Method for synthesizing water-soluble imidazoline quaternary ammonium salt corrosion inhibitor

A technology of water-soluble imidazoline and quaternary ammonium salt, which is applied in the preparation of water-soluble imidazoline quaternary ammonium salt corrosion inhibitor and the field of quaternization of imidazoline, which can solve the problems of unfriendly environment, strong toxicity, and great harm to production personnel. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

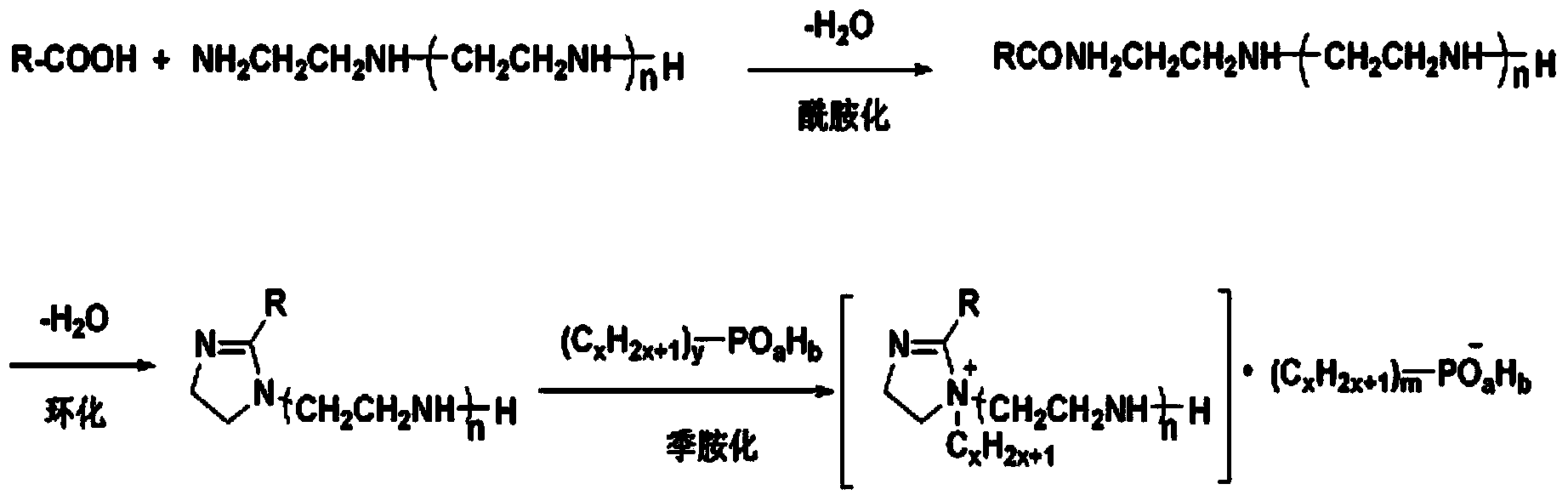

Method used

Image

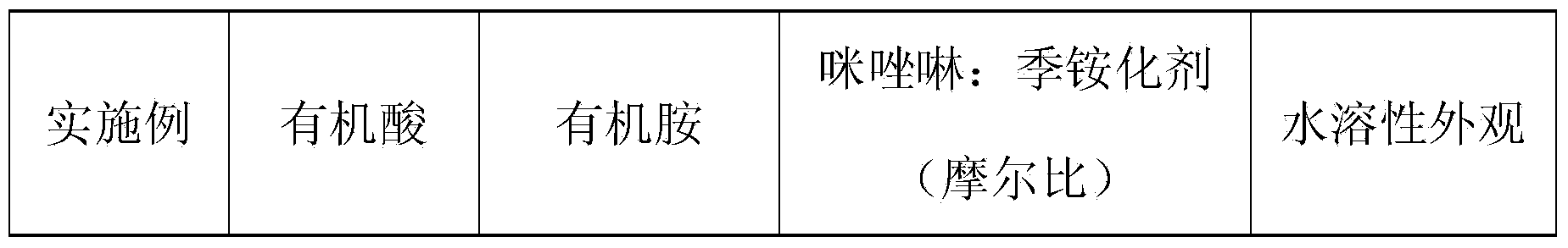

Examples

Embodiment 1

[0027] step one

[0028] Under the protection of nitrogen, add oleic acid and diethylenetriamine accurately in sequence to the reactor with thermometer, stirrer, condenser and water separator, the molar ratio is 1:1.1, and add dry 50g of xylene as a solvent, after adding the solvent, reflux at 120°C for 2.5h to separate the water generated by the amidation reaction; then gradually raise the temperature to 210°C, keep it warm for 1h, evaporate the solvent and unreacted amine; then raise the temperature Heat the reaction at 240°C for 3 hours, steam the water generated by the cyclization reaction; finally cool the reactant to obtain imidazoline.

[0029] step two

[0030] Add the imidazoline synthesized in step 1 to the reactor with a thermometer, agitator, and condenser tube, and use 50 g of ethanol as a solvent, turn on the mechanical stirring, and add dimethyl phosphite dropwise into the reactor at 50° C., wherein The reactants are imidazoline and dimethyl phosphite, the rea...

Embodiment 2

[0032] Add the imidazoline synthesized in Step 1 of Example 1 into the reactor with a thermometer, agitator, and condenser tube, and use 50 g of ethanol as a solvent, turn on the mechanical stirring, and add dimethyl phosphite dropwise to the reactor at 50°C Among them, the reactants are imidazoline and dimethyl phosphite, and the reaction molar ratio is 1:0.75. At this temperature, stir and react for 1 h, and cool to obtain a reddish-brown imidazoline quaternary ammonium salt corrosion inhibitor.

Embodiment 3

[0034] Add the imidazoline synthesized in Step 1 of Example 1 into the reactor with a thermometer, agitator, and condenser tube, and use 50 g of ethanol as a solvent, turn on the mechanical stirring, and add dimethyl phosphite dropwise to the reactor at 50°C Among them, the reactants are imidazoline and dimethyl phosphite, and the reaction molar ratio is 1:1.0. At this temperature, stir and react for 1 h, and cool to obtain a reddish-brown imidazoline quaternary ammonium salt corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com