Patents

Literature

126 results about "Dimethyl phosphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

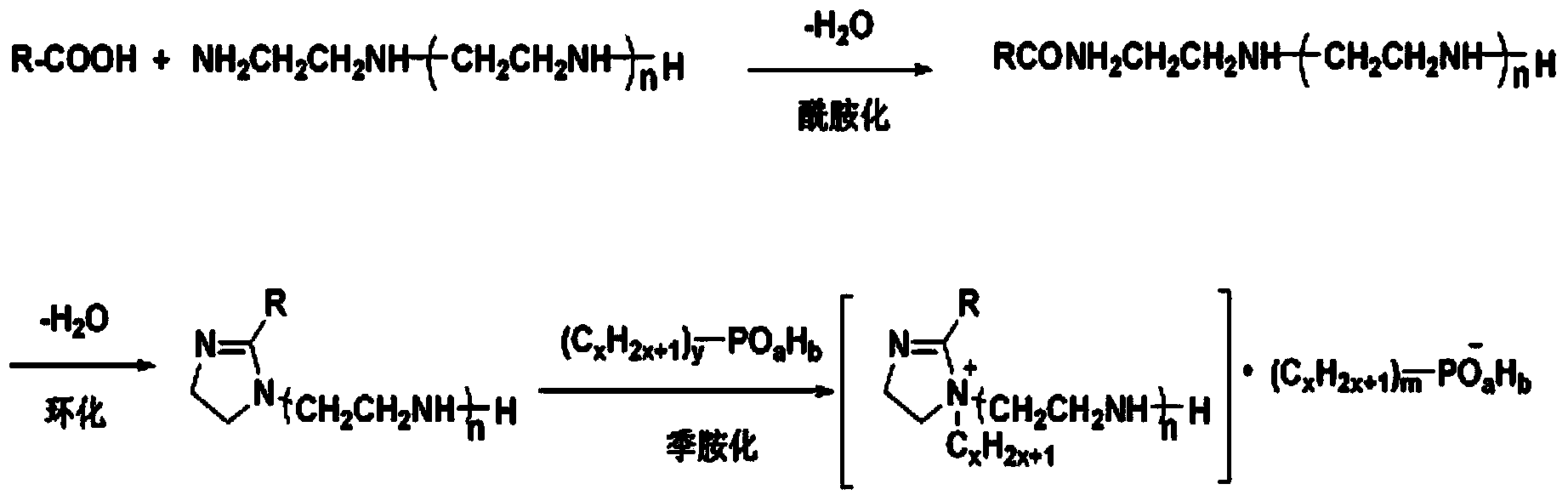

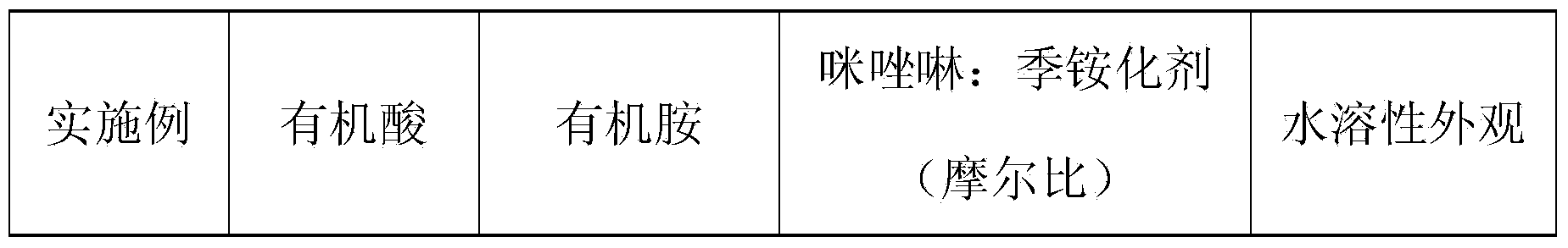

Method for synthesizing water-soluble imidazoline quaternary ammonium salt corrosion inhibitor

ActiveCN103554027ALow freezing pointGood water solubilityGroup 5/15 element organic compoundsSolubilityOrganic acid

The invention discloses a method for synthesizing a water-soluble imidazoline quaternary ammonium salt corrosion inhibitor. The method is characterized by comprising the following steps of performing amidation reaction on reaction raw materials organic acid and organic amine to synthesize amide, performing amide cyclization reaction to obtain imidazolidine, and quaternizing the oil-soluble imidazolidine by using a quaternizing agent such as dimethyl phosphite to synthesize the water-soluble imidazoline quaternary ammonium salt corrosion inhibitor. Evaluation tests show that an obtained product is high in water solubility and corrosion inhibition rate.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

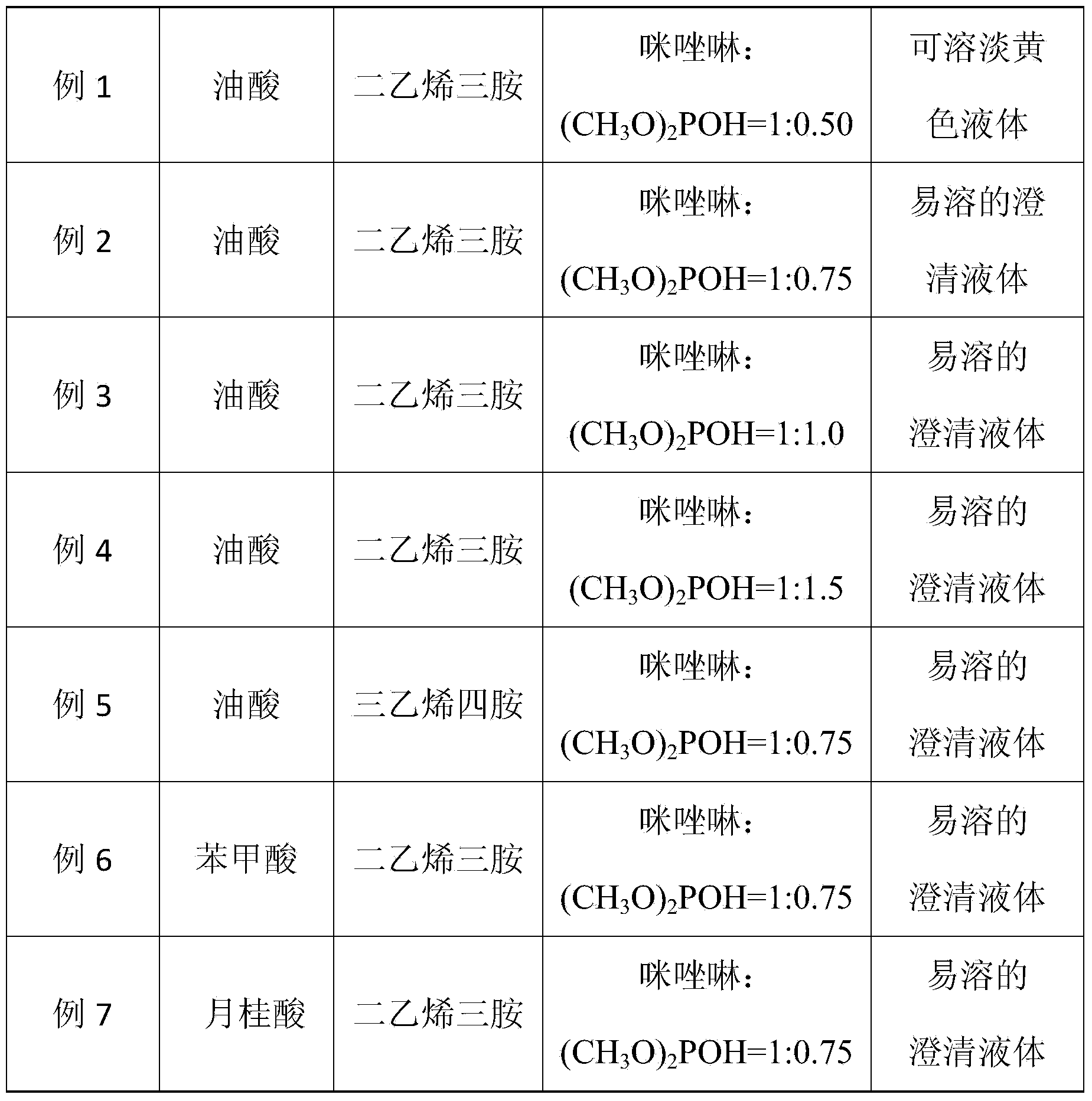

Cyclic production method of glyphosate

ActiveCN103012474AAvoid influenceReduce pollutionBiocideGroup 5/15 element organic compoundsEvaporationHigh pressure

Owner:HANGZHOU JINFADA CHEM IND

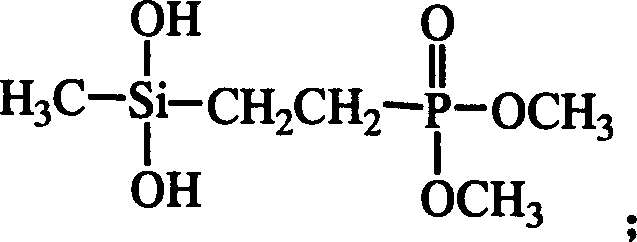

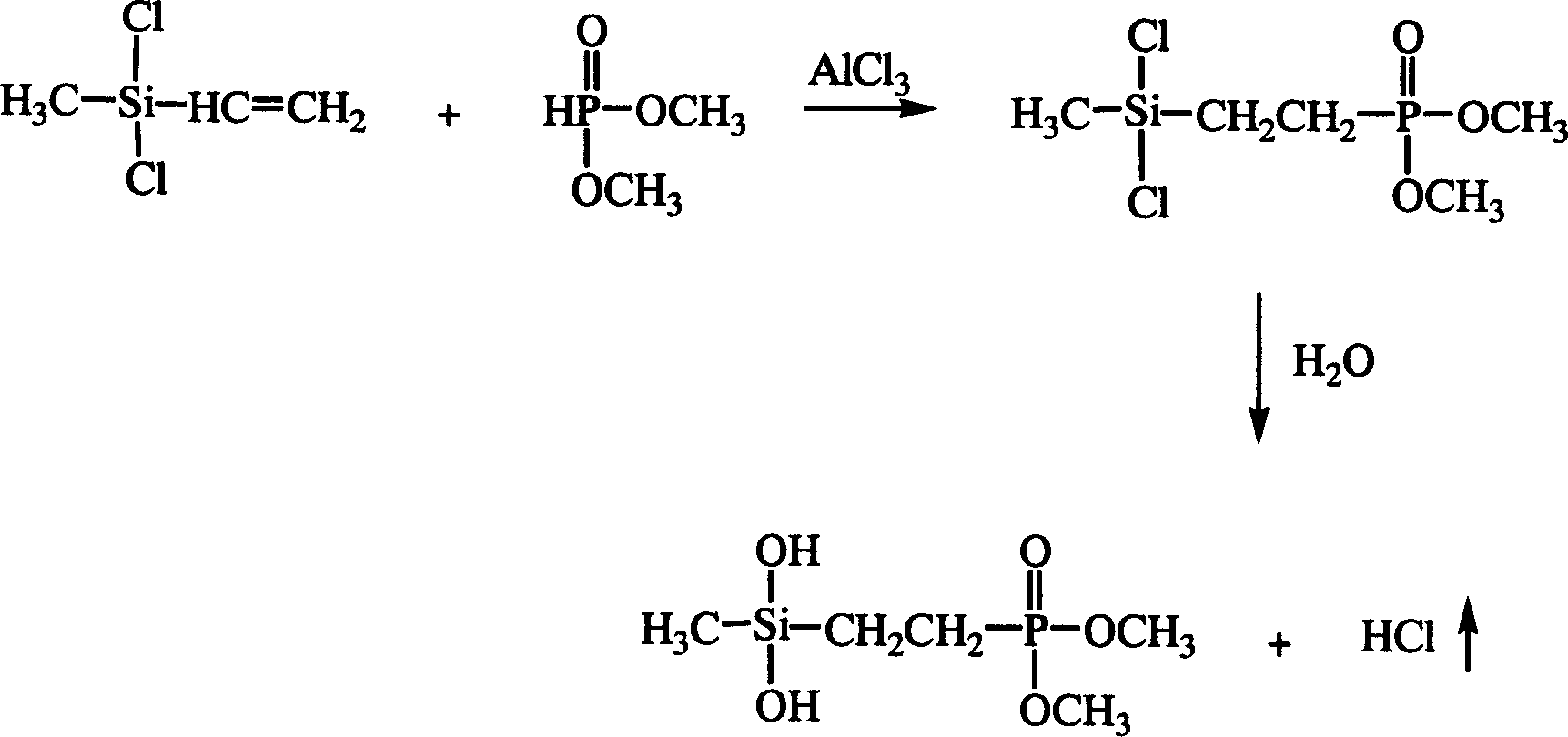

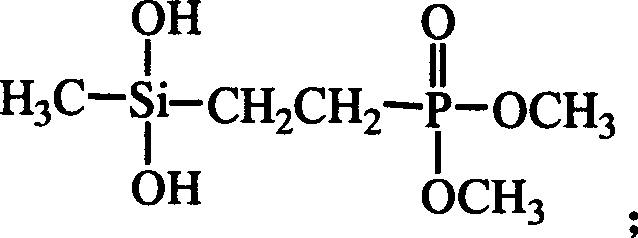

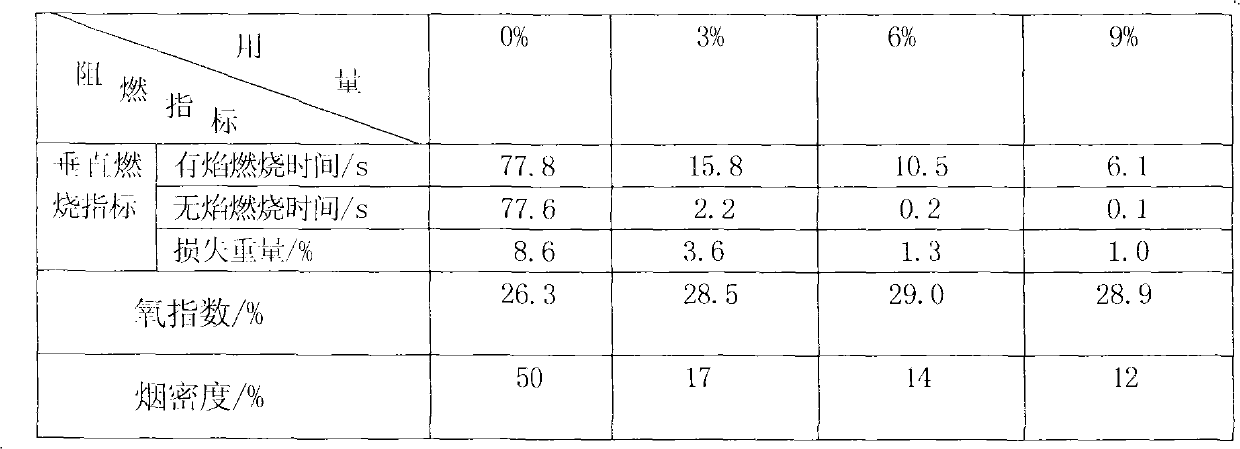

Silicon phosphonate containing fire rotardant and its synthesis method

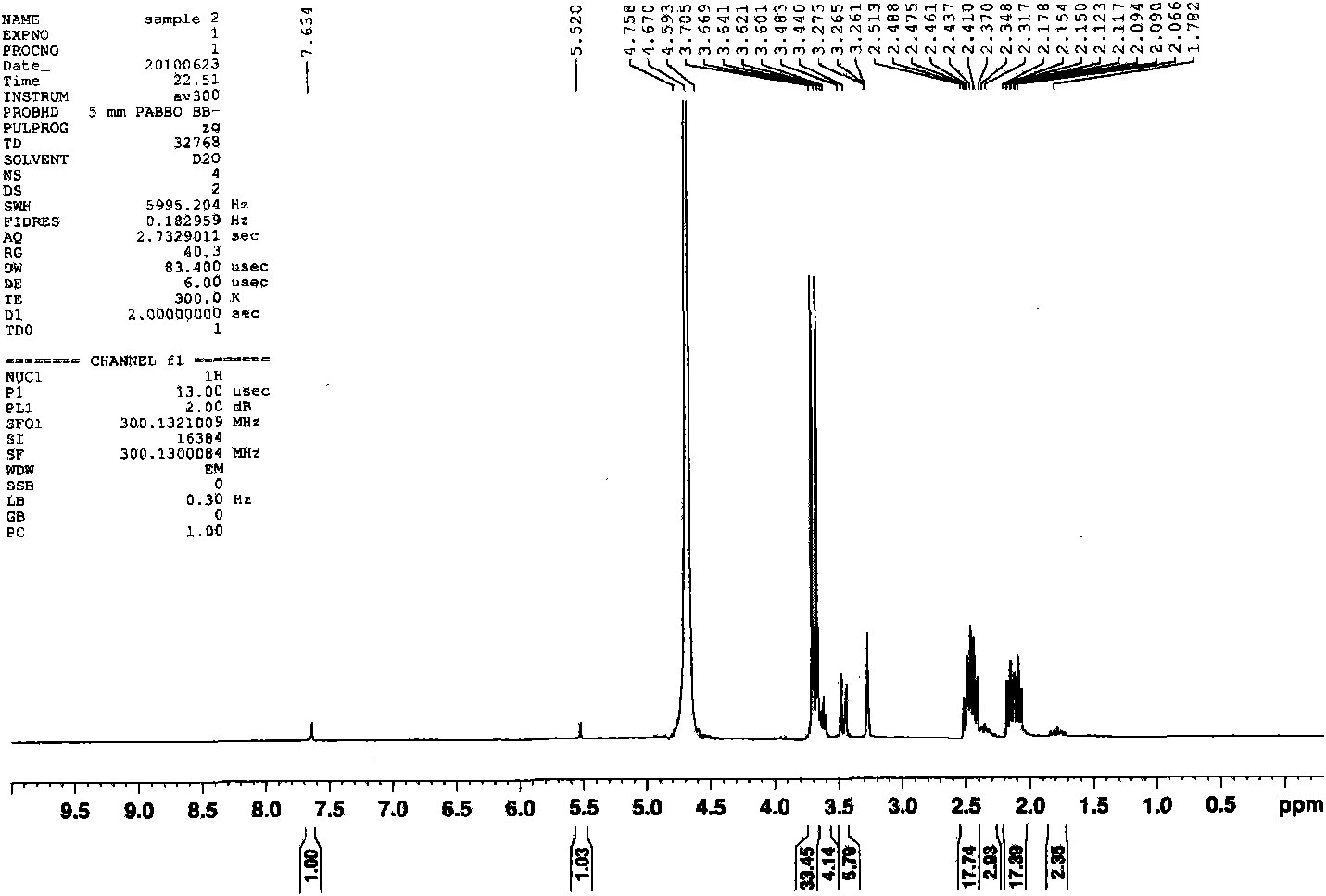

A Si-contained phosphonate as fire retarding agent used for fabrics is prepared through proportionally mixing methylvinyl dichlorosilane with solvent, stirring, adding dimethyl phosphite and catalyst, stirring under protection of N2, heating, reflux, collecting fraction, cooling, adding water, stirring, oil-water separating, and distilling water phase to obtain fire retarding agent SP.

Owner:ZHEJIANG HENGYI GRP CO LTD +1

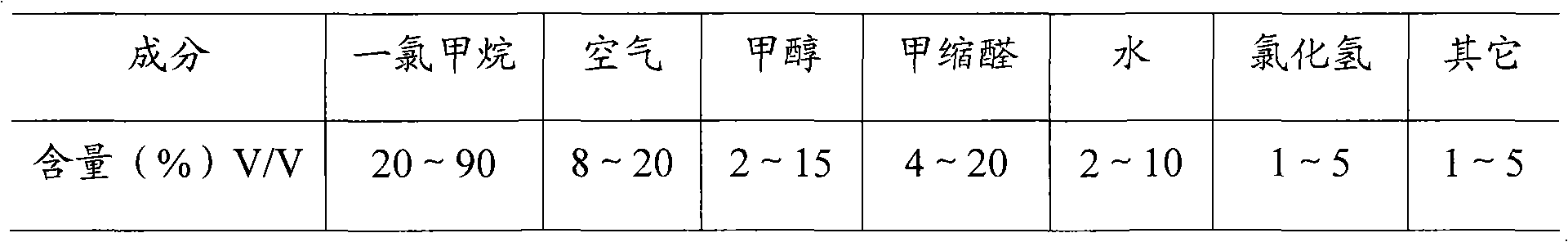

Recovery method of monochloro methane

InactiveCN102101821AAvoid the hassle of fillingAvoid it happening againHalogenated hydrocarbon preparationMolecular sieveRecovery method

The invention discloses a recovery method of monochloro methane, which comprises the following steps: washing tail gas which is generated in the preparation process of glyphosate acid or dimethyl phosphite, adsorbing through a molecular sieve, and condensing, wherein the adsorption temperature of the molecular sieve is 10-50 DEG C. The method disclosed by the invention effectively overcomes the defects that waste acid can be generated and an organic solvent is used in the existing technique for purifying and recovering monochloro methane. In addition, the molecular sieve selected in the invention can effectively adsorb methylal, thereby reducing a great deal of washing water and effectively relieving the pressure on environmental protection. The invention has favorable economic benefit and environmental benefit, avoids the trouble of filling concentrated sulfuric acid, lowers the cost, avoids the generation of the waste sulfuric acid, and solves the problems of emission and treatment of the waste sulfuric acid, thereby realizing environmental-protection production in deed; and meanwhile, the invention can effectively enhance the adsorption efficiency of the molecular sieve, and lower the energy consumption and production cost.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

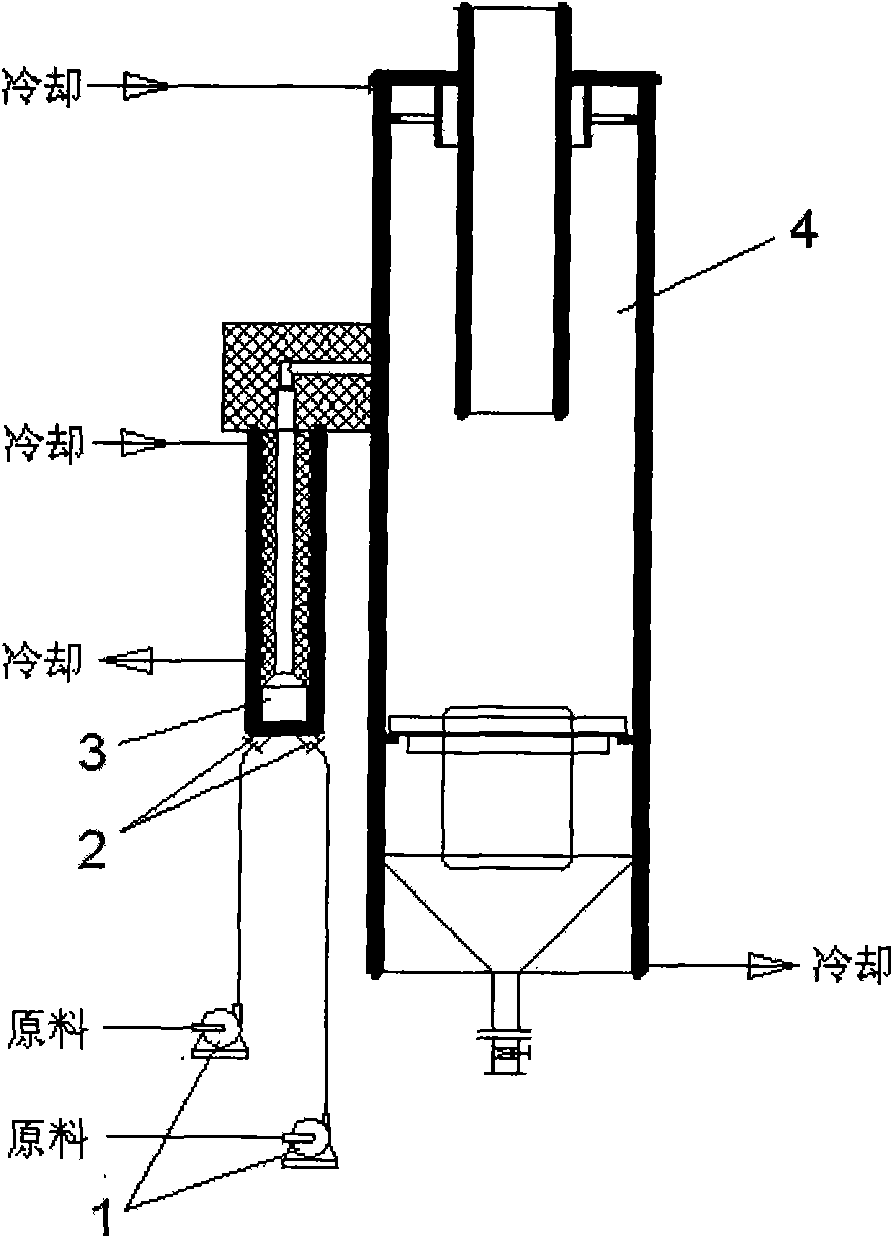

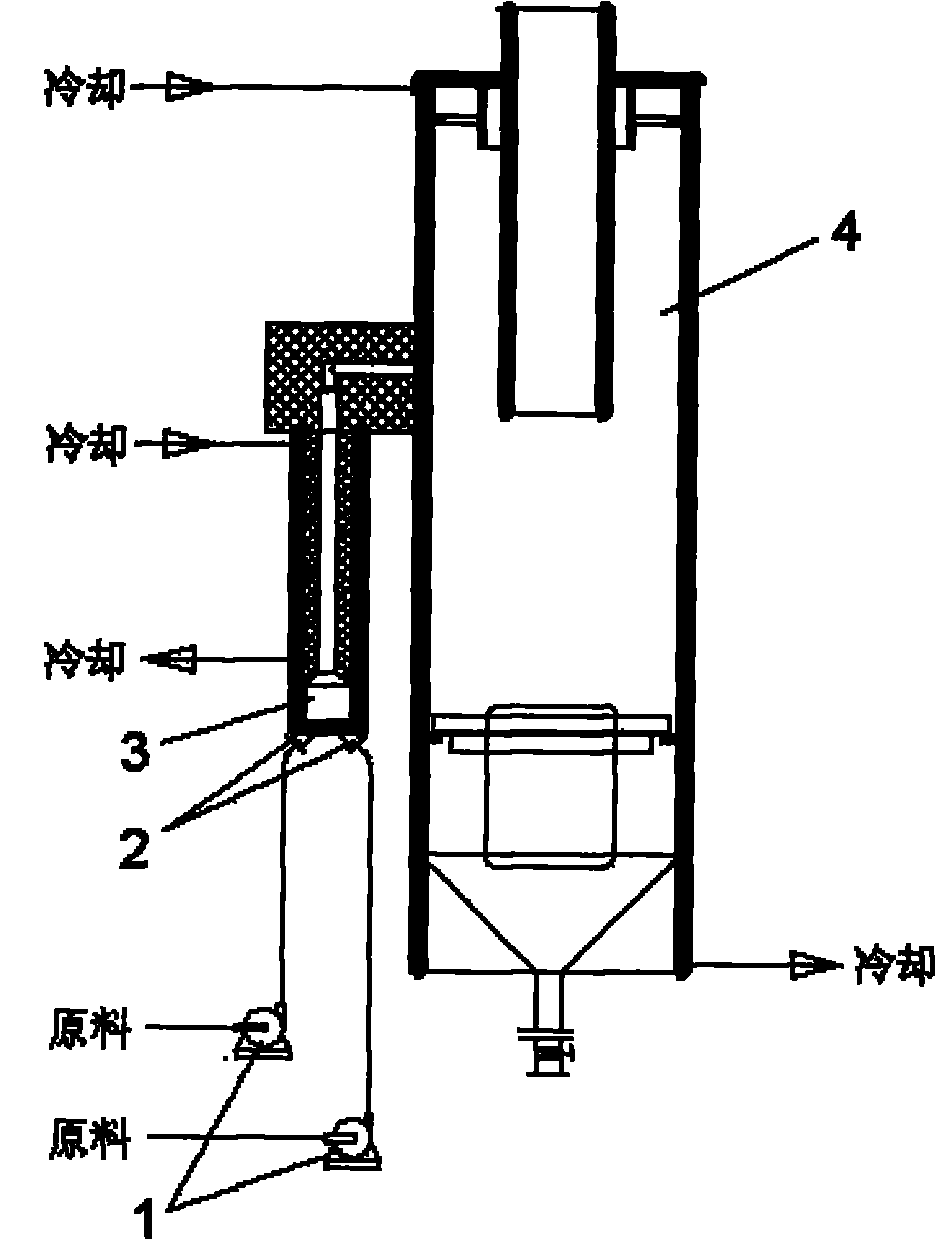

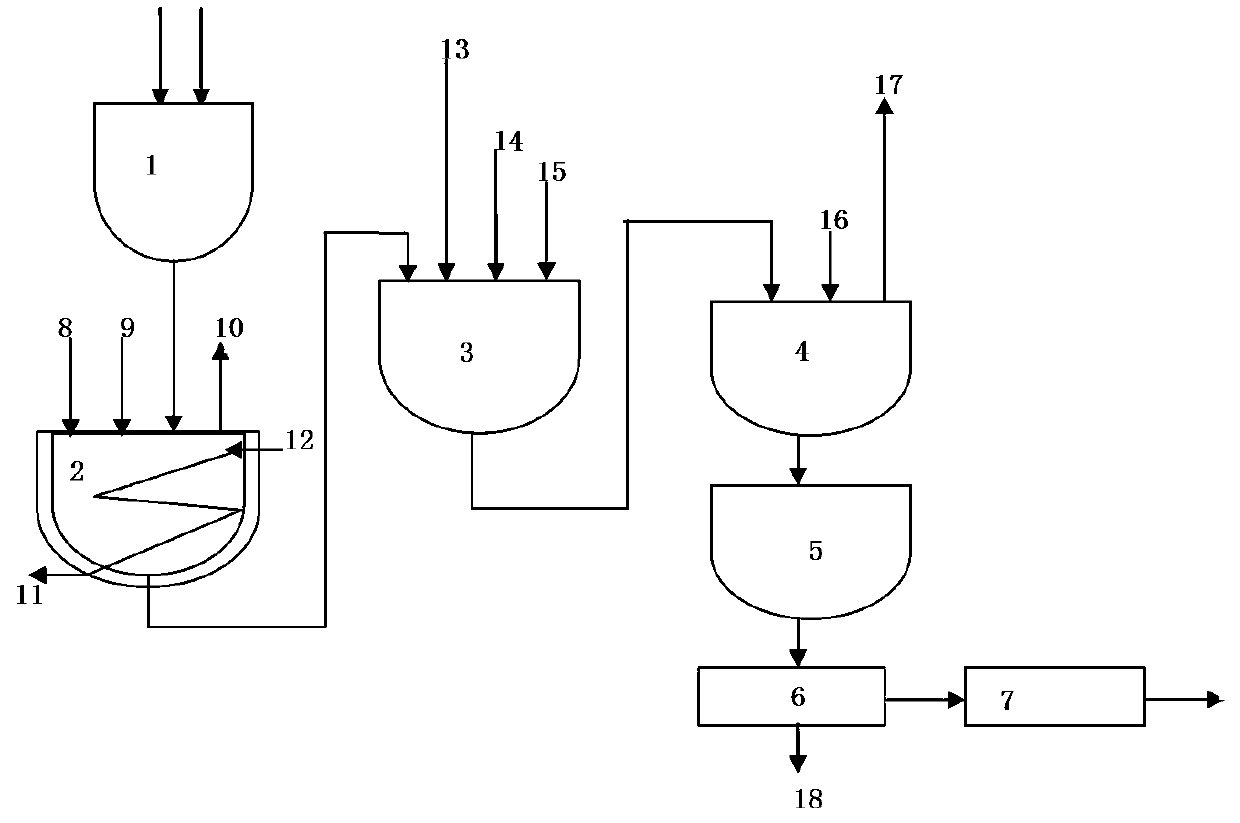

Production method of dimethyl phosphite

ActiveCN101870712AAvoid acidolysis side effectsImprove effective conversion rateGroup 5/15 element organic compoundsChemical/physical/physico-chemical nozzle-type rreactorsLiquid productCyclone

The invention relates to a production method of dimethyl phosphate, which takes phosphorus trichloride and methyl alcohol as raw materials for reaction. The method comprises the steps of: in a reaction chamber space having cross injection angle and the injection structures of the raw materials, respectively and continuously injecting and sending the phosphorus trichloride and the methyl alcohol which are based on the molar ratio of 1: (3.0-3.1) into the reaction chamber space through respective injection structures by corresponding pumping mechanisms for mixing together and reaction; then, introducing reaction material into a centrifugal cyclone separator with the pressure lower than that of the reaction chamber space along the tangential direction, and leading noncondensable gas and condensing liquid product to have centrifugal cyclone separation; and collecting the liquid dimethyl phosphate product descending along the inner wall of the centrifugal cyclone separator. The method can rapidly complete the reaction and the separation for products, effectively reduces the contact between HCl and the dimethyl phosphate, inhibits the occurrence of side reaction, improves the yield and the quality of the product, and greatly reduces the energy consumption.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD +1

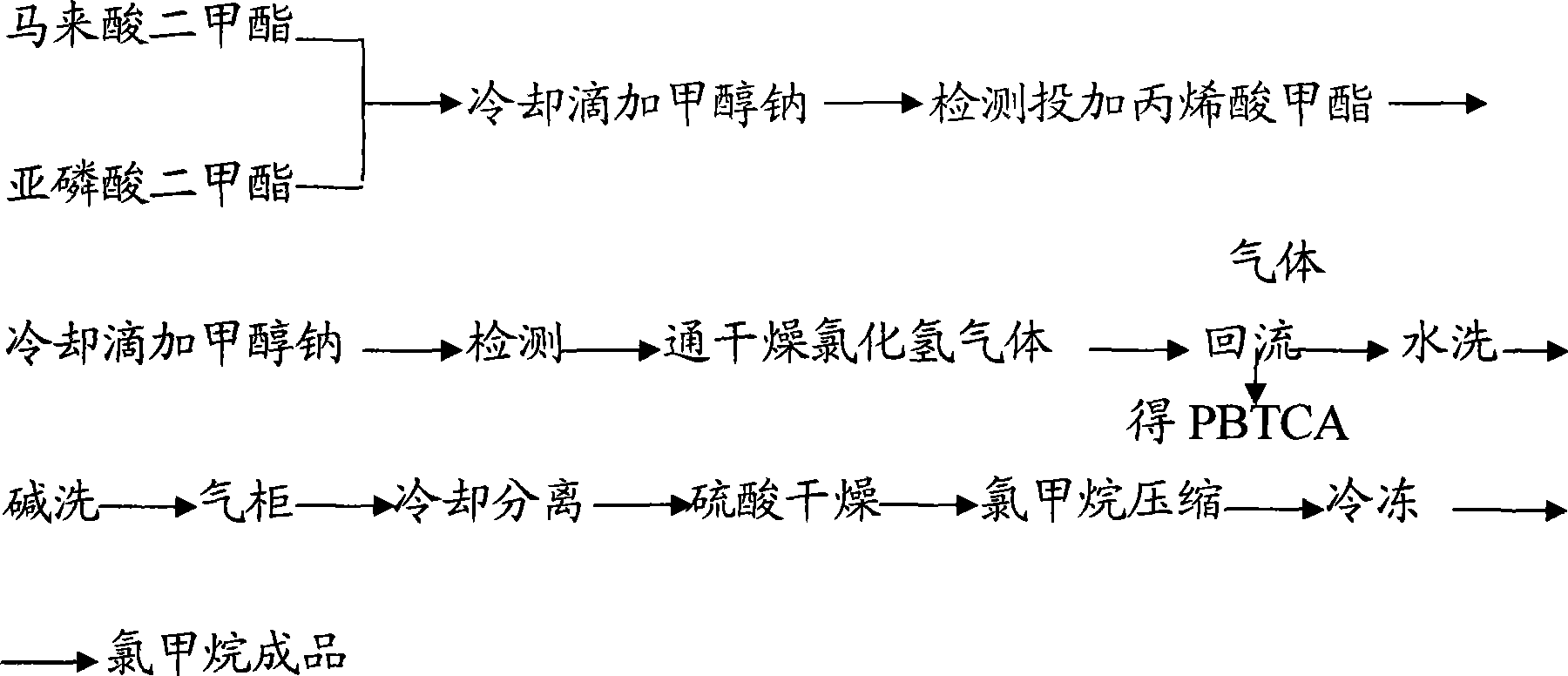

Novel technique for coproduction of 2-phosphonobutane-1,2,4-tricabroxylic acid and methyl chloride

ActiveCN101503426AIn line with environmental protection industry policyProfit maximizationGroup 5/15 element organic compoundsScale removal and water softeningDimethyl phosphiteChemistry

The invention relates to a novel process for producing 2-phosphonobutane-1,2,4-tricarboxylic acid co-production methyl chloride. The process comprises the following steps: firstly, putting dimethyl maleate and dimethyl phosphite in a reaction kettle, and dripping sodium methoxide to prepare a semi-finished phosphono succinic acid tetramethylester; then adding methyl acrylate in the semi-finished phosphono succinic acid tetramethylester; cooling and dripping sodium methoxide to obtain a midbody 2-phosphonobutane-1,2,4-tricarboxylic acid pentamethyl ester; leading chlorine hydride gas into the midbody; carrying out circumfluence for hours to obtain a finished product 2-phosphonobutane-1,2,4-tricarboxylic acid; opening a methyl chloride recovering device to recover methyl chloride; discharging methyl chloride gas into a gas cabinet through a vacuum pump, and then discharging the methyl chloride gas after being dried to a condenser through a methyl chloride compressor; and finally, collecting liquid methyl chloride in a methyl chloride storage tank for standby selling. The process conforms to the environment protection requirement, can maximize the benefit of hydrochloric acid with low added value, obtains the methylated chemical product, i.e. the methyl chloride, and can reduce the cost and save energy.

Owner:CHANGZHOU JIAYOU CHEM CO LTD

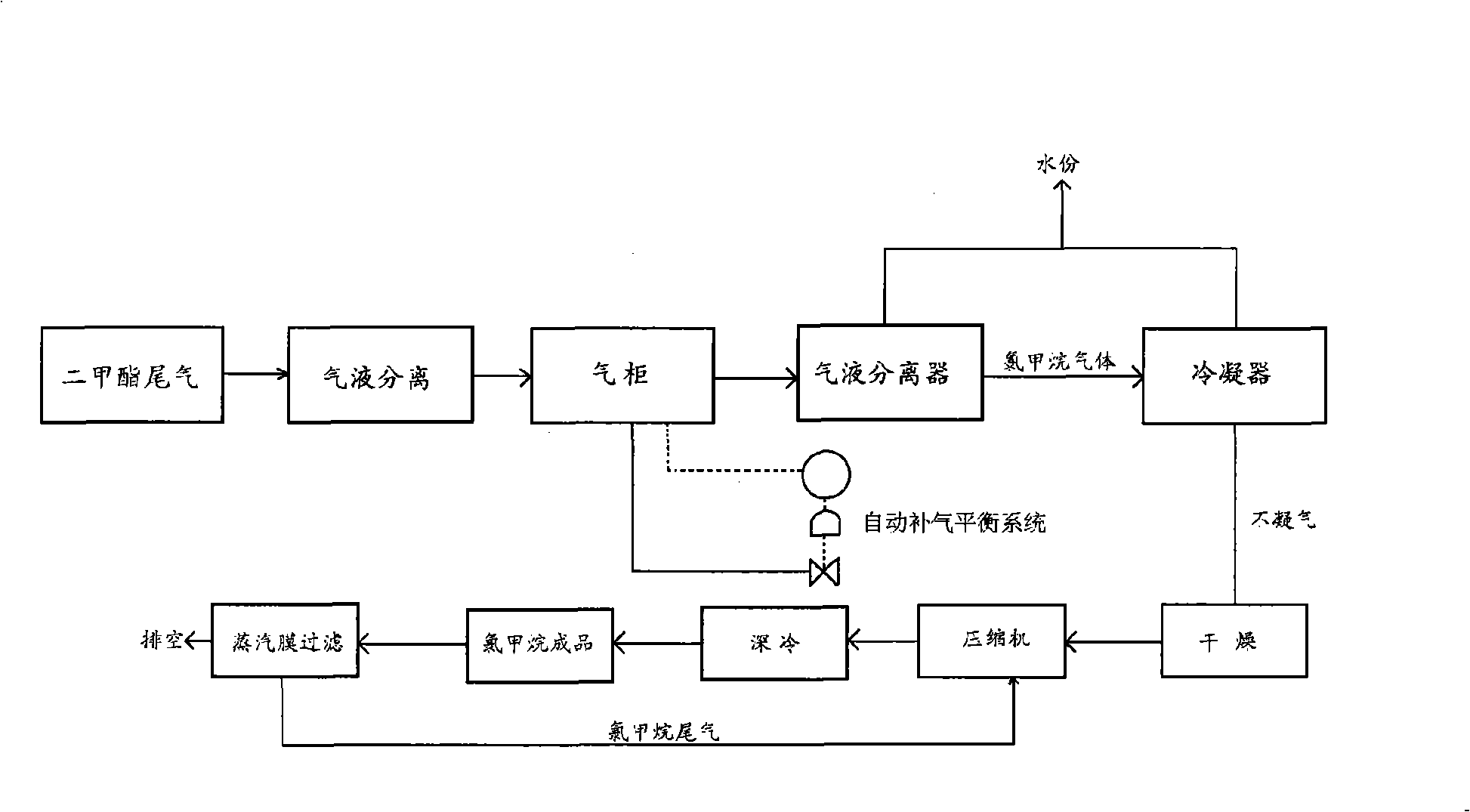

Method for recovering methyl chloride in discharged tail gas of glyphosate / dimethyl phosphate production

ActiveCN101407444ASolve the problem of gas productionFix stability issuesGroup 5/15 element organic compoundsDispersed particle separationDimethyl phosphitePhosphate

The invention discloses a method for recycling methyl chloride in tail gas emitted by glyphosate / dimethyl phosphite production, wherein, after gas-liquid separation, condensation, bathing, alkali cleaning, and drying are carried out on tail gas from the production technology of glyphosate / dimethyl phosphite, arid methyl chloride is compressed by a compressor and then copiously cooled to obtain methyl chloride; partial non-condensable gas unable to be absorbed through a freezing method is fed in the compressor through methyl chloride filtered by an organic vapor membrane to be compressed again; the rest gas is discharged to the upper air. The method for recycling methyl chloride in tail gas emitted by glyphosate / dimethyl phosphate production has the advantages that through the technology of combined copious cooling and organic vapor membrane recycling, the adoption of a DCS automatic air supply balanced system, and the core of a novel ripple packing tower, multi-level bathing, alkali cleaning, absorbing, and drying are carried out for repeatedly recycling methyl chloride gas, thus solving the problems of numerous gas production and unstable gas production of recycled methyl chloride, guaranteeing stable running of equipment, improving productivity effect, and improving recovery rate of methyl chloride from 93 percent to more than 99.5 percent; and environmental benefits and economic benefits are outstanding.

Owner:HUBEI TAISHENG CHEM

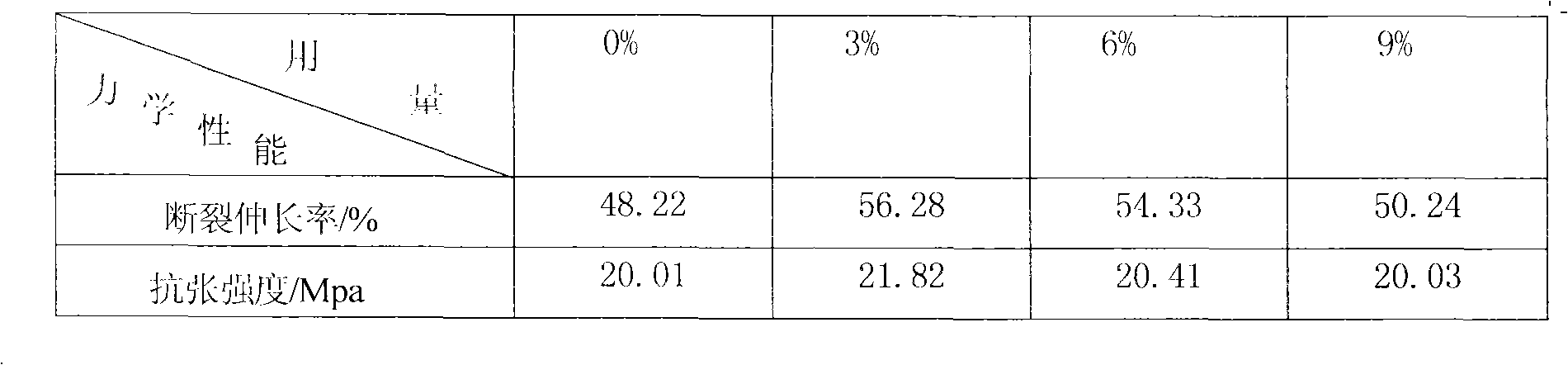

Preparation method of retanned intumescent flame retardant

InactiveCN101768450AGood compatibilityImprove bindingTanning treatmentDimethyl phosphiteAcrylonitrile

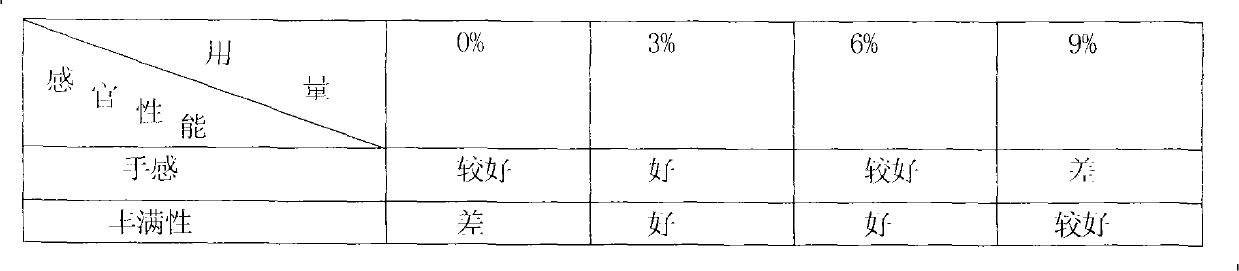

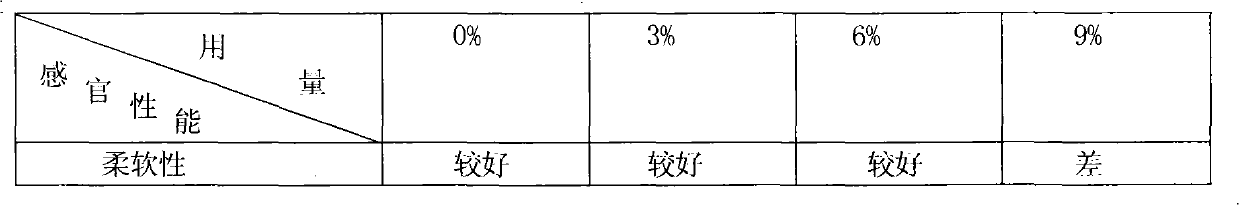

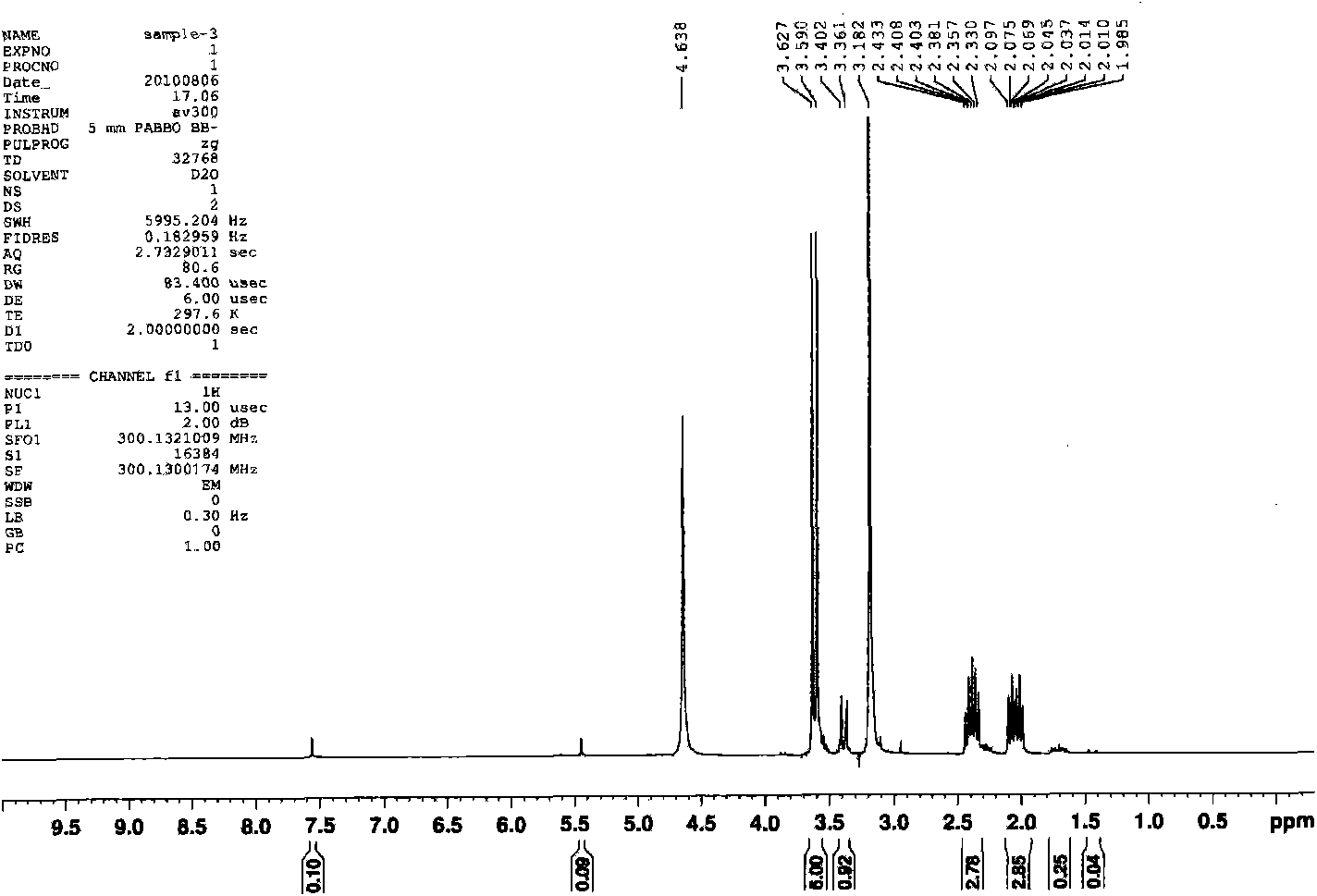

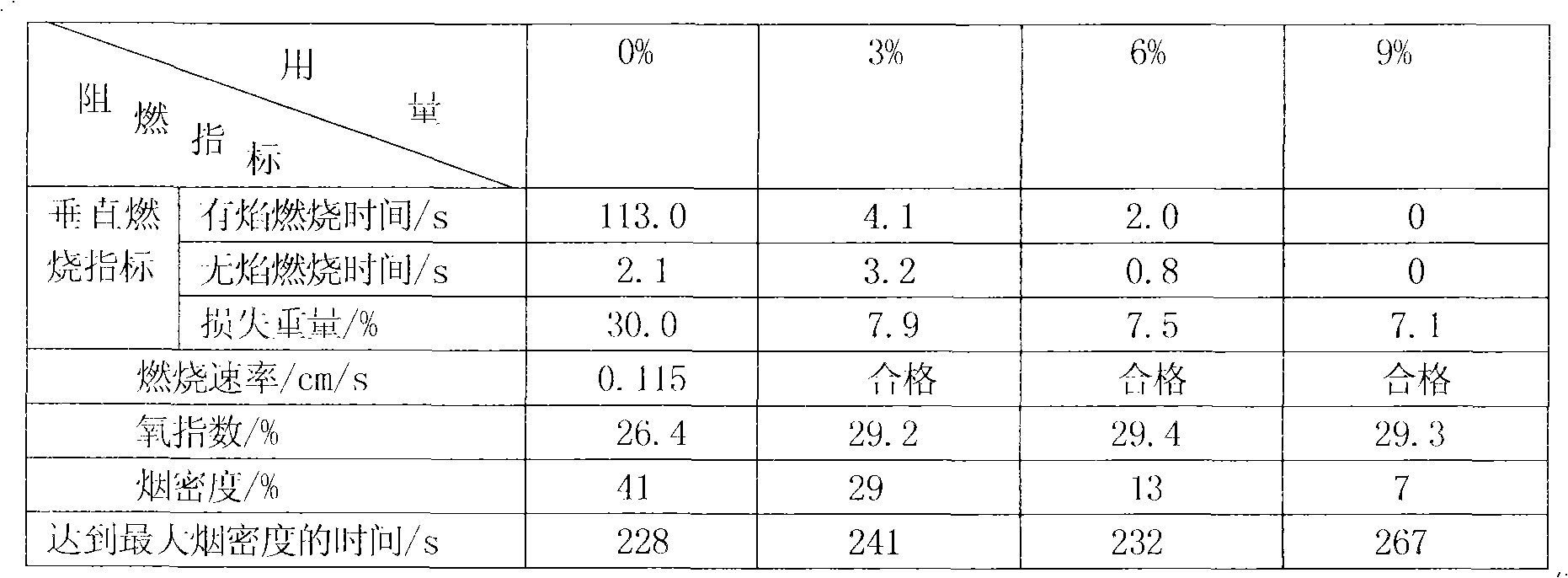

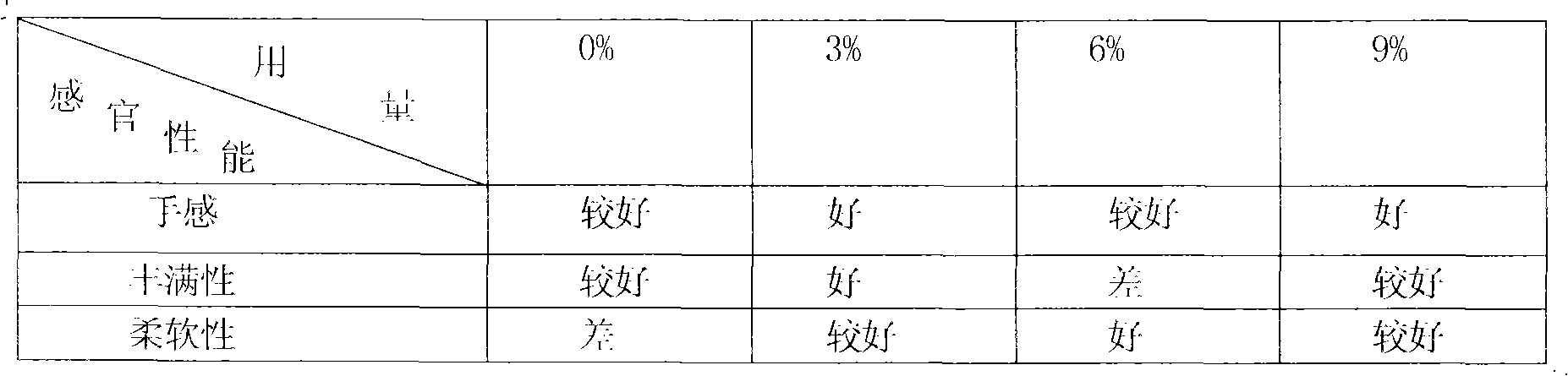

The invention discloses a preparation method of a retanned intumescent flame retardant, which comprises the following steps: adding a catalyst into dimethyl phosphite, evenly mixing, adding acrylamide, acrylonitrile and maleic anhydride for reaction, and obtaining colorless transparent liquid A; using alkaline solution for regulating the pH of the transparent liquid A to 5-7, dripping glyoxal, and carrying out reaction for obtaining light yellow liquid B; and adding melamine into the light yellow liquid B for reaction, and obtaining reddish brown retanned intumescent flame retardant C. A product synthesized by the preparation method not only has good flame resistance, which can lead leather to achieve the difficult-flammability by adding 3% of the weight of the leather of the product, but also has good compatibility with the leather, thereby improving the hand feel, the fullness, the softness and the mechanical performances of the leather.

Owner:SHAANXI UNIV OF SCI & TECH

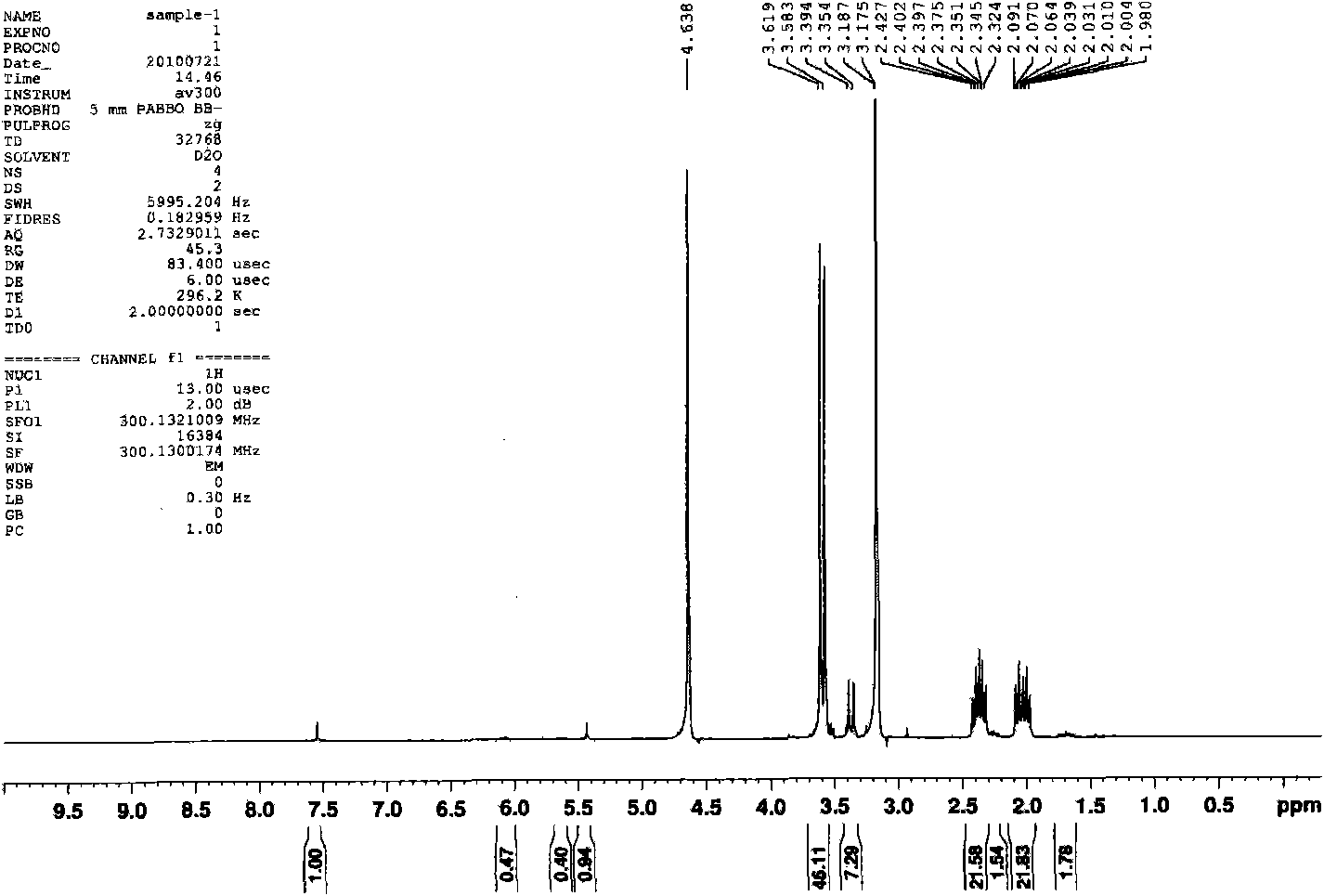

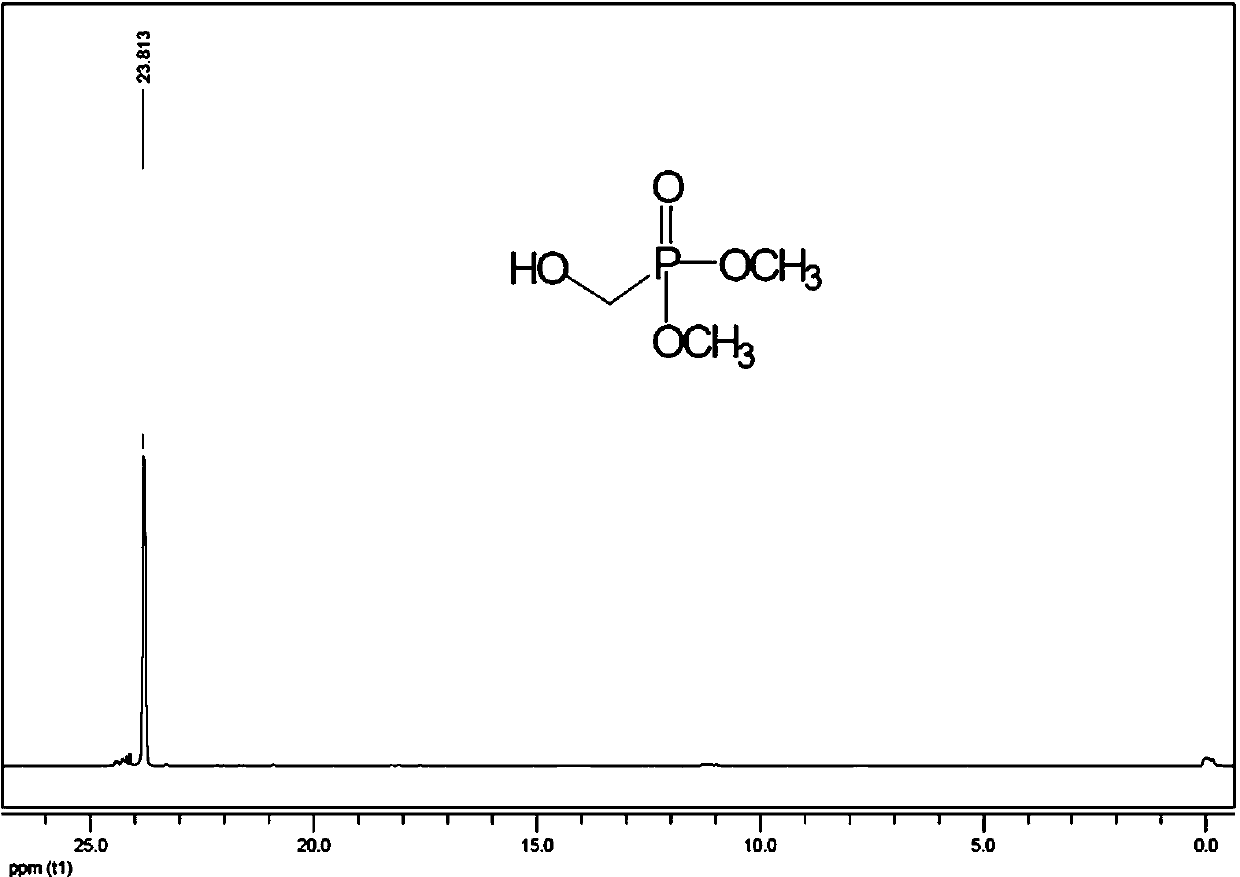

Method for preparing N-hydroxymethyl-3-(dimethoxyphosphoryl) propionamide

ActiveCN102060873AIncrease concentrationReduce usageGroup 5/15 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalDimethyl phosphite

The embodiment of the invention discloses a method for preparing N-hydroxymethyl-3-(dimethoxyphosphoryl) propionamide, which comprises the following steps of: leading acrylamide, dimethyl phosphite and a catalyst to react in a solvent to obtain dimethyl (3-amino-3-acyl propyl) phosphonate, wherein the catalyst is a nonacid compound of alkaline earth metal; leading dimethyl (3-amino-3-acyl propyl) phosphonate to react with formaldehyde to obtain the N-hydroxymethyl-3-(dimethoxyphosphoryl) propionamide. In the invention, the nonacid compound of alkaline earth metal is used as the catalyst. Because the nonacid compound of alkaline earth metal is solid matter, the reactants including acrylamide and dimethyl phosphite can be in good contact with the solid catalyst. Meanwhile, the surface of the solid catalyst has high catalyst concentration to ensure that the catalyst is easy to initiate the reaction. Thus, the preparation method provided by the invention ensures short reaction time and high reaction efficiency.

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing retanning-type leather fire retardant

InactiveCN101781572AHigh flame retardant efficiencyImprove bindingTanning treatmentDimethyl phosphitePolyol

The invention discloses a method for preparing a retanning-type leather fire retardant, comprising the following steps: firstly adding a catalyst in dimethyl phosphite and mixing, and adding acrylamide to react to obtain colorless and transparent liquid A after the catalyst is dissolved; regulating the pH value of the product A to be 6.5-7 by aqueous alkali, boosting the temperature of a reactionsystem to 70-90 DEG C, and dropwise adding glutaraldehyde to react to obtain light yellow transparent liquid B; and regulating the pH value of the product B to be 3-5 by acid, and adding polyol to react to obtain the brown-yellow oily liquid retanning-type fire retardant. The product synthesized by the preparation method of the invention has fire resistance and good retannage, can improve handfeel, fullness and softness and increase mechanical properties for leather; and the fire-retardant level of the leather can be realized by only using the fire retardant the dosage of which is 3% of the leather.

Owner:SHAANXI UNIV OF SCI & TECH

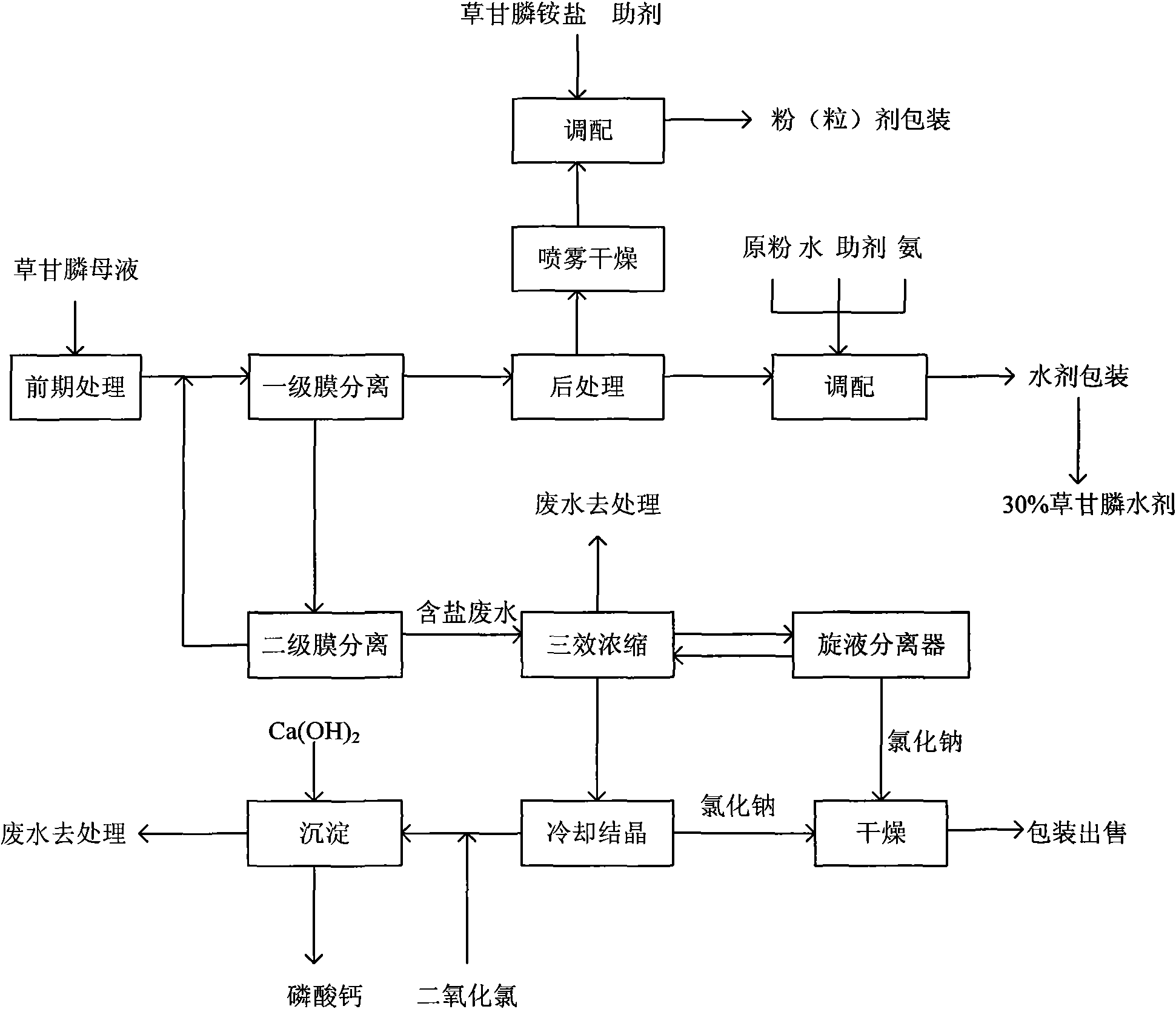

Method for preparing glyphosate preparation with 30 to 70 percent of effective ingredient by glyphosate mother liquid

InactiveCN101589724AReduce consumptionLess waste waterBiocideWater/sewage treatment bu osmosis/dialysisAdditive ingredientPotassium hydroxide

The invention discloses a method for preparing glyphosate preparation with 30 to 70 percent of effective ingredient by glyphosate mother liquid. The method comprises the following steps that: mother liquid containing 1 to 4 percent of glyphosate in production of the glyphosate is prepared by a dimethyl phosphite method, and enters a primary film separation device to separate light mother liquid and extract mother liquid, wherein the extract mother liquid contains 5 to 10 percent of the glyphosate, and has salt concentration less than 2.0 percent; the light mother liquid enters a secondary film separation device to separate thick mother liquid and secondary light mother liquid, and the thick mother liquid returns to the inlet of the primary film separation device; after the extract mother liquid is subjected to pretreatment, the extract mother liquid is added with glyphosate raw powder, accessory ingredient and ammonia (or one of isopropylamine, potassium hydroxide and potassium carbonate) to be prepared into 30 to 70 percent glyphosate preparation; the secondary light mother liquid is subjected to multieffect evaporation concentration, crystallization, centrifugal separation and dry recovery of a byproduct NaCl; and after the separated mother liquid is oxidized, the mother liquid is added with calcium hydroxide to remove phosphor and precipitate calcium phosphate. The method prepares the glyphosate preparation over 30 percent by the glyphosate mother liquid, recovers the byproduct in the mother liquid, and greatly reduces treatment amount of wastewater producing the glyphosate.

Owner:ZHEJIANG LINGHUA CHEM GROUP

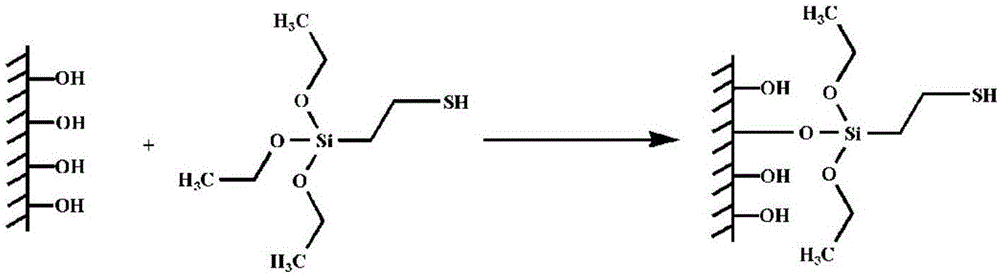

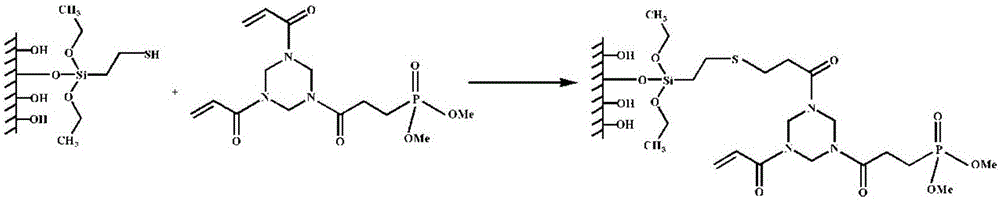

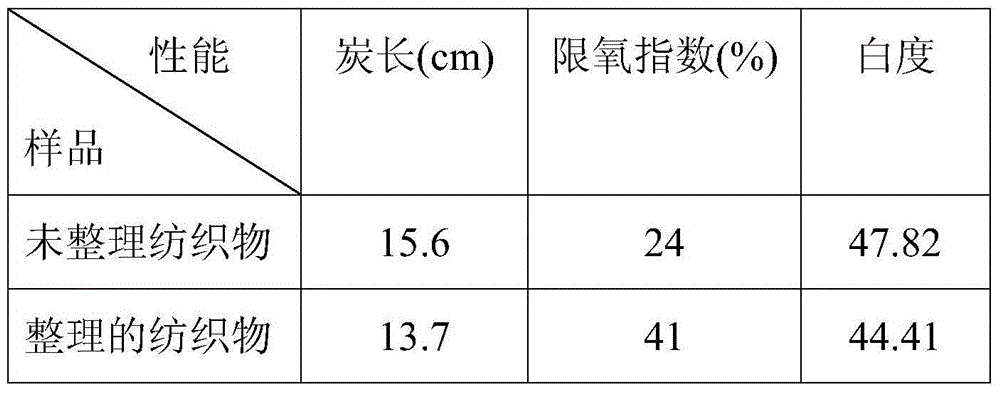

Durable flame-retardant finish method for cotton fabric based on ultraviolet light curing reaction

InactiveCN106637960ANo harmSimple methodPhysical treatmentHeat resistant fibresDimethyl phosphiteUltraviolet lights

The invention relates to a durable flame-retardant finish method for a cotton fabric based on ultraviolet light curing reaction. The method comprises the following steps: washing a cotton fabric, then putting into an acidic 1-5wt% thiohydroxy-containing silane coupling agent solution, dipping to perform thiohydroxy modification, and drying to obtain a thiohydroxy modified cotton fabric; (2) taking 1,3,5-triacryloylhexahydro-1,3,5-triazine TAHT and dimethyl phosphite DP, adding 1,8-diazabicycloundec-7-ene DBU, and reacting over night while stirring to obtain flame retardant DHTP; and (3) preparing the flame retardant DHTP in the step (2) into a solution, dipping the thiohydroxy modified cotton fabric in the step (1) in the DHTP solution to perform ultraviolet light curing reaction, washing with water, and drying to obtain a flame-retardant cotton fabric. The method provided by the invention is simple and easy to implement; the cotton fabric can keep the original moisture absorption property and other excellent properties; and the cotton fabric is endowed with flame retardancy while the durability is improved, has the advantages of obvious flame-retardant effect, safety and long-lasting action, and can not do harm to human bodies and environments, thereby having favorable application prospects.

Owner:DONGHUA UNIV

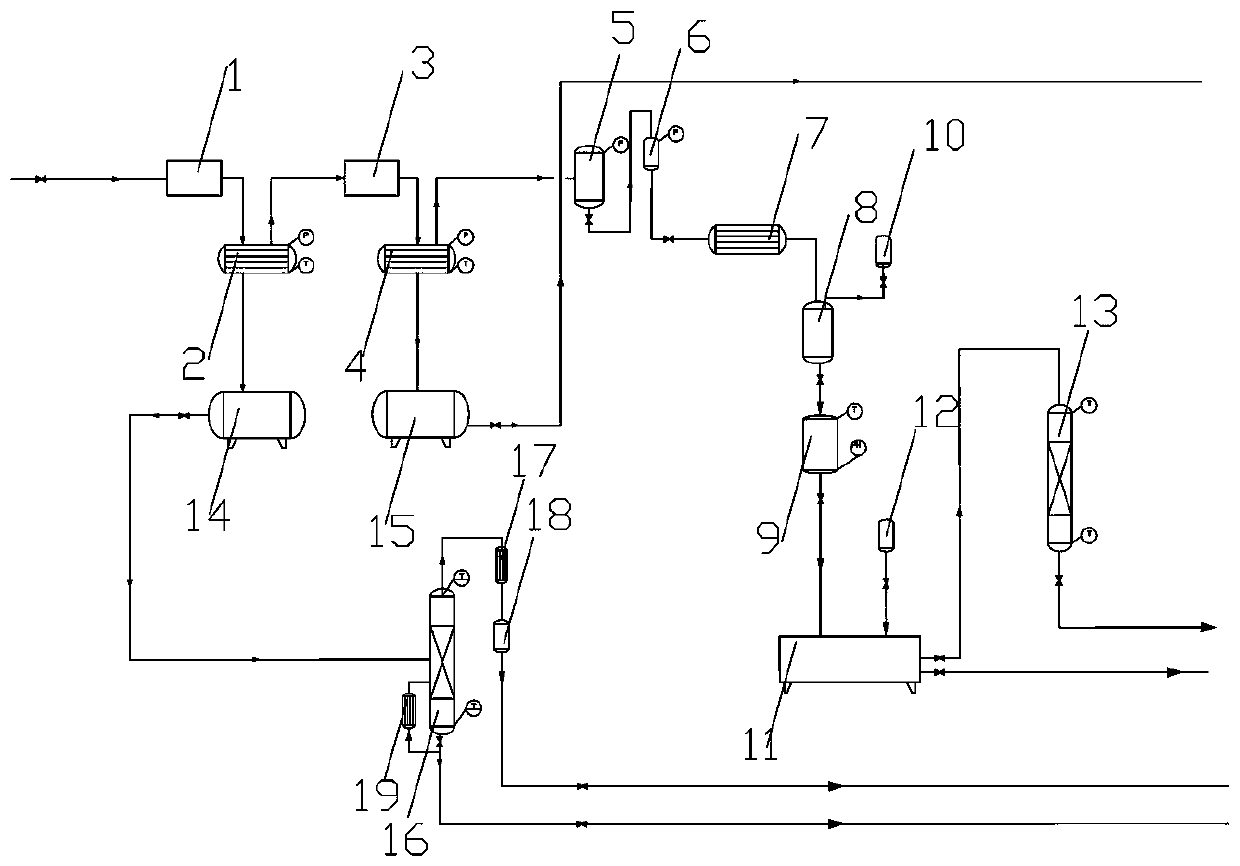

Device and process for applying dimethyl phosphite byproduct hydrogen chloride to synthesis of glyphosate

ActiveCN110128469AHigh purityQuality improvementGroup 5/15 element organic compoundsHalogenated hydrocarbon separation/purificationDesolvationSolvent

The invention provides a method and a device for applying dimethyl phosphite hydrogen chloride tail gas to synthesis of glyphosate. The method comprises the following steps: conveying dimethyl phosphite tail gas into a compressor through a pipeline, and carrying out primary pressurized condensation to obtain a high-boiling-point alcohol water solution and non-condensable gas; carrying out cryogenic treatment on the non-condensable gas in a secondary pressurized condenser, separating the product to obtain hydrogen chloride gas, and storing the hydrogen chloride gas in a hydrogen chloride gas cabinet; carrying out an acidolysis reaction on the hydrogen chloride gas and the synthesis liquid in a hydrolysis kettle, then carrying out heating desolvation and deacidification and feeding the product into a cooling crystallization process; and then carrying out solid-liquid separation through a washing device, and finally drying the product to obtain the glyphosate raw medicine. According to the method, the hydrogen chloride and the methyl chloride are separated through pressurization and condensation, then the methyl chloride enters a refining procedure, and the separated hydrogen chlorideis applied to the glyphosate production mode, so that the introduction of water in a reaction system can be reduced, the steam consumption during solvent recovery is reduced, and the wastewater amount is reduced. The water for glyphosate production is reduced, the wastewater treatment and energy consumption are reduced at the same time, and the economic and environmental benefits are remarkable.

Owner:内蒙古兴发科技有限公司

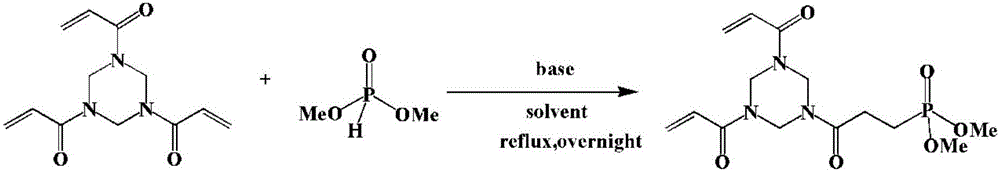

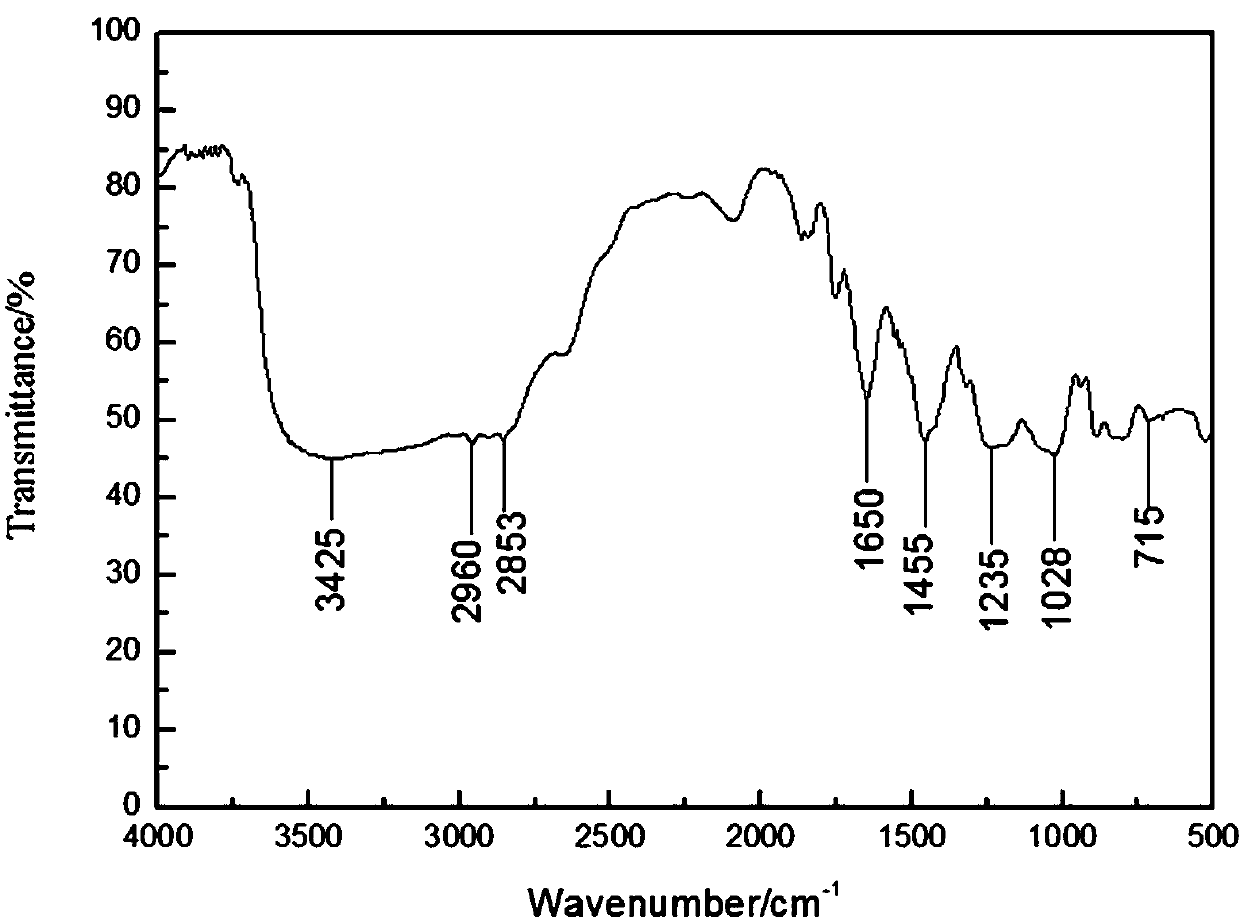

Phosphorus-nitrogen-silicon compound containing triazine ring and its preparation method

InactiveCN103980315BImprove thermal stabilityImprove charcoal abilityGroup 5/15 element organic compoundsFibre treatmentPhosphorous acidDimethyl phosphite

The invention relates to a reactive flame retardant, specifically a phosphorus-nitrogen-silicon compound containing a triazine ring and a preparation method thereof. In the first step, paraformaldehyde is dissolved in methanol, potassium carbonate solid is added, and the solution is cooled To 0°C, add dimethyl phosphite dropwise while stirring, then warm up to room temperature, filter off potassium carbonate after 1h, and remove methanol from the filtrate under reduced pressure to obtain a colorless oil, which is intermediate Ⅰ. Compared with the prior art, the phosphorus-nitrogen-silicon compound containing triazine rings of the present invention has the following beneficial effects: 1. The phosphorus, nitrogen, and silicon three flame-retardant elements are concentrated in one molecule, which improves the flame retardant Thermal stability, char formation and flame retardant synergistic effect; 2. The synthesis process conditions are stable, the reaction process is easy to control, the production cost is low, and it has good flame retardant effect when the amount of addition is small, and can be used for various fabrics flame retardant treatment.

Owner:ZHONGBEI UNIV

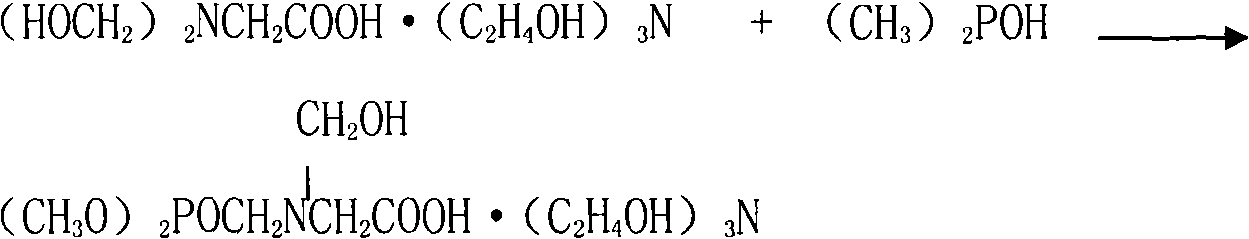

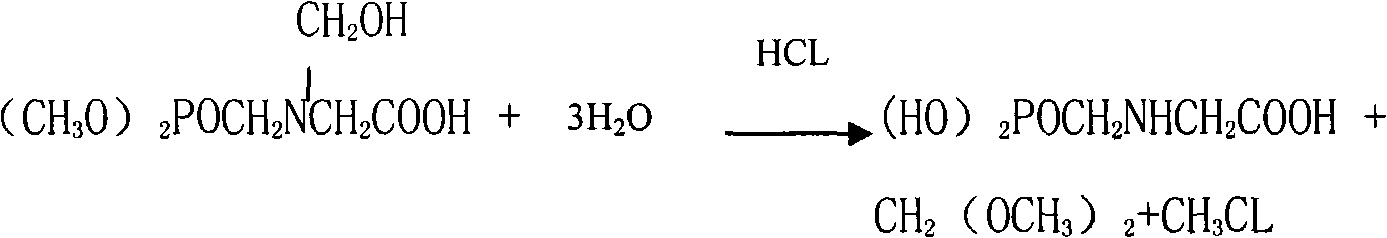

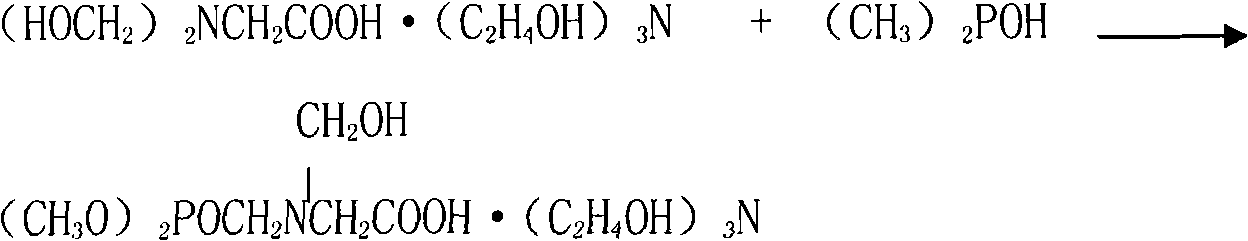

New process for preparing N-phosphonomethyl iminodiacetic acid

InactiveCN1458157AImprove economyGood environmental benefitsGroup 5/15 element organic compoundsIminodiacetic acidDimethyl phosphite

The new process of preparing N-phosphonomethyl iminodiacetic acid (NPMIDA) as the intermediate for synthesizing glyphosate features the materials including alkyl phosphite and / or C1-C4 formaldehyde alcohol. Especially, the residual liquid produced in the dimethyl phosphite producing process and acetal produced in dimethyl phosphite process of producing glyphosate are used. In the same time, chloromethane for synthesizing methyl chlorosilane may be obtained.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

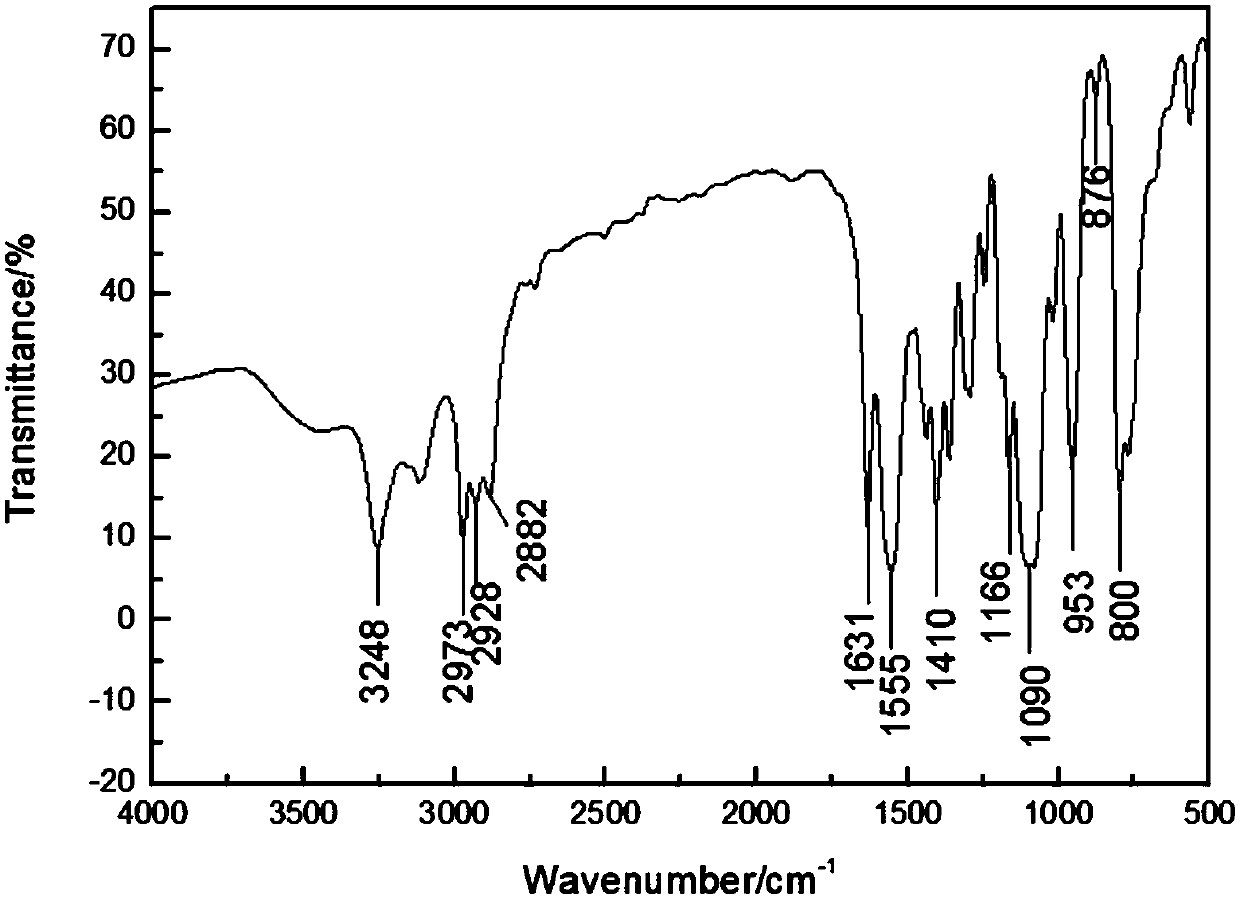

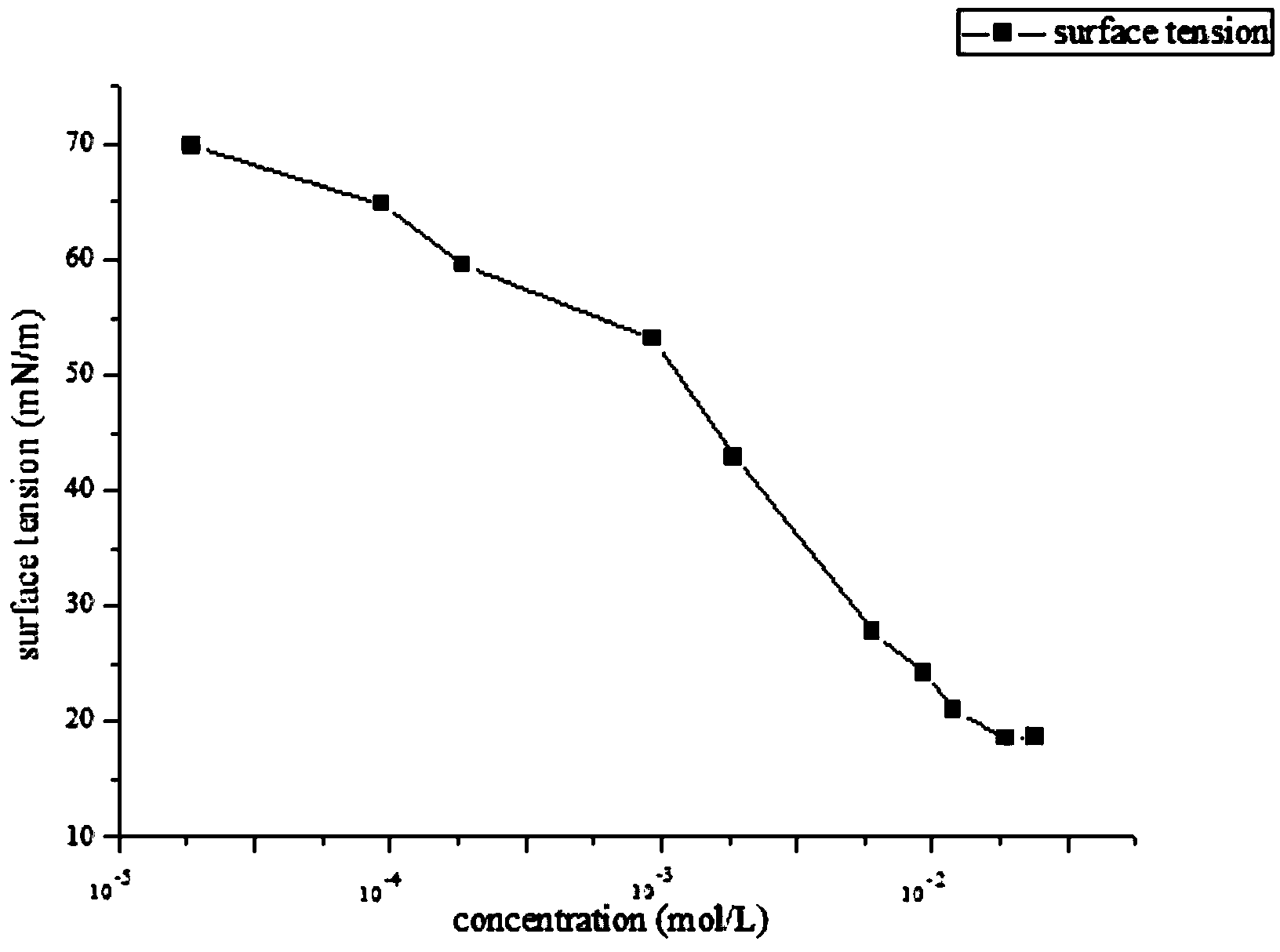

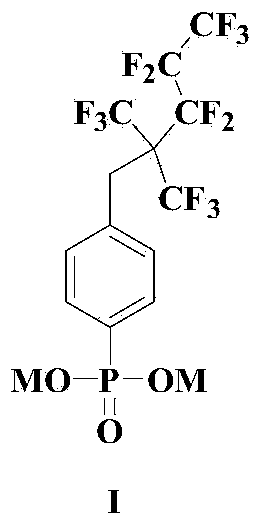

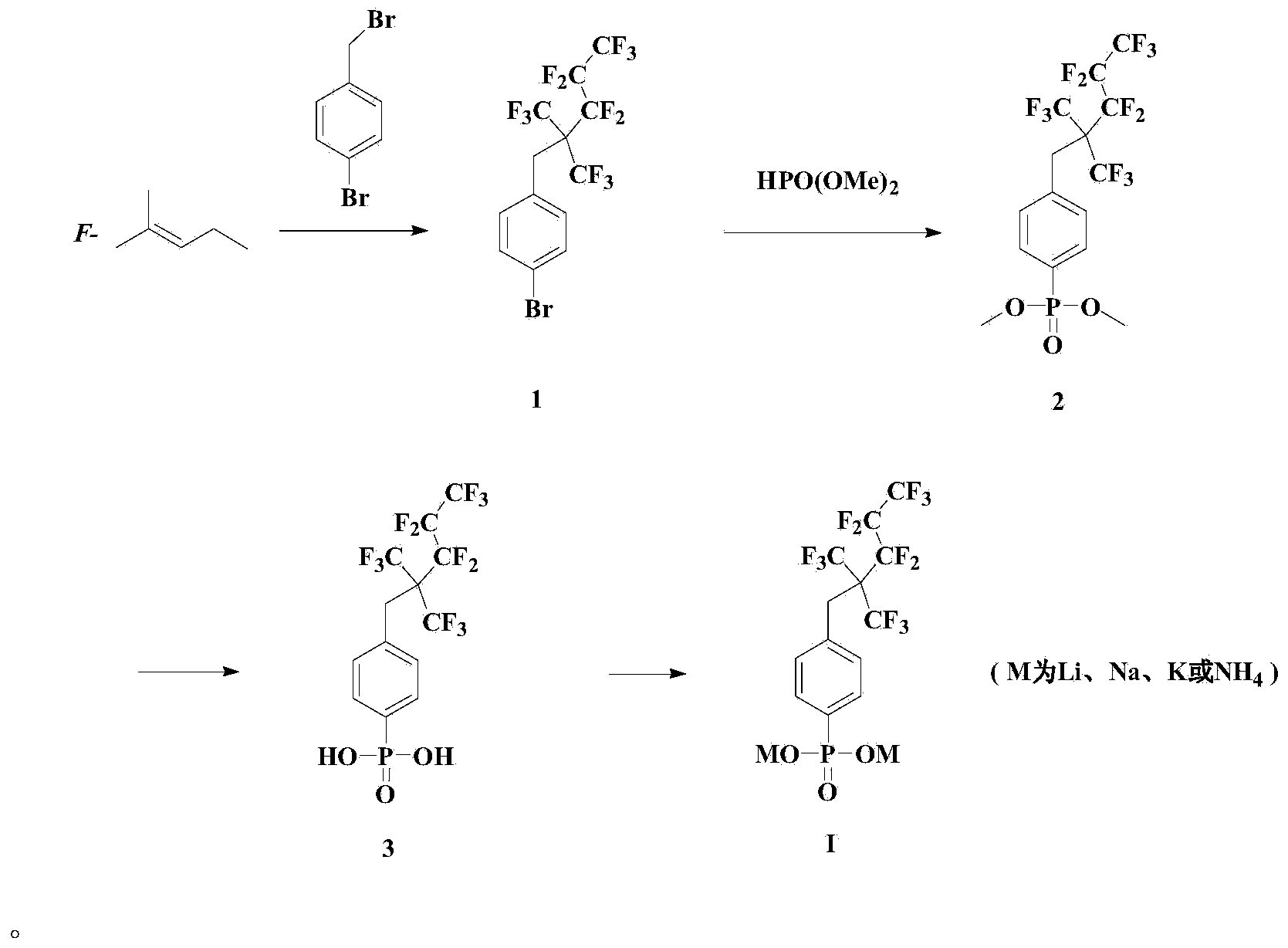

Anionic fluorocarbon surfactant and preparation method thereof

ActiveCN103877909ARaw materials are easy to getSimple processGroup 5/15 element organic compoundsTransportation and packagingOrganic acidDimethyl phosphite

The invention relates to an anionic fluorocarbon surfactant and a preparation method thereof. The structural formula of the anionic fluorocarbon surfactant is as follows: CF3CF2CF2C(CF3)2CH2C6H4PO(OM)2, wherein M is equal to Li, Na, K or NH4. The preparation method comprises the following steps: (1) reacting hexafluoropropylene dimer and p-Bromobenzyl bromide to generate a fluorine-containing intermediate compound 1; (2) coupling the fluorine-containing intermediate compound 1 with dimethyl phosphite to obtain a fluorine-containing intermediate compound 2; (3) hydrolyzing the fluorine-containing intermediate compound 2 to generate a fluorine-containing organic acid 3; and (4) neutralizing the fluorine-containing organic acid 3 with alkali to obtain a product. The method has the advantages of being, simple, low in cost and good in repeatability, and raw materials can be easily obtained. The surface tension performance of the product is good.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

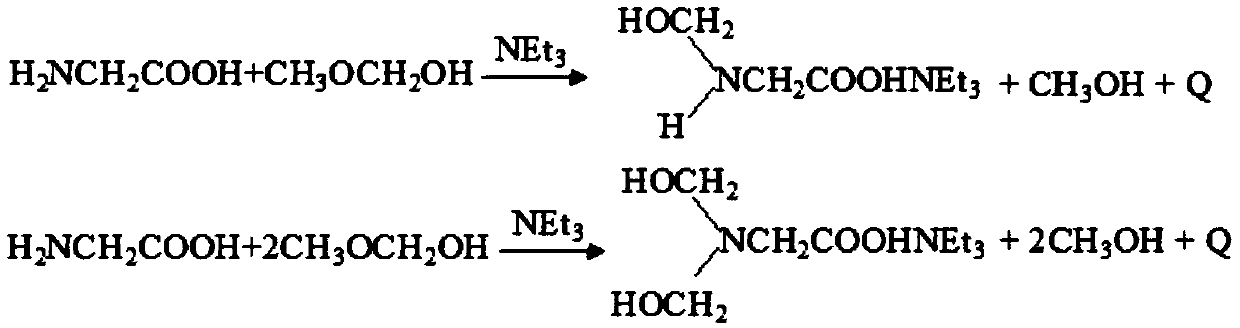

Method for synthesizing and preparing glyphosate with glycine method

ActiveCN102040623ALow impurity contentReduce the amount requiredBiocideOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationTRIETHANOLAMINE HYDROCHLORIDE

The invention relates to a method for synthesizing and preparing glyphosate with a glycine method. Paraformaldehyde, glycine and dimethyl phosphite are used as raw materials for reaction, methanol is used as a solvent, and alcohol amine is used as a catalyst to carry out glyphosate condensation synthesis reaction; after the processes of the condensation reaction are finished, hydrochloric acid orhydrogen chloride (HCl) gas is introduced in a condensation solution to form ethanolamine hydrochloride; after the ethanolamine hydrochloride is filtrated and separated, the hydrochloric acid is continuously added in the condensation solution for hydrolysis to obtain the glyphosate; after dealcoholization, alkali is added to adjust pH, the glyphosate is precipitated from cooling crystals, and washed and dried to obtain finished products. Mother liquid is condensed to prepare a glyphosate aqueous solution. The alcohol amine can be triethanolamine, diethanol amine, monoethanolamine, carbinolamine, dimethylaminoethanol and the like, and in particular to the triethanolamine. The mole ratio of hydrogen chloride gas introducing amount to the added related alcohol amine is 1:(1-1.5). In the invention, triethanolamine Hydrochloride can be recovered through ordinary filtration and separation, the yield of the triethanolamine Hydrochloride can reach 95%, and the content of the triethanolamine Hydrochloride can reach more than 99%; and the recovered triethanolamine Hydrochloride can be neutralized with NaOH to transform into the triethanolamine as raw materials for production in repeated use, and can be used as products for sale.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP +1

Fireproof emulsion paint

InactiveCN105062264AGood weather resistanceImprove water resistanceFireproof paintsAnti-corrosive paintsPhosphateKetone

The invention discloses fireproof emulsion paint. The fireproof emulsion paint comprises acrylic acid emulsion, polyurethane emulsion, epoxy resin, a fire retardant, expanded perlite, titanium dioxide, nanometer silica sol, silicon powder, nanometer titanium dioxide, zinc trifluoroacetylacetonate, dodecafluoroheptyl methacrylate, a film forming auxiliary agent, sorbitan monopalmitate, lauric acid, an antifoaming agent, hydroxyethyl cellulose, methyl ethyl ketone, N-phenyl-N'-cyclohexyl p-phenylenediamine, potassium citrate, dimethyldiallylammonium chloride and water. The fire retardant comprises dimethyl phosphite, methylvinyldichlorosilane, 3-aminopropyltriethoxysilane, 5-ethyl-5-butyl-2-chloro-1,3,2-dioxaphosphorinane, potassium tripolyphosphate, cetyl pyridinium bromide, decabromodiphenyl ethane, aluminum dihydrogen phosphate, calcium borate, melamine and cyanuric acid. The fireproof emulsion paint has excellent flame resistance, good fire retardancy, good adhesion to a base material and good decorative effects.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

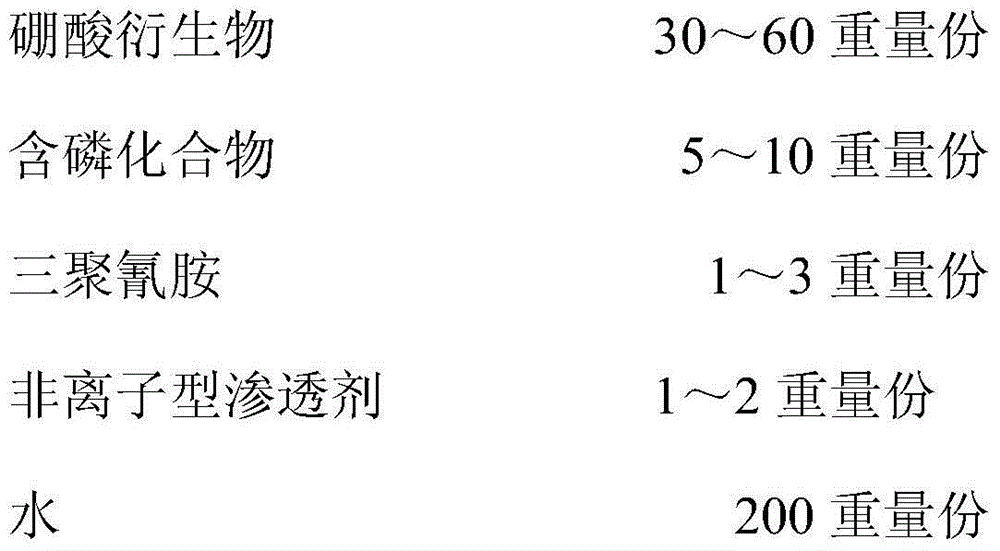

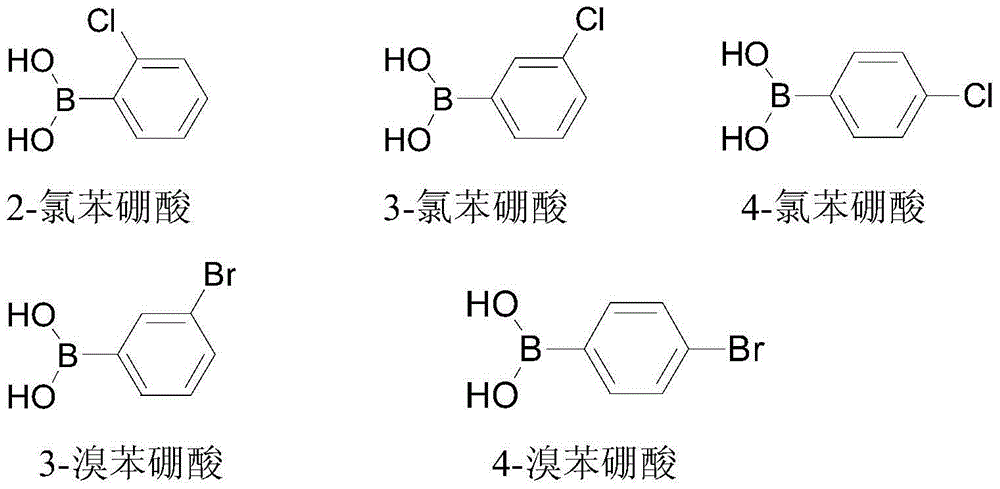

Flame-retardant finishing agent and use thereof

InactiveCN105316936AImprove flame retardant performanceOutstanding flame retardant durabilityFibre treatmentDimethyl phosphiteMonopotassium phosphate

The invention discloses a flame-retardant finishing agent and a use thereof. The flame-retardant finishing agent comprises, by weight, 30-60 parts of a boric acid derivative, 5-10 parts of a phosphorus-containing compound, 1-3 parts of melamine, 1-2 parts of a non-ionic osmotic agent and 200 parts of water. The boric acid derivative is one of 2-chlorophenylboronic acid, 3-chlorophenylboronic acid, 4-chlorophenylboronic acid, 3-bromophenylboronic acid and 4-bromophenylboronic acid. The phosphorus-containing compound is one of ammonium dihydrogen phosphate, dimethyl phosphite, monopotassium phosphate and monocalcium phosphate. The flame-retardant finishing agent is prepared from the boric acid derivative as a main raw material, the flame-retardant finishing agent is used for treating a textile so that a high flame resistance textile is obtained, and the high flame resistance textile has good flame resistance and outstanding flame retardation endurance and thus the flame-retardant finishing agent has a wide application prospect in a high flame retardation requirement material such as an outdoor tent.

Owner:戴李宗

Synthesis method of glyphosate

InactiveCN101875671AShort synthesis timeHigh yieldGroup 5/15 element organic compoundsHerbicides and algicidesFiltrationSynthesis methods

The invention relates to a synthesis method of glyphosate, which comprises the following steps: (1) respectively pouring paraformaldehyde, methanol and triethylamine into a reaction kettle, controlling the temperature of the reaction kettle to be 30-50 DEG C, and reacting for 0.5-2h under stirring; (2) adding glycine into the reaction kettle, controlling the temperature of the reaction kettle to be 30-50 DEG C, and reacting for 0.5-2h under stirring; (3) adding dimethyl phosphite into the reaction kettle, controlling the temperature of the reaction kettle to be 55-65 DEG C, and reacting for 0.5-1.5h under stirring; (4) controlling the temperature of the reaction kettle to be 40-50 DEG C, adding hydrochloric acid into the reaction kettle, increasing the temperature of the reaction kettle to be 110-135 DEG C, and preserving the temperature and precipitating for 1-2h; and (5) after heat preservation and precipitating, cooling, crystallizing, carrying out suction filtration, and then, drying to obtain glyphosate raw powder. By increasing the temperature of condensation reaction, the invention shortens the synthesis time of the glyphosate and improves the yield of the glyphosate; and the obtained glyphosate raw powder has larger particles.

Owner:SUZHOU JIAHUI CHEM

Recovery method of rectification residual liquid of dimethyl phosphite

InactiveCN105753899AHigh purityReduce generationGroup 5/15 element organic compoundsPhosphorous acidRecovery methodPhosphorous acid

The invention provides a recovery method of a rectification residual liquid of dimethyl phosphite. The preparation process comprises steps as follows: methanol and phosphorus trichloride are sprayed to an esterification reaction kettle slowly; a proper amount of ammonia is added to crude dimethyl phosphite in a neutralization tank slowly for neutralization; materials in the neutralization tank are sent to a rectifying tower to be rectified, dimethyl phosphite is completely distilled off, and a rectification residual liquid of dimethyl phosphite is left; the rectification residual liquid of dimethyl phosphite is transferred to a reaction kettle; the rectification residual liquid is subjected to activated carbon decoloration; the decolored liquid is filtered; a proper amount of hydrochloric acid is dropwise added to the filtered liquid, the mixture is sufficiently stirred until acidolysis is sufficient; tail gas generated in the acidolysis process is sent to a chloromethane recovery pipeline in a workshop; after acidolysis is finished, a phosphorous acid water solution in the kettle is concentrated and crystalized. Clean production is realized, discharge of three wastes is reduced, the recovery rate of byproducts is increased, and the production cost is reduced.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Method for recovering phosphorous acid by acidolysis of dimethyl phosphite distillation residual liquid

The invention discloses a method for recovering phosphorous acid by acidolysis of dimethyl phosphite distillation residual liquid. Dimethyl phosphite residual liquid is subjected to the steps of filter pressing, acidolysis, secondary acidolysis concentration, crystallization, material washing and the like to obtain phosphorous acid. In the method for recovering phosphorous acid by acidolysis of dimethyl phosphite distillation residual liquid, phosphorous acid is recovered by combination of high-temperature distillation and temperature-lowering crystallization, the recovery efficiency is high, and the existing chloromethane recovering device is utilized for recovering chloromethane during the recovery process of phosphorous acid, and therefore, the recovery benefit is further enhanced.

Owner:HUBEI TAISHENG CHEM

Production technology of dimethyl phosphite

InactiveCN105713037AHigh purityReduce generationGroup 5/15 element organic compoundsMolecular sieveDimethyl phosphite

The invention provides a production process of dimethyl phosphite, and its preparation process is as follows: first, methanol and phosphorus trichloride are sprayed into the esterification reaction kettle slowly and relatively in the form of mist, and at the same time, the upper half of the reaction kettle is filled with Nitrogen, the reaction is exothermic, and the condenser is used to condense. After the reaction is completed, the solid in the esterification reactor is crude dimethyl phosphite; secondly, slowly spray the crude dimethyl phosphite in the neutralization tank into atomized ammonia For neutralization, the material in the neutralization tank is a mixture of dimethyl phosphite and ammonium chloride; the material in the neutralization tank is sent to the rectification tower for rectification, all of which are distilled out, and the remaining rectification residue of dimethyl phosphite liquid; finally, the rectification raffinate is filtered through molecular sieves, and then the rectification raffinate is rectified. The invention can improve the purity of dimethyl phosphite, so that the purity of dimethyl phosphite is 95.6%.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Technology for recovering chloromethane washing wastewater in glyphosate production

InactiveCN105753901AReduce consumptionHigh recovery rateGroup 5/15 element organic compoundsFractionating columnMethanol

The invention provides a technology for recovering chloromethane washing wastewater in glyphosate production. The technology comprises the following steps: paraformaldehyde and dimethyl phosphite are subjected to a condensation reaction under the actions of methyl alcohol and trimethylamine; glyphosphonic acid is generated under the action of hydrochloric acid, and a large amount of tail gas containing chloromethane is produced; the tail gas is washed through a water scrubber, and gas after washing is processed through a carbon tetrachloride absorption tower; wastewater after washing is transferred into a distillation tower, the temperature is increased to 58 DEG C, and evaporated gas is collected and cooled to 20 DEG C for storage; the distillation tower is heated to 75 DEG C, and evaporated gas is collected and cooled to 15 DEG C for storage. With adoption of the technology, the chloromethane washing wastewater is subjected to recovery treatment, so that consumption of methyl alcohol in production can be reduced, and the production cost can be saved.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Synthesis process of glyphosate intermediate dimethyl phosphite

InactiveCN107501318AAvoid acidolysis side effectsImprove effective conversion rateGroup 5/15 element organic compoundsDimethyl phosphiteGlyphosate

The present invention relates to a synthesis process of glyphosate intermediate dimethyl phosphite, the steps are as follows: methanol is metered through a methanol metering tank and enters an esterification reactor, phosphorus dichloride is metered through a metering tank and enters the esterification reactor, materials enter the esterification reactor simultaneously in ratio, after esterification reaction, a material liquid flows into a deacidification kettle via an inner liquid seal tube, a gas generated by the esterification reaction returns back to the esterification reactor via a first condenser and a secondary condenser, hydrogen chloride is removed form the material liquid in the deacidification kettle under high vacuum and steam heating conditions, and after deacidification by the deacidification kettle, the material liquid enters a rectifying kettle for rectifying. Continuous production of the dimethyl phosphite can be achieved, a great development space is provided for production capacity improvement and further significant reduction of operating cost, and purity is increased to 99.0% or more.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Glyphosate synthesis technology

InactiveCN105622666AIncrease conversion rate per passHigh yieldGroup 5/15 element organic compoundsDepolymerizationDimethyl phosphite

The invention discloses a glyphosate synthesis technology. The glyphosate synthesis technology comprises a depolymerization reaction process, an addition reaction process, a condensation reaction process, a hydrolysis reaction process and a crystallization process. The glyphosate synthesis technology solves the problem that the glyphosate synthesis condensation reaction cannot occur under the waterless conditions. In the addition reaction and condensation reaction processes, the reaction liquid is dehydrated through a dehydration device so that reaction product moisture is reduced, dimethyl phosphite consumption is reduced, a reaction yield is improved, raw materials are saved and a cost is reduced.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

Hydrosis process improvement method for synthesizing glyphosate by alkyl ester process

InactiveCN103421043AHigh solid yieldReduce washing water consumptionGroup 5/15 element organic compoundsParaformaldehydeMethanol

The invention relates to a hydrosis process improvement method for synthesizing glyphosate by an alkyl ester process. The method comprises the following steps: at the temperature of 40-50 DEG C, feeding paraformaldehyde, methyl alcohol and triethylamine as materials into a reaction kettle, stirring, adding glycine after the materials are clarified, adding dimethyl phosphite after the mixture is clarified, rising the temperature to be 50-60 DEG C, and keeping the temperature for 50 min; reducing the temperature to be 30 DEG C, and adding hydrochloric acid; slowing rising the temperature after stirring for 30 min to evaporate methyl alcohol; rising the temperature to be 110-125 DEG C; adding water into the reaction kettle, reducing the temperature to be below 70 DEG C, and externally cooling with cold water to reduce the temperature of the reaction kettle to be below 10 DEG C; adding triethylamine, controlling the temperature to be 15-25 DEG C, and reaching the reaction endpoint when the pH value in the reaction kettle is 0.5-1.5; transferring the materials to a crystallization kettle, reducing the temperature to be below 10 DEG C to crystallize the materials for a time; filtering, washing and drying the crystal to obtain glyphosate technical.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Glyphosate synthesis technology and device

PendingCN110862413AFast depolymerization reactionThorough responseGroup 5/15 element organic compoundsBiotechnologyPhosphorous acid

Provided is a glyphosate synthesis technology. The glyphosate synthesis technology is characterized in that a metal alkoxide organic compound is adopted as a catalyst for glyphosate synthesis and particularly for depolymerization and addition during glyphosate synthesis. The glyphosate synthesis technology includes the following steps: an alcohol and paraformaldehyde are mixed and stirred to be uniform, the catalyst is added into a mixture solution or directly added into an alcohol solution of formaldehyde, and a transparent mixture solution is generated; triethylamine and glycine are added into the transparent mixture solution, stirring is conducted to carry out an addition reaction, and after the addition reaction is finished, dimethyl phosphite is added into the mixture solution to carry out a condensation reaction; and after the condensation reaction is finished, hydrochloric acid is added into the mixture solution to carry out hydrolysis, and then through crystallization, washingand drying, glyphosate is obtained. According to the technical scheme of the glyphosate synthesis technology, the specific catalyst is adopted, therefore, glyphosate synthesis reaction speed and selectivity are improved, reaction speeds of depolymerization and addition are high, the reactions are conducted completely, the final yield of a glyphosate product obtained through the glyphosate synthesis technology is increased by 3% or above compared with the final yield of a glyphosate product obtained through traditional technologies, and thus the glyphosate synthesis technology has a reaction advantage, an energy-saving advantage, a coat advantage and an environment-friendly advantage.

Owner:HUBEI TAISHENG CHEM

Ethylene propylene diene monomer sealing element

The invention discloses an ethylene propylene diene monomer sealing element, prepared from the following raw materials in parts by weight: 40-60 parts of ethylene propylene diene monomer, 20-40 parts of styrene-butadiene rubber, 15-25 parts of polyurethane rubber, 20-30 parts of polypropylene fibers, 4-10 parts of glass fibers, 15-25 parts of alumina whiskers, 4-8 parts of sepiolite powder, 2-4 parts of naphthenic oil, 2-4 parts of a silane coupling agent, 2-4 parts of dimethyl phosphite, 1-2 parts of chlorinated paraffin, 0.5-1.3 parts of dibutyl phthalate, 2-4 parts of phenolic resin, 0.3-0.9 part of sodium persulfate, 1.5-2.5 parts of 1,1,3,3-tetramethylbutyl hydroperoxide and 2-5 parts of an anti-aging agent. The ethylene propylene diene monomer sealing element has good toughness, excellent shock and abrasion resistance, good corrosion and aging resistance, easily available raw materials and low production cost.

Owner:安徽亚兰密封件股份有限公司

Method for synthesizing glyphosate at low cost

ActiveCN101875673AReduce consumptionReduce pollutionGroup 5/15 element organic compoundsHerbicides and algicidesGlycineDimethyl phosphite

The invention relates to a method for synthesizing glyphosate at low cost, which comprises the following steps: (1) putting paraformaldehyde, methanol and triethylamine in a reaction kettle, controlling the kettle temperature to be at 30-50 DEG C, and stirring for 0.5-2 hours; (2) putting glycine into the reaction kettle, controlling the temperature to be at 30-45 DEG C, and stirring to react for 0.5-2 hours; (3) putting dimethyl phosphite and methanol into the reaction kettle, controlling the temperature to be at 45-60 DEG C, and stirring to react for 1-3 hours; (4) and controlling the kettle temperature to be at 40-50 DEG C, putting hydrochloric acid into the reaction kettle, heating to 110-135 DEG C, desolventizing for 1-2 hours, crystallizing, filtering under reduced pressure and drying to obtain the glyphosate raw powder. Compared with the prior art, by changing the mode of putting methanol, methanol can be saved by 10-15% per batch, thereby reducing the consumption of methanol, saving the cost and increasing the utilization ratio of workshop appliances.

Owner:SUZHOU JIAHUI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com