Patents

Literature

635results about How to "Low freezing point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

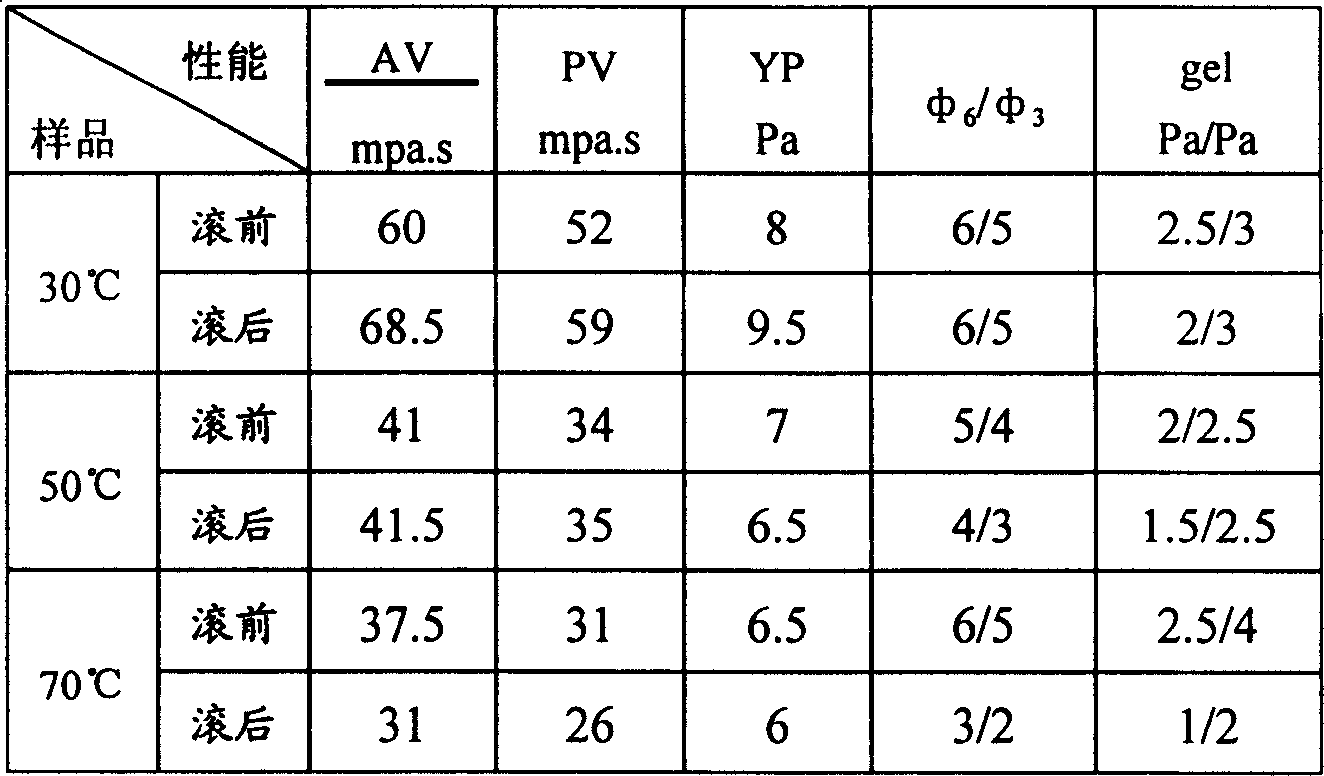

Drilling fluid with synthesized substrate

A synthetic basic well-drilling liquid is proportionally prepared from the basic liquid composed of basic liquid and aqueous solution of CaCl2, primary emulsifier, secondary emulsifier, wetting agent, flowing regulator, filter loss reducer and organic earth through mixing. Its advantages are no pollution and high effect to protect oil-bearing stratum.

Owner:CNOOC TIANJIN BRANCH +3

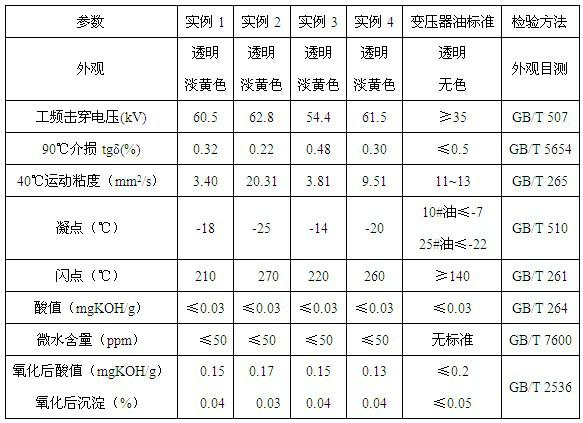

Vegetable insulating oil, and preparation method of vegetable insulating oil

InactiveCN102682869AImprove performanceReduce the temperatureLiquid organic insulatorsBase-materialsVegetable oilAnti oxidant

The invention relates to vegetable insulating oil based on vegetable oil, and a preparation method of the vegetable insulating oil. The insulating oil is prepared by the steps of using refined vegetable oil as raw material, carrying out ester exchange reaction on low-molecular alcohol, refining and washing after the reaction, rinsing, distilling under reduced pressure in order to remove water and alcohol, de-coloring, de-acidifying, filtering, de-watering deeply, finally adding antioxidant and pour point depressant. The insulating oil prepared by the method has the characteristics of high flashing point, low viscosity, low pour point, low acidity, low brackish water content, excellent dielectric constant, low dielectric loss and high breakdown voltage and has good physical and chemical performance and electrical performance.

Owner:CHINA ELECTRIC POWER RES INST

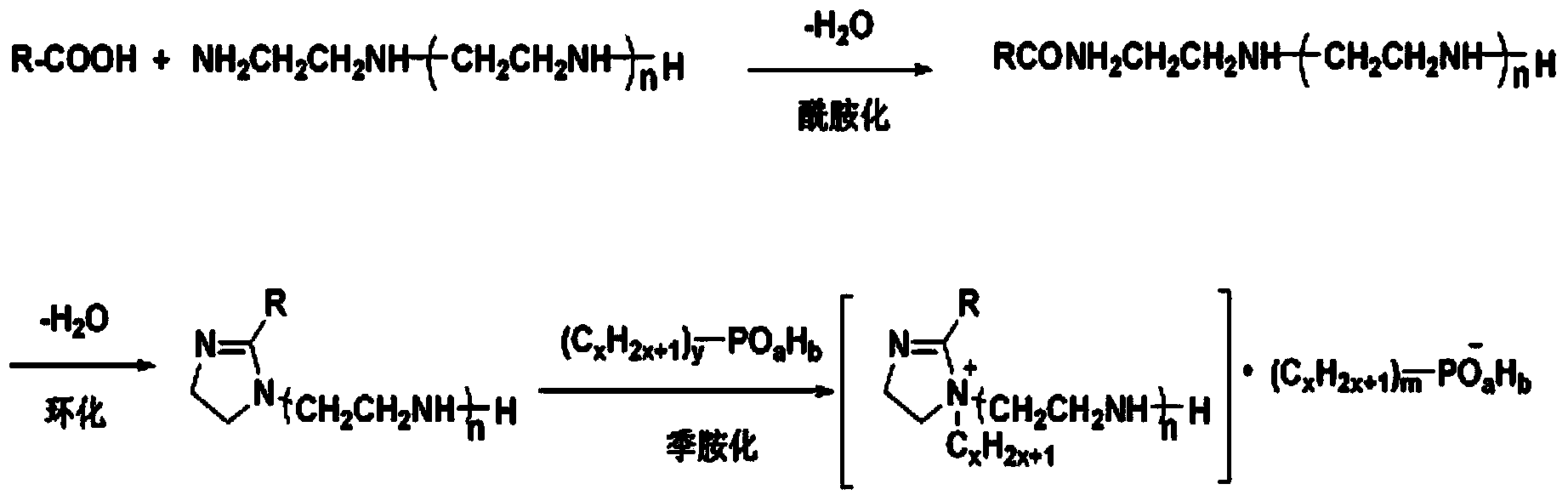

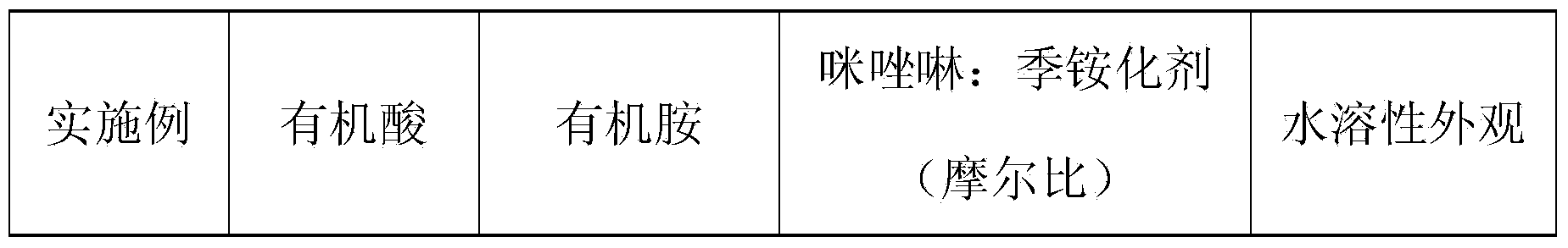

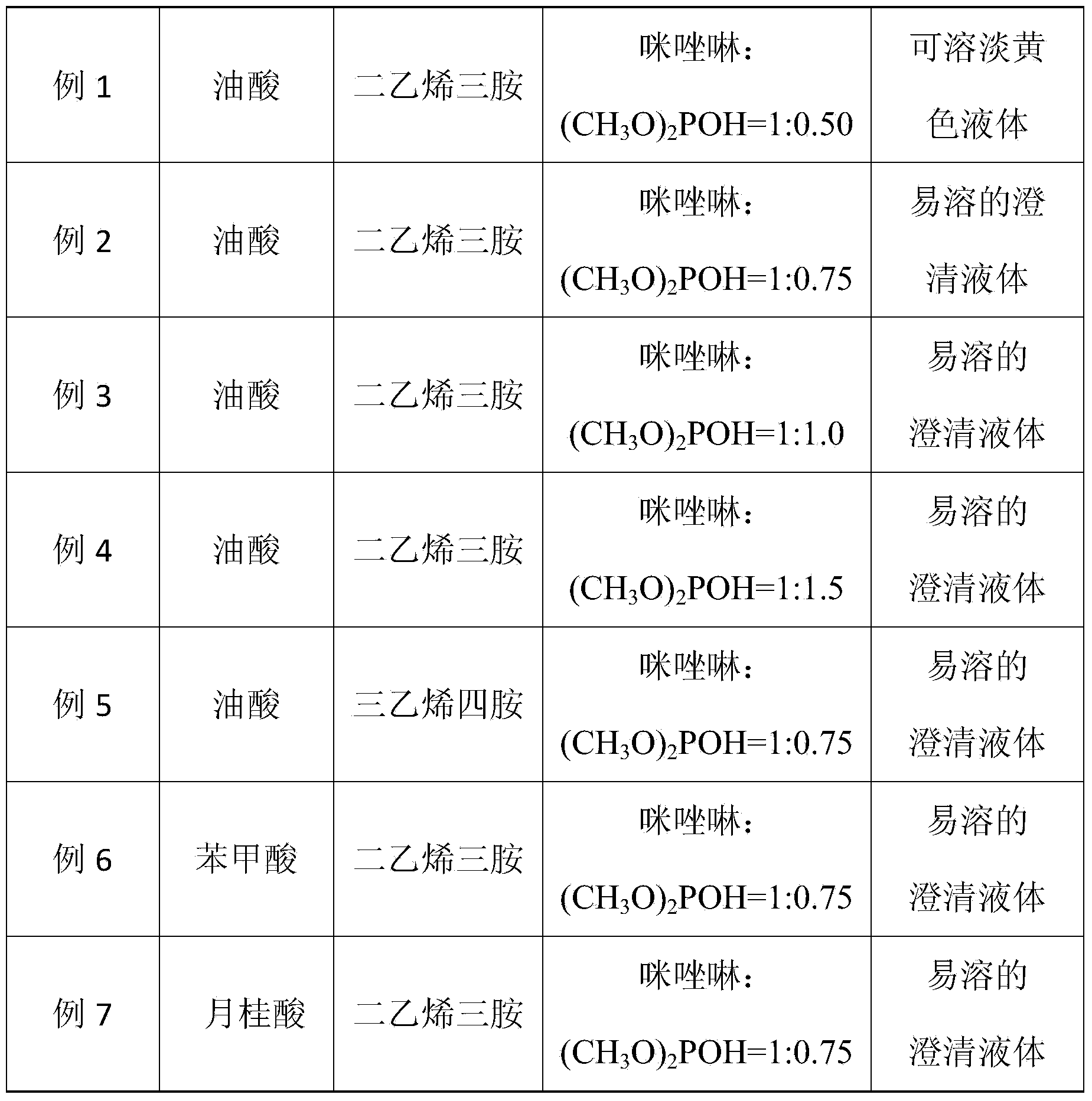

Method for synthesizing water-soluble imidazoline quaternary ammonium salt corrosion inhibitor

ActiveCN103554027ALow freezing pointGood water solubilityGroup 5/15 element organic compoundsSolubilityOrganic acid

The invention discloses a method for synthesizing a water-soluble imidazoline quaternary ammonium salt corrosion inhibitor. The method is characterized by comprising the following steps of performing amidation reaction on reaction raw materials organic acid and organic amine to synthesize amide, performing amide cyclization reaction to obtain imidazolidine, and quaternizing the oil-soluble imidazolidine by using a quaternizing agent such as dimethyl phosphite to synthesize the water-soluble imidazoline quaternary ammonium salt corrosion inhibitor. Evaluation tests show that an obtained product is high in water solubility and corrosion inhibition rate.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

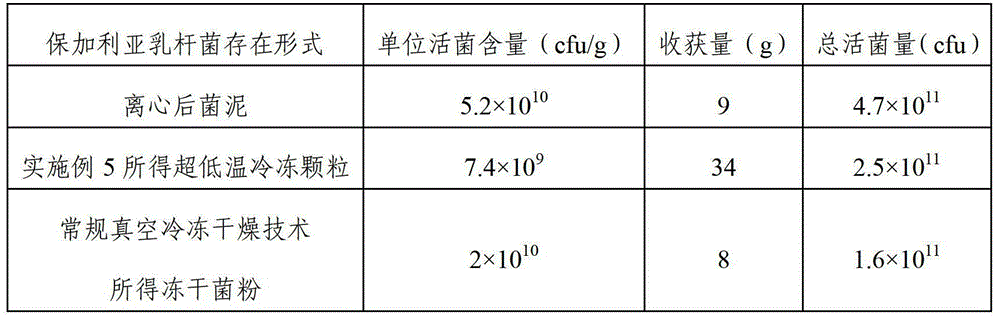

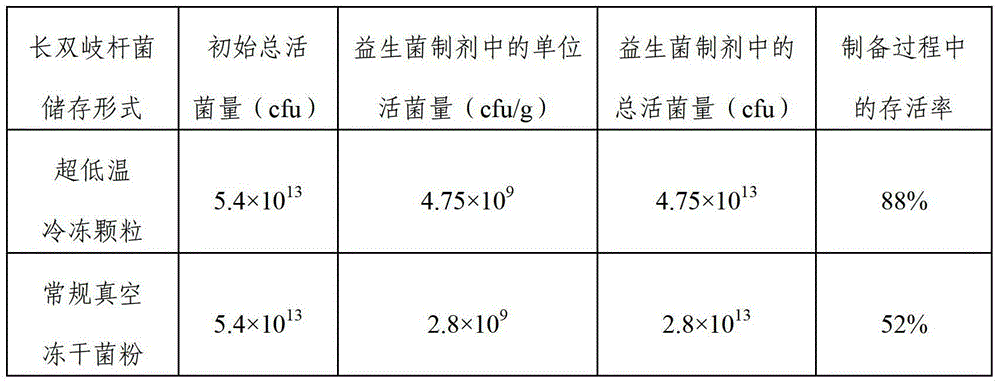

Probiotic ultralow temperature refrigeration technology and applications thereof in probiotic preparation

ActiveCN103333840AHigh activityLow freezing pointBacteriaFood preparationBacterial strainRefrigeration

The invention discloses a probiotic ultralow temperature refrigeration technology, a formula of a total-salt cryoprotectant which is suitable for the probiotic ultralow temperature refrigeration technology, and probiotic ultralow temperature refrigeration particles prepared by using the probiotic ultralow temperature refrigeration technology. The probiotic ultralow temperature refrigeration technology comprises following steps: (1) preparing a fermentation medium; (2) culturing probiotics; (3) centrifuging; (4) preparing the cryoprotectant; (5) adding the cryoprotectant; and (6) quick-freezing and moulding. The invention also provides a probiotic preparation prepared by using the probiotic ultralow temperature refrigeration particles, and a preparation method of the probiotic preparation. The probiotic ultralow temperature refrigeration particles are probiotic refrigerated bacterial strains which do not need to be dried and possesses advantages of fast refrigeration speed, high living bacterial rate and excellent rehydration performance. The probiotic ultralow temperature refrigeration particles contain water, can be dissolved in solutions more quickly, and are capable of preventing probiotic cells from damage caused by rehydration of normal low temperature refrigeration dried probiotic powder, and increasing the living bacterial rate of the probiotic preparation greatly.

Owner:THANKCOME BIOLOGICAL SCI & TECH CO LTD

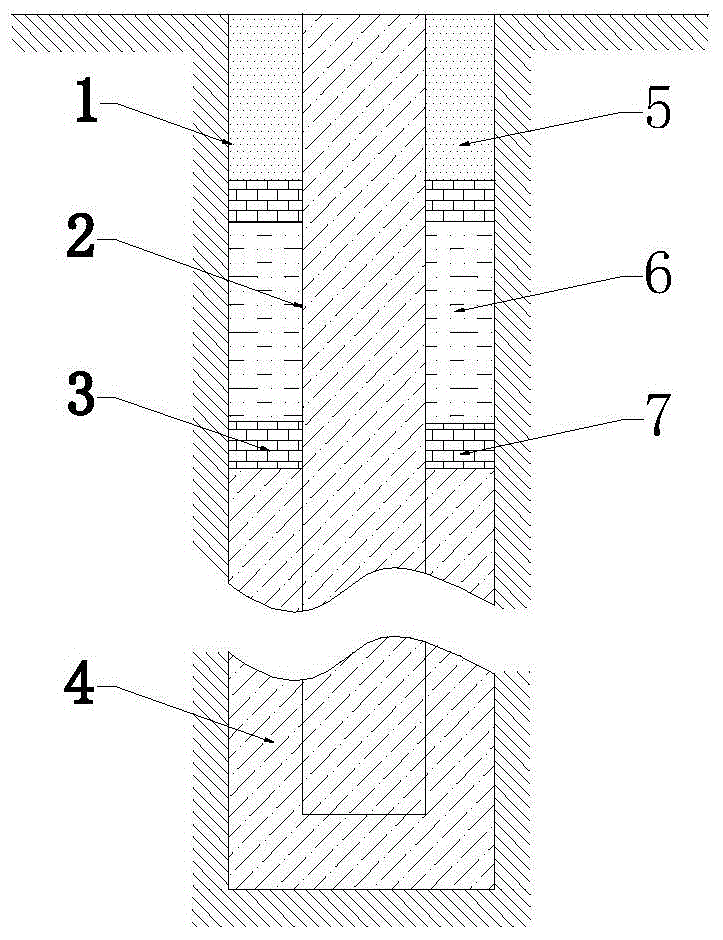

Supercritical carbon dioxide completion fluid

InactiveCN104910881AAvoid pollutionLow viscosityDrilling compositionSealing/packingOil and natural gasCement slurry

The invention belongs to the technical field of petroleum and natural gas well completion, and relates to a supercritical carbon dioxide completion fluid. The supercritical carbon dioxide completion fluid is prepared by mixing a preflush spacer fluid, a supercritical carbon dioxide flushing solution and a post-flush spacer fluid according to a volume ratio of 2-5:100:1-5. When the supercritical carbon dioxide completion fluid is used, the supercritical carbon dioxide flushing solution and a cementing slurry are prepared on the ground, the preflush spacer fluid and the post-flush spacer fluid are prepared, the preflush spacer fluid, the supercritical carbon dioxide flushing solution, the post-flush spacer fluid and the cementing slurry are sequentially pumped into a well head through a present fluid device in order to flush, the cementing slurry solidifies after the flushing, and an alkaline substance is injected from an annulus to remove carbon dioxide in the supercritical carbon dioxide flushing solution in order to prevent pollution of carbon dioxide to atmosphere and corrosion of carbon dioxide to bushings. The supercritical carbon dioxide completion fluid has the advantages of easily available raw materials, scientific principle, use convenience, good cementing effect, low cost, effective reduction of the thickness of mud cakes, and improvement of the cleanliness and roughness of the mud cakes.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

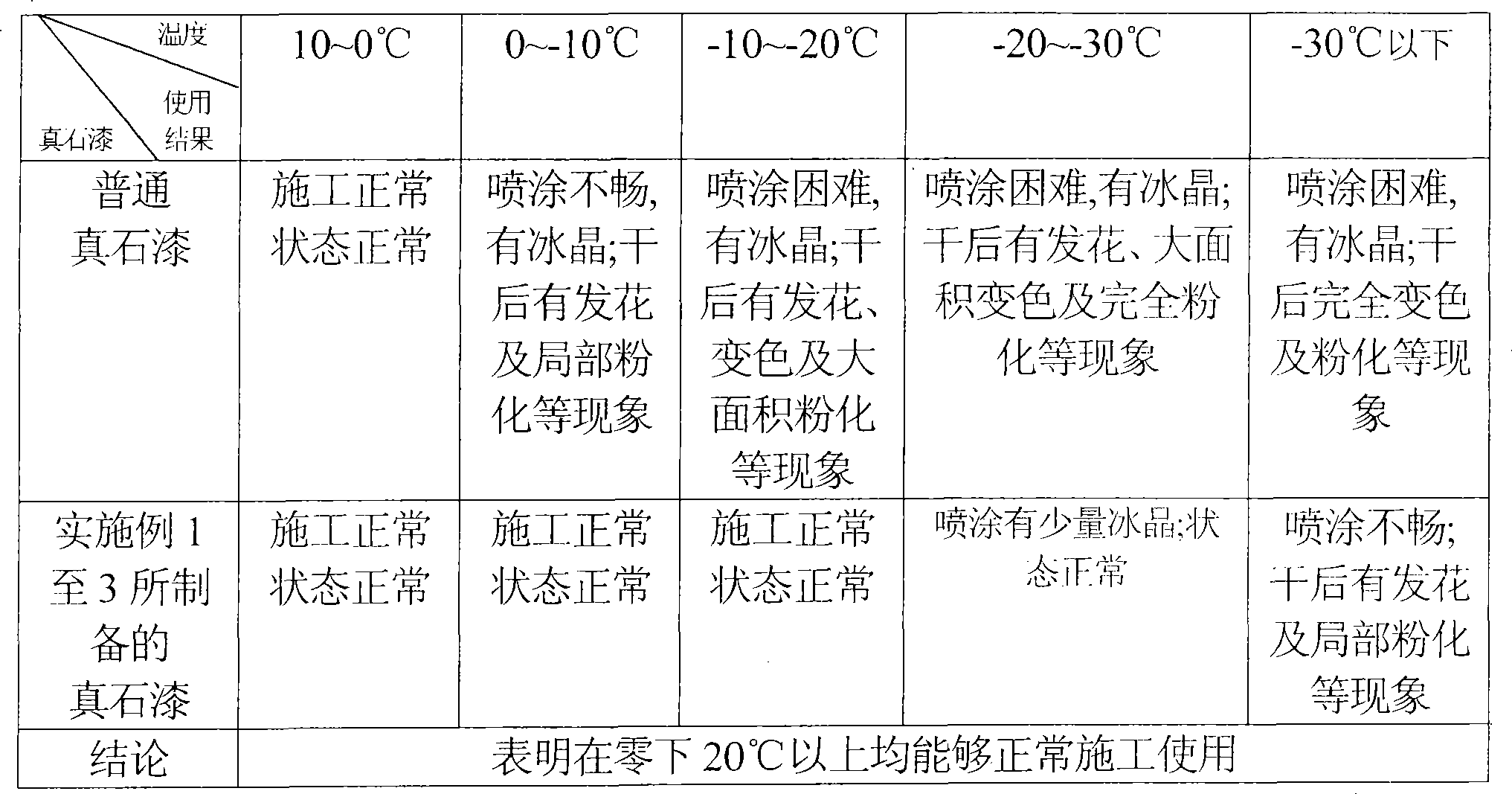

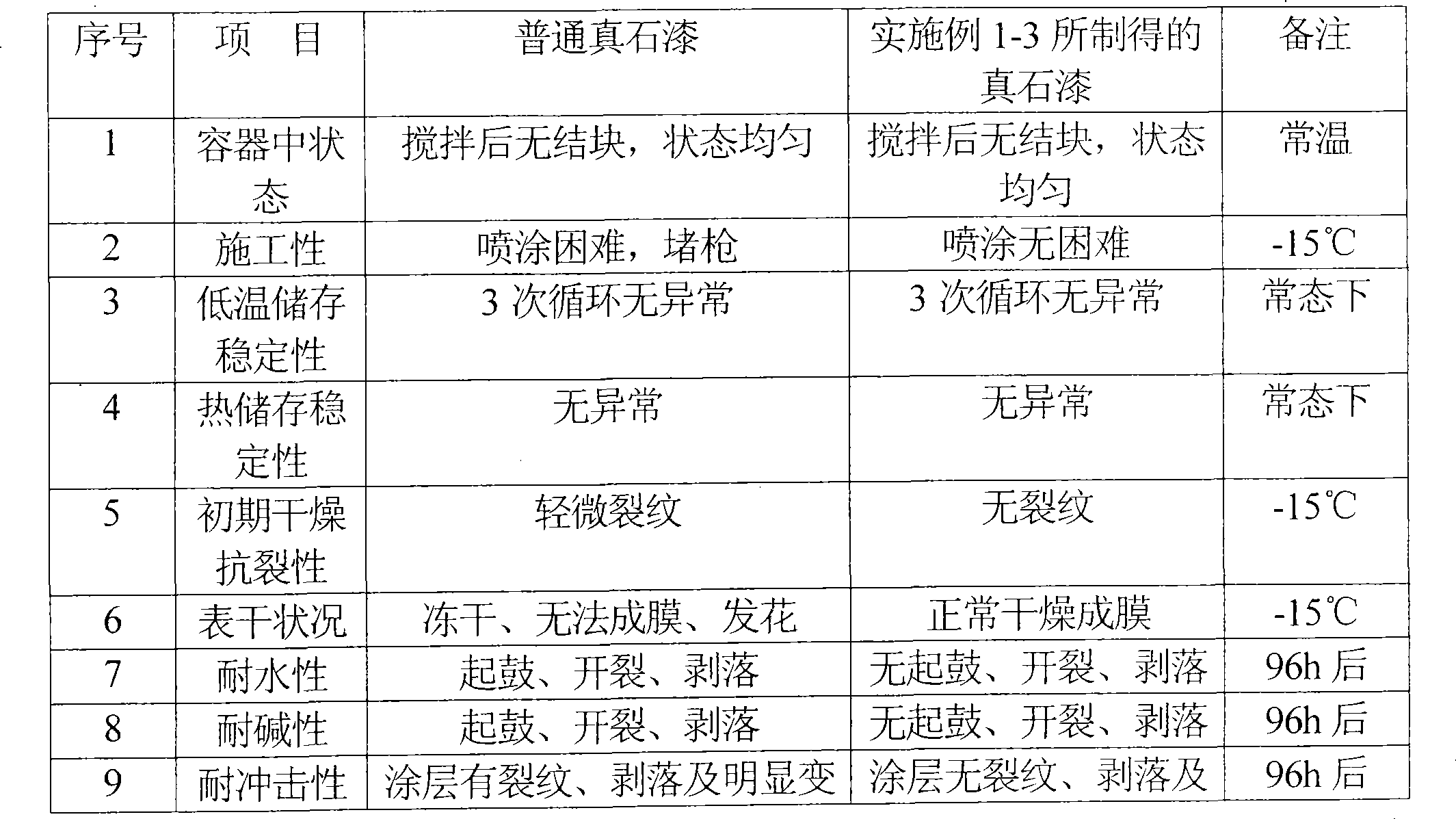

Environment friendly antifreezing stone-like paint and preparation thereof

The invention discloses an environment freeze protection stone paint, which comprises the following raw material components according to the parts by weight: 0.1-5 of fibrin aqueous solution of 1-4% concentration, 0.8-1.2 of glycol, 50-70 of colored sand of 41-80 mesh, 5-25 of colored sand of 81-120, 17-23 of KE025 acrylic emulsion, 0.6-0.9 of alcohol ester-12 addition agent, 0.02-0.06 of foam killer, 0.01-0.1 of thickness agent and 0.02-0.06 of neutralizing agent. Meanwhile, the invention also discloses a preparation method for the stone paint. The stone paint has the environment and freeze protection performance, provides powerful guarantee for being suitable for winter construction, in particular to various severe conditions of winter construction in the northern area of our country.

Owner:许军 +1

Special private care wet tissue for women

InactiveCN103340816AGood killing effectNo side effectsCosmetic preparationsToilet preparationsSide effectIrritation

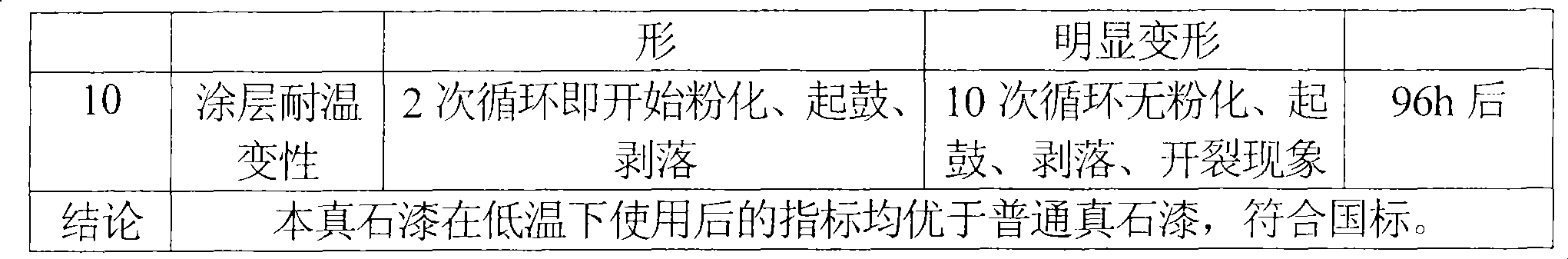

The invention provides a special private care wet tissue for women. The private care wet tissue is produced through the following steps of: preparing a wet tissue stock solution from a nanosilver solution, water soluble vitamin E, hyaluronic acid, lauric acid modified superoxide dismutase, chamomile flower water, a hydrolyzed pearl solution, a saponin extract, 1,2-propylene glycol, isothiazolinone and deionized water at a certain ratio; evenly and dropwise adding the wet tissue stock solution on a nonwoven spunlace membrane; then hermetically packaging the nonwoven spunlace membrane. For use, the special private care wet tissue for women provided by the invention only needs to be put to flatly cover the private part of a woman, and after a short wait, the wet tissue is used for wiping the private part of the women back and forth a plurality of times. The private care wet tissue special for women provided by the invention is capable of sterilizing and disinfecting the private part of the woman, and also capable of moisturizing and cleaning the skin of the private part; the private care wet tissue has no any side effect and no any irritation.

Owner:深圳市妍倩科技有限公司

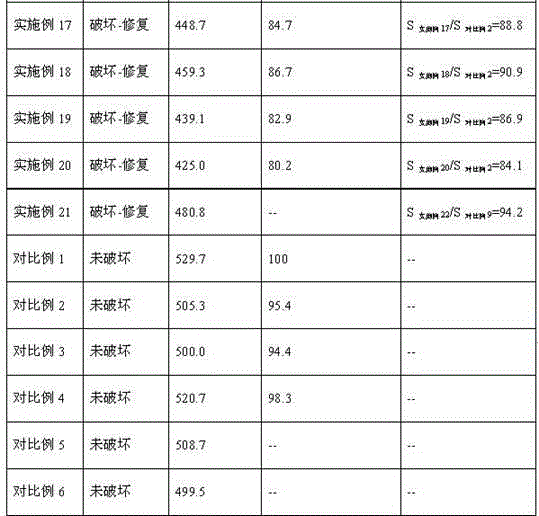

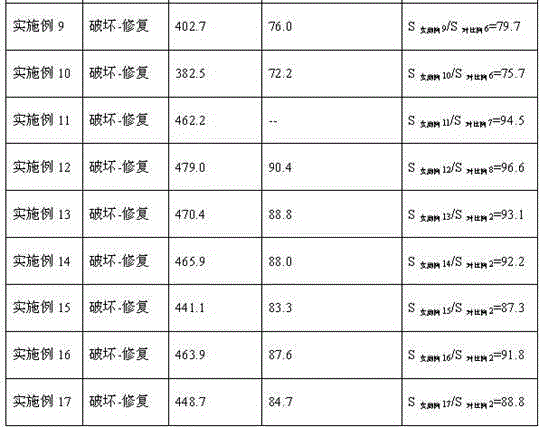

Room-temperature self-repairing fiber-reinforced epoxy composite material and preparation method thereof

The invention discloses a room-temperature self-repairing fiber-reinforced epoxy composite material and a preparation method thereof. According to the method, a repairing agent is loaded in a capillary tube, and buried among fiber-reinforced epoxy composite material layers, and the repairing agent contains a certain amount of foaming agent. After being formed, the composite material is heated above the decomposition temperature of the foaming agent, so that the interior of the capillary tube produces positive pressure. When the material is damaged to cause the breakage of the capillary tube, the repairing agent can fast flow to a breakage surface and produce reaction under the promotion of pressure, thus rebinding cracks together and repairing the damage of the material. The material has the outstanding characteristics that the capillary tube can provide enough repairing agent, so that the material has higher repair efficiency; through the introduction of the foaming agent, the repairing agent in the capillary tube can be guaranteed to fast flow automatically when the material is damaged.

Owner:SUN YAT SEN UNIV

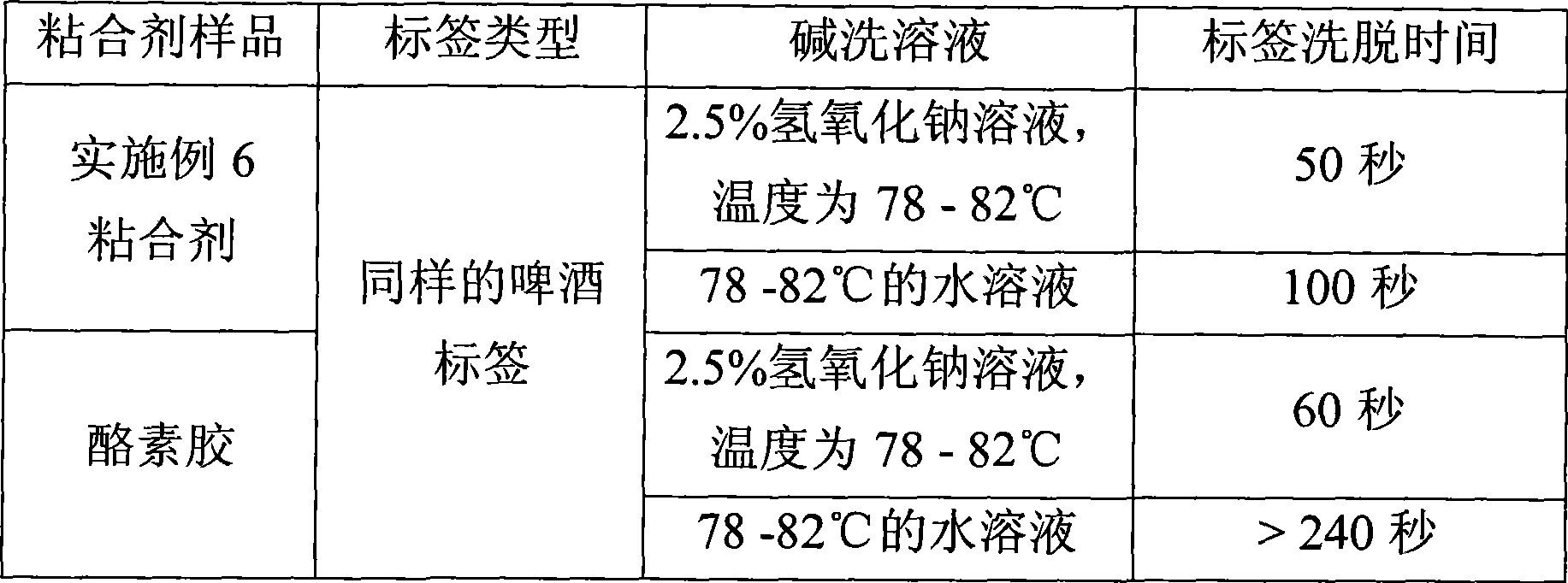

Adhesive, preparation and use thereof

InactiveCN101440269AGood initial adhesionLow freezing pointProtein waste adhesivesStarch adhesivesEnzymatic hydrolysisAdhesive

The invention provides an adhesive for labeling, which comprises 1 to 40 percent of animal glue, 0 to 45 percent of emulsion, 0 to 20 percent of starch, 5 to 40 percent of diluting agent, 0 to 10 percent of cross-linking agent, 0 to 5 percent of thickening agent, 0.001 to 2 percent of additive, and 20 to 50 percent of water. The adhesive has the advantages of good initial adhesion, low solidification point, good water resistance, strong enzyme hydrolysis resistant stability, elution in non-alkaline high temperature water and so on, well meets the requirements of improving production speed, improving the qualification rate of the production and recovering containers at present, and is particularly used for labeling beer bottles.

Owner:HENKEL KGAA

Anti-reburning environment-friendly power transmission line forest fire extinguishing agent

The invention discloses an anti-reburning environment-friendly power transmission line forest fire extinguishing agent. The anti-reburning environment-friendly power transmission line forest fire extinguishing agent comprises the following components in parts by weight: 5-20 parts of ammonium carbonate, 10-45 parts of ammonium polyphosphate, 10-30 parts of sodium silicate, 1-10 parts of a foaming agent, 0.5-5 parts of polyethylene glycol, 1-5 parts of a thickening agent, 4-10 parts of a composite anti-freezing agent and 55-80 parts of water, wherein the foaming agent is selected from one of alkylethoxylate carboxylate, an imidazoline amphoteric surfactant and a biological surfactant; the composite anti-freezing agent is a compound which is prepared by compounding inorganic salt and polyhydric alcohol according to a mole ratio of (1 to 3)-(1 to 9). All the raw materials of the anti-reburning environment-friendly power transmission line forest fire extinguishing agent are environment-friendly materials, so that the fire extinguishing agent is free of fluorine compound, toxicity, smell and pollution; a fire retardant is added into the fire extinguishing agent, so that the fire extinguishing agent is capable of effectively preventing the fire from spreading and is high in fire extinguishing efficiency; the environment-friendly surfactant serves as the foaming agent, so that the fire extinguishing agent is high in foaming performance and is capable of effectively isolating contact between the combustion material and the air and accelerating the fire extinguishing speed; the anti-freezing agent is compounded by the inorganic salt and polyhydric alcohol, so that the freezing point of the fire extinguishing agent is reduced to be -30 DEG C.

Owner:STATE GRID CORP OF CHINA +2

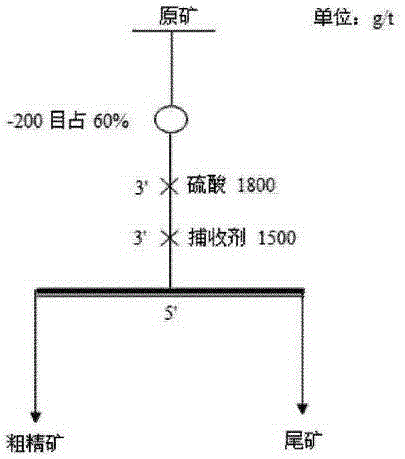

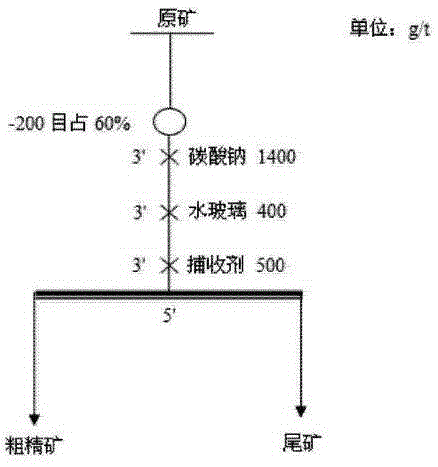

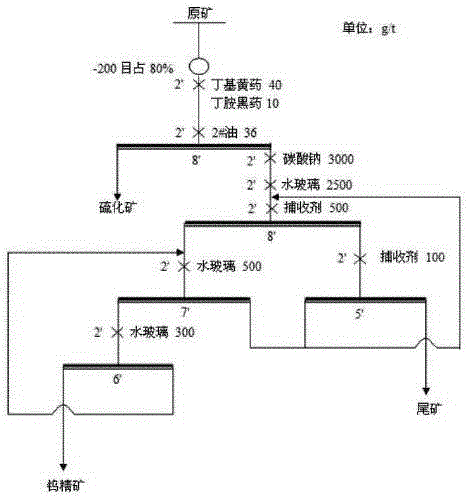

Non-sulfide mineral flotation collector, preparation method thereof and application thereof

The invention discloses a non-sulfide mineral flotation collector, a preparation method thereof and an application thereof, and belongs to the technical field of mineral flotation collectors. The non-sulfide mineral flotation collector is obtained by mixing phosphoric acid-2-ethylhexyester or / and 2-ethylhexyl phosphoric acid-2-ethylhexyl ester and sodium oleate or oxidized paraffin soap and the like for use. The non-sulfide mineral flotation collector has the characteristics of good water solubility, good dispersion, strong selective adsorption capacity on target minerals and the like, and is mainly used for floatation separation of useful minerals in ilmenite, scheelite, wolframite, phosphorite, bauxite, rare earth ores, tin ores, fluorite mines or manganese carbonate ores. The preparation method for the non-sulfide mineral flotation collector is simple in process, easy to control in operation, wide in raw material source, low in cost, safe and environmentally-friendly, high in product recovery rate, and easy to realize industrial production.

Owner:河南天鸿新材料科技有限公司

Water-based extinguishing agent and preparing method

The invention discloses a water-based extinguishing agent. The water-based extinguishing agent is prepared by raw materials including, by mass percent, 20% to 50% of a composite coagulant reduction agent, 0.5% to 2.0% of a thickening agent, 7% to 20% of a fire retardant, 4% to 10% of a stabilizing agent, 4% to 16% of a micro-foaming agent, 0.5% to 4% of a hardness-resisting agent, 0.2% to 5% of a solubilizing agent, 0.1% to 0.5% of a corrosion remover and the balance water. According to the water-based extinguishing agent, a food additive serves as a main raw material, a fluorocarbon surfactant is not contained, and the agent has the beneficial effects of being low in solidifying point, high in fire extinguishing cooling speed, capable of rapidly extinguishing fires of solids, liquid, gas and electrified and cooking objects, high in after-combustion resistance capacity, meanwhile, free of harms and pollutions to plants, animals, soil and water, capable of achieving complete biodegradation, energy-saving and environment-friendly.

Owner:浙江环亚消防新材料股份有限公司

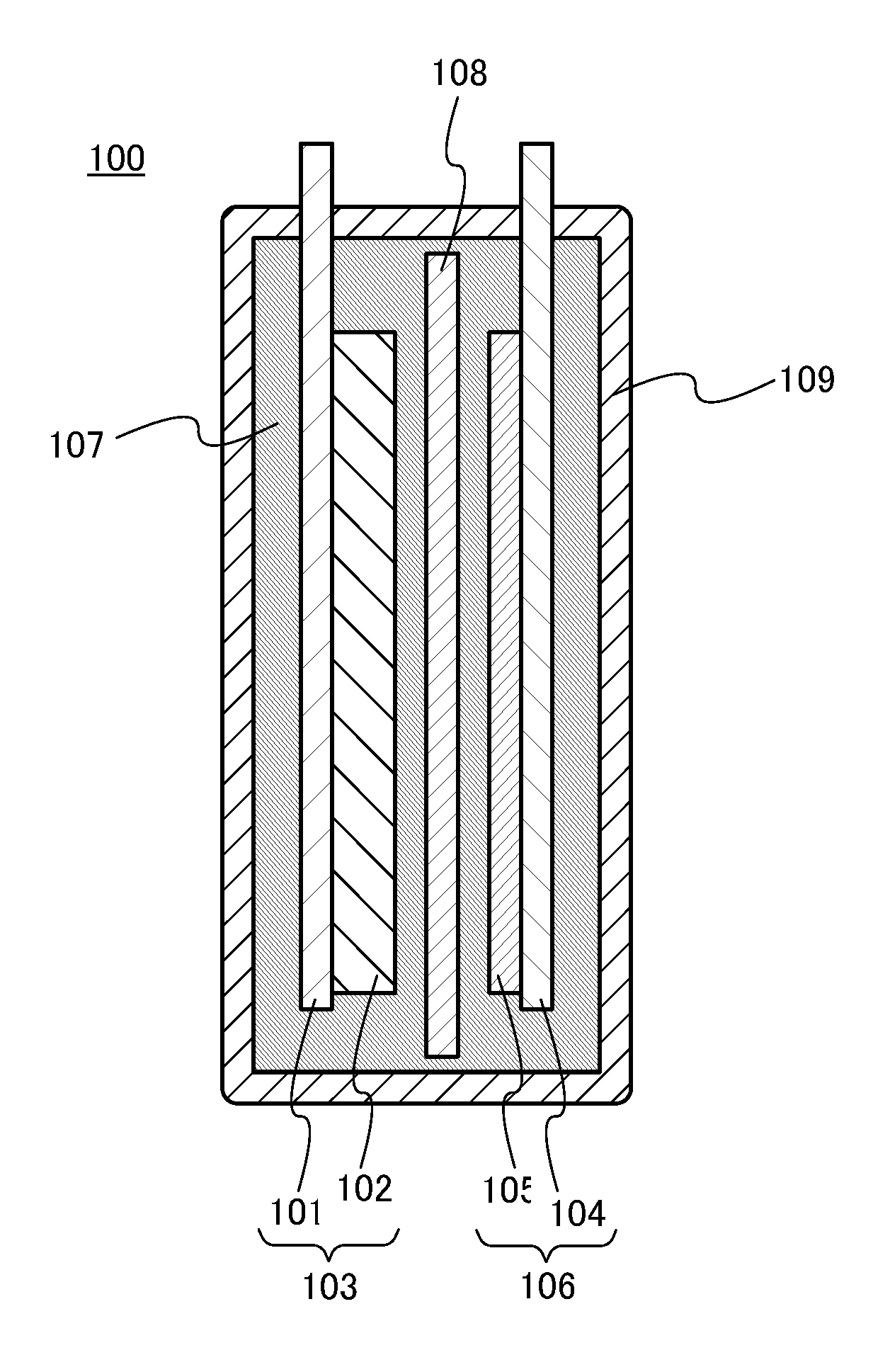

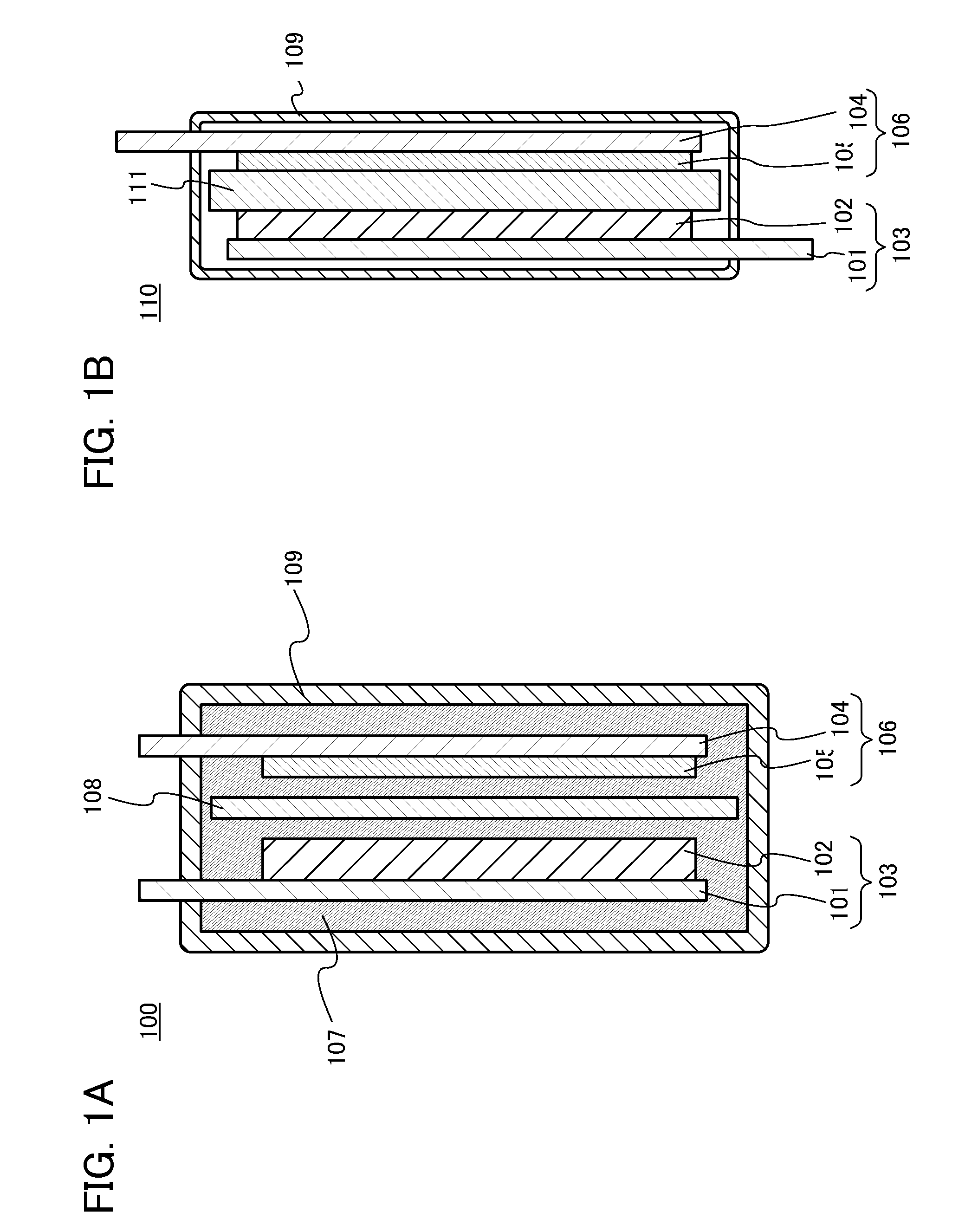

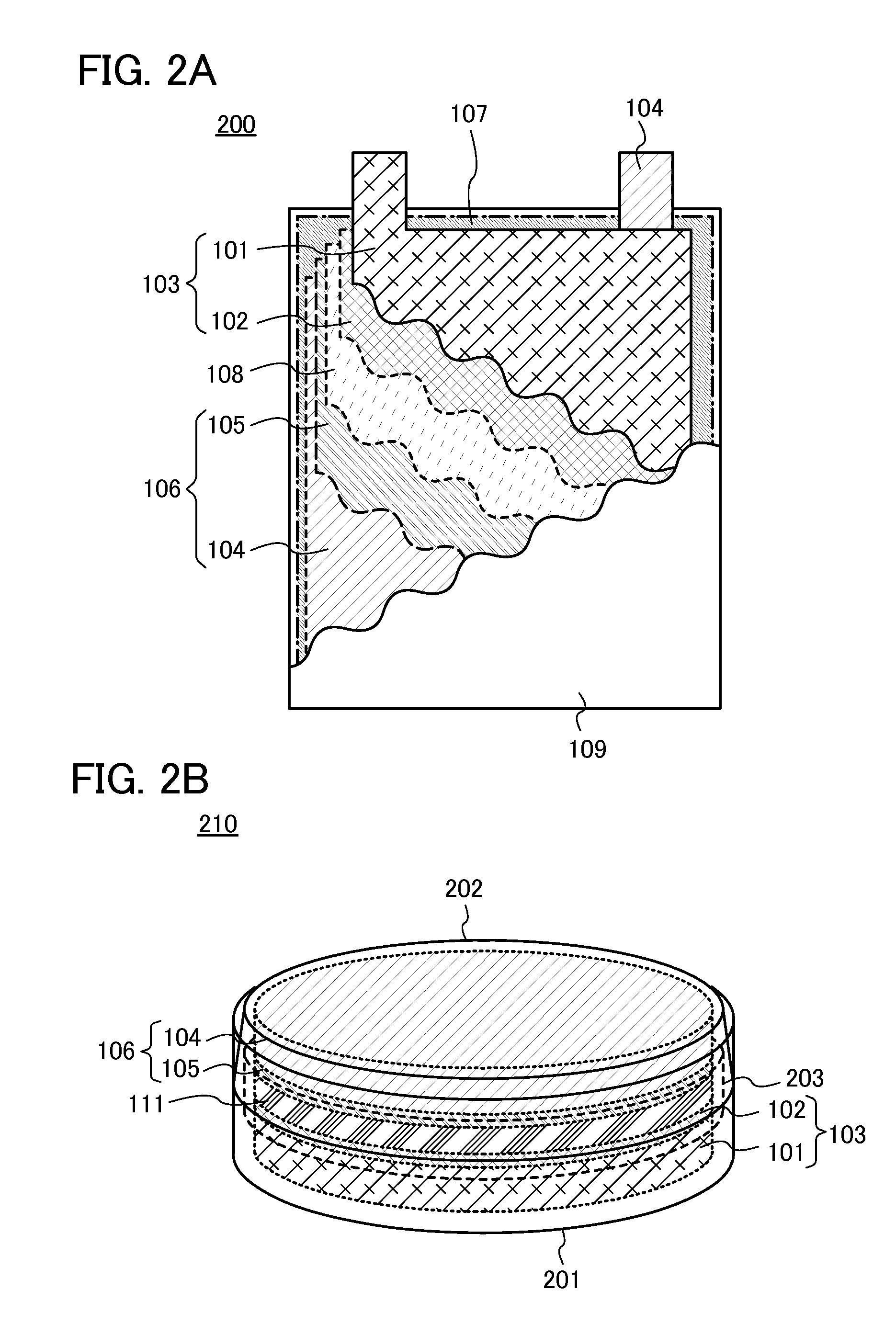

Nonaqueous solvent and power storage device

InactiveUS20120328960A1Excellent reduction resistanceLow freezing pointHybrid capacitor electrolytesElectrolytic capacitorsQuaternary ammonium cationPhysical chemistry

A nonaqueous solvent having excellent reduction resistance, which can be applied to an electrolyte solution, is provided. Further, a nonaqueous solvent which can be used in a wide temperature range and applied to an electrolyte solution is provided. Furthermore, a high-performance power storage device is provided. A nonaqueous solvent containing at least an ionic liquid including an alicyclic quaternary ammonium cation having one or more substituents and a counter anion to the alicyclic quaternary ammonium cation, and a freezing-point depressant is provided. A power storage device including the nonaqueous solvent for an electrolyte solution is also provided.

Owner:SEMICON ENERGY LAB CO LTD

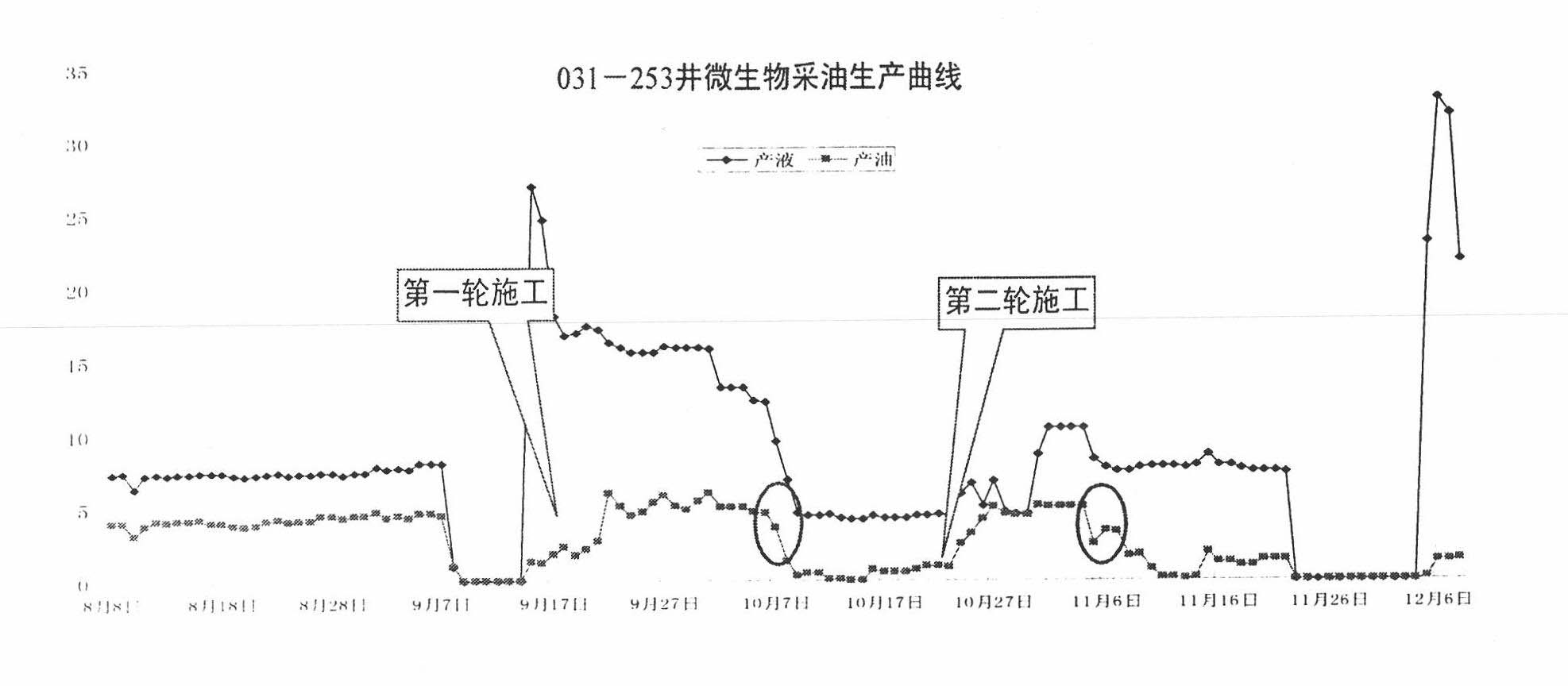

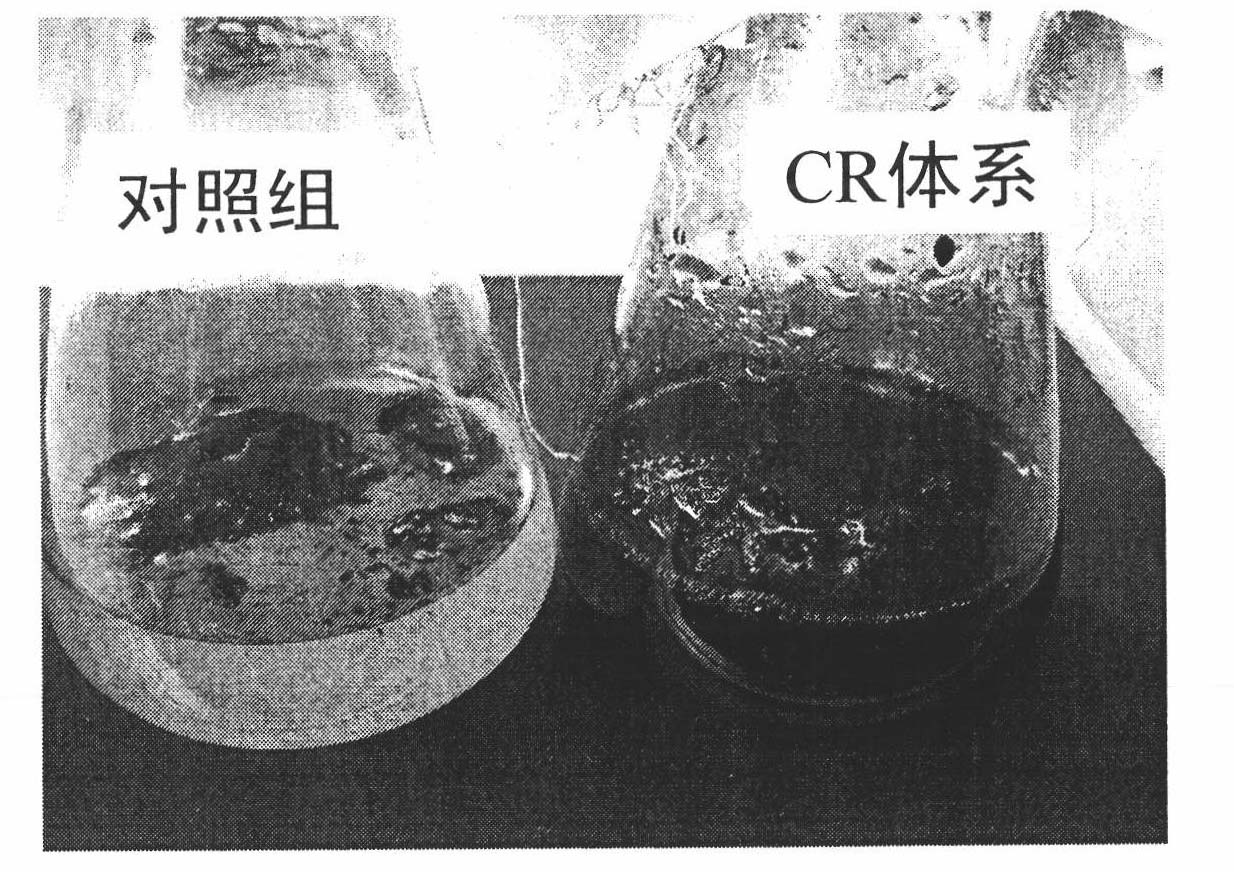

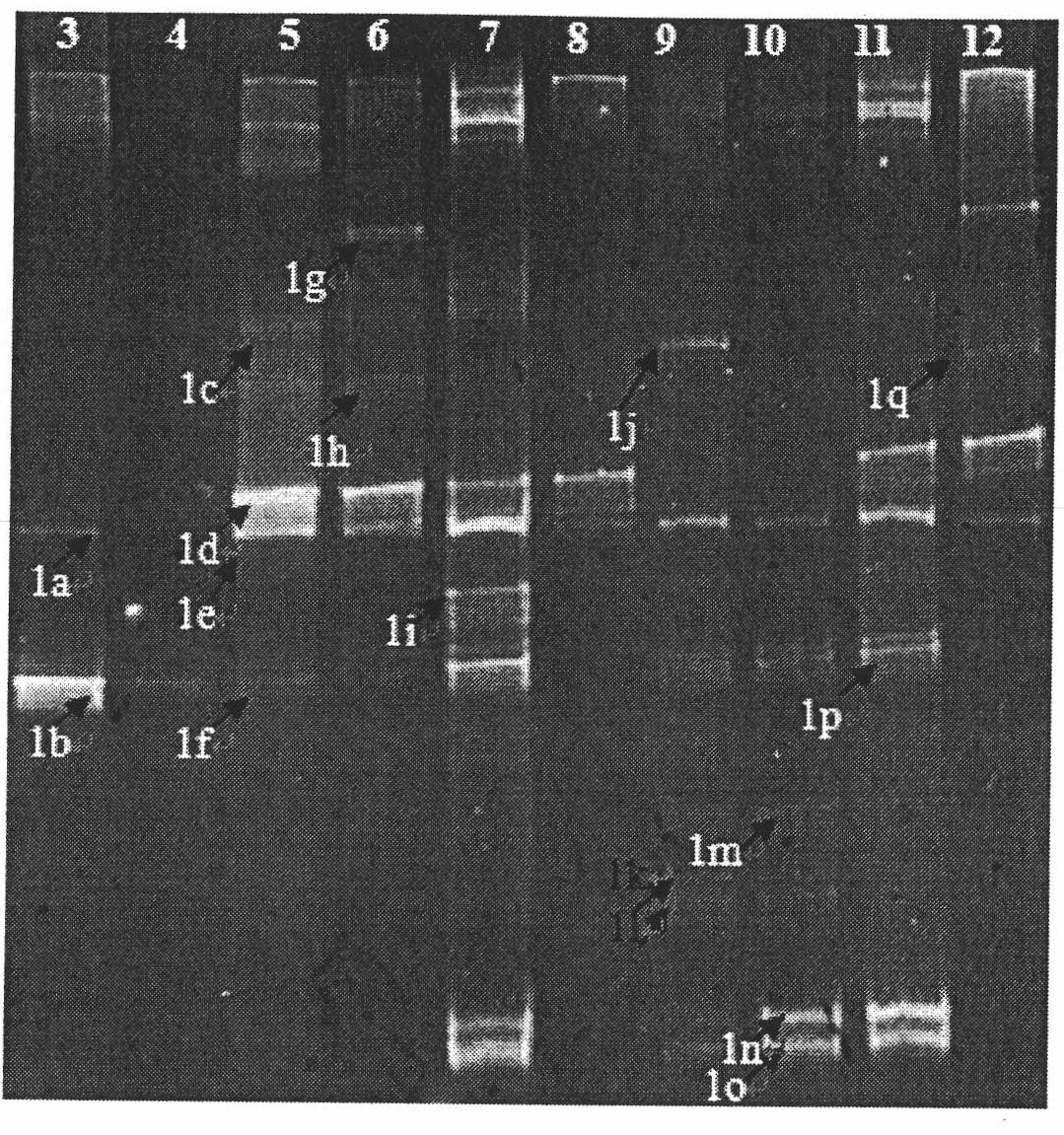

Method for increasing oil recovery ratio by utilizing symbiotic reproduction and complex metabolism and microbial preparation

The invention discloses a method for increasing the oil recovery ratio by utilizing symbiotic reproduction and complex metabolism and a microbial preparation, the CR-CM principle is mainly utilized for periodically injecting exogenous oil production microbes, an activating agent and air into a target oil layer, and an endogenous and exogenous oil production microbial new system (CR) is established in the oil layer by greatly activating endogenous oil production microbes. All the oil production microbes in the CR system are mutually linked through a biological chain through the technical control, and the complex metabolism (CM) which is conductive to oil production is further produced, thereby realizing the purposes of increasing the oil and increasing the recovery ratio under the dual-function of the oil production microbes and complex metabolites thereof. The method can not only increase the oil production, but also improve the oil reservoir conditions, increase the final recovery ratio by more than 4% and prolong the exploitation time by 3-5 years. For an oil field with high viscosity and high wax content, the method can reduce the viscosity of thick oil by more than 24%, reducea freezing point by 5-10 DEG C, increase the final recovery ratio by more than 5% and prolong the exploitation time by more than 5 years.

Owner:华汉生态修复新技术有限公司

Anti-aging skincare mask containing crithmum maritimum

InactiveCN107334725ALow freezing pointEasy to synthesizeCosmetic preparationsToilet preparationsFennel extractCentella asiatica extract

The invention discloses an anti-aging skincare mask containing crithmum maritimum. The anti-aging skincare mask is prepared from a skin conditioner component, an auxiliary component and water, wherein the skin conditioner component is prepared from 2%-6% by mass of butanediol, 2%-5% by mass of glycerin, 0.1%-0.5% by mass of a crithmum maritimum extract, 1%-5% by mass of a pseudoalteromonas fermentation product extract, 1%-5% by mass of acetyl hexapeptide-8, 0.5%-3% by mass of a Centella asiatica extract, 0.5%-2% by mass of D-panthenol, 0.03%-0.1% by mass of sodium hyaluronate, 1%-5% by mass of Chamomile German water, 0.5%-3% by mass of corn protein amino acids, 1%-3% by mass of a lotus extract, 0.5%-2% by mass of bio-saccharide gum-1 and 0.1%-0.3% by mass of allantoin. The anti-aging skincare mask containing crithmum maritimum can inhibit lipid peroxidation and inflammatory reaction, rebuild water balance and brighten complexion and has effects of preserving moisture, resisting aging, brightening the complexion and realizing anti-allergic repair.

Owner:广州蜜妆生物科技有限公司

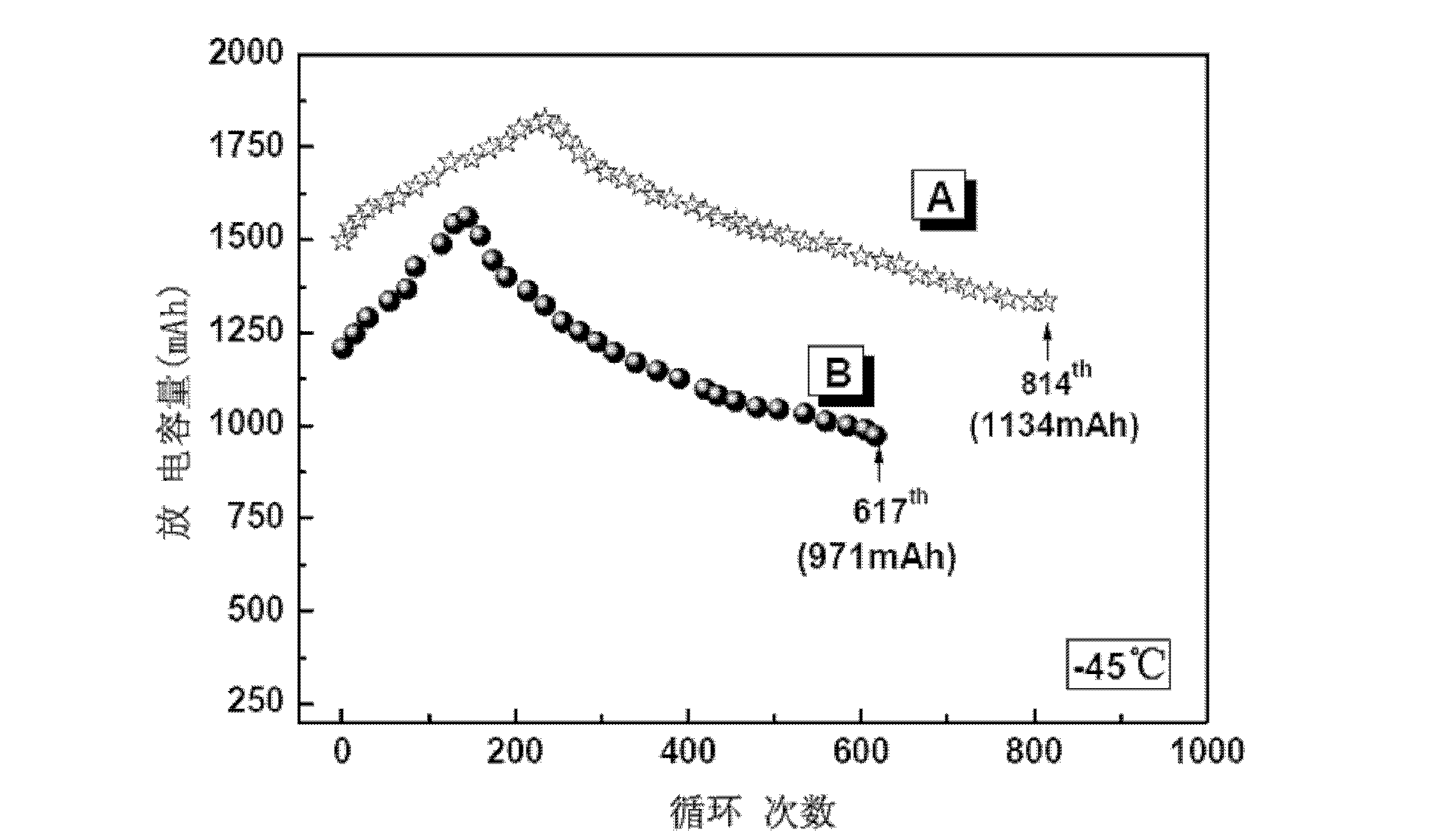

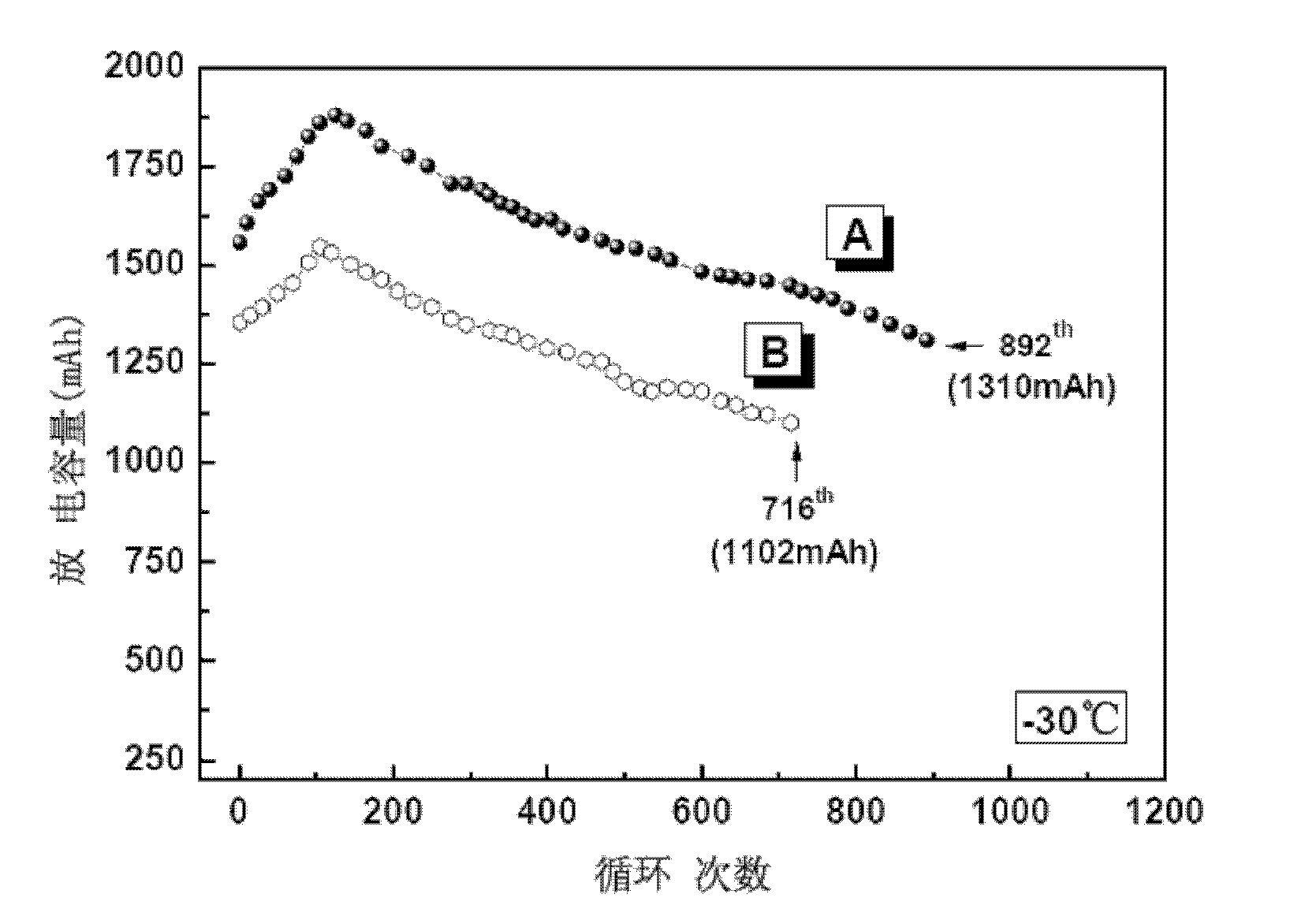

Electrolyte for lithium ion battery and preparation method thereof

ActiveCN102637901AGood effectImprove charge and discharge efficiencySecondary cellsLithium oxideLithium hydroxide

The invention discloses an electrolyte for a lithium ion battery and a preparation method thereof. The electrolyte consists of a main electrolyte, an electrolyte additive, a main solvent and a solvent additive. The preparation method comprises the following steps of: A. under the condition of vacuum or inert gas protection, respectively mixing the main solvent and the solvent additive with a drying agent (lithium oxide) which is dried to be at constant weight in advance, and mixing and filtering to remove the lithium oxide and lithium hydroxide sediment; B. uniformly mixing the dried main solvent and the dried solvent additive from the step A; and C. adding a main electrolyte mixture and an electrolyte additive into the solvent mixed in the step B, and agitating and dissolving under the vacuum and inert gas protection to prepare a solution with the mass mol concentration of the main electrolyte of 0.5-1.5 M. The electrolyte has the advantages of abundant resources, low price and no toxin, effectively improves the work temperature range of the battery and effectively prolongs the circulating service life of the battery, so that various types of the lithium ion batteries are manufactured; and the electrolyte is particularly suitable for manufacturing a lithium ion power battery with high power capacity and high multiplying power charging and discharging capacity.

Owner:广州云通锂电池股份有限公司

Oil-containing sludge treatment method and process flow

ActiveCN103130390AReduce gas productionLow freezing pointSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeTreatment system

The invention belongs to an oil-containing sludge treatment method, and particularly relates to a method and process flow for treating oil-containing sludge having an oil content of more than 10%. The method is characterized by comprising the following steps: for oil-containing sludge having a water content of more than 70%, adding pH regulator, and regulating the pH value to 7-8; adding inorganic flocculant and organic flocculant, and performing dehydration treatment; after dehydration, feeding the oil-containing sludge into a pyrolysis device, performing low-temperature pyrolysis, and feeding gas generated by the pyrolysis into a gas recovery device for recycling; performing oil-water separation on the generated oil and water through an oil-water separation device, feeding the separated oil into an oil storage tank for recycling, and feeding the separated water into a sewage treatment device or an oilfield water treatment system; and adding igniter, combustion improver, binder and desulfurizer into the remaining sludge after the pyrolysis, feeding into a fuel preparation device, and preparing into fuel for utilization. The invention solves the technical problem on oil-containing sludge treatment for oilfield and refinery enterprises, and achieves the purposes of effectively recycling resources, saving energy, reducing emission and protecting environment.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

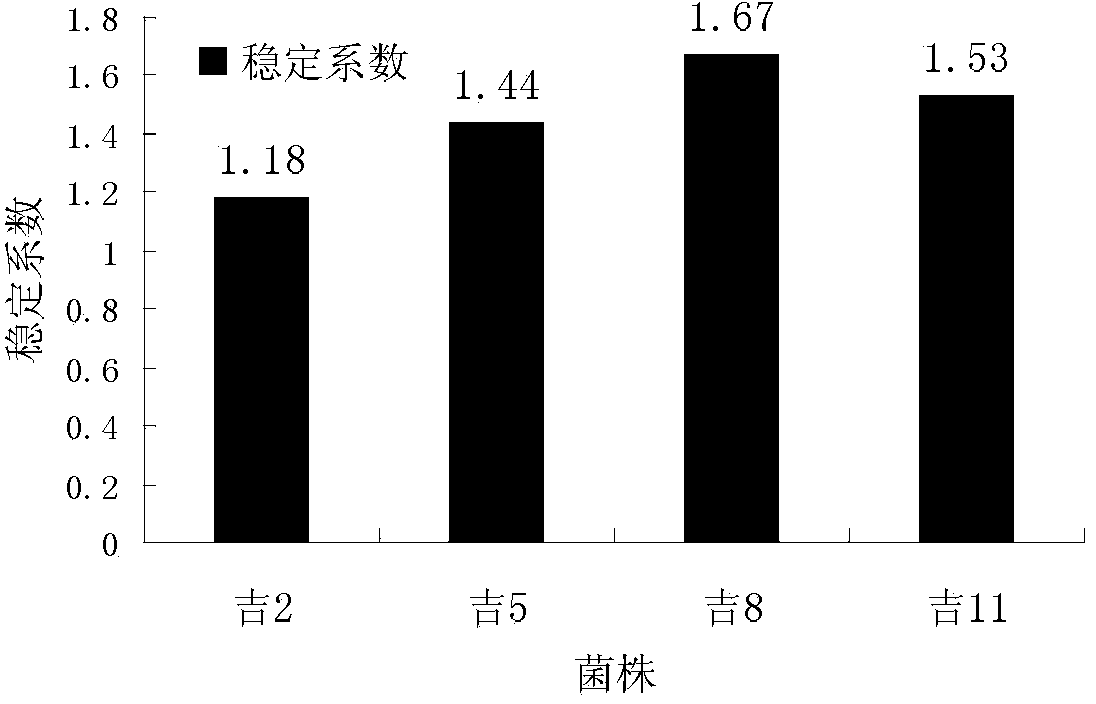

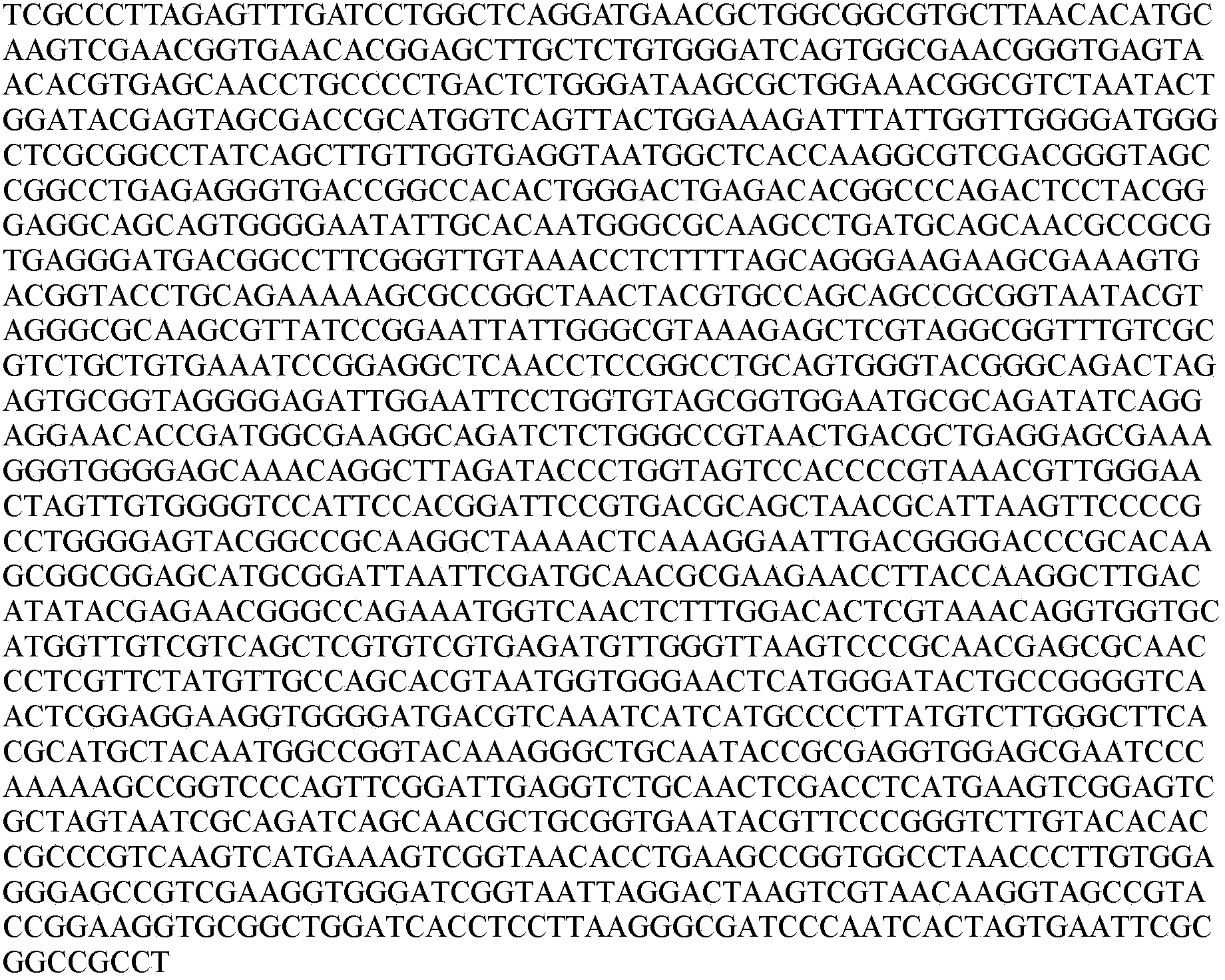

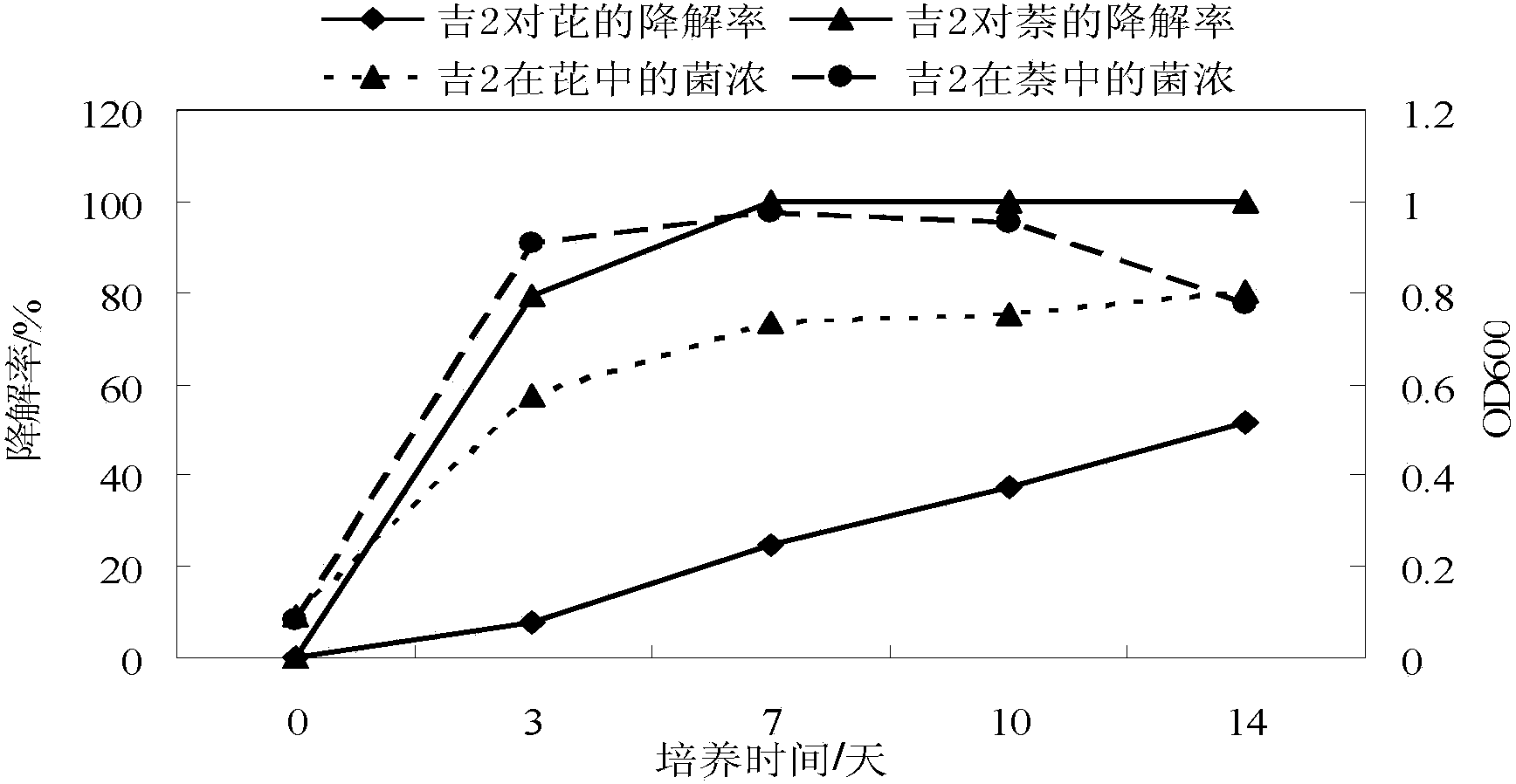

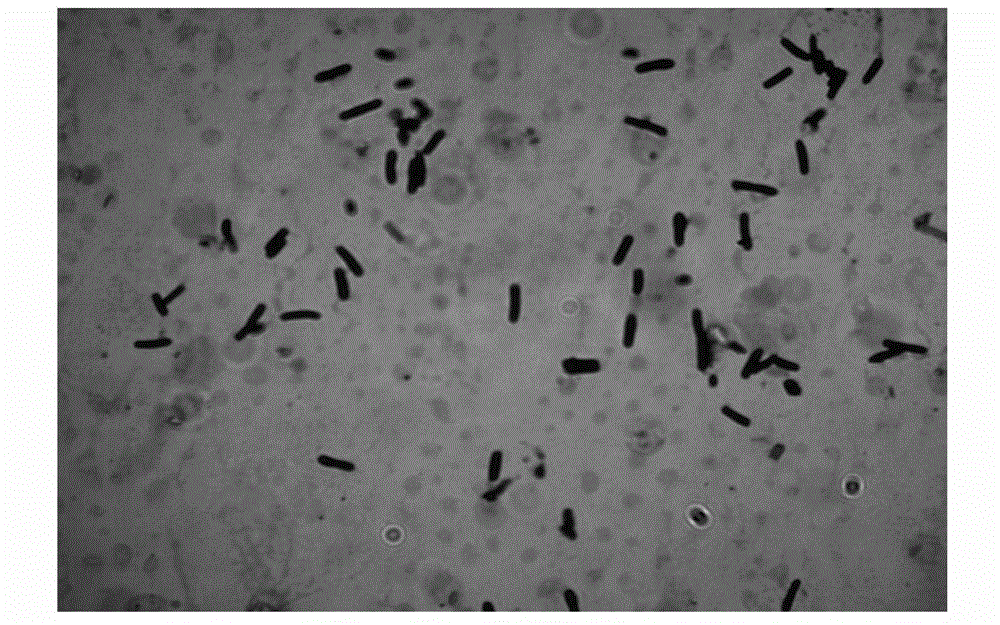

Microbacterium oxydans for degrading polycyclic aromatic hydrocarbon and application thereof

ActiveCN104342392ALow viscosityLow freezing pointBacteriaTransportation and packagingPolycyclic aromatic hydrocarbonMicrobial enhanced oil recovery

The invention provides a microbacterium oxydans for degrading a polycyclic aromatic hydrocarbon and the application thereof. Particularly, the invention provides a microbacterium oxydans Ji2 strain with a preservation number of CGMCC No.9072 and the application effect of the microbacterium oxydans in emulsifying and degrading crude oil and the polycyclic aromatic hydrocarbon and performing indoor physical simulation oil displacement. According to the microbacterium oxydans strain, the crude oil can be emulsified and degraded under aerobic and anaerobic conditions by taking the crude oil or the polycyclic aromatic hydrocarbon as the only carbon source and energy source, the degradation rate of the degraded polycyclic aromatic hydrocarbon, such as naphthalene is up to 100 percent, and analysis on the degraded crude oil shows that aromatic hydrocarbon and colloid, which are the components of the crude oil, are mainly degraded. The stain can be used for degrading the polycyclic aromatic hydrocarbon in an environment by the performance of the stain, and can also be applied to microbial enhanced oil recovery, and the oil recovery is improved.

Owner:PETROCHINA CO LTD

Energy-saving environment-protecting abrasion-proof canned carbon-hydrogen refrigerant

InactiveCN101270274ASolve the problem of cylinder wear and tearLittle effect of loadChemical industryHeat-exchange elementsAlkaneSolubility

The invention relates to an energy-saving environmental-protection type abrasion resistant canned hydrocarbon refrigerant, which comprises propane and isobutane. The energy-saving environmentally-protective abrasion resistant canned hydrocarbon refrigerant is characterized in that the energy-saving environmentally-protective abrasion resistant canned hydrocarbon refrigerant further comprises low temperature refrigeration lubricating oil; the propane accounts for 54 to 65 percent; the isobutane accounts for 30 to 40 percent, and the low temperature refrigeration lubricating oil accounts for 3 to 8 percent. The hydrocarbon refrigerant is prepared by mixing mixed alkane with certain proportion and the low-temperature refrigeration lubricating oil in proper amount, thus effectively solving the problem of the prior hydrocarbon refrigerant that a compressor is abraded frequently and a cylinder bore is scuffed frequently due to the characteristics of being too dry and excellent oil solubility, The hydrocarbon refrigerant with mixed alkane disclosed by the invention belongs to natural working fluid, is free of fluorine without influence on warming-up of the global climate. Compared with R12 and R134a, the freezing point is lower; the latent heat of vaporization is larger; the specific energy of constant entropy compression is smaller so that the compressor works more easily. The flowing property is better; the delivery pressure is lower; the load of the compressor is lower; fuel consumption is reduced and the energy-saving rate can reach 10 percent to 20 percent when the air conditioners are running.

Owner:周飞

Nano-silver antibacterial agent and preparation method thereof

InactiveCN103999873AIncrease viscosityImprove antibacterial propertiesBiocideDisinfectantsEmulsionAntibacterial agent

The invention provides a nano-silver antibacterial agent which includes nano-silver antibacterial stock solutions. Nano-silver is included in the nano-silver antibacterial stock solutions, and the content of the nano-silver is 0.00025 mol / kg to 0.02 mol / kg. The invention further provides a preparation method of the nano-silver antibacterial agent. The nano-silver antibacterial agent can be foam emulsion and sprays in a flow state, can be used as washing-free sprays, and is convenient for people to use when cleaning with water is inconvenient in travel.

Owner:杜一挺

Coagulation-reducing viscosity-reducing agent for high-coagulation thickened oil

ActiveCN102618243AReduce viscosityGood depressing effectFluid removalDrilling compositionPolyacrylamideSODIUM DODECYL BENZENE SULFONATE

The invention relates to a coagulation-reducing viscosity-reducing agent for high-coagulation thickened oil. By weight percentage, the coagulation-reducing viscosity-reducing agent for the high-coagulation thickened oil comprises the following materials: 0.1% to 0.2% of anion polyacrylamide, 5% to 10% of sodium acrylate-setanol acrylate copolymer, 5% to 15% of sodium dodecyl benzene sulfonate, 1%to 2% of mixture of hexafluoropropylene oxide dipolymer amide sulphobetaine and hexafluoropropylene oxide dipolymer amide amine oxide, 1% to 2% of sodium hydroxide and the balance water. The coagulation-reducing viscosity-reducing agent can disperse high-coagulation thickened crude oil, reduces the freezing point of the crude oil to above 0 DEG C and enables the viscosity of the crude oil to be smaller than 300mPa*s at the normal temperature. The using concentration of the coagulation-reducing viscosity-reducing agent can be controlled at 0.1% to 0.5%, is lower by one magnitude order than that (3% to 7%) of a traditional surfactant, is not limited by hydrophile-lipophile balance values and phase inversion temperature (PIT) and can emulsify the high-coagulation thickened oil at the temperature above the freezing point of the crude oil.

Owner:PETROCHINA CO LTD

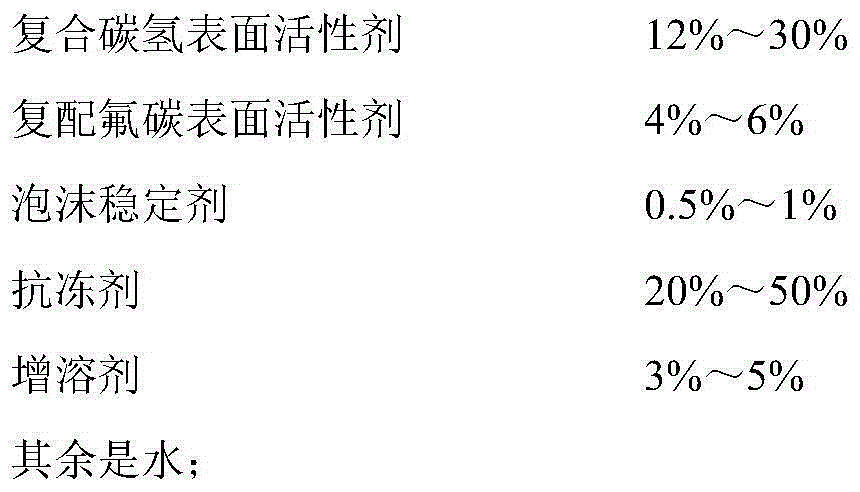

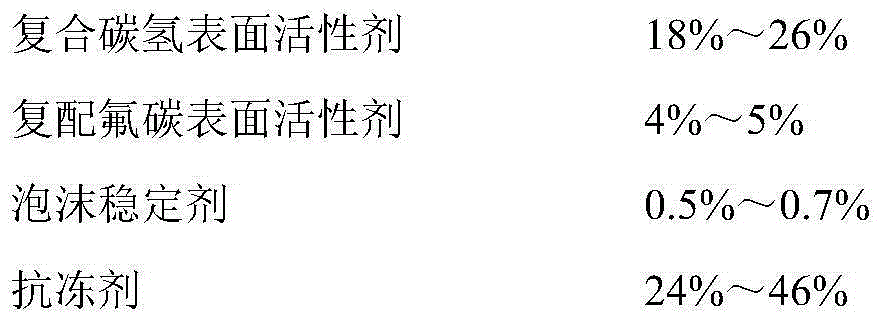

Cold-resistant anti-fusible aqueous film forming foam extinguishing agent

InactiveCN104998366AImprove freezing pointLow freezing pointFire extinguisherWater solubleFluorocarbon

The invention relates to a cold-resistant anti-fusible aqueous film forming foam extinguishing agent. The cold-resistant anti-fusible aqueous film forming foam extinguishing agent consists of the following gradients in percentage by mass: 12-30 percent of a composite hydrocarbon surfactant, 4-6 percent of a compounded fluorocarbon surfactant, 0.5-1 percent of a foam stabilizer, 20-50 percent of an antifreeze agent, 3-5 percent of a solubilizer and the balance water, wherein the composite hydrocarbon surfactant is a composition of an ampholytic surfactant and a nonionic surfactant. The cold-resistant anti-fusible aqueous film forming foam extinguishing agent disclosed by the invention is mainly applied to prevention and extinguishing of fire caused by hydrocarbon substances and polar solvents (water-soluble substances), can be normally used at an environment temperature of -25 DEG C and is especially applicable to storage and use in extremely-cold regions. Besides, by adopting a daily-necessity-level hydrocarbon surfactant and a fluorocarbon surfactant which is free of PFOS (Perfluorooctane Sulfonates), the cold-resistant anti-fusible aqueous film forming foam extinguishing agent disclosed by the invention is good in degradation property, quick and safe in degradation and free of environmental pollution.

Owner:江苏锁龙消防科技股份有限公司

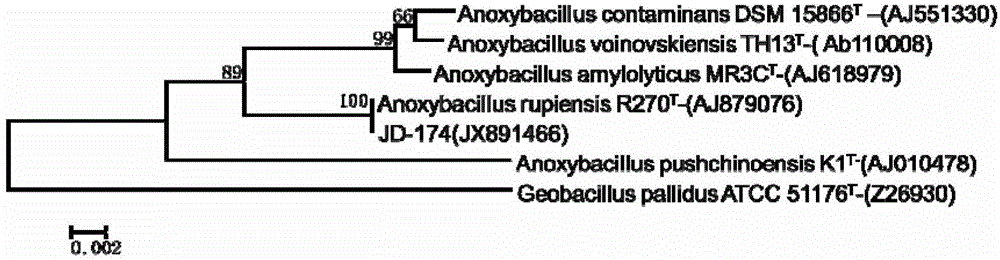

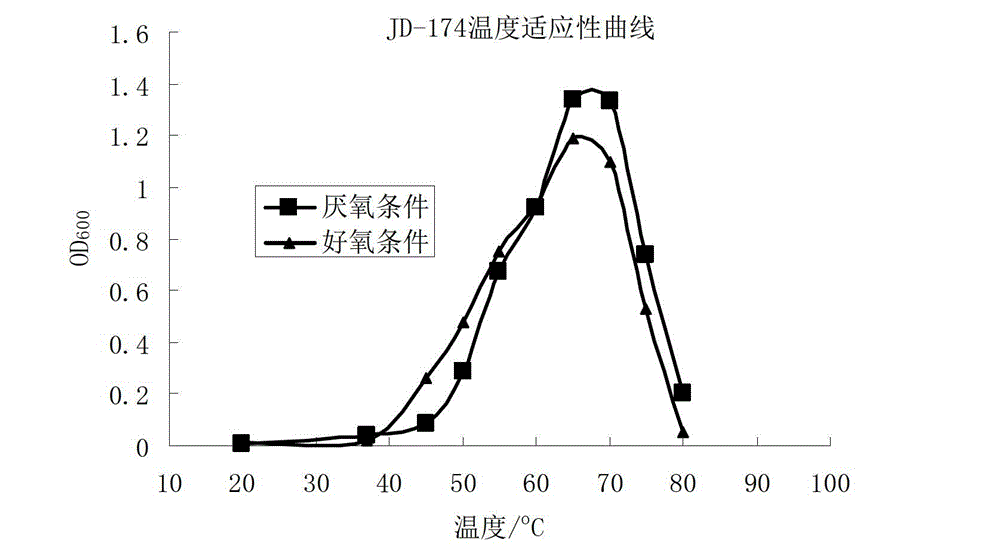

Anoxybacillussp and application thereof

ActiveCN102911902AImprove degradation rateLow freezing pointBacteriaMicroorganism based processesFungicideMicrobial oil

The invention discloses anoxybacillussp, a fungicide of the anoxybacillussp and application. The anoxybacillussp (Anoxybacillussp) JD-174 is separated from an oil sample from a high-temperature oil well, and is stored with a number of CGMCC No.6570. The invention also discloses a microbial agent comprising the anoxybacillussp and a nutrient culture medium. The invention further discloses the application of the anoxybacillussp and the microbial agent in petroleum extraction. The anoxybacillussp or the fungicide the anoxybacillussp can degrade and emulsify raw petroleum or diesel, and can effectively reduce viscosity and a freezing point of raw petroleum, and improve liquidity of the raw petroleum. By being used as a microbial oil displacement agent, the anoxybacillussp or the fungicide of the anoxybacillussp can obviously improve a recovery ratio of the petroleum.

Owner:北京世纪金道石油技术开发有限公司 +1

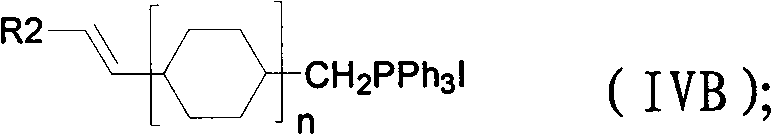

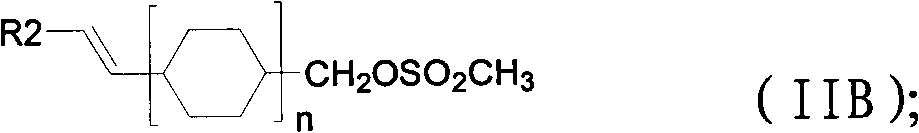

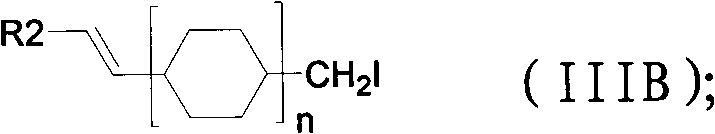

Divinyl liquid crystal compound and preparation method thereof

ActiveCN101928199AWide phase change rangeGood chemical stabilityLiquid crystal compositionsOrganic compound preparationStructural formulaPhosphine

The invention relates to a divinyl liquid crystal compound and a preparation method thereof. A structural formula of the divinyl liquid crystal compound is expressed as the following general formula I, wherein R1 represents hydrogen, C1-8 straight-chain alkyl or C2-8 straight-chain vinyl; R2 represents hydrogen or C1-8 straight-chain alkyl; A represents benzene ring or 1,4-cyclohexane ring; and nis equal to 1 to 2 and m is equal to 0 to 2. The preparation method for the divinyl liquid crystal compound comprises that: corresponding phosphine salt and aldehyde undergo wittig reaction in the presence of alkali to generate cis and trans mixed alkene, and then the cis and trans mixed alkene is transformed into trans alkene. The invention has the advantages that: a series of negative liquid crystals are developed, have wider liquid crystal phase change range, good chemical stability and excellent use value and can reduce the freezing point and improve the clearing point when added into mixed liquid crystal and increase the absolute value of a negative dielectric constant.

Owner:VALIANT CO LTD

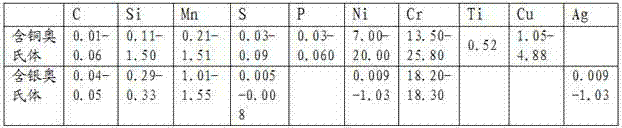

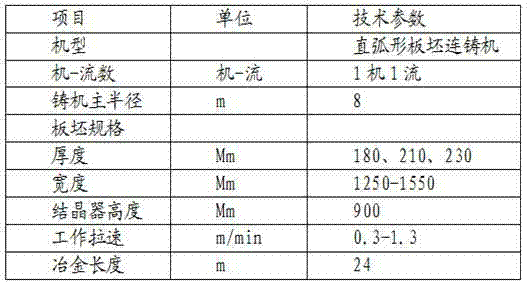

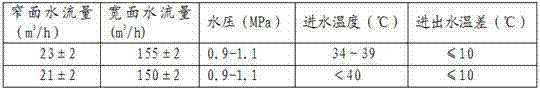

Crystallizer casting powder for austenite antibacterial stainless steel

ActiveCN103785808AMeet the needs of shrinkage characteristicsGood control of heat transferHeat resistanceField tests

The invention discloses continuous casting crystallizer casting powder for austenite antibacterial stainless steel. The alkalinity of the continuous casting crystallizer casting powder ranges from 1.0 to 1.1, and the continuous casting crystallizer casting powder can achieve a very good heat transfer control effect and meet the requirement for shrinkage characters of the austenite antibacterial stainless steel. The viscosity is set as 0.10 Pa*s-0.18 Pa*s at the temperature of 1300 DEG C, so that the casting powder flows in gaps between blank shells and a crystallizer copper plate more evenly, casting blanks are lubricated, the requirement for the consumption of the crystallizer casting powder is met, and the viscosity is mainly controlled Al2O3, MgO and F-. The melting point ranges from 1130 DEGC to 1190 DEG C, heat resistance of the casting powder is increased, the heat transfer uniformity index of the crystallizer casting powder is increased, and cracks are difficult to produce. Raw materials of the continuous casting crystallizer casting powder are easy to obtain, and cost is relatively low. By means of field tests, the casting powder is melt uniformly and stably, the indentation rate of the edges of the casting blanks is decreased by about 9.5%-19%, quality of the casting blanks is improved, and smooth operation of processes of a steel mill is guaranteed.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

700V high-voltage aluminum electrolytic capacitor electrolyte

InactiveCN106252079AHigh molecular weightLow mobilityLiquid electrolytic capacitorsSalicylic acidGluconic acid

Disclosed is a 700V high-voltage aluminum electrolytic capacitor electrolyte. The electrolyte comprises 50-80% of main solvent, 20-50% of auxiliary solvent, 5-20% of main solute, 2-10% of auxiliary solute, 0.1-1% of auxiliary additive and 5-15% of spark additive, wherein the main solute comprises one or more of azelaic acid, ammonium hydrogen azelate, ammonium sebacate, decane dicarboxylic acid, 7, 9-dimethyl-7, 9-dimethoxy carbonyl-1, 11-dodecane dicarboxylic acid, and 7, 8-dimethyl-7, 8-dimethoxy carbonyl-1, 14 tetradecane dicarboxylic acid; and the auxiliary solvent comprises one or more of ammonium salicylate, salicylic acid, oxalic acid, malonic acid, succinic acid, ammonium benzoate, ammonium maleate, ammonium hydrogen maleate, ammonium adipate and hexanedioic acid. The spark voltage of the electrolyte is greater than 700V; and in addition, the electrolyte is simple to prepare, stable in performance and excellent in related parameters.

Owner:HUNAN AIHUA GRP

Waterproof coating of carton

ActiveCN102704330AGood chemical stabilityImprove insulation performanceCoatingsPaper forming aids additionParaffin waxEmulsion

The invention relates to a waterproof coating, in particular to a waterproof coating of a carton, which comprises the following components in weight part: 30-120 parts of paraffin micro-emulsion, 50-90 parts of simethicone, and 4-8 parts of emulsifier. The waterproof coating is prepared according to a method as follows: (1) heating the paraffin micro-emulsion to 50-180 degree C; (2) adding simethicone and stirring for 0.5-3 hours; and (3) adding the emulsifier, stirring at a high speed for 10-40 minutes, and cooling to the room temperature. The waterproof coating of the carton, disclosed by the invention, has no pollution on the human body and the environment, can be combined with the base material firmly, and has excellent waterproof property.

Owner:ANHUI JINDUN PAINT

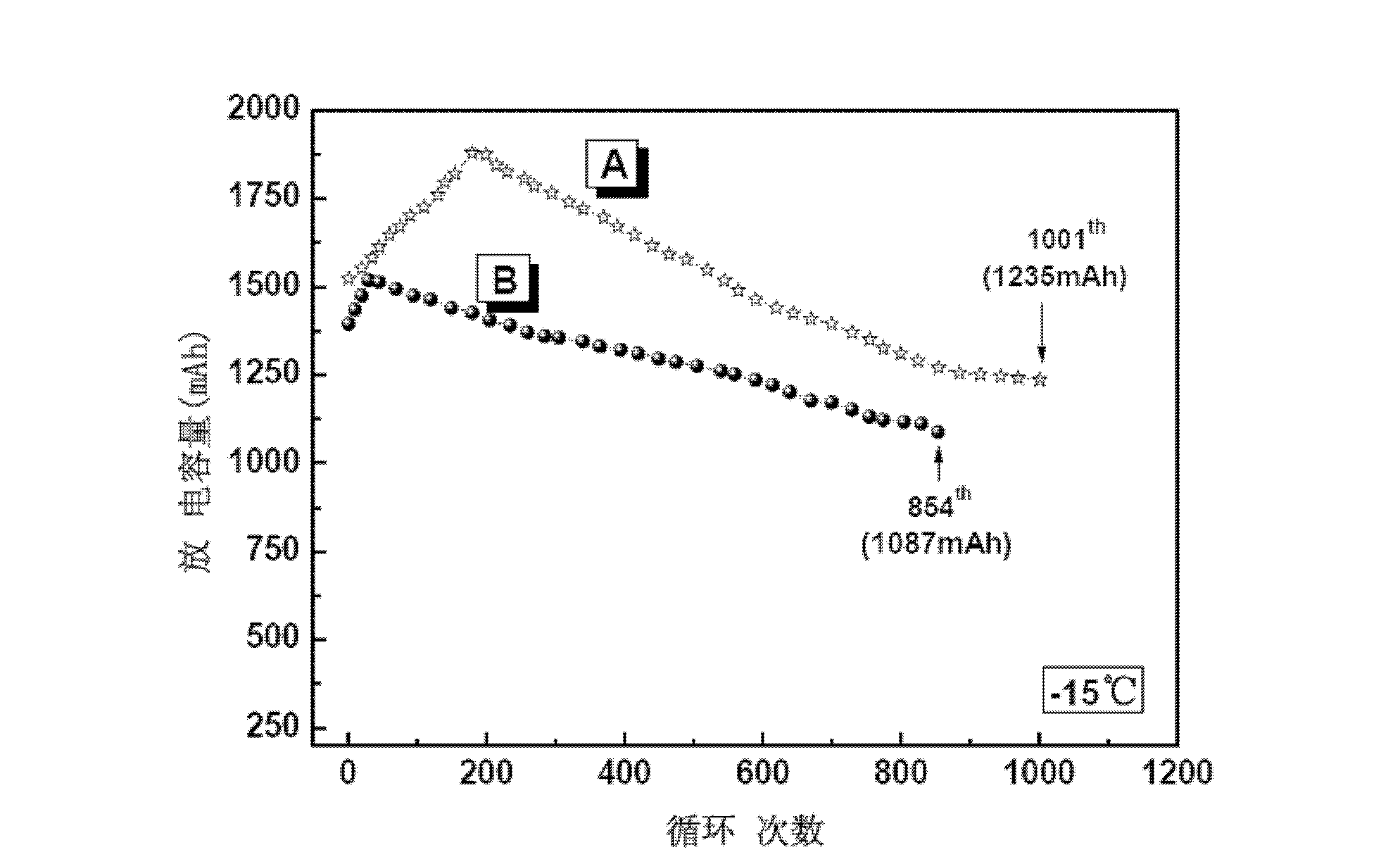

Electrolyte of lithium ion battery discharging at ultra-low temperature

ActiveCN107069094AGood low temperature performance and high rate discharge performanceLow freezing pointSecondary cellsOrganic electrolytesSingle useLithium electrode

The invention relates to the technical field of lithium ion battery, and particularly relates to an electrolyte of a lithium ion battery discharging at an ultra-low temperature. The electrolyte is composed of a lithium electrolyte salt, a cyclic ether compound, an organic carbonate, an ethylene glycol dimethyl ether, and a N,N-dimethyl trifluoroacetamide, wherein the lithium electrolyte salt is prepared by mixing lithium hexafluorophosphate, lithium bisoxalatoborate(LiBOB) and lithium oxalate difluoro borate(LiODFB) by a mass ratio of 3:1:1. According to the invention, the freezing point of the mixed solvent can be decreased obviously by mixing the organic additive N,N-dimethyl trifluoroacetamide with an organic carbonate, so that a low temperature electrolyte can be formed; and with the electrolyte prepared from lithium hexafluorophosphate, lithium bisoxalatoborate and lithium oxalate difluoro borate in a reasonable proportion, not only the weakness that the single use of the lithium hexafluorophosphate lacks temperature stability is overcome, but better low-temperature performance and better high-rate discharge performance are exhibited.

Owner:福建省劲德电源科技有限公司

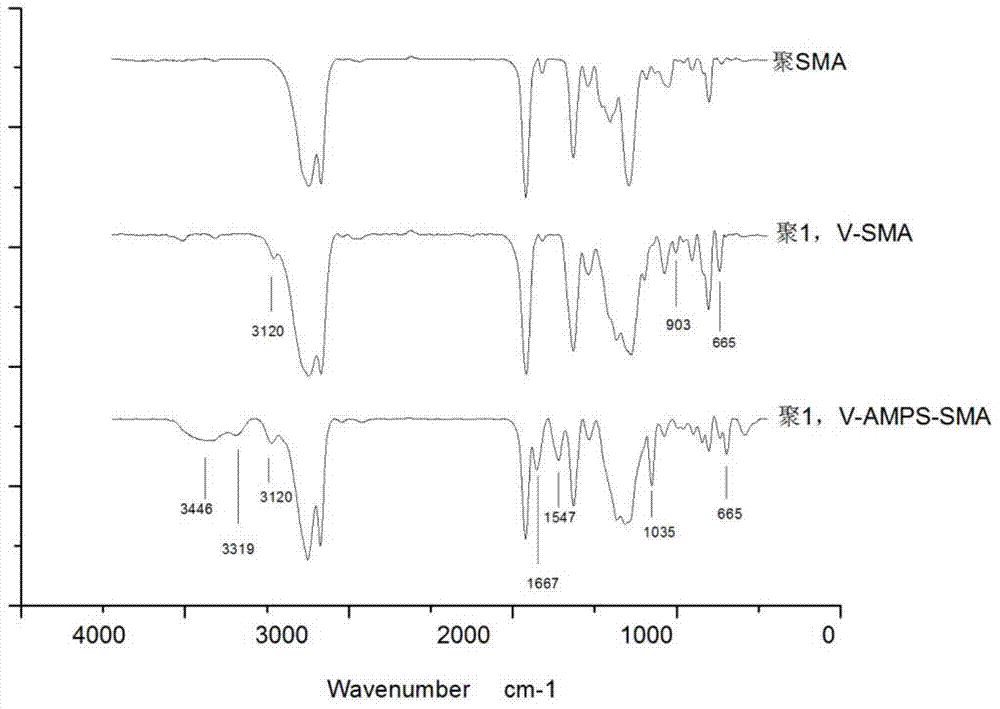

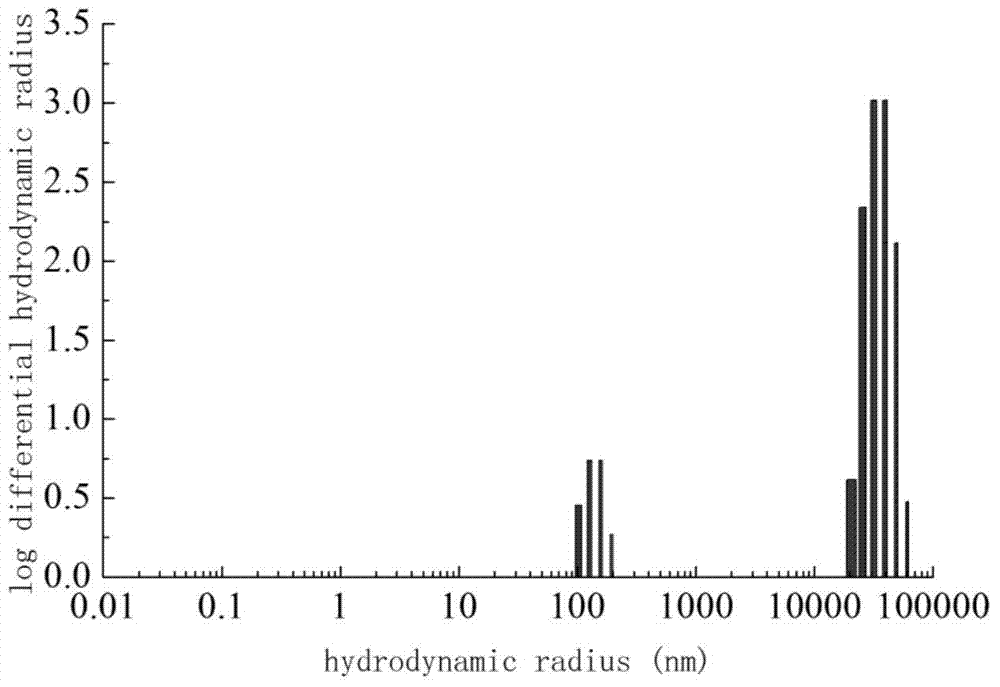

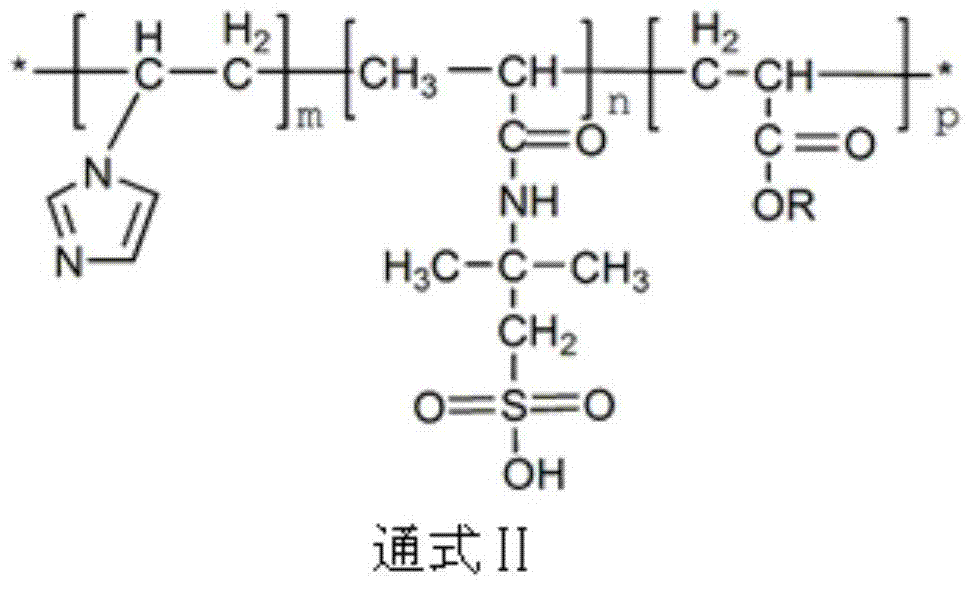

High wax thickened oil nanocomposite pour-point depressant and preparation method thereof

InactiveCN104327213AImprove pour point depressing effectProlong the action timeDrilling compositionMaterials preparationWax

The invention discloses a high wax thickened oil nanocomposite pour-point depressant, which belongs to the high-molecular nano-material preparation field. The material comprises poly(vinyl imidazole-2-acrylamide-2-methyl propane sulfonic acid-higher alkyl methacrylate). The preparation method comprises the following steps: 1)preparing poly(vinyl imidazole-2-acrylamide-2-methyl propane sulfonic acid-higher alkyl methacrylate), and 2)processing a reaction solution of poly(vinyl imidazole-2-acrylamide-2-methyl propane sulfonic acid-higher alkyl methacrylate) to obtain the poly(vinyl imidazole-2-acrylamide-2-methyl propane sulfonic acid-higher alkyl methacrylate) powder. The nano pour-point depressant has the advantages of good depression effect, low cost, simple production, clean process, no pollution, easy acquisition of the products, easy transportation and preservation. Through the experiment, the net pour point depression amplitude of the nano pour-point depressant to high wax thickened oil at Daqing dandong station is 8 DEG C which is better than the pour point depression effect (net pour point depression amplitude is 5 DEG C) of EVA on the market.

Owner:SHANDONG UNIV

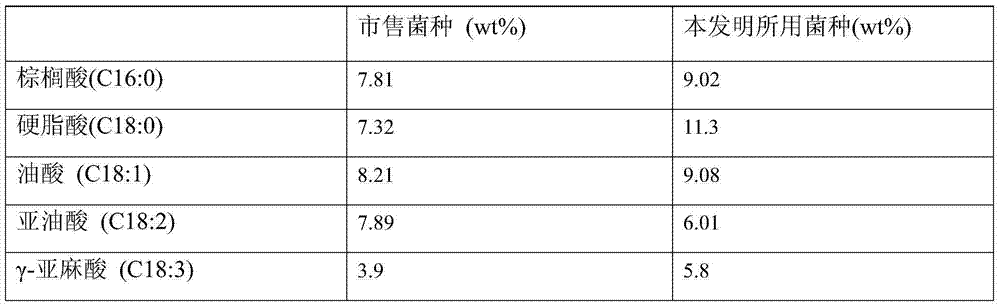

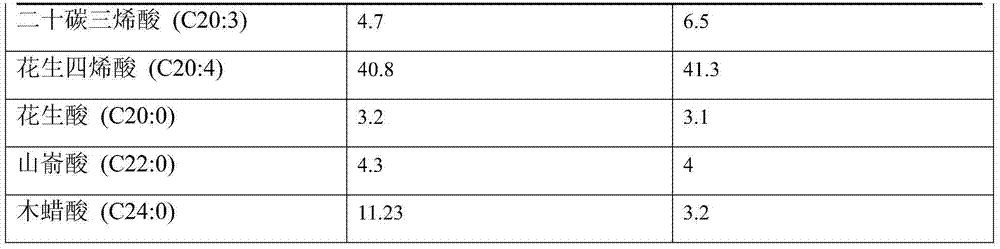

Method for producing arachidonic acid grease by utilizing mortierella alpina mutant strain, and arachidonic acid grease produced by method

ActiveCN103571896AImprove qualityLow freezing pointMicroorganism based processesFermentationMicrobiologyFermentation

The invention relates to a method for producing arachidonic acid grease by utilizing a mortierella alpina mutant strain, and the arachidonic acid grease produced by the method. The method comprises the steps that the mortierella alpina mutant strain is fermented; a fermentation product is collected; aftertreatment is performed; the arachidonic acid grease is obtained. The mortierella alpina mutant strain (mortierella alpina ZR36) is preserved in China Center For Type Culture Collection (CCTCC) on September 13, 2013; the preservation address is Wuhan University, Wuhan City, China; the preservation number is CCTCC NO:M2013419. The total content of saturated fatty acid, particularly above eicosanoic long-chain saturated fatty acid in the arachidonic acid grease produced by the mortierella alpina mutant strain is relatively low (lower than 15wt%); a freezing point of the arachidonic acid grease is relatively low (low to 4 DEG C); the arachidonic acid grease cannot be frozen or crystallized even if at a lower temperature; saturated fatty acid cannot be separated out; the arachidonic acid grease can keep clear and transparent, and has higher quality.

Owner:CABIO BIOTECH WUHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com