Probiotic ultralow temperature refrigeration technology and applications thereof in probiotic preparation

An ultra-low temperature freezing and probiotic preparation technology, which is applied in the application, bacteria, food preparation and other directions, can solve the problems of damage to the activity of probiotic strains, reduce the number of viable probiotic bacteria, etc., and achieve easy storage, fast freezing speed, and viable bacteria rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

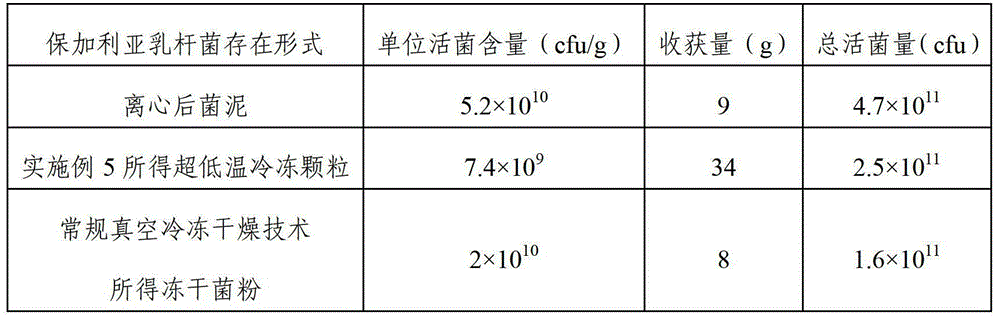

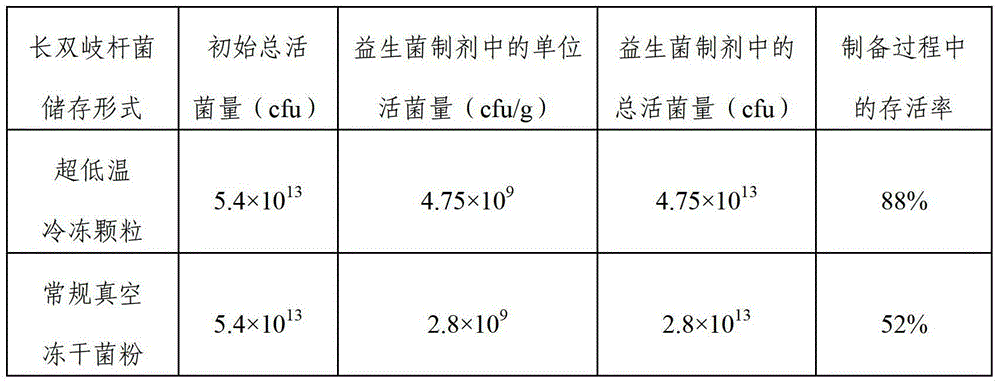

[0057] Example 1 Preparation of Probiotic Ultra-low Temperature Frozen Granules

[0058] The preparation method of probiotic ultra-low temperature frozen granules described in this embodiment is as follows:

[0059] (1) Preparation of fermentation medium: configure 5L of medium, by weight percentage, the proportion of each component in the medium is lactose 1%, glucose 2%, peptone 2%, yeast extract 1%, diammonium hydrogen citrate 0.5% 、K 2 HPO 4 0.1%, 0.5% anhydrous sodium acetate, 0.02% magnesium sulfate, the rest is distilled water, adjust the pH to 6.5, after preparation, sterilize at 121°C for 20 minutes, and set aside;

[0060] (2) Cultivate probiotics: Inoculate Lactobacillus bulgaricus, Streptococcus thermophilus, and Bifidobacterium lactis into the above-mentioned culture medium according to the inoculum amount of 5%, and cultivate them at a temperature of 37°C and a rotation speed of 50rpm for 16 hours, and then in Place at 15°C for 3 hours to obtain a probiotic fe...

Embodiment 2

[0067] Embodiment 2 A kind of yogurt starter granules that can be directly taken orally

[0068] A kind of preparation method of the directly oral yoghurt starter granule of the present embodiment comprises the following steps:

[0069] (1) Prepare 10 kg of compound raw materials, including dry materials and two kinds of probiotic ultra-low temperature frozen granules prepared in Example 1. The composition of dry materials is 2 kg of starch, 1 kg of sweet orange powder, 3 kg of erythritol, 2 kg of lactose, β -Polydextrose 1kg, all raw materials are passed through 80 mesh sieves to form fine powder for granulation;

[0070] (2) Mix the above dry materials evenly in the mixer;

[0071] (3) Under the storage condition of -20°C, take out 0.4kg of the ultra-low temperature frozen starter granules prepared in Example 1 and 0.6kg of the bifidobacterium granules prepared in Example 1, and melt at room temperature to re-form the bacterial suspension to obtain 0.4kg Bacterial suspensi...

Embodiment 3

[0075] Example 3 Preparation of Probiotic Ultra-low Temperature Frozen Granules

[0076] The preparation method of probiotic ultra-low temperature frozen granules described in this embodiment is as follows:

[0077] (1) Preparation of fermentation medium: 5L of medium is prepared, and the distribution ratio of each component in the medium is 2% lactose, 1% glucose, 1% peptone, 2.5% yeast extract, and 1% diammonium hydrogen citrate 、K 2 HPO 4 0.5%, 0.1% anhydrous sodium acetate, 0.05% magnesium sulfate, the rest is distilled water, adjust the pH to 6.5 with NaOH solution, sterilize at 121°C for 20 minutes after preparation, and set aside;

[0078] (2) Cultivate probiotics: Inoculate Lactobacillus acidophilus, Streptococcus thermophilus, and Lactobacillus rhamnosus into the above-mentioned culture medium according to the inoculation amount of 5%, and cultivate them at a temperature of 37°C for 16 hours, with a stirring speed of 50rpm , and then placed at 15°C for 5 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com