Welding technique of electric resistance welding and stud welding of unmatched materials

A welding technology, resistance welding technology, applied in the direction of resistance welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of low metal resistance, inability to weld, mismatching welding materials, etc., to improve contact resistance, improve weldability, The effect of improving weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

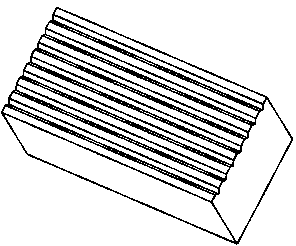

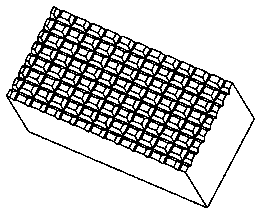

[0028] Resistance spot welding: welding of two-layer boards, after roughening the welding surface of the thicker board (such as figure 1 , figure 2 ), and then solder. If the plates are thicker, roughen the welding surfaces of the plates before welding. For the welding of three-layer boards and four-layer boards, roughen the plates on all welding surfaces (the upper and lower sides of the middle plate are roughened, and the plates on the outer two sides are only roughened on the welding surface. Thinner plates can not be roughened), and then welded.

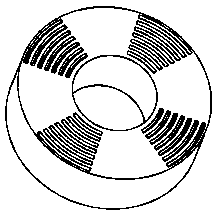

[0029] Resistance projection welding: When welding, only the welding surface of the plate can be roughened (such as image 3 , Figure 4 , Figure 5 ), or only on the nut (eg Figure 6 ) bumps can be roughened, and the bumps of the sheet and projection welding nuts (or bolts) can also be roughened at the same time, depending on the thickness of the sheet and the size of the bumps.

[0030] Resistance butt welding: when wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com