Device and process for applying dimethyl phosphite byproduct hydrogen chloride to synthesis of glyphosate

A technology of dimethyl phosphite and hydrogen chloride is applied in the fields of compounds of Group 5/15 elements of the periodic table, organic chemistry, chemical instruments and methods, etc. The effect of reducing energy consumption and energy consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

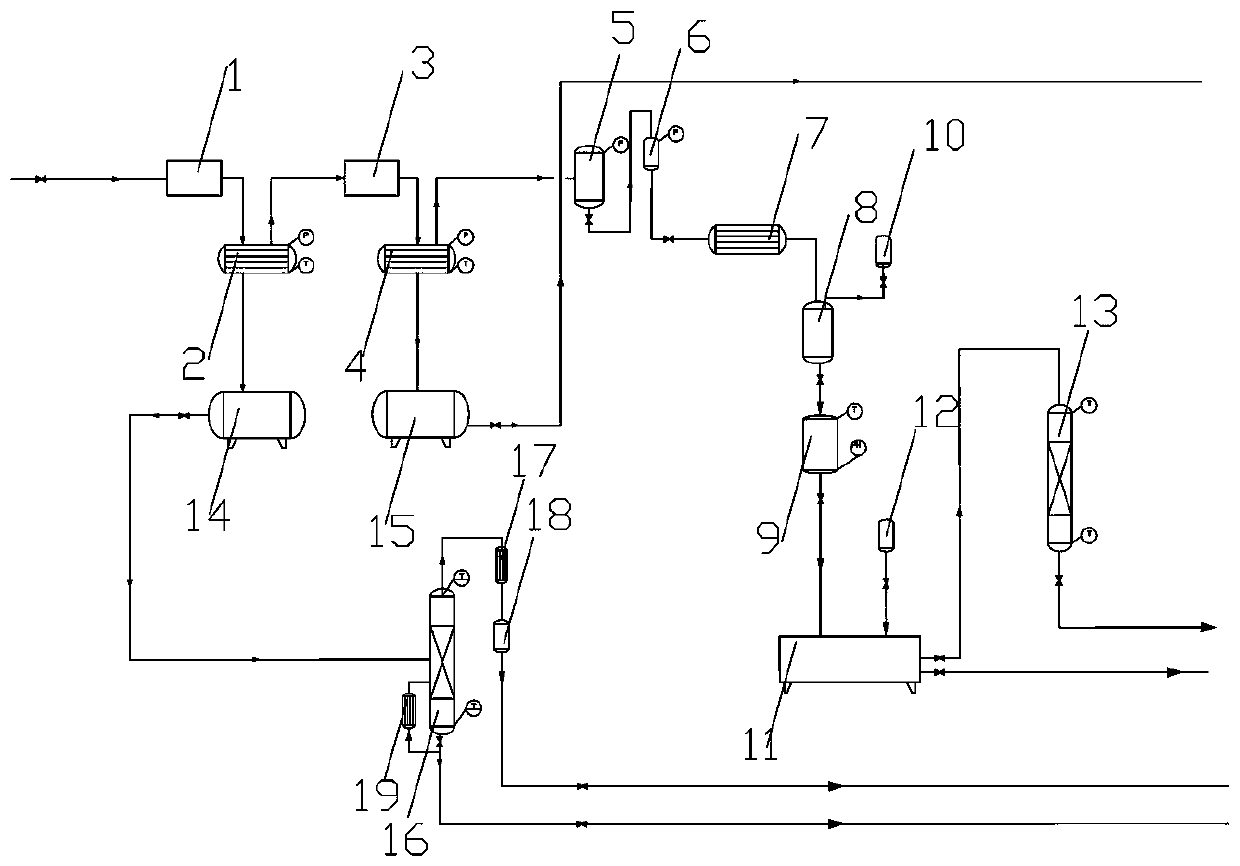

[0030]A device for synthesizing glyphosate with dimethyl phosphite by-product hydrogen chloride, the dimethyl phosphite tail gas pipeline is connected to compressor one 1, compressor one 1 is connected to primary condenser 2, and primary condenser 2 Connect with compressor two 3, compressor two 3 is connected with secondary condenser 4, secondary condenser 4 is connected with hydrogen chloride gas cabinet 5, hydrogen chloride gas cabinet 5 is connected with gas buffer tank 6, gas buffer tank 6 is connected with hydrolysis mixer 7 is connected, the hydrolysis mixer 7 is connected with the hydrolysis kettle 8, the hydrolysis kettle 8 is connected with the crystallizer 9, the crystallizer 9 is connected with the solid-liquid separation device 11, the solid-liquid separation device 11 is connected with the drying device 13, and the drying device 13 is connected to the product packaging area. The hydrolysis kettle 8 is provided with a solvent recovery device 10; the solid-liquid se...

Embodiment 2

[0032] In the traditional dimethyl phosphite production process, when hydrogen chloride is produced as a by-product, hydrochloric acid is generally recovered first, and then methyl chloride is recovered. In this process, the absorbed water is soft water, and the cost in the production process is relatively high. There are many hydrochloric acid indicators, such as calcium and magnesium ions, etc., and the water intake during the subsequent hydrolysis of glyphosate is increased, which increases the cost of precipitation and post-treatment of mother liquor. In this process, the link of absorbing and reusing hydrochloric acid with soft water is cancelled, and the tail gas by-product of dimethyl phosphite is condensed by pressure and graded to separate hydrogen chloride, methyl chloride and other gases, and hydrogen chloride is directly used in the synthetic acid hydrolysis process . The water (alcohol) solution condensed by the primary condenser during the pressurized condensatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com