Patents

Literature

106results about How to "Increase section size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

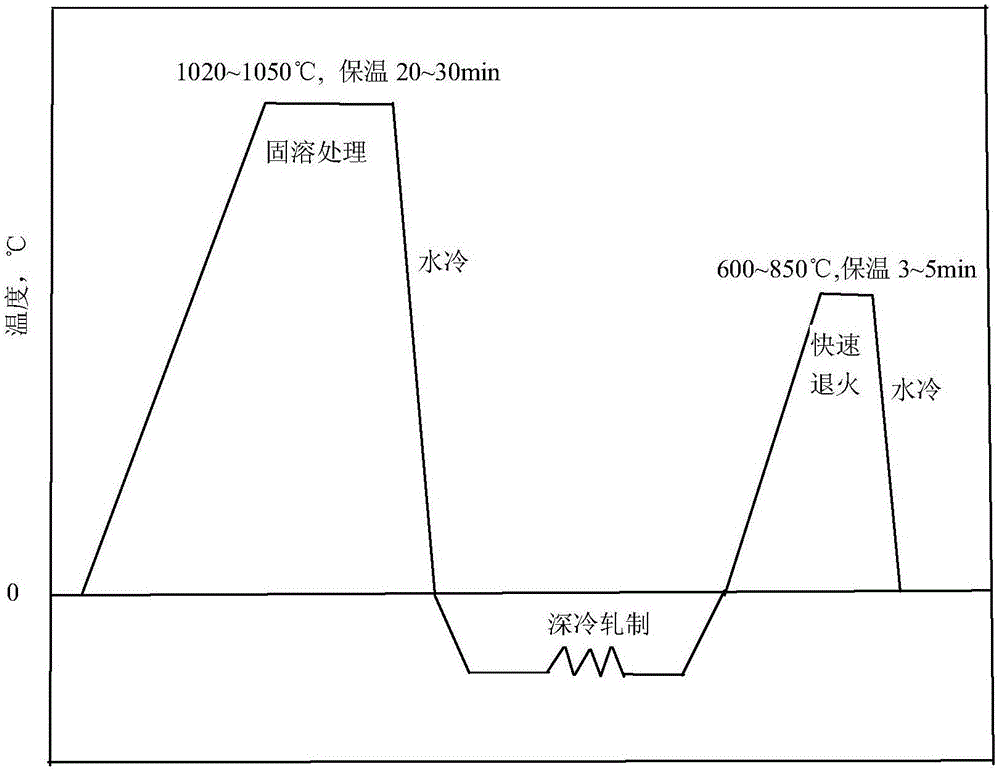

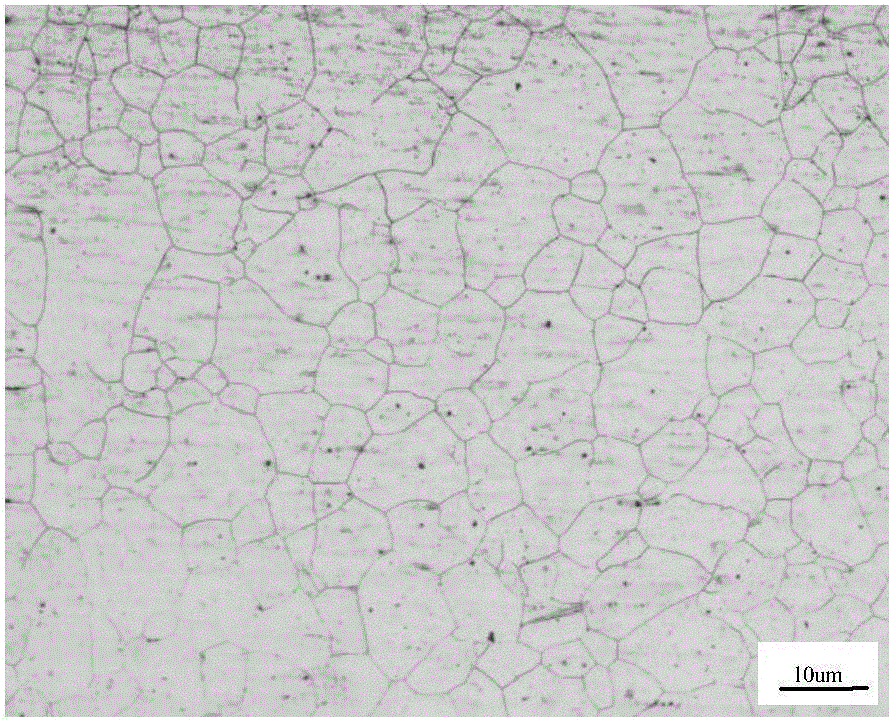

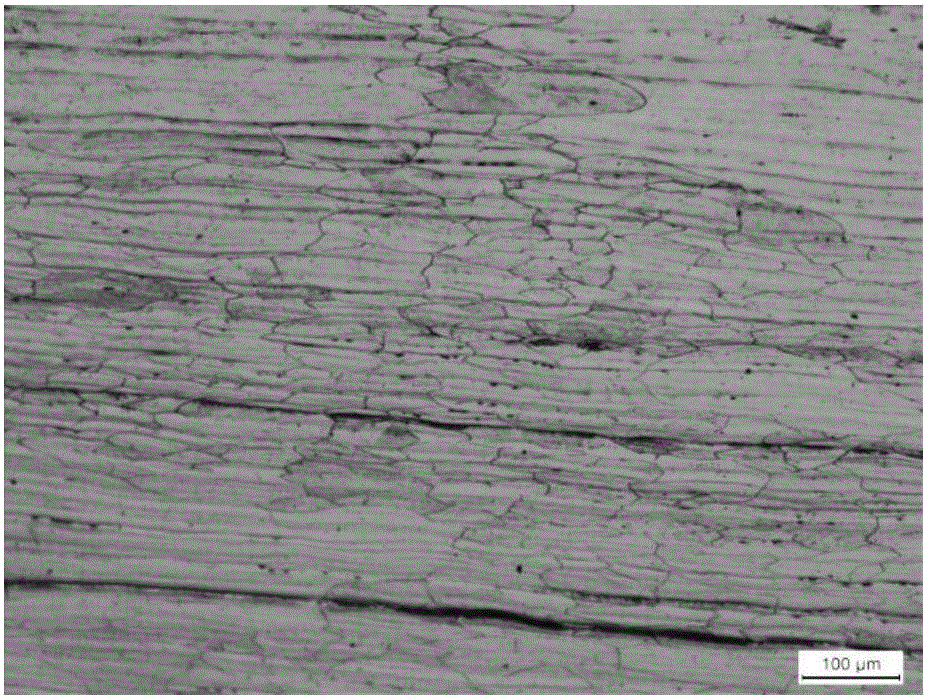

Method for preparing nanocrystalline austenitic stainless steel plate through deep cooling rolling-rapid annealing

ActiveCN106435131ARemarkable grain refinement effectIncreased strength and plasticitySteel platesAustenitic stainless steel

The invention provides a method for preparing a nanocrystalline austenitic stainless steel plate through deep cooling rolling-rapid annealing and belongs to the field of stainless steel manufacturing. The method comprises the steps that (1) an austenitic stainless steel blank is hot-rolled after being subjected to heat preservation at the temperature of 1150 DEG C-1250 DEG C and then is air-cooled to the room temperature after being water-cooled to 150 DEG C-200 DEG C, and a hot-rolled plate is prepared; (2) deep cooling rolling is conducted, specifically, the hot-rolled plate is subjected to solid solution treatment, after an oxide layer on the surface is removed, deep cooling rolling is conducted, the steel plate is subjected to liquid nitrogen treatment before cold rolling per pass, and a deep cooling rolled stainless steel plate is prepared; and (3) the deep cooling rolled stainless steel plate is air-cooled to the room temperature after being subjected to heat preservation at the temperature of 600 DEG C-850 DEG C, so that the nanocrystalline austenitic stainless steel plate is prepared. The yield strength of the stainless steel plate prepared by the method is 956-1170 MPa, the tensile strength is 1130-1380 MPa, the percentage elongation after fracture is 18%-52%, and the product of strength and elongation is 55000-58080 MPa.%. According to the method for preparing the nanocrystalline austenitic stainless steel plate through deep cooling rolling-rapid annealing, the time is short; the efficiency is high; energy sources are saved; the cost is low; and a sample piece large in section size is easy to produce.

Owner:NORTHEASTERN UNIV

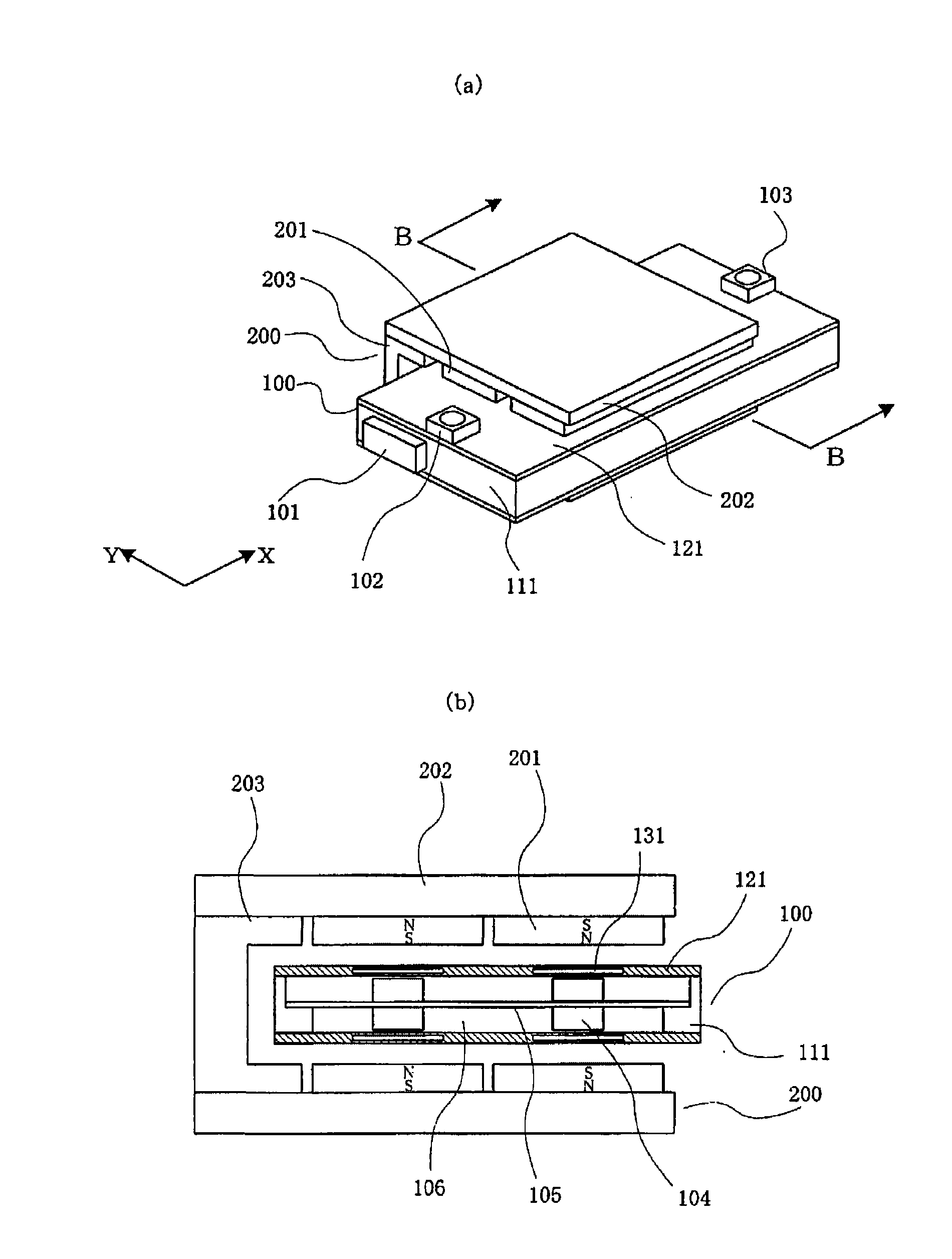

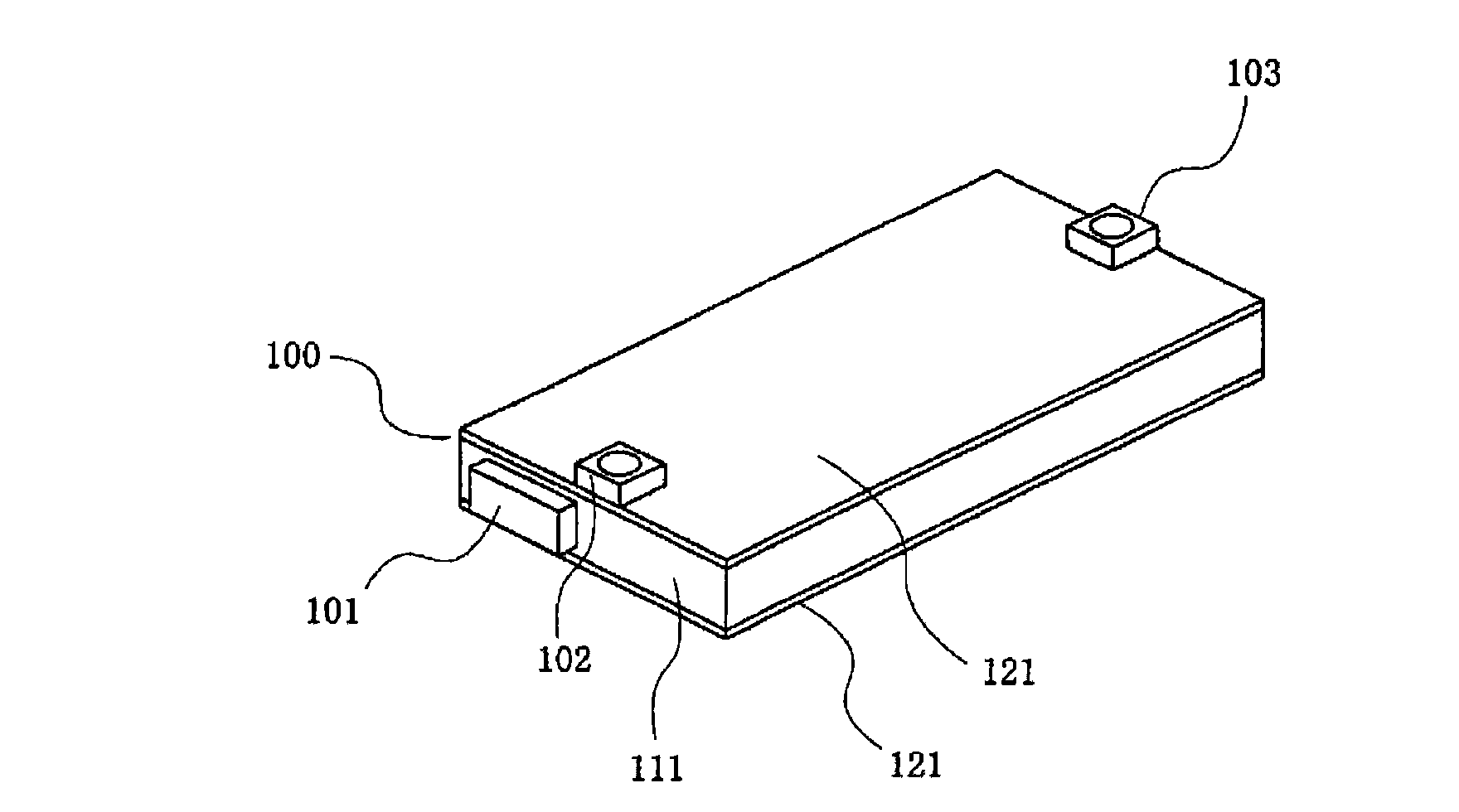

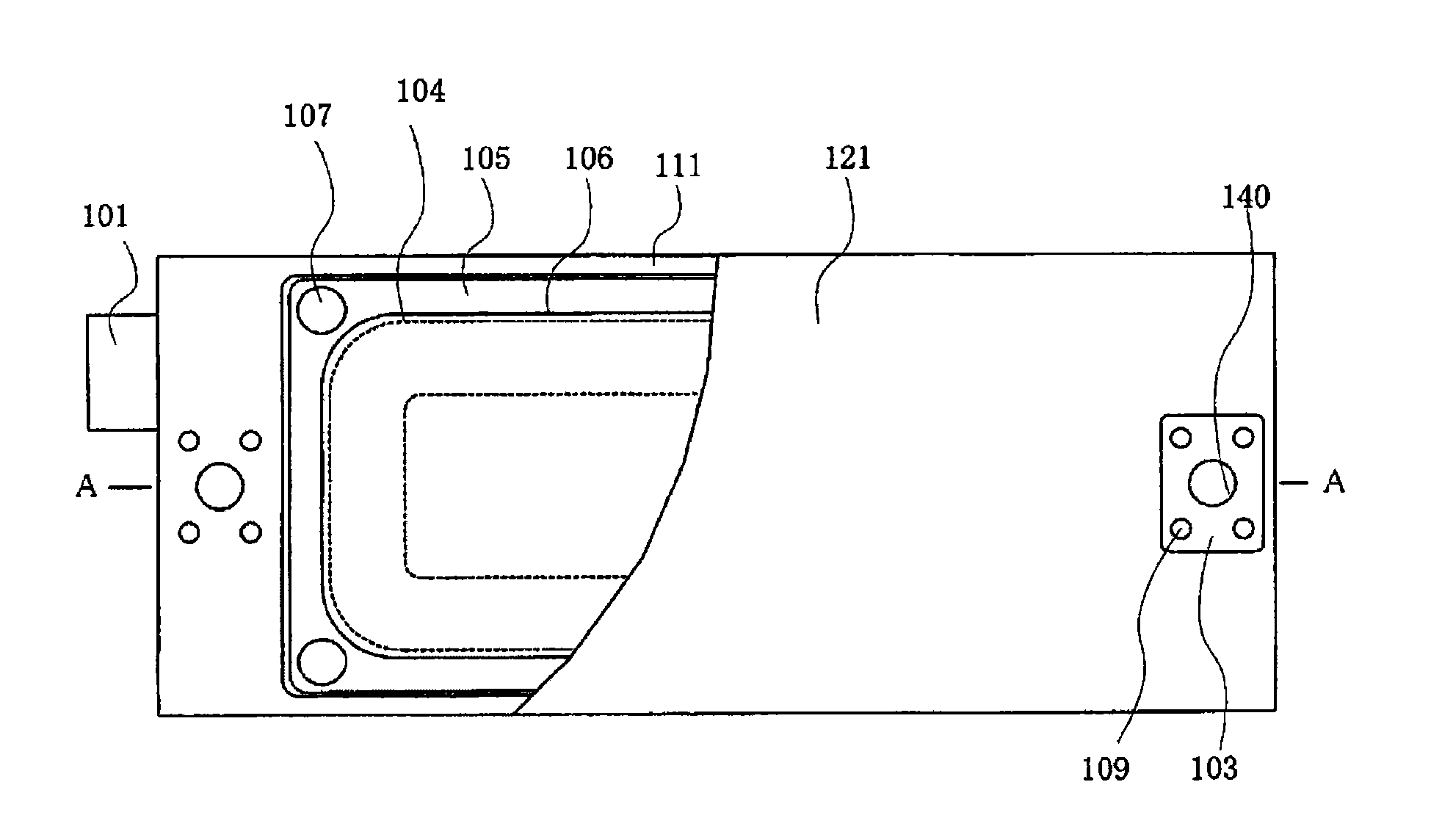

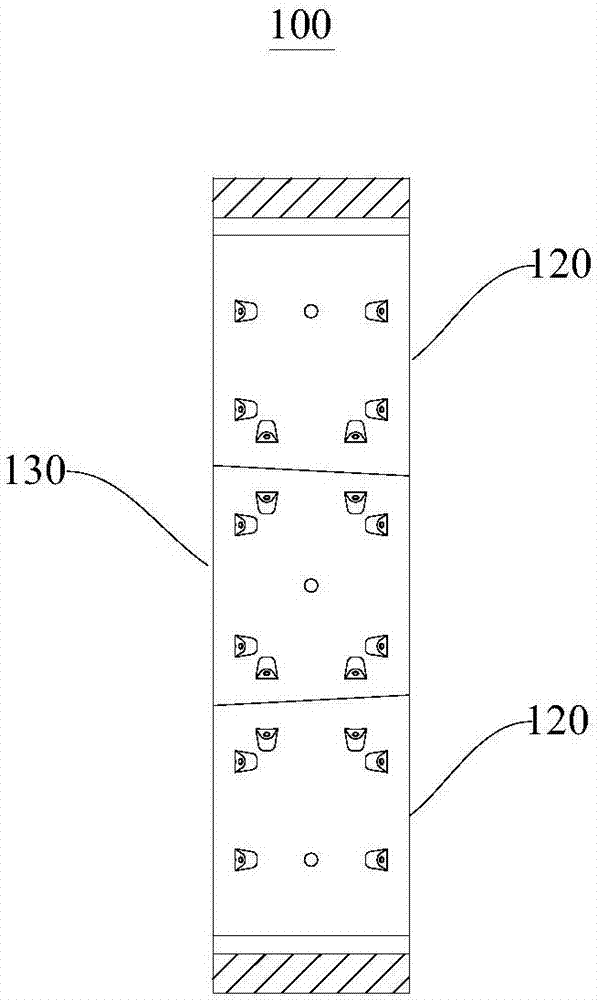

Canned linear motor armature and canned linear motor

InactiveCN101657956AEliminate insulation resistance reductionReduce temperature riseMagnetic circuitCooling/ventillation arrangementBrake forcePressure increase

A canned linear motor armature and a canned linear motor of water cooling type are provided. The insulation reliability of a canned linear motor armature is improved. The temperature rises of both the linear motor surface and the armature winding are reduced. Even if the coolant pressure increases, the can neither breaks nor deforms. The weight of the armature is lightened. The viscosity braking force is reduced. In the canned linear motor armature, the armature winding (104) is surrounded with a picture-frame-shaped case (111), both the openings of the case (111) are closed with flat can (121), and coolant passages (131) are provided inside the can (121) and on the top surface of the coil side of the armature winding (104).

Owner:YASKAWA DENKI KK

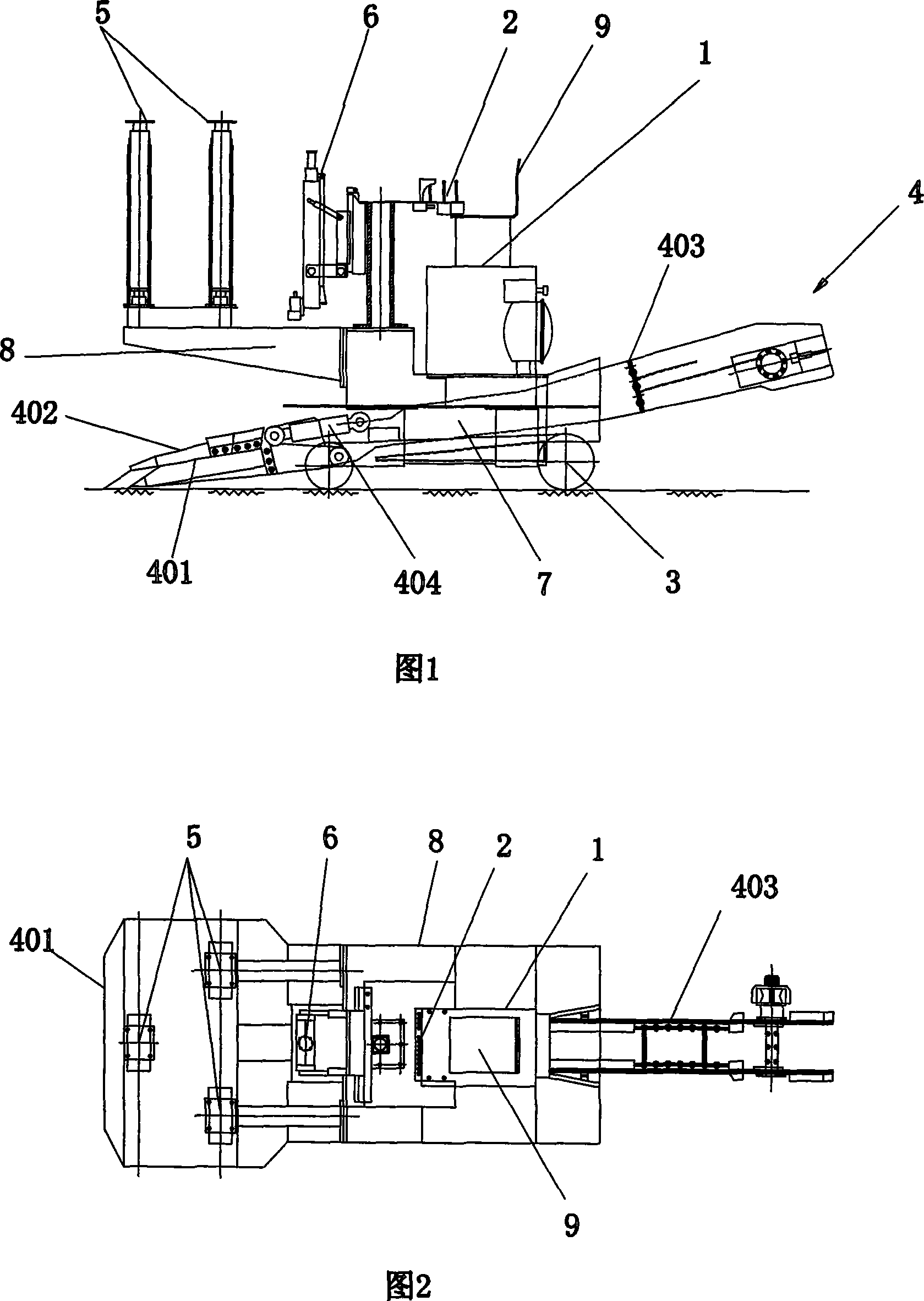

Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

InactiveCN101025086AIncrease the speed of excavationExcavation section is largeUnderground miningSurface miningResource recoveryEngineering

The invention provides a blast-winning, coal loading, coal conveying and anchor rod-timbering mechanical integrated operating method and device. And the device mainly comprises: hydraulic system, hydraulic control table, track walking part, coal loading and conveying part, timbering part, and hydraulic anchor rod machine, and the method uses integrated device, scraper conveyor and gate coal conveyor; and its drivage circulating speed is 1m to 1.5 m, blast-winning and after the fumes have settled, making the integrated device enter into the operating site, and after completing coal loading and conveying, making anchor rod timbering; after completing the anchor rod timbering operation, making the integrated device exit the operating site and over 20 meters distant from the operating site, and then making drilling and blasting operation. And it improves explosion level of blast winning and resources recovery, and reduces operators.

Owner:闫振东

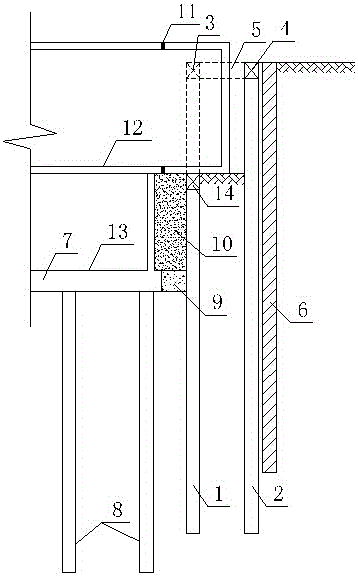

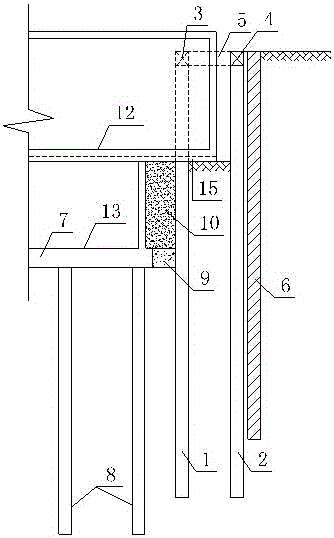

Double-row pile support structure capable of fully utilizing basement space and construction method of double-row pile support structure

The invention relates to a double-row pile support structure capable of fully utilizing basement space and a construction method of the double-row pile support structure, and belongs to the field of building construction and room buildings. A crown beam I is arranged on the top of a front row pile, and a crown beam II is arranged on the top of a rear row pile. The top of the front row pile and the top of the rear row pile are connected through a connecting beam I. A waterproof curtain pile is arranged in a pile rear soil body of the rear row pile. After a field is leveled, all project piles are constructed according to the design. A connecting beam II is poured on the top of the cut front row pile. The connecting beam II and a negative layer basement bottom plate are integrally poured. The part between the front row pile and a minus-two floor basement outer wall is filled with layering compaction filling soil. The part between the front row pile and a minus-two floor basement bottom plate is filled with plain concrete. According to the double-row pile support structure, double-row piles are changed into a single-row-pile structure with the same rigidity by means of the equal-rigidity replacement principle of the double row piles and the single row piles, the horizontal displacement of a support structure system can be controlled, and meanwhile the foundation pit support cost can be greatly reduced; and good economical efficiency is achieved in a foundation pit project with basements with multiple layers.

Owner:KUNMING UNIV OF SCI & TECH

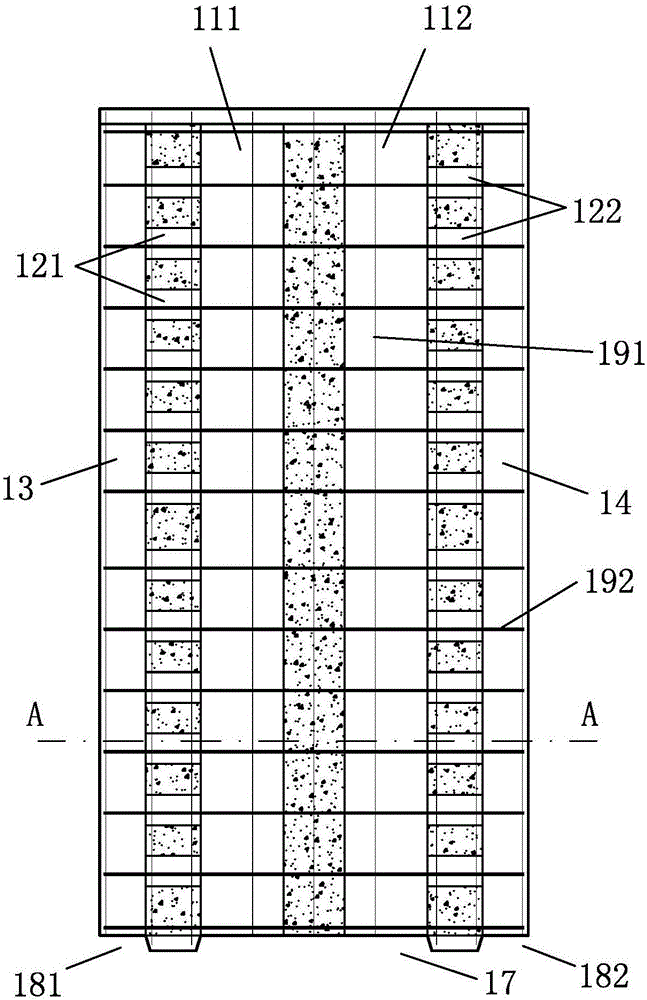

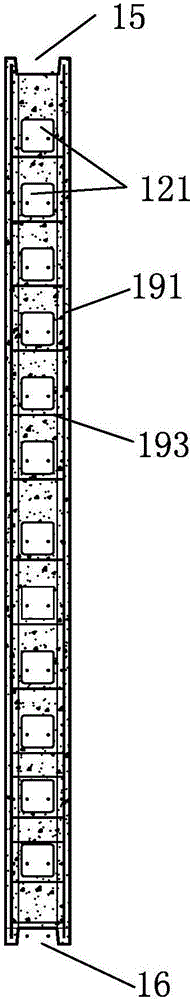

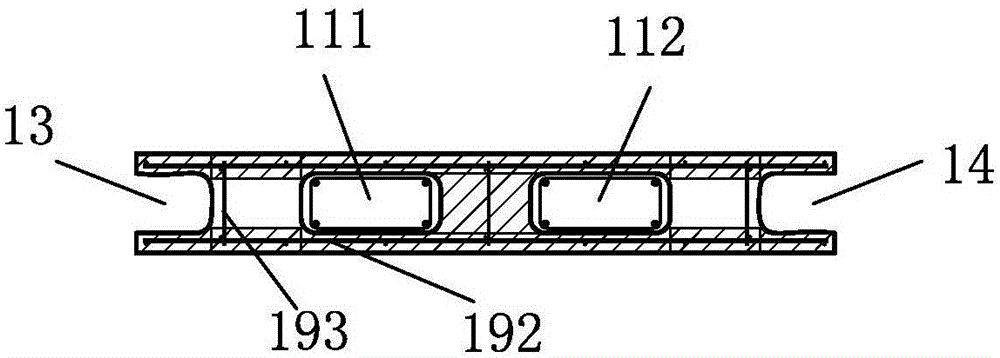

Concrete prefabricated panel, prefabricated building formed by same and construction method

PendingCN106499116AShorten the lengthReduce workloadDischarging arrangementWallsEngineeringBuilding design

The invention discloses a concrete prefabricated panel and a prefabricated building formed by the same. A nonpenetrating transverse hole is formed in the panel. The panel adopts a structure that the transverse hole is preserved in the edge rib of the panel, a horizontal steel bar meeting the splicing length required by codes for architectural and structural design is inserted into the hole, a transverse hole penetrating the whole panel is not required to be formed, the splicing of a horizontal steel bar between prefabricated panels can be achieved, the transverse transfer requirement is met, and the requirement of an earthquake resistant code of architectural design is met. The length of the inserted horizontal steel bar is greatly shortened, the cost is lowered, the workload and construction difficulty for penetrating the penetrating transverse steel bar are reduced, and the method is simple to implement, simple and effective, an excellent earthquake resistant effect can be achieved, and meanwhile the prefabricated panel is more convenient to produce and manufacture and higher in quality.

Owner:BEIJING EVEREST GREEN BUILDING TECH

Method for preparing composite Cu-Fe-Ag nano material at original position with high intensity and high conductance

A method of preparing high intensity and high conducting in-situ nano-composite: Cu-Fe-Ag. The steps: (1) Prepare Cu-Fe-Ag by using medium freguency induction furnace to smelt, and dealt it with ultrasonic or strong electric pulse. Make the ingot casting by water-cold Cu-model: (2) Forge the ingot casting and then draw it multiple times in room temperature in order to made Fe-icrostructural elongate by stretch until it forms nano fiber. (3) Heat treatment it when its cold forming process strain quantum is 2 - 3 so the soild-solution of Fe and Al can separate out as natrium rice level particles; (4) In the following forming process , this particles join in distortion, and form the enhanced fiber which particles are smaller than before. This process can make the material enhanced more. The present invention mixes the thinning of as-cast microstructure and deformation together. It increases the electric while enhances the intensity of the materials, and also can obtain materials in large sectional dimension.

Owner:SHANGHAI JIAO TONG UNIV

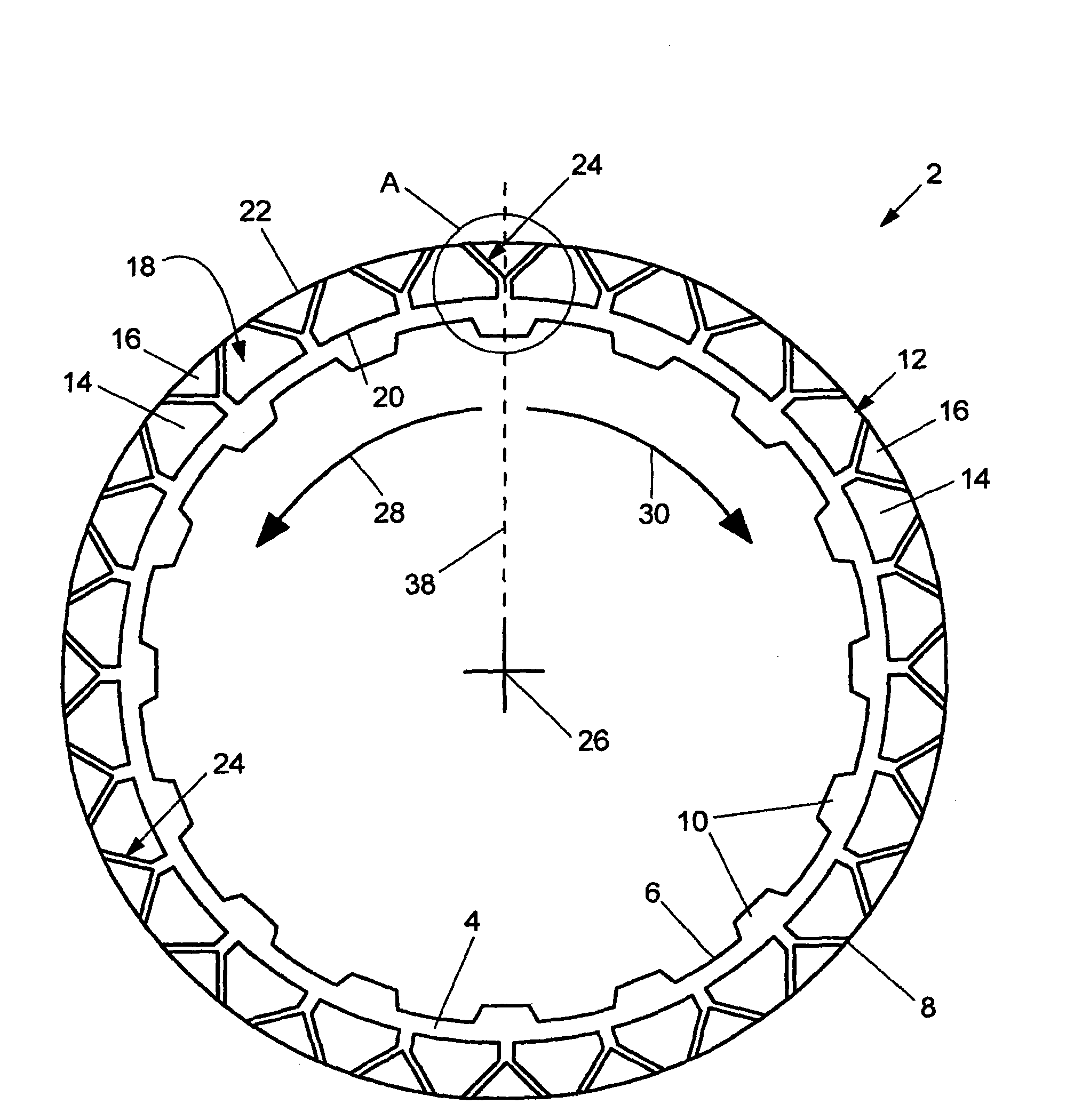

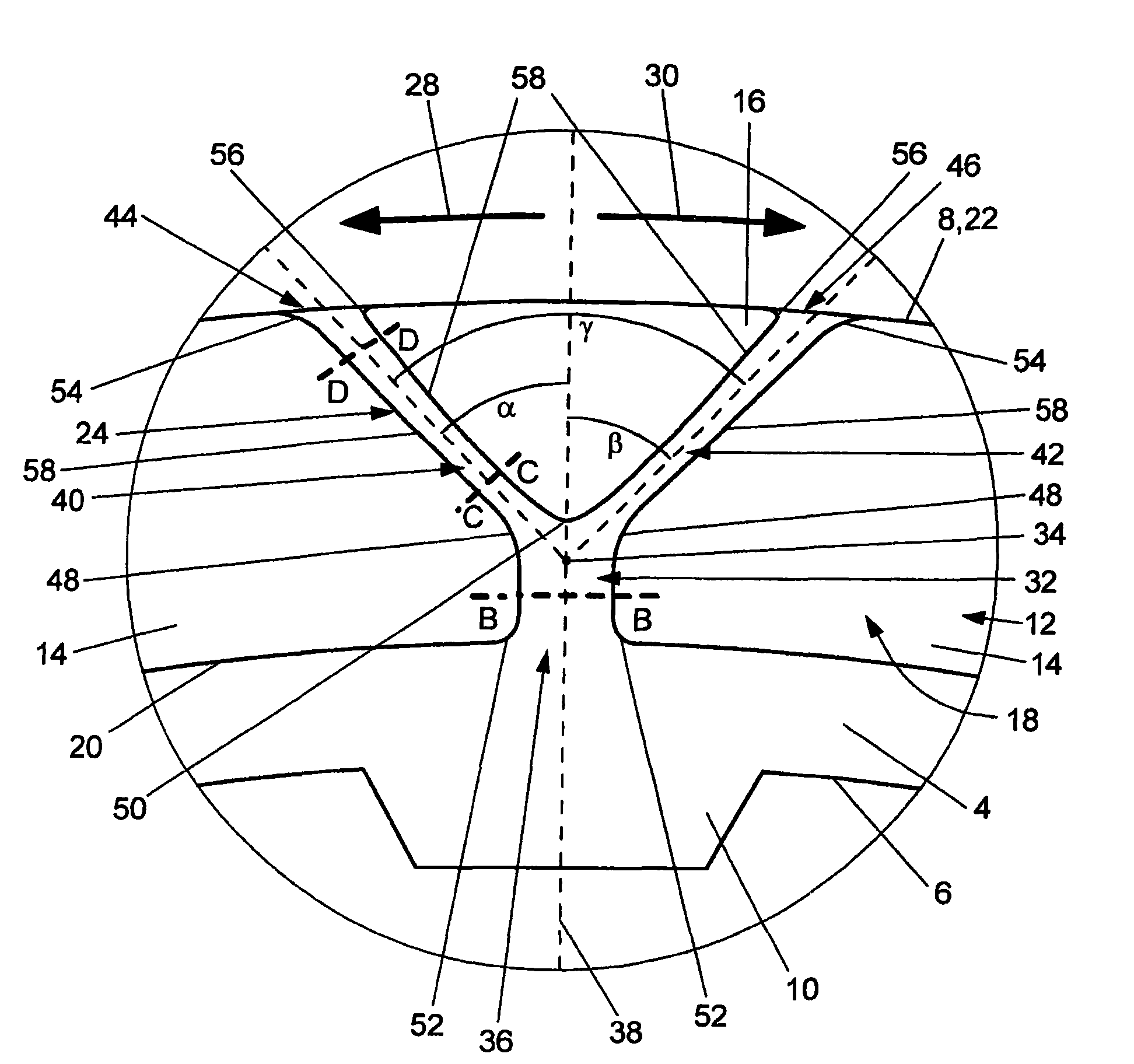

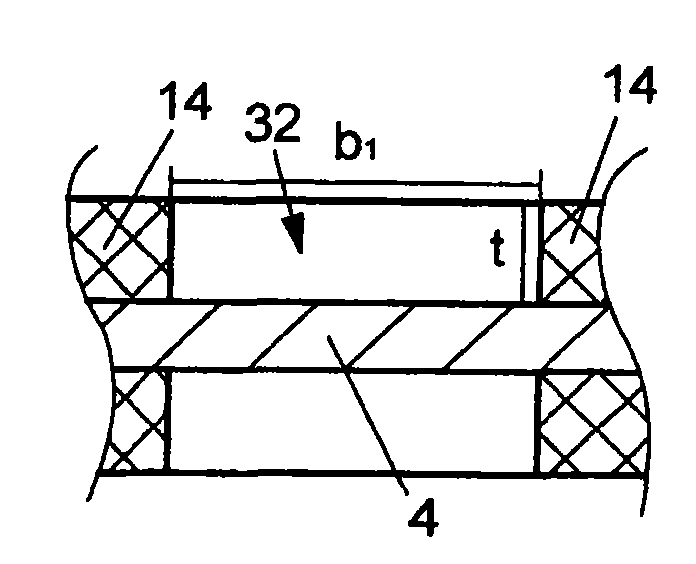

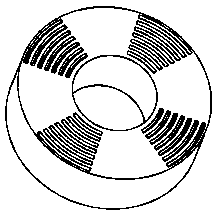

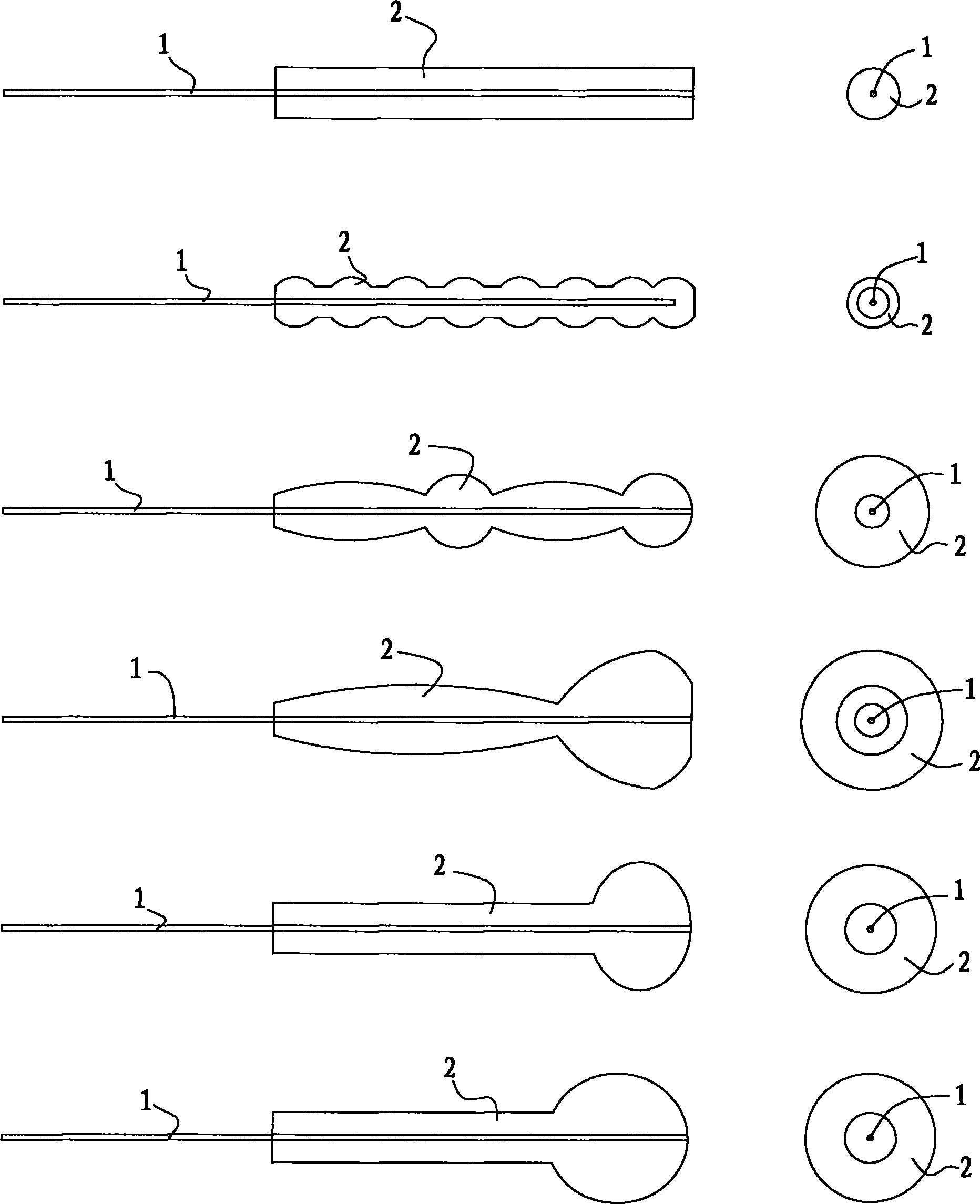

Friction part for a frictionally acting device, and frictionally acting device having a friction part of said type

InactiveCN101517256APromote absorptionAvoid vortexFriction clutchesFriction liningMechanical engineeringPhysics

The present invention relates to a friction part (2) for a frictionally acting device, having an annular friction face (18) which has an inner edge (20) and an outer edge (22), wherein at least one set of grooves (24) is provided in the friction face (18), which set of grooves (24) has a first groove (32) which extends from the inner edge (20) or the outer edge (22) to a branching point (34) between the inner edge (20) and the outer edge (22), and a second and third groove (40, 42) which extend in each case from the branching point (34) to the other edge (22, 20). According to the invention, the second groove (40) is inclined in the one peripheral direction (28) and the third groove (42) is inclined in the other peripheral direction (30) of the friction face (18) with respect to a radial line (38) through the branching point (34). The present invention also describes a frictionally acting device having a friction part (2) of said type.

Owner:BORGWARNER INC

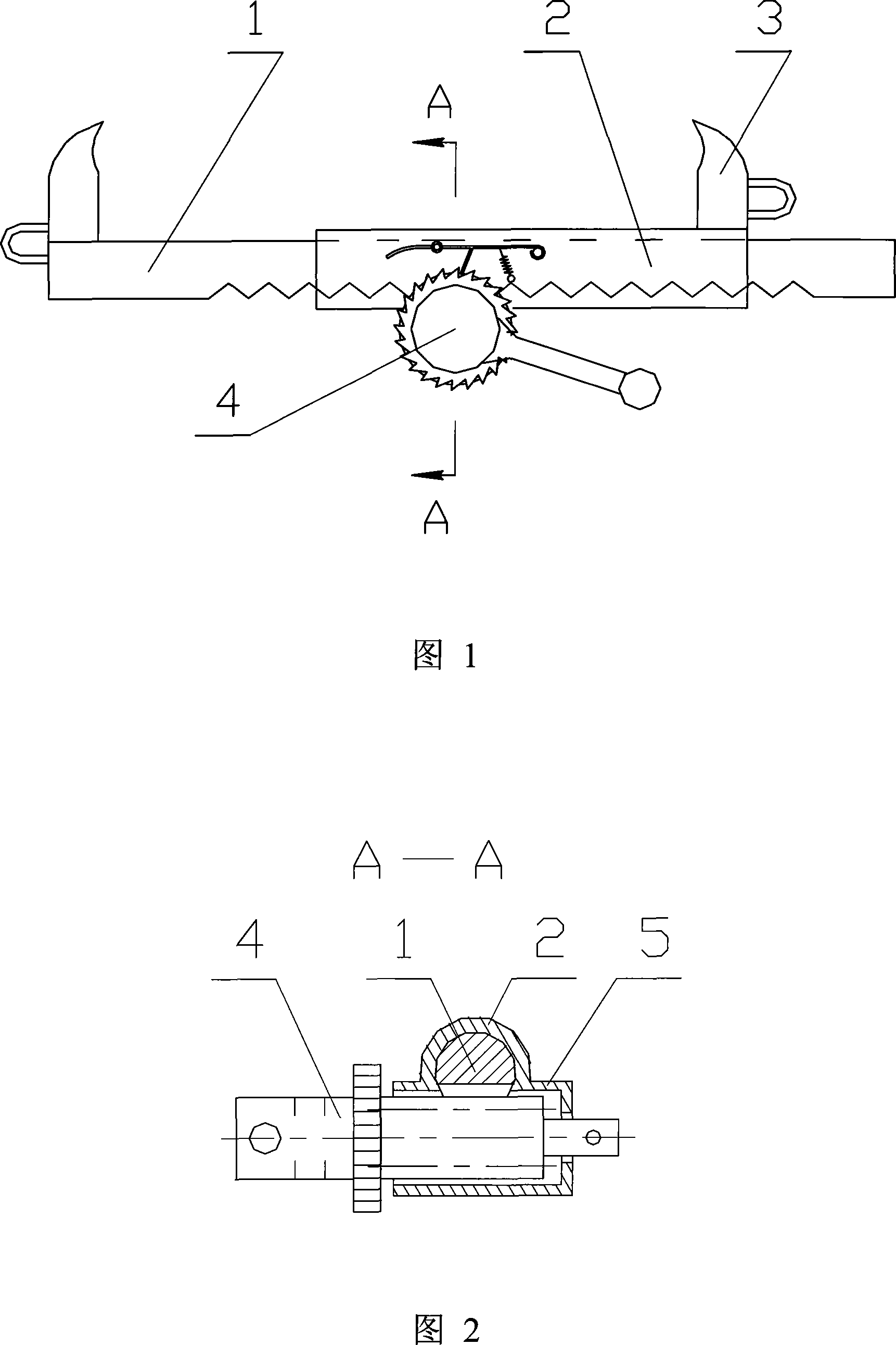

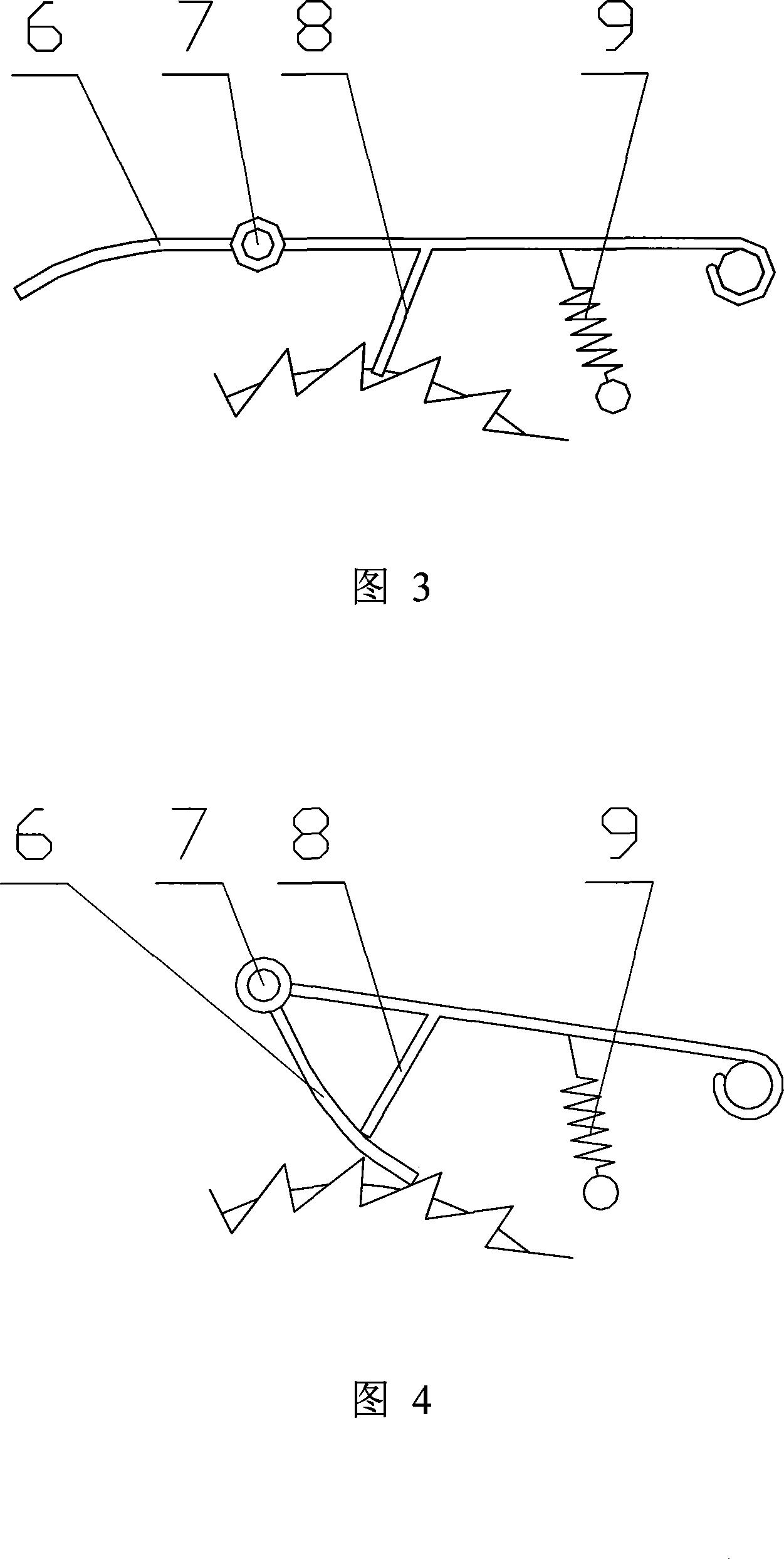

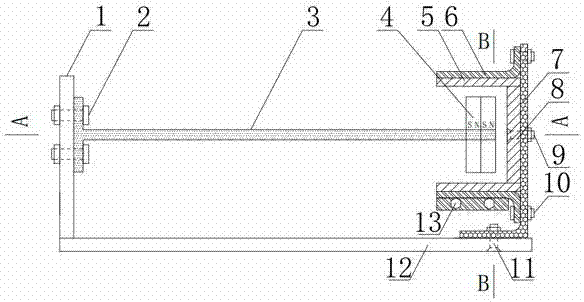

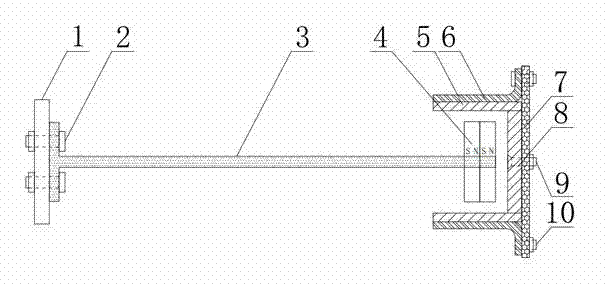

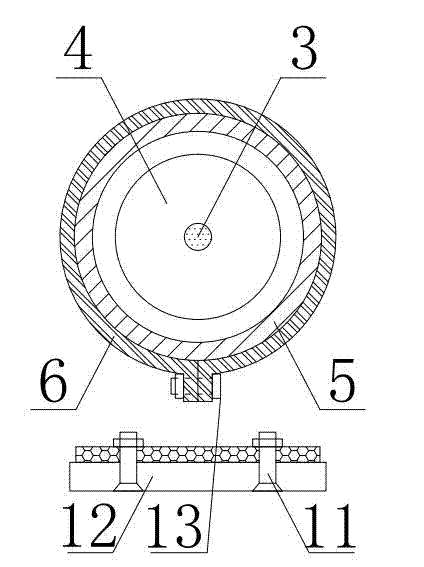

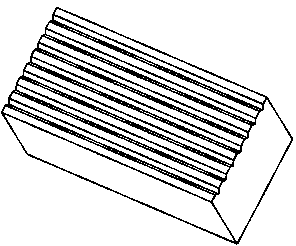

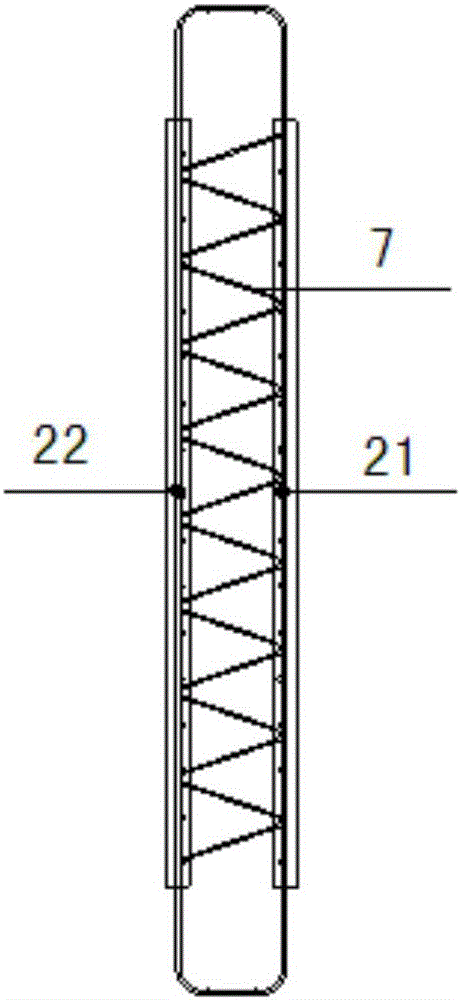

Chain tightening device

ActiveCN101108478AHigh strengthIncrease section sizeMetal-working hand toolsEngineeringMechanical engineering

The invention discloses a chain tightener of high efficiency and strong bearing and loading capability, which comprises a drag hook and a force application device, a gear strip is positioned in the gear strip sleeve, the drag hook is arranged on the gear strip and the gear sleeve, a sleeve is arranged under the gear strip sleeve, the upper part of the sleeve and the lower part of the gear strip sleeve are communicated vertically; the force application device is positioned in the sleeve, the gear axle of the force application device is hinged with the gear strip. The force application device is composed of a rotating axle and a non-return structure, one end of the rotating axle is arranged with a rotating handle and a gear plate is arranged in middle, a gear axle is arranged corresponding to the gear strip, the other end of the rotating axle is a step axle, a pin hole is arranged on the step axle penetrating through the bottom hole of the sleeve, a pin is arranged in the pin hole. The no-return structure is composed of a gear plate and the flexible braking structure. The flexible braking structure is composed of a spring, a gear pole and a hinge shaft, the two ends of the spring are fixed on the gear strip sleeve shell and the gear pole respectively, one end of the gear pole is fixed on the gear strip sleeve shell, the other end is hang in the air and provided with a hinge shaft, a top gear is arranged in the middle, the fold plate and the gear pole are hinged. The invention is used for chain tight of scraper conveyor.

Owner:CHANGZHI YUANLU MINING EQUIP

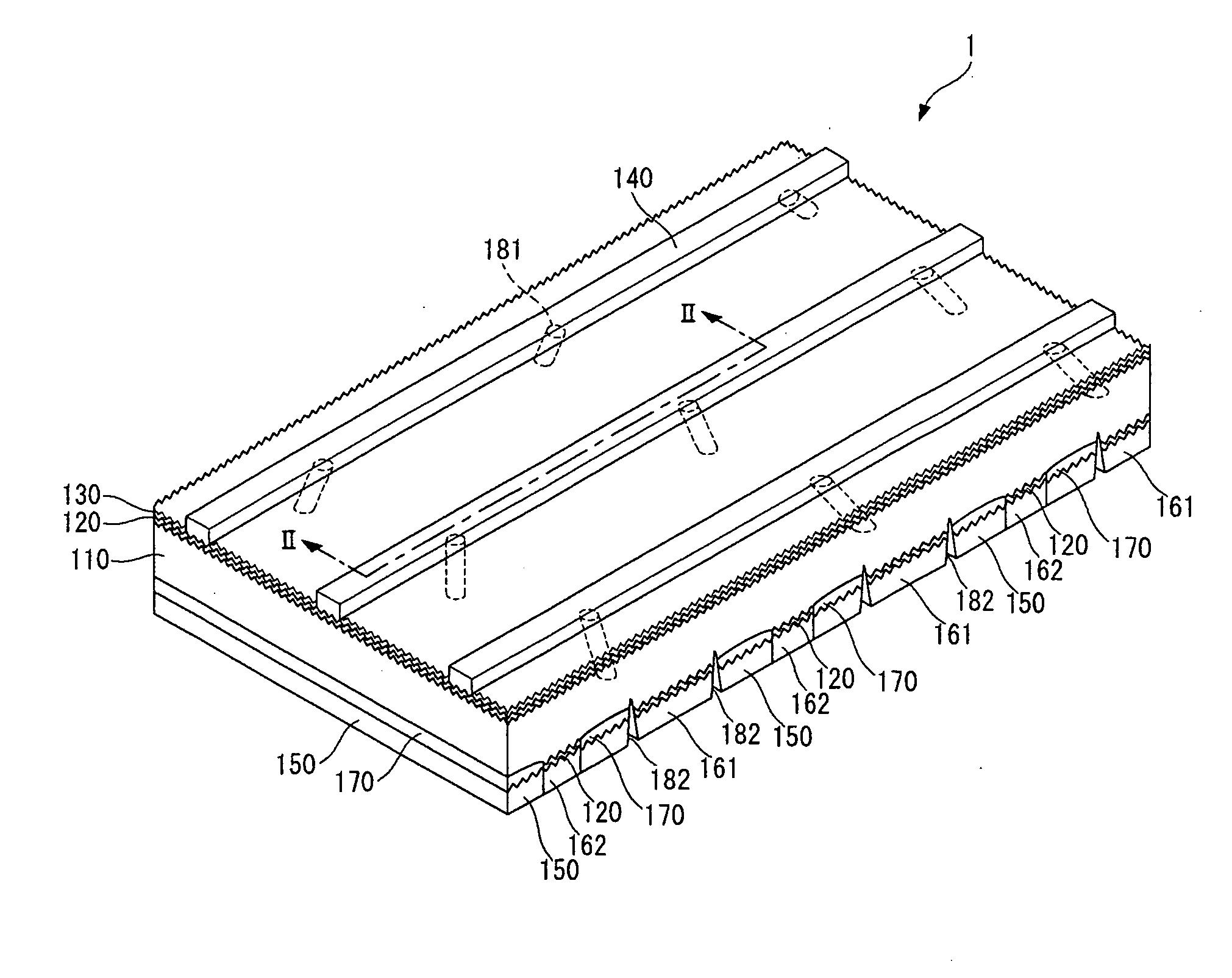

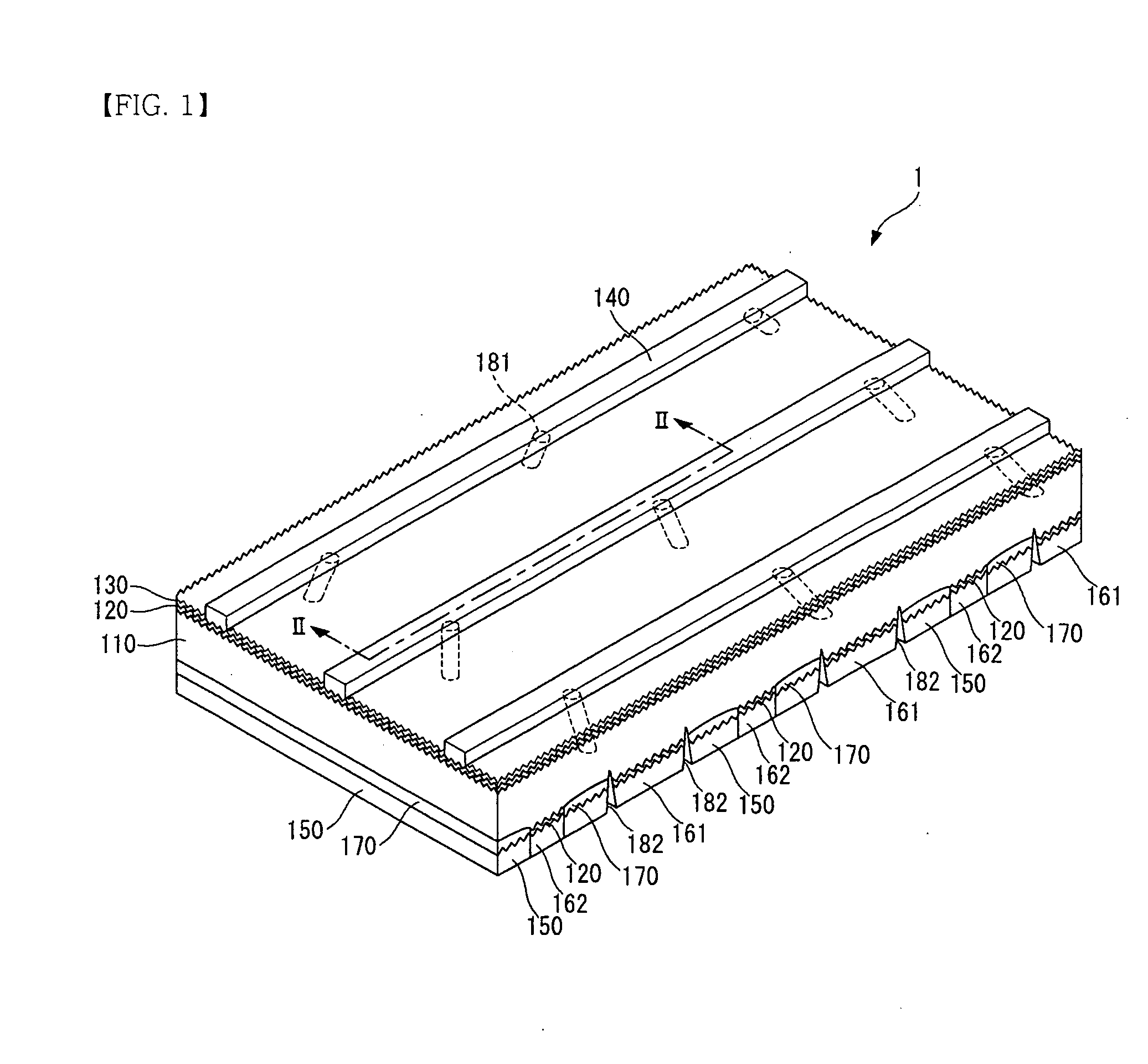

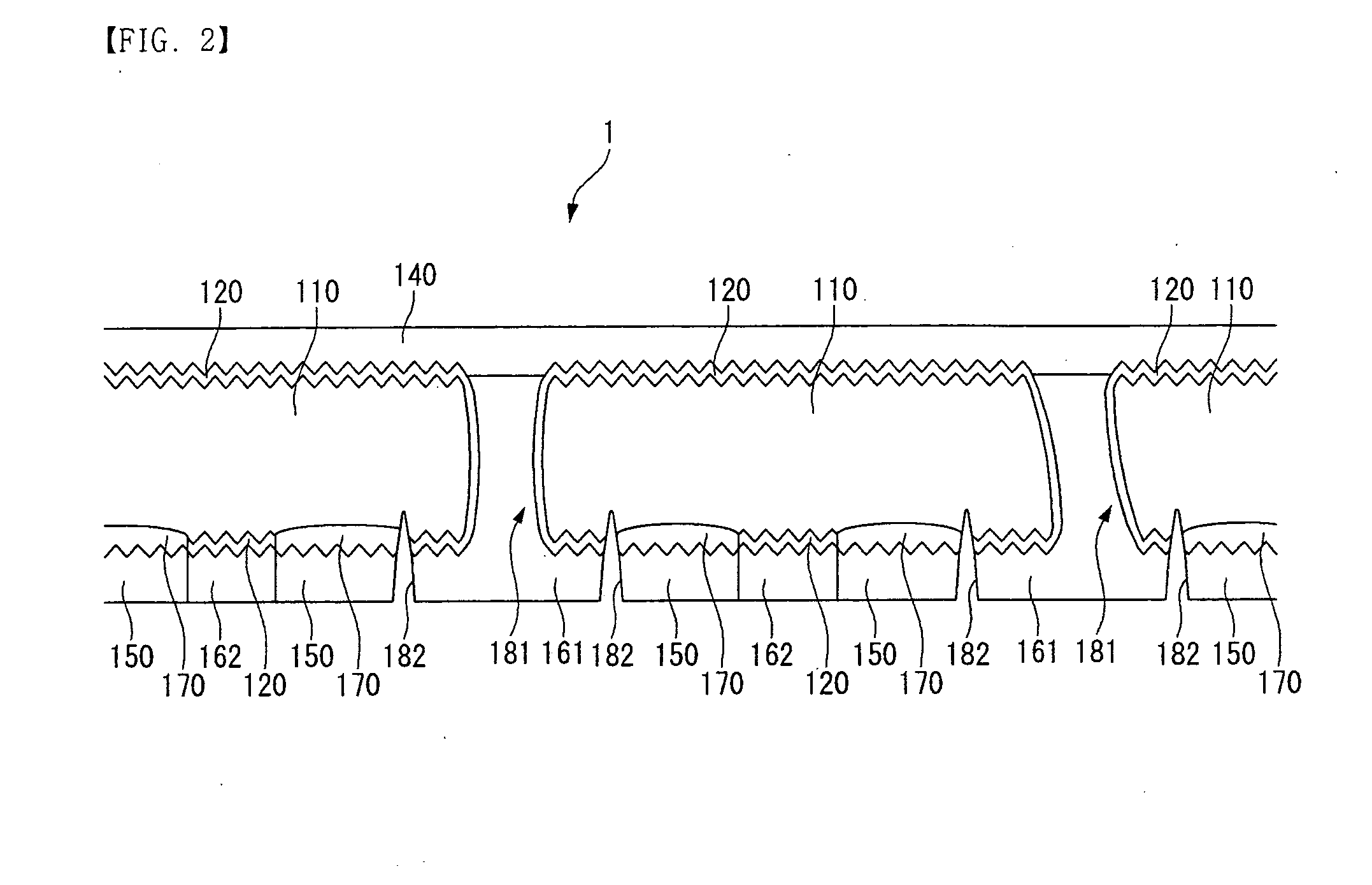

Solar cell

ActiveUS20100258178A1Increase section sizeIncrease in sizeSemiconductor/solid-state device detailsSolid-state devicesSolar cellElectrode

A solar cell comprises a substrate configured to have a plurality of via holes and a first conductive type, an emitter layer placed in the substrate and configured to have a second conductive type opposite to the first conductive type, a plurality of first electrodes electrically coupled to the emitter layer, a plurality of current collectors electrically coupled to the first electrodes through the plurality of via holes, and a plurality of second electrodes electrically coupled to the substrate. The plurality of via holes comprises at least two via holes having different angles.

Owner:SHANGRAO JINKO SOLAR TECH DEV CO LTD

Tuned mass damper for vibration-damping experiment of structure model and design method

The invention discloses a tuned mass damper (TMD) for the vibration-damping experiment of a structure model. The tuned mass damper comprises a mass block, an elastic element, an energy dissipation element and a support angle bar, wherein the mass block adopts ring permanent magnets and small iron blocks adsorbed on the ring permanent magnets; the elastic element adopts a horizontal aluminum bar cantilever beam structure; the energy dissipation element adopts electromagnetic damping, when the mass block is horizontally or vertically vibrated, a copper plate and a copper tube which are mounted on the support angle bar cut a magnetic induction line generated by the moving permanent magnets, and structural vibrating energy is gradually converted into heat energy to be consumed. According to the invention, through unique structural design, the TMD can satisfy the requirements of the structure model for the vibration-damping experiment in the horizontal direction and in the vertical direction at the same time; the permanent magnets required by the energy dissipation element are directly used as the mass block of the TMD, and the structure is compact; the damping parameter and the frequency parameter of the TMD are completely separated, and quantification regulation can be made, so that precise simulation for the excellent damping parameter of the TMD for in the vibration-damping experiment of the structure model in the horizontal direction or the vertical direction can be realized.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

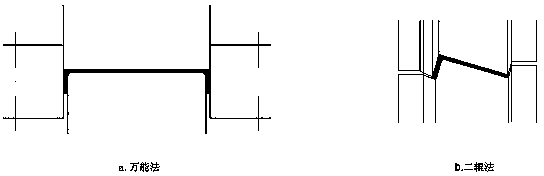

Welding technique of electric resistance welding and stud welding of unmatched materials

InactiveCN103357999AReduce consumptionImprove welding effectArc welding apparatusResistance welding apparatusUndermatchingElectrical resistance and conductance

The invention relates to a welding technique of electric resistance welding and stud welding. When two unmatched materials are welded, the thicknesses or the cross section sizes of the materials are obviously different, and the welding part of the material with higher thickness and larger cross section size is subjected to the surface roughening treatment, so the weldability of the material is improved. Although the thicknesses or diameters of the two welding materials are matched, when the thicknesses are higher or the cross section sizes are larger, the welding parts of the welding materials are simultaneously subjected to the roughening treatment, the weldability of the materials is improved, and consumption of electric energy is reduced. For metals with higher electric resistance welding difficulty, such as aluminum and aluminum alloy, the weldability can also be improved. The roughening treatment of the metal surfaces is realized through cutting, forging and pressing and the like, and a certain removal function is realized for the plated layer which has an effect on the welding, such as surface zinc plating.

Owner:何强

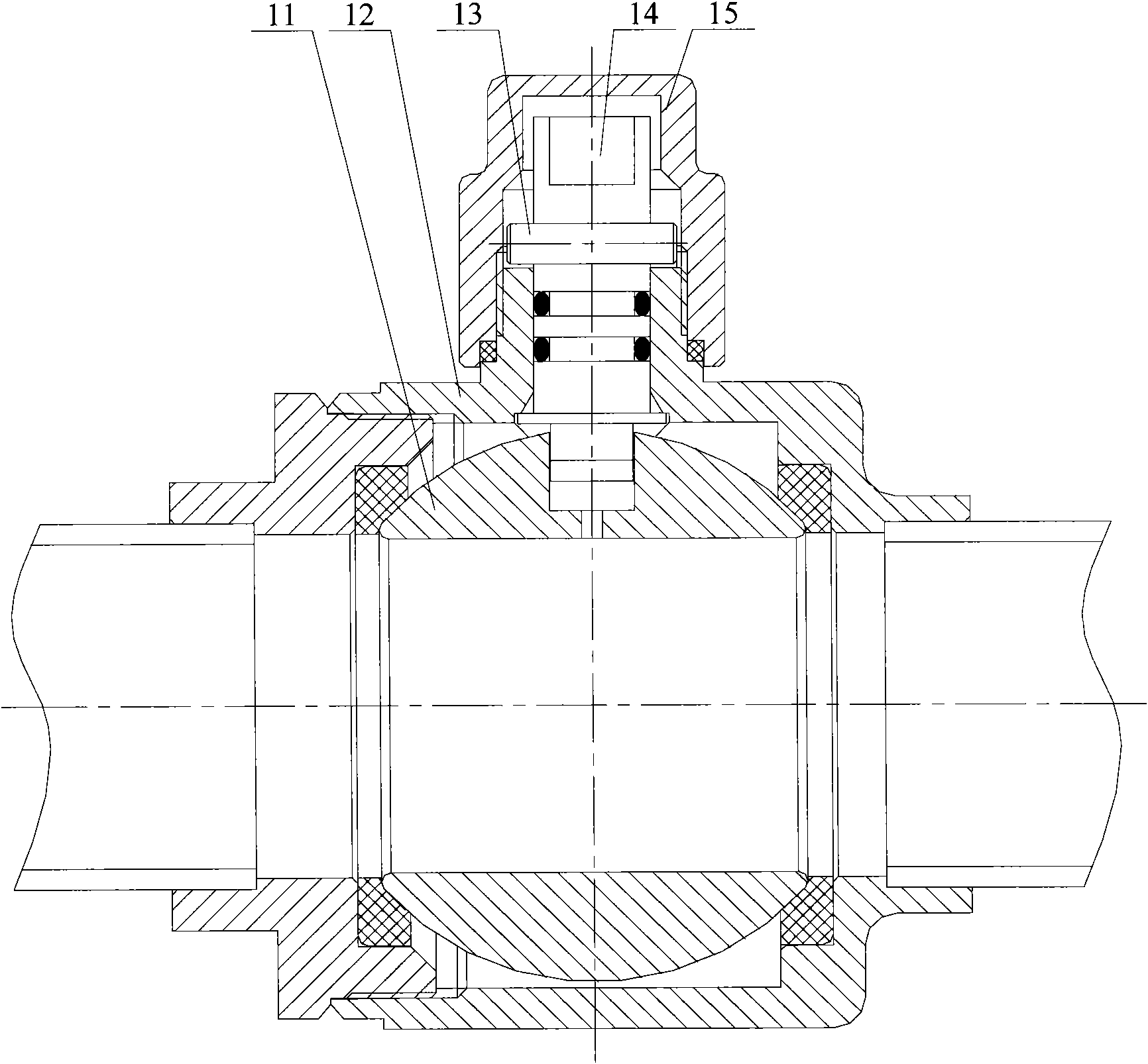

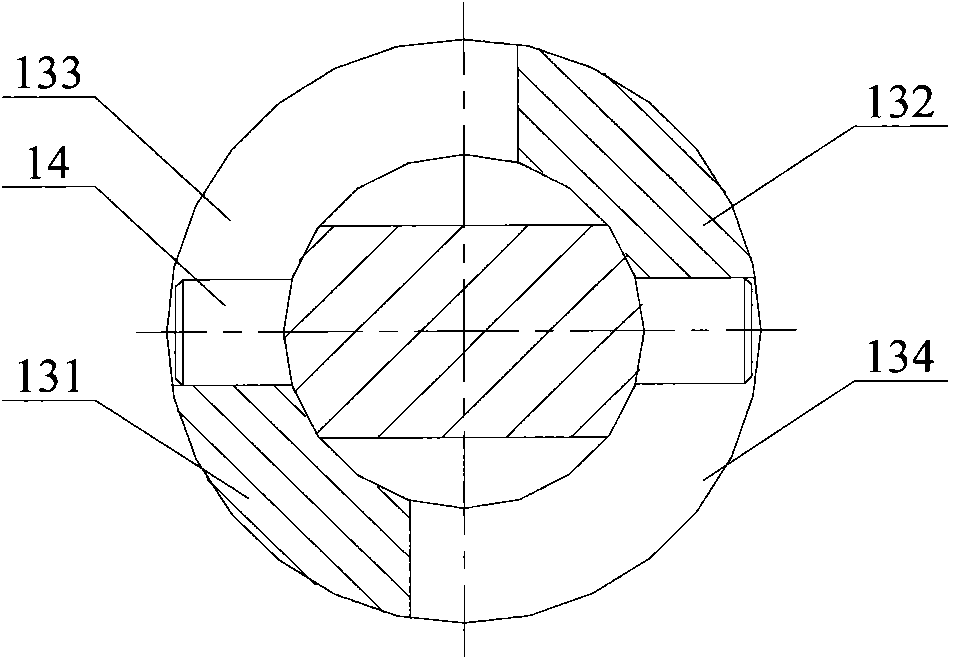

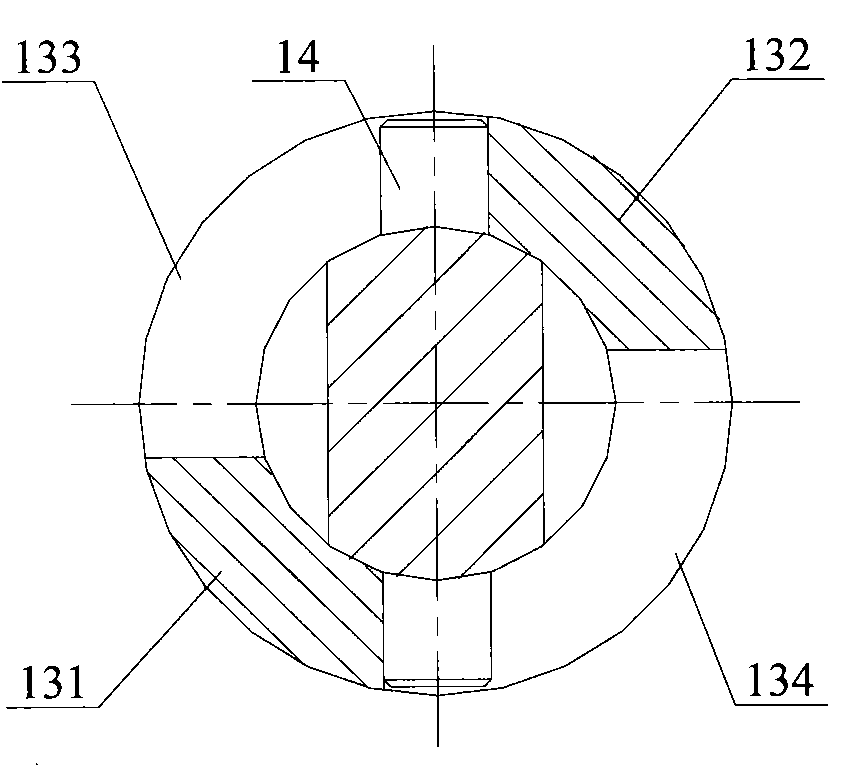

Ball valve

The invention discloses a ball valve comprising a locking part and a positioning boss, wherein the locking part is arranged on a valve rod, and the positioning boss is arranged on the valve body; the extending part of the locking part is matched with the positioning boss so as to limit the full-open position and the full-closed position of the ball valve; the anti-bending section of the locking part is rectangular, and the height-breadth ratio h / b of the rectangle anti-bending section satisfies the condition that h / b is less than 6 and is more than 1; the ball valve has better anti-bending property. Preferably, the positioning boss is provided with a first positioning surface and a second positioning surface, the deflection angle for the locking part to extend between the first positioning surface and the second positioning surface is 180 degrees; when the extending part rotates to the middle position between two positioning surfaces, the ball valve is in the full-open position and the full-closed position; when the extending part rotates to the position on which the side end surface is abutted with the first positioning surface or the position on which the other end surface is abutted with the second positioning surface, the ball valve is in the full-open position and the full-closed position. Thus, the valve rod can rotate within the range of 180 degrees so as to greatly improve the adaptability and the maneuverability of the ball valve.

Owner:ZHEJIANG SANHUA CO LTD

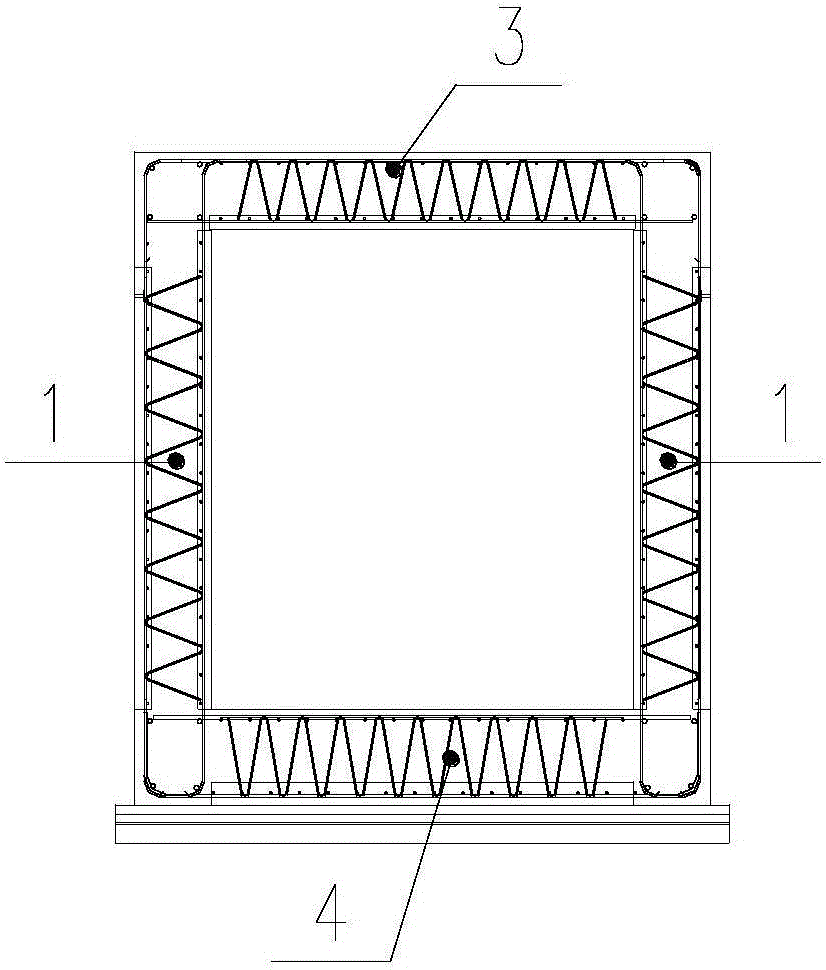

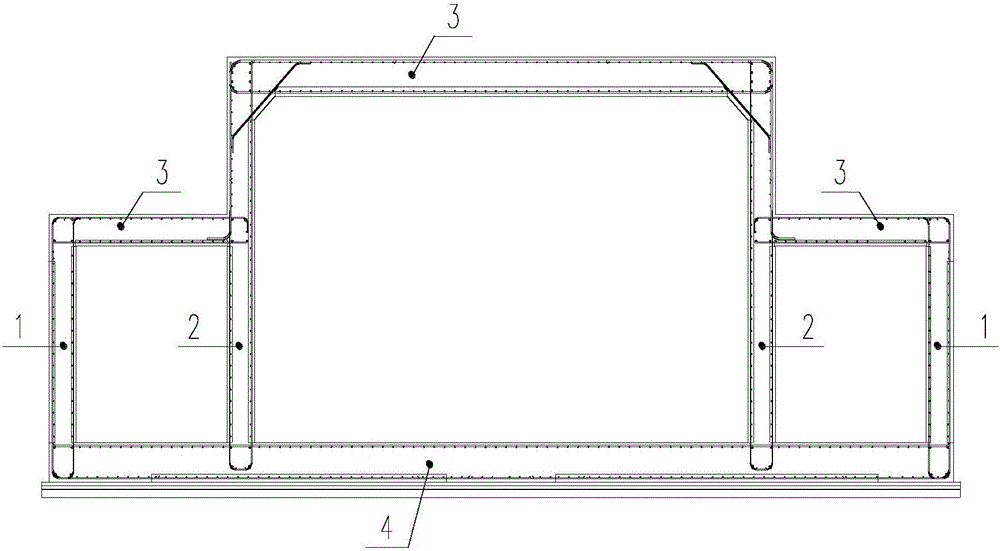

Assembled monolithic underground pipe gallery, drainage ditch or flood ditch

InactiveCN106836280AReduce pollutionLots of wet workArtificial islandsGround-workRebarProtection layer

The invention relates to the technical field of prefabricated concrete municipal structures. Proposed the assembly of integral integrated pipe gallery, drainage ditch or flood ditch, including laminated roof, laminated bottom or cast-in-place bottom and laminated exterior wall panels, laminated roof includes prefabricated roof layer and roof cast-in-place layer, laminated bottom Including the prefabricated floor of the bottom slab and the cast-in-place layer of the bottom slab, the cast-in-place bottom slab includes the cast-in-place layer of the bottom slab, and the laminated exterior wall panel includes the prefabricated exterior wall panel and the cast-in-place layer of the exterior wall panel; the laminated bottom slab or cast-in-place floor is set on the foundation cushion Or on the waterproof layer (or waterproof protective layer), configure steel bars on the prefabricated parts of all composite components. After the prefabricated parts are assembled on site, add the necessary force and structural steel bars, and pour concrete to form an assembled integrated integrated pipe gallery, drainage ditch or flood ditches. The invention can give full play to the advantages of on-site pouring and factory prefabrication, reduce on-site wet work, shorten the construction period, improve construction quality, ensure the integrity of the comprehensive pipe gallery, drainage ditch or flood ditch, and have good waterproof performance.

Owner:DALIAN SANCHUAN BUILDING TECH CO LTD

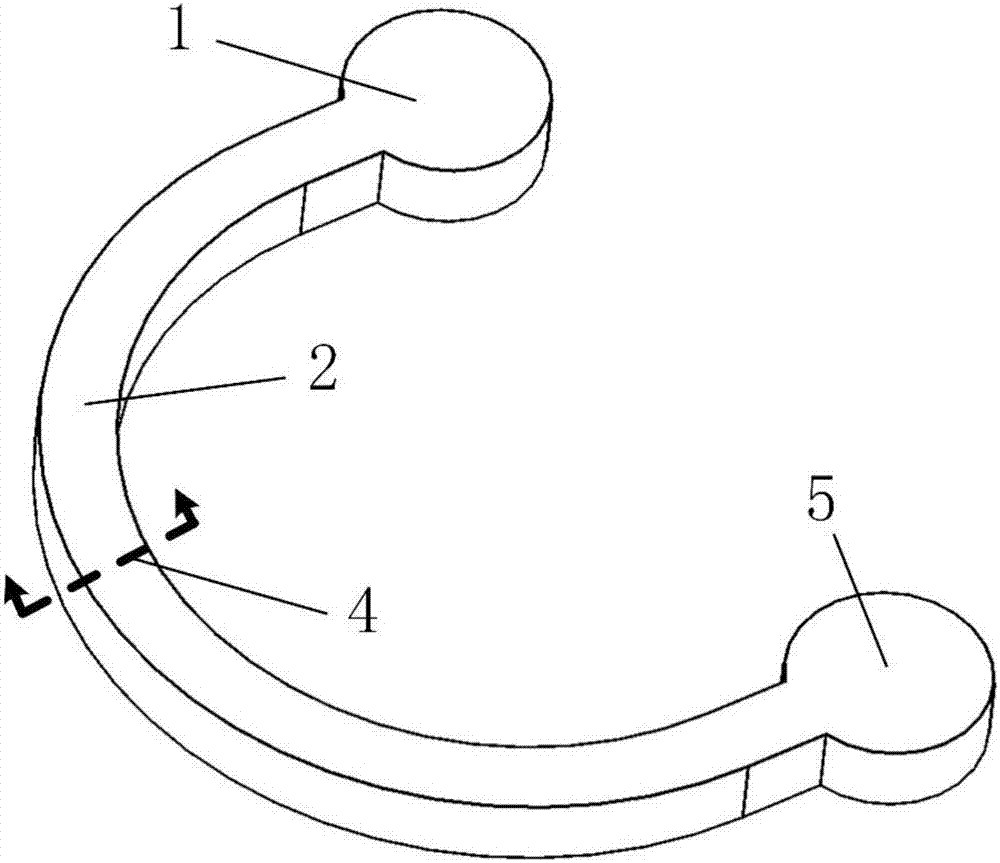

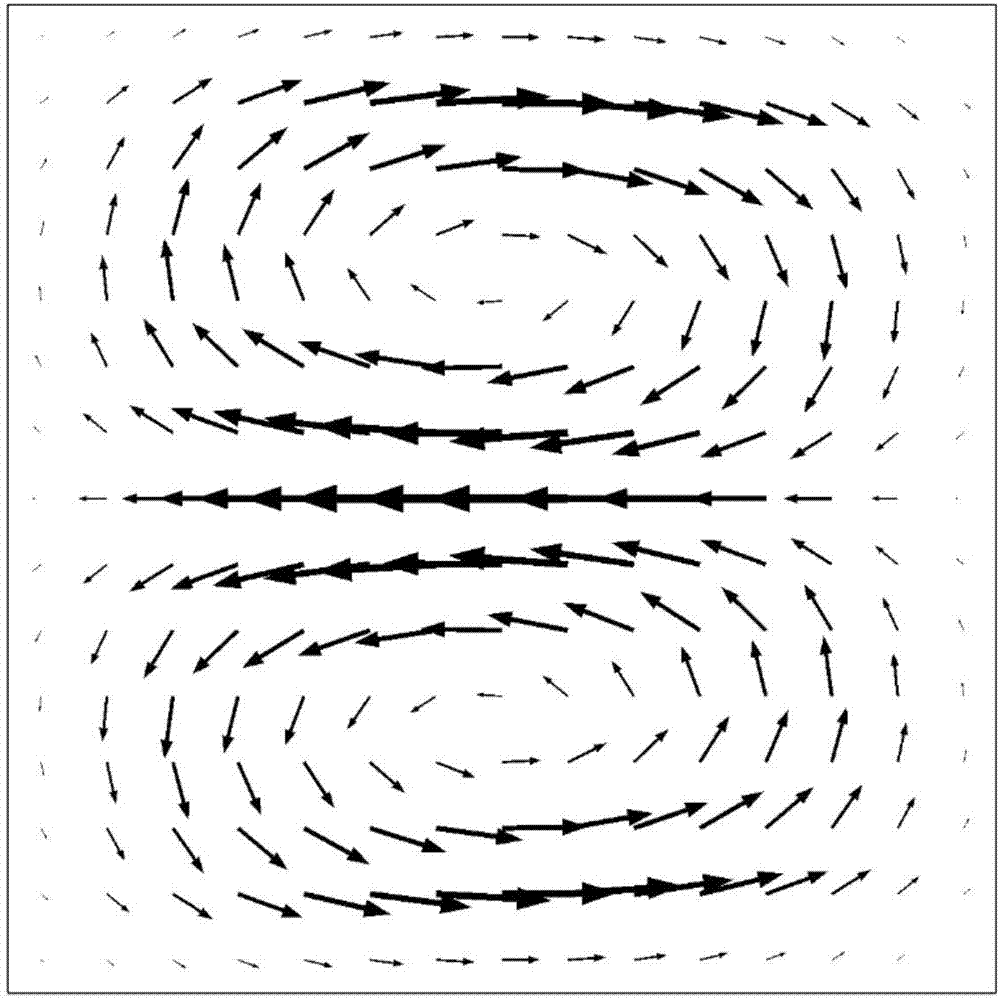

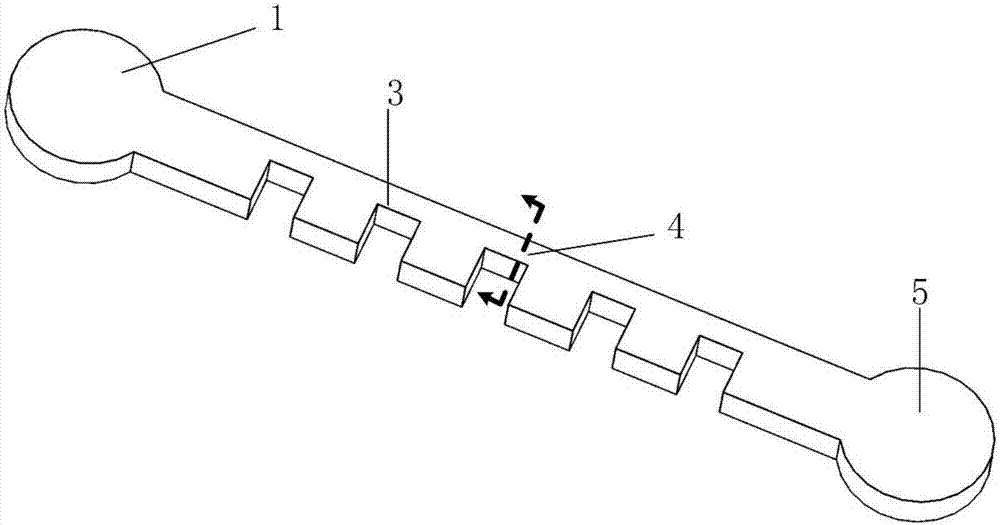

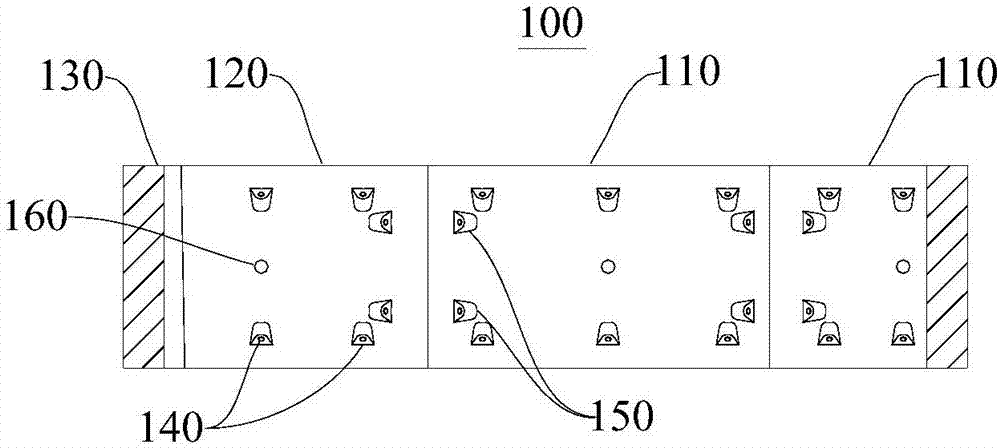

Enhanced secondary flow-based inertial focus chip

ActiveCN107159326AIncrease section sizeShorten the lengthLaboratory glasswaresFluid controllersElectrical and Electronics engineeringInertia

The invention discloses an enhanced secondary flow-based inertial focus chip and belongs to the technical field of microflow control. The chip is formed by bonding two chip layers, wherein a microchannel is formed on one chip layer bonding surface; and two ends of the microchannel are respectively connected with an inlet and an outlet. The enhanced secondary flow-based inertial focus chip is characterized in that the microchannel is a channel with curvature, and the channel with the curvature generates a first secondary flow (Dene flow); and a plurality of lug boss structures are distributed on the wall surface of the channel, so that the channel is a variable cross section channel and generates a second secondary flow (secondary flow caused by a geometric structure). The microflow control chip can be used for sorting, separation, counting and detection of particles or cells and is also applicable to occasions, such as fluid mixing and sample pre-processing. Two secondary flows are generated during flowage of fluids through the inertial focus chip which simultaneously adopts two secondary flows, meanwhile, directions of the two secondary flows are enabled to be the same, the two secondary flows are overlapped, the strength of the secondary flows is enhanced, and a guidance effect of the secondary flows is enhanced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

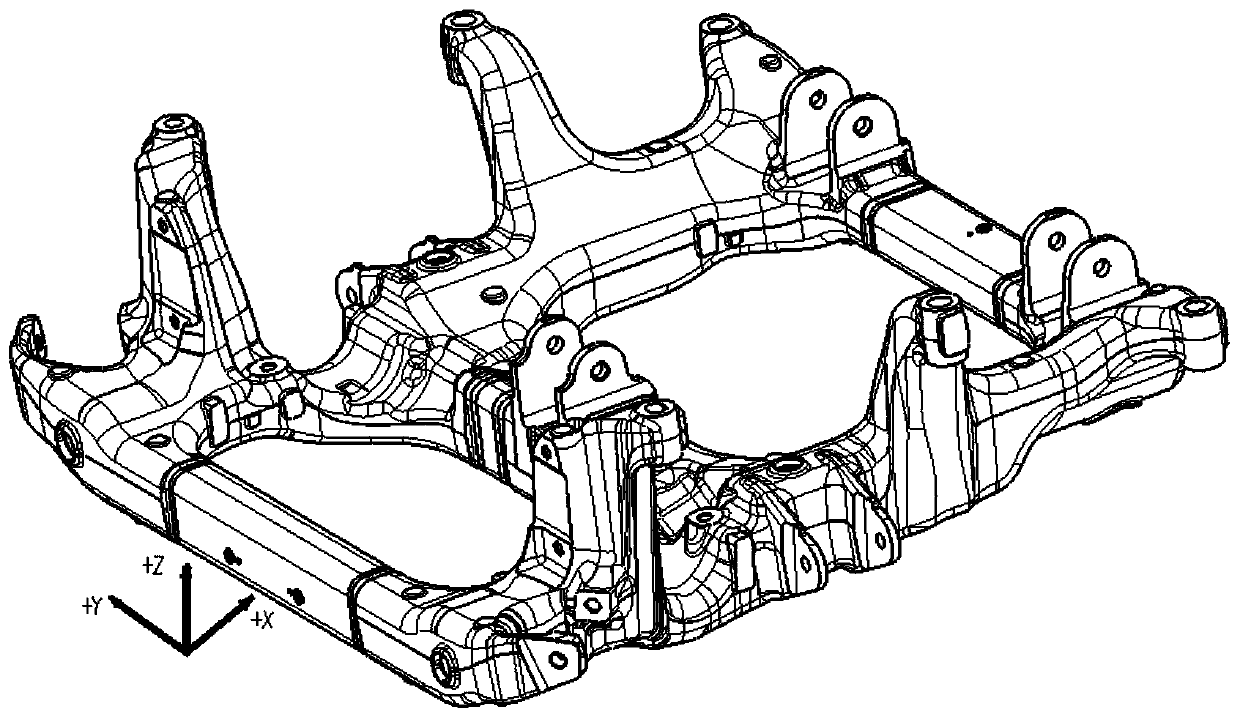

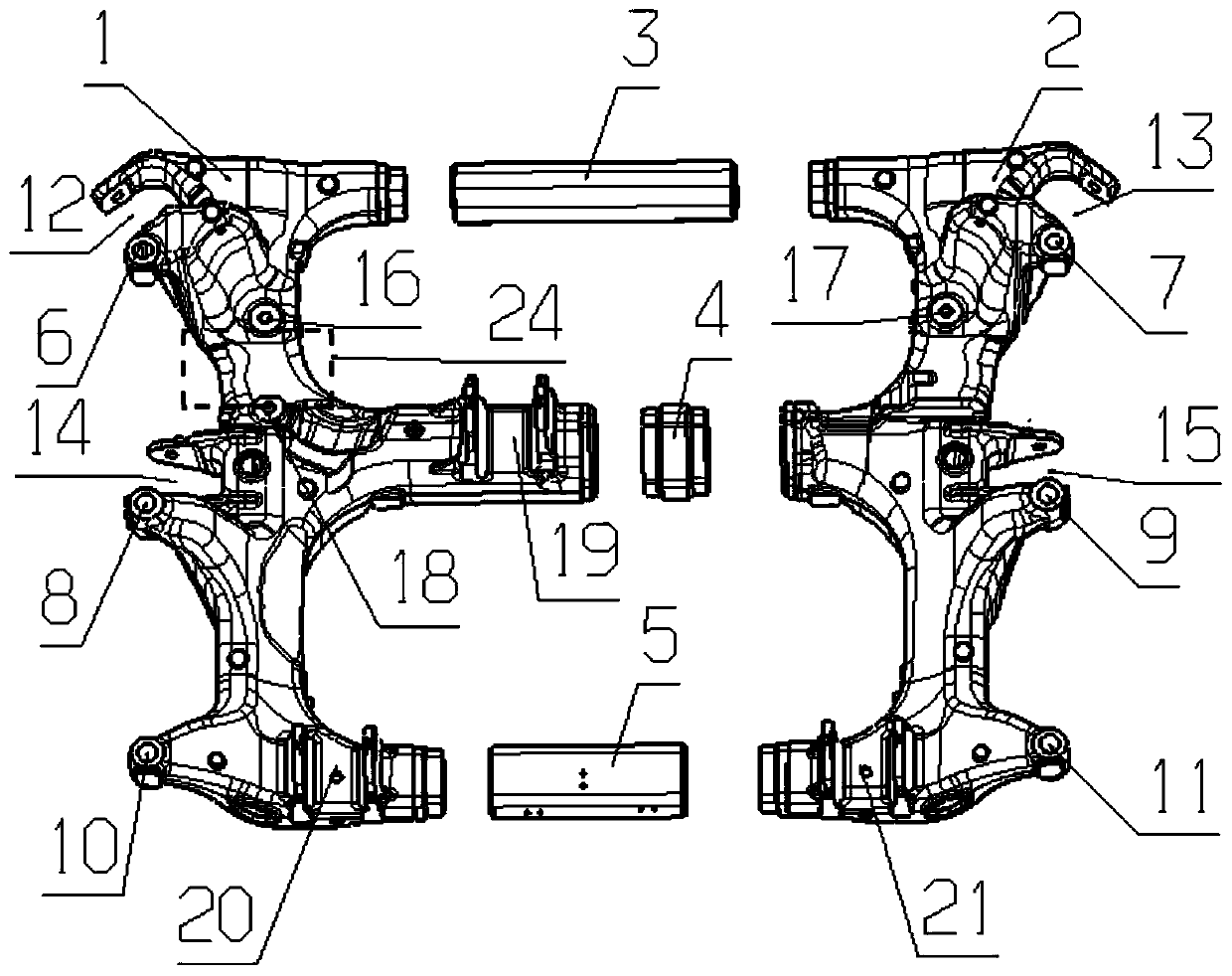

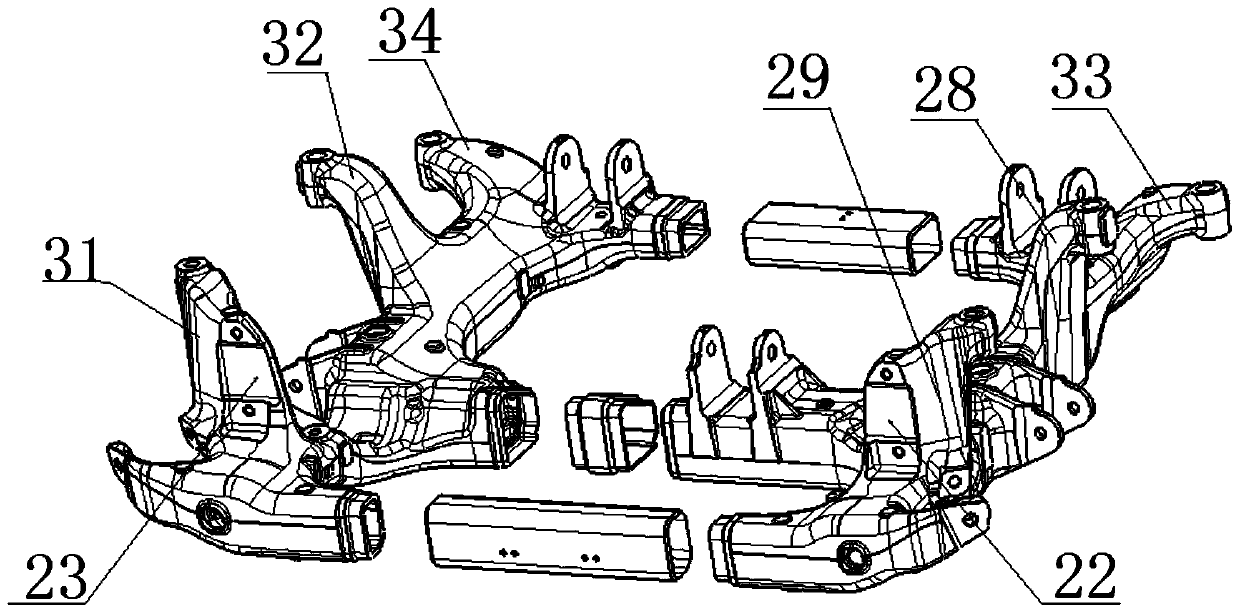

Auxiliary frame obtaining through welding hollow cast aluminum and aluminum profiles

ActiveCN110203284ASolve the unmanufacturableSolve casting difficultiesUnderstructuresDouble wishbone suspensionVehicle frame

The invention belongs to the technical field of passenger car parts, and particularly relates to an auxiliary frame obtained through welding hollow cast aluminum and aluminum profiles. The auxiliary frame comprises a left hollow cast body, a right hollow cast body, a front cross beam, a middle cross beam, a rear cross beam, a left front control arm installation support, a left front car body installation hole supporting column, a left rear control arm installation support, a left middle car body installation hole supporting column, a left rear car body installation hole supporting column, a right front control arm installation support, a right front car body installation hole supporting column, a right rear control arm installation support, a right middle car body installation hole supporting column, a right rear car body installation hole supporting column, a front suspension installation support of a power assembly, a left rear suspension installation support of the power assembly and a right rear suspension installation support of the power assembly. The problem that the inblock cast of the large-scale aluminum auxiliary frame is difficult is solved, the arrangement, function and crashworthiness requirements of Macpherson double wishbone suspension on the auxiliary frame are met, and the advantages of high strength, high rigidity, light weight and the like are achieved.

Owner:CHINA FIRST AUTOMOBILE

Short process preparation method of high-strength high-conductivity deformation-processed Cu-Cr-Ag in-situ composite material

The invention discloses a short process preparation method of a high-strength high-conductivity deformation-processed Cu-Cr-Ag in-situ composite material. The short process preparation method comprises the following steps: (1) a Cu-Cr-Ag ternary alloy cast ingot is cast by adopting a method combining medium-frequency induction melting and graphite mould pouring; (2) the cast ingot is placed in a zone melting-directional solidification furnace for directional solidification treatment, so that Cr dendritic crystals form directionally arrayed micro nanoscale fiber in the axial direction; (3) a material subjected to the directional solidification treatment is subjected to multipass cold drawing deformation, so that the micro nanoscale fiber formed in a directional solidification process is further refined to be nanoscale fiber; and (4) comprehensive regulation on the strength, the conductivity, the elongation percentage, and the like of the material is carried out by adopting final aging heat treatment. The continuous directionally arrayed micro nanoscale fiber is formed through as-cast structure control, with the combination of the cold drawing deformation, alloying and the final aging heat treatment, the preparation technological process is shortened, the cold deformation strain capacity is reduced, the size of the final material is increased significantly, the final material can acquire stable and good use comprehensive performances, and the application scope of the deformation-processed Cu-based in-situ composite material can be widened in the field of high and new technologies.

Owner:NANCHANG INST OF TECH +1

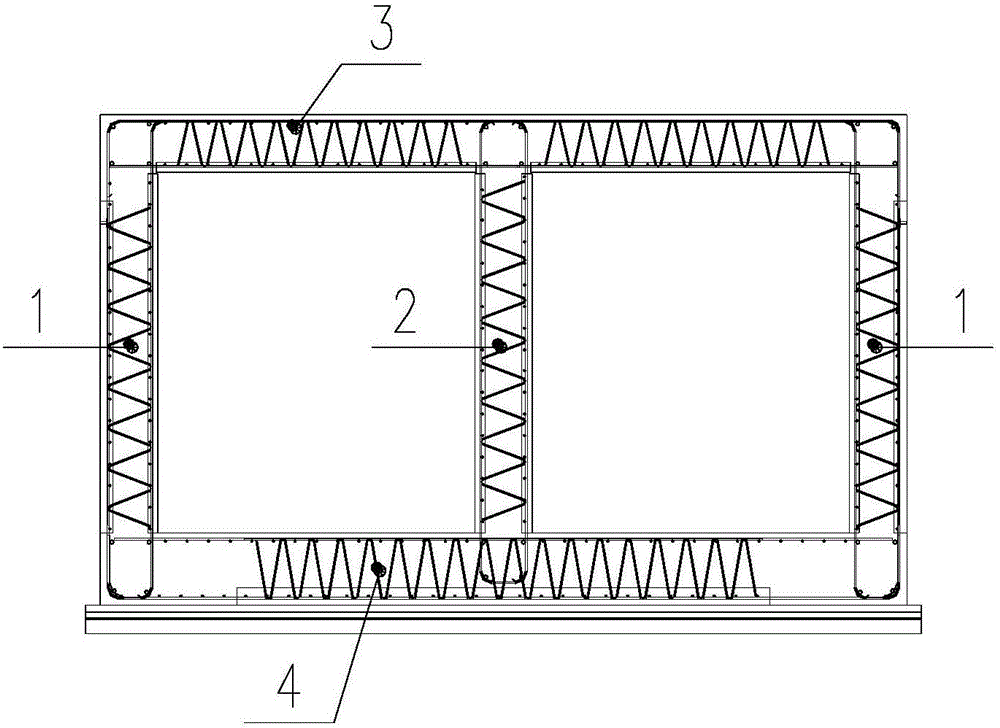

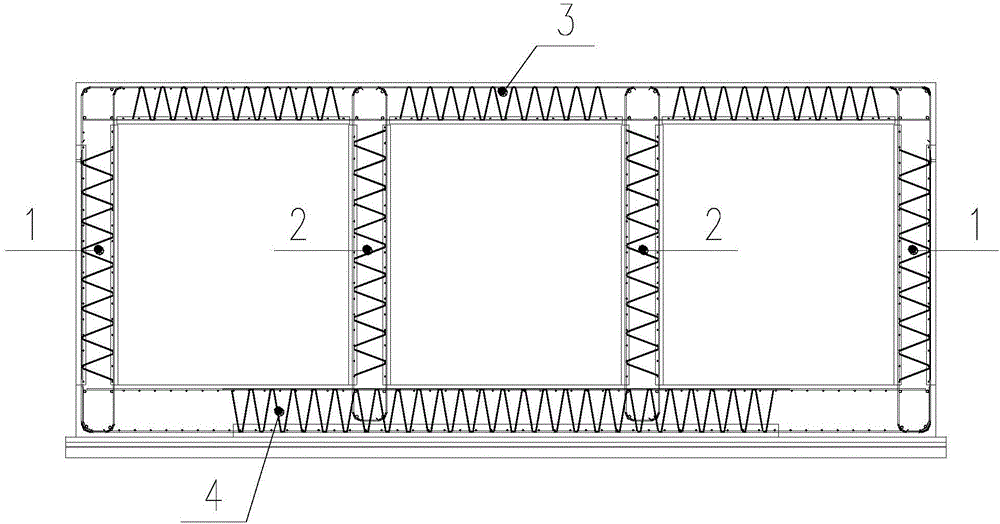

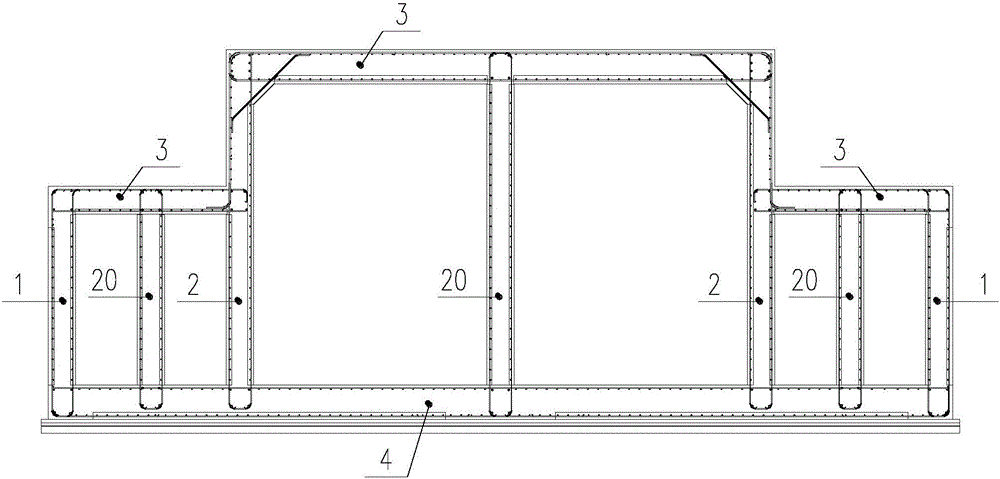

High and low bin assembling integrated utility tunnel or draining canal

InactiveCN106638671AReduce pollutionLots of wet workArtificial islandsSewerage structuresWork periodUtility tunnel

The invention relates to the technical field of prefabricated concrete municipal structures, and provides a high and low bin assembling integrated utility tunnel or draining canal. The high and low bin assembling integrated utility tunnel or draining canal comprises high bin and low bin overlapping top plates, an overlapping bottom plate or cast-in-situ bottom plate, an overlapping outer wall plate and an overlapping high and low bin transition wall plate. The high bin and low bin overlapping top plates adopt overlapping top plates of the same structure. The overlapping top plates, the overlapping bottom plate, the overlapping outer wall plate and the overlapping high and low bin transition wall plate are each composed of a prefabricated part and a cast-in-situ part. The overlapping bottom plate or the cast-in-situ bottom plate is arranged on a basic pad layer or waterproof layer (or waterproof protective layer). Steel bars are arranged on the prefabricated parts of all the overlapping members. After the prefabricated parts are assembled on site, necessary stress and construction steel bars are added, and concrete is poured, so that the high and low bin assembling integrated utility tunnel or draining canal is formed. The high and low bin assembling integrated utility tunnel or draining canal can give the advantages of on-site casting and factory prefabrication into full play, reduce on-site wet operation, shorten the work period, improve construction quality, and guarantee the integrity, and is good in waterproof performance.

Owner:DALIAN SANCHUAN BUILDING TECH CO LTD

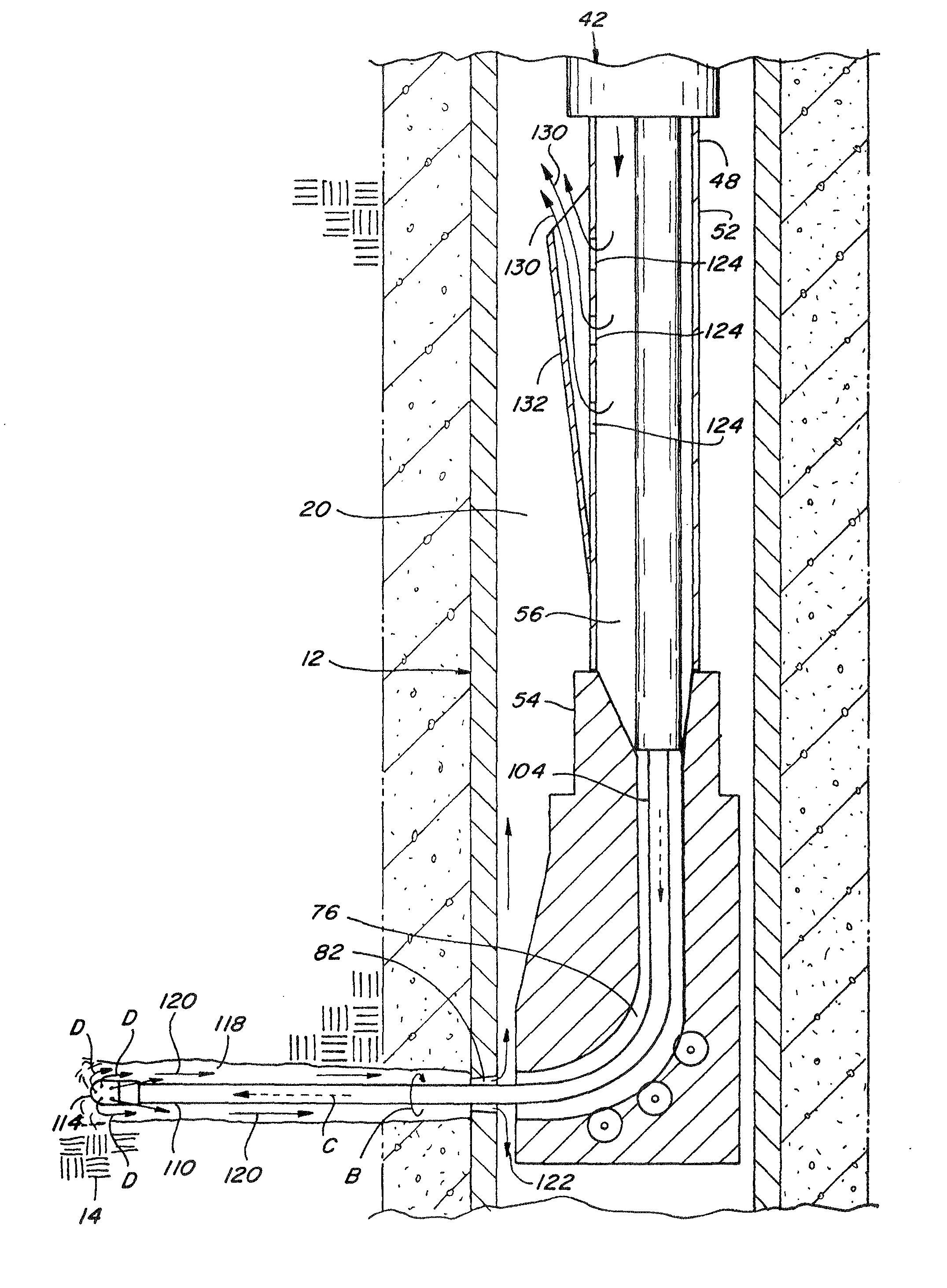

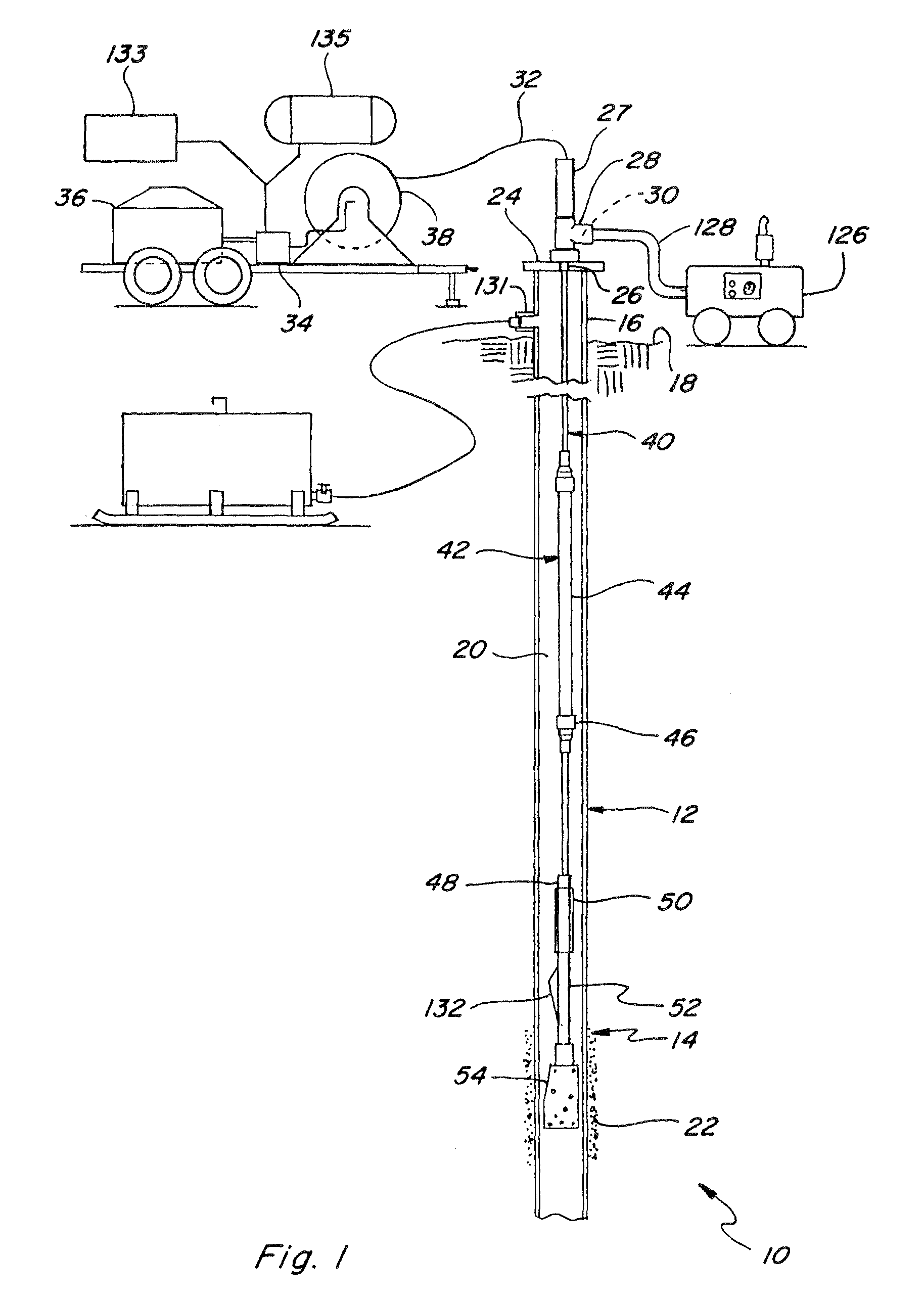

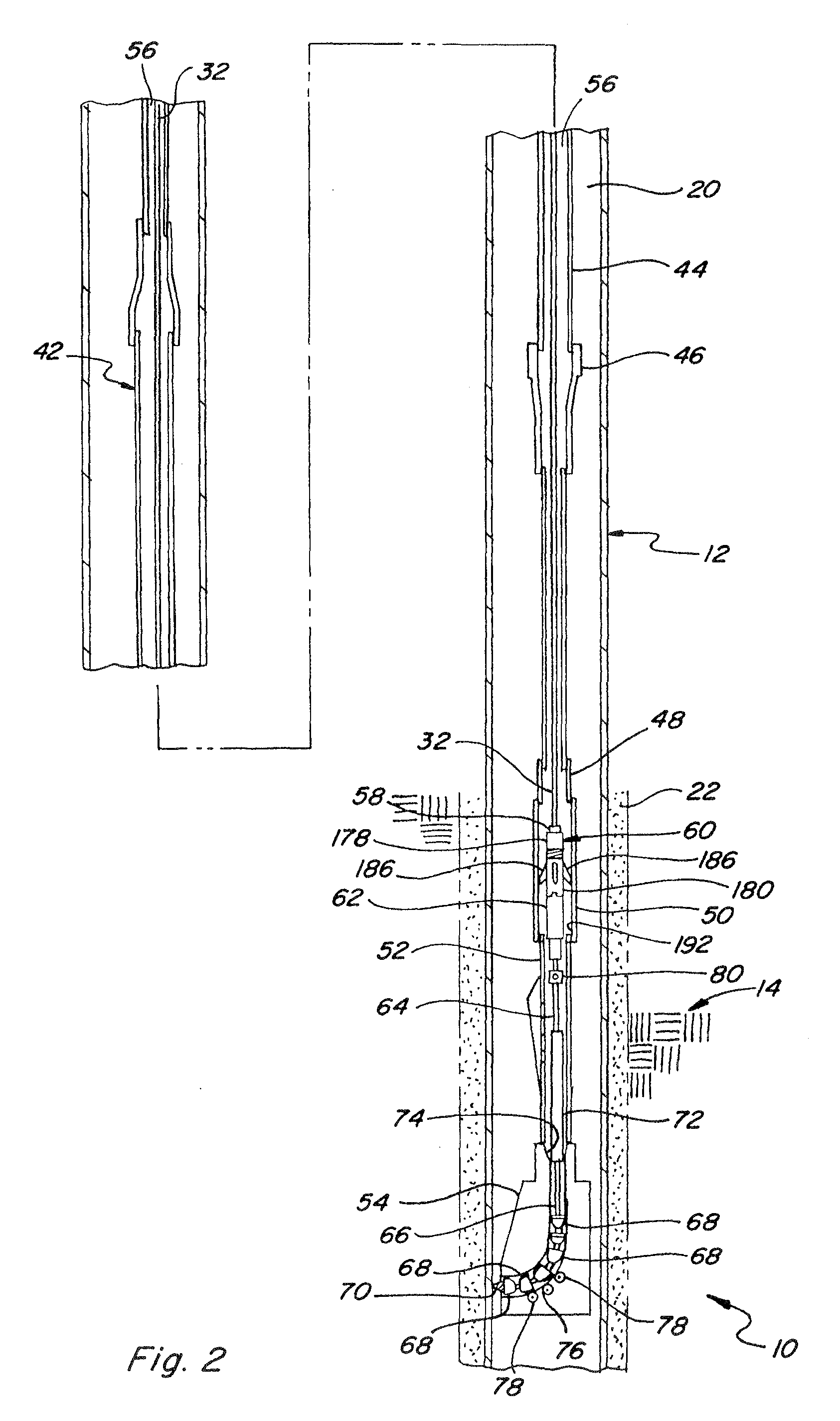

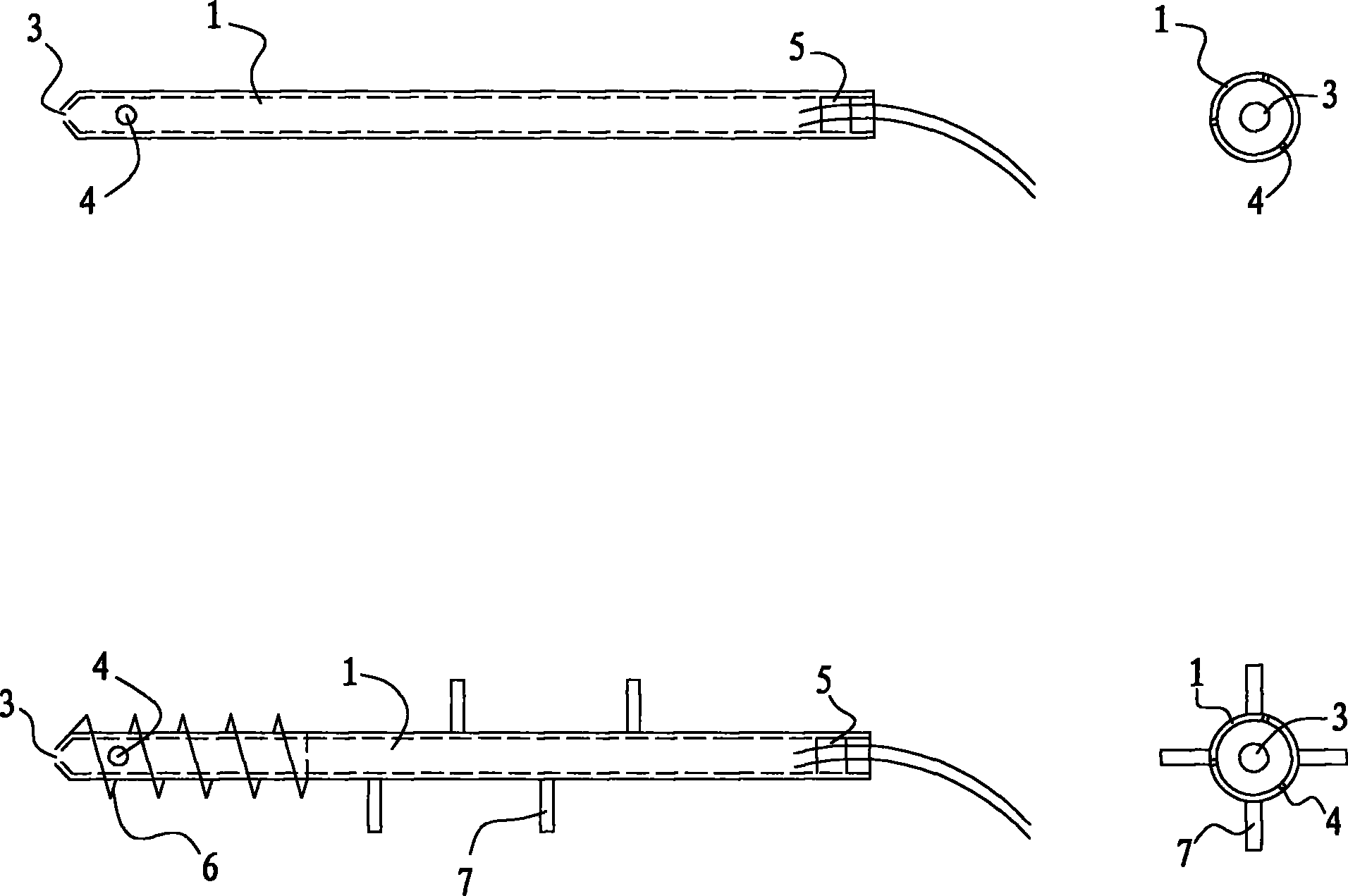

Method and apparatus for lateral well drilling with enhanced capability for clearing cuttings and other particles

ActiveUS20090255732A1Avoid enteringIncrease section sizeArtificial islandsLiquid/gas jet drillingEmulsionHydrostatic head

Apparatus for clearing particles from a lateral drilling operation in strata beside a well. The drilling apparatus is part of a down hole unit and is configured for extending from a lateral opening of the unit into a lateral passage in the adjacent strata, and the operation of the drilling apparatus discharges particles from the lateral passage toward the lateral opening. The invention deflects or redirects the particles discharged from the lateral passage, away from the lateral opening, to prevent clogging or blocking of an internal passage or elbow through the down hole unit, using a pressurized fluid such as a gas or an emulsion. The pressurized fluid can also be configured for carrying the particles upwardly through the well to the surface, and for reducing or removing a hydrostatic head in the well.

Owner:LATJET SYST

Construction technology of reelingly stirring to eject anchor tube pile

InactiveCN102839661AOvercome the difficulties of forming holes, easy to collapse holes and other shortcomingsIncrease construction costsBulkheads/pilesEngineeringCement slurry

The invention discloses a construction technology of reelingly stirring to eject an anchor tube pile, comprising the following steps: 1) positioning: aligning a hollow anchor pipe to a required hole site; 2) drilling: driving the anchor pipe to drill in soil with anchor rod construction equipment; 3) grouting: drilling while ejecting cement slurry to the soil through the anchor pipe with grouting equipment; 4) pile-forming: separating the construction equipment from the anchor pipe after forming the anchor pipe pile for reelingly stirring to eject, and locking a shell cover. The beneficial effects of construction technology are as follows: 1) using the anchor rod construction technology and the grouting technology to simultaneously work, constructing to reelingly stir to eject the anchor pipe in non rock soil of various simple and complex geological conditions, thereby effectively overcoming defects of difficult pore-forming and easy hole collapse of traditional anchor in soft soil layer when constructing, and the like; 2) simultaneously performing to reelingly stir to eject the anchor pipe and the grouting technology, no need dado, disposable pile-forming, thereby greatly simplifying the construction technology, quickening the construction speed and reducing the engineering cost.

Owner:严平

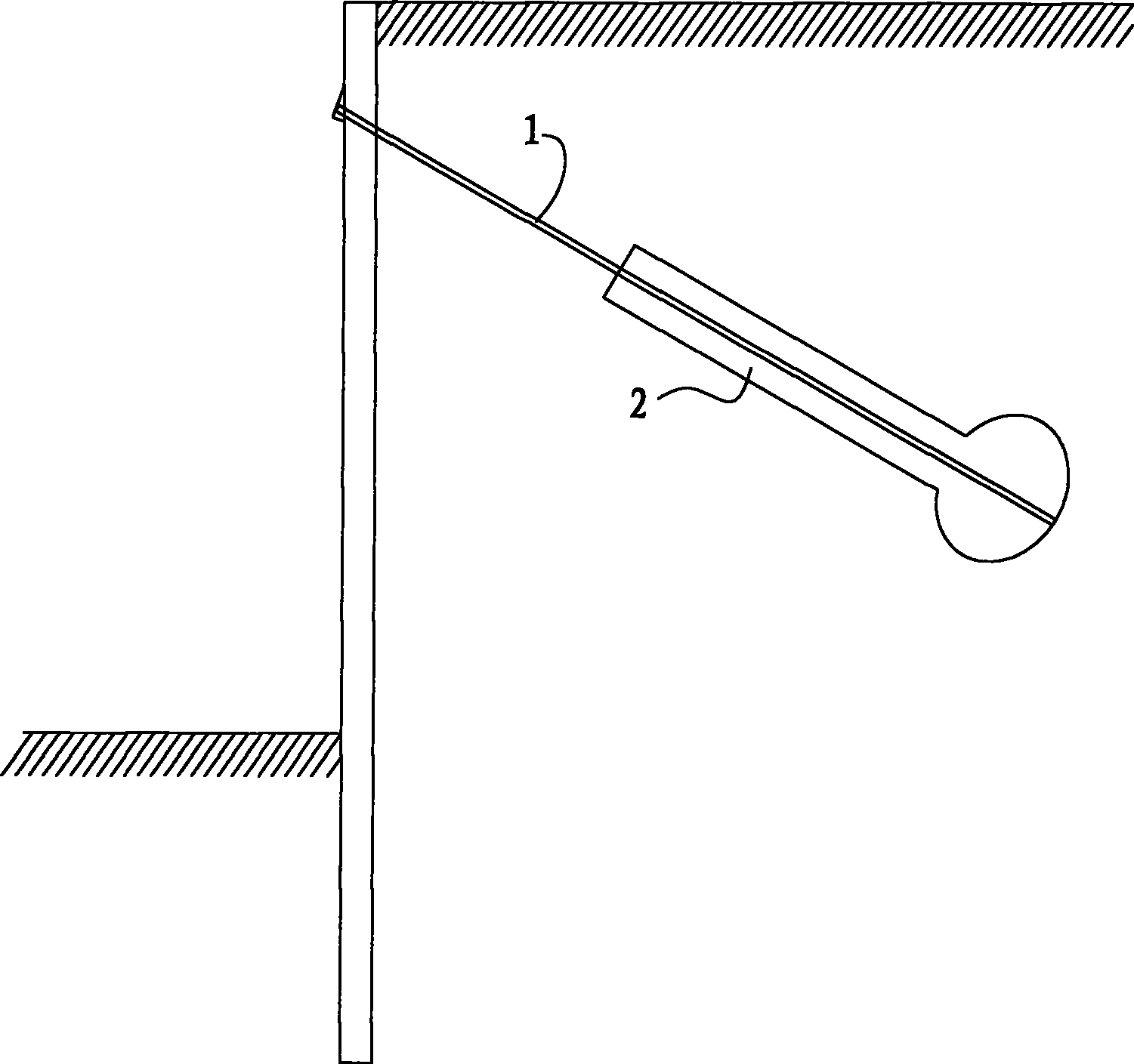

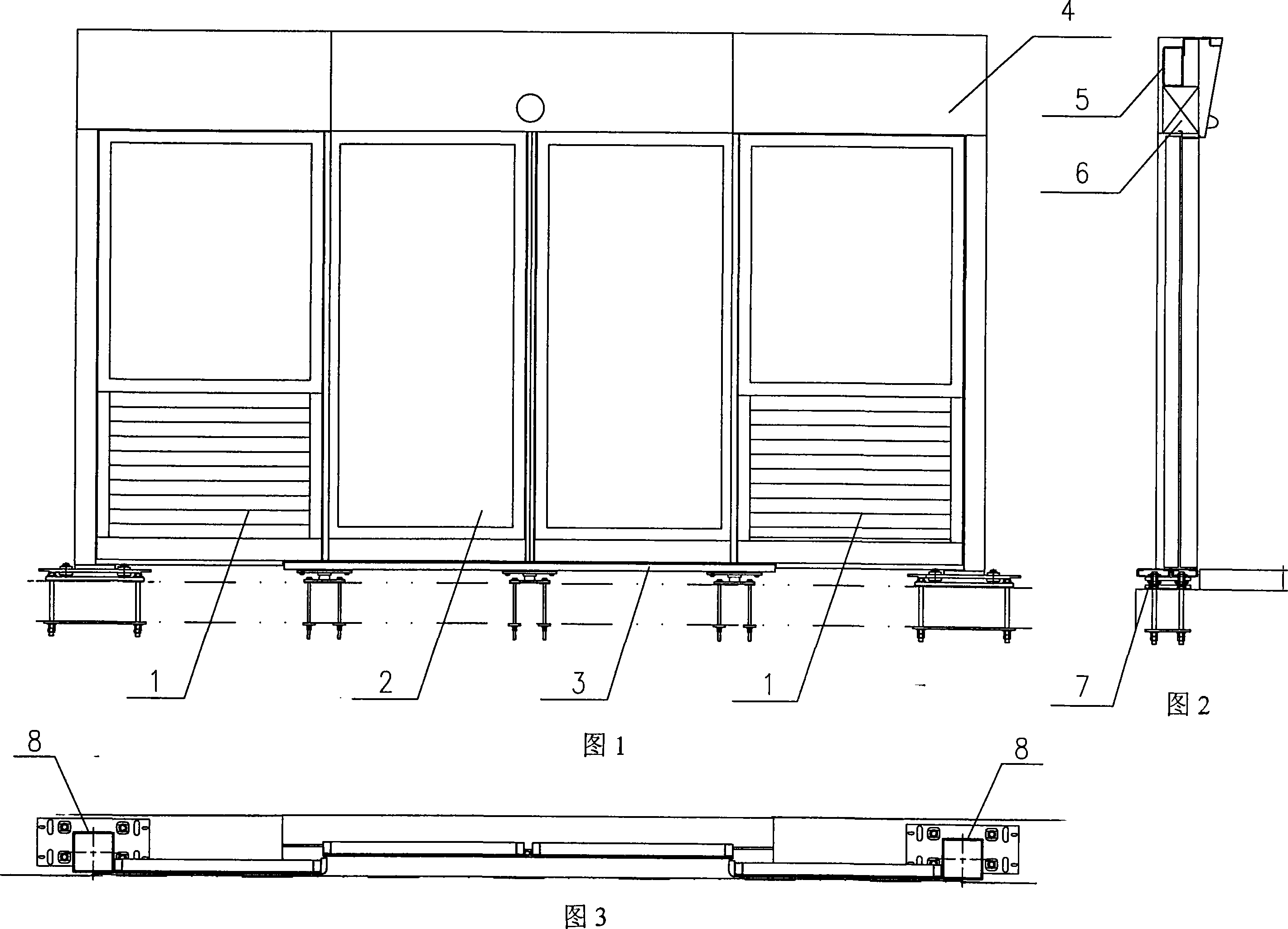

Overall high safety door without upper supporting

InactiveCN101144362AIncrease section sizeSimple structureRailway componentsWing arrangementsAutomobile platformEngineering

The invention relates to an overall height type safety door without a support at the upper part used for a metro elevated platform, a railway platform, an automobile platform. The connection with any device not required by the upper part of the overall height type safety door is solved through increasing an upright column cross section. The structure comprises a fixed door / an emergency door, a sliding door, a threshold, a top box, a cross beam, a load supporting driving mechanism, a bottom support and a upright column, wherein, the lower part of the fixed door / the emergency door is arranged on the threshold and the bottom support, the upper part of the fixed door / the emergency door is arranged on the device of the top box, the threshold is installed on the bottom support, the sliding door is installed on the load supporting driving mechanism at the lower part of the cross beam in a hanging way. The present invention has the advantages that because the section size of the upright column is big enough, the whole bearing structure holding a enough strength can be guaranteed, therefore to realize that the upper part of the overall height type safety door requires no connection with any device, under the function of a combined load, the integrated deformation of the overall height type safety door does not exceed a specified value, the normal operation is guaranteed, and the present invention has the characteristics of simpleness and reliability.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

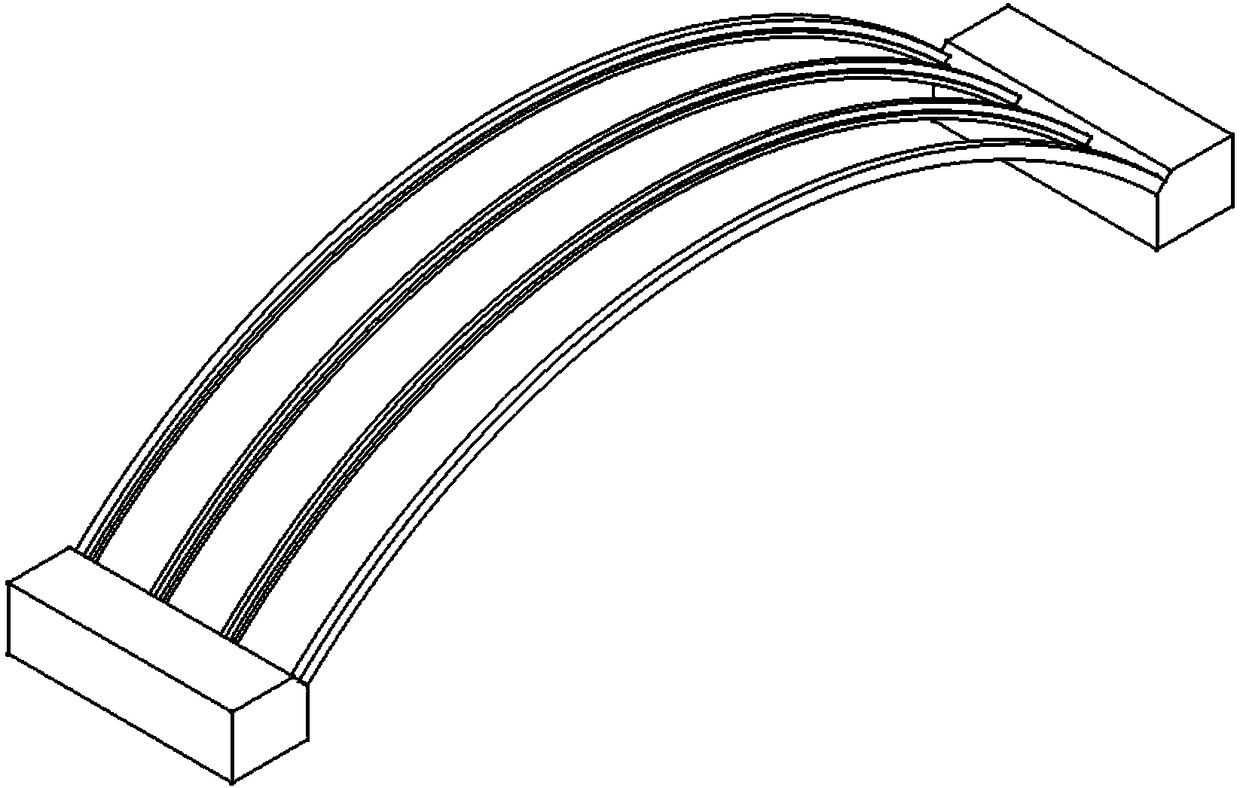

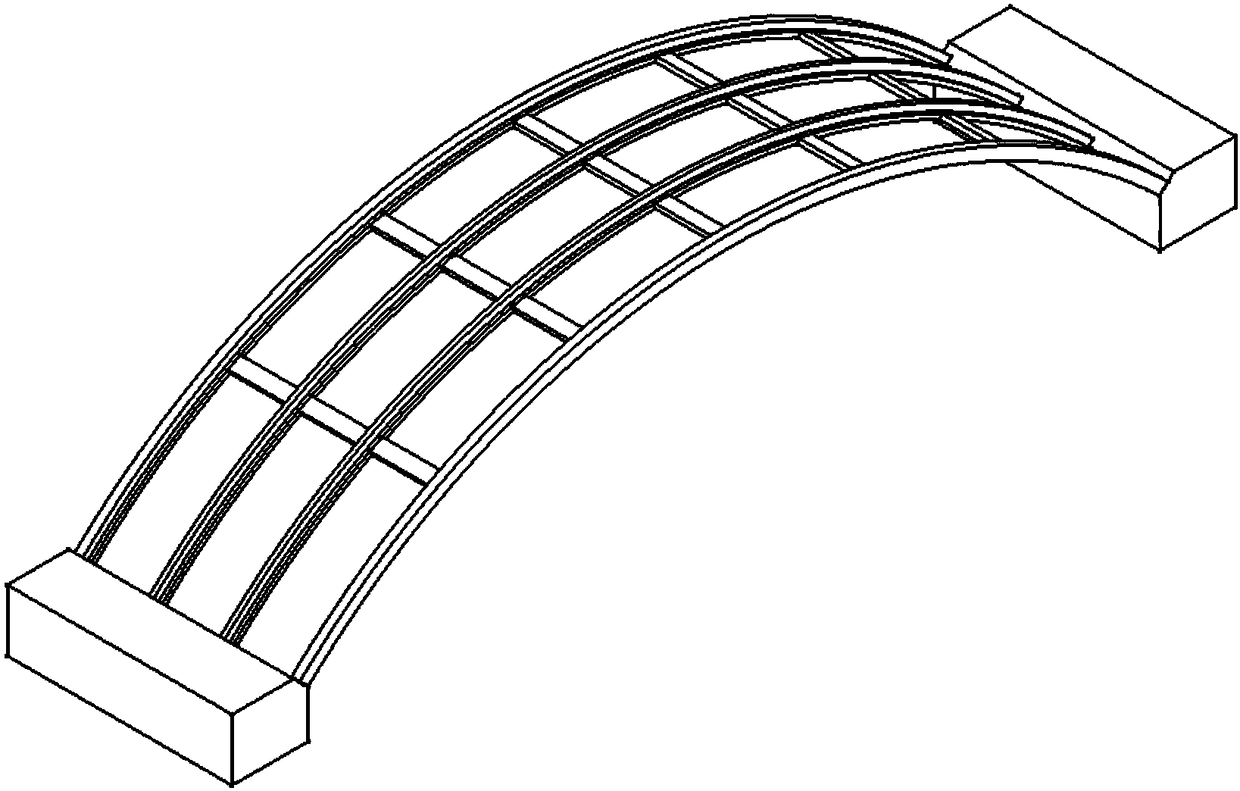

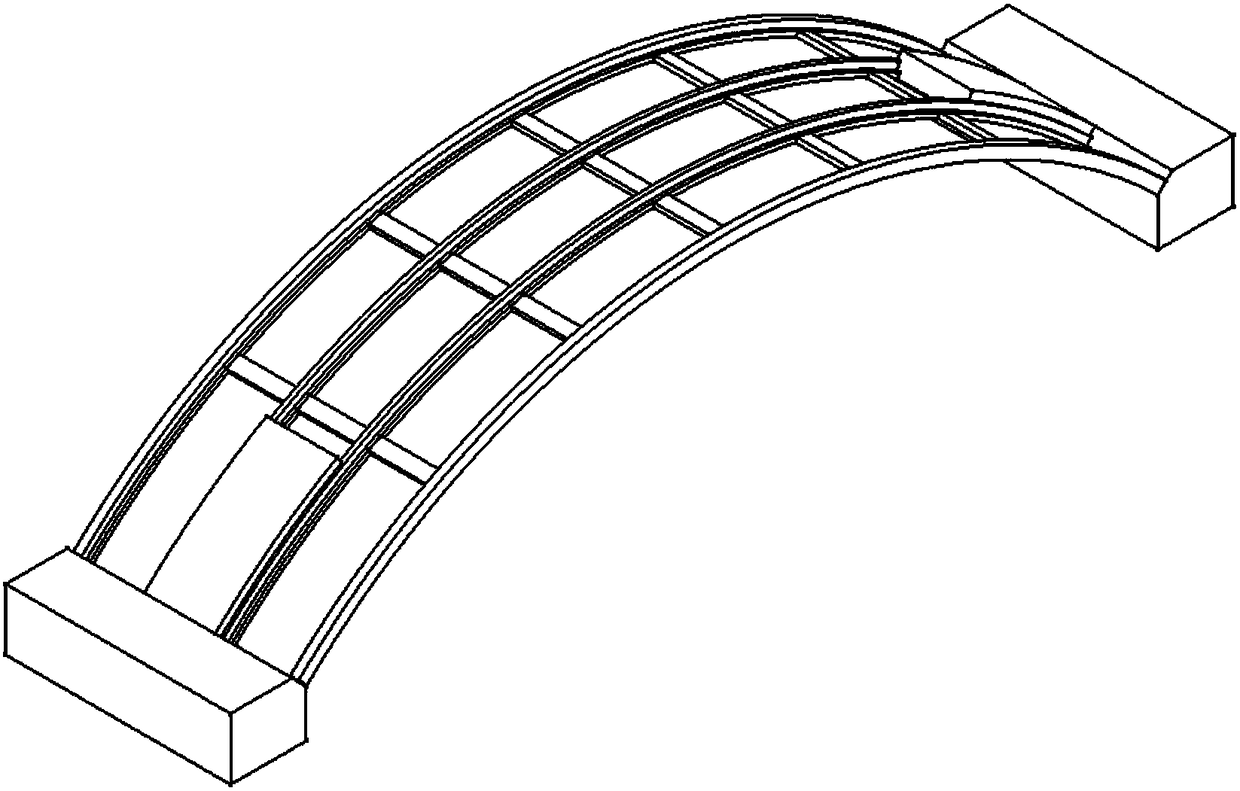

Novel RC-masonry combined arch bridge structure and construction method

PendingCN108374320AIncrease section sizeAvoid losing practical use valueBridge structural detailsBridge erection/assemblyFull bridgeAbutment

A novel RC-masonry combined arch bridge structure is composed of a first-stage structure, a second-stage structure and a building on an arch, wherein a whole space structure composed of RC arch ribs,RC cross beams and pier abutments serves as the first-stage structure; the RC arch ribs and the cross beams of the first-stage structure are prefabricated section by section in the early stage of construction, hoisted section by section, combined and cast in place into a whole. When the whole first-stage structure reaches design strength, masonry arch plates are built on the first-stage structurestrip by strip and section by section to serve as the second-stage structure, wherein the middle arch rib masonry arch plate is built first, and then the edge arch rib masonry arch plates are built. According to the thickness of a main arch ring, a later-stage structure or the building on the arch built on the second-stage structure layer by layer is determined till the whole bridge is formed, andconstruction is finished. According to the construction method, the RC arch ribs play a role in bearing components, and an arch frame formed by the arch ribs is a formwork support for later-stage structure construction, so that the waste caused when the arch frame in a traditional masonry arch bridge support construction method only serves as a construction support and is detached after the archring is built is avoided.

Owner:CHANGAN UNIV

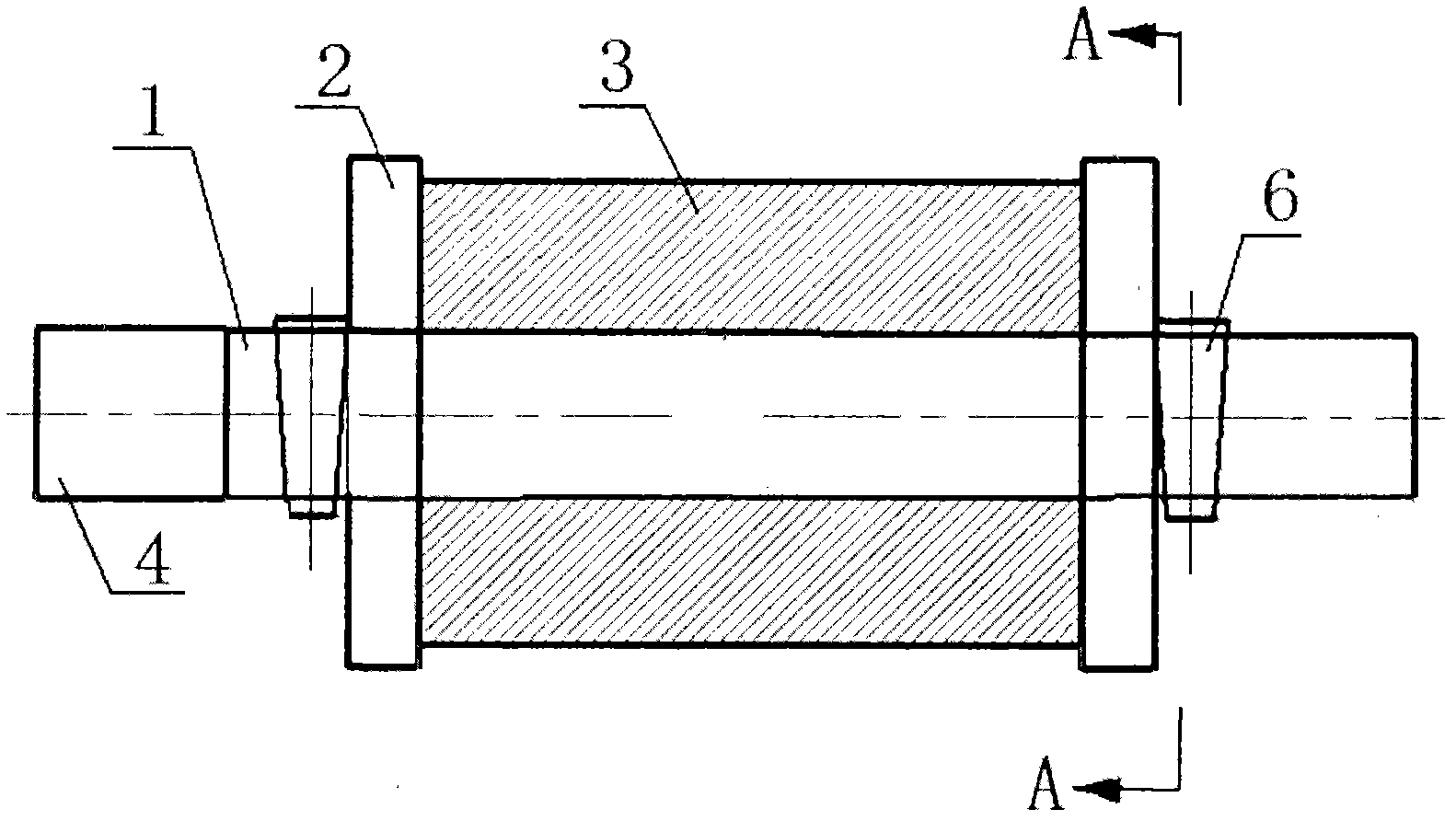

Semi-closed tool for forging hollow nuclear power main pipe

ActiveCN102632179AReduce segregationIncrease section sizeForging/hammering/pressing machinesNuclear engineeringNuclear power

The invention discloses a semi-closed tool for forging a hollow nuclear power main pipe, which comprises a mandrel. Two retainer rings are disposed on the mandrel, the nuclear power main pipe is sandwiched between the two retainer rings, positioning structures which are used for positioning the two retainer rings are disposed among the outer sides of the two retainer rings and the mandrel, and at least one end of the mandrel is provided with a prism section. The tool can be used for forging an inner hole of the nuclear power main pipe via an integral hollow forging forming process by the aid of a hollow steel ingot, can be effectively used for forging the nuclear power main pipe, can lead the wall of the nuclear power main pipe to deform uniformly, and achieves effects of refining grains, improving structures and promoting uniformity of metal flowing ingredients, so that a fine forging structure is obtained.

Owner:JIANGYIN NANGONG FORGING

Method for processing profiled bar with asymmetrical cross section

InactiveCN103386416AImprove rolling conditionsRolling realizationMetal rolling arrangementsWork in processEngineering

The invention discloses a method for processing a profiled bar with an asymmetrical cross section. The method is characterized in that a to-be-rolled profiled bar with the asymmetrical cross section is subjected to mirror pairing and combining in the direction of a vertical axis (Y axis), converting the asymmetrical cross section into a symmetrical cross section, improving the rolling condition, then rolling the bar with a symmetrical cross section by a four-roll universal mill, and finally dissecting the rolled semi-finished product with the symmetrical cross section by a metal dissecting device, so as to obtain two qualified finished bars which have the asymmetrical cross sections and are the same in size and shape. The method has the advantages that the rolling condition of the profiled bar with the asymmetrical cross section is improved, so the rolling by the four-roll universal mill is realized; and the rolling speed is high, the rolling efficiency is high, and the production capability is greatly improved.

Owner:钱奕峰

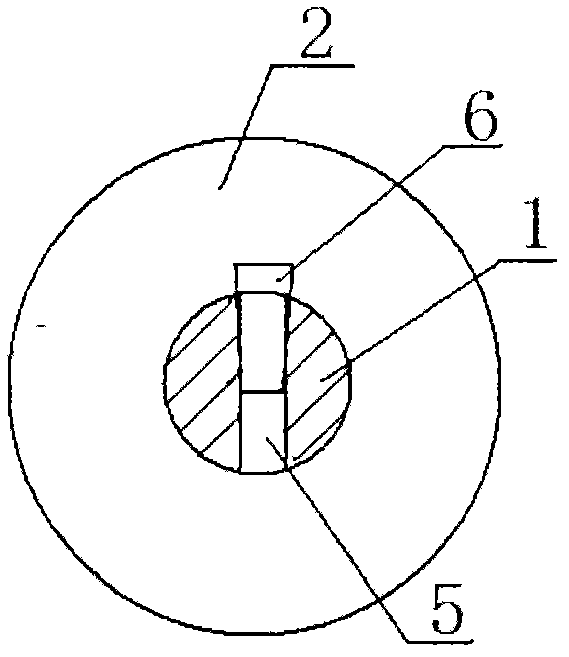

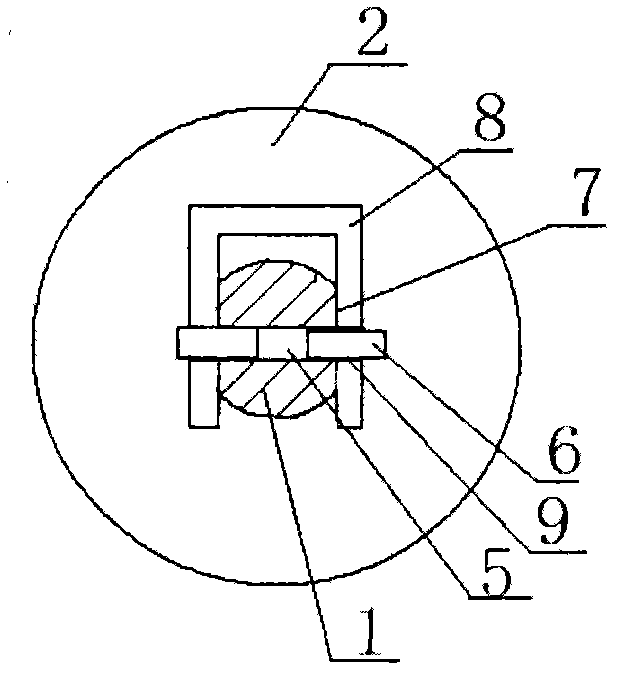

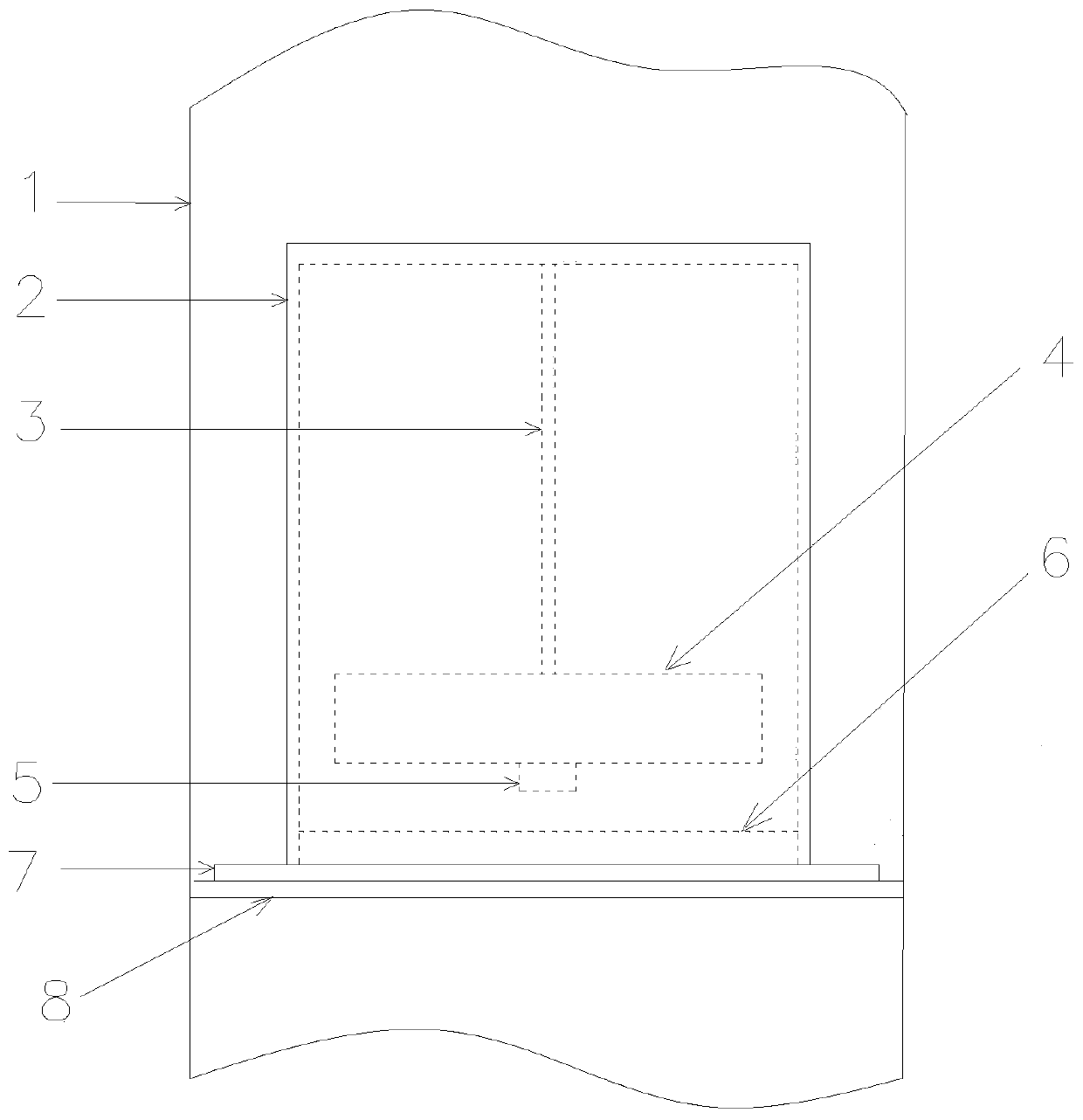

Fan tower tube vibration control eddy current tuning mass damper

PendingCN111021568AGood vibration reduction effectGood weather resistanceProtective buildings/sheltersShock proofingVibration controlMagnetic damping

The invention provides a fan tower tube vibration control eddy current tuning mass damper. The mass damper is arranged inside a fan tower tube (1) and comprises a sleeve (2), a base plate (7) arrangedat the bottom of the sleeve (2) and a copper plate (6) and a permanent magnet (4) which are arranged inside the sleeve (2). The permanent magnet (4) is suspended at the top of the sleeve (2). The copper plate (6) is fixed to the base plate (7) and can perform vibration reduction on a fan tower tube, and the damping effect is good. The magnitude of magnetic damping can be flexibly adjusted, and the large adjusting range is obtained. The damper is arranged inside the fan tower tube (1), a connecting plate (8) is fixed to the inner wall of the fan tower tube (1) in a welded mode, and the weatherresistance is good. The rigidity of the damper is changed by changing the diameter and length of a suspender (3), the rigidity of the damper is adjustable flexibly, no mechanical friction problem orsealing problem exists, and the reliability and durability are good.

Owner:CHINA ELECTRIC POWER RES INST +1

Special-shaped steel pipe column reinforced concrete ring beam construction method

InactiveCN106284688AGuarantee the construction qualitySolve the problem of installation and moldingBuilding constructionsSocial benefitsReinforced concrete

The invention provides a special-shaped steel pipe column reinforced concrete ring beam construction method and belongs to the technical field of building construction. The construction method comprises the steps that a steel pipe concrete column is connected with a reinforced concrete beam; a beam-column joint processing method of an annular bracket is adopted by joint processing; a corresponding steel bracket is additionally arranged during machining of the steel pipe column, specifically, the steel bracket is formed by welding a steel plate which is 22 mm thick; a ring beam and a frame beam are bound to the steel bracket; main steel bars of the beam are anchored into main steel bars of the inner side of the ring beam; and concrete of the frame beam and a slab are poured. Due to the facts that the steel bracket is located in the middle of the ring beam, and the main steel bars of the lower row of the ring beam are located on the inner side of the steel bracket, ring beam steel bars cannot be bound on a machining site and then suspended like a conventional ring beam, and an on-site binding construction mode is adopted. Through practice examination of the method in engineering, the installation problem of ring beam joint steel bars is solved; and according to the method, safety is guaranteed, the construction quality is good, the speed is high, the comprehensive construction cost is low, and the economic benefits and social benefits are remarkable.

Owner:CHINA CONSTR EIGHTH ENG DIV

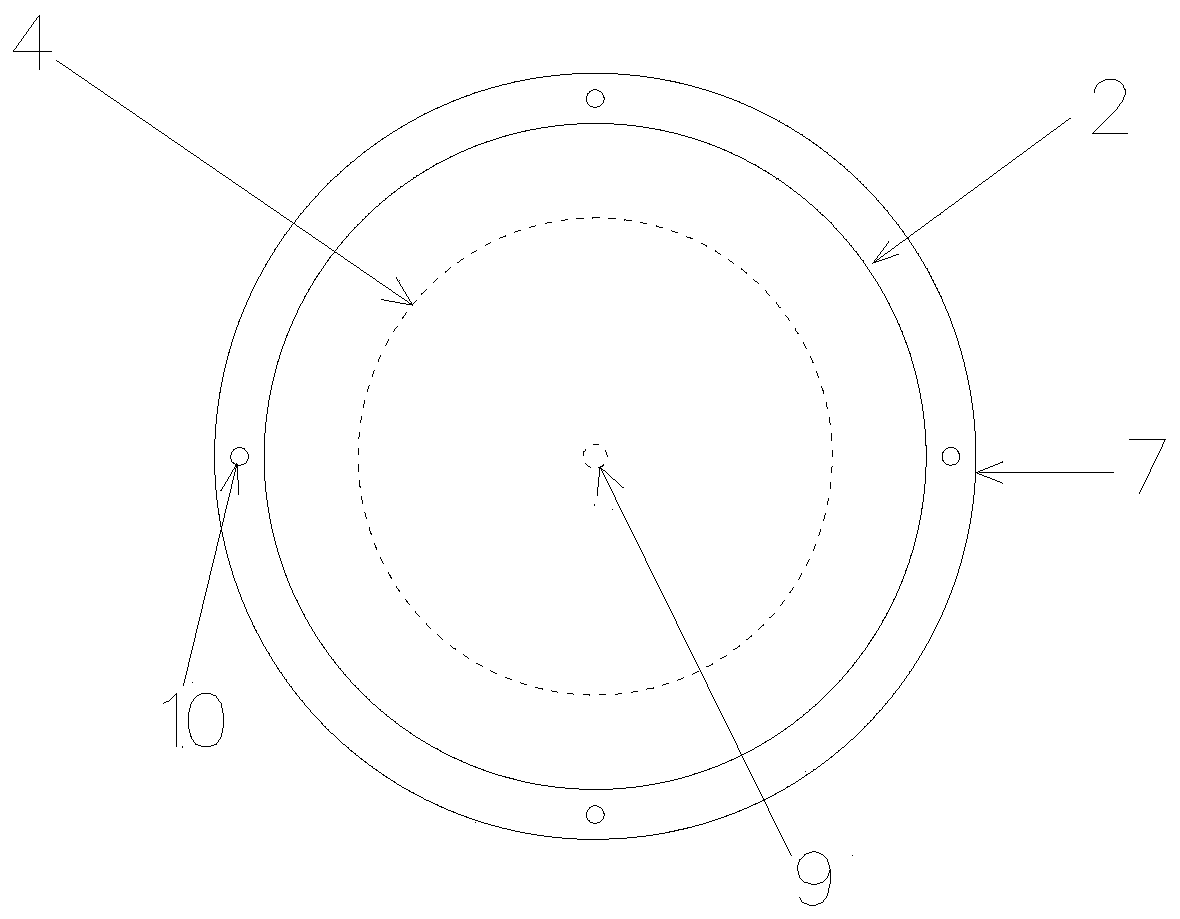

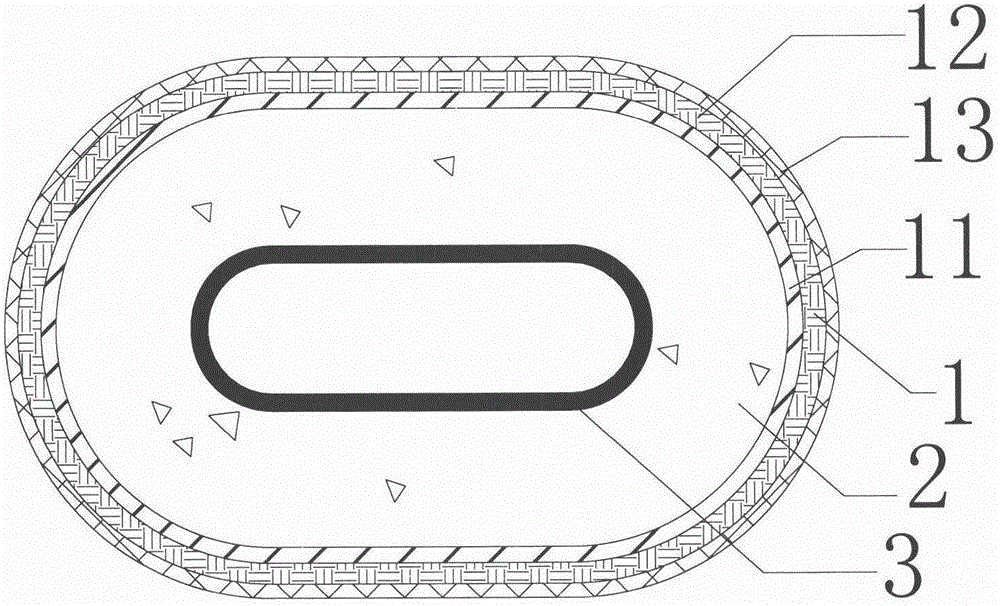

Bamboo composite pipe-steel pipe internal-external constraint concrete composite structure

PendingCN106592869AReduce dosageImprove bearing capacityStrutsPillarsShock resistanceFiber orientation

The invention discloses a bamboo composite pipe-steel pipe internal-external constraint concrete composite structure. The bamboo composite pipe-steel pipe internal-external constraint concrete composite structure is characterized in that the cross section of the bamboo composite pipe-steel pipe internal-external constraint concrete composite structure is sequentially composed of a bamboo composite pipe (1), sandwich concrete (2) and an inner steel pipe (3) from outside to inside; the bamboo composite pipe (1) sequentially comprises an isolating layer (11), a bamboo fiber strengthened composite layer (12) and an outer protective layer (13) from inside to outside; the bamboo fiber strengthened composite layer (12) is formed by continuously and evenly winding and solidifying one or more layers of bamboo fibers which are impregnated with resin adhesive on the outer wall of the isolating layer (11); the included angle between the fiber direction of the bamboo fibers and the circumferential direction of the bamboo composite pipe (1) ranges from minus 45 degrees to 45 degrees; the outer surface of the bamboo fiber strengthened composite layer (12) is coated with the outer protective layer (13); the inner steel pipe (3) is located in the cross section; the space between the bamboo composite pipe(1) and the inner steel pipe (3) is filled with the sandwich concrete (2); and the inner steel pipe (3) is internally hollow. The structure is high in bearing capacity, good in stiffness, ductility and shock resistance and has good construction performance and durability, the cross section inertia moment is large, concrete consumption is low, and construction cost is low; and the sustainable bamboo source in China is sufficiently utilized, and property advantages good toughness and high longitudinal tension strength of bamboo t are brought into play to the maximum extent.

Owner:NANJING FORESTRY UNIV

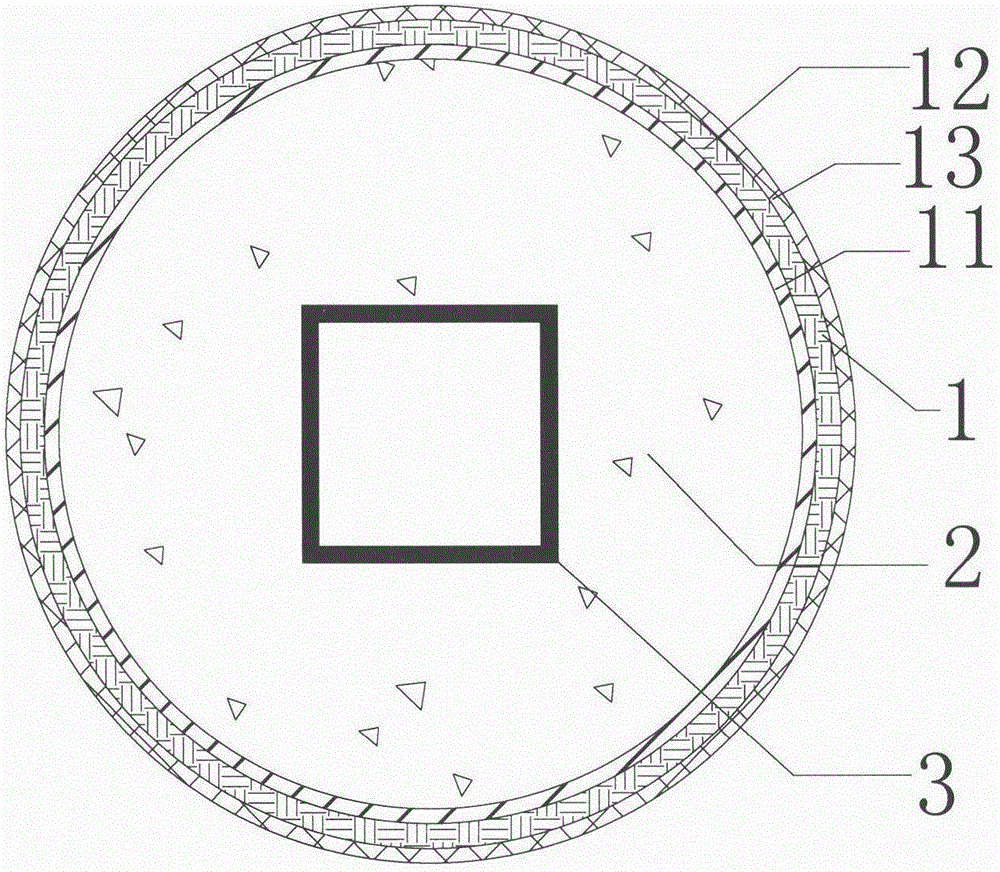

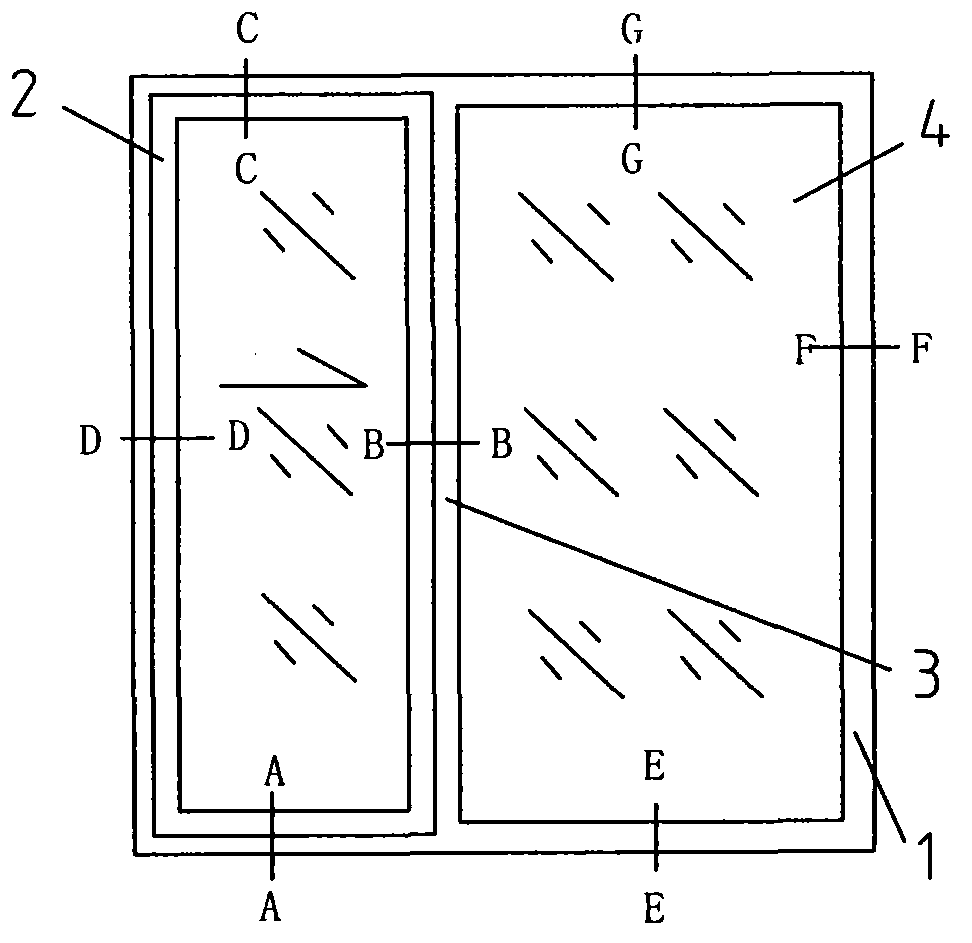

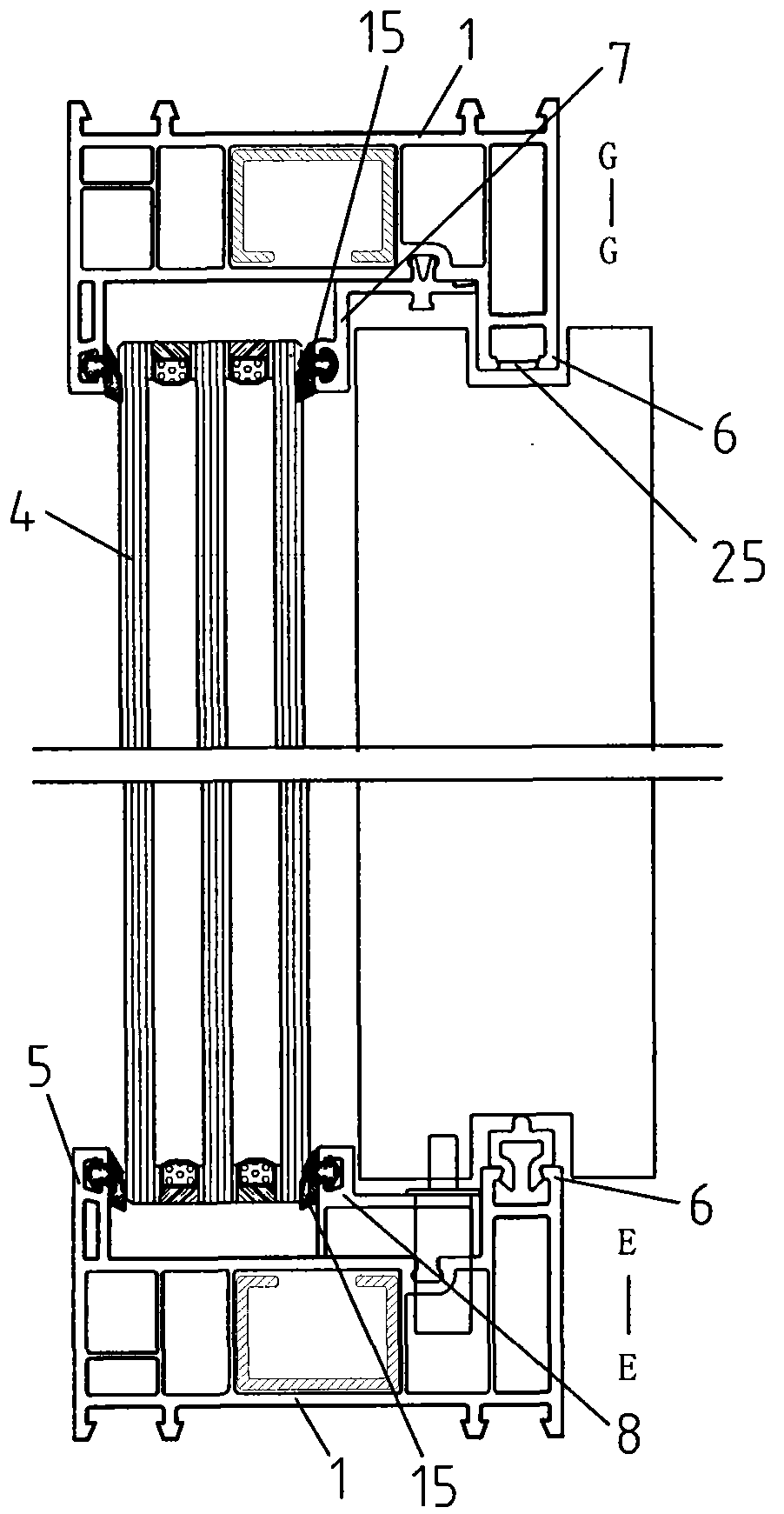

Energy-saving safe sliding window

ActiveCN104074437AImprove qualityReduce energy consumptionWindow/door framesWing arrangementsSlide windowEngineering

The invention discloses an energy-saving safe sliding window with good sealing performance and safety performance. The energy-saving safe sliding window comprises a window frame (1), a sliding window frame (2) and a muntin frame (3), wherein fixed glass (4) is arranged between the muntin frame (3) and the window frame (1) arranged at one side of the muntin frame. The energy-saving safe sliding window is mainly characterized in that the integral cross section of the window frame (1) is in a U shape; an outer bulge (5) arranged at the outdoor side of the window frame (1) is higher than a bulge arranged at the indoor side as a slide rail (6); in addition, the width of the slide rail (6) is greater than the width of the outer bulge (5); a removable strip (25) is formed on the upper surface of the slide rail (6) through pressing a shallow groove onto the upper surface of the slide rail (6); glass press strips are respectively arranged between the four (upper, lower, left end right) edges of the fixed glass (4) and a transverse frame of the window frame (1); a small ridge (11) is arranged on one end surface of one side, far away from the fixed glass (4), of the muntin frame (3), wherein the end surface faces to indoor space; the sliding window frame (2) capable of sliding and moving along the slide rail (6) is arranged on the slide rail (6); and a lower transverse frame of the window frame (1) is provided with a position limiting device (16).

Owner:北京安居建研科技有限公司

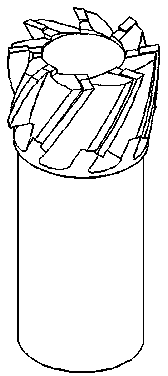

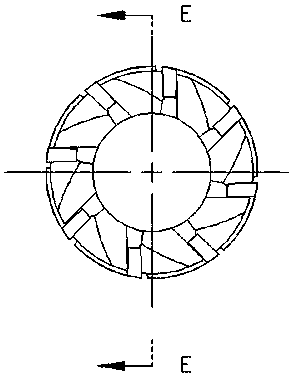

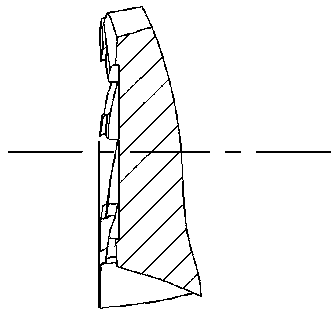

A finish-milling high-precision guide-surface welding type cemented carbide spiral end mill

The invention discloses a finish-milling high-precision guide-surface welding type cemented carbide spiral end mill. The end mill has a tooth number of 8-10 and is thick-teeth type. Adjacent blade angles are 36-45 degrees. Helix angles of adjacent blades of side blades are different, and are 35 degrees and 30 degrees respectively. The end mill is especially suitable for finish-milling four items, namely a lathe bed, a column, a carriage, a horizontal bearing-surface and a side bearing-surface, of a machine, wherein the horizontal bearing-surface and the side bearing-surface are used in a workbench for placing a precision linear rail. The end mill is also suitable for finish-milling a plane surface and a step surface, and is a cemented carbide spiral end mill belonging to finish machining and semi-finish machining numerical control. The end mill employs a new material as the material of the cemented carbide blade and geometrical parameters of the end mill blade change greatly. The horizontal bearing-surface and the side bearing-surface machined by the end mill have high precision, and meet drawing precision completely without needs of spading, scraping or finish grinding. The end mill has a long service lifetime and a low cost performance ratio. The price of the end mill is only one fourth of the price of import cutting tools. Machinability of the end mill is not worse than the same kind of import cutting tools having a brand of Japan OSG, SUMITOMO, etc..

Owner:江苏苏铃精工机械有限公司

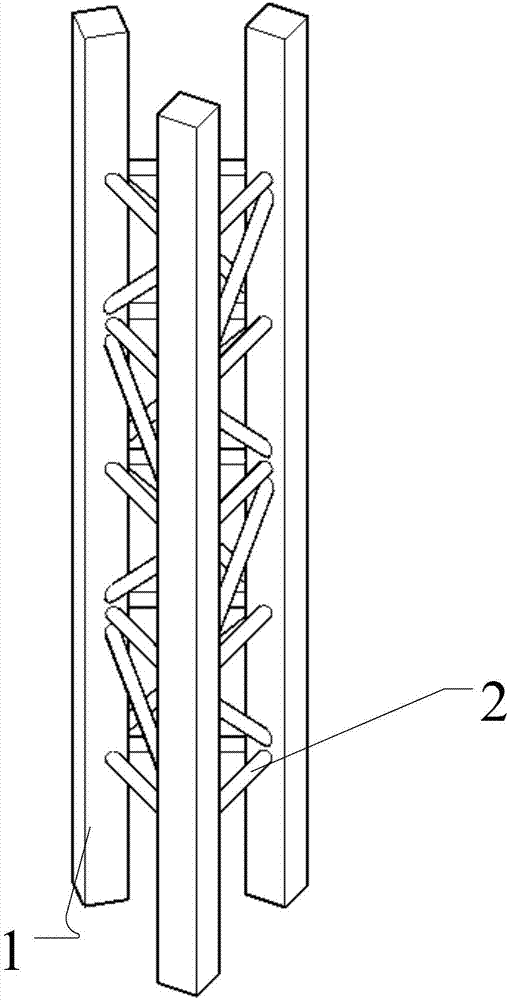

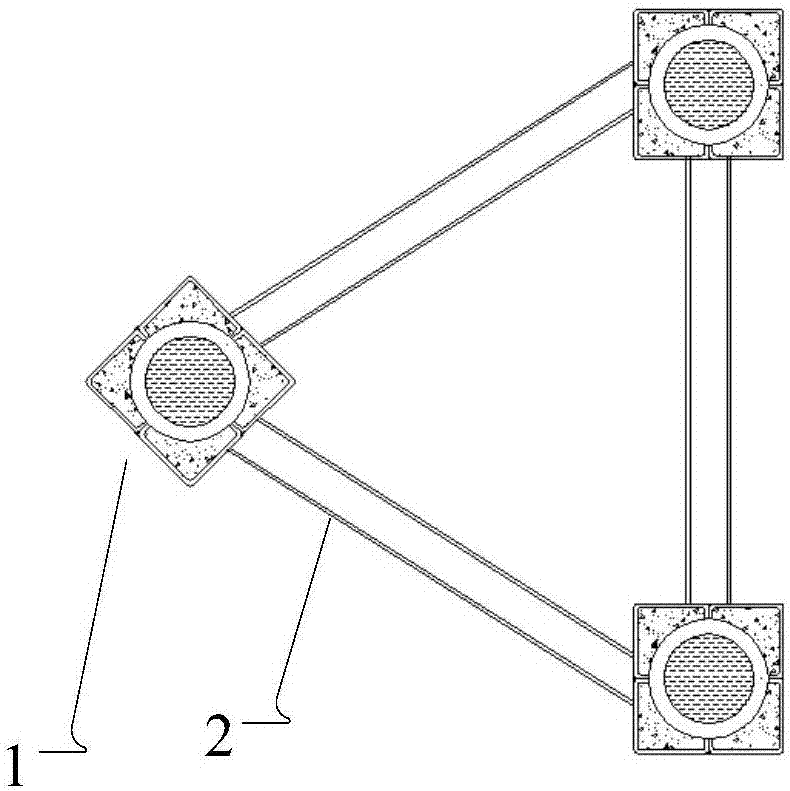

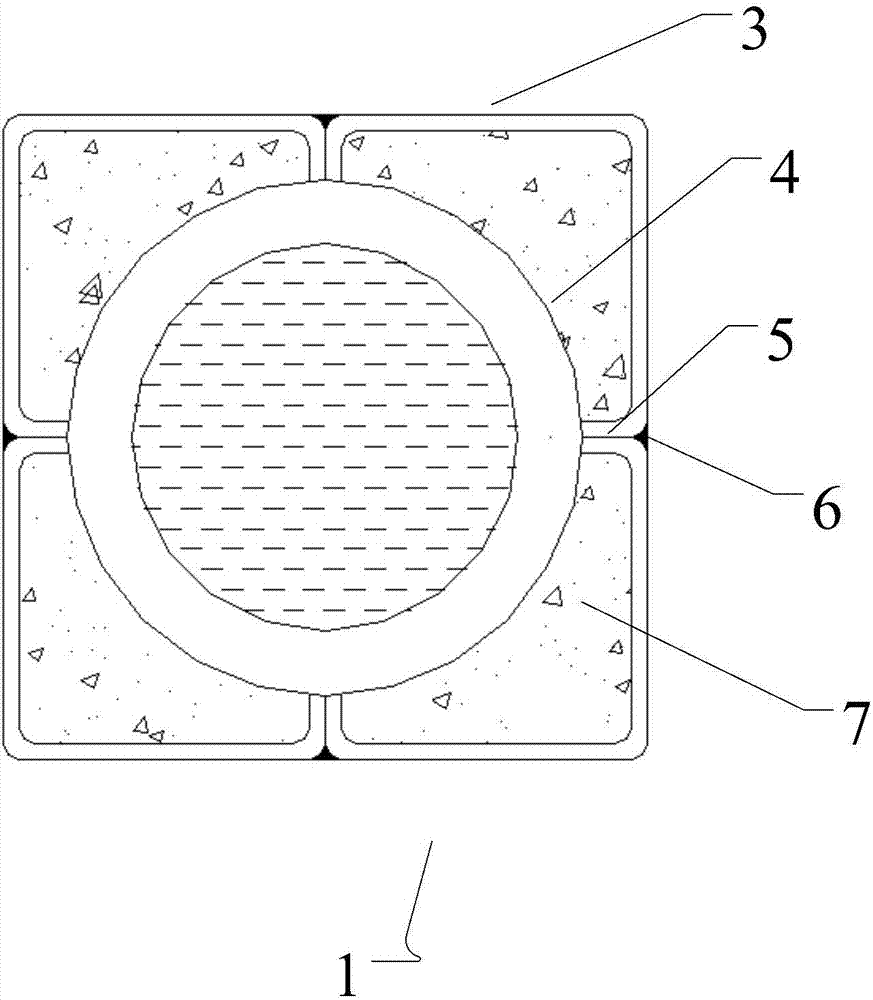

Self-elevating novel latticed pile leg for ocean platform

InactiveCN107165147AIncrease section sizeEasy to installArtificial islandsUnderwater structuresShock resistanceEngineering

The invention discloses a new lattice type pile leg of a self-elevating offshore platform, comprising a pile leg body arranged in parallel with a triangle, and is characterized in that: the pile leg body comprises a square steel pipe, and the inside of the square steel pipe is arranged along the length direction The stiffening rib is welded with a circular steel pipe, the interior of the circular steel pipe is hollow with water, and the space between the square steel pipe and the circular steel pipe is filled with concrete. The novel lattice type pile legs of the self-elevating offshore platform of the invention have the characteristics of high stability, strong bearing capacity, low cost, strong corrosion resistance, excellent seismic resistance, convenient maintenance and long service life.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

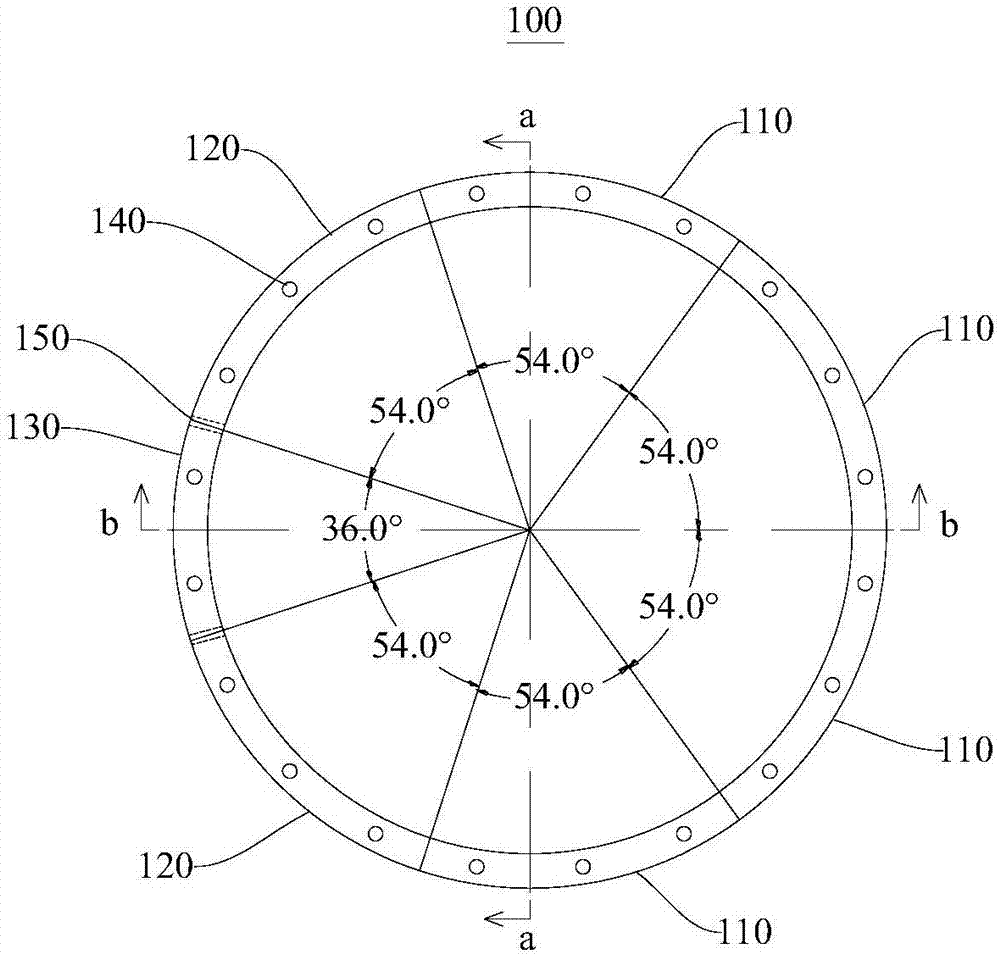

Shield tunnel lining ring suitable for quick metro lines

PendingCN106948837AIncrease section sizeMeet large size requirementsUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a shield tunnel lining ring suitable for quick metro lines. The lining ring is in a 4+2+1 block type and comprises 4 standard blocks, 2 adjacent blocks and 1 top sealing block, wherein the four standard blocks are spliced together, the two adjacent blocks are each connected to the two sides of the four standard blocks, and the top sealing block is connected between the two adjacent blocks, central angles of the standard blocks and the adjacent blocks are 54 degrees, and a central angle of the top sealing block is 36 degrees. The shield tunnel lining ring suitable for quick metro lines disclosed by the invention can meet a requirement of quick metro for the tunnel lining ring, and the provided block type is convenient to construct and has high longitudinal rigidity and good stability.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com