Patents

Literature

176results about How to "Accurate gripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

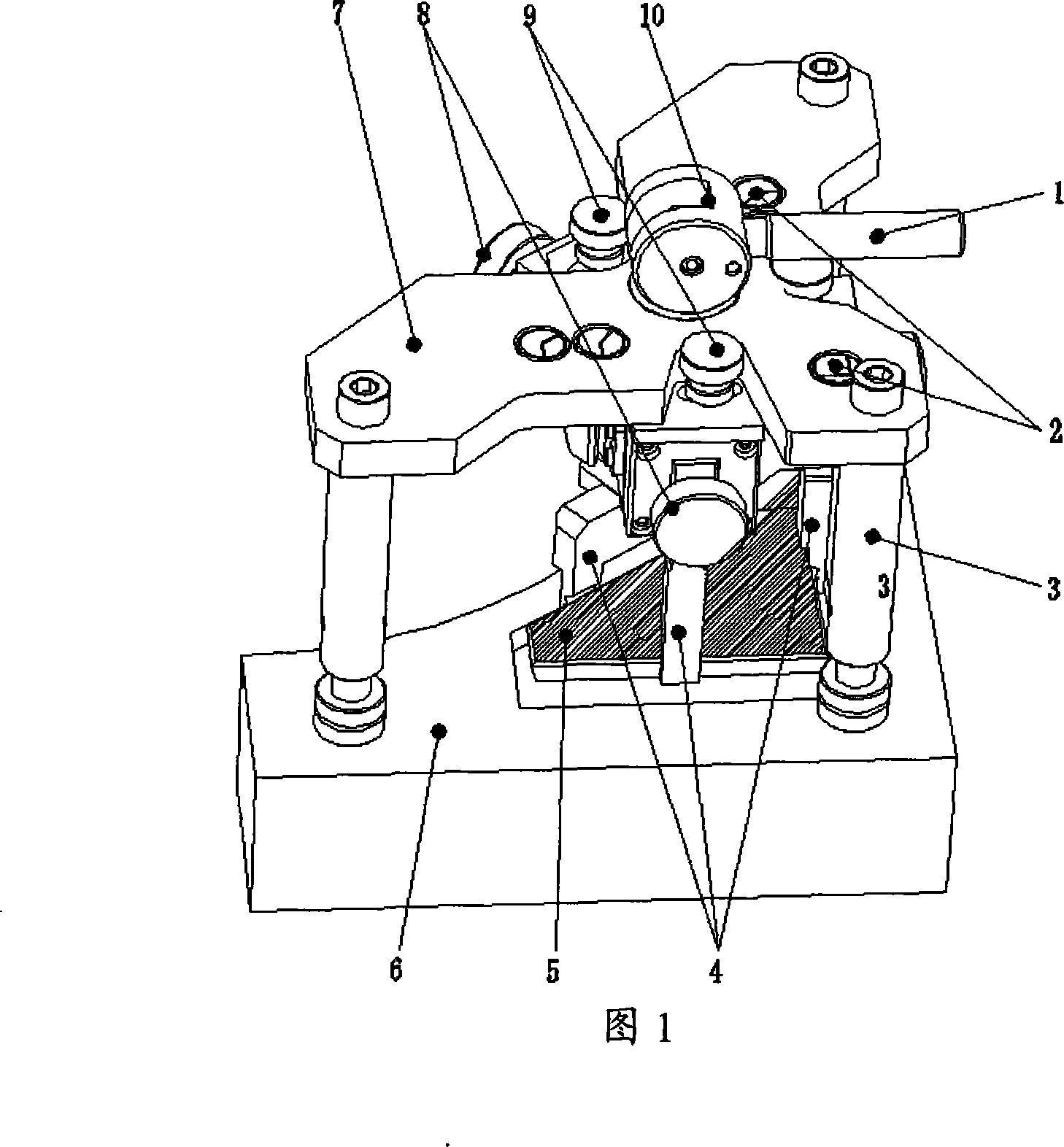

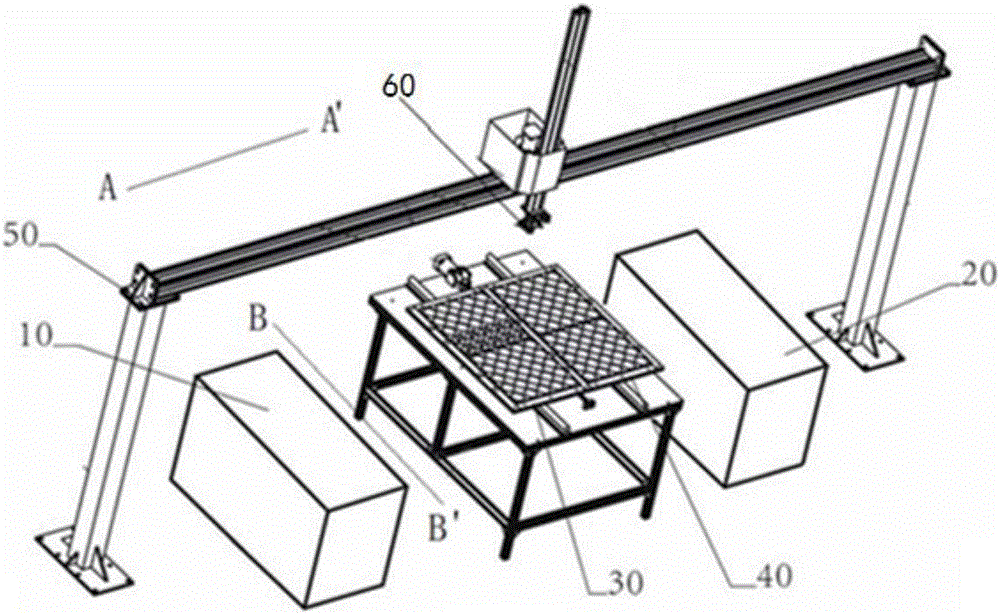

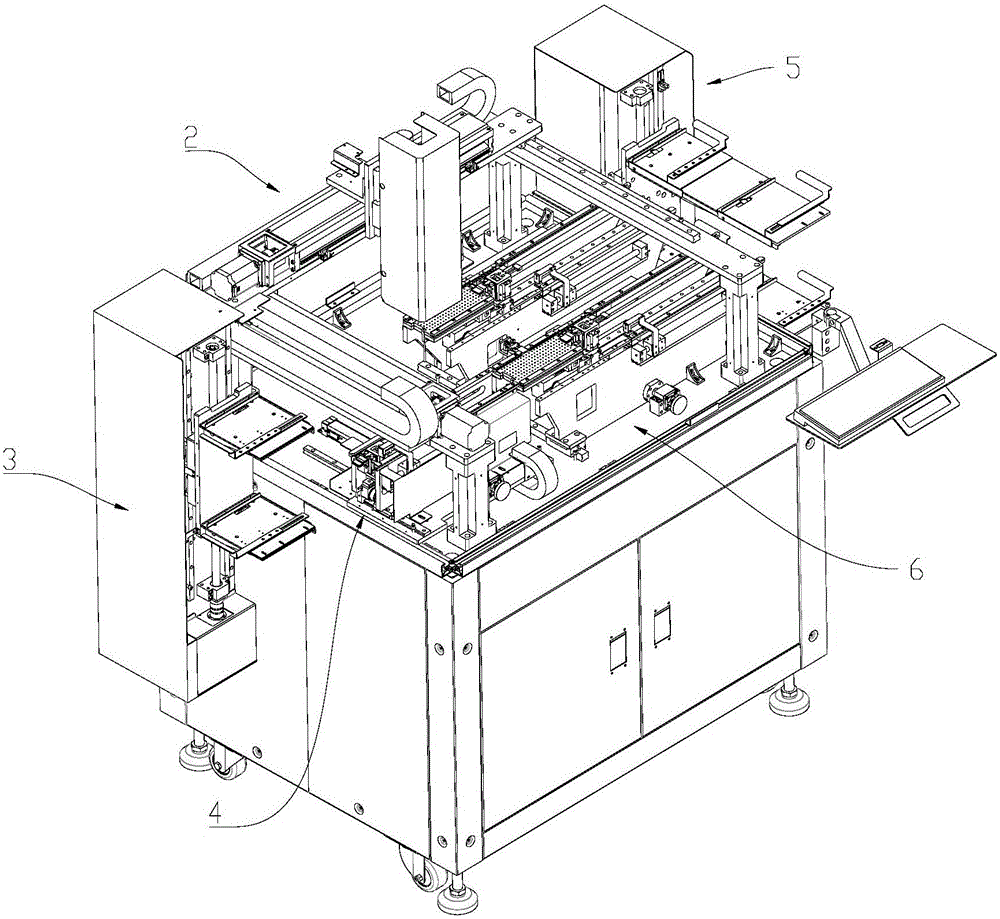

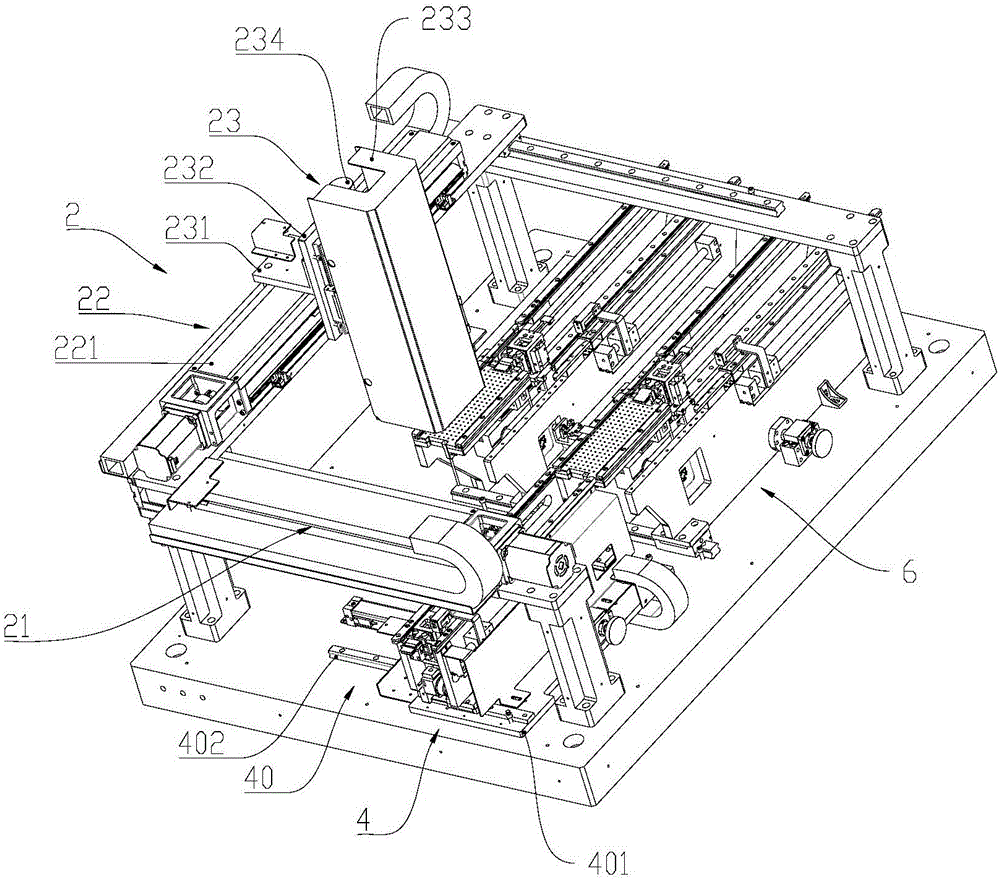

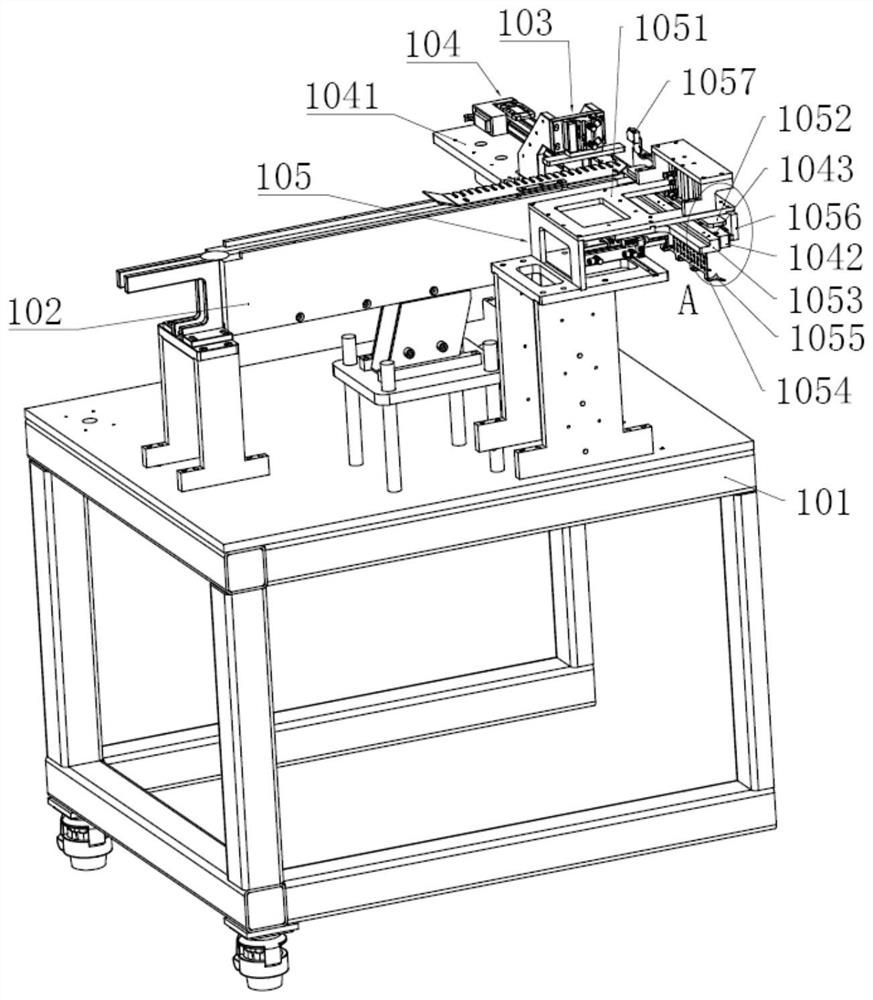

Robot flexible punching workpiece handling system based on visual system

ActiveCN103111535AReduce heat damageReduce contact areaProgramme-controlled manipulatorMetal-working feeding devicesPunchingControl system

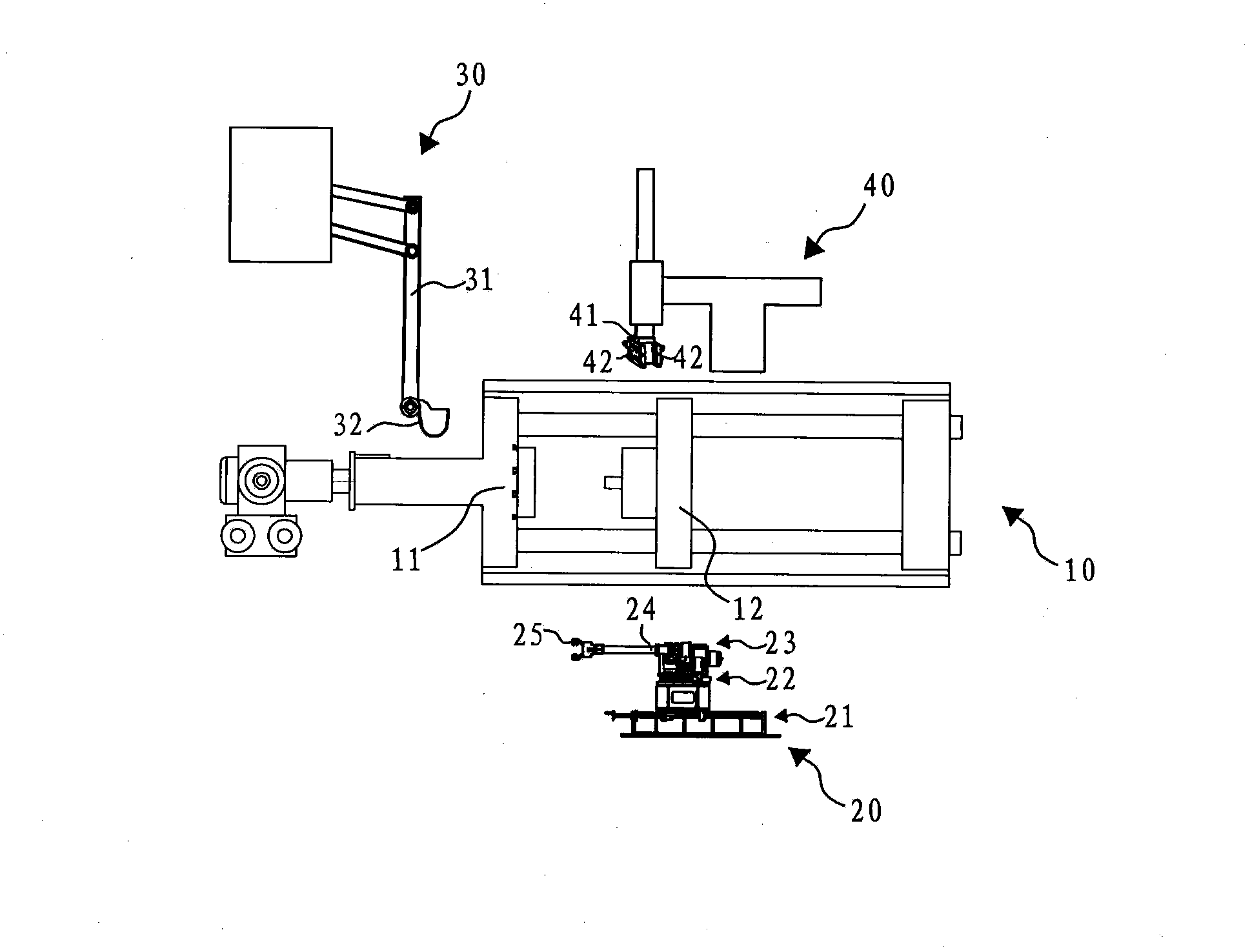

The invention discloses a robot flexible punching workpiece handling system based on a visual system. The visual system is arranged opposite to a punching workpiece of a positioning platform to conduct photo taking and coordinate analysis and sends final coordinate data to a robot control system. The robot control system controls the arm of a robot to move, so that a fixture is enabled to clamp the stamping workpiece quickly and accurately to conduct punching in a punching machine, and the robot control system controls the arm of the robot to move after the punching, so that the fixture is enabled to clamp the punching workpiece which is punch formed to a material discharging platform. The whole handling process is completed by the robot, therefore handing automation is achieved, and thus labor intensity is small and efficiency is high.

Owner:CHANGSHA CTR ROBOTICS

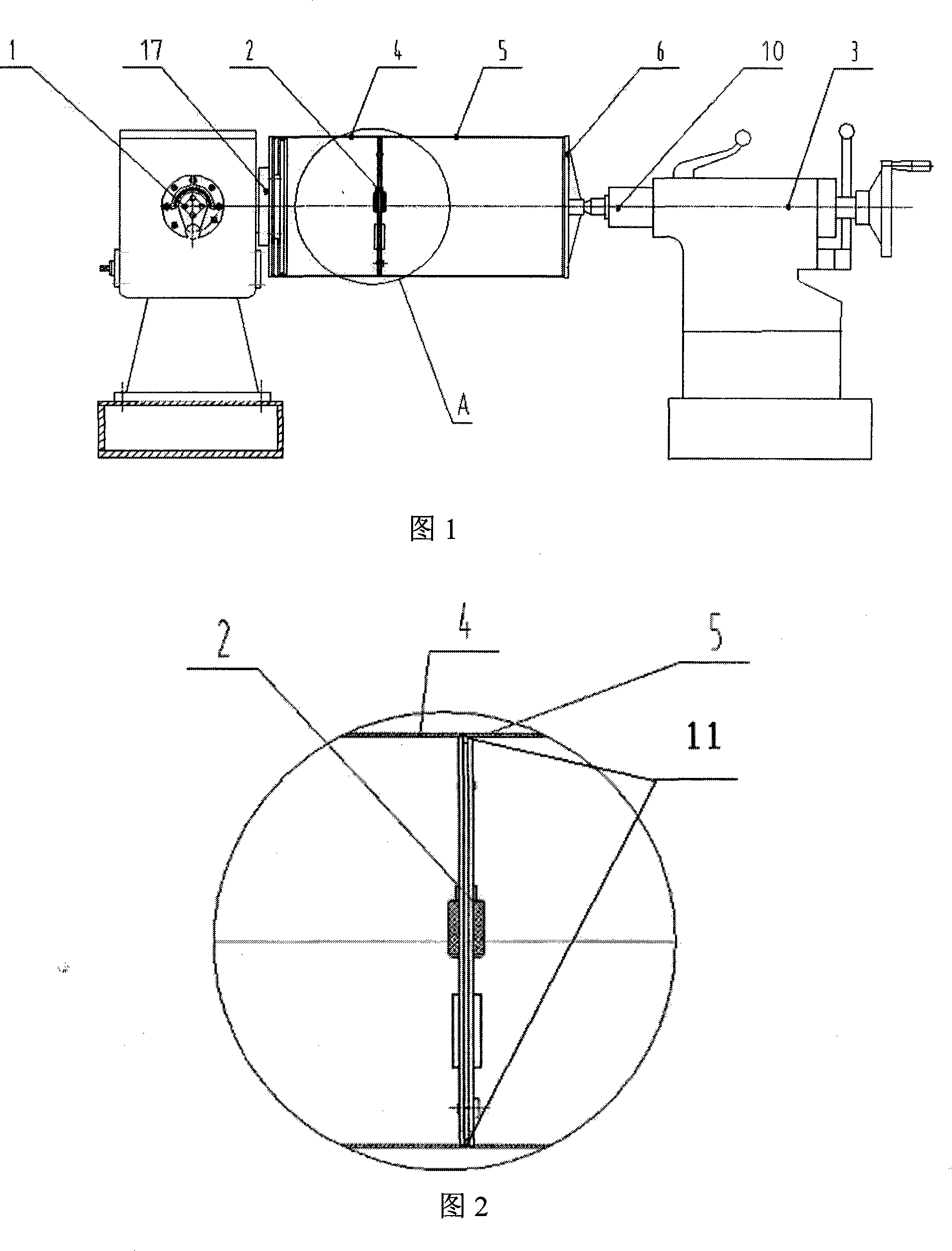

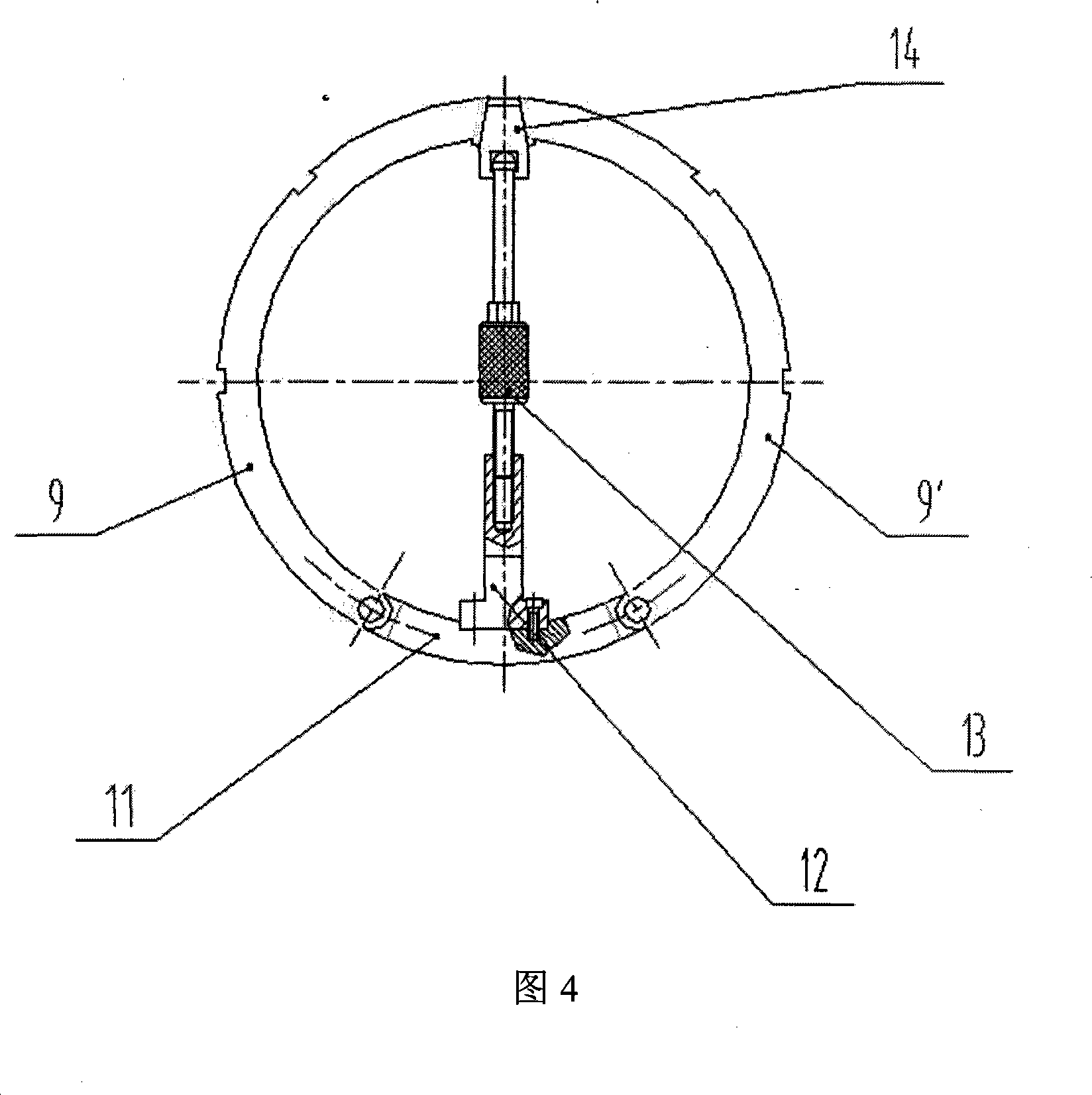

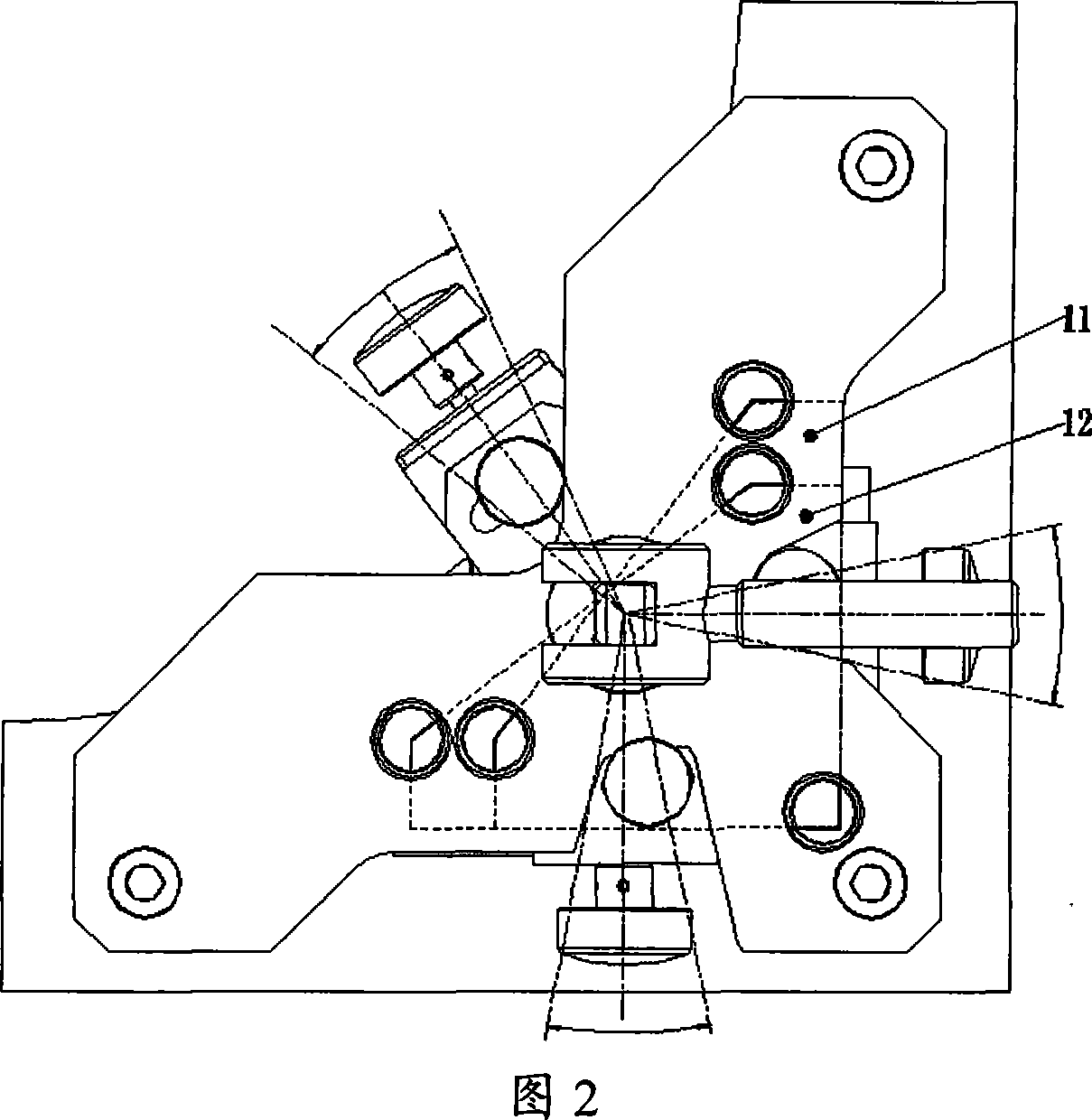

Thin walled cylinder girth laser welding tong

InactiveCN101229612ARealize rotary motionAccurate splicingWelding/cutting auxillary devicesAuxillary welding devicesGyrationEngineering

The invention discloses a circular seam laser welding fixture for a thin-wall cylinder, which comprises a head frame, an extended ring, a rear frame of a machine tool and a top plate. When in operation, the extended ring is placed between the head frame and the rear frame of the machine tool and sleeved in a place where two workpieces to be welded are spliced; one non-splicing end of the workpiece is retained and positioned on a spindle of the head frame while the other non-splicing end is attached to a positioning surface of a baffle; a top point of the rear frame of the machine tool is arranged in a top point hole of the baffle. By adopting a retractable extended ring, the invention realizes the correct splicing and retaining of the thin-wall cylinder; the gyration of the cylinder can be realized by a way that the head frame with the function of turning drives a head part of the cylinder and a tail part of the cylinder is supported by the rear frame and the top plate; meanwhile, the splicing precision also meets the requirement of the laser welding. A worm-and-gear mechanism of the spindle in the head frame can accomplish the precise gyration of the workpiece and the head frame with a turnover function is convenience for feeding and discharging of a longer workpiece. The invention has the advantages of precise positioning, reliable and convenient fixture, convenient application, high efficiency, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

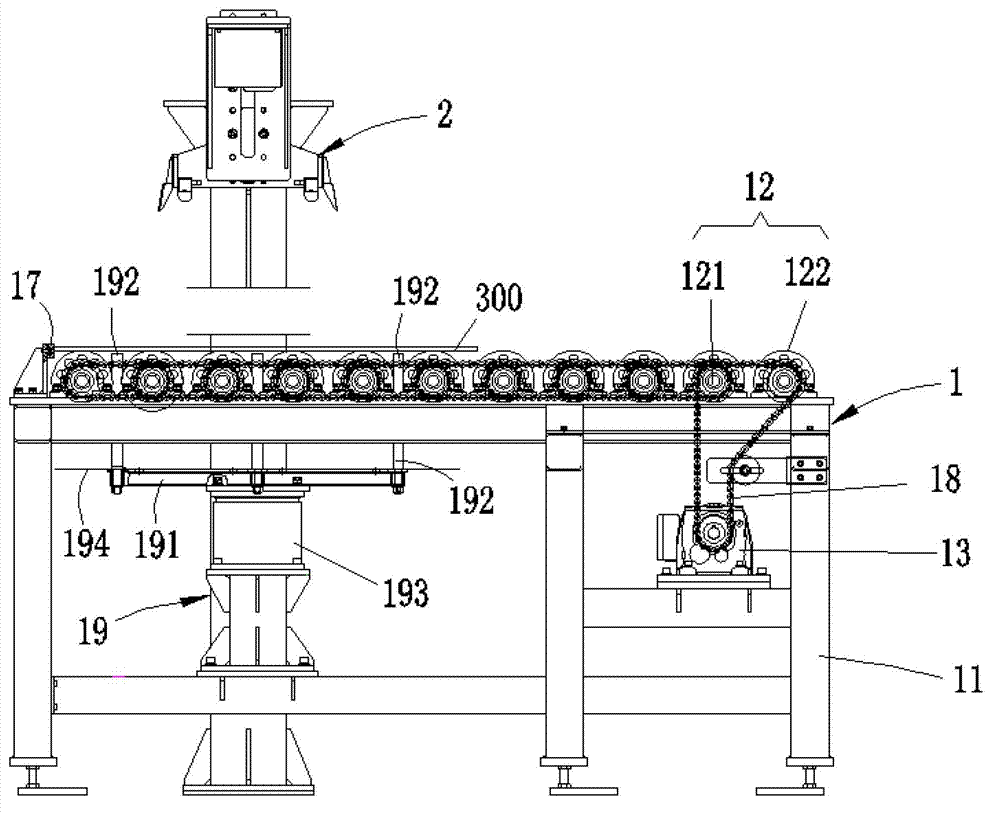

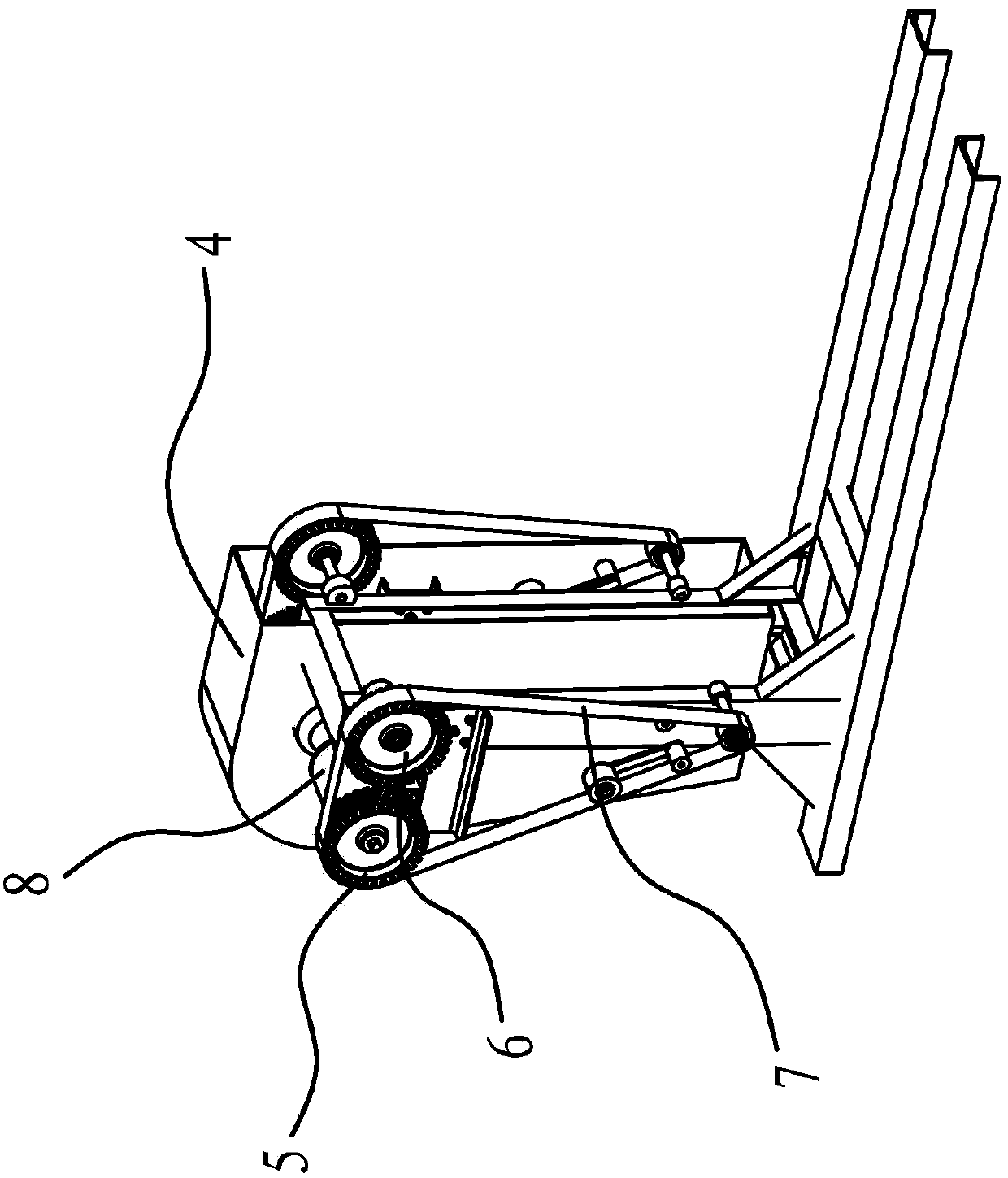

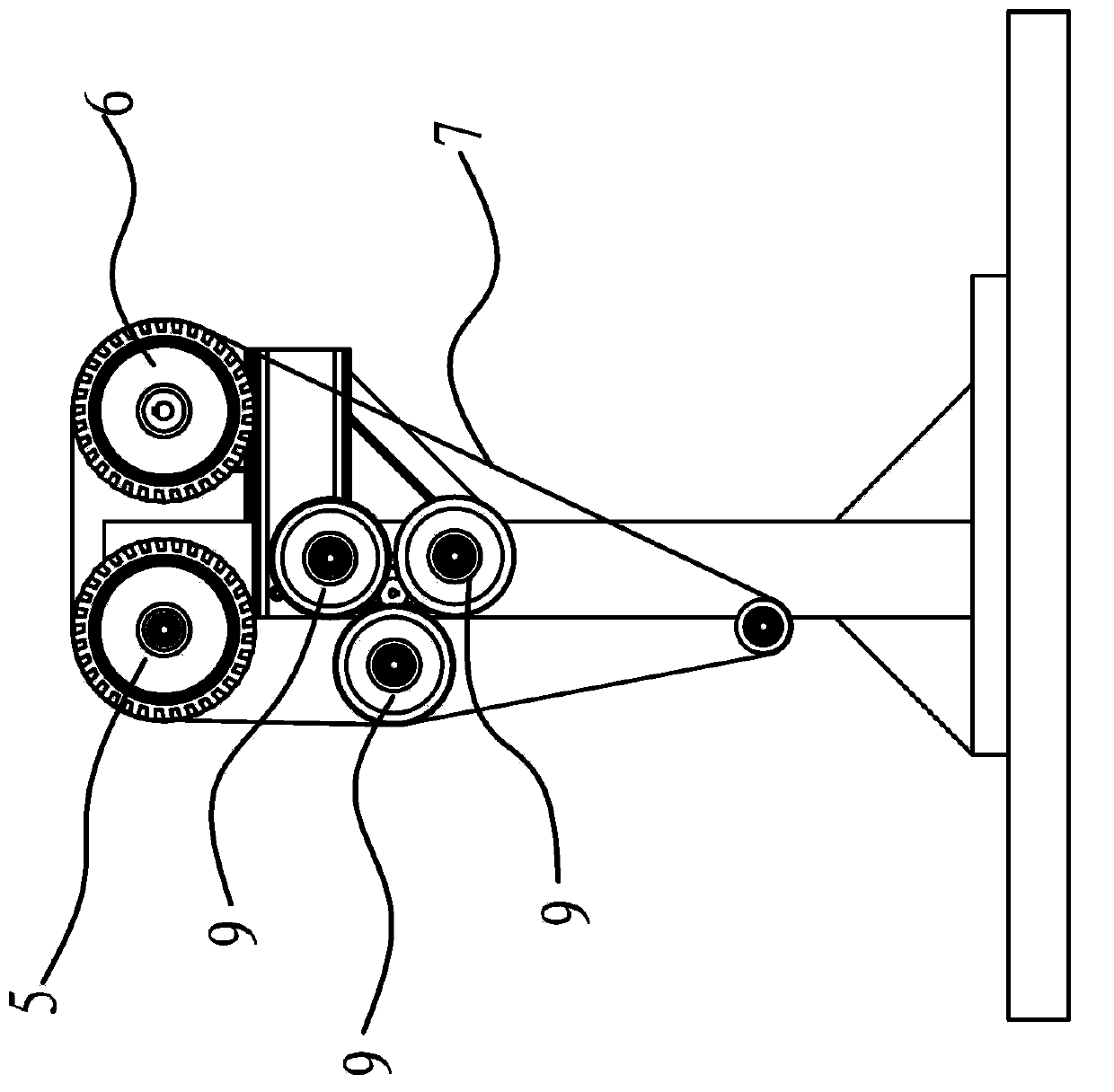

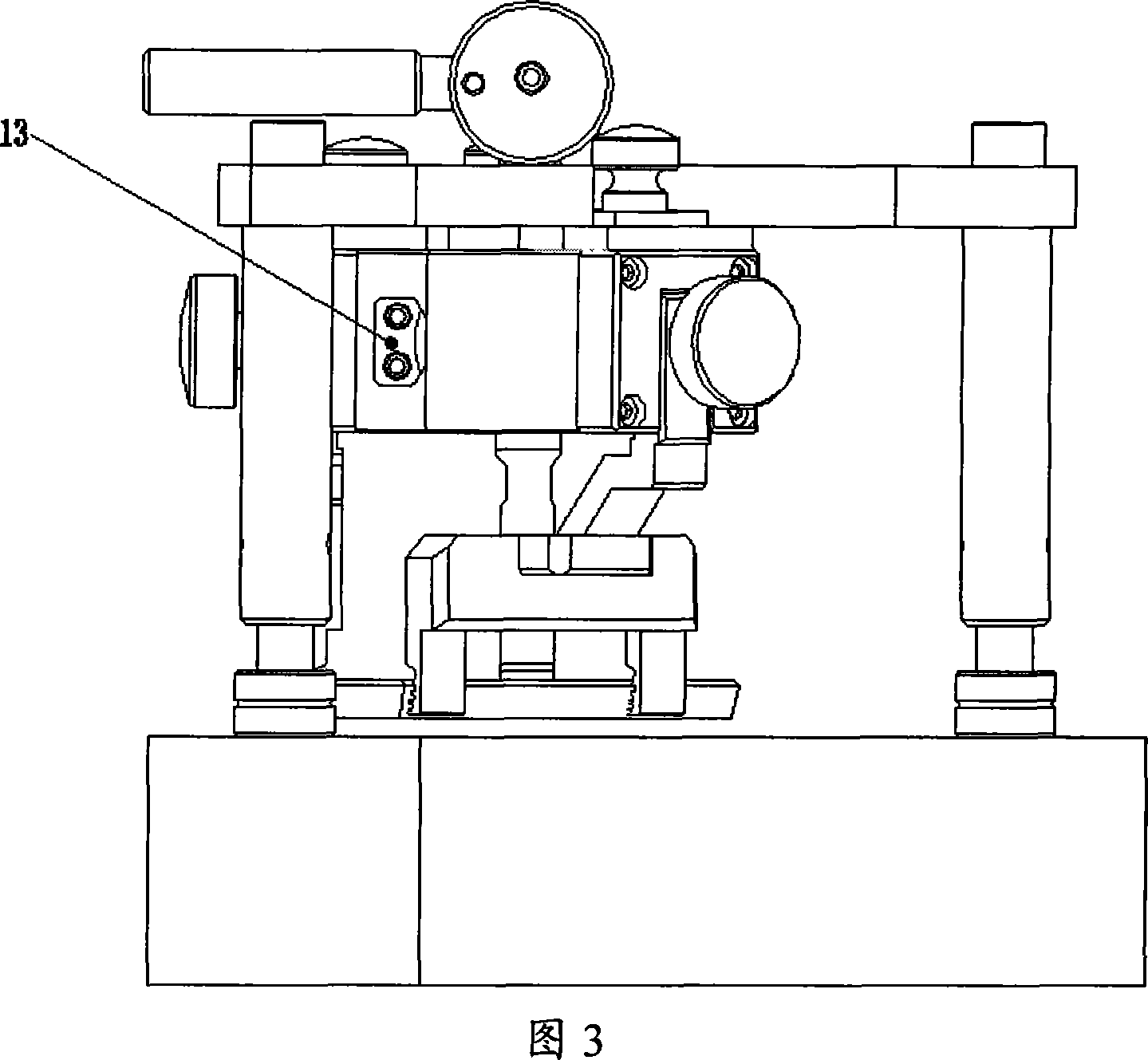

Workpiece automatic machining system and grinding method of surface of workpiece

ActiveCN103419111AHigh precisionImprove integrityBelt grinding machinesMechanical engineeringEngineering

The invention provides a workpiece automatic machining system and a grinding method of the surface of a workpiece, and belongs to the technical field of machines. The problems that an existing grinding polishing machine is not unified in machining precision and not uniform in workpiece forming are solved. The workpiece automatic machining system comprises a machining center which conducts machining work on the workpiece, and further comprises a grinding unit which is adjacent to the machining center. The grinding unit is provided with a mechanical arm and a plurality of grinding machines, and the mechanical arm can clamp and convey the workpiece which has been machined at the machining center to the grinding machines to be ground. The workpiece automatic machining system and the grinding method of the surface of the workpiece have the advantages of being high in automatic degree, good in uniformity of workpiece forming, high in grinding precision and the like.

Owner:WUHU HUIYING AUTOMATIC EQUIP CO LTD

Device and method for detecting deformation of the viscoelastic magnet

ActiveUS7663362B2Easy to detectAccurate grippingMagnetic field measurement using flux-gate principleForce measurementMagnetic fluxMagnet

Owner:SONY CORP

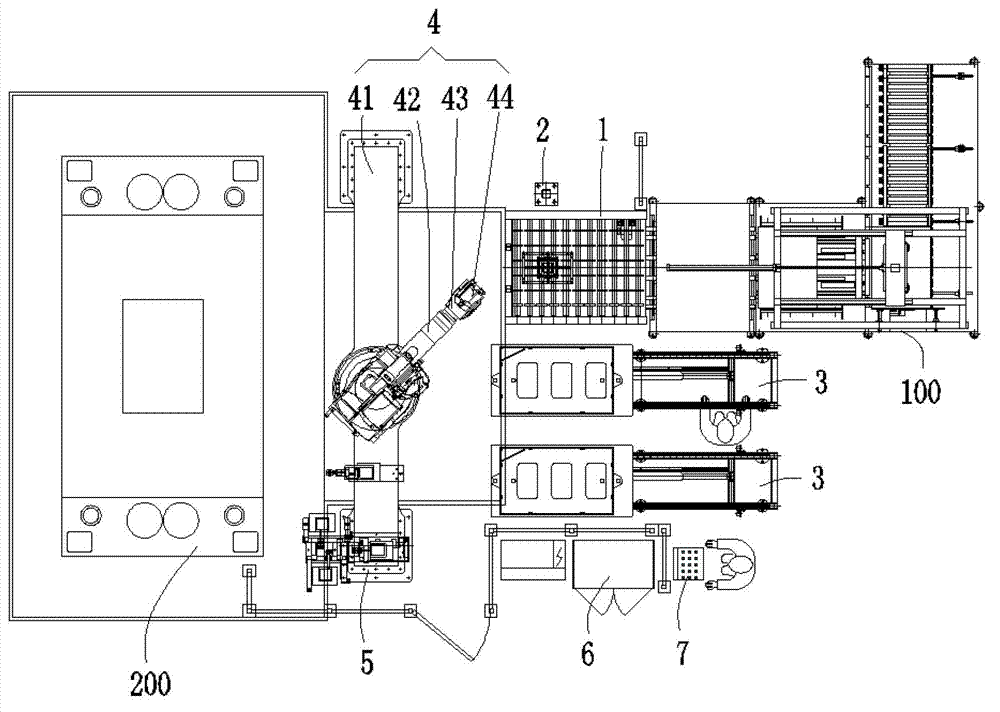

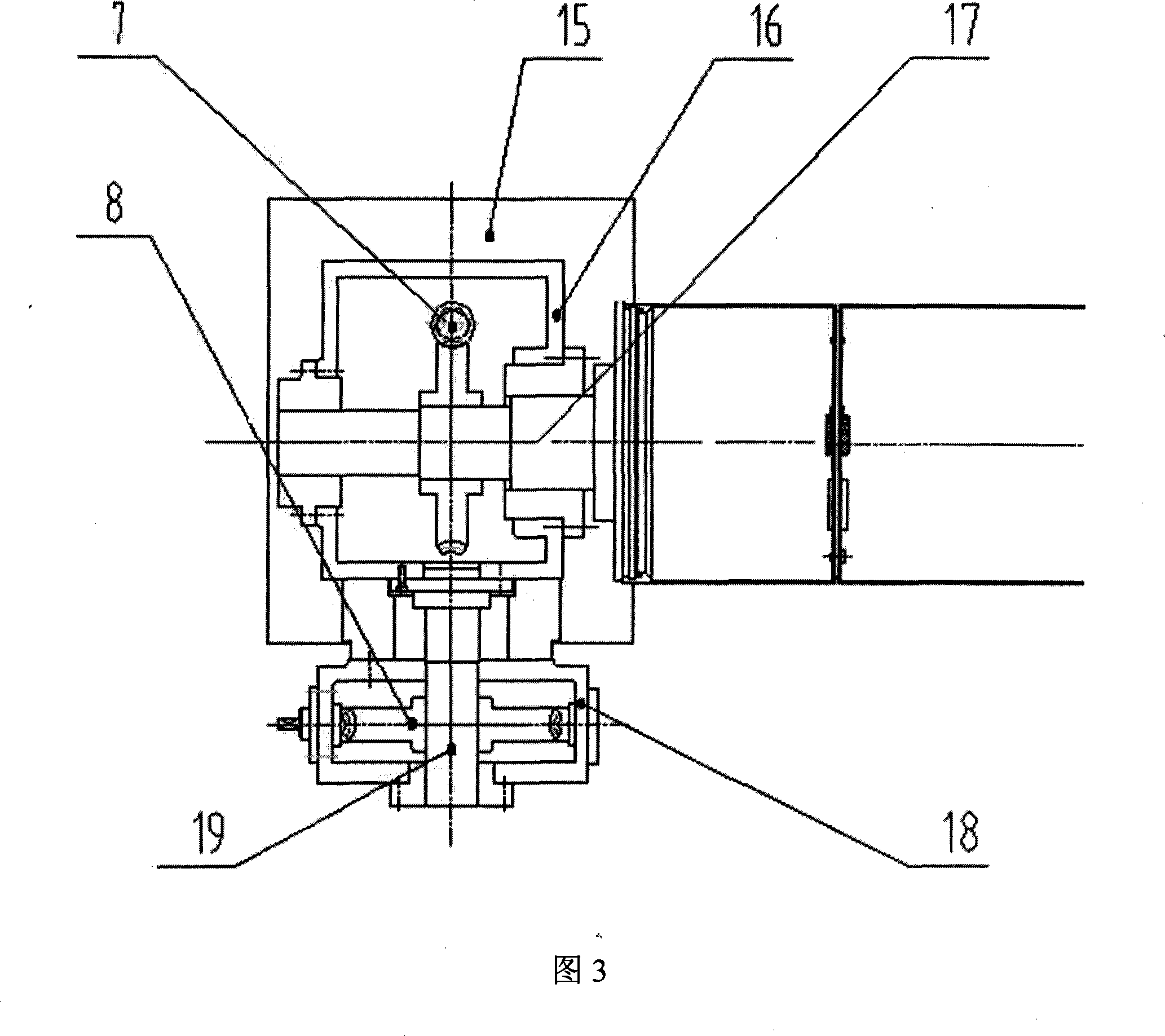

Automated pressure casting system

The invention discloses an automated pressure casting system which comprises a pressure casting machine, a reverse knockout machine, a spraying machine and a ladler. The pressure casting machine is provided with a fixed mould and a movable mould, the reverse knockout machine is arranged on the side of the movable mould and provided with a horizontal moving mechanism, a rotating mechanism and an arm driving mechanism, the rotating mechanism is mounted on the horizontal moving mechanism, the arm driving mechanism is mounted on the rotating mechanism and provided with a manipulator for automatically clamping products, the ladler is provided with a mechanical arm, a ladle is arranged at the end of the mechanical arm and can ladle melt to pour the melt onto the pressure casting machine, the spraying machine is a fixed-point spraying machine or a rotatable spraying machine, the fixed-point spraying machine is provided with a fixed-point spraying device, and the fixed-point spraying device is provided with a plurality of nozzles which can be adjusted according to requirements of different pressure casting moulds.

Owner:DONGGUAN LINGRUI MACHINERY

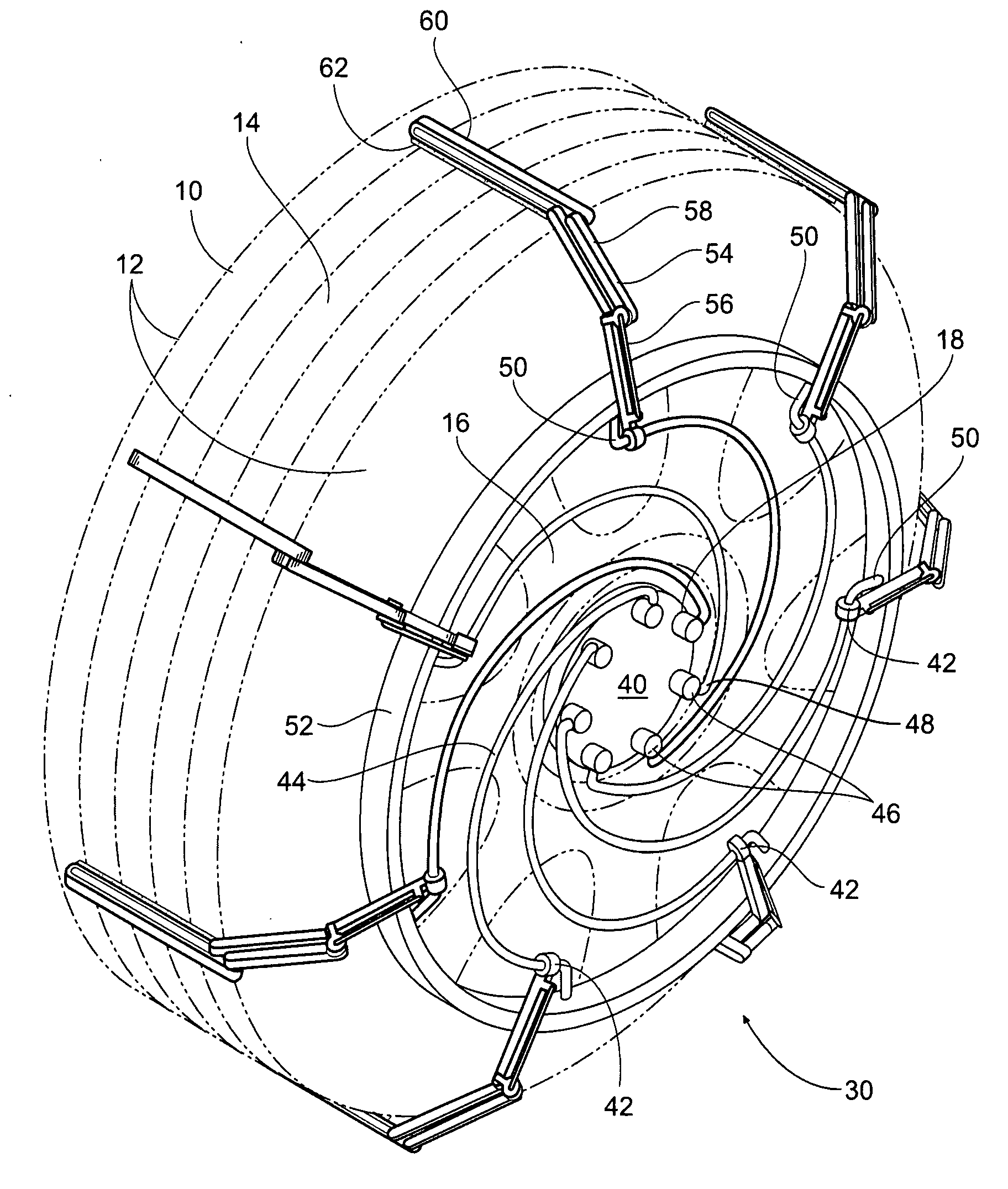

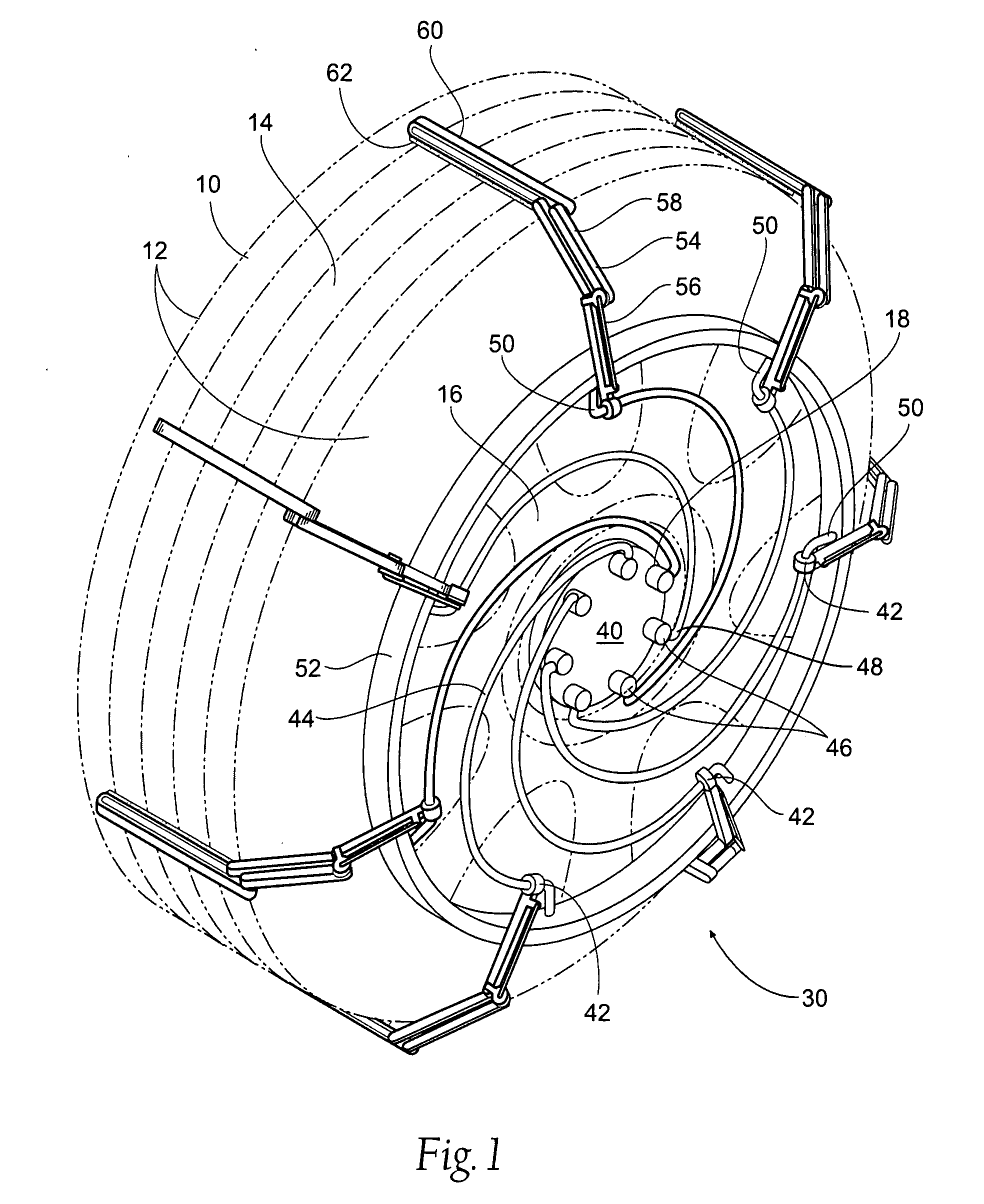

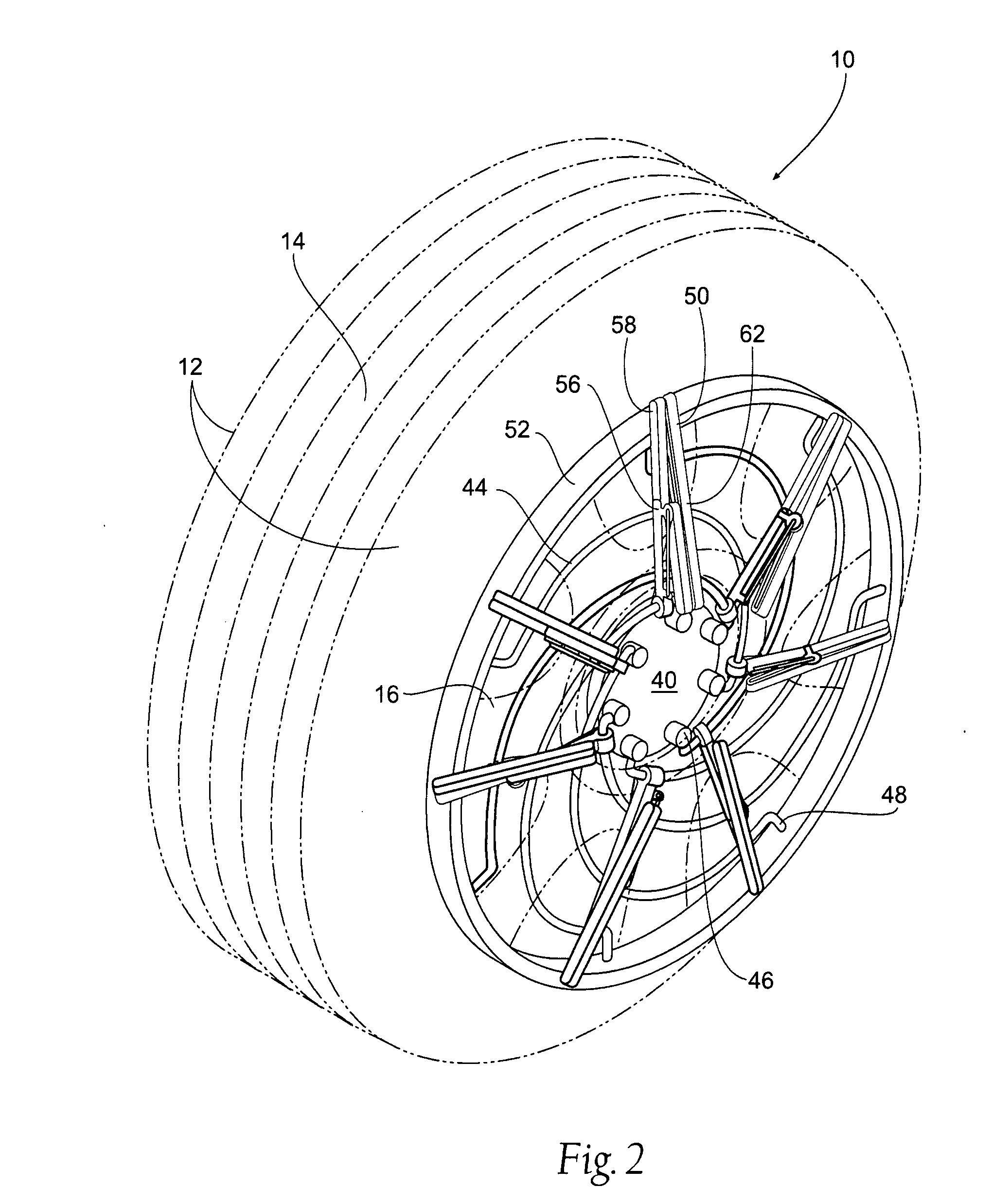

Traction device for a vehicle tire

InactiveUS20090056848A1Accurate grippingAccurate captureTyre tread bands/patternsWheels with plate-like shoesEngineeringMechanical engineering

A traction device for a tire having a hub for attachment to the tire's wheel. At least one arm extends outwardly from the hub, with the arm attached to a gripping section that is capable of contacting the tire. A reversible, rotatable cam attached to the arm and the gripping section controls the movement of the device.

Owner:MALTEZOS ILIAS F

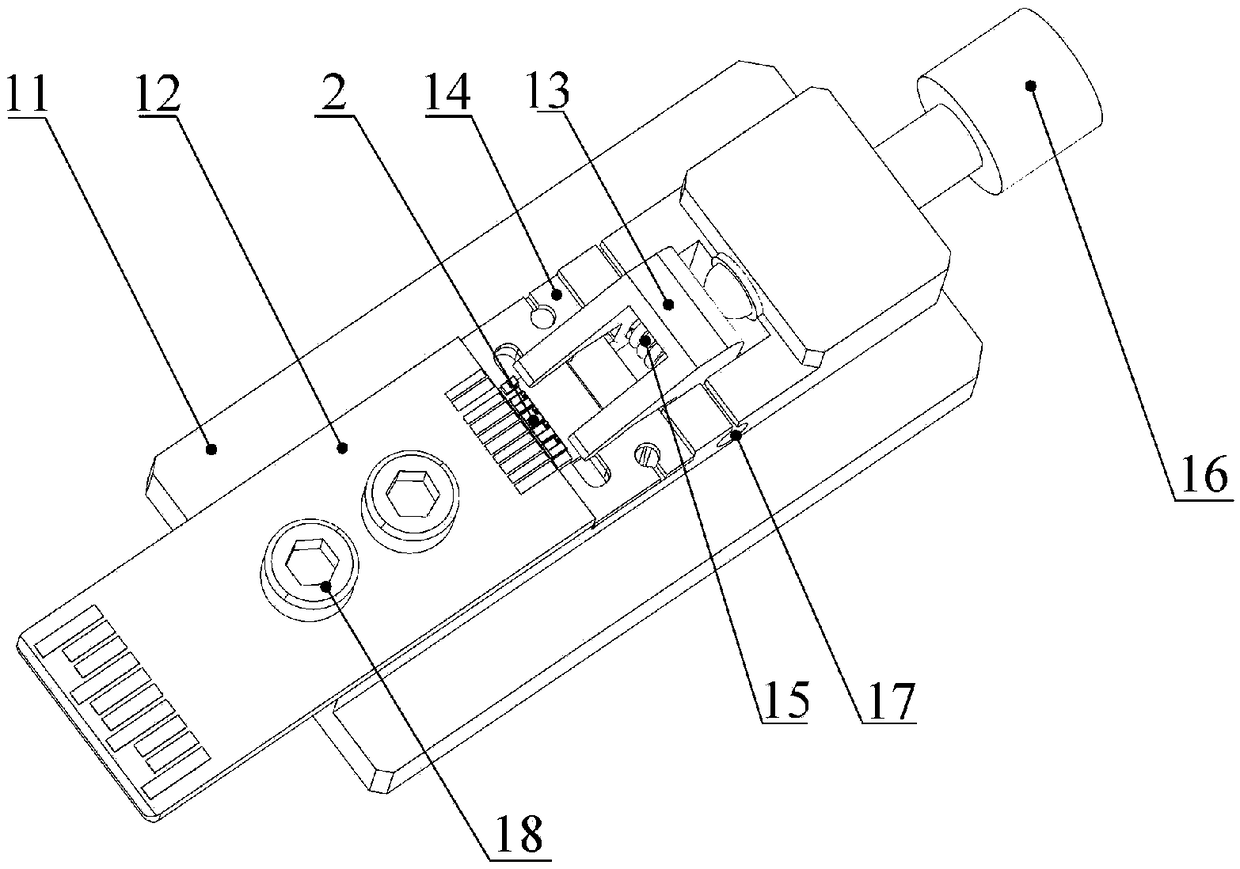

Automatic feeding device for stud welding

The invention discloses an automatic feeding device for stud welding. The automatic feeding device for stud welding comprises a machine frame, a longitudinal placing device for placing studs to be welded, a transverse pushing device for installing the longitudinal placing device and capable of transversely moving back and forth between a first position and a second position of a horizontal workstation of the machine frame, a longitudinal pushing device capable of longitudinally moving back and forth between a third position and a fourth position of a vertical workstation of the machine frame, a movable clamp fixed at the lower end of the longitudinal pushing device and capable of clamping a stud pushed to the second position by the transverse pushing device when the longitudinal pushing device moves to the third position, and a controller for performing data transmission and connected with the longitudinal placing device, the transverse pushing device, the longitudinal pushing device and the movable clamp. The automatic feeding device for stud welding is high in working efficiency, free of workpiece blockage, small in noise and electricity-saving, and can help to save the production cost.

Owner:佛山市玛雅数控设备有限公司

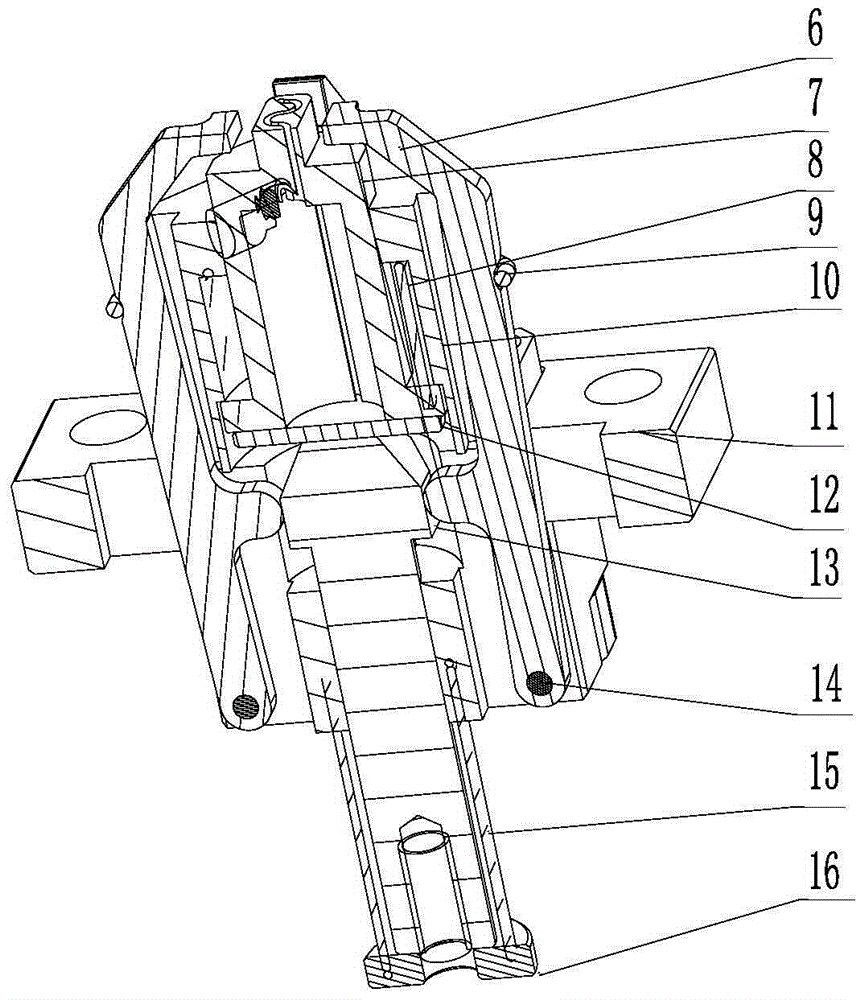

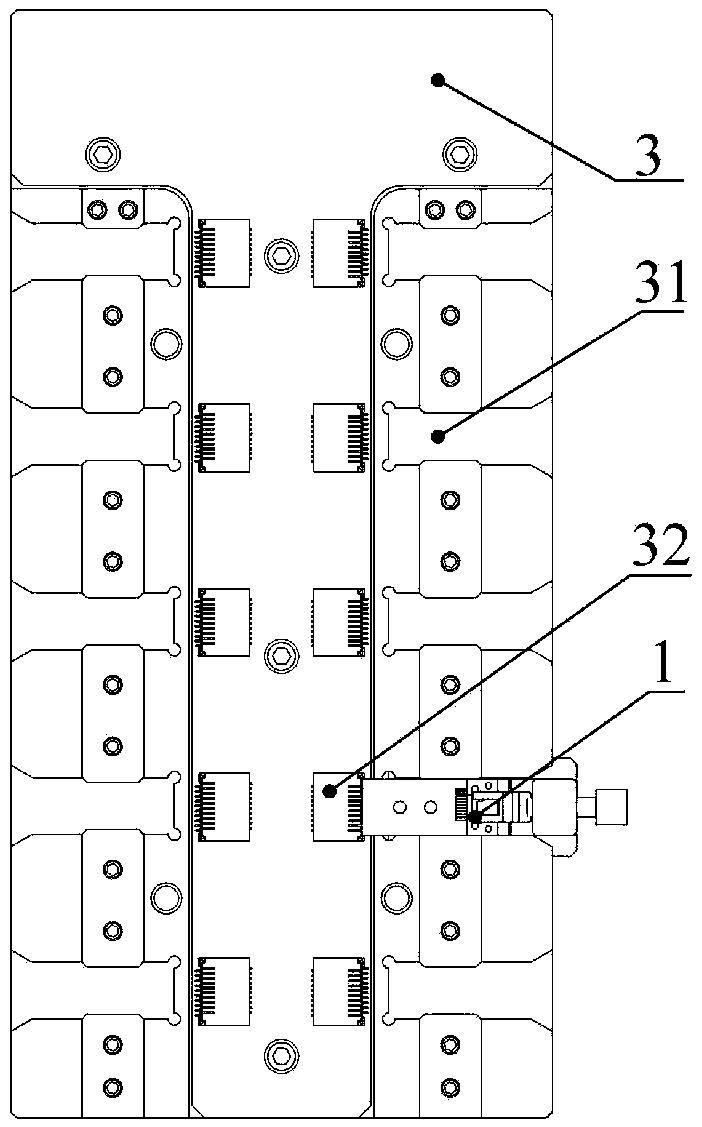

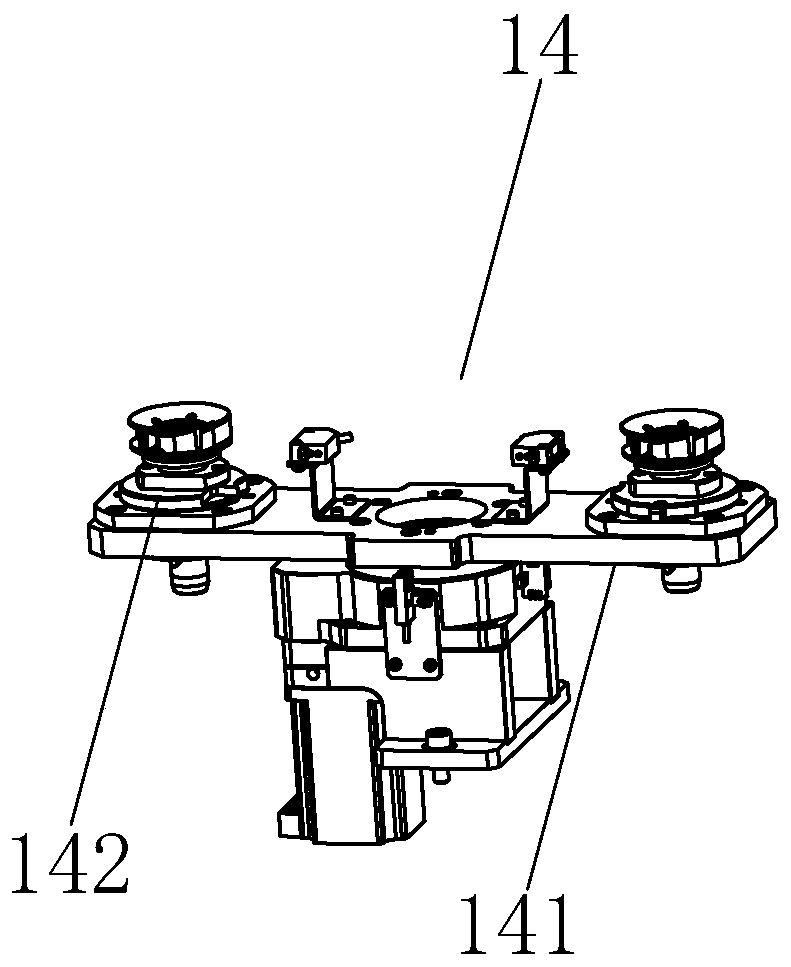

Correction and ejection mechanism for screen cloth

The invention belongs to the technical field of material locating, and particularly relates to a correction and ejection mechanism for screen cloth. The correction and ejection mechanism comprises correction clamping jaws, a screen cloth suction head, a suction head sliding sleeve, a fixed seat and an ejector rod. The suction head sliding sleeve is fixedly arranged on the fixed seat. The screen cloth suction head is inserted in the suction head sliding sleeve and can move in the axial direction. A center through hole coaxial with the suction head sliding sleeve is formed in the fixed seat. The ejector rod is inserted in the center through hole and abuts against the screen cloth suction head. The correction clamping jaws hinged to the fixed seat are arranged on the outer side of the suction head sliding sleeve in the circumferential direction. Protruding structures in contact with the ejector rod are arranged on the inner sides of the correction clamping jaws. The ejector rod can move in the axial direction under the action of external force, and therefore the correction clamping jaws are opened or closed, and the screen cloth suction head is ejected or retracted. The screen cloth is sucked, corrected and located synchronously, and is ejected after being located. The correction and ejection mechanism is in the structure of an independent system, local fast replacement can be achieved, and mounting and adjusting are convenient.

Owner:GOERTEK INC

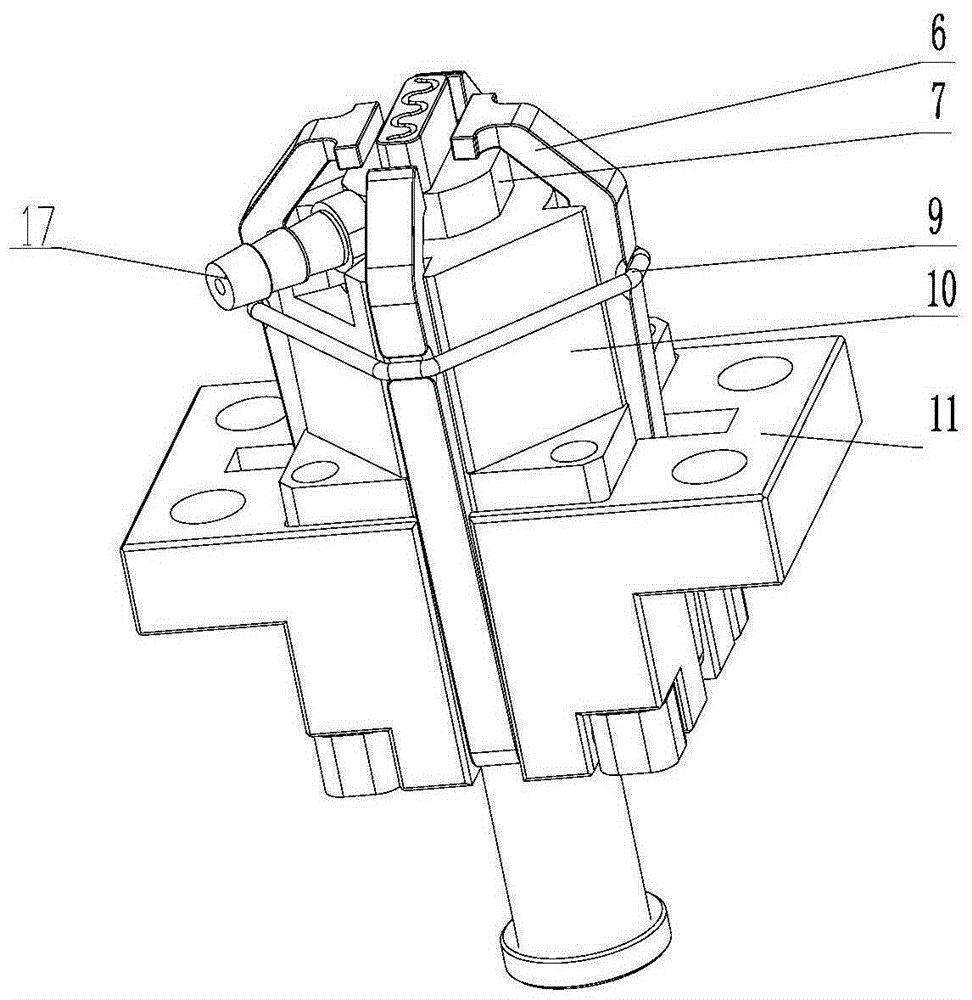

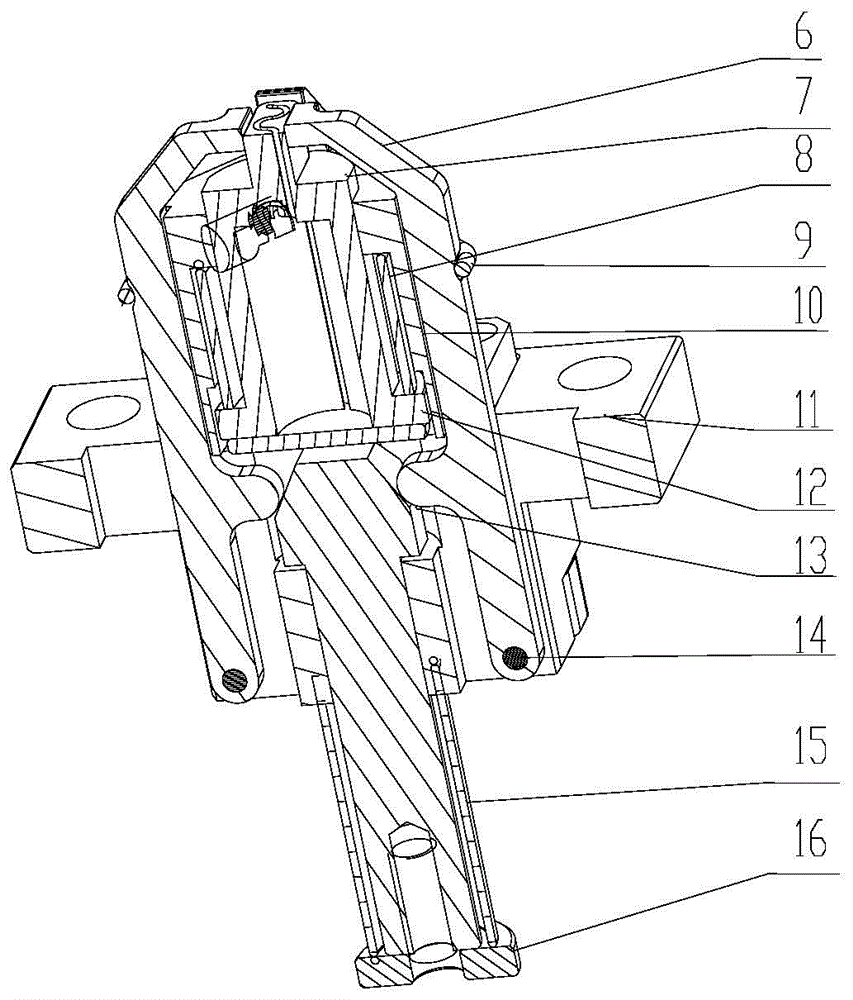

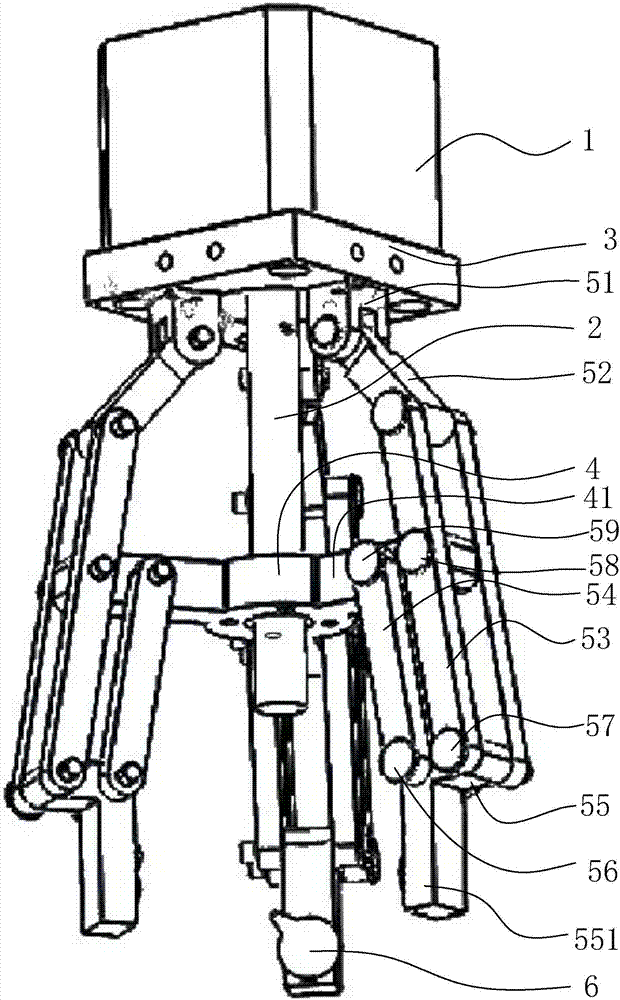

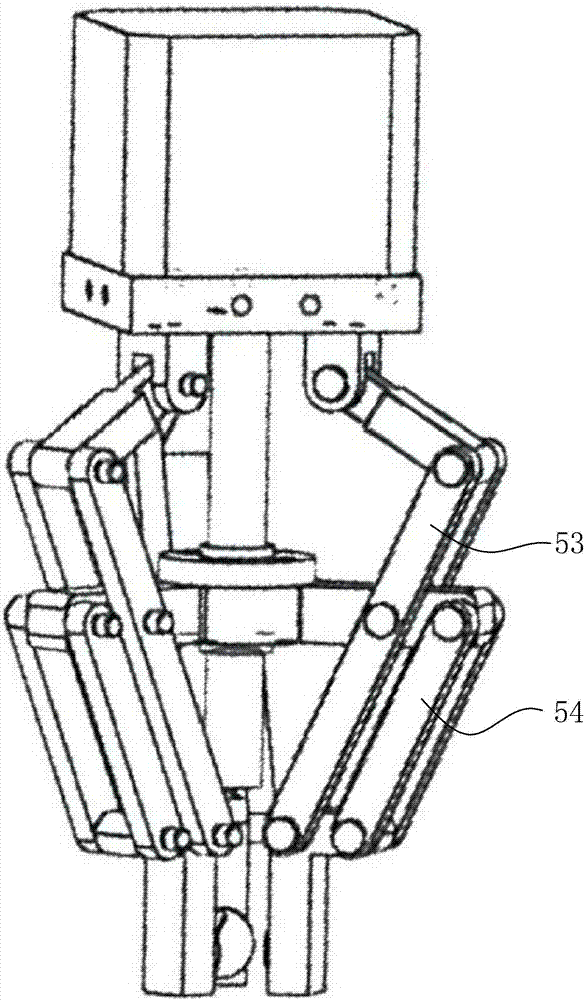

Mechanical paw

The invention discloses a mechanical paw. A driving module can drive a lead screw to rotate. In the rotating process of the lead screw, a servo lead screw nut will move up and down, and therefore the included angle formed between a first rod and a second rod is changed. According to the principle of parallelogram, a linkage rod connected with a third rod will produce displacement in the horizontal direction, and therefore clamping is achieved. Due to the fact that each driving component is of a simple connection rod structure, reliability is quite high, the service life is quite long, transmission of the servo lead screw nut and the driving lead screw is quite precise, and therefore the mechanical paw can achieve accurate clamping. Meanwhile, the servo lead screw nut and the driving lead screw can achieve the effects of reducing the speed and increasing torque and clamping force. Accordingly, the problems that an existing mechanical paw is large in size and high in weight as the existing mechanical paw needs to be additionally provided with a speed reducing mechanism is avoided.

Owner:FOSHAN UNIVERSITY

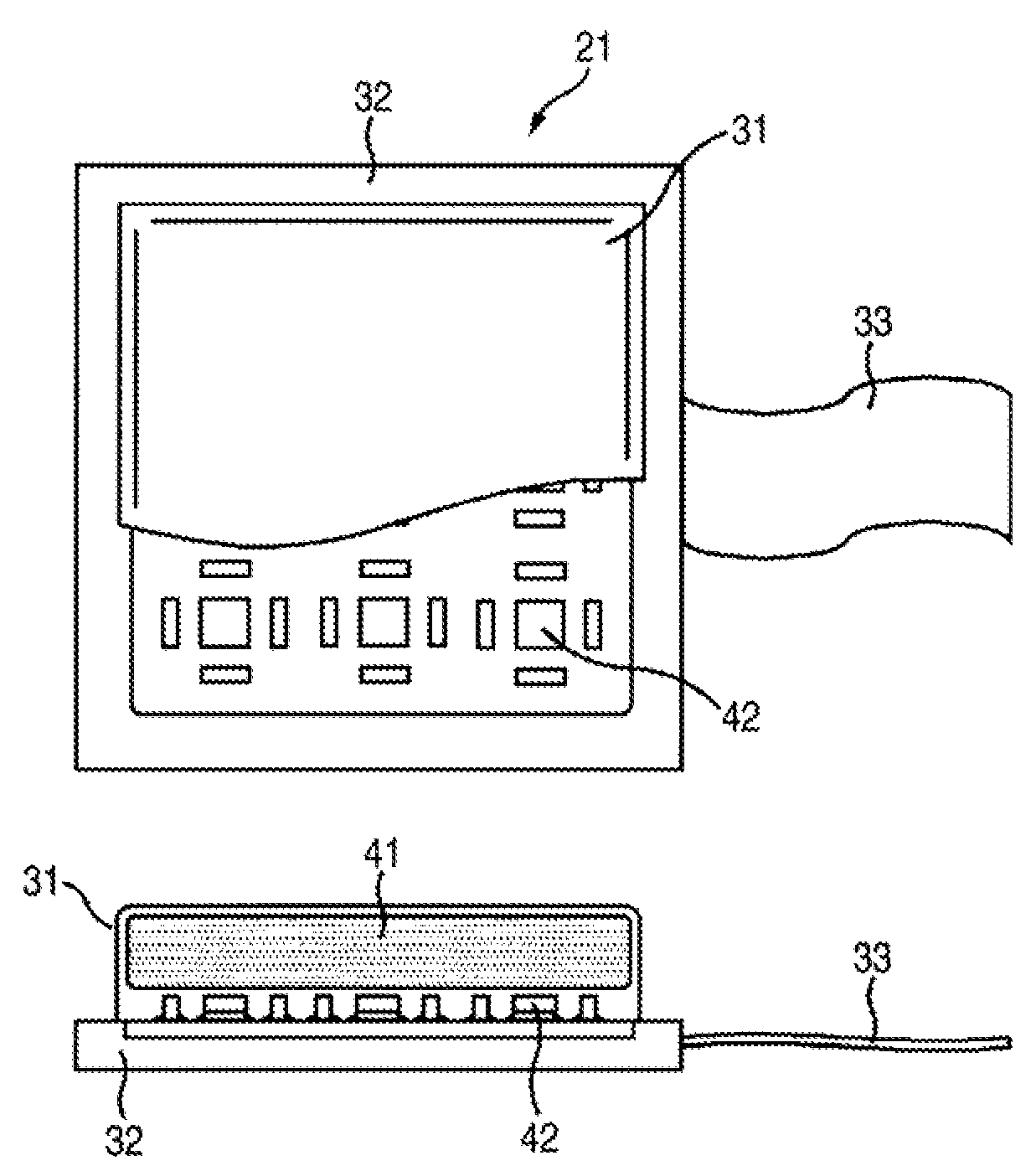

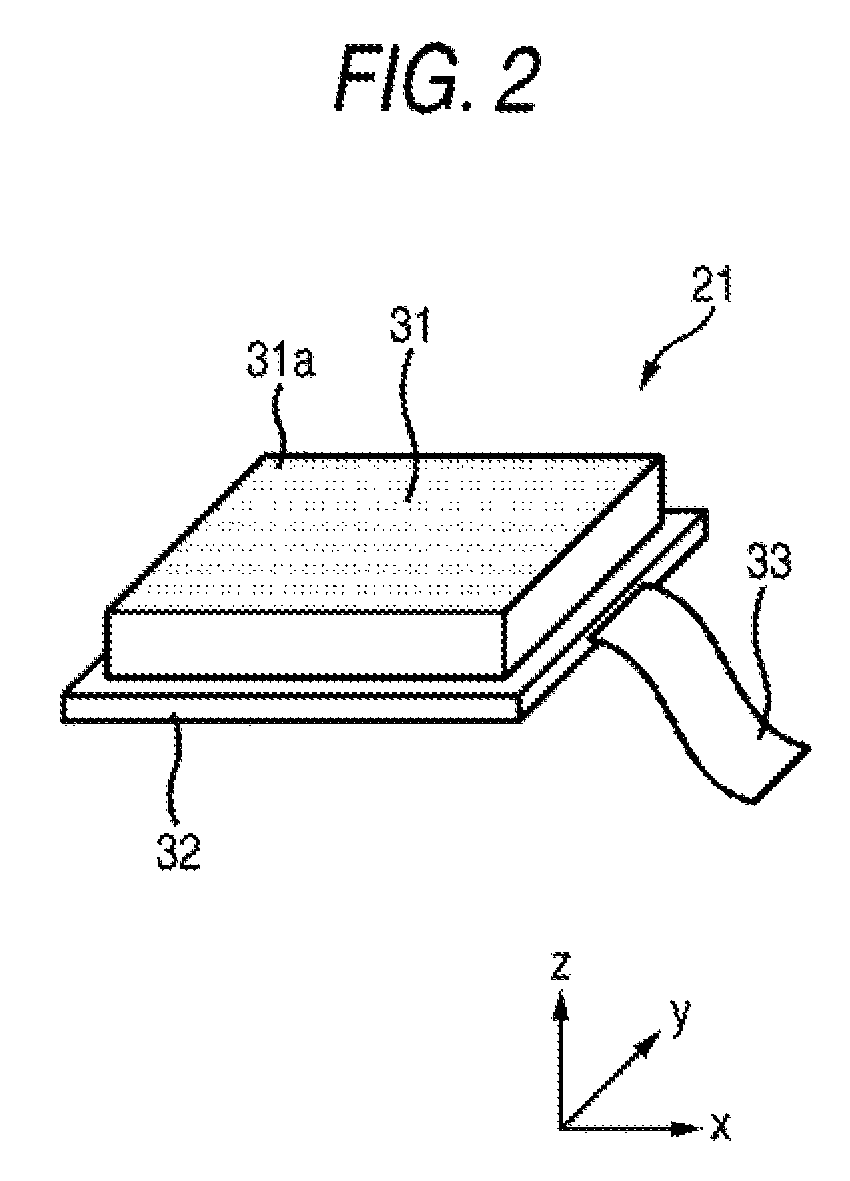

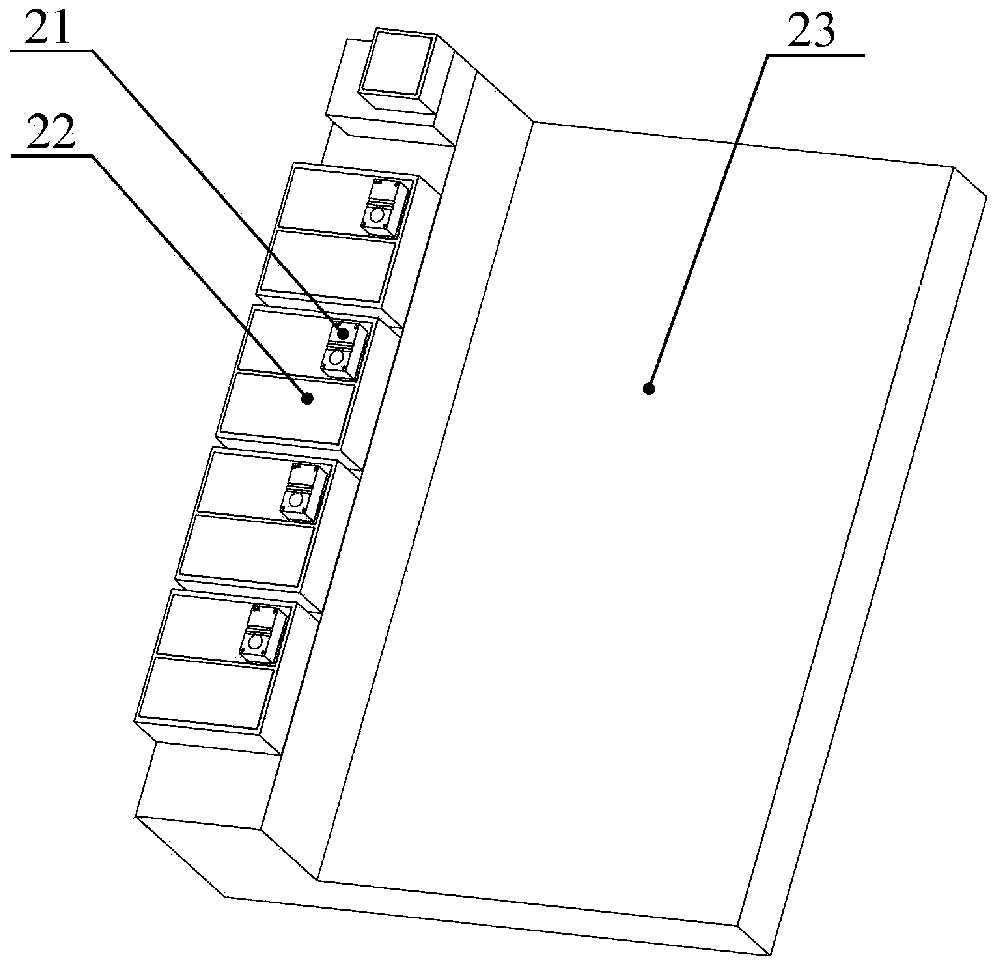

Aging device and aging method for laser device chip

InactiveCN109324213AEasy to grabAccurate grippingElectrical testingMeasurement instrument housingAge methodOptical communication

The invention relates to the field of optical communication device manufacturing, and provides an aging device and an aging method for a laser device chip. The device comprises a clamp and a chip assembly, wherein the clamp is used for clamping the chip assembly, the chip assembly comprises the laser device chip and a chip carrier, and the laser device chip is fixed to the surface of the chip carrier; the clamp comprises a substrate and a PCB connecting plate, a positioning plate and a pressing block which are installed on the substrate in sequence, the positioning plate is used for placing and positioning the chip assembly, and the PCB connecting plate is used for the connection of the laser device chip and a power supply circuit; the pressing block is movably installed on the surface ofthe substrate, one end of the pressing block is positioned above the positioning plate, and the chip assembly can be compressed or loosened by rotating the pressing block. The laser device chip is fixedly pasted onto the chip carrier, the chip carrier can be clamped by the clamp directly conveniently, quickly, stably, reliably and accurately during aging, chip clamping is realized, the chip damageis reduced, and the clamp is simple in operation and low in cost and can be used repeatedly, so that the problem of chip aging is solved.

Owner:WUHAN TELECOMM DEVICES

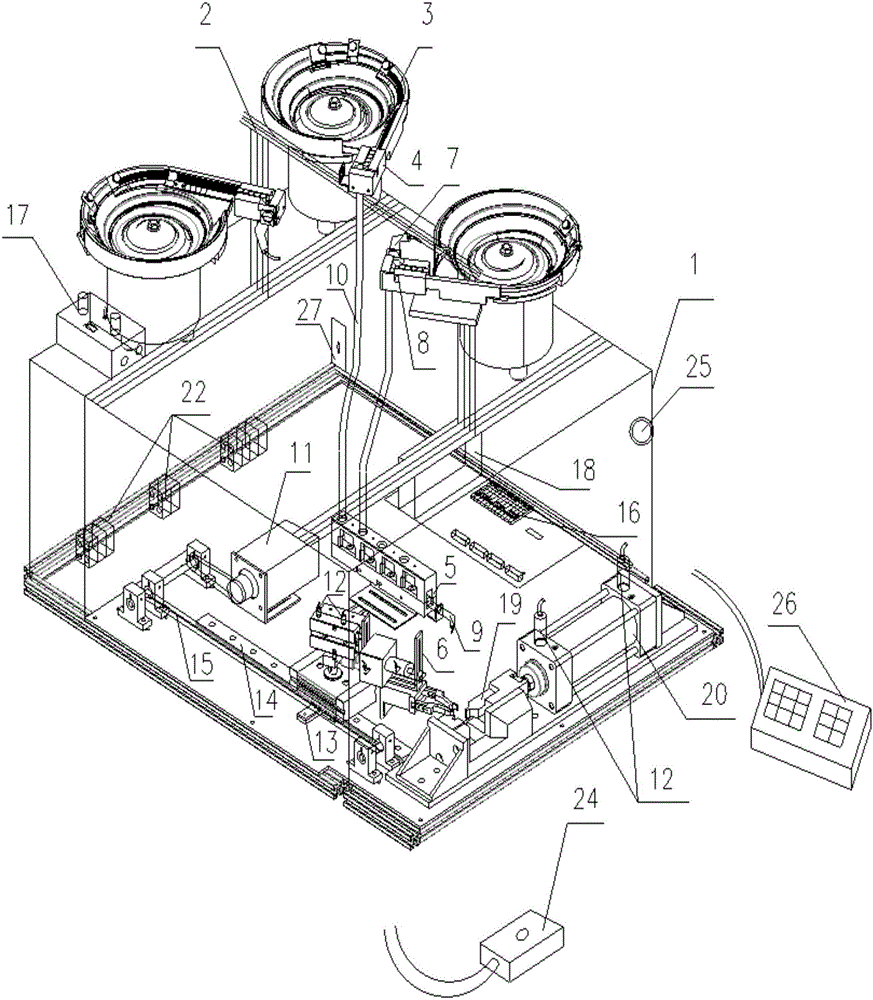

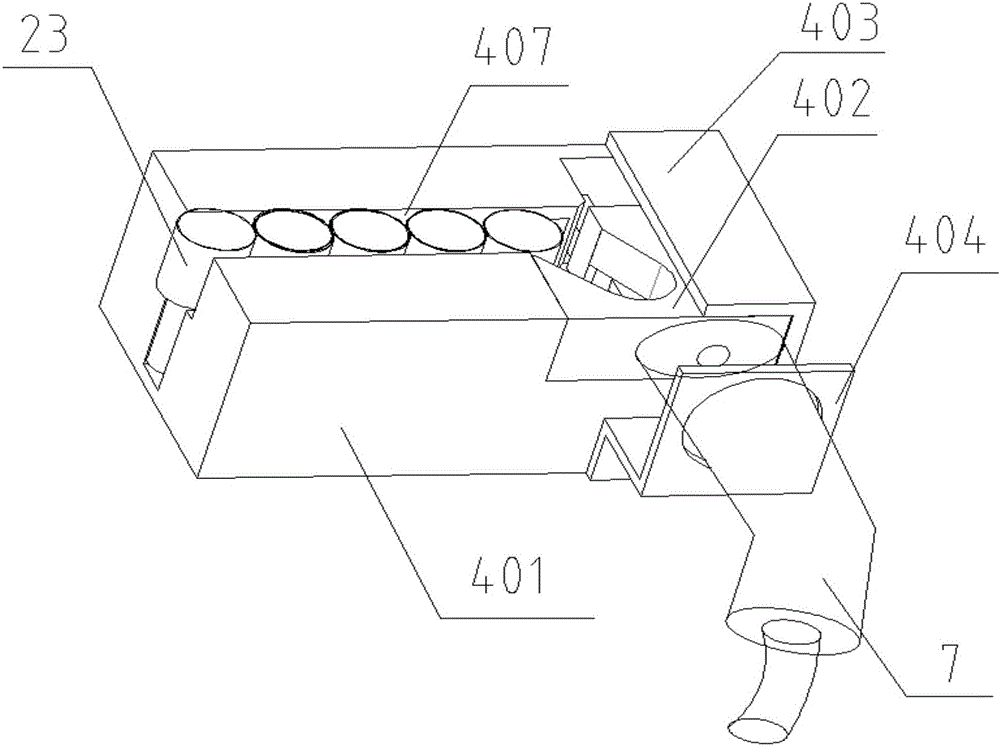

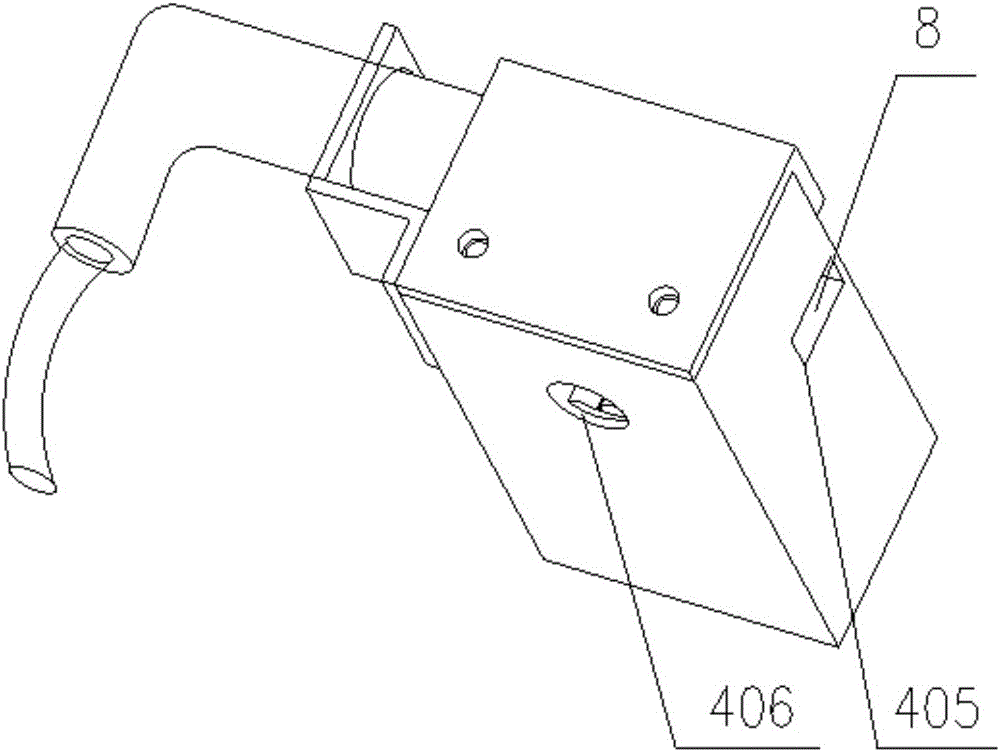

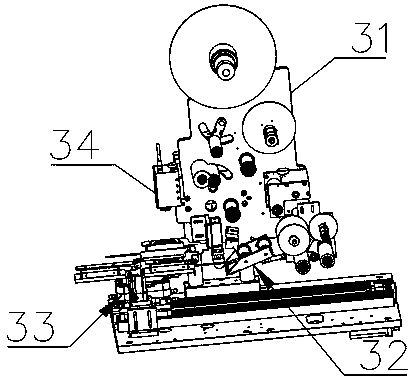

Four-color bulk terminal crimping machine

ActiveCN105703195ARealize automatic arrangementAccurate grippingLine/current collector detailsMicrocontrollerVibration control

The invention belongs to the technical field of an electrical device, relates to a novel terminal crimping machine, in particular to a four-color bulk terminal crimping machine. The main body structure of the four-color bulk terminal crimping machine comprises a protective cover, a support, vibration discs, escapement devices, a centering device, a manipulator, escapement air cylinders, escapement sensors, a dropping air cylinder, a transmission pipe, a motor, a solenoid valve, a pulley, a guide rail, a synchronous belt, a singlechip microcomputer, a vibration disc controller, a power supply transformer, mechanical pincers, a mechanical pincers air cylinder, a dropping sensor, a relay, terminals, a terminal machine controller, a power supply, an air source, a control stepping plate, a wire and a pipe line. With the arrangement of escapement devices and the centering device which are in correspondence to the four vibration discs and the control of the singlechip microcomputer, the plurality of terminals are simultaneously and automatically pressed; the novel terminal crimping machine has the advantages of simple structure, reliable principle, low preparation cost, high crimping efficiency, high crimping quality rate and application environment friendliness.

Owner:QINGDAO SPELSBERG ELECTRICAL ENG TECH CO LTD

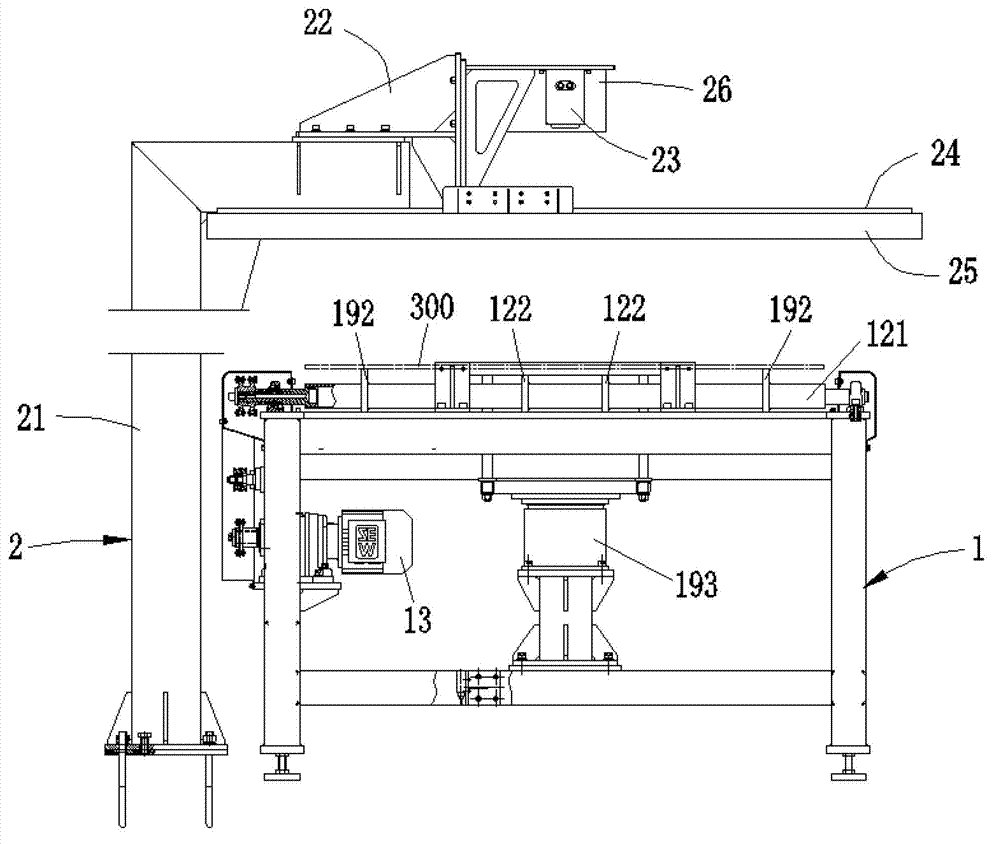

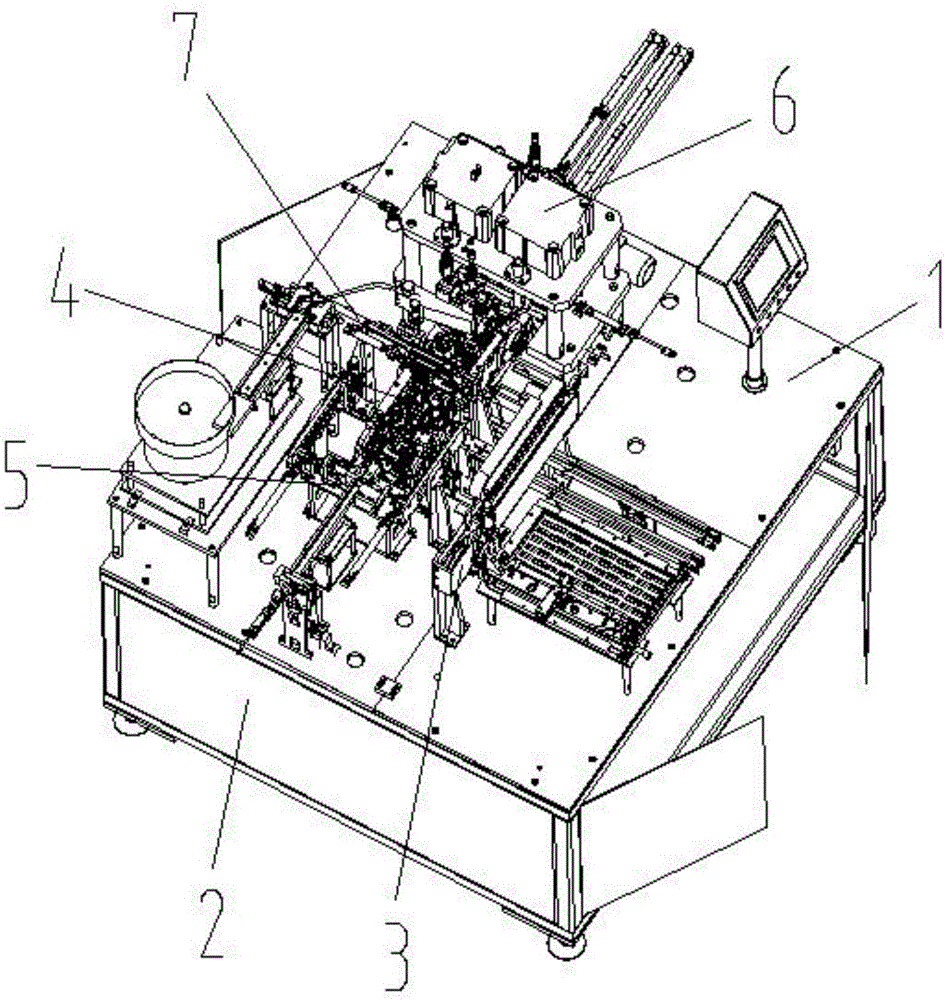

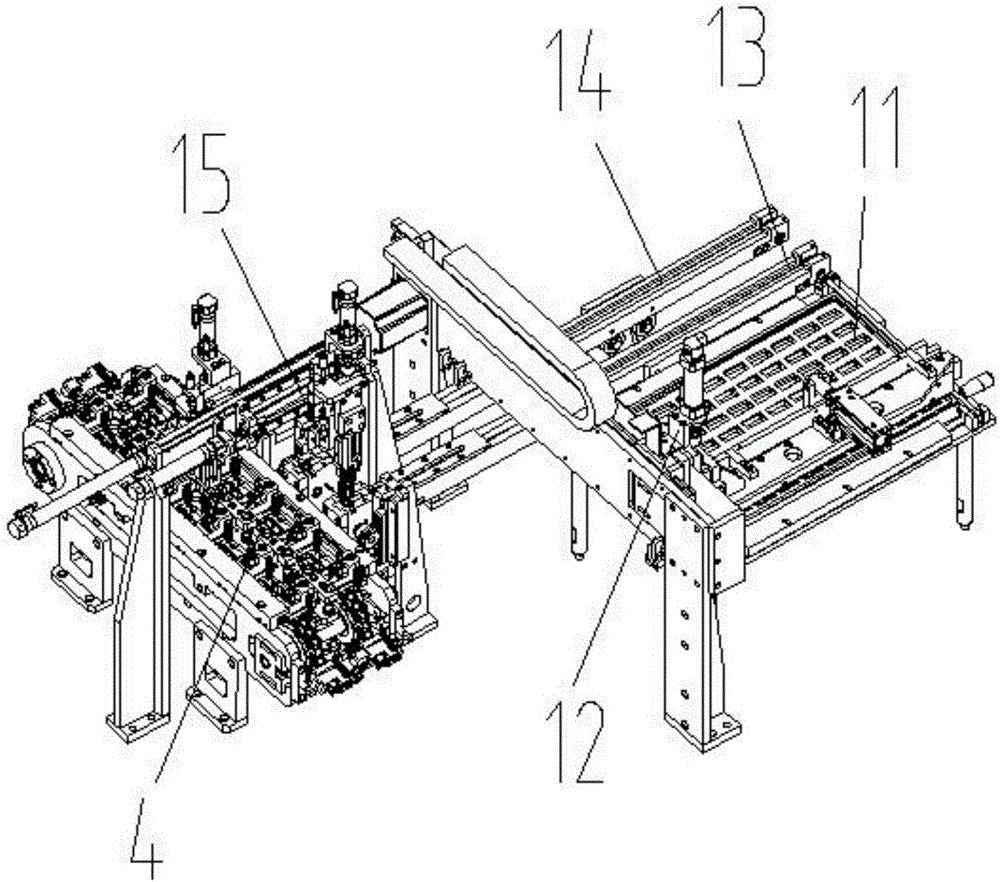

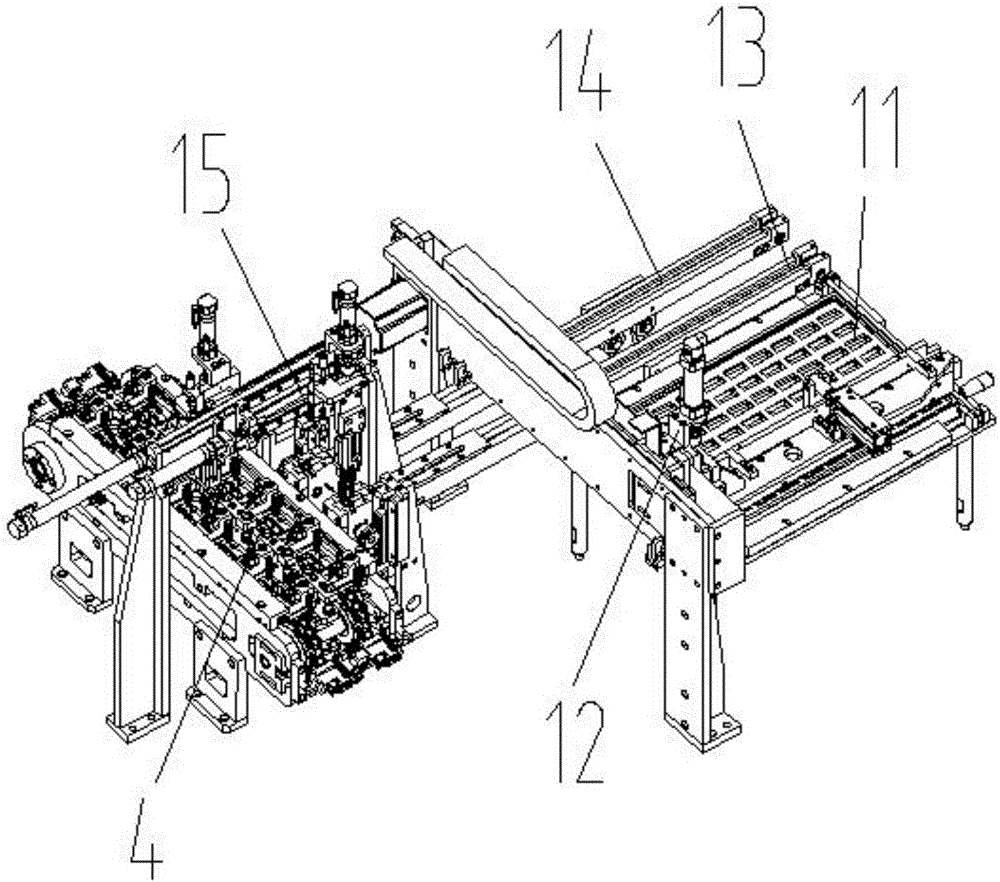

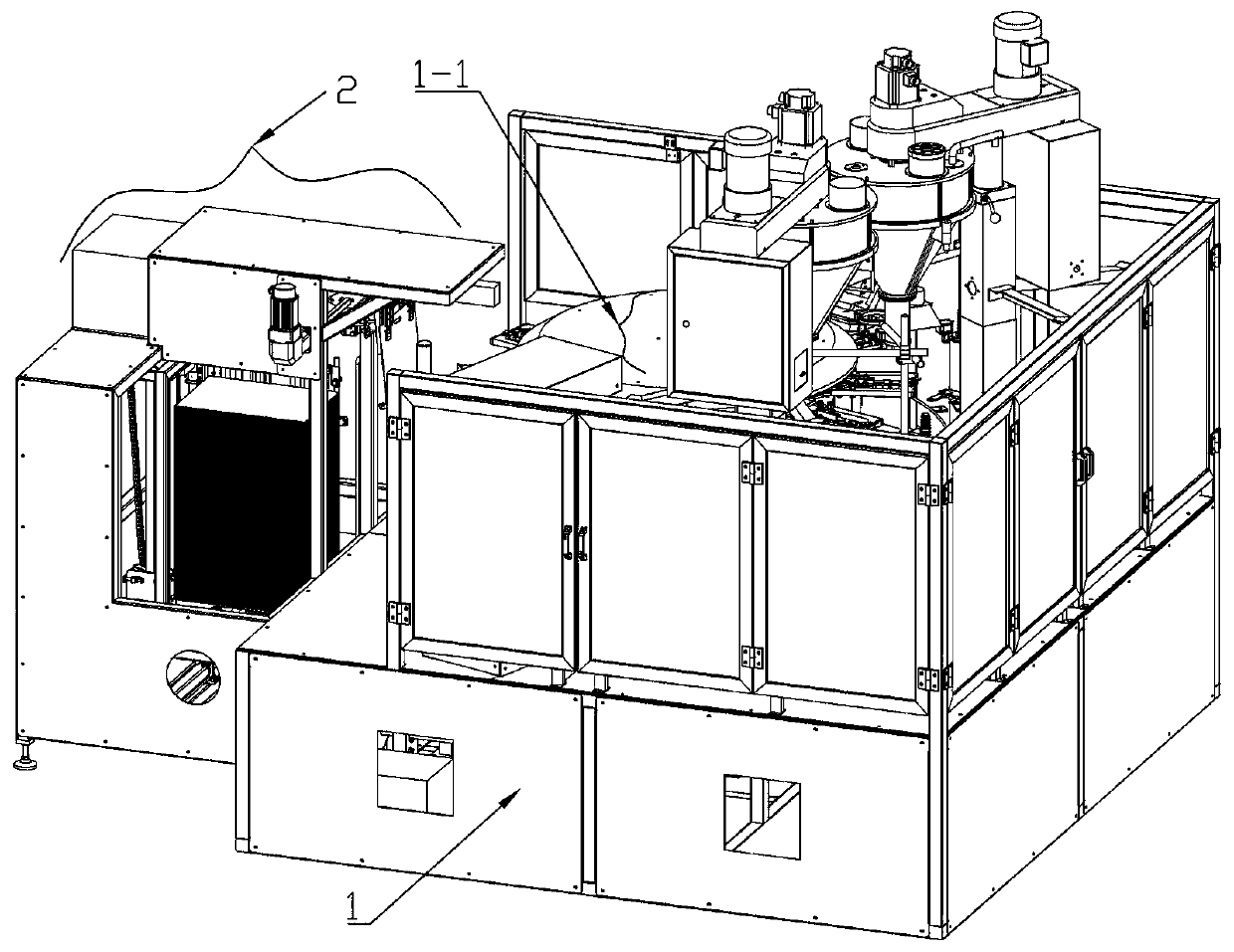

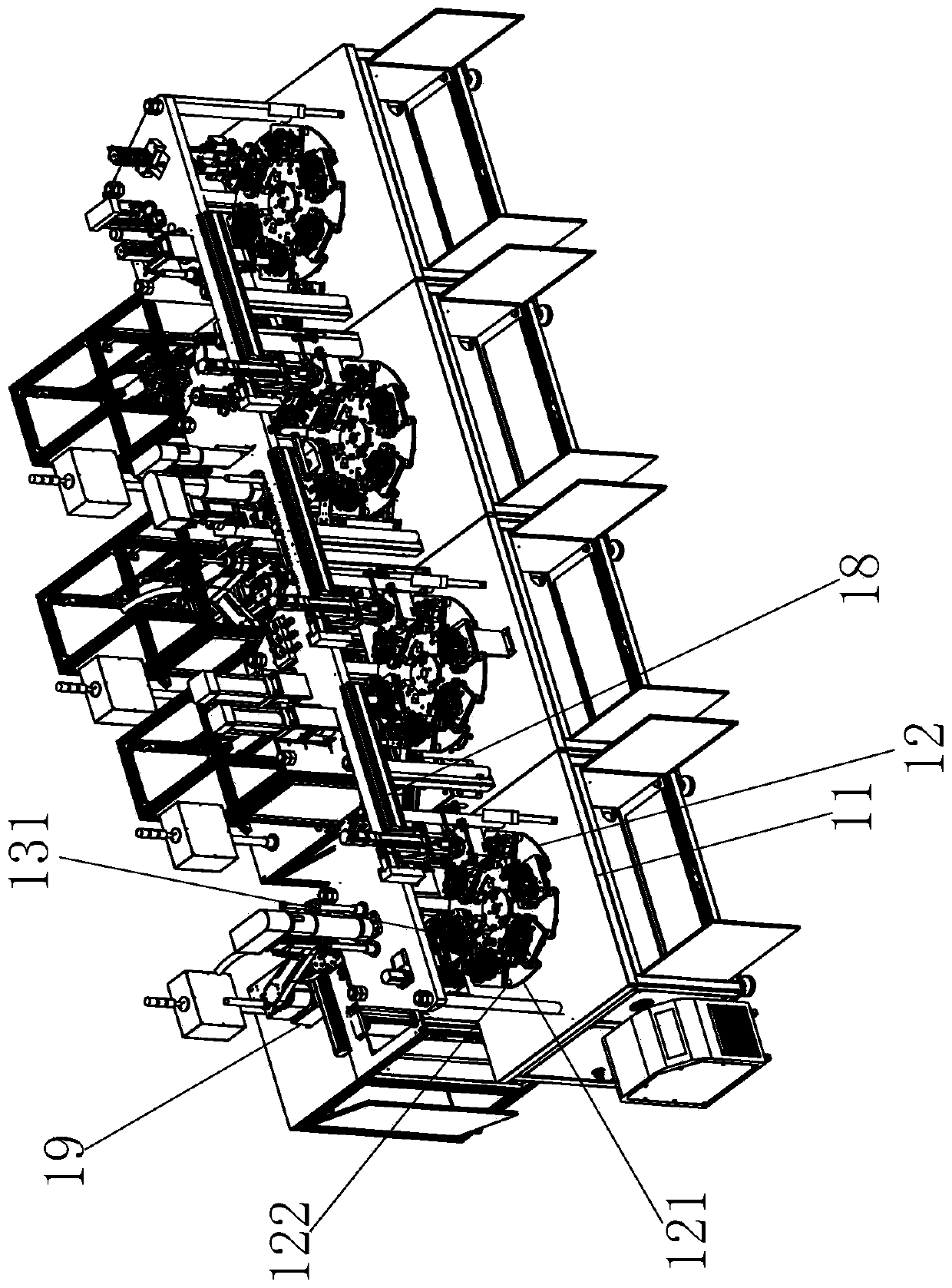

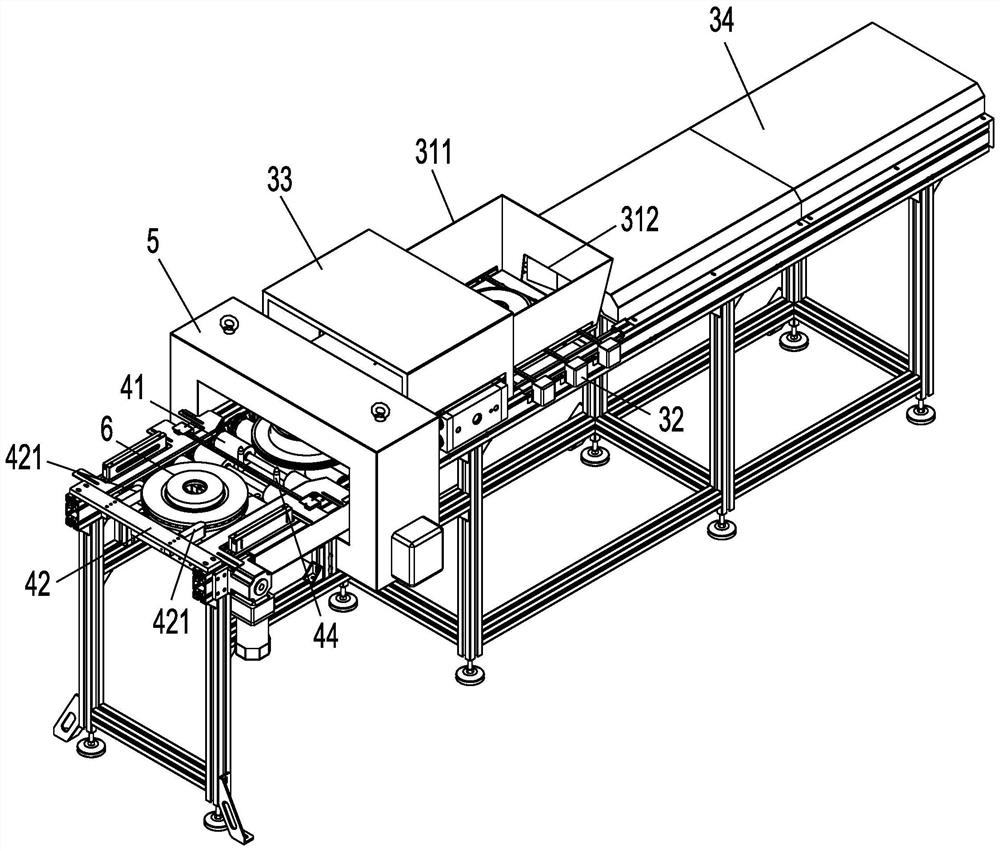

Butt joint-precise inductor assembly machine

ActiveCN106736506AImprove docking accuracyReduce inertial effectsAssembly machinesRing deviceDistribution control

The invention relates to a butt joint-precise inductor assembly machine. The machine comprises a frame and a power distribution control box; the frame is provided with a conveying device; an iron sheet inserting device, a pressing ring device and an iron core inserting device are arranged above the conveying device in sequence; the conveying device is matched with a positioning device; the positioning device includes a positioning base arranged on a conveying base; the positioning base is provided with a positioning lifting cylinder; the positioning lifting cylinder is provided with a positioning lifting block matched with a positioning lifting slide rod on the positioning base; and the positioning lifting block is provided with a positioning pin matched with a positioning pin sleeve arranged on a conveying carrier. The machine is provided with the positioning device in the conveying device; and through insertion matching between the positioning pin arranged on the positioning lifting block and the positioning pin sleeve arranged on the conveying carrier of the conveying device, the conveying device stops conveying, the inertia influence is eliminated, the butt joint precision between the conveying carrier and each assembly part is improved, and the yield is largely increased.

Owner:TONGXIANG YAORUN ELECTRONICS

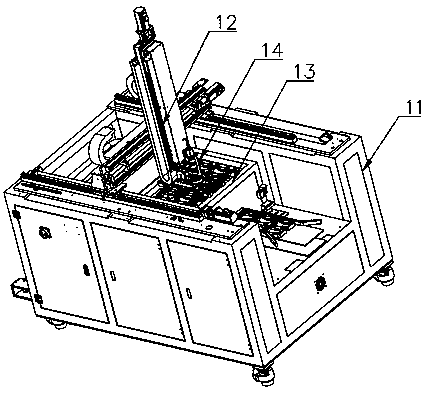

Clamping plate device for epoxy plate stacking robot

The invention discloses a clamping plate device for the epoxy plate stacking robot. The device comprises a device body, an installation frame and clamping jaws, the installation frame is fixedly installed on the outer surface of the upper end of the device body through bolts, and a horizontal movement device and a front-back movement device are installed at the positions, close to the outer side,of the outer surface of the lower end of the device body. The invention discloses a clamping plate device for an epoxy plate stacking robot. Firstly, the clamping jaws can synchronously move towards the middle; therefore, the epoxy plate can be accurately clamped; the epoxy plate can be completely limited; the condition that the epoxy plate falls off in the carrying process is avoided; the epoxy plate carrying stability can be improved, so that the stacking speed of the epoxy plates can be increased, the stacked epoxy plates can be separated, people can independently package the epoxy plates conveniently, finally, the position of the stacking robot connector is limited, accidents caused by looseness of the stacking robot connector are avoided, and better use prospects are brought.

Owner:安徽唯宏新材料科技有限公司

Clamp device with adjustable manipulator angle

InactiveCN101219539AProtection from damageAccurate grippingGripping headsManipulatorElectrical and Electronics engineering

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

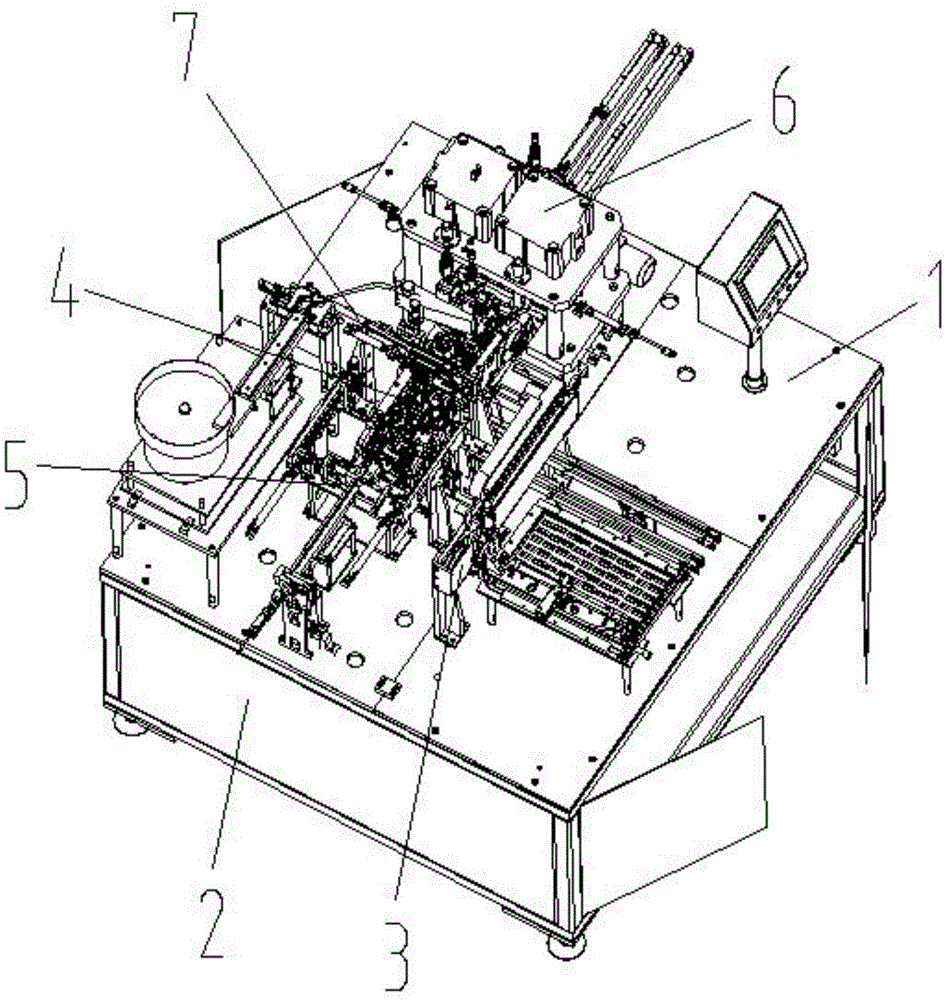

Full-automatic double-side film sticking production line for electronic product

The invention discloses a full-automatic double-side film sticking production line for an electronic product. The full-automatic double-side film sticking production line is characterized by comprising a feeding part, an upper transfer part, a front side film sticking part, a transfer turnover part, a back side film sticking part, a lower transfer part, a discharging part and a conveying belt; theconveying belt sequentially communicates with the feeding part, the upper transfer part, the front side film sticking part, the transfer turnover part, a rear surface film sticking part, the lower transfer part and the discharging part; the back side film sticking part and the front side film sticking part are of the same structure; the lower transfer part and the upper transfer part are of the same structure; the discharging part and the feeding part are of the same structure; the back side film sticking part is arranged at the next station of the transfer turnover part; the lower transfer part is arranged at the next station of the back side film sticking part; and the discharging part is arranged at the next station of the lower transfer part. The full-automatic double-side film sticking production line disclosed by the invention is high in automation degree, saves labor, lowers the production cost, improves the production efficiency, increases the percent of qualified products andachieves a good market application value.

Owner:郑州众益德网络科技有限公司

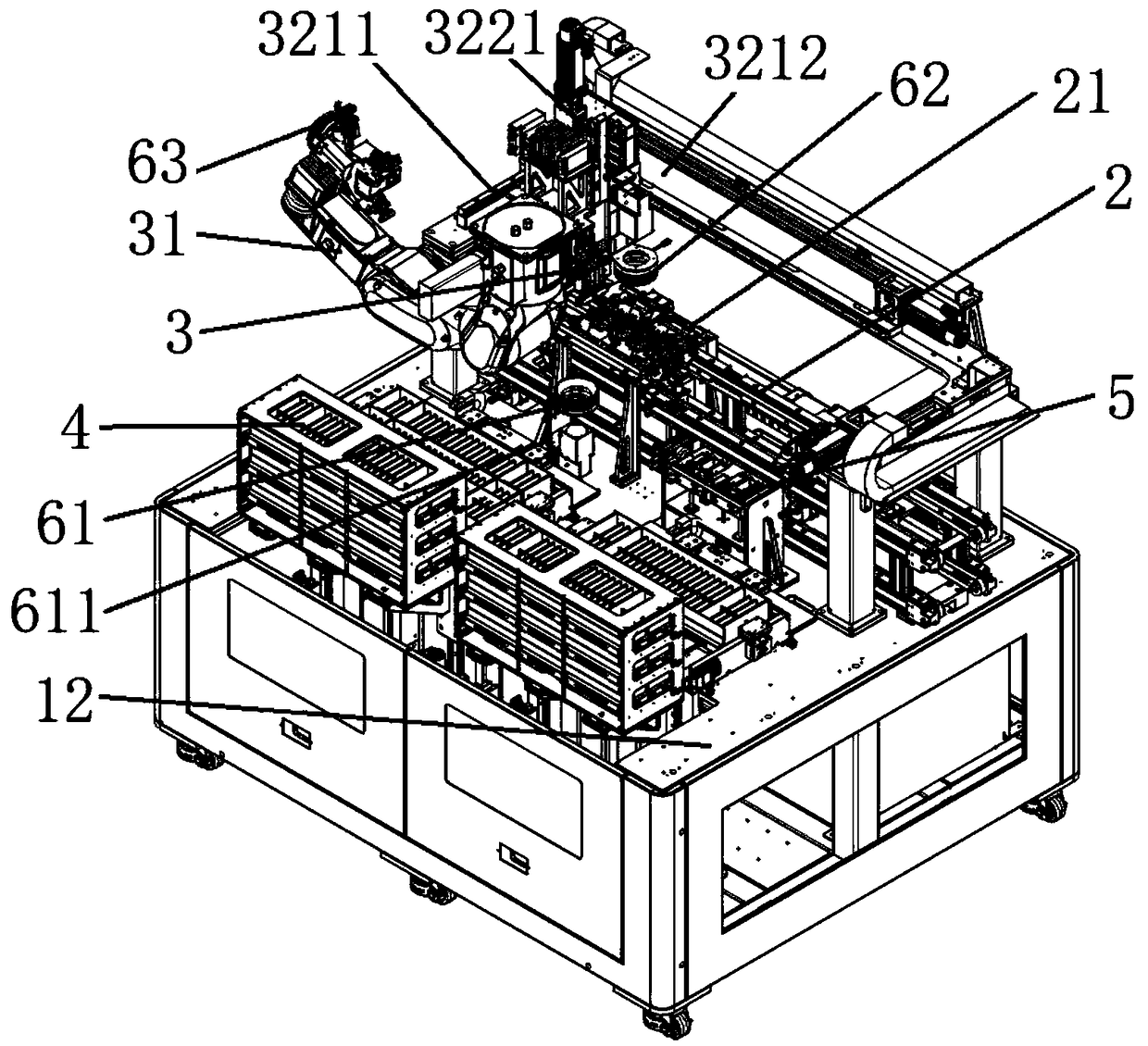

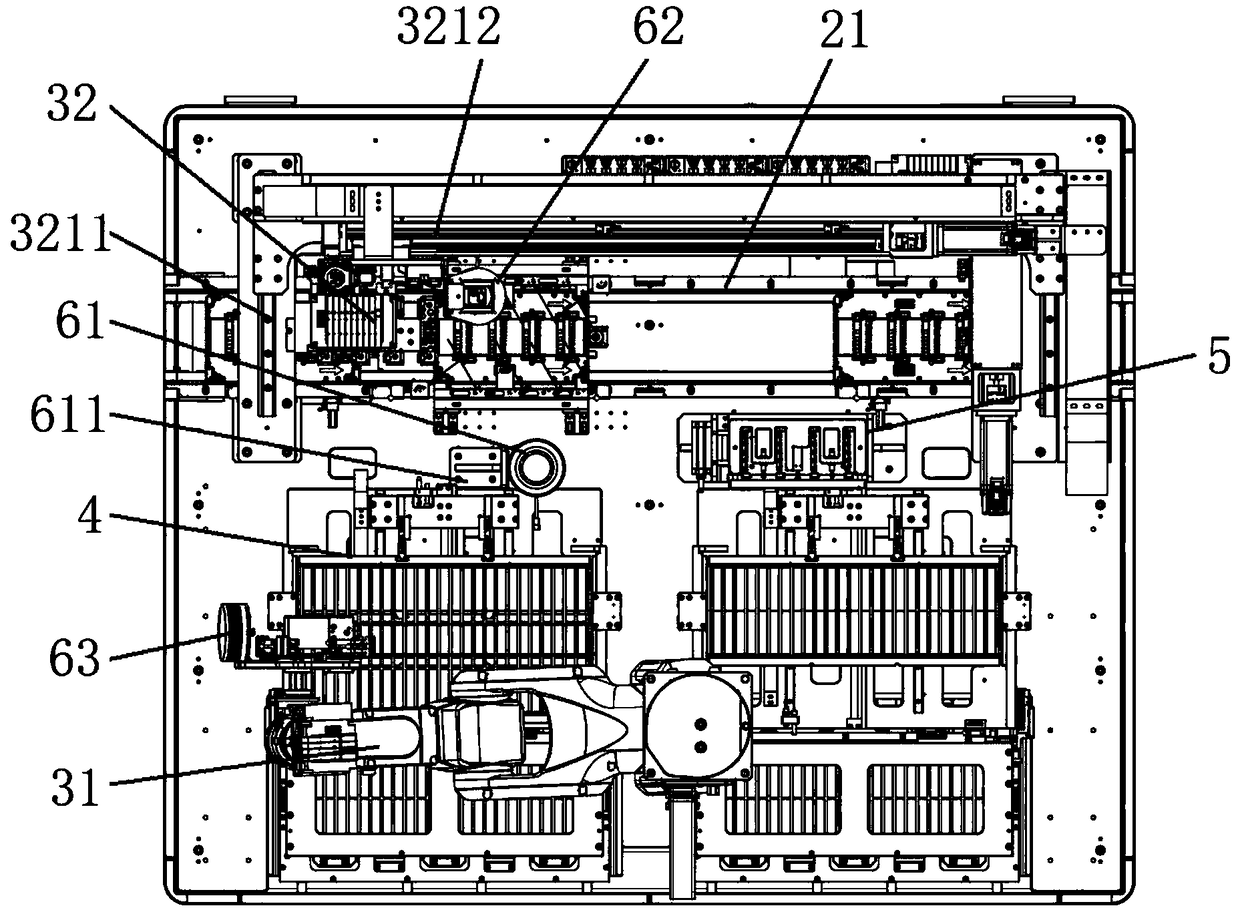

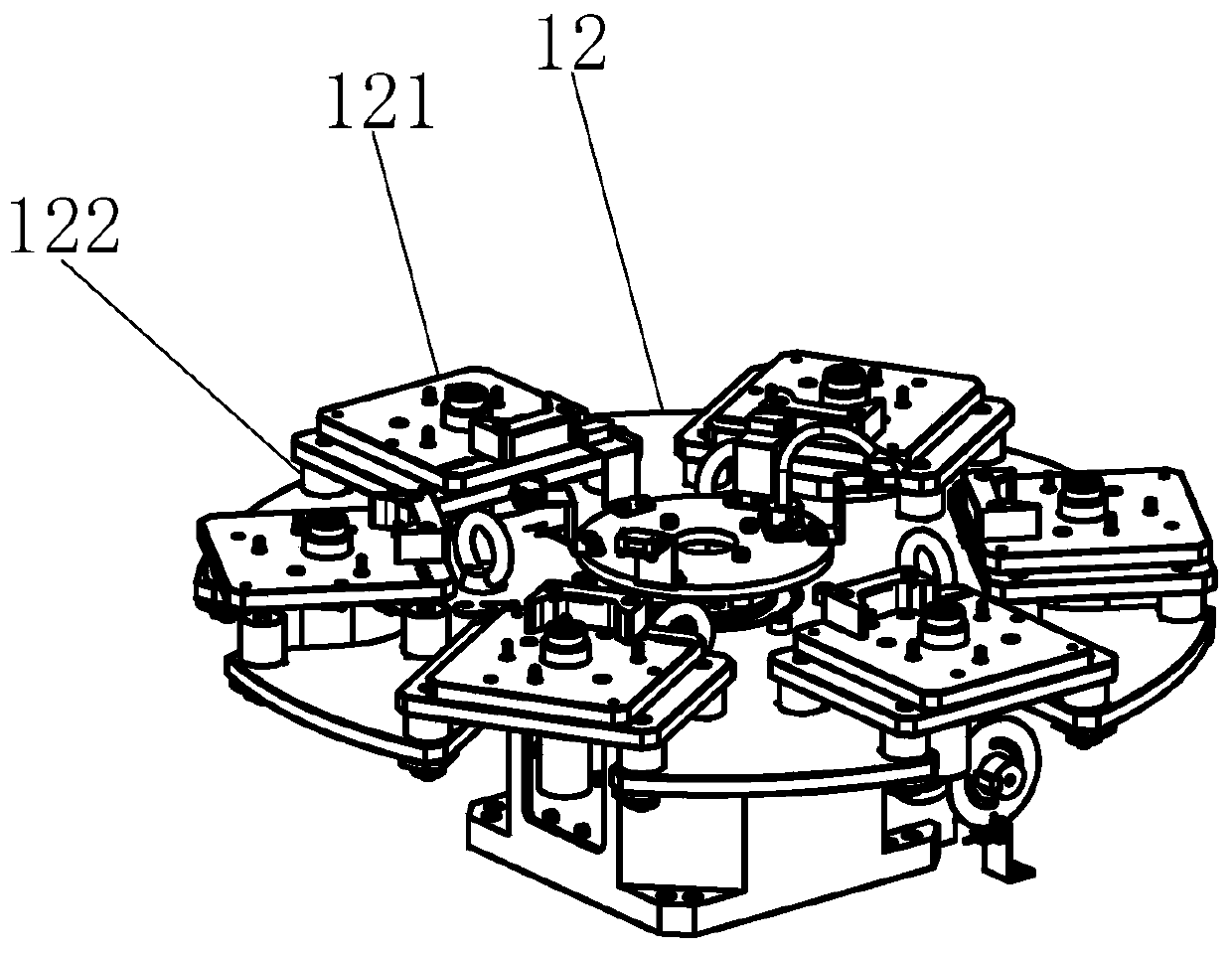

Automatic assembling machine of inductor

ActiveCN106670791AReduce consumptionRealize integrated operationAssembly machinesMetal working apparatusDistribution controlInductor

The invention relates to an automatic assembling machine of an inductor. The automatic assembling machine comprises a rack and a distribution control box; a conveying device is arranged on the rack; a loading and unloading device is arranged at the upper middle part of the conveying device; a sheet inserting device of an iron sheet is arranged on the left side of the conveying device; a ring pressing device and a core inserting device of an iron core are arranged on the right side of the conveying device; the loading and unloading device is composed of a charging disc arranged on the rack; the charging disc is matched with a loading conveying groove and an unloading conveying groove which are formed in the rack through a fetching device; and the loading conveying groove and the unloading conveying groove are matched with a conveying carrier on a conveying chain through a transferring device. According to the automatic assembling machine, with adoption of the conveying chain which runs anticlockwise as a conveying part, a loading station can be arranged adjacent to an unloading station; and meanwhile, with equipment of a matched loading and unloading station and adoption of the same charge disc as a skeleton and a finished product loading part, integral operation of the loading and unloading is realized, the assembly efficiency is greatly improved, the occupying space is saved, and the energy consumption in the conveying process is reduced.

Owner:TONGXIANG YAORUN ELECTRONICS

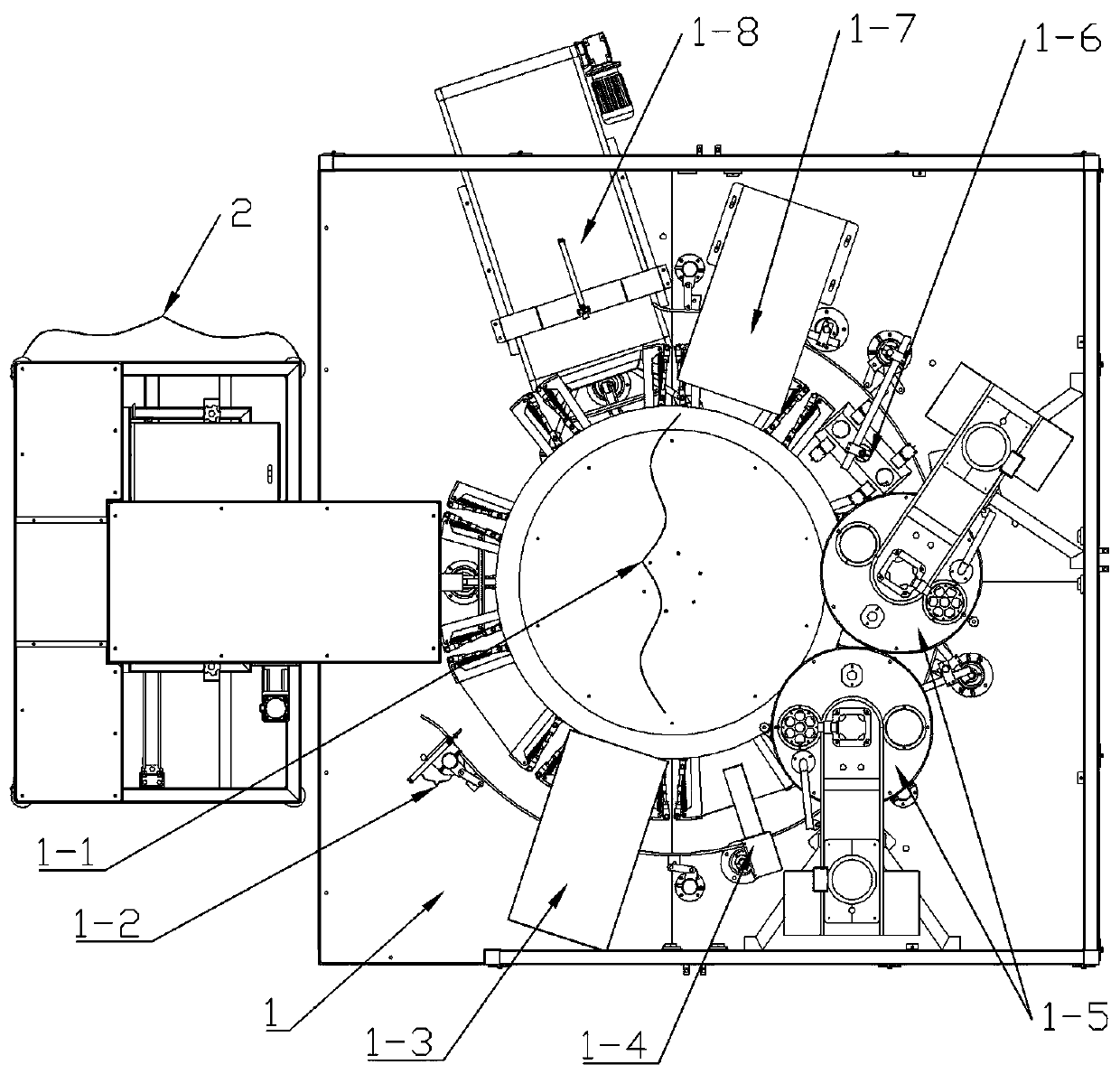

Ten-station flour packing machine

PendingCN110626554ACompact structureSmall footprintPackaging automatic controlEngineeringDust collector

The invention discloses a ten-station flour packing machine which comprises a working platform, a bag supplying mechanism, a packing bag detection mechanism, a bag opening mechanism, an opening detection mechanism, two filling machines, a dust collector, a sealing machine and an output conveyor belt. A center transposition mechanism is arranged at the center of the working platform. The packing bag detection mechanism, the bag opening mechanism, the opening detection mechanism, the filling machines, the dust collector, the sealing machine and the output conveyor belt are mounted on the workingplatform and are successively arranged around the center transposition mechanism. The bag supplying mechanism is located on one side of the working platform and faces a position between the packing bag detection mechanism and the output conveyor belt. A vacancy is reserved between the packing bag detection mechanism and the output conveyor belt. The ten-station flour packing machine is compact instructure and small in occupied space, and can achieve automatic filling. By arranging the two filling machines: one is used and the other is standby. When one of the filling machines fails, the other filling machine can be started immediately to replace the failed filling machine, and the failed filling machine is maintained specially during stop production for maintenance, so that normal production is not affected.

Owner:河南济开电器有限公司 +1

Material picking device

PendingCN109132523AAccurate grippingAccurate placementConveyorsControl devices for conveyorsEngineeringMechanical engineering

Owner:SUZHOU RS TECH

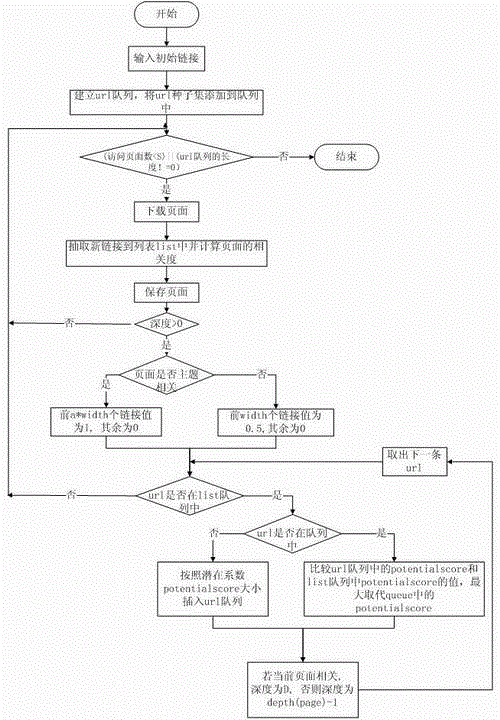

Crawler algorithm for capturing webpage in online shopping mall

InactiveCN102982184AAccurate grippingReasonable designSpecial data processing applicationsUniform resource locatorWeb page

The invention relates to a crawler algorithm for capturing a webpage in an online shopping mall, which comprises the following steps: acquiring a page in the online shopping mall according to an initial link and adding a seed set in the page to a url queue; downloading the page according to the initial link, adding a new link to a list queue, and computing the degree of correlation of the page; setting a corresponding link value according to the depth of the page and the degree of correlation between the page and a topic; for the url existing in both the list queue and the url queue, comparing the potential coefficient in the url queue with that in the list queue to update the potential coefficient in the url queue; for the url existing in the list queue but not in the url queue, inserting the url to the url queue according to the potential coefficient; and finally, setting the depth according to the degree of correlation of the current page. The algorithm is favorable for precisely capturing the webpage in the online shopping mall related to the topic, and is rational in design and good in running effect.

Owner:FUJIAN NORMAL UNIV

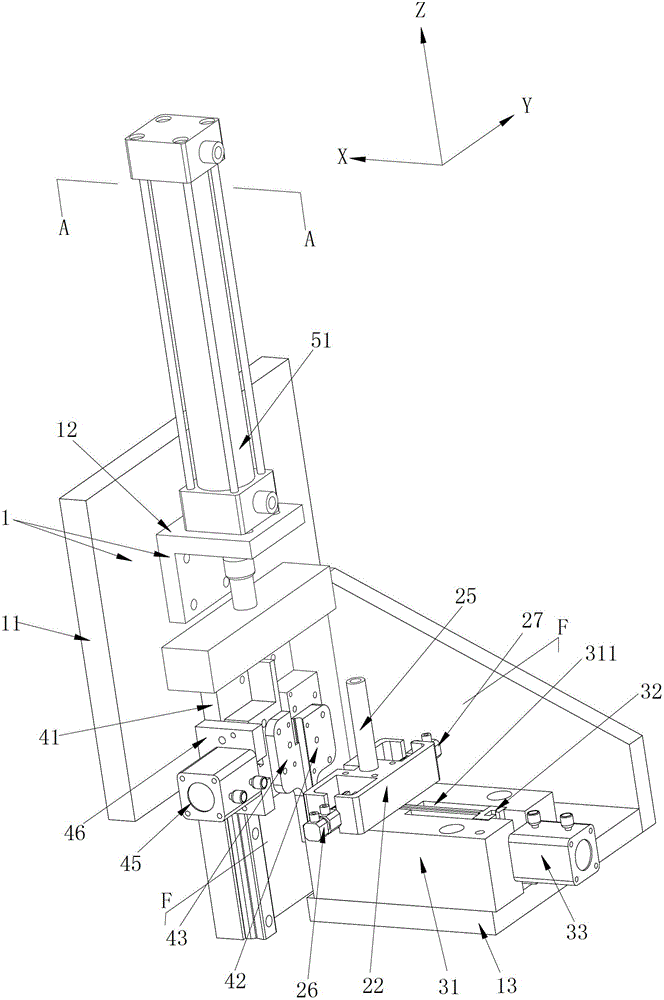

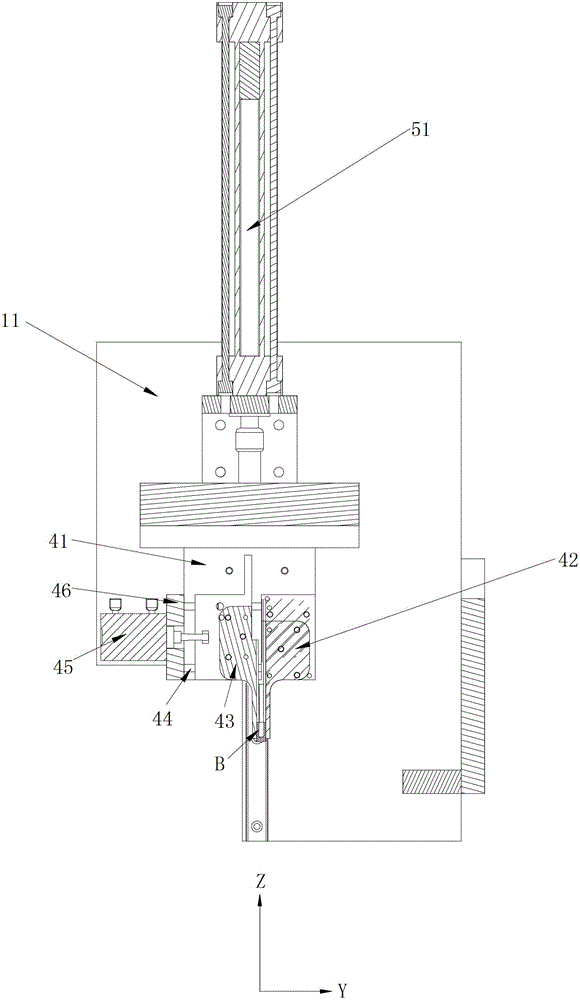

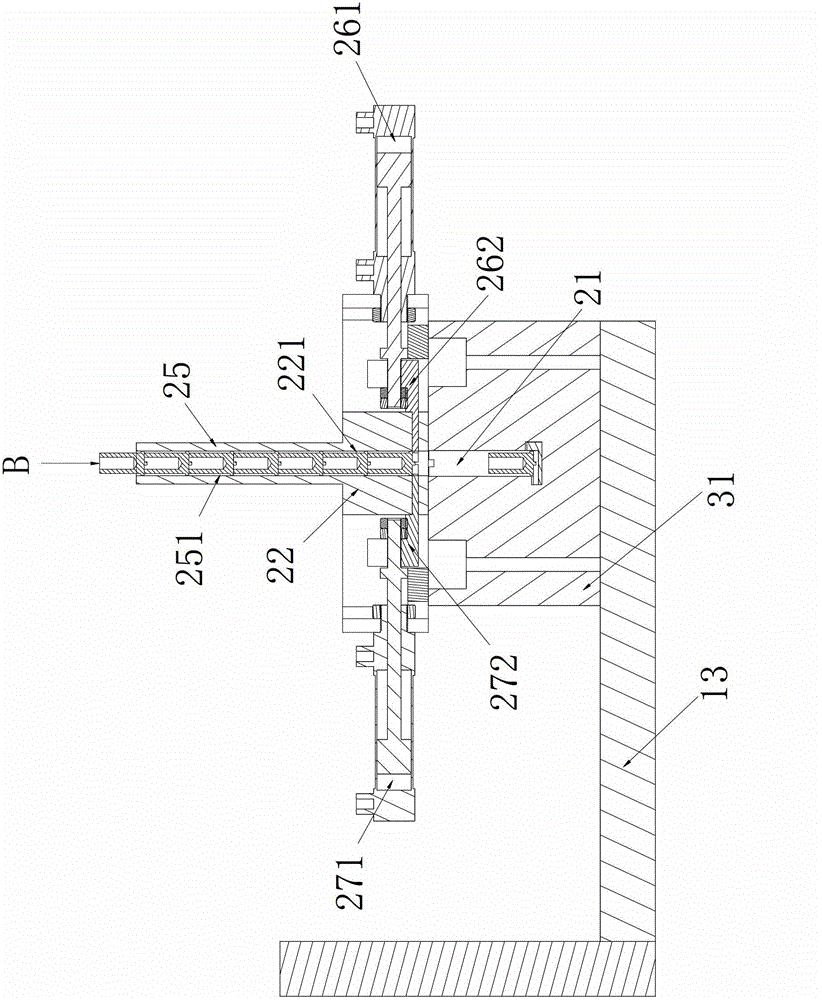

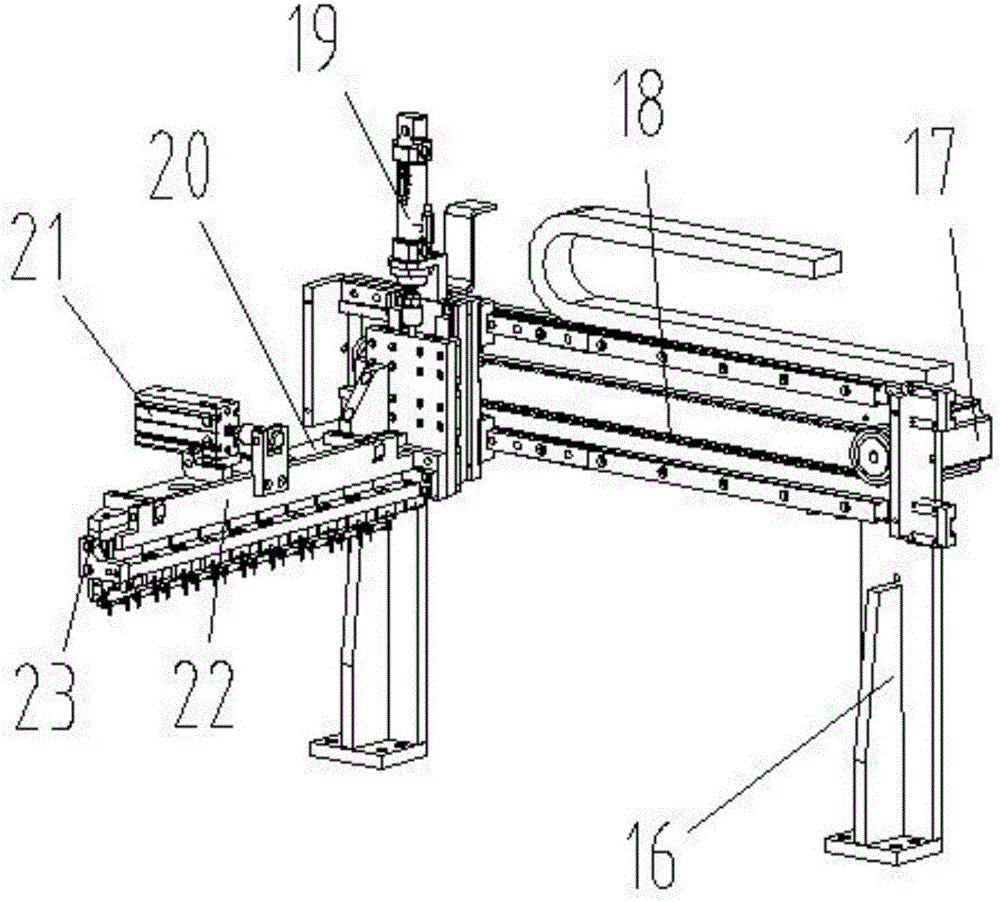

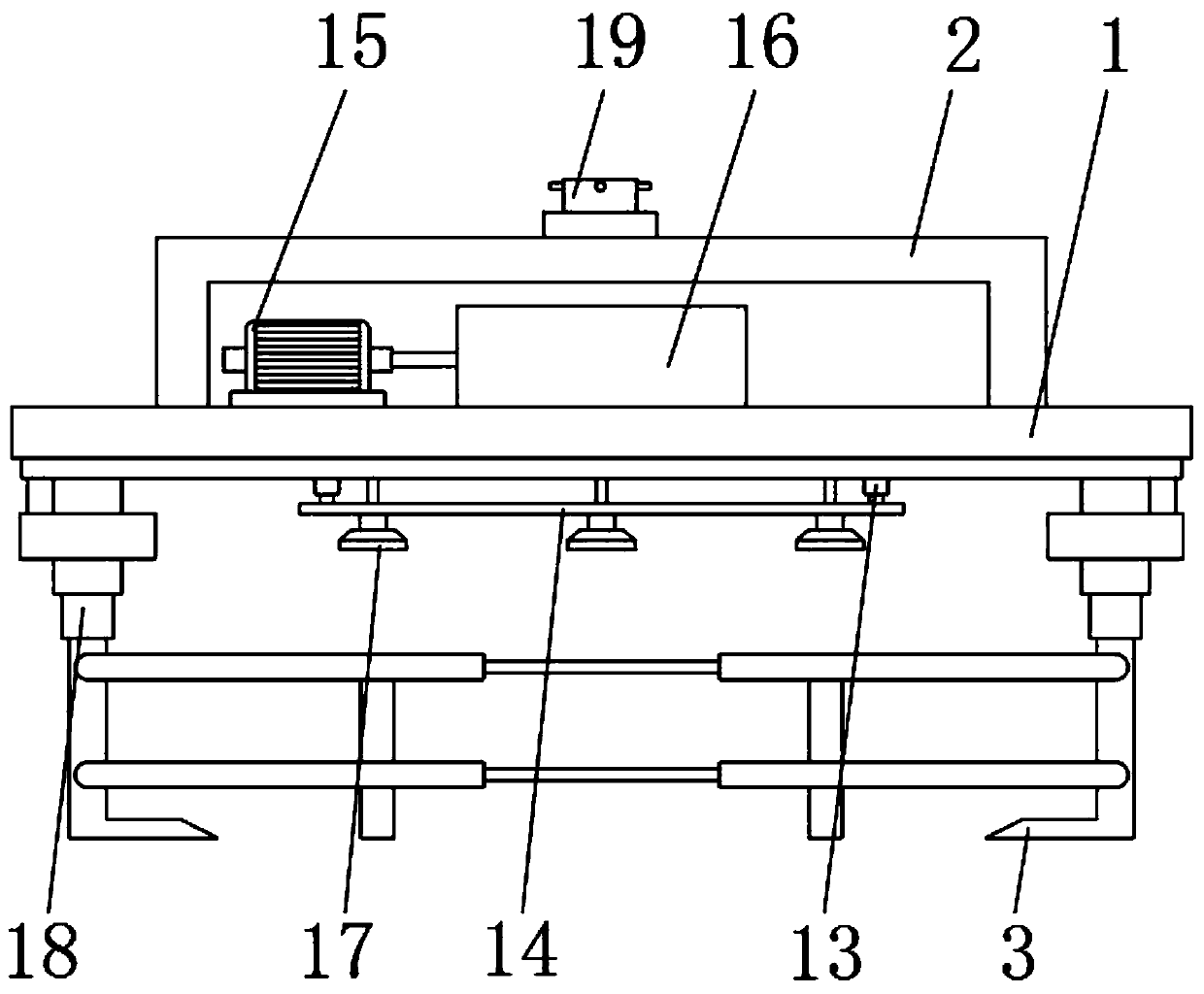

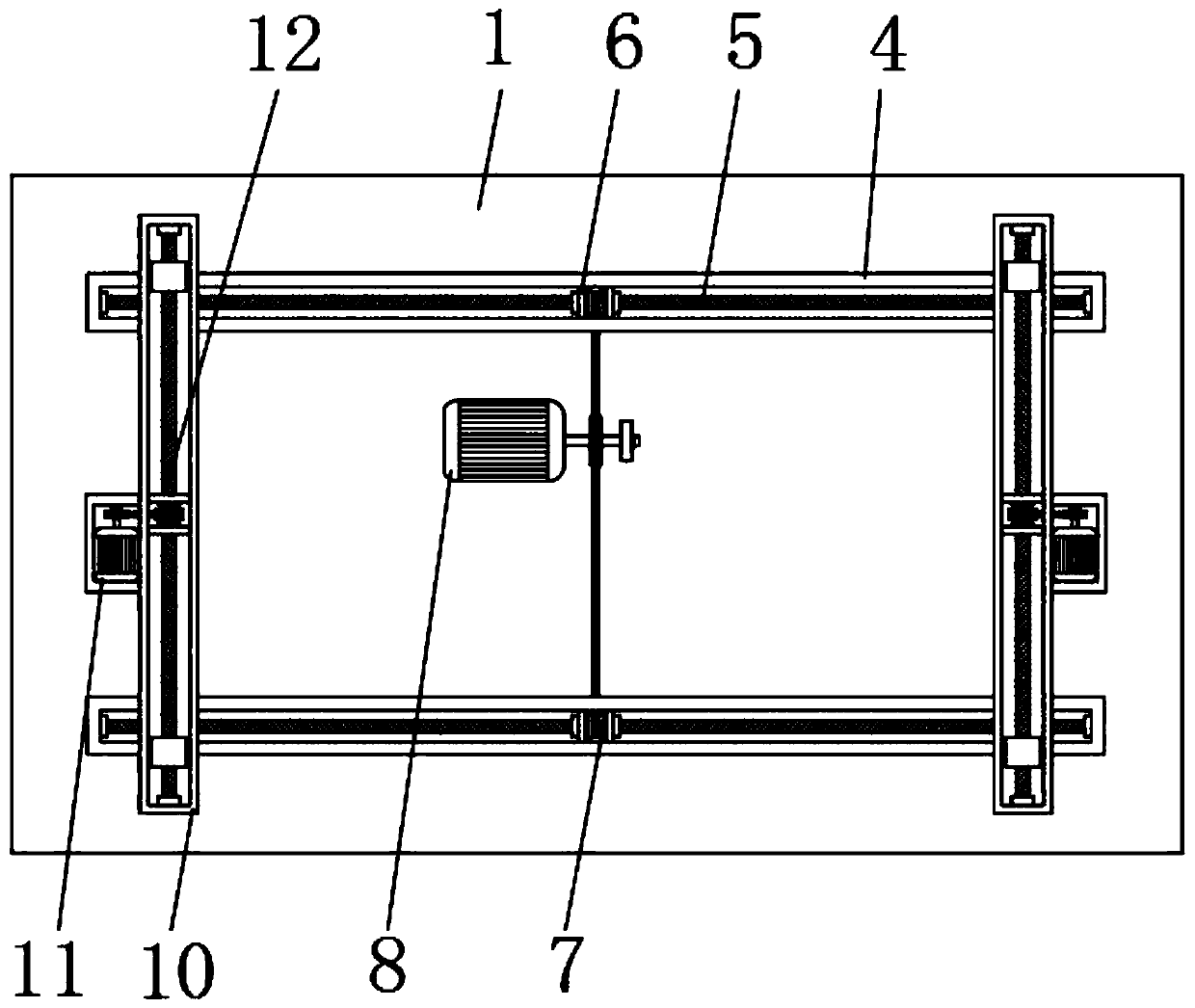

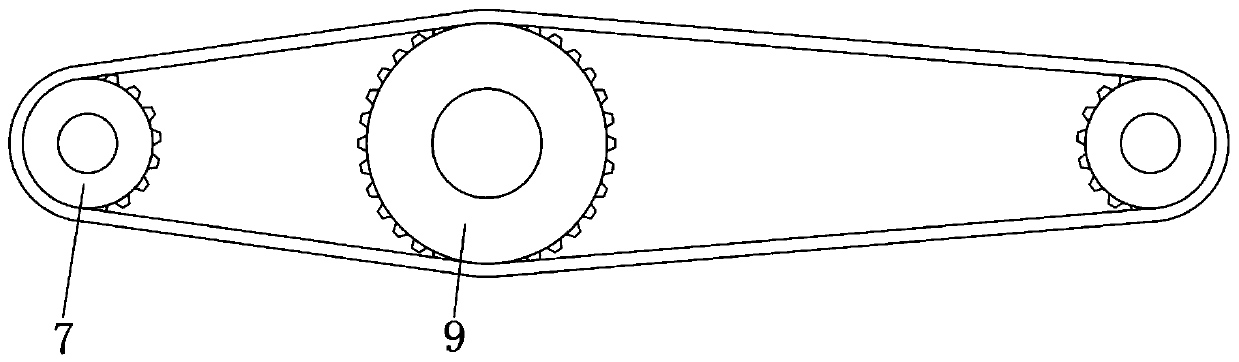

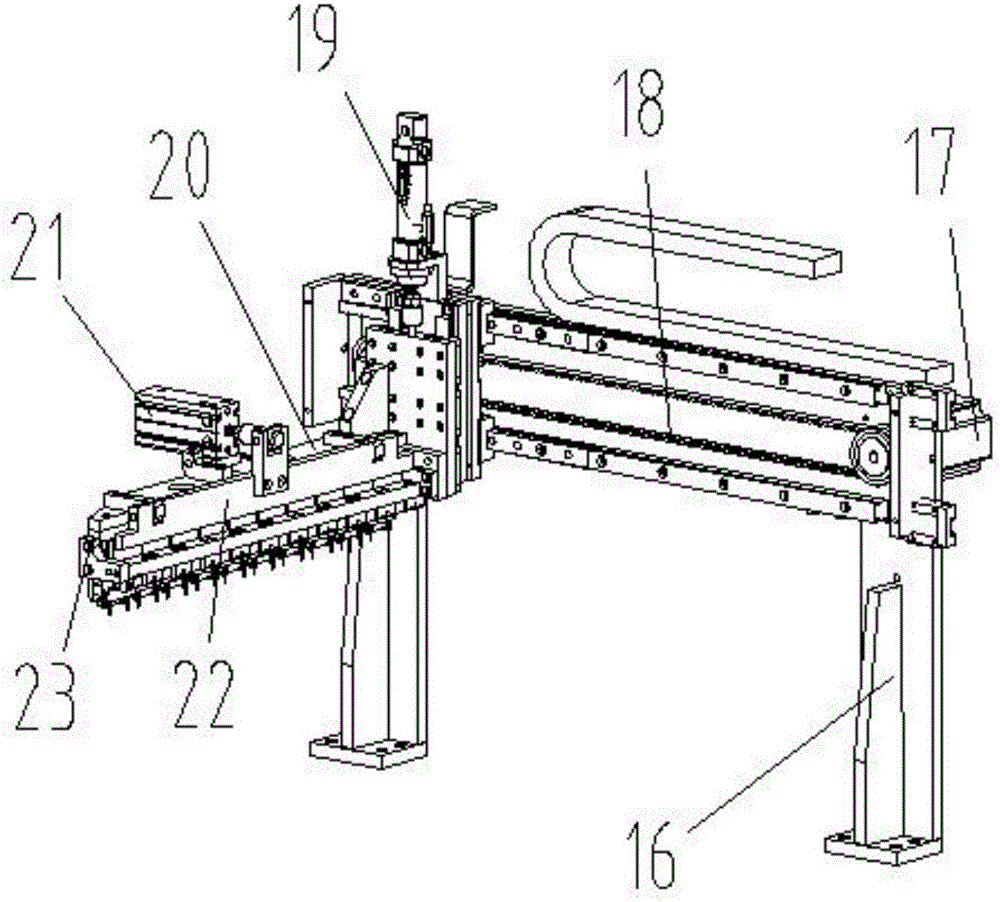

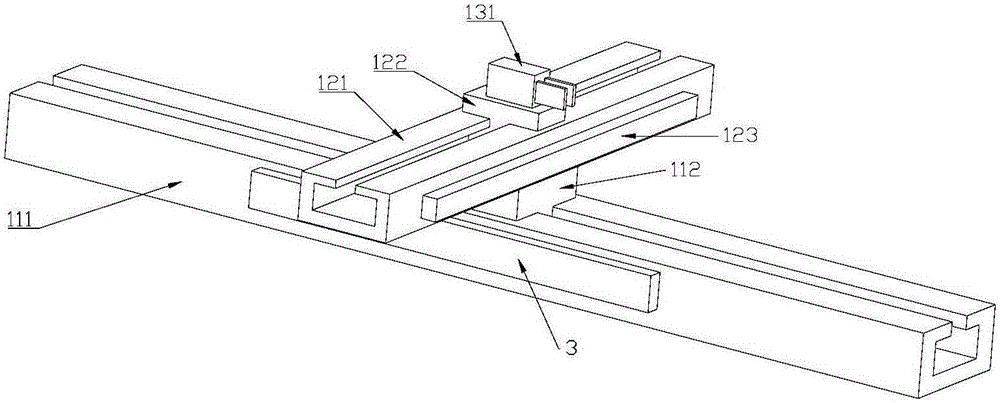

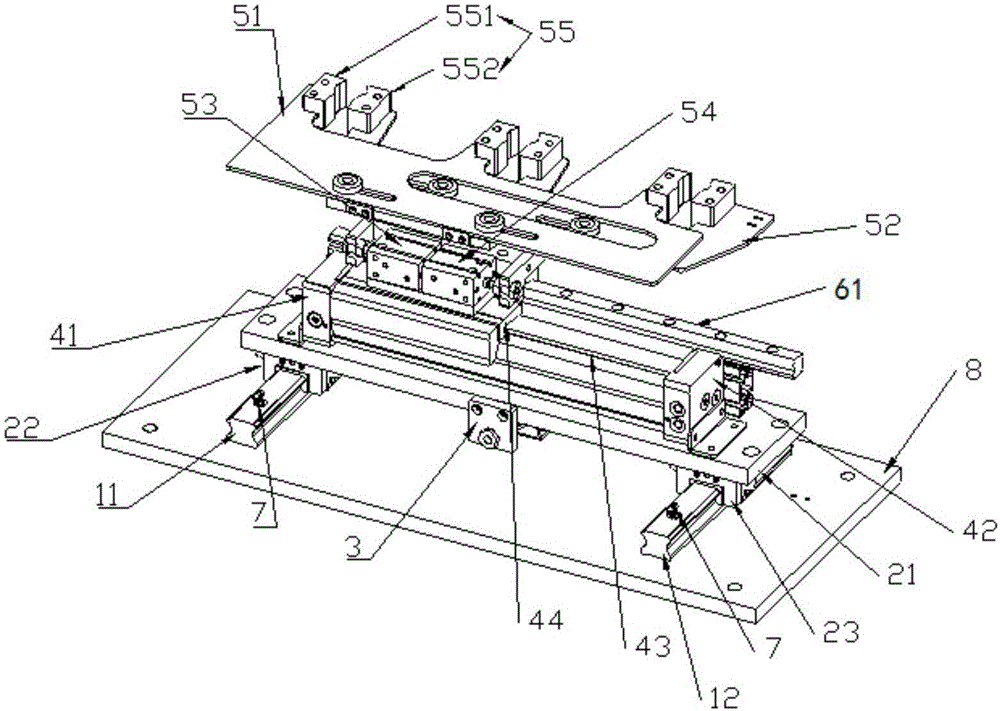

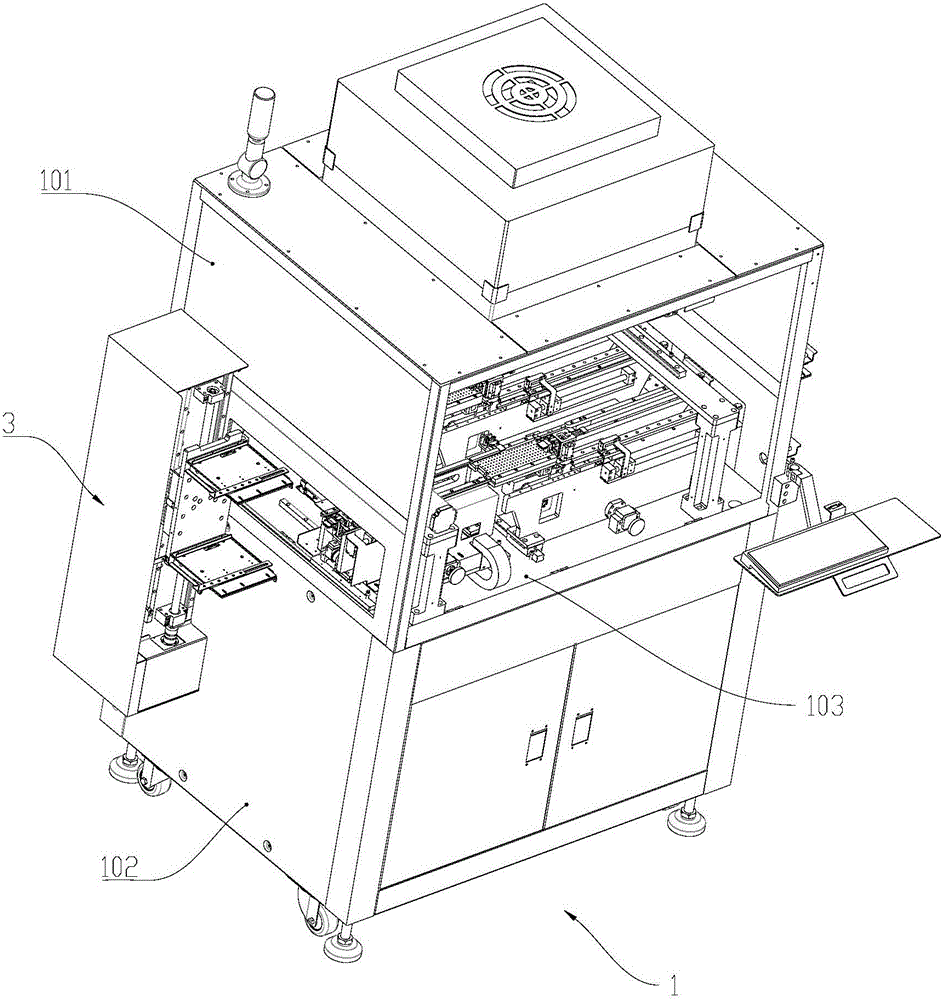

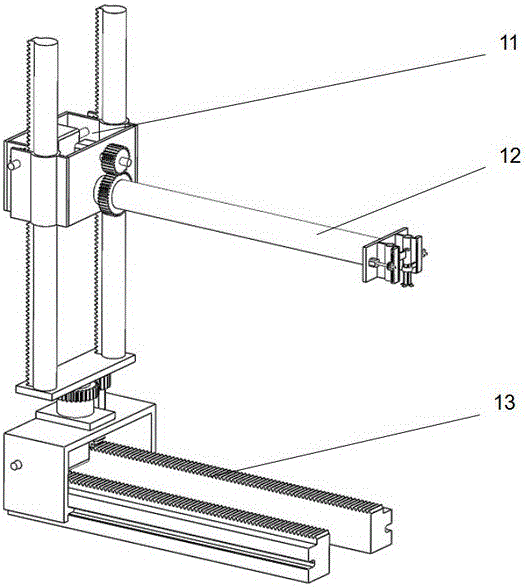

Manipulator and machine tool

PendingCN106826884AAccurate grippingAlleviate the technical problem of low grasping accuracyGripping headsMetal working apparatusControl engineeringManipulator

The invention provides a manipulator and a machine tool and relates to the technical field of auxiliary machining equipment. The manipulator comprises a longitudinal moving assembly, a horizontal moving assembly and a clamping assembly, wherein the longitudinal moving assembly comprises a first track, a first slider and a first driving part which is used for driving the first slider to move longitudinally along the first track in the horizontal direction; the horizontal moving assembly comprises a second track, a second slider and a second driving part which is used for driving the second slider to move horizontally along the second track in the horizontal direction; the first slider is fixedly connected with the second track, the second slider is fixedly connected with the clamping assembly, and horizontal movement and longitudinal movement are performed in mutually perpendicular directions. The technical problem of lower grabbing precision caused by the fact that a manipulator device enables central position of a grabbed to-be-machined workpiece to deviate easily in the prior art is solved.

Owner:NINGBO ZEE AUTOMATION EQUIP

Testing machine for semiconductor packaging products

ActiveCN105789080AAccurate detectionImprove detection efficiencySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingButt jointPulley

The invention discloses a testing machine for semiconductor packaging products. The testing machine comprises a frame, a testing mechanism, a material loading mechanism, a movable channel accessing mechanism, a material discharging mechanism and at least one set of fixed channel material receiving mechanism, wherein the testing mechanism tests whether the products tested are qualified, the material loading mechanism supports a first material loading box, the movable channel accessing mechanism is in butt joint with the material loading mechanism and is used for clamping the products to be tested, the front end of the fixed channel material receiving mechanism is in butt joint with the tail part of the movable channel accessing mechanism, the fixed channel material receiving mechanism comprises two parallelly arranged second clamping plates, a material sucking assembly in butt joint with the tail part of the movable channel accessing mechanism, a second grabbing assembly and a second belt pulley assembly arranged on the downstream of the material sucking assembly, the material discharging mechanism supports a second material loading box which is used for containing tested products. The testing machine can rapidly and accurately test appearance defects of the products, and ensures high detection accuracy and efficiency. Labor intensity is reduced, labor force is saved, and the production cost is lowered.

Owner:刘媛媛

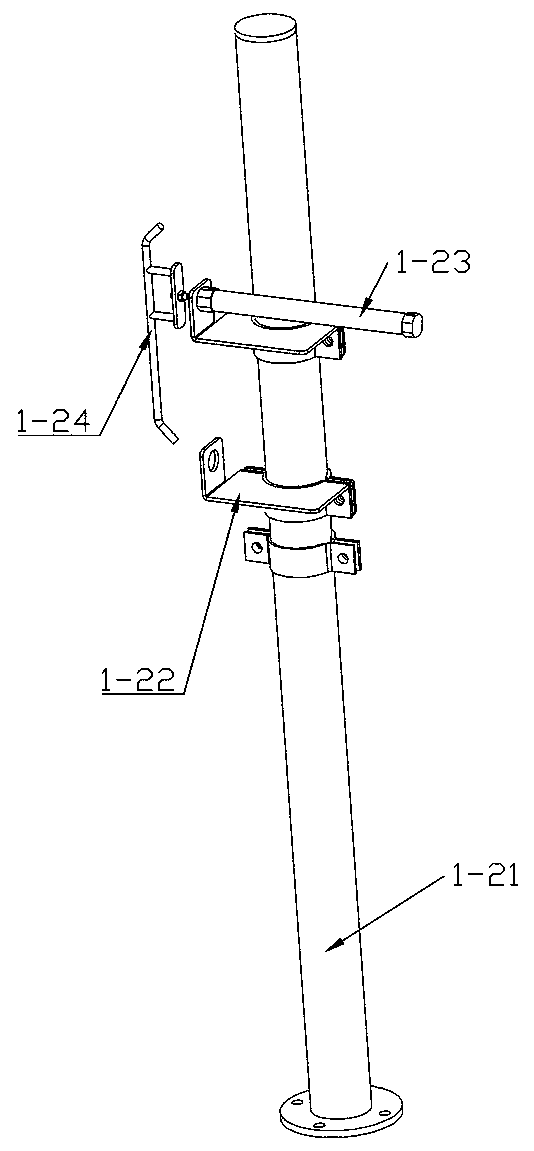

Water pump assembling equipment and water pump assembly line

PendingCN109746676AImprove assembly efficiency and assembly qualityImprove efficiencyLiquid surface applicatorsAssembly machinesTransfer mechanismAssembly line

The invention relates to the technical field of water pump assembly assembling, in particular to water pump assembling equipment and a water pump assembly line. The water pump assembling equipment adopts a turnplate for conveying water pumps, assembling assemblies are arranged above and below the turnplate correspondingly, a transfer assembly is arranged in an area between one of the assembling assemblies and the turnplate, and transfers a workpiece to a position corresponding to the assembling assemblies and a pump body, the assembling assemblies can be used for pressing the workpiece into the pump body, automatic assembling is achieved, and the water pump assembling efficiency and quality are improved; and according to the water pump assembly line, a pump body transfer mechanism is arranged on the assembling equipment, since the pump body is arranged on the turnplate in a circumferential arranging mode, the pump body transfer mechanism can rotate by a certain angle and can accuratelygrip or clamp the pump body on the turnplate, the pump body is automatically transferred to the next procedure, automatic water pump assembling is achieved, and the assembling efficiency is improved.

Owner:珠海迈超智能装备有限公司

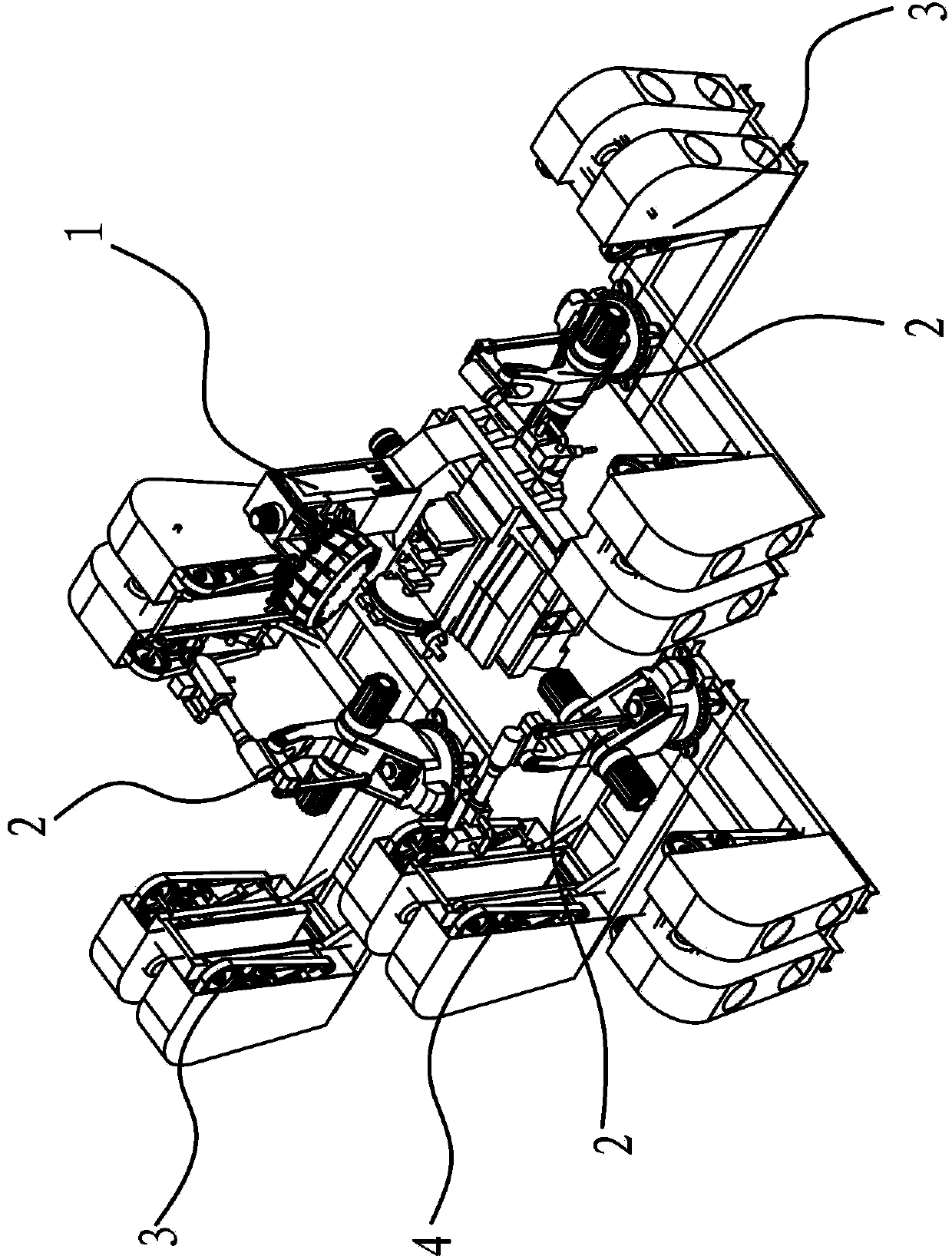

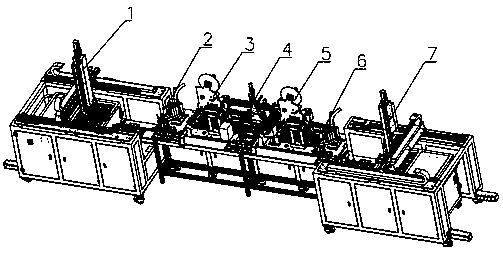

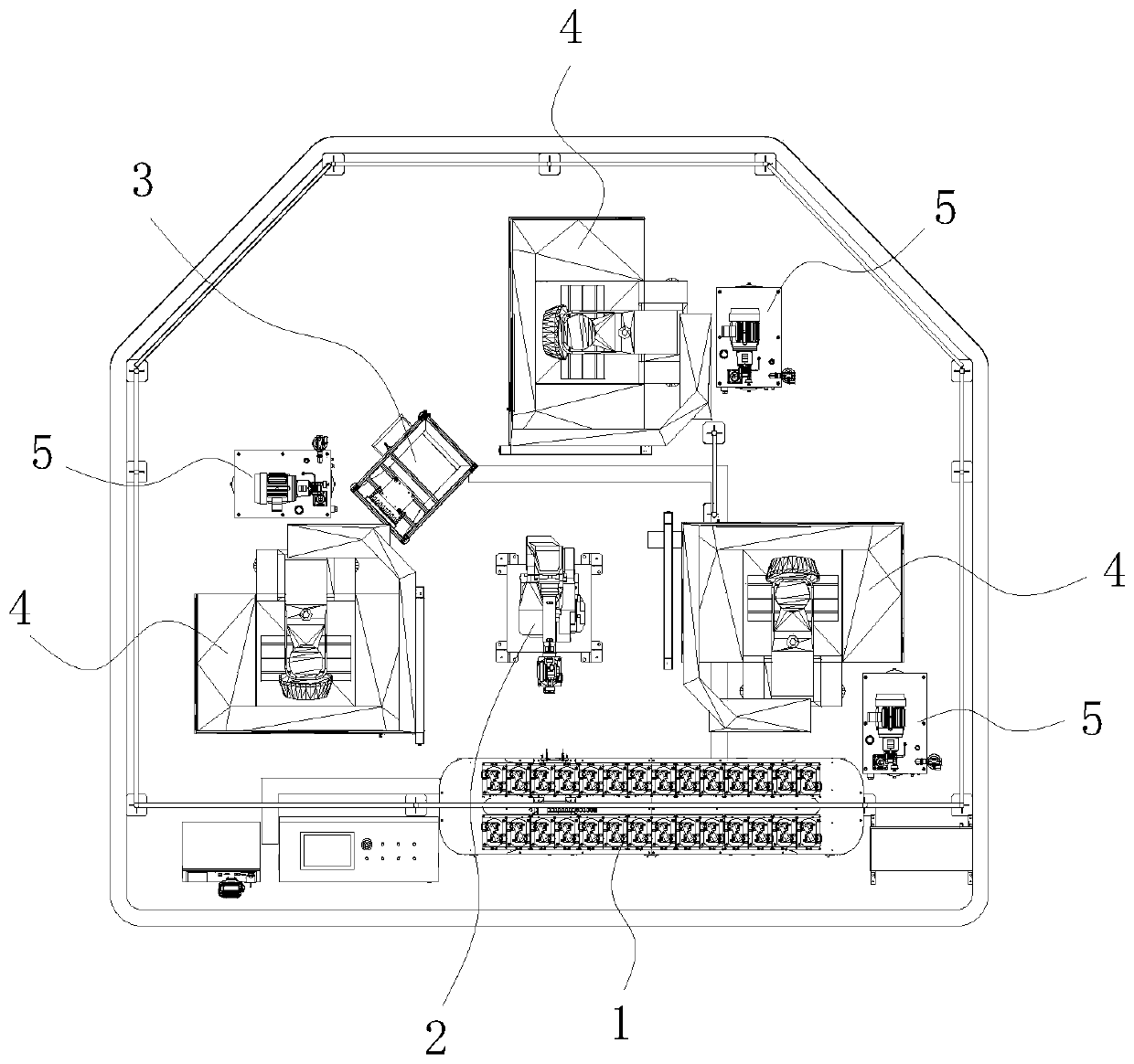

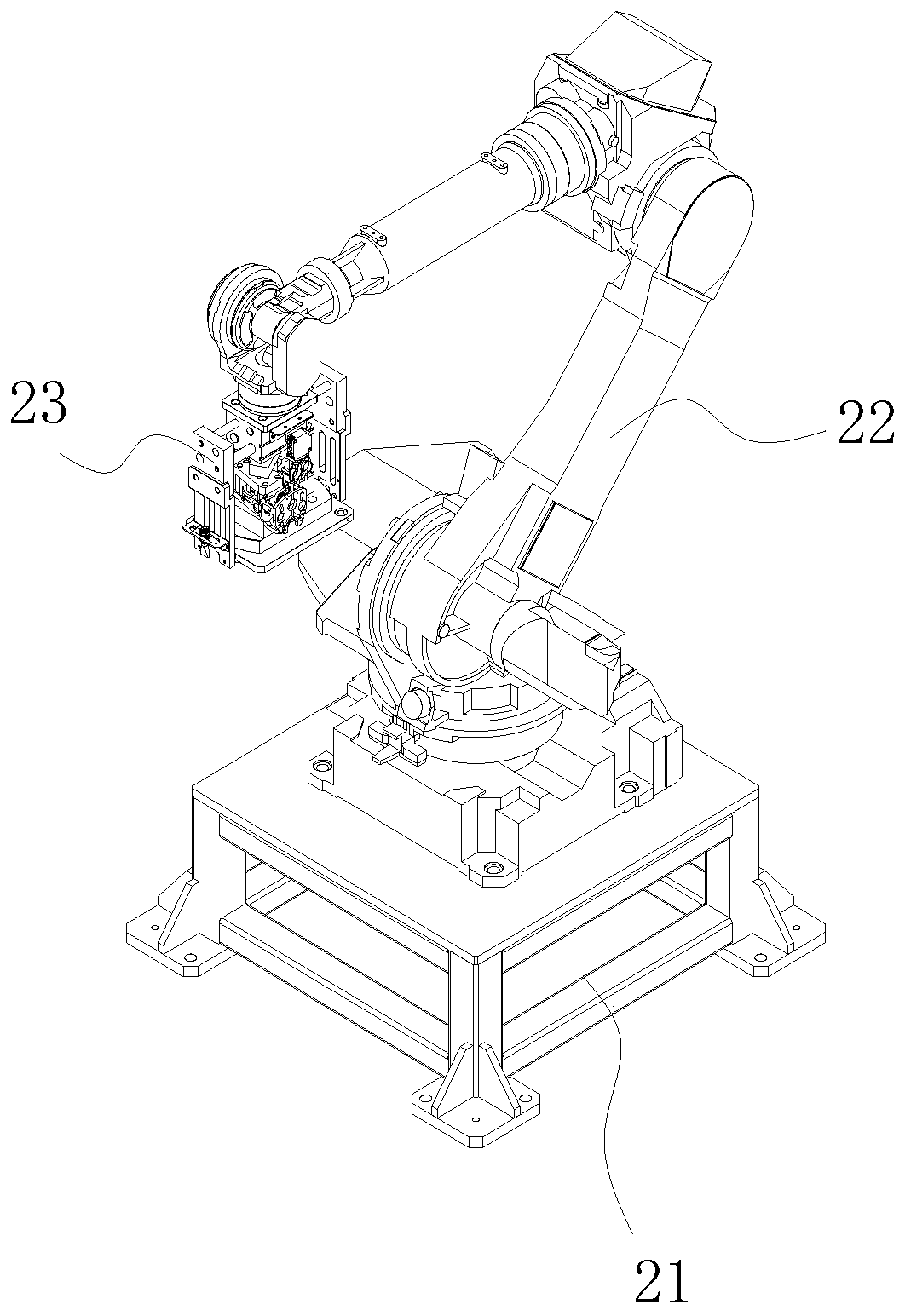

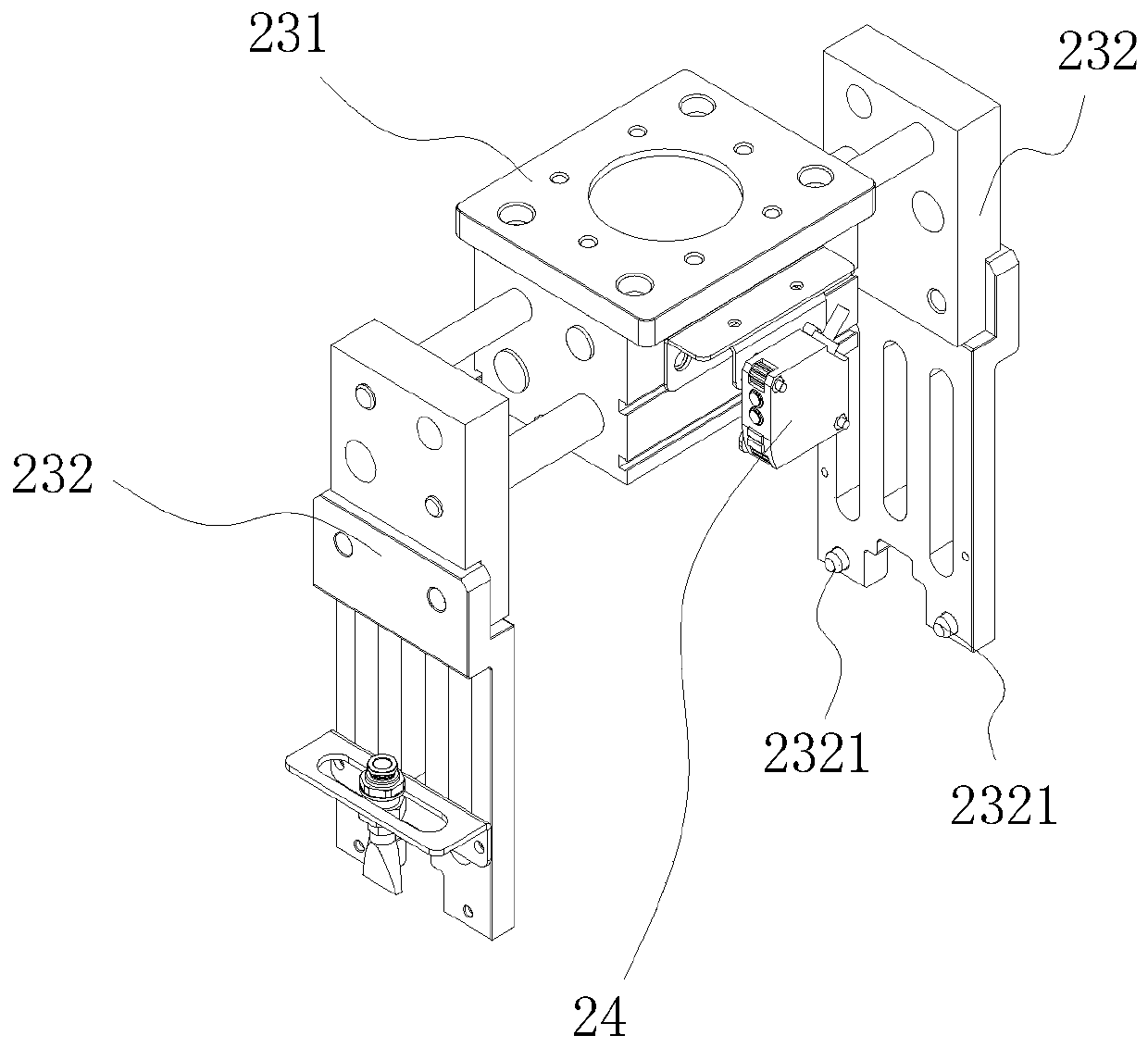

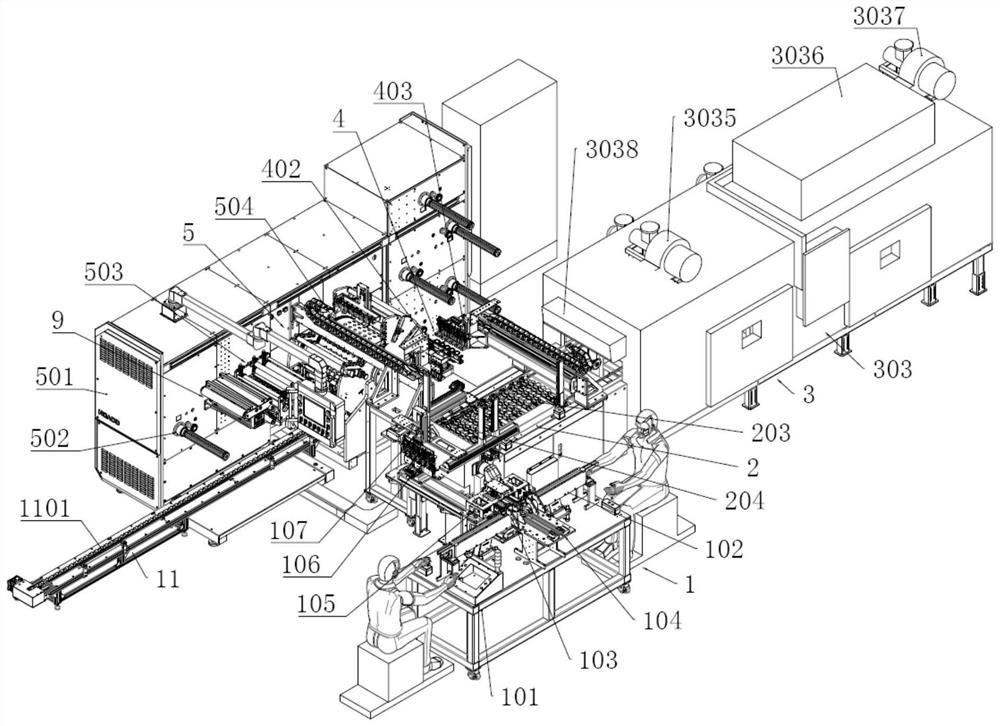

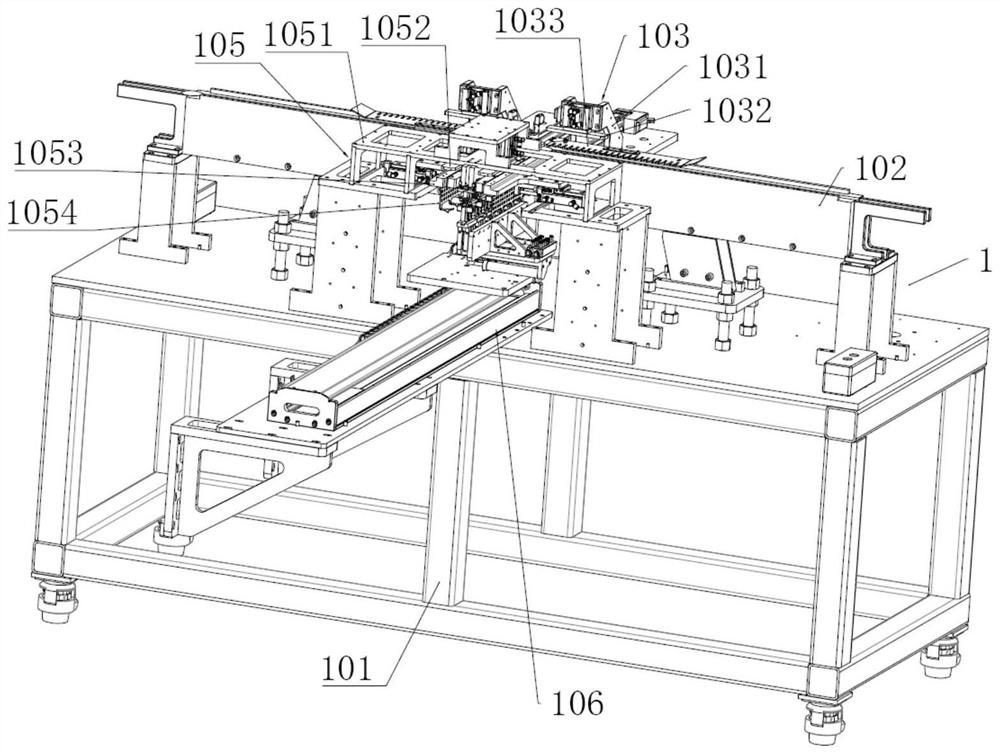

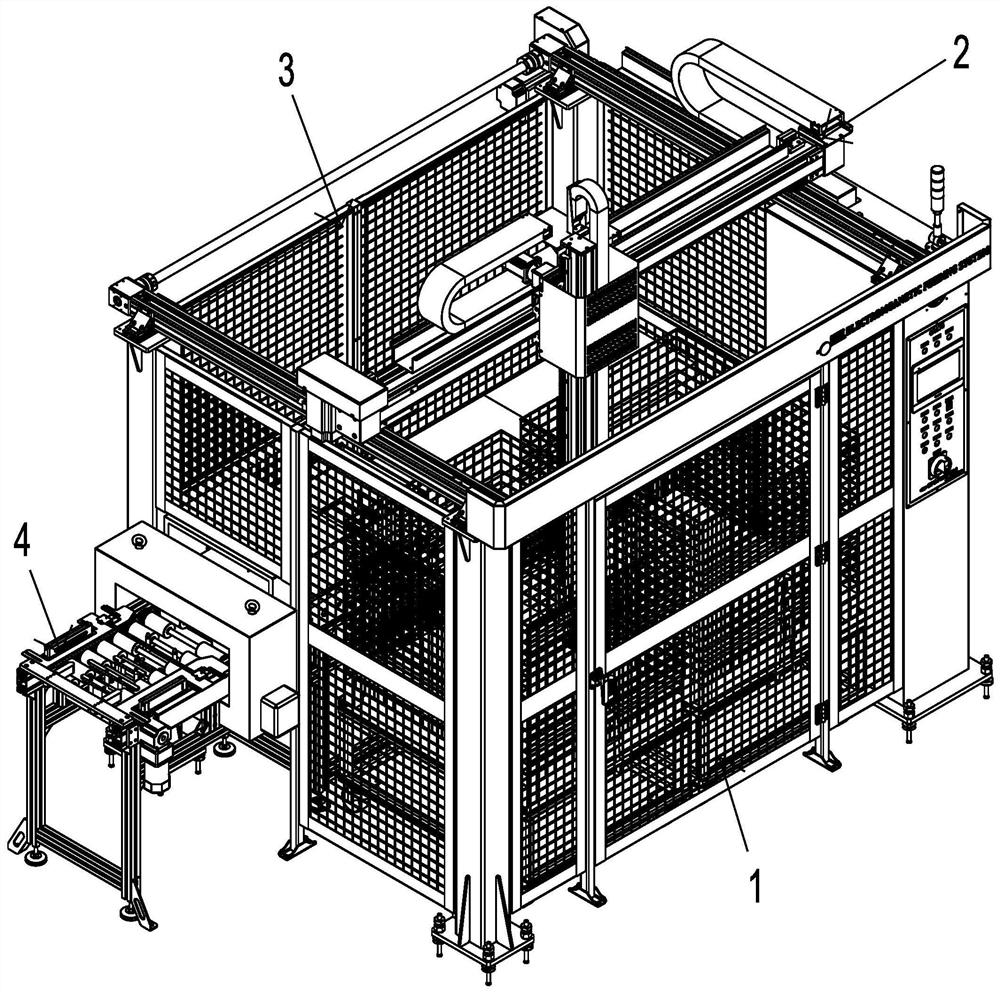

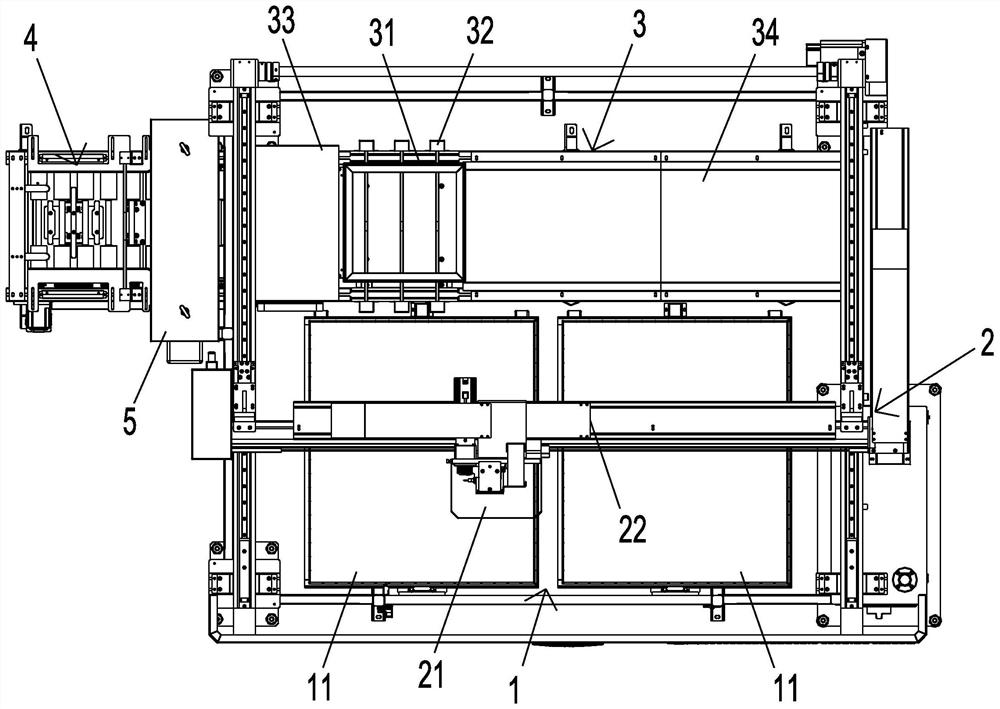

Small-batch multispecies automatic production line device and machining method thereof

ActiveCN111482848AHigh degree of automationSolve technical problems of repeated processingCleaning using liquidsMetal working apparatusNumerical controlProduction line

The invention discloses a small-batch multispecies automatic production line device. The small-batch multispecies automatic production line device comprises a feeding table, a robot device, a cleaningmachine and numerical control equipment, wherein the feeding table is used for conveying machined parts; the robot device is used for clamping the machined parts from the feeding table and is furtheradjacent to the feeding table; and the cleaning machine and the numerical control equipment are arranged on the periphery of the robot device. Due to the fact that the small-batch multispecies automatic production line device disclosed in the invention is provided with a cleaning table, the defect that products still need to be manually cleaned after the machined parts are machined in the prior art is overcome, the robot device can accurately clamp the machined parts through the small-batch multispecies automatic production line device, and thus machining errors are reduced. The small-batch multispecies automatic production line device further has the beneficial effect of being capable of machining production of the different machined parts and the effect of preventing scraps from splashing in the machining process. The invention further discloses a machining method of the automatic production line device. The machining method is applied to machining of the machined parts through theautomatic production line device.

Owner:杭州纳志机器人科技有限公司

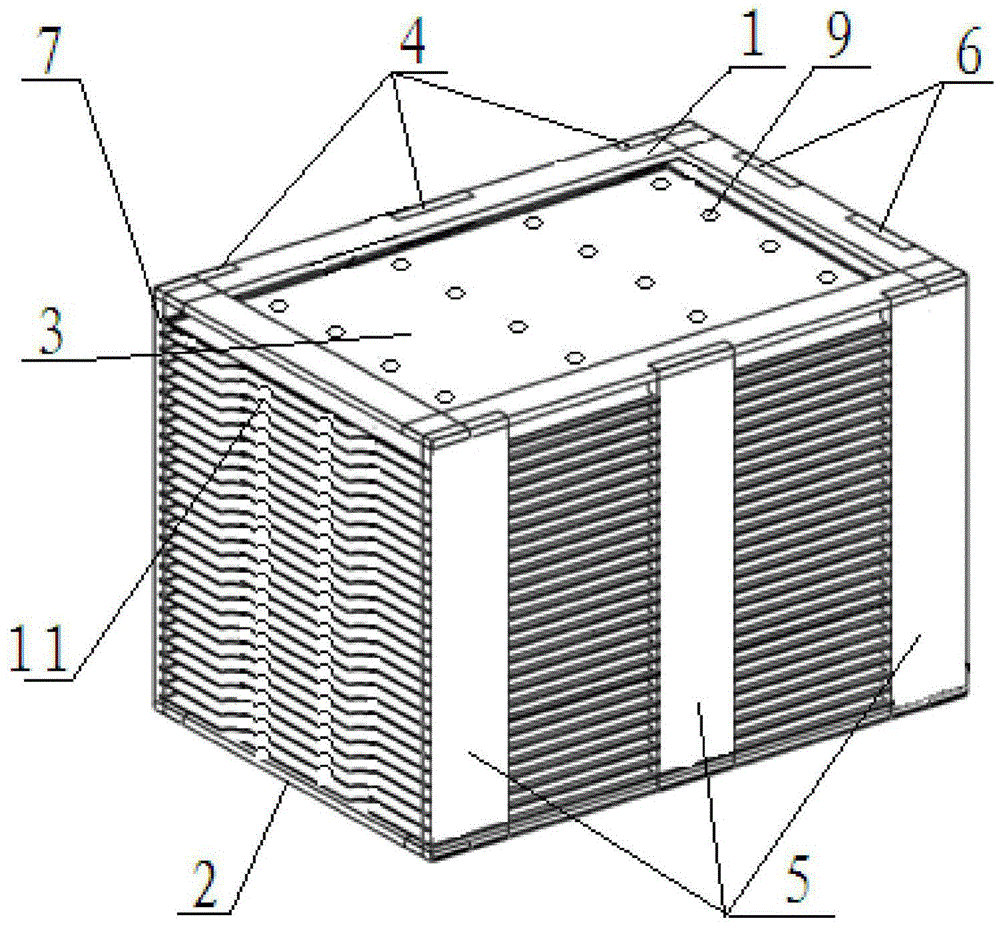

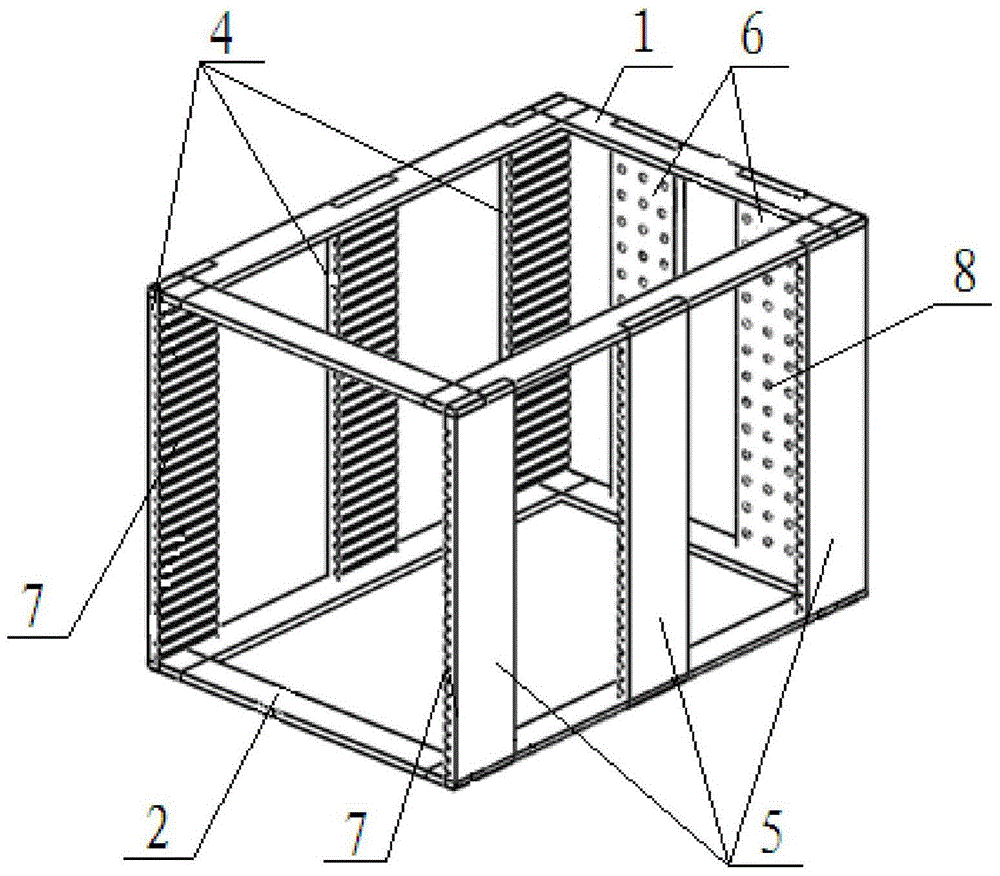

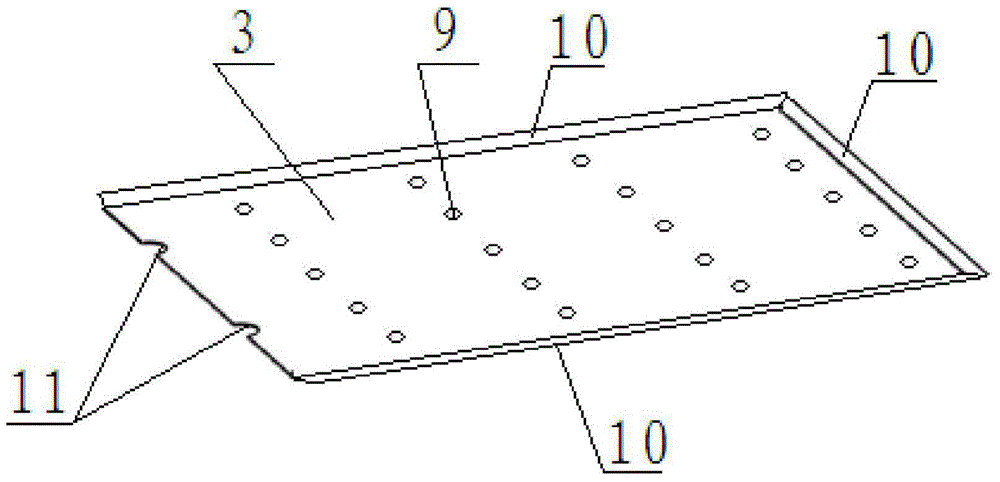

Clamp for preparing graphene and method for preparing graphene

The invention relates to a clamp for preparing graphene and a method for preparing graphene. The clamp comprises a horizontal top frame, a bottom frame and a loading tray, wherein the top frame and the bottom frame are fixedly connected through a first side plate, a second side plate and a baffle plate, which are vertically arranged; both the top frame and the bottom frame are of plane structures with openings in the middle parts; the top frame, the bottom frame, the first side plate, the second side plate and the baffle plate form a quad structure with an opening in one side surface; the first side plate and the second side plate are oppositely arranged in parallel; a plurality of tray grooves are uniformly formed in both the first side plate and the second side plate; two opposite side edges of the loading tray are respectively inserted in the tray grooves. The clamp reasonably utilizes the limited growth space in a process cavity, so that the quantity of the graphene thin films prepared in one batch is increased to the greatest extent to realize the minimization of the resource waste and the maximization of the cost while ensuring the quality of the prepared graphene thin films.

Owner:CHONGQING GRAPHENE TECH +1

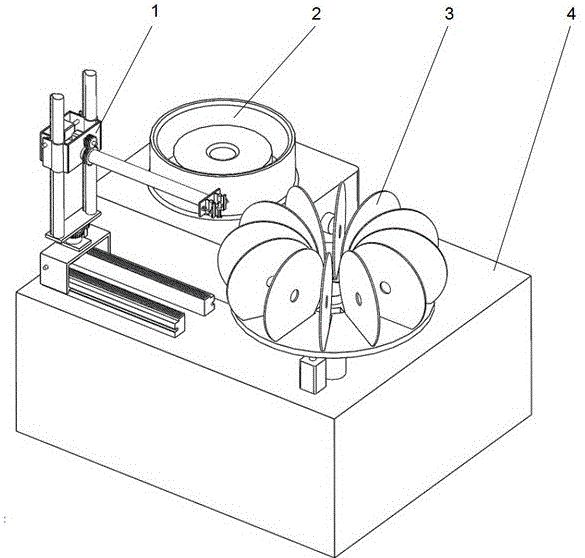

Automatic abrasive disc switch device of metallographic grinder

InactiveCN105751058ASimple structureEasy to operateGrinding wheel securing apparatusGrinding drivesEngineeringUltimate tensile strength

The invention discloses an automatic abrasive disc switch device of a metallographic grinder. The device comprises an automatic disc replacing system, a grinder main control table, a disc library mechanism and a rack, wherein the automatic disc replacing system, the grinder main control table and the disc library mechanism are fixed on the rack respectively; the grinder main control table controls automatic operation of the whole device; when an abrasive paper disc or a polishing disc of the grinder needs to be replaced, corresponding signals are transferred to step motors, and the step motors respond to corresponding signals to control the left-right movement and rotation of a control mechanism, control the up-down movement and rotation of a clamping mechanism and control the clamping and placing of a clamp holder so as to realize automatic replacement of the abrasive paper disc and the polishing disc of the grinder; and according to the automatic abrasive disc switch device, an idle center belt of disc abrasive paper of a disc grinder is fully used, the structure is simple and easy to operate, the abrasive disc can be accurately clamped, the working time of experimenters can be shortened, and the working strength of experimenters is alleviated, and the operation efficiency of the metallographic grinder is effectively improved.

Owner:JILIN UNIV

Plunger paste production line and production process

ActiveCN113955395AEasy to transportEasy to dipLiquid surface applicatorsConveyorsMaterial transferIndustrial engineering

The invention relates to the technical field of plunger paste production, and provides a plunger paste production line and a production process. The plunger paste production line comprises a rotary conveying device, the rotary conveying device is connected with a gum dipping and drying device, the gum dipping and drying device is connected with a material transferring device, and the material transferring device is connected with a plunger paste assembling device; the rotary conveying device comprises a rotary conveying frame, a rotary chain and a positioning jig; the gum dipping and drying device comprises a gum dipping mechanism, a gum homogenizing mechanism and a drying box body; the material transferring device comprises a material transfer table, a material transfer mechanism and a material taking and placing mechanism; and the plunger paste assembling device comprises an assembling frame, and an axial adjusting type material shaft, a slotting assembly, a satellite type rotating assembly, a finished product taking mechanism and a multi-action material moving mechanism are arranged on the assembling frame. The production process of automatic feeding of plunger paste semi-finished products, gum dipping, drying, transferring, plunger paste assembling and attaching, and automatic discharging and collection of finished plunger paste in the plunger paste production process is achieved, and the plunger paste production efficiency is greatly improved.

Owner:SHANDONG HOACO AUTOMATION TECH

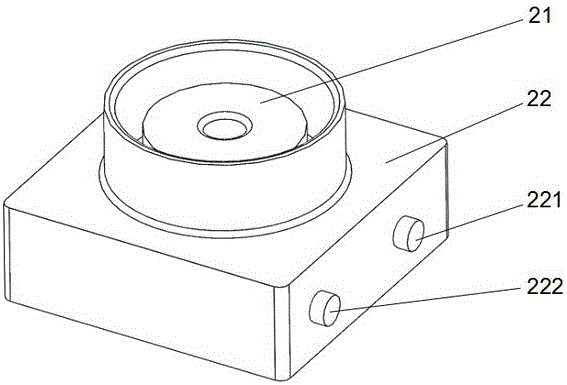

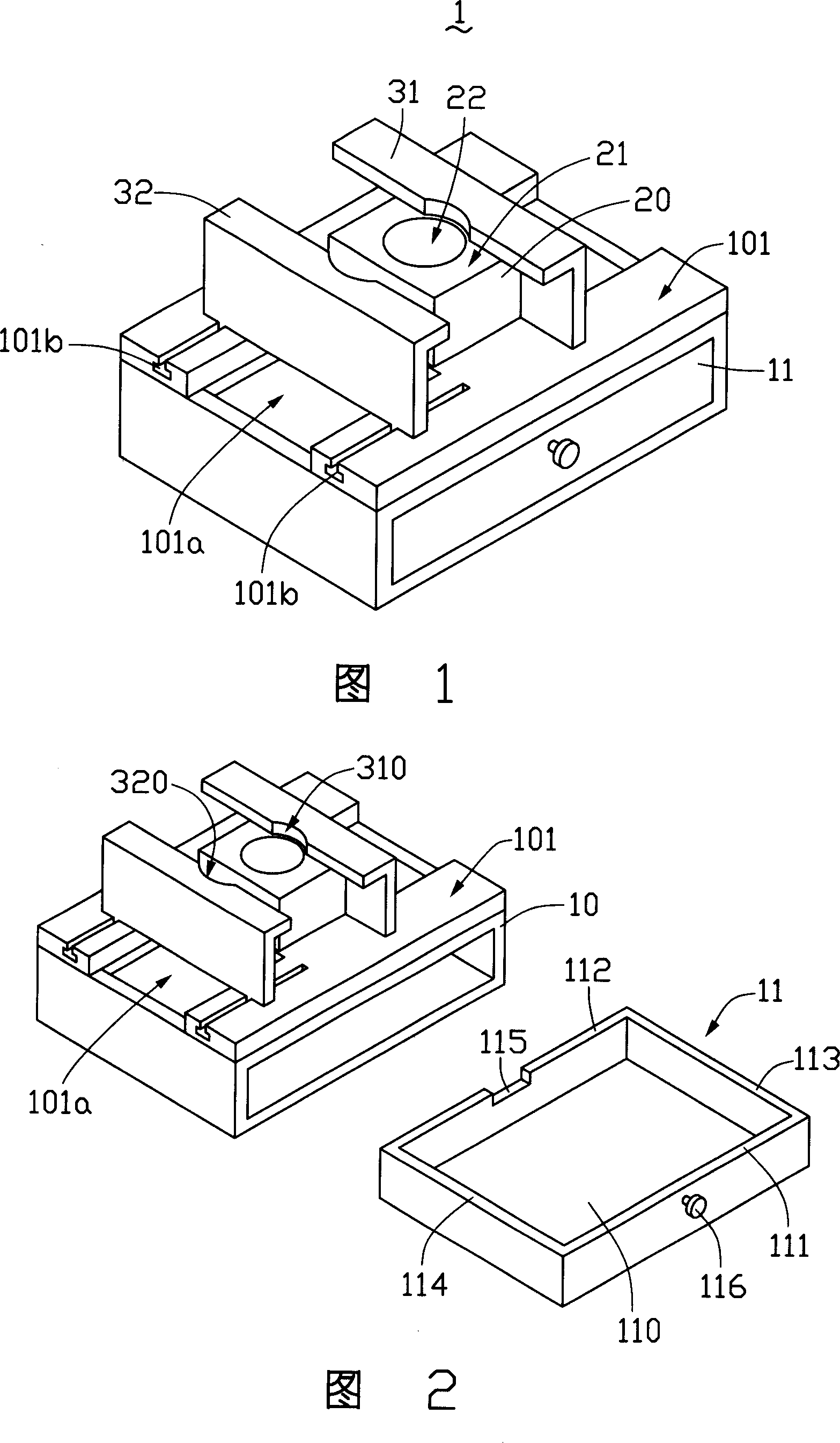

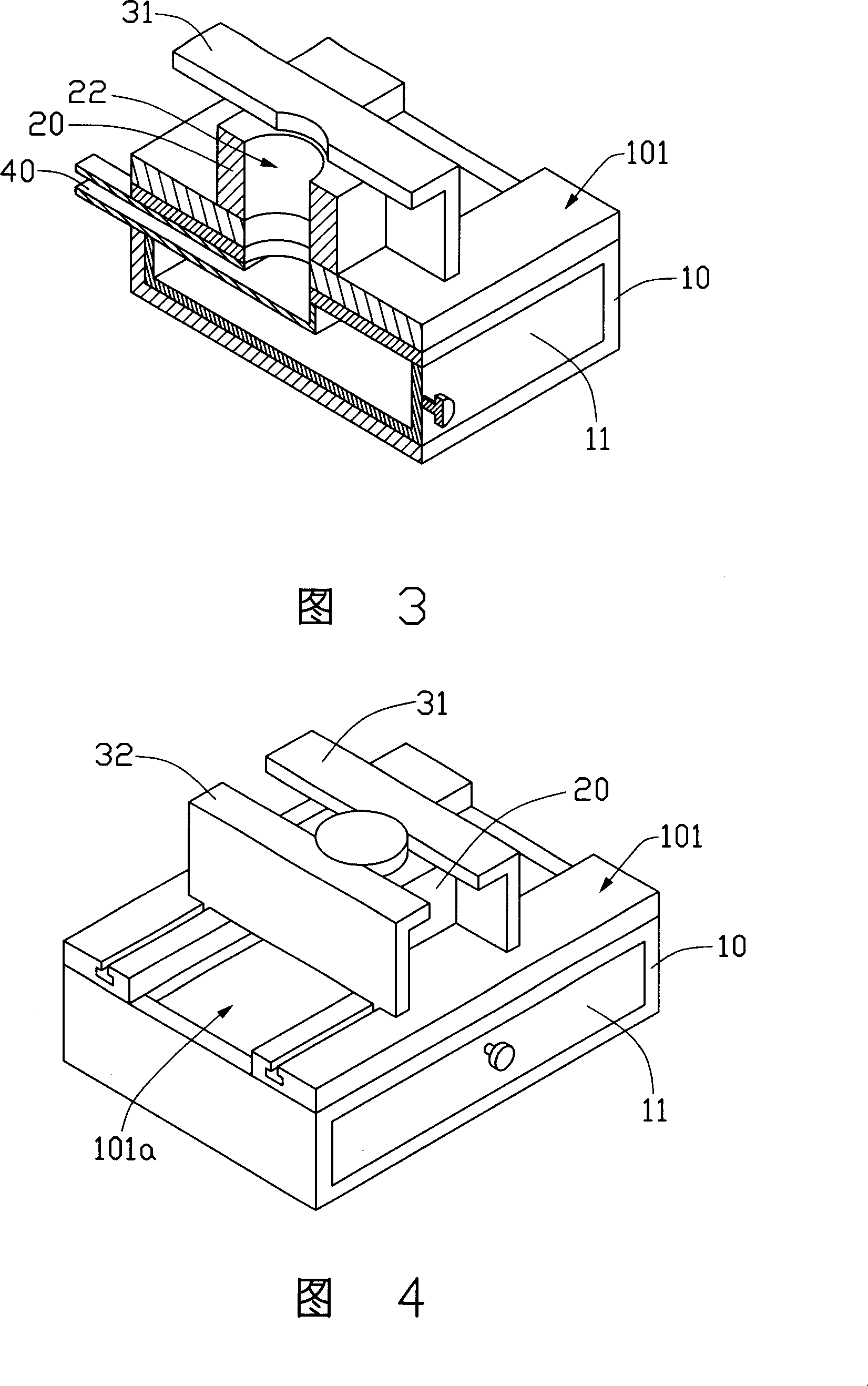

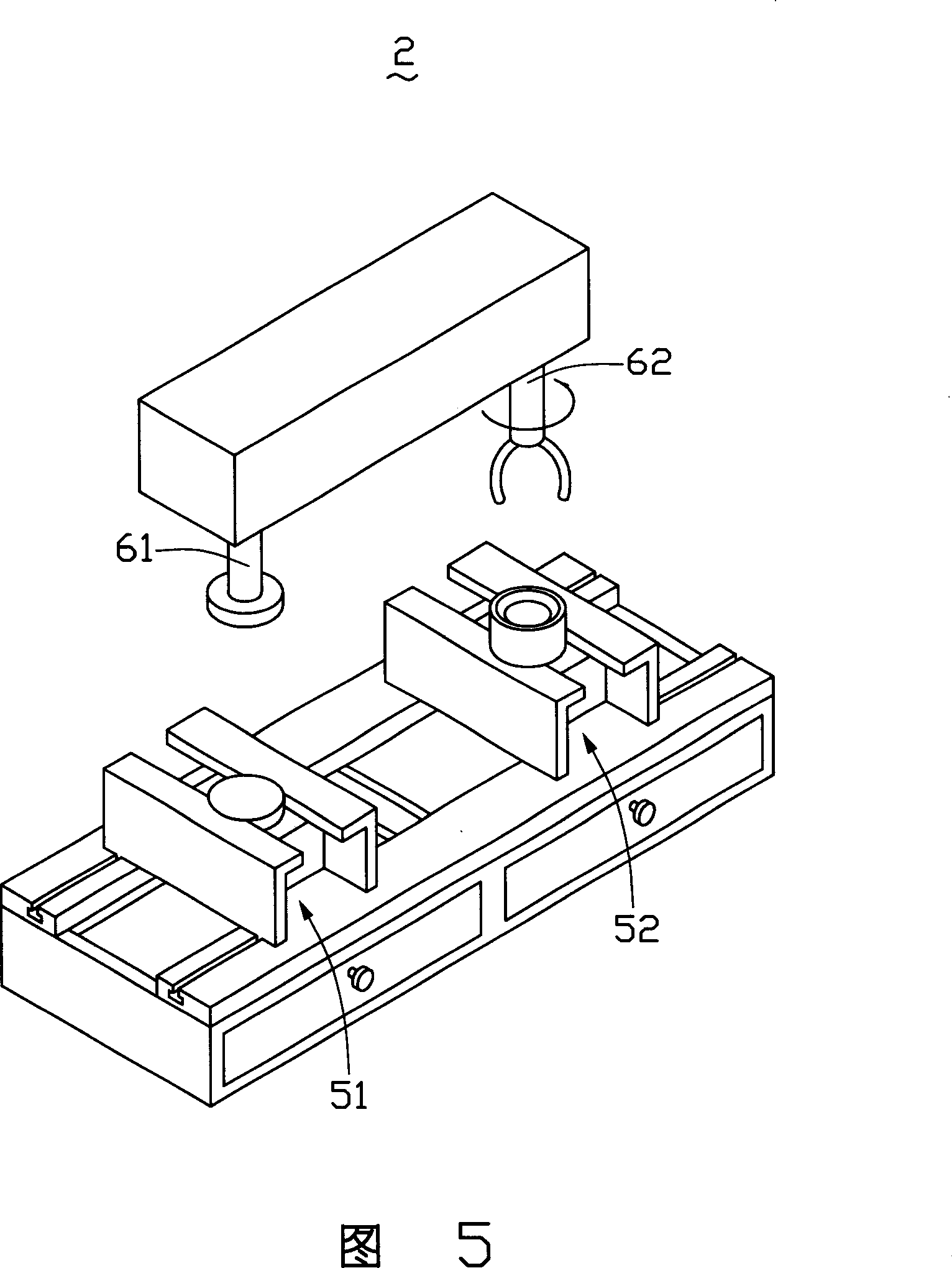

Positioning device and lens module assembling apparatus

A positioning device for lens module component and lens cone comprises a base, a bearing body on the surface of the base for the lens module component or lens cone, and the first and the second positioning block for the lens module or the lens cone, a storage drawer inside the base with its surface with notch connected to the storage drawer. It also provides a lens module assembly device for the said positioning device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

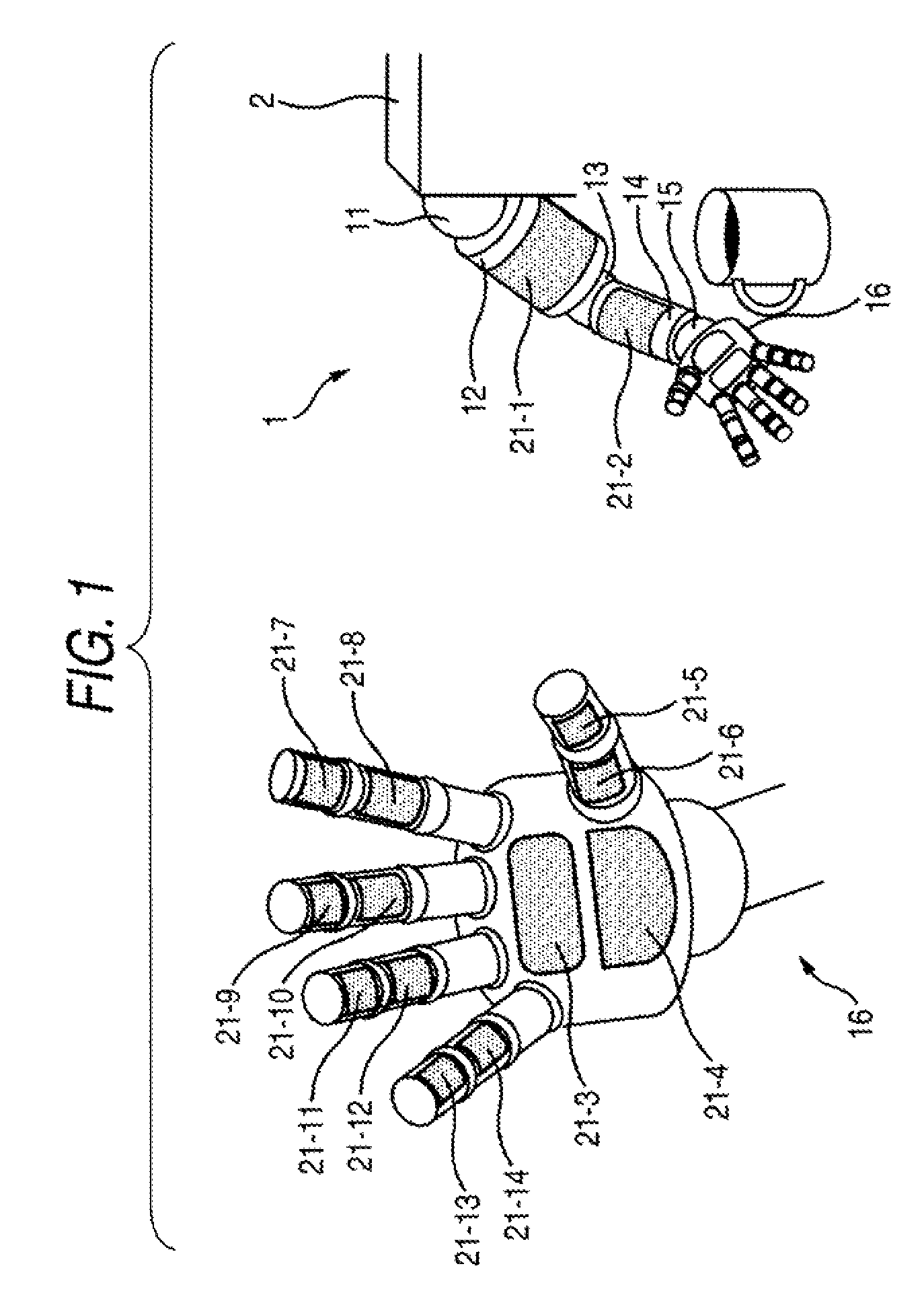

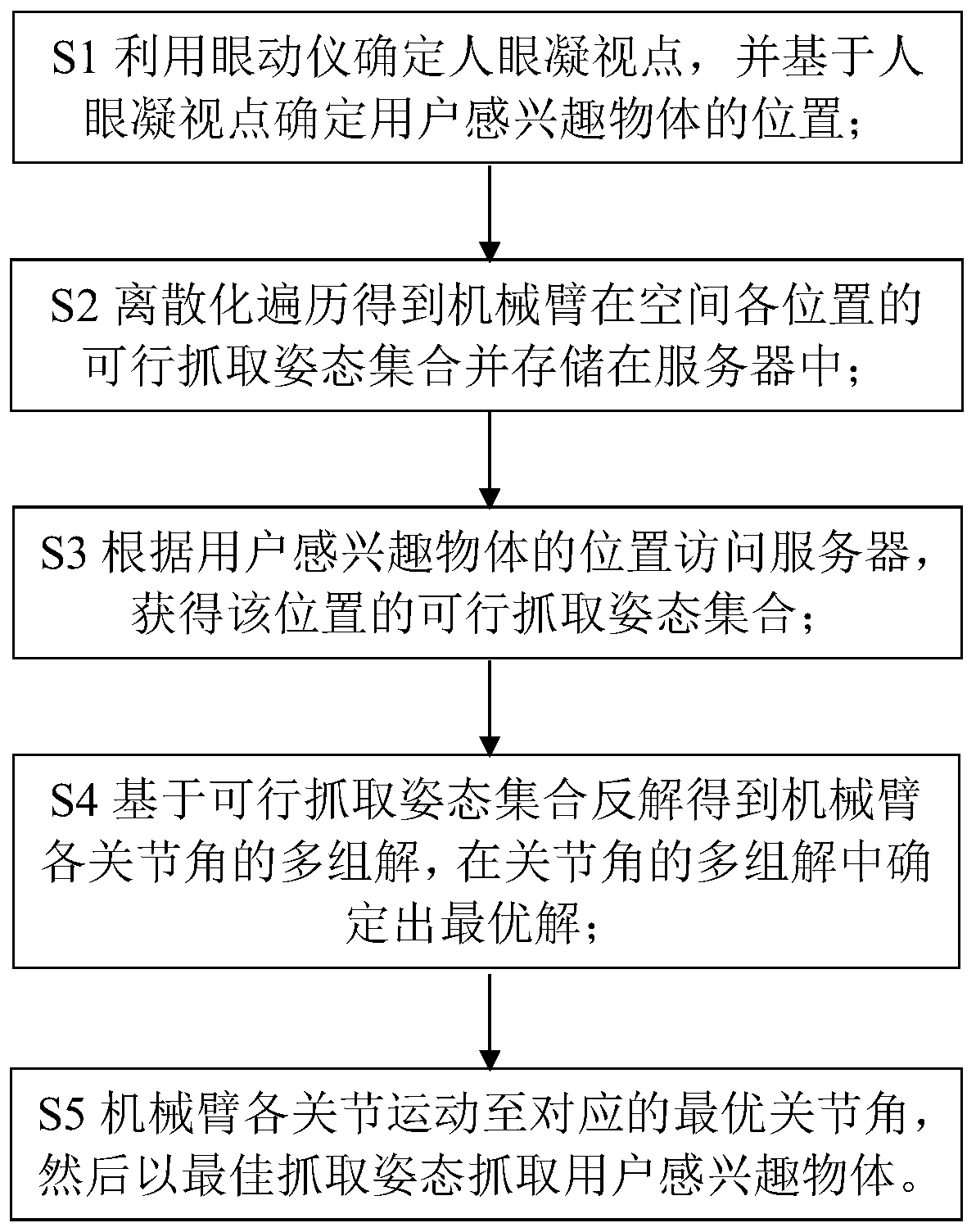

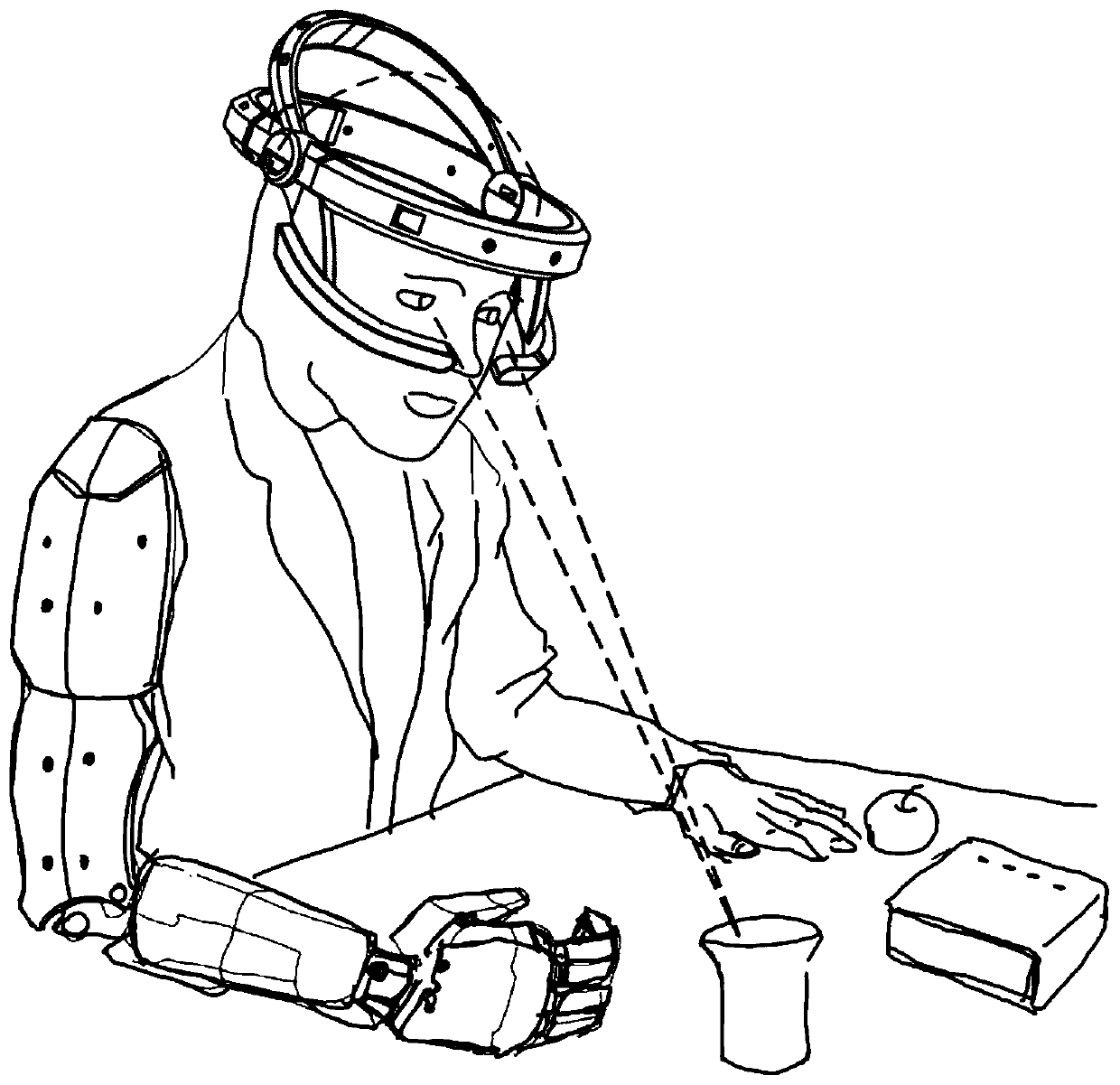

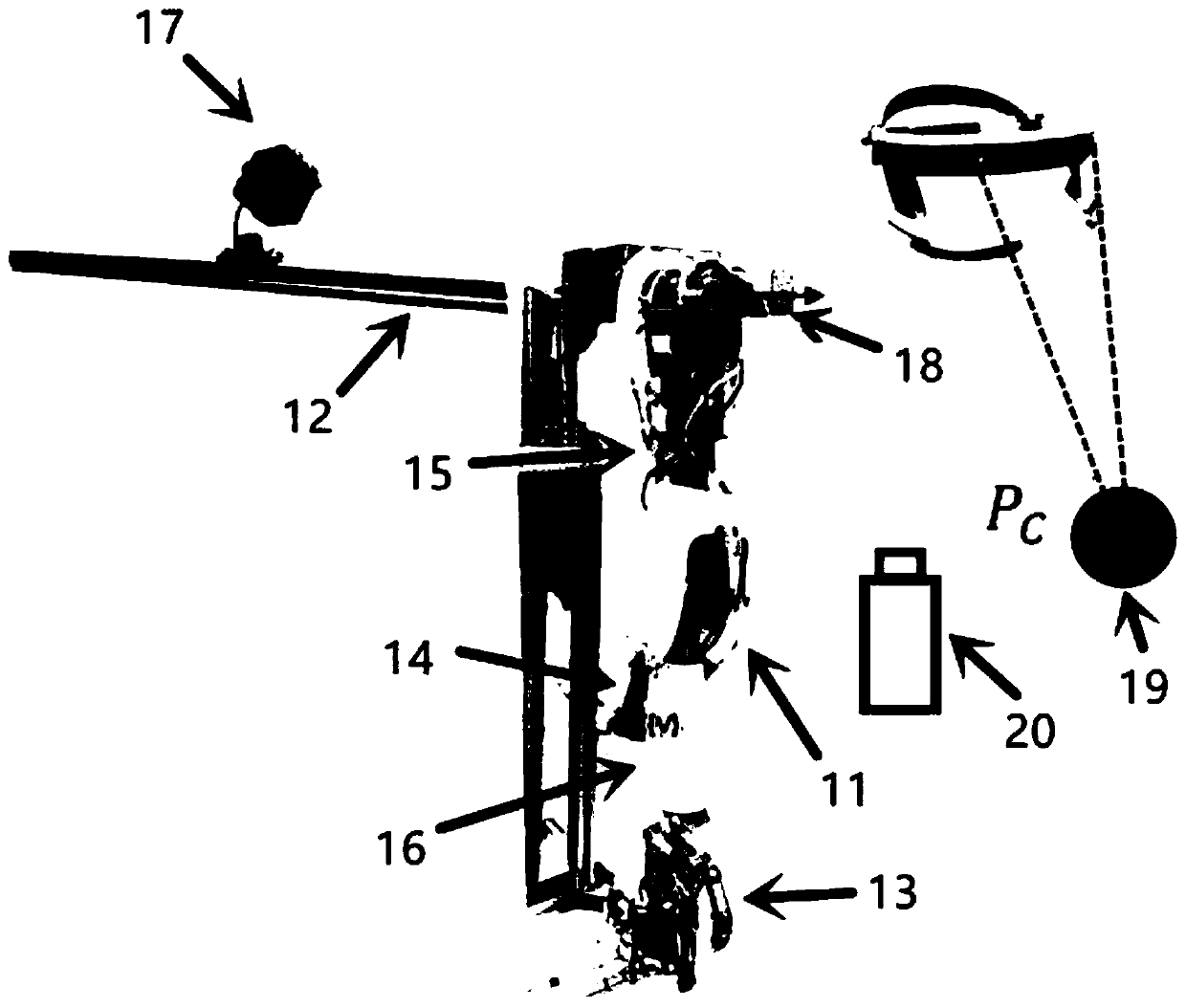

Hand-eye coordination grabbing method based on human eye gaze point

ActiveCN110605714AAccurate captureEasy to operateProgramme-controlled manipulatorArm movingDiscretization

The invention belongs to the technical field of hand-eye coordination, and particularly discloses a hand-eye coordination grabbing method based on a human eye gaze point. The method comprises the steps of S1, determining the human eye gaze point by using an eye movement instrument, and determining the position of an object of interest of a user based on the human eye gaze point; S2, performing discretization traversal to obtain a feasible grabbing gesture set of a mechanical arm at each position in space and storing the feasible grabbing gesture set in a server; S3, accessing a server according to the position of the object of interest of the user so as to query and obtain the feasible grabbing gesture set of the position; S4, obtaining multiple groups of solutions of each joint angle of the mechanical arm based on inverse solutions of each grabbing posture in the feasible grabbing posture set, and determining an optimal solution from the multiple groups of solutions of the joint angles, namely obtaining the optimal joint angle corresponding to each joint of the mechanical arm; and S5, making each joint of the mechanical arm move to the corresponding optimal joint angle, and grabbing the object of interest of the user in the optimal grabbing posture. The method has the advantages of accurate grabbing and convenient operation.

Owner:HUAZHONG UNIV OF SCI & TECH

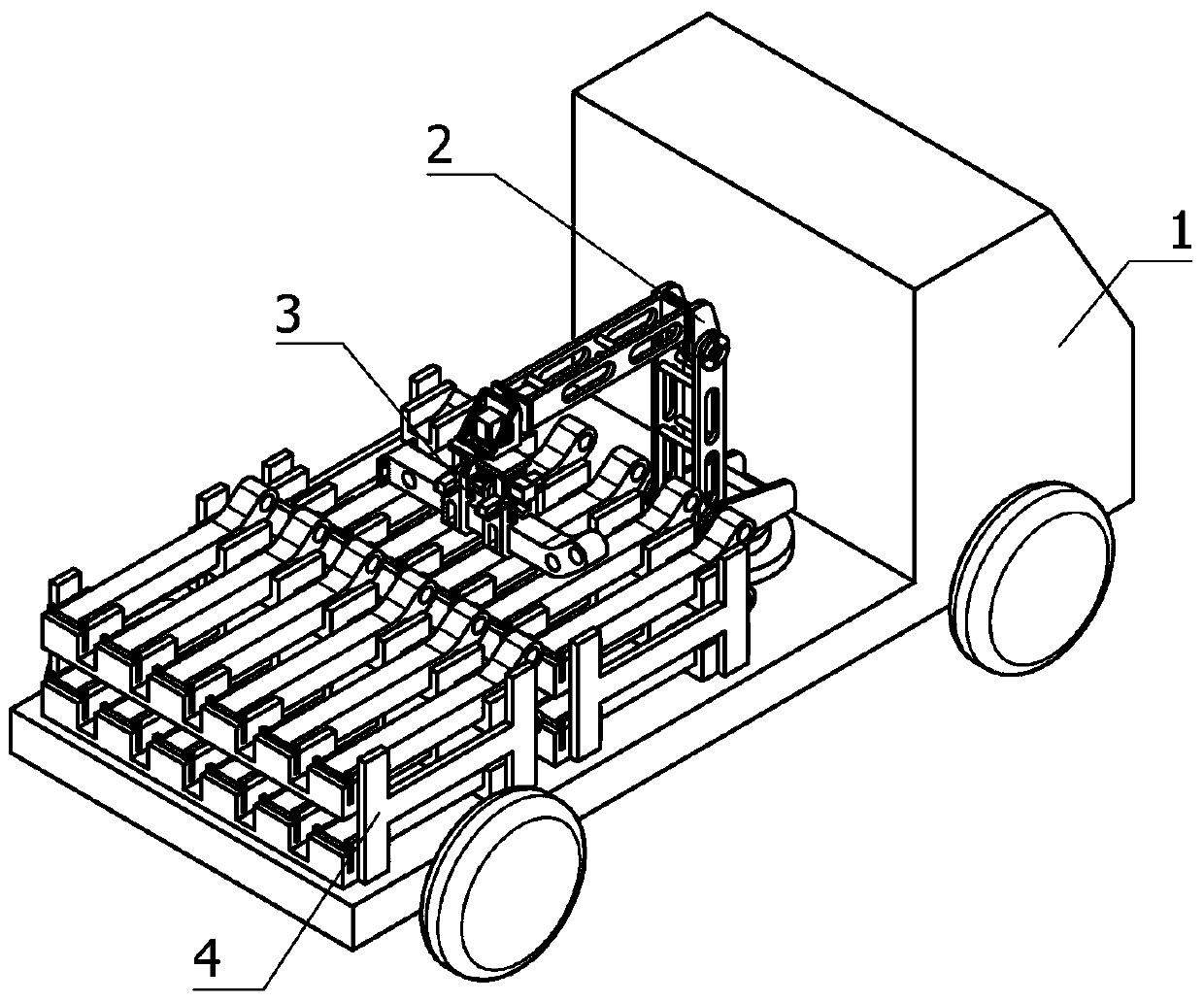

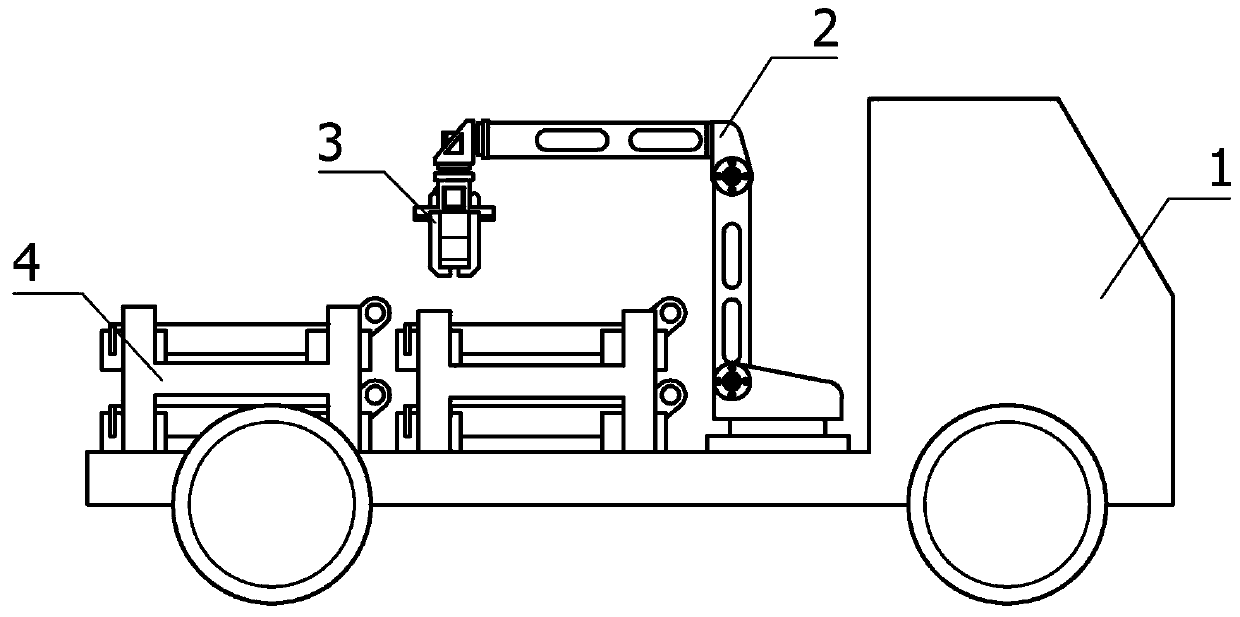

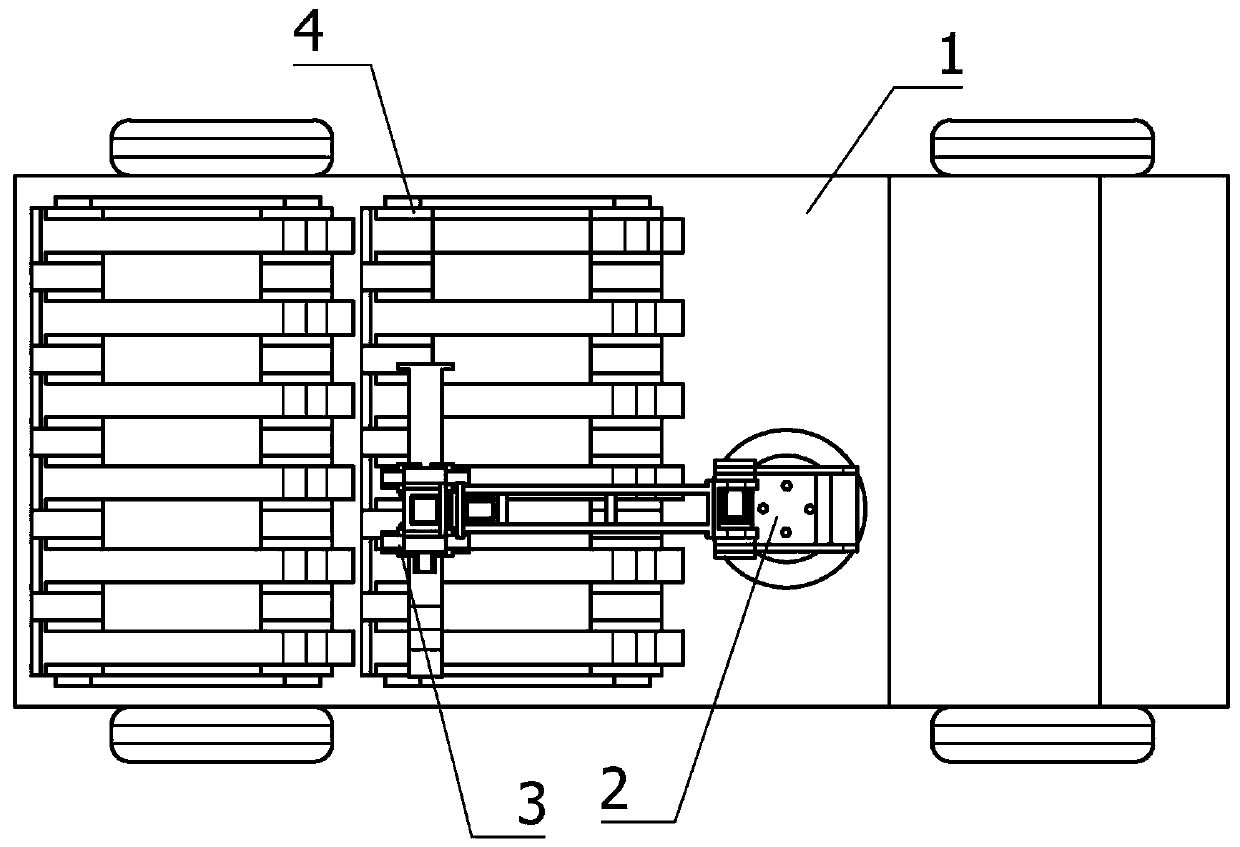

Intelligent auxiliary robot for mounting bridge guardrail

ActiveCN110952455APlace stableRealize auxiliary installation workBridge structural detailsBridge erection/assemblyRobot handControl engineering

The invention relates to the field of bridge construction, in particular to an intelligent auxiliary robot for bridge guardrail installation. The intelligent auxiliary robot comprises a vehicle body,a five-axis manipulator capable of being flexibly adjusted at multiple angles is mounted above the vehicle body; a guardrail clamping jaw capable of clamping a bridge guardrail is arranged at the output end of the manipulator; a guardrail placing frame is arranged under the guardrail clamping jaw; the guardrail placing frame is horizontally and fixedly mounted at the top of the vehicle body. According to the intelligent auxiliary robot for bridge guardrail installation, the problems that during bridge installation, the manual work intensity is too high, and installation is inaccurate are solved; the guardrail placing frame can carry more bridge guardrails; the placement and the taking are convenient; the working efficiency of bridge guardrail installation is improved, more loads are achieved, the time consumed by back-and-forth material taking is shortened, the five-axis mechanical arm can flexibly carry and rotate the bridge guardrails, subsequent manual installation work of the bridge guardrail is facilitated, a stable and accurate rotating effect can be provided, and the installation precision is improved.

Owner:HENAN UNIVERSITY

Magnetic suction type workpiece grasping precise positioning device

PendingCN111747112AAccurate grippingEasy to operateConveyorsControl devices for conveyorsCircular discEngineering

The invention relates to a magnetic suction type workpiece grasping precise positioning device. The magnetic suction type workpiece grasping precise positioning device includes a feeding mechanism, apiece-movement mechanism, a correction mechanism and a fine positioning mechanism; the feeding mechanism includes a feeding frame for stacking workpieces; and the piece-movement mechanism includes anelectromagnetic suction assembly and a transfer assembly for driving the electromagnetic suction assembly to move back and forth between the feeding frame and the correction mechanism. The purpose ofthe invention is to provide a magnetic suction type workpiece grasping precise positioning device applied to the automatic feeding of disc-shaped workpieces, which can transfer arbitrary stacked workpieces and realize accurate positioning. The advantages of the magnetic suction type workpiece grasping precise positioning device are as follows: the magnetic suction type workpiece grasping precise positioning device includes the feeding mechanism, the piece-movement mechanism, the correction mechanism and the fine positioning mechanism, the piece-movement mechanism can absorb the workpieces arbitrary stacked on the feeding mechanism and correct the front and back directions through the correction mechanism, and finally, precise positioning is performed by the fine positioning mechanism, which facilitates the subsequent processing operations or precise grasping by mechanical arms, so that automatic feeding is realized.

Owner:福州鸿基自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com