Patents

Literature

850results about How to "Good rehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coarse cereal instant rice and preparation method thereof

ActiveCN103564344ABlocking stickingPrevent too softFood ingredient functionsFood preparationPearl barleyGram

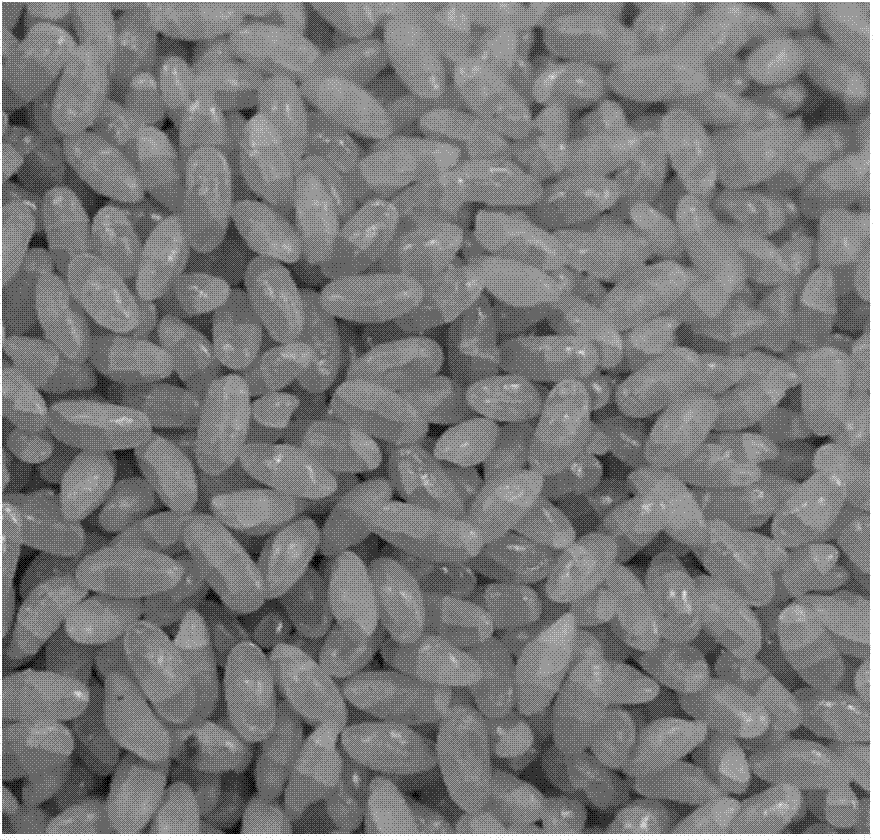

The invention discloses a coarse cereal instant rice and a preparation method of the coarse cereal instant rice. The coarse cereal instant rice is mainly prepared by conducting extrusion curing, cutting, pelletizing, drying, then baking and puffing on coarse cereal powder, starch and solid vegetable oil, wherein the coarse cereal is selected from one or combination of corn flour, rice flour, sorghum flour, buckwheat, pearl barley flour, black rice four, sweet potato flour, millet flour, coarse rice powder, glutinous rice flour, red rice flour, soybean flour, red bean flour, green gram starch, black bean flour, oat powder and wheat flour. The coarse cereal instant rice provided by the invention adopts a loose porous structure inside, so that the coarse cereal instant rice is good for digesting and absorbing and is excellent in rehydration property, the rehydration time is relatively short, the rehydrated rice is in full grain, and the coarse cereal instant rice is chewy and not hard or sticky when being eaten.

Owner:王金玺

Stage method for improving uniform expansion effect of granular fruits and vegetables during microwave spouted drying

The invention discloses a stage method for improving the uniform expansion effect of granular fruits and vegetables during microwave spouted drying, which belongs to the technical field of the processing of fruit and vegetable foods. The method mainly comprises the steps of: performing selection, washing, dicing, enzyme killing by blanching, and color protection treatment on fruit and vegetable raw materials; placing the pretreated fruit and vegetable cubes into a microwave spouted drying bed; setting the microwave power and the air inlet heating temperature; then performing the combined drying of stage hot air drying and microwave drying; and controlling different spouted air intakes at different drying stages, wherein the uniform expansion effect of products is improved during the quick microwave drying. The method has the advantages that the method ensures that the granular fruits and vegetables are evenly heated in a microwave field through a hot air and microwave spouted drying stage method, has quick moisture evaporation, ensures that the fruits and vegetables have porous structures after the drying, effectively improves the expansion degree of the products, also improves the expansion effect of the products and ensures the uniform expansion of the products while the granular fruits and vegetables are quickly dried, and has the characteristics of good preservation of nutrient content and good qualities of color luster, sense and the like.

Owner:JIANGNAN UNIV +1

Method for preparing nutrition convenient rice by bi-screw secondary compression

The invention relates to a twin-screw double extrusion preparation method for nutrition-fortification instant rice, belonging to the broken rice deep processing field. The invention primarily makes use of broken rice as the raw material together with the accessory materials, such as cereal, food additive, micronutrient and salt, all of which are conditioning compounded with water added, followed by a high temperature extrusion, a second low temperature extrusion, cutting and shaping, drying, cooling, and packing process. The invention is characterized in that the innovation of applying the twin-screw double extrusion preparation process not only overcomes the disadvantages of the traditional process or that combined with the single screw process, but also significantly promotes the production efficiency of the instant rice with good rehydration characteristics and rich nutrition. After adding an appropriate portion of hot water of 90 to 100 degrees centigrade, the nutrition-fortification instant rice can be rehydrated within 3 to 5 minutes, providing a similar composition and appearance with the nature rice.

Owner:JIANGNAN UNIV

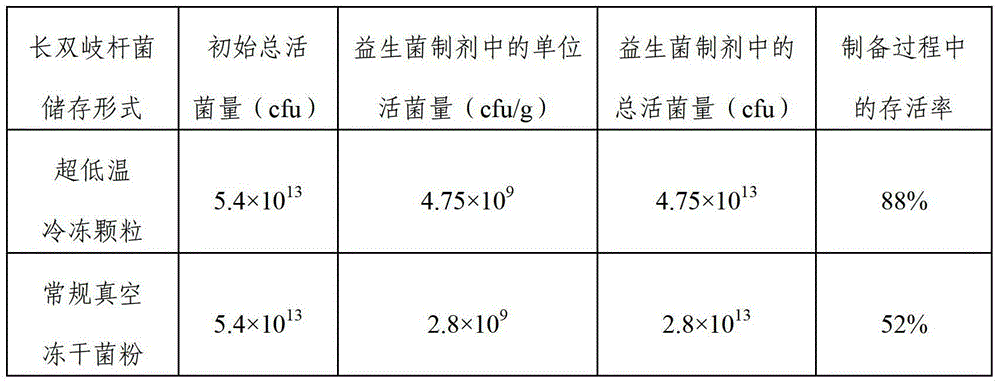

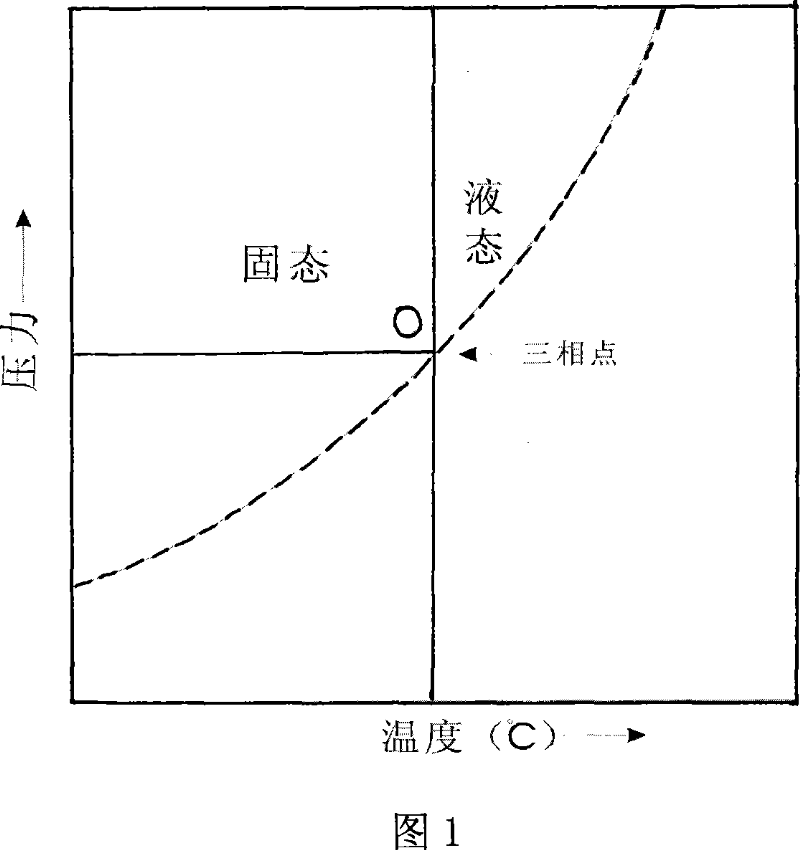

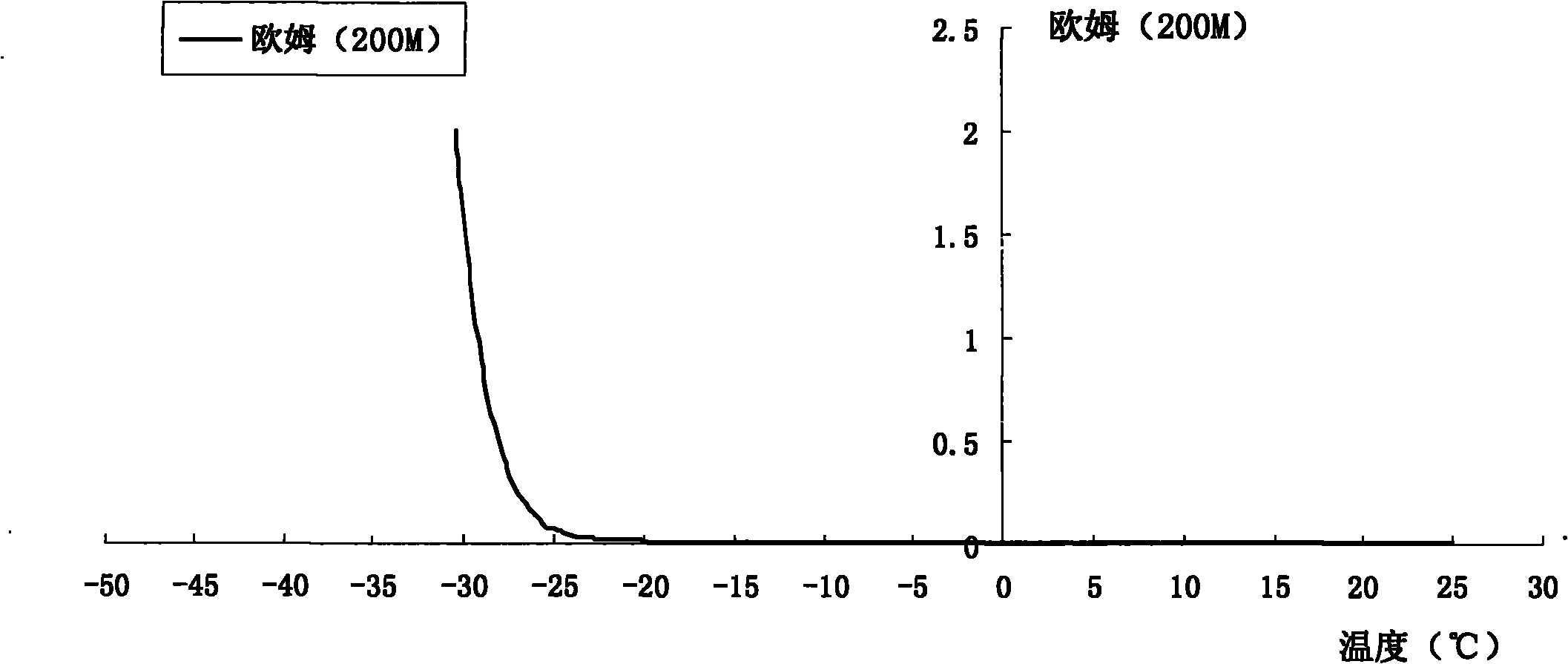

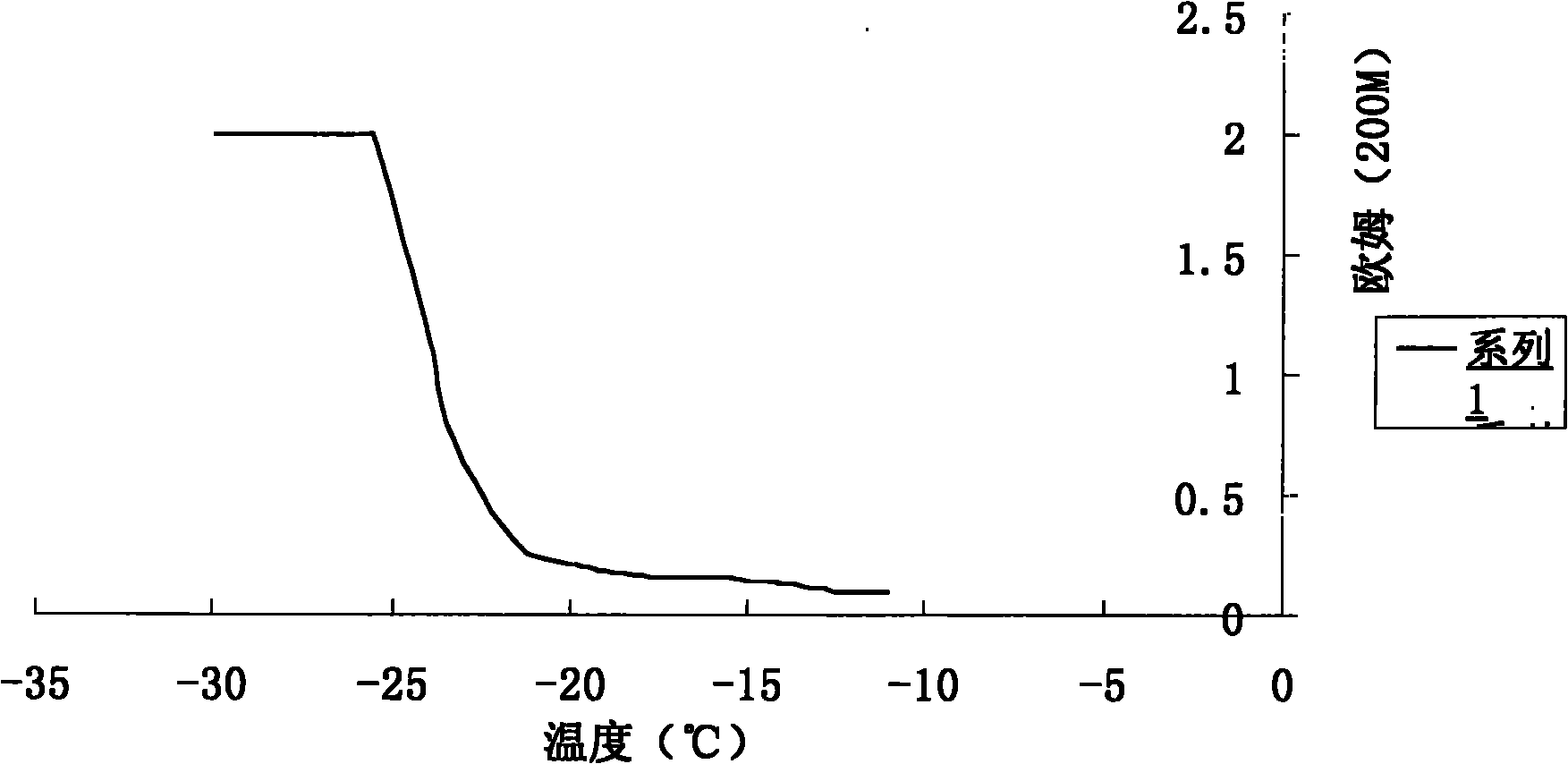

Probiotic ultralow temperature refrigeration technology and applications thereof in probiotic preparation

ActiveCN103333840AHigh activityLow freezing pointBacteriaFood preparationBacterial strainRefrigeration

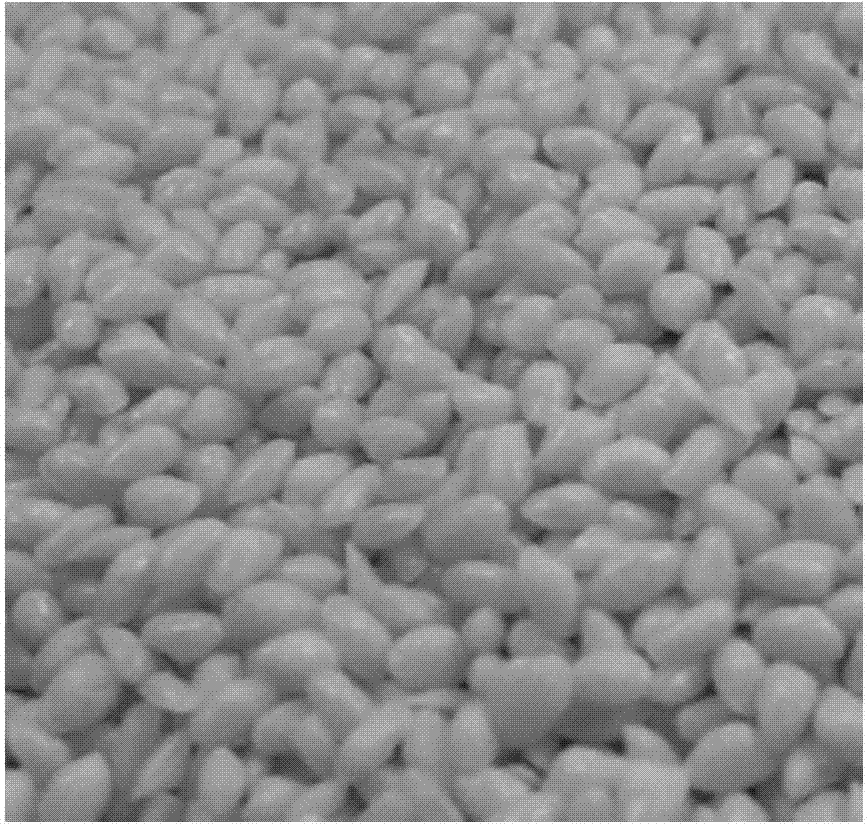

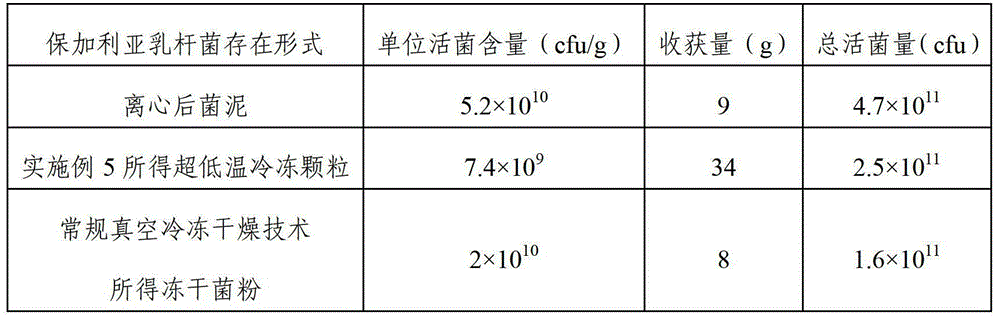

The invention discloses a probiotic ultralow temperature refrigeration technology, a formula of a total-salt cryoprotectant which is suitable for the probiotic ultralow temperature refrigeration technology, and probiotic ultralow temperature refrigeration particles prepared by using the probiotic ultralow temperature refrigeration technology. The probiotic ultralow temperature refrigeration technology comprises following steps: (1) preparing a fermentation medium; (2) culturing probiotics; (3) centrifuging; (4) preparing the cryoprotectant; (5) adding the cryoprotectant; and (6) quick-freezing and moulding. The invention also provides a probiotic preparation prepared by using the probiotic ultralow temperature refrigeration particles, and a preparation method of the probiotic preparation. The probiotic ultralow temperature refrigeration particles are probiotic refrigerated bacterial strains which do not need to be dried and possesses advantages of fast refrigeration speed, high living bacterial rate and excellent rehydration performance. The probiotic ultralow temperature refrigeration particles contain water, can be dissolved in solutions more quickly, and are capable of preventing probiotic cells from damage caused by rehydration of normal low temperature refrigeration dried probiotic powder, and increasing the living bacterial rate of the probiotic preparation greatly.

Owner:THANKCOME BIOLOGICAL SCI & TECH CO LTD

Processing method of whole-grain instant porridge

The invention discloses a processing method of whole-grain instant porridge. According to the method, whole-grain flour is subjected to pretreatment, and the whole-grain instant porridge can be prepared through extrusion forming primary Alpha treatment, low-temperature drying and high-temperature secondary Alpha treatment. The instant porridge prepared by the method has the moisture content being lower than 10 percent and the Alpha degree being high than 95 percent. The processing method disclosed by the invention is simple, convenient and feasible, the continuous degree of the processing process is high, the prepared whole-grain instant porridge has good rehydration effect and can be rehydrated within 3 to 4 minutes through being immersed by hot water, various kinds of nutritional ingredients of the original whole grain are maintained, the mouth feeling is excellent, the eating by customers is convenient, and the storage time of products is prolonged.

Owner:SCI RES INST OF NAT FOOD & STRATEGIC RESERVES ADMINISTATION

Freeze-dried fermented glutinous rice and preparation method thereof

ActiveCN102304446ARetain nutrientsFull of nutritionAlcoholic beverage preparationAdditive ingredientFreeze-drying

The invention relates to a preparation technique of freeze-dried fermented glutinous rice, which comprises the following steps: elutriating glutinous rice to remove impurities, and soaking; boiling, and cooling to 28-30 DEG C; dispersing, evenly spreading, adding sterilized water, adding distillery yeast, evenly mixing, and fermenting; after finishing fermentation, carrying out solid-liquid separation, pre-freezing the solid part, and carrying out vacuum freeze-drying and vacuum packaging; and carrying out microwave sterilization and vacuum packaging on the liquid part. In the invention, the solid part is subjected to vacuum freeze-drying, so that the original quality of the material is maximally maintained, and the storage time of the freeze-dried fermented glutinous rice is longer. The sweet wine is subjected to microwave sterilization, so that the growth and development of microbes in the sweet wine are postponed, and the microbes can even die, thereby effectively protecting the massive effective constituents in the sweet wine from damage, and maintaining the original shape, color, flavor and nutritional ingredients of the product; and the freeze-dried fermented glutinous rice has the characteristics of energy saving, consumption reduction, no harm to human health, and favorable rehydration property. The technique provided by the invention is simple and convenient to operate; the prepared fermented glutinous rice is free of preservative, has the advantages of no loss of nutritional ingredients, good flavor and long storage time, and is convenient and quick to eat; and the invention is applicable to industrial production.

Owner:HUNAN AGRICULTURAL UNIV

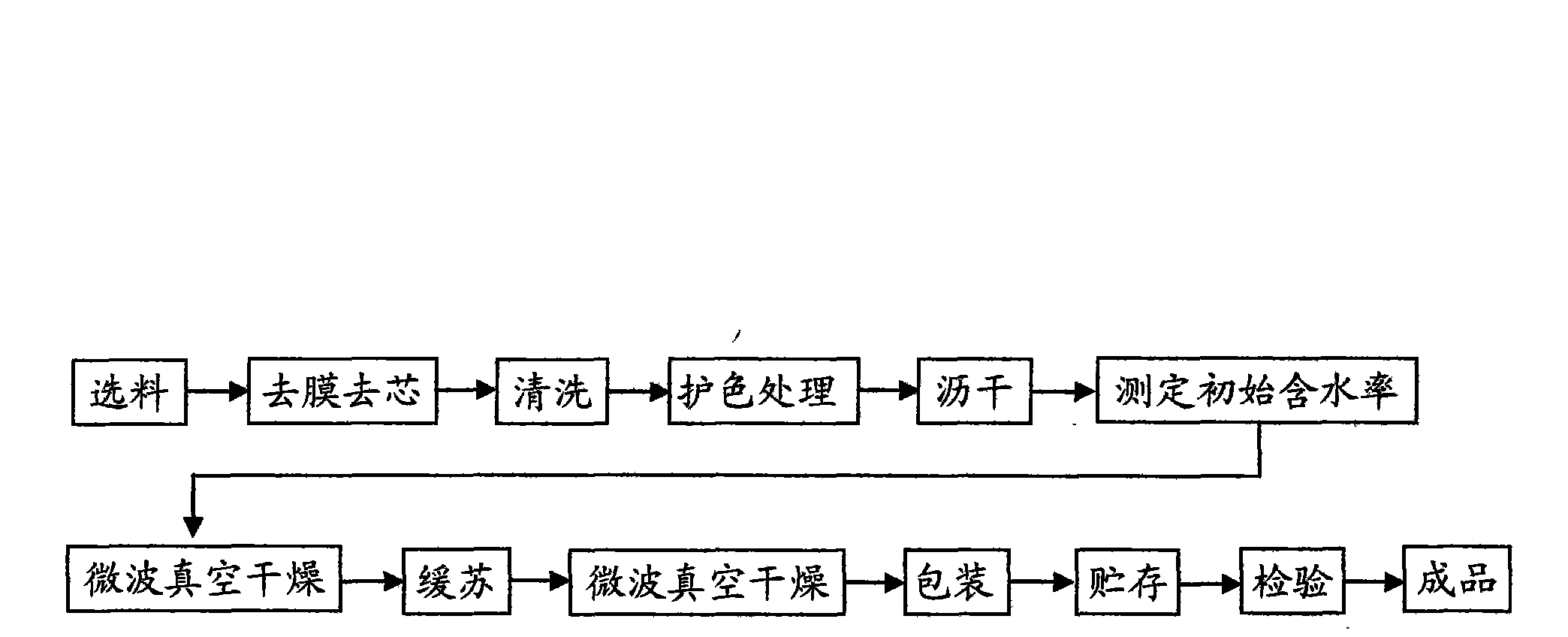

Microwave vacuum drying process for lotus seed

The invention provides a microwave vacuum drying process for lotus seeds, comprising the following steps of: selecting materials, removing films and cores, protecting color, dewatering, vacuum drying by microwave, packaging and storing, thus preparing the dry lotus seed product. The process aims at improving the quality research of the dry lotus seed and reducing the energy consumption, dries the fresh lotus seeds by microwave vacuum drying technology, improves the quality of the lotus seeds, and prolongs the shelf life of the product; the application of the high combination drying technology inaugurates another dry preparation way for drying preparation of fresh lotus seeds; the process is easy for instant control and the production is environment-protective; and the real continuous automatic clean production can be realized.

Owner:FUJIAN AGRI & FORESTRY UNIV

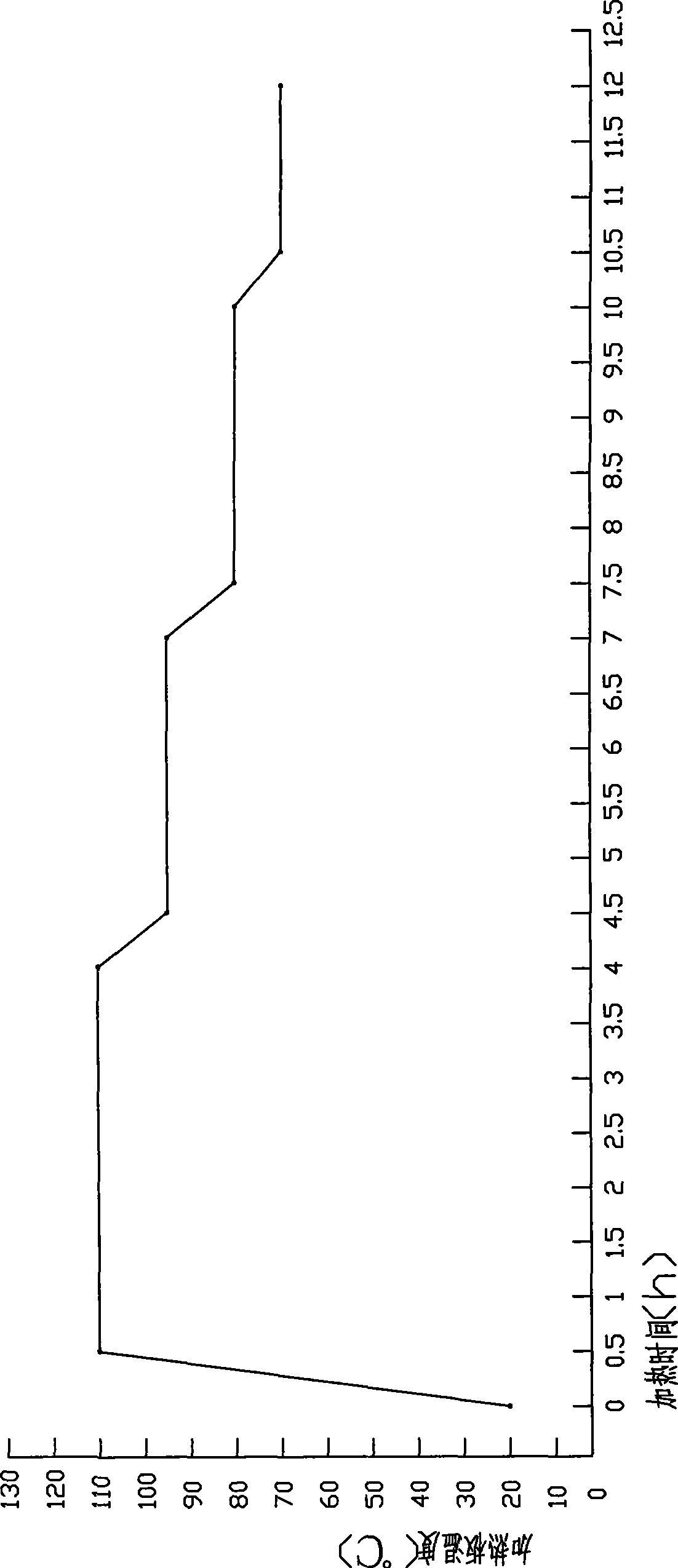

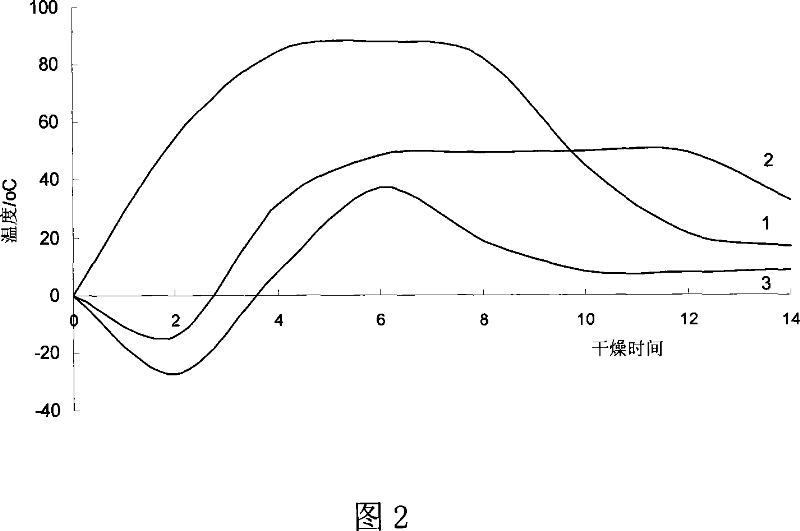

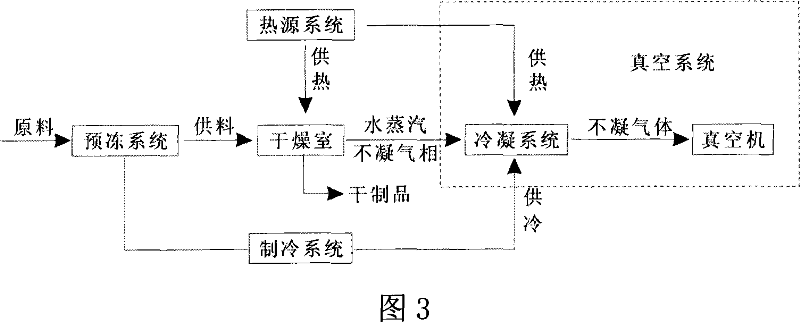

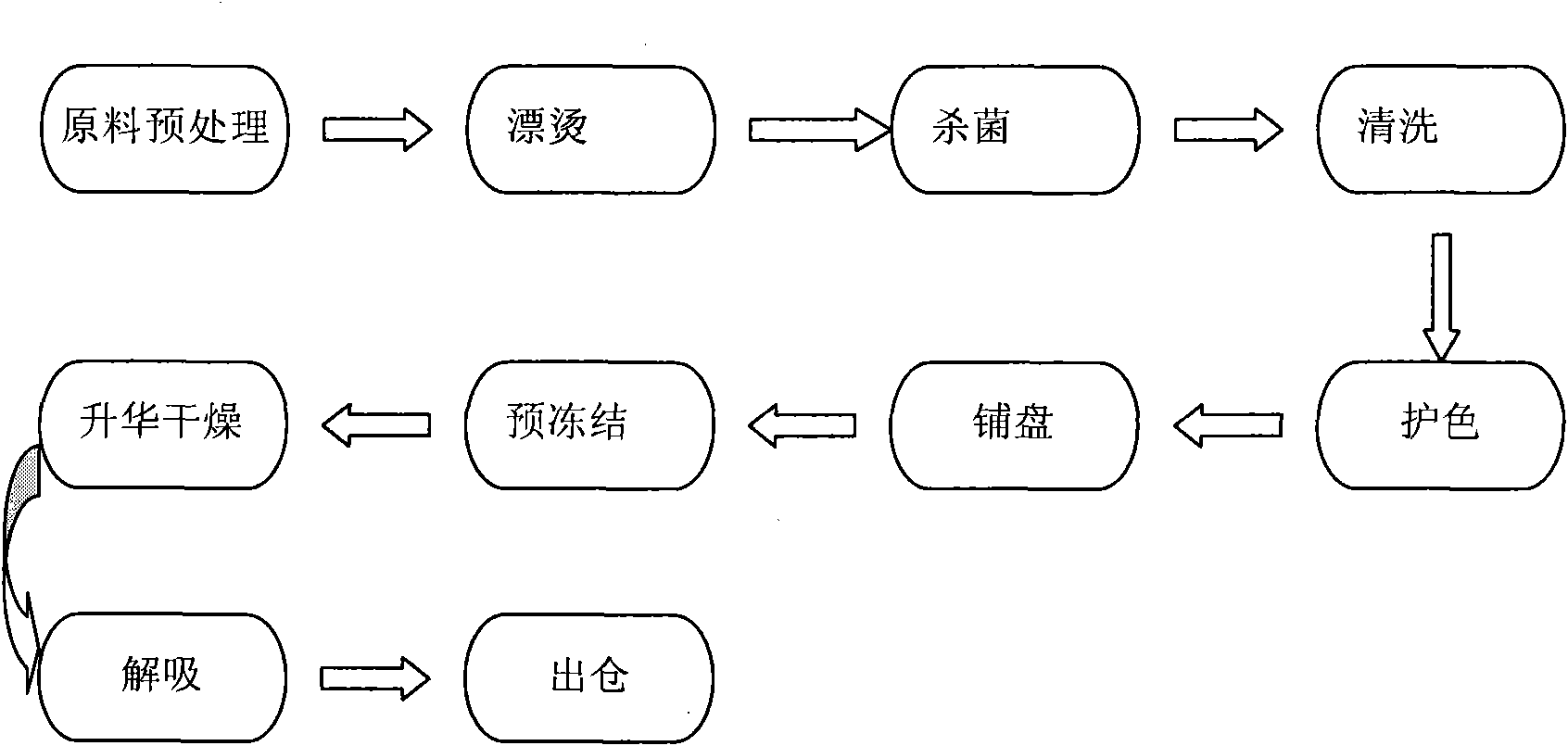

Method for processing string beans through vacuum freeze drying

InactiveCN101543238ASolve poor rehydrationEasy to eatFruits/vegetable preservation by freezing/coolingConvenience foodFreeze dry

The invention discloses a method for processing string beans through vacuum freeze drying, which comprises the following steps: using fresh string beans or frozen string beans as raw materials, soaking the string beans for color conservation, and performing the processes of blanching, cooling, removing water, traying, rapid freezing, vacuum freeze drying, sorting, metal detection and packaging, wherein the temperature change of a heating plate in a vacuum freeze drying system device is controlled reasonably in the process of heating and drying. The method has the advantages that the product has the green color of normal string beans, has the smell of normal string beans, the moisture content is less than or equal to 6 percent, the rehydration of the product is more than or equal to 70 percent, the product can be eaten directly or used as an adjuvant added into fast foods such as instant noodle, instant bean vermicelli, instant soup and the like.

Owner:HUBEI XINMEIXIANG FOODS

Production technique for chicken powder with great freshness flavor

ActiveCN103689522AIncrease umamiImprove sensory qualityFood ingredientsFood preparationMonosodium glutamateAdditive ingredient

The invention discloses a production technique for chicken powder with a great freshness flavor, and belongs to the technical field of processing food seasoning. The chicken powder comprises the following materials according to mass: 30kg of fresh chicken skeletons, 30kg of fresh chicken, 7kg of maltodextrin, 2.5kg of disodium nucleotide, 0.1kg of sodium citrate, 7kg of trehalose, 10kg of edible salt, 10kg of monosodium glutamate, 2kg of lentinula edodes, 1kg of radix puerariae, and 0.4kg of pepper; the production technique comprises the steps: pretreating active ingredients, and carrying out high-temperature high-pressure sealed cooking, fine treatment, enzymolysis for flavor, mixing, spray drying, filling and capping. According to the production technique, the processes are simple, the energy consumption can be reduced, the loss of flavor components can be effectively reduced and sufficient release of flavor substances is promoted, the chicken powder is rich in chicken flavor, harmonious in saline taste, delicate flavor and perfume, luminous in color, good in rehydration property, smooth in mouthfeeling, free from sand grains, and milkily white in soup feeling.

Owner:GUANGDONG JIALONG FOOD

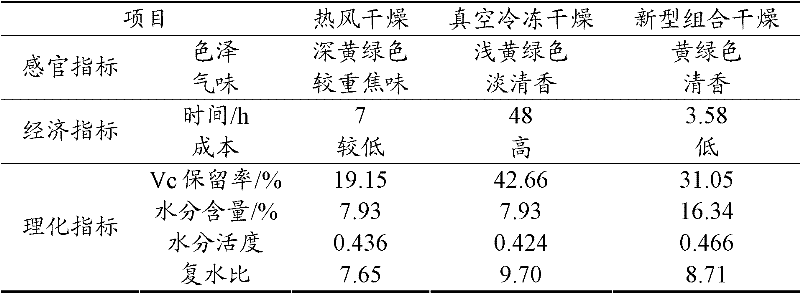

Production method of evaporated vegetables

InactiveCN102308869AAvoid damageGood puffing effectFruits/vegetable preservation by dehydrationMicrowaveWater activity

The invention relates to a production method of evaporated vegetables. The method comprises the following steps: pretreating a vegetable raw material, performing a first hot air drying for reducing the moisture content of the vegetable to 60%-70%, carrying out a microwave drying for reducing the moisture content of the vegetable to 30%-40%; then carrying out an osmotic treatment, and performing a second hot air hot air drying for reducing the moisture content of the vegetable to 10%-20%, wherein the water activity is 0.64-0.44, the rehydration rate is 3.1-7.6. According to the invention, when the vegetable is dried to low moisture content, the vegetable can be performed an infiltration process by penetrating fluid, therefore the penetrating fluid can be absorbed by vegetable, the penetrating fluid is evenly distributed which makes the vegetable possessing special nutrition characteristics and makes the final product possessing the high-moisture content and the low moisture activity. The production method of the invention is capable of effectively raising the organoleptic quality and rewatering performance, raising the preservability of the product and simultaneously reducing the production cost.

Owner:JIANGNAN UNIV

Tea processing and producing method

InactiveCN101301012AFresh tasteImprove cultural connotationPre-extraction tea treatmentFreeze-dryingAdditive ingredient

The present invention provides a tea processing and production method combining traditional process and vacuum freeze drying technique, which comprises the steps of selecting materials, deactivating enzymes, sorting, stacking, freezing, vacuum freeze-drying, shaping, classifying and packaging. The present applies freezing, vacuum freeze-drying in the tea processing technique, which not only preserves the original nutrition ingredients in the tea furthest, but also endows the products with fresh color, whole shape, good water reabsorbing capacity and fresh taste, effectively enhances the cultural connotation and commercial value of the tea and has wide prospect.

Owner:吕坤秋

Method for making microwave vaccum frozen and dried lemon piece

InactiveCN1849921AExtended production periodSolve the problem of excessive pesticide residuesFood preservationMicrowaveFreeze-drying

The present invention relates to a production method of microwave vacuum freeze-dried lemon slices. Said method includes the following steps: (1), sorting lemon fruit; (2), storing lemon fruit under the condition of constant temperature; (3), utilizing ozone to degrade pesticide residue on the lemon fruit and make sterilization; (4), cutting head and tail of lemon fruit, cleaning the lemon fruit by using ozone water and sterilizing; (5), slicing; (6), freezing sliced lemon; (7), prefreeze-drying; (8), microwave vacuum-drying; and (9), sealing and packaging so as to obtain the invented product.

Owner:SICHUAN HUATONG LEMON

High-strength bionic collagen membrane and preparation method thereof

The present invention provides a preparation method of high-strength bionic collagen membrane. The preparation method is by conducting gradient dialysis process on collagen to rearrange collagen molecules into an ordered structure, and endow the molecules with more consistent and more extensive collagen fiber orientation, thus improving the mechanical properties of the material. The collagen membrane prepared by using the method has similar appearance, structure and performance to natural dura and amnion of mammals, and good rehydration, and is free to bend and fold after water absorption; the bionic collagen membrane with high tensile strength can be stitched by using suture and can be used in clinical guided tissue regeneration or repair of various tissues.

Owner:BEIJING PAISHENG BIOTECH CO LTD

Production method for ready-to-eat instant nutritive edible fungus soup

The invention discloses a production method for ready-to-eat instant nutritive edible fungus soup, which belongs to the technical field of deep processing of agricultural products. The production method mainly comprises the steps of selecting, cleaning, precise cutting, mixed boiling, spreading, pre-freezing and microwave vacuum freeze drying on screened raw materials such as edible fungi, thus obtaining the product which is subjected to nitrogen-filled packaging after being taken out of storage. The raw materials of the edible fungus soup is dewatered by a microwave vacuum freeze drying technology according to a modern food nutrition principle, so that the original color, aroma, taste and nutrients of the product are kept to the hilt, and compared with those of a conventional process, the drying efficiency is remarkably improved, the production cycle is shortened, the production cost is effectively reduced, and the special sterilizing effect of microwaves further guarantees the product quality at the same time. The edible fungus soup produced by the method is flat in shape, bright in color and luster, rich in nutrition, good in water regaining effect and long in storage time, and a feasible new way is provided for deep processing and utilization of the edible fungi.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Preparation method of freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes

The invention provides a preparation method of freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes. The preparation method comprises the following steps of cleaning fruits and vegetables, performing pulping, mixing and blending pulp with yoghourt, performing homogenizing, adding cereals, nuts and fruit granules, performing stirring, performing membrane filling, performing quick-freezing, performing demolding, performing vacuum freeze drying, and performing packaging so as to obtain the freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes. The freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes are produced by a vacuum freeze drying technique, so that original thermal sensitivity components and antioxidation components of products canbe sufficiently guaranteed, the color and the fragrance of fruits and vegetables and the activity of probiotics can also be guaranteed, and transportation and long term storage are facilitated; and besides, the cereals, the nuts and the fruits cooperate, so that the nutrition is more balanced.

Owner:清谷田园食品有限公司

Processing method of Hami melon pulp and products therefrom

InactiveCN1711853AReduce lossesColor unchangedFruit and vegetables preservationVitamin CFreeze-drying

A method for preparing the meat of Hami melon includes such steps as providing fresh Hami melon, washing, disinfecting peeling, slicing immersing in the solution of edible citric acid and the solution of ascorbic acid for 15-30 min in order to protect color, quick freezing vacuum freeze drying and packing.

Owner:SOUTH CHINA AGRI UNIV

Recombined fruit and vegetable coarse cereal instant food and machining method thereof

InactiveCN102960633APromote digestionFood convenienceFood preparationAdditive ingredientHuman health

The invention relates to a machining method of instant foods with comprehensive nutrition, and particularly relates to the recombined fruit and vegetable coarse cereal instant food and a machining method thereof. Fruits and vegetables, and meats are dehydrated by using a vacuum freezing and drying method; coarse cereals are cooked by using a puffing method; the frozen and dried fruits and vegetables, and the frozen and dried meats are mixed with the puffed coarse cereals, dextrin and milk powder to carry out superfine grinding; and compound probiotics are added so that the final products are obtained. The method disclosed by the invention keeps nutritional components in ingredients to the greatest extent and provides probiotics which are beneficial to human health. The formula is formed by natural raw materials and any preservative is added; and the recombined fruit and vegetable coarse cereal instant food is natural and healthy, has comprehensive and balanced nutrition, is easily digested, is suitable for being used by people of all ages, and is particularly suitable for being used for nutrition replenishing, used as extra meals or replaced meals for students or tourists.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES +1

Tea coffee solid beverage and preparation method thereof

InactiveCN103202362AStrong fragranceGood rehydrationPre-extraction tea treatmentRoasted coffee treatmentCoffeaNutrition

The invention relates to a solid beverage, and in particular relates to a tea coffee solid beverage and a preparation method thereof. The tea coffee solid beverage comprises the following materials according to mass ratio: 80-120 parts of Vietnam medium coffee beans, 60-80 parts of Yunnan small coffee beans, 140-160 parts of Dianhong Kungfu tea, 55-65 parts of vegetable fat powder and 46-50 parts of white sugar. The preparation method comprises the following steps of: A. mixing; B. baking; C. crushing; D. extracting; E. concentrating; F. homogenizing; G. sterilizing; H. cooling and drying; and I. packaging. The mixing ratio of the Vietnam medium coffee beans to the Yunnan small coffee beans is proper, the tea coffee solid beverage is high in content of caffeine, fragrant, pure and mild in flavor and high in content of effective nutritional ingredients after the working procedures of baking, crushing, extracting and concentrating. The extraction of distilled water of coffee mixed powder and red tea powder is proper in temperature and moderate in time. The finished product can be good in reconstitution property without residues, and the color, the fragrance, the taste and the nutritional ingredients of coffee and red tea can be well maintained.

Owner:普洱漫崖咖啡实业有限公司

Pure nature low temperature baked cooked pumpkin powder and production method thereof

InactiveCN103960608AGood colorGood rehydration performanceFood preparationPumpkin seedProcess engineering

The present invention provides pure nature low temperature baked cooked pumpkin powder and a production method thereof. The production process comprises: carrying out screening, washing, peeling, pulp removing, seed taking and slicing to decompose into pumpkin slices, pumpkin peel, pumpkin pulp and pumpkin seeds; immersing and blanching the pumpkin slices so as to reduce nutrition loss of the pumpkin, immersing and blanching the pumpkin slices with boiling salt water with a temperature of more than or equal to 95 DEG C until achieving a semitransparent state, taking out, dewatering, cutting into strips, carrying out 50-60 DEG C constant temperature vacuum baking processing on the cut pumpkin slice strips, the cut pumpkin peel strips, the cut pumpkin pulp strips and the pumpkin seeds with low temperature baking equipment to obtain cooked and dried pumpkin product, carrying out a mixing stirring sterilization treatment on the cooked and dried pumpkin product, and grinding with a crushing machine to obtain the cooked pumpkin powder with the particle fineness of more than or equal to 120 mesh, wherein the cooked pumpkin powder maintains the nutritional components and the good color of the pumpkin, presents the microscopic porous structure, has good rehydration, can be directly taken through infusion with boiling water, and can further be used as other food preparation materials, and the baked and cooked pumpkin powder, the baked and cooked pumpkin peel powder, the baked and cooked pumpkin pulp powder and the baked and cooked pumpkin seed powder after sterilization can be directly eaten.

Owner:程长青

Method of preparing pawpaw freezed dry superfine powder

InactiveCN101040692AUnique physical propertiesGood rehydrationFood preparationFruits/vegetable preservation by dehydrationSolubilityFreeze-drying

The invention provides a method for preparing pawpaw freeze-drying powder, comprising pretreatment, refrigerating, drying, decomposing, drying, and breaking, for resolving the problems as long-time fresh holding, storage, and deep treatment. The inventive produce has special physical property, better solubility, high activity, and held color, taste and smell or pawpaw, to be used as main materials of following deep treatment.

Owner:白河天裕农业高新技术有限公司

Method for swelling and watering fruit or vegetable type food at ambient temp.

ActiveCN1792284ANo pollution in the processNo generationFruits/vegetable preservation by dehydrationAdditive ingredientDrying

Owner:JIANGSUCHINA PALARICH

Bamboo shoot sulfur-free drying process

InactiveCN101869135AGood color and flavorMaintain colorFruits/vegetable preservation by dehydrationSulfurImpurity

The invention relates to a bamboo shoot sulfur-free drying process, which is characterized by comprising the following steps: (1) raw material preparation, during which fresh phyllostachys praecox shoots with a base part of which the diameter is greater than 3 centimeters, washing the fresh phyllostachys praecox shoots to remove impurities, removing sheaths, cutting off aged parts, and cutting the shoots along longitudinal axes to obtain bamboo shoot blocks; (2) soaking the bamboo shoot blocks in color protecting solution for 20 to 90 minutes, wherein the ratio of the bamboo shoot blocks to the color protecting solution is 1g:3-4ml; (3) blanching color protection treatment, during which blanching the bamboo shoot blocks, which are soaked in the color protecting solution, in the color protecting solution at 80 to 100 DEG C for 2 to 10 minutes, and immediately washing the bamboo shoot blocks with water after the blanching; (4) permo-treatment, during which the bamboo shoot blocks, which are blanched for color protection, are soaked in osmotic solution for 20 to 40 minutes, and the ratio of the bamboo shoot blocks to the osmotic solution is 1g:3-4ml; (5) drying; and (6) packaging to obtain dry bamboo shoot products. The dry shoots prepared by the invention is short in rehydration time, convenient, sanitary and long in storage life and provides good raw material guarantee for the subsequent bamboo shoot deep processing.

Owner:JIANGNAN UNIV

Jewel orchid healthcare tea and preparation method

The invention discloses a jewel orchid healthcare tea and a preparation method. The method comprises the following steps of: carrying out sterilizing and enzyme killing on jewel orchid by adopting a microwave sterilization technology; dipping honey or sugar into the jewel orchid by utilizing a vacuum dipping technology; and then, processing and preparing the jewel orchid into any oral healthcare tea through freeze drying. The processed jewel orchid tea has vivid color and luster, short preparation time, easiness of operation, smooth product surface, good toughness, damage resistance and maintenance of original color, fragrance, smell, shape and nutrient content. The invention provides a jewel orchid healthcare tea with portability, easiness of storage, complete shape, dryness and rich nutrients for markets.

Owner:杨军

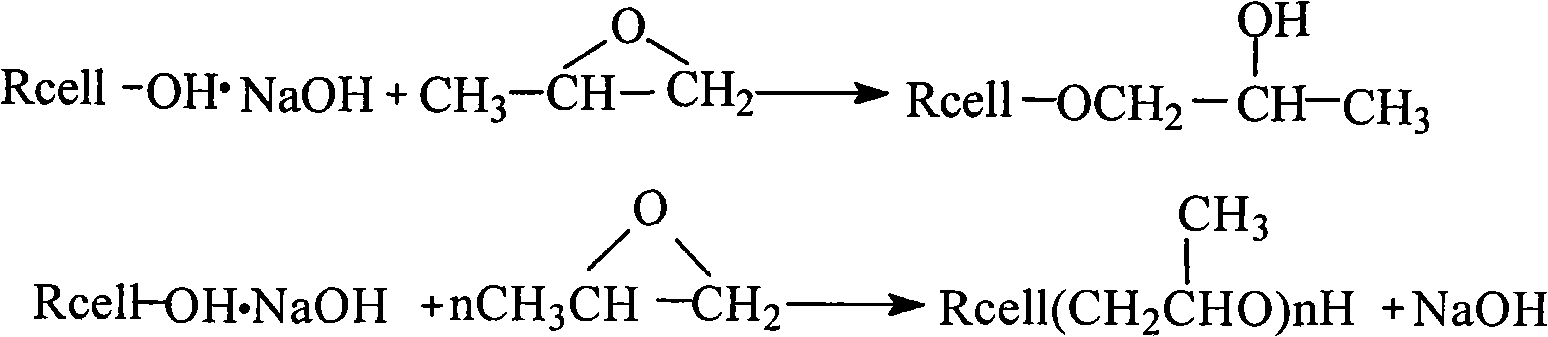

Method for preparing bacterial cellulose membrane with high rehydration

The invention relates to a method for preparing a bacterial cellulose membrane with high rehydration, which comprises the following steps: (1) performing alkaline treatment on bacterial cellulose hydrogel membrane of which bacteria and culture medium are removed; (2) performing etherification treatment on the processed membrane; (3) performing neutralization reaction on the etherified membrane to obtain a bacterial cellulose membrane subjected to hydroxypropylation; and (4) drying the bacterial cellulose membrane subjected to hydroxypropylation to obtain the bacterial cellulose membrane with high rehydration. The method aims at the defect of low rehydration performance of the prior bacterial cellulose membrane, uses a method of hydroxypropylation modification of the bacterial cellulose surface to destroy a part of hydrogen bonds in cellulose; a rehydration rate test finds that the dried bacterial cellulose membrane subjected to hydroxypropylation has high rehydration and reswelling capability; and the bacterial cellulose membrane subjected to hydroxypropylation can be used for preparing biologic composite materials, and has importance significance on biomedical materials and the like.

Owner:TIANJIN UNIV OF SCI & TECH

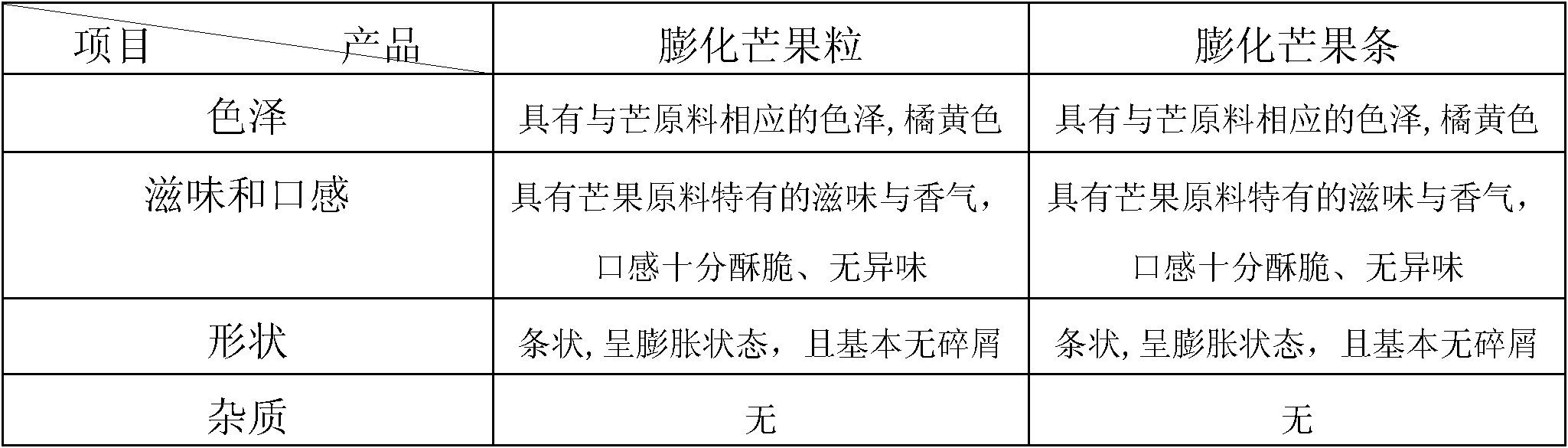

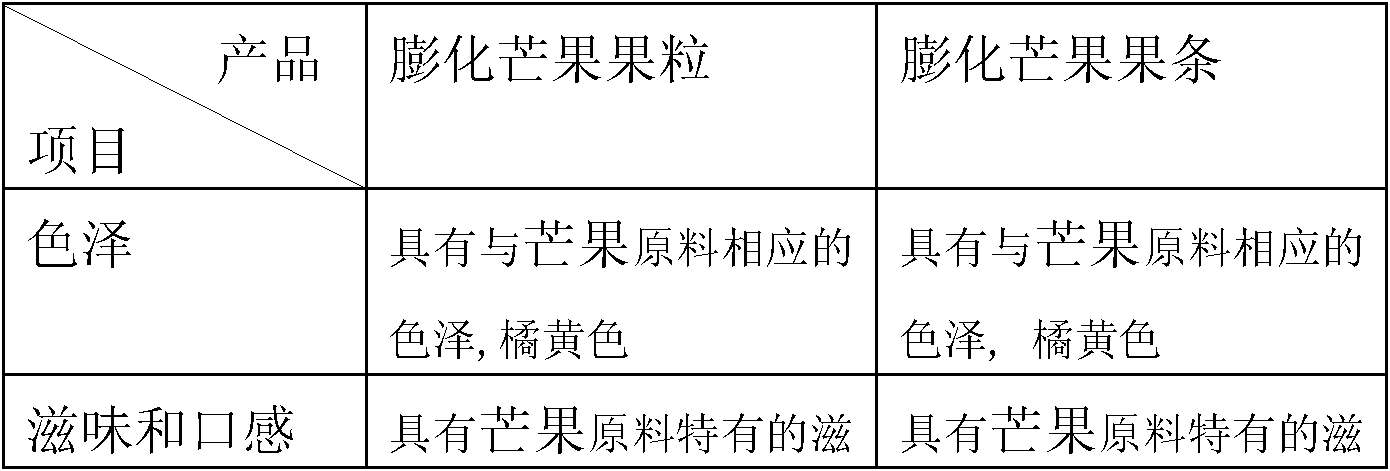

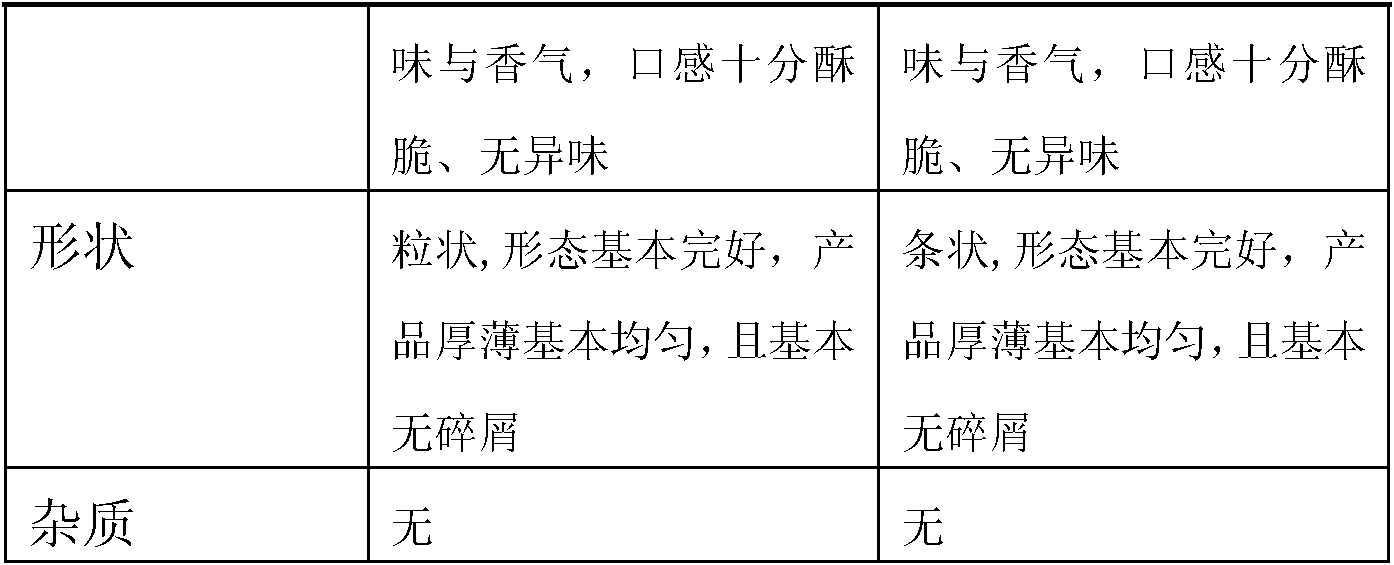

Puffed mango and preparation method thereof

The invention discloses a puffed mango and a preparation method thereof. The method comprises the following steps of putting the pulps of mango into a puffing tank; then carrying out variable-temperature and pressure-difference puffing on the pulps of mango; and the process of the variable-temperature and pressure-difference puffing comprises the following steps: 1) raising the temperature in thepuffing tank to 70-90 DEG C, raising the pressure in the puffing tank to a pressure 0.1-0.3 MPa higher than the atmospheric pressure outside the puffing tank, and keeping the temperature and the pressure, so that the surface temperature of a mango is consistent with the temperature in the puffing tank; 2) reducing the pressure in the puffing tank to a vacuum state, and reducing the temperature to60-80 DEG C under vacuum, then keeping the pressure and the temperature under vacuum, so that the moisture content of the pulps of mango is 3-5%; and 3) reducing the temperature in the puffing tank to 10-30 DEG C, and keeping the temperature 30-60 minutes under vacuum so as to obtain the puffed mango. The method is a new technique for processing vegetable slices; and by using the method disclosedby the invention, the nutrient compositions and flavors of raw materials can be kept furthest, no additive is used in the process of processing, and the defect that fried products contain a small amount of oils is avoided.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Production process of freeze-dried burdock

InactiveCN101889603AKeep shapeMaintain colorFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingFreeze-dryingRoom temperature

The invention relates to a production process of freeze-dried burdock, which is characterized by comprising the following steps: taking fresh burdock as a raw material, cleaning with water, dicing, sterilizing, cooling, and precooling on a freezing plate for 12-24 hours; freezing the precooled and diced burdock; drying the frozen and diced burdock in a vacuum drier, wherein the drying process is divided into a sublimation drying stage and a resolution drying stage, the vacuum degree in the sublimation drying stage is 80-120 Pa, and the vacuum degree in the resolution drying stage is 1-10 Pa; and after finishing drying, cooling, vacuumizing and carrying out nitrogen gas packing to obtain the freeze-dried burdock. The process is simple and reasonable, and can reserve the food tissues, nutritional components and flavored substances in the burdock. The freeze-dried product has the advantages of favorable rehydration property, light weight and the like, and can be stored at room temperature.

Owner:LIANYUNGANG KUCHIFUKU FOODS

Method for freezing and drying mango

InactiveCN101961047AGood rehydrationMaintain propertiesFruit and vegetables preservationMicroorganismFreeze-drying

The invention provides a method for freezing and drying mango. In the method, pretreated mango puddings are processed according to the following steps and control conditions: blanching the mango puddings with hot water at 95 DEG C for 60 to 180 seconds; sterilizing the mango puddings by 3000ppm sodium hypochlorite disinfectant for 10 minutes; soaking the blanched and sterilized mango puddings into the complex liquid of 0.015 percent ascorbic acid and 0.01 percent malic acid for 10 to 15 minutes for color protection; and then freezing and drying. The control conditions are as follows: in sublimation drying stage, the vacuum degree is 40 to 60 Pa and the temperature of a heating plate is 35 to 45 DEG C; and in analysis drying stage, the vacuum degree is 40 to 60 Pa and the temperature of a heating plate is 45 to 55 DEG C. The technology solves the problem of mango during processing including discoloration, loss of favor, serious loss of nutrition and excessive microorganism.

Owner:GUANGXI UNIV +1

Method for producing unfried instant stewed noodles

The invention relates to a method for producing unfried instant stewed noodles, which comprises the following raw materials in percentage by weight: 80 to 90 percent of high protein flour, 10 to 20 percent of starch, 2 to 3 percent of edible salt, 2 to 5 percent of edible glue and 0.2 to 0.5 percent of composite alkali. In the invention, the technology of making noodles by drawing out the dough by hand is combined with a microwave drying technology and a heated-air drying technology; when the microwave drying technology is acted on noodles, the heated air drying is used to lead the evaporation velocity of water on the surfaces of the noodles to be higher than the evaporation velocity of water in the noodles; and when the heated air drying technology is acted on noodles, the evaporation velocity of water in the noodles is higher than the evaporation velocity of water on the surfaces of the noodles, so the moisture contents in and on the surface of the product produced by using the two drying technologies are relatively consistent. Therefore, the method is helpful for stabilizing the product quality, can ensure the width of the stewed noodles and the characteristic of rubbery and smooth noodles, and causes the stewed noodles with the local characteristics of Henan after subjected to drying treatment capable of being stored six months at a normal temperature.

Owner:HENAN HONGGAOLIANG FOOD

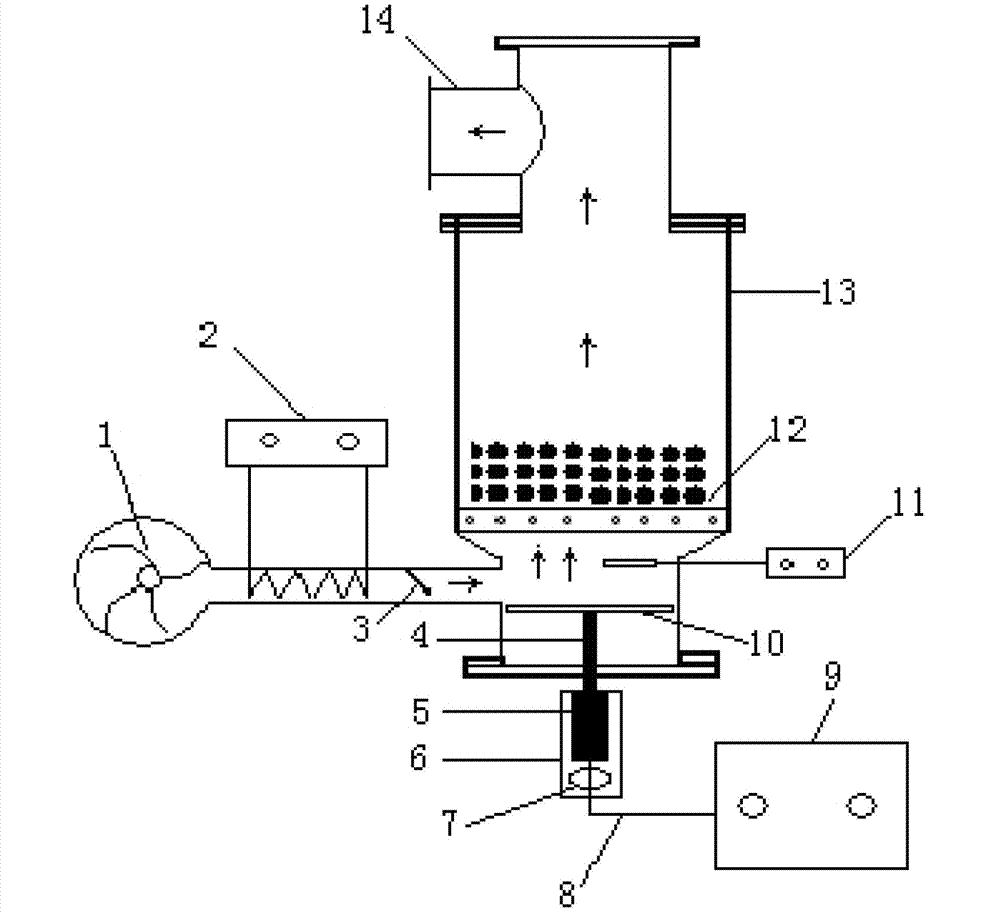

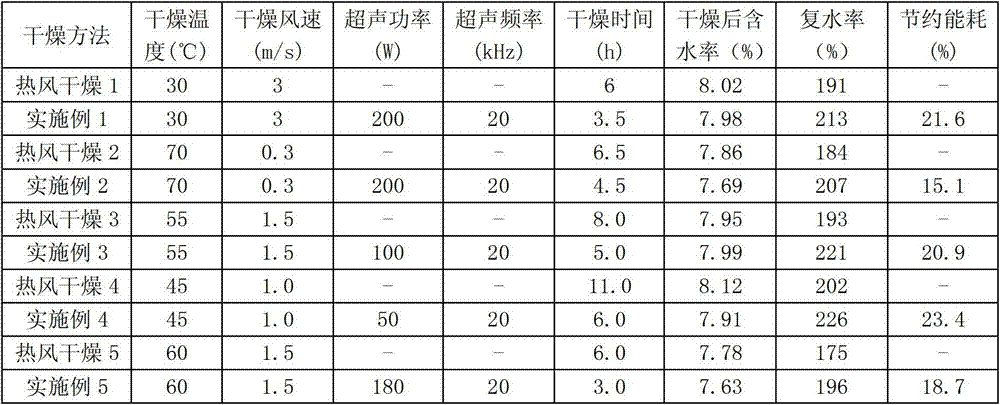

Ultrasonic and hot air combined carrot drying method and ultrasonic and hot air combined drying device

InactiveCN103109919AChange traitsIncrease the gapFood processingFruits/vegetable preservation by dehydrationProcess engineeringUltrasonic irradiation

The invention discloses an ultrasonic and hot air combined carrot drying method and an ultrasonic and hot air combined drying device. The ultrasonic and hot air combined carrot drying method comprises the following steps of: (1) pretreatment of a carrot raw material, namely washing and slicing fresh carrots; and (2) ultrasonic and hot air combined drying, namely, putting carrot slices on a sieve, sequentially starting a heating and blowing device and an ultrasonic irradiation device, and carrying out ultrasonic and hot air combined drying on the carrot slices, wherein the drying temperature is 30-70 DEG C, the drying air speed is 0.3-3m / s, the ultrasonic power is 100-200W, the ultrasonic frequency is 20kHz, the distance between the ultrasonic irradiation device and the sieve is 5-15cm and the drying time is 3-6 hours. According to the ultrasonic and hot air combined carrot drying method, an ultrasonic technology is directly and effectively coupled to a hot air drying process, so that the heat transfer and mass transfer efficiencies in the drying process are improved, the drying time is shortened, the energy consumption is saved and the product quality is improved.

Owner:HENAN UNIV OF SCI & TECH

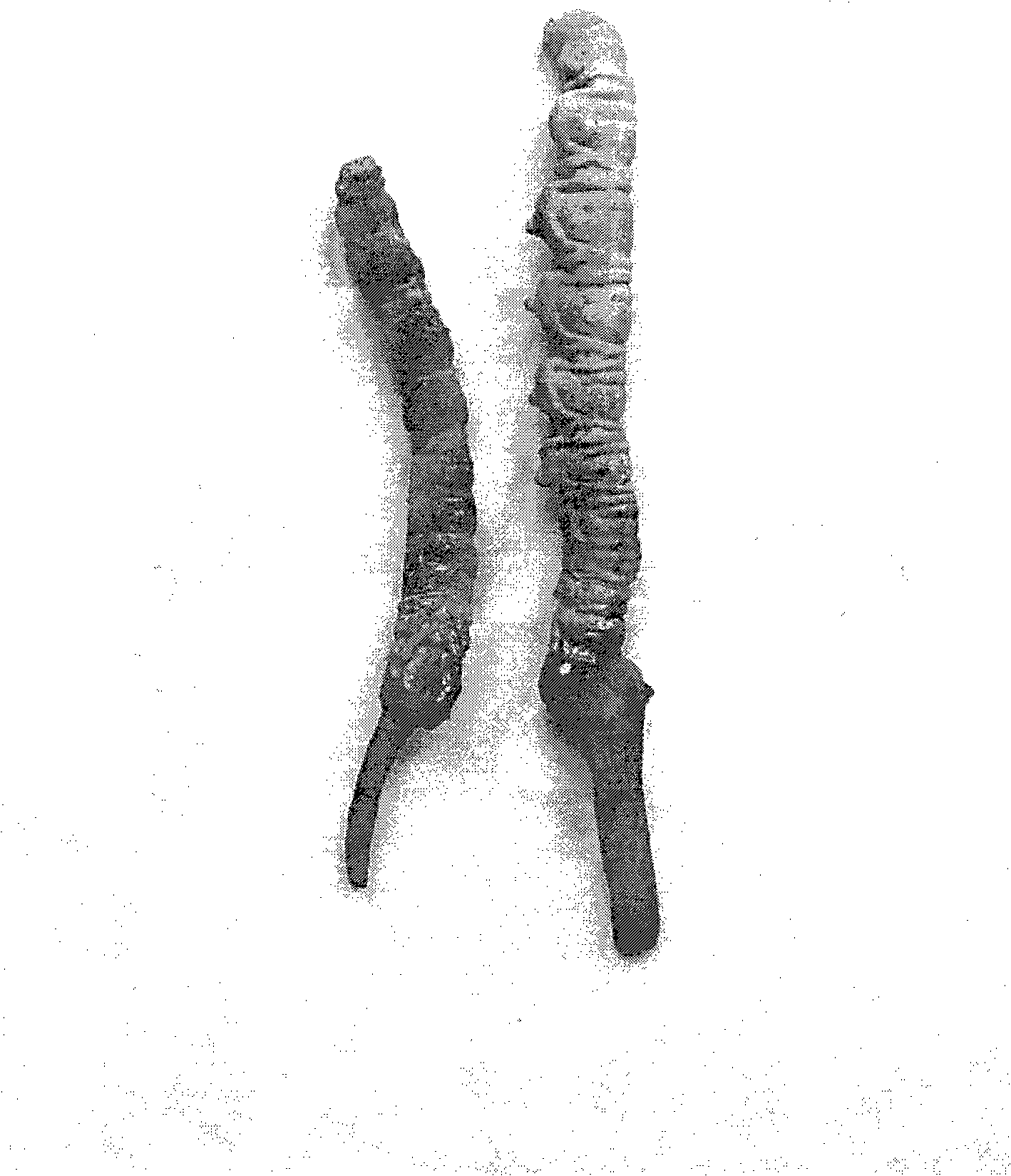

Biological vacuum freezing and drying method for aweto

InactiveCN101317562AFresh colorStrong fragranceDead plant preservationPlant ingredientsPreservation methodsOphiocordyceps sinensis

The invention relates to aweto biological vacuum freezing and drying method, belonging to the field of preservation method of animals and plants. The aweto biological vacuum freezing and drying method comprises the steps as follows: (1) the aweto absorbs low-temperature atomized water molecular, the water absorption is 75-80%; (2) quick freezing is carried out for 2-5 hours at the temperature of -50-55 DEG C; (3) the vacuum freezing and drying are carried out for 2-20 hours at the temperature of -45-55 DEG C, so as to lead the moisture content of the finished product to achieve 5-9%. The product obtained by the invention can achieve sanitary requirement of edible fungi which can be directly eaten; the product has good water absorption, really achieves the original shape, colour, tastes and nutritive effect of purely wild aweto, improves the real additive values of the aweto and is suitable for long-term storage.

Owner:吕坤秋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com