Patents

Literature

143results about How to "Save production water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

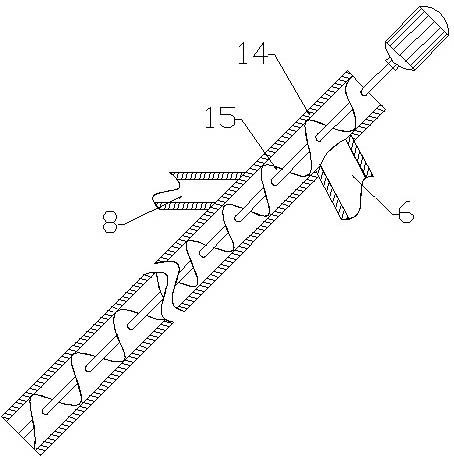

Synchronous ditching ridging fertilizing seeder for paddy field

ActiveCN101622923AAchieve deep coverageSolve deep problemsPlantingFertiliser distributersWater savingSeeder

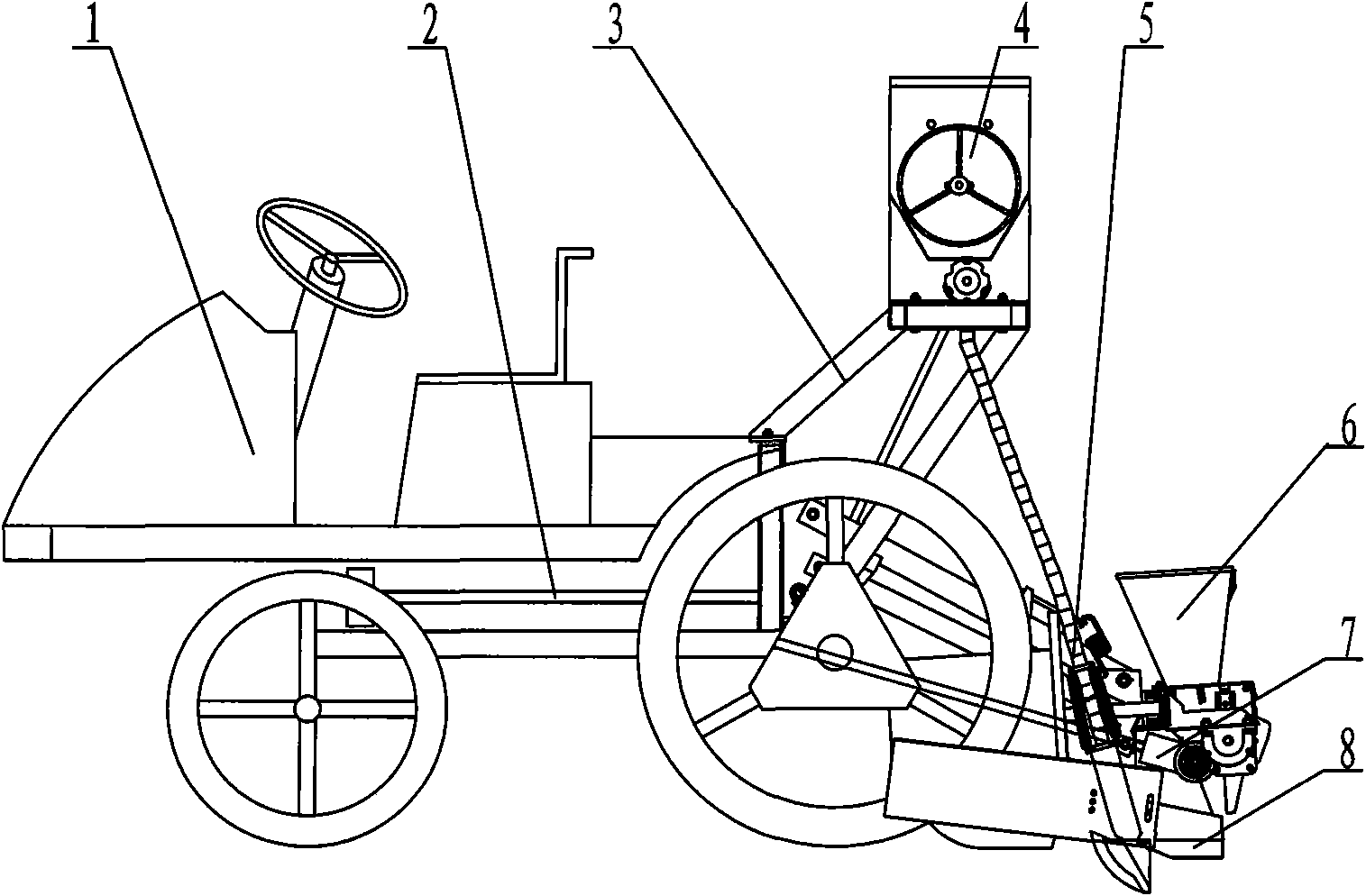

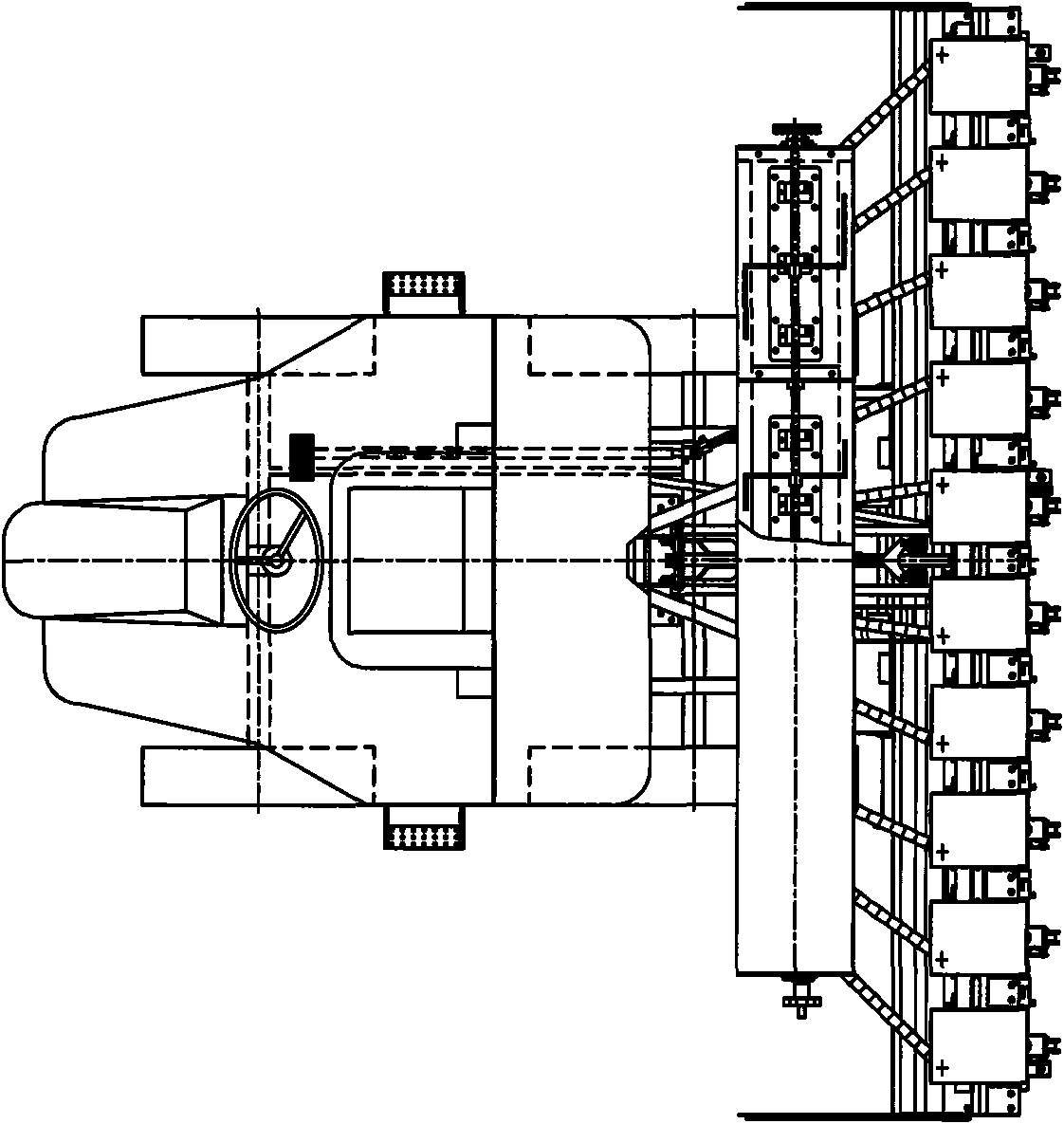

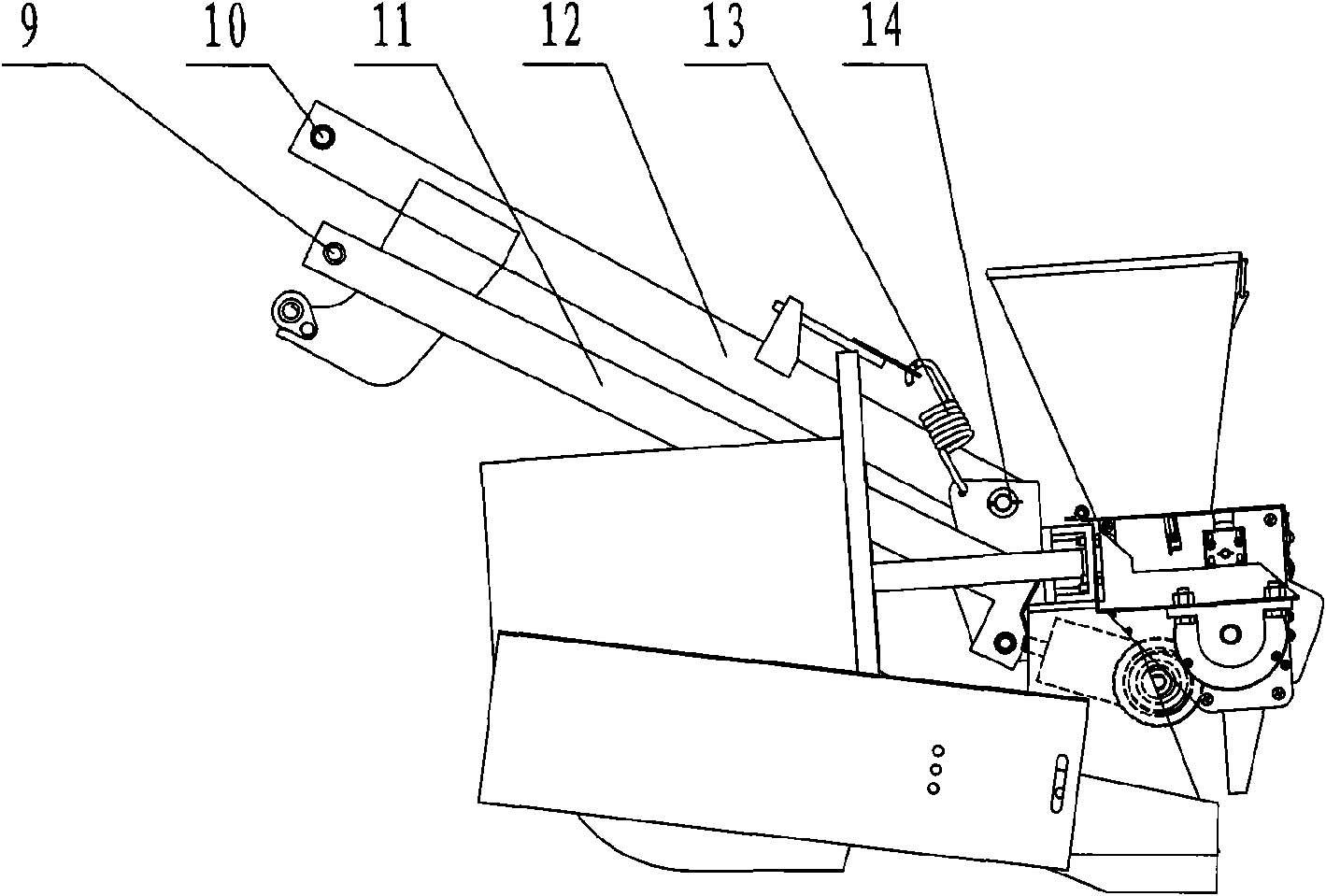

The invention discloses a synchronous ditching ridging fertilizing seeder for paddy field, comprising a power machine, a fertilizing power driving system installed on the power machine, a fertilizer ejecting system, a hanging device, a sowing system, a sowing power driving system and a ditching device. The hanging device is installed at the back part of the power machine and is connected with the sowing system to control the sowing system and the ditching device installed below a sliding plate in the sowing device to be lifted up or to be lifted down; the power machine is respectively drives the sowing system and the fertilizer ejecting system by the sowing power driving system and the fertilizing power driving system. The ditching device is synchronously ditched with water storing ditches, sowing ditches and fertilizing ditches, wherein ridges are formed between each two water storing ditches, and the sowing ditches and the fertilizing ditches are positioned on the ridges. The invention can realize synchronous ditching, synchronous ridging, synchronous fertilizing and paddy production with water saving and fertilizer saving, can increase the yield of the paddy to be more than 10%, save the fertilizer to be more than 20%, and has obvious ecological benefit and economic benefit.

Owner:SOUTH CHINA AGRI UNIV

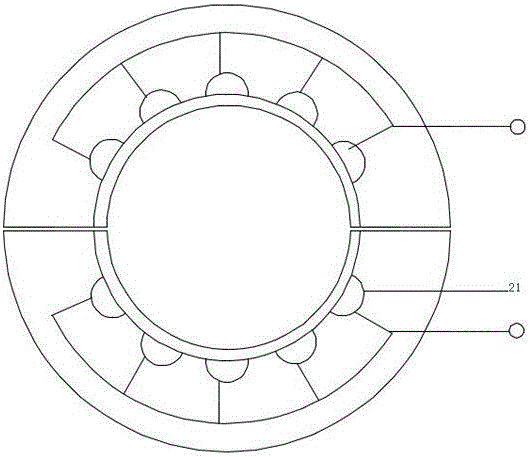

Polyvinyl formal sponge material with uniform abscesses and rapid imbibition and preparation method thereof

ActiveCN102020816ASolution can not be reusedSolve the shortcomings of high closed cell rate and slow water absorption rate of the productPharmaceutical non-active ingredientsAbsorbent padsCross-linkLiquid waste

The invention discloses a polyvinyl formal sponge material with uniform abscesses and rapid imbibition and a preparation method thereof. The material comprises polyvinyl alcohol, a cross-linking agent, a catalyst and a pore-forming agent, wherein the cross-linking agent is formaldehyde or paraformaldehyde or formaldehyde solution. The preparation method comprises the following steps of: stirring 2-9 parts of polyvinyl alcohol in 100-200 parts of water of which the temperature is 60-98 DEG C to obtain solution, and adding 0.05-8 parts of pore-forming agent to the solution; fully emulsifying the pore-forming agent to form evenly dispersed continuous solution phase; then adding 1-26 parts of catalyst and 1-15 parts of cross-linking agent or 5-50 parts of recovered liquid waste, 1-8 parts of catalyst and 1-15 parts of cross-linking agent, and mixing; pouring the mixture into a mould after 1-60 min for cross-linking reaction for 0.1-2 hours to form the abscesses under the action of the pore-forming agent; and continuing to heat and cure for 2-18 hours to prepare the polyvinyl formal sponge material. The invention has the advantages of good hydrophily, high compression strength, high dry wetting rate, high imbibition ratio and the like.

Owner:克林纳奇(荆州)高分子科技有限公司

Straw bio-enzyme degradation aid and degradation pulping process

InactiveCN102230288AThe role of strong biological enzymesHigh activityPulp bleachingAlkylphenolStrong acids

The invention relates to a straw bio-enzyme degradation aid in the technical field of straw degradation, which comprises the following components in percentage by weight: 8 to 10 percent of cellulase, 6 to 11 percent of lipase, 6 to 10 percent of alpha-1,4-glucose hydrolase, 4 to 10 percent of catalase, 6 to 20 percent of urea, 6 to 16 percent of magnesium sulfate, 8 to 15 percent of fatty alcohol-polyoxyethylene ether, 11 to 15 percent of alkylphenol polyoxyethylene ether OP and the balance of excipient. A degradation pulping process for the straw bio-enzyme degradation aid comprises the following steps of: cleaning straw, cutting into segments, putting the segments into a quick pulping machine, adding water and the straw bio-enzyme degradation aid, mixing uniformly, and heating to the temperature of between 50 and 60 DEG C in the quick pulping machine for rubbing to perform reaction for 1 to 1.5 hours; and adding hydrogen peroxide for bleaching, and when the whiteness is more than 70 percent which is required by International standard organization (ISO), stopping the reaction to obtain paper pulp. The degradation pulping process is non-pollution, thermophilic digestion is avoided, strong base and strong acid are not used, the requirement of environment-friendly pulping is met, waste water is not discharged during pulping, a large amount of water for production and energy canbe saved, the production cost is reduced, and the pulping speed is accelerated.

Owner:TAIAN QINENG CHEM TECH

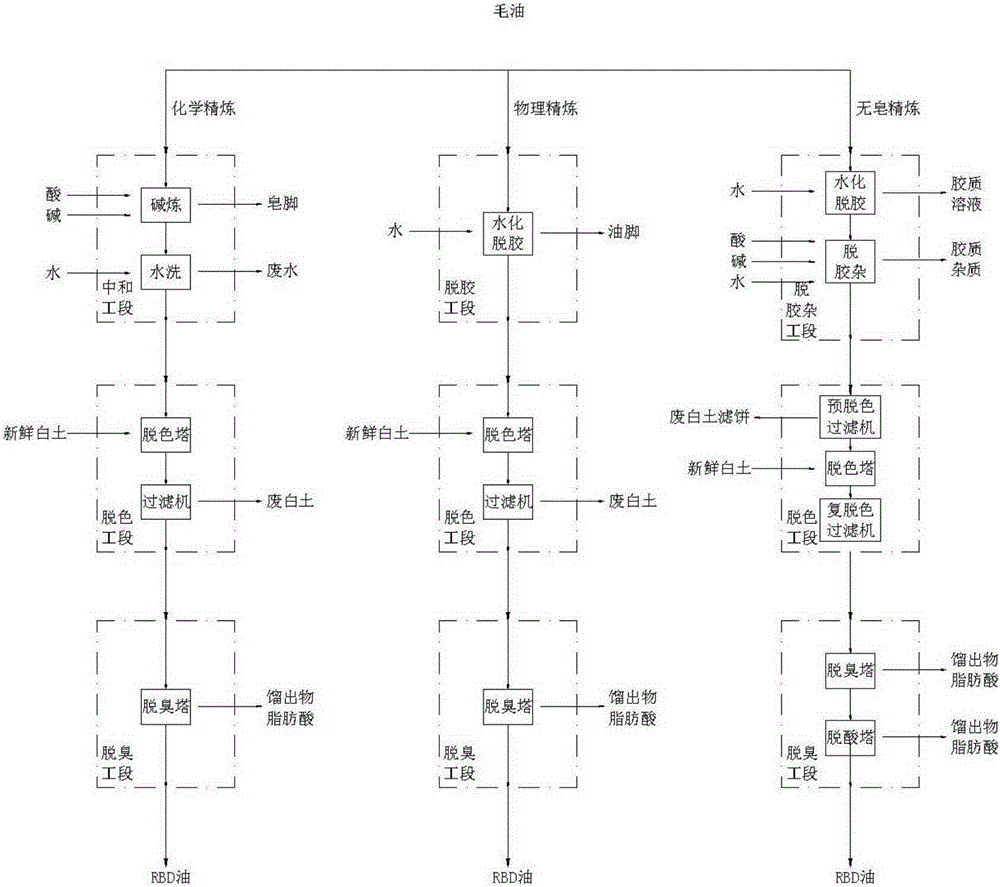

Edible plant oil non-soap refining method

InactiveCN105176676AExcellent refining effectPromote innovation and developmentFatty-oils/fats refiningHydration reactionFlocculation

The invention relates to an edible plant oil non-soap refining method. The method comprises the following steps: 1, dephosphorizing and removing impurities: adding water to crude oil, carrying out a hydration reaction, separating hydratable phospholipids obtained after the reaction, adding an acid to acidify the hydratable phospholipids in the crude oil, adding an alkali and water, carrying out a flocculation reaction, centrifuging, and carrying out vacuum solvent removal drying on obtained light phase isolates to obtain dephosphorized oil; 2, decoloring: heating the dephosphorized oil, pre-decoloring through allowing a filter to be in contact with a primary decolored decoloring adsorbent filter cake, allowing the pre-decolored crude oil to enter a decoloring reaction pot and to be mixed with a decoloring adsorbent in order to carry out secondary decoloring, and filtering through the filter to obtain decolored oil; and 3, depickling and deodorizing: heating the decolored oil, allowing the heated decolored oil to enter a combined deodorizing tower, decoloring and depickling, allowing the decolored and depickled oil to enter a post-depickling tower, post-depickling, cooling, and carrying out fine filtration to obtain product oil. No soap stocks are generated in the edible plant refining process, so the method is suitable for processing all oil products, especially oils with high phosphorus content and high acid value.

Owner:广州市正德生物科技有限公司

Process for preparing algin with fresh kelp as raw material

The related preparation method for algin with kelp comprises: adding 200wt% water to dip kelp for 30min, cutting up, dipping with formaldehyde, and cleaning with water; digesting with Na2CO3 solution to obtain muddy liquid, filtering, diluting, centrifugal separating to obtain clear glue solution; adding CaCl2 to obtain calcium alginate; using diluted HCl to remove calcium; neutralizing, dewatering, grinding, adding CaCO3 powder, granulating, drying, cooling, and grinding to obtain the product. This invention improves yield with low cost.

Owner:XUSN GROUP

Oxidation prevention process used for lithium ion battery copper foil

InactiveCN105039947ASolve prone to wrinklesSolve the yield problemMetallic material coating processesCapacitancePotassium hydroxide

The invention provides an oxidation prevention process used for lithium ion battery copper foil. The method comprises the steps that a semi-finished copper foil product which is not oxidized is introduced into an anti-oxidation passivation solution to be soaked, then squeezed dry through a squeeze roll, dried through hot air of an oven and directly wound, and a copper foil product is obtained after the oxidation prevention process. The anti-oxidation passivation solution comprises, 100-200 g / m<3> of benzotriazole, 0-1000 g / m<3> of chromic anhydride, 0.1-2 g / m<3> of rare earth metals of phosphoric acid, 0.1-2 g / m<3> of organic silane coupling agents, 10-30 L / m<3> of ethyl alcohol, and the balance water. The pH value is adjusted to be 5.5-8.5 through alkali such as sodium hydroxide and potassium hydroxide. The process is free of pollution to the environment; an anti-oxidation film of the produced copper foil product is moderate, even and consistent in thickness; the copper foil product is high in electrical conductivity and wettability, and the properties of the capacitance, the number of times of charge and discharge and the service life of a lithium ion battery can be effectively improved.

Owner:ANHUI TONGGUAN COPPER FOIL

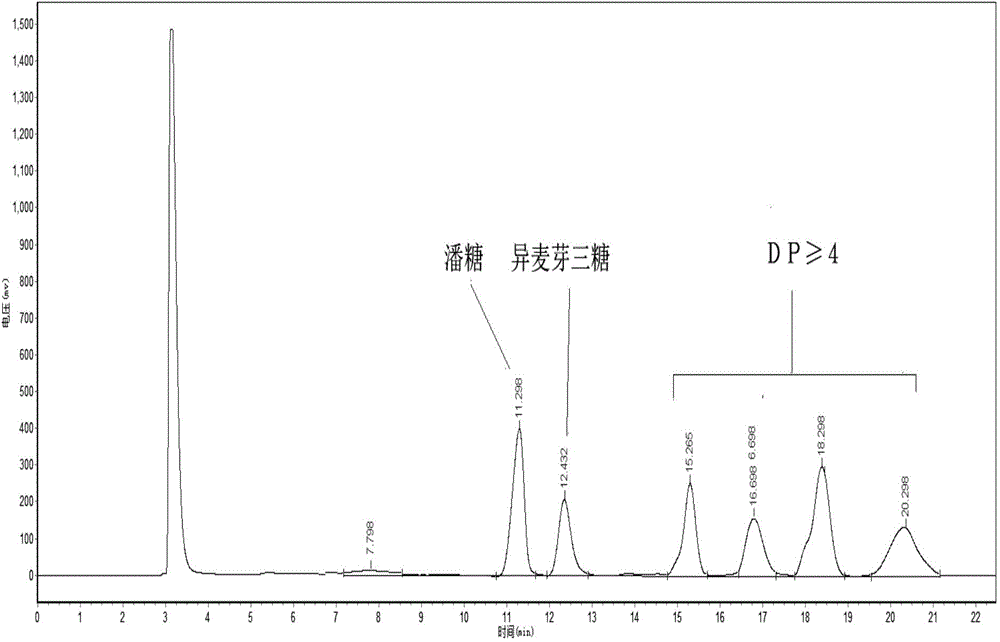

Preparation method of isomaltooligosacharide

ActiveCN104152512AIncrease contentIncrease concentrationFermentationChromatographic separationIsomaltooligosaccharide

The invention relates to a preparation method of isomaltooligosacharide. The preparation method comprises the following steps of 1, adding water into a starch raw material, adjusting a concentration and a pH value of the slurry, and adding high temperature-resistant alpha-amylase into the slurry to obtain starch slurry, 2, carrying out liquidation on the starch slurry to obtain a liquefied liquid, 3, adding maltotriose generation enzyme (AMANO AMT1.2L) and pullulanase (GENENCOR OPTIMAX L-1000) into the liquefied liquid, carrying out thermal-insulation saccharification, and carrying out enzyme denaturalixation to obtain a saccharified liquid, 4, adding alpha-glucosidetransferase into the saccharified liquid for a reaction to produce a primary trans-glucoside saccharified liquid, adding alpha-glucosidetransferase into the primary trans-glucoside saccharified liquid for a reaction, and carrying out enzyme denaturalixation to obtain a trans-glucoside saccharified liquid, and 5, carrying out decoloration on the trans-glucoside saccharified liquid, carrying out filtration, carrying out ion exchange, carrying out chromatographic separation, carrying out concentration and carrying out drying to obtain isomaltooligosacharide. The preparation method greatly improves contents of sugars such as panose, isomaltotriose and tetrasaccharide having polymerization degrees greater than or equal to 3 in the reaction product liquid.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

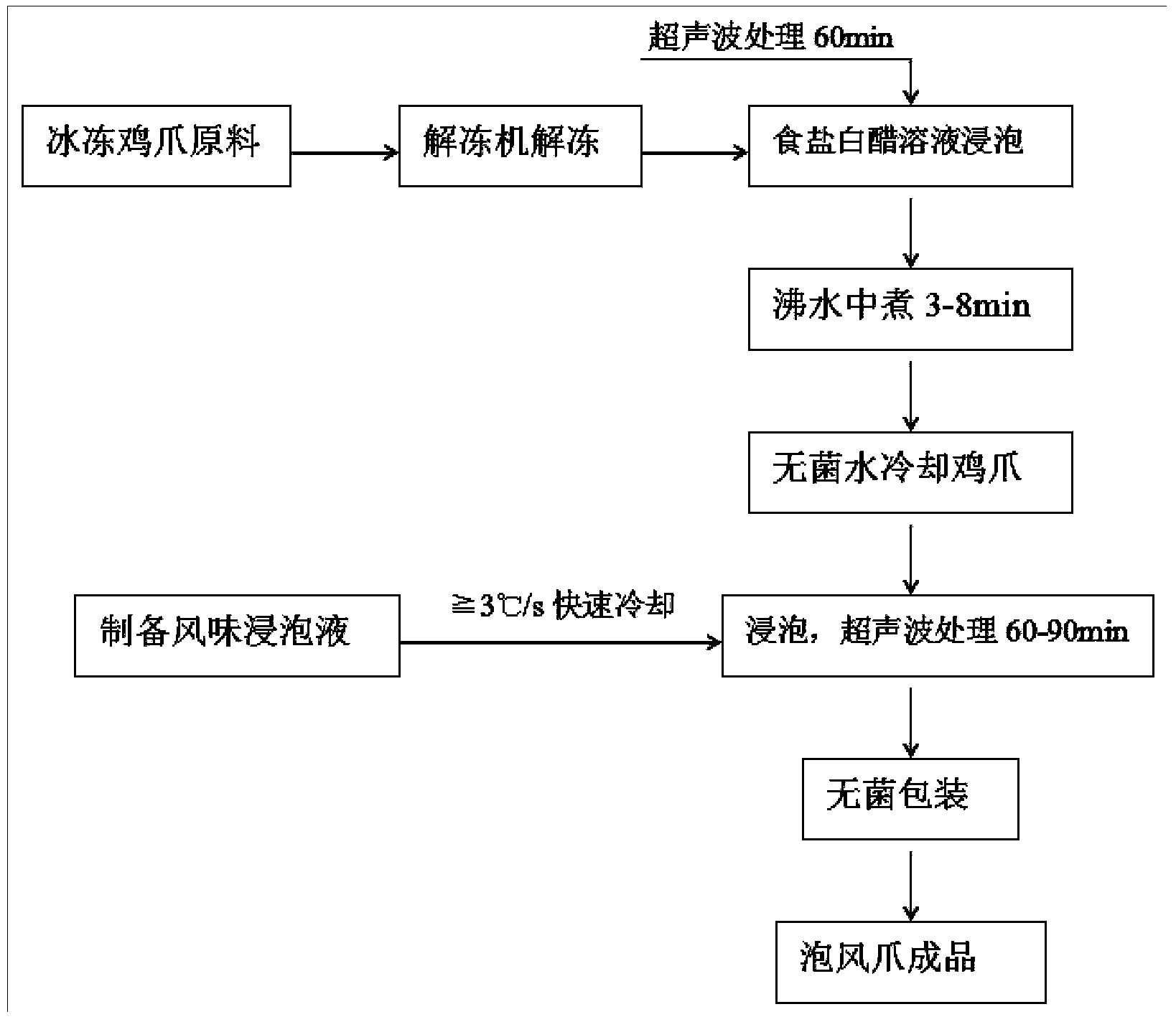

Rapid production method of pickled chicken claws

ActiveCN103907950AShorten the soaking timeImprove securityNatural extract food ingredientsFood ultrasonic treatmentChicken-clawsPreservative

The invention discloses a method for rapidly producing pickled chicken claws. The method comprises the following steps: 1, clearing and unfreezing chicken claws; 2, soaking the chicken claws with a liquid having 1-2% of salt and 5-10% of white vinegar and treating by ultrasonic wave; 3, boiling the treated chicken claws together with the liquid having 1-2% of salt and 3-4% of white vinegar for 3-8min; 4, cooling the boiled chicken claws by aseptic cold water added with 2-3% of white vinegar; 5, preparing a flavored soak liquid; 6, adding the cooled chicken claws in the flavored soak liquid and treating by the ultrasonic wave for 60-90min; and 7, vacuum-packing the pickled chicken claws to obtain finished products. The method for rapidly producing pickled chicken claws is characterized in that the soak liquid used by the pickled chicken claws is subjected to a fast cooling technology such that the soak liquid can achieve commercial sterilization, ultrasonic treatment is used in the soaking process for shortening soaking time, an irradiation technology is not used and only biological preservatives or extracts of fruits and vegetables are used as preservatives, and the shelf life is more than one year by computing according to current standards.

Owner:CHONGQING TECH & BUSINESS UNIV

Phosphogypsum high-strength wall brick and its production method

The invention discloses a high-intensity ardealite wall brick and the producing method. And the composition weight ratio of semi-hydrated ardealite to anhydrous ardealite to flyash to coagulant is (70-85) : (12-20 ): (15-20 ): (15-25), where the coagulant is 12-20% silicasol water solution. And the invention uniformly blends them in sprinkling mode, mechanically places the mixture into a mould and shapes in high pressure, mechanically demoulds, and naturally hydrates to make it. And the invention firstly uses large amount of ardealite raw material in building materials, where the synthetic utilization of ardealite is up to 80%; and it is low-cost and saves land resources. After processed, it accords with national stipulated nuclear radiation indexes, has high hardness, reduces equipment investment and reduces cost of product.

Owner:重庆金仓龙新型建材有限公司

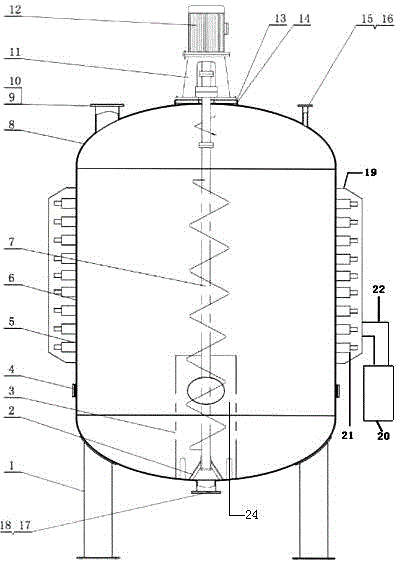

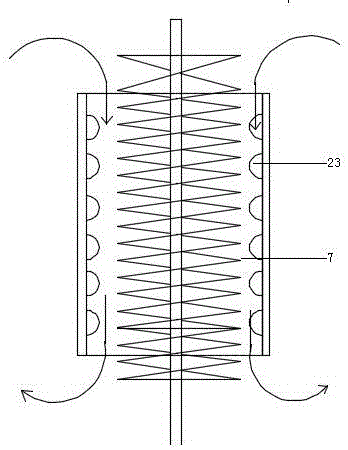

Ultrasonic-assisted bio-enzyme ligin removing method and device thereof

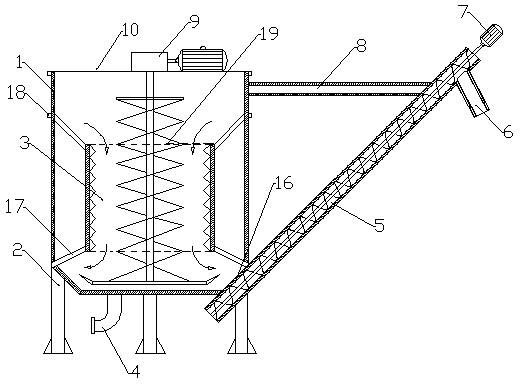

ActiveCN106087508ARealize the purpose of industrialized mass productionPulping speed is fastCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpFiberEngineering

The invention relates to the technical field of biodegradation, in particular to an ultrasonic-assisted bio-enzyme ligin removing method and a device thereof. The method comprises the steps that wood fiber raw materials such as reed or bamboo willows are purified, then soaked with water and ground into filamentous fibers; water and a bio-enzyme ligin removing auxiliary are mixed evenly, and the filamentous fibers are added; air is introduced, the temperature is raised, an ultrasonic generator is started, and a constant-temperature and constant-pressure reaction is carried out; hydrogen peroxide is added into the materials for a reaction, and the reaction is terminated when the whiteness of pulp is higher than or equal to 75% ISO. The device used in the method comprises a bucket, a feeding port, a safety valve, a motor, a coupler, an air inlet, a water inlet, a pulp outlet and a supporting part. A mechanical rubbing and stirring device is arranged in the bucket, and the ultrasonic generator and an ultrasonic transducer are further arranged outside the bucket and are connected through a connecting device. According to the ligin removing method and the device, the treatment cycle is short, and the treatment capability and efficiency are high.

Owner:福建祥业实业有限公司

Method for recovering sodium sulfate from white carbon black mother solution

ActiveCN103318923ASave production waterReduce energy consumptionEnergy inputAlkali metal sulfites/sulfatesFiltrationCentrifugation

The invention discloses a method for recovering sodium sulfate from a white carbon black mother solution, and the white carbon black mother solution is generated during production of white carbon black produced by a precipitation method. The method comprises the steps of: (1) preliminary filtration, (2) evaporation and concentration, (3) precision filtration, (4) evaporation and crystallization, and (5) centrifugation, wherein the evaporation and the concentration of the step (2) are carried out in a hot-blast-stove tail-gas water-film de-dusting tower, and the evaporation and the concentration are carried out utilizing waste heat of hot-blast-stove tail gas generated during production of white carbon black produced by a precipitation method. A sodium sulfate solution which is used for hot-blast-stove tail-gas water-film de-dusting replaces process water, so that process water is saved; evaporation and concentration of the sodium sulfate solution are carried out utilizing waste heat of hot-blast-stove tail gas, so that recovering sodium sulfate from the sodium sulfate solution which is a byproduct of white carbon black becomes an economical method; the sodium sulfate solution which is a byproduct generated during the production of white carbon black is employed as tail-gas water-film de-dusting water of white carbon black drying hot-blast stove, evaporation and concentration of the sodium sulfate solution are carried out utilizing waste heat of hot-blast-stove tail gas, and then anhydrous sodium sulfate is produced; and energy consumption is reduced, so that double advantages are achieved.

Owner:FUJIAN YUANXIANG CHEM

Comprehensive utilization method for solid wastes and waste acid in production process of titanium dioxide

The invention discloses a comprehensive utilization method for solid wastes and waste acid in the production process of titanium dioxide. The comprehensive utilization method comprises the following steps of: firstly, respectively treating acidolysis waste slag, ferrous sulfate and calcium sulfate dehydrate which are generated in the production process of the titanium dioxide by adopting a sulfuric acid method through drying, crushing and other methods for later use; secondly, uniformly mixing 70-80 parts by weight of iron pyrite, 1-10 parts by weight of acidolysis waste slag, 1-5 parts by weight of ferrous sulfate and 1-10 parts by weight of calcium sulfate dehydrate to obtain raw ore for producing sulfuric acid, calcining the raw ore in a fluidized bed furnace to obtain furnace gas meeting the production requirement of the sulfuric acid, carrying out purification procedures such as cooling, dust removal and dehydration on the furnace gas obtained in the second step and then converting and absorbing the treated furnace gas by adopting a catalyst to obtain the sulfuric acid. According to the comprehensive utilization method disclosed by the invention, wastes generated in the production process of titanium dioxide are reasonably utilized and the recycling of resources is realized.

Owner:LUOHE XINGMAO TITANIUM IND

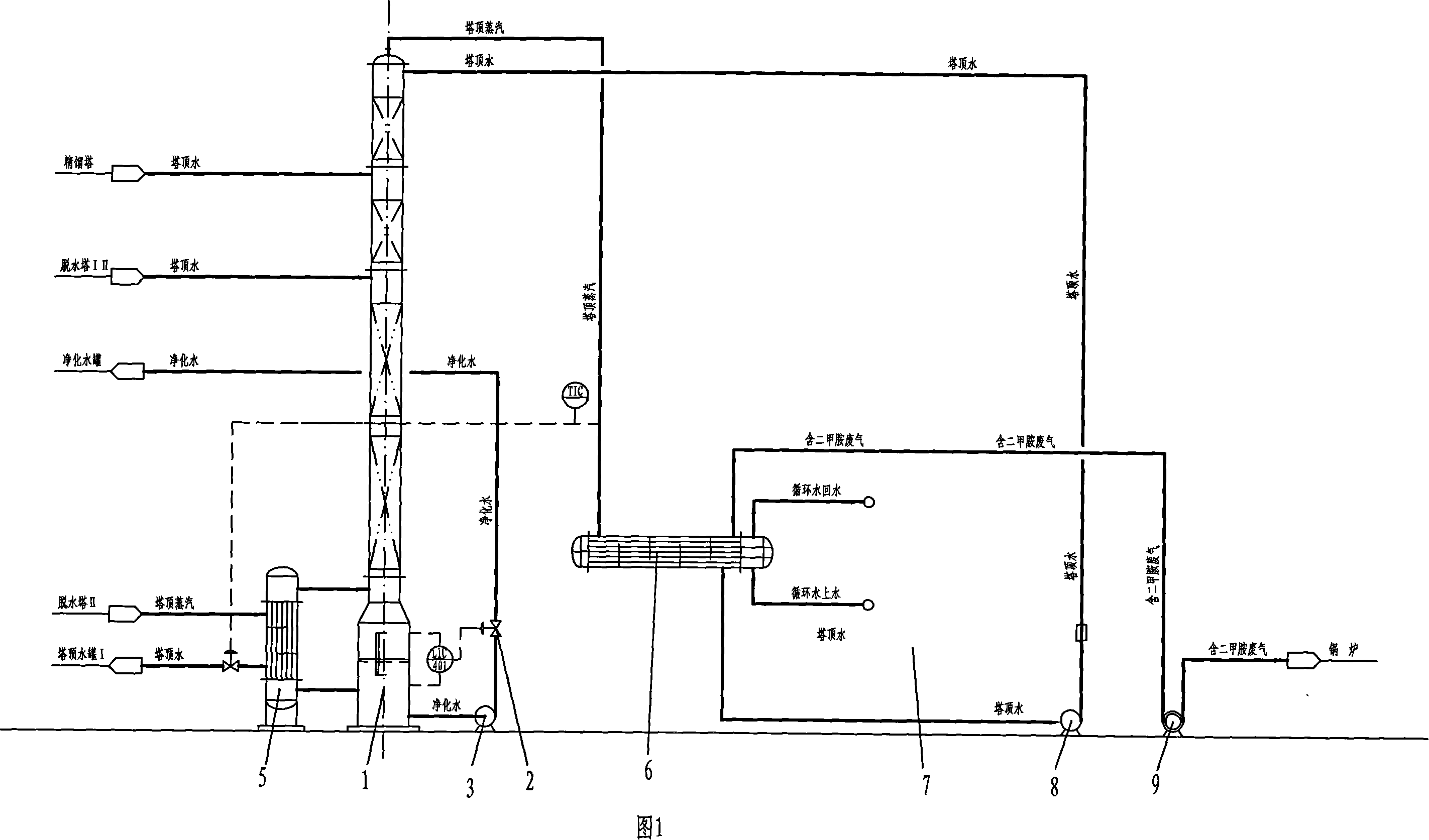

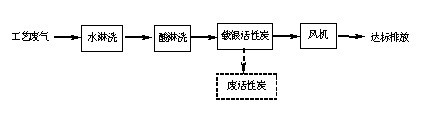

Method for treating waste gas from dimethylamine recovery by synthetic leather dimethyl formamide

InactiveCN101139302AReduce pollutionReduce spendingChemical industryCarboxylic acid amide separation/purificationDistillationVacuum pump

The present invention is a treatment method of synthesizing the leather dimethyl formamide and recycling the dimethylamine emission. The method comprises the preheating, de-amine and drainage to form the top water de-amine technology of the DMF recycling tower; the concentration of the top water dimethylamine of the dehydration tower I and the dehydration tower II in the recycling of the three towers is relatively low and the top water dimethylamine is sent into the middle section of the de-amine tower; the concentration of the top water dimethylamine of the distillation column is relatively high and the top water dimethylamine is sent into the upper section of the de-amine tower for filtering downward; the dimethylamine in the water on the tower top is taken away by the lifting steam in the de-amine tower; the purified water after the removal of the dimethylamine is collected in the tower kettle and then enters the storage tank for the recycling in the wet production; the inside of the de-amine tower consists of four sections of high-efficient wire packing; the pressure of the vacuum work is 16 KPa; the temperature on the tower top is 50 DEG C; the tower reactor is 55 DEG C; the tower reactor of the de-amine tower is heated with the vapor on the top of the dehydration tower II and the distillation column, or is directly heated with the left steam of the boiler; the dimethylamine exhaust is pumped out by the vacuum pump; the concentration of the dimethylamine is 20 percent to 30 percent; and the dimethylamine exhaust is sent to the boiler for burning; the energy-saving and exhaust-discharging effects are good. Compared with the device of the same category, the required heat and cooling water are greatly lowered; the economic benefit and social benefit are obvious.

Owner:YANTAI DONGJIE ENVIRONMENTAL PROTECTION MACHINERYENG +1

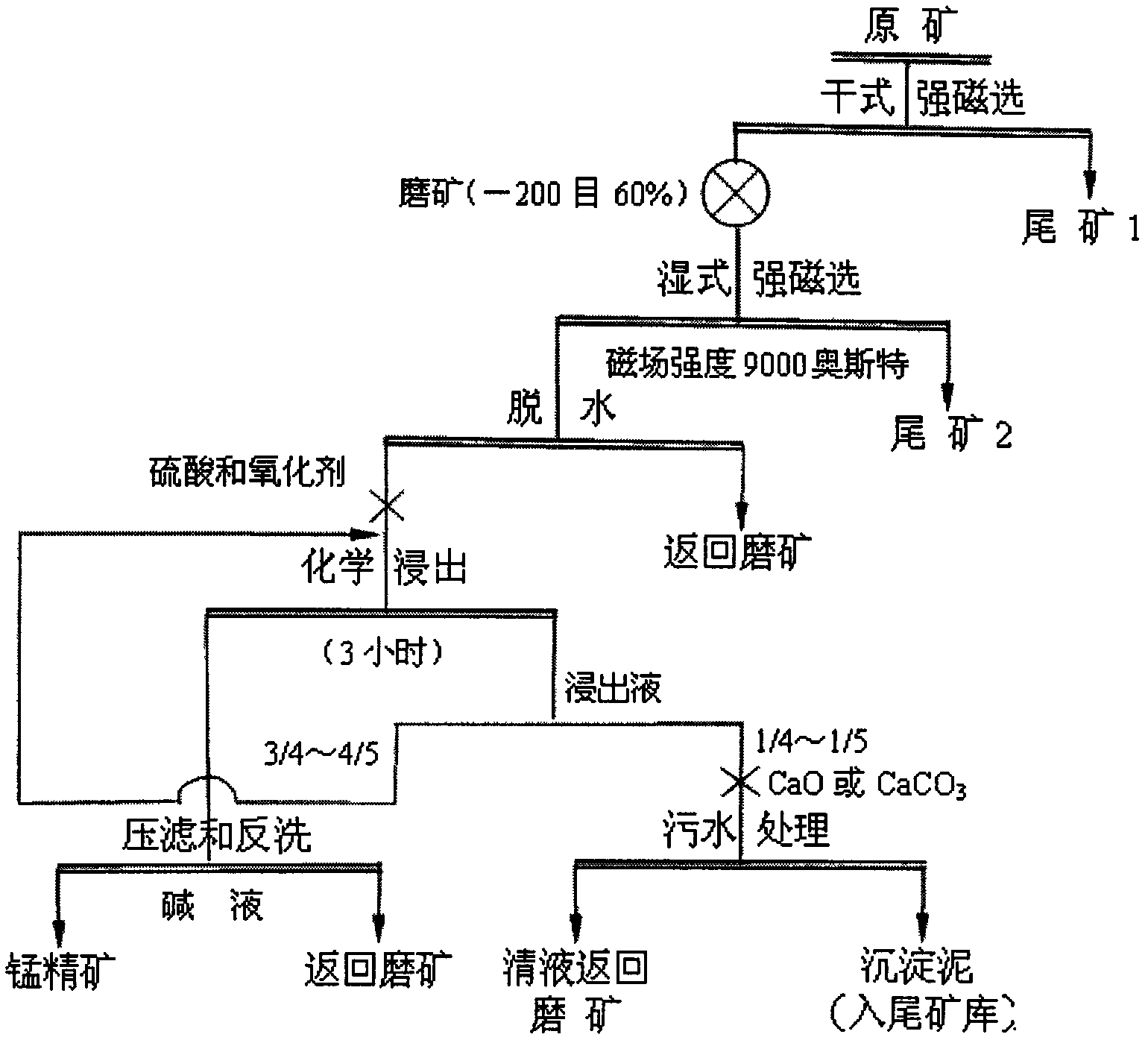

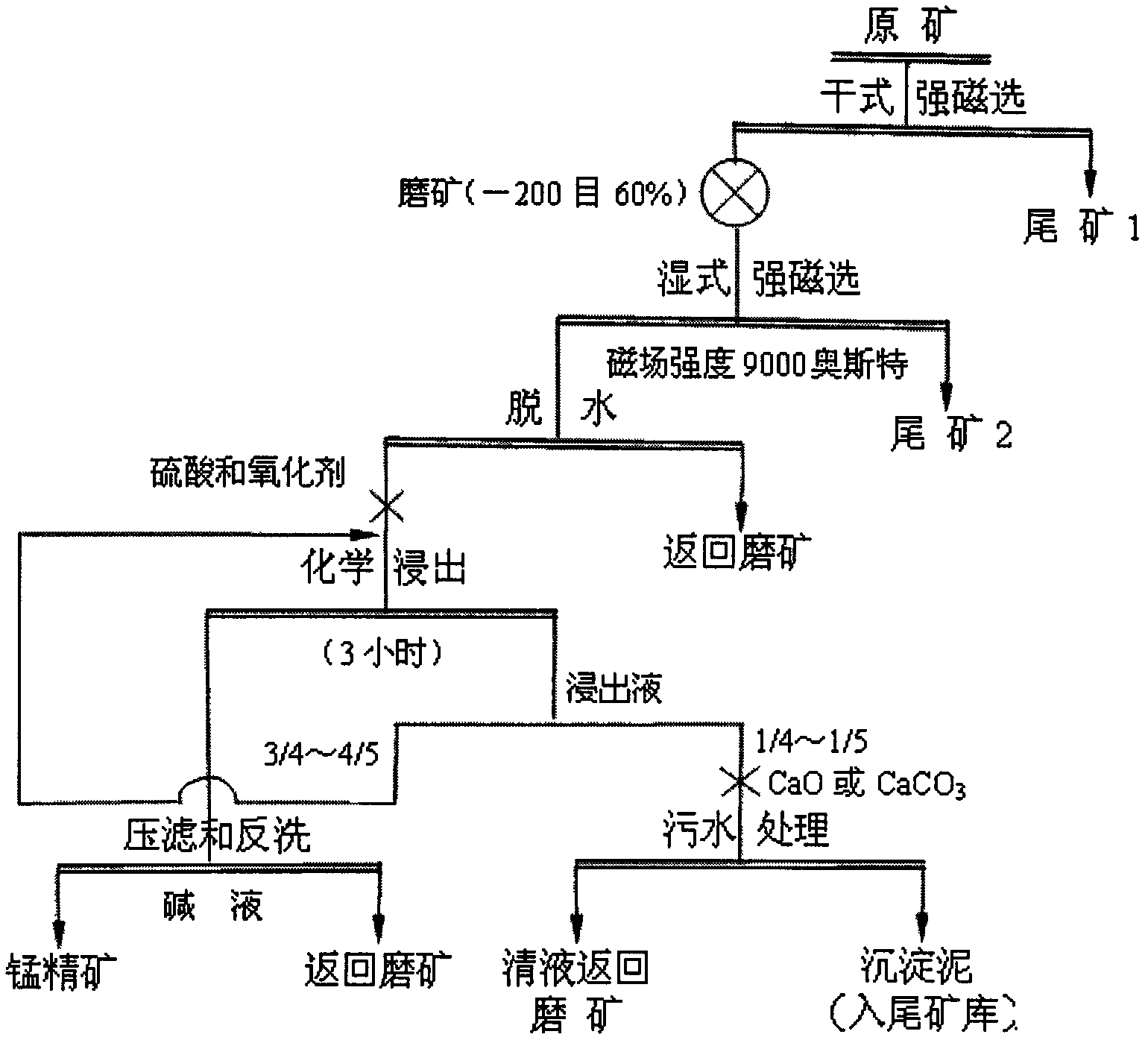

Beneficiation method for high armangite

InactiveCN102174672AReduce the amount of ore entering the grindingAchieve friendlyProcess efficiency improvementWet separationWater useManganese

The invention discloses a beneficiation method for high armangite. The method comprises the following steps of: performing dry-type strong magnetic separation with the magnetic field intensity of 12,000 to 14,000 oersted on the high armangite which comprises 35 to 39 weight percent of manganese and 4 to 6 weight percent of arsenic and serves as a raw material; finely grinding until 60 weight percent of high armangite has the particle size of -0.074 mm by using a ball mill; performing wet-type strong magnetic separation with the magnetic field intensity of 8,000 to 10,000 oersted; performing awet-type chemical extraction reaction by using acid for 2 to 4 hours; and performing neutralization treatment on precipitates by using alkali liquor to obtain a manganese concentrate product which comprises more than or equal to 53.81 weight percent of manganese and less than or equal to 0.35 weight percent of arsenic, wherein the total recovery rate of the manganese is more than or equal to 80 percent. The technology is simple in process flows, and the method is applied to the treatment of minerals similar to tilasite CaMg (F / AsO4); operation wastewater is returned to ore grinding operation for recycling, so that water used during production is saved; leaching residues are treated by calcium salt to meet the emission standard, so that the method is environment-friendly; and the method isrelatively high in economic benefits, social benefits and ecological benefits.

Owner:广西壮族自治区地质矿产测试研究中心

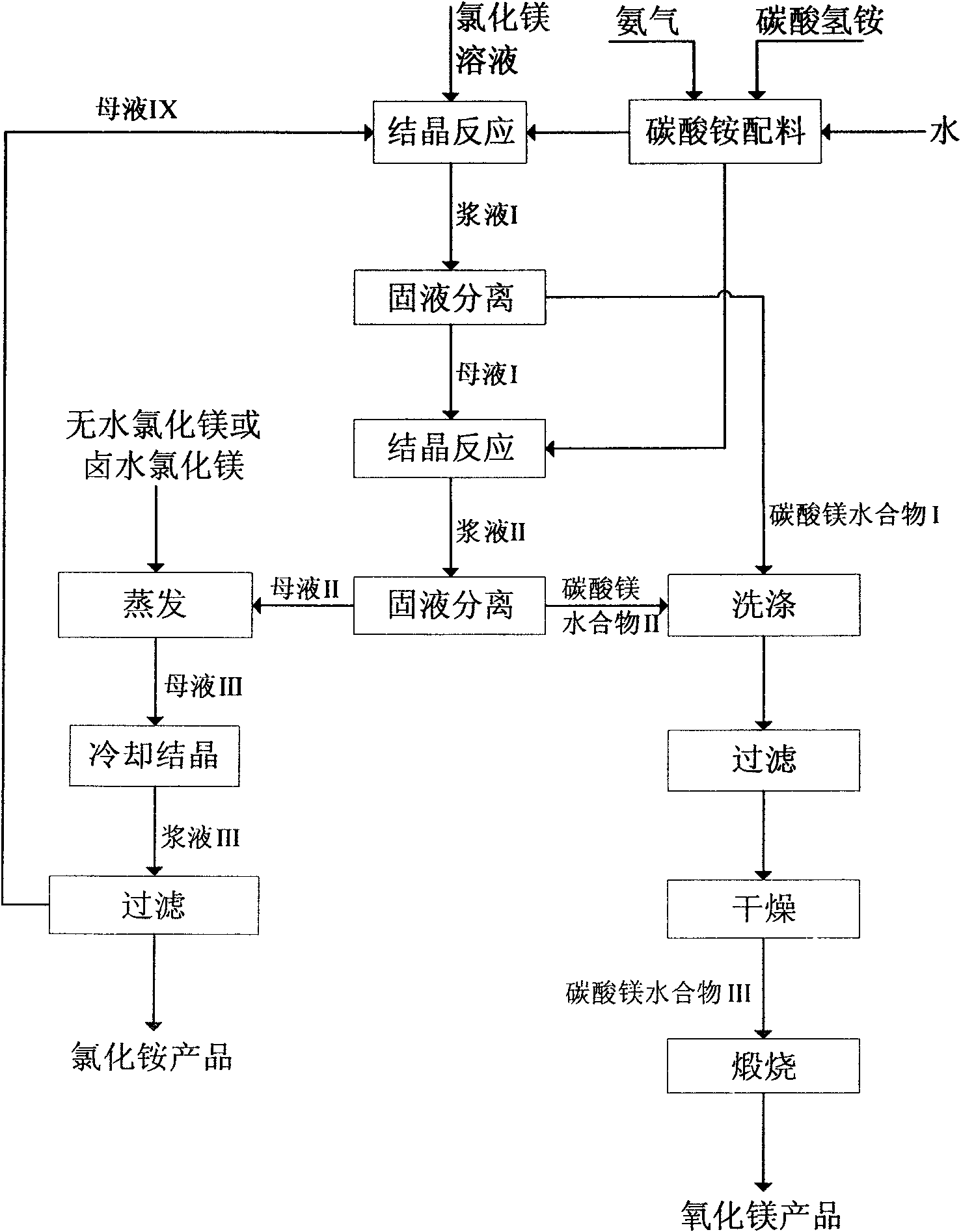

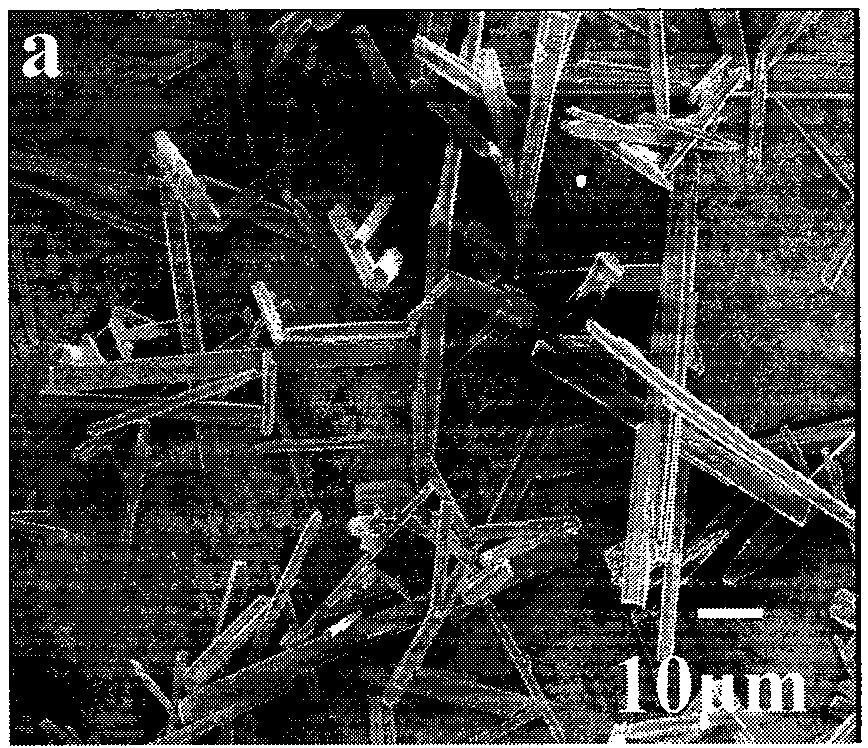

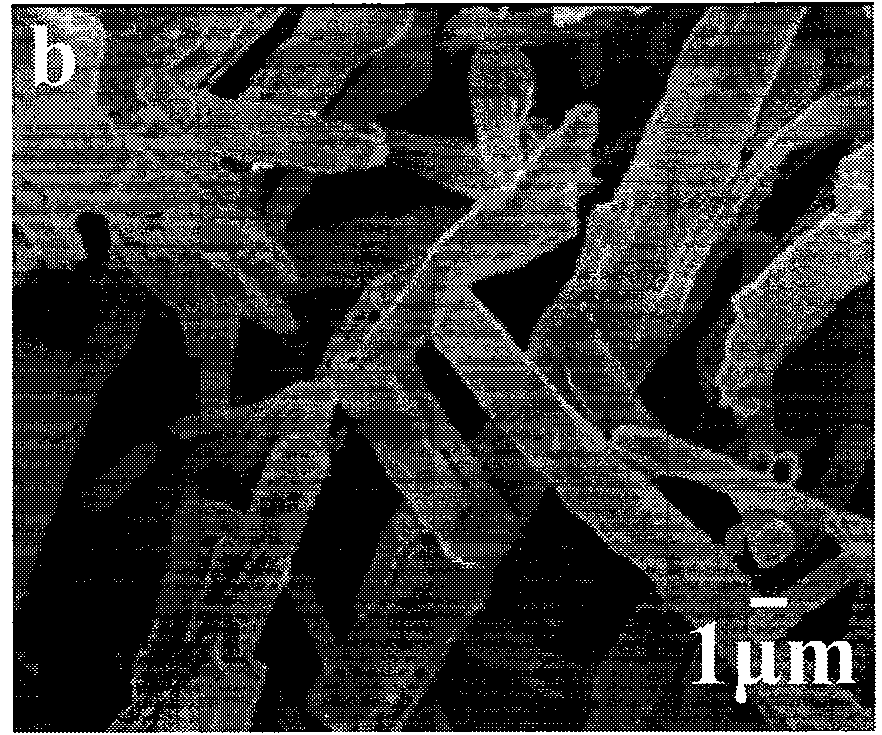

Method for producing magnesium oxide with co-production of ammonium chloride by taking magnesium carbonate hydrate as intermediate

InactiveCN101993097AHigh purityGood filtration propertiesMagnesium carbonatesAmmonium halidesMagnesium saltSeawater

The invention belongs to the field of inorganic salt chemical industry and fertilizer production, particularly relates to a method for producing magnesium oxide with co-production of ammonium chloride by taking magnesium carbonate hydrate as an intermediate. The method comprises the following steps of: with anhydrous magnesium chloride or bittern magnesium chloride as a raw material and with ammonia and ammonium bicarbonate as precipitating agents, obtaining the magnesium carbonate hydrate intermediate (the purity reaches 97-99 percent) with favorable crystal form by controlling process conditions; calcining the obtained magnesium carbonate hydrate intermediate to prepare magnesium oxide (the purity reaches 95-99 percent); adding salt to mother liquor enriched with ammonium salts and evaporating, salting out and cooling to separate out ammonium chloride, and filtering to obtain the ammonium chloride, wherein the mother liquor is circularly taken as a raw material. The method aims at producing needle-shaped or spherical magnesium carbonate hydrate by utilizing rich magnesium chloride brine from salt lakes, or magnesium chloride brine from seawater, or anhydrous magnesium chloride used for producing titanium sponge by-products, and other magnesium salt materials, thereby preparing high-purity magnesium oxide with the simultaneous co-production of ammonium chloride fertilizer. The method of the invention has strong maneuverability and is easy to realize industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

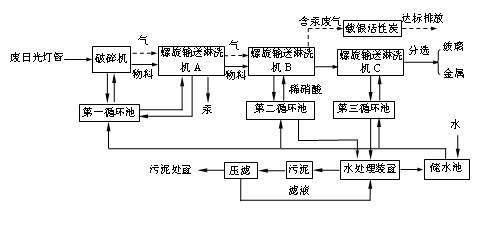

Innocent treatment method for mercury-containing waste tube

ActiveCN102110560ALow costAvoid Volatile PollutionGlass recyclingElectronic waste recyclingActivated carbonSulfur

The invention relates to the improvement on an innocent treatment method for a mercury-containing waste tube. The method is characterized by comprising the following steps of: crushing the waste tube in water; performing at least three processes of washing, namely water washing, dilute nitric acid washing and water washing on the crushed tube in turn; separating and removing mercury on tube fragments; separating tube head metal from glass fragments through magnetic separation, wherein the whole treatment process is linked up in an airtight way and is performed in a sealed state; performing air draft guidance on gas emitted from the water surface under negative pressure; performing water and dilute nitric acid drip washing; and filtering and separating the mercury by using silver-carried activated carbon or sulfur-carried activated carbon, and discharging. The method has a simple and practical process, is energy saving, is suitable for automatic operation, and has the advantages of lowcost, simple and practicable process and the like; and by the method, the mercury is not released to the outside, and automatic treatment can be realized.

Owner:YIXING SUNAN SOLID WASTE TREATMENT

Method for producing alcohol raw material utilizing sugar plant mud waste sugar

This patent provides a method to produce alcohol using discarded sugar materials from sugar refinery's mud. In the sugarcane refinery, the sugar juice is filtered in the press filter as normal technology, stop filtering when the filter mud is spreaded all over the press filter. use sugar condensed water to wet the mud until saturation, then continue to filter the mud for 1-6 min. Collect the filtered sweet water, send to the alcohol factory to replace the molasses diluted water of alcohol fermentation process, clean up the mud in the press filter, then filter sugar juice over again. Using the sweet water instead of molasses's diluted water during the alcohol fermentation, water consumption can be saved, the burden of sludge treatment can be alleviated, and the alcohol productivity can be increased 0.5-1%, all of which contributed to increase enterprise's efficiency.

Owner:GUANGXI YUEGUI GUANGYE HOLDINGS CO LTD

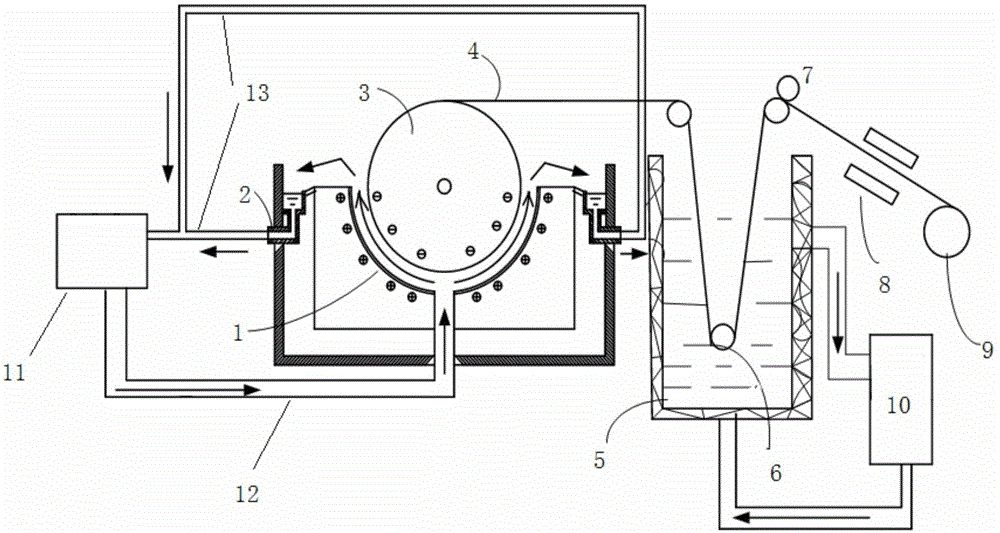

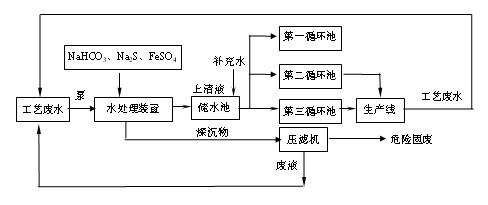

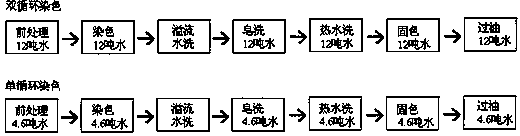

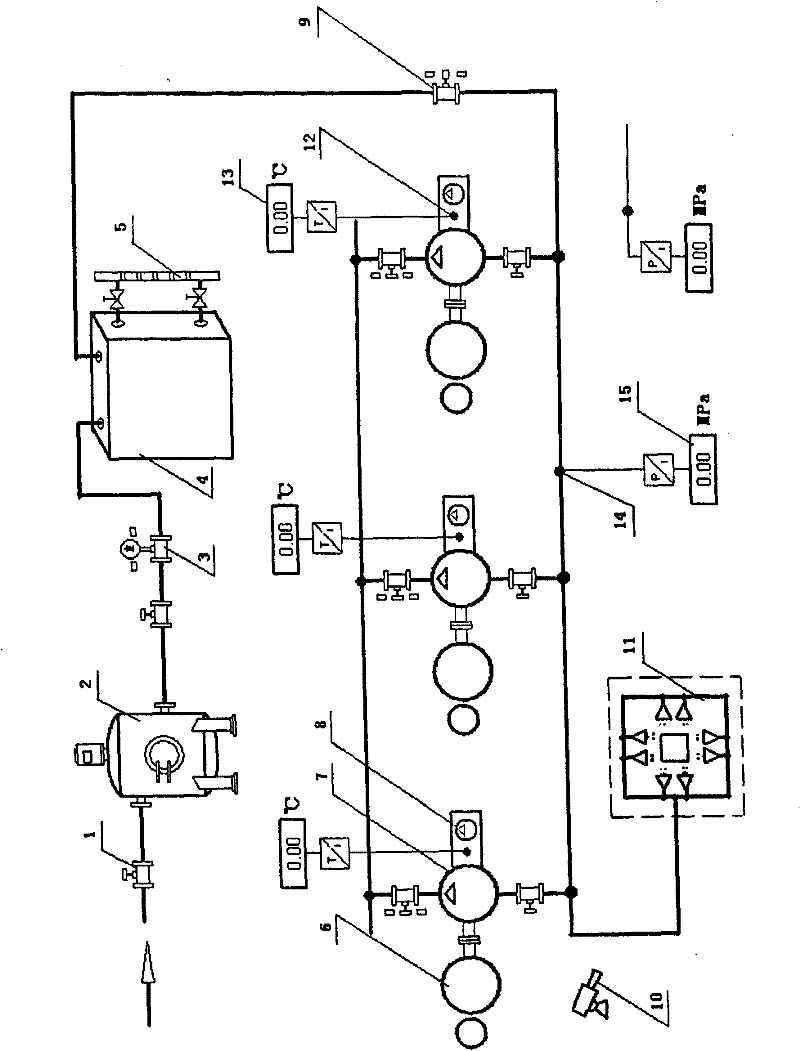

Waste water recycling pad dyeing long machine and waste water recycling method thereof

InactiveCN101748576AEmission reductionReduce dosageTextile treatment machine arrangementsHigh concentrationWater discharge

The invention discloses a waste water recycling pad dyeing long machine and a waste water recycling method thereof. The waste water recycling pad dyeing long machine comprises a desizing, scouring and bleaching combined machine, a mercerizer, a first recovery processing box, a second recovery processing box, a third recovery processing box, a first recovery pump, a second recovery pump, a third recovery pump, a light alkali recovery pool, a dilatation evaporator, an alkali dosing pool, a recovery pool, a recovery pump and connecting pipelines. The method comprises the following steps: a. introducing washing waste water into the first recovery processing box and then pumping into a scouring machine after filtering; b. introducing light alkali with high alkali concentration into the dilatation evaporator for processing through the recovery pool, then introducing processed high-concentration alkali liquor into the mercerizer for reuse and introducing processed water into an oxygen bleaching washing box for use; and c. introducing oxygen bleaching process water into the second recovery processing box and then introducing into a desizing machine washing box for use after filtering. The invention has the advantages of small waste water discharge, high efficiency, energy conservation, etc., saves a large amount of production water and alkali, and meets requirements of energy saving and emission reduction.

Owner:李传海

Unidirectional circulation dyeing process for cheese

ActiveCN103726244ALess power consumptionAvoid layer differenceTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentDyeingEngineering

The invention provides an unidirectional circulation dyeing process for cheese. The unidirectional circulation dyeing process for the cheese is characterized in that a single circulation mode is adopted by dyeing liquor, and the dyeing liquor is driven to circulate from the interior of the cheese to the exterior of the cheese through the changing of the rotating speed of a main pump in a dyeing vat. According to the unidirectional circulation dyeing process for the cheese, a dyeing pulse technique and a spray technique are adopted to change a circulation mode of the dyeing process as single outflow dyeing, only half or even lower water level of raw materials are soaked by the dyeing liquor, dyeing can be carried out, the bath ratio can be lowered to 1:3, and production water consumption can be reduced greatly.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

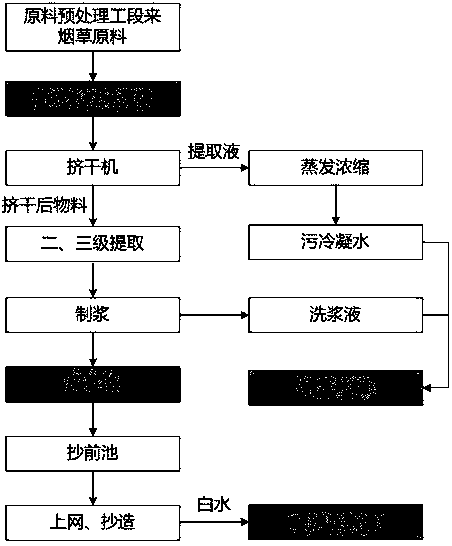

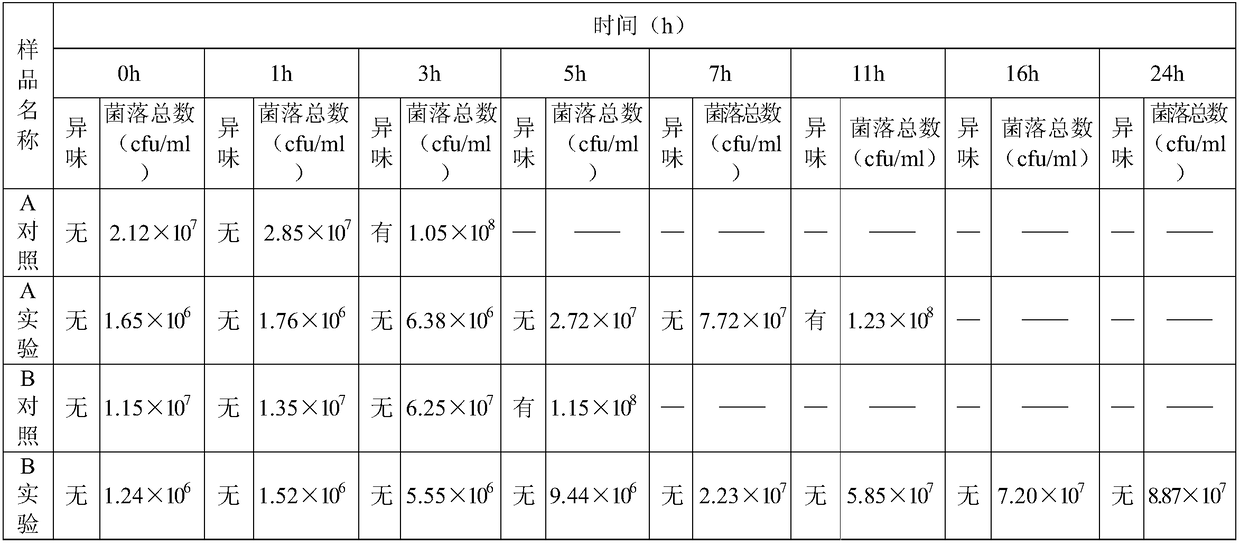

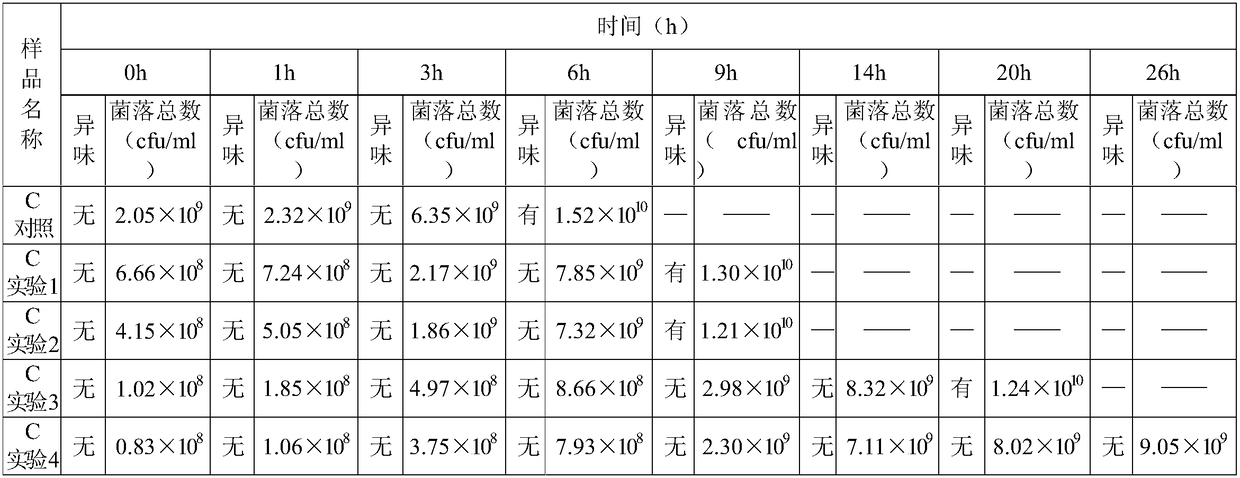

Method for maintaining freshness of materials of system for producing reconstituted tobaccos by paper-making process

ActiveCN108523207AGuaranteed freshnessGuarantee product qualityTobacco preparationHigh concentrationMicrowave

The invention provides a method for maintaining freshness of materials of a system for producing reconstituted tobaccos by a paper-making process. With the aid of the combination of one or two of means such as microwave, ultrasonic wave, ultraviolet and high temperature, the method mainly comprises the steps of carrying out online physical sterilization treatment on an extracting solution and an extracted material, finished slurry, slurry washing liquid, foul condensate and clear water; and setting a high-concentration aquapulper, a slurry forming pond, a diluting water tank and a clear watercollecting tank as treatment points. After being subjected to online physical sterilization treatment, the extracting solution and the extracted material, the finished slurry, the foul condensate, theslurry washing liquid and the clear water can separately retained for 24 h, 26 h, 192 h and 240 h or above, products and corresponding fresh samples of the reconstituted tobaccos do not have odors bysensory contrast, and the total number of colonies is smaller than the corresponding critical value of the total number of colonies and the total number of colonies of smelly samples which are not subjected to online physical sterilization. Chemical additives are not introduced in the process, the method is simple and convenient to operate and high in safety, and the quality of reconstituted tobacco products and the stability of production and running are ensured.

Owner:HENAN CIGARETTE IND TOBACCO SLICE

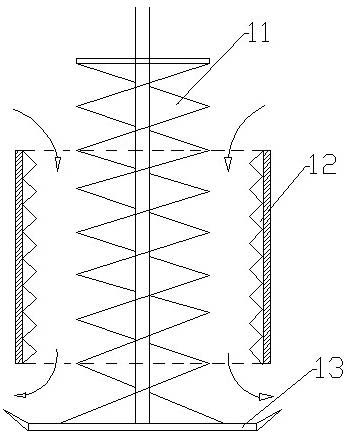

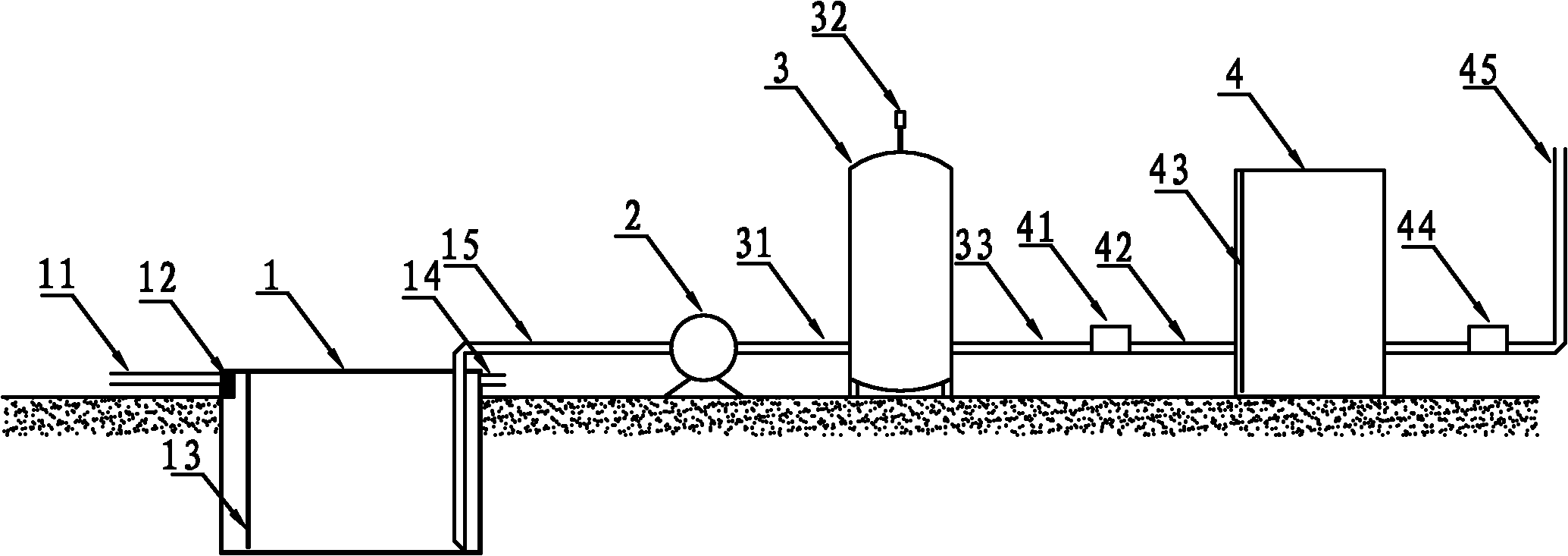

Wet-method dust removal device for powder grinding machine

ActiveCN104826723ALow costReduce energy consumptionCombination devicesDirt cleaningEngineeringCheck valve

The invention belongs to the field of molding powder processing dust removal, and particularly relates to a wet-method dust removal device for a powder grinding machine. The wet-method dust removal device comprises one or more draught fans and dust guide pipes, wherein the draught fan is provided with dust discharging pipes and is communicated with the dust guide pipes by virtue of the dust discharging pipes, an opening of each dust discharging pipe is formed in the inner side of the corresponding dust guide pipe, the openings in all the dust discharging pipes are consistent in direction, and each opening is away from a starting end and is provided with a check valve for preventing dust from returning into the corresponding dust discharging pipe; the tail end of each dust guide pipe faces downwards, a collection tank with water is arranged right below the dust guide pipes, the tail end of each dust guide pipe is connected with dust filter cloth of a tubular structure, the upper end of the dust filter cloth is provided with a water sprayer, the lower end of the dust filter cloth stretches to be below the water surface in the collection tank, the collection tank is connected with one or more precipitation tanks, and a water pump is arranged in the last precipitation tank and is connected to the water sprayer by virtue of a water pipe. The wet-method dust removal device is simple in structure and has advantages of low cost, good dust removal effect, capability of recycling dust, environmental protection, energy conservation and the like.

Owner:ZHEJIANG CHAOLANG ADVANCED MATERIALS

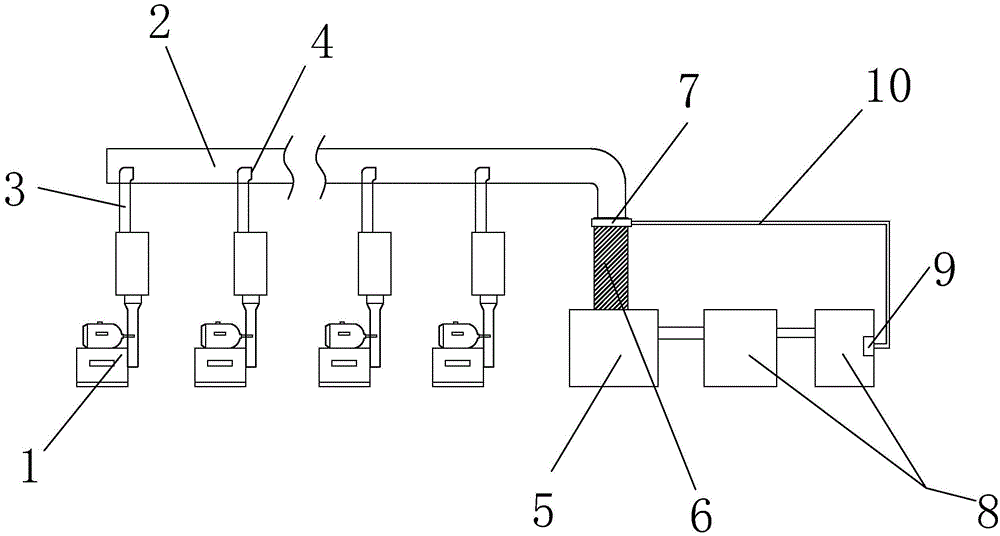

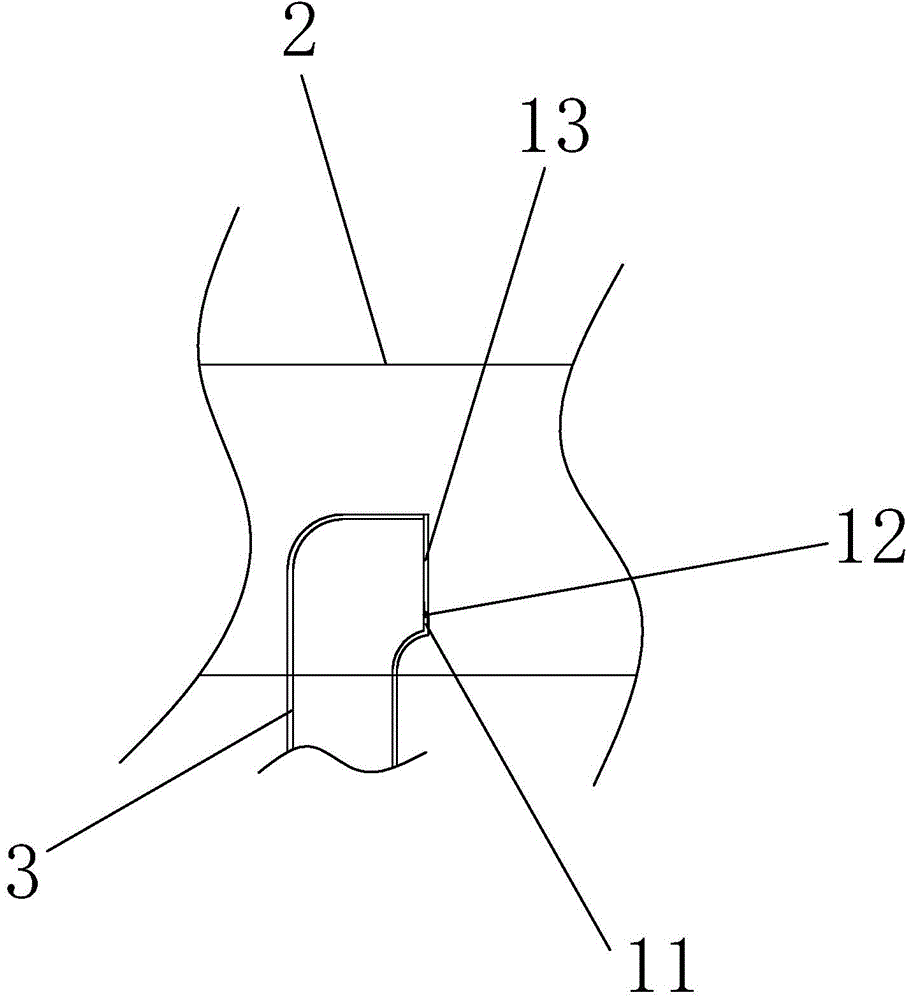

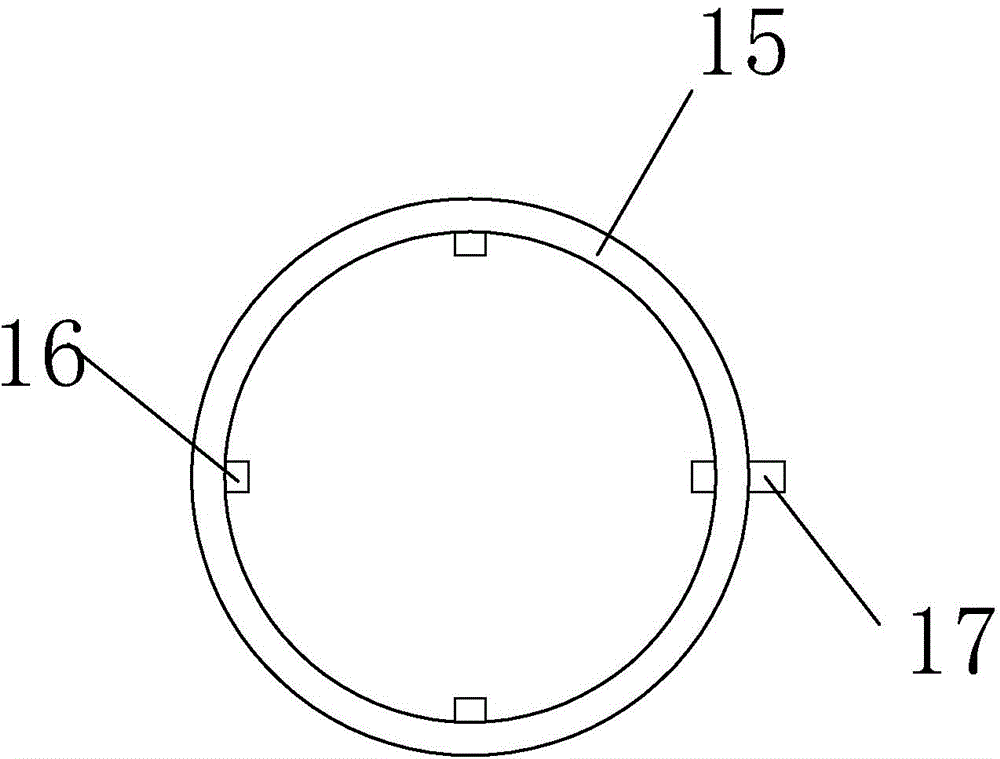

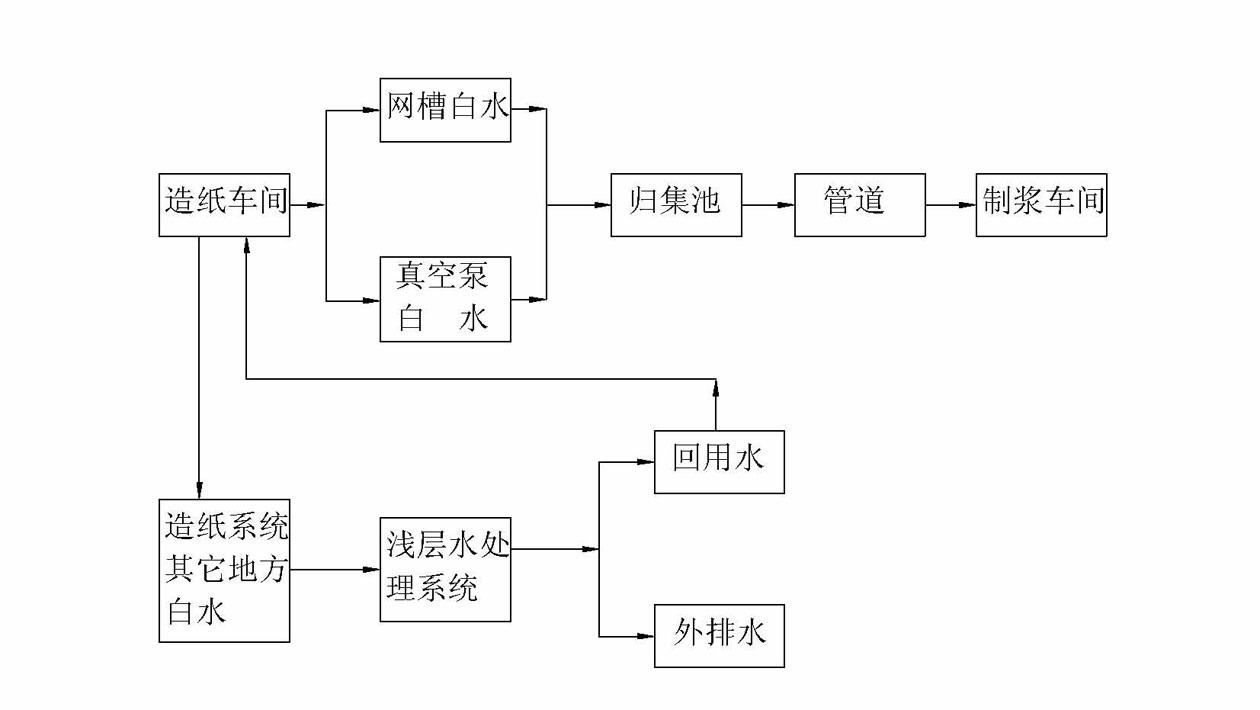

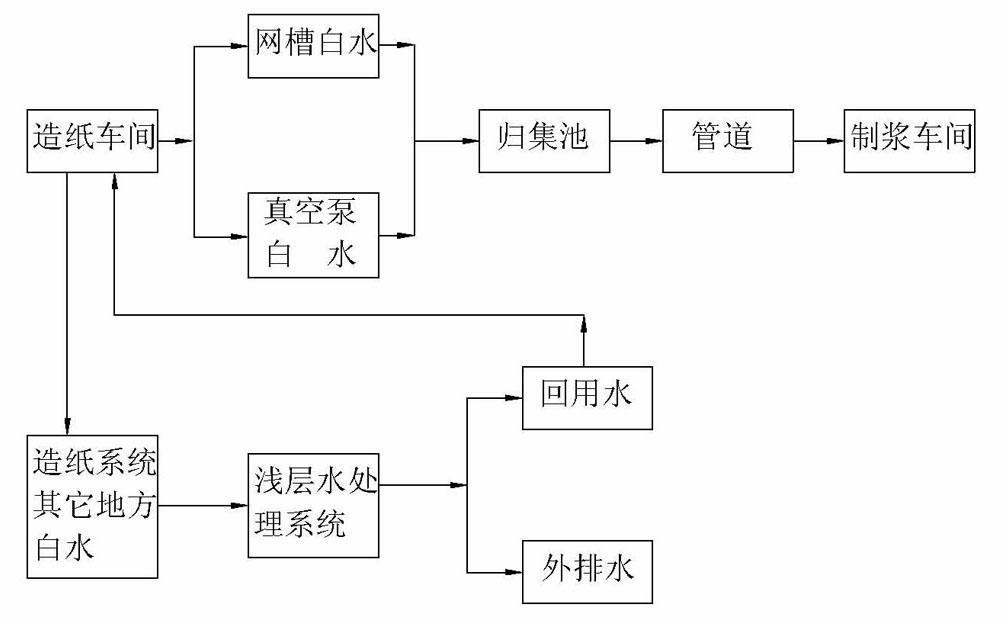

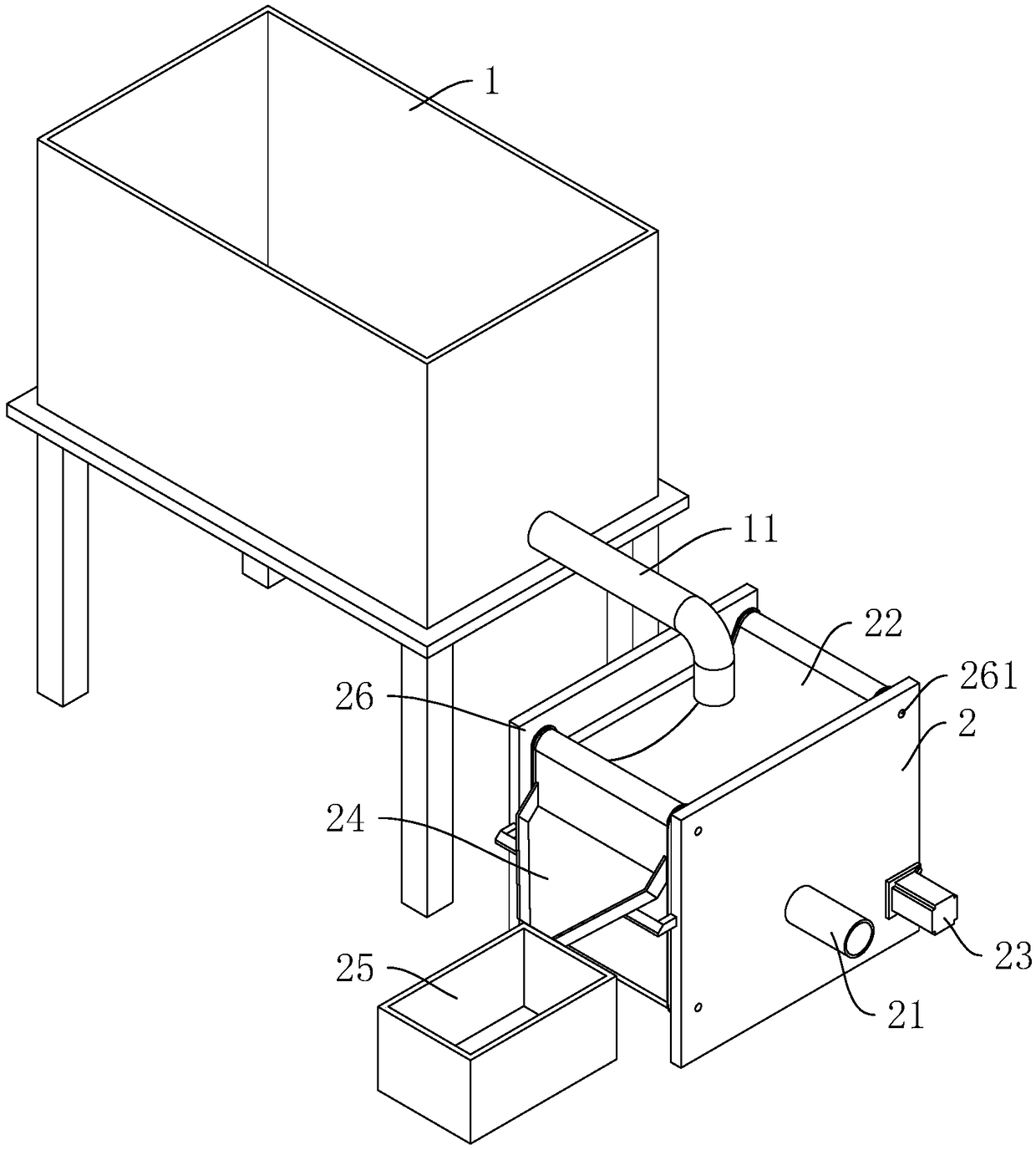

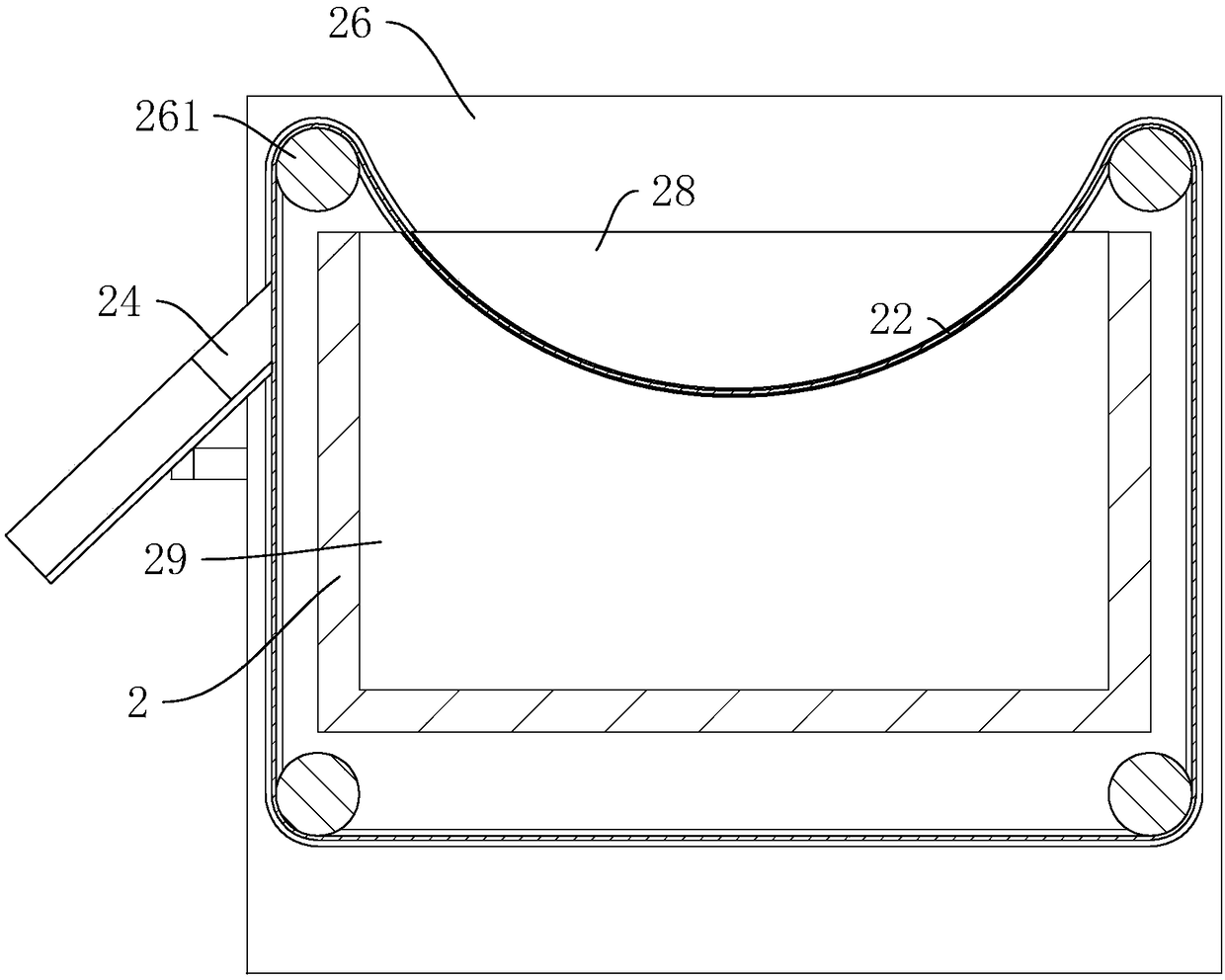

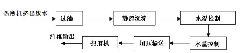

Recycle process of white water of papermaking system

InactiveCN102102306AEmission reductionSave production waterPulp liquor regenerationWater/sewage treatment by flotationEnvironmental resistanceTreatment costs

The invention discloses a recycle process of white water of a papermaking system, which comprises the following steps in sequence: (1) delivering the white water generated by a papermaking mesh vat and a vacuum pump in a papermaking workshop to a collecting tank; (2) delivering the white water to a pulping workshop to be supplied to a pulper for pulping; (3) delivering sewage generated by other parts of the papermaking system to a shallow water treatment system to be treated, and delivering 80 to 90 percent of the treated sewage back to the papermaking workshop to be reused, and draining the residual sewage after the sewage meets the emission standard; and (4) pressing staple fiber waste pulp generated in the shallow water treatment system to dryness through a filter press, and packaging the dried waste pulp. By the recycle process of white water, the white water generated in different parts is treated in different ways according to the respective characteristics, thus not only the treatment cost of white water is greatly reduced, but also plant fibers in the white water is recycled to the maximum extent, and the economic benefit is further improved; and the vast majority of white water is recycled, thus the sewage discharge of papermaking enterprises is reduced, and significant social benefit and environmental protection benefit are created.

Owner:C&S PAPER CO LTD

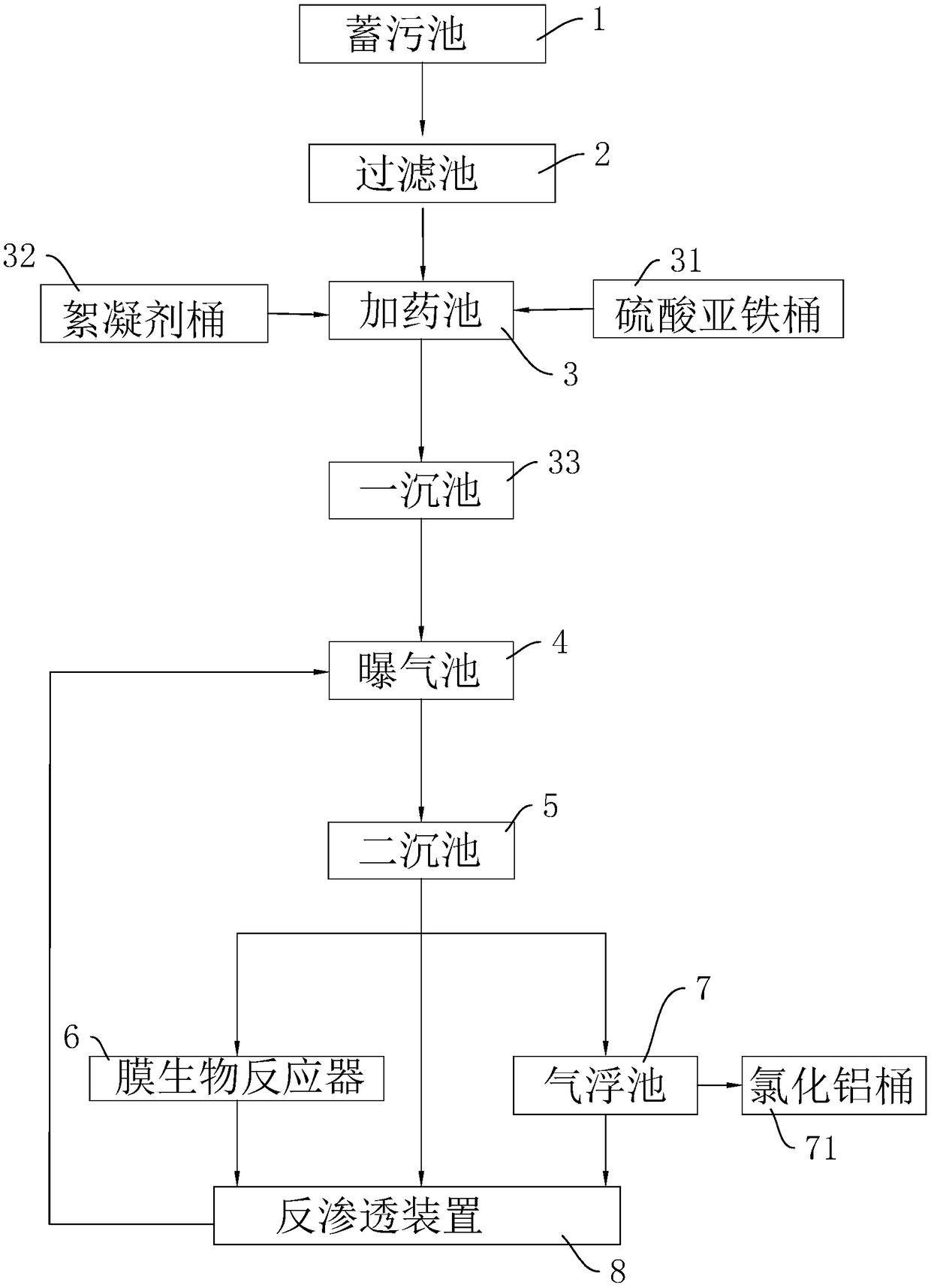

Printing and dyeing textile sewage treatment system

InactiveCN108623091AProcessing will not affectImprove processing efficiencyTreatment involving filtrationMultistage water/sewage treatmentSewageMembrane bioreactor

The invention discloses a printing and dyeing textile sewage treatment system, which belongs to the field of sewage treatment equipment and solves the problems that when treated sewage is unqualifiedthrough detection, the sewage needs to return into an aeration tank to be treated again, so that the normal sewage treatment is influenced; the sewage treatment efficiency is reduced. The printing anddyeing textile sewage treatment system is mainly characterized by sequentially comprising a sewage storage pool, a filtering pool, a primary precipitation pool, an aeration pool and a secondary precipitation pool, wherein the secondary precipitation pool is connected with a membrane bioreactor. The printing and dyeing textile sewage treatment system has the advantages that the structure is reasonable; sewage which is still unqualified after the treatment is discharged into the membrane bioreactor to be treated, so that the normal sewage treatment is not influenced; the goal of improving the sewage treatment efficiency is improved.

Owner:嘉兴市锦福缩染有限公司

Flavor enhancement for strong-flavor rapeseed oil

InactiveCN108395926ARich flavorSimple production processFatty-oils/fats refiningFatty-oils/fats productionFlavorDistillation

The invention discloses a flavor enhancement for strong-flavor rapeseed oil. The method comprises the following steps: removing impurities from a raw material rapeseeds, and stir-frying and pressing the seeds to obtain crude rapeseed oil and rapeseed cakes; breaking the rapeseed cakes to obtain rapeseed cake powder; adding water to the rapeseed cake powder, performing uniform mixing, distilling the obtained solution, collecting steam distilled in the distillation process, and condensing the steam to obtain a condensate; adding edible salt to the condensate to obtain a saline solution having aconcentration of 10-15%, uniformly mixing the saline solution with the crude rapeseed oil, performing hydration, and removing the obtained hydrated layer to obtain an oil layer; and washing the oil layer with water, and dehydrating the washed oil layer to obtain the strong-flavor rapeseed oil. The method fully utilizes the flavor components of the rapeseed oil in the rapeseed cakes to make the rapeseed oil product have a strong flavor, and combines rapeseed oil flavor enhancement with hydration degumming to simplify the production process and save water for production, and the flavor components of the rapeseed oil are fully dissolved in the rapeseed oil in the hydration degumming process in order to improve the economic benefit of rapeseed oil production.

Owner:成都市新兴粮油有限公司

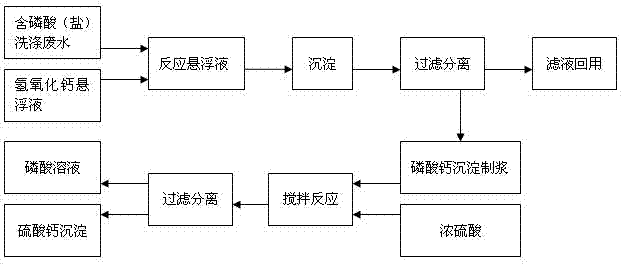

Phosphate radical ion recycling method for activated carbon washes with method of phosphoric acid

InactiveCN102530898ASave production waterReduce manufacturing costPhosphoric acidActivated carbonEnvironmental chemistry

The invention belongs to the recycling field of phosphoric acid (salt) in the production process of activated carbon, and particularly relates to a phosphate radical ion recycling method for activated carbon washes with the method of phosphoric acid, which includes the following steps: enabling calcium hydroxide to be prepared into calcium hydroxide suspension, adding the suspension to washes generated in the activated carbon production process with the method of phosphoric acid, fully mixing for reaction to form calcium phosphate sediment, filtering, enabling the calcium phosphate sediment to be prepared into pulp, adding concentrated sulfuric acid, fully mixing for reaction to generate phosphoric acid and calcium sulfate sediment, and filtering and recycling phosphoric acid. The phosphate radical ion recycling method utilizes reaction between calcium hydroxide and waste water containing phosphate radical ions to generate high-purity calcium phosphate sediment and recyclable water with low content of phosphate radical ions, thereby recycling phosphate radical ions and saving water for production. The phosphate radical ion recycling method is simple in process operation, easy to popularize industrially and low in production cost, and has remarkable economic benefits. Raw materials can be obtained easily.

Owner:FUJIAN YUANLI ACTIVE CARBON

Method for synthesizing L-ascorbyl palmitate

The invention discloses a method for synthesizing L-ascorbyl palmitate, which comprises the following steps: grinding L-ascorbyl palmitate into fine powder; at 25 to 20 DEG C, slowly adding the L-ascorbyl palmitate fine powder into pure sulfuric acid so that the L-ascorbyl palmitate fine powder dissolves in the sulfuric acid; adding L-ascorbyl palmitate in an amount which is 0.95 times the molar number of L-ascorbyl palmitate into the reaction solution, adding dehydrating agent into the reaction solution, and continuing reaction for 6 to 7 hours; pouring the generated reaction solution into broken ice, filtering out coarse product, drying and washing with water; heating the prepared coarse L-ascorbyl palmitate, dissolving the coarse L-ascorbyl palmitate in ethyl acetate, and decolorizing and purifying the solution by particle active carbon; and subjecting the obtained solution to reduced-pressure distillation and concentration, cooling feed liquid to 0 DEG C and discharging to obtain L-ascorbyl palmitate white powder. When the method disclosed by the invention is used, the production efficiency can be improved greatly, the production period is shortened, the product yield is increased, the product quality is improved, and the dose of palmitic acid is reduced (only 5 percent more is required).

Owner:HEBEI WELCOME PHARMACEUTICAL CO LTD

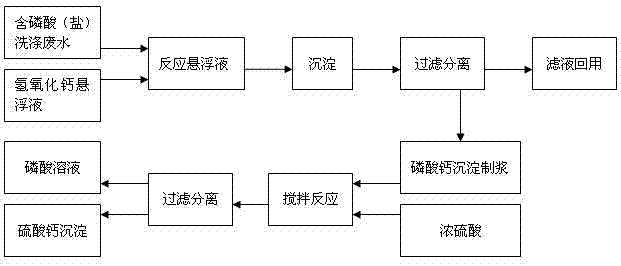

Method for circulated utilization of mother liquor of alpho-naphthol, beta-naphthol ethyl naphthol production

InactiveCN1994932AEmission reductionEfficient use ofOrganic chemistryOrganic compound preparationSulfite saltWastewater

The invention discloses a new circulating utilizing method of mother liquid in the methyl naphthol and beta-naphthol manufacturing course, which comprises the following steps: adding little water in the dilute stove before putting alkali fusing material; making solid sodium sulfite display flow crystal pattern; transmitting into filter autoclave; filtering; separating mother liquid through sulfonated sodium salt; transmitting into filter autoclave; washing; filtering; combining filtrate; transmitting into acidifying segment; entering subsequent course; obtaining the product; recycling the sodium sulfite to manufacture naphthol.

Owner:江苏华达化工集团有限公司

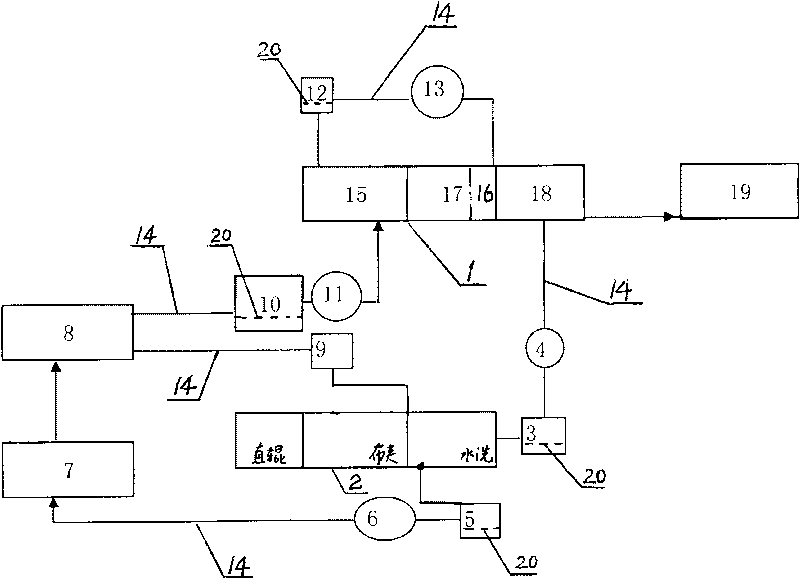

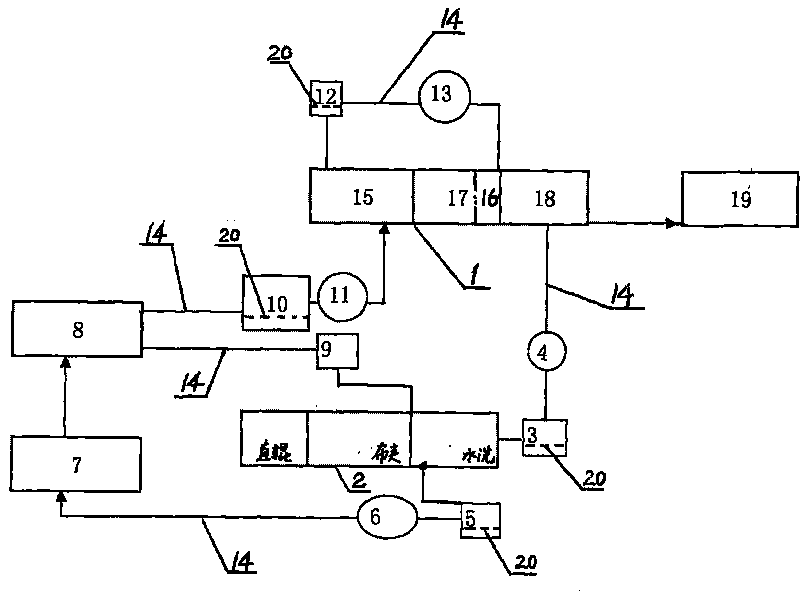

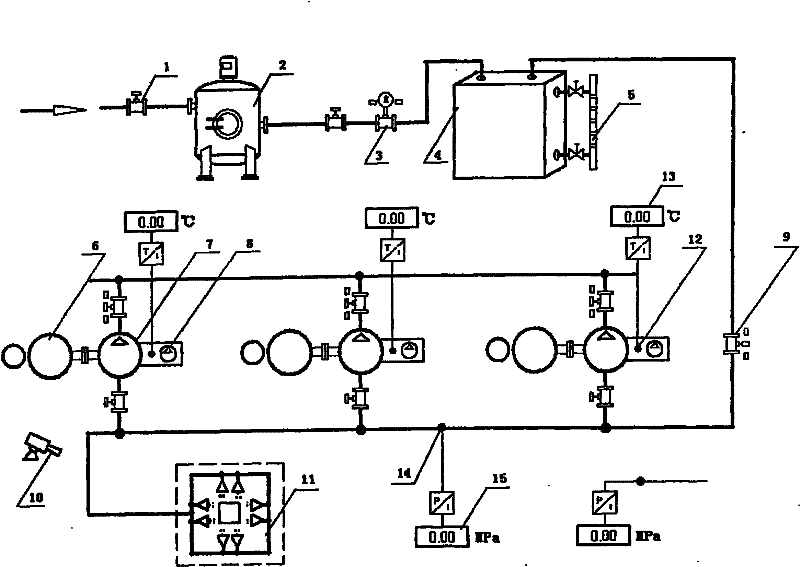

Device for recycling silicon wafer cleaning wastewater

ActiveCN101947523AEmission reductionImprove reuse rateCleaning using liquidsElectricityWater storage tank

The invention relates to a device for recycling silicon wafer cleaning wastewater. The device comprises a recycled water reservoir, a booster water pump, a pressure water tank and a degumming machine water storage tank which are communicated with one another, wherein a first liquid level sensor is arranged in the recycled water reservoir; the pressure water tank is provided with a pressure sensor; the first liquid level sensor and the pressure sensor are electrically connected with an electric controller of the booster water pump; a second liquid level sensor is arranged in the degumming machine water storage tank; and the second liquid level sensor is electrically connected with a first electromagnetic valve and a second electromagnetic valve. The invention can make full use of the wastewater discharged by a cleaner for the degumming machine, thereby improving the recovery rate of the wastewater, effectively saving the production water and reducing wastewater discharge; moreover, the invention also can omit a wastewater recycling device carried by the cleaner and the degumming machine and save production cost as well as equipment cost.

Owner:无锡品源科技咨询有限公司

Automatic circulating water descaling system for hot-rolled rod and wire steel

InactiveCN102259119AReduce manufacturing costHigh degree of automationWork treatment devicesMetal rolling arrangementsWater filterWater circulation

An automatic circulating water descaling system for hot-rolled bar and wire steel, the invention discloses an automatic circulating water descaling system for billets. It is composed of automatic backwashing water filter, high-level water tank, pneumatic jet valve, plunger pump descaling box and electric control cabinet. Its working method is: the descaling water enters the high-level water tank after being filtered. The signal generated by detecting the water level of the water tank by the magnetic float level gauge controls the closing of the electric water supply valve. The descaling water enters the descaling box header after being pressurized by the plunger pump after a steady flow. When the hot metal detector first detects the temperature of the billet head, it sends out a signal to control the closing of the pneumatic injection valve. The descaling water falls into the descaling box after descaling. When the hot metal detector detects the temperature of the tail of the billet, a signal is sent to control the automatic opening of the pneumatic injection valve. The water in the descaling tank is circulated to the head tank. Because the system is equipped with pneumatic injection valve, electric water supply valve, magnetic float liquid level gauge, etc., the degree of automation is greatly improved. Because of the return water pipeline, the descaling water can be recycled, which saves a lot of production water and reduces the production cost of the enterprise.

Owner:YINGKOU FLUID EQUIP MFG GRP

Recycling method of leading waste water into grinding chamber body in MDF production

InactiveCN101798766ASolve processing problemsRelieve stressMultistage water/sewage treatmentFibrous raw materialsSocial benefitsWastewater

The invention relates to a recycling method of leading waste water into a grinding chamber body in a MDF production. The waste water extruded from a defibrator in the MDF hot grinding technology is filtered and deposited. The temperature of the waste water is controlled within 20 to 70 degrees centigrade. The waste water is transmitted to the grinding chamber body of the defibrator to be recycled. The method solves not only the difficult processing problem of the waste water extruded from the defibrator but also the water shortage problem of the hot grinding process, saves production water supply, recycles lignin, hemicellulose and other condensates in the waste water, makes the best use of energy resources, saves the cost of processing the waste water and has the obvious characteristic of saving energy, and environmental protection and good economic and social benefit.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com