Tuned mass damper for vibration-damping experiment of structure model and design method

A tuned mass damping and vibration reduction test technology, which is applied to springs/shock absorbers, mechanical equipment, magnetic springs, etc., can solve the problems of TMD, such as difficult adjustment of damping parameters, inability to provide quantitative decision-making reference for vibration reduction optimization design, etc., to achieve The inherent damping is small, the effect of reducing magnetic circuit loss and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be described in further detail with regard to preferred embodiment:

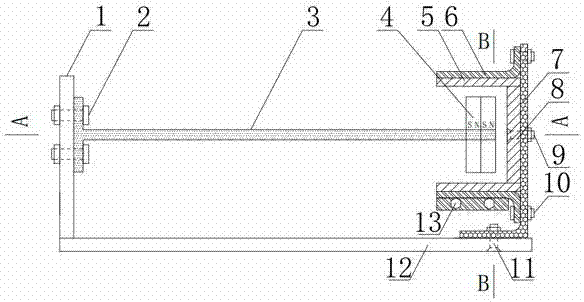

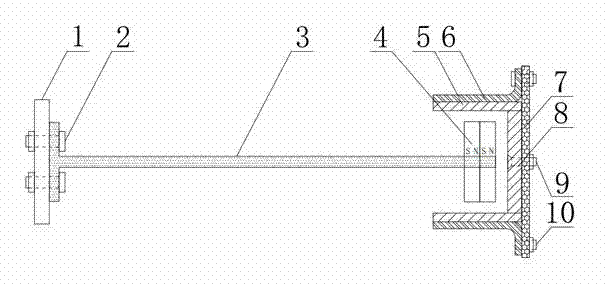

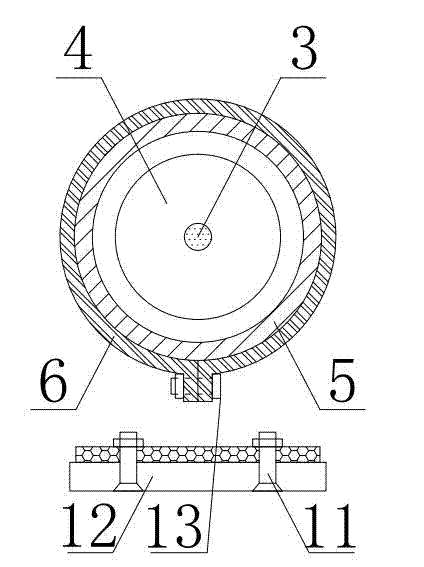

[0035] see figure 1 , figure 2 , image 3 , a tuned mass damper for two-way vibration reduction tests of structural models, including a bottom plate 12, a vertical plate 1, a mass block, an elastic element, an energy dissipation element, and a support device for fixing the energy dissipation element, and the vertical plate 1 is fixed on One end of the bottom plate 12 and the other end of the bottom plate 12 are fixed with a supporting device, the supporting device adopts angle steel 7, and there are two waist-shaped holes at the bottom of the angle steel 7, which are connected with the bottom plate through countersunk head bolts and nuts 11 to realize the horizontal movement of the angle steel on the bottom plate, and the elastic The component adopts a cantilever beam 3, which is made of a solid aluminum rod with a small ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com