Recycling method of leading waste water into grinding chamber body in MDF production

A fiberboard, medium-density technology, applied in fiber raw materials, fiber raw material processing, chemical instruments and methods, etc., can solve problems such as carbon deposition, and achieve the effects of reducing costs, saving production water, and achieving good economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

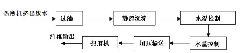

[0010] The waste water (average 2000kg per hour) extruded by the thermal mill is introduced into the launder, and after being filtered and slag-removed by a roller net with a mesh diameter of 6mm, the waste water flows into the sedimentation tank, and after static flow sedimentation, it is suspended in the waste water by gravity method. The sand and other sundries in the waste water can be removed to remove sand and other sundries. After the precipitated wastewater (temperature is 27°C) enters the water tank through the overflow tank, the temperature of the wastewater is controlled. When the temperature drops to 20°C, the wastewater is heated to keep the temperature of the wastewater between 20-70°C. The heated wastewater is transported to the grinding chamber of the thermal refiner through the pre-installed interface of the thermal refiner by a quantitative high-pressure water pump. The amount of wastewater pumped into the grinding chamber of the thermal refiner is 1200kg per ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com