Patents

Literature

417 results about "Age method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

#AGE METHOD. The 1st universal youth-enhancing treatment by DIBI MILANO inspired by epigenetics, the science of genes. An innovative formula that works at the heart of the cell, restructuring the damage caused by hormonal and skin aging, by smoothing lines, minimizing expression lines and deep wrinkles, and strengthening the structure of the skin.

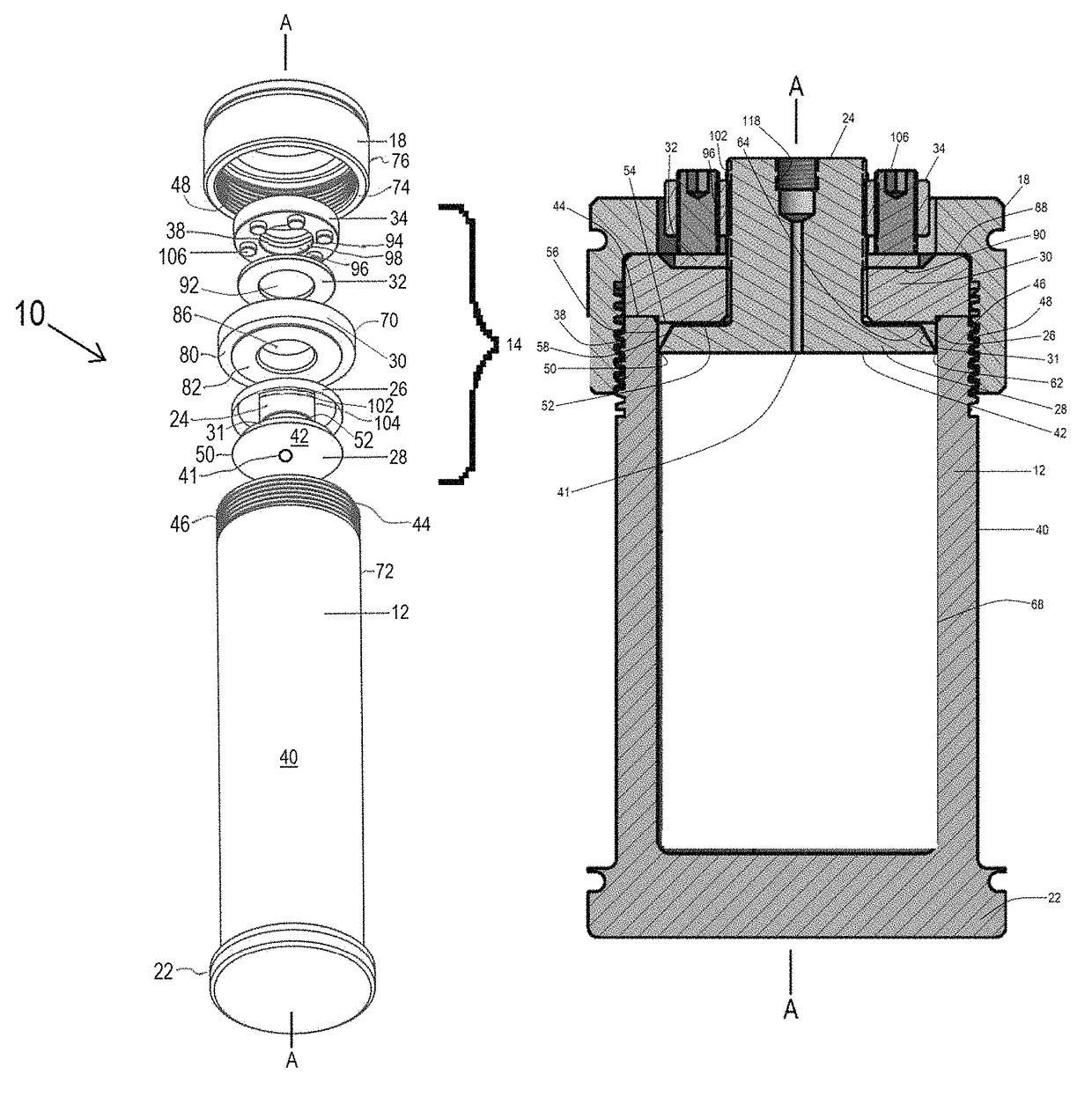

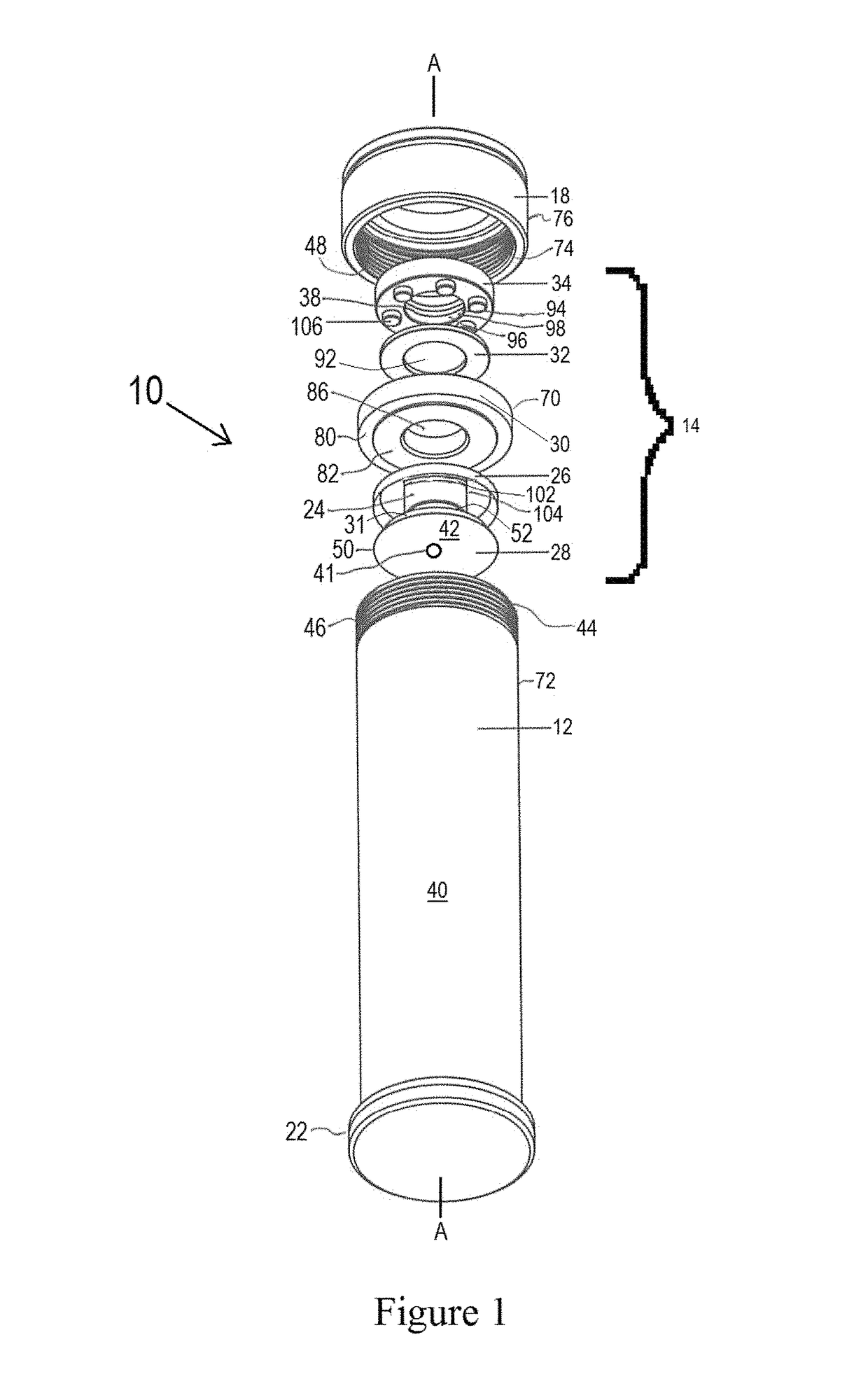

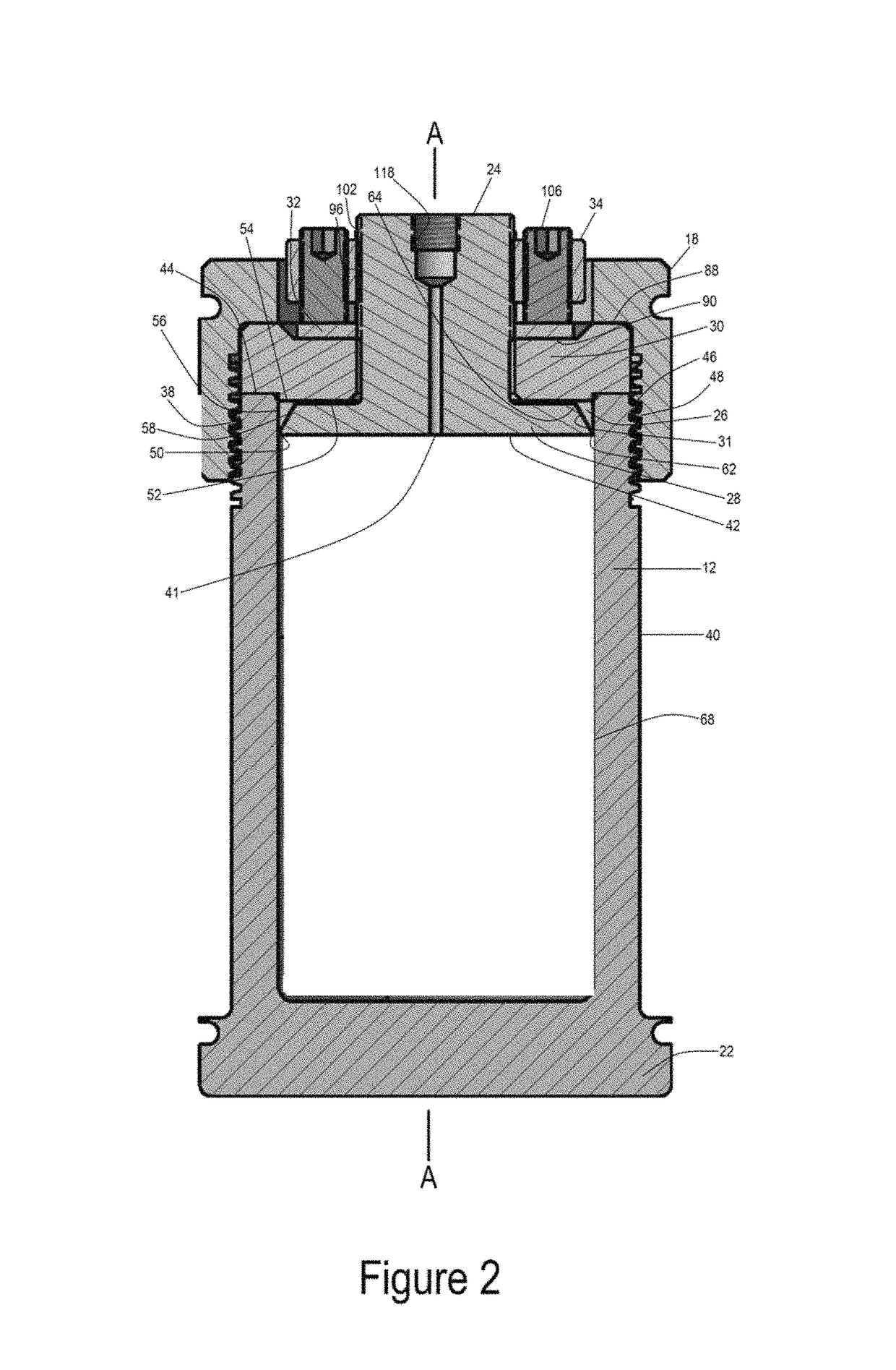

High temperature fluid sample aging cell

ActiveUS9784667B2Engine sealsWeather/light/corrosion resistanceAge methodPressure controlled ventilation

Owner:OFI TESTING EQUIP

Magnesium alloy and preparation method thereof

The invention discloses a magnesium alloy and a method for preparing the same. The weight percentage compositions of the magnesium alloy as follows: 7 to11 percent by weight of Gd, 2 to 5 percent by weight of Y, 0.3 to 0.6 percent by weight of Zr, 0 to 1.0 percent by weight of Zn, the balance Mg and incidental impurity elements. The method for preparing the alloy comprises alloy melting, refining, casting, solid solution, extrusion deformation and two artificial aging methods, to produce heat resistant magnesium alloy extruded bar with high strength and high toughness. The tensile properties of the magnesium alloy at room temperature manufactured by adopting direct artificial aging is: tensile strength sigma b is between 450 and 480 MPa, sigma 0.2 is between 390 and 425 MPa, delta 5 is between 3 and 5 percent; when test specimen is heated to 250 DEG C for 10 min, the tensile strength sigma b is more than or equal to 300 MPa. The tensile properties of the magnesium alloy at room temperature manufactured by adopting dual artificial aging is: tensile strength sigma b is between 380 and 395 MPa, sigma 0.2 is between 280 and 290 MPa, delta 5 is between 15 and 21 percent; when test specimen is heated to 250 DEG C for 10 min, the tensile strength sigma b is more than or equal to 260 MPa. The invention produces the heat resistant magnesium alloy of high strength and high toughness with the density of no more than 1.93g / cm3, which can satisfy the demands of density, strength and toughness, and heat resistance of metal materials in specific fields.

Owner:GRIMAT ENG INST CO LTD

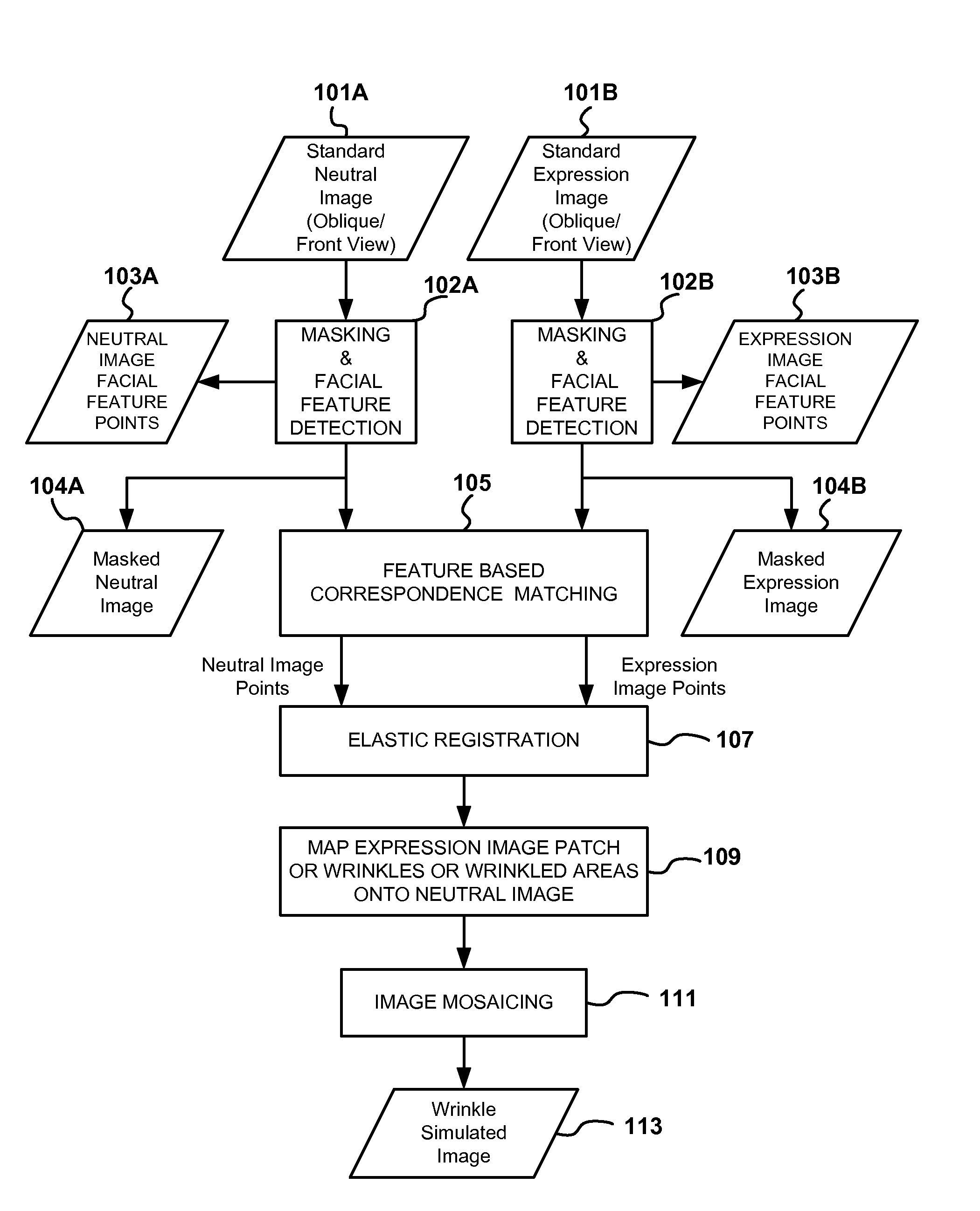

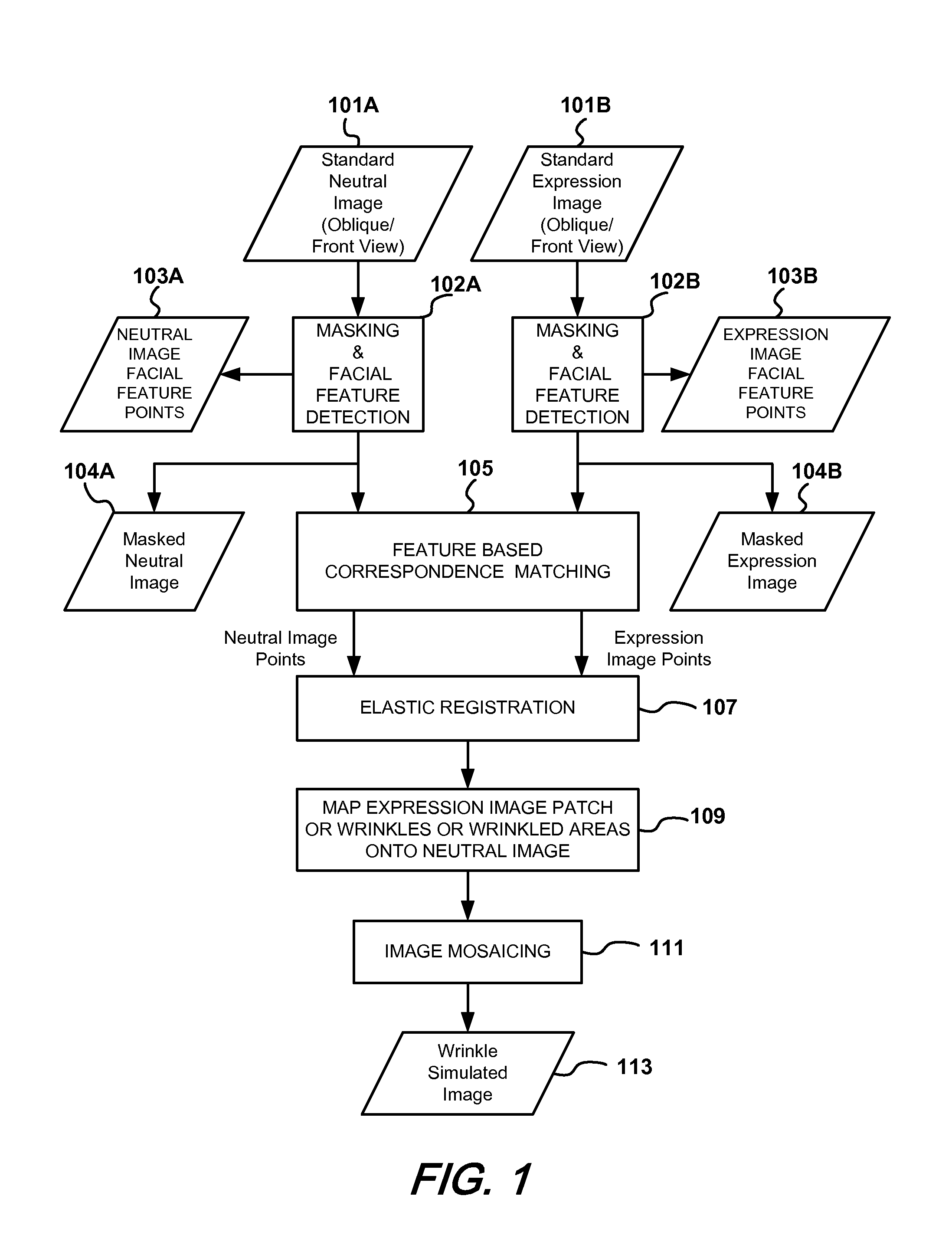

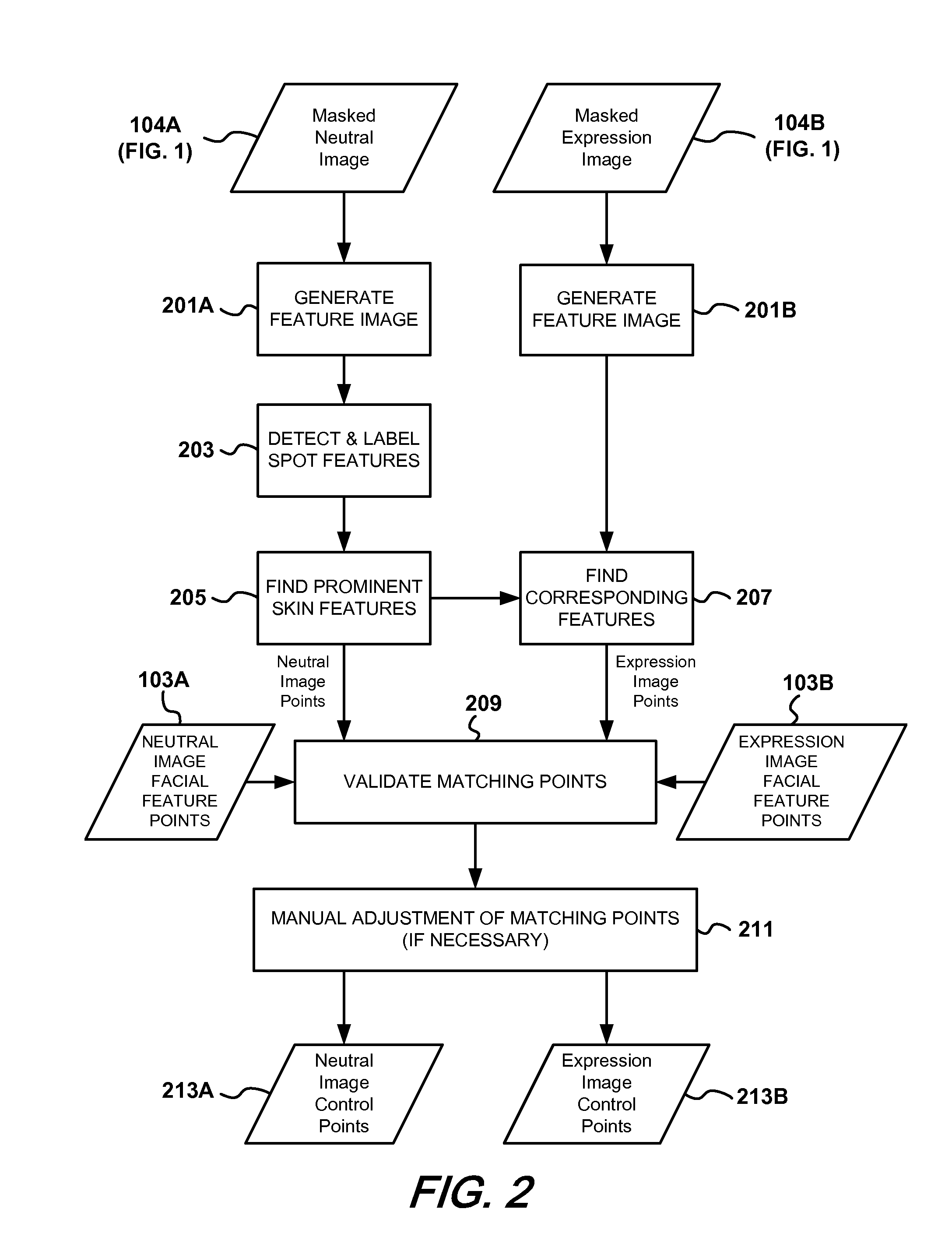

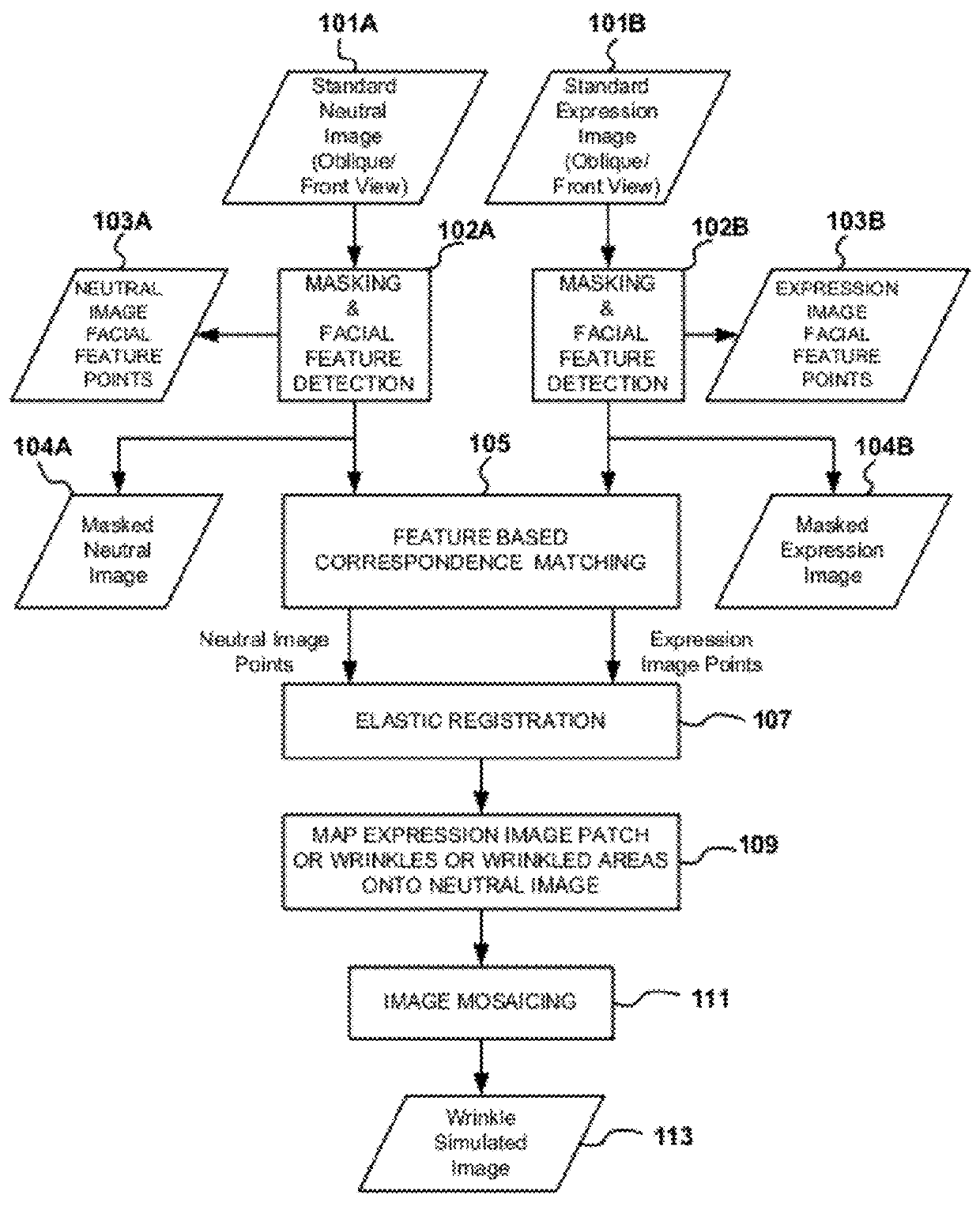

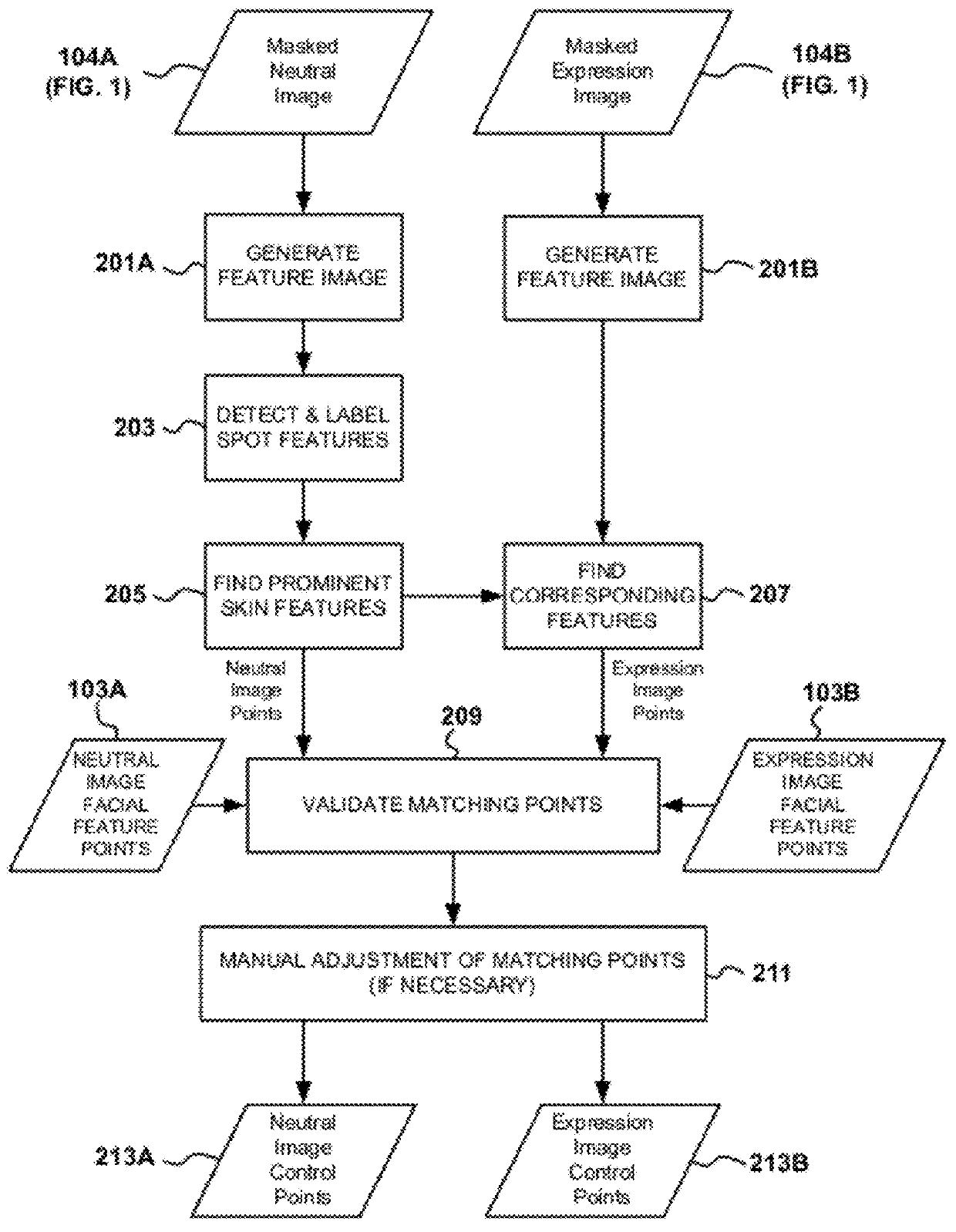

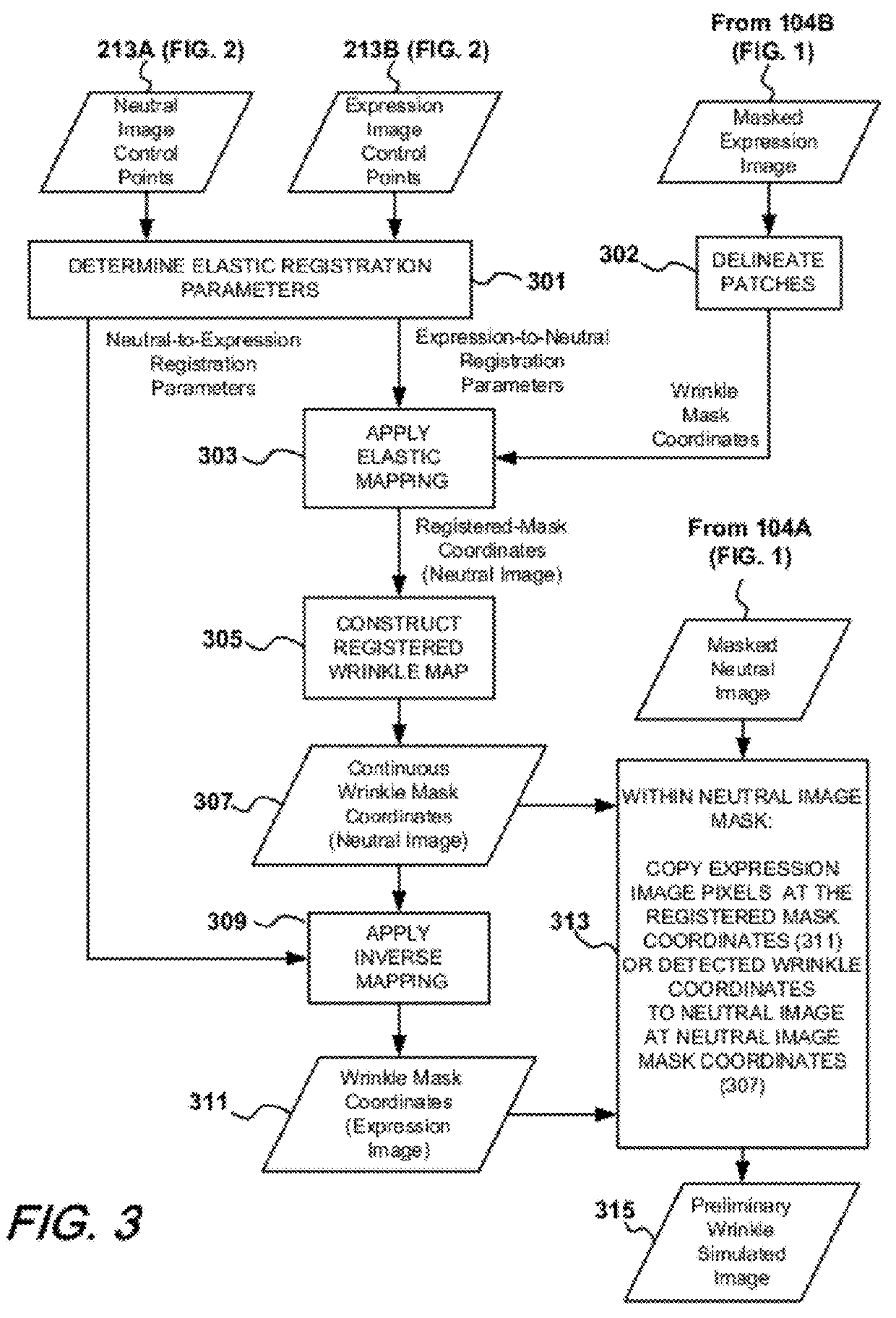

Method and apparatus for realistic simulation of wrinkle aging and de-aging

ActiveUS20090028380A1Accurate and realistic simulationRealistic predictionImage enhancementImage analysisComputer animationWrinkle skin

Methods and systems are disclosed to realistically simulate facial wrinkle aging of a person using a neutral state (natural look) image and one or more expression images (e.g., smile, frown, pout, wink) that induce wrinkles. The neutral and expression images are processed to simulate wrinkle aging by registering the wrinkles that are visible in the expression image onto the neutral image, thereby generating a wrinkle-aged simulated image. Advantageously, a person's own wrinkle histological data is utilized, hence providing an accurate and realistic wrinkle aging simulation. Similarly, the neutral image is processed to eliminate all visible wrinkles thereby generating a wrinkle de-aged simulation image. Additionally, blending of a neutral image with an aged or de-aged simulation image is disclosed, where the degree of blending is based on statistical modeling of skin condition with age and / or expected outcome of a particular type of treatment. The methods and systems disclosed have wide applicability, including, for example, areas such as dermatology, cosmetics and computer animation, among others.

Owner:THE PROCTER & GAMBLE COMPANY

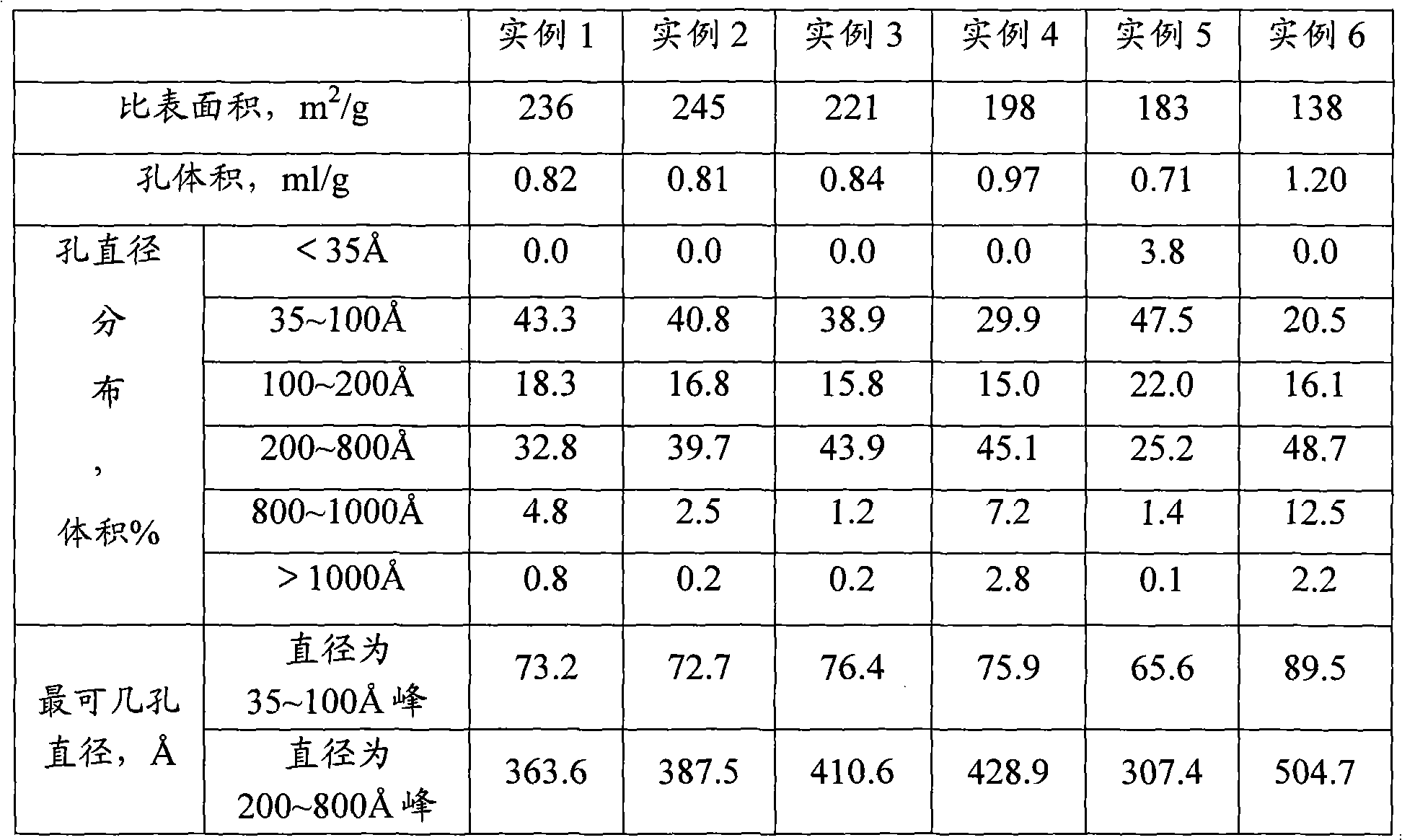

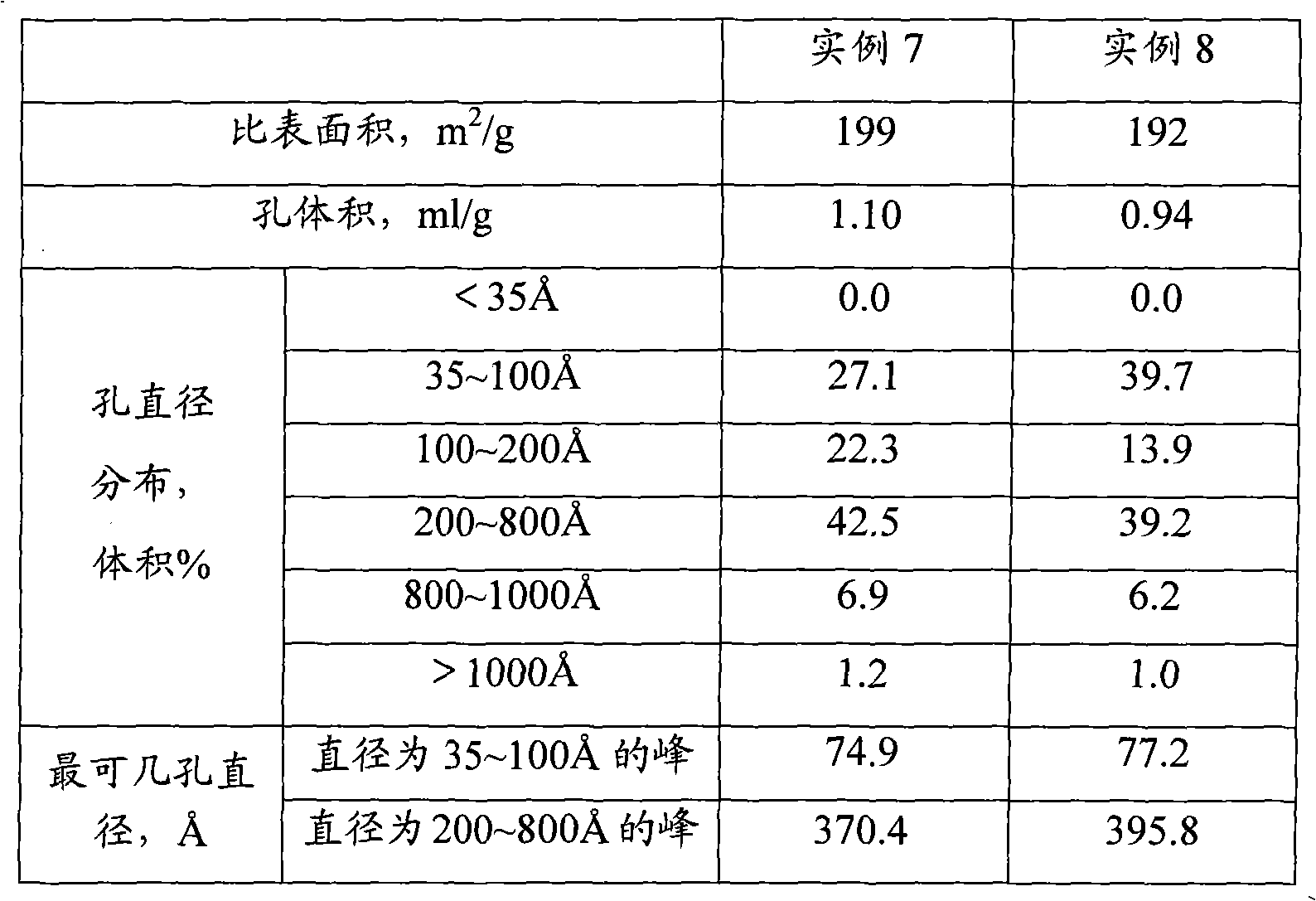

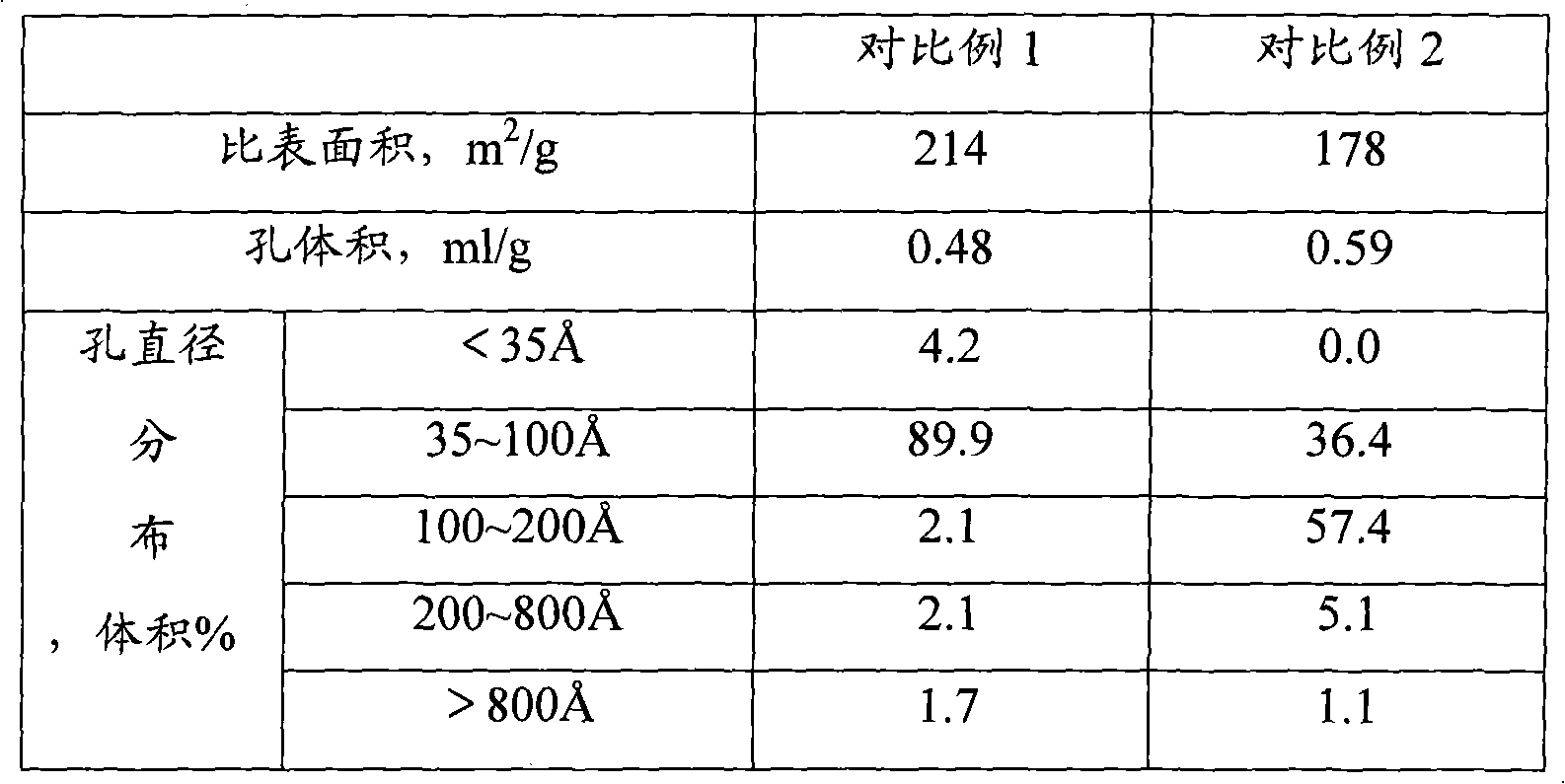

Macroporous aluminum oxide with bimodal pore distribution and preparation method thereof

ActiveCN102030351AAvoid flying temperatureReduce manufacturing costAluminium oxides/hydroxidesPore distributionOrganic solvent

The invention discloses macroporous aluminum oxide with bimodal pore distribution. The pore volume of the macroporous aluminum oxide is 0.6 to 3.0ml / g, the specific surface area is 90 to 300sq.m / g, wherein the pores with aperture of between 35 and 100 angstroms account for 20 to 55 percent of the total pore volume, and the most probable aperture is between 50 and 90; and the pores with aperture of between 200 and 800 angstroms account for 20 to 55 percent of the total pore volume, and the most probable aperture is between 300 and 600. The aluminum oxide is prepared by a two-section aging method without a hole expansion agent or an organic solvent, so the raw materials are saved, the flow is simplified, and the production cost is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for promoting white spirit aging

ActiveCN102703297AAccelerated agingLow costAlcoholic beverage preparationAge methodHazardous substance

The invention discloses a method for promoting white spirit aging. The method promotes the association of molecules in the wine as well as the collision of molecular energy through the heating temperature control and ventilation treatment, and can quickly promote the white spirit aging. Through the aging method, the aging time of the white spirit can be obviously shortened, and the content of total acid and total ester reaches the national standard; and moreover, the content of harmful substances in the white spirit is effectively reduced in short time, and the need for large-scale industrialization is met. The method disclosed by the invention has a very broad market prospect.

Owner:广东省九江酒厂有限公司

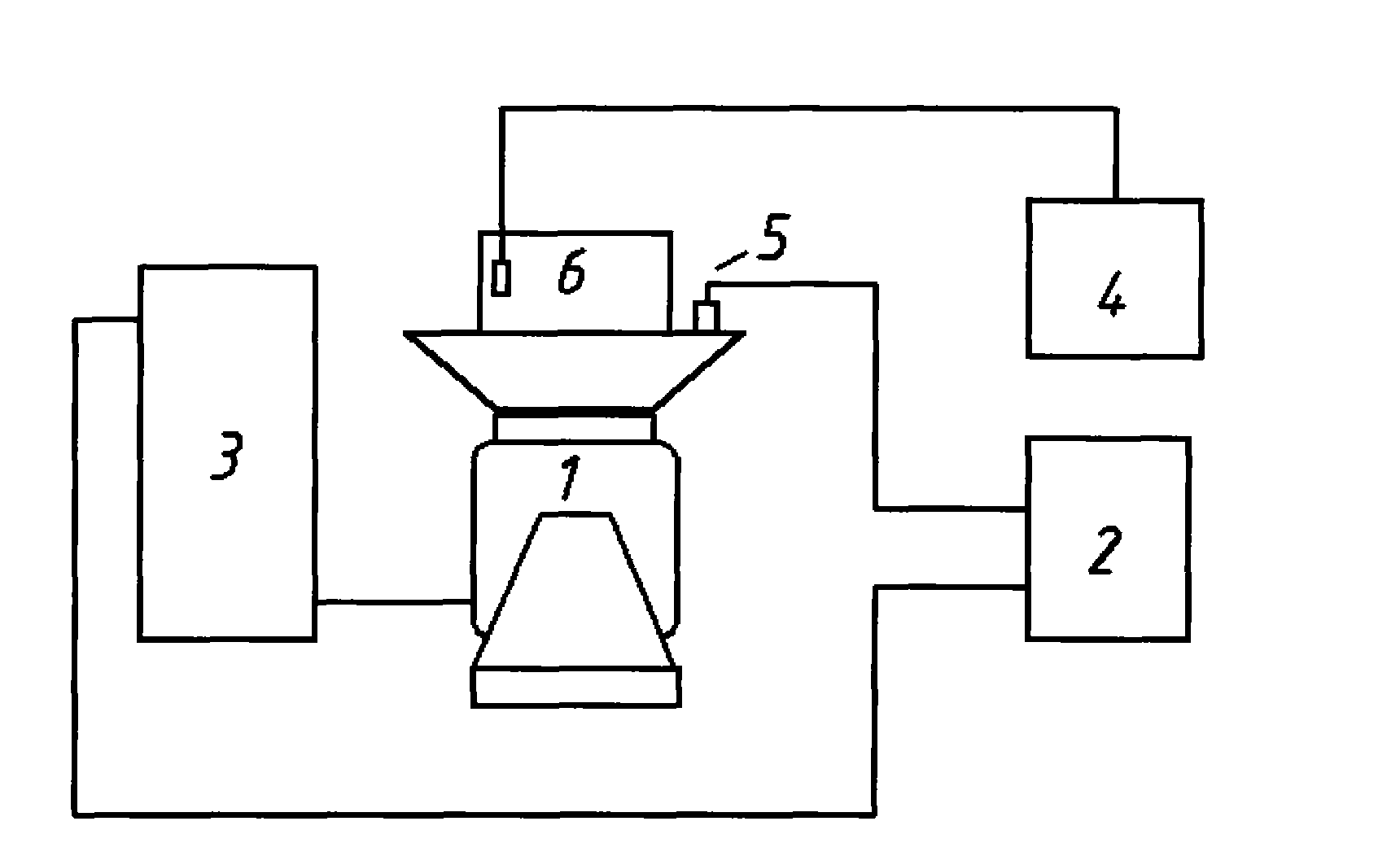

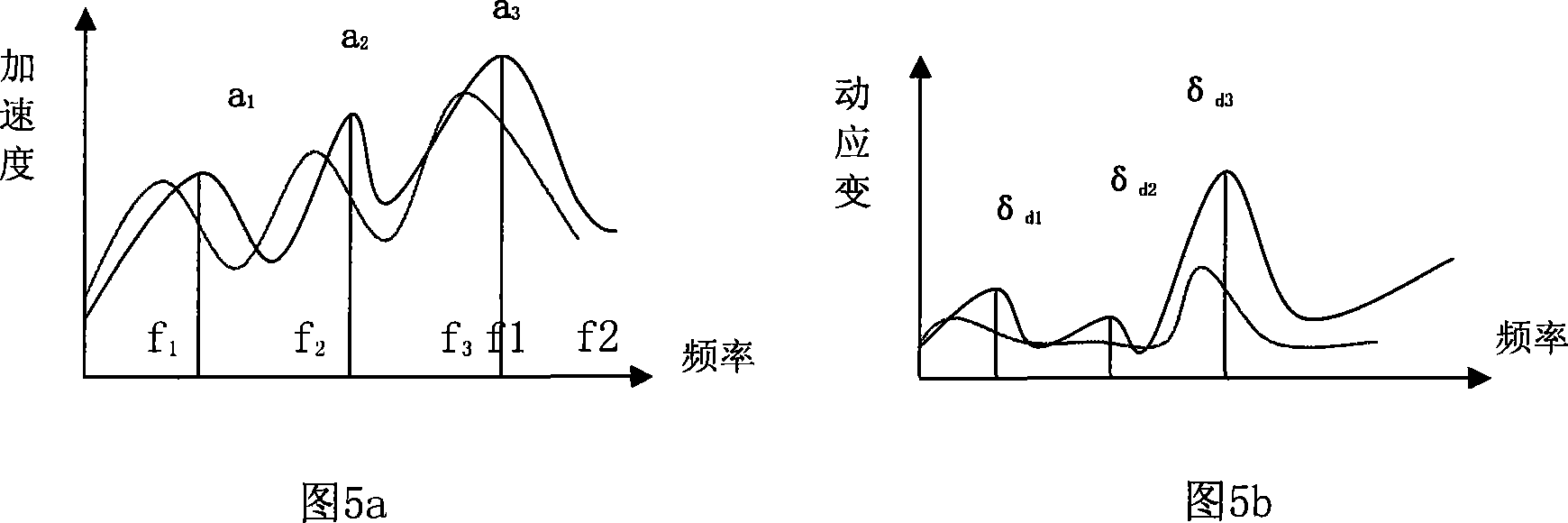

Vibration aging method and device employing electric vibratory test system

ActiveCN101492766AEfficient and fast processingSimple processMechanical vibrations separationVibration testingVibration controlAge method

The invention relates to a vibration stress relief method using an electric vibration experimental system and a device thereof. The method comprises the following steps: residual stress in a workpiece is measured, and dynamic stress level applied during vibration stress relief for the workpiece is determined; frequency spectrum analysis for the workpiece is carried out by an electric vibration table to preferably choose a plurality of harmonic frequencies; the exciting force of sinusoidal fixed-frequency or frequency sweep is randomly applied on the workpiece, the dynamic stress level of the workpiece is detected in real time in the process of force application, and proper exciting force is chosen according to parameters adjusting the exciting force of vibration table; under proper exciting force, continuous ageing treatment for the workpiece is carried out till the operation is finished after reaching the set time. The device comprises the electric vibration table, a dynamic stress measuring system and a vibration controller. The invention has simple technique and low operation cost, and is suitable for workpieces with different sizes; the process is high-efficient and fast, and saves energy and protects environment; furthermore, the device has simple structure and convenient operation, small occupying space and low energy consumption, and is widely applied to the technical field of machining.

Owner:苏州长菱测试技术有限公司

Method for producing instant straight rice vermicelli

The invention discloses a method for producing instant straight rice vermicelli, and belongs to the technical field of food processing. The rehydration property and eating quality of the instant straight rice vermicelli are improved on the basis of a one-step aging method, as well as strong cavatition and a uniform inner-outer drying effect during cooperative drying of ultrasonic wave and medium-short wave infrared rays. The method mainly comprises the following steps: by selecting early indica rice as raw materials, performing immersing, crushing, flour stirring, dual-screw extrusion, aging, re-steaming and washing, and then performing cooperative drying through the ultrasonic wave and medium-short wave infrared rays to obtain the instant straight rice vermicelli which is low in breakage rate, excellent in rehydration property and good eating quality.

Owner:XUZHOU NAILI MACROMOLECULE TECH CO LTD

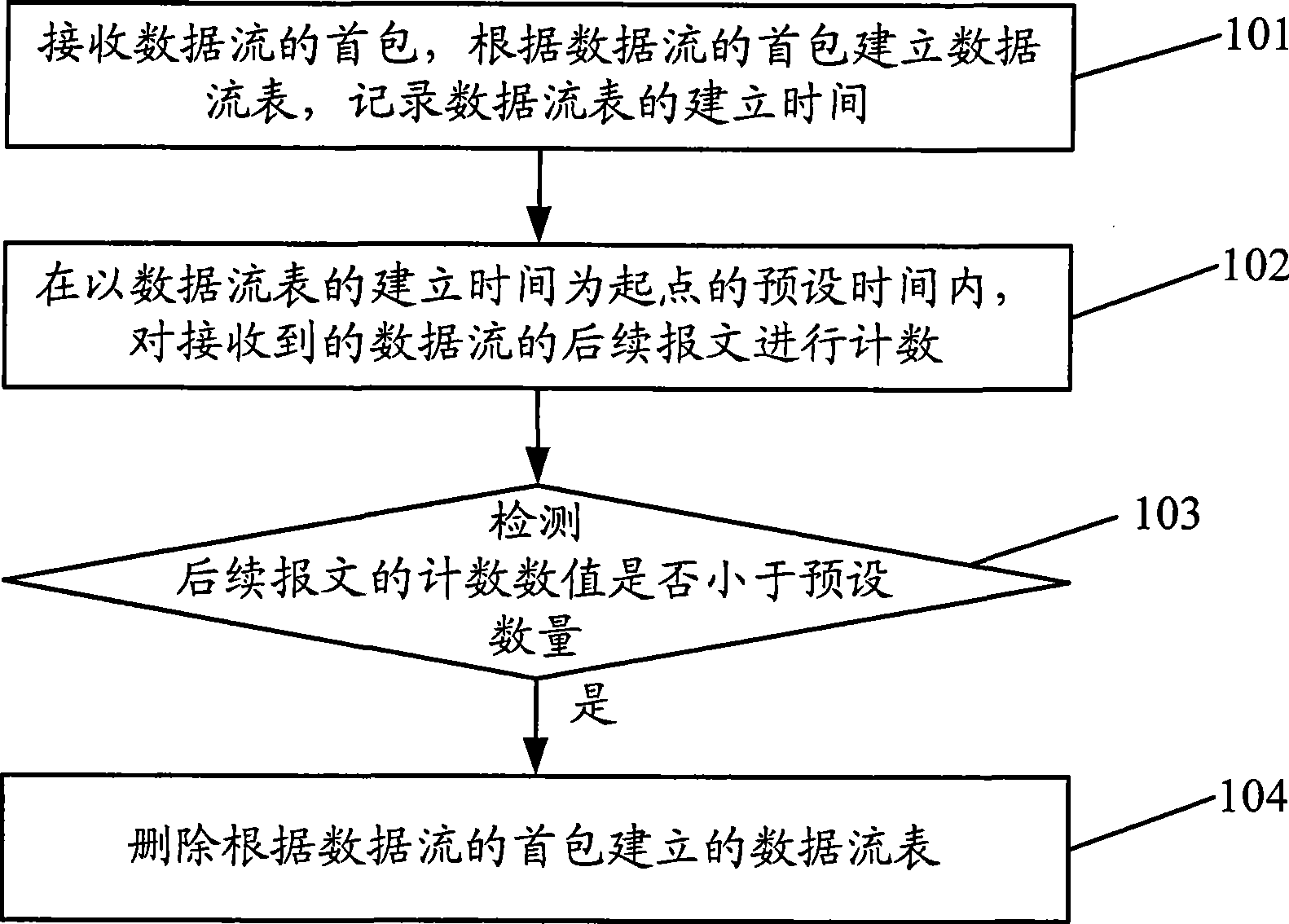

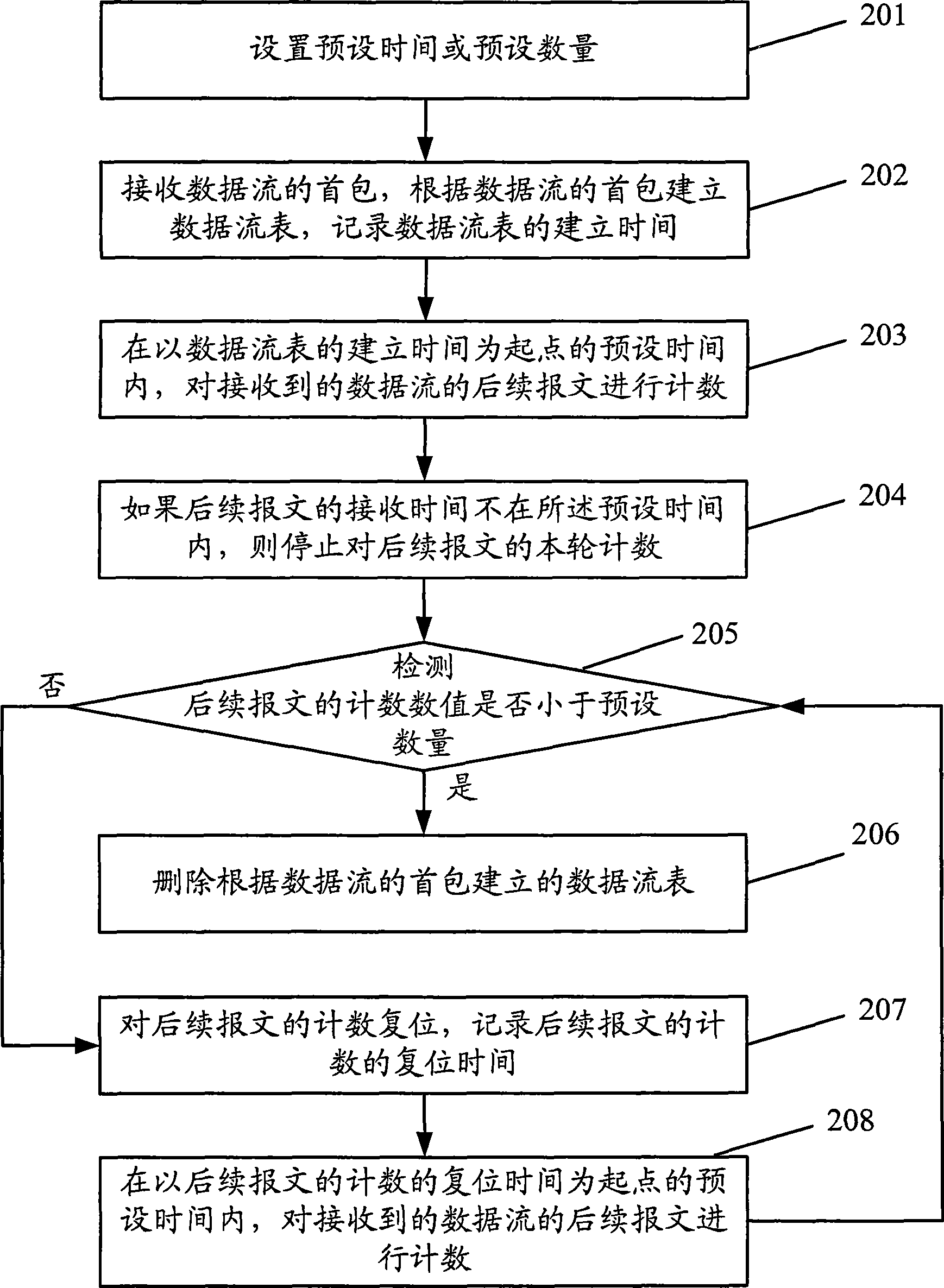

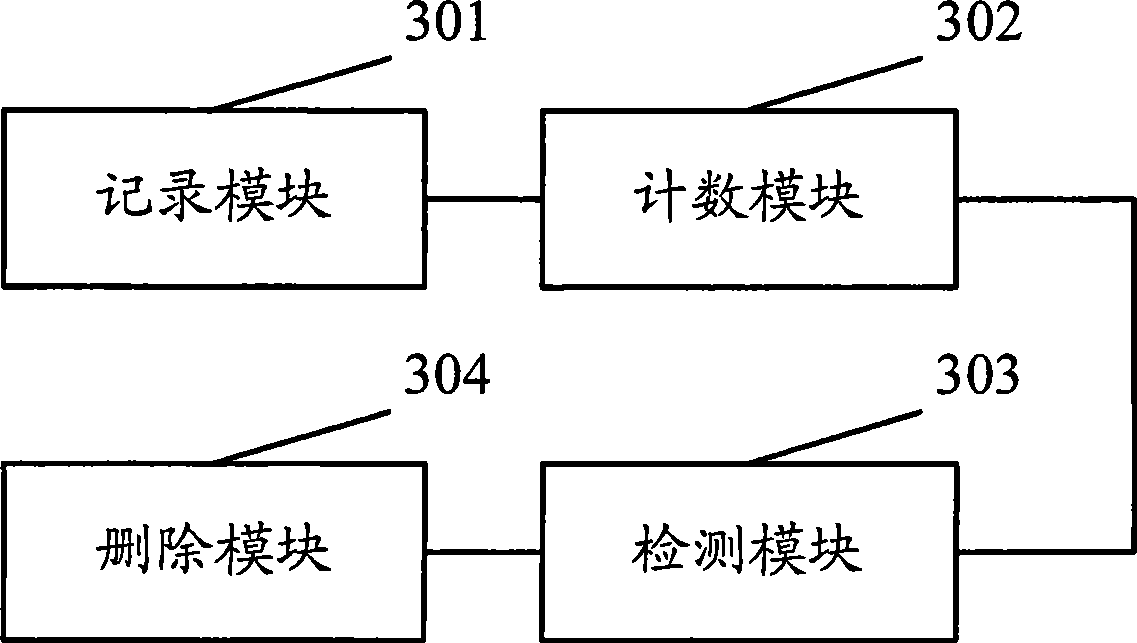

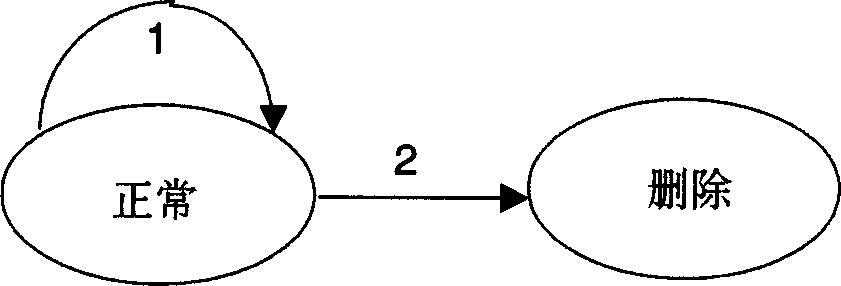

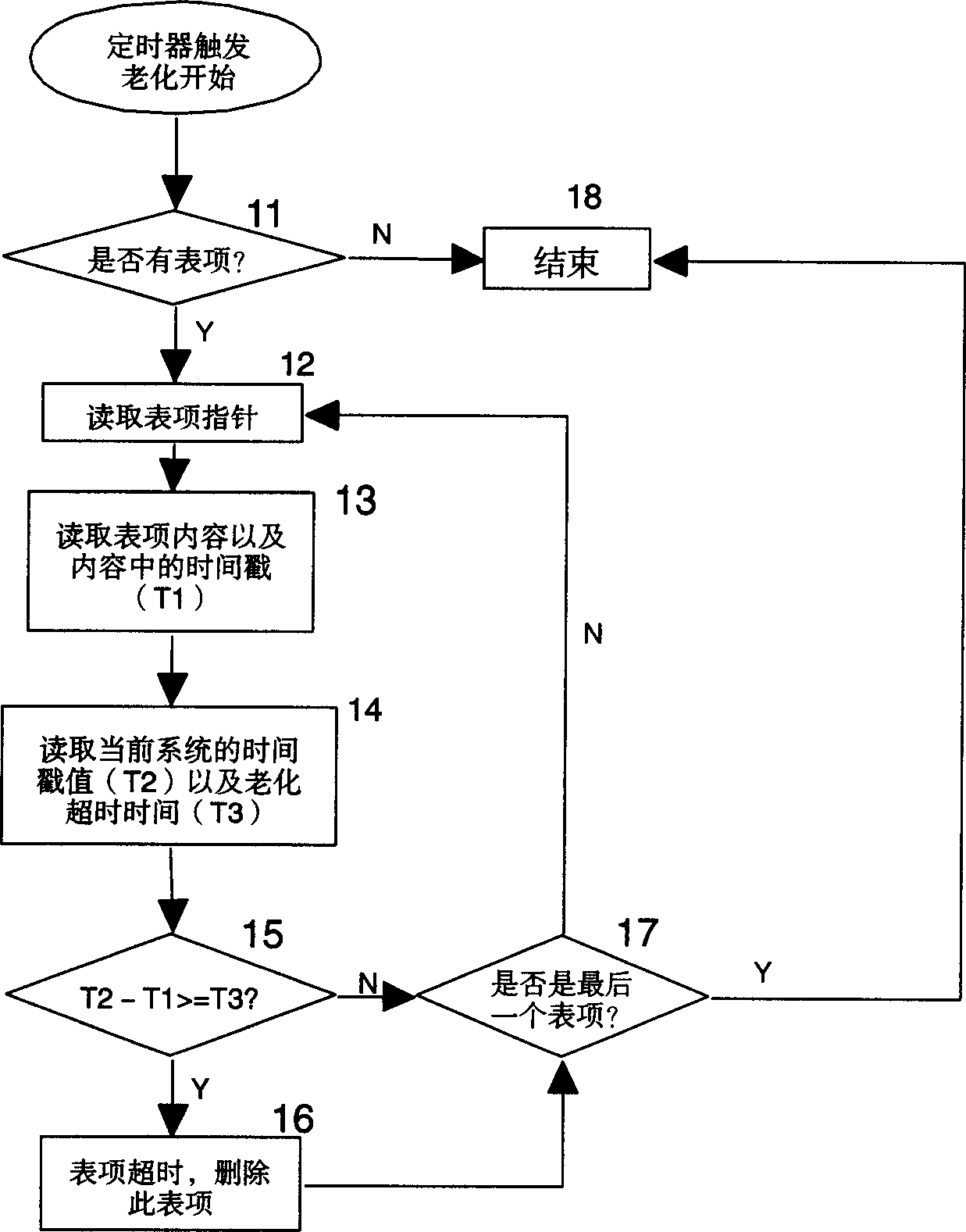

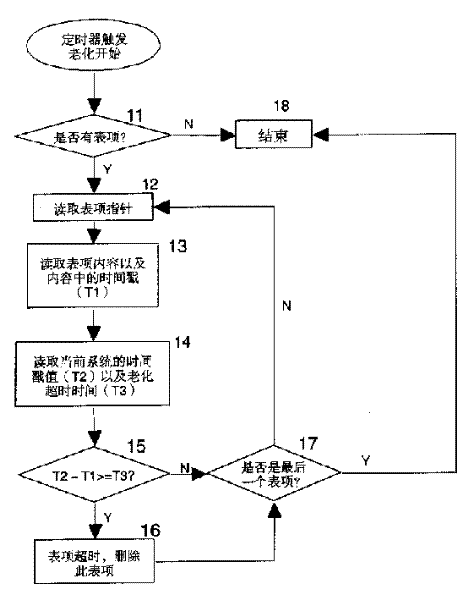

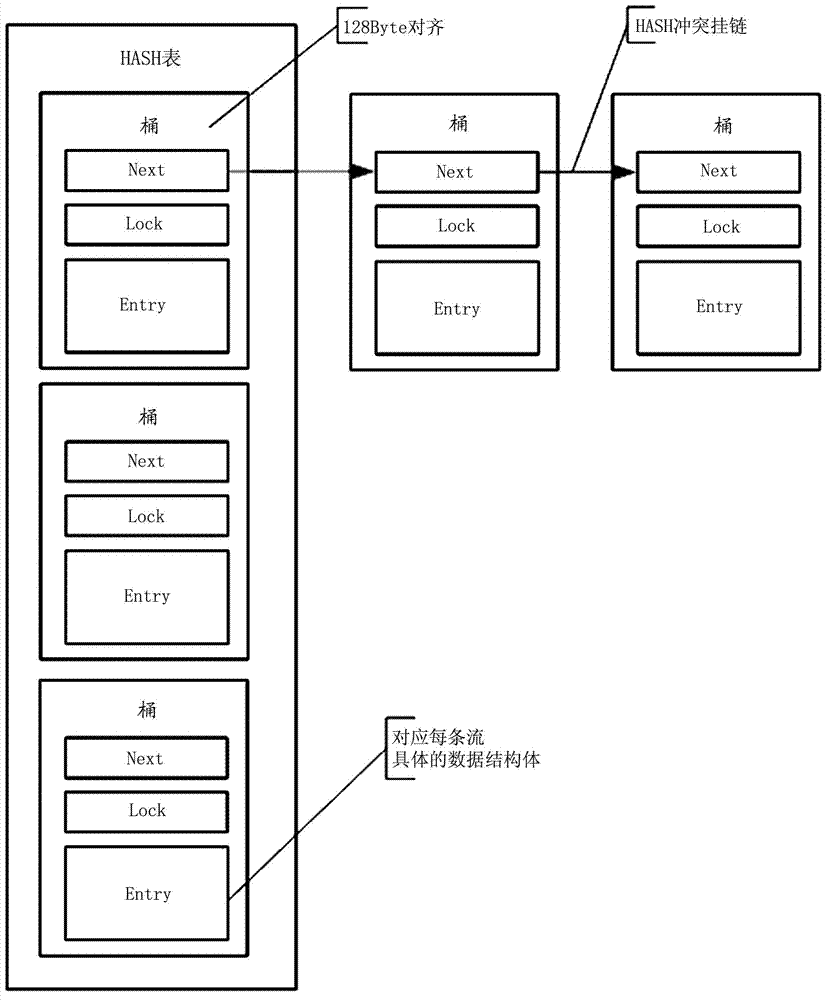

Aging method, apparatus and system for data stream list

The inventive example discloses a data stream list degradation method, device and system. The method comprises: receiving first packet of data stream, establishing data stream list according to first packet of data stream, recording the establishment time of data stream list, counting following messages of received data stream in preset time using establishment time of the data stream as starting point, checking if counting number of following messages is smaller than preset number, if so, deleting the data stream list. The inventive example adopts degradation method based on counting following messages, accelerates degradation of data stream list, and reduces occupation of data stream for memory.

Owner:XFUSION DIGITAL TECH CO LTD

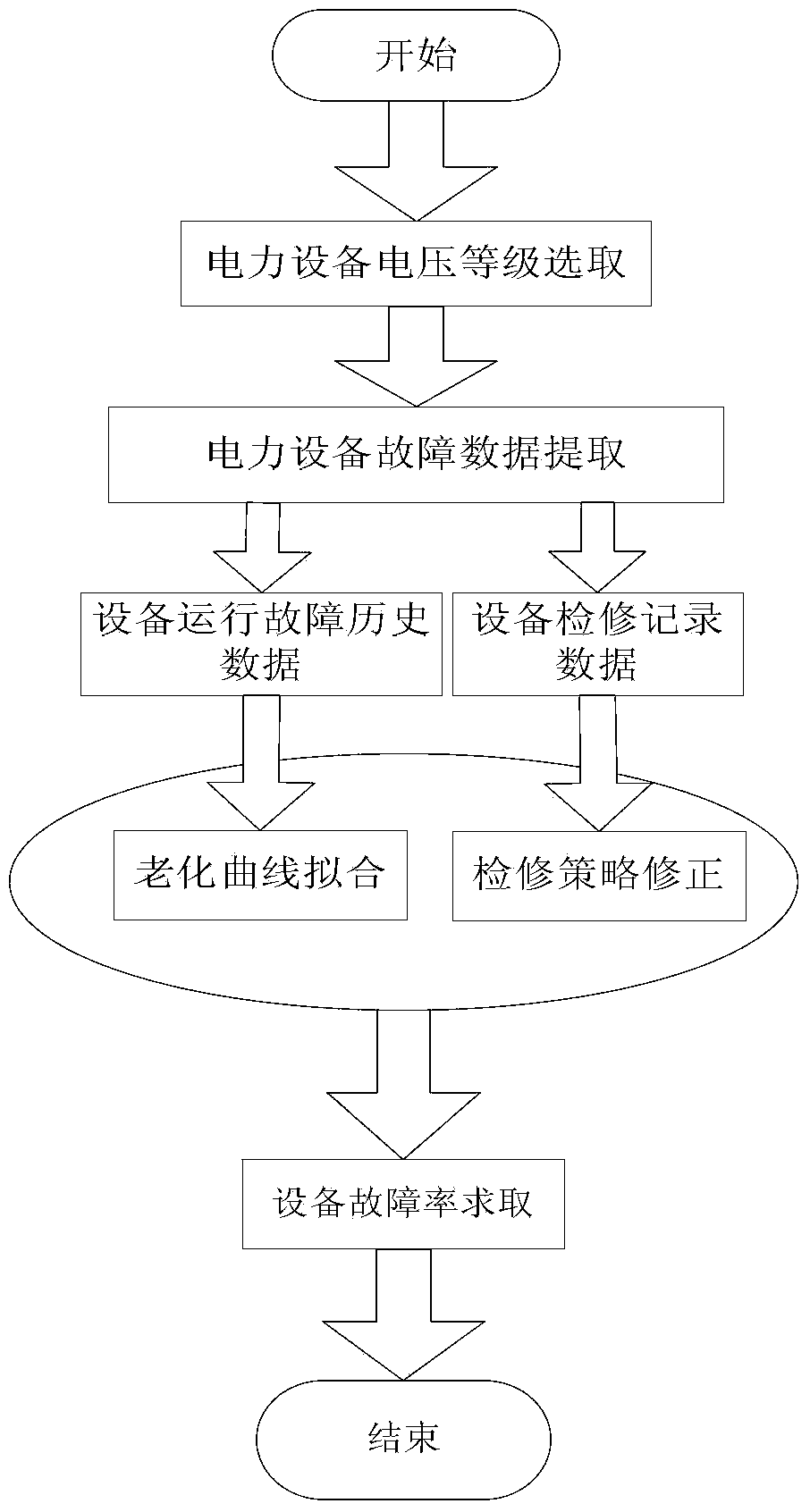

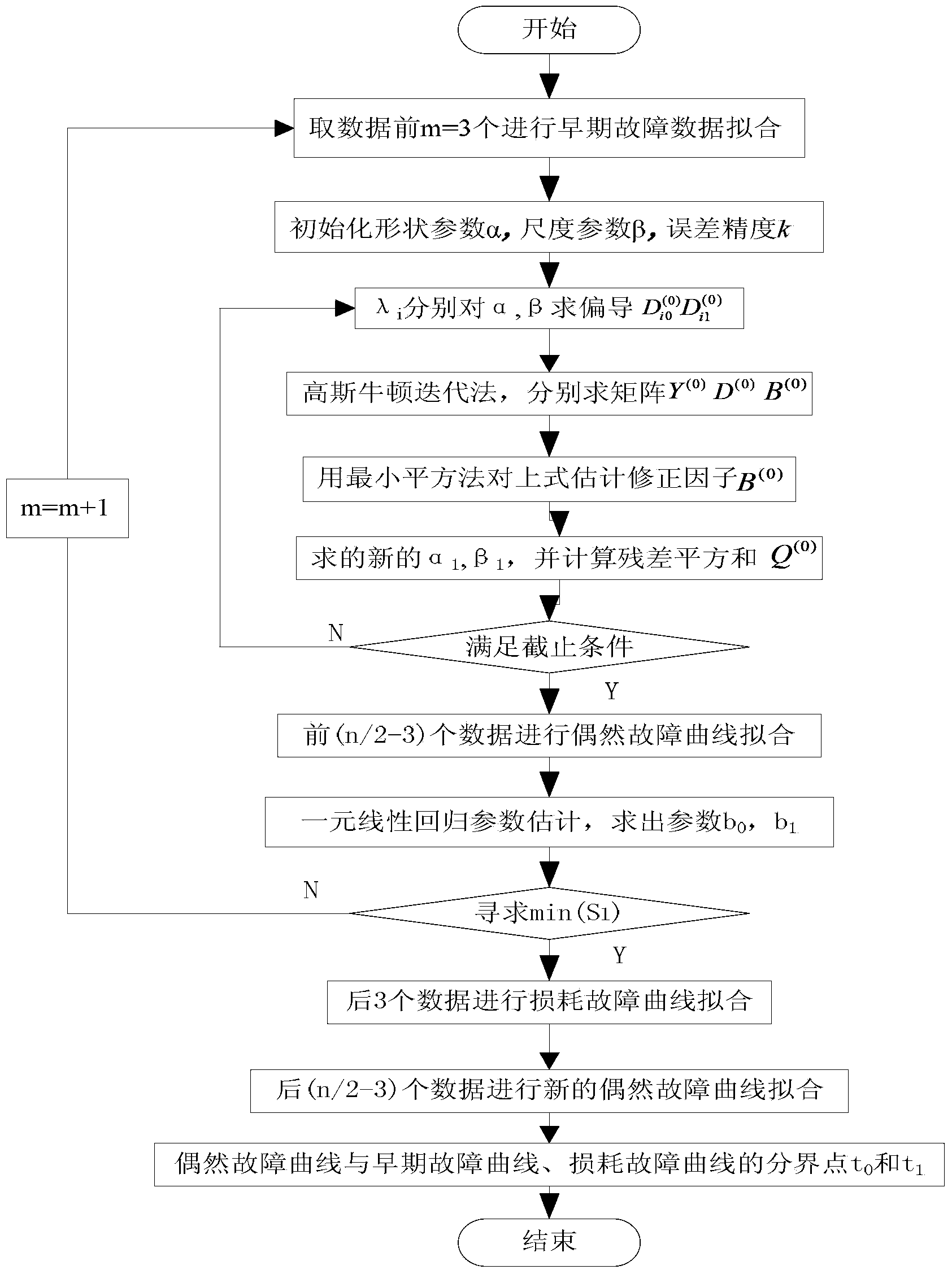

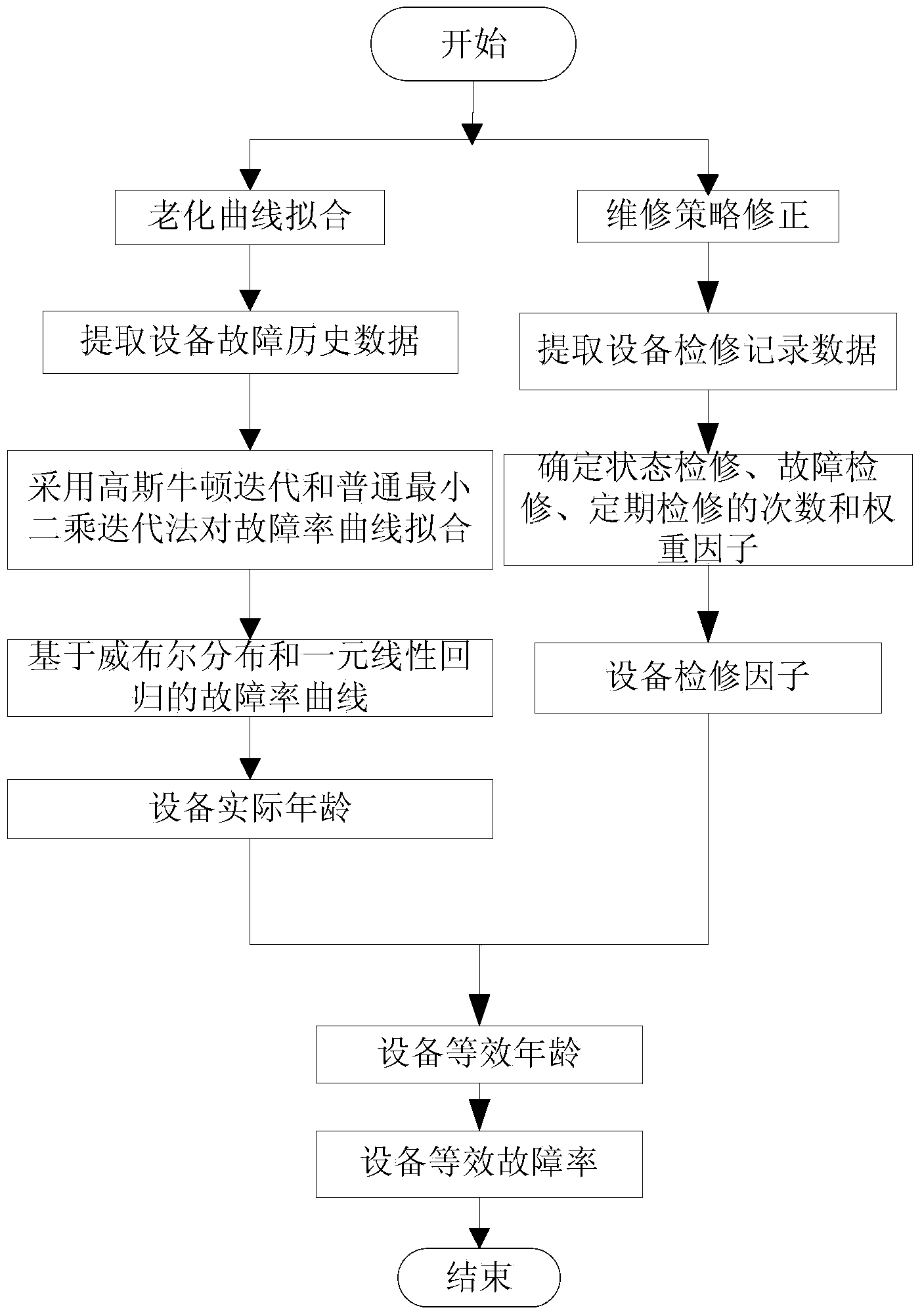

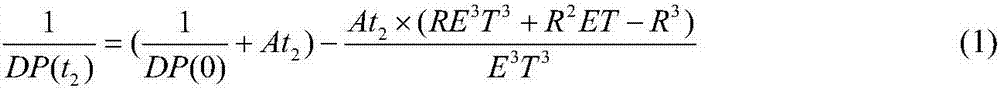

Power equipment fault rate prediction method considering aging factors

The present invention discloses a power equipment fault rate prediction method considering aging factors. The power equipment fault rate prediction method comprises the steps of fitting a fault rate curve by utilizing the characteristics of a weibull distribution of possessing shape parameters, possessing a great flexibility on data fitting and being able to describe the stages of a bathtub curve completely, and carrying out parameter estimation by applying a Gauss-Newton iterative method to obtain the demarcation points of the stages respectively. In addition, the fault rate prediction method of the present invention also considers the influence of different maintenance policies on the device fault rate, and applies an equivalent age method to solve the actual fault rate of a device. The device fault rate obtained by utilizing the method in the present invention is closer to the reality, and the prediction accuracy of the power equipment fault rate can be improved effectively, thereby guaranteeing the accuracy of the reliability and risk evaluation of a system, and providing correlated reliable bases for the dispatching and maintenance of the system.

Owner:STATE GRID CORP OF CHINA +1

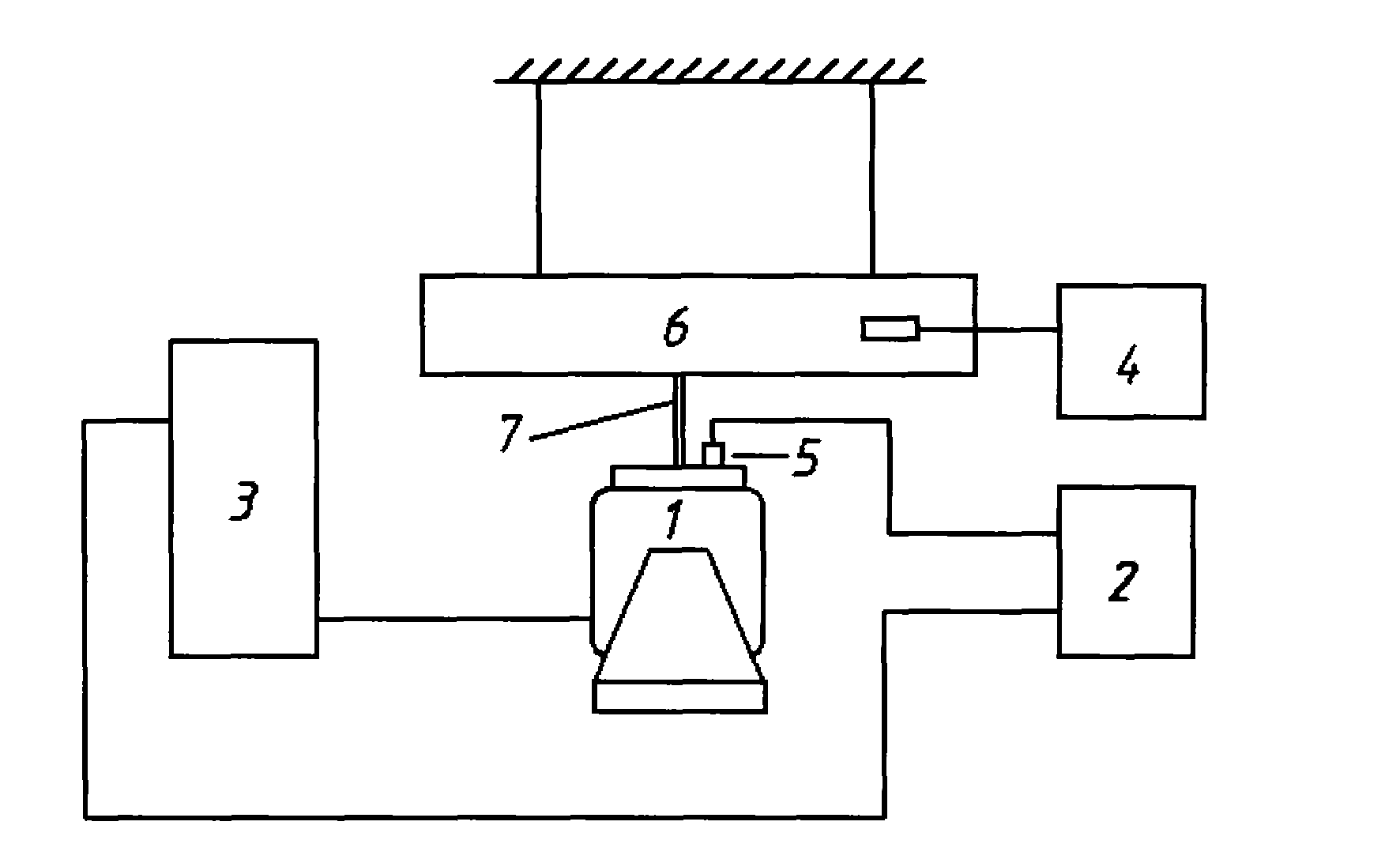

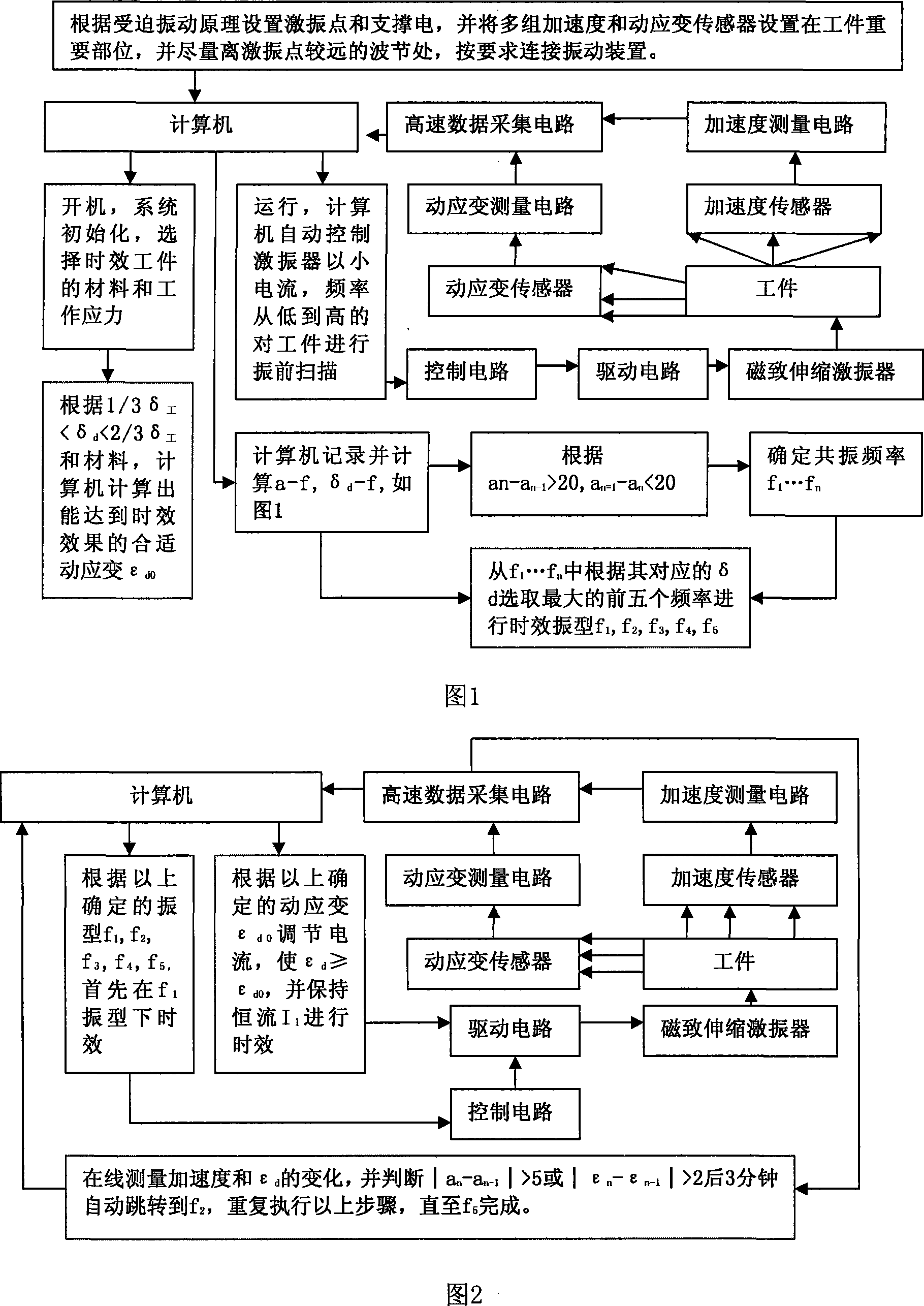

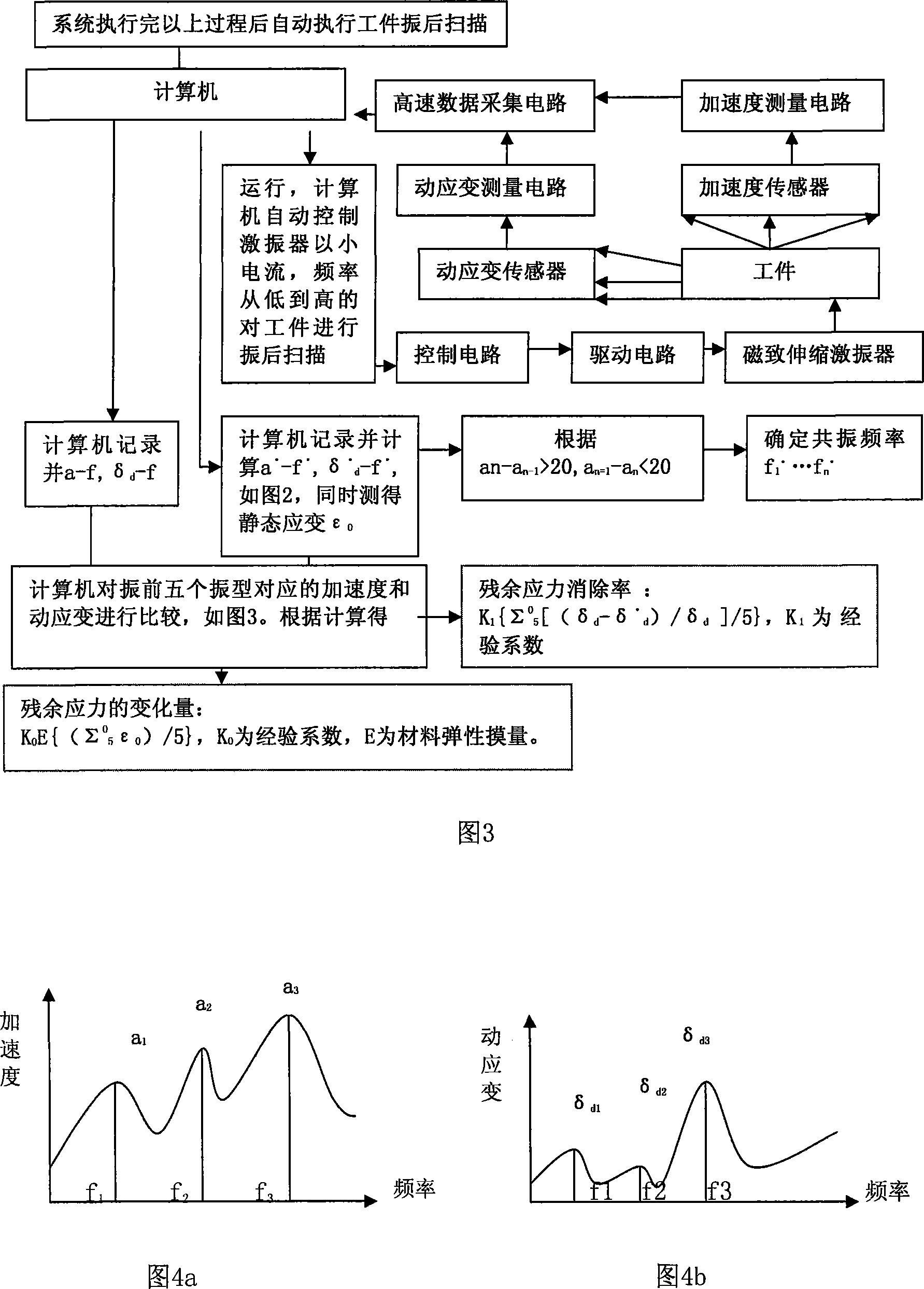

Novel vibration aging method

InactiveCN101225466ASolve the problem that manual adjustment affects real-time performanceMeet the requirements of dynamic stressMechanical vibrations separationAge methodStress variation

The invention discloses a vibration aging method, comprising a computer, a magnetostrictive vibration exciter, an acceleration sensor and a dynamic strain sensor. The vibration aging method is characterized in that the vibration exciter loads on the workpiece and exerts a cyclist exciting force, two sensors are respectively positioned on the easily cracking and deforming area of the workpiece, the sensors are analyzed and different frequency, the corresponding relationship between the dynamic strains and sorting are done by the computer, selecting the frequencies corresponding to the first biggest dynamic strains as the typical vibration, adjusting the working current and time of the vibration exciter, making the vibration exciter to vibrate at the above frequency till the aging is finished. The vibration aging method has the advantages of using the magnetostrictive vibration exciter as a vibration source, regulating the exciting force by the computer, timely responding the vibration variation to meet the dynamic stress, controlling the vibration source to vibrate at the resonation frequency by the computer, timely tuning the output current of the vibration exciter, analyzing and judging the vibration mode and the vibration time of the vibration aging, lively measuring the dynamic stress variation, and outputting the correct remaining stress variation as the prove for the experiment.

Owner:郝俊山

Aging method after dying of all-cotton knitting clothes

InactiveCN101008140AGood hygroscopicityImprove breathabilityPhysical treatmentDyeing processAge methodDying processes

A method for aging the clothes after dying process comprises that: cleaning the dyed clothes; selecting pumex and putting some pumex into strong oxidant solution to be immerged, taking out and drying, to obtain wet pumex; putting dry and wet pumexes into the chamber of grinder; putting clothes into chamber, grinding and taking out clothes to obtain the grinded aged clothes; washing that washing clothes in washing machine, leading in clean water, heating, adding oxalic acid or sodium thiosulphate to wash and adjust pH value, discharging water, leading in water, adding sodium thiosulphate, neutralizing and washing, controlling pH value, softening, dewatering, drying, cleaning to obtain the final product. The inventive clothes have soft, flexile and wet-adsorption properties.

Owner:CHANGSHU HONGQIAO SAND WASH

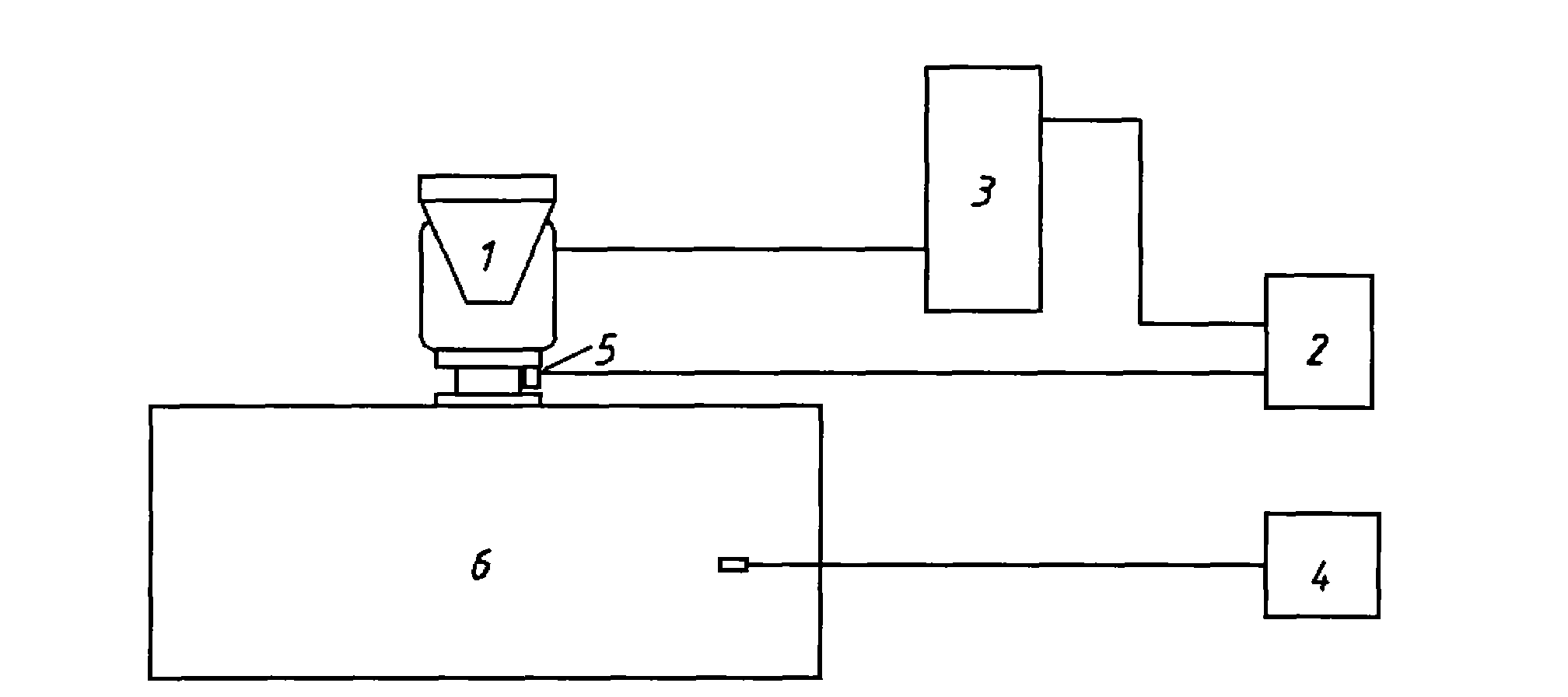

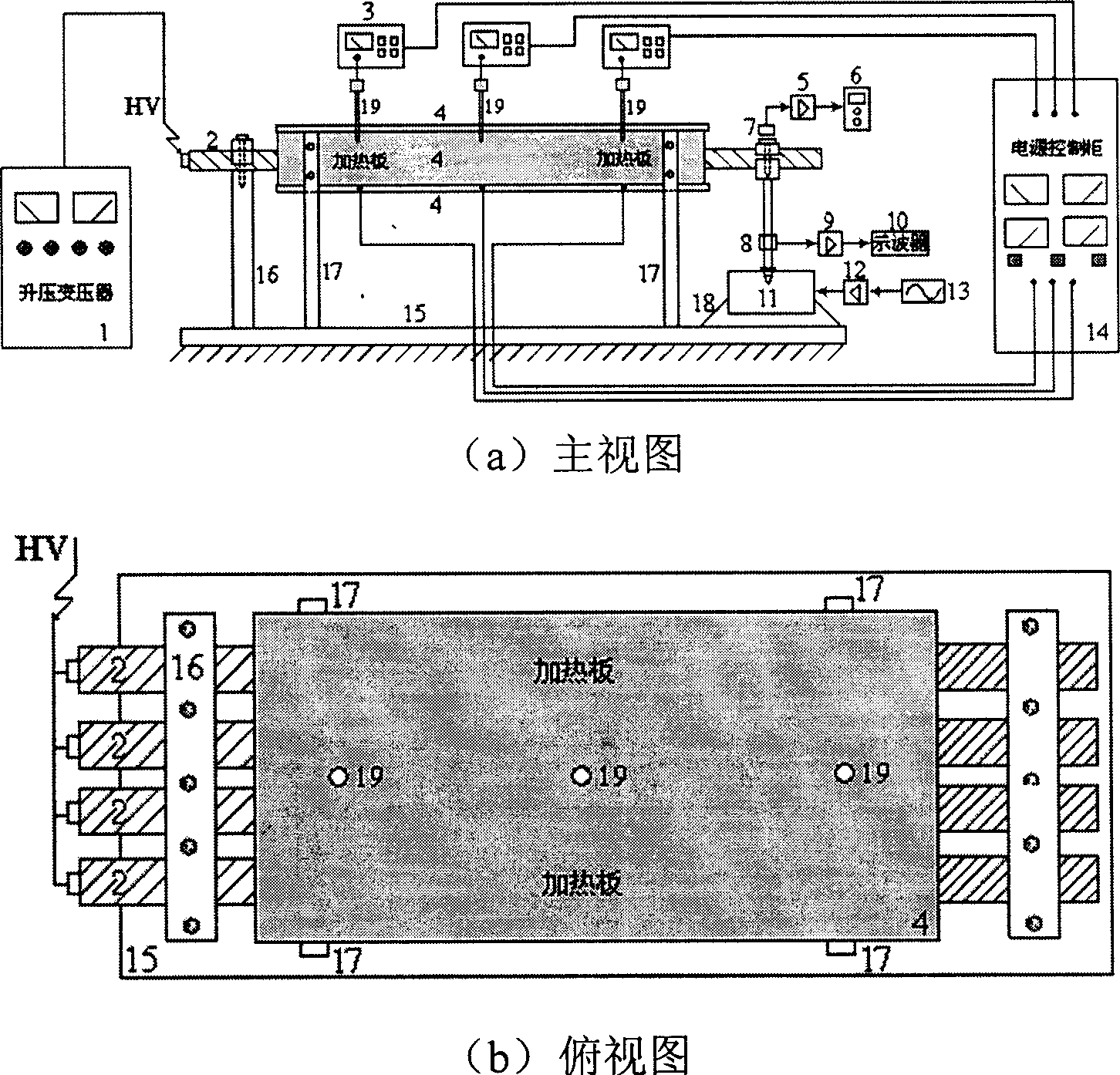

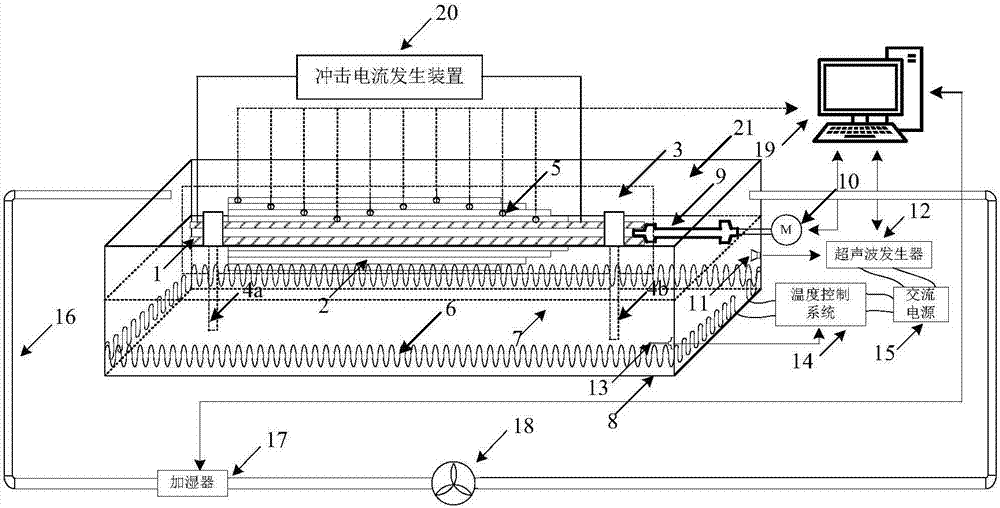

Electric machine stator wire bar multifactor ageing device and method

InactiveCN1402413AGuaranteed long-term agingAnti-slipWindings insulation materialManufacturing dynamo-electric machinesAge methodTransformer

The invented aging device and aging method for investigating the aging rule, the life test and quality analysis of the insulation of the stator wire bar. The invented device can apply the aging stresses of the electricity, heat, mechanism as well as the thermal and mechanical stress to the wire bar tested so as to simulate the aging process of the sample of the stator wire bar without damaging the sample. The transformer provided the electric aging factor. The heating plate provides the thermal aging factor. The temperature control device controls the thermal aging temperature. The vibration generator provides the vibration stress. Adjusting the output waveform of the signal generator can change the mode of the vibration. The heating and cooling cycles can be scheduled. Thus, the four aging stresses can be combined in order to meet different aging requirement.

Owner:XI AN JIAOTONG UNIV

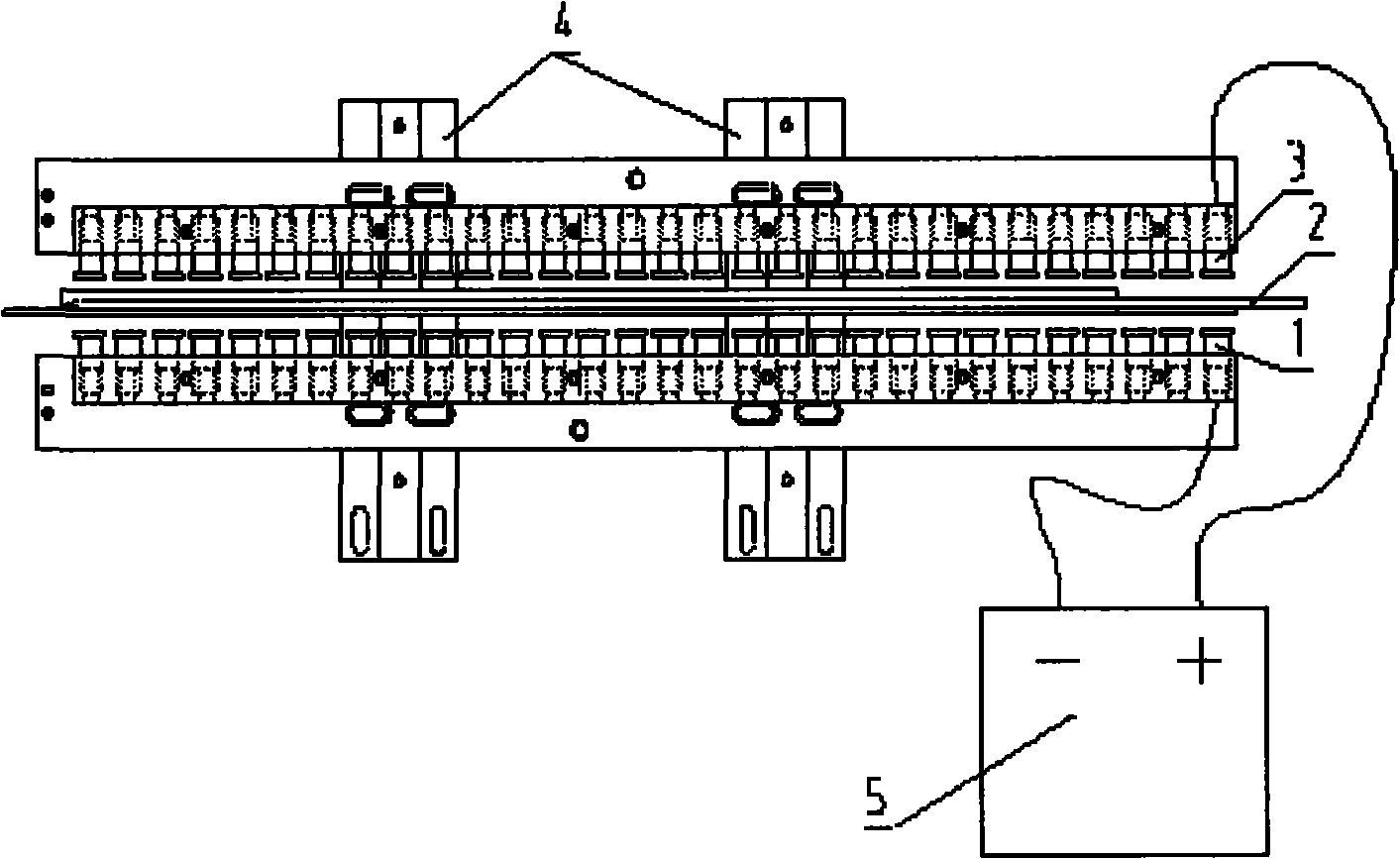

Preprocessing method and apparatus for aging aluminium electrolysis capacitor

InactiveCN101329944AAccelerated agingSpeed up agingElectrolytic capacitorsCapacitor manufactureAluminium electrolysisAge method

The invention relates to an aging method applied to processing an aluminum electrolytic capacitor and a device thereof, and provides a preprocessing method of an aluminum electrolytic capacitor before aging and a device thereof. Before aging, a charging process of the aluminum electrolytic capacitor is carried out; the current loaded to the two electrodes of the capacitor is DC current or pulse current, the current value is 30A to 150A; the voltage value is 6.3V to 120V; in the current and voltage, the burr and raw edge produced in material cutting and nail coiling processes of the aluminum electrolytic capacitor can be burned. The device of the invention consists of an anode contact (1), an isolation insulation board (2), a cathode contact (3), a sliding seat (4) of the anode and cathode contacts and a fixed power source (5). When in charge, the device can straighten the bent anode and cathode lines, thereby being conducive to aging and clipping of the capacitor. Therefore, aging speed can be increased and aging efficiency can be improved.

Owner:HUNAN AIHUA GRP

Data aging method for network processor

The present invention discloses a data ageing method for network processor. Said method includes the following steps: firstly, setting data ageing time interval; according to said time interval, when the data is operated, setting or updating time stamp value of said data; when the data is undergone the proces sof ageing operation, utilizing obtained system time stamp value, and according to the difference of system time stamp value and time stamp value of data which is greater than or equal to the set data ageing time interval or not, judging that said data storage is over time or not, if it is over time, deleting said data. Said method not only can raise efficiency of ageing operation, but also can ensure safety of data.

Owner:HUAWEI TECH CO LTD

Method and apparatus for realistic simulation of wrinkle aging and de-aging

ActiveUS8391639B2Accurate and realistic simulationRealistic predictionImage enhancementImage analysisComputer animationWrinkle skin

Methods and systems are disclosed to realistically simulate facial wrinkle aging of a person using a neutral state (natural look) image and one or more expression images (e.g., smile, frown, pout, wink) that induce wrinkles. The neutral and expression images are processed to simulate wrinkle aging by registering the wrinkles that are visible in the expression image onto the neutral image, thereby generating a wrinkle-aged simulated image. Advantageously, a person's own wrinkle histological data is utilized, hence providing an accurate and realistic wrinkle aging simulation. Similarly, the neutral image is processed to eliminate all visible wrinkles thereby generating a wrinkle de-aged simulation image. Additionally, blending of a neutral image with an aged or de-aged simulation image is disclosed, where the degree of blending is based on statistical modeling of skin condition with age and / or expected outcome of a particular type of treatment. The methods and systems disclosed have wide applicability, including, for example, areas such as dermatology, cosmetics and computer animation, among others.

Owner:THE PROCTER & GAMBLE COMPANY

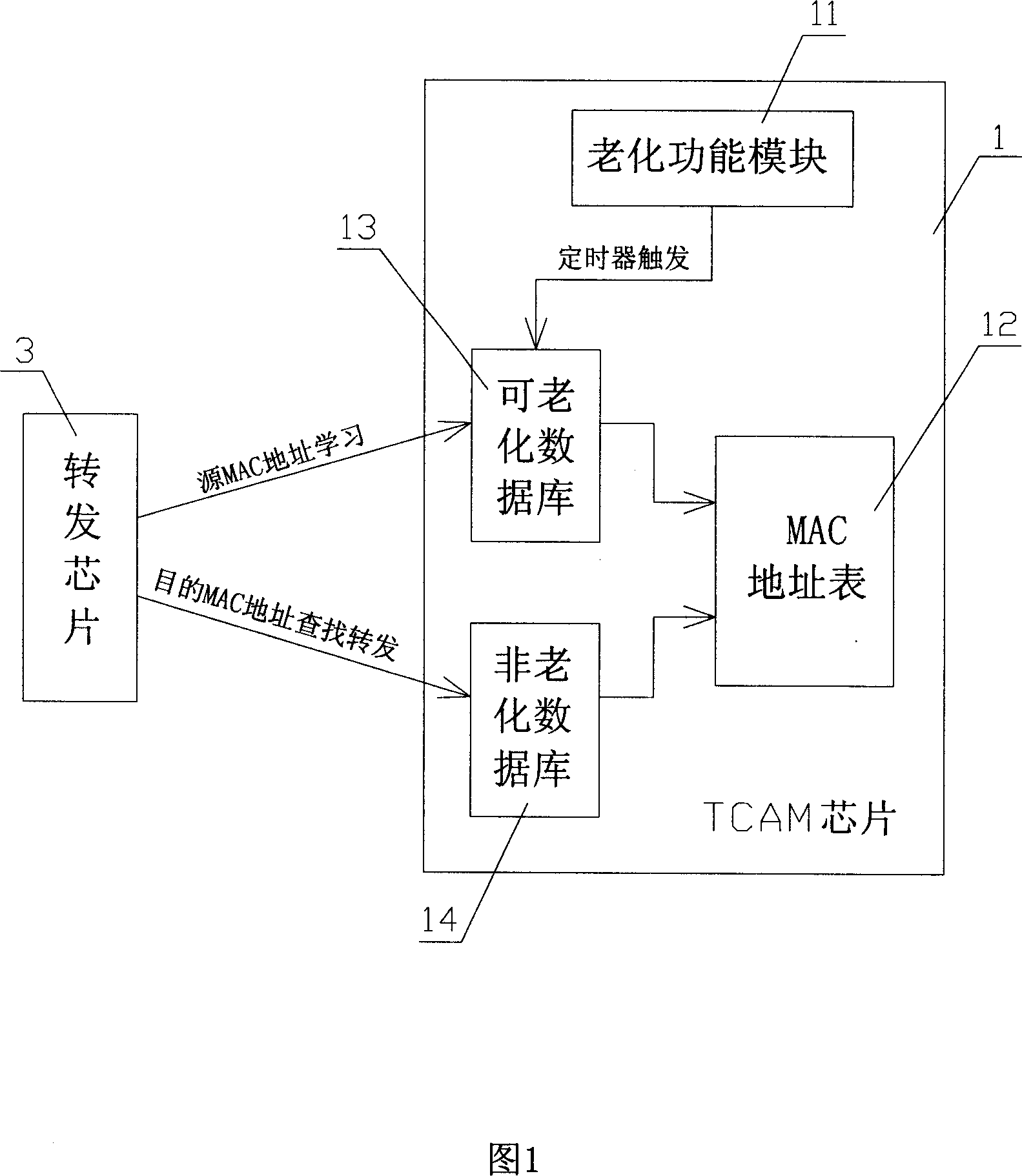

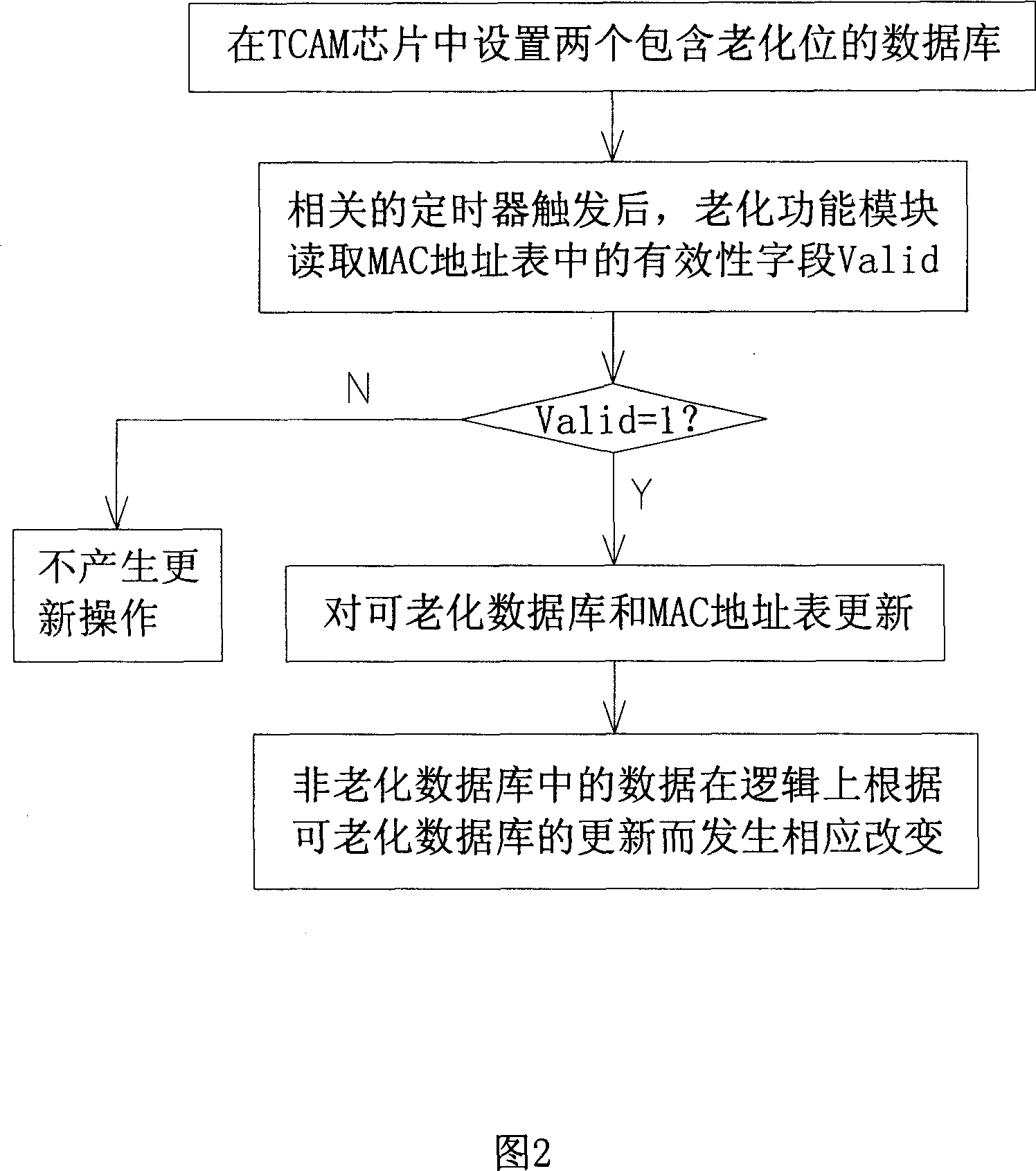

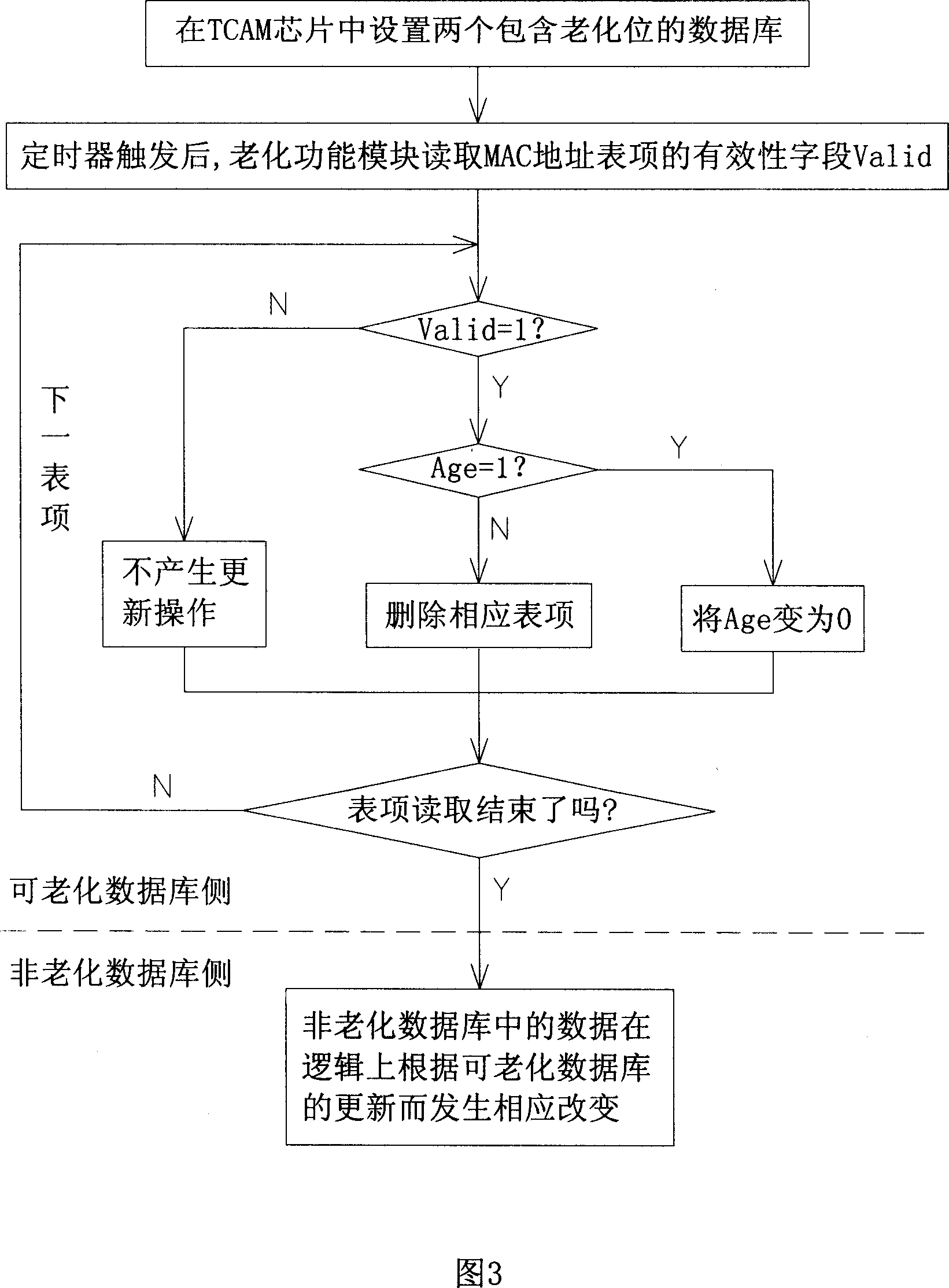

MAC address table ageing, operation method and process system thereof

InactiveCN101047670AComply with the basic requirements of switching and forwardingFinding Operations Realistically PossibleHybrid switching systemsProcess systemsAge method

This invention relates to an ageing and operation method and a process system for MAC address list, in which, the ageing method includes: A, setting two databases including ageing bits in a TCAM chip, an ageing functional module can operate data in one database only, which is the ageing one the other is non-ageing one, B, the ageing functional module operates the ageing bit data of the ageable database relatively and the address list operation method includes: in the study of the source MAC address, related process is done by the ageable database and data in it are renovated if the item in the MAC address list is hit, if a new item is inserted, then data of the ageable database and the MAC address list are initialized, B, when looking up at the target MAC address, the non-aged database looks up at the MAC address list, which meets the requirement of exchange and transmission and realizes hardware operation.

Owner:HUAWEI TECH CO LTD

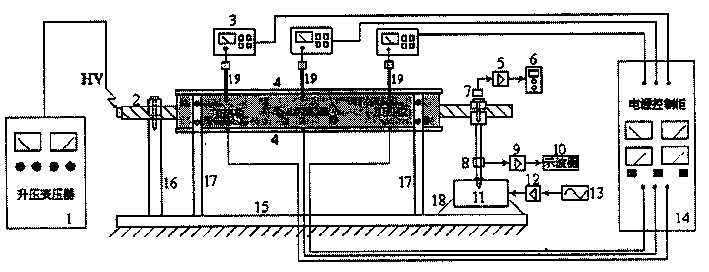

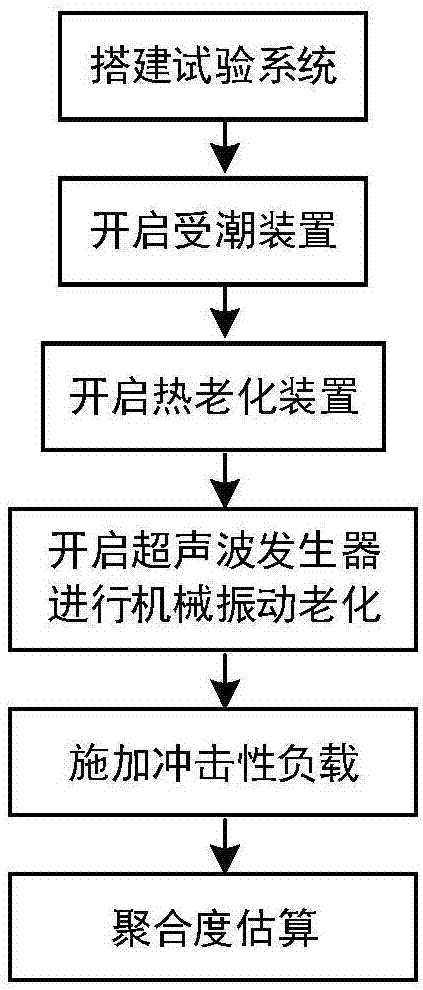

Multi-factor combined aging experiment method for bushing main insulation

The invention discloses a multi-factor combined aging experiment method for bushing main insulation. An experiment system is firstly built, and a capacitor core (3) is subjected to wetting treatment and insulation oil (7) is heated; thermal aging- and mechanical vibration-aging treatment is then carried out on the capacitor core (3), impact load is applied to the capacitor core (3) after the wetting process is over, the moisture-distribution state of an outer insulation layer of the capacitor core (3) is recorded, the degree of polymerization DP(t) at the time after the thermal aging process of the capacitor core (3) is over is calculated, and the aging state is evaluated. Based on the aging method, the moisture distribution and diffusion state of a traction transformer bushing under a harsh environment and impact load can be simulated, the experiment efficiency is greatly improved, and great significance is realized for study on the aging mechanism of the traction transformer bushing main insulation and evaluation on the wetting state of the traction transformer aged bushing.

Owner:SOUTHWEST JIAOTONG UNIV

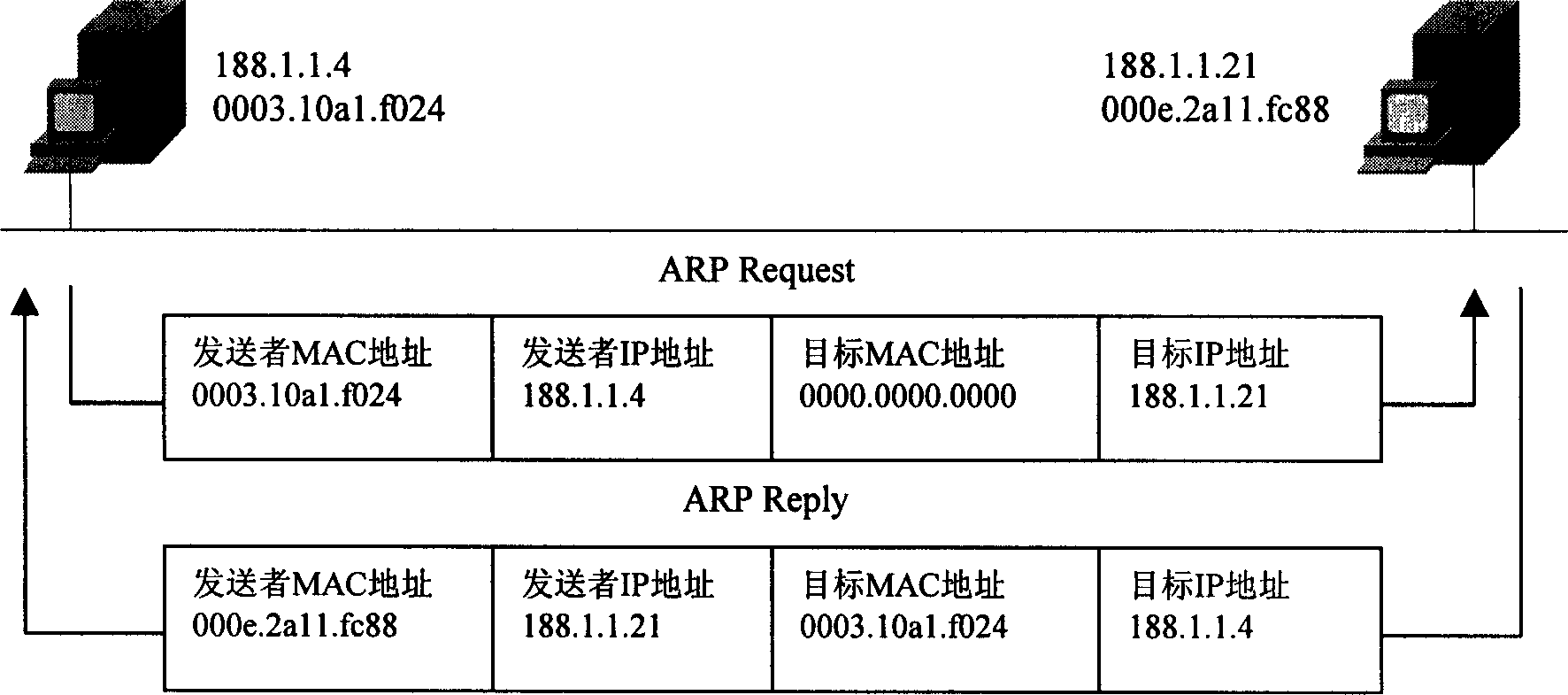

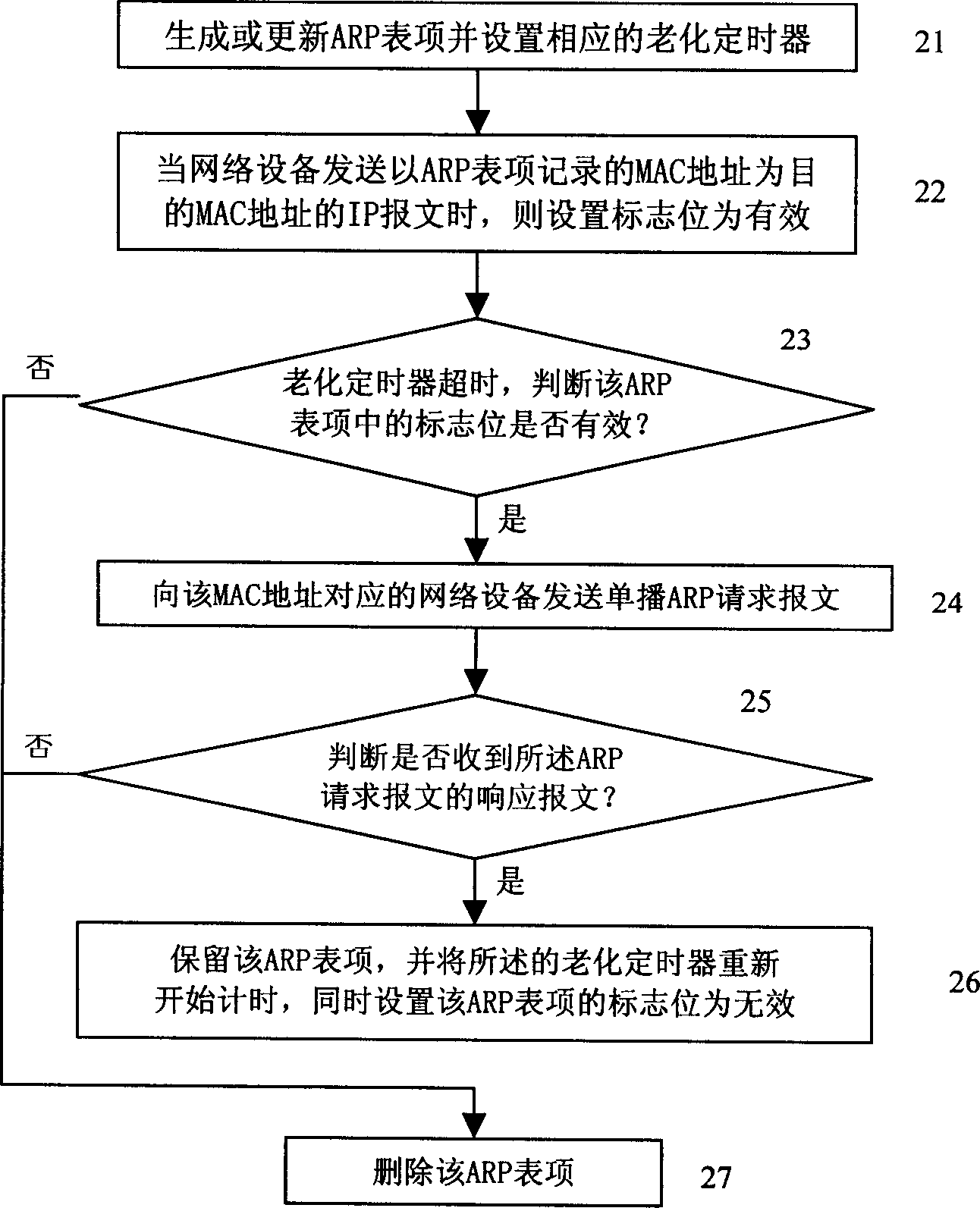

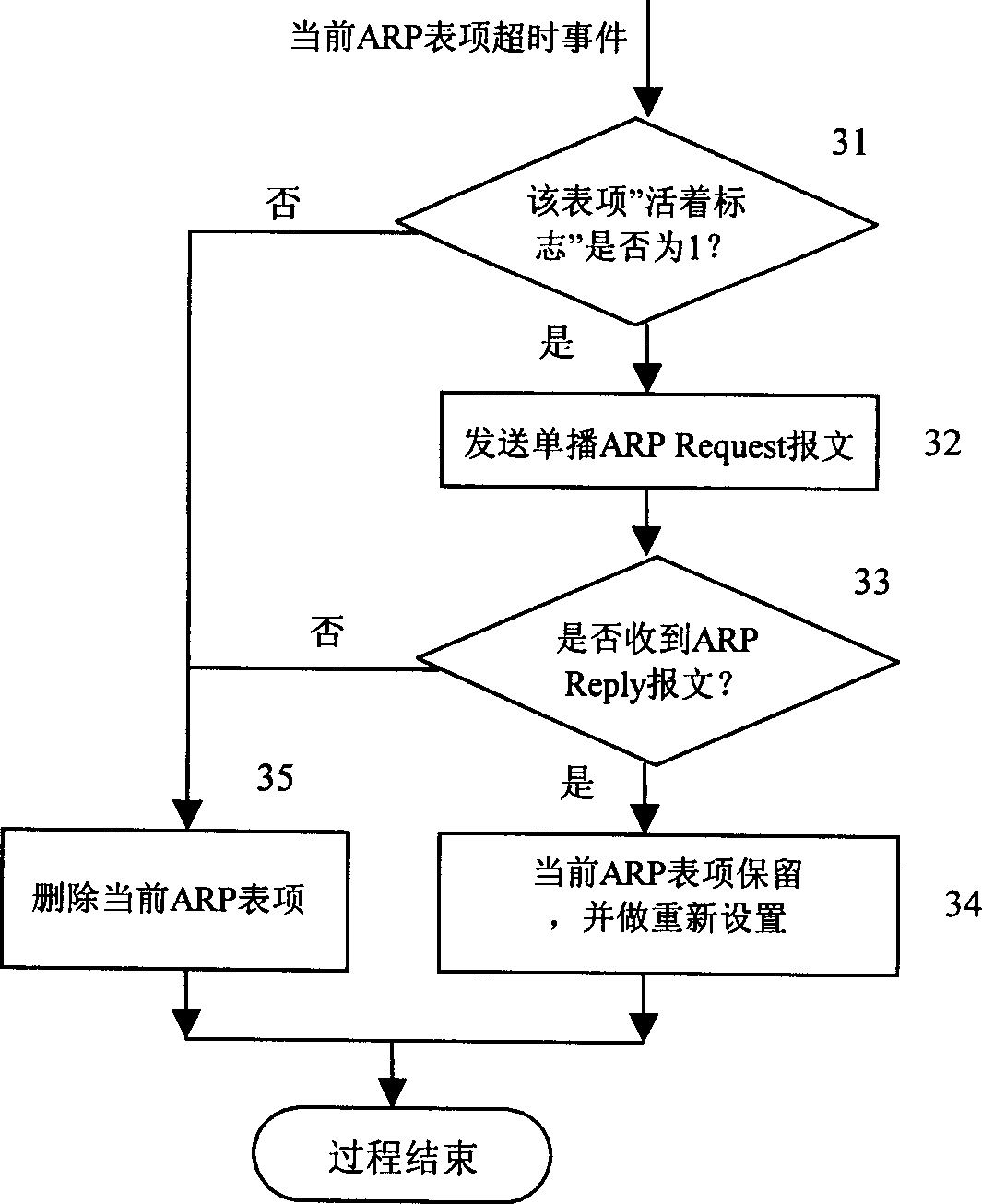

Ageing method for address analytic protocol cache table item in network device

InactiveCN1783874AReduce in quantityReduce the burden onTransmissionAddress Resolution ProtocolAge method

This invention relates to cache list item aging method for address resolution protocol in network equipment. It contains aging process to relative ARP list item according to the MAC address corresponded network equipment on line or not if the aging timer being overtime in APR list item aging timing period. Said invention avoids the list item being deleted. Said invention reduces the APR Request message number and load, and data loss.

Owner:HUAWEI TECH CO LTD

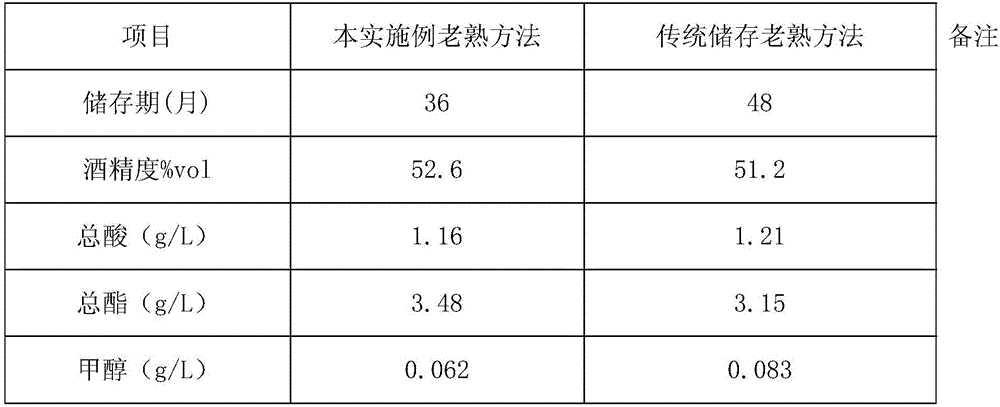

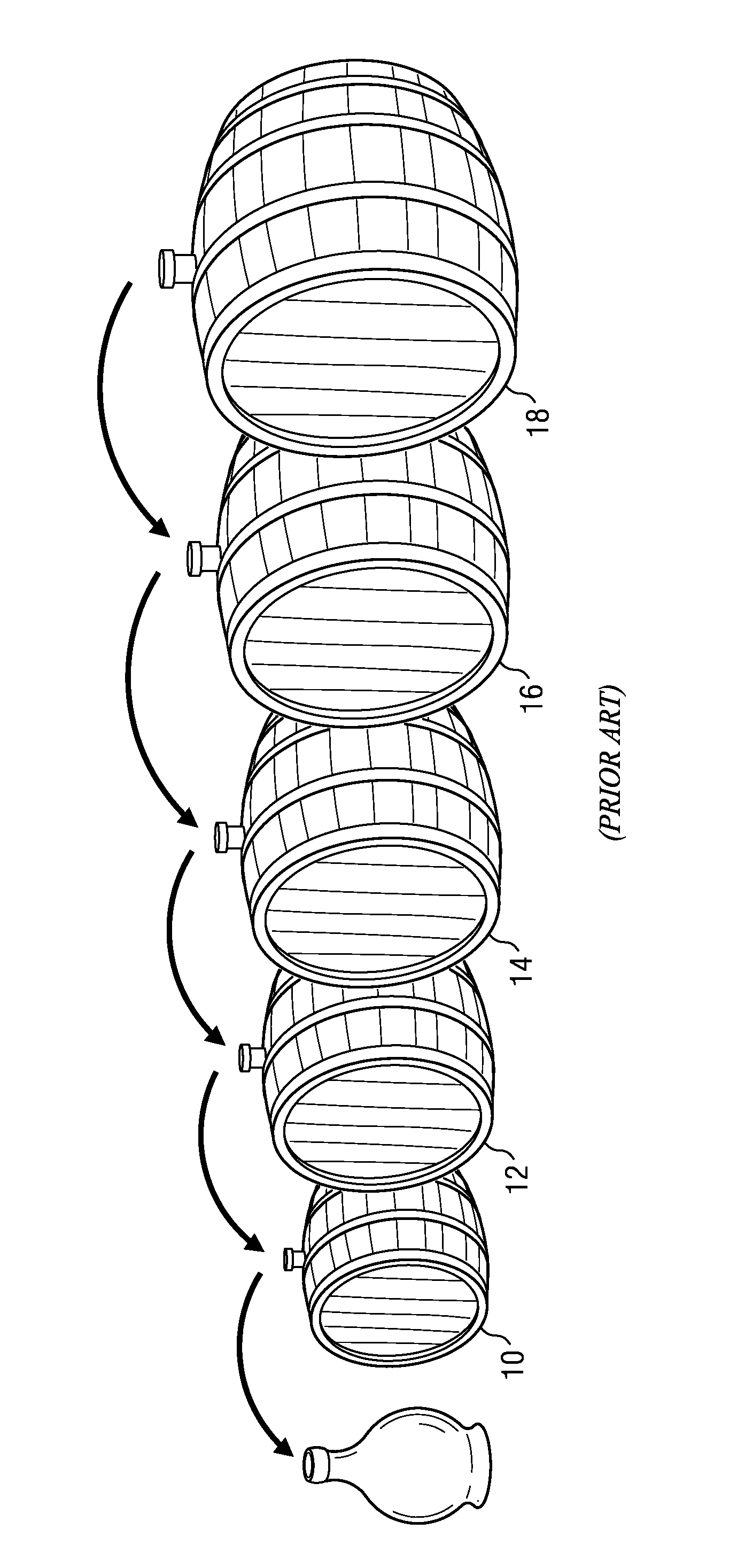

Baijiu storing and ageing method

InactiveCN105907589AImprove storage aging effectMethanol reductionAlcoholic beverage preparationAlcoholAge method

The invention relates to a Baijiu storing and ageing method, and belongs to the technical field of Baijiu brewing. By changing the storage container, environment, time and method in the Baijiu brewing process, the quality of Baijiu is improved. The method includes the early stage of storing and ageing, the middle stage of storing and ageing and the later stage of storing and ageing. The Baijiu storing and ageing effect is improved, the content of impurities, namely methyl alcohol and fusel oil in liquor is reduced by 20% or above, the sensory judgment result is remarkably better than that of a traditional Baijiu storing and ageing method, the storing cycle is shortened by 25%, and production cost is reduced.

Owner:信丰恒隆麦饭石酒业有限公司

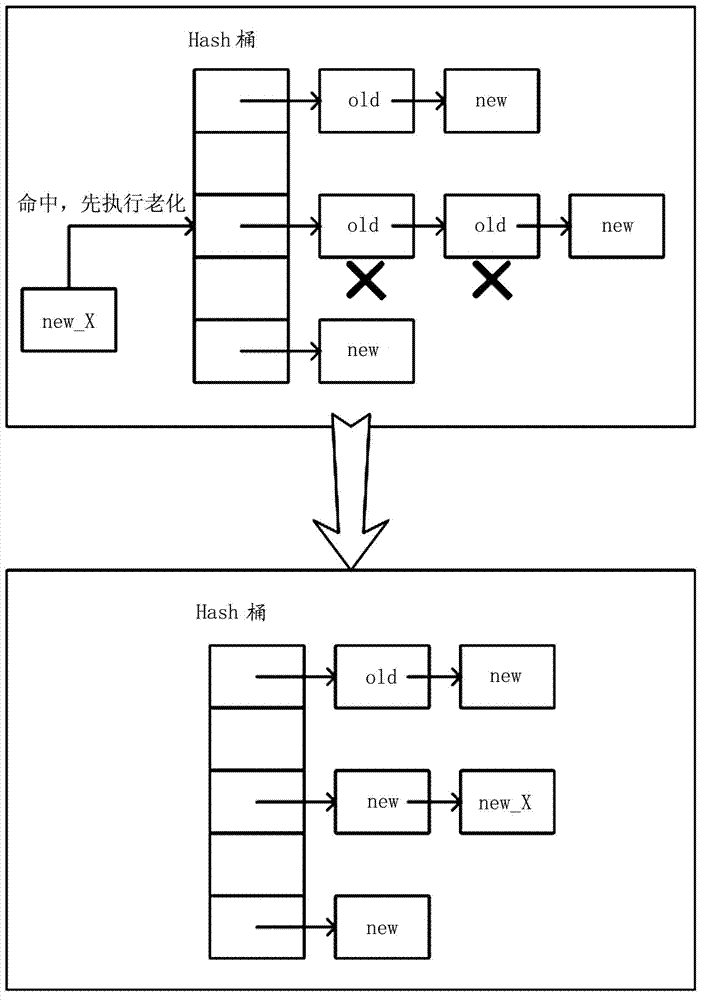

Stream aging method and network appliance

InactiveCN101247353AAvoid early terminationSave resourcesNetworks interconnectionAge methodOperating system

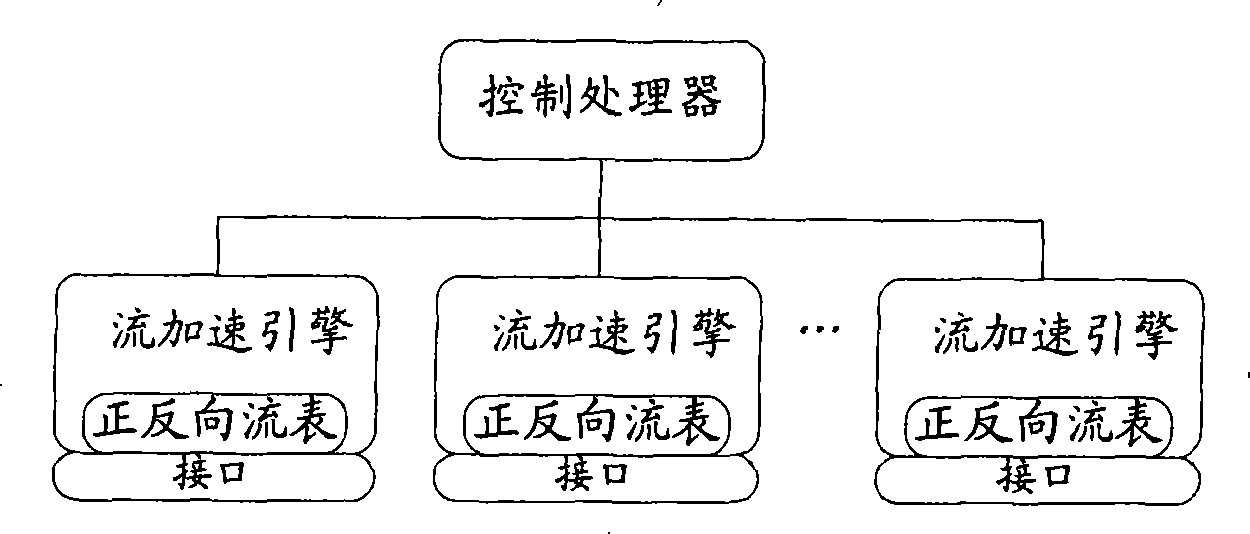

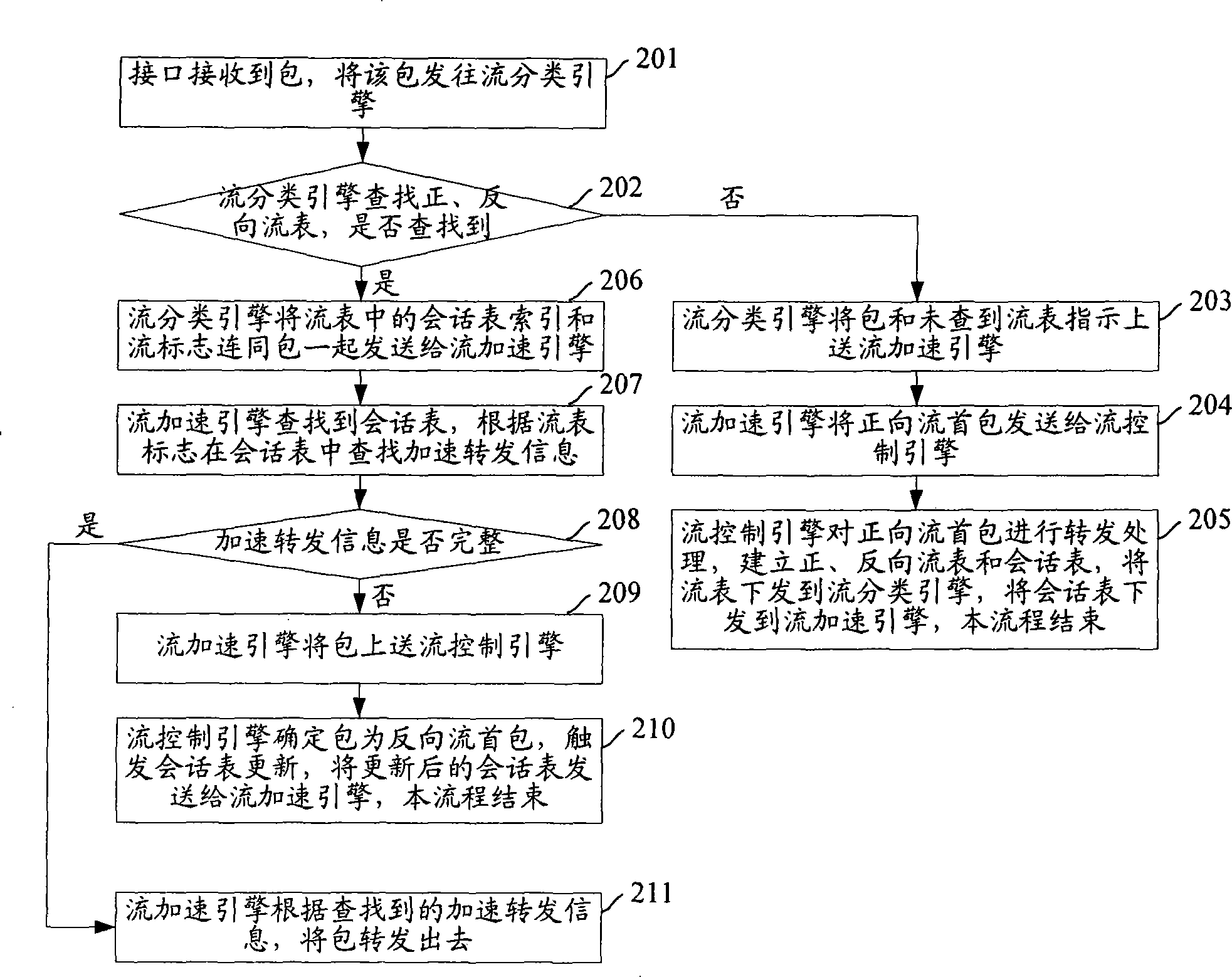

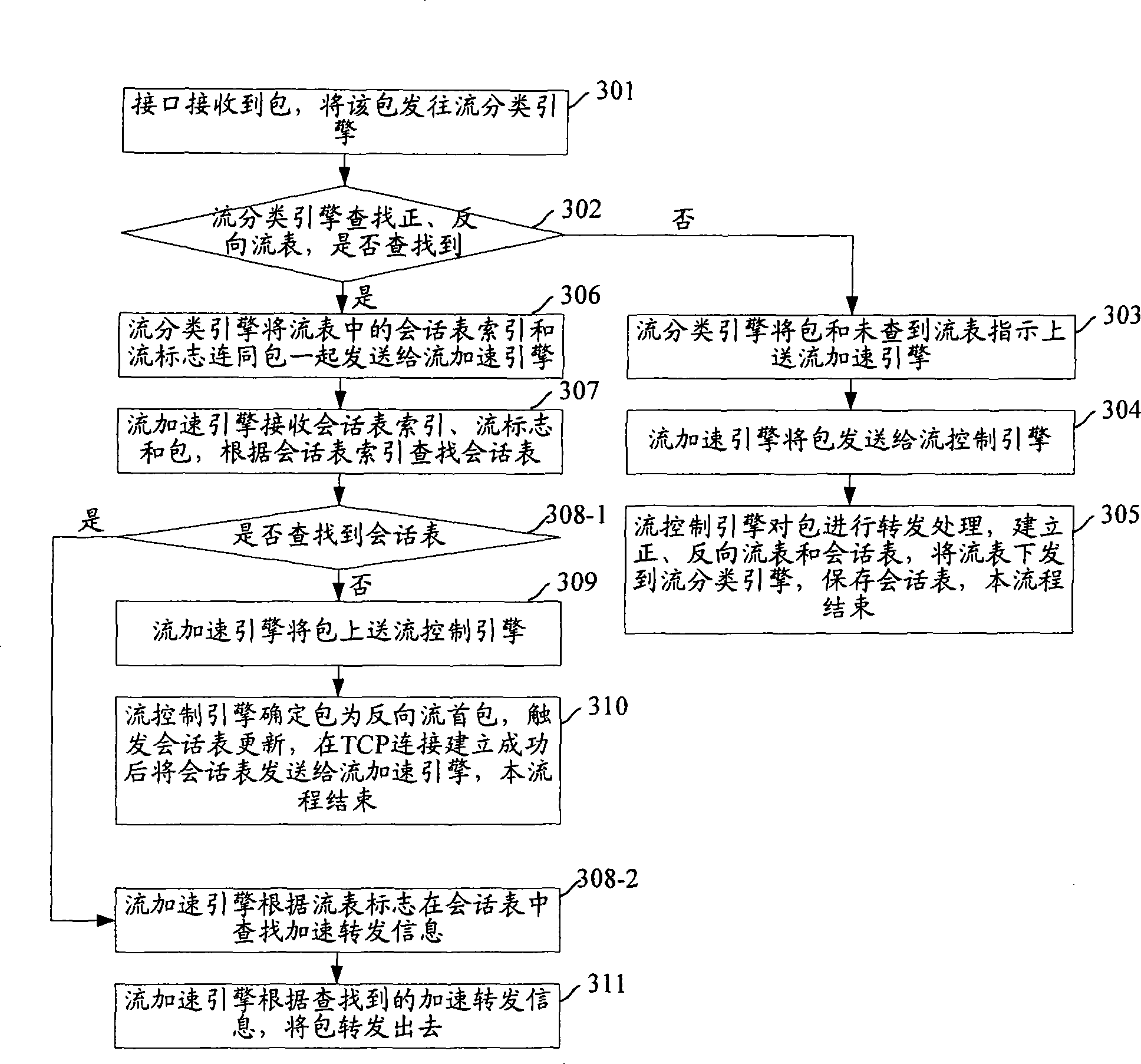

The invention discloses a stream aging method and network device. The method comprises steps of: establishing a forward directional stream table, a reverse directional stream table and a session table, wherein the forward and reverse directional stream tables comprise identifier information and a session table index of the stream, the session table comprises accelerating transmitting information of the forward and reverse directional streams; receiving the forward and reverse directional stream packages, searching the forward and reverse directional stream tables according to the identifier in the package; searching the session table according to the session table index in the stream table; transmitting the package according to the accelerating transmitting information in the session table; when the session table hit exceeds, deleting the session table and corresponding forward and reverse directional stream tables. The invention relates the forward and reverse directional stream tables with unified session tables. Stream aging depends on aging of the session tables, which avoids session early termination caused by unilateral stream termination and saves resources.

Owner:NEW H3C TECH CO LTD

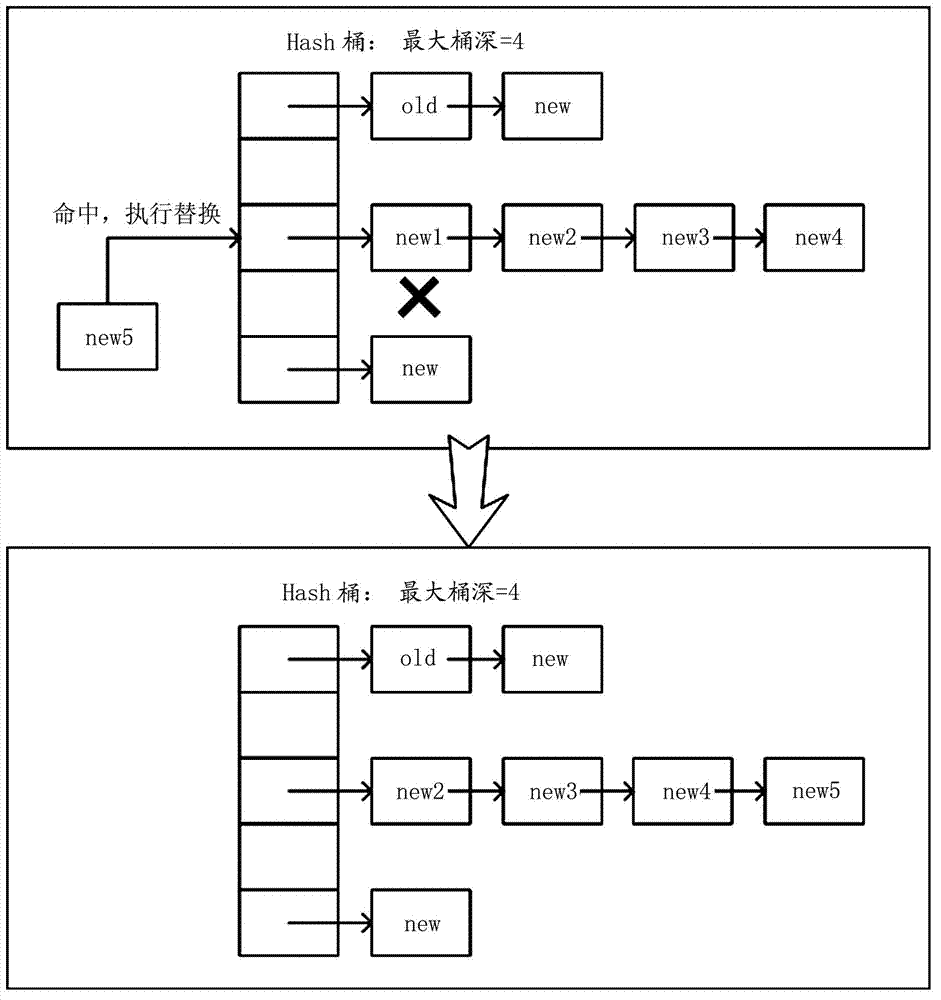

Flow table aging method and device of quick forwarding engine, and switch

ActiveCN102780641AImprove effectivenessIncrease forwarding rateData switching networksAge methodSoftware engineering

The invention provides a flow table aging method and device of a quick forwarding engine, and a switch. The flow table aging method of the quick forwarding engine comprises the following step: when Hash is matched with a Hash bucket comprising at least one flow table item through five-element information in a flow table in the form of a Hash table, deleting the flow table items of which the creating time is longer than a preset time period according to a creating time stamp of each flow table item in the matched Hash bucket.

Owner:BEIJING HAN NETWORKS TECH CO LTD

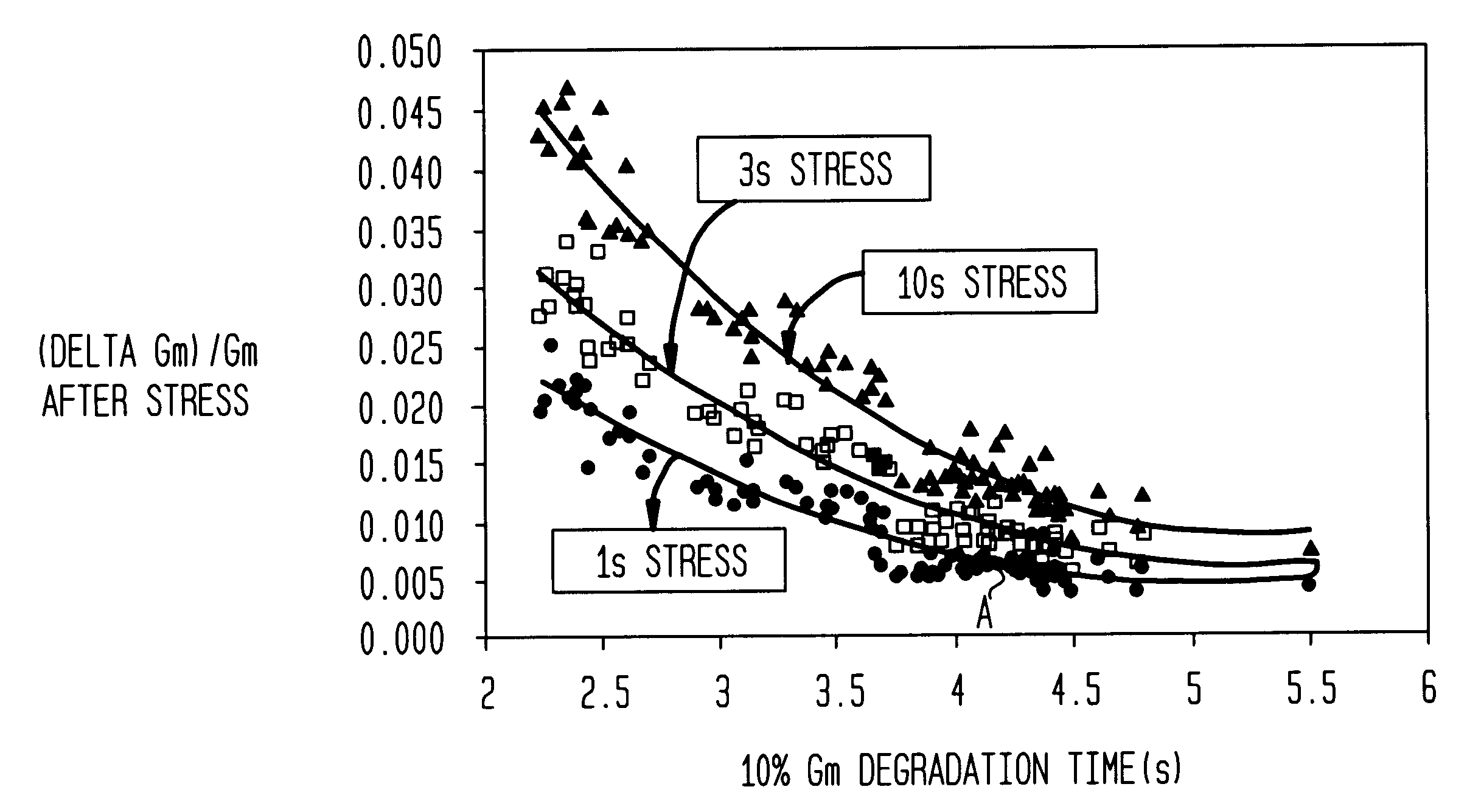

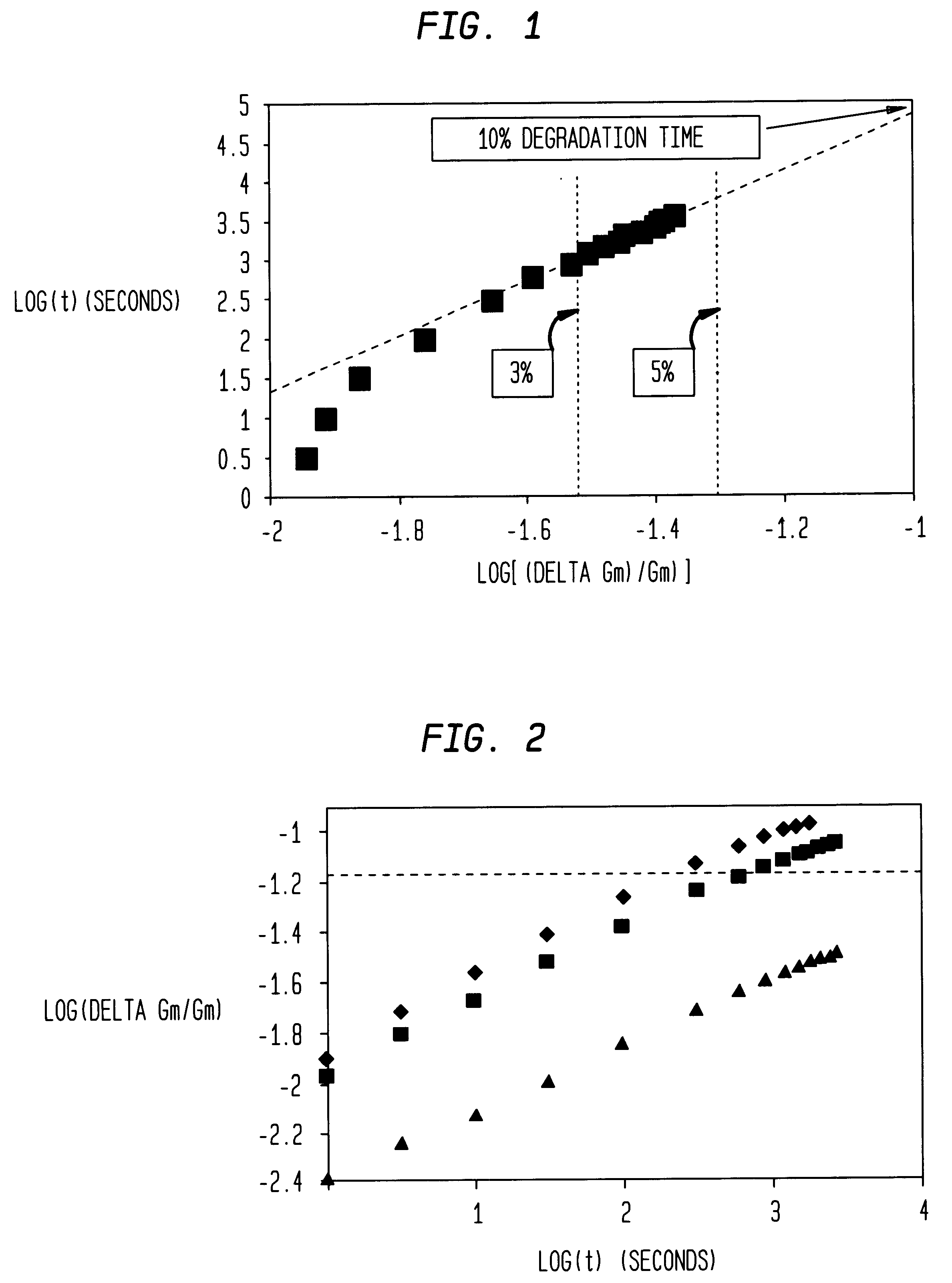

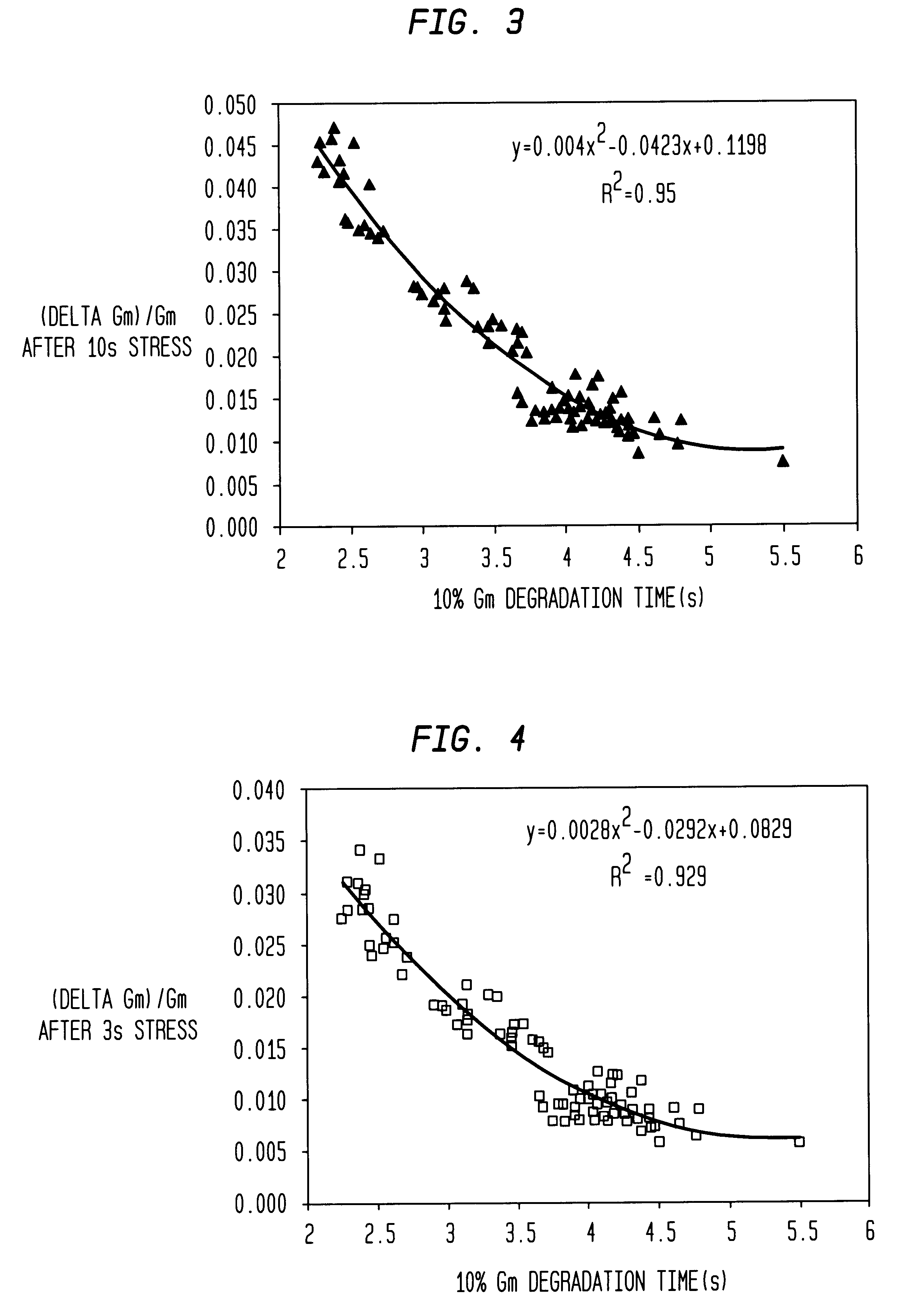

Using fast hot-carrier aging method for measuring plasma charging damage

InactiveUS6524872B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAge methodTime efficient

The invention relates to the measurement and monitoring of plasma-damage, and to the evaluation of the lifetime of integrated circuits under nominal operating conditions. The method calculates the intrinsic, or damage-free, lifetime of a particular transistor device by measuring the change in transconductance as a function of time for a given device over a short period of time. The change in the transconductance as a function of time, i.e., the slope of the degradation curve, is measured and then compared to a reference value. The present invention thus allows the use of hot-carrier stress method to determine plasma damage in a time efficient manner without the need of applying high acceleration voltages.

Owner:BELL SEMICON LLC +1

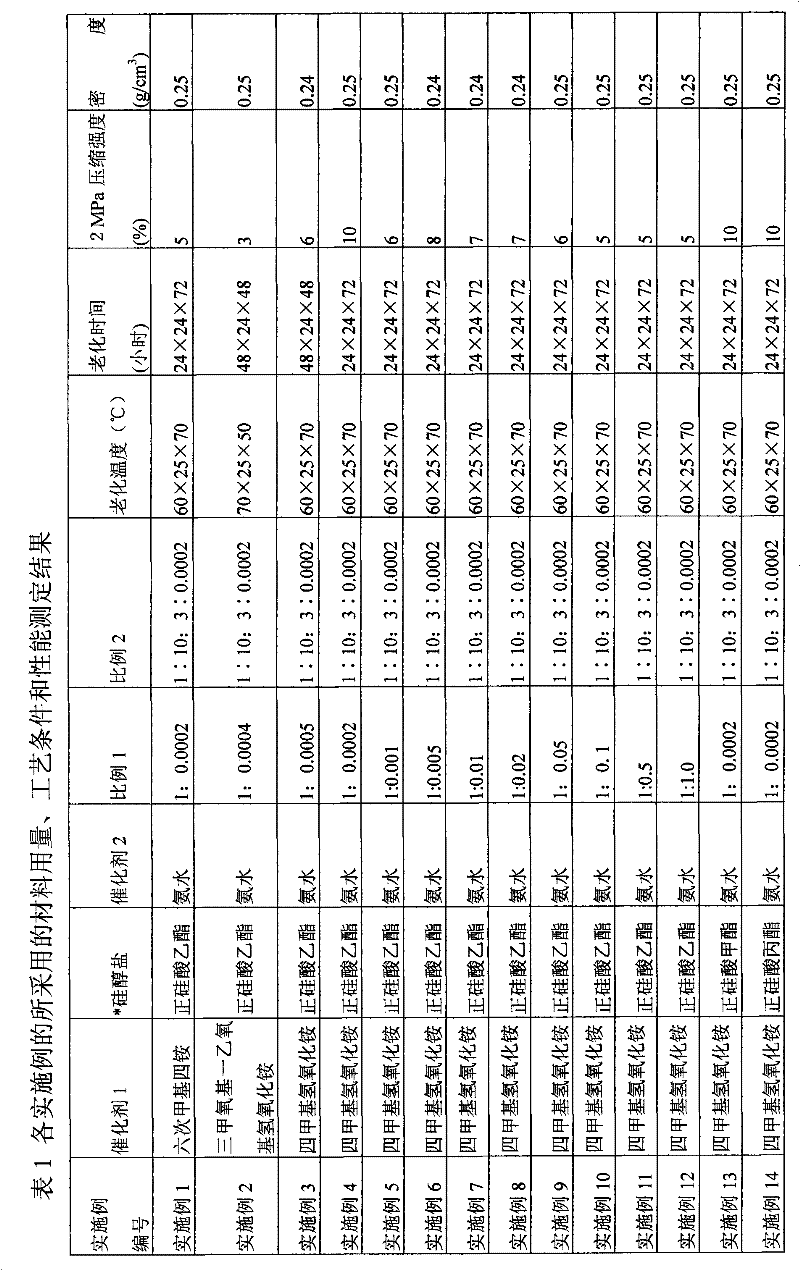

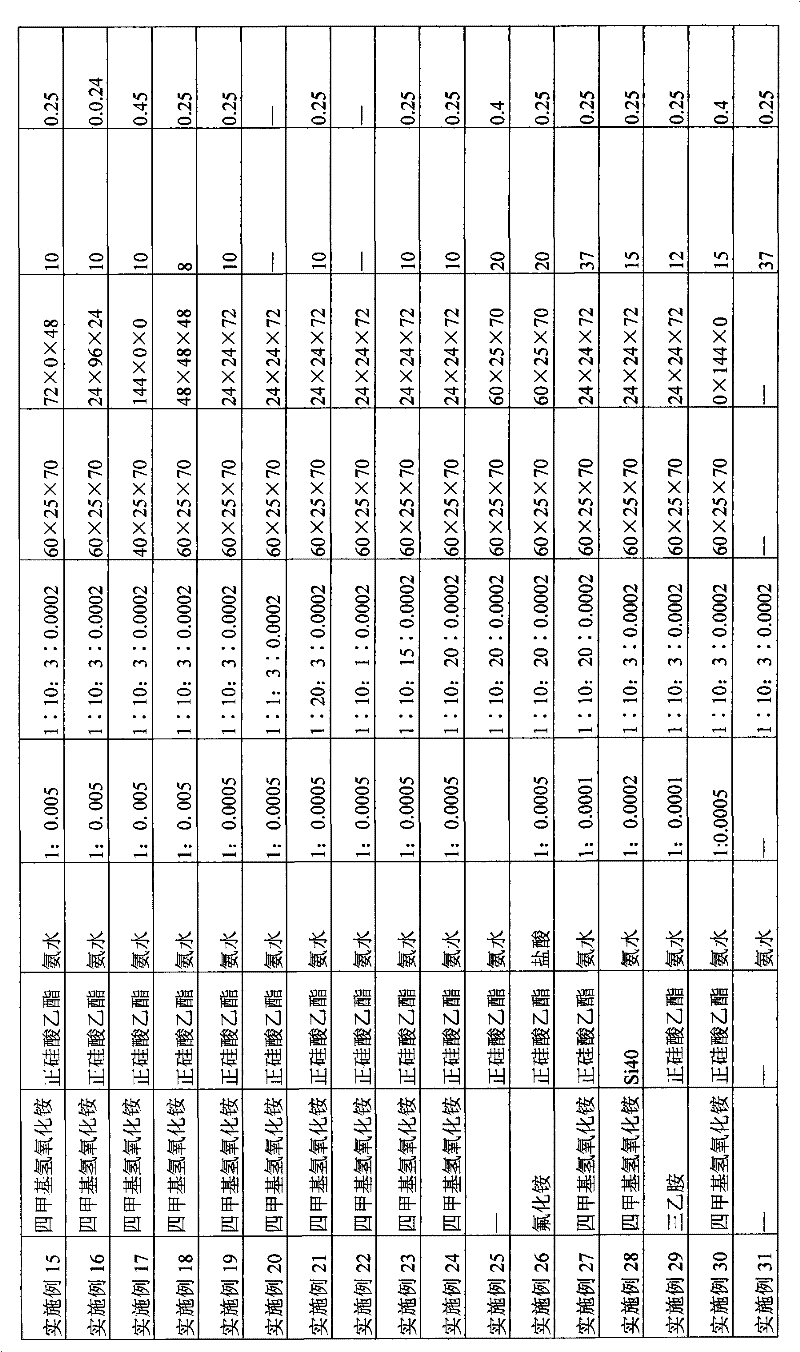

Method for improving strength of aerogel composite material

ActiveCN102515181AHigh strengthIncrease the degree of reaction polymerizationSilicaBulk chemical productionAge methodFiber

The invention relates to a method for improving the strength of a silica aerogel composite material, particularly to an ageing composition for ageing silicon wet gel, an ageing method for silicon wet gel and a method for preparing a fibre composite silicon aerogel material by the ageing method. The ageing composition contains silica-alkoxides and a catalyst, especially an alkalescent catalyst. The ageing method may be performed in conditions such as repeated heating. The fibre composite silicon aerogel material prepared by the method disclosed by the invention has the advantages of being good in thermal stability and high in strength of aerogel composite material. Moreover, the method is simple in process, high in safety, as well as low in equipment demand and investment.

Owner:海鹰空天材料研究院(苏州)有限责任公司

Flavouring compositions and methods for making same

InactiveUS20110318459A1Rapid manufacturing methodRapid productionFood shapingVinegar preparationAge methodFlavouring agent

Methods for synthesizing traditional balsamic vinegar, conventional balsamic vinegar, and Parmesan cheese flavouring compositions are provided for easily synthesizing these flavourings for use in or with food products for flavour addition, enhancement, and / or substitutes for flavourings typically obtained only after long aging methods.

Owner:FRITO LAY TRADING CO GMBH

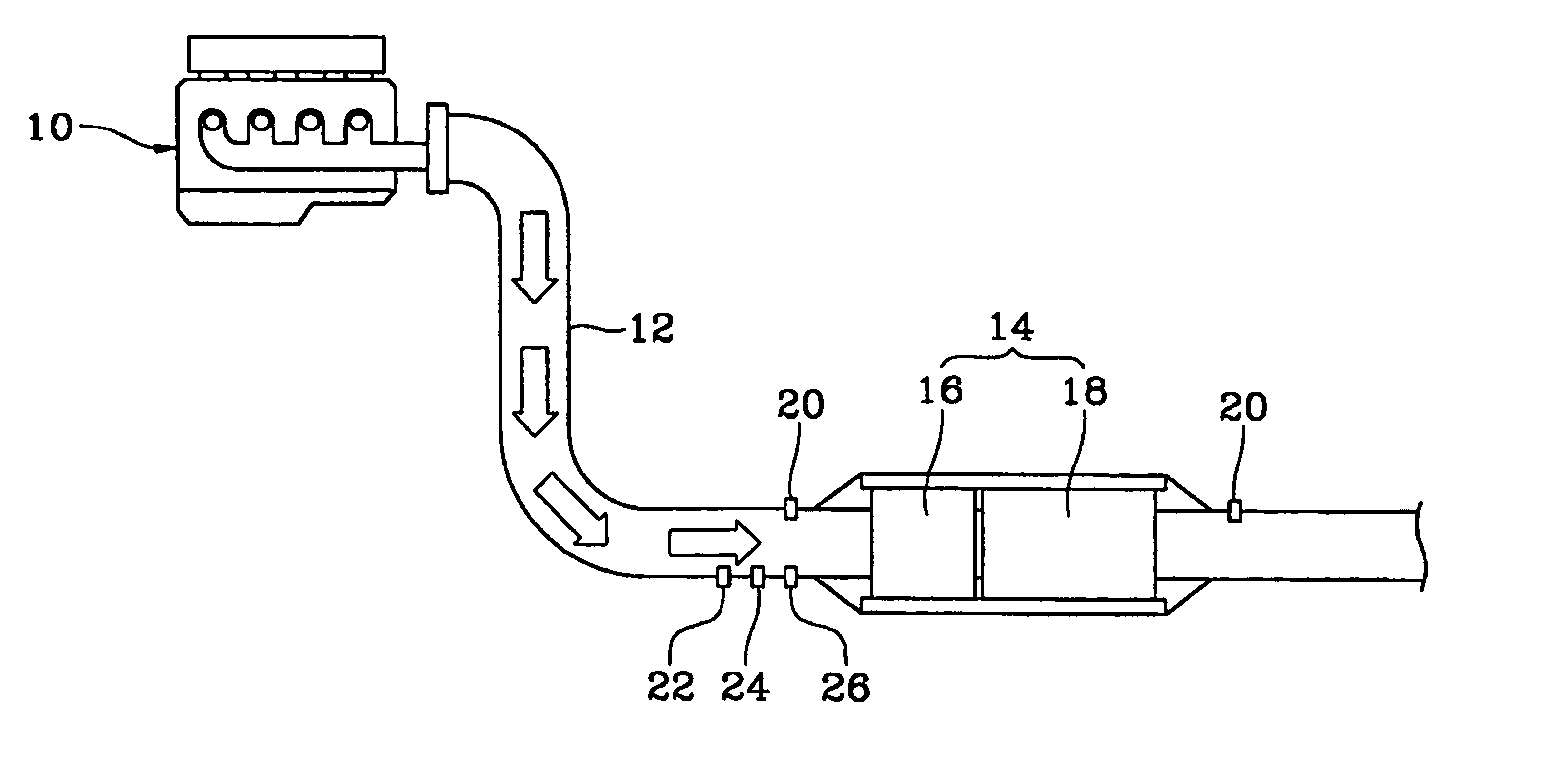

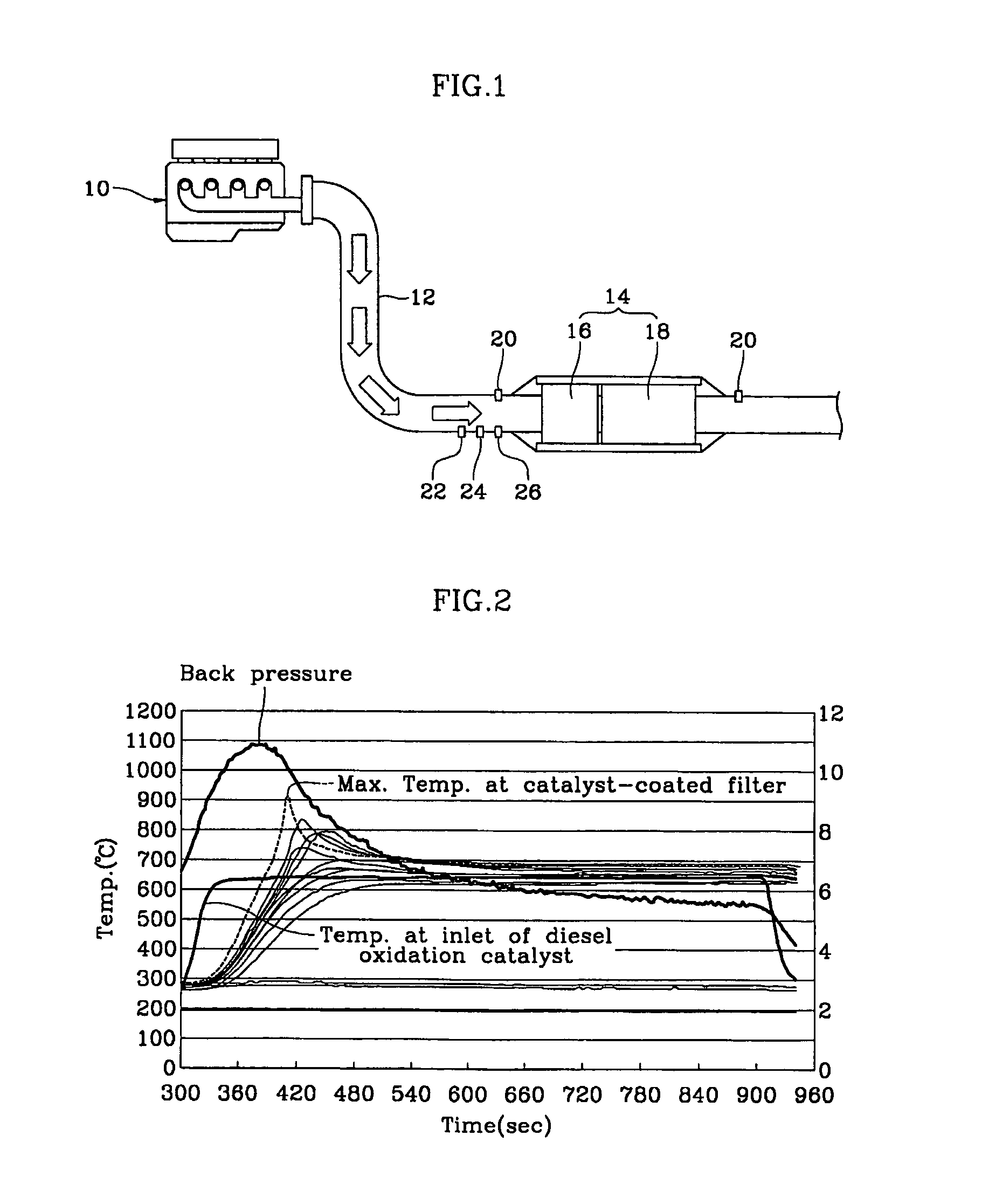

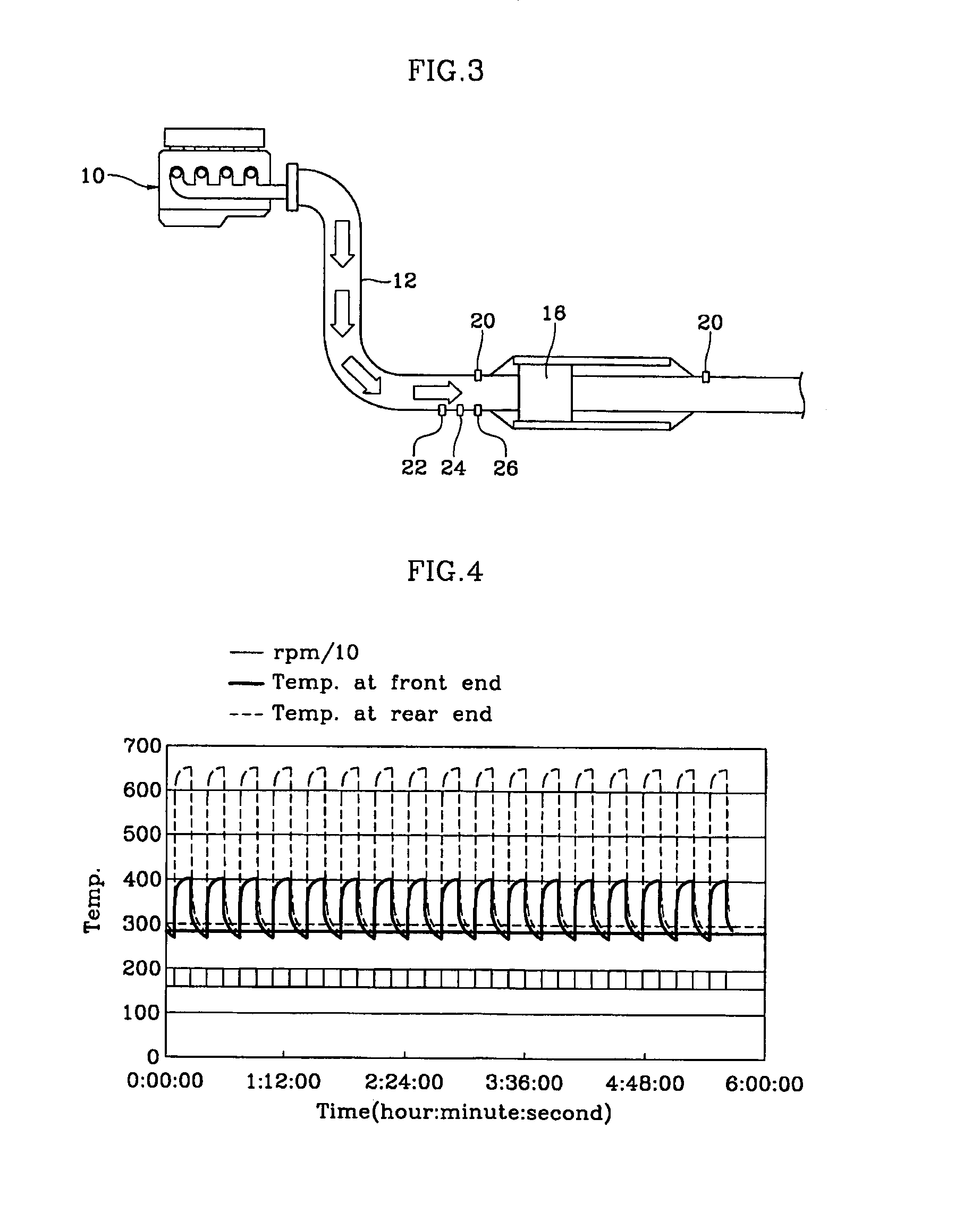

Method for aging catalyzed particulate filter system

ActiveUS7174779B1Shorten the timeLow costInternal combustion piston enginesExhaust apparatusAge methodFilter system

Disclosed herein is an aging method which can support an aging test for a catalyzed diesel particulate filter system through the post-injection of fuel according to a regeneration logic for a filter, thereby remarkably reducing the time and cost necessary for developing new diesel vehicles that meet regulations relevant to exhaust gas.

Owner:HYUNDAI MOTOR CO LTD

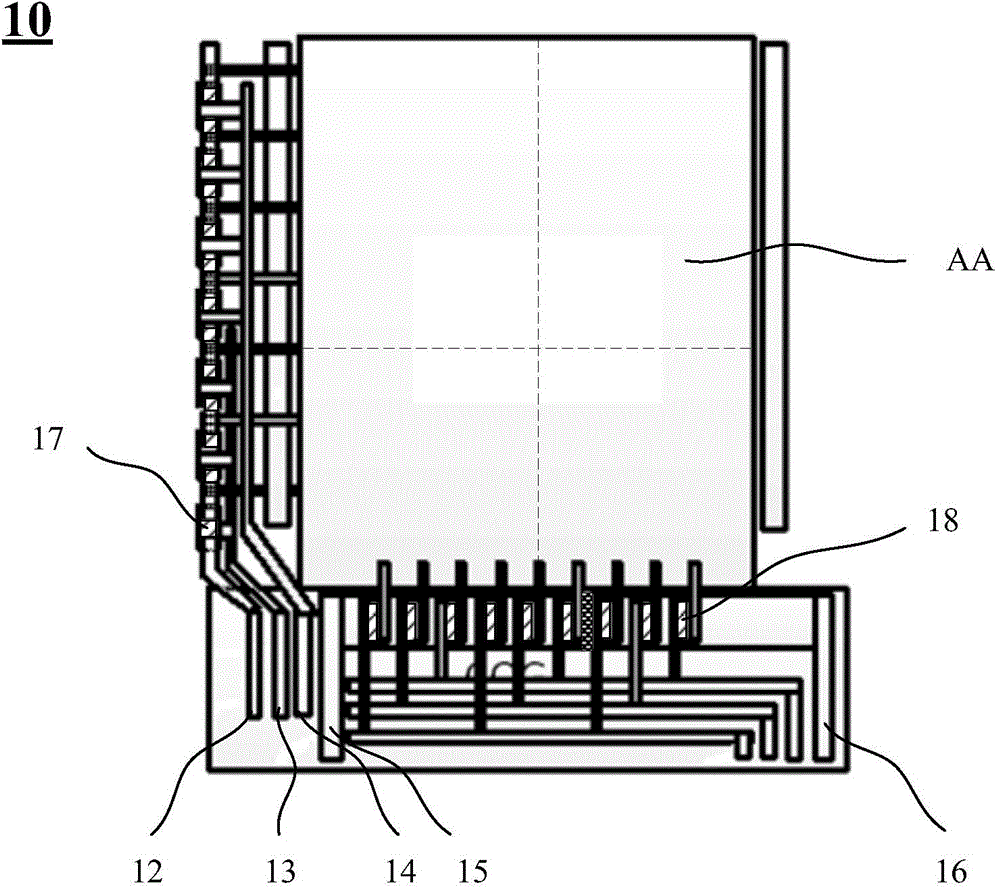

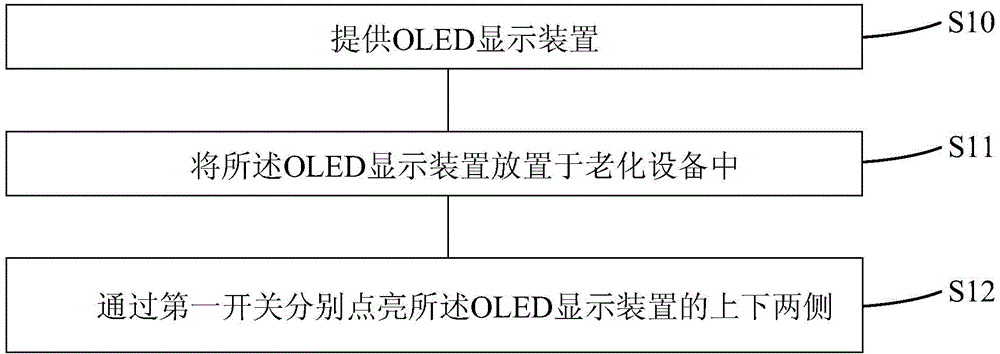

OLED display device and aging method thereof

InactiveCN105788510ASmall pressure dropAvoid Large Differences in CurrentStatic indicating devicesAge methodPower flow

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

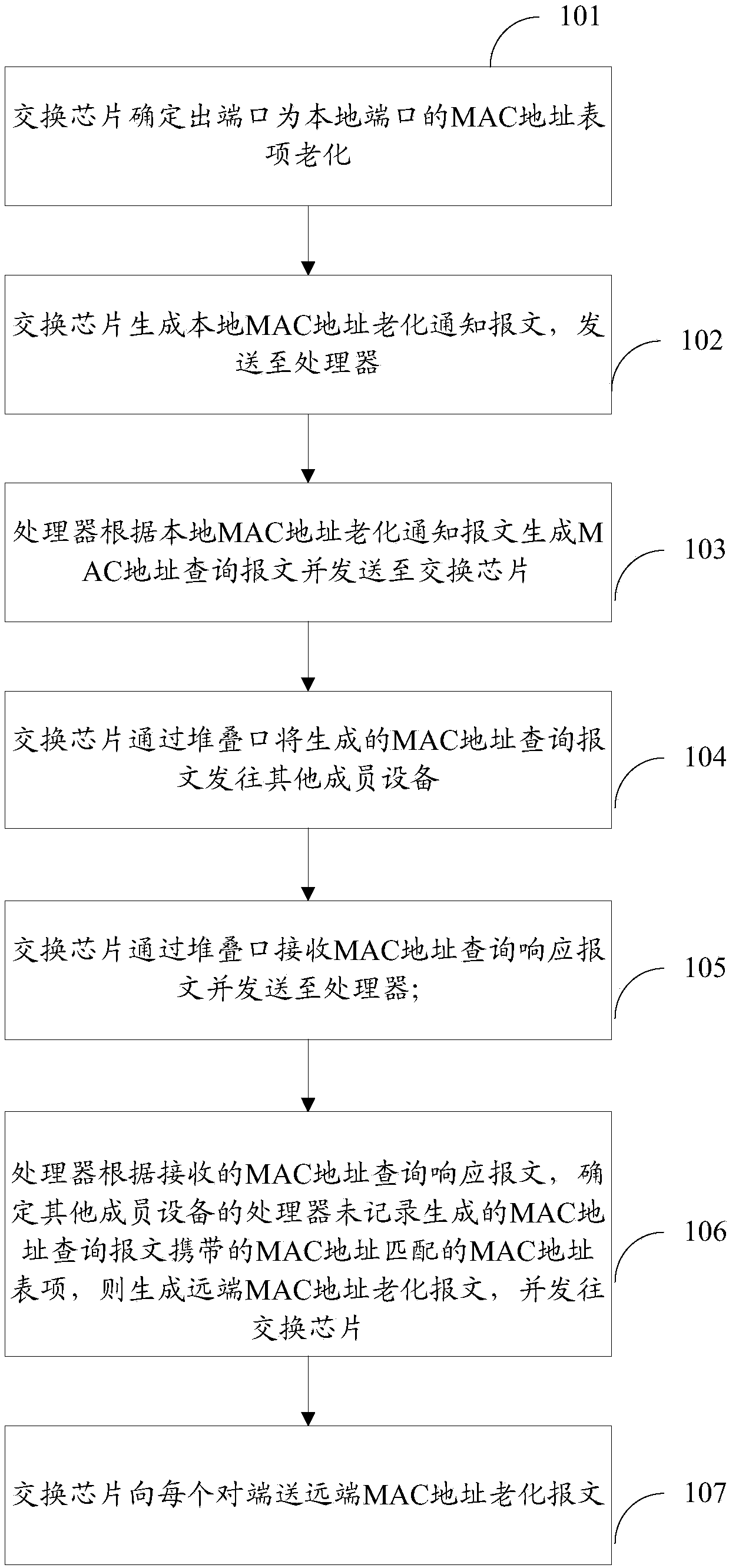

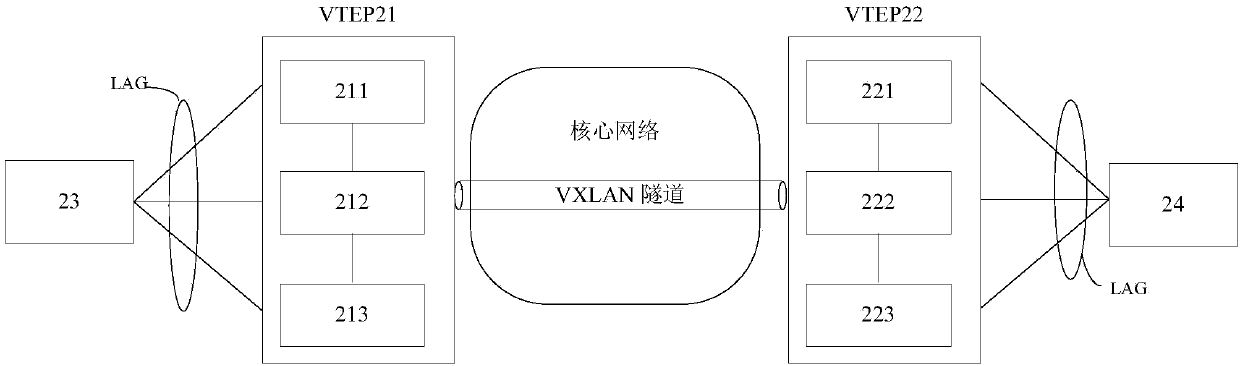

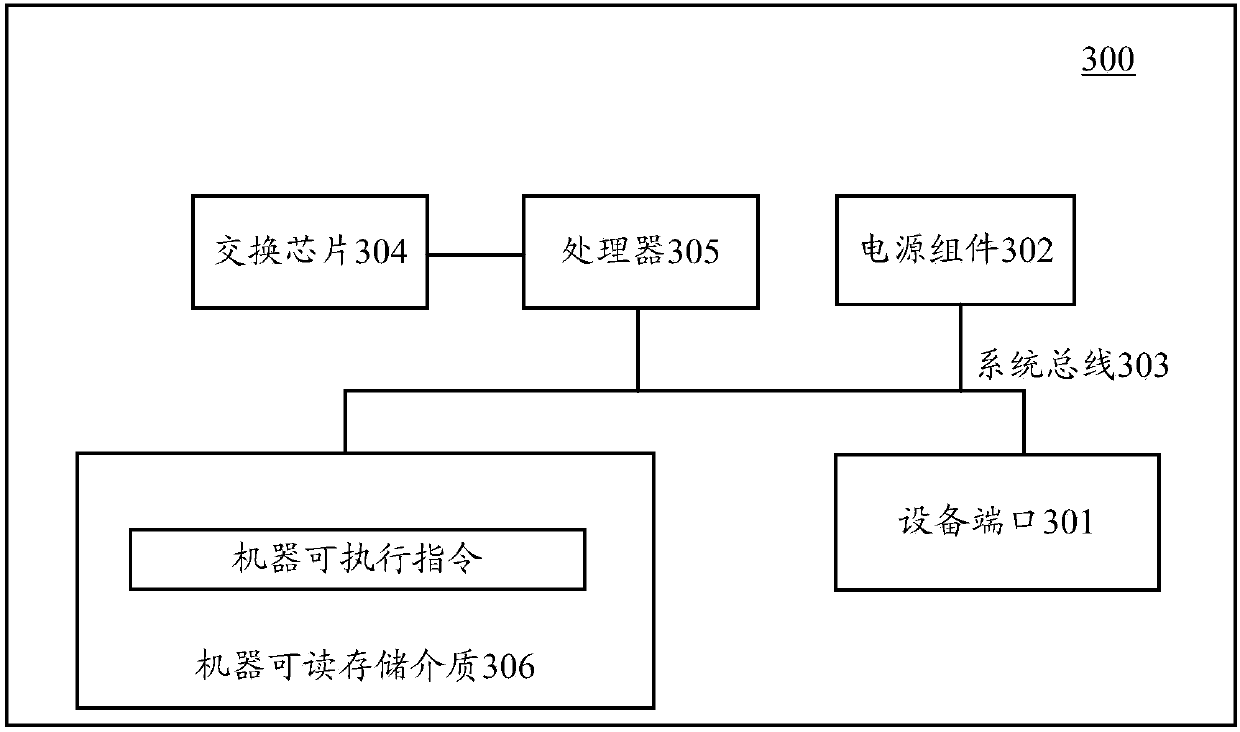

Address ageing method and device

The invention provides an address ageing method and device applied to member equipment used as a stack system of a virtual extensible local area network VXLAN tunnel terminal. In the device, a switchchip determines that a port is the MAC address entry ageing of a local port, and generates a local MAC address ageing notification message to send to a processor; the processor generates a MAC addressquery message according to the local MAC address ageing notification message and sends the same to the switch chip; the switch chip sends the generated MAC address query message to other member equipment through a stacking port, and receives a MAC address query response message through the stacking port and sends the same to the processor; the processor determines this equipment as the last service processing equipment according to the MAC address query response message received from other member equipment, and then generates a remote MAC address ageing message and sends the same to the switch chip; the switch chip ensures that the aged MAC addresses of all member equipment of the stack system are notified to other opposite ends by connecting the each opposite end to send the remote MAC address ageing message.

Owner:NEW H3C TECH CO LTD

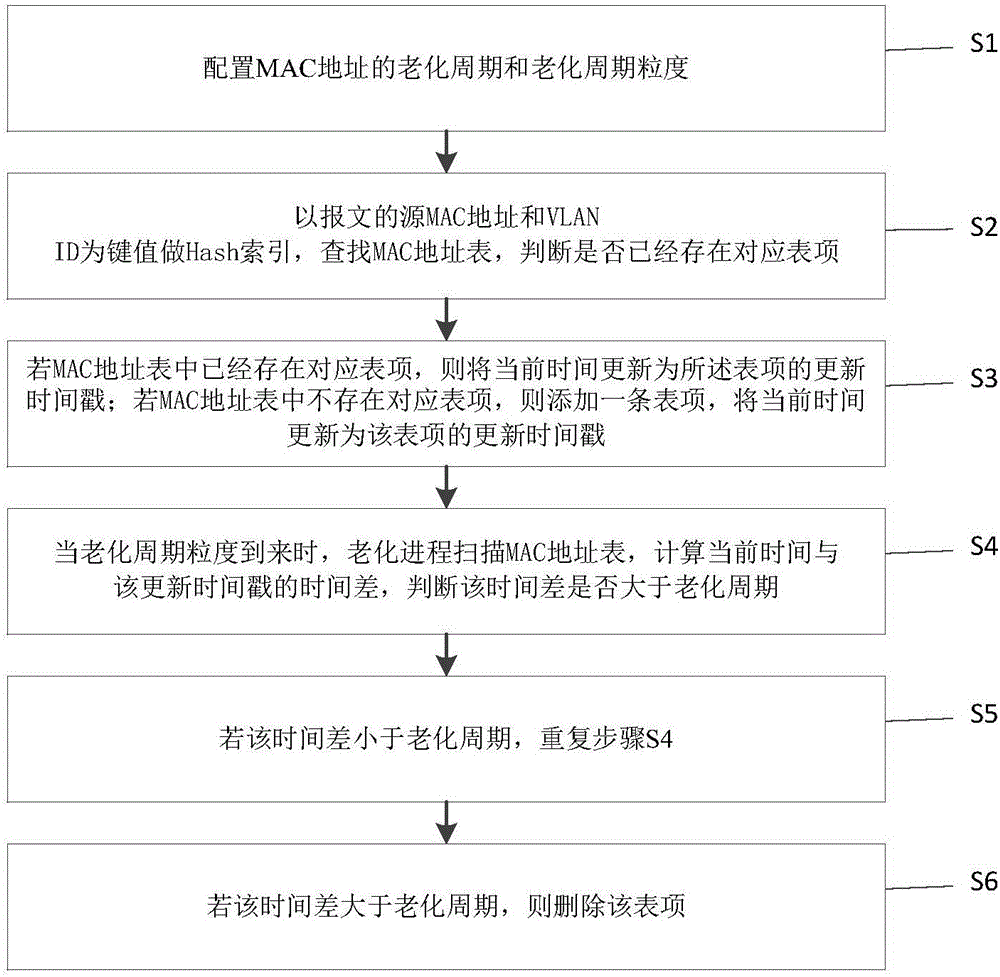

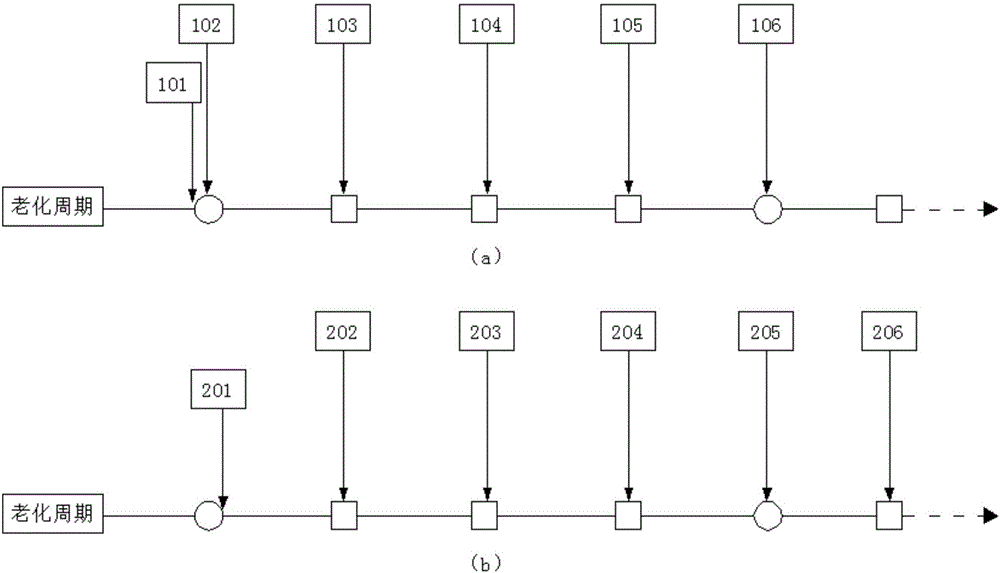

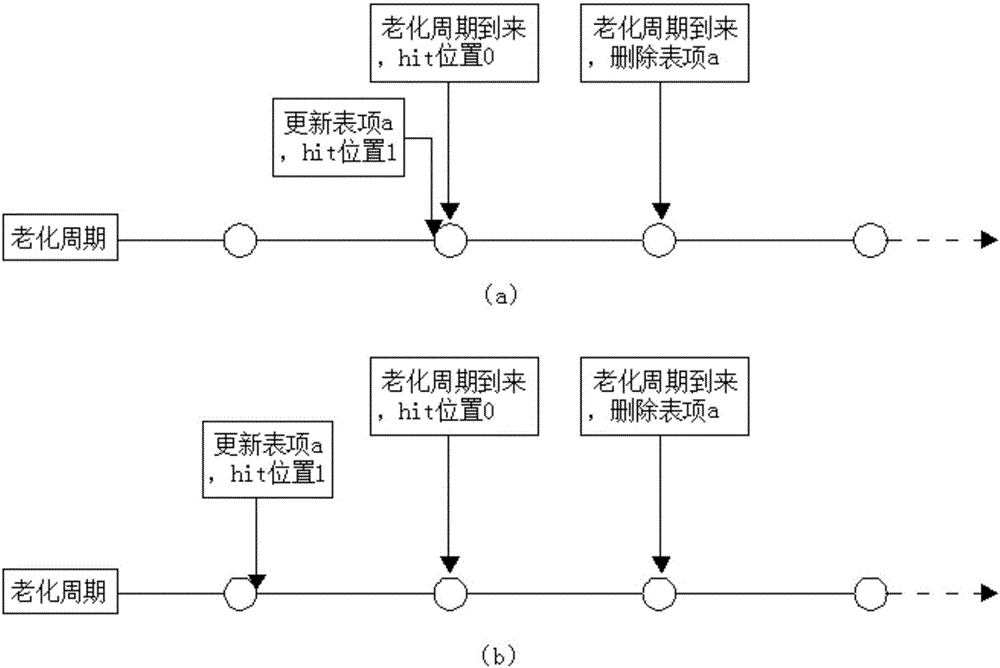

Switcher MAC address aging method

InactiveCN105959430AForwarding behavior is accurateImprove effective utilizationTransmissionAge methodGranularity

The invention provides a switcher MAC address aging method, and the method comprises the following steps: S1, configuring the aging period and granularity of an MAC address; S2, taking the source MAC address and VLAN ID of a message as key values, making a Hash index, and judging whether there is already a corresponding item or not; S3, updating the current time as an updated time stamp of a table item if the corresponding table item is in an MAC address list, or else, adding one table item, and updating the current time as the updated time stamp of the table item; S4, scanning the MAC address list in an aging process when the aging period granularity arrives, calculating the time difference between the current time and the updated time stamp, and judging whether the time difference is greater than an aging period or not; S5, repeatedly carrying out the step S4 if the time difference is less than the aging period; S6, deleting the table item if the time difference is greater than the aging period. The method reduces the error of aging time, enables the forwarding behavior of a switcher to be more accurate, and improves the effective utilization rate of the MAC address list.

Owner:SHENZHEN FORWARD IND CO LTD

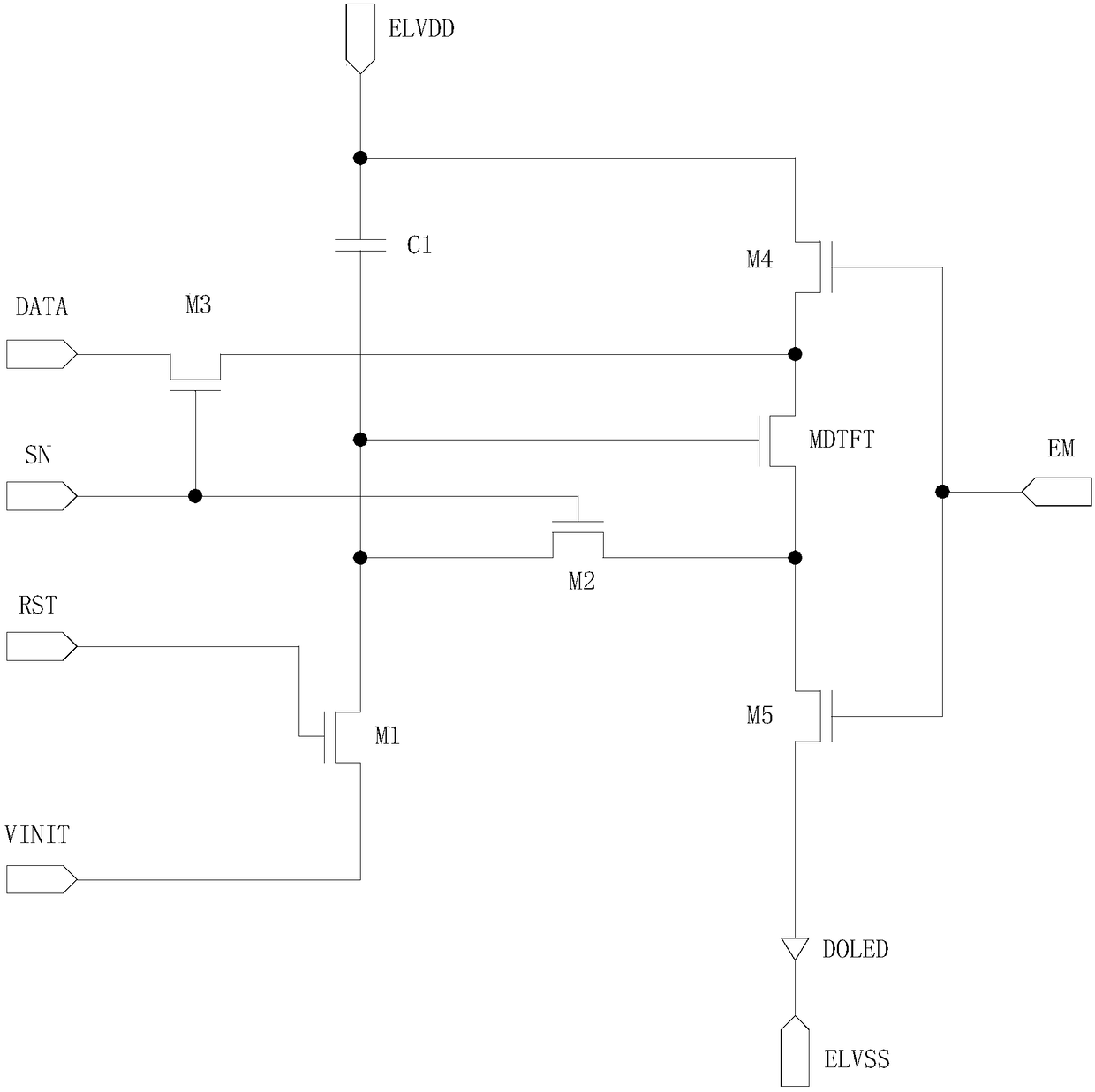

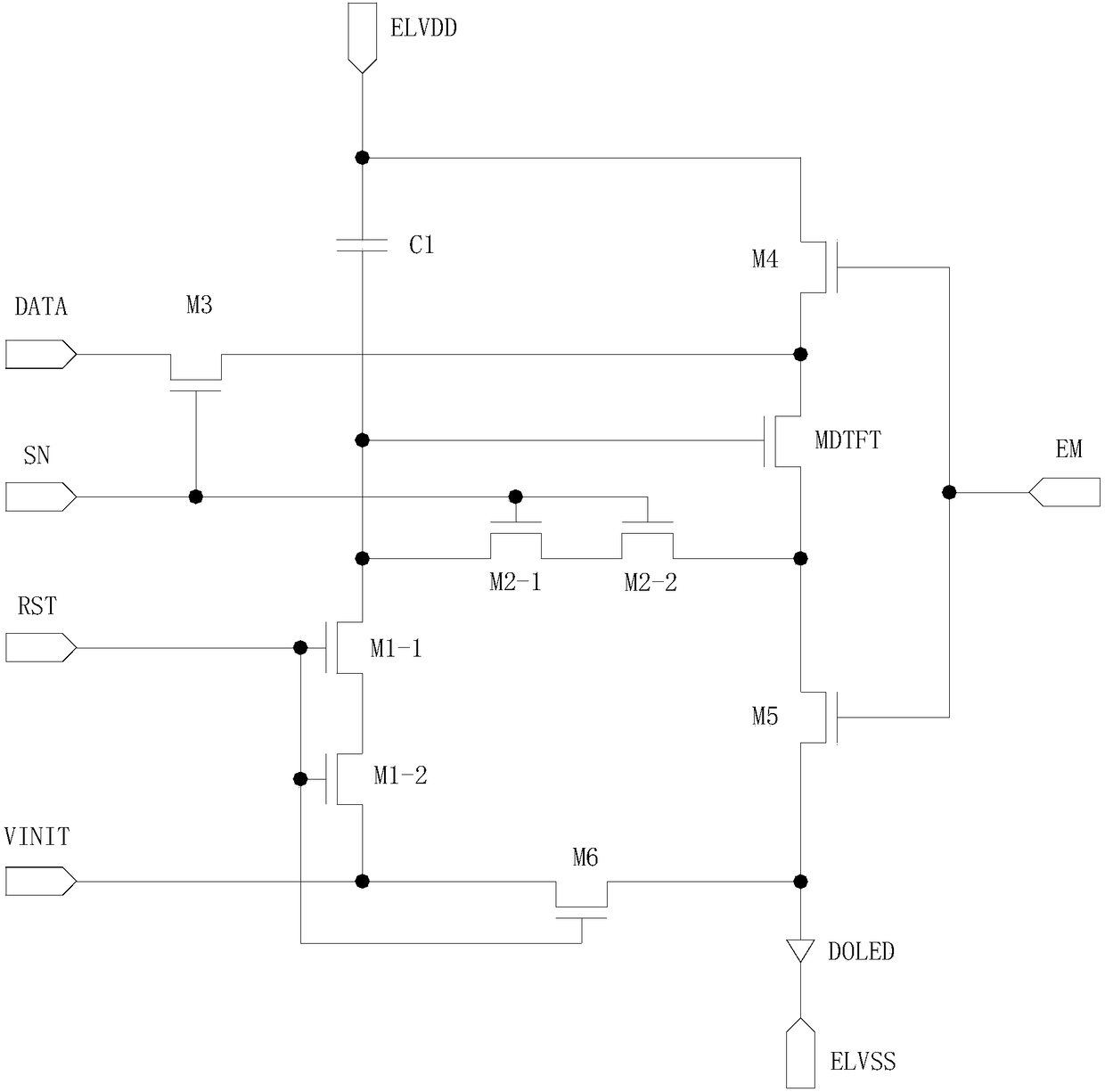

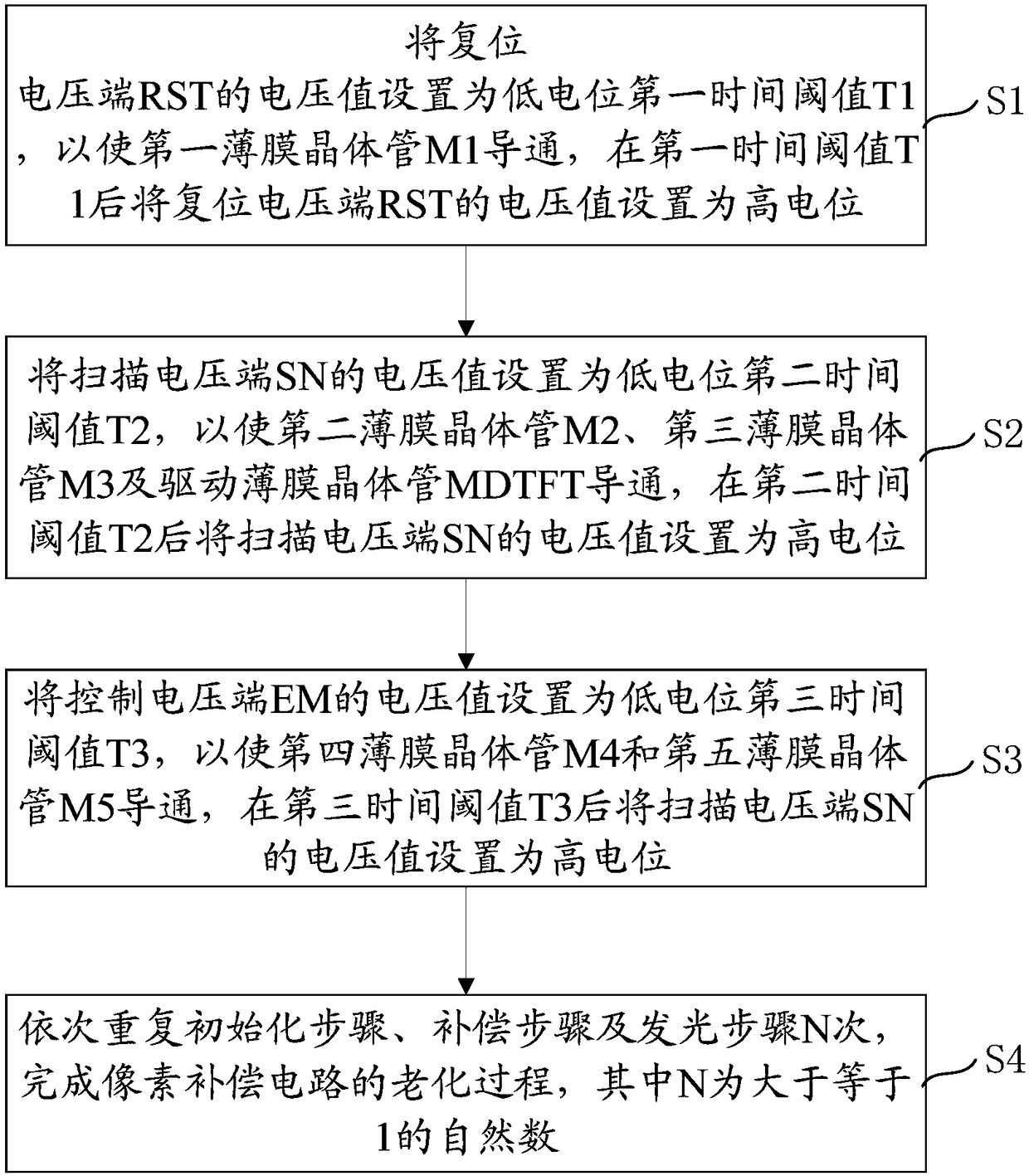

Pixel compensation circuit and aging method thereof

InactiveCN108288454AFast and efficient initializationAchieve reverse biasStatic indicating devicesAge methodEngineering

A pixel compensation circuit and an aging method thereof are disclosed. The pixel compensation circuit comprises a first thin film transistor, a second thin film transistor, a third thin film transistor, a fourth thin film transistor, a fifth thin film transistor, a driving thin film transistor, a capacitor, a luminous diode, a reset voltage end, an initial voltage end, a first voltage source end,a scanning voltage end, a data voltage end, a control voltage end and a second voltage source end, wherein the voltage value of the initial voltage end is greater than that of the first voltage source end, the voltage value of the data voltage end is greater than that of the initial voltage end, and the voltage value of the first voltage source end is greater than that of the second voltage source end. The pixel compensation circuit and the aging method rearrange the defective electrons of the drive thin film transistor MDTFT channel and interface in an abnormal working state by driving the reverse bias of the thin film transistor, thereby reducing the leakage current of the drive thin film transistor.

Owner:TRULY HUIZHOU SMART DISPLAY

Fermented red date wine and brewing method thereof

InactiveCN102051308AQuick peelFull bodiedMicroorganism based processesAlcoholic beverage preparationAge methodUltrafiltration

The invention discloses a brewing method of fermented red date wine and belongs to the technical field of wine brewing. The extraction of red date juice is finished by a method of heating extraction, enzymolysis and ultrasonic wave complex extraction, so that the juice extraction time is shortened and the juice yield is improved; and the brewing of the red date wine is finished by an artificial ageing method combining methods of adding oak sheets, ultrasonic wave ageing, high pressure impulse ageing and ultrafiltration, so that the red date wine ageing time is shortened, the labour and the production cost are saved, and the production efficiency and the enterprise interest are improved. The obtained red date wine has a full wine body, is rose or red, clear and transparent, and has pure, elegant, pleasant and harmonious fragrance of red date and wine.

Owner:山西悦卜林创业投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com