Method for synthesizing and preparing glyphosate with glycine method

A technology of glycine method and glyphosate, which is applied in the direction of botany equipment and methods, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc., can solve problems such as limited use, achieve less impurity content, reduce The total amount of waste water and the effect of easy concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

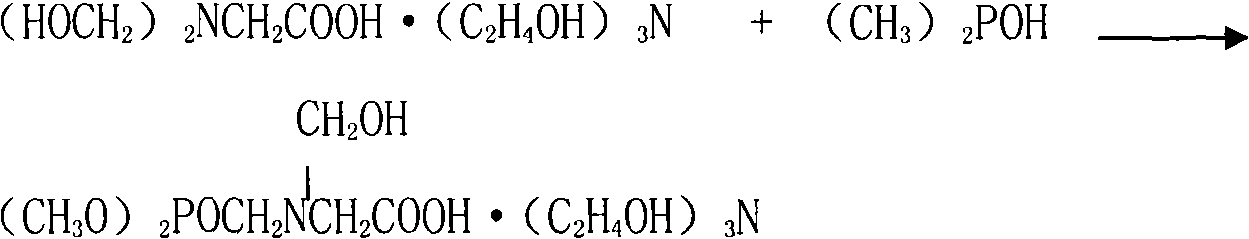

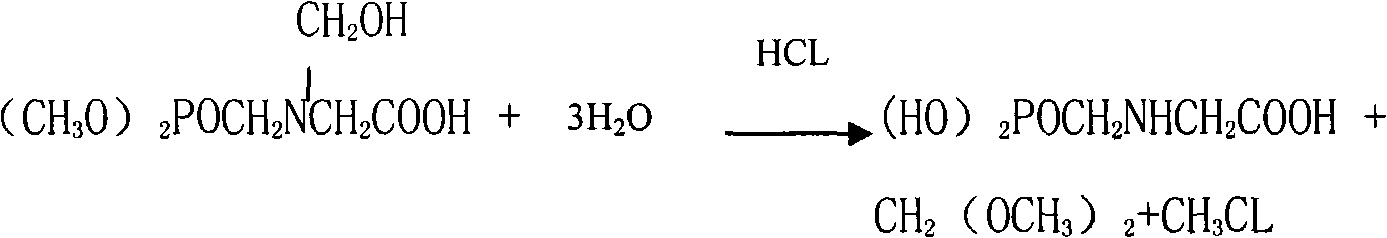

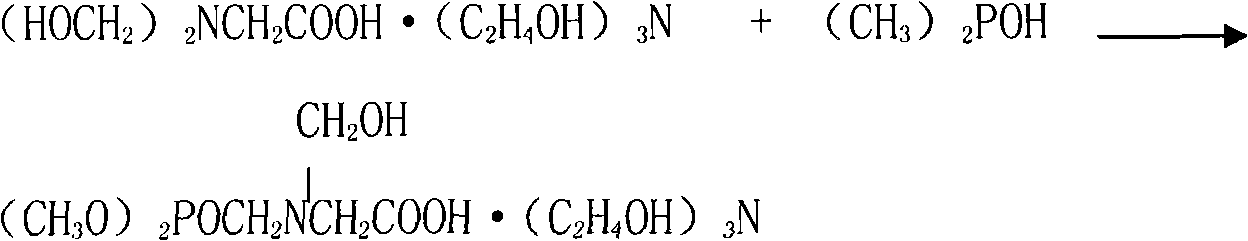

Method used

Image

Examples

Embodiment 1

[0037] Add 12.2g of paraformaldehyde, 86g of methanol, and 32.2g of triethanolamine into a 500ml four-neck flask, raise the temperature to 40°C and stir for half an hour, add 15g of glycine, continue stirring for 1 hour, add 25g of dimethyl phosphite, and rise to the condensation reaction After completion, feed 8.7g of HCl gas, wait for the precipitation of triethanolamine hydrochloride, separate triethylamine hydrochloride from the reaction solution by vacuum pump filtration, add 50ml of hydrochloric acid to the reaction solution, carry out acidification and hydrolysis, and heat up to 120°C Keep warm for half an hour, add 20ml of water, 10ml of 30% NaOH, adjust the pH value of the solution, discharge the material after cooling for 8 hours, and obtain 24g of dry base glyphosate (content 95%) after washing and filtering, 198g of the solution, glyphosate in the solution The phosphine content is 1.2%, and the total yield can reach more than 77%. The recovery rate of triethanolami...

Embodiment 2

[0039] Add 12.2g of paraformaldehyde, 86g of methanol, 32.2g of triethanolamine, 15g of glycine, and 25g of dimethyl phosphite into a 500ml four-neck flask, raise the temperature to 40°C, stir for 1 hour, and feed HCl gas after the condensation reaction is completed. 9g, after triethanolamine hydrochloride is precipitated, separate triethanolamine hydrochloride from the reaction solution by vacuum pump filtration, add 50ml hydrochloric acid to the reaction solution, carry out acidification and hydrolysis, heat up to 120°C for half an hour, add water 20ml, 30% NaOH 10ml, adjust the pH value of the solution, discharge after cooling for 8 hours, get dry base glyphosate (content 95%) 24g after washing and filtering, solution 198g, glyphosate content 1.2% in the solution, total yield It can reach more than 75%, and the recovery rate of triethanolamine hydrochloride can reach more than 95%. The content of triethanolamine hydrochloride can reach more than 99%.

Embodiment 3

[0041]Add 12.2g of paraformaldehyde, 86g of methanol, 20.4g of dimethylethylamine, 15g of glycine, and 25g of dimethyl phosphite into a 500ml four-neck flask, raise the temperature to 40°C, and stir for 1 hour until the condensation reaction is completed Feed HCl gas 12g, treat that dimethylethylamine hydrochloride is separated out, isolate dimethylethylamine hydrochloride from the reaction solution through vacuum pump filtration, add hydrochloric acid 50ml again in the reaction solution, carry out acidification hydrolysis, Heat up to 120°C and keep warm for half an hour, add 20ml of water, 10ml of 30% NaOH, adjust the pH value of the solution, and discharge the material after cooling for 8 hours. After washing and filtering, 24g of dry base glyphosate (content 95%), 198g of solution, and 198g of solution are obtained. The content of glyphosate in the medium is 1.2%, the total yield can reach more than 75%, and the recovery rate of dimethylethylamine hydrochloride can reach mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com