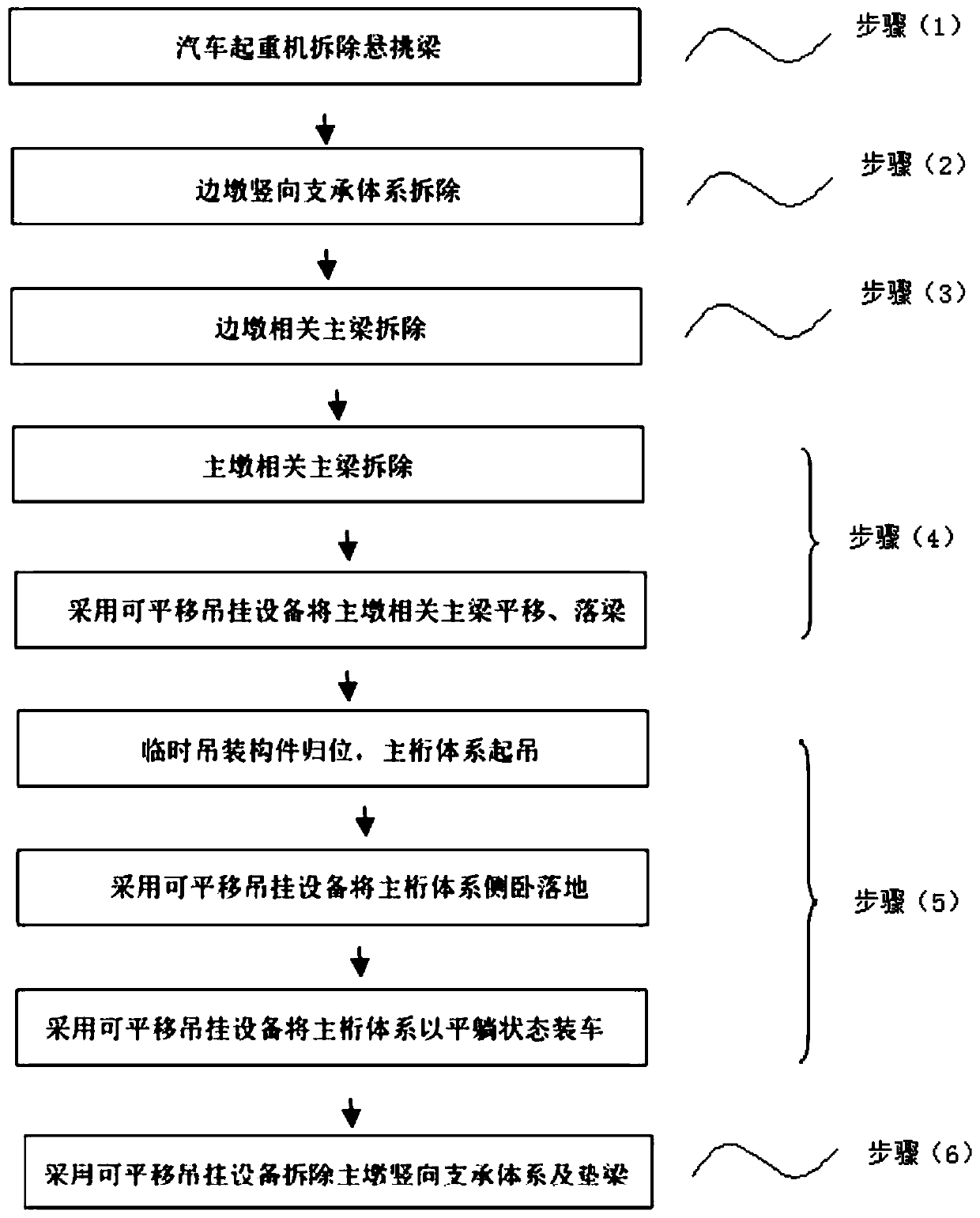

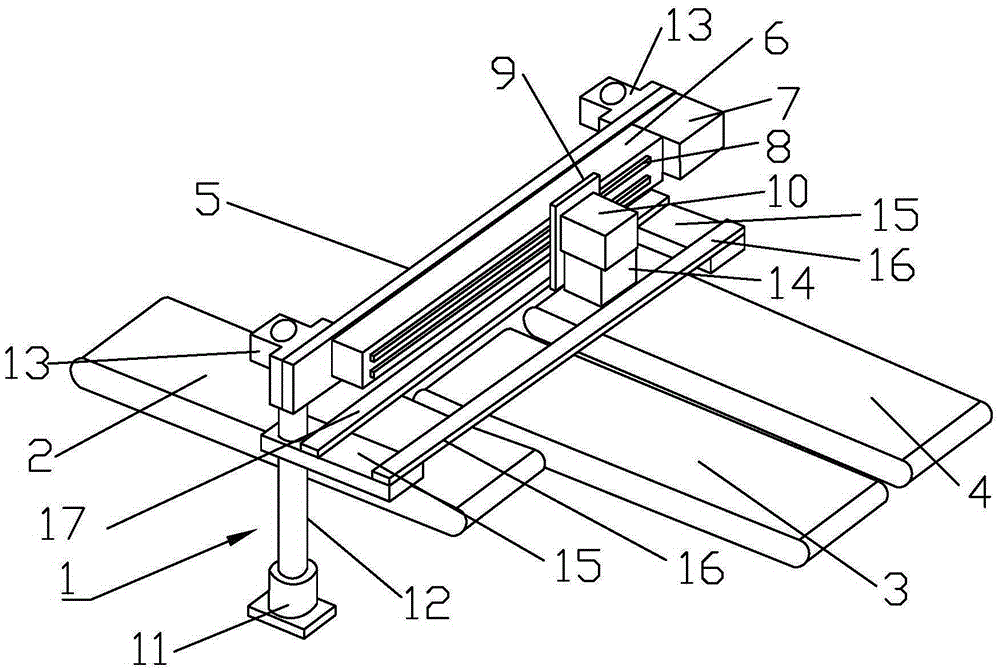

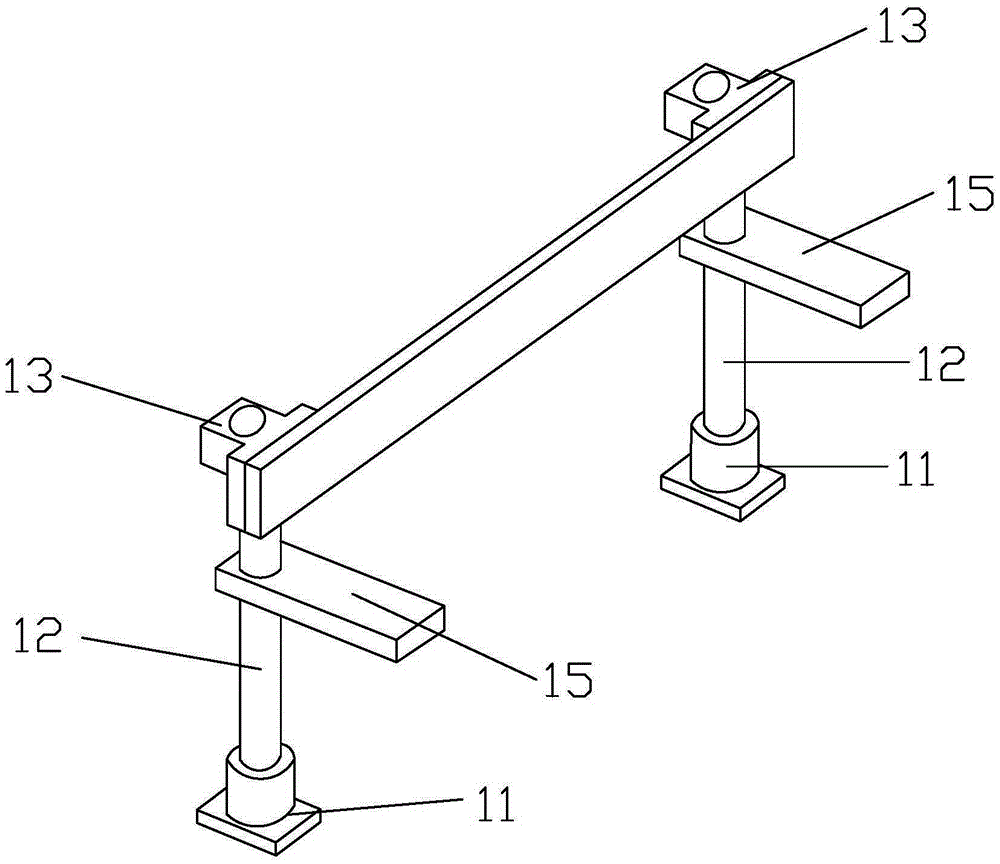

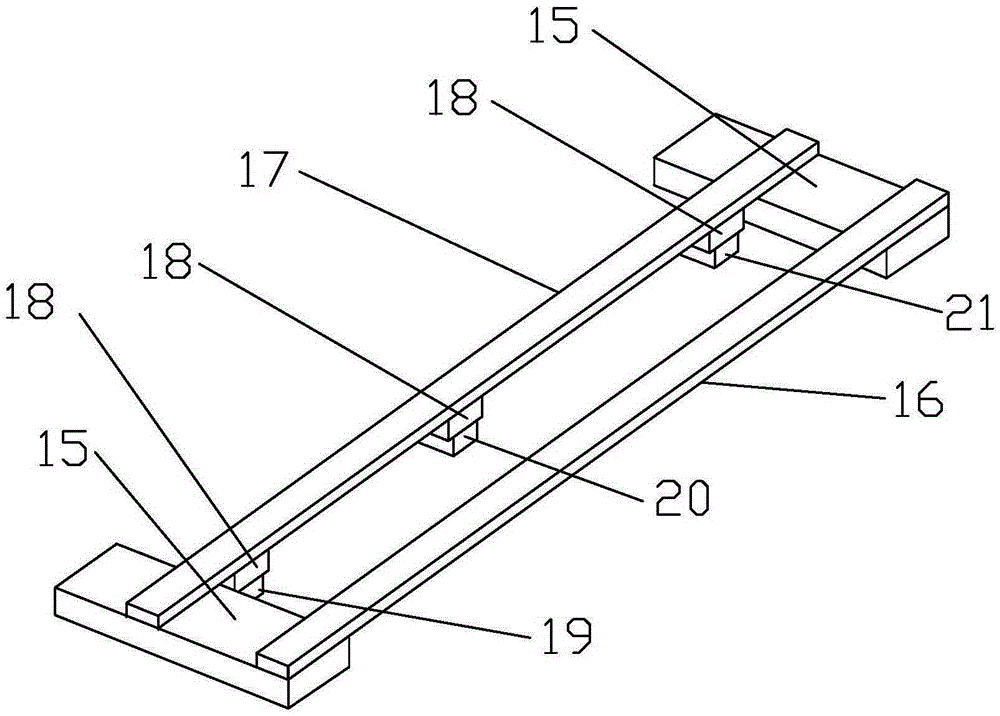

Detachment construction method and fixture for temporary support system for precast-small-box-girder hidden capping beam of road bridge

ActiveCN110747761ARealize vertical hoistingAchieve horizontal movementBuilding repairsBridge erection/assemblyPierCantilever

The invention discloses a detachment construction method and fixture for a temporary support system for a precast-small-box-girder hidden capping beam of a road bridge. The detachment construction method comprises the following steps: (1) detaching a cantilever beam; (2) detaching an abutment pier support system, and loading; (3) detaching an outer-side main beam section connected with the abutment pier support system, and loading; (4) detaching a main beam middle-part beam section connected with a main pier support system, translating and dropping the beam; (5) hoisting a main truss system, laterally dropping the main truss system to the ground, and loading; and (6) detaching a main pier vertical support system and a bearing beam. Therefore, according to the detachment construction methodand fixture, the possibility of rapid detachment for the large temporary support system (the temporary support system for the precast-small-box-girder hidden capping beam of the road bridge) in the projection range of precast small box girders after the precast small box girders are erected, is achieved, and the requirements of traditional large automobile cranes, crawler cranes and other equipment on an operation space are avoided.

Owner:NINGBO MUNICIPAL ENG CONSTR GROUP

Conveying device applied to glass production line

InactiveCN105417152ASolve shipping problemsSimple structureCharge manipulationConveyor partsProduction lineEngineering

The invention discloses a conveying device applied to a glass production line. The conveying device comprises a machine base and conveying belts. The conveying belts are arranged below the machine base. The conveying belts comprise the feeding conveying belt and the production conveying belts. The production conveying belts comprise the first production conveying belt and the second production conveying belt. A carrying device is arranged on the machine base and comprises a horizontal moving mechanism, a vertical lifting mechanism and a clamping mechanism. A horizontal installation plate is arranged on the machine base and provided with a horizontal moving mechanism. The horizontal moving mechanism comprises a horizontal fixing frame and a horizontal moving motor. The horizontal fixing frame is provided with a horizontal moving guide rail which is connected with a vertical lifting mechanism. The vertical lifting mechanism comprises a lifting air cylinder installation seat and a vertical lifting air cylinder. The lifting air cylinder installation seat is provided with the vertical lifting air cylinder. The vertical lifting air cylinder is connected with a clamping mechanism. The conveying device is simple in structure, scientific, convenient to use, high in pertinence, high in automation degree, high in work efficiency and capable of well solving the transportation problem of the glass production line.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

Highly automatic plate-overturning and plate-picking production line for producing large-size decorative plates

The invention discloses a highly automatic plate-overturning and plate-picking production line for producing large-size decorative plates. The highly automatic plate-overturning and plate-picking production line comprises a material mixing machine set, a material distribution mechanism, a kiln, a kiln tail fixed roller table, a kiln furniture, a plate-picking mechanism, a deviation-correcting mechanism and an overturning mechanism, wherein a belt conveyor is disposed between the material mixing unit and the material distribution mechanism; an inlet and an outlet of a material distribution machine position of the material distribution mechanism are respectively equipped with a deviation-correcting roller table and a receiving roller table; the other end of the receiving roller table is connected with a conveying roller table in a matching manner; a kiln inlet and a kiln outlet are respectively equipped with a kiln-incoming roller table and a kiln-outgoing roller table; shuttling roller tables are disposed between the kiln-incoming roller table and the conveying roller table and are used for conveying in a matching manner; the kiln-outgoing roller table is equipped with the shuttling roller tables and the kiln tail fixed roller table which are used for conveying in a matching manner; the kiln tail fixed roller table is sequentially matched with the plate-picking mechanism and the deviation-correcting mechanism for conveying along the movement direction of rollers; and the overturning mechanism and the shuttling roller tables are also disposed between the kiln tail fixed roller table and the deviation-correcting roller table.

Owner:佛山市创瓷窑炉有限公司

Tuned mass damper for vibration-damping experiment of structure model and design method

The invention discloses a tuned mass damper (TMD) for the vibration-damping experiment of a structure model. The tuned mass damper comprises a mass block, an elastic element, an energy dissipation element and a support angle bar, wherein the mass block adopts ring permanent magnets and small iron blocks adsorbed on the ring permanent magnets; the elastic element adopts a horizontal aluminum bar cantilever beam structure; the energy dissipation element adopts electromagnetic damping, when the mass block is horizontally or vertically vibrated, a copper plate and a copper tube which are mounted on the support angle bar cut a magnetic induction line generated by the moving permanent magnets, and structural vibrating energy is gradually converted into heat energy to be consumed. According to the invention, through unique structural design, the TMD can satisfy the requirements of the structure model for the vibration-damping experiment in the horizontal direction and in the vertical direction at the same time; the permanent magnets required by the energy dissipation element are directly used as the mass block of the TMD, and the structure is compact; the damping parameter and the frequency parameter of the TMD are completely separated, and quantification regulation can be made, so that precise simulation for the excellent damping parameter of the TMD for in the vibration-damping experiment of the structure model in the horizontal direction or the vertical direction can be realized.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

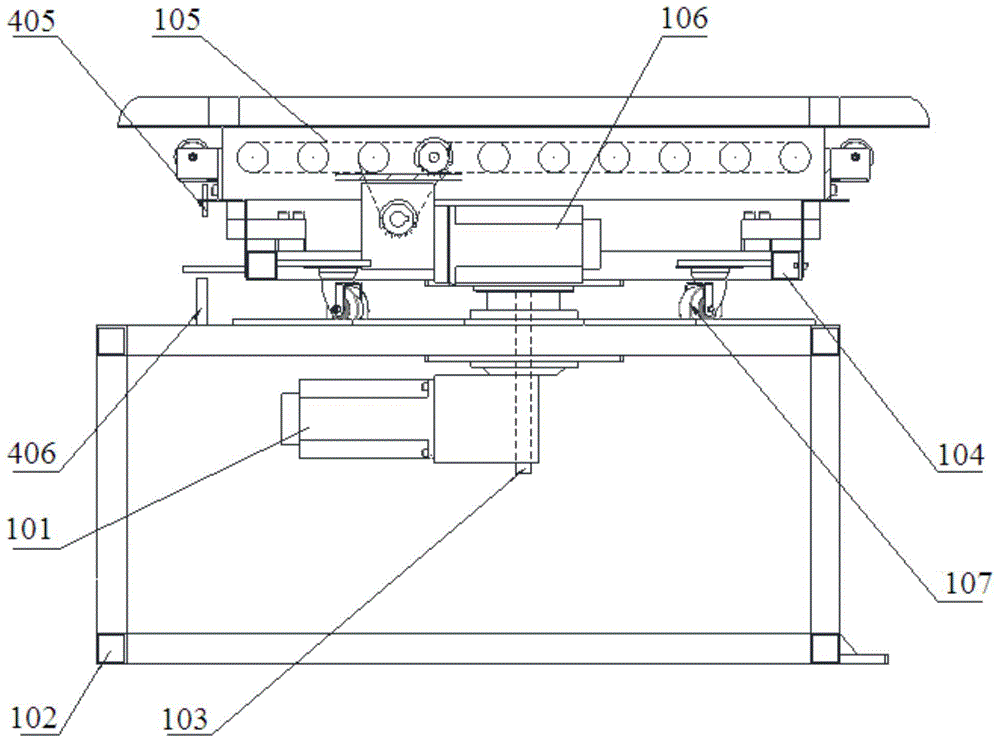

Comprehensive rock impacting breaking test stand

InactiveCN104634673AAchieve horizontal movementRealize layoutMaterial strength using single impulsive forceMaterial strength using repeated/pulsating forcesChanging equipmentSingle impact

The invention discloses a comprehensive rock impacting breaking test stand which comprises a rotating speed sensor, a propelling part, a rock drill, a displacement sensor, a travel switch, a rear support, a lifting table, a thrust rack, a rotating rack and a pendulum bob part. Optional height adjustment in the operating range, horizontal movement of rock and change of the included angle between a tool and the rock can be realized, holes in large rock at different regular positions are formed, the empty hole effect of the rock is researched, the research of rock breaking by combining impacting and rock breaking methods in other forms is realized by virtue of rapid replacement equipment, and the research of rock impacting breaking under single impact and continuous impact conditions is realized. The comprehensive rock impacting breaking test stand disclosed by the invention can serve as both research equipment in a lab and performance detection equipment in factories of rock drills, hydraulic hammers, down-the-hole drills and the like.

Owner:CHINA UNIV OF MINING & TECH

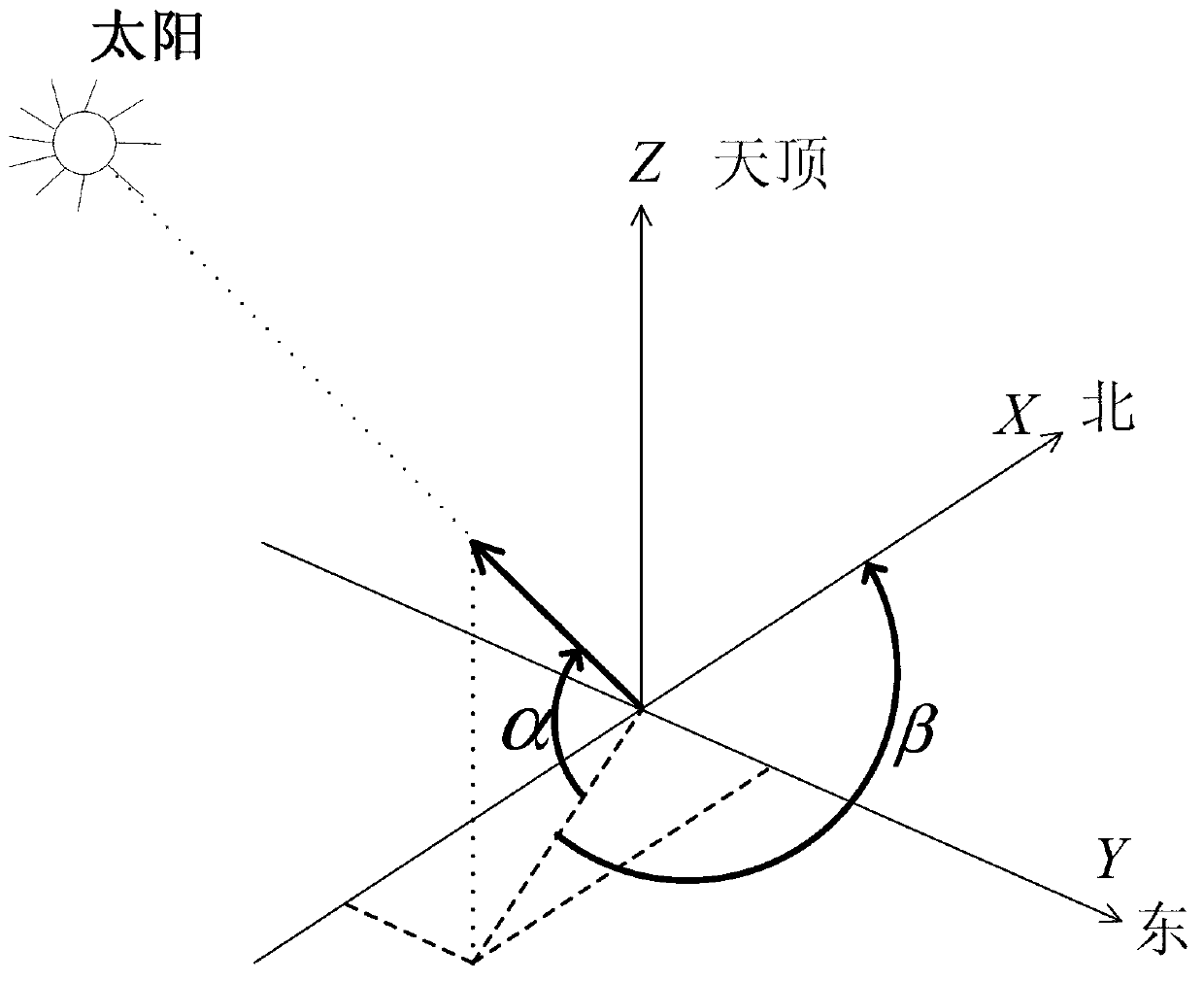

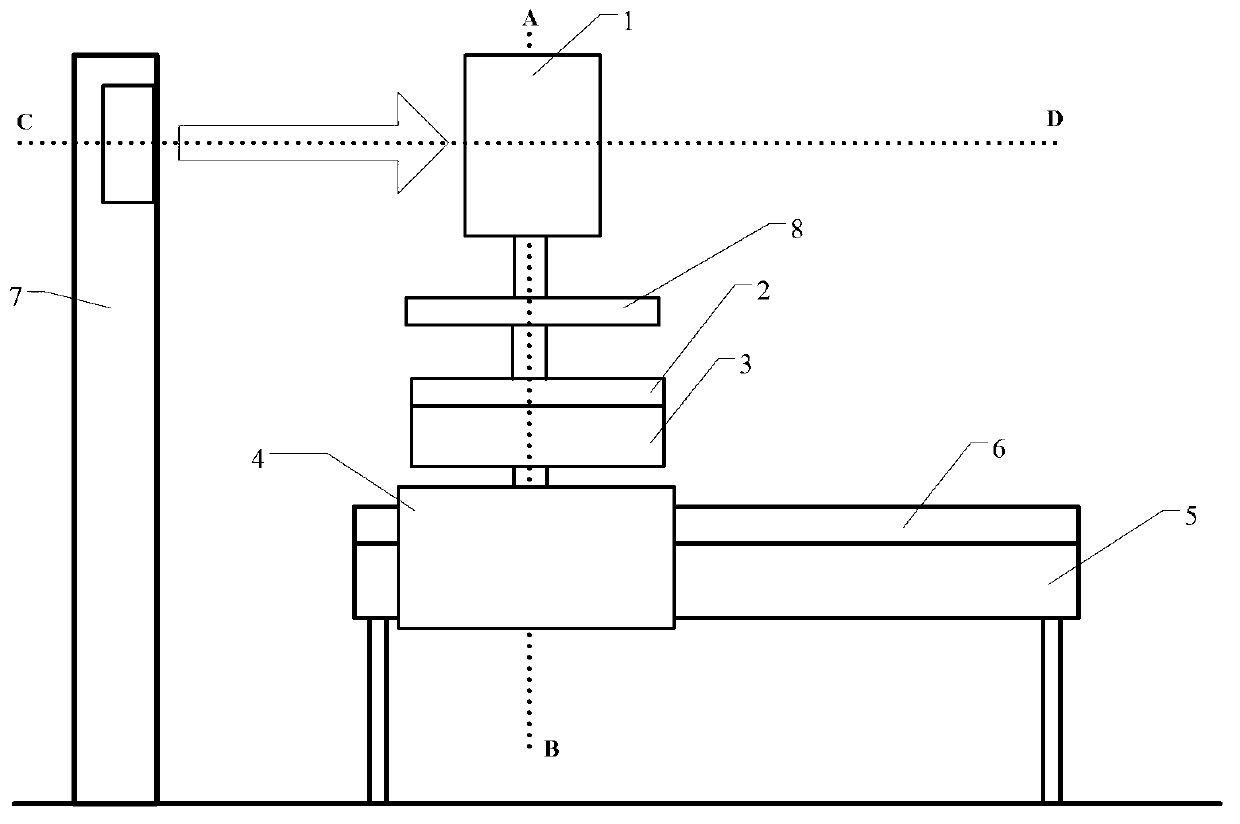

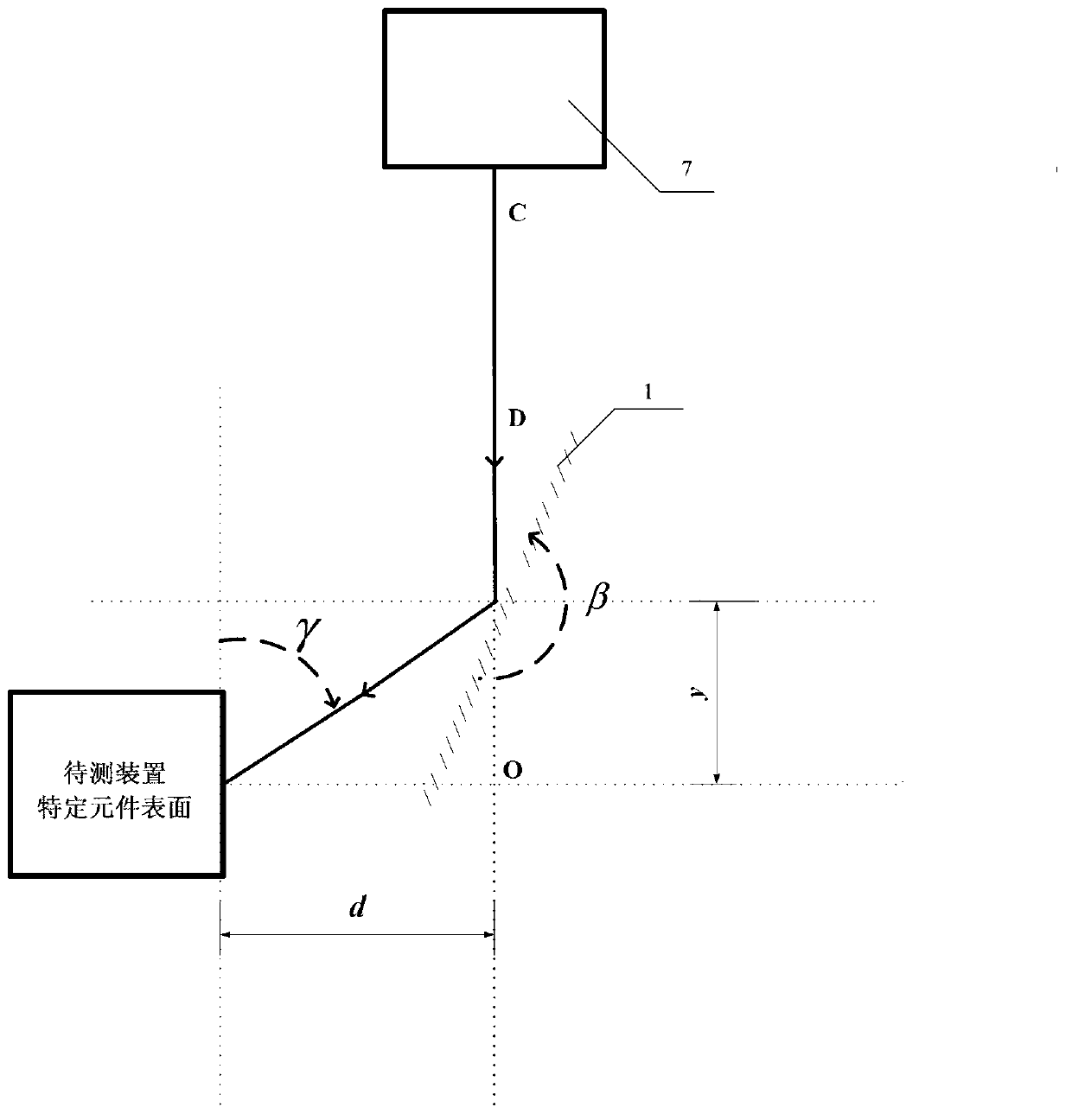

Device and method for simulating sun illumination by manually adjusting azimuth angle

InactiveCN102789237AAchieve horizontal movementRealize solar lighting simulationPosition/direction controlVertical planeMeasurement device

The invention relates to a device and a method for simulating sun illumination by manually adjusting an azimuth angle and belongs to the technical field of sun tracker detection. According to the device provided by the invention, a height adjusting device is connected with a plane reflecting mirror; a plane reflecting mirror inclined angle measuring device is connected with a plane reflecting mirror azimuth angle rotating mechanism; the plane reflecting mirror is connected with the plane reflecting mirror azimuth angle rotating mechanism through a rotating shaft and is fixed above a movable platform; the movable platform is arranged on a shifting moving guide rail; and a shifting measuring device is connected with the shifting moving guide rail. The method provided by the invention comprises the following steps: aligning light with the plane reflecting mirror; measuring the shortest vertical distance d from a principal optic axis of emergent light of a small-size solar simulator to a specific element surface of a to-be-detected device; and obtaining the azimuth angle gamma of the simulated sunlight according to a shifting measuring value y of the plane reflecting mirror and an inclined angle beta between the plane reflecting mirror and a vertical plane. The sun illumination simulation by manually adjusting the azimuth angle of the sunlight is realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

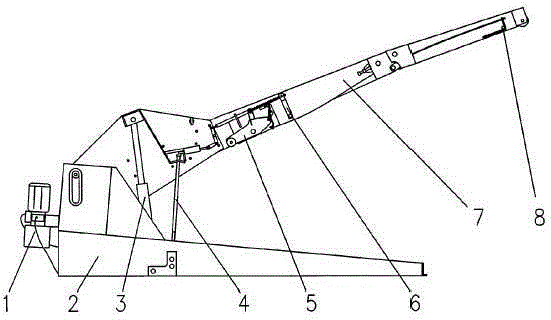

Bilateral container loader

InactiveCN101830191AAchieve vertical liftAchieve horizontal movementVehicle with pivoted armsHydraulic cylinderVehicle frame

The invention discloses a bilateral container loader, and aims to provide a loader with a self-walking function, which can meet transport requirement after being furled, and can operate ground-to-ground and vehicle to vehicle loading and unloading operation. The loader comprises an engine, a frame, two hoisting systems with the same structure respectively installed on two ends of the frame, a self-walking system, a rear axle and a suspension system. The hoisting system consists of a suspension arm device and a landing leg device, the suspension arm device comprises a guide pillar and a T-shaped lifting arm connected with a lifting driving system, two sides of the horizontal part of the T-shaped lifting arm are respectively hinged with a folding type horizontal arm stretching mechanism, and the landing leg device comprises two supporting units each of which comprises a fixed support seat, a horizontal expansion support seat, a swing leg, a connecting bar, a swing driving mechanism and a horizontal expansion driving mechanism. The self-walking system comprises two wheels, a support shaft for connecting the two wheels, a support, an overturning hydraulic cylinder, a steering hydraulic cylinder, a square steering shaft and a self-walking driving mechanism.

Owner:MILITARY TRANSPORTATION UNIV PLA

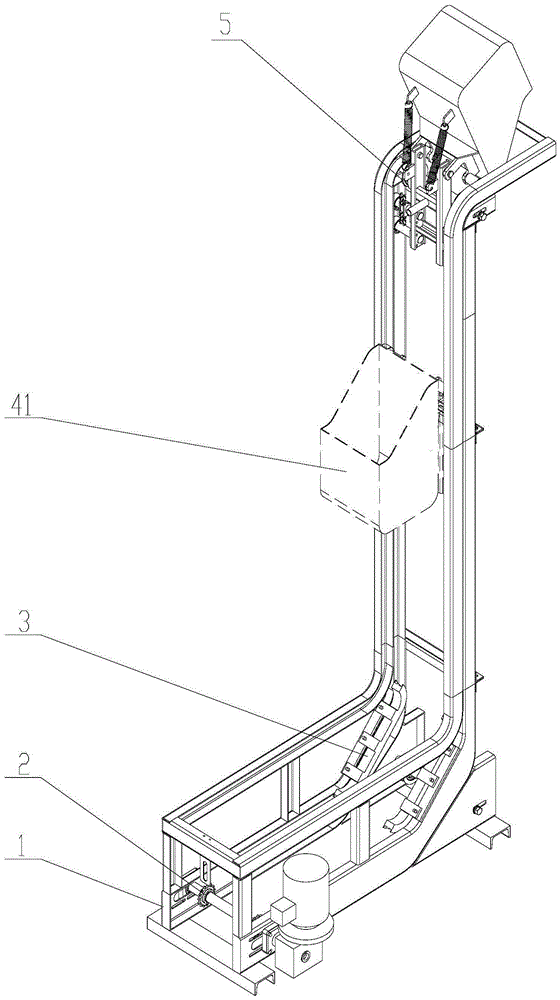

Material conveying device

ActiveCN105217238AImprove structural stabilityNot easy to deform and damageConveyorsClosed loopSprocket

The invention discloses a material conveying device. The device comprises a rack, guide rails which are arranged at two sides of the rack, a movable support assembly arranged at the bottom part of a hopper, and a driving sprocket assembly for supplying power to enable the motion of the hopper, wherein the guide rails include a front wheel guide rail, and a rear wheel guide rail which is arranged at the bottom part of the front wheel guide rail; the front wheel guide rail and the rear wheel guide rail are provided with horizontal sections and vertical sections; vertical gaps are formed in the tail ends of the front wheel guide rail and the rear wheel guide rail; the movable support assembly comprises a fixing end which is fixed to the hopper, and a hinging end which is hinged to the fixing end; a forward moving wheel and a rear moving wheel which are correspondingly matched with the front wheel guide rail and the rear wheel guide rail are correspondingly arranged at the fixing end and the hinging end; a closed-loop driving rope which is connected with the driving sprocket assembly is connected with a connector which is fixed to the movable support assembly. With the adoption of the material conveying device, a material receiving opening of the hopper can be kept in a horizontal state all the time; in addition, the material conveying device is high in structure stability, and not liable to be deformed and damaged.

Owner:长沙开元仪器有限公司

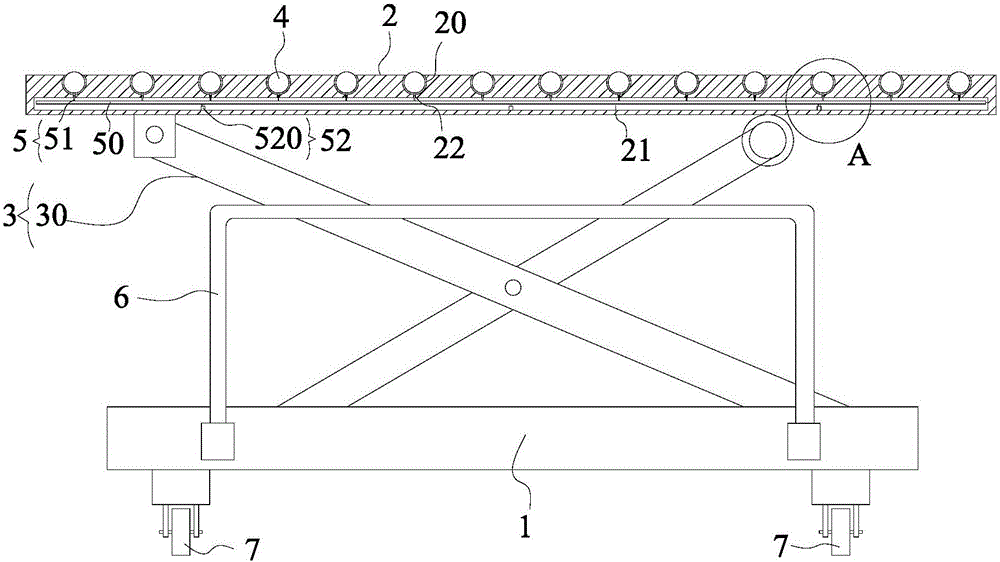

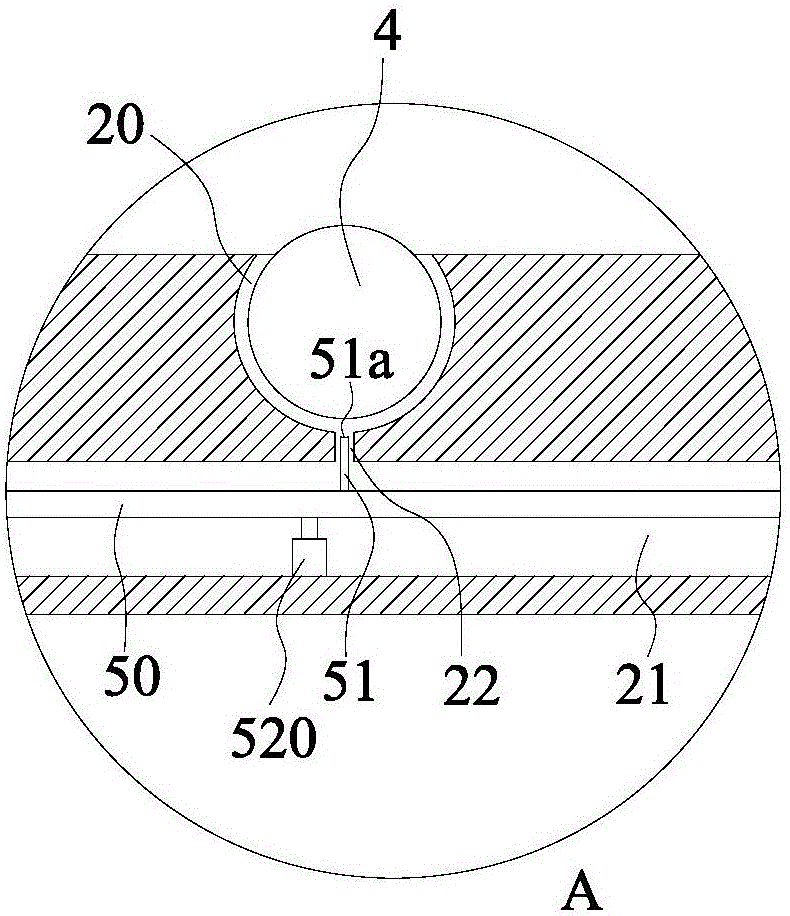

Ball hydraulic lifting operation platform

ActiveCN105800503AAchieve horizontal movementEasy to operateLifting framesRollersControl engineering

The invention relates to a ball hydraulic lifting operation platform. The ball hydraulic lifting operation platform comprises a base, a bearing platform and a lifting mechanism, wherein multiple embedding groove holes are formed in the upper surface of the bearing platform. The lifting operation platform further comprises balls respectively embedded in the embedding groove holes and capable of freely rotating, and a brake device for braking the balls to stop rotating, wherein the upper surfaces of the multiple balls are leveled; and the brake device is hidden in the bearing platform. The ball hydraulic lifting operation platform can realize horizontal product movement through setting of the balls, can achieve the moving stop effect under the effect of the brake device, an is more practical, simple in operation and convenient for actuation.

Owner:SUZHOU COMPORT HYDRAULIC ELEVATORING MACHINERY CO LTD

Automatic mark making system and method for cotton bale

ActiveCN104943920AAchieve horizontal movementConvenient and safe sewing bagPackagingAutomatic controlEngineering

The invention relates to an automatic mark making system and method for a cotton bale. The system comprises a bale rotating platform, a mark making spray head, an embedded mark making spray head driving device and an automatic control device; the mark making spray head is arranged on the embedded mark making spray head driving device, and one side or two sides of the bale rotating platform are each provided with one embedded mark making spray head driving device; when only one side of the bale rotating platform is provided with the embedded mark making spray head driving device, and after the bale rotating platform conveys one end of the cotton bale to the mark making position, the automatic control device starts the mark making spray head and the embedded mark making spray head driving device to conduct spray marking of cotton bale information on the end of the cotton bale; after mark making is completed, the automatic control device makes the mark making spray head and the embedded mark making spray head driving device stop and controls the bale rotating platform to rotate to convey the other end of the cotton bale to the mark making position, and spray marking of the cotton bale information is conducted on the other end of the cotton bale; when the two sides of the bale rotating platform are each provided with the embedded mark making spray head driving device, the automatic control device starts the mark making spray head and the embedded mark making spray head driving device to conduct spray marking of the cotton bale information on the two ends of the cotton bale simultaneously.

Owner:北京智棉科技有限公司

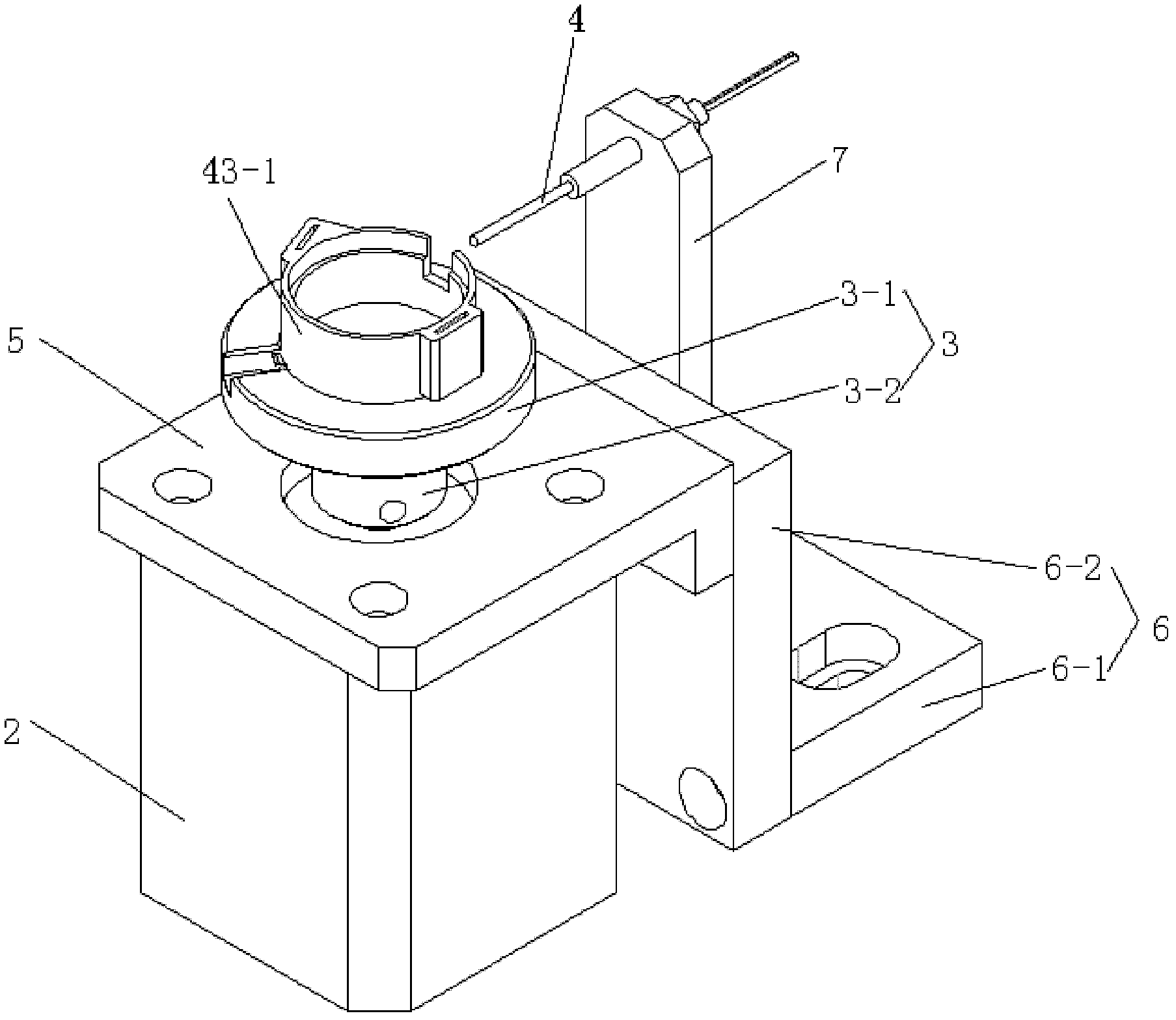

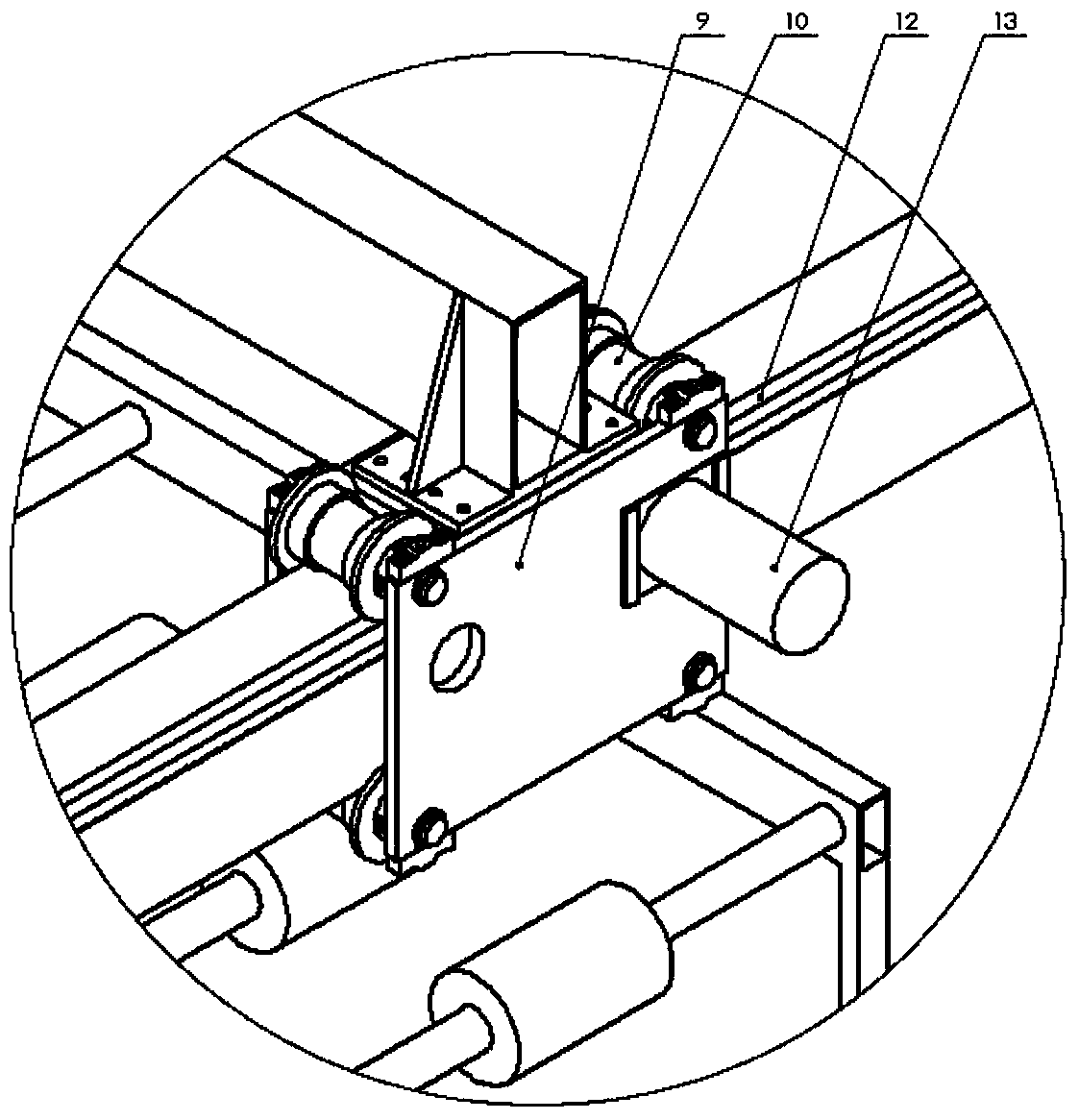

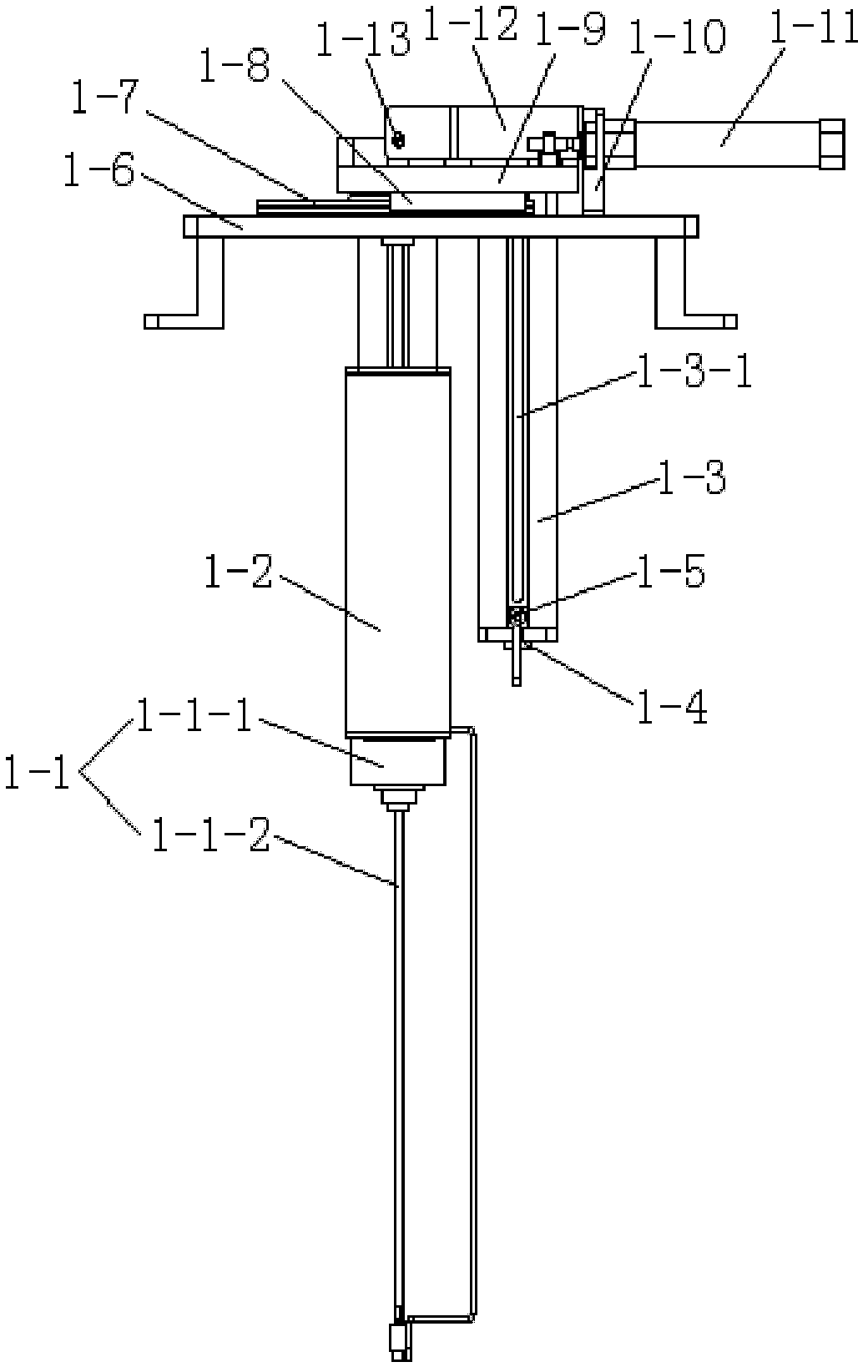

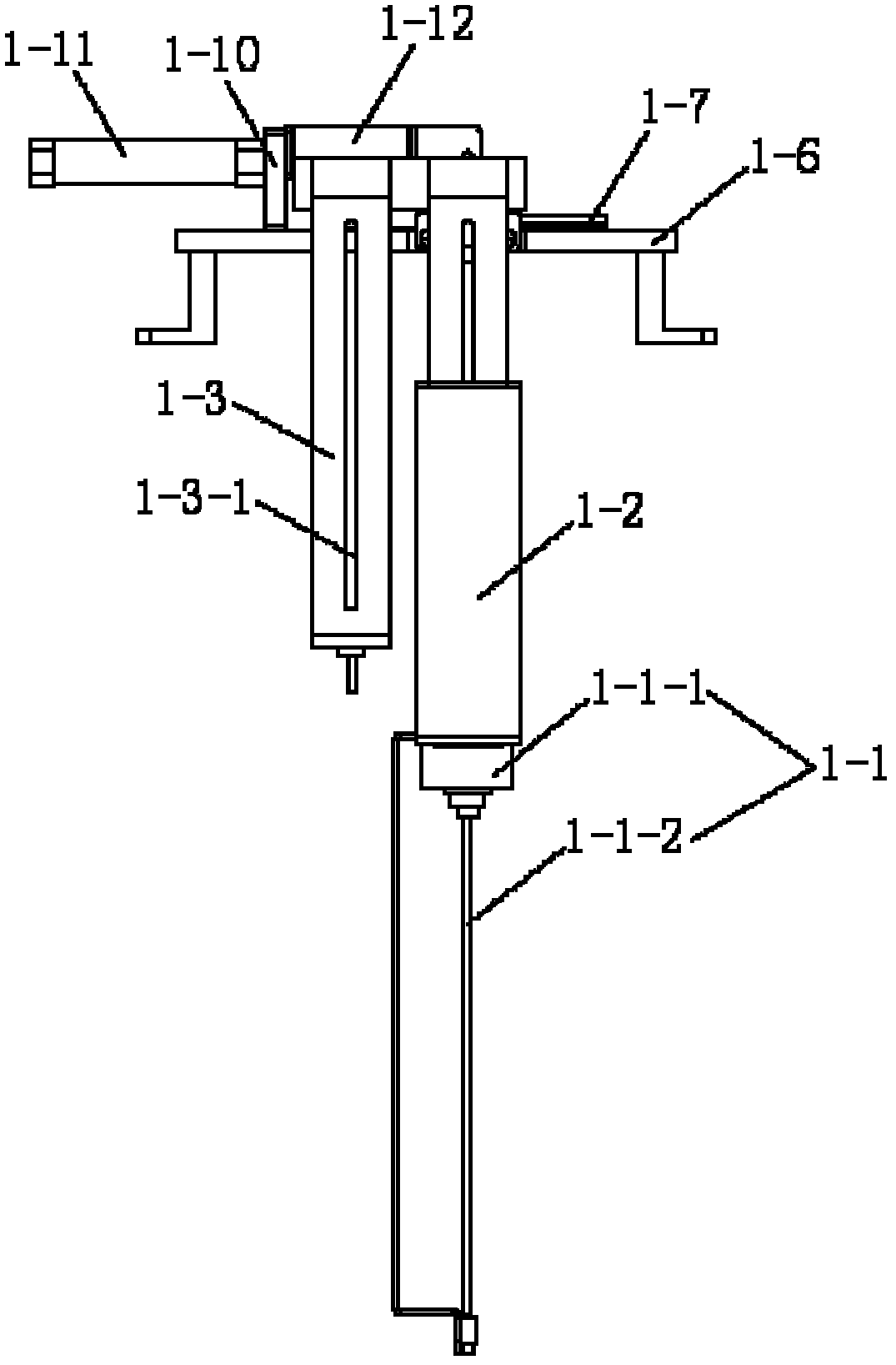

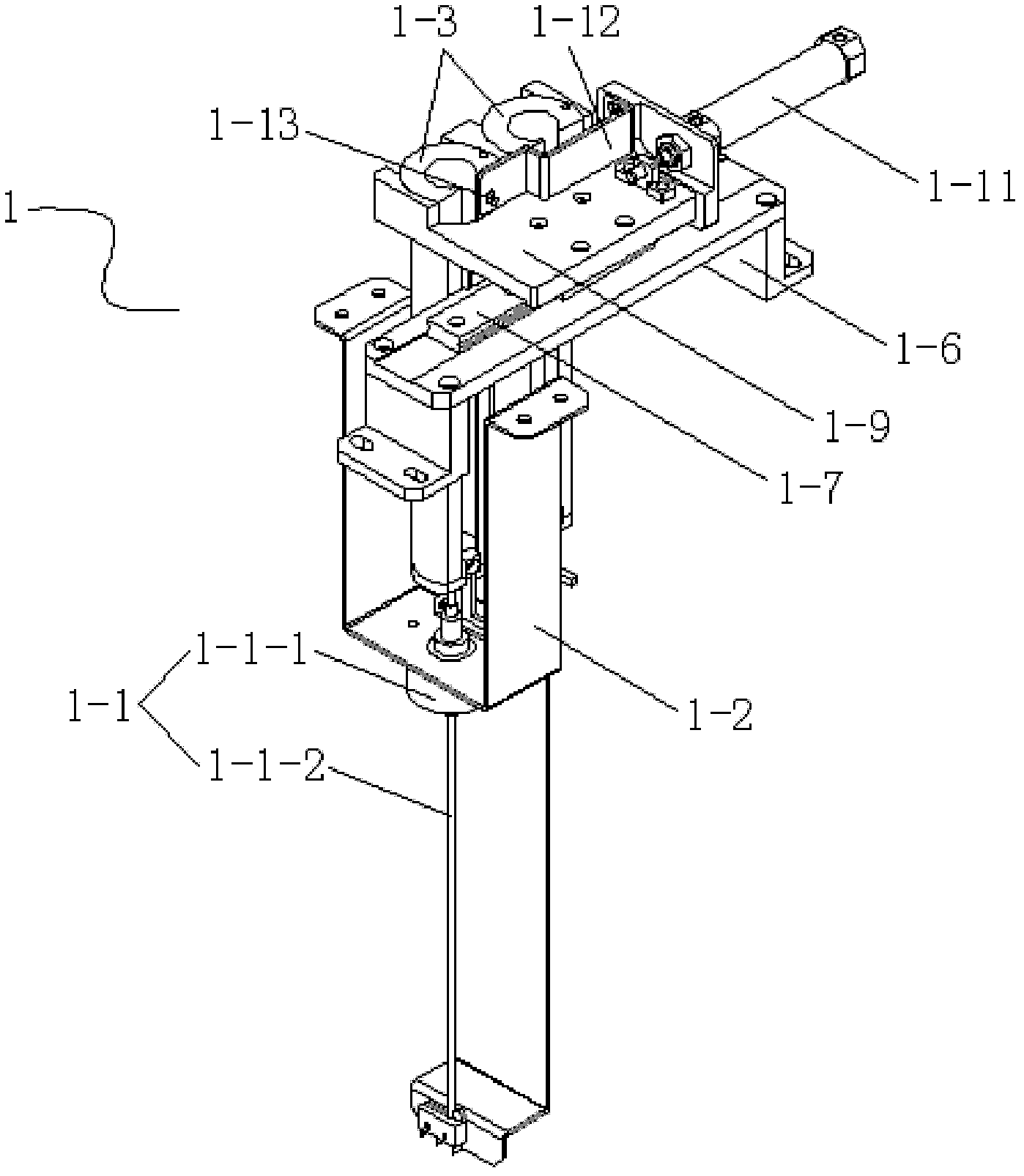

Buzzer placing mechanism

ActiveCN102848179ARealize automatic feeding processRealize automatic placementMetal working apparatusProduction lineIndustrial engineering

The invention discloses a buzzer placing mechanism. The buzzer placing mechanism comprises an automatic feeding device and a carrying device which are fixed on a working table; a buzzer is placed on the automatic feeding device; and the carrying device absorbs the buzzer and places the buzzer in a buzzer housing. The buzzer is placed on the automatic feeding device, and the carrying device absorbs the buzzer and places the buzzer in the buzzer housing, so that the buzzer is automatically fed and placed; and the buzzer placing mechanism can be a part of an automatic buzzer assembly production line, thereby saving labor and improving working efficiency and product quality.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

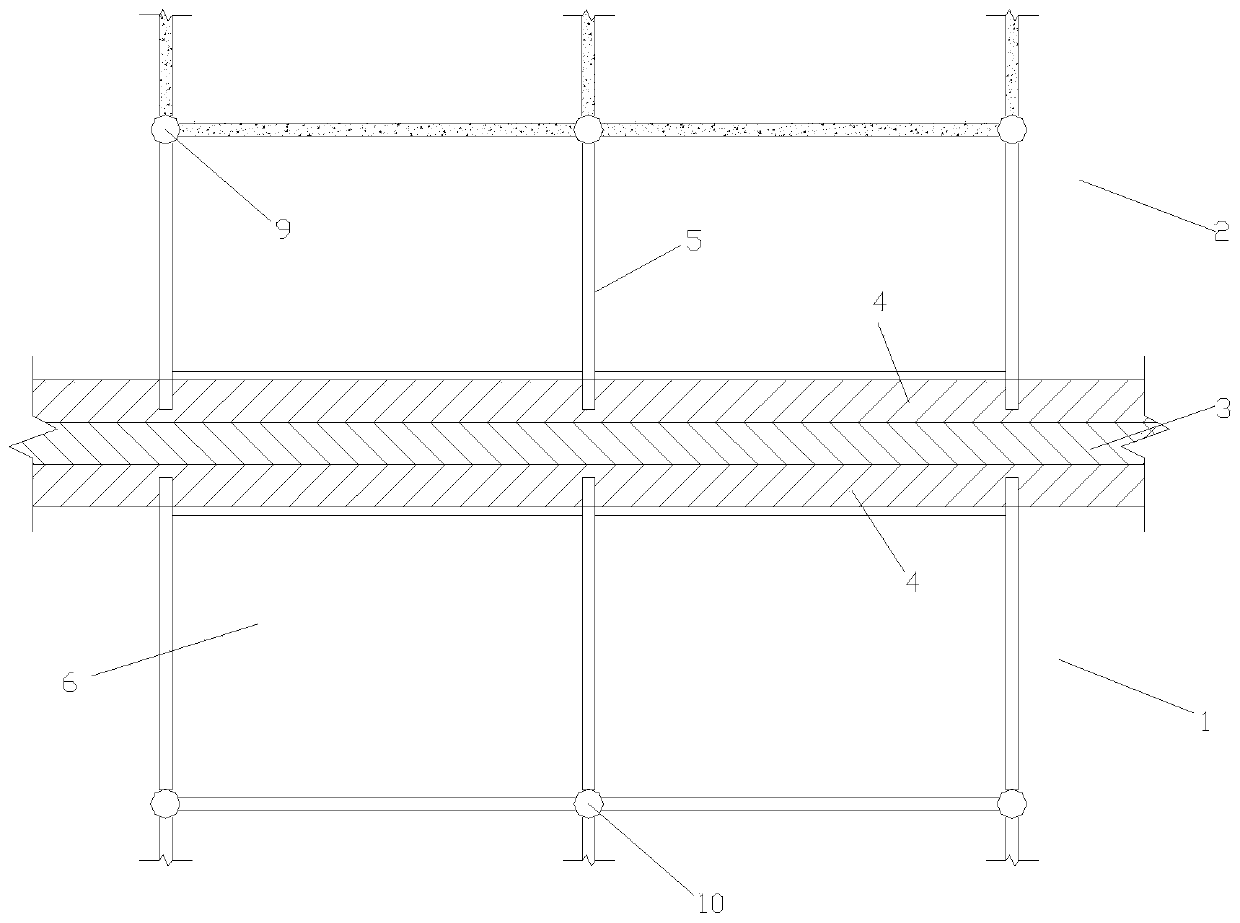

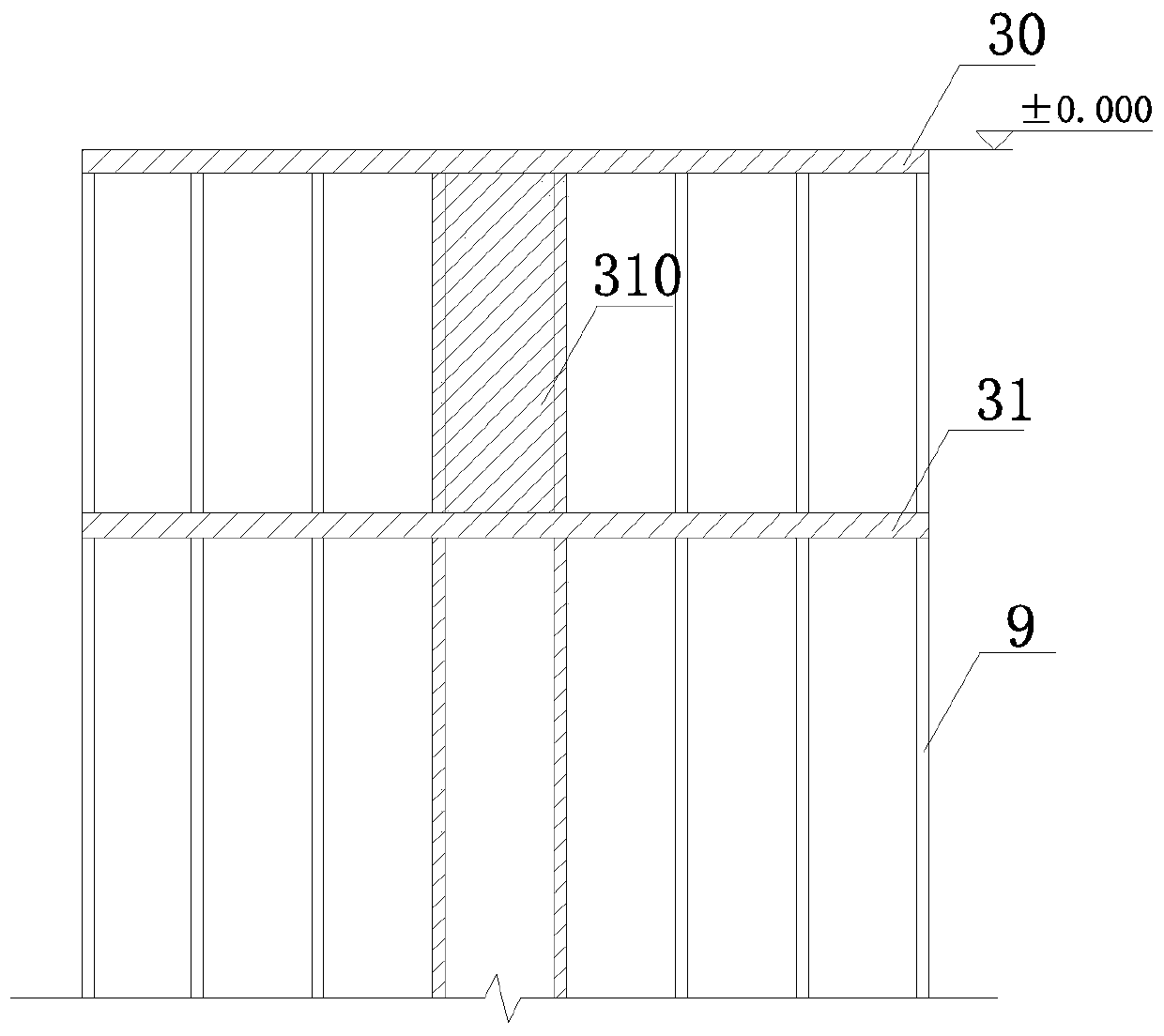

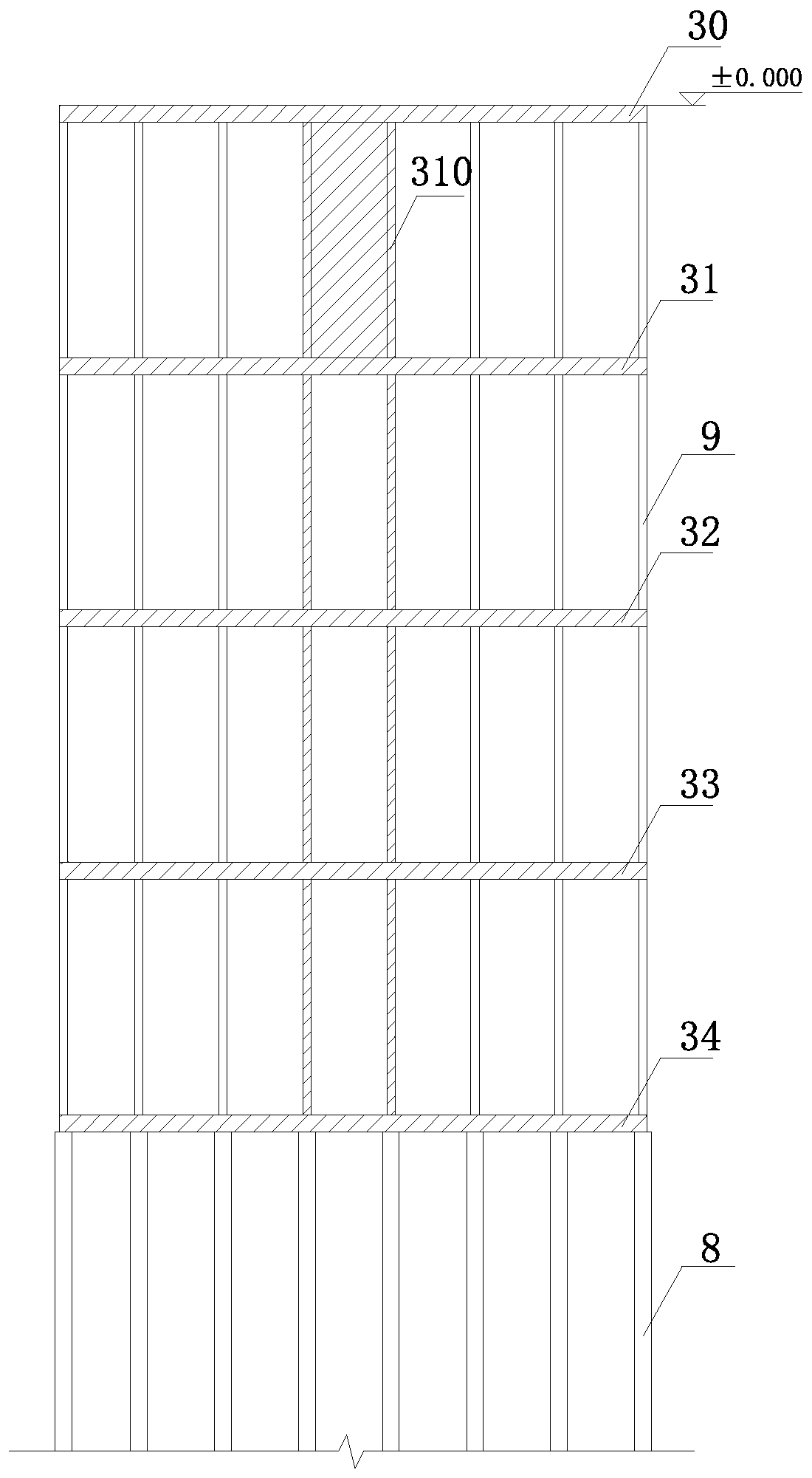

Basement staged top-down construction method

The invention relates to a basement staged top-down construction method, and belongs to the technical field of construction of the underground structure by a top-down construction method. The construction method comprises the steps that firstly, construction of a vertical force transmission structure and a staged underground diaphragm wall is conducted; steel columns, a storey B1 horizontal structure, a storey B0 horizontal structure and a storey B1 core tube of the basement are constructed by adopting a bottom-up construction method, to form a box body bearing structure; other storeys of thebasement are sequentially constructed by adopting the top-down construction method, and the construction of a shear wall of the core tube of the basement is completed by adopting the bottom-up construction method; and finally, after construction of the second-stage basement is completed, the staged diaphragm wall is disassembled from top to bottom, and connection and communication of horizontal steel beams are completed. The box body bearing structure has good integrity and high rigidity, stress of an overground structure can be smoothly transmitted to the steel columns and cast-in-place pilesbelow the box body bearing structure, the problem of uneven settlement caused by large local pile foundation stress is prevented, and the problems of staged underground diaphragm wall dismantling andhorizontal steel beam extension butt joint are further solved.

Owner:SHANGHAI CONSTR NO 1 GRP

Building curtain wall decoration automation operation construction device

InactiveCN111593897AAvoid dangerQuick installationWallsBuilding material handlingKeelArchitectural engineering

The invention relates to the technical field of building curtain wall equipment, in particular to a building curtain wall decoration automation operation construction device. The building curtain walldecoration automation operation construction device comprises a fixed base, telescopic supporting feet, a flip mechanism and a clamping mechanism, the telescopic supporting feet are fixedly arrangedat four corners on the lower surface of the fixed base, and fixed devices are arranged at the lower end of each telescopic supporting foot. A moving plate is arranged on the upper surface of the fixedbase, a horizontal pushing mechanism is arranged between the fixed base and the moving plate, the flip mechanism comprises a rotating frame arranged at the left end of the surface of the moving plate, a flip strip plate is rotatably arranged in the rotating frame, the right end surface of the flip strip plate is connected with two inclined bars, and strip slide mouths are formed in the inclined bars. The whole installation process is fast, operators are not required to connect and fix a main keel and an auxiliary keel directly, and the danger of the operators in construction is avoided.

Owner:王永峰

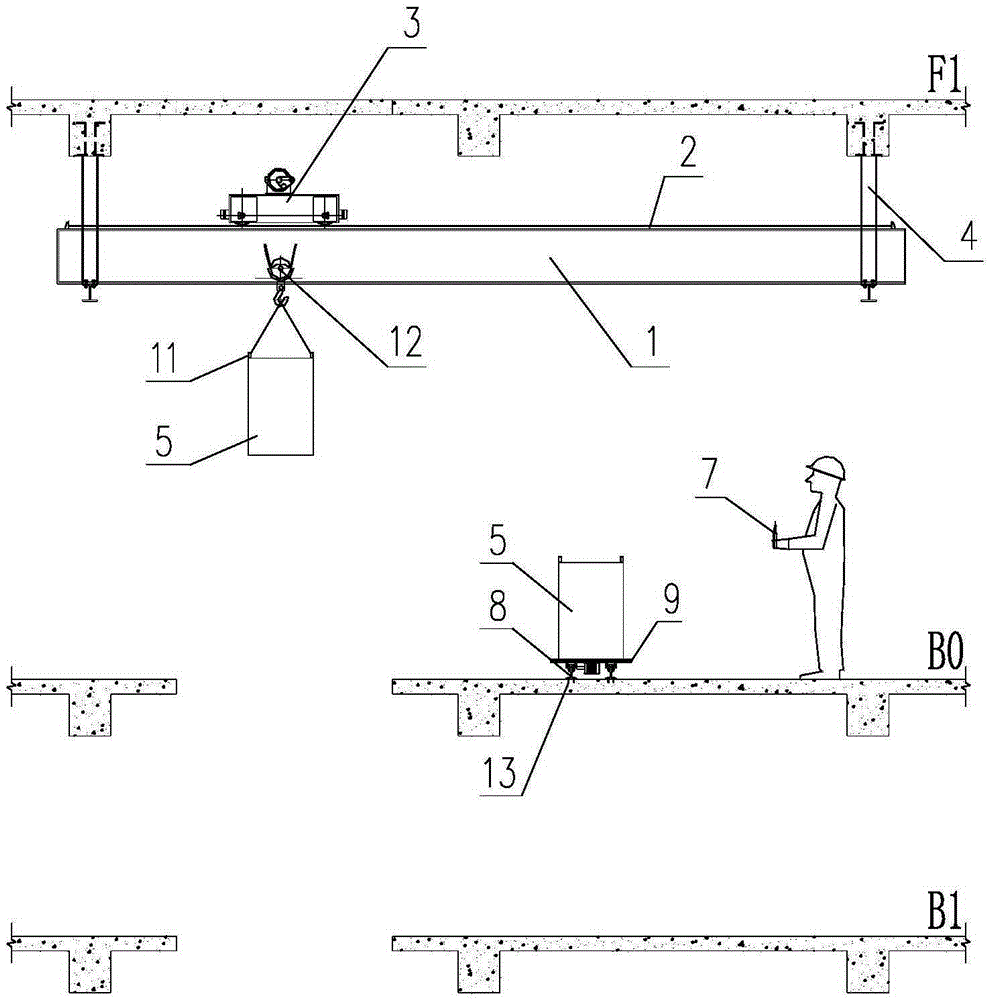

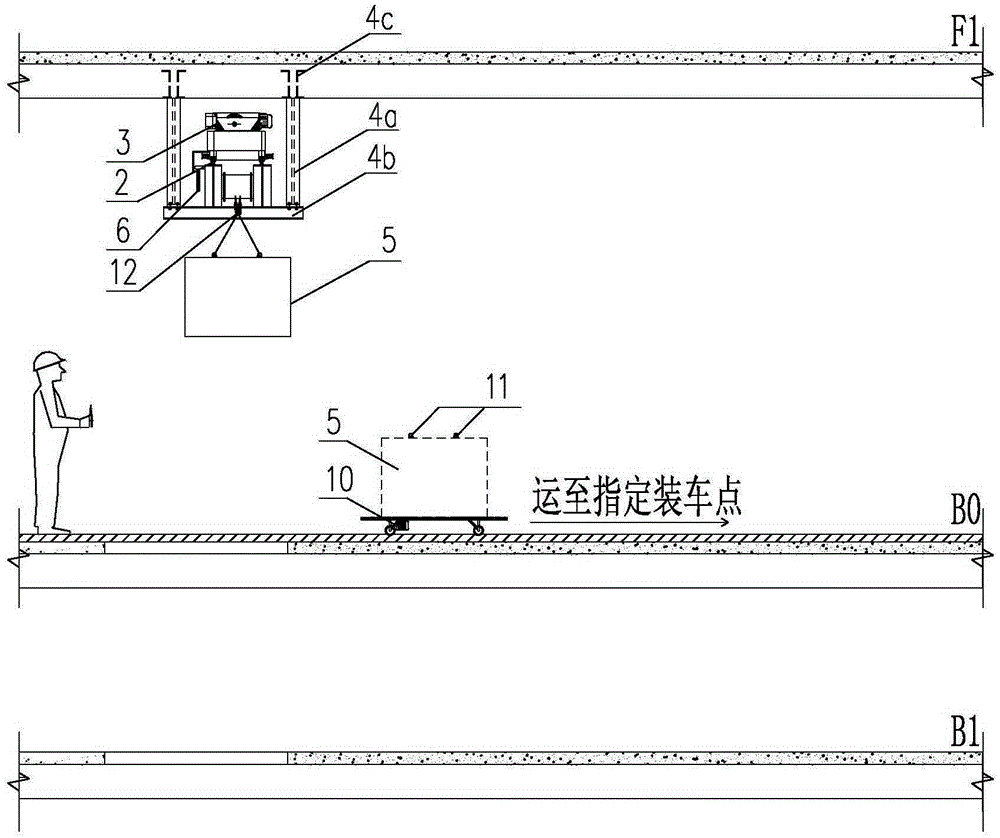

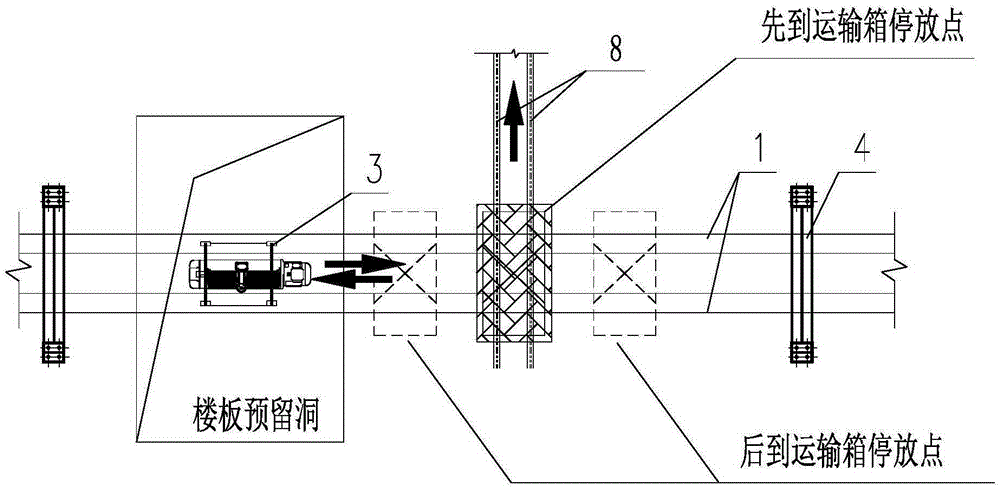

Hanging type unearthing device for bidirectional synchronous reversed construction and construction method

ActiveCN105401582AReduce investmentReduce construction costsArtificial islandsExcavationsBasementArchitectural engineering

The invention provides a hanging type unearthing device for bidirectional synchronous reversed construction and a construction method. A conveying box, filled with wastes produced by basement construction, is lifted out of the ground and transferred onto a long-distance horizontal conveying device through a hanging type crane and then is conveyed to an appointed loading position by utilizing the long-distance horizontal conveying device, the wastes in the conveying box are unloaded into a conveying vehicle by utilizing other cranes, and the empty conveying box is put onto the long-distance horizontal conveying device again, then conveyed back through the long-distance horizontal conveying device and finally conveyed to a basement through the hanging type crane for repeated use. With the adoption of the hanging type unearthing device and the construction method, the cleaning and conveying efficiencies of underground engineering wastes can be effectively improved, the investment of large machines near an unearthing reserved hole in an underground structure is effectively reduced, the construction cost is lowered, and the influence of underground waste cleaning and conveying construction on upper part structure construction can also be greatly lowered.

Owner:SHANGHAI CONSTR NO 1 GRP

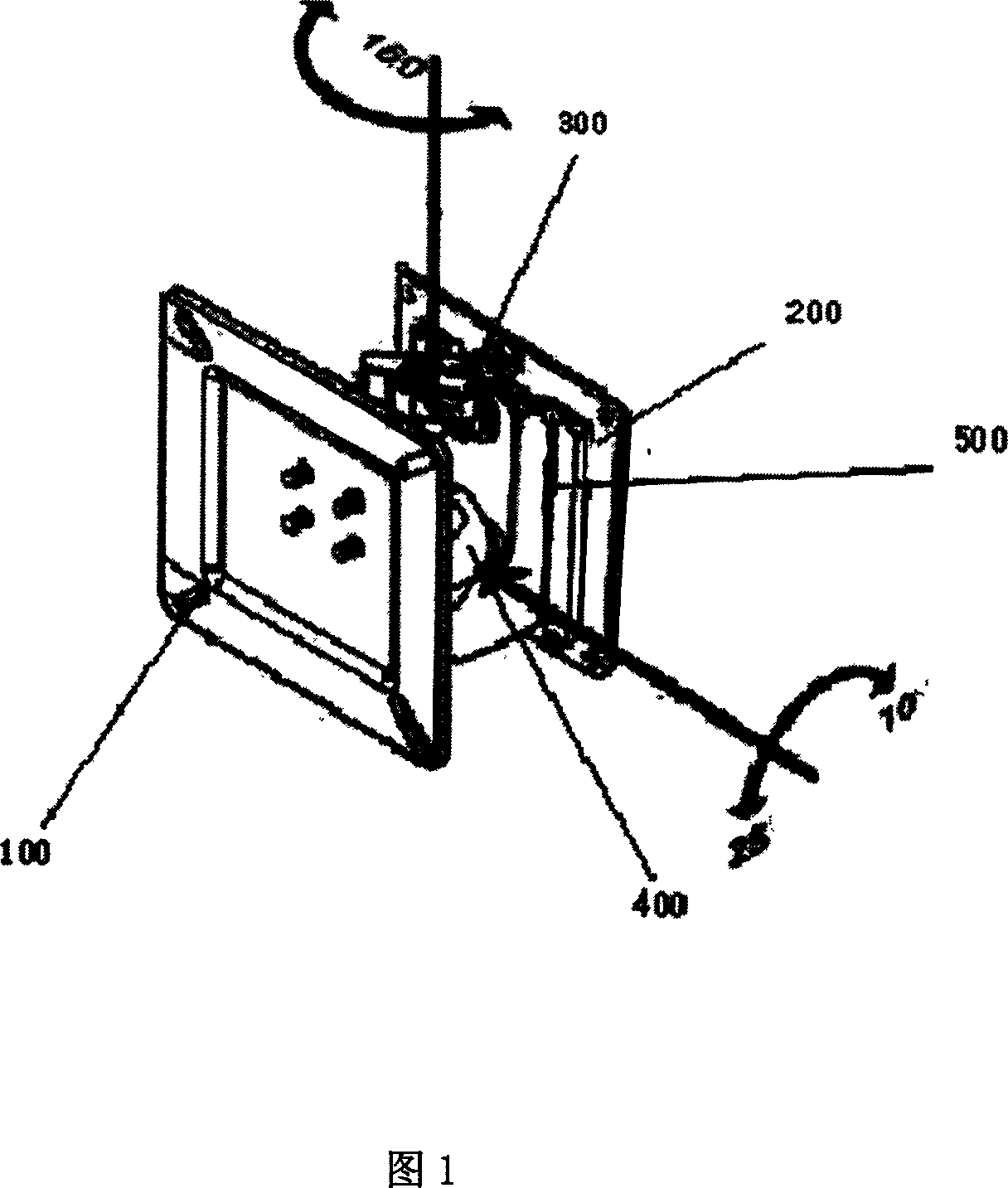

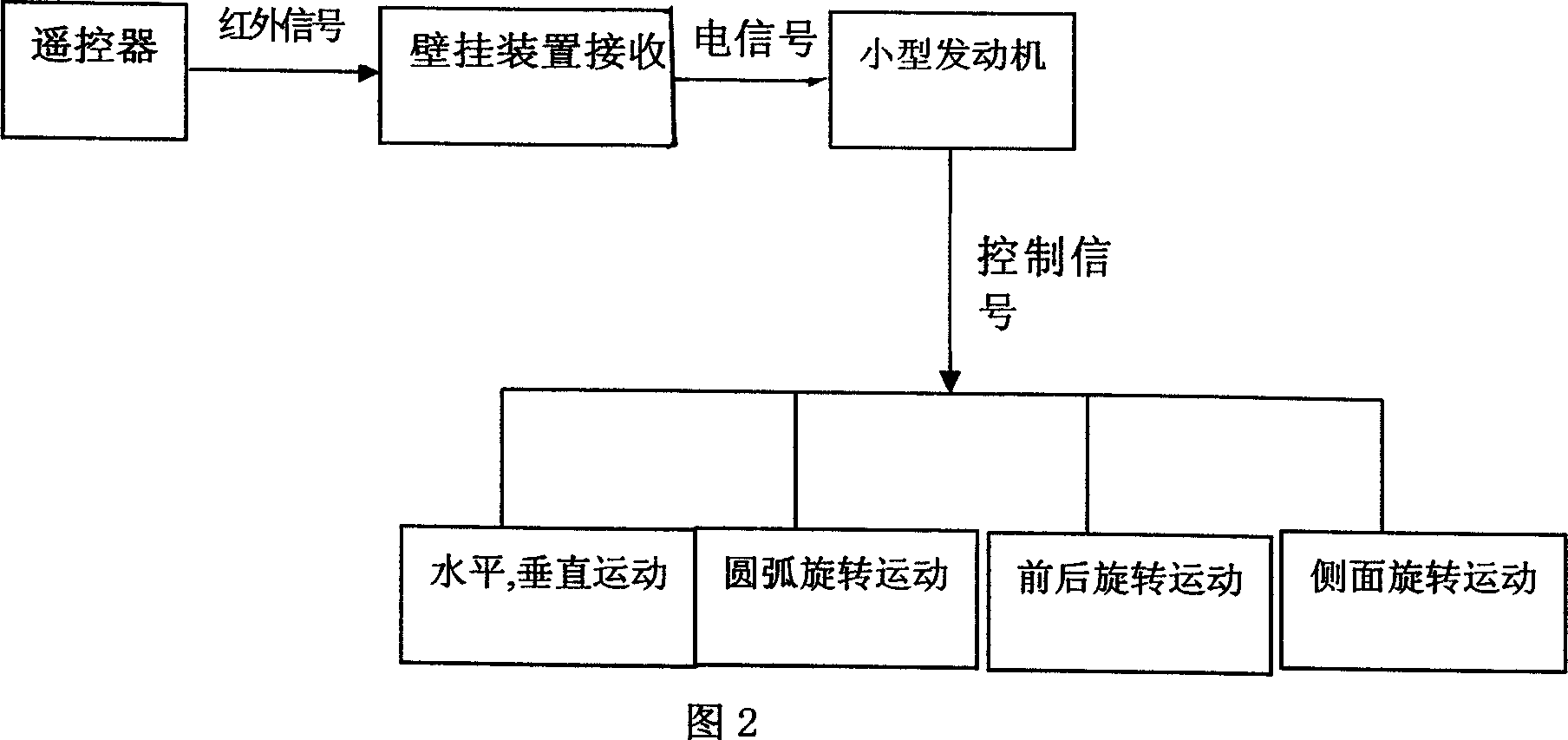

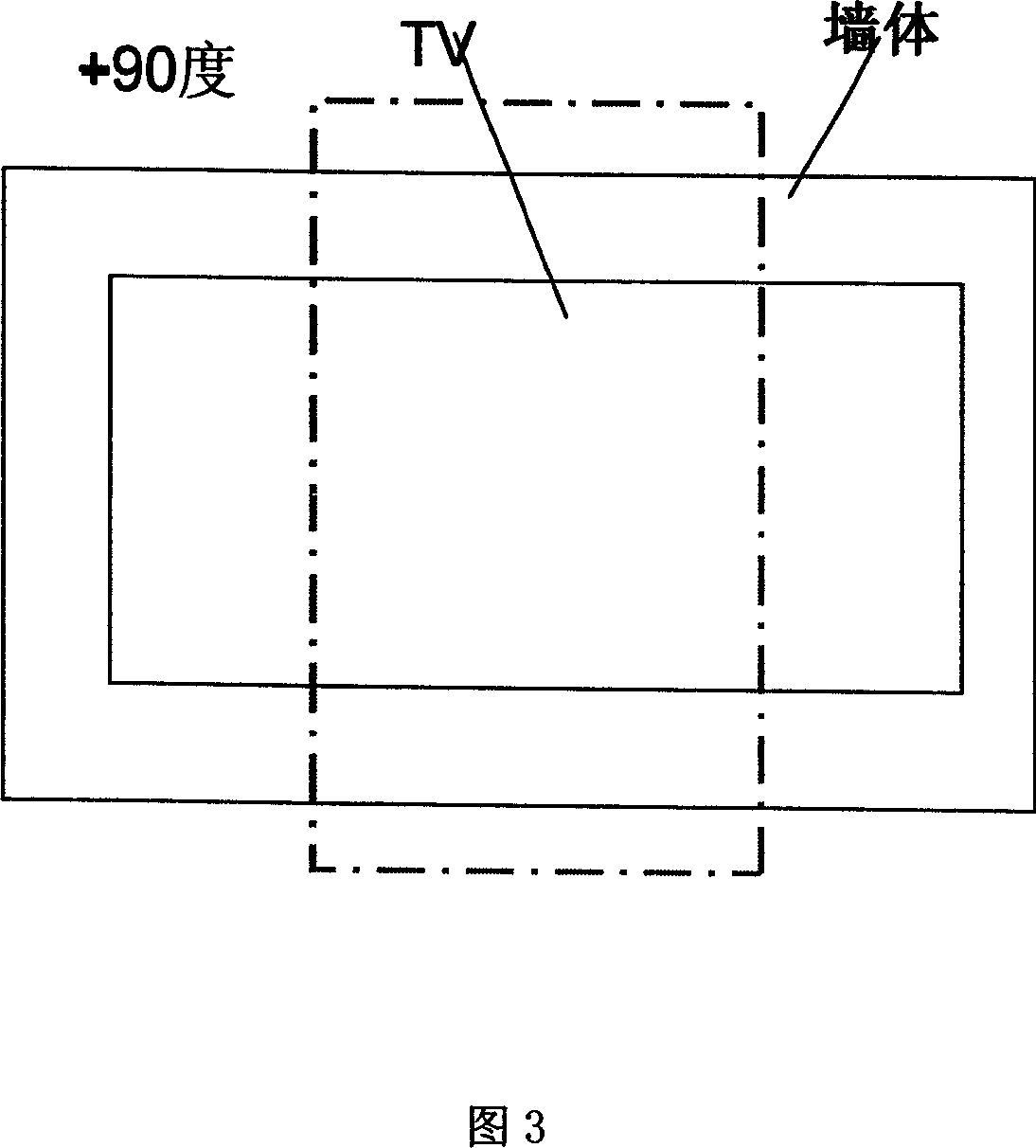

Remotely controlled adjustable wall hanging components

InactiveCN1921589AMeet various needsStable supportTelevision system detailsColor television detailsLiquid crystalEngineering

The invention relates to a remote-control adjustable wall-mounted element, which comprises the support fixed on the wall, the support fixed at the back of television, a horizontal guide bar for horizontally moving television, a vertical guide bar for vertically moving the television, a rotational central axle for rotating the television, a remote controller for emitting the position of user, and a receiver for receiving the information sent from remote controller and controlling the motion of television. The invention can realize remote control via remote controller, to adjust the position of television, with simple structure. And it can support plasma or liquid crystal television stably.

Owner:LG ELECTRONICS(NANJING) PLASMA CO LTD

Multi-hoisting point two-dimensional transmission automatic rope arranging compound crane

InactiveCN102616692AReduce weightSave structure cost and equipment costWinding mechanismsEngineeringMotor drive

The invention relates to a multi-hoisting point two-dimensional transmission automatic rope arranging compound crane which comprises a base, a frame, a reducing brake motor and a rope arranging roller. The output shaft of the reducing brake motor drives the rope arranging roller to rotate; the crane is characterized in that two ends of the rope arranging roller are rotationally installed between two supporting wallboards; lower parts of the supporting wallboards are glidingly installed on sliding bars symmetrically installed at two ends of the upper part of the frame; a movable base plate is longitudinally and fixedly installed at one end of the frame; a horizontal screw penetrating through the inner part of the roller is fixedly installed on the movable base plate; the horizontal screw is matched with a nut installed at the axle center of the end part of the rope arranging roller; and a deflecting pulley group is installed on the frame at the lower part of the rope arranging roller. The crane integrates a boom machine and the deflecting pulley group into a whole, a motor drives a winding drum to drive a hoisting cable to lift weights, meanwhile, the horizontal movement of the winding drum is realized, and two-dimensional transmission mode is realized, so that automatic rope arranging function is realized during small-space and multi-angle installation, and meanwhile, the crane has the advantages of low cost, easiness in installation and high safety.

Owner:马超

Chinese herbal piece cutting-off machine

The invention discloses a Chinese herbal piece cutting-off machine, and belongs to the field of cutting-off machines. The Chinese herbal piece cutting-off machine comprises a first box and a second box. The second box is fixedly connected to the top wall of the first box through supporting rods. The supporting rods are slidably connected with a transverse plate through sliding grooves. A cutter isconnected to the bottom of the transverse plate. A rack is fixedly connected to the bottom of the transverse plate. A discharging mechanism is connected to the end, away from the transverse plate, ofthe rack. A locking mechanism corresponding to the discharging mechanism is connected to the side wall of the first box. A cam mechanism is connected to the second box. The output end of the cam mechanism abuts against the transverse plate. A collection box is connected into the first box. A feeding port corresponding to the collection box is formed in the top of the first box. The Chinese herbalpiece cutting-off machine can replace manual work to cut off medicinal materials and has a good discharging effect.

Owner:HUBEI CHANGJIANGYUAN PHARMA

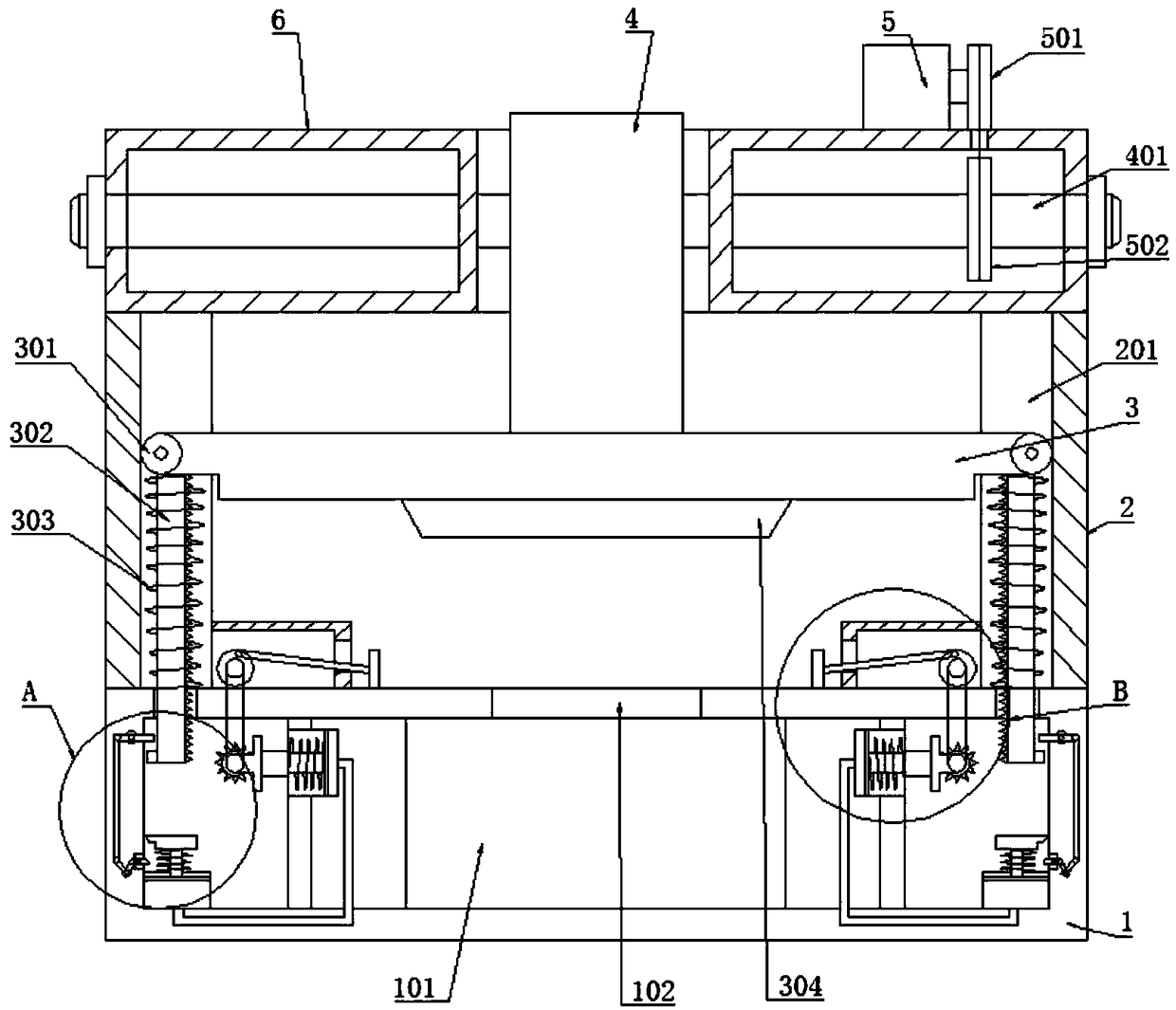

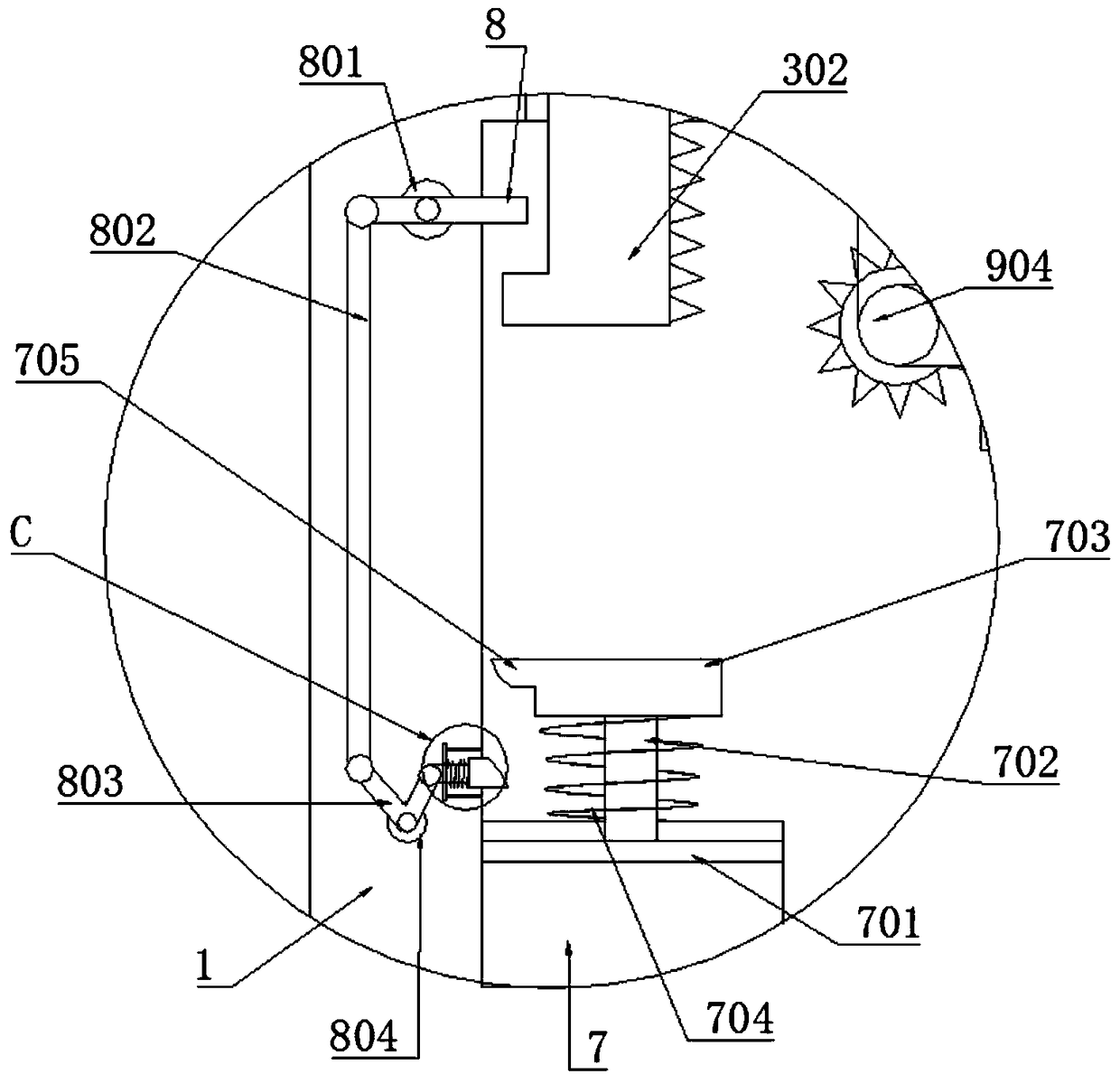

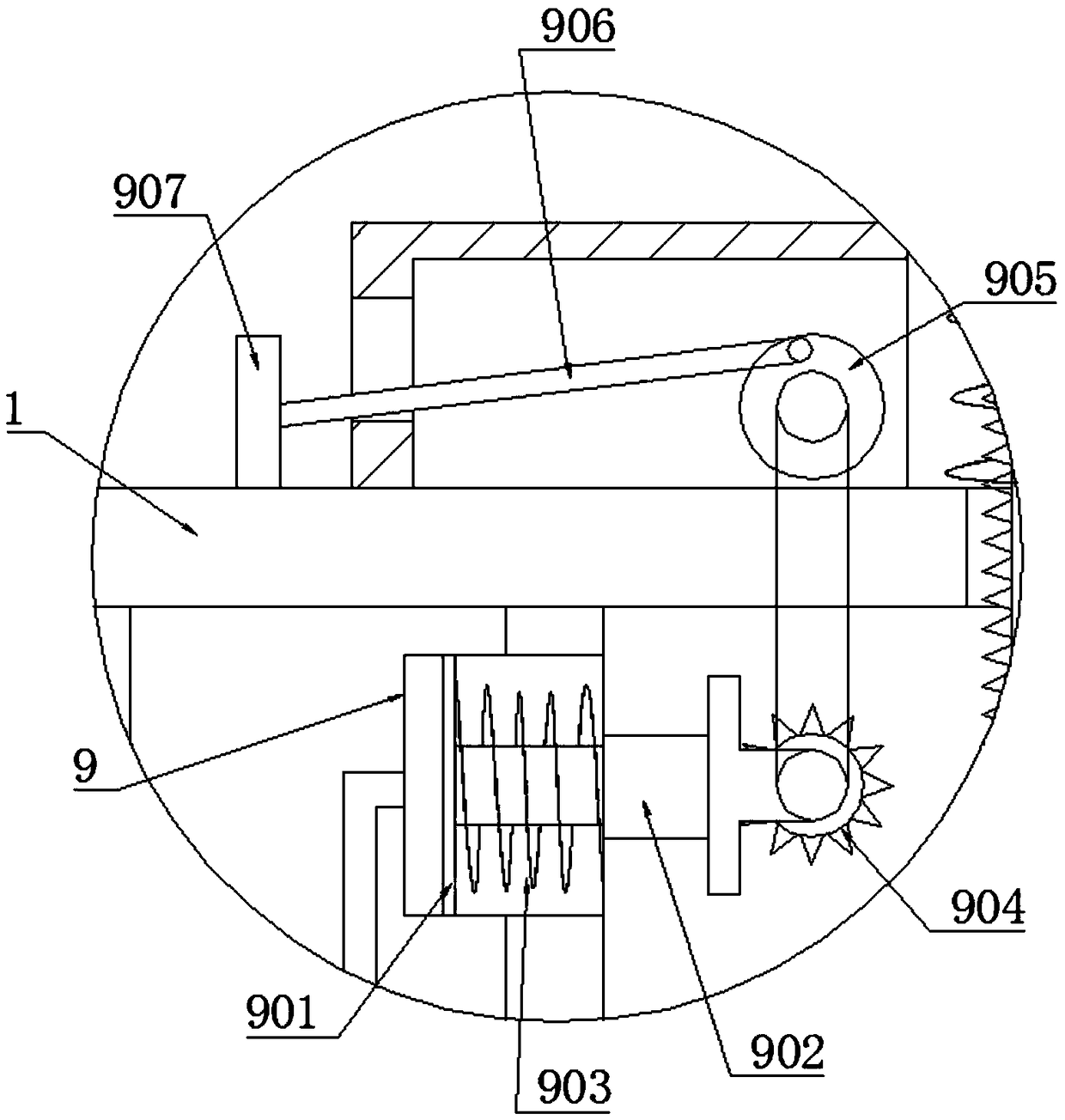

Chain transmission transferring device

The invention relates to a chain transmission transferring device which comprises a vehicle frame (9), a transmission system and a driving system, wherein the transmission system comprises two groups of chain transmission mechanisms, a differential motion bevel gear mechanism and a lifting mechanism, the two groups of chain transmission mechanisms are respectively connected with the driving system, the differential motion bevel gear mechanism is connected with the two groups of chain transmission mechanisms and enables the vehicle frame (9) to move horizontally, the lifting mechanism is connected with the differential motion bevel gear mechanism and enables a transferring container to lift, chain wheels (5) are respectively connected to the two sides under the vehicle frame (9), and the chain wheels (5) arranged on the two sides under the vehicle frame (9) are respectively matched with chains (15) of the two groups of chain transmission mechanisms. The chain transmission transferring device is simple, compact, flexible and ingenious in structure, the opposite pulling directions and the rotating speeds of the two chains of the two groups of the chain transmission mechanisms are changed to realize the horizontal moving operation and the lifting operation of the transferring container on the vehicle frame, the double-chain long-distance transmission is used, and a driving motor can be conveniently arranged and maintained on the outer side of a screening layer, namely an area with which a person can be in direct contact.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com