Patents

Literature

563 results about "Stud welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stud welding is a technique similar to flash welding where a fastener or specially formed nut is welded onto another metal part, typically a base metal or substrate. The fastener can take different forms, but typically fall under threaded, unthreaded, or tapped. The bolts may be automatically fed into the stud welder. Weld nuts generally have a flange with small nubs that melt to form the weld. Weld studs are used in stud welding systems. Manufacturers create weld studs for the two main forms of stud welding: capacitor discharge stud welding and drawn arc stud welding...

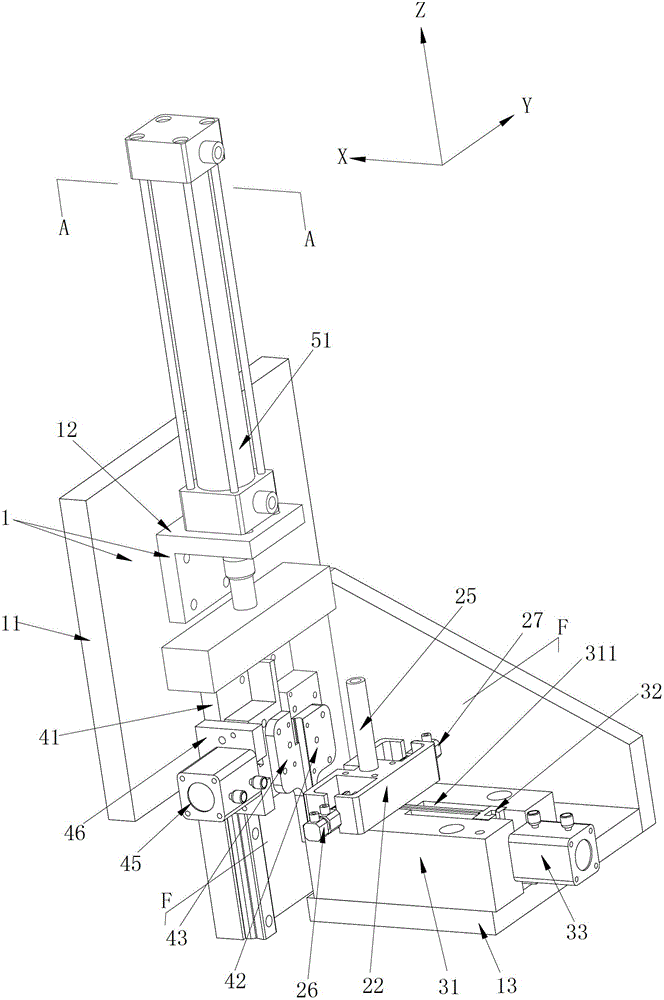

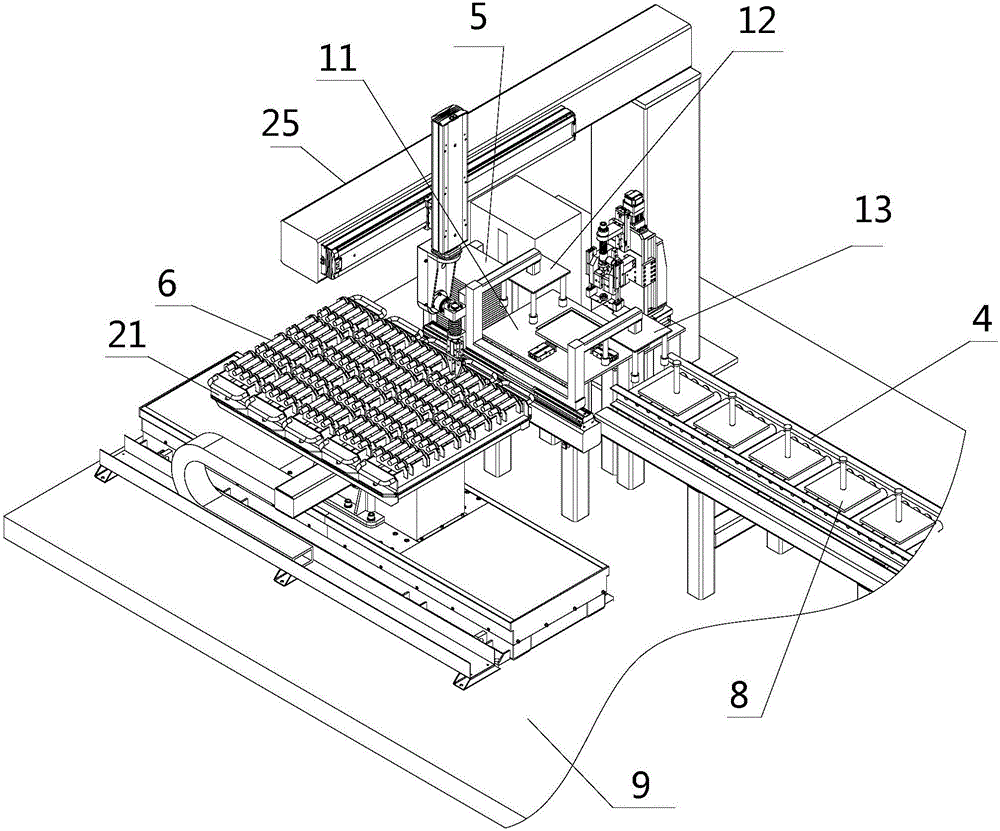

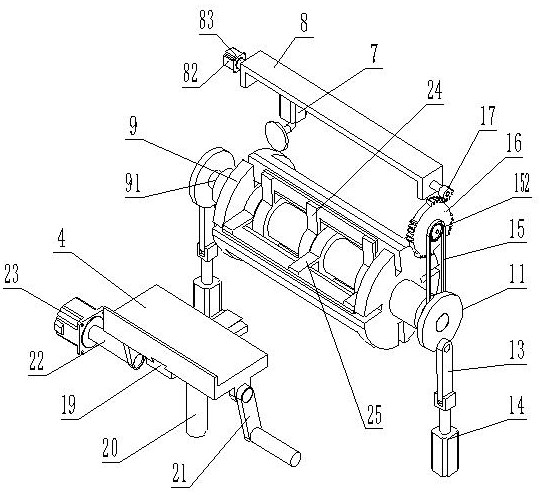

Stud flexible welding device and method

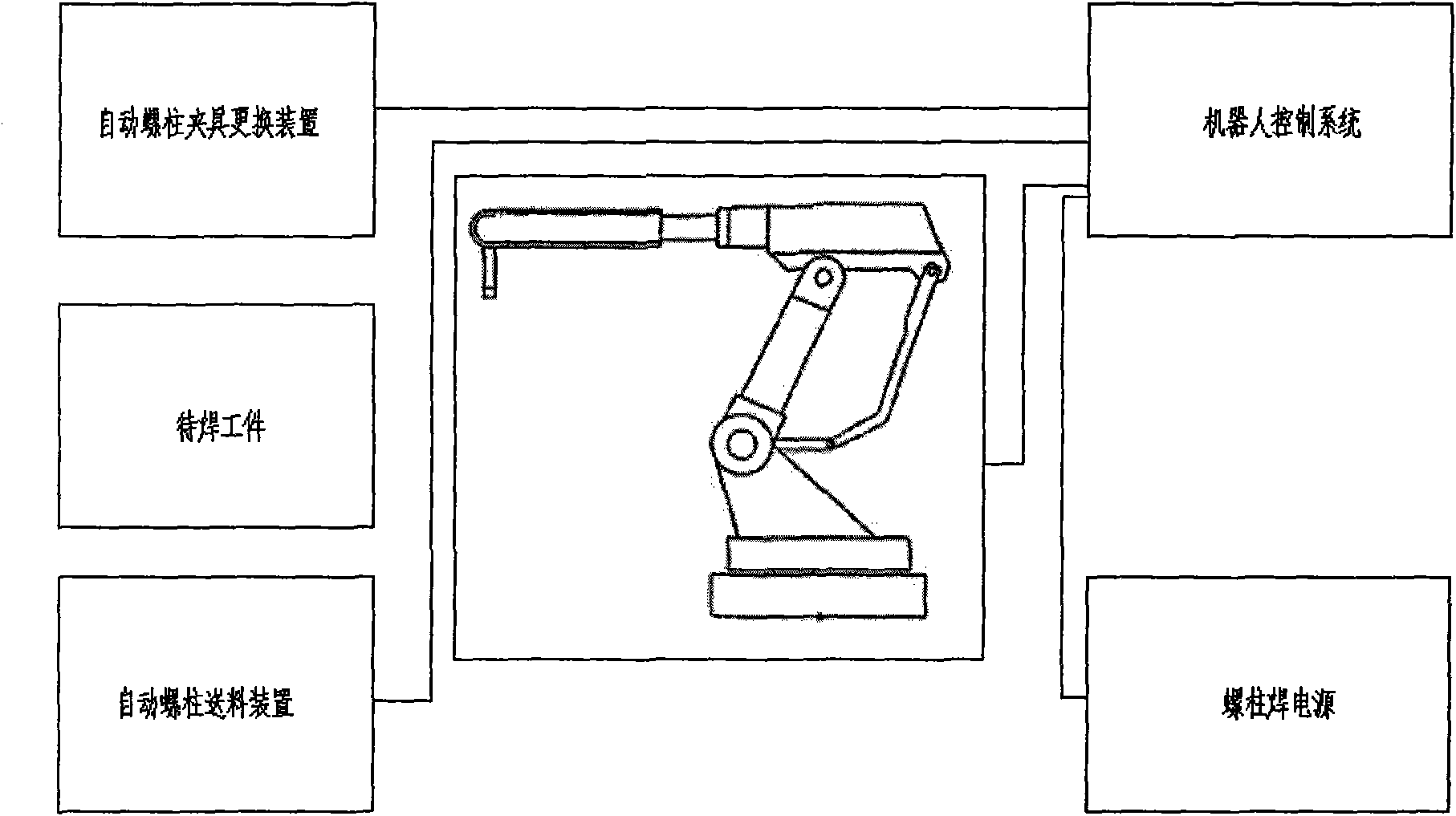

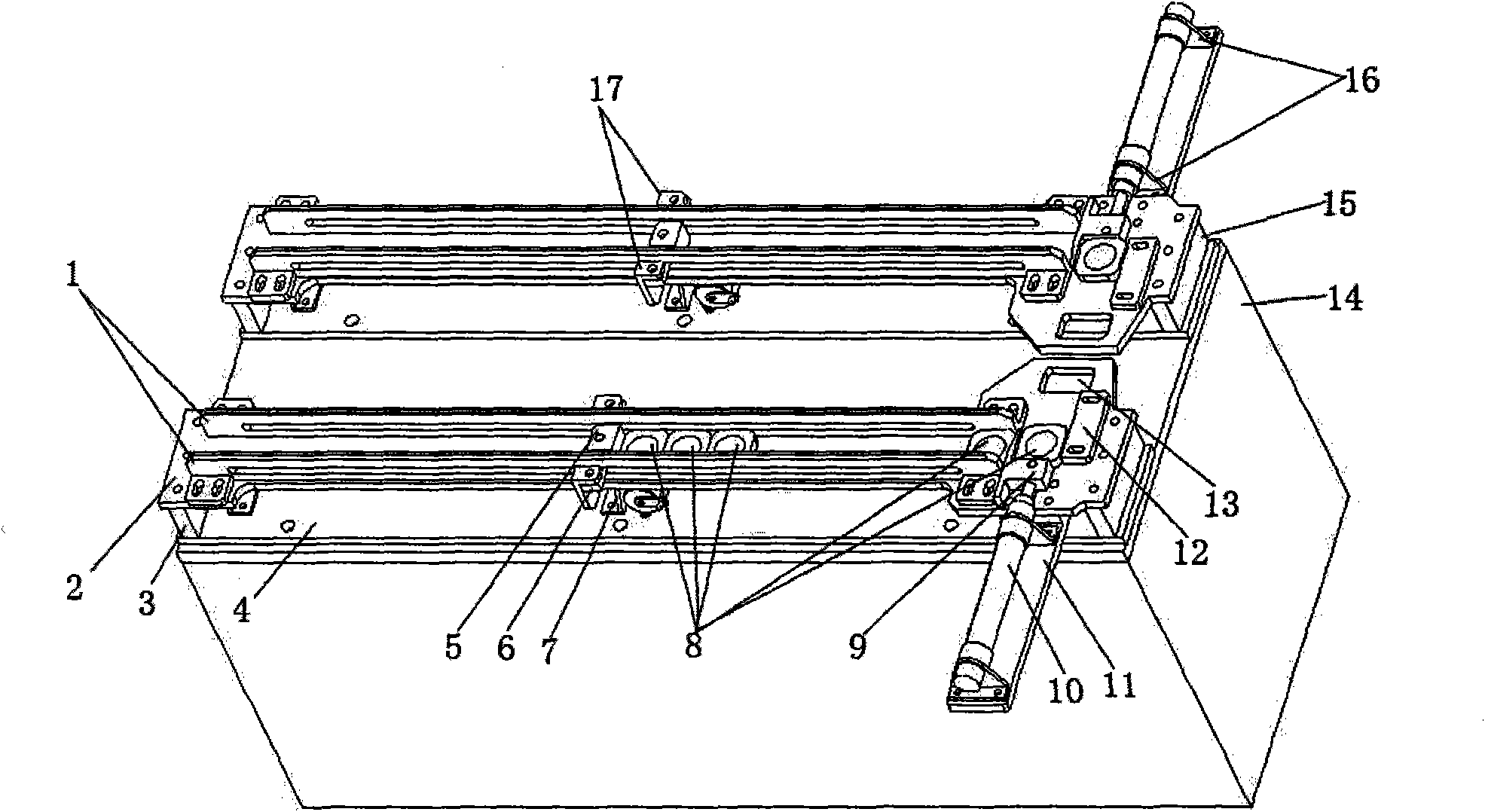

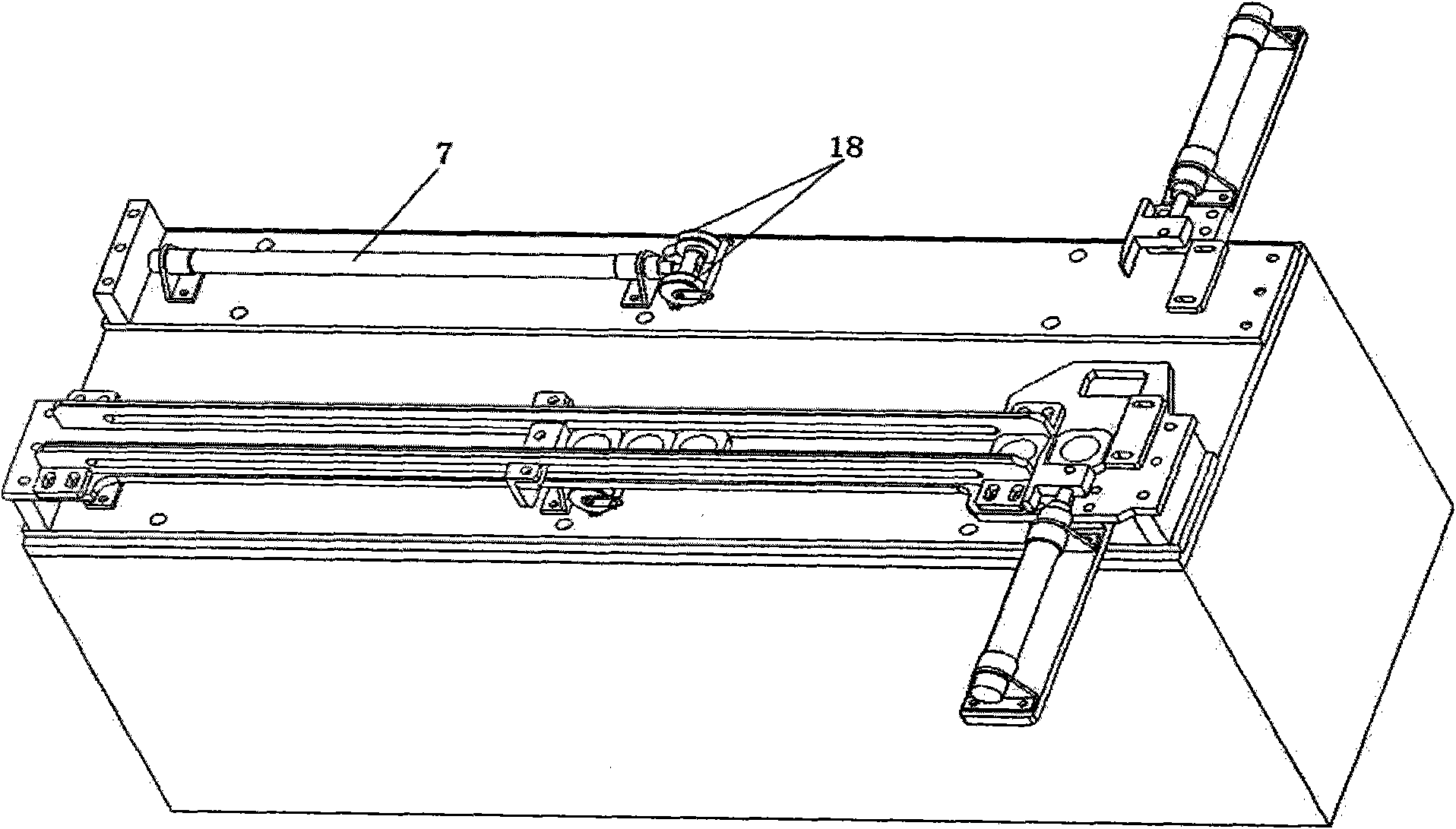

ActiveCN102114568ARealize automatic clampingLarge size spanArc welding apparatusControl systemControl signal

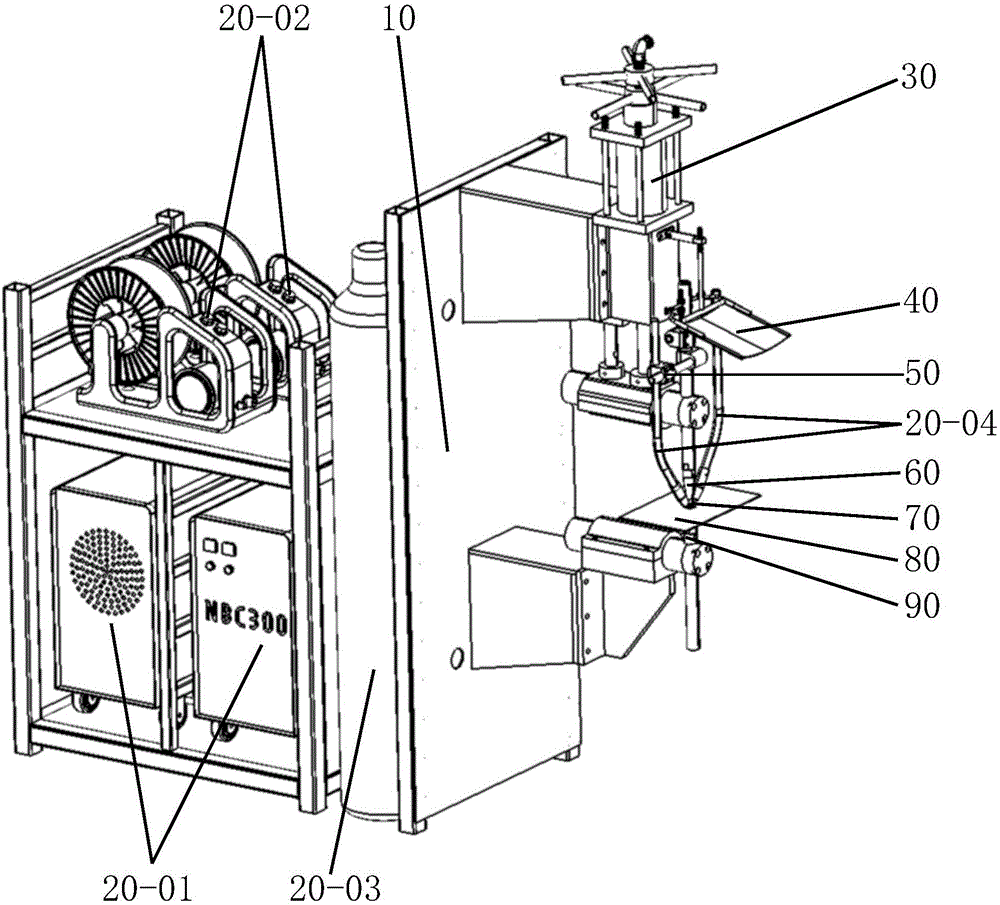

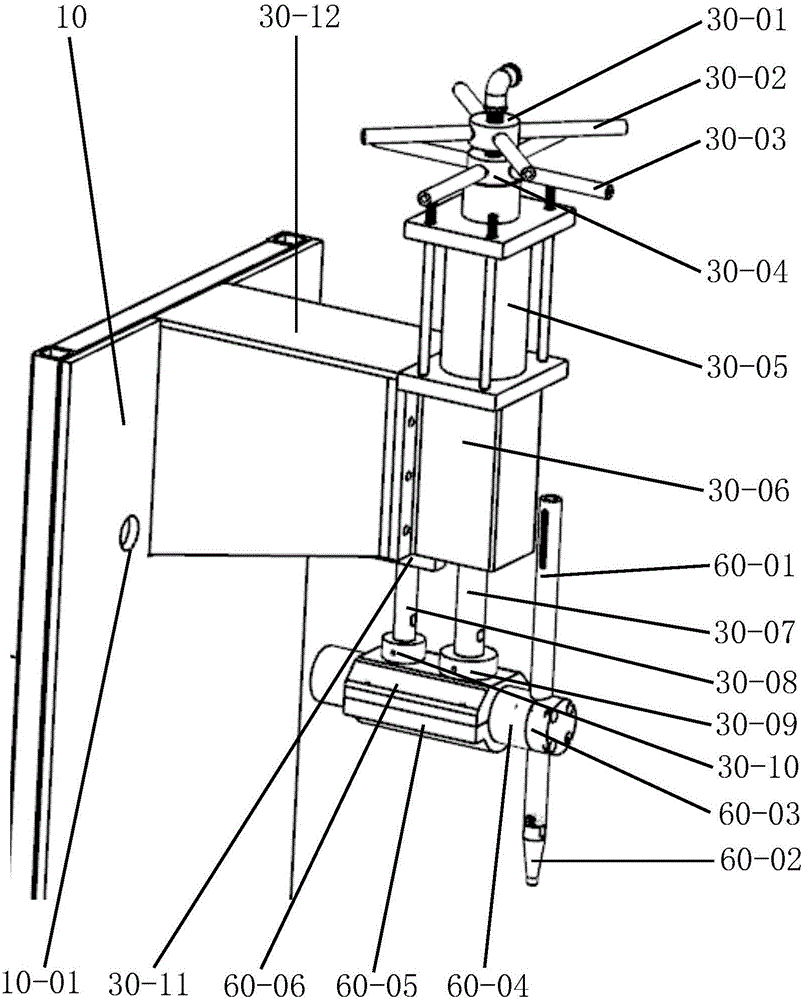

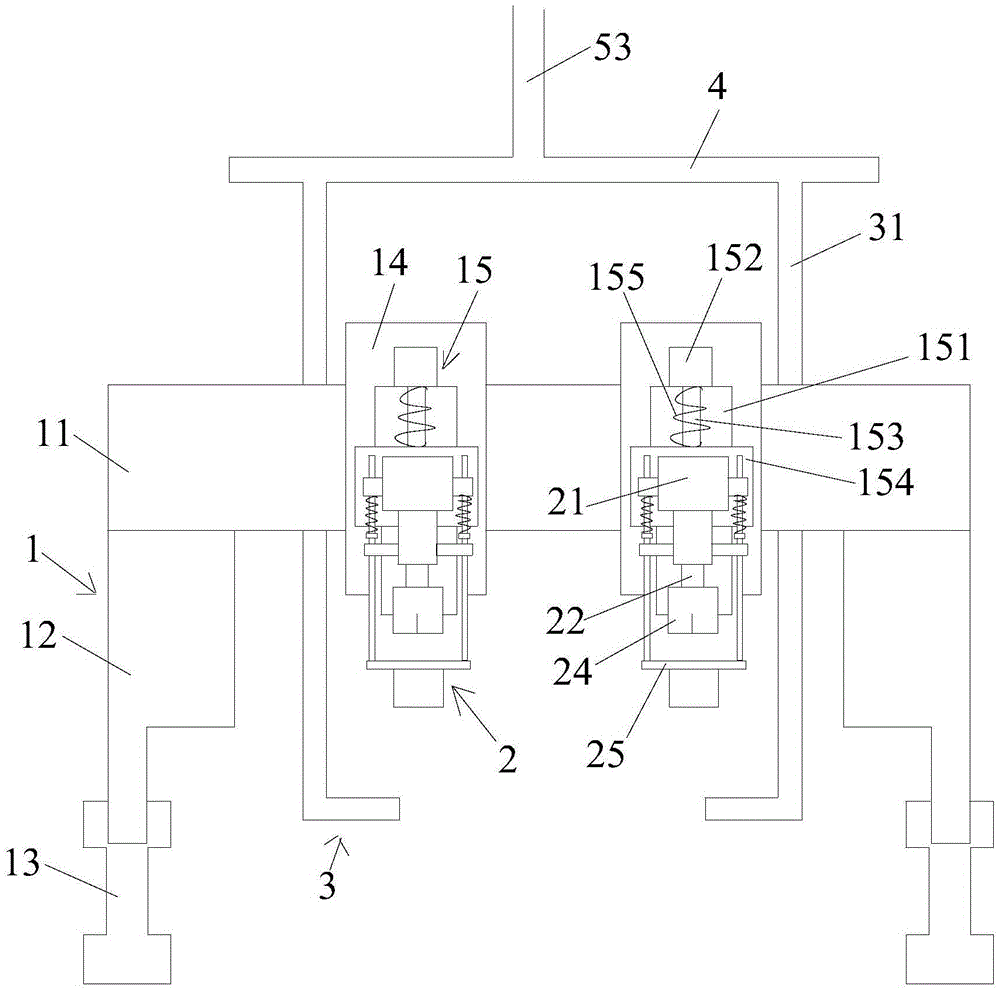

The invention discloses a stud flexible welding device and method. The stud flexible welding device comprises a welding robot, a robot control system, an automatic stud welding gun, an automatic stud feeding device, an automatic stud welding and clamping device and an automatic stud welding jig replacing device, wherein the welding robot, the automatic stud welding gun, the automatic stud feeding device, the automatic stud welding and clamping device and the automatic stud welding jig replacing device are connected with the robot control system to receive a control signal of the robot control system; the automatic stud feeding device is used for conveying studs; the automatic stud welding and clamping device is used for setting precompression amount required in an automatic clamping and welding process of studs and ceramic rings; and the automatic stud welding jig replacing device is used for assembling and disassembling the automatic stud welding and clamping device. The invention can be used for carrying out automatic feeding.

Owner:NANJING UNIV OF SCI & TECH

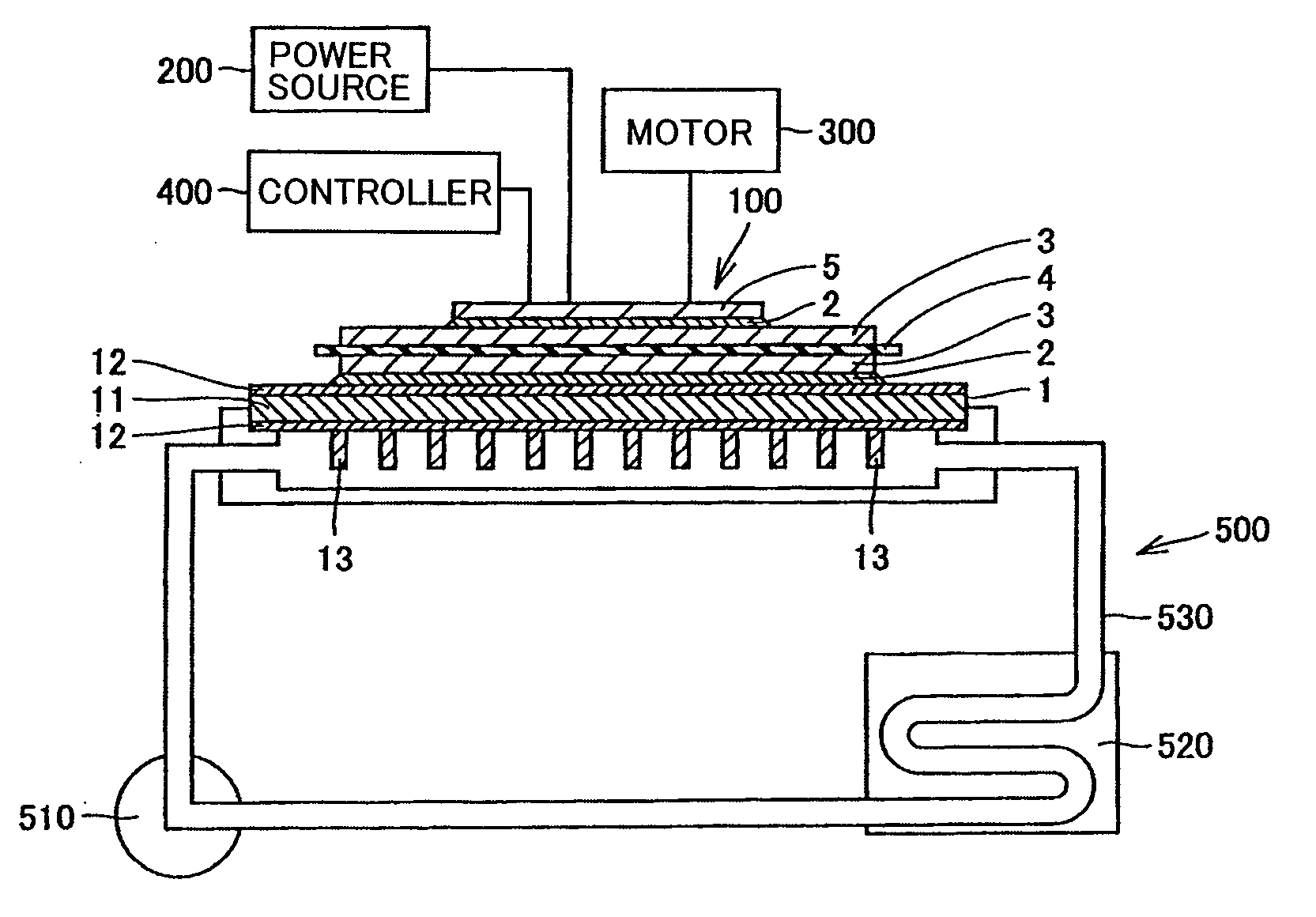

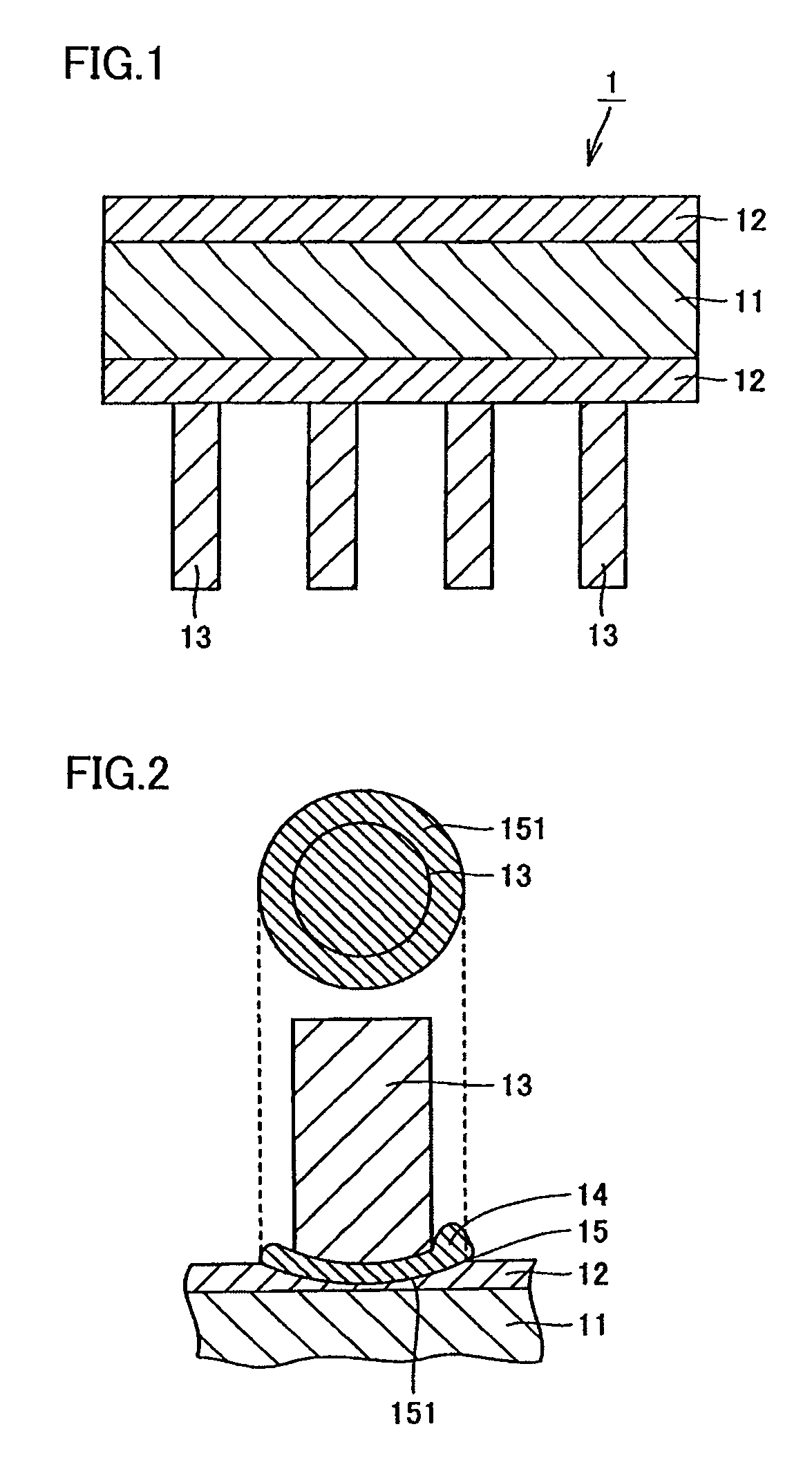

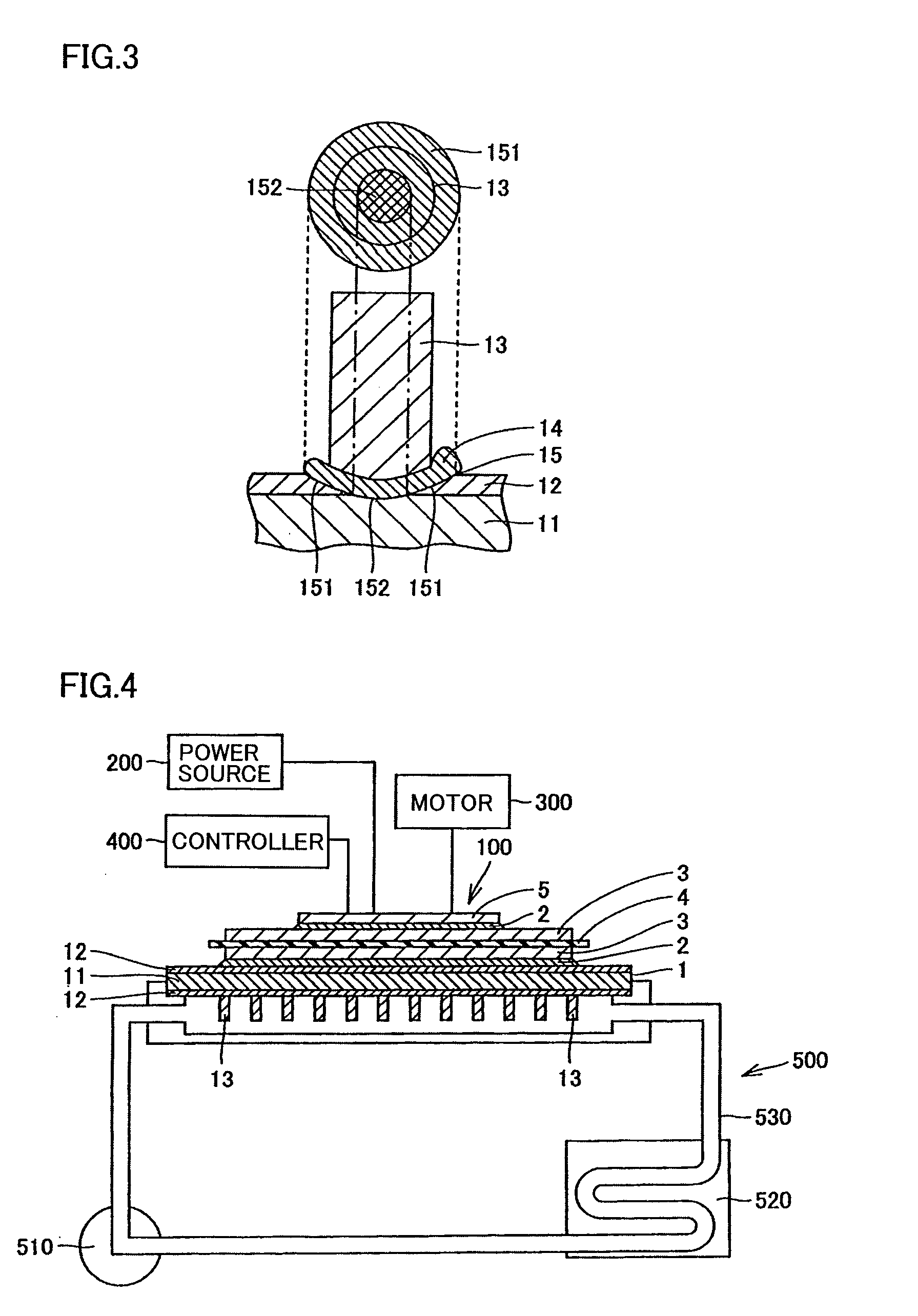

Heat spreader for semiconductor device and method for manufacturing the same

InactiveUS20100206537A1Avoid easy fracturingAvoid breakingSemiconductor/solid-state device detailsSolid-state devicesSurface layerAlloy

Provided are a heat spreader for a semiconductor device, which can be joined such that a multitude of pin-shaped fins are not easily fractured even when the heat spreader for a semiconductor device is incorporated in a heat dissipation structure for a semiconductor device, in which direct cooling is performed by using water, and a method for manufacturing the heat spreader for a semiconductor device. The heat spreader (1) for a semiconductor device comprises: a plurality of columnar members (13) joined onto at least one of surfaces of a plate-like member (11, 12) by stud welding; and a joining layer (14) formed between the plate-like member (11, 12) and the columnar members (13). The plate-like member (11, 12) includes a base material (11) and surface layers (12). The surface layers (12) and the columnar members (13) are made of a material containing aluminum or an aluminum alloy. A thickness of the plate-like member (11, 12) is 0.5 mm through 6 mm and a thickness of each of the surface layers (12) is 0.1 mm through 1 mm. The joining layer (14) has a joining interface (15) on a boundary with the plate-like member (11, 12). A proportion of an area of the joining interface (15) being present in the surface layer (12) is greater than or equal to 50% and less than or equal to 100%, converted in terms of a plane projected to the one of the surfaces of the plate-like member.

Owner:ALLIED MATERIAL

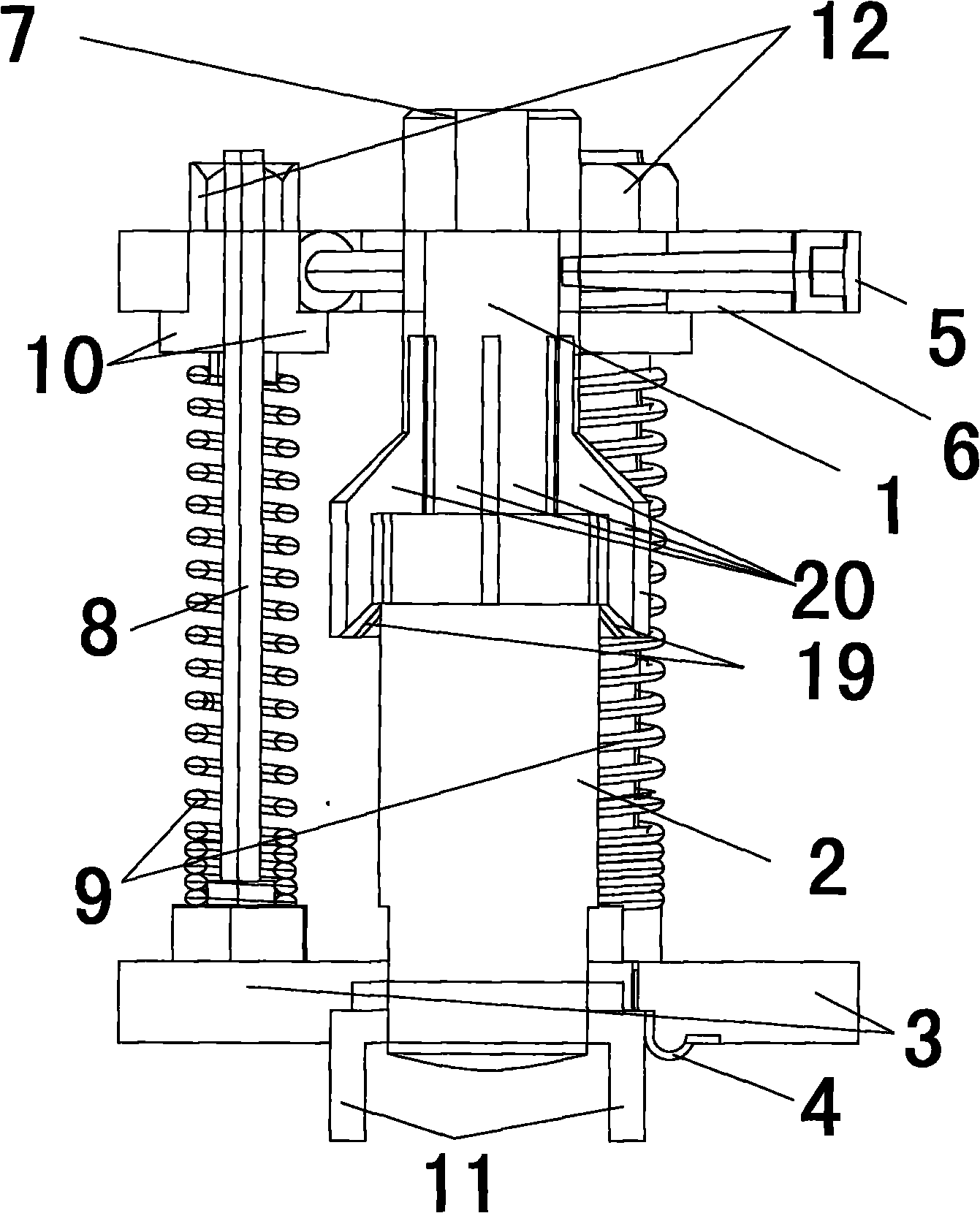

Arc stud welding gun and the welding method thereof

InactiveCN101032779AControllable movementGuaranteed upsetting forceElectrode supporting devicesElectrical resistance and conductanceElectricity

The present invention discloses one kind of stud welding gun with force measuring sensor and its welding process. During welding and after the stud moves to contact with the workpiece, the contact force is transmitted through the resistance strain gage in the pressure sensor, which is connected be the rotating mechanism of the welding gun and the stud fixture, to the data acquiring card of the control computer. After the detected contact force reaches the set value, the welding current to the stud fixture is turned on, the motion controller connected electrically to the motor makes the motor rotate reversely and the stud is raised for ignite electric arc. During welding feed, the welding current is first turned off, the motion controller drives the motor to rotate and the stud is fed to the workpiece; and after the detected feeding pressure of the stud to the workpiece reaches the set value, the motor is stopped.

Owner:XI AN JIAOTONG UNIV

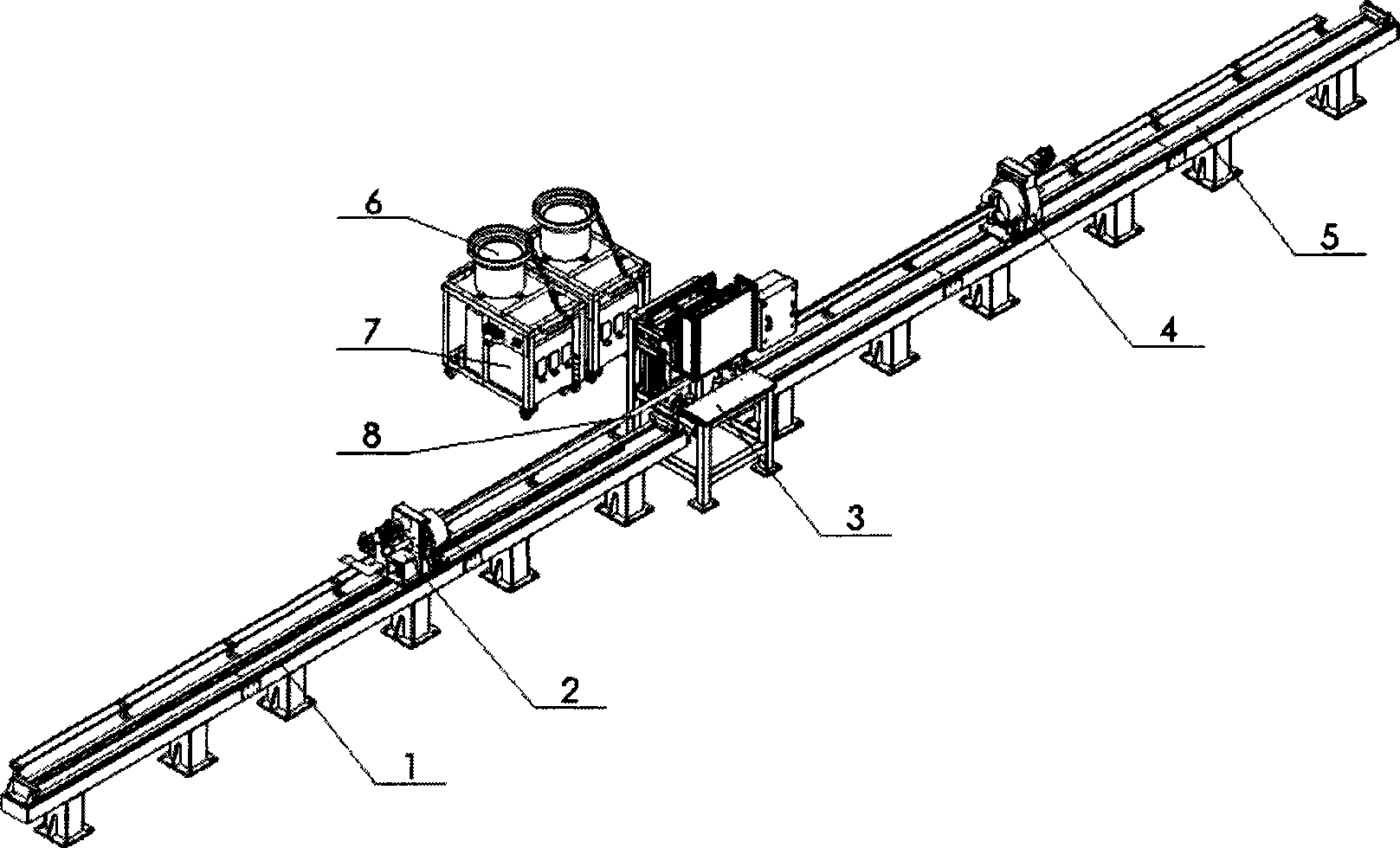

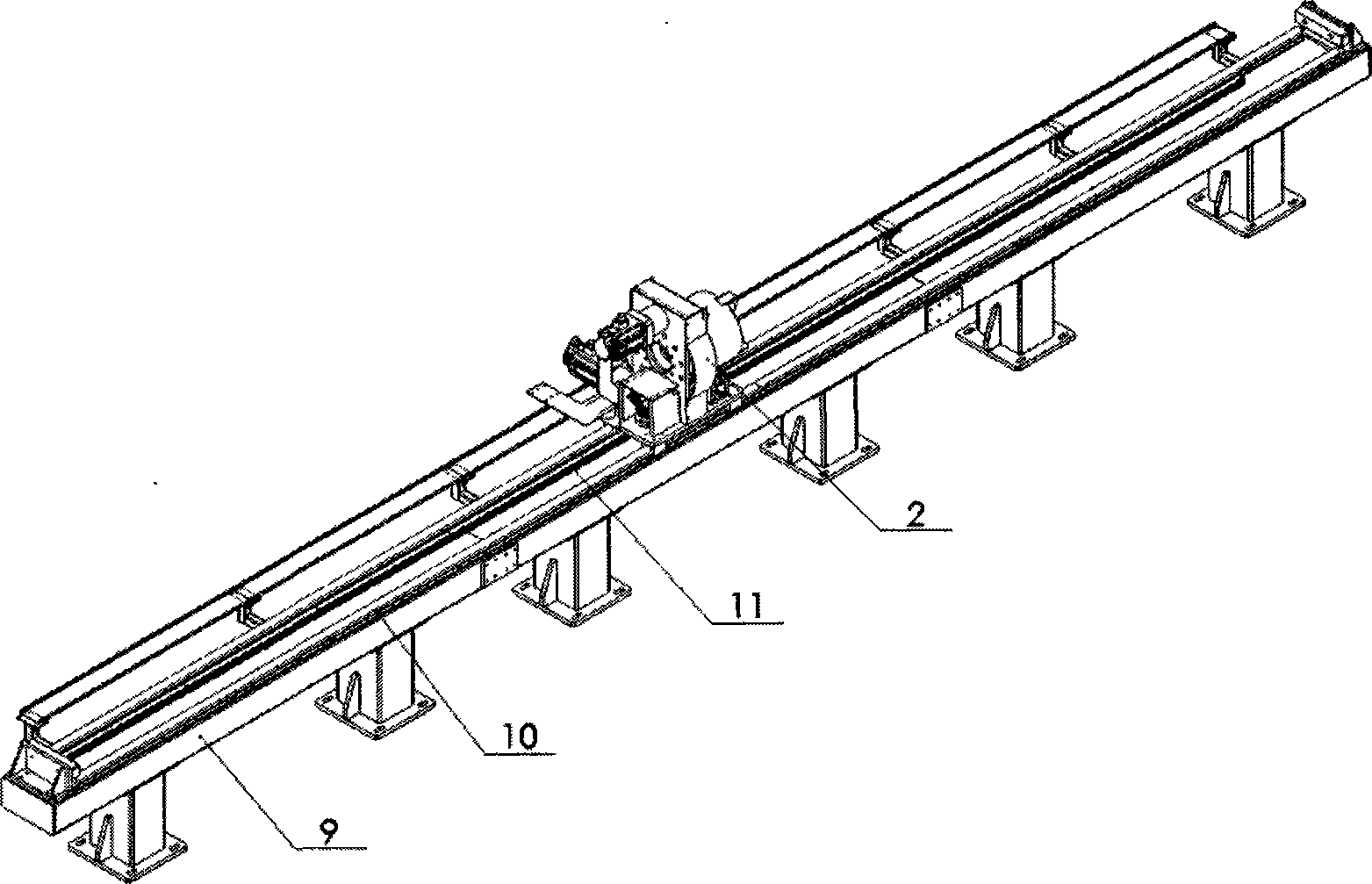

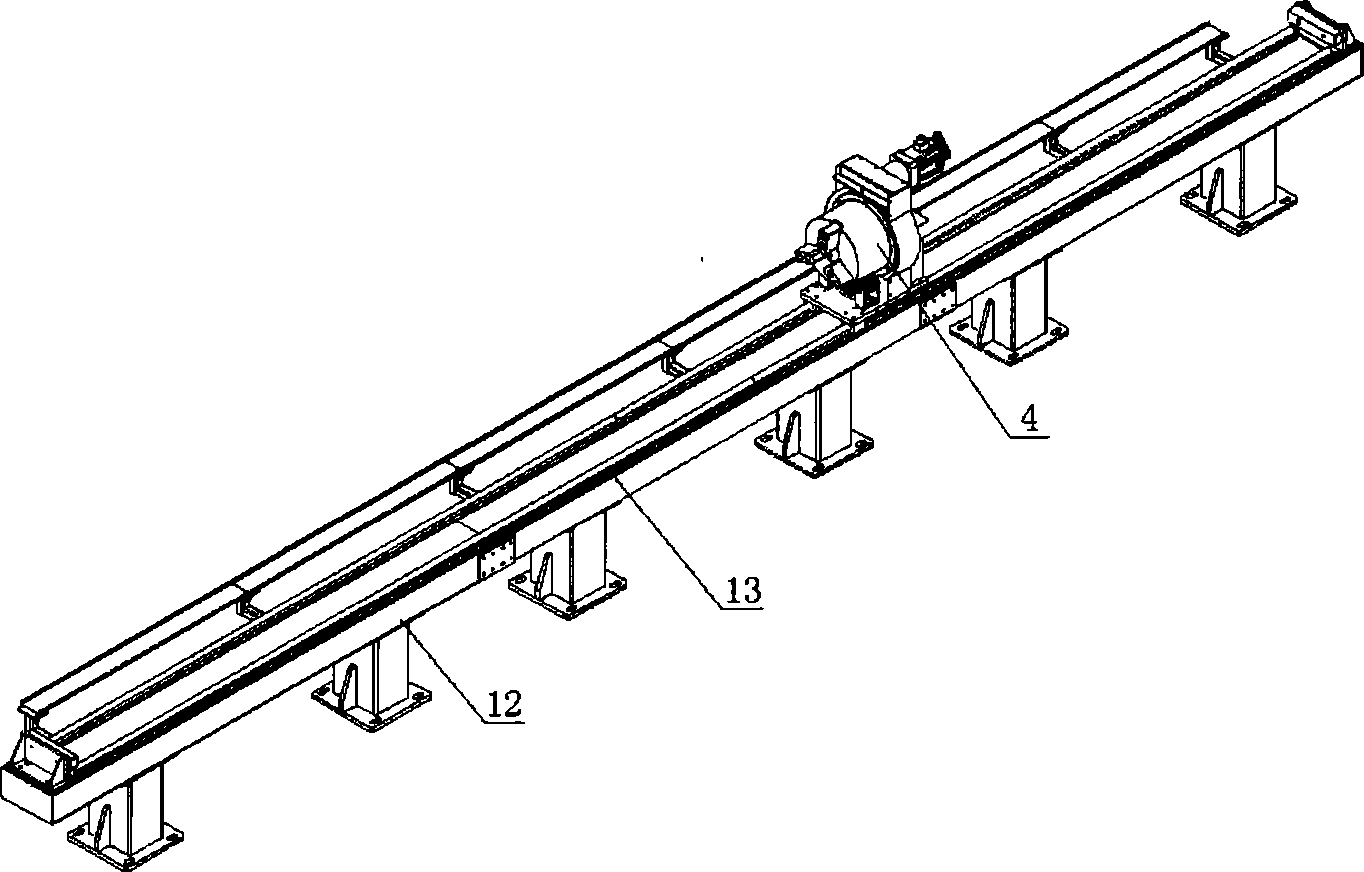

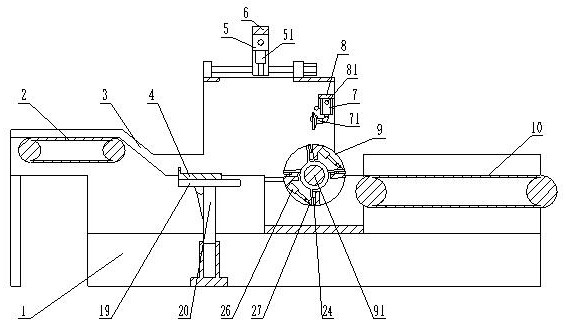

Full-automatic single-tube pin welding device

ActiveCN101422844AFully automatedReduce torsional deformationWelding accessoriesStud weldingEngineering

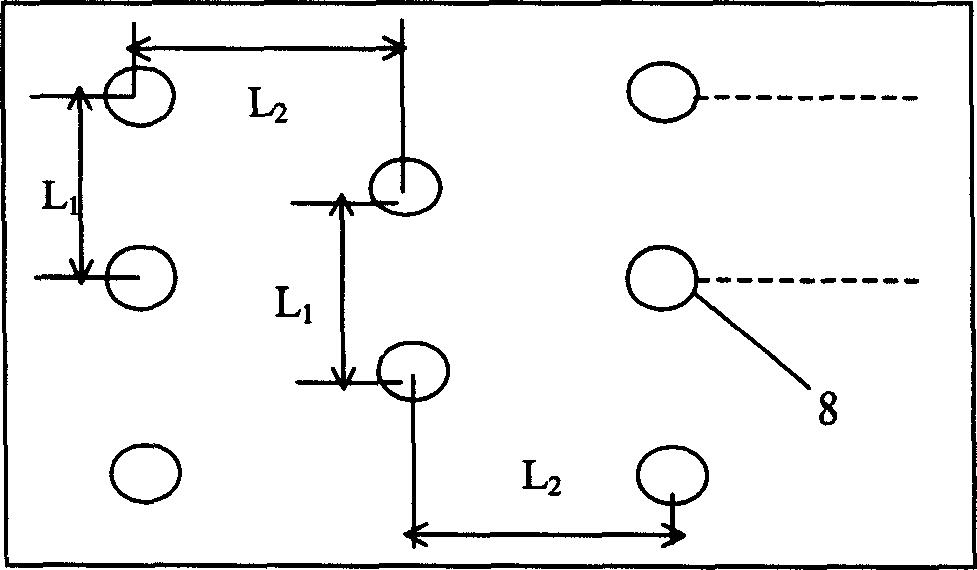

The invention relates to a full-automatic single tube and pin welding machine which belongs to the technical field of welding, and the welding machine comprises a machine bed at a driving end, a machine bed at a driven end, a driving feeding mechanism, a welding operation machine, a driven feeding mechanism, an automatic charging mechanism and a welding host. The driving feeding mechanism and the driven feeding mechanism realize the horizontal feeding of a welded steel pipe along the longitudinal direction of the welding machine and the radial rotary feeding motion of the steel pipe, the welding operation machine is provided with a pneumatic welding fixture and two automatic stud welding guns, the pneumatic welding fixture realizes the holding and positioning of the steel pipe according to production tact in the welding process, and the horizontal distance between the two stud welding guns and the vertical distance between the automatic stud welding guns and the welded steel pipe are adjustable. The automatic charging mechanism realizes the automatic pin charging process. The welding machine has simple structure, the feeding motion of two degrees of freedom can be realized by a servo motor, the positioning precision is high, the clamping action of the welding fixture and the charging process are pneumatically controlled, and the operation is convenient. The welding machine can complete pin welding operation automatically or manually.

Owner:EUROCRANE

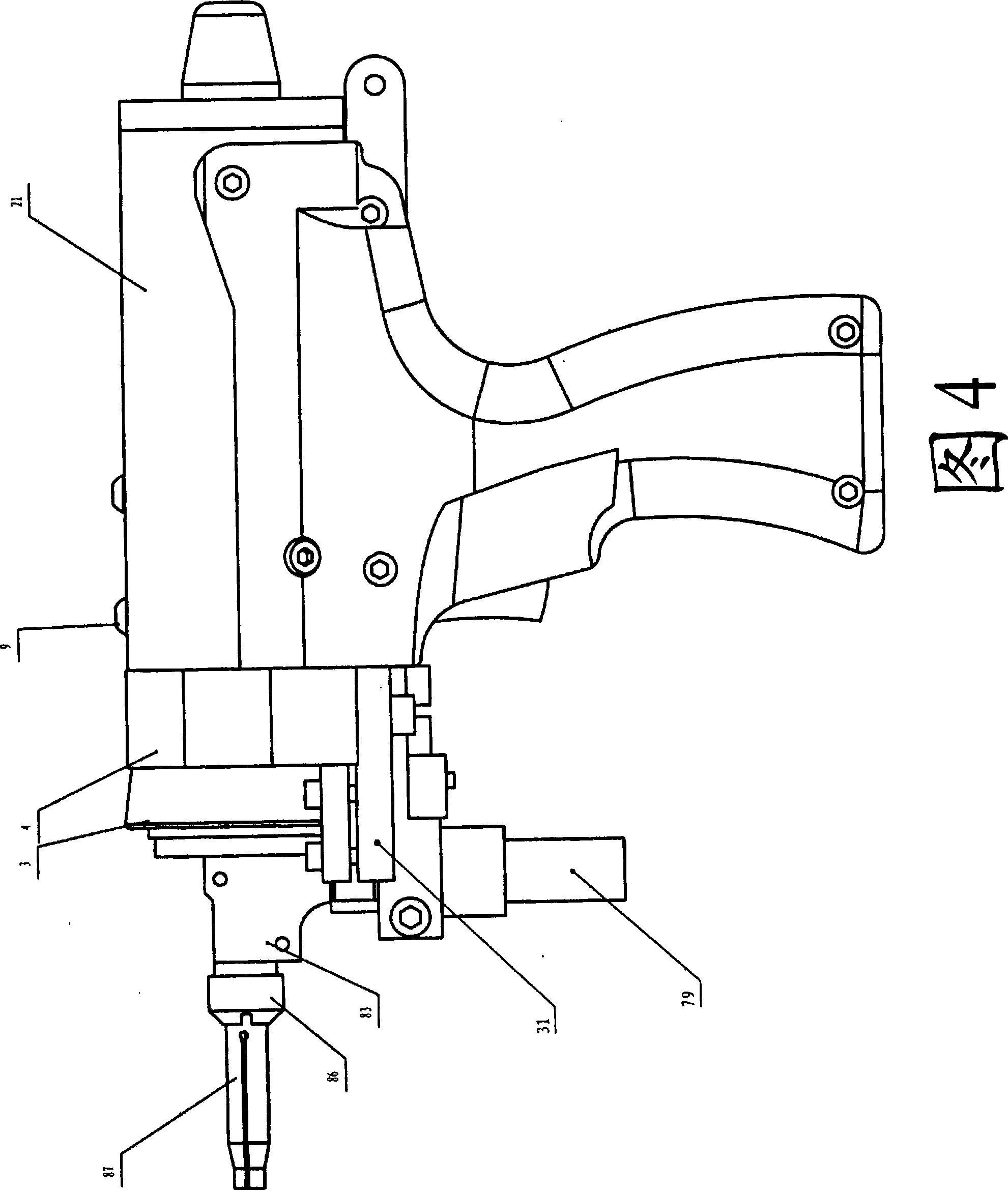

Arc discharge type double-screw bolt welding gun

InactiveCN101376193ARealize automatic feedingRealize chargingElectrode supporting devicesEngineeringStud welding

The invention discloses a drawn-arc type stud welding gun, which comprises a fixed component and a movable component. A stud receiver component and a cylinder piston component are arranged at the middle part of the movable component; the stud receiver component is mounted at the front end of the cylinder piston component, and an arc-shaped screw transporting slide is formed therein; a conducting clamping head of the receiver component is mounted in front of the stud receiver component, the penetrating inner hole thereof is communicated with a screw outlet port of the arc-shaped screw transporting slide and a screw inlet port of the arc-shaped screw transporting slide of the receiver component is communicated with the outside of the welding gun; and a piston rod of the cylinder piston component is coaxial with the inner hole of the conducting clamping head; and when the piston of the cylinder piston component moves forward, the piston rod thereof enters the inner hole of the conducting clamping head through the arc-shaped screw transporting slide of the stud receiver component, and the air passage of the cylinder piston component is communicated with the outside of the welding gun. The drawn-arc type stud welding gun can realize the automatic feeding and loading of the stud welding screws after the automatic feeding device is connected with the stud welding power source, thereby greatly improving the welding speed of the stud welding screws and reducing the labor intensity of workers at the same time.

Owner:SHENZHEN HONGBAI TECH IND

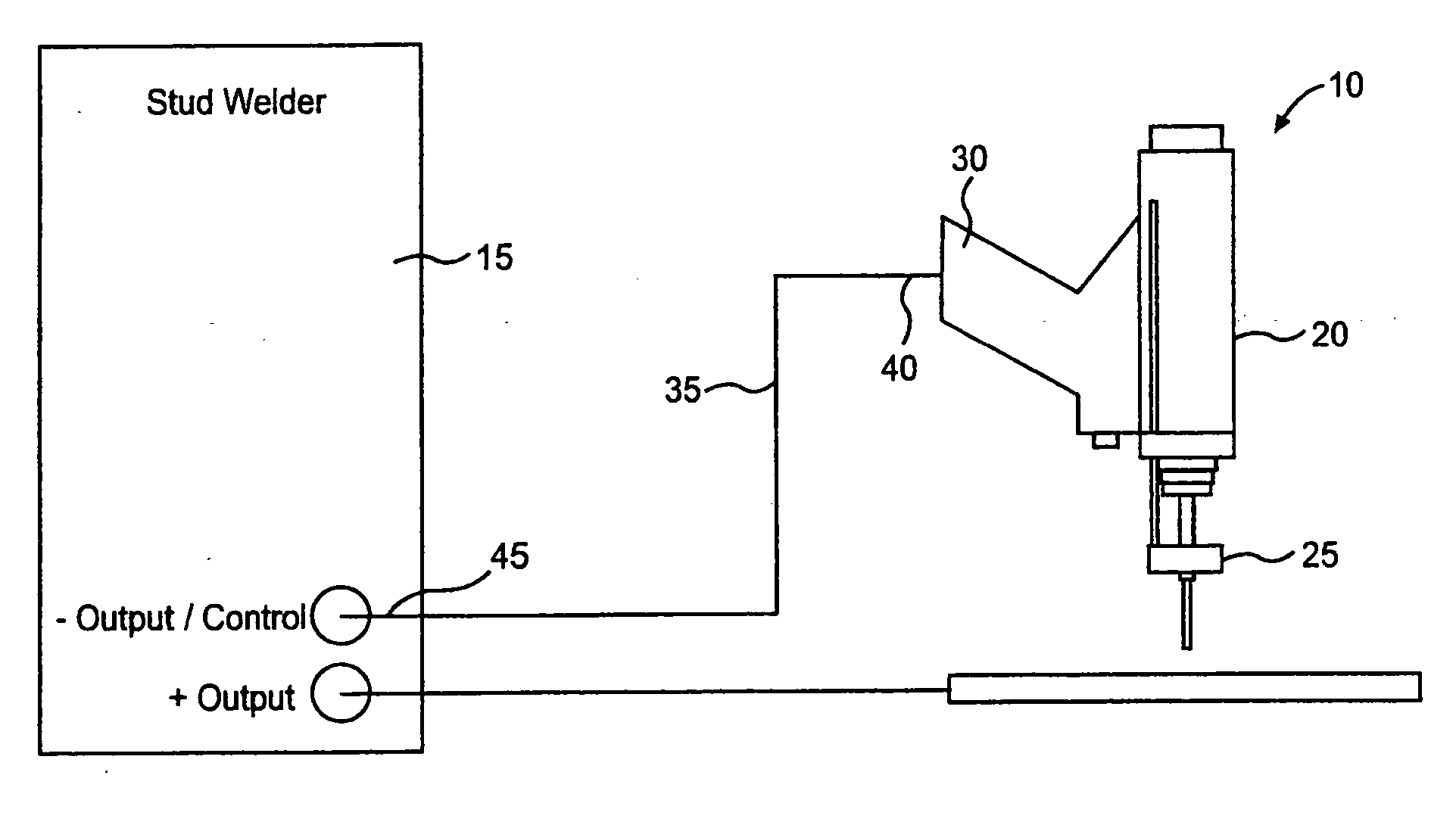

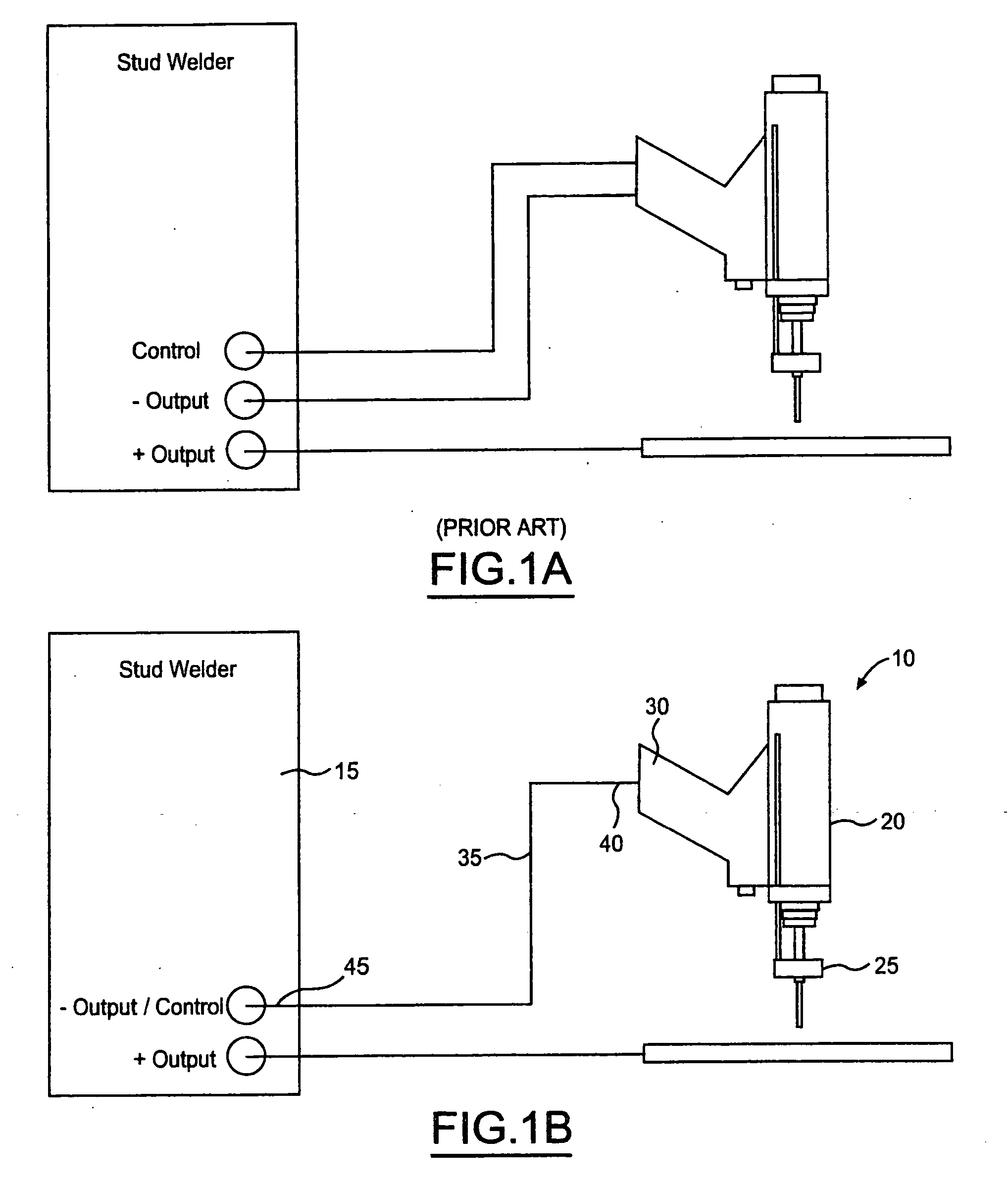

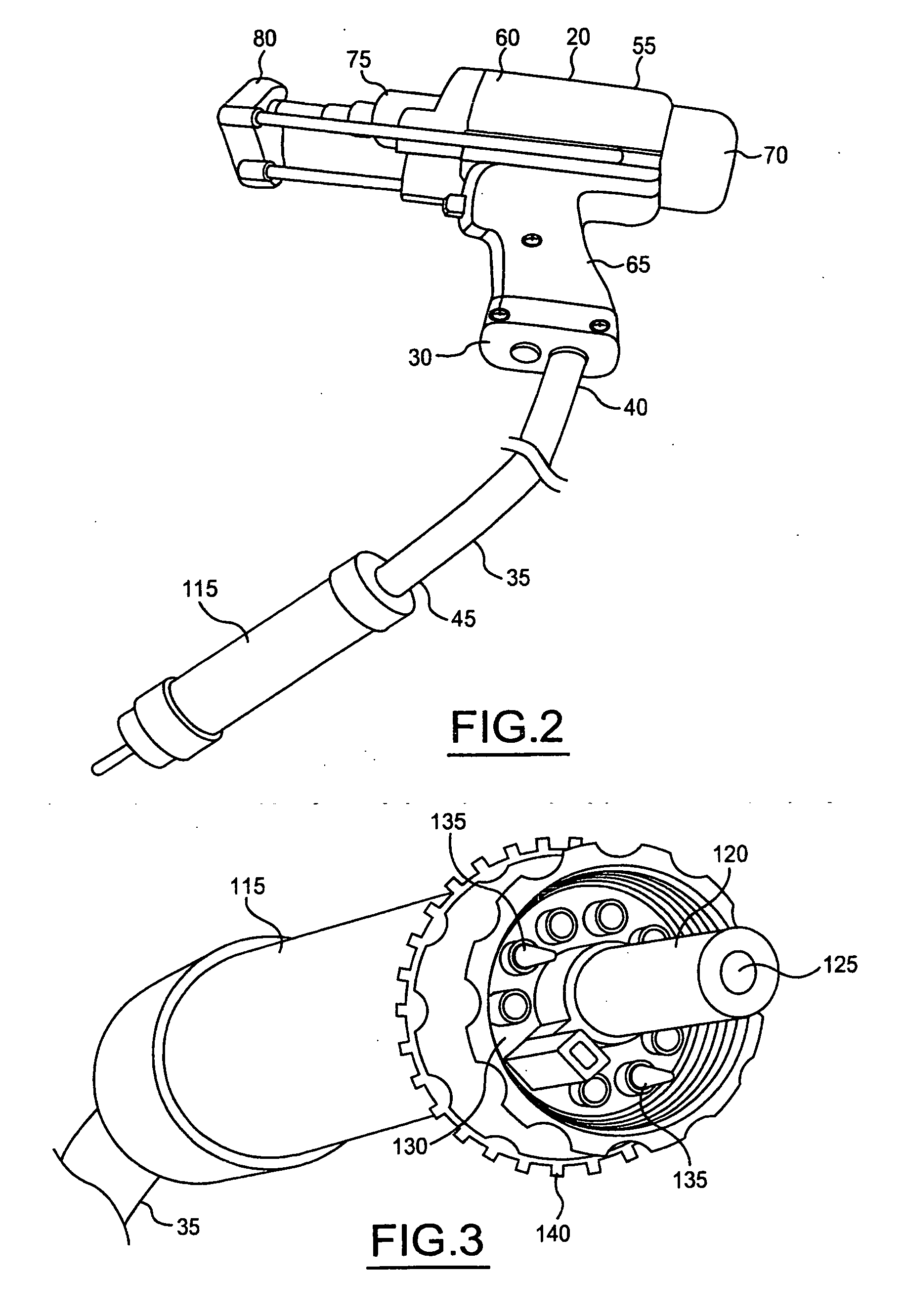

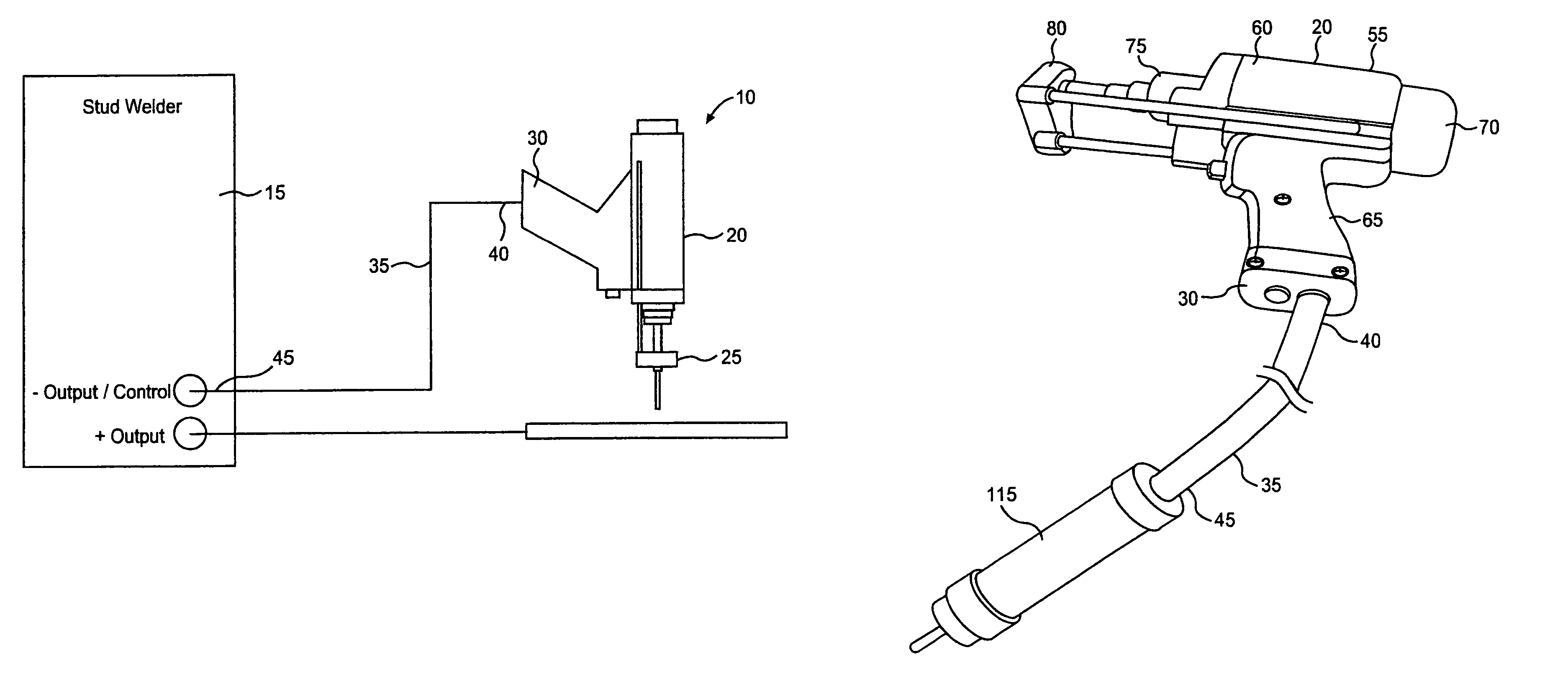

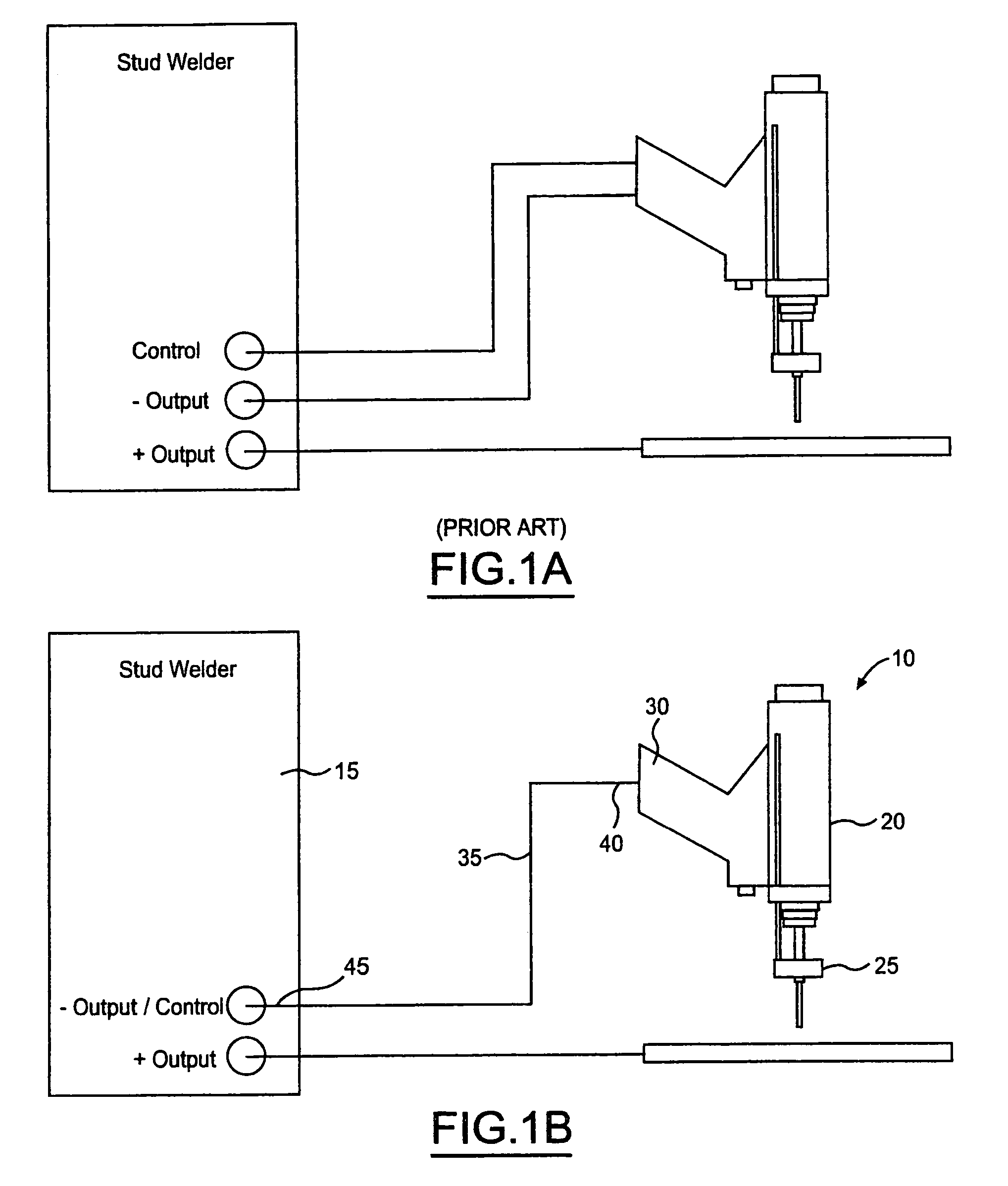

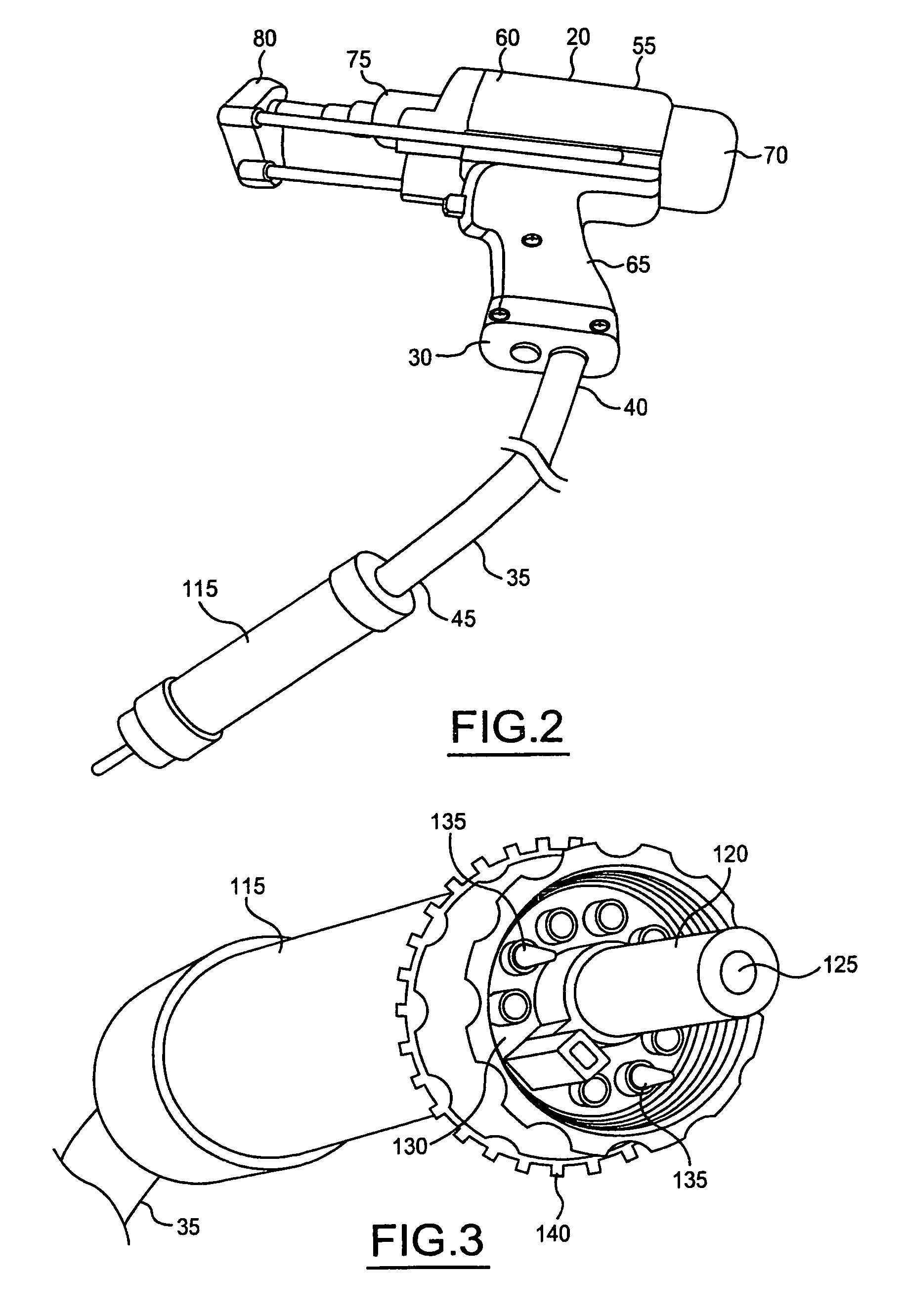

Stud welding apparatus with composite cable

A stud welding apparatus includes a power supply and a stud welding tool having a welding head portion and a cable receiving portion. A composite cable having first and second ends is coupled at a first end to the stud welding tool at the cable receiving portion and to the power supply at the second end of the composite cable. If the stud feeder is present, the second end of the composite cable can be coupled to the stud feeder. The composite cable includes a conductor having no individual electrical isolation and at least one control lead electrically isolated from the conductor. The conductor and the at least one control lead are surrounded by an outer non-conductive layer.

Owner:NELSON STUD WELDING

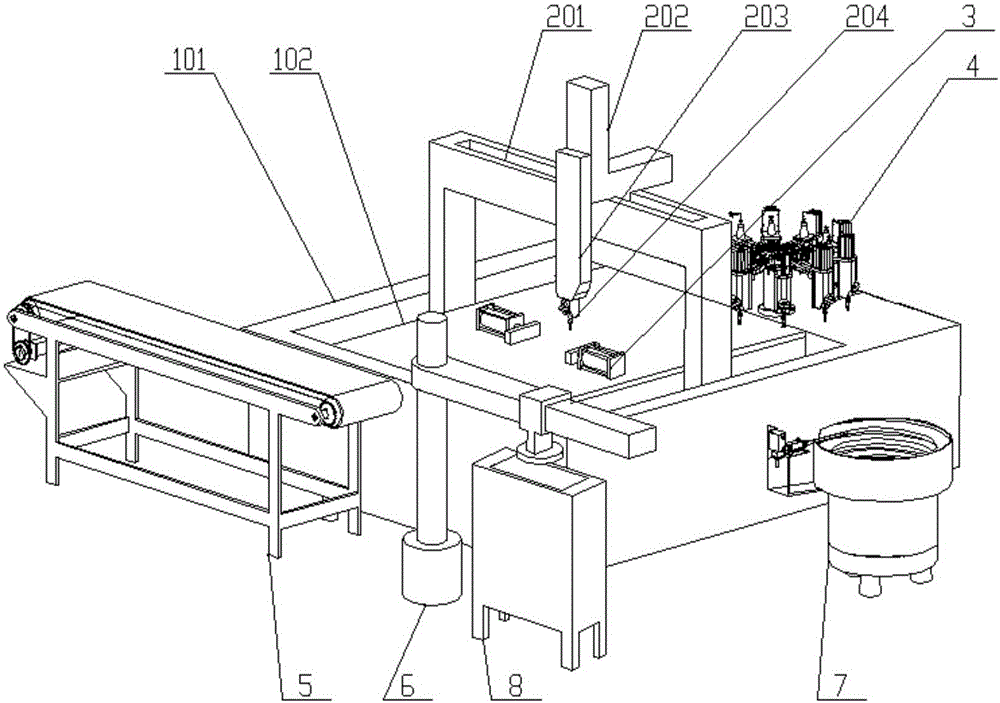

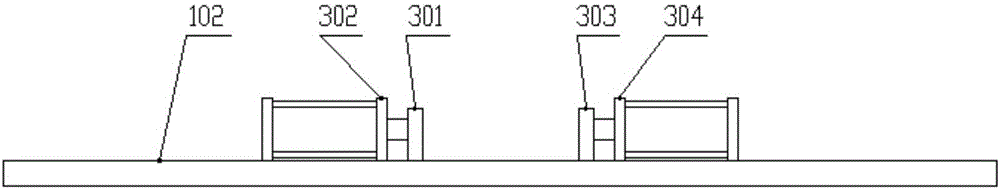

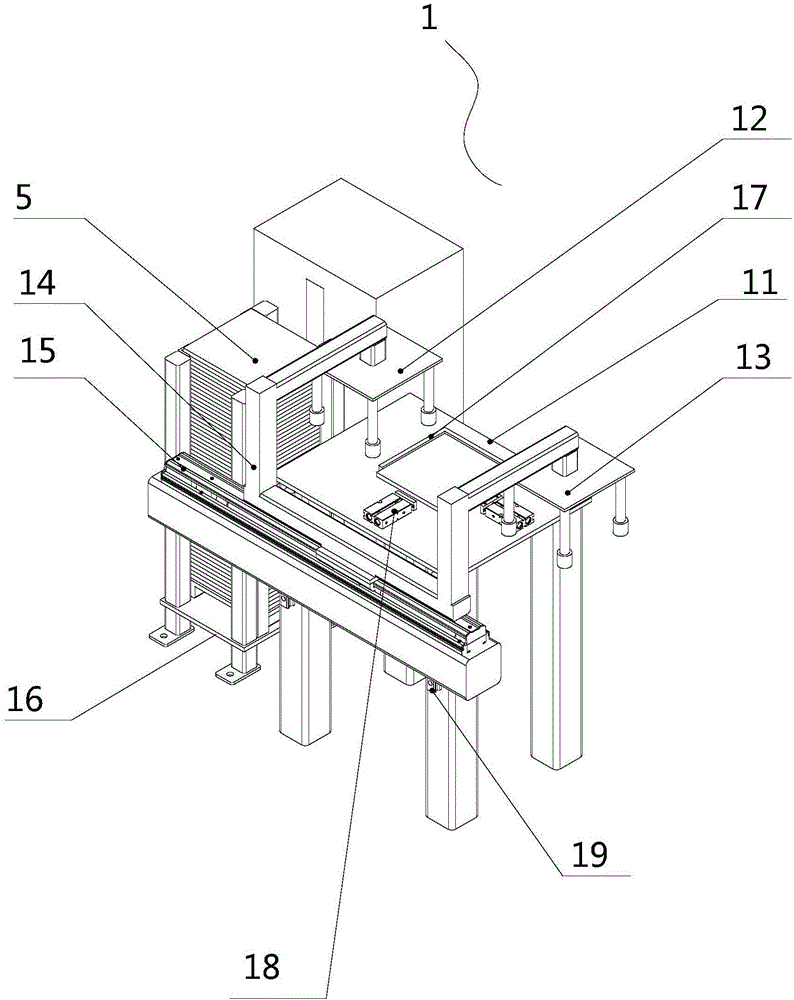

Full-automatic stud welding equipment

InactiveCN106392275AFully automatedIncrease productivityElectrode supporting devicesWelding accessoriesRotational axisEngineering

Provided is full-automatic stud welding equipment. The full-automatic stud welding equipment comprises a rack, a welding mechanism, a workpiece clamp mechanism, a welding gun chamber mechanism, a conveyor belt mechanism, a workpiece manipulator mechanism, a stud feeding mechanism and a to-be-welded workpiece box. The welding mechanism comprises a longitudinal movement cross beam, a transverse movement shaft, a vertical movement shaft and a welding gun. The welding gun chamber comprises a case, a shaft cover, a welding gun chamber rotary shaft, welding gun clamps, springs and a disk. The conveyor belt mechanism comprises a rack, a belt, rollers, bearings, a motor, a first chain wheel, a second chain wheel, a first chain and a second chain. The workpiece manipulator mechanism comprises a machine base, a manipulator rotary shaft, a lifting shaft, a manipulator moving shaft and a chassis. The full-automatic stud welding equipment can achieve automation of the whole stud welding process, time and labor are saved, the production efficiency can be improved, the workpiece positioning precision is high, and meanwhile, the problem that the diameter of studs welded by a single stud welding machine is simplex is solved.

Owner:JIANGXI UNIV OF SCI & TECH

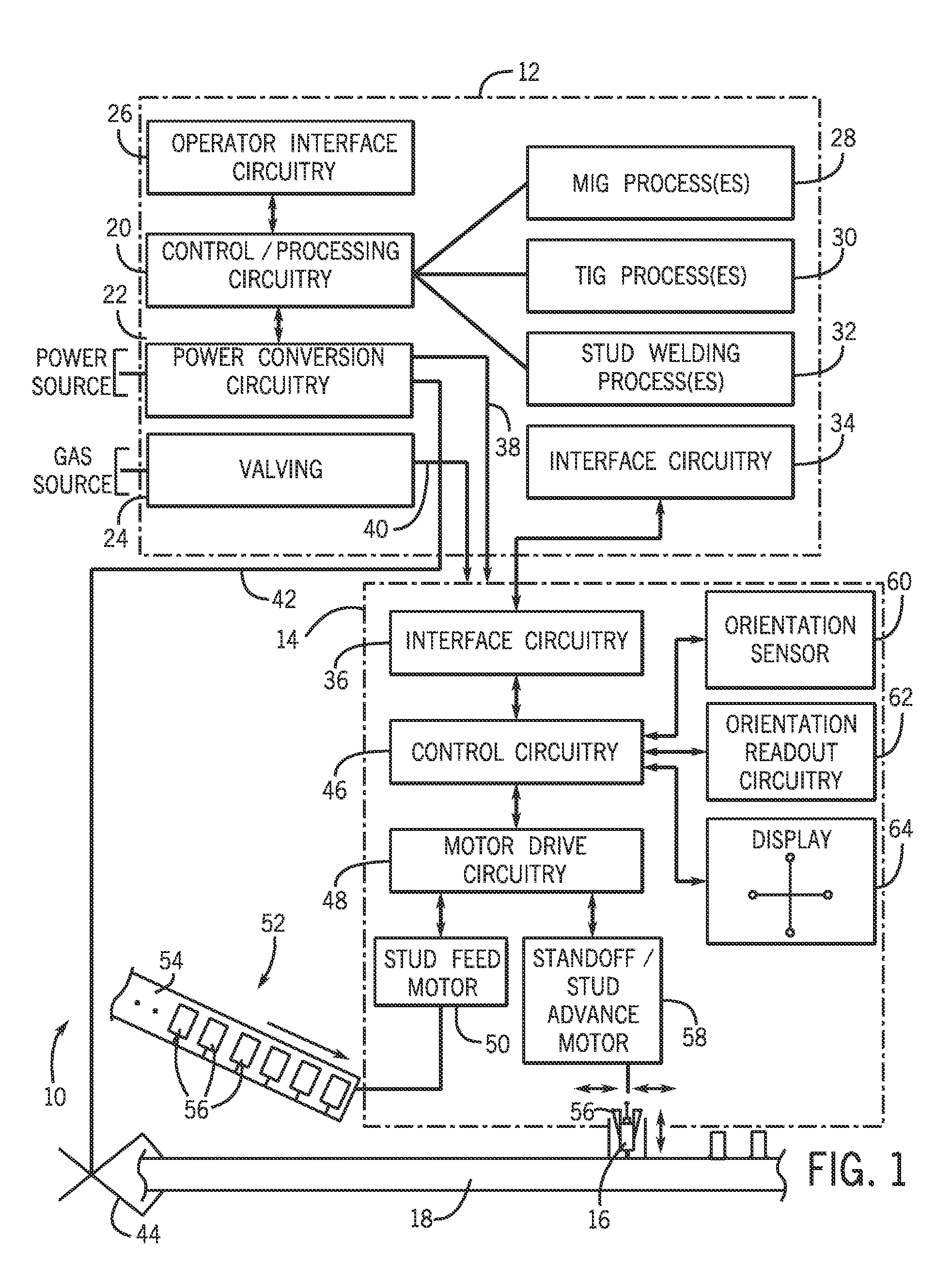

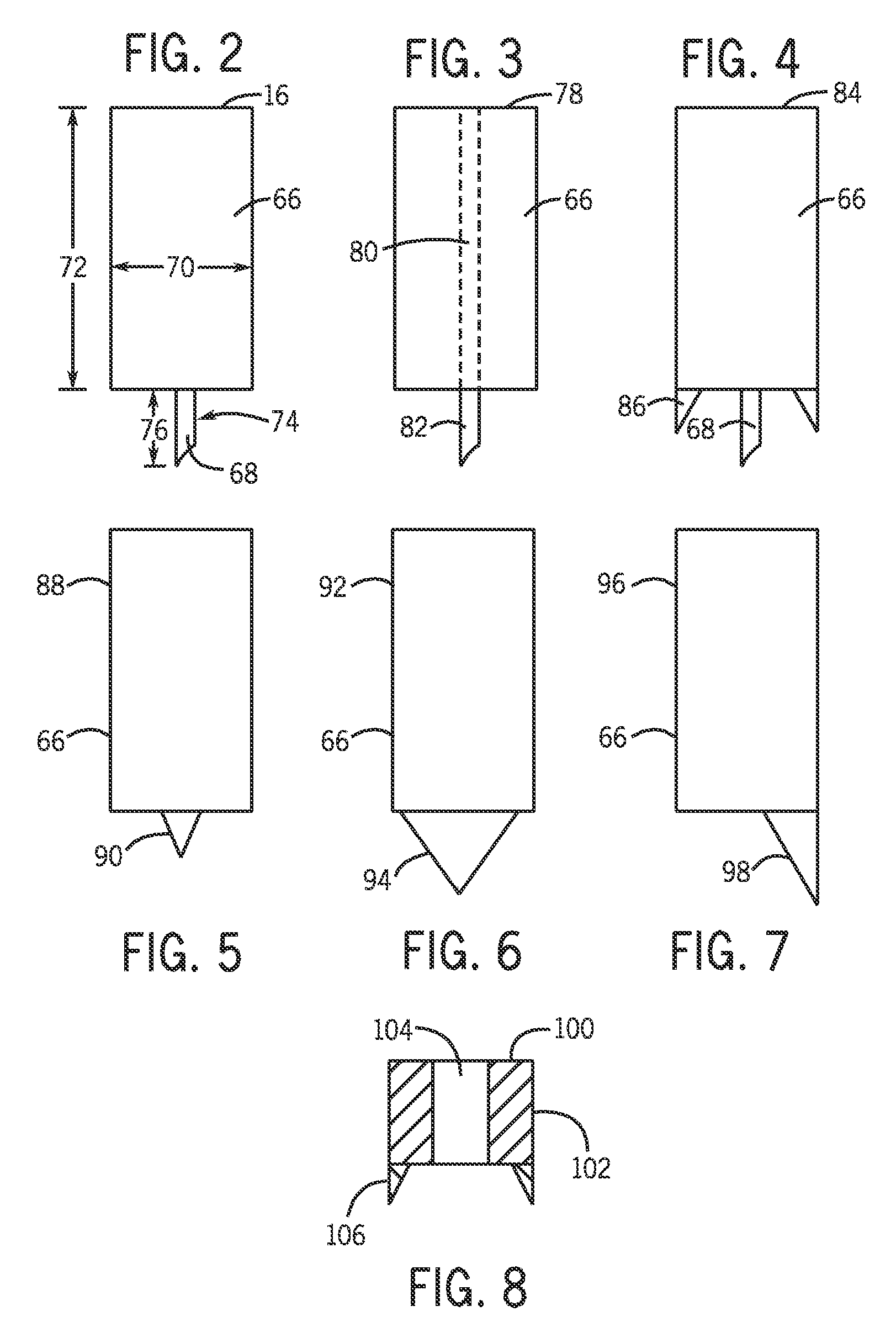

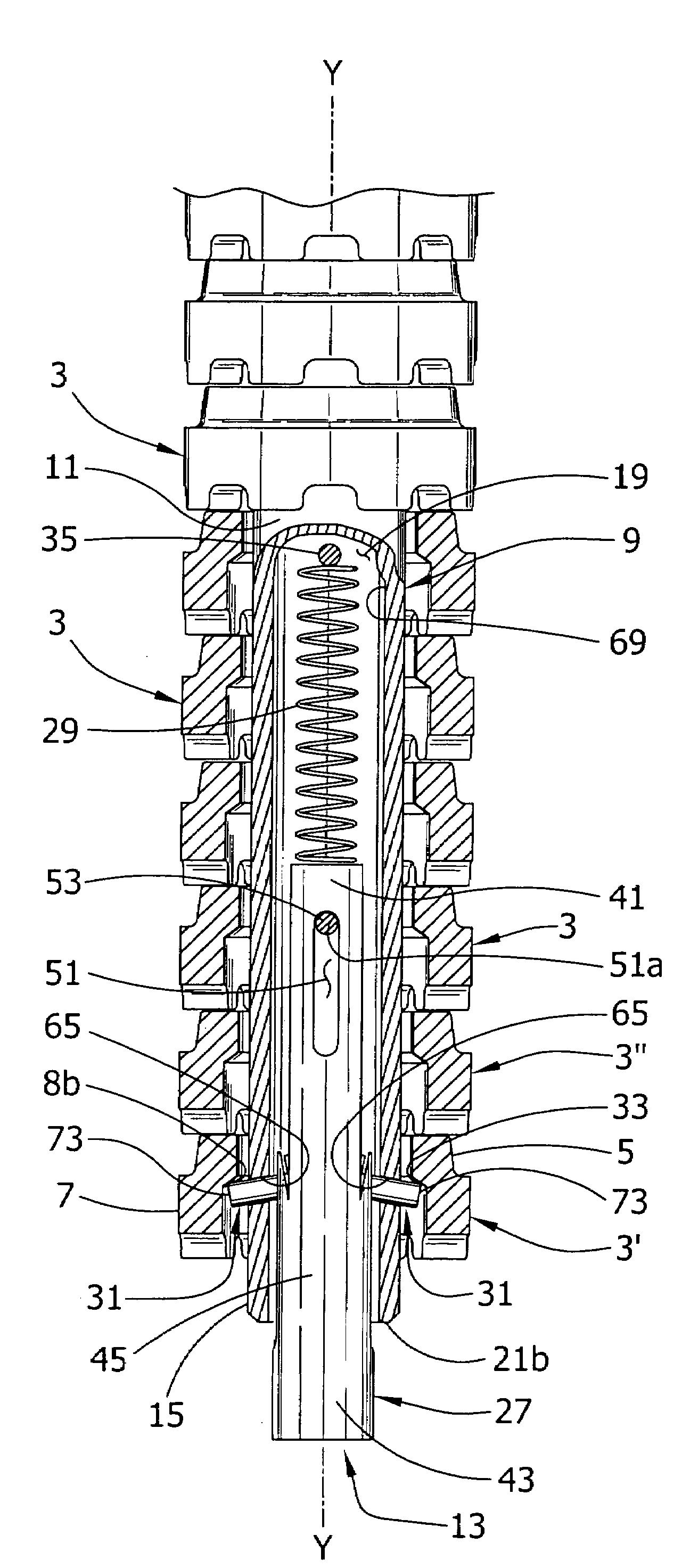

Stud welding system, consumables, and method

ActiveUS20130015163A1Reduce weight and sizeImprove verticalityArc welding apparatusWelding/cutting media/materialsStud weldingEngineering

A stud welding process may be performed by a power supply that is adapted for other welding processes, such as MIG, TIG, and so forth. A stud welding gun may receive studs preloaded in a magazine or other support. Studs are charged into the chuck of a stud welding gun and positioned where desired over a surface. An extension, such as a wire-type electrode may extend from the stud and aid in establishing the welding arc. The stud may be shielded by a nozzle or other shield to obviate the need for ceramic ferrules. Orientation of the stud welding gun may be detected, displayed and used as a basis for initiating and completing the stud welding process once the gun and / or stud is properly positioned.

Owner:ILLINOIS TOOL WORKS INC

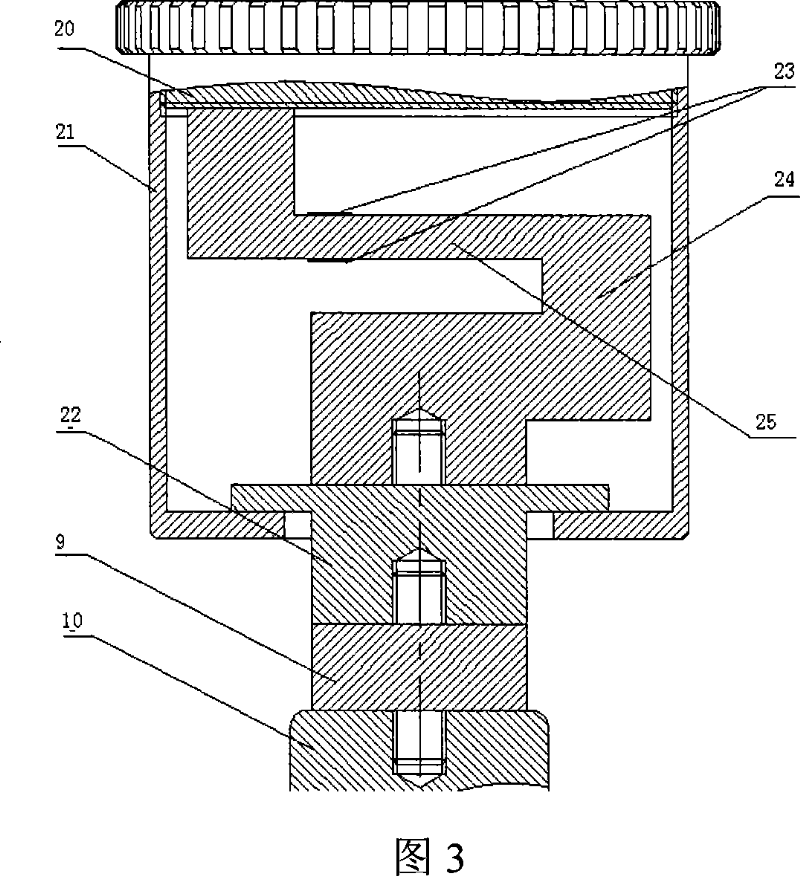

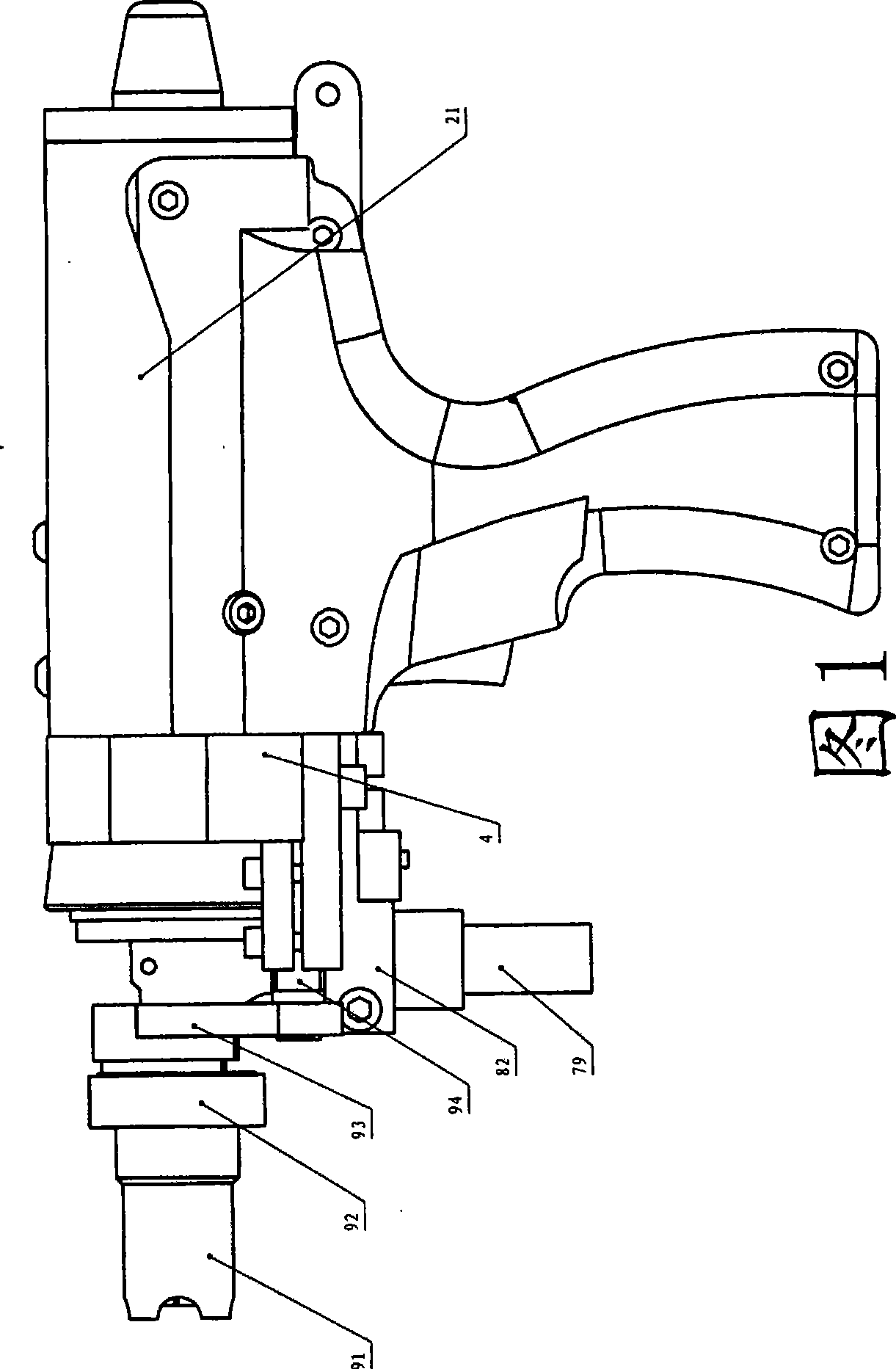

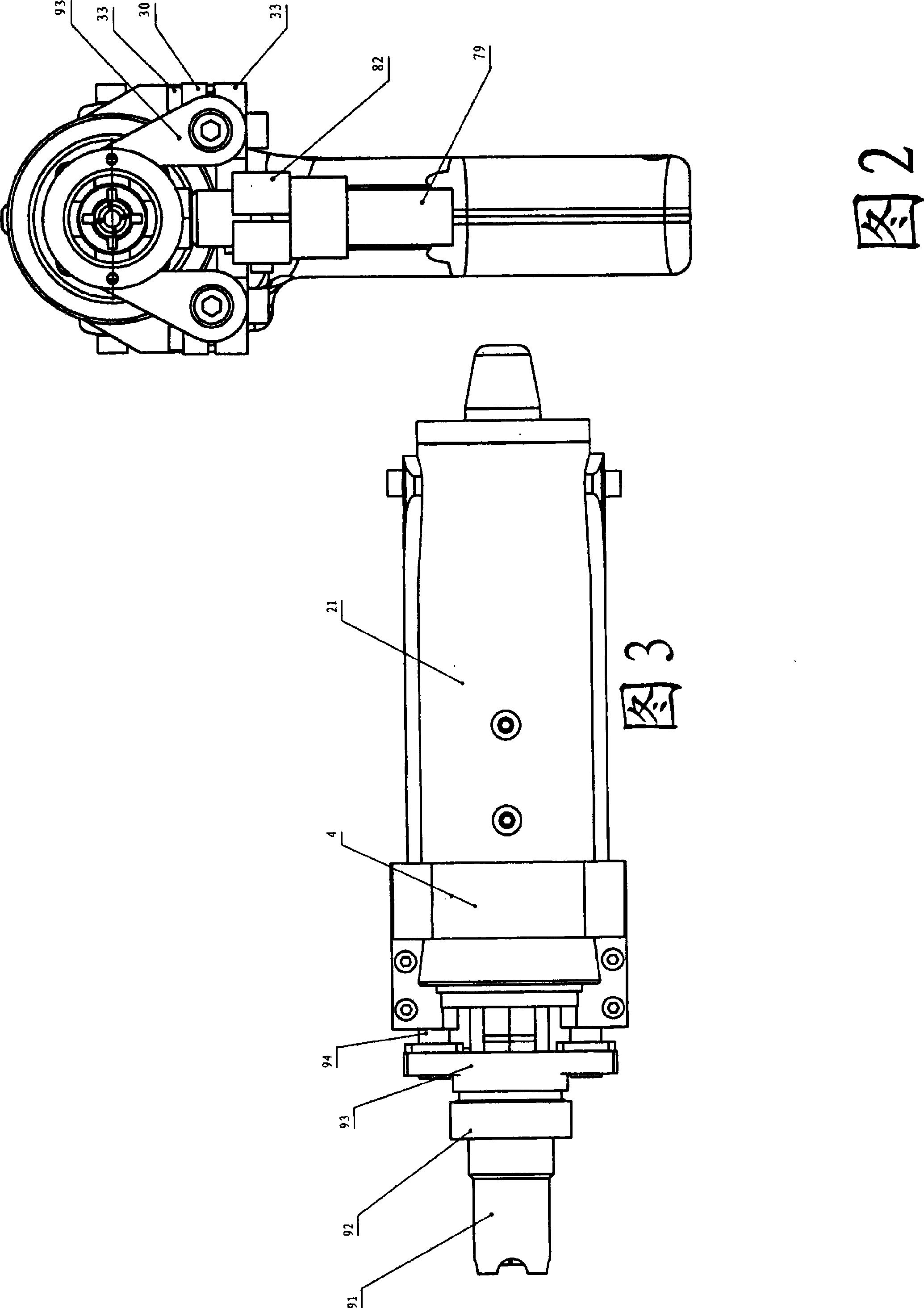

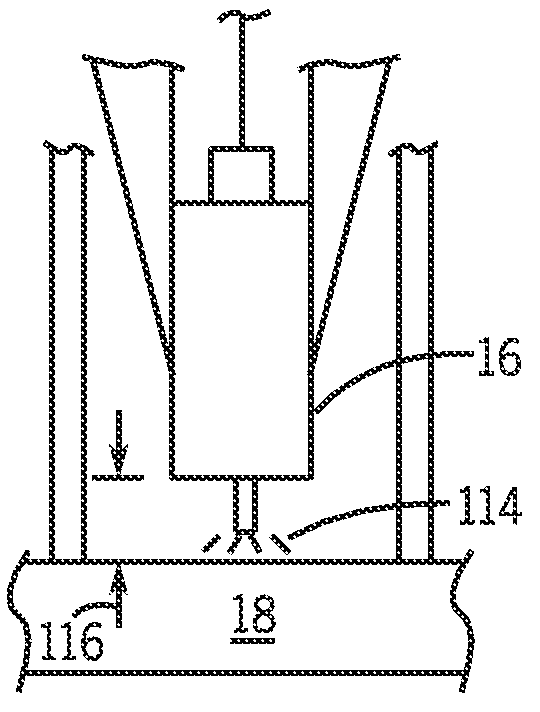

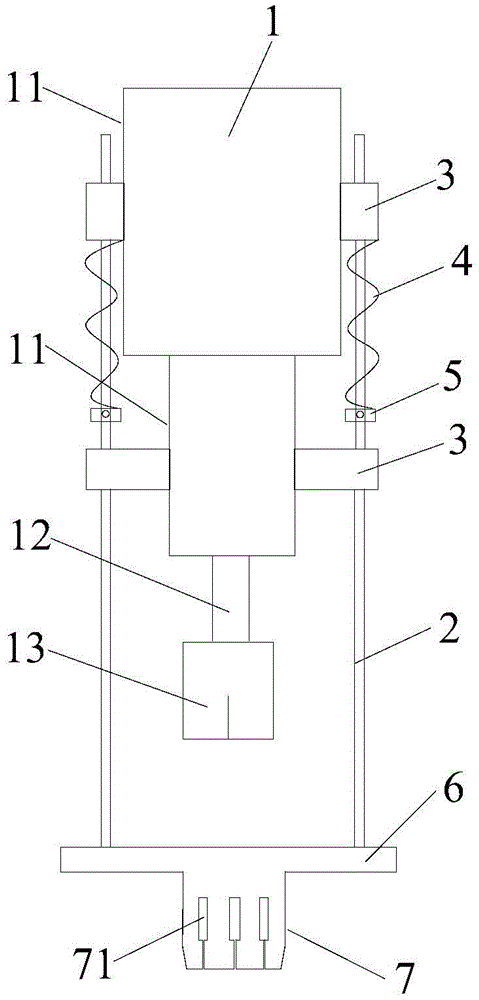

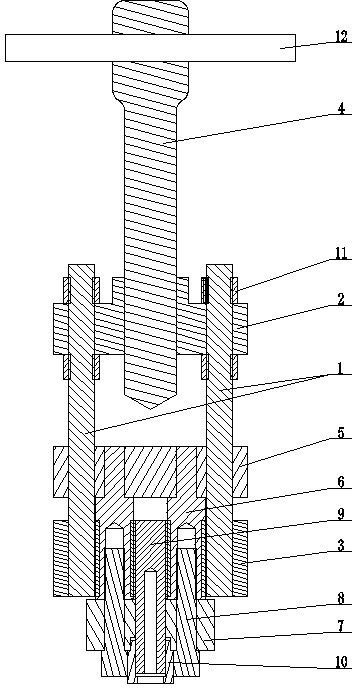

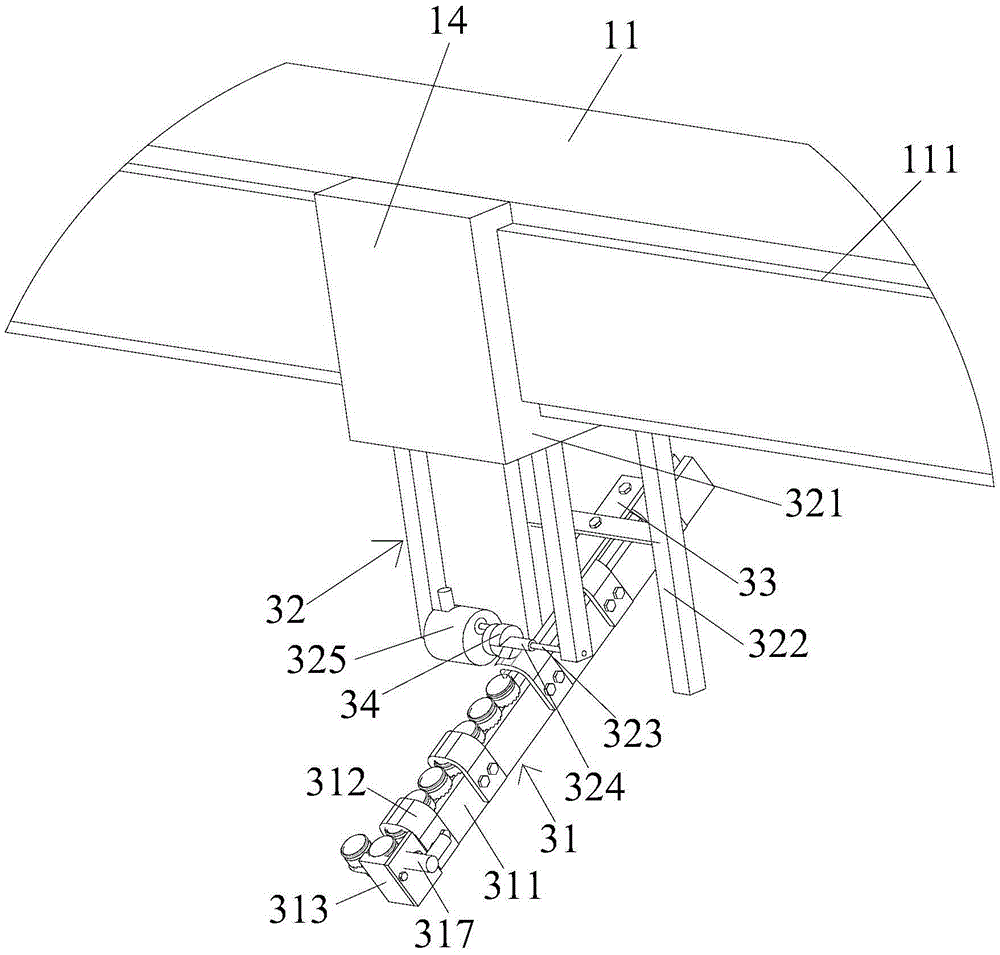

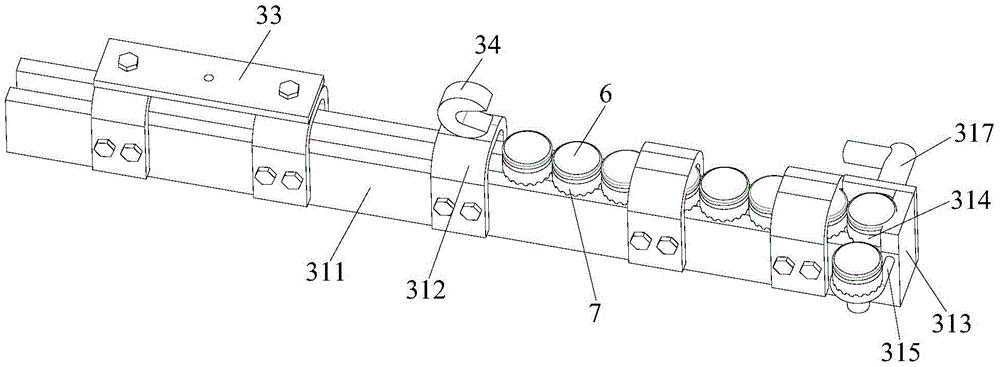

Automatic welding gun for realizing arc stud welding of T-shaped welding stud

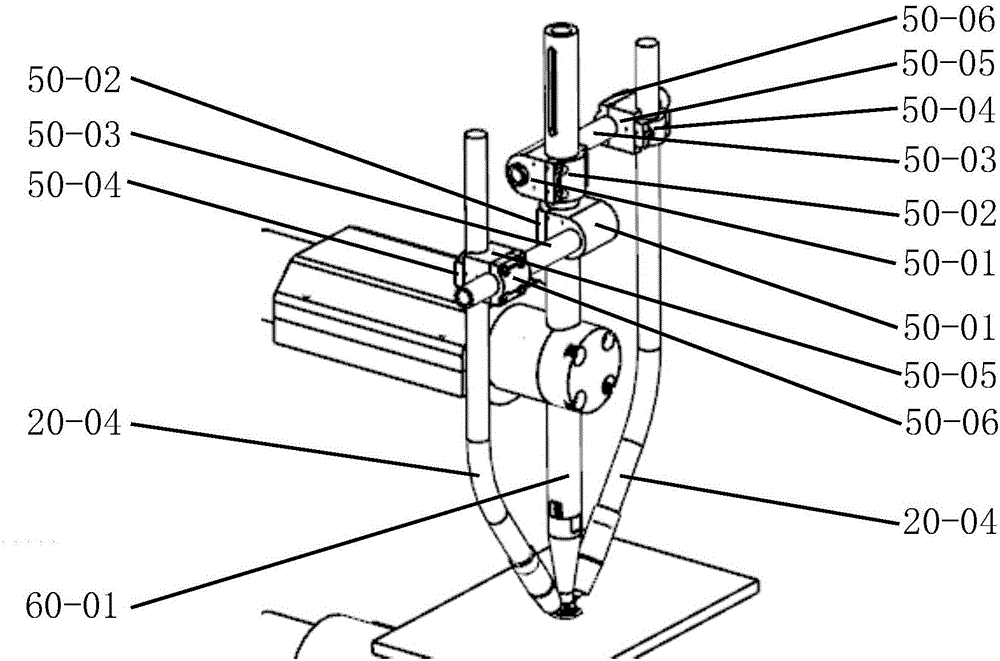

ActiveCN105618908ARealize automatic grippingAchieve separationElectrode supporting devicesStud weldingEngineering

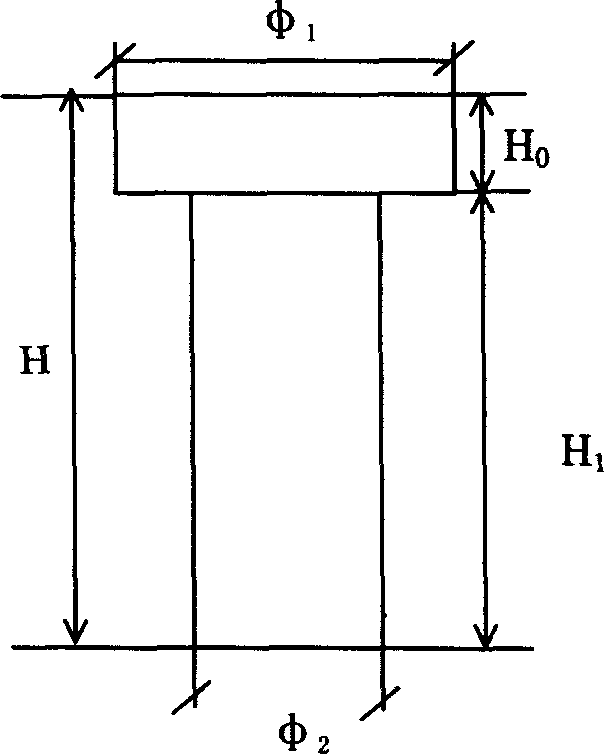

The invention discloses an automatic welding gun for realizing arc stud welding of a T-shaped welding stud. The automatic welding gun comprise a welding gun main body; the welding gun main body comprises a shell, a main shaft body, a welding stud clamping head, and a driving mechanism which is used for driving the main shaft body to perform lifting motion; guide columns are arranged at the two sides of the shell; guide sleeves are respectively arranged at the upper and lower parts of the shell at each side; the guide column at each side penetrates into the upper and lower guide sleeves at the same side; a spring sleeves the guide column positioned between the upper and lower guide sleeves; a limiting block is arranged at the lower end of the spring; the lower ends of the guide columns at the two sides are fixedly connected with a fixing seat; a passing hole for the welding stud clamping head to smoothly pass through is formed on the fixing seat and under the welding stud clamping head; a ceramic ring clamping head, under the passing hole, is fixedly connected with the bottom of the fixing seat. The welding gun disclosed by the invention is capable of realizing automatic clamping and separation of the T-shaped welding stud and a ceramic ring for the first time, can be matched with a robot or a three-axis motion platform in use, and is capable of realizing automatic arc stud welding of the T-shaped welding stud.

Owner:胡长建

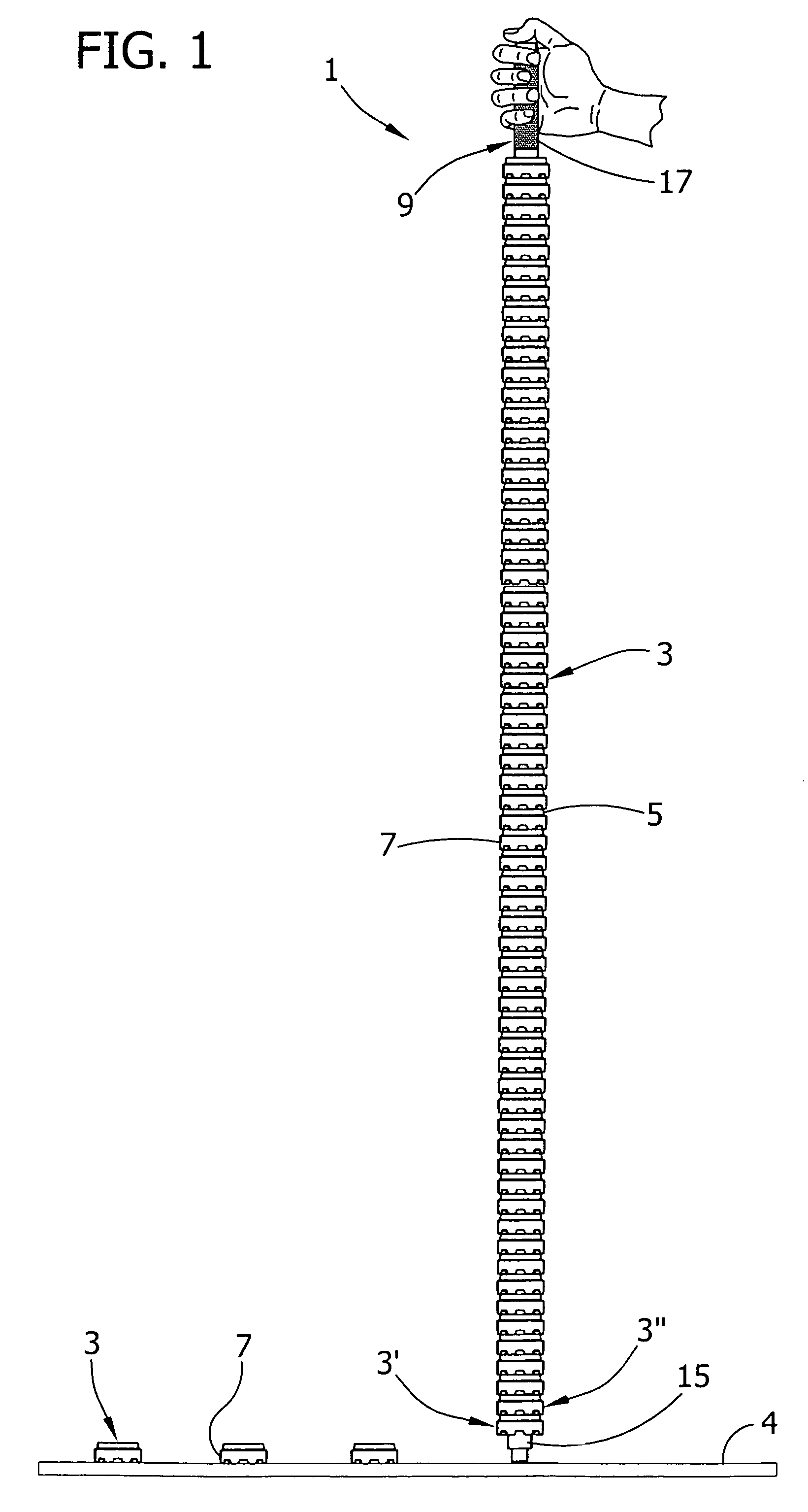

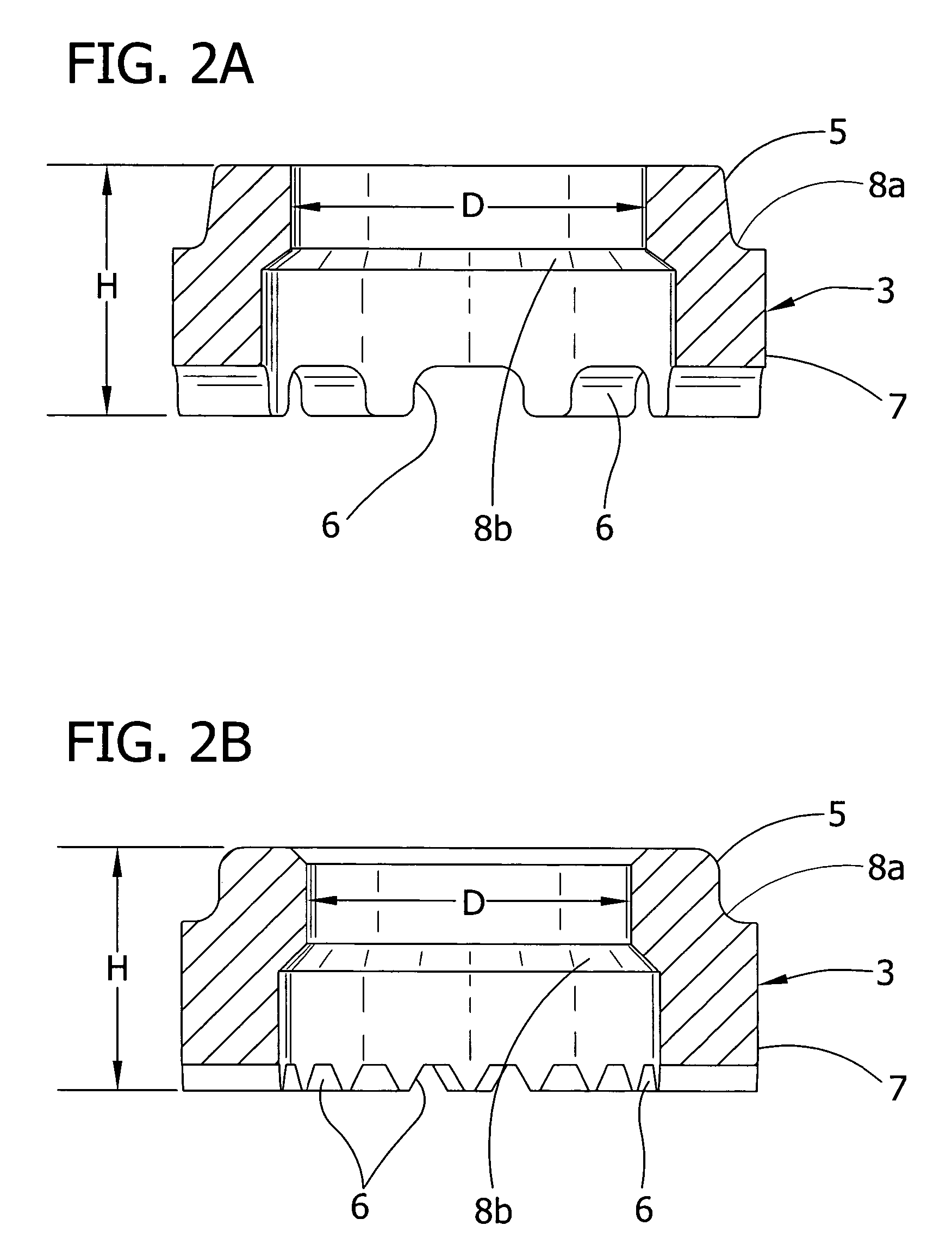

Ferrule dispenser and ferrule package therefor

This invention relates to a ferrule dispenser for dispensing stud welding ferrules and to a package of ferrules for use with the dispenser. The dispenser comprises a rod that supports a spring loaded cam system. The cam system moves relative to the rod and includes a compression spring and a cam. The spring and cam work together to bias a pair of ferrule release pins inward and outward of the rod, selectively holding ferrules on an outer surface of the rod or releasing them onto a work surface. The package of ferrules used with the dispenser includes multiple sets of ferrules, each set including multiple ferrules uniformly stacked on a spindle. Each spindle has one open end that can pass through an opening in a handle of the dispenser and down a center bore of the dispenser for loading the ferrules from the spindle onto the dispenser.

Owner:NEW RULE PROD

Stepping electric arc stud welding gun

InactiveCN1544194AWith arc length adjustmentArc length adjustmentArc welding apparatusMelting tankWelding power supply

The invention is a step arc stud welding gun, including frame and step machine, where there is leading screw fixed on the shaft of the step machine, the leaking screw is connected with a driving nut, the driving nut is fix together with a guide plate, and there is a clamp set at the bottom end of the driving nut. Before welding, use the welding gun to clamp the stud to place it on the workpiece surface, start up the step machine to make the driving nut to drive the clamp so as to lift the stud, at the same time, switch on the welding power supply to induce arc; when welding, make the driving nut to drive the clamp to move down so as to send the stud to the melting tank, and terminate the welding current to form welding joint. It uses step machine as power control unit so as to be able to more accurately set lift height, down feeding depth, and lift and down feeding speed for the stud, and by sampling the arc length, can implement the adjustment of are length.

Owner:XI AN JIAOTONG UNIV

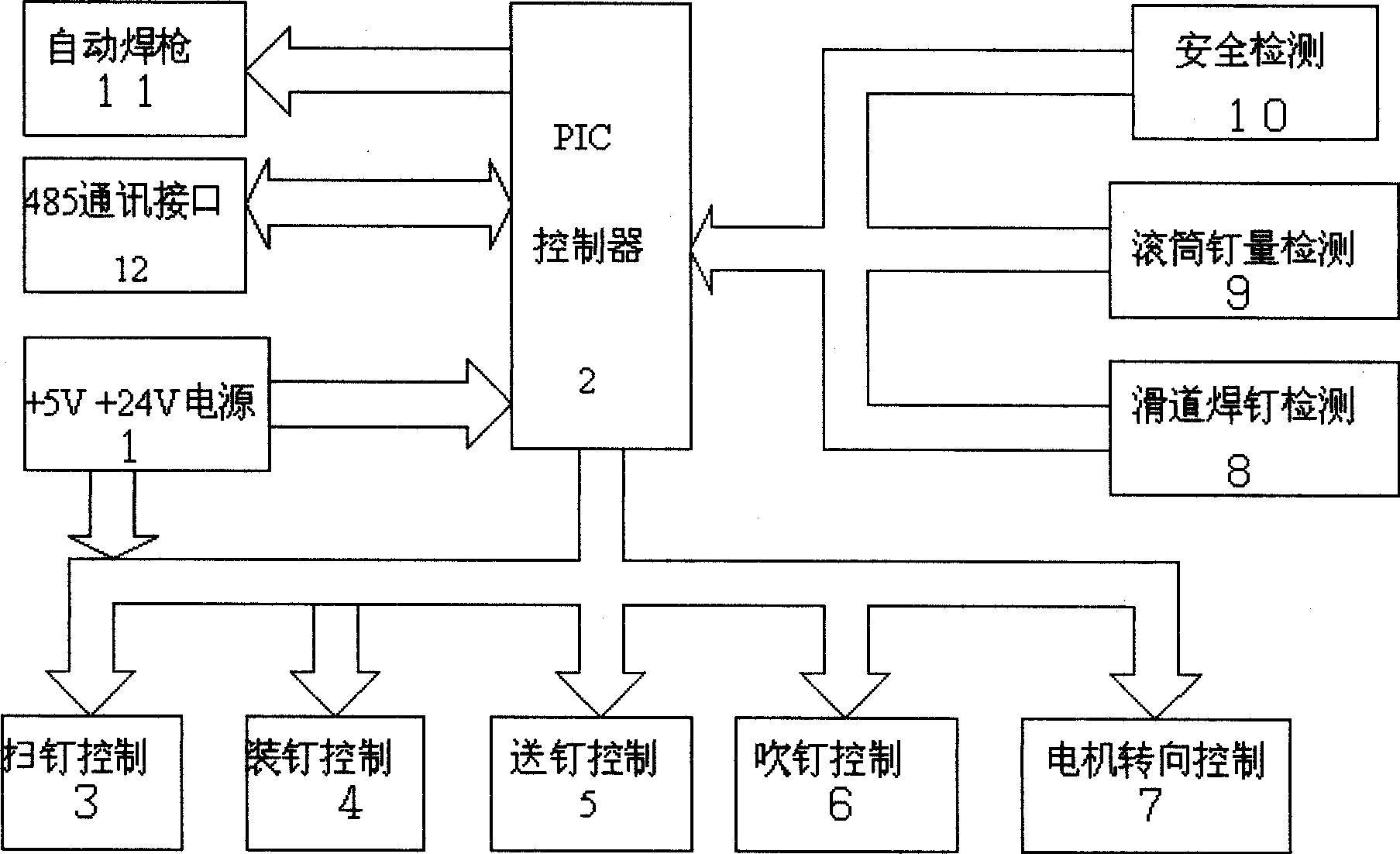

Automatic feeding device for stud welding

The invention discloses an automatic feeding device for stud welding. The automatic feeding device for stud welding comprises a machine frame, a longitudinal placing device for placing studs to be welded, a transverse pushing device for installing the longitudinal placing device and capable of transversely moving back and forth between a first position and a second position of a horizontal workstation of the machine frame, a longitudinal pushing device capable of longitudinally moving back and forth between a third position and a fourth position of a vertical workstation of the machine frame, a movable clamp fixed at the lower end of the longitudinal pushing device and capable of clamping a stud pushed to the second position by the transverse pushing device when the longitudinal pushing device moves to the third position, and a controller for performing data transmission and connected with the longitudinal placing device, the transverse pushing device, the longitudinal pushing device and the movable clamp. The automatic feeding device for stud welding is high in working efficiency, free of workpiece blockage, small in noise and electricity-saving, and can help to save the production cost.

Owner:佛山市玛雅数控设备有限公司

Paving method of sleel bridge surface composite layer

This invention relatesto a paving method of one pavement material of steel bridge surface, including the following steps: 1) preparation of lightweight concrete of steel mixing fiber and plain lightweight concrete; 2) pre-treatment of steel bridge surface; 3) peg soldering by the method of arc stud welding; 4) steel net bonding: to bind the steel net to the peg by steel thread; 5) choice of inherent stress steel thread and infliction of inherent stress: inherent stress steel thread situates below the natural axis, inflict the inherent stress by pretensioned system, with the controlling stress between 38-42%fptk; 6) pave one layer of lightweight concrete of steel mixing fiber on the steel bridge surface, and then pave one layer of plain light concrete to the light weight concrete of steel mixing fiber; 7) pave one layer of asphalt conctete on the plain light weight concrete. This invention can efficiently solve such technical difficulties as rutting, traction and cuddling, improve greatly road qualities of the pavement and prolong the application life of steel bridge.

Owner:WUHAN MUNICIPAL CONSTR GROUP

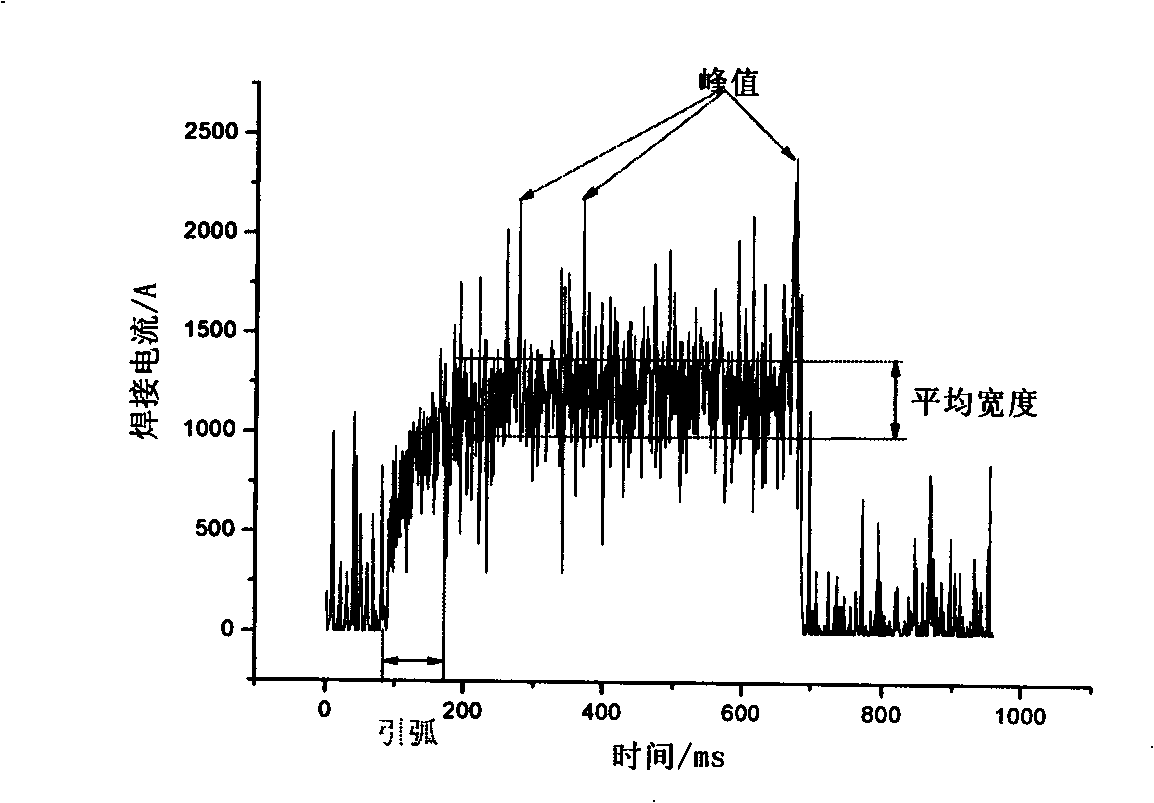

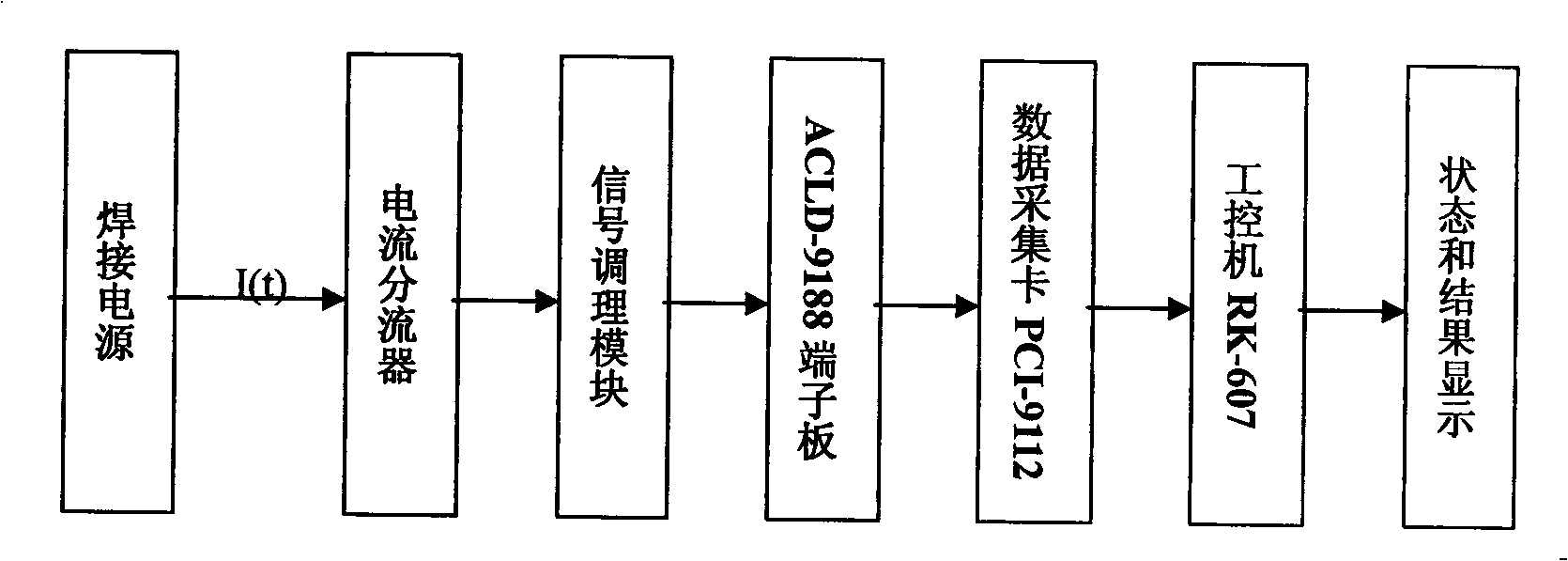

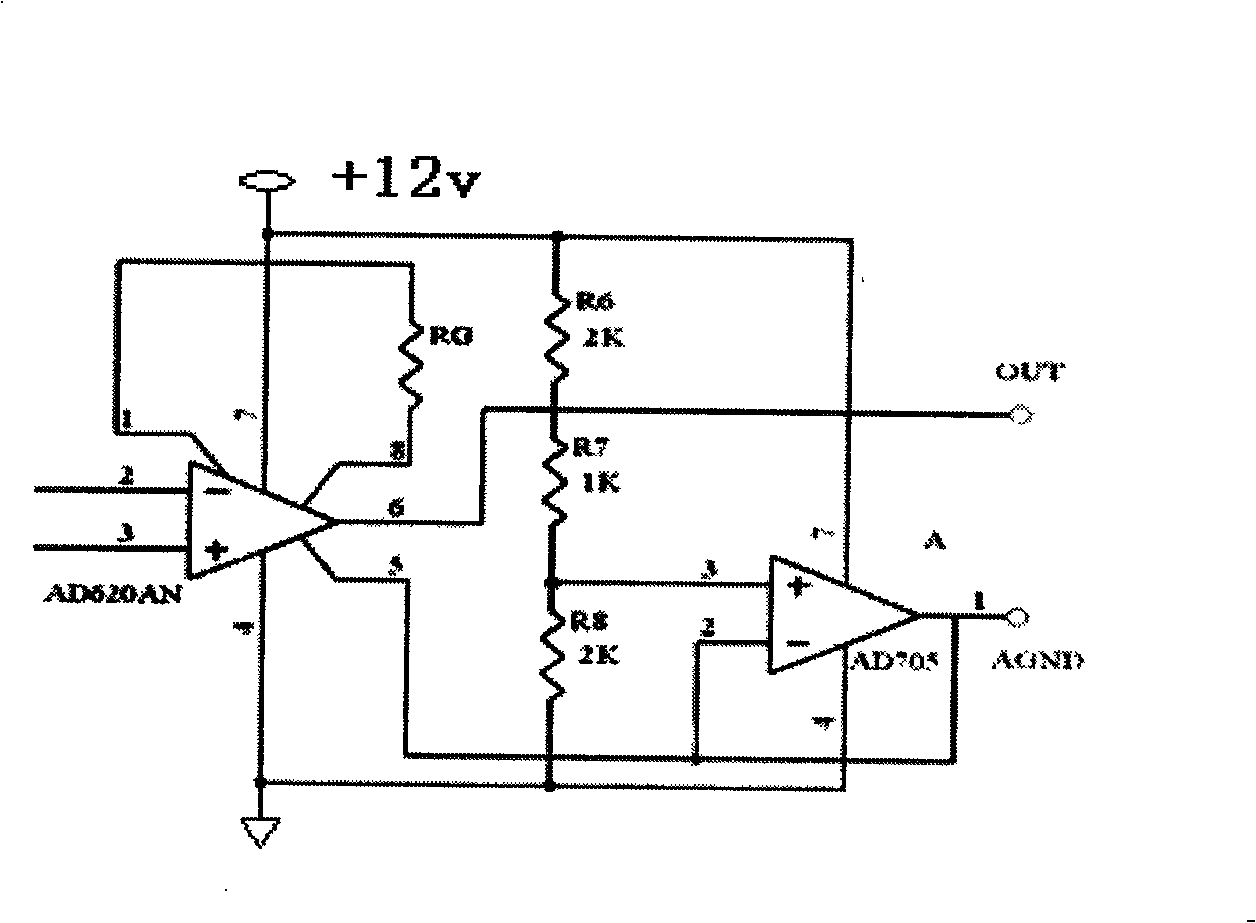

Electric arc stud welding waveform detection device and quality evaluation method thereof

InactiveCN101354369AReasonable handlingEasy to handleMaterial analysis by electric/magnetic meansArc welding apparatusStud weldingHandling system

The invention discloses an electric arc stud welding waveform testing device and a quality evaluating method thereof. The electric arc stud welding waveform testing device implements waveform processing to electric current signals through a hardware waveform processing system and a software waveform processing system in the stud welding process, obtains the electric current waveform in the stud welding process, further obtains five quality parameters including arc generating time, an average value of electric arc burning currents, a fluctuating range of the electric arc burning currents, arc burning time and an instantaneous electric current value before arc blowout, contrasts the five quality parameters with standard waveform parameters, and consequently gives quick quality evaluation of finished welding. The quality evaluating method is a nondestructive and real-time test method, prevents a good welding adapter from being damaged in detection, can realize the 100 percent detection of the stud welding adapter, overcomes the detection omission problem that is caused by the fact that only 2 to 5 percent of the stud welding adapters are randomly inspected in traditional methods, and can simultaneously realize the detection with inner defects such as air holes and incomplete fusion and the like which are hard to be realized by the traditional appearance test methods.

Owner:XI AN JIAOTONG UNIV

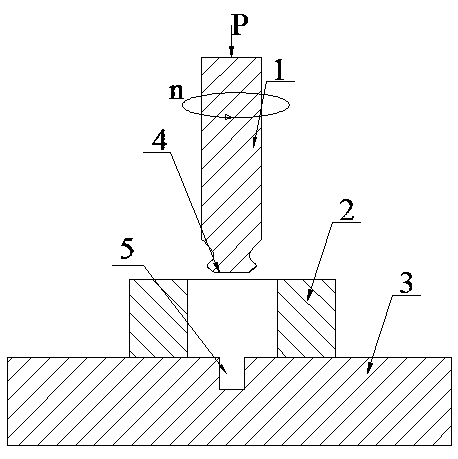

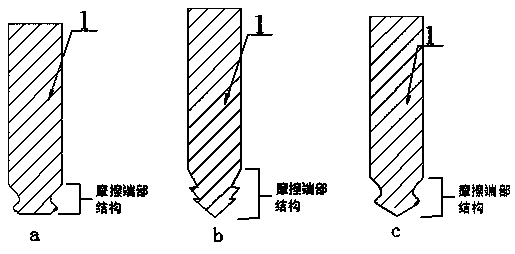

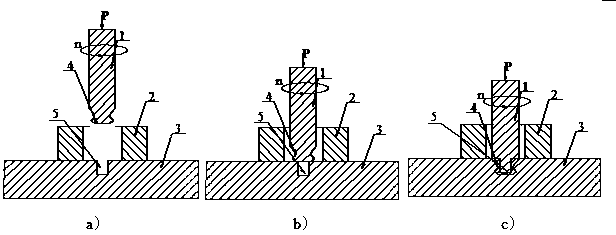

Steel stud and thick aluminum plate frictional stud welding method

ActiveCN103846545AReduce the impactGuaranteed flatnessWelding/soldering/cutting articlesNon-electric welding apparatusStud weldingWeld strength

The invention discloses a steel stud and thick aluminum plate frictional stud welding method, which is characterized in that the welding end part of a steel stud is subjected to certain structural design, the steel stud is rotated, is applied with frictional acting force, and is contacted and rubbed with an aluminum plate, and the steel stud is slowly embedded into the thick aluminum plate. Double characteristics of frictional stud welding and threaded connection are realized, so that a welded joint with good performance is manufactured. By the method, steel studs with middle and small diameters are welded with thick aluminum plates. According to the method, the welding strength of the stud welding can be obviously improved, the influence of defects in common welding on the joint quality is reduced, and the service life is greatly prolonged.

Owner:NANJING UNIV OF SCI & TECH +1

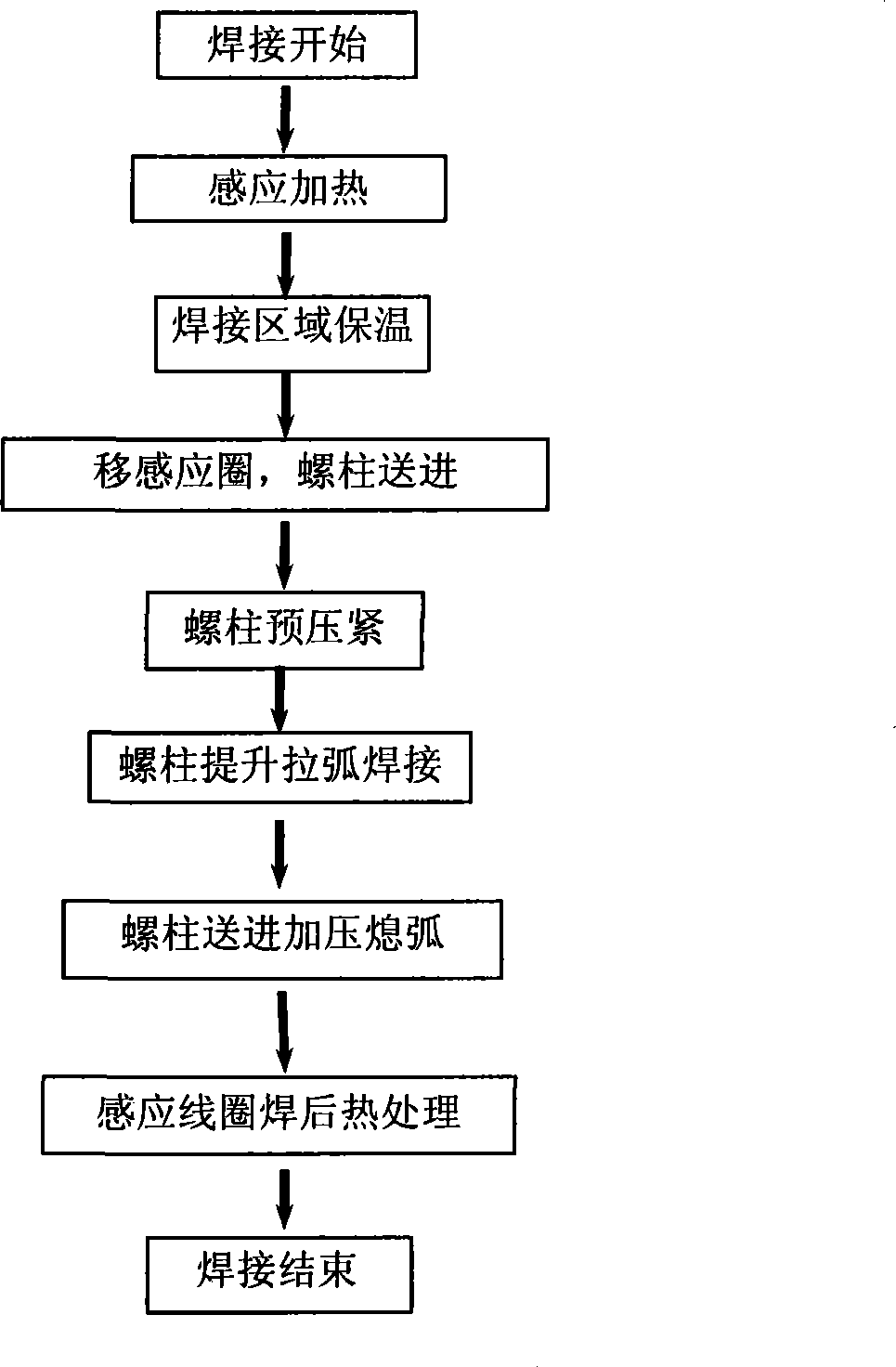

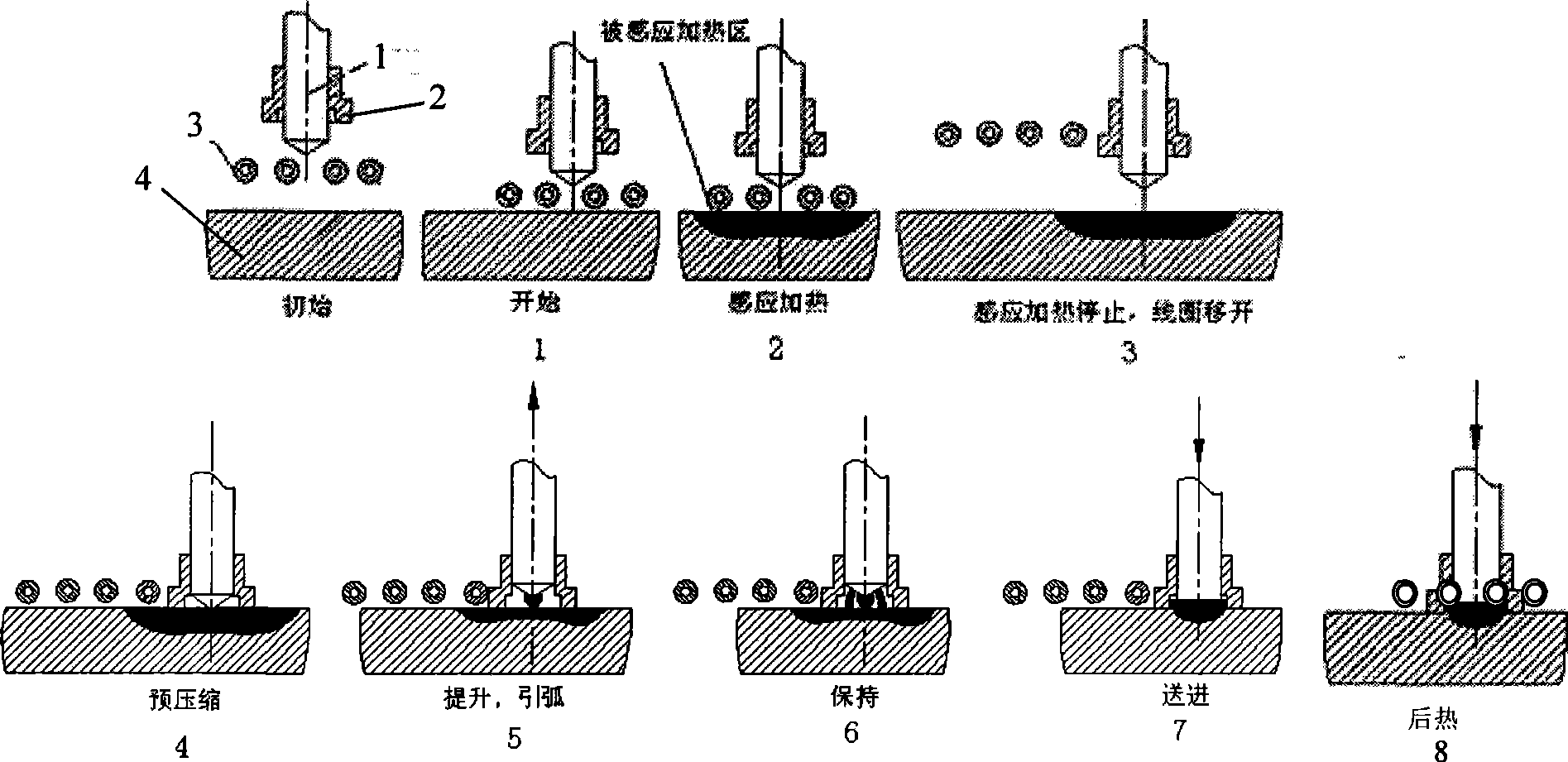

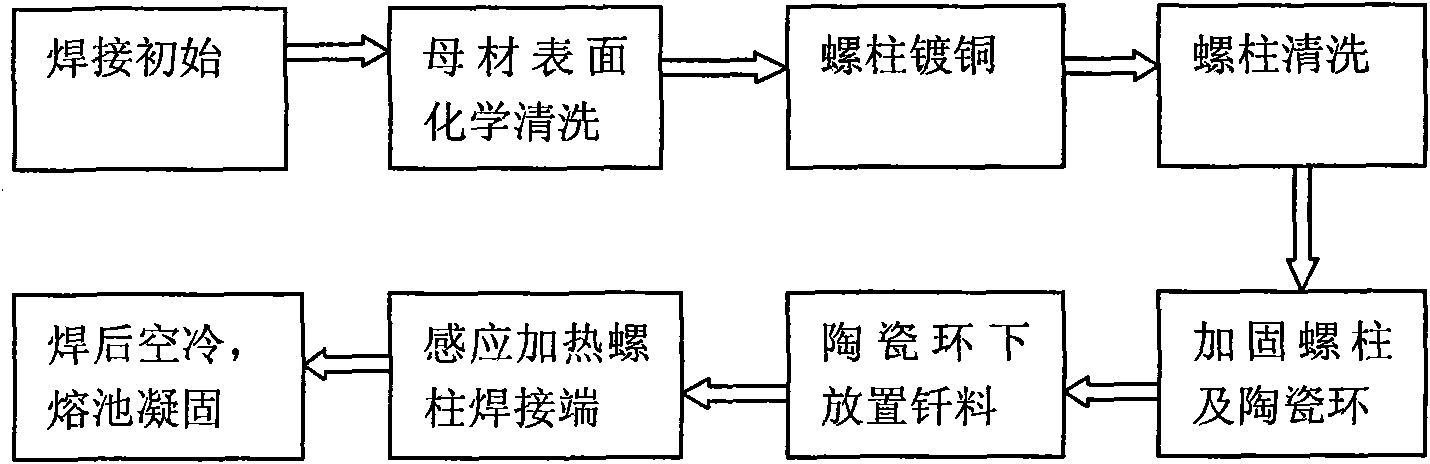

Induction and electrical arc composite heat source stud welding method

ActiveCN101468419AConvenient for preheating before weldingAutomate operationArc welding apparatusEngineeringStud welding

The invention discloses a method for welding a stud with composite heat resources of induction and electrical arc. The method comprises: an induction heating power supply is adopted to heat a position to be welded, and the induction heating power supply stops working when reaching the preset time and temperature; an electric arc stud welding machine starts working, the end head of the stud carries out striking arc and arcing on the position to be welded, and the stud is sent to a melting pool, cooled and solidified after the melting pool is formed; and an induction coil carries out heat treatment on a joint after welding. The method can weld a board with a thick and large size and realize metallurgical bonding of the stud and a steel board base body. The welding process can realize automatic operation with high efficiency. The joint strength can reach more than 100 percent of the stud strength, and the inner melting rate of the joint is 100 percent. A ceramal sleeve is adopted to protect and obtain the welding joint without inclusions or oxidation. The method can be used for welding a steel board and a steel stud, or an aluminum alloy board and an aluminum alloy stud, or a copper alloy and a copper alloy stud and so on.

Owner:NANJING UNIV OF SCI & TECH

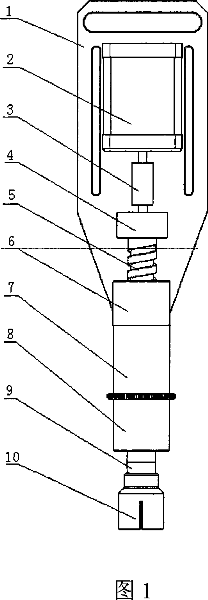

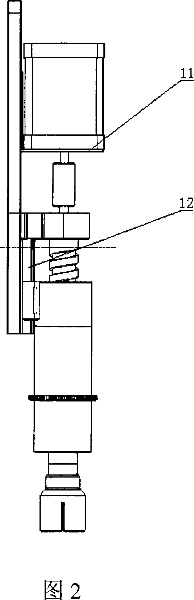

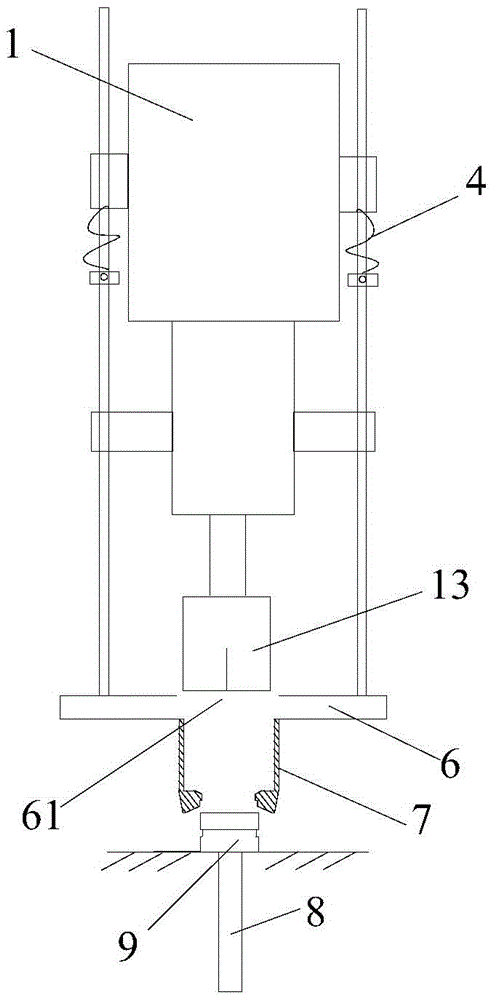

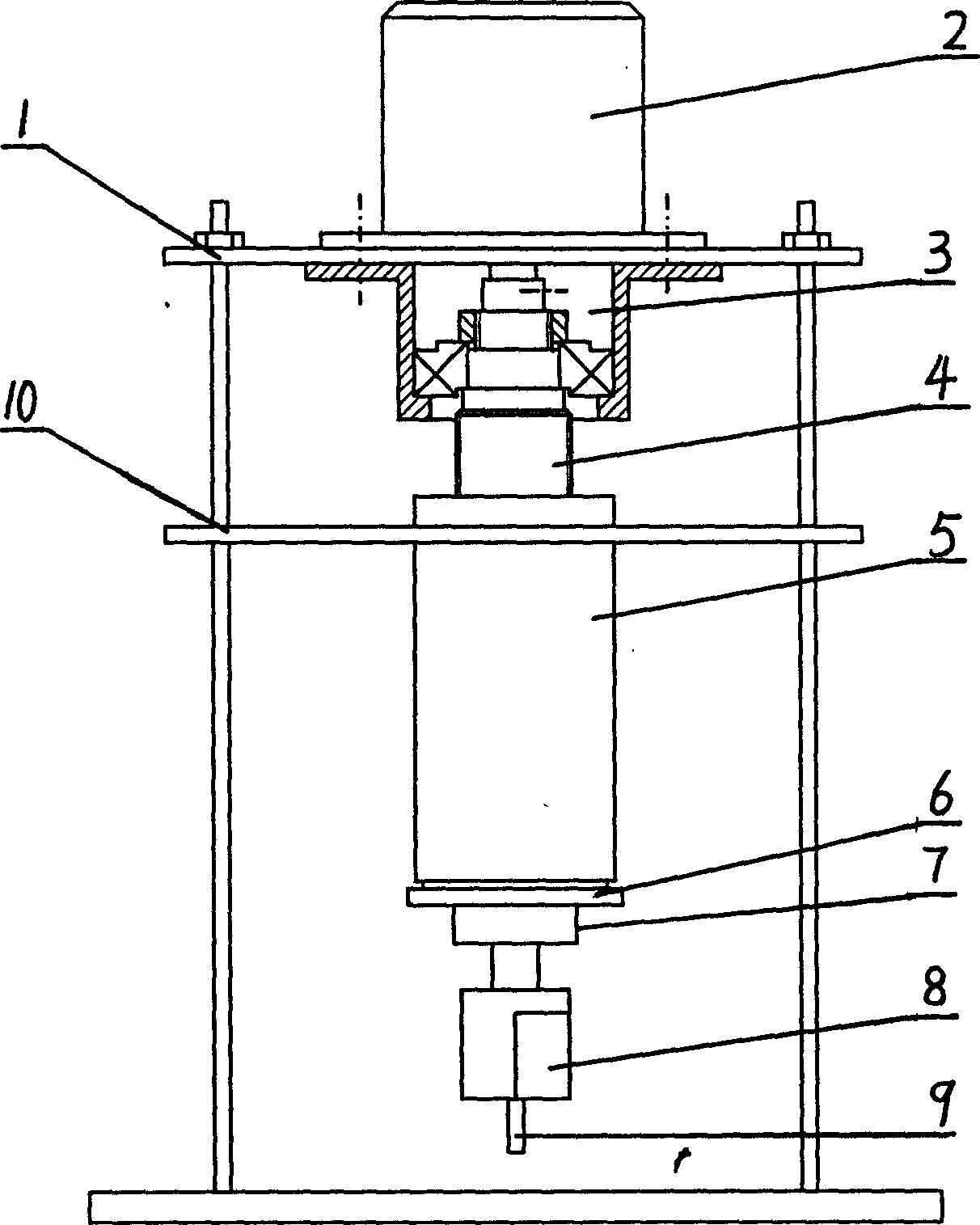

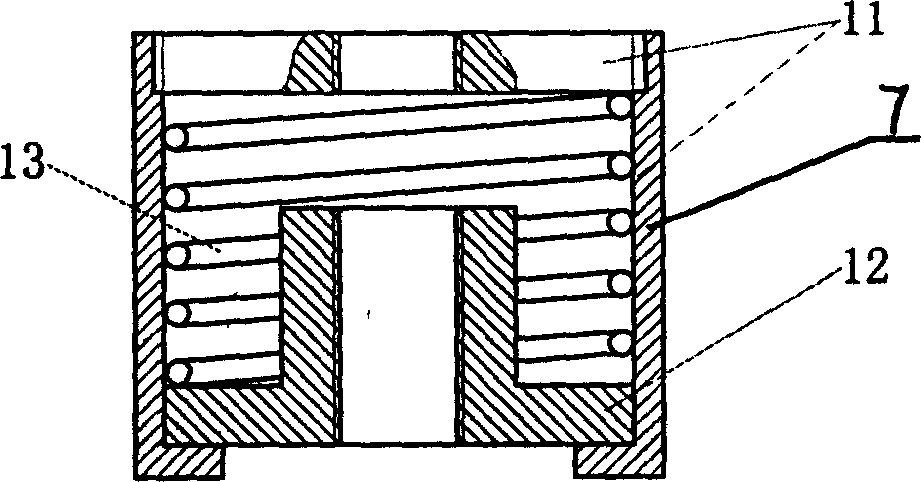

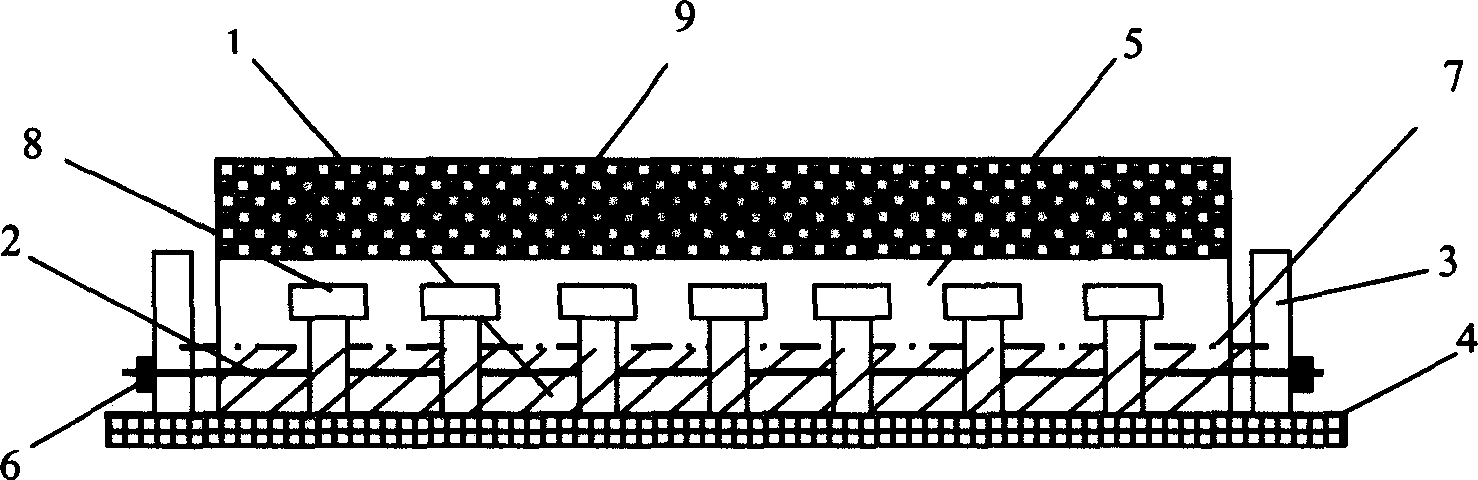

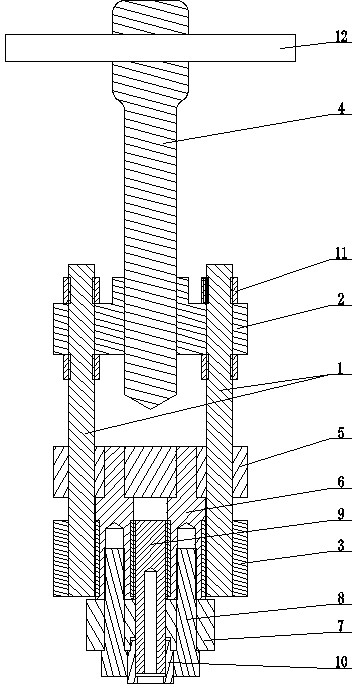

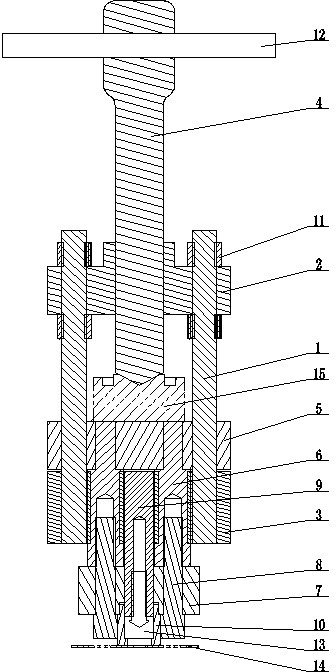

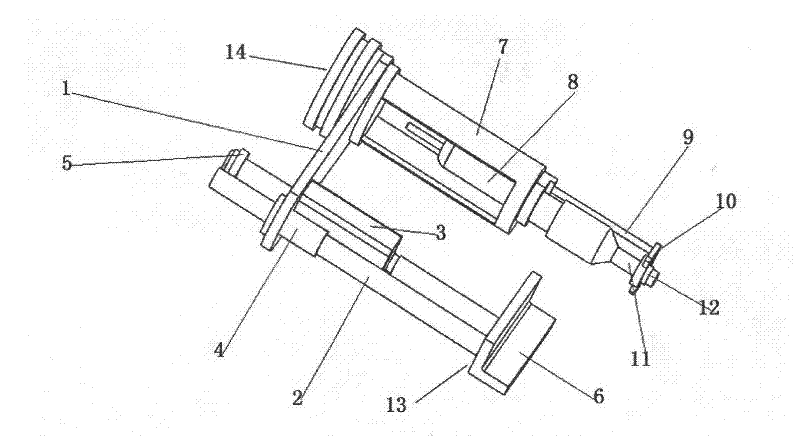

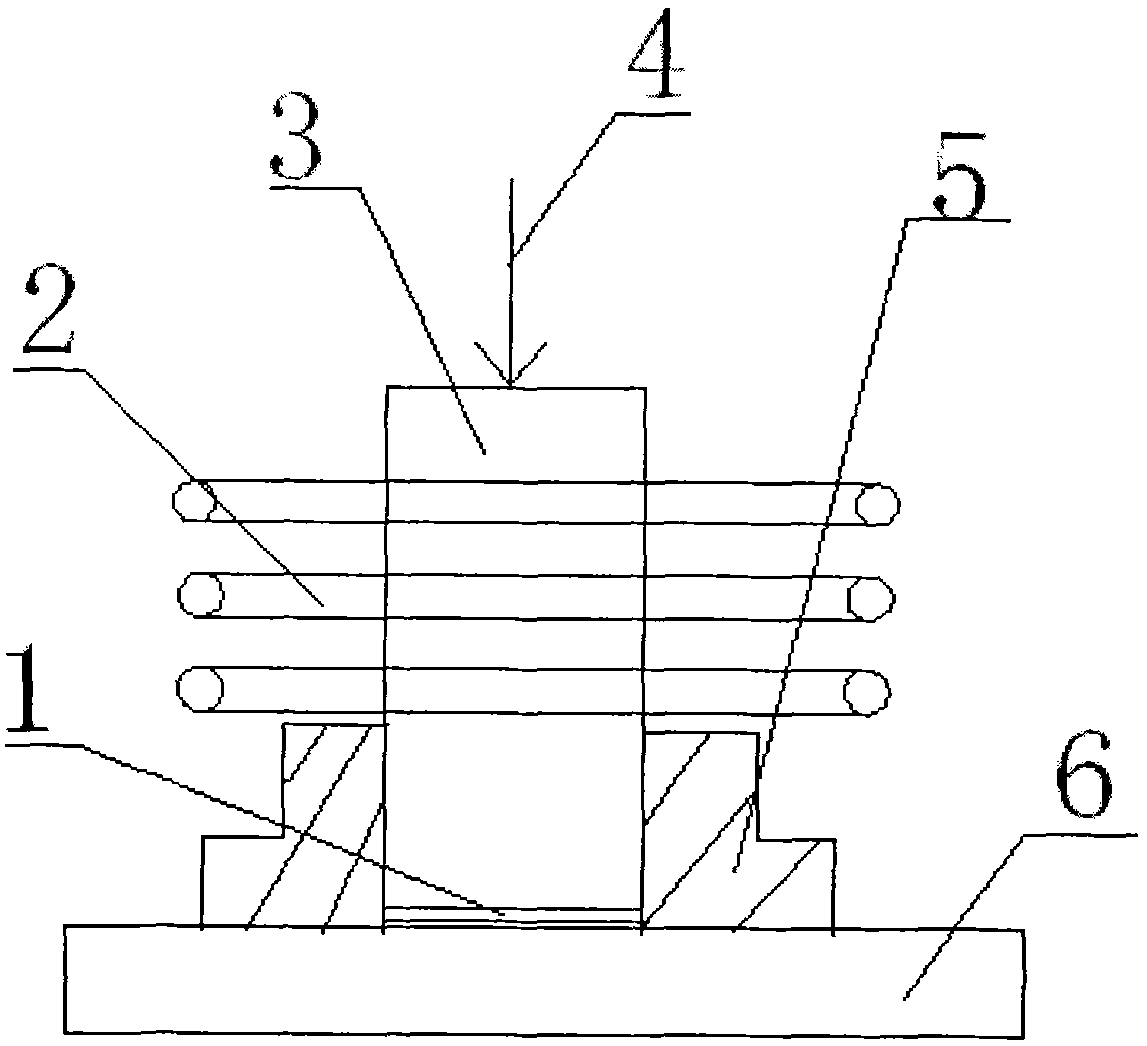

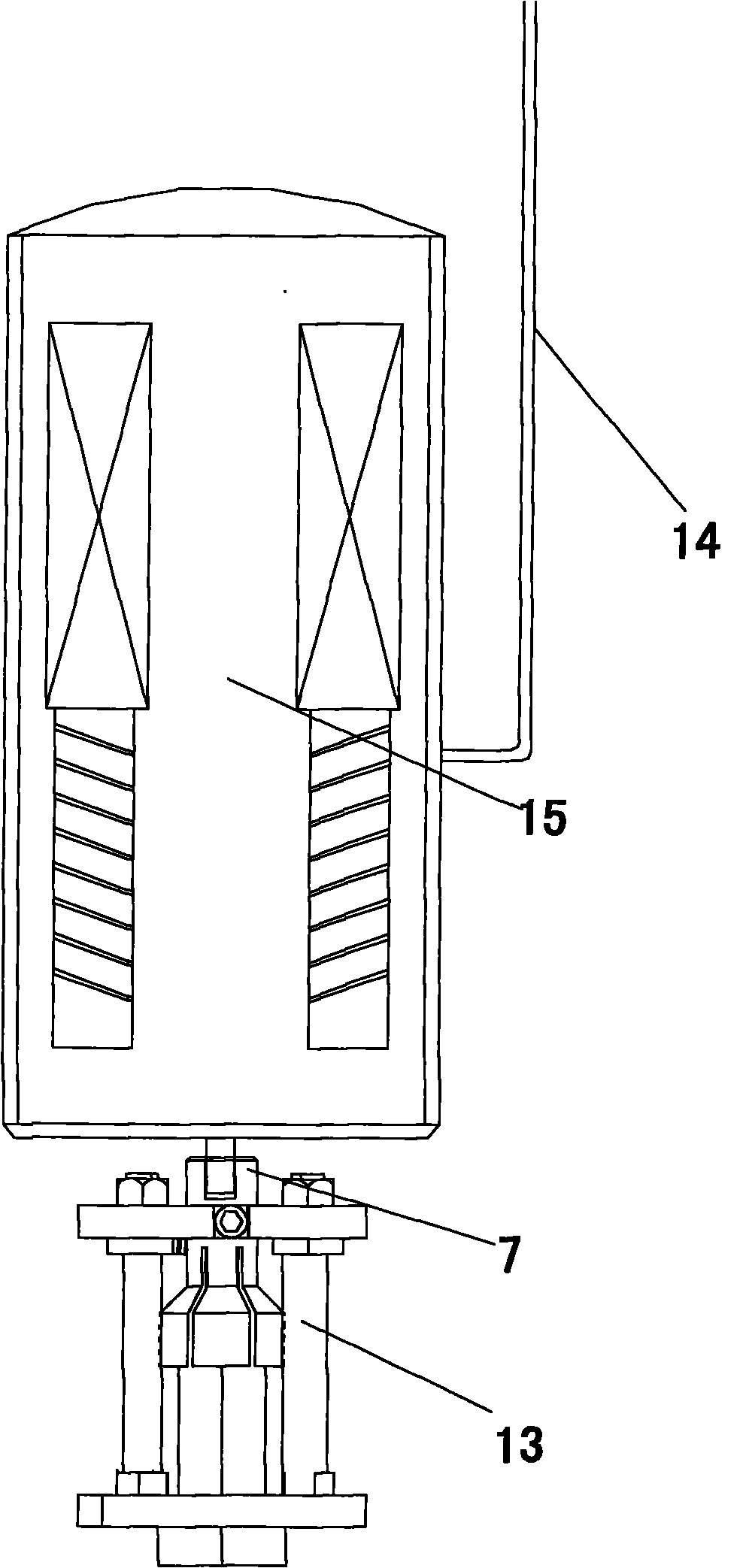

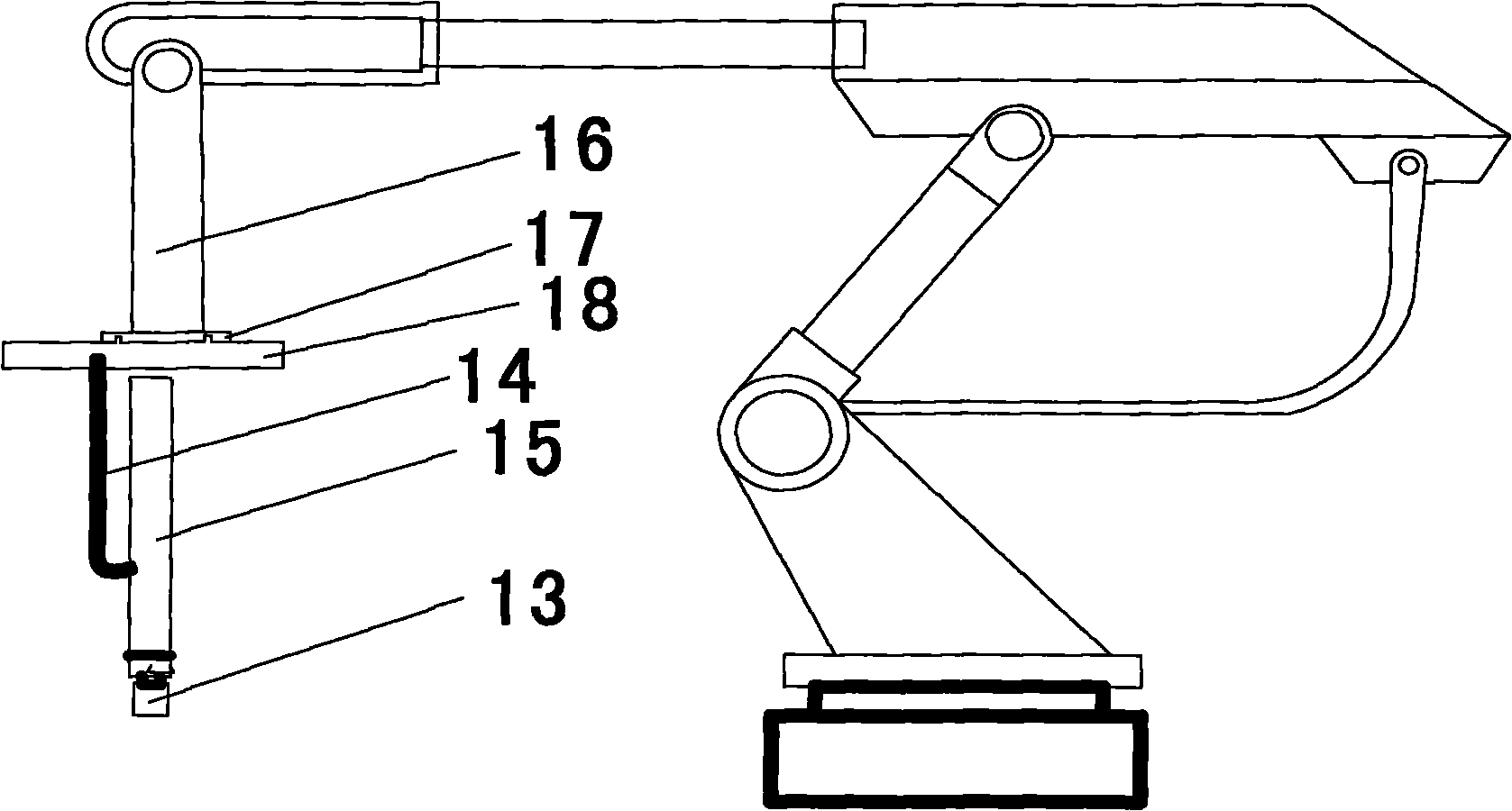

Tooling for detecting welding strength of stud welding

ActiveCN102323151AAvoid shakingGuaranteed accuracyMaterial strength using tensile/compressive forcesNon destructiveArchitectural engineering

The invention discloses a tooling for detecting welding strength of stud welding. An upper support (2) is fixed at upper ends of two connecting guide rods (1), and a lower support (3) is fixed at lower ends; the middle part of the upper support (2) is sleeved with a thimble (4) from up to down; a bearing (5) is disposed below the thimble (4); two bearing guide rods (6) are sleeved with the lower support (3); a bearing block (7) is disposed below the lower support (3); two bolts (8) pass through the bearing block (7) from down to up and extend into corresponding bearing guide rods (6); a nut sleeve (9) is disposed between the two bolts (8); the upper end of the nut sleeve (9) is fixed with the lower support (3); the lower end of the nut sleeve (9) extends into a bearing sleeve (10). The invention has a simple structure, is convenient and rapid for operation, has accurate and reliable detection results, is applicable to destructive tests or non-destructive tests of stud welding strength, has wide application scope, and strong generality.

Owner:力帆科技(集团)股份有限公司

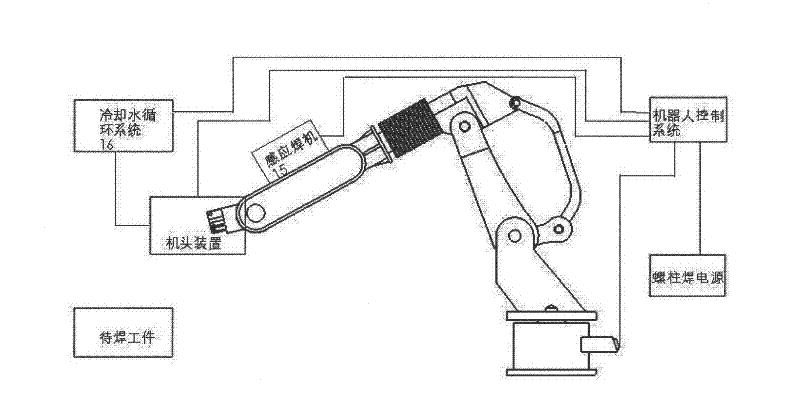

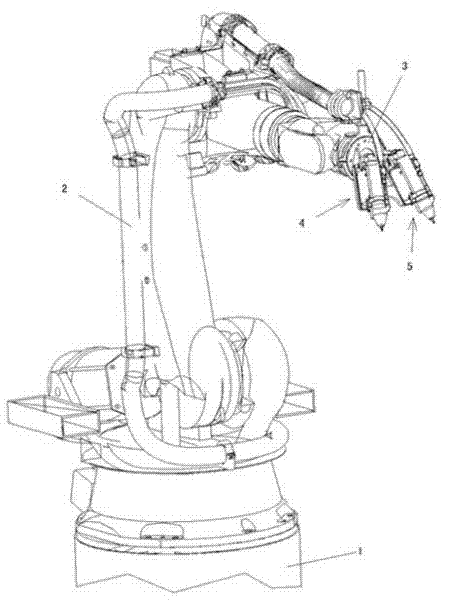

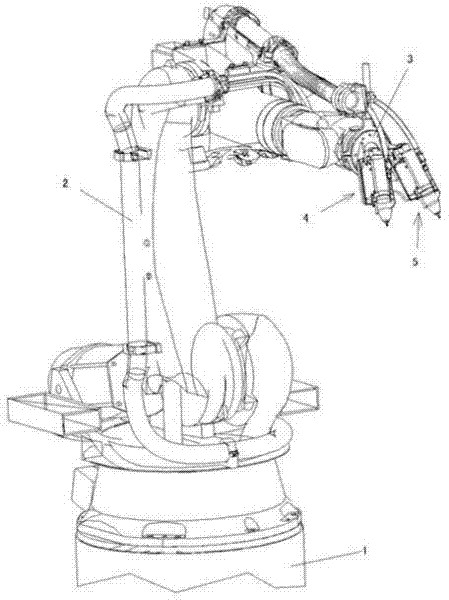

Hybrid heat source stud welding method using welding robot and hybrid heat source stud welding system with welding robot

InactiveCN102489845AAchieve weldingEfficient integrationArc welding apparatusStud weldingEngineering

The invention discloses a hybrid heat source stud welding method using a welding robot and a hybrid heat source stud welding system with the welding robot. The welding robot moves to a workpiece at the position of a stud to be welded, and a cylinder moves to place an induction heating ring on the workpiece at the position of the stud to be welded; an induction welder and a cooling water circulating system are started to perform induction heating for the workpiece at the position of the stud to be welded; the cylinder moves to lift the induction heating ring off the workpiece after induction heating; the welding robot moves to move a stud welding gun onto the workpiece at the position of the heated stud to be welded; the stud welding gun is started to weld the workpiece, and the welding robot moves to remove a head device and move the induction heating ring onto the welded stud; and post-weld heat treatment can be performed for the stud. The welding method and the welding system are used for automatically welding the stud with a hybrid heat source based on robot technology, and can be used for effectively integrating the automatic stud welding gun with the robot.

Owner:NANJING UNIV OF SCI & TECH

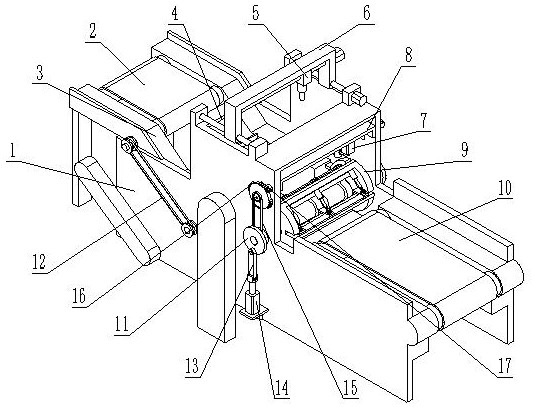

Full-automatic box plate and screw welding device for anchoring box

ActiveCN106425051AIngenious structural designCompact layoutWelding accessoriesStud weldingEngineering

The invention discloses a full-automatic box plate and screw welding device for an anchoring box. The full-automatic box plate and screw welding device comprises a box plate and finished product synchronous-transfer mechanism, a screw feeding mechanism, a stud welding mechanism and a finished product delivery mechanism, wherein the box plate and finished product synchronous-transfer mechanism comprises a material tray positioning rack, a sucking disc material-taking device and a box plate storage plate, the sucking disc material-taking device comprises left and right electromagnetic sucking discs arranged side by side, and the two electromagnetic sucking discs are connected together through a sucking disc supporting frame. The screw feeding mechanism comprises a screw storage pallet and a screw taking manipulator. The stud welding mechanism comprises a base, a welding bearing frame, a welding bearing plate, a metal chuck, a stud welding machine and a ceramic ring compression piece. Compared with the prior art, the full-automatic box plate and screw welding device has the following advantages that automatic feeding, automatic welding and automatic delivery are integrated, the welding quality and production efficiency are greatly improved, and the welding device is ingenious in structural design, compact in layout and suitable for popularization and usage.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Automatic welding equipment for automobile part welding and using method thereof

ActiveCN112621004ARealize automated productionImprove welding process efficiencyEdge grinding machinesWelding/cutting auxillary devicesStud weldingIndustrial engineering

The invention discloses automatic welding equipment for automobile part welding and a using method thereof, and relates to the technical field of automobile welding equipment. The automatic welding equipment comprises a workbench, the workbench is provided with a first conveying belt and a second conveying belt which are used for conveying parts, the first conveying belt is arranged at the feeding end, and the second conveying belt is arranged at the discharging end; and a feeding mechanism, a clamping assembly, a welding mechanism and a grinding mechanism are arranged between the first conveying belt and the second conveying belt, the welding mechanism is arranged above the side, close to the first conveying belt, of the clamping mechanism, and the grinding mechanism is arranged over the clamping mechanism. By means of the automatic welding equipment, through PLC control, automatic production of stud welding is achieved, and the welding and machining efficiency is improved; and meanwhile, welding and grinding integration is achieved, the welding process is optimized, and the labor cost is saved.

Owner:GUANGZHOU ZSROBOT INTELLIGENT EQUIP CO LTD

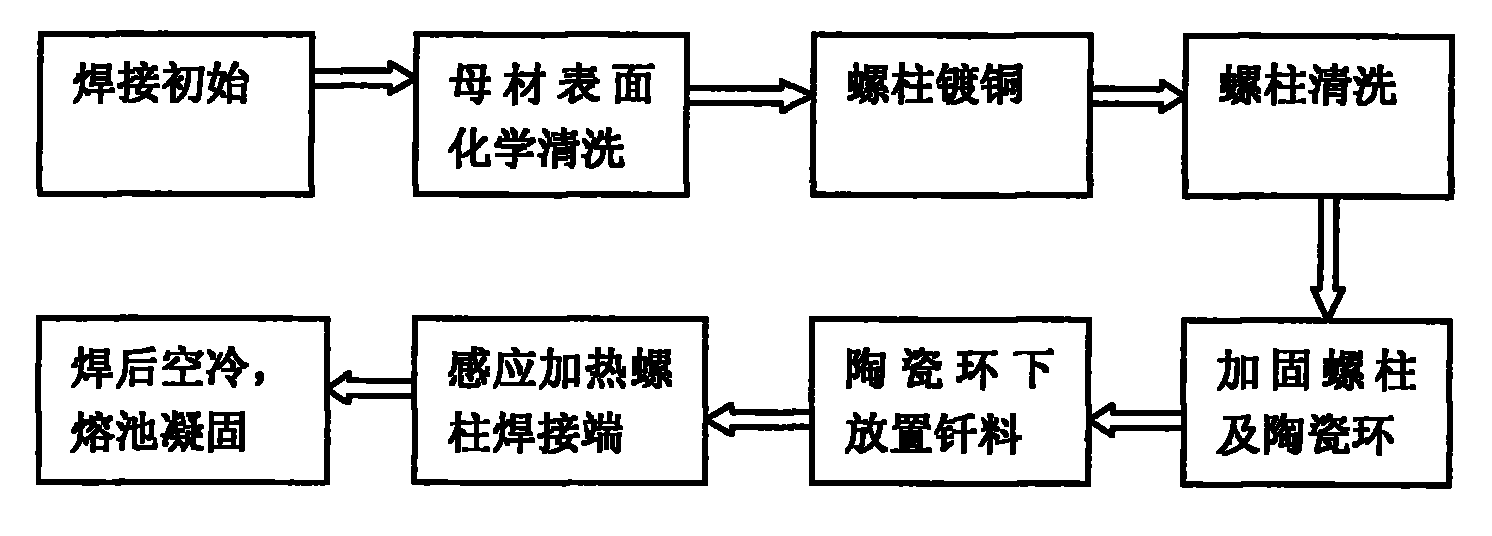

Method of pre-copper-plated induction welding-brazing of aluminum-steel stud bolt

ActiveCN102114561AImprove welding qualityEasy to operateSoldering apparatusWelding/soldering/cutting articlesFriction weldingCopper plating

The invention discloses a method of pre-copper-plated induction welding-brazing of an aluminum-steel stud bolt, which comprises the following steps: processing a steel stud bolt into a flat-bottom no-nut-cap type and conducting copper immersion plating to one end of the steel stud bolt; carrying out chemical cleaning to the surface of an aluminium base material and brazing filler metal; cleaning the surface of an aluminium base material and a brazing filler metal with alcohol, fast drying, and coating a layer of brazing protective agent on the surface of the base material; horizontally placing the aluminum base material, vertically placing the copper-plated end of the steel stud bolt on the aluminum base material, applying vertical downward pressure on the copper-plated end of the steel stud bolt, and filling enough cleaned brazing filler metal on the contact surface of the two; placing a ceramic ring matched with the stud bolt at the contact position of the copper-plated end of the steel stud bolt and the aluminum base material, and filling the brazing filler metal in the ceramic ring; and sheathing an induction heating coil at a welding end of the stud bolt, heating the induction heating coil and completing the welding. The invention can realize the welding of the small-diameter steel stud bolt and the aluminum base material, and has wide range of application to the thickness of plates.

Owner:NANJING UNIV OF SCI & TECH

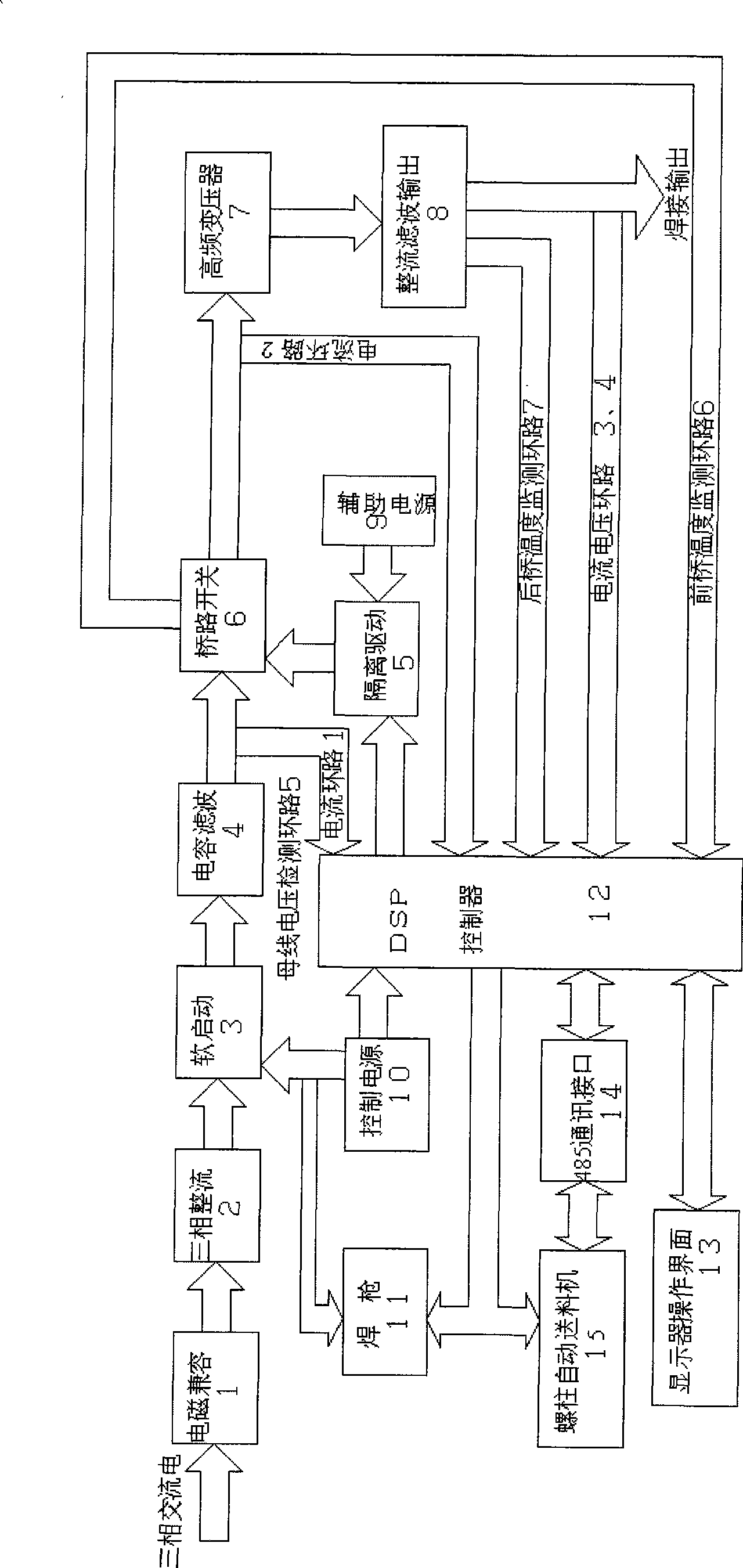

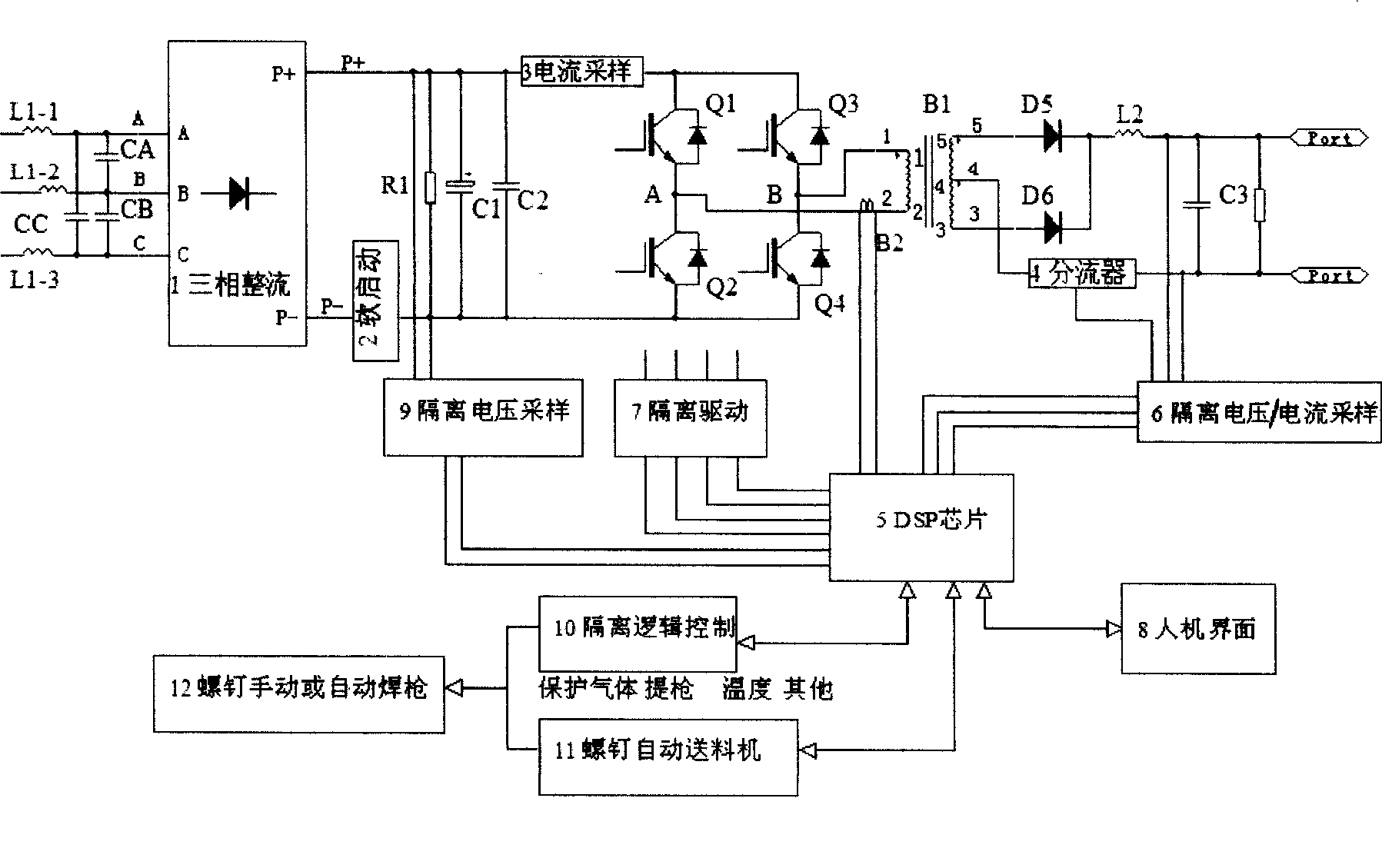

High-frequency inversion stud welding equipment and controlling means thereof

ActiveCN101462197AAdjustment frequency is highSolution to short lifeAc-dc conversion without reversalTransformersTransformerFeedback circuits

The invention discloses a device for welding a high-frequency inverter stud and a method for controlling the same. The device for welding the high-frequency inverter stud comprises a triphase rectifying circuit, an inversing circuit, a high-frequency transformer, a rectifying and filtering circuit, a DSP controller and a current feedback circuit. The current feedback circuit samples from the output end of the rectifying and filtering circuit, and a sampling value is input to the signal input end of the DSP controller; the inversing circuit comprises an IGNT bridge switching circuit and an isolated drive circuit; and the DSP controller can generate PWM signals, and the on-off of the IGNT bridge switching circuit is controlled by the isolated drive circuit. The invention provides the devicefor welding the high-frequency inverter stud and the method for controlling the same, and the device has the advantages of small volume and high power of the transformer, relative simple hardware circuit, high control accuracy, long service life of electrical elements, and good reliability and stability.

Owner:SHENZHEN HONGBAI TECH IND

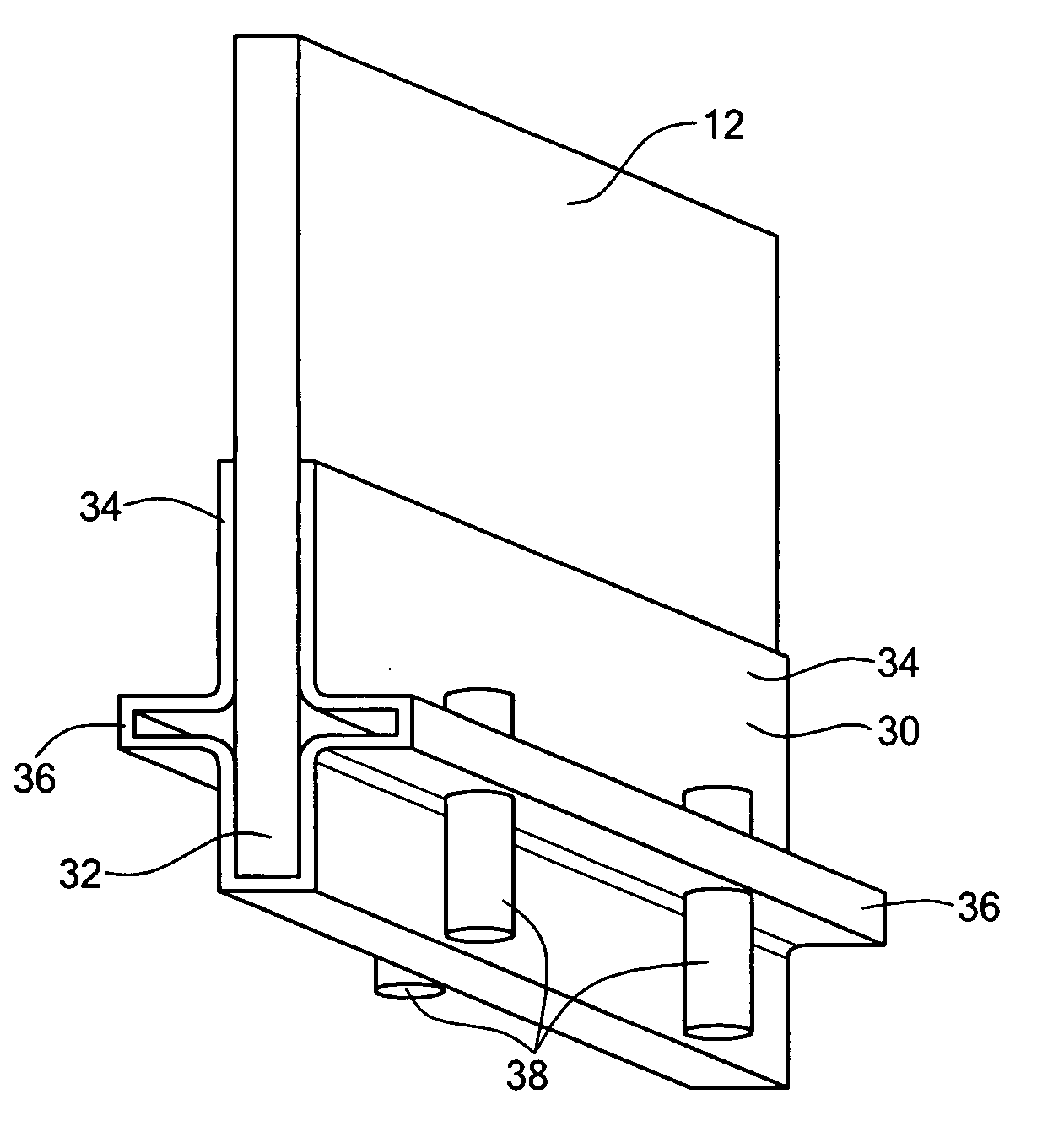

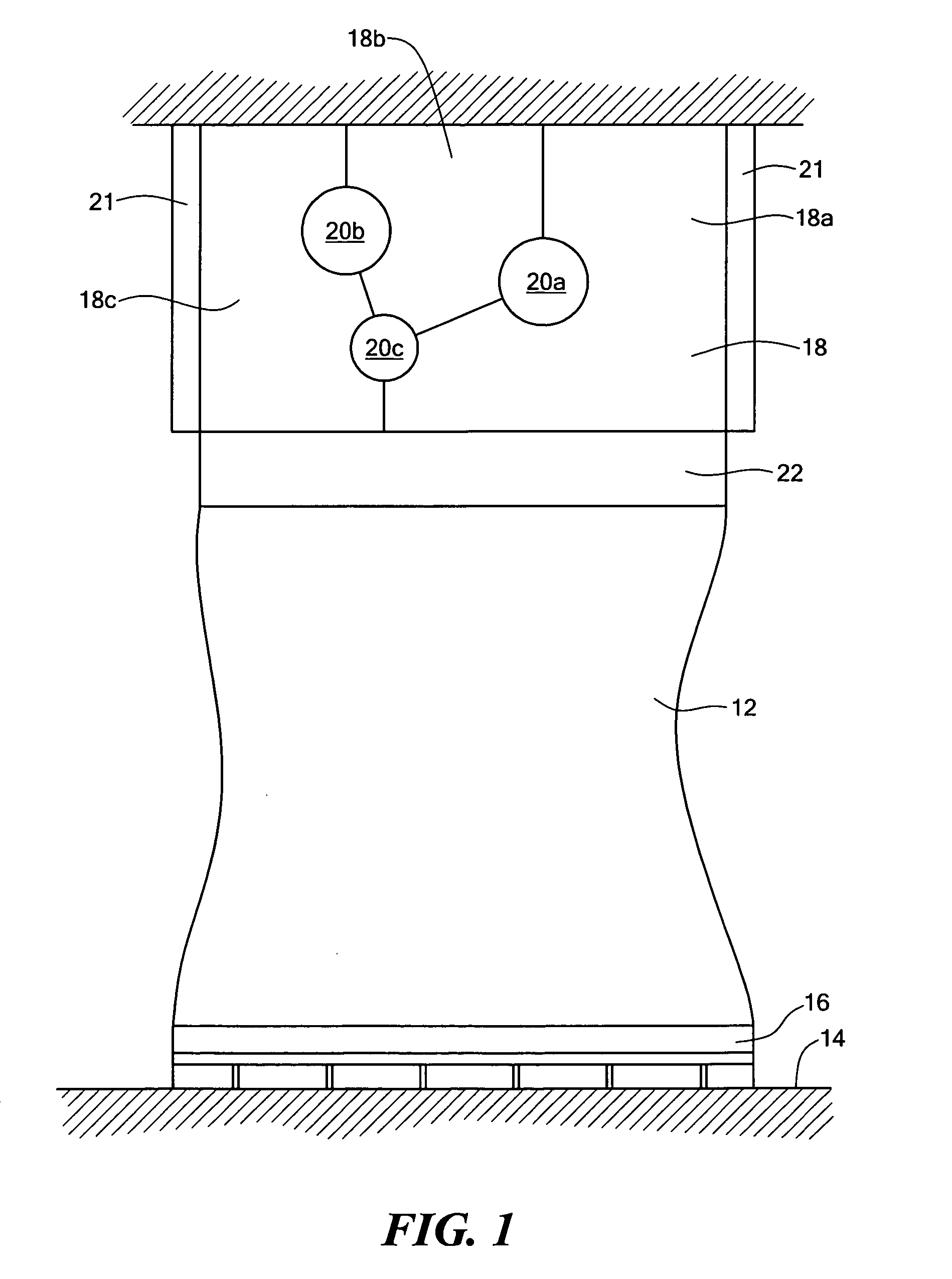

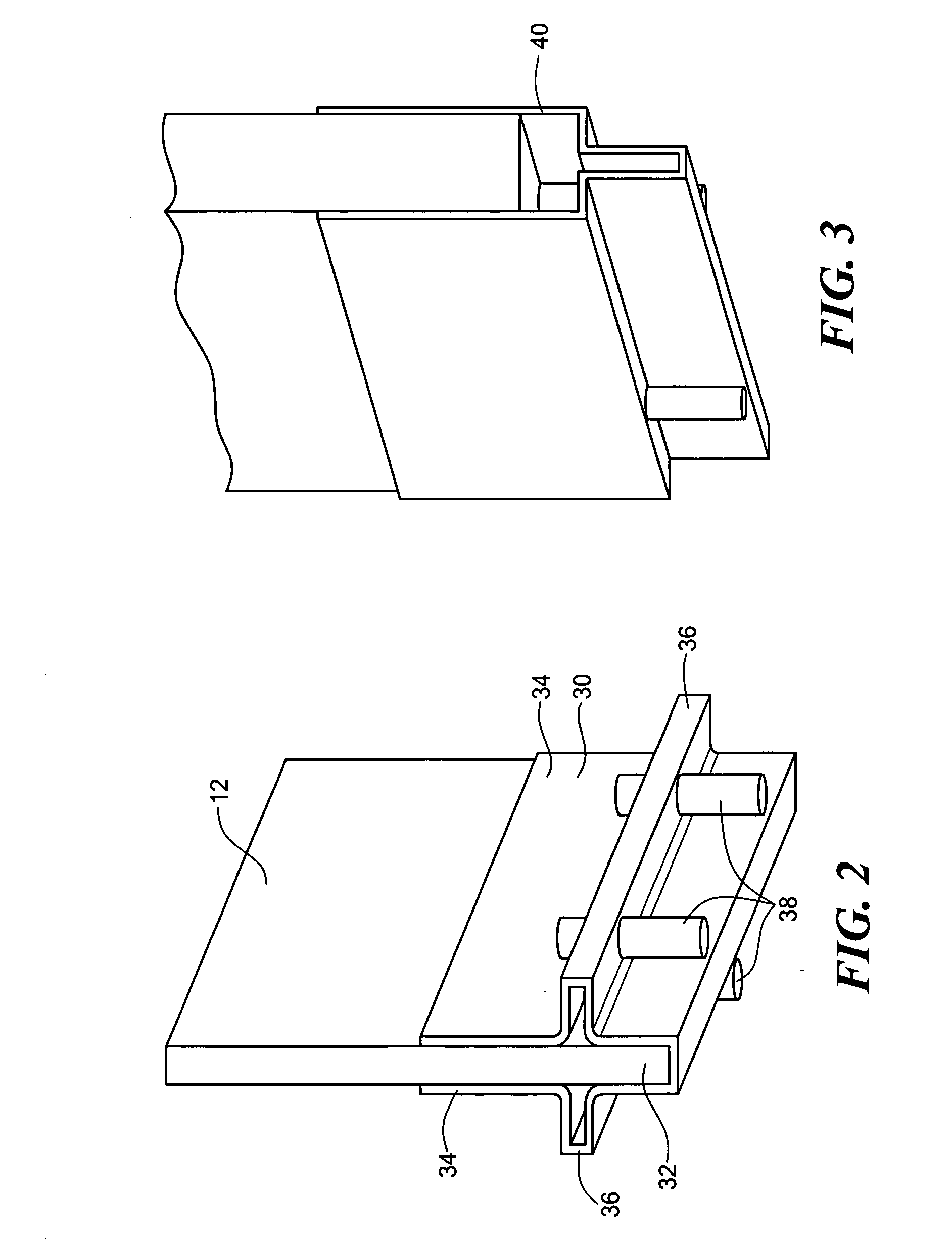

Joiner panel system

InactiveUS20050072087A1Easy to installReduce the time required for installationRoof covering using tiles/slatesLaminationFiberMicrosphere

A joiner panel system is formed from a composite material and includes a panel attached to a deck by a coaming or shoe and attached at its upper edge by a curtain plate that fits around obstructions at the ceiling area. The shoe can be readily installed to an uneven steel deck by stud welding to reduce installation time or attached to a composite material deck. A curtain plate fabrication method uses a laser scan or close range photogrammetry of the overhead area to optimize and automate the cutting of curtain plate sections. The curtain plate sections can then be readily installed in the overhead area. A composite material panel to provide good flame, smoke and toxicity properties and good mechanical properties is formed from a phenolic resin foam material, micro-balloons to reduce the weight and density, and reinforcing fibers and powder material to improve the mechanical properties. The panel can be formed by a method in which the core and face skins are co-cured to provide a good bond.

Owner:KAZAK COMPOSITES

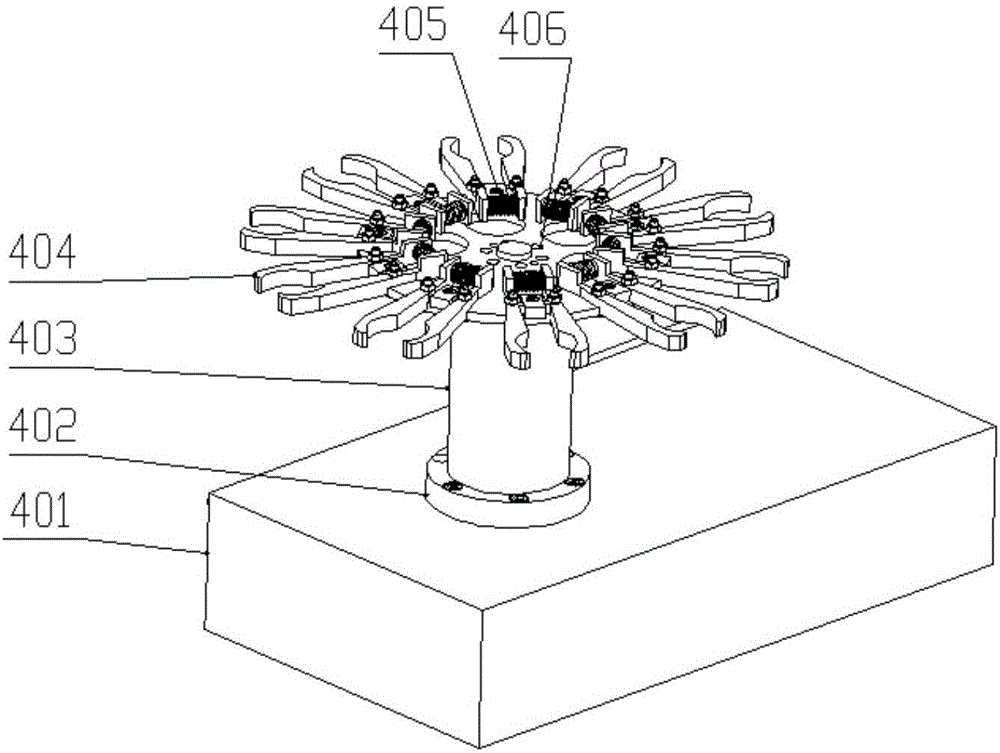

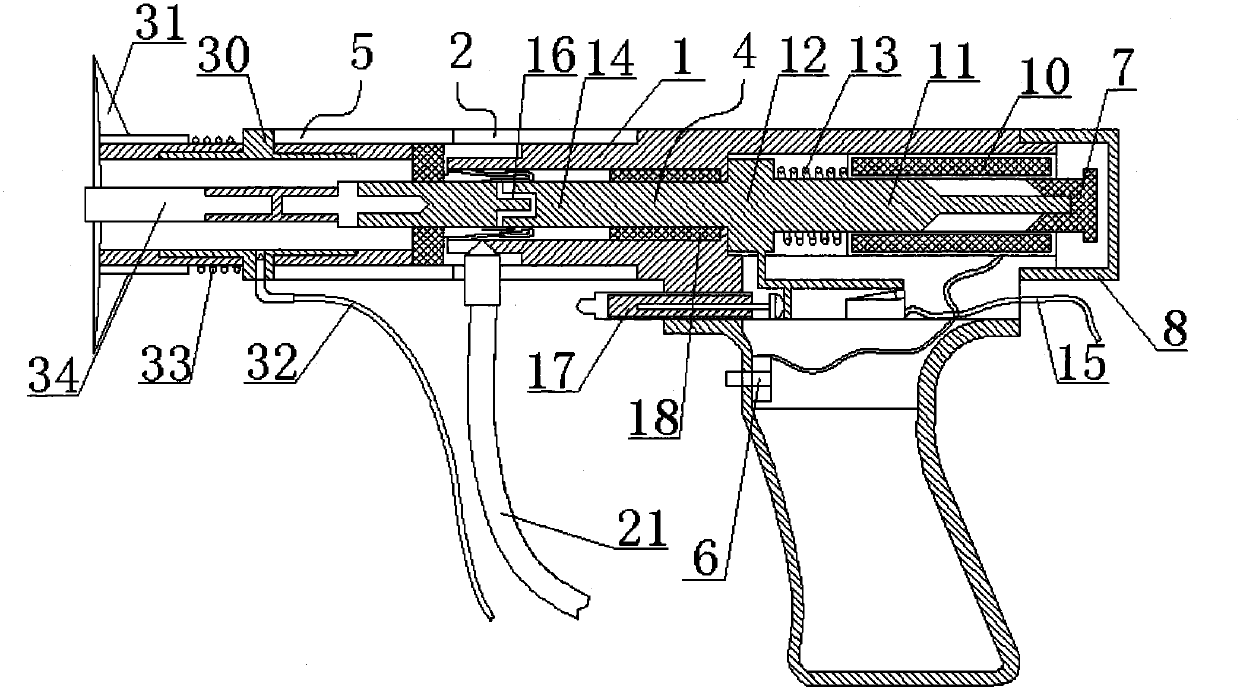

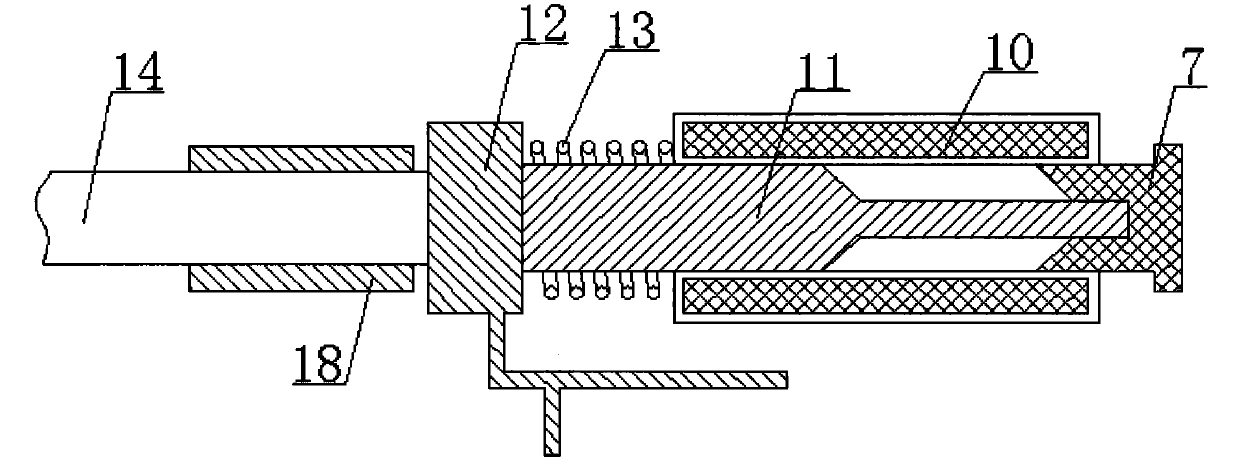

Robotic automatic large-diameter stud welding gun

ActiveCN102114567AGood effectRealize automatic weldingElectrode supporting devicesMaximum diameterEngineering

The invention discloses a robotic automatic large-diameter stud welding gun which comprises a welding gun main body and a welding gun clamp, wherein, the welding gun clamp comprises an upper plate, a lower plate, an upright post, a spring, a jacket and spring leaves; the jacket is arranged in the central position of the upper plate; the jacket penetrates through the upper plate and is fixedly connected with the upper plate; a plurality of elastic blades are arranged at the lower part of the jacket; the blades can grab studs stuck into the blades by virtue of the own elasticity; the lower plate is arranged under the upper plate; the upper plate and the lower plate are connected with each other through the upright post; the outer part of the upright post is sheated with the spring; the upper plate can move up and down along the upright post; a through-hole is formed in the center of the lower plate; the diameter of the through-hole is greater than the maximum diameter of the studs; a plurality of the spring leaves are arranged on the periphery of the through-hole; the spring leaves are uniformly distributed around the through-hole; and the spring leaves can clip ceramic rings penetrating into the spring leaves by virtue of the own elasticity. The robotic automatic large-diameter stud welding gun can be matched with a robot to achieve fully automatic welding, and achieves high effeciency.

Owner:NANJING UNIV OF SCI & TECH

Stud welding robot for automobile welding line

InactiveCN102513666AReduce the number of equipmentMeet the needs of welding with different specificationsArc welding apparatusEngineeringStud welding

The invention discloses a stud welding robot for an automobile welding line, which comprises a base. A robot body is mounted on the base, a connecting plate is fixed to an upper six-axis tip of the robot body, and a first stud welding gun and a second stud welding gun are mounted on the connecting plate through connecting supports. The stud welding robot for the automobile welding line has the advantages that at least two stud welding guns are mounted on the connecting plate, so that the requirements of different specifications of welding can be met, the number of robots is decreased, equipment investment is reduced, and stud welding guns of different specifications do not need to be switched during welding so that time and labor are saved and welding speed is increased.

Owner:大连奥托股份有限公司

Welding method and equipment for multifunctional threaded fastener

ActiveCN105880895AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStud welding

The invention discloses a welding method and equipment for a multifunctional threaded fastener. The welding method comprises MAG welding, TIG welding, MIG welding, stud welding and MIG brazing. The threaded fastener and a workpiece are positioned by a positioning mechanism of the equipment, a welding gun is clamped by a clamping mechanism, a pressing force is transmitted to a pressing mechanism by a power component, the threaded fastener and the workpiece are pressed by the pressing mechanism, the welding gun is driven to move downwards at the same time, and the threaded fastener and the workpiece are welded by a welding mechanism. Compared with existing arc welding equipment for welding the threaded fastener, the method and the equipment have the advantages that the efficiency is improved by 2 to 4 times; moreover, the problems of poor stability of conventional resistance projection welding of the threaded fastener, incapability in welding medium- and high-carbon steel, alloy steel, dissimilar metals and dissimilar materials, incapability of welding on the sidewall of a U-shaped sheet metal part, various hollow and solid pipe fittings and thick plates, incapability of abreast welding of the threaded fastener and the workpiece and the like are solved. In addition, the invention further provides MIG-brazed and flame-brazed fastener and a workpiece used for welding a threaded fastener and positioned by a light beam.

Owner:何强

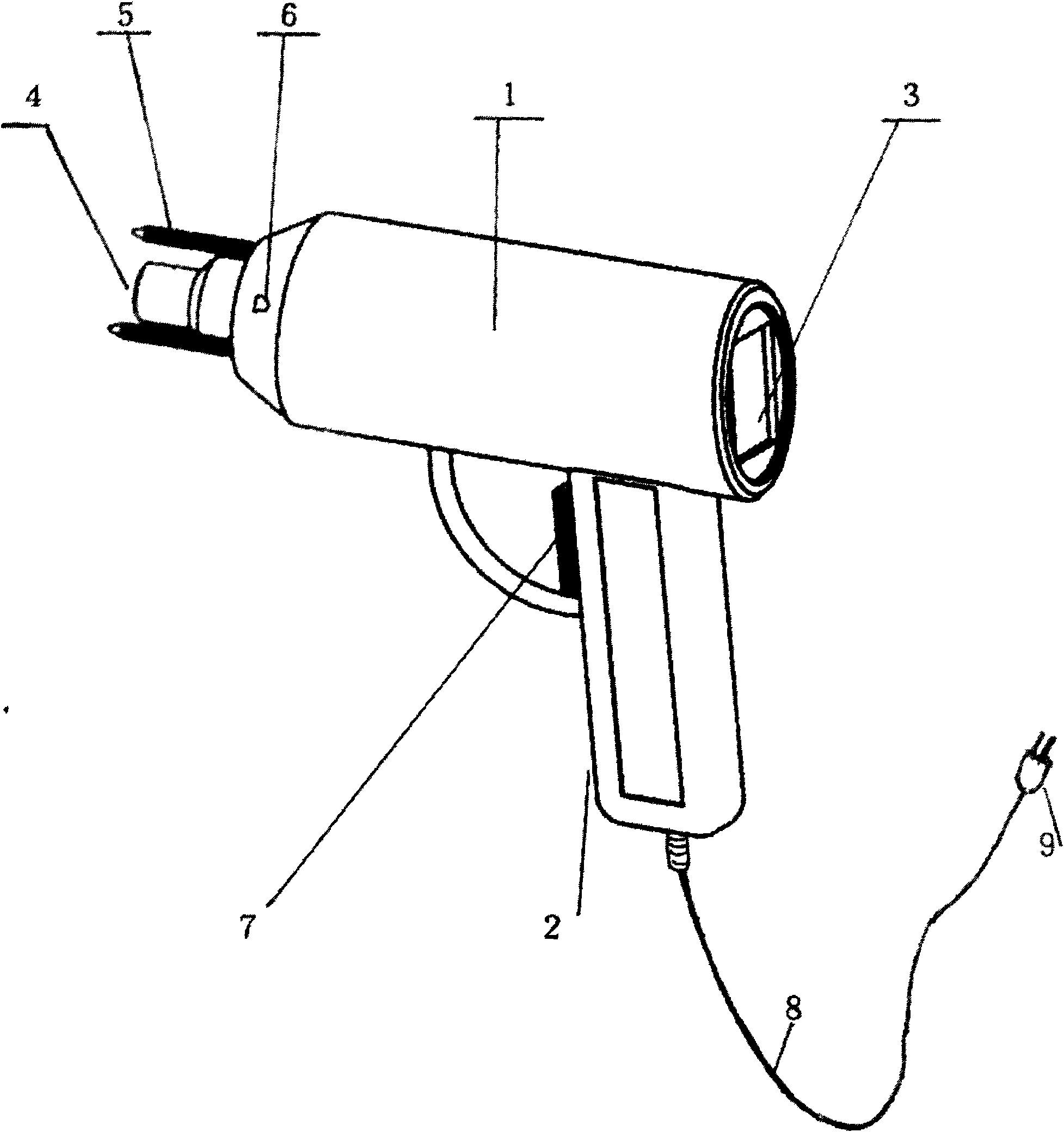

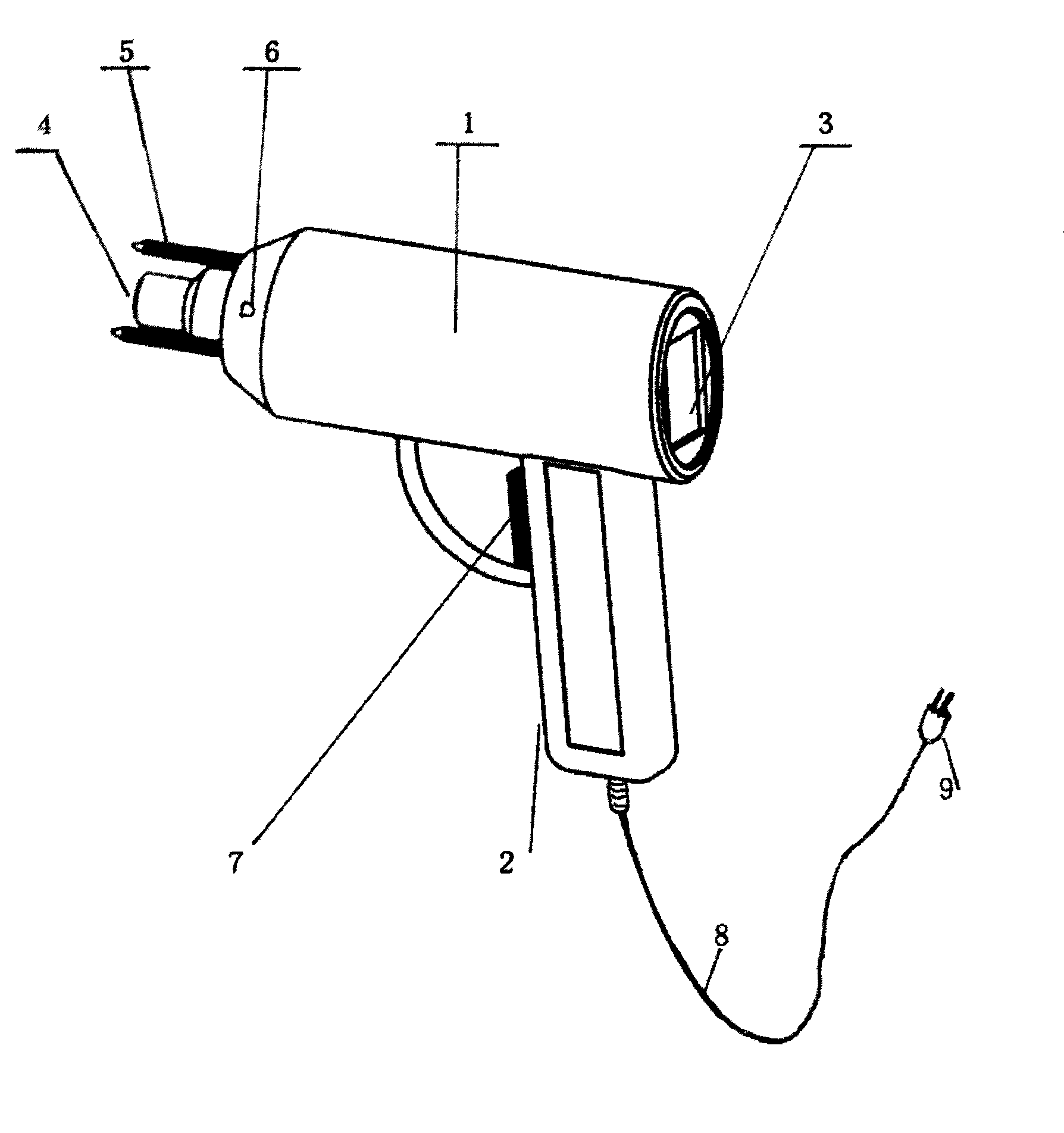

Ultra-miniature stud welding machine

InactiveCN101920383AReduce volumeReduce weightElectrode supporting devicesWelding accessoriesCapacitanceLaser transmitter

The invention relates to an ultra-miniature stud welding machine which combines and integrates a traditional stud welding machine and a welding gun into a whole and is structurally characterized in that a traditional electrolytic capacitor for energy storage is changed into a ceramic capacitor and combined in an appropriate mode. The power supply box of the stud welding machine is saved, the whole machine is made into the shape of a gun, a traditional grounding wire is eliminated and changed into a horizontal positioning claw on the welding gun to be concurrently used as a ground wire, and in order to obtain better welding positioning, a laser transmitter positioned in cross-line coordinates is also installed on the ultra-miniature gun-shaped stud welding machine.

Owner:徐小羚

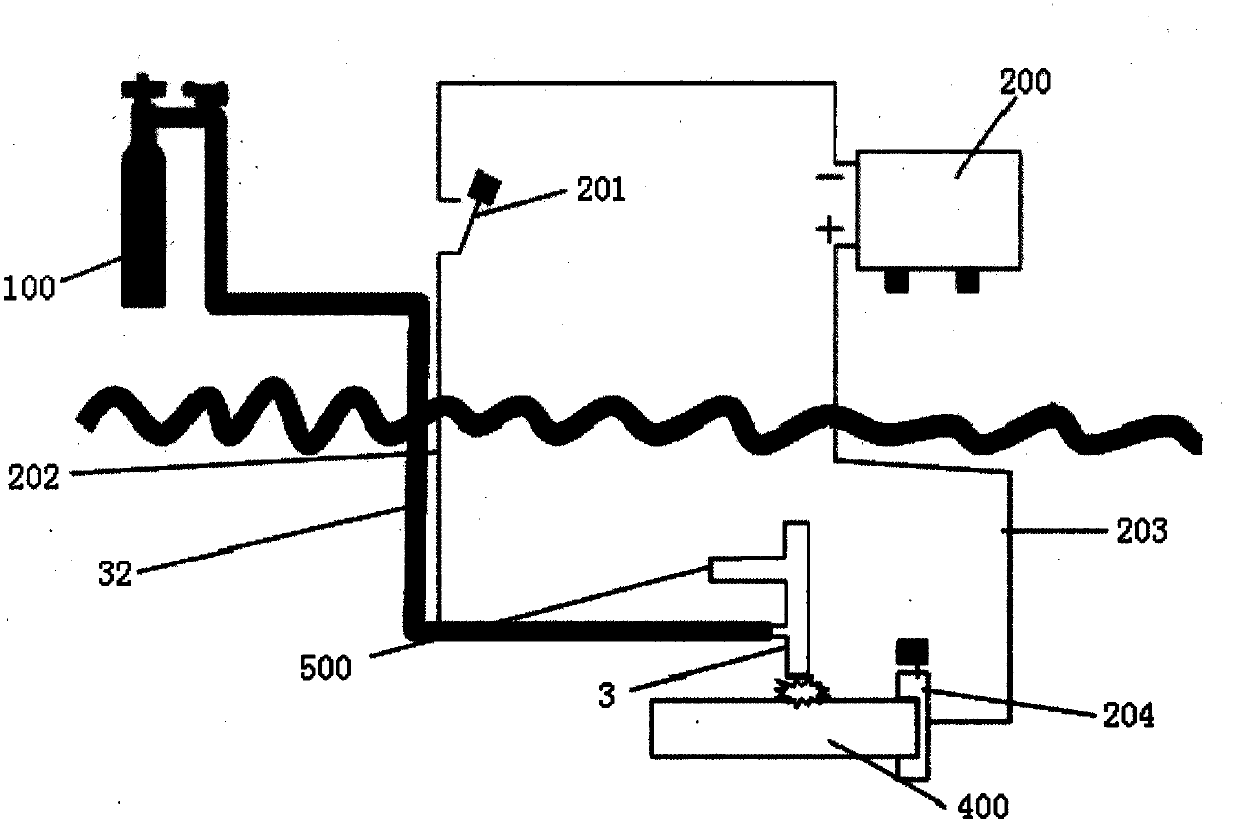

Underwater multifunctional stud welding device and welding method thereof

ActiveCN104259637AQuick repairShort welding timeShielding gas supply/evacuation devicesWelding/cutting media/materialsWelding power supplyStud welding

The invention belongs to underwater welding cutting equipment, in particular relates to a underwater multifunctional stud welding device and a welding method thereof. The underwater multifunctional stud welding device mainly consists of a high-power welding power supply, a welding cutting set, an air supply system, a welding cable and a control system, wherein the air supply system comprises an air storage bottle, a pressure reducer and a corresponding air supply pipeline; and the welding cable comprises a welding ground, a cable fixing clamp, a welding gun welding cable and a welding gun control cable. The underwater multifunctional stud welding device has such characteristics as short welding time, good underwater welding quality, no need of operation by special underwater welders, reduction of fastening pieces and all-position welding, can realize such multiple functions as underwater stud welding, underwater manual arc welding and underwater electricity-oxygen cutting, and provides a whole set of solutions for such underwater emergency repair as damaged part repairing, repair plate stud fixation and reinforcement seal welding of damaged ships. The underwater multifunctional stud welding device can perform quick underwater repair without needing the ships to dock for drainage, so that the repair resource and cost are largely reduced, and the repair efficiency is improved.

Owner:THE PLA NAVY SUBMARINE INST

Stud welding apparatus with composite cable

A stud welding apparatus includes a power supply and a stud welding tool having a welding head portion and a cable receiving portion. A composite cable having first and second ends is coupled at a first end to the stud welding tool at the cable receiving portion and to the power supply at the second end of the composite cable. If the stud feeder is present, the second end of the composite cable can be coupled to the stud feeder. The composite cable includes a conductor having no individual electrical isolation and at least one control lead electrically isolated from the conductor. The conductor and the at least one control lead are surrounded by an outer non-conductive layer.

Owner:NELSON STUD WELDING

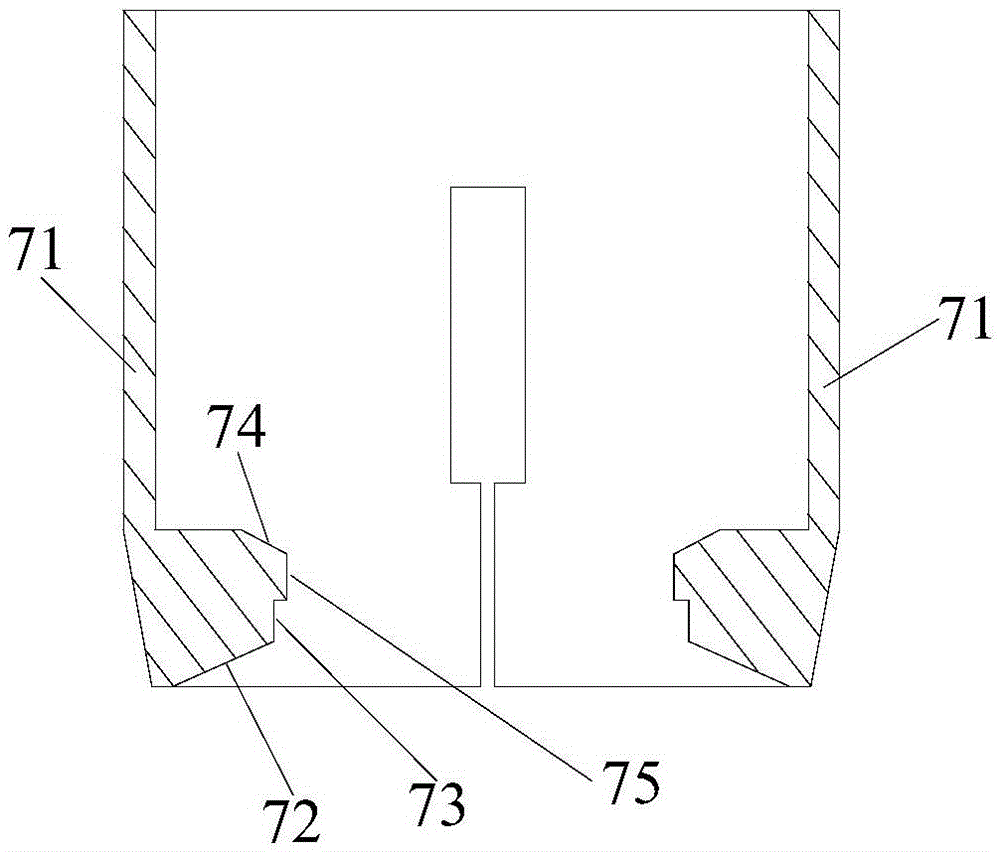

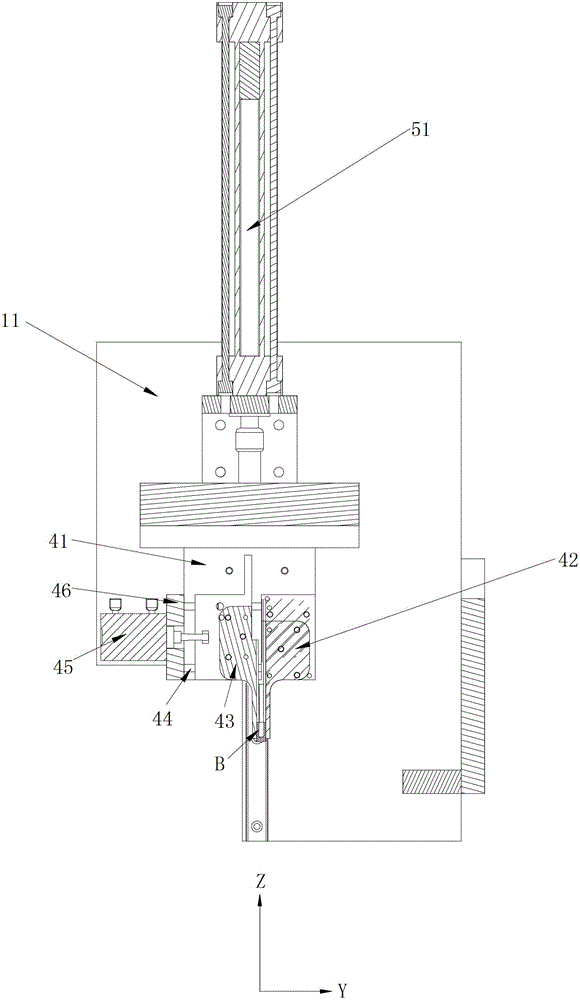

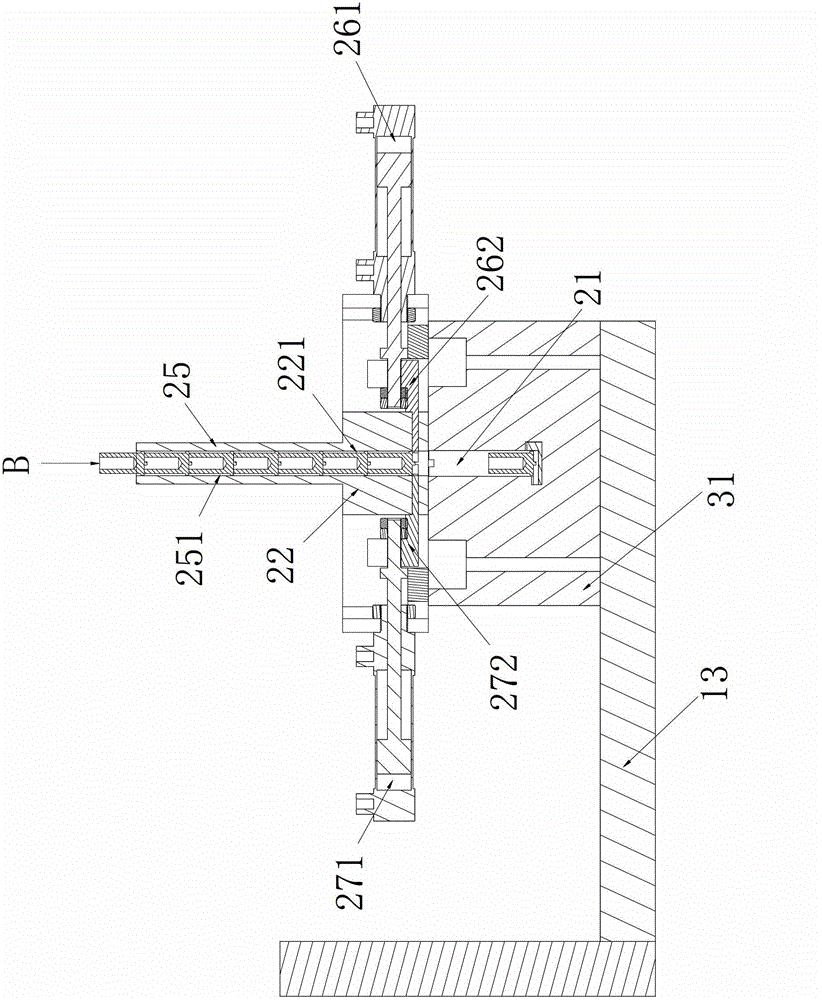

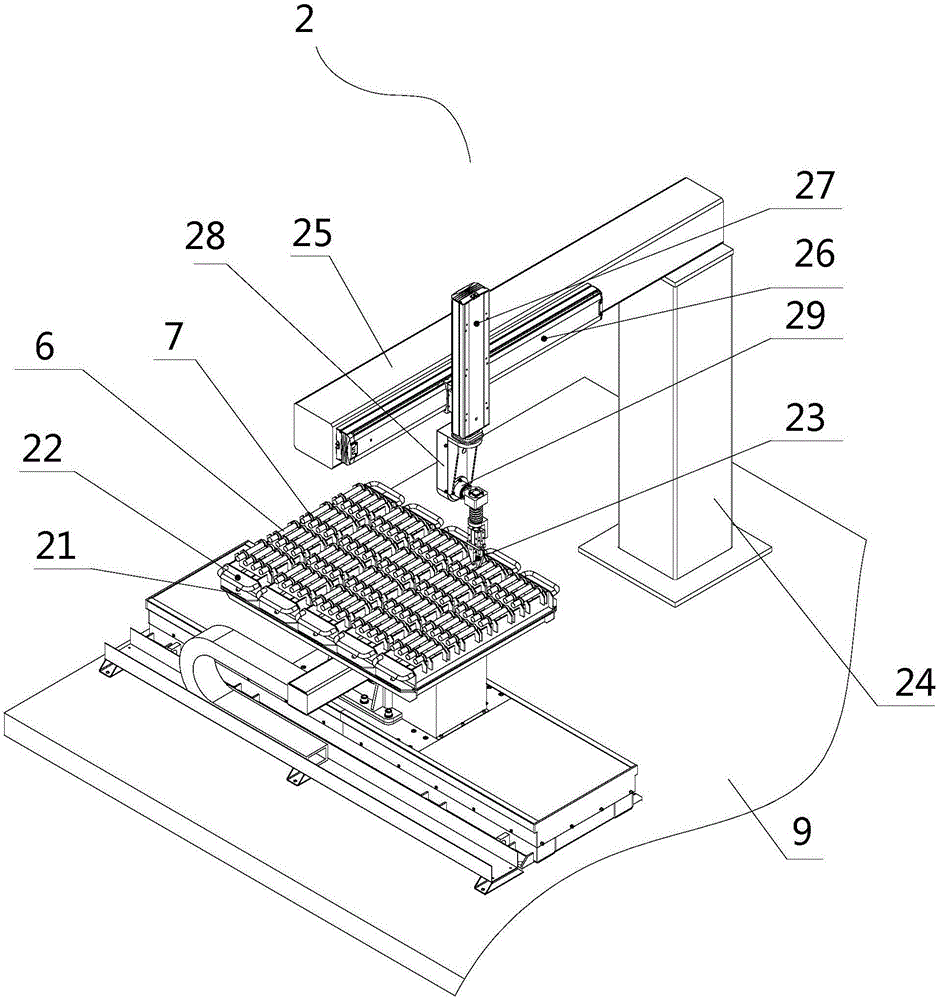

Device for realizing full-automatic stud welding of T-type welding stud

ActiveCN105598564AImplement auto-socketingRealize automatic deliveryWelding accessoriesStud weldingEngineering

The invention discloses a device for realizing full-automatic stud welding of a T-type welding stud. The device comprises a three-axis moving platform, multiple automatic welding guns, multiple automatic feeding mechanisms, a conveying track for conveying the T-type welding stud sleeved by a ceramic ring and an automatic sleeving mechanism for the T-type welding stud and the ceramic ring, wherein the up-down, left-right and back-forth movement of the automatic welding gun is realized through the three-axis moving platform; the automatic feeding mechanisms can move left and right or back and forth; a feed port of each automatic feeding mechanism is connected with the conveying track for conveying the T-type welding stud sleeved by the ceramic ring; and a feed port of the conveying track is connected to an output track of the automatic sleeving mechanism for the T-type welding stud and the ceramic ring. By adopting the device disclosed by the invention, automatic sleeving of the T-type welding stud and the ceramic ring, automatic conveying of the T-type welding stud sleeved by the ceramic ring and automatic clamping and release of the T-type welding stud and the ceramic ring by the welding gun are realized for the first time; and in combination with the three-axis moving platform, full-automatic arc stud welding of the T-type welding stud is realized for the first time, and the welding efficiency and quality of the T-type welding stud are remarkably improved.

Owner:胡长建

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com