Automatic feeding device for stud welding

A technology of automatic feeding and pushing device, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of increasing production costs, low efficiency, waste of electric energy, etc., to save production costs, improve work efficiency, and save electric energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

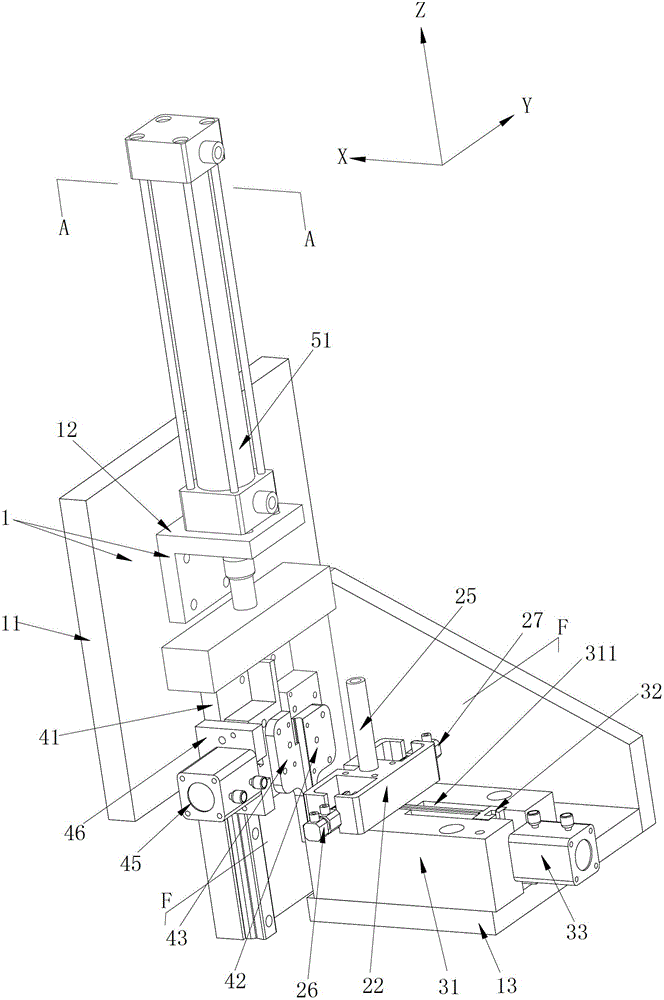

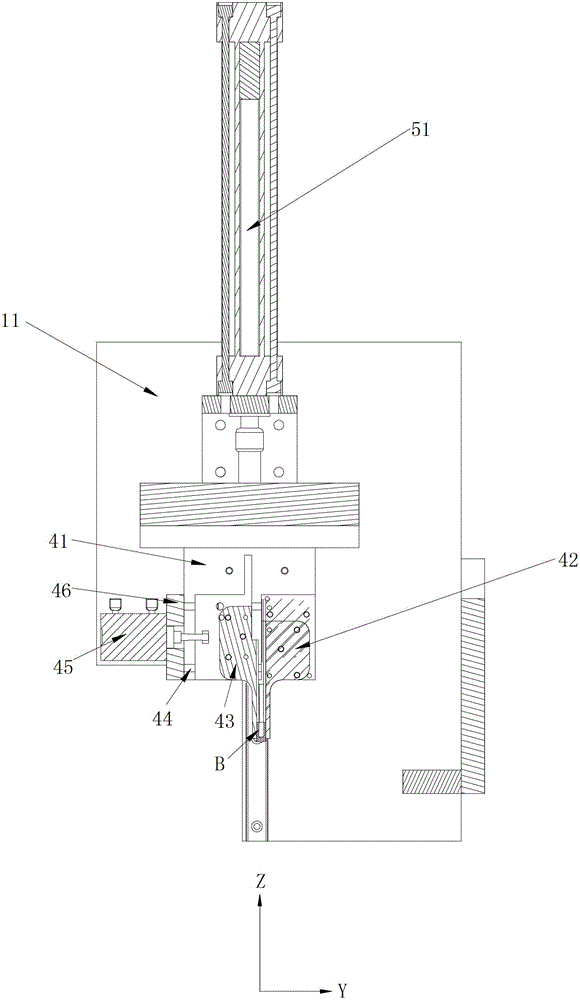

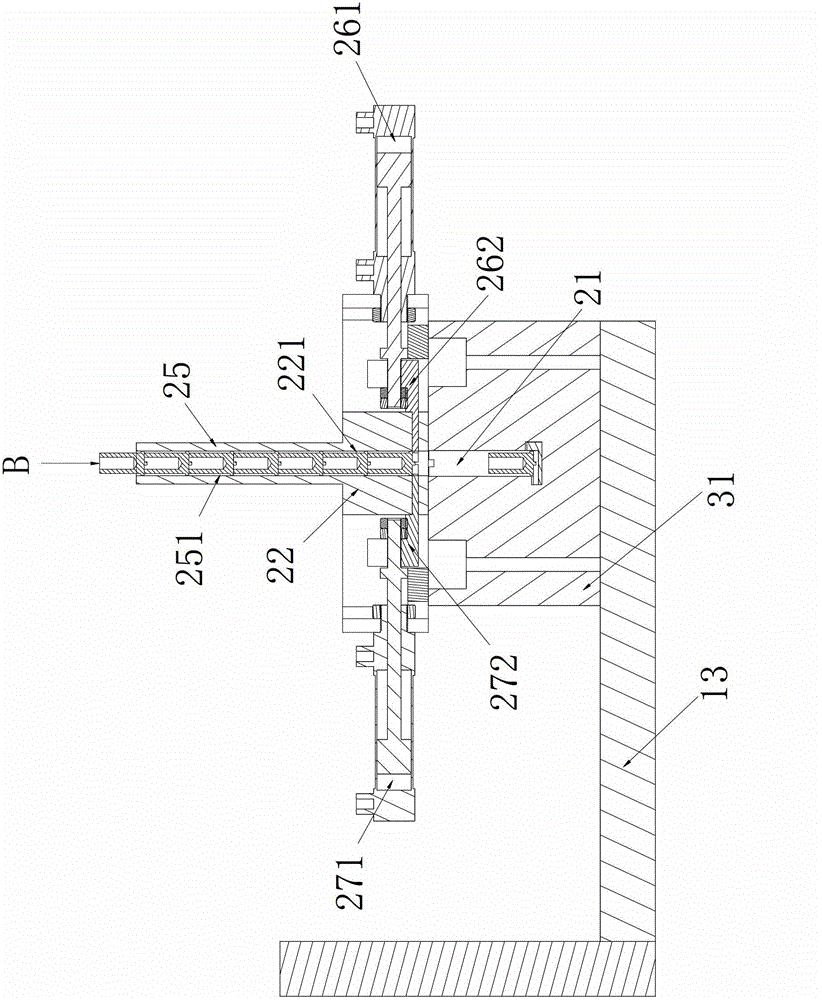

[0049] Figure 1 to Figure 11 Shown is the structure of the first embodiment of the stud welding automatic feeding device of the present invention, including a frame 1, which is used to place the longitudinal discharge device of the stud B to be welded, and is used to install the vertical discharge device and can be used in The horizontal pushing device that moves back and forth horizontally between the first position and the second position of the horizontal station of the frame 1, and the longitudinal push that can move back and forth longitudinally between the third position and the fourth position of the vertical station of the frame 1 device, which is fixed at the lower end of the longitudinal pushing device and clamps the movable clamp of the stud B pushed to the second position by the horizontal pushing device when the longitudinal pushing device moves to the third position, and is used for data transmission to connect the vertical discharging The controller (T (figure ...

Embodiment 2

[0074] Figure 12 Shown is the structure of the second embodiment of the stud welding automatic feeding device of the present invention, which is the same as Figure 1 to Figure 11 The only differences in the structure of the first embodiment shown are:

[0075] In order to realize the multi-station feeding function, specifically, the number of the longitudinal discharging device is multiple, and the number of the horizontal pushing device is multiple, and the vertical discharging device corresponds to the horizontal pushing device one by one The automatic feeding device for stud welding also includes a screw drive device for transferring the horizontal pushing device to the horizontal station one by one; the screw drive device is connected to the controller through data transmission.

[0076] Specifically, the screw drive device includes a support plate 61, a screw 62 extending vertically, and a servo motor 63 for driving the screw 62 to rotate under the action of the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com