Preprocessing method and apparatus for aging aluminium electrolysis capacitor

A technology of aluminum electrolytic capacitors and pretreatment devices, which is applied in the direction of electrolytic capacitors, capacitors, capacitor manufacturing, etc., and can solve problems such as capacitor failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

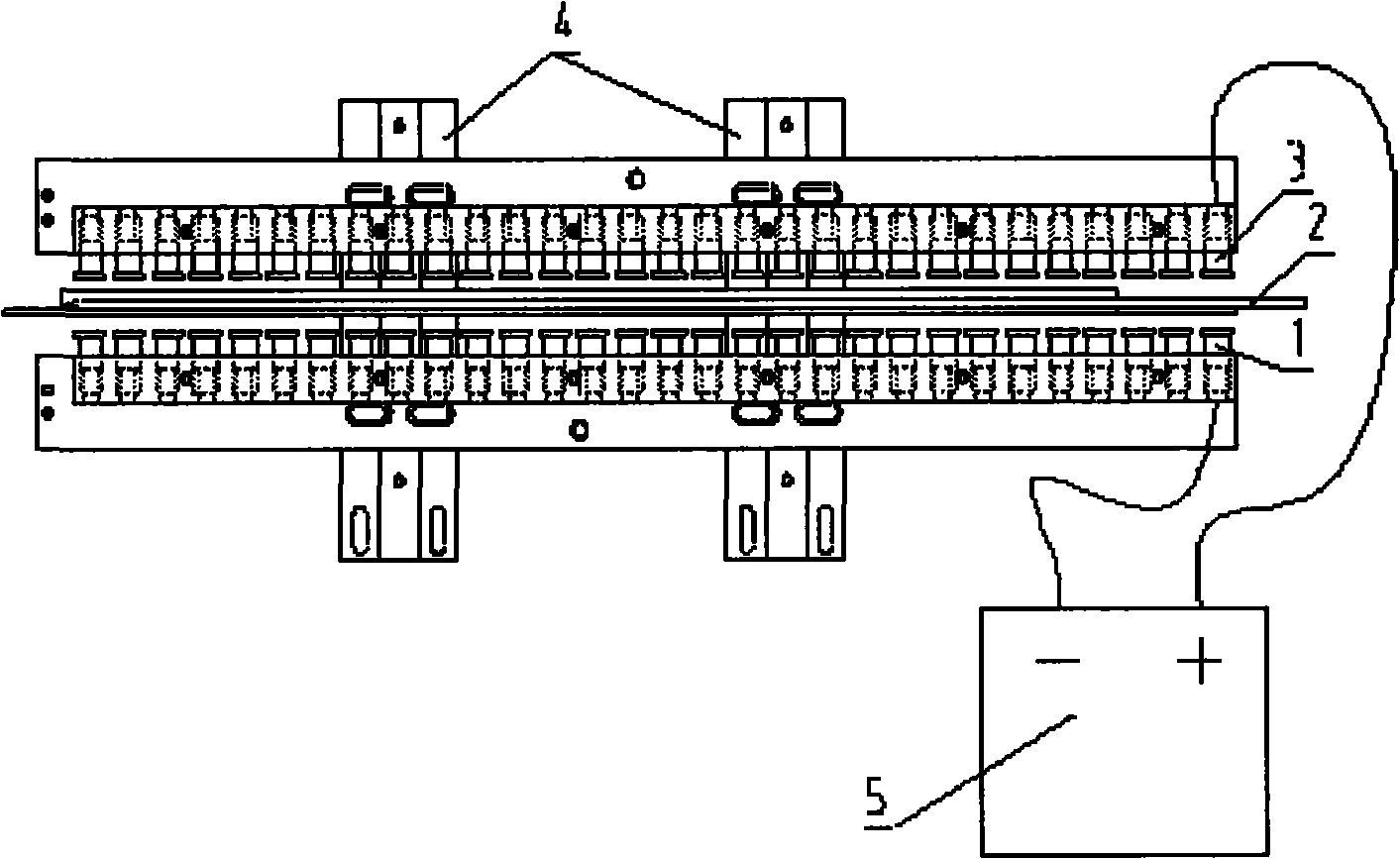

[0006] The embodiment of the accompanying drawings provides a pre-treatment charging device for an aluminum electrolytic capacitor before aging, which consists of a positive contact (1), an insulating separator (2), a negative contact (3), and a positive and negative contact sliding seat (4) , Fixed power supply (5) is formed. In use, the insulating and separating plate (2) supports the processed aluminum electrolytic capacitor, and the two lead wires of the capacitor are separated by the insulating and separating plate (2). Before aluminum electrolytic capacitors, charge pretreatment is carried out by this device. If it is automatic aging equipment, the device can be installed on the feeding machine. The feeding machine sends the aluminum electrolytic capacitor to the pretreatment charging device, and after charging, it is sent to the fixture and input into the aging furnace for aging.

[0007] If the aluminum electrolytic capacitor of 160V and 10uF is processed, the device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com