Aging device and aging method for laser device chip

An aging device and laser technology, applied in the direction of measuring devices, measuring device shells, electrical measuring instrument components, etc., can solve problems such as difficult direct clamping, time-consuming reliability, easy damage and dirt, and reduce damage to chips Possibility, convenient and fast power supply, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

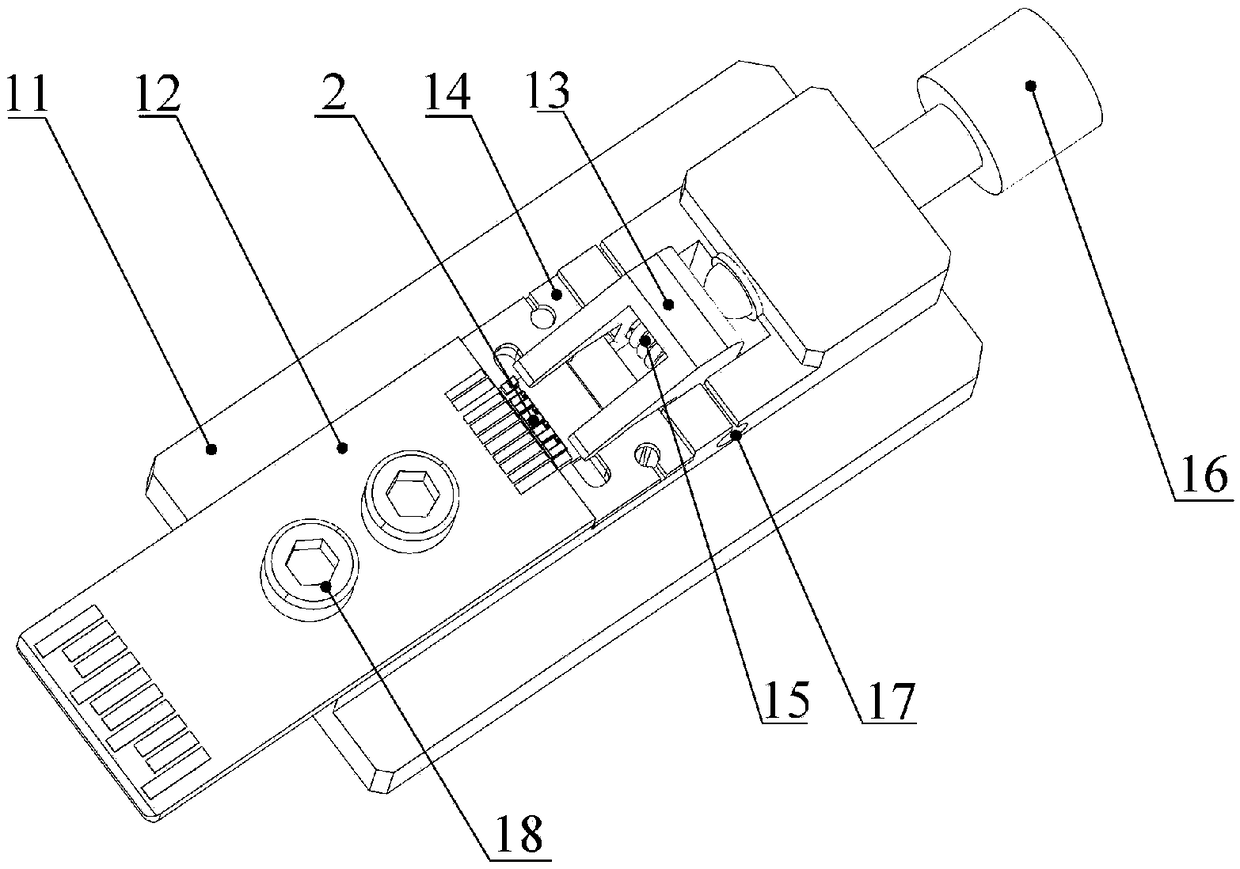

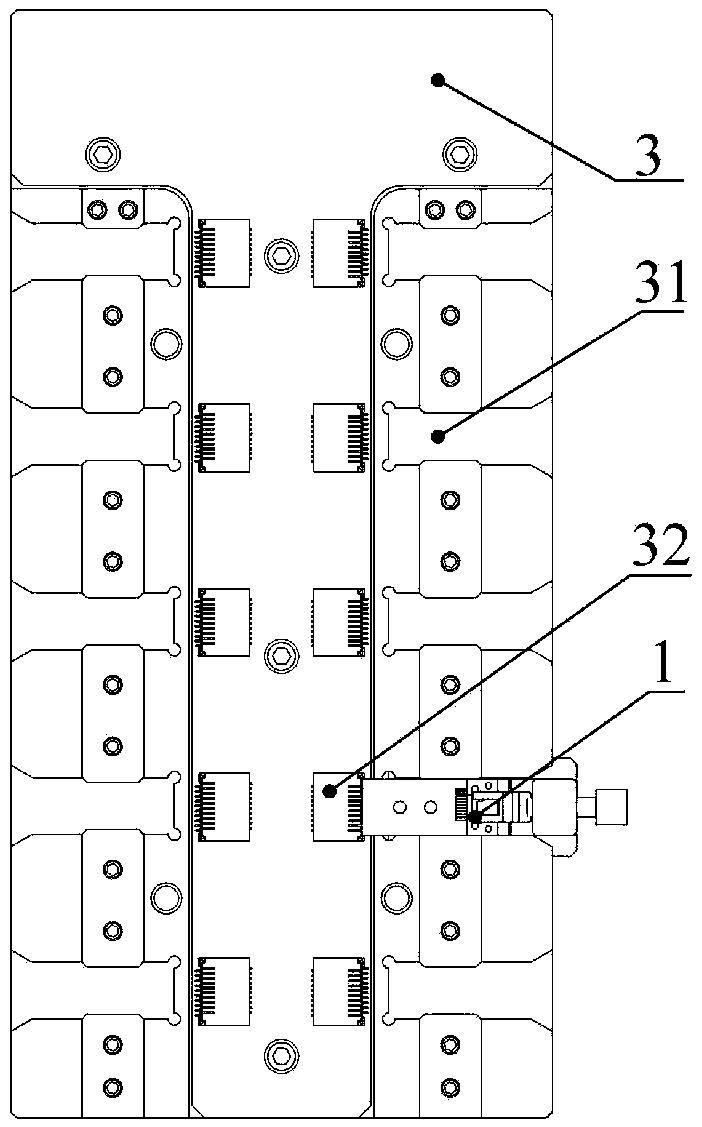

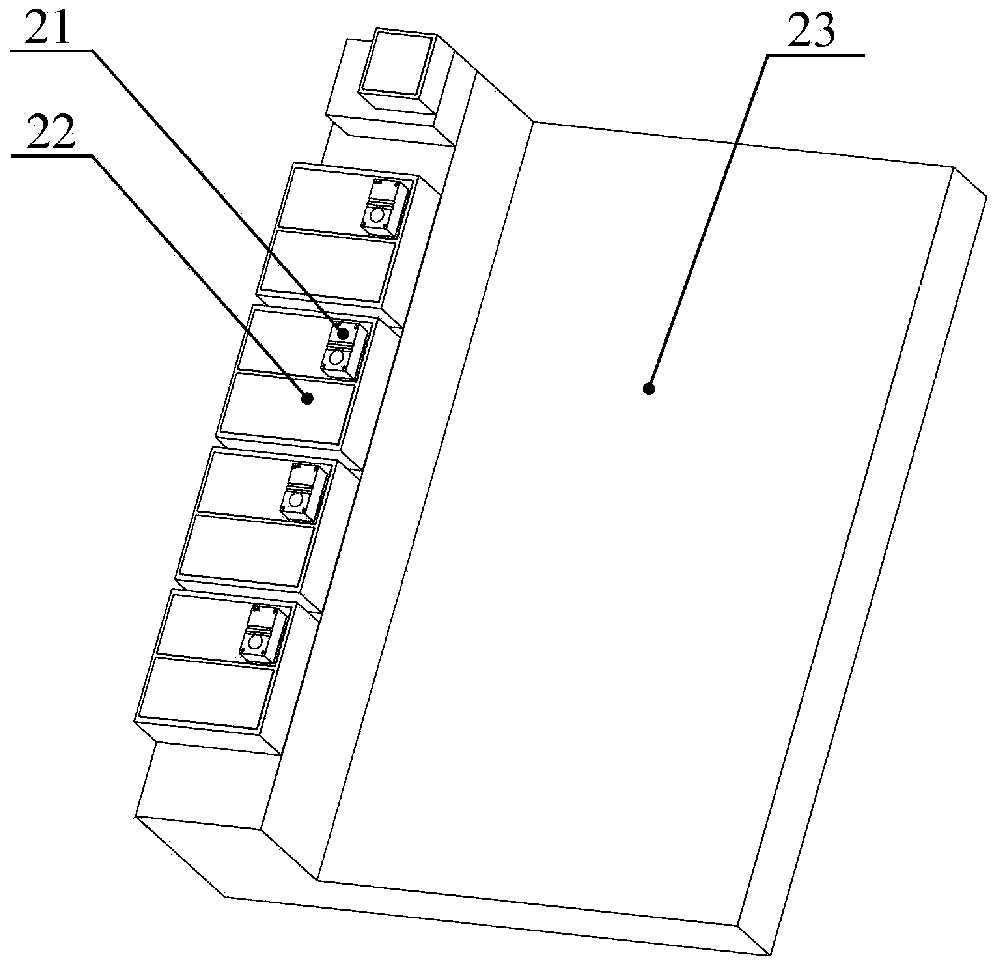

[0040] An embodiment of the present invention provides an aging device for a laser chip, such as Figure 1-Figure 3 As shown, it includes a clamp 1 and a chip component 2 , and the clamp 1 is used to clamp the chip component 2 . Wherein, considering that the size of the laser chip is very small, it is not easy to clamp, and direct clamping is easy to cause damage, the method of clamping the chip assembly is adopted in the present invention, and the chip assembly 2 includes a laser chip 21 and a chip carrier, and the laser chip 21 fixed on the surface of the chip carrier, the chip carrier is used to be clamped, since the size of the chip carrier is much larger than the laser chip, it is easier to clamp and will not cause damage to the laser chip;

[0041]The clamp 1 includes a base 11, a PCB connecting plate 12 and a pressing block 13, the PCB connecting plate 12 is fixedly installed on the surface of the base 1, and the pressing block 13 is movably installed on the surface of ...

Embodiment 2

[0054]On the basis of the above-mentioned embodiment 1, the embodiment of the present invention also provides a laser chip aging method, which is completed by using the aging device in embodiment 1. Refer to Figure 10 , the aging method specifically includes the following steps:

[0055] Step 201, assemble the clamp 1, adjust the screw push rod 16, so that the first end of the pressing block 13 is in a tilted state.

[0056] according to figure 1 As shown, with reference to the structure introduction in Embodiment 1, the PCB connection plate 12, the positioning plate 14, the pressure block 13, the torsion spring 15 and the screw push rod 16 are respectively installed on the base Seat 11 surface, and by rotating the screw push rod 16, the pressure block 13 is as follows Figure 6 In the state shown, the left end of the pressure block 13 is in a tilted state under the tension of the torsion spring 15, so as to facilitate the placement of the chip assembly 2.

[0057] Step 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com