Power equipment fault rate prediction method considering aging factors

A technology for power equipment and aging factors, applied in prediction, calculation, instruments, etc., can solve the problems of ignoring the influence of power equipment aging factors and maintenance strategies, and not fully reflecting the distribution of equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

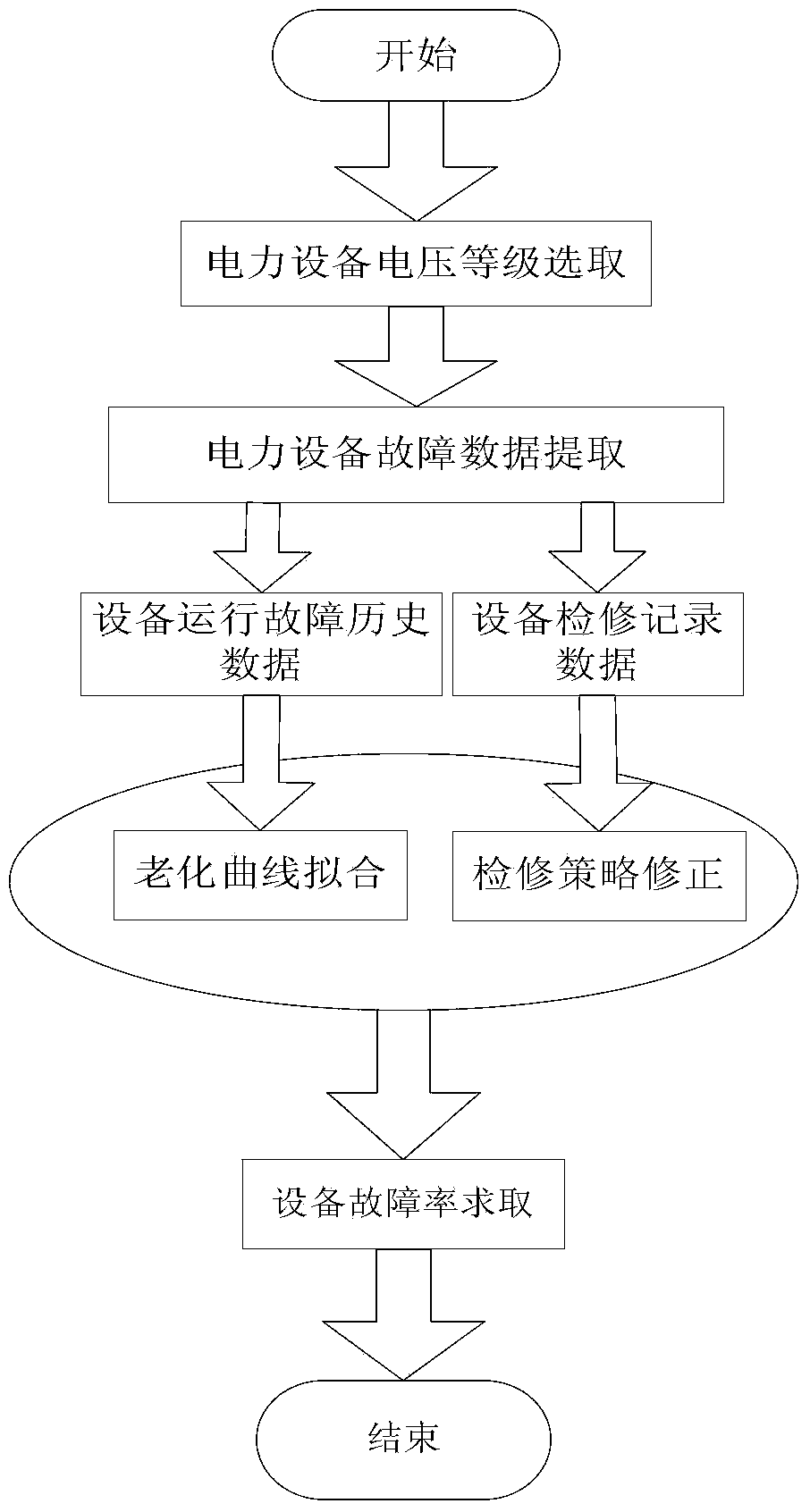

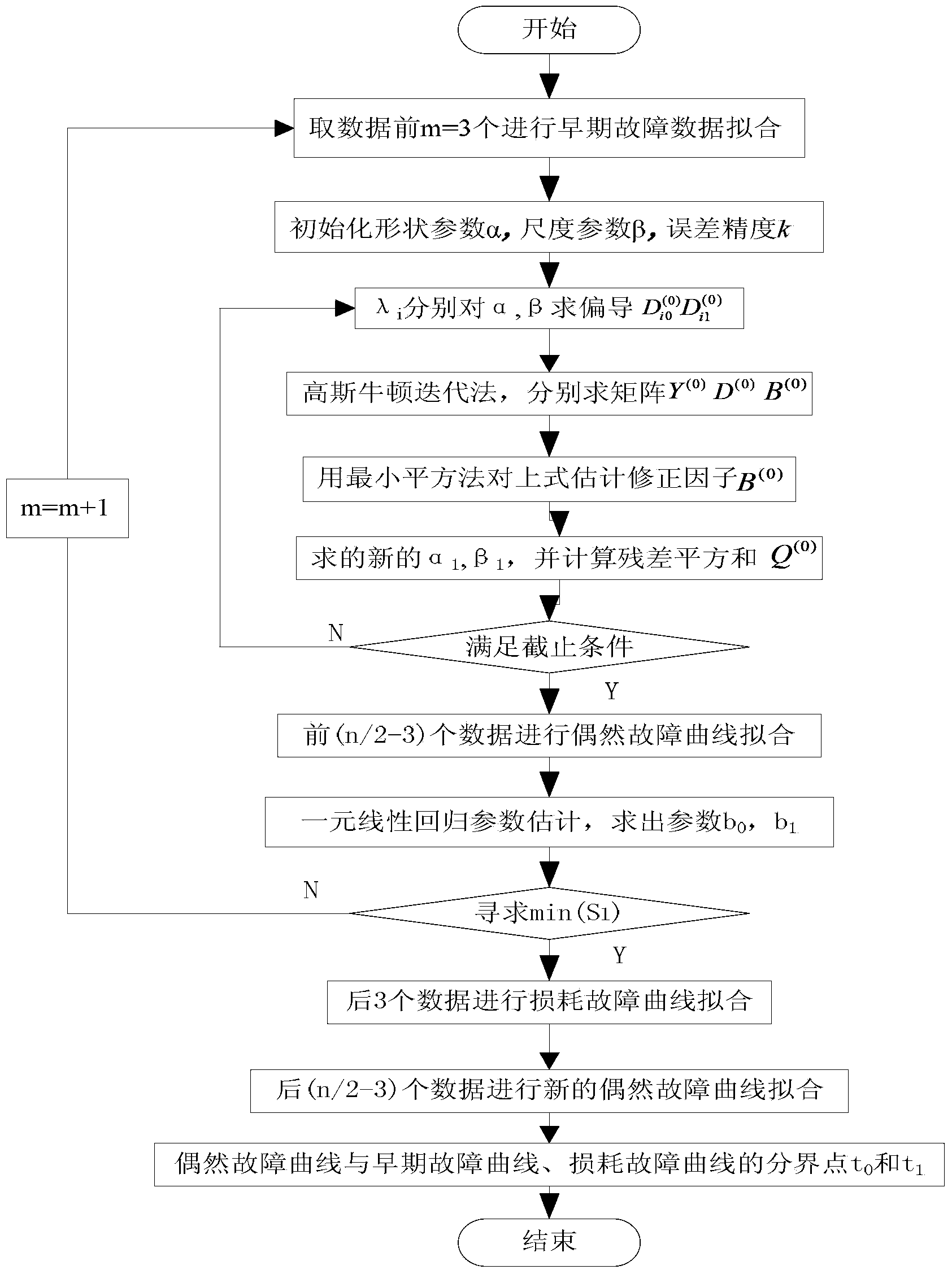

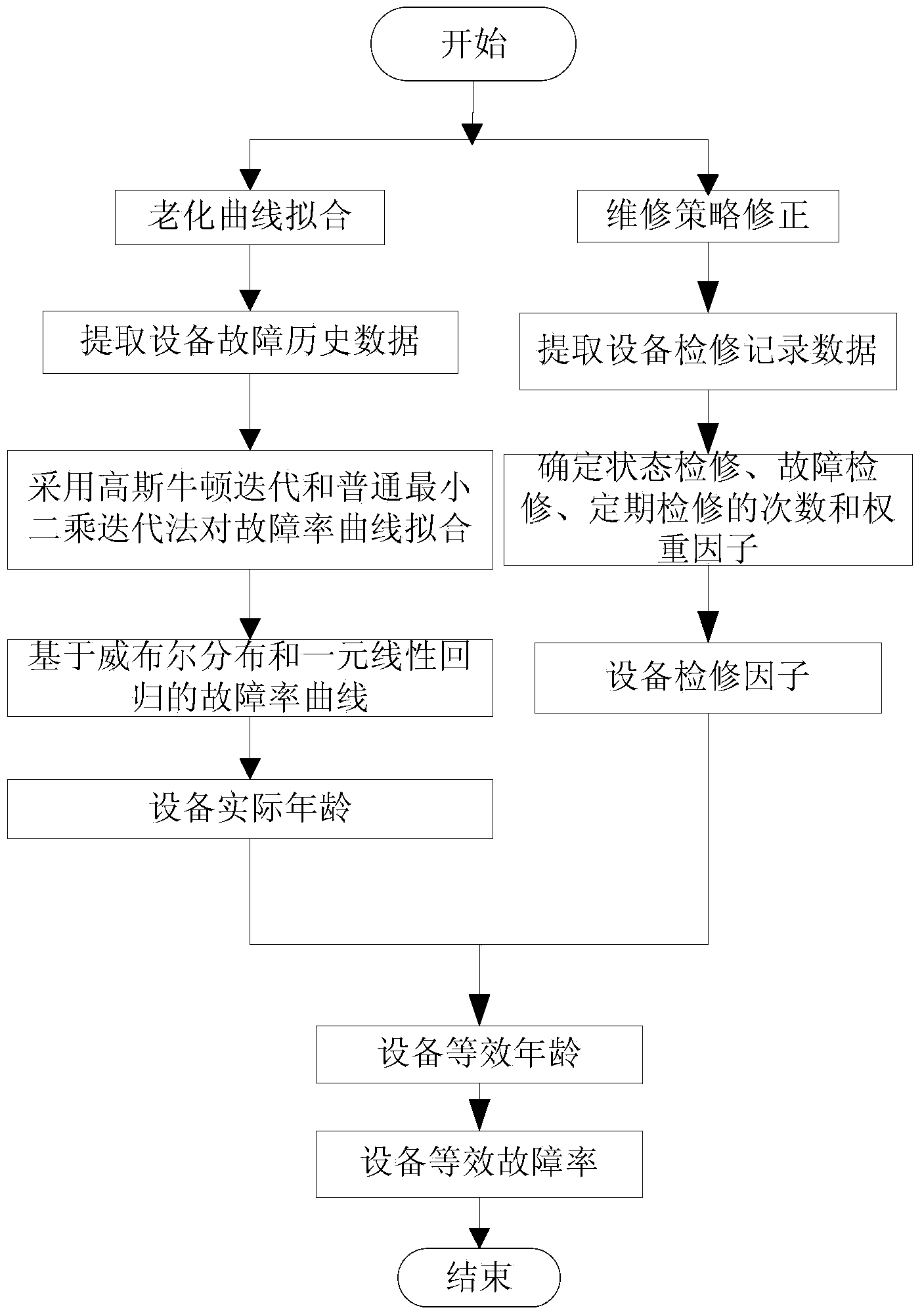

[0069] combine Figures 1 to 3 As shown, the method of predicting the failure rate of power equipment considering aging factors includes the following steps:

[0070] a Select n groups of equipment operation fault data, the independent variable of each group of fault data is time t, and the dependent variable failure rate is λ i , Select the first m groups of data from the n groups of data, let m=3, and perform curve fitting on the first m groups of data:

[0071] a1. Initialization parameters, including aging curve parameters and iteration equation related parameters: g (0) =(α 0 ,β 0 ), where α is the shape parameter, β is the scale parameter, the allowable error precision k and the number of iterations l;

[0072] a2. Failure rate λ i Calculate the partial derivative function for α and β respectively to get

[0073] a3. Calculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com