Patents

Literature

98 results about "Defibrator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The defibrator is a thermo mechanical pulping refiner in which the pulp material, such as wood chips, is ground in an environment of steam between a rotating grinding disc (rotor) and a stationary disc (stator) each with radial grooves that provides the grinding surface. Wood chips are fed into the centre and are broken down as the centrifugal force pushes them towards the circumference of the discs where the grooves are finer to produce wood fibre. The size of the refined fibres can to some extent be controlled by altering the distance between the discs where a closer distance produces finer fibres but also requires higher grinding force. The capacity per machine is largely determined by the size of the machine, as well as the motor speed 1500 rpm or 1800 rpm.

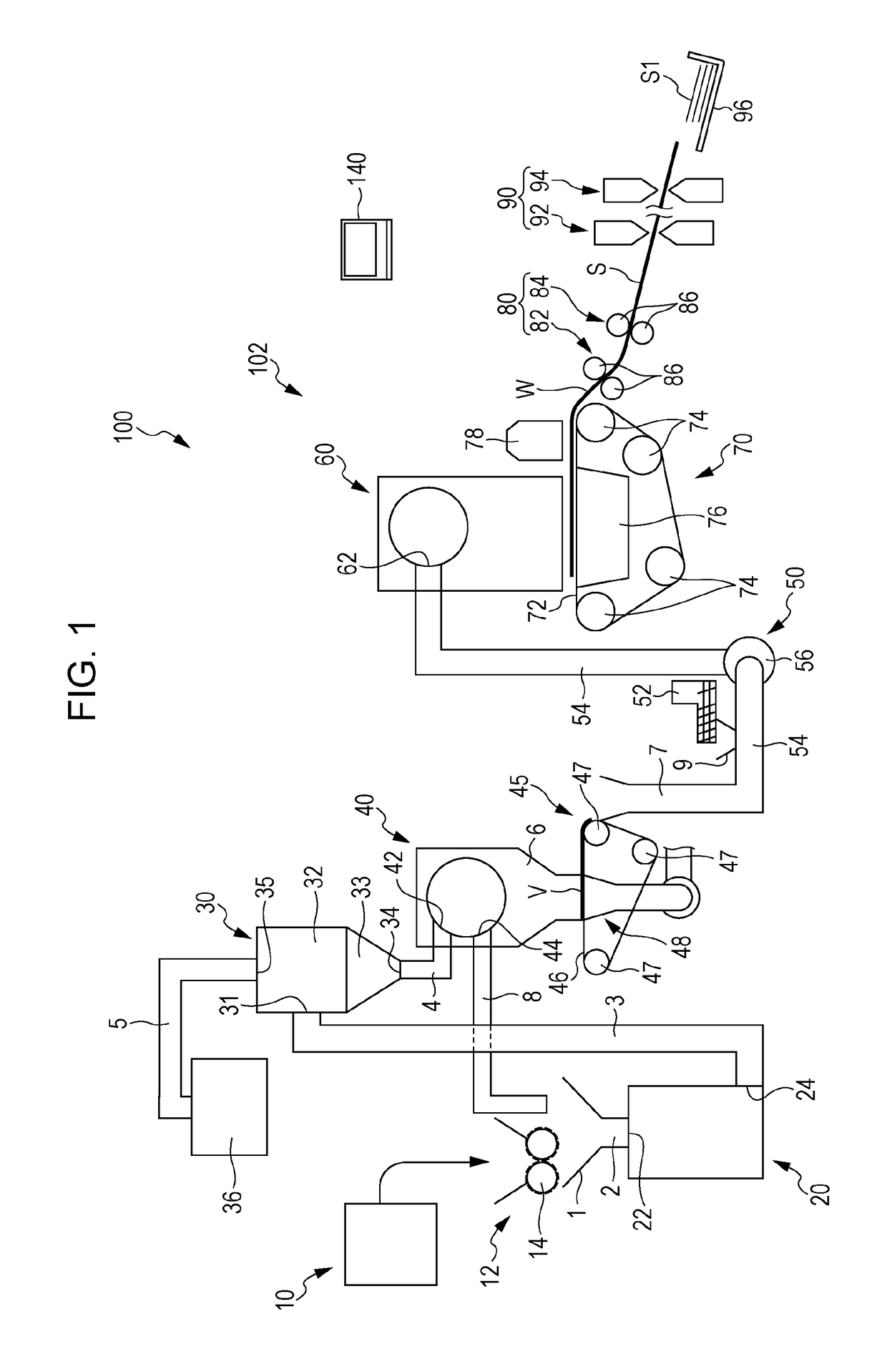

Paper recycling system and paper recycling method

InactiveUS20140027075A1Improve the level ofHigh whitenessPaper recyclingFlat articlesPaper recyclingPulp and paper industry

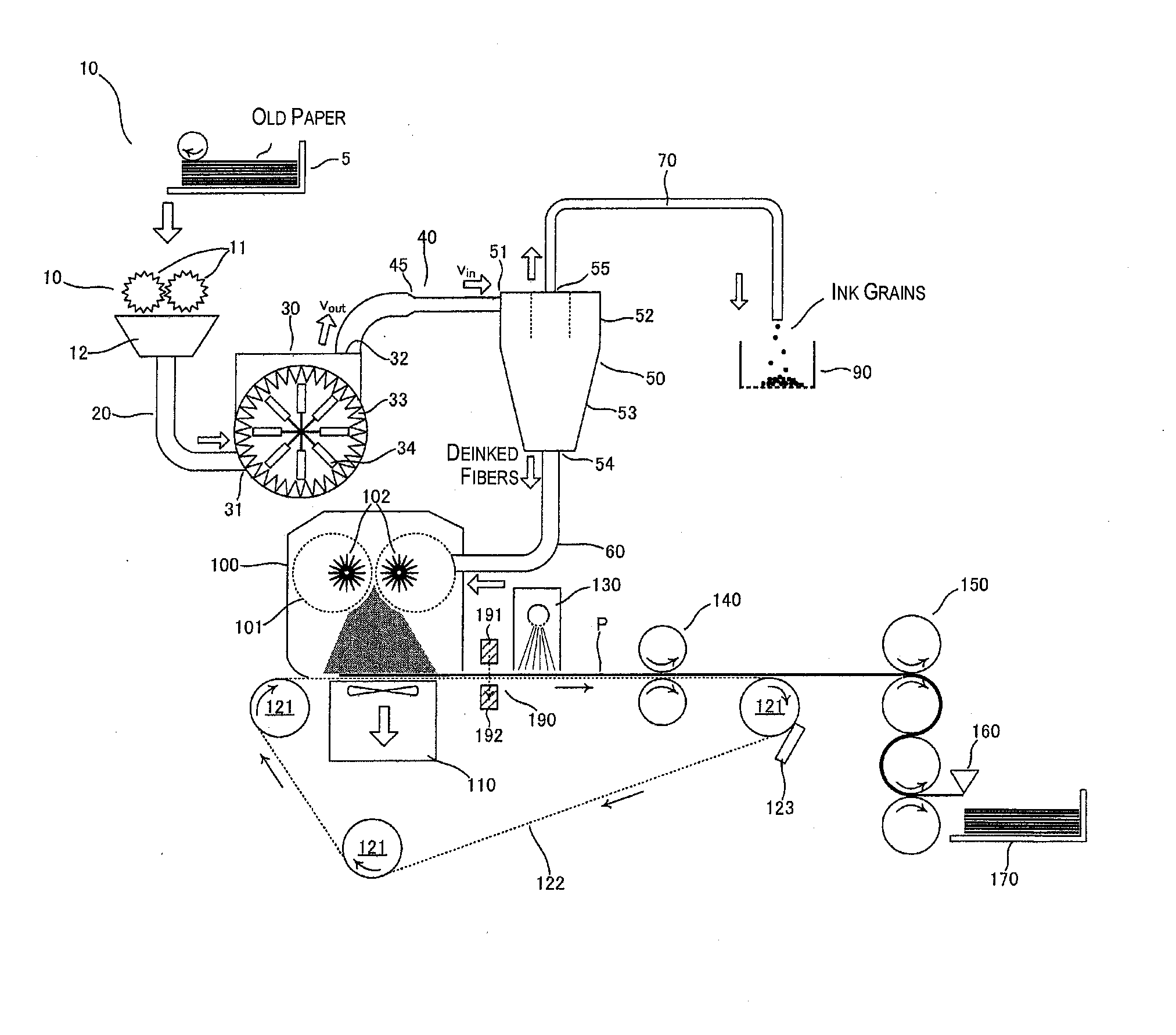

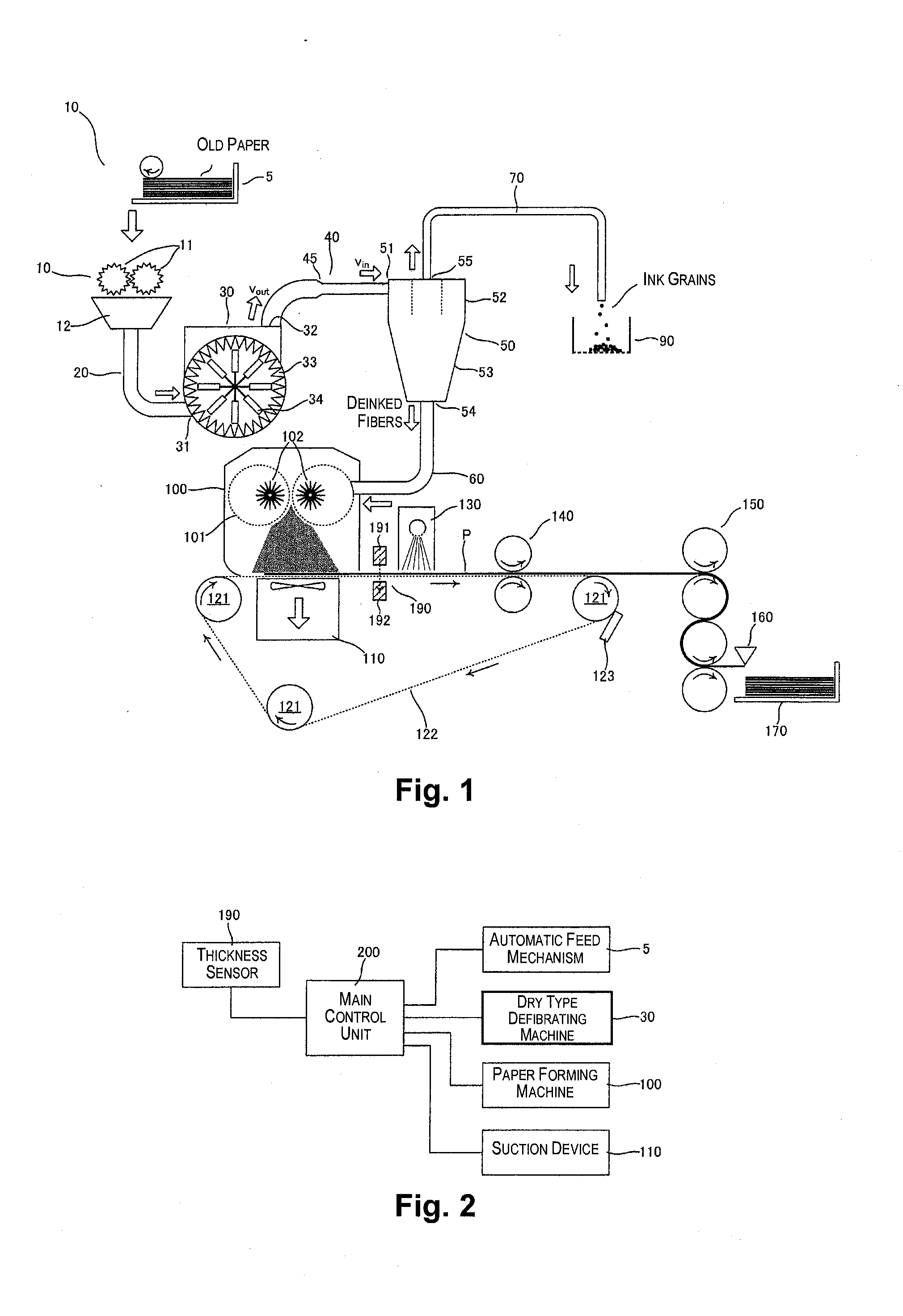

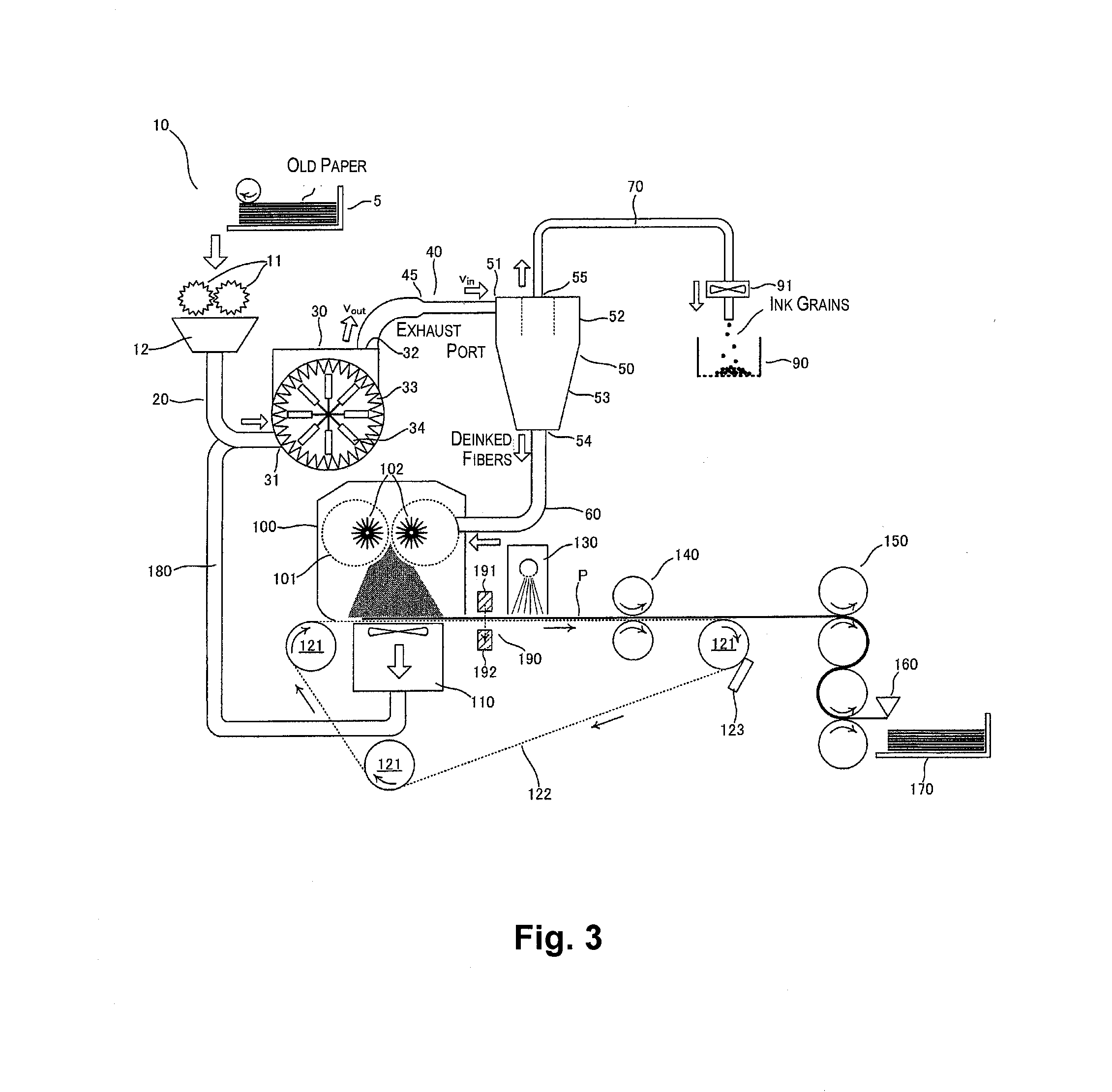

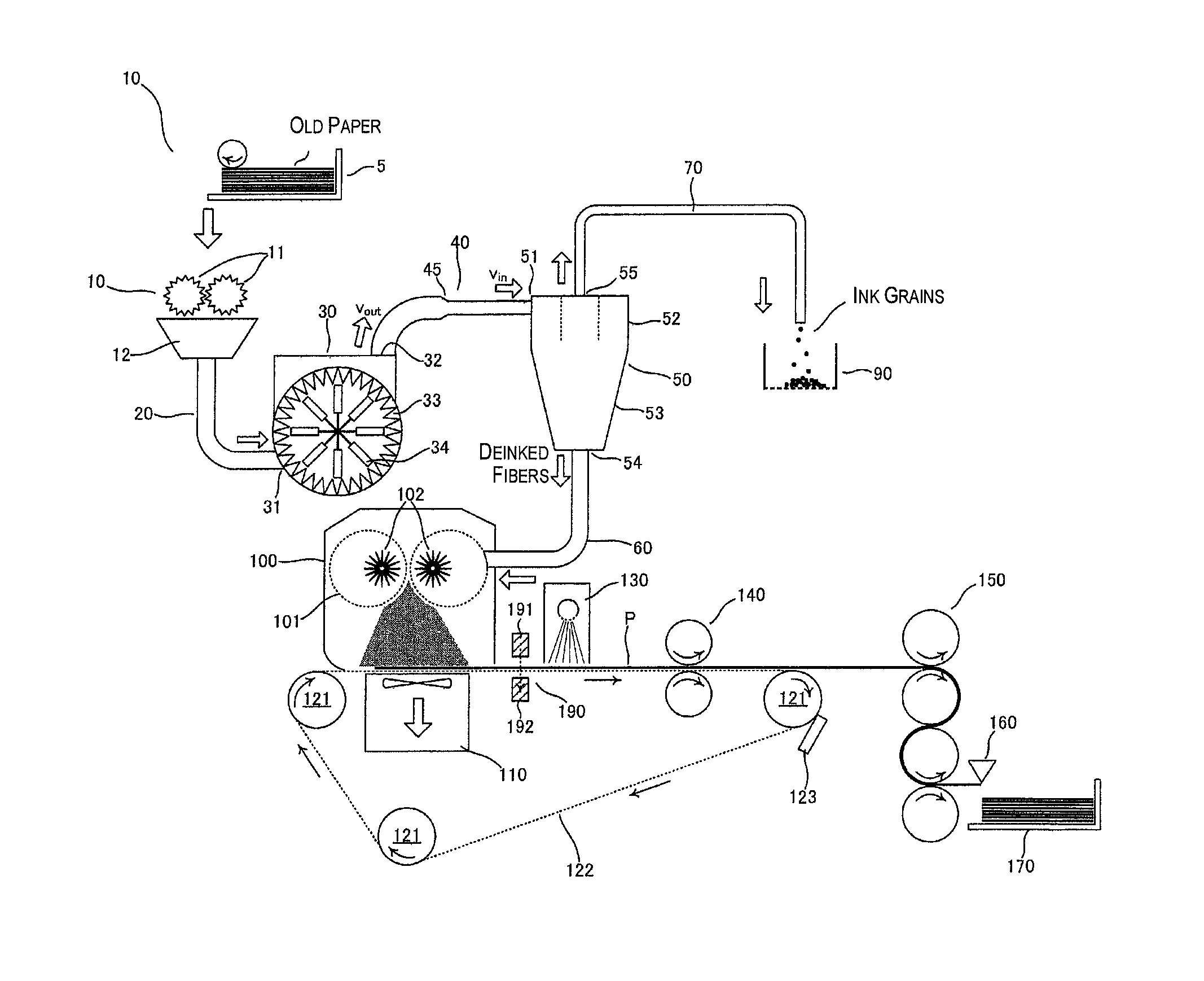

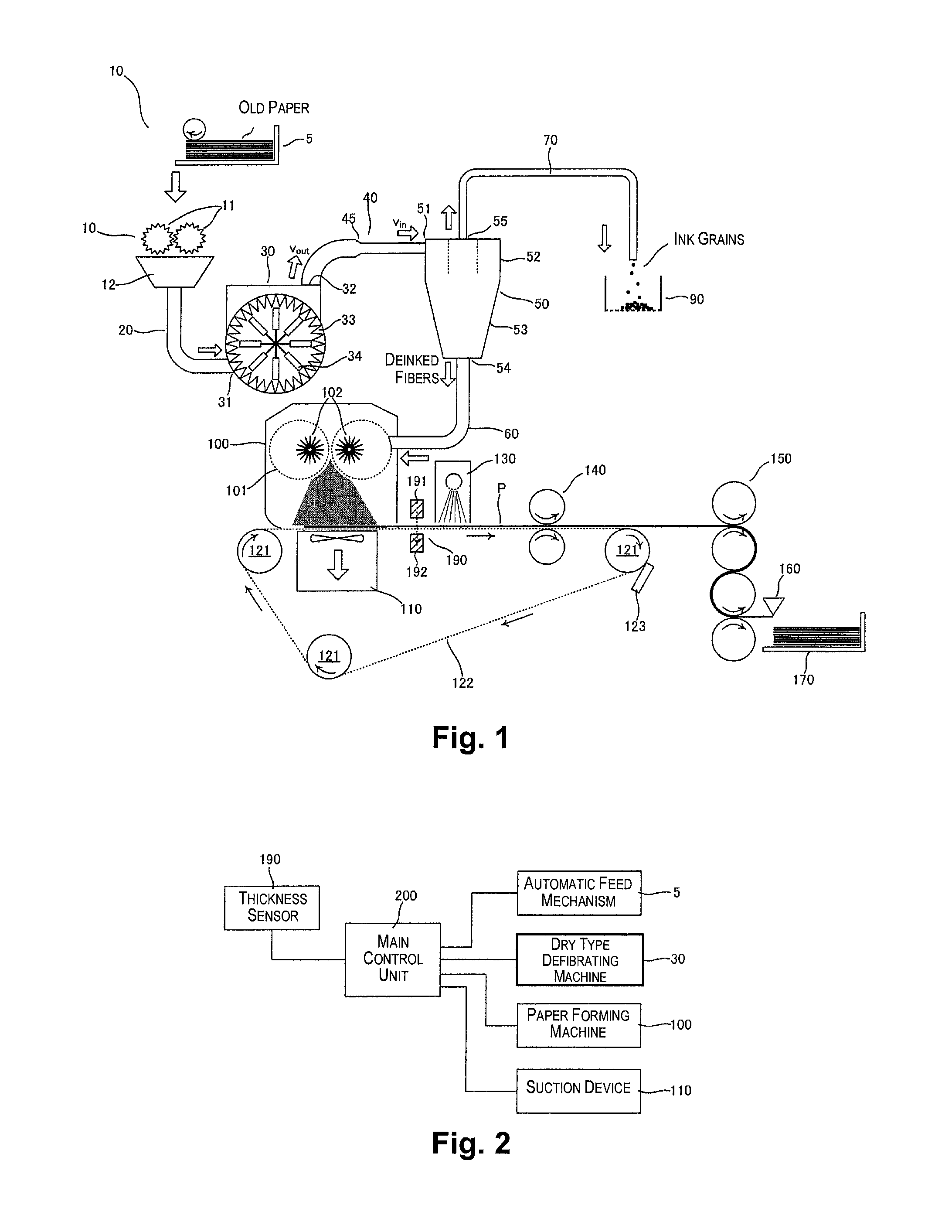

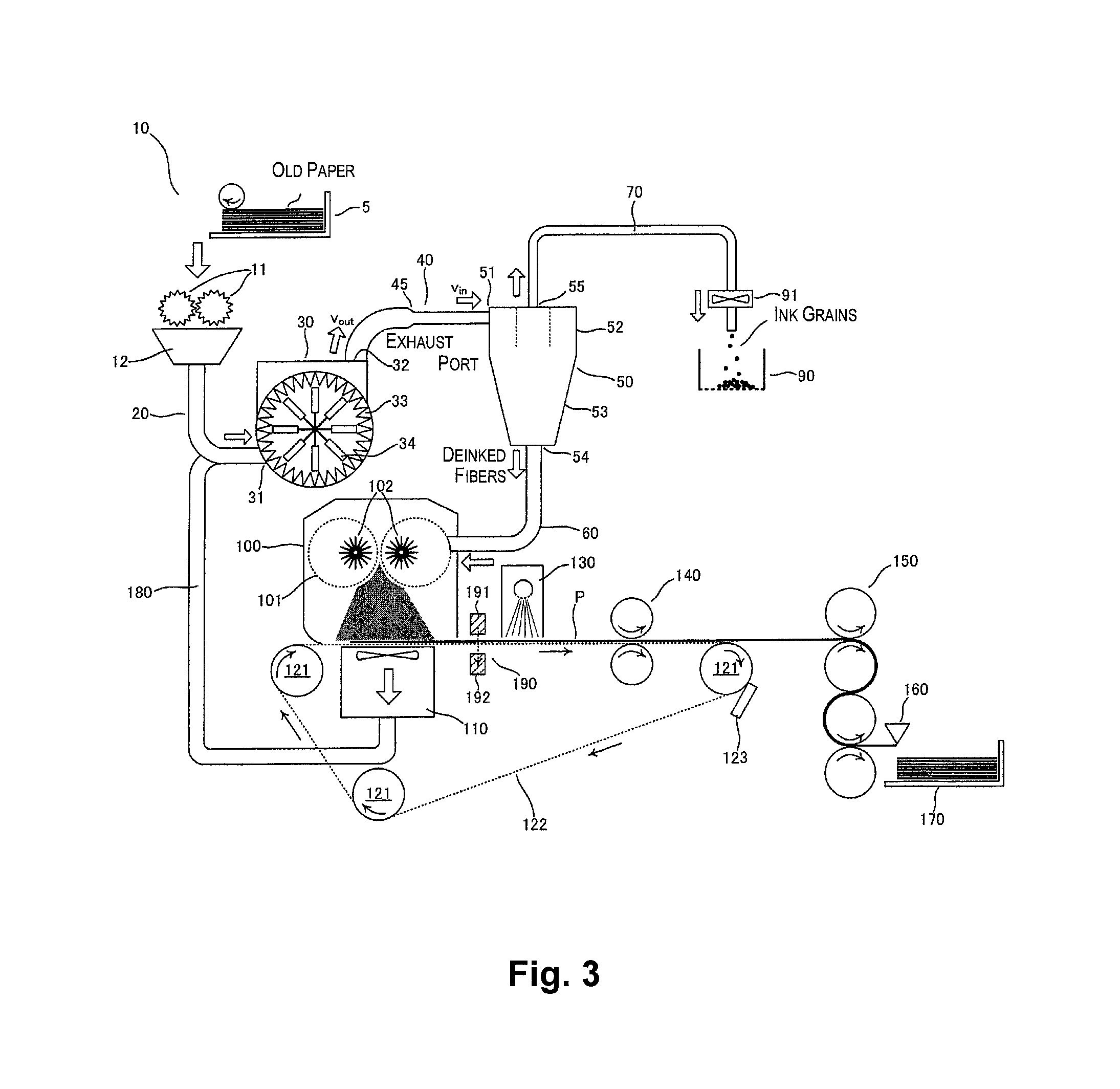

To provide a paper recycling device capable of recycling paper of increased whiteness level that can be widely used for applications other than paper for newspapers, the paper recycling device of the present invention has a dry type defibrator for crushing and defibrating paper, a first transport pipe for transporting defibrated material that was defibrated by the dry type defibrator, a cyclone for air classifying and deinking the defibrated material transported by the first transport pipe, a second transport pipe for transporting the defibrated material that was deinked by the cyclone, and a paper forming machine for forming paper with the defibrated material transported by the second transport pipe.

Owner:SEIKO EPSON CORP

Paper recycling system and paper recycling method

Owner:SEIKO EPSON CORP

Bobbin paper production technology

ActiveCN104278594AAvoid pollutionSave resourcesWaste product additionSpecial paperHigh concentrationBobbin

The invention discloses a bobbin paper production technology which comprises the following steps: (1) papermaking reclaimed pulp undergoes high-concentration degritting and disk milling and then is placed into a coarse pulp tank; (2) waste paper is crushed by a pulper, and crushed paper pulp undergoes high-concentration degritting and then is placed into the coarse pulp tank; (3) coarse pulp in the coarse pulp tank is separated by a defibrator; (4) medium-concentration degritting is carried out; (5) fine screening and concentration are carried out; (6) the pulp is placed into a concentration tank; (7) the pulp undergoes disk mill and then is placed into a finished product tank; (8) the pulp is delivered to a machine chest, and paper mill sludge is added into the machine chest; (9) drifting is carried out through a drifting system, and a water repellent agent is added; (10) the raw material is conveyed to a net part of a paper machine, a dry strength agent is added into the net part, and starch is sprayed; (11) the raw material is processed by a press part of the paper machine; (12) the raw material is processed by a drying part of the paper machine; and (13) finished paper is reeled. According to the invention, reclaimed pulp and paper mill sludge which are generated during the papermaking process are fully utilized for production of bobbin paper. Thus, resources are saved; cost is reduced; and environmental pollution is also avoided.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

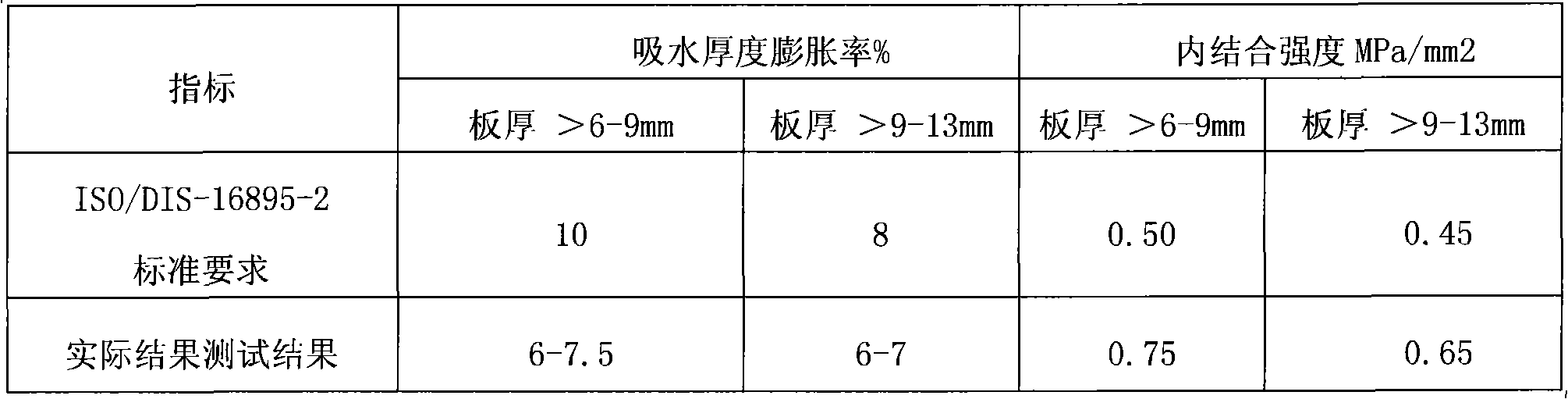

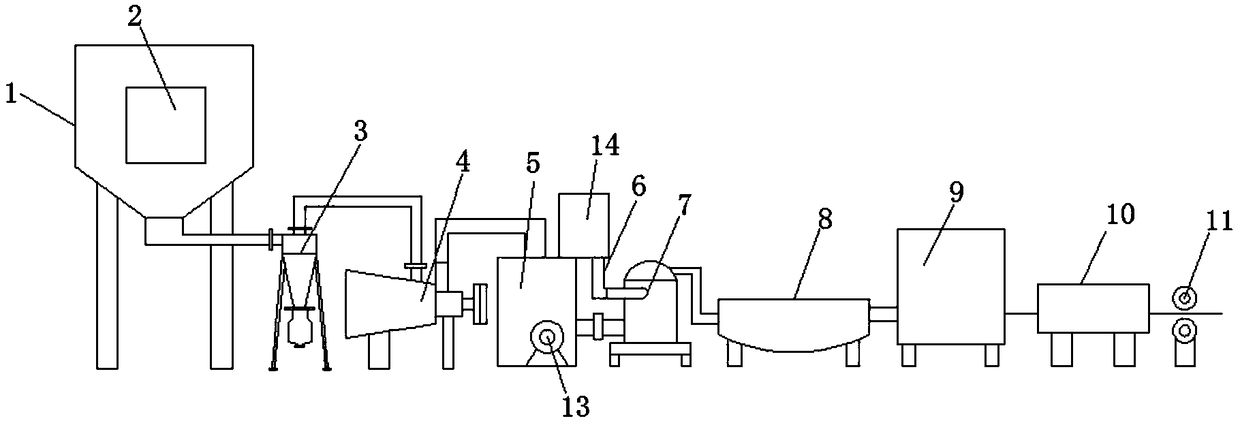

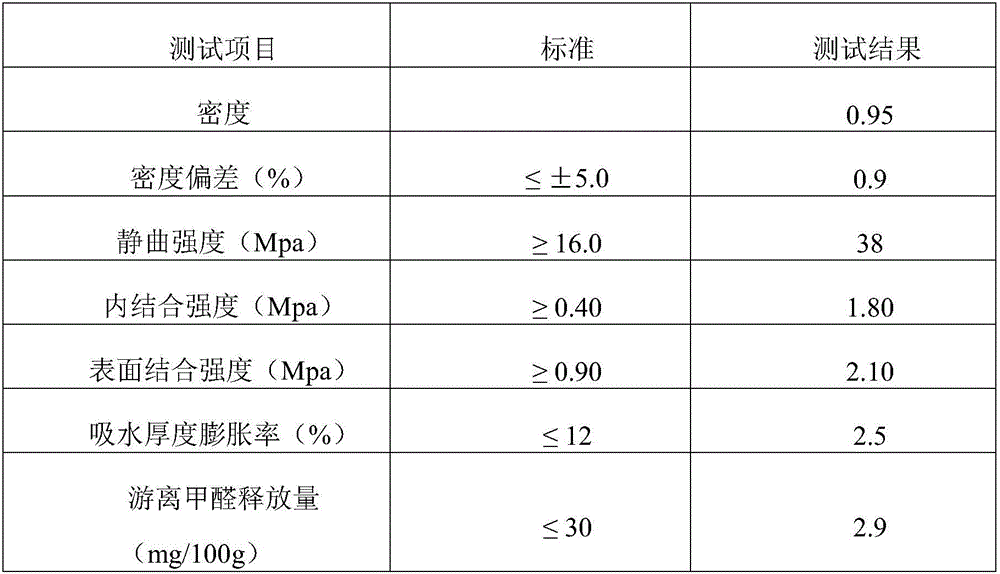

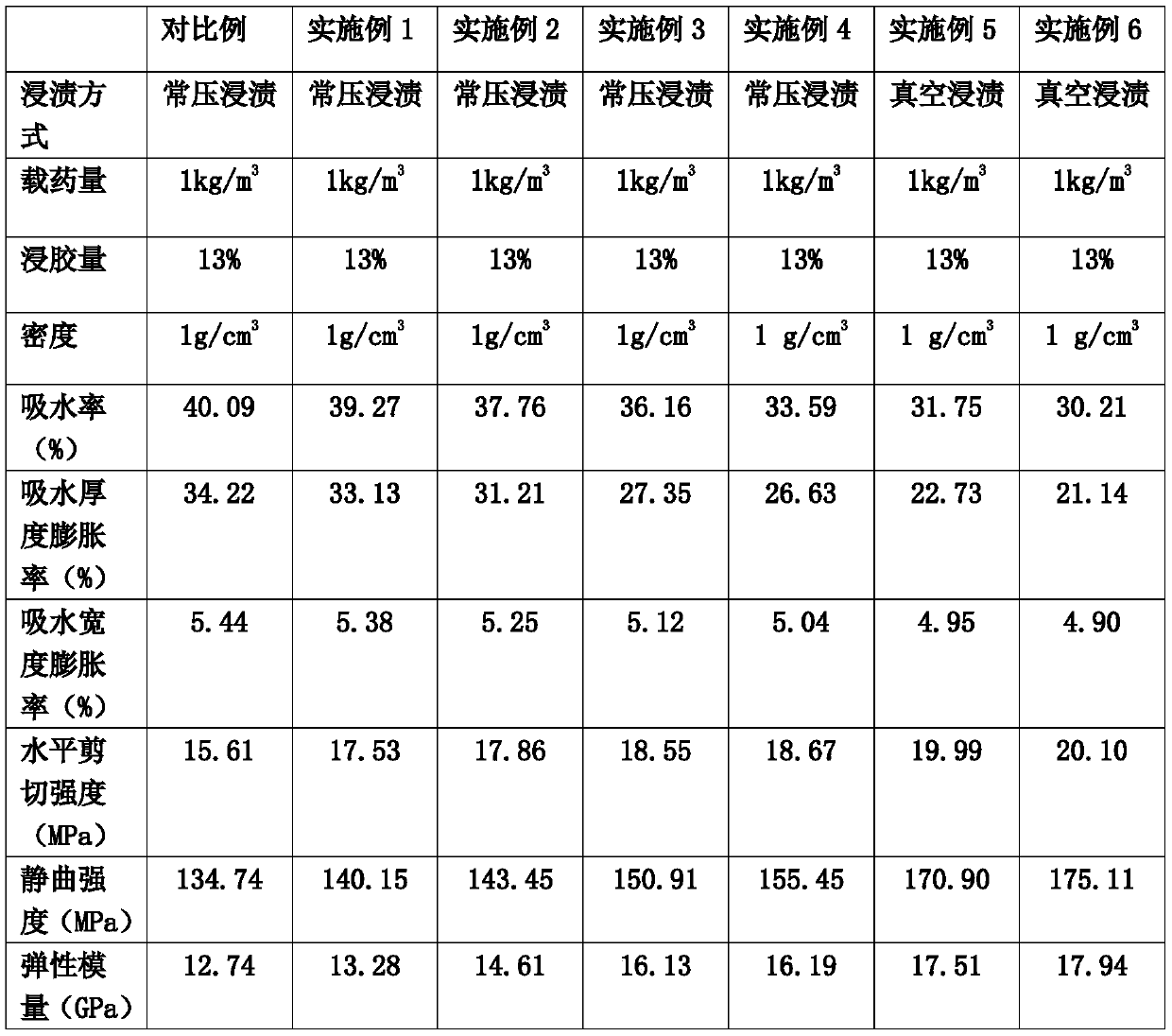

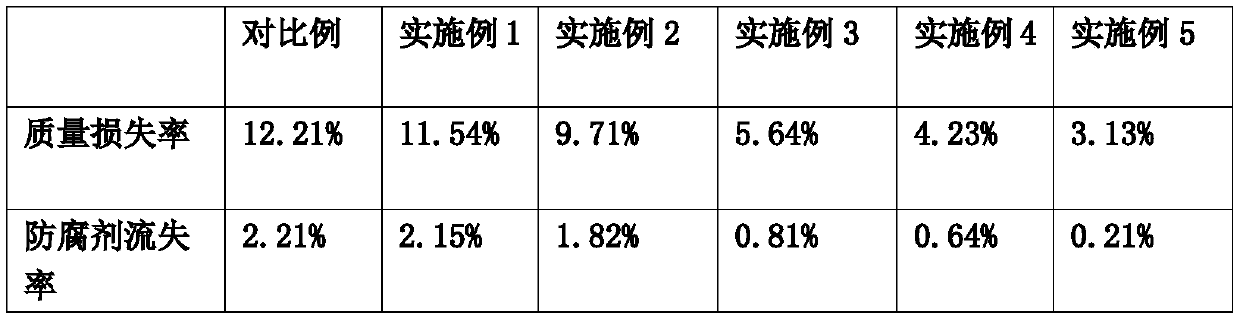

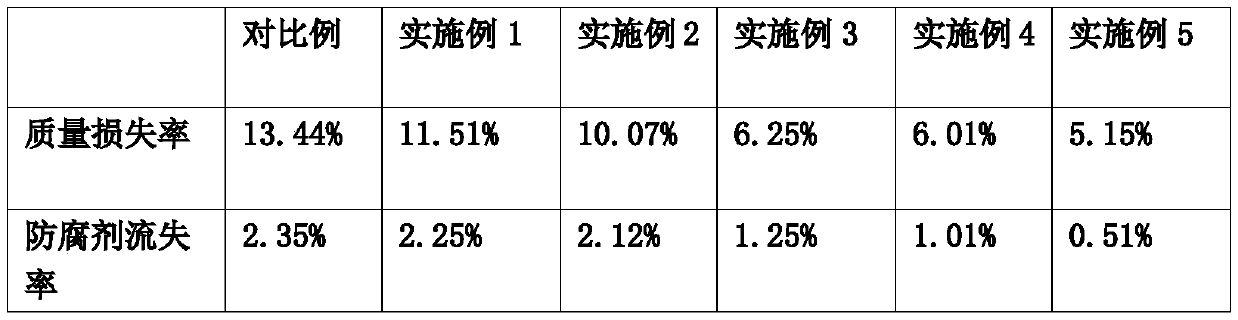

Manufacturing method of high-moisture-proof and high-density fiber board

ActiveCN101549519AIncrease the reasonable degree of polymerizationImprove waterproof performanceAldehyde/ketone condensation polymer adhesivesFlat articlesWaxHigh density

The invention provides a manufacturing method of high-moisture-proof and high-density fiber board, pertaining to the technical field of board manufacture. The method comprises the following steps: melamine-formaldehyde resin and urea resin are respectively prepared, and then the melamine-formaldehyde resin and the urea resin are mixed into a mixed glue before use; after lumber is chipped into wood chips, the wood chips are cooked and then prepared into wood fiber by defibrating of a defibrator, the mixed glue of the melamine-formaldehyde resin and the urea resin prepared before use, a solidified agent and wax waterproof agent are added to the wood fiber in the fiber ejecting pipe of the defibrator, the wood fiber is dried, paved and shaped, the pavement density is adjusted, and the wood fiber is pressed into board by a thermocompressor. The method is convenient and safe in operation and can respectively enhance the rational polymerization degree of the mixed glue and improve the waterproof property and glue-joint strength of the mixed glue and the stability during the use and storage period. The high-density fiber board prepared by the method is more applicable to a moist condition.

Owner:DONGYING ARTIFICIAL BOARD FACTORY

Manufacturing method of high density fiberboard for whitened type E1 grade floor substrate

InactiveCN102407553ASmall aspect ratioReduce cellulose contentWood working apparatusFlat articlesHexamethylenetetraminePhosphoric acid

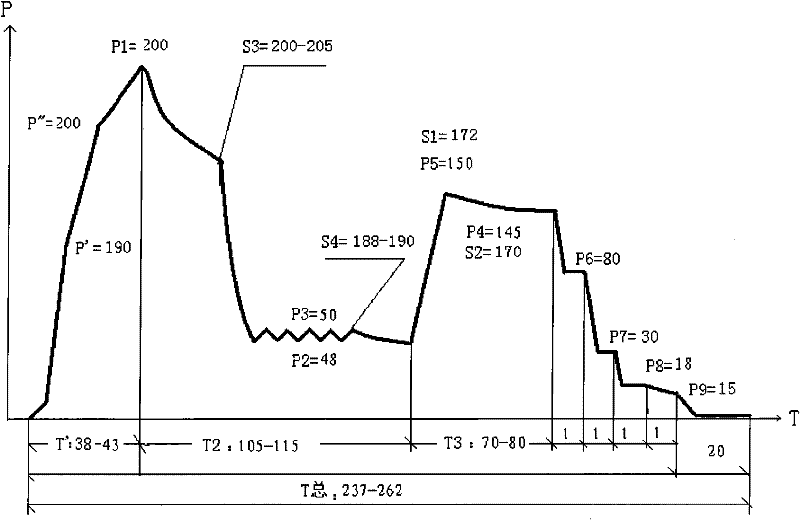

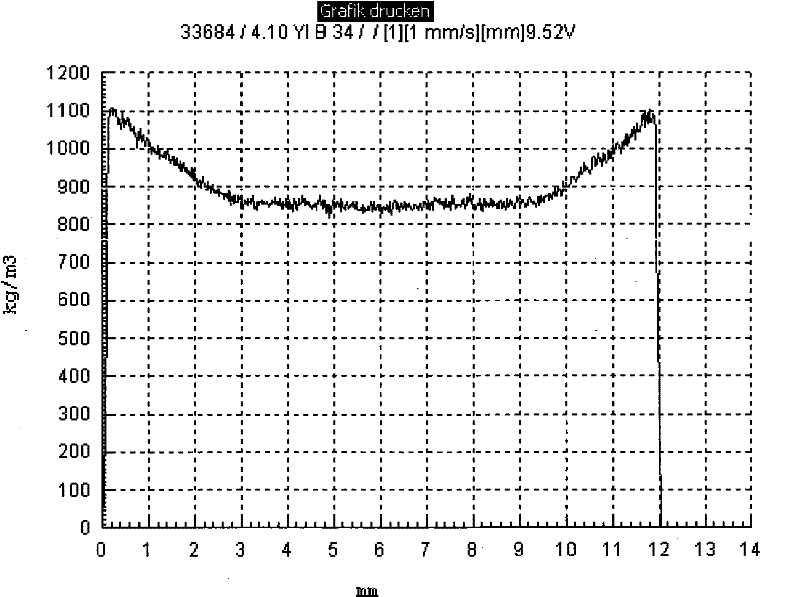

The invention relates to a manufacturing method of a high density fiberboard for a whitened type E1 grade floor substrate, which comprises the steps of wood chipping and screening, pre-stewing and stewing, defibrator process for causing fiber separation, concoction of E1 grade urea formaldehyde resin glue, curing agent preparation, the application of urea-formaldehyde glue, curing agents and paraffins, drying, paving, hot pressing, cooling and tempering, and sanding and saw cutting, and is characterized in that woods are selected from major diameter cottonwoods with diameters larger than 8cm, are evenly chipped and are then placed in an outdoor storage yard to be fermented for 5 to 15 days; in the concoction process of the E1 grade urea formaldehyde resin glue, urea is added at 5 times; and the curing agents are formed by preparing phosphoric acid accounting for 3 to 5 percent of the total content, urotropin accounting for 1 to 3 percent of the total content, triethanolamine accounting for 1 to 3 percent of the total content, and ammonium sulfate accounting for 19 to 21 percent of the total content. The obtained whitened type E1 grade floor substrate has the advantages of little surface impurity, fine and smooth fiber, white color, good visual effect, reasonable density distribution and moderate intensity, and is frequently used for producing top grade indoor laminate flooring and composite floors.

Owner:DARE TECH

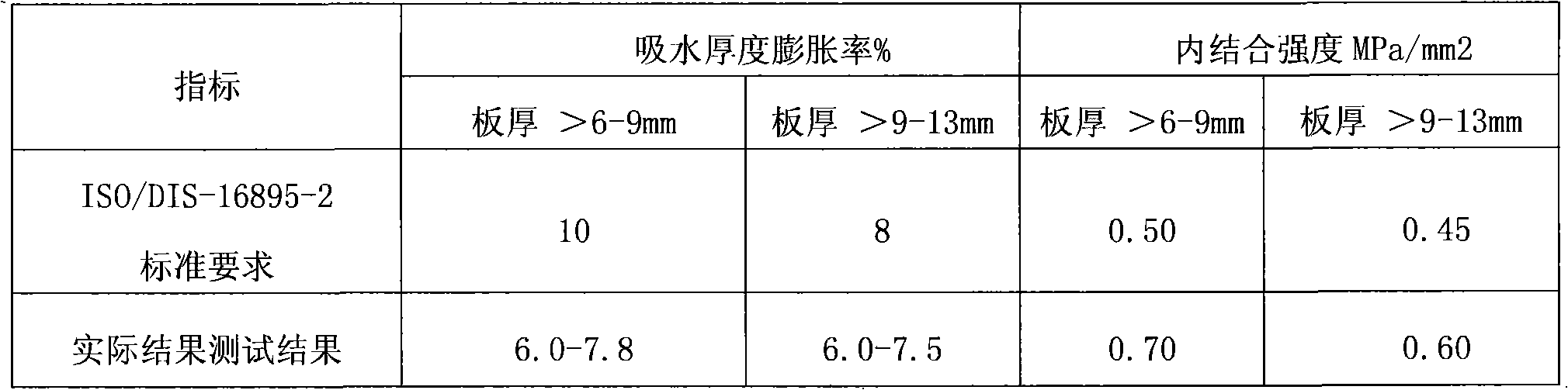

Manufacturing method of medium- and high-density flame-retardant fiber board

ActiveCN101549518AThe production method is easy to implementThe production method is implemented accuratelyDrying solid materials with heatDigestersDefibratorFire retardant

The invention provides a manufacturing method of medium-high-density flame-retardant fiber board, pertaining to the technical field of board manufacture. The method is as follows: lumber is chipped and cooked to be softened and then quantitatively controlled to enter a defibrator for rapid defibrating by a helical discharge control system, a flame retardant mixture consisting of the mixing solution of carbamide, low-polyphosphate and borate is sprayed into the defibrating room of the defibrator at the pressure higher than that of the defibrator so as to eject wood fiber after the wood fiber is mixed with the flame retardant mixture, melamine modified urea formaldehyde resin adhesive is added to the wood fiber in a fiber ejecting pipe of the defibrator, and the wood fiber ejected and mixed is pressed into board by a thermocompressor after being dried, paved and shaped. The method mixes the flame retardant and the wood fiber rapidly while defibrating fiber under the condition of high temperature, high humidity, high pressure and high speed. The flame retardant is coated evenly on the surface of wood fiber cells, and ensures a uniform flame retardant effect both at interior and exterior, thus leading to a best flame retardant effect of the wood fiber.

Owner:DONGYING ARTIFICIAL BOARD FACTORY

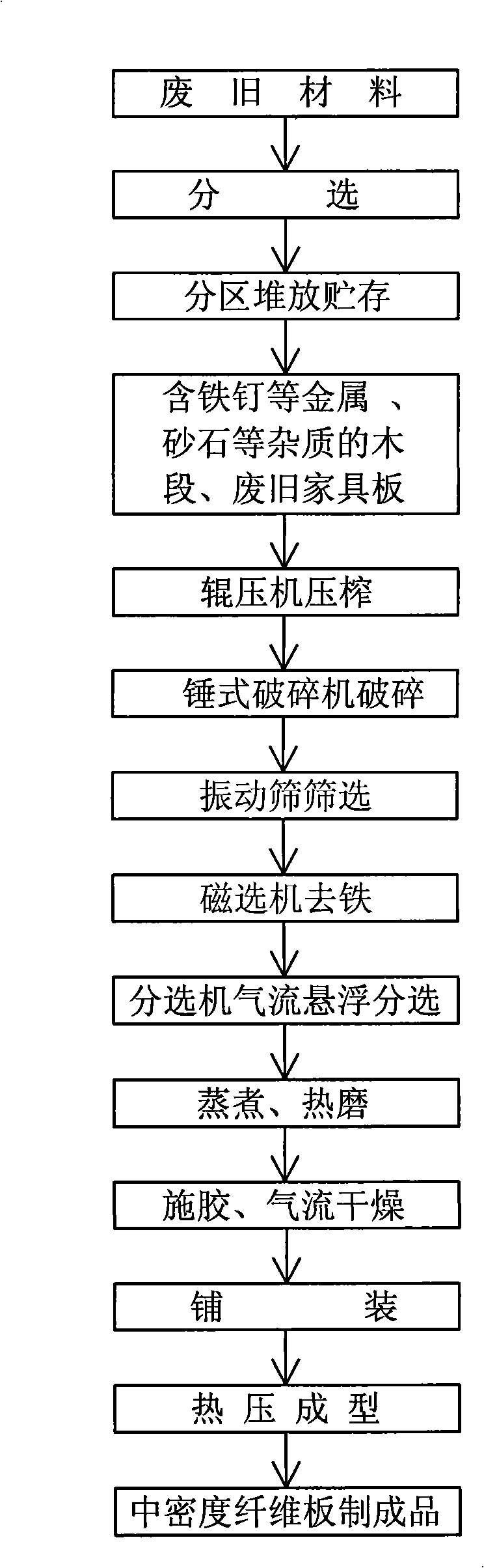

Production method of medium-density fiberboard using waste and old wood

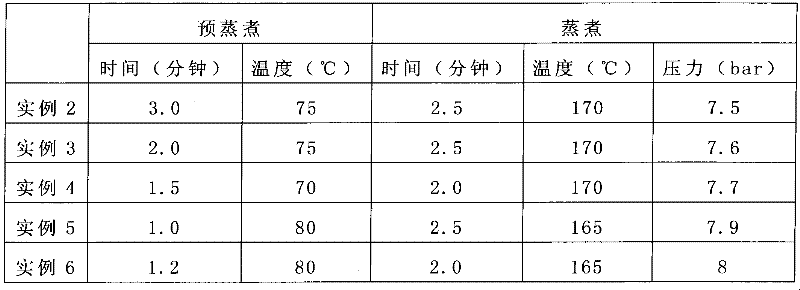

InactiveCN101357469AQuality assuranceLow impurity contentFlat articlesDomestic articlesSteam pressureEngineering

The invention relates to a method for producing medium density fibre boards by utilizing waste wood. The method comprises: waste materials are smashed, processed by steam stewing for softening in a stewing tank, then sent to the millstone cavity of a thermofiner for processing by defibrator process to be fibre-shaped wood pulp, the fibre-shaped wood pulp is in a discharge pulp pipe and sent to a tube-typed drier for carrying out airflow drying process by applying glue by a rubber pipe and relying on steam pressure, and then is sent into a pressing machine for hot press molding after being paved by a paver. The method is characterized in that: the waste materials are wood sections containing steel nails and waste furniture boards, the smashing process comprises: a rolling press is adopted for squeezing, kneading and cutting the waste materials, then the waste materials are impacted by a hammer-typed crusher, thus facilitating the wood materials to be crushed into debris and the impurities in the wood materials to be loose and the steel nails to be separated; the crushed materials are screened by a vibration screen for wiping off small sand, stones and dust impurities; iron type metal grains are wiped off in a magnetic separator, suspending and sorting relying on airflow are carried out in a sorter for wiping off the impurities such as sandstones and non-iron metals. By adopting the production method, the waste furniture and the wood sections containing steel nails can be utilized by removing impurity.

Owner:吉发

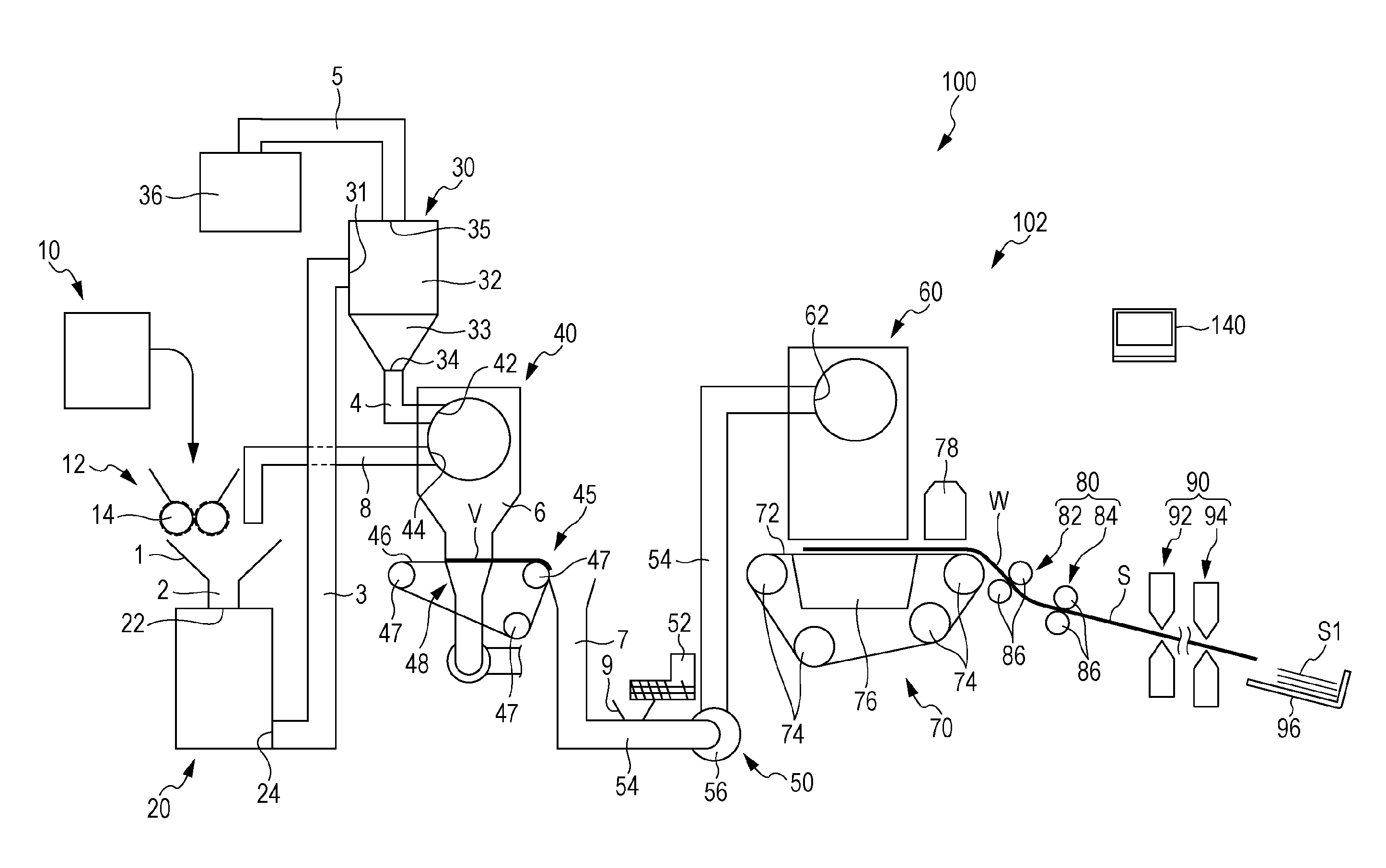

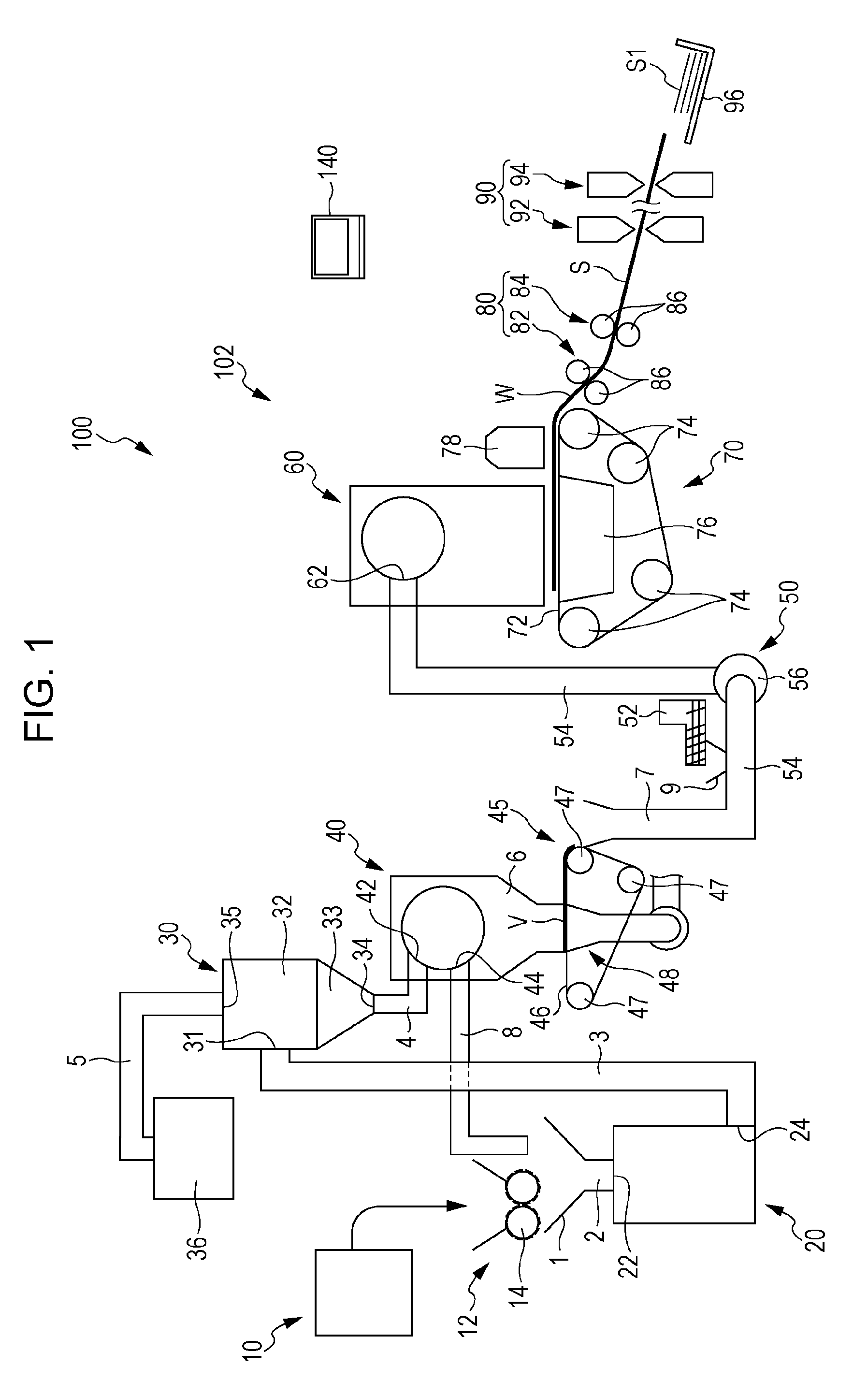

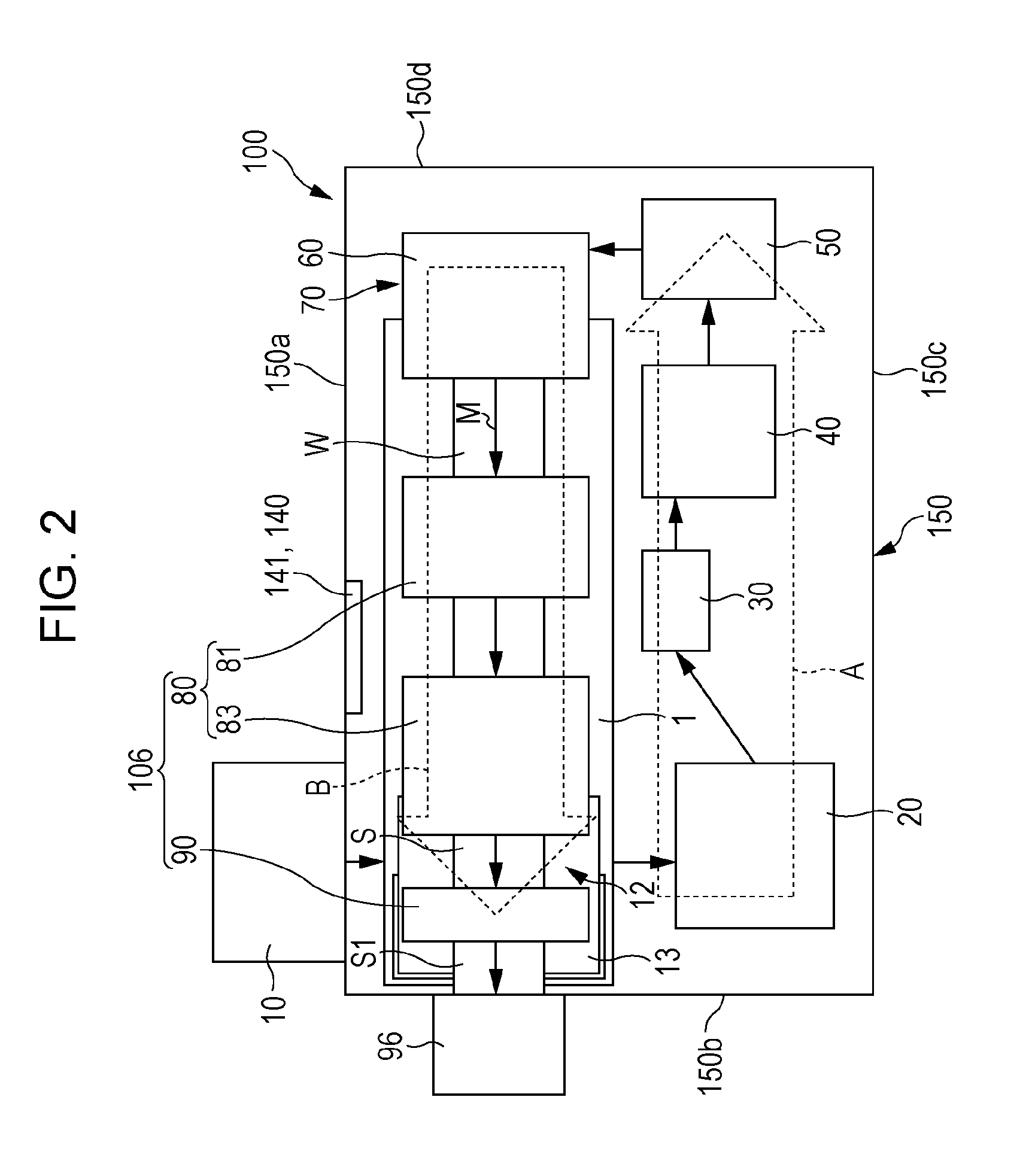

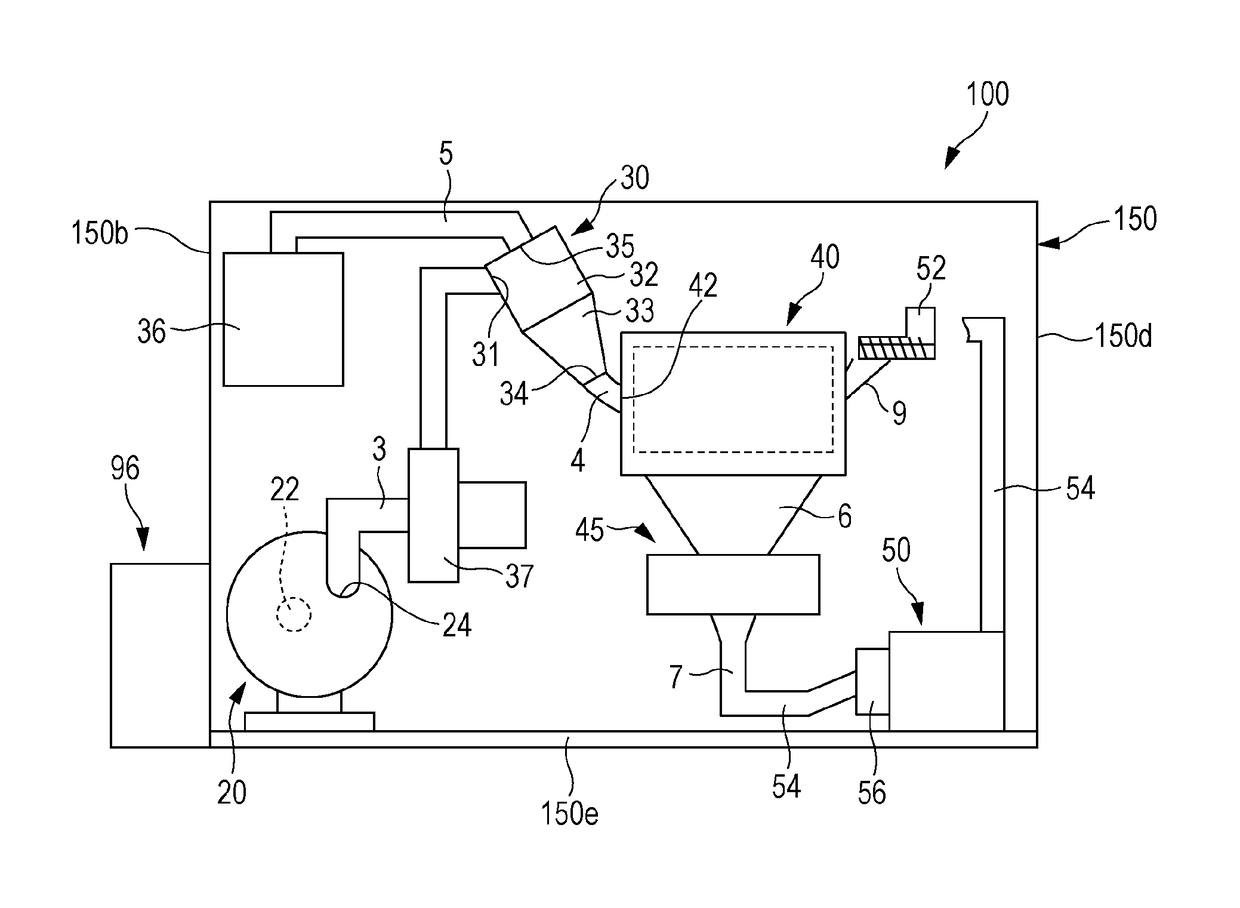

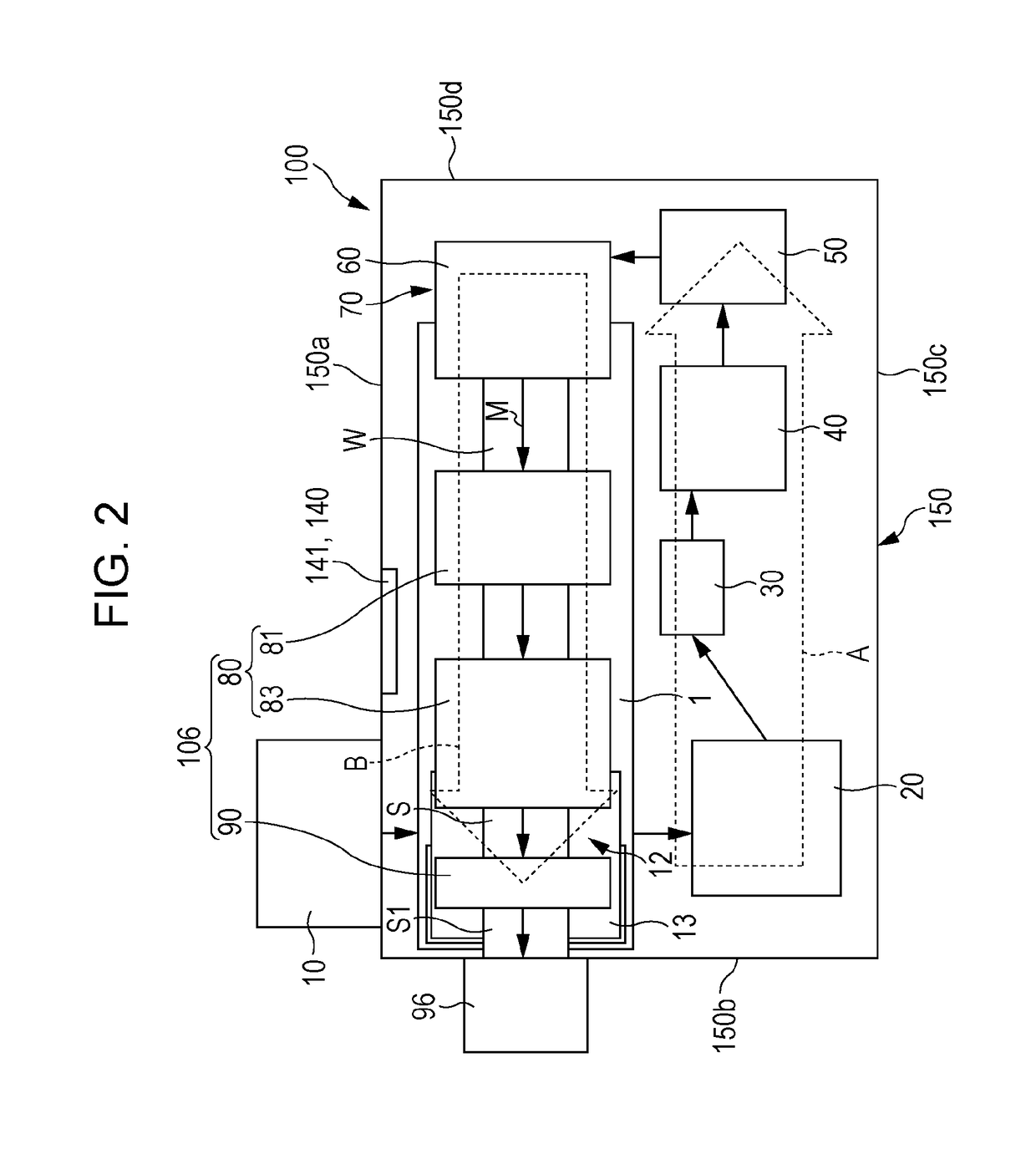

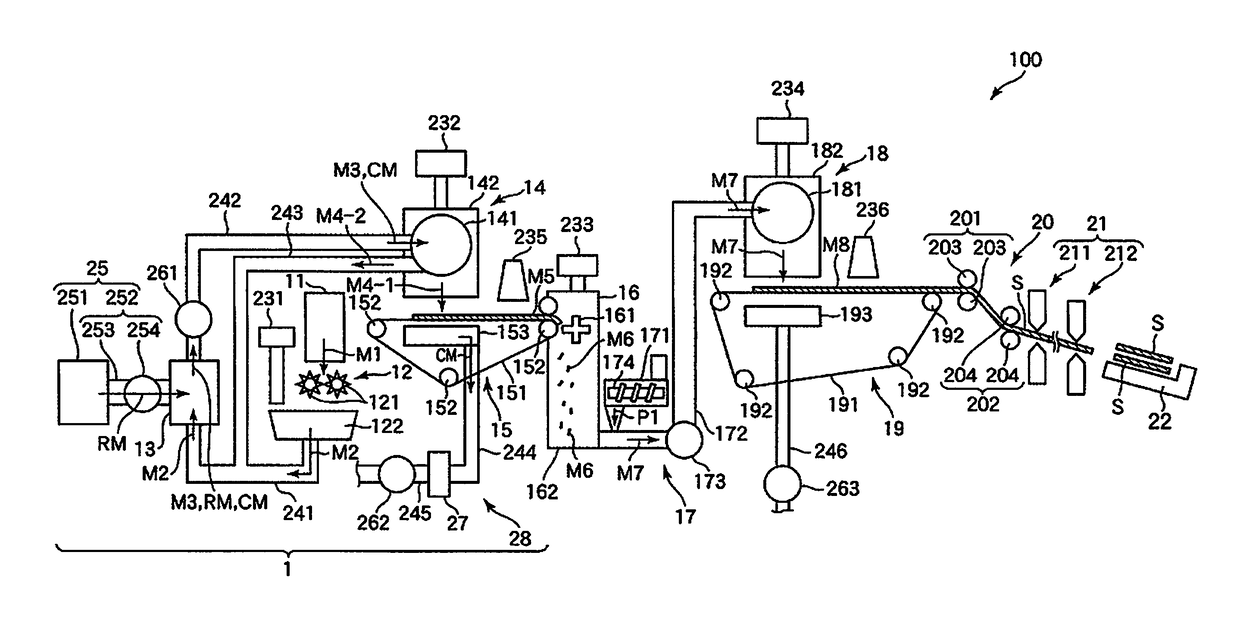

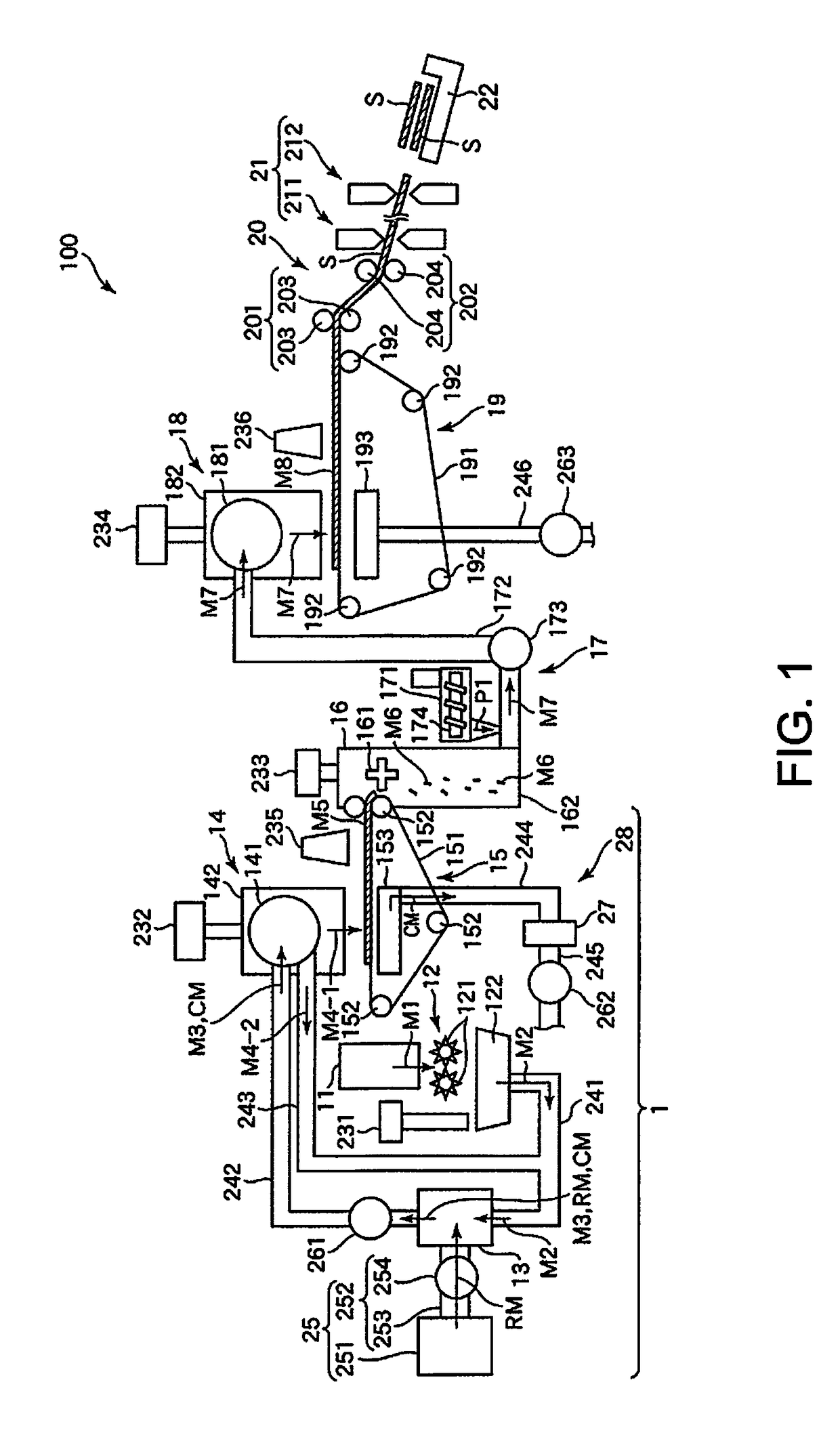

Sheet manufacturing apparatus

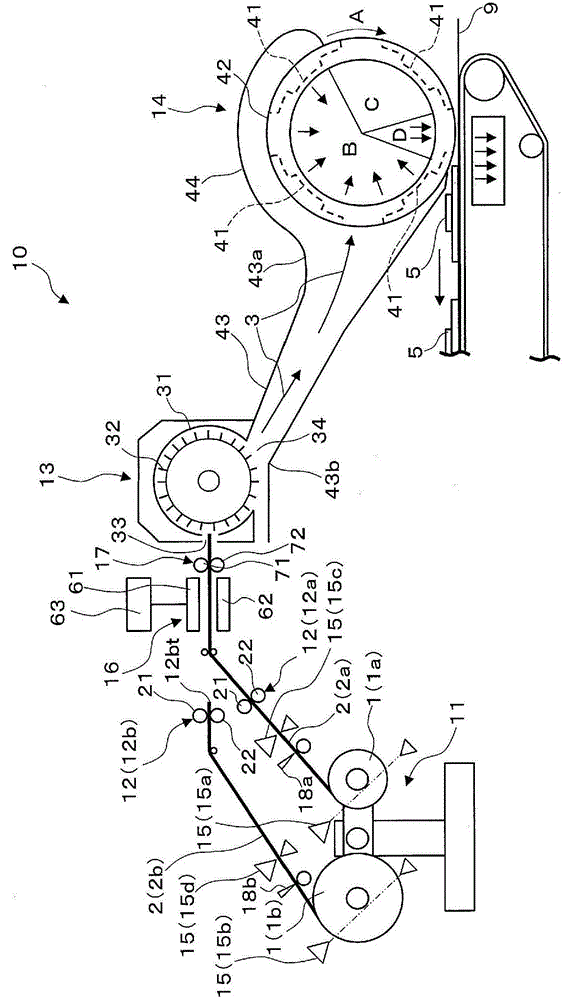

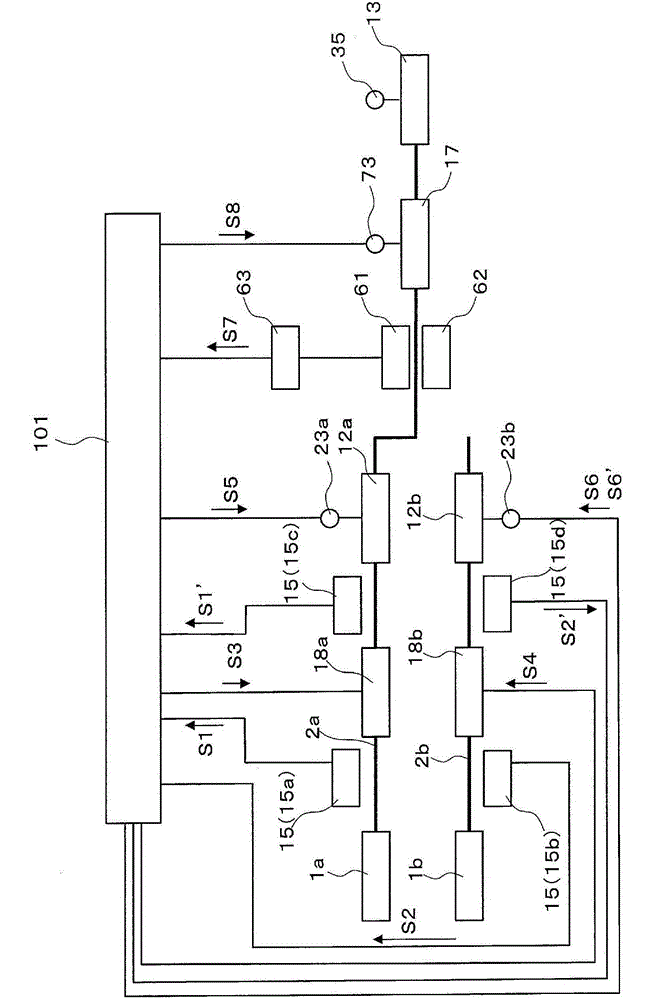

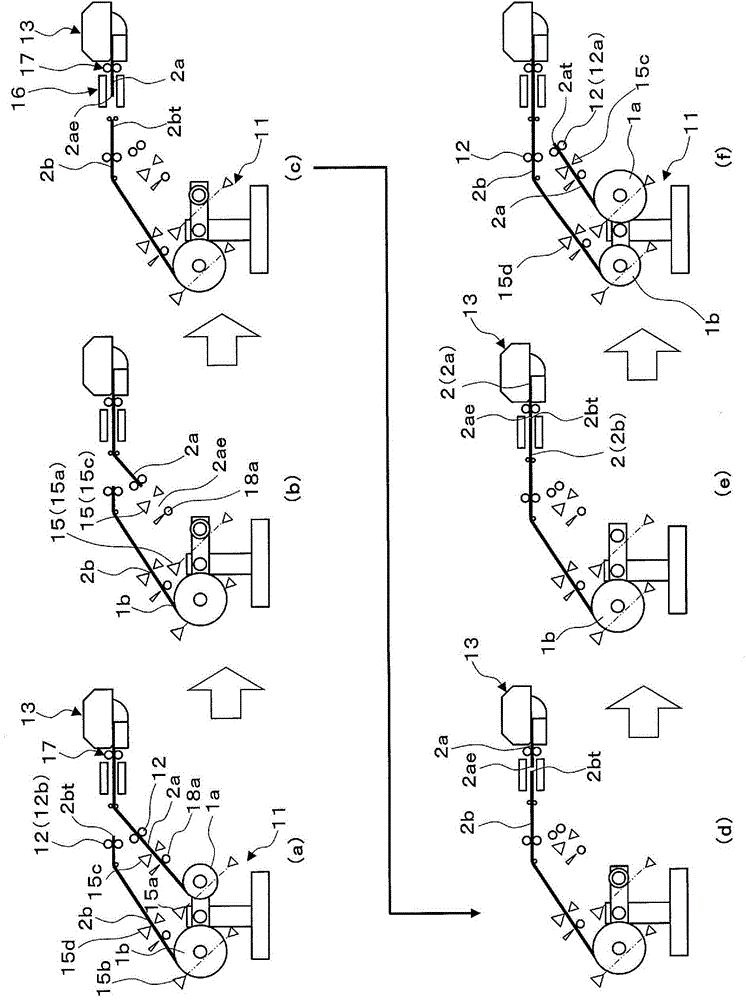

ActiveUS20160258112A1Increased ease of installationWasted spacePaper recyclingPress sectionManufactured apparatusCrusher

A sheet manufacturing apparatus includes a crusher unit, a defibrator unit, a second web forming unit, and a shaping unit. The crusher unit coarsely crushes a raw material that contains fibers into coarsely crushed pieces. The defibrator unit defibrates coarsely crushed pieces into defibrated material. The second web forming unit forms a web by accumulating defibrated material. The shaping unit forms a sheet from the web. The crusher unit is positioned vertically below the shaping unit.

Owner:SEIKO EPSON CORP

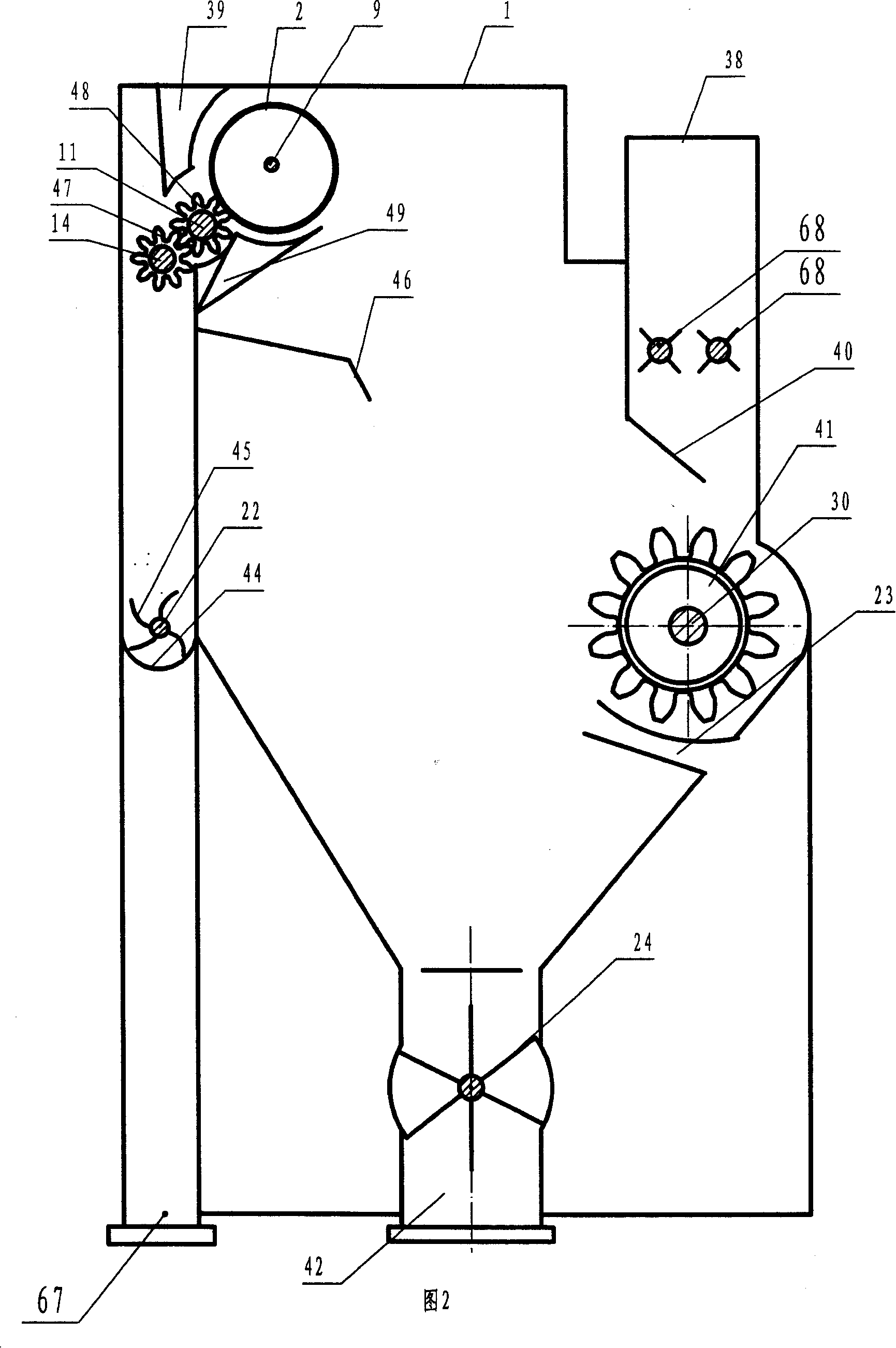

Seed cotton isomerism defibrator

InactiveCN101173370AIntegrity guaranteedEnsure comprehensivenessVegetable fibre separation from seedsFibre separationIsomerismsPulp and paper industry

The invention relates to a machine used for separating foreign fibre from seed cotton, which is characterized in that a plurality of winding rollers are arranged inside the intra-cavity under the inlet of the body and a guide plate is arranged on a longitudinal side of the winding rollers, a mass ejection roller is arranged under the outlet of the guide plate, and a makeup air port is arranged under the mass ejection roller; a net cage, a removing roller and a poking roller are arranged on the other side of the intra-cavity of the body, a wind screen and a wind limited plate are respectively arranged at the upper side and the lower side of the net cage and the removing roller, a back partition board is arranged under the wind limited plate, a screw conveyor and a screw conveyor groove are arranged under the poking roller, and a channel communicated with the foreign fibre outlet is arranged at the bottom of the screw conveyor groove; the lower part of the intra-cavity is funnel-shaped, and an airlock is arranged between the upper and lower ends of the lower outlet of the body. The invention has the advantages of significantly decreasing the textile cost, ensuring the continuity of scale production, sky-high running rate of equipments, consumedly reducing the human labor intensity, consumedly shortening the downtime, and significant rising of quality index of the produced lint cotton compared with other removing methods.

Owner:周义

Manufacturing process for bamboo and wood composite fiberboards

ActiveCN103586958AQuality improvementReduce manufacturing costWood working apparatusDomestic articlesParaffin oilsWoodchips

The invention discloses a manufacturing process for bamboo and wood composite fiberboards. The manufacturing process comprises the steps of material screening, cleaning, digesting, hot grinding, glue mixing and gluing, drying, pavement forming, hot pressing and cooling. In the wood chip selection process, the ratio of bamboos to woods is 1:3.5-1:4; in the digesting process, the digesting pressure is 7.3-7.7 bar, and the digesting time is 0.8-1.2min; in the hot grinding process, fiber separation is conducted on the digested wood chips through a defibrator, and fusion paraffin is added into the defibrator, wherein the paraffin applying amount is 4.0-4.5kg, and the defibrator power is 180-190kwh / t; in the glue mixing and gluing process, a tackiness agent and a curing agent are mixed for gluing, wherein the tackiness agent amount is 12-12.5%; in the drying process, the moisture content of dried fiberboards is 10-11%. The bamboo and wood composite fiberboards manufactured based on the manufacturing process for the bamboo and wood composite fiberboards are stable in quality, and the fiberboard performance can meet performance requirements of pure wood fiber boards; in addition, due to the fact that bamboo woods are cheaper than woods, production cost can be greatly reduced, and production effectiveness is improved.

Owner:大亚木业(肇庆)有限公司 +1

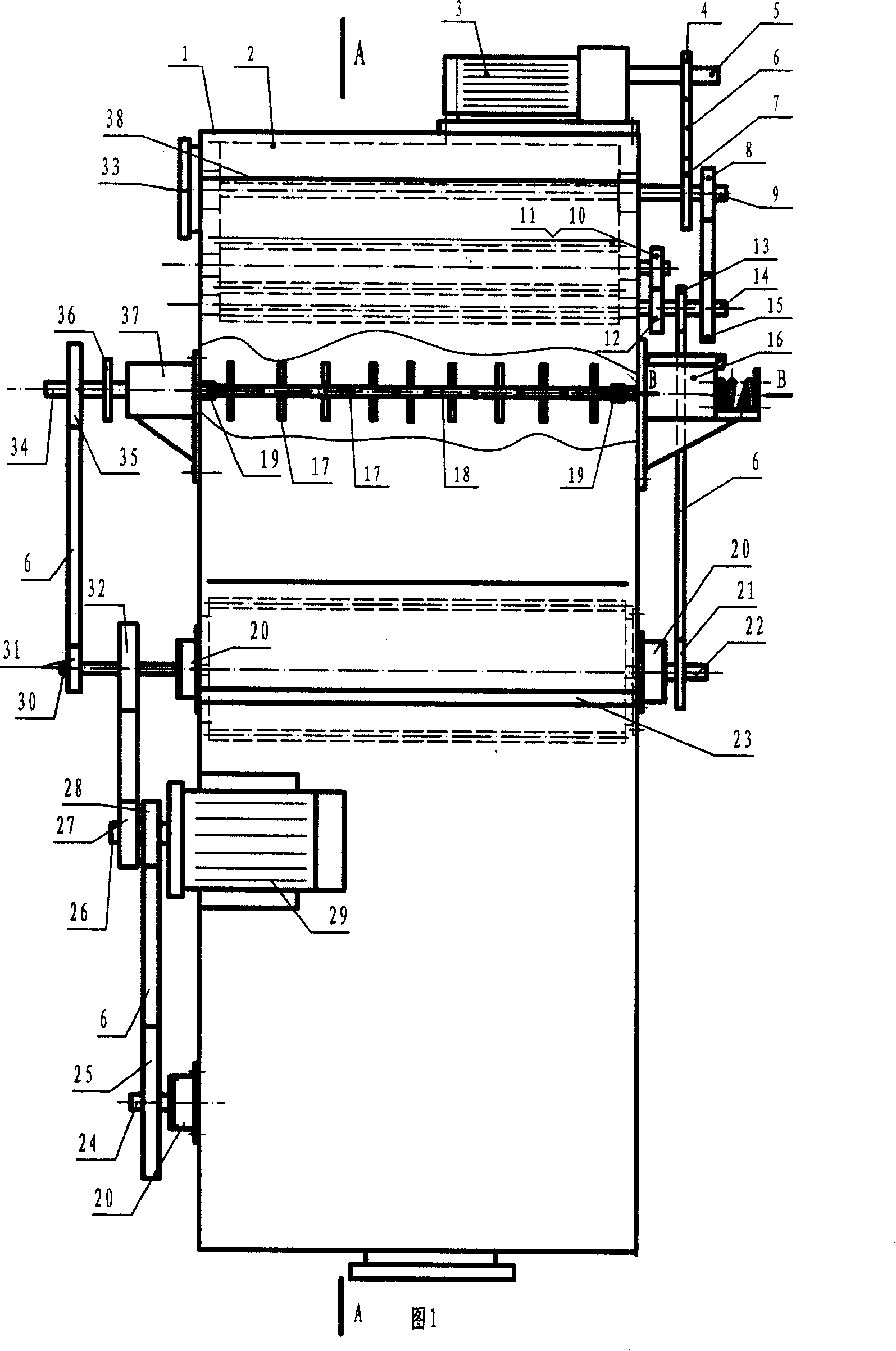

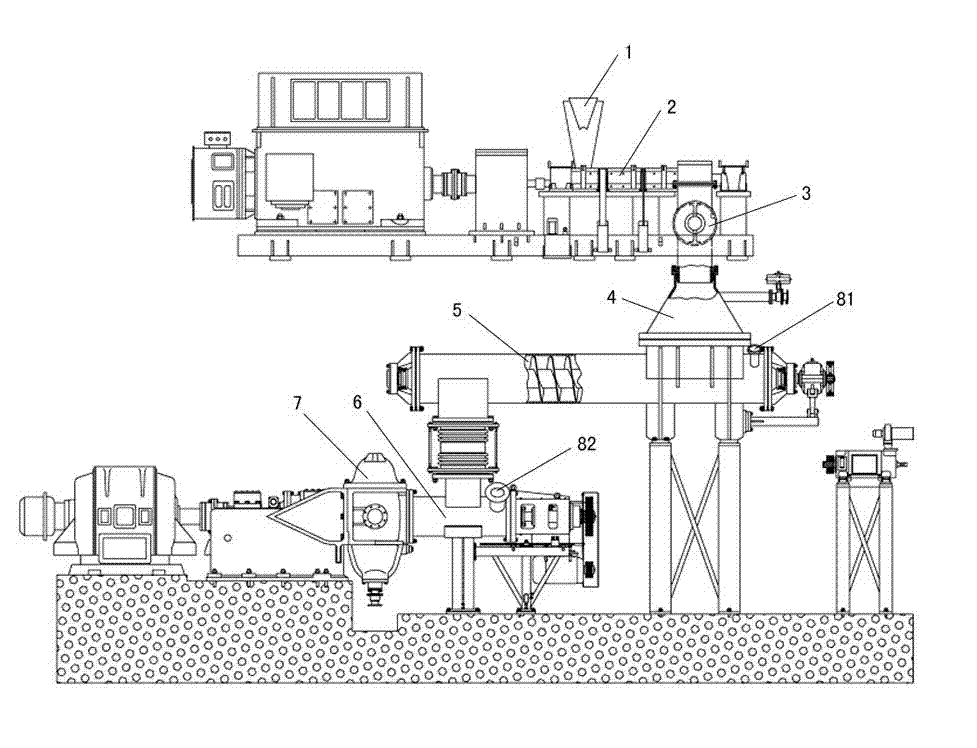

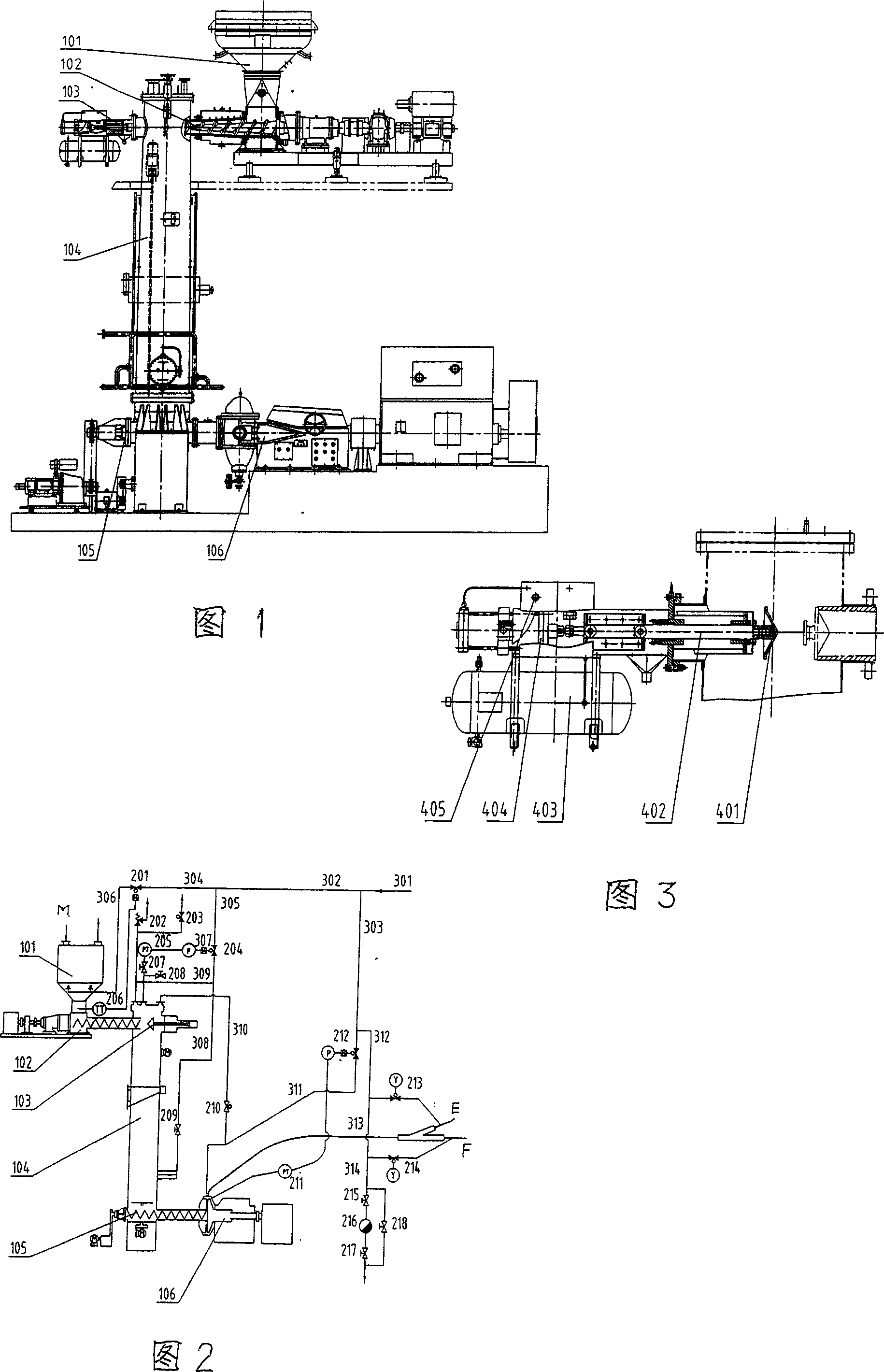

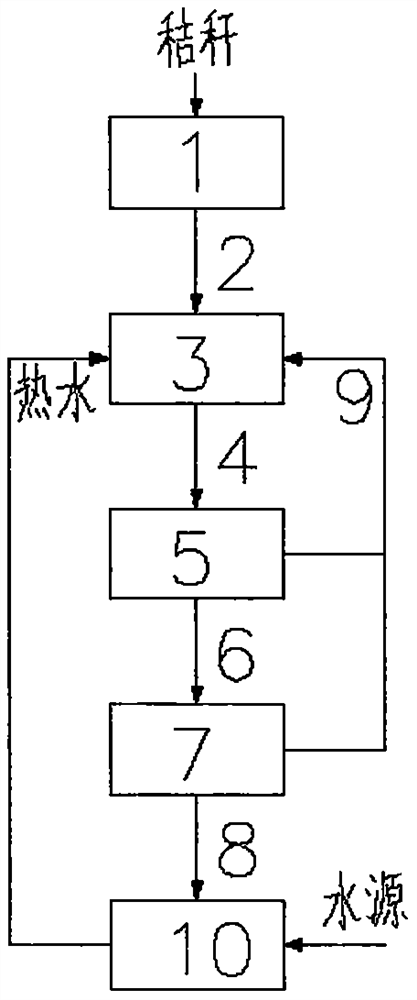

Defibrator system and defibrination method thereof

InactiveCN103088684AIncrease profitIncrease production capacityFibrous raw materialsPulp beating/refining methodsControl systemWood fibre

The invention provides a defibrator system and a defibrination method of the defibrator system, wherein the defibrator system comprises a feed hopper and a defibrator. The feed hopper is longitudinally arranged on the front end of a twin-screw extruder, a back-jet resisting device, a vertical drop hopper, a horizontal preheat tank with screw conveying, a belted screw feeder and the defibrator are sequentially arranged on the rear end of the twin-screw extruder, and steam balance control systems are arranged on inlet and outlet of the horizontal preheat tank. The defibrination method of the defibrator system comprises the following steps: feeding wood chips of a certain specification into the longitudinally arranged feed hopper; conducting primary dissociation and conquassation on the wood chips through dynamic extrusion of the twin-screw extruder; feeding the conquassated wood chips into the vertical drop hopper; conducting precooking on the conquassated wood chips dropping into the horizontal preheat tank by self-weight at temperature from 110 to 130 degrees centigrade in the horizontal preheat tank; feeding the precooked conquassated wood chips into the defibrator by the belted screw feeder through the screw conveying of the horizontal preheat tank; and forming wood fiber with high physical property after defibration of the defibrator. The defibrator system and the defibrination method of the defibrator system are high in using raw materials and capable of improving capacity by at least 50 percents.

Owner:JIEYA TECH KUNSHAN CO LTD

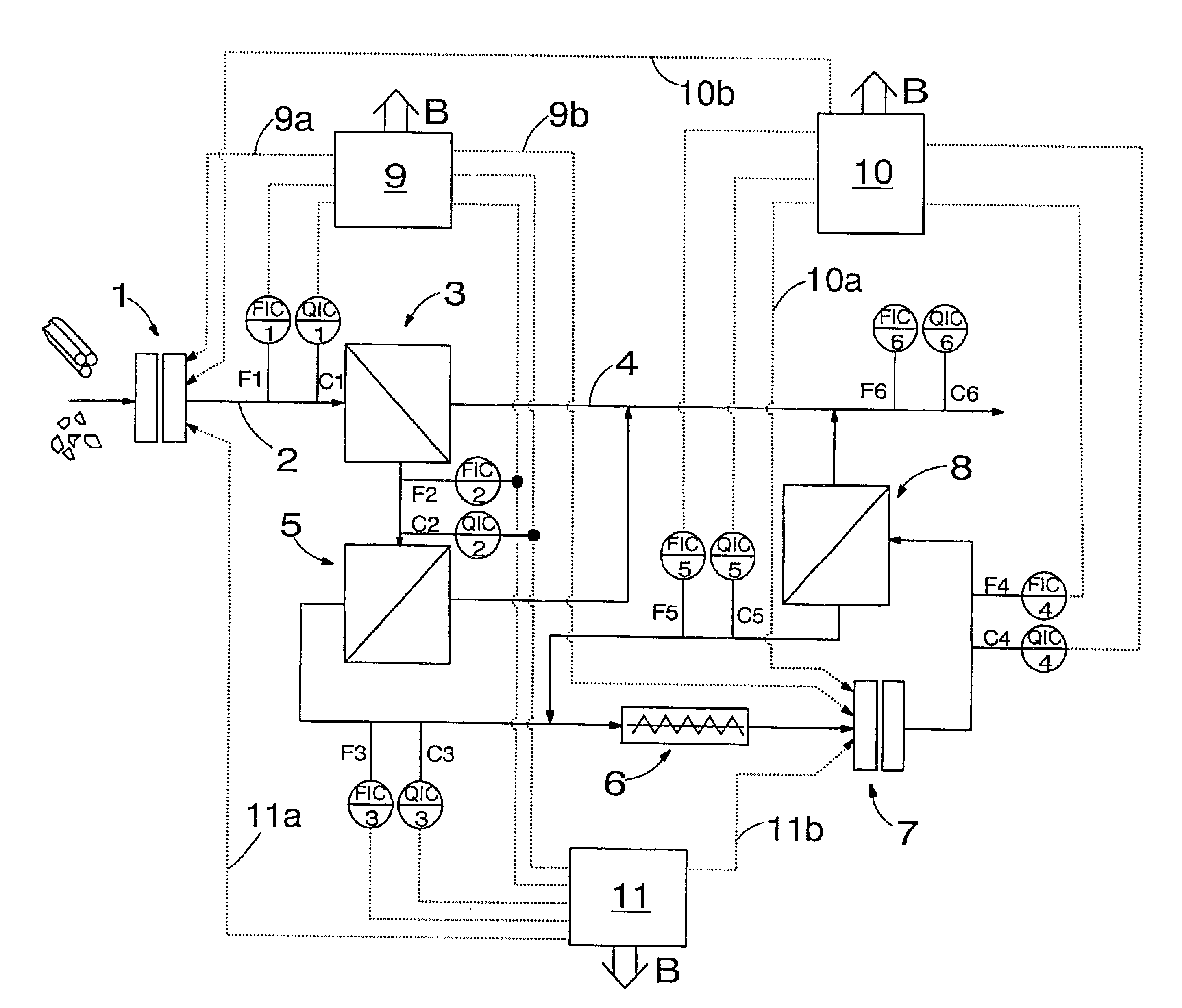

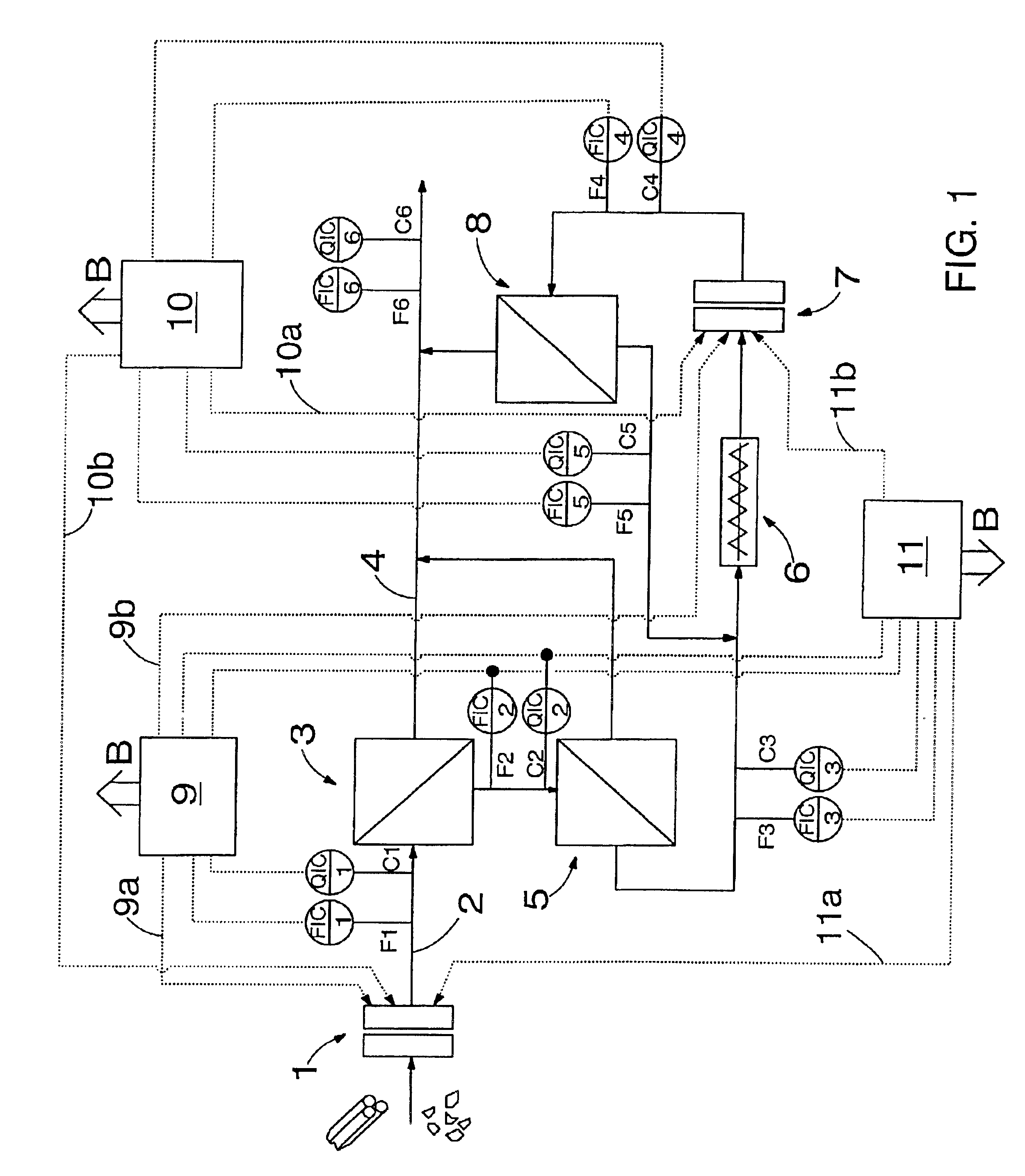

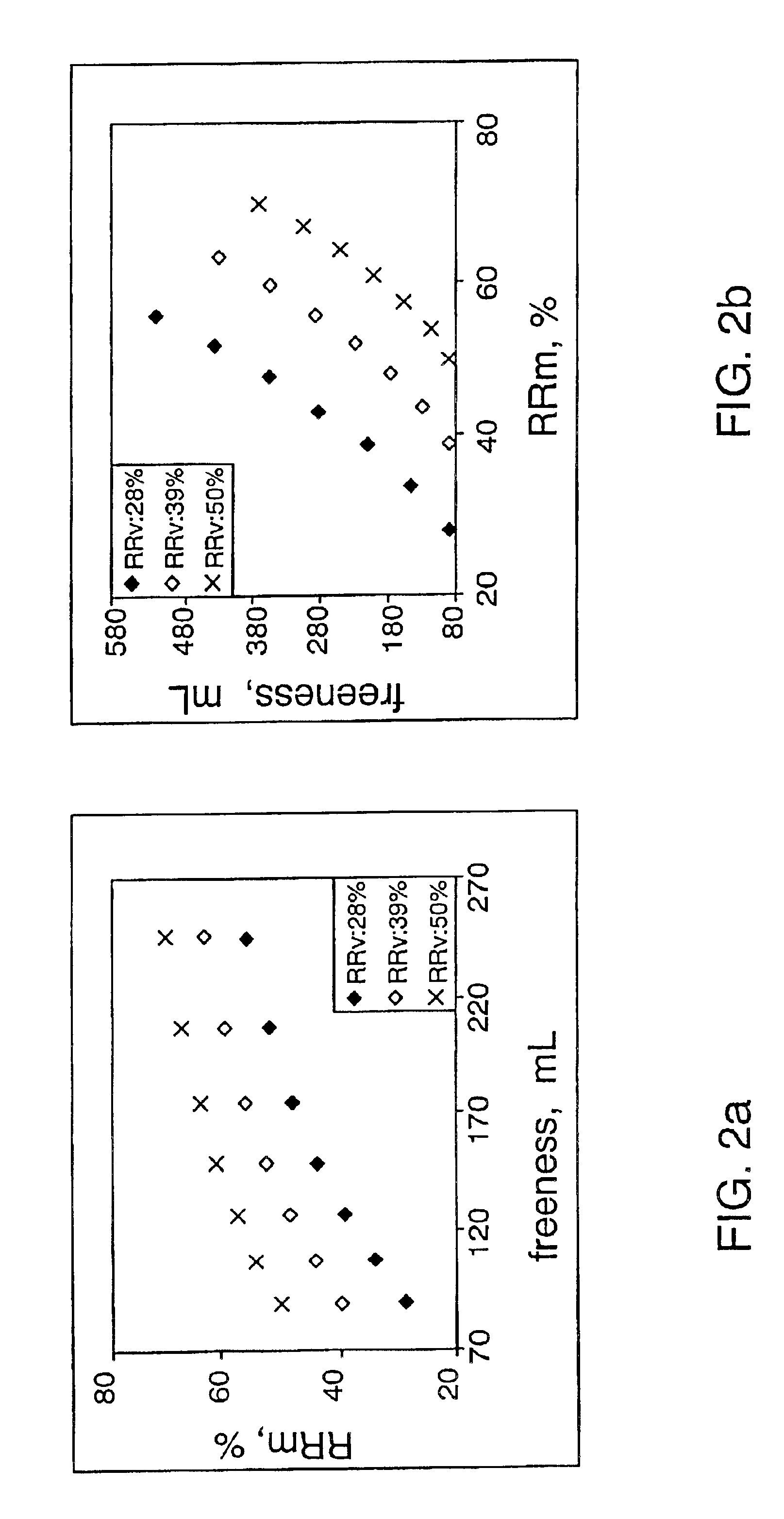

Method for controlling quality of pulp

InactiveUS6846381B2Quality improvementBeating/refining control devicesFats/resins/pitch/waxes removal in pulpWaste productPulp and paper industry

A method for controlling the quality of pulp. Pulp produced by mechanical defibering of wood is screened to provide at least two fractions, of which the accept that has passed the screening phase is carried forward for use and the reject that has not passed the screening is removed from the screening phase. The consistency of the reject that is to be removed from the screening is measured and the consistency value thus obtained is used for controlling the defibrator to adjust the quality of the accept.

Owner:VALMET TECH INC

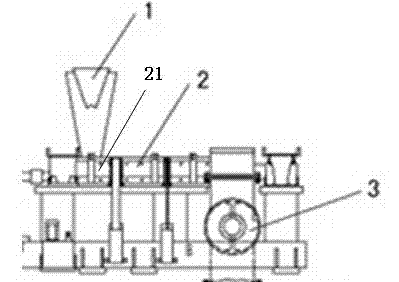

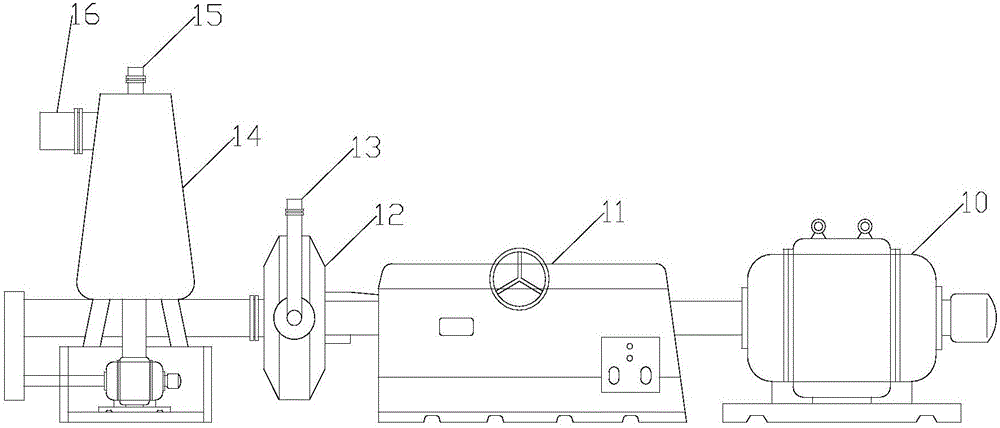

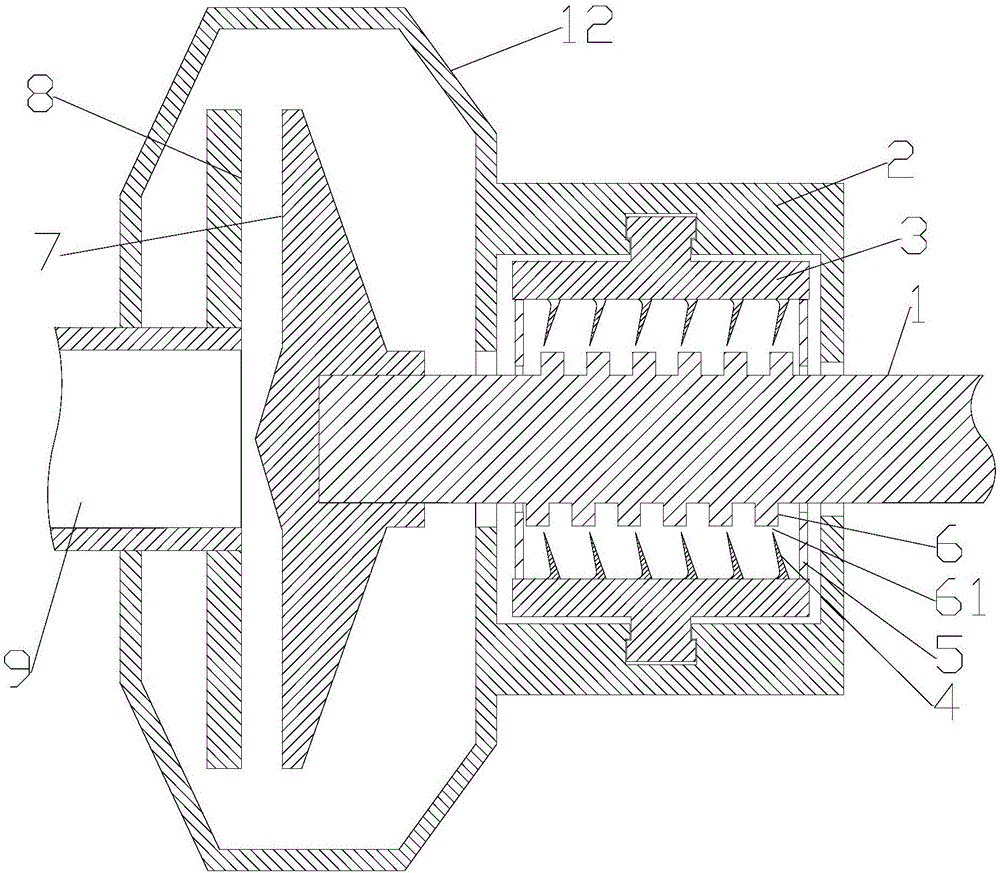

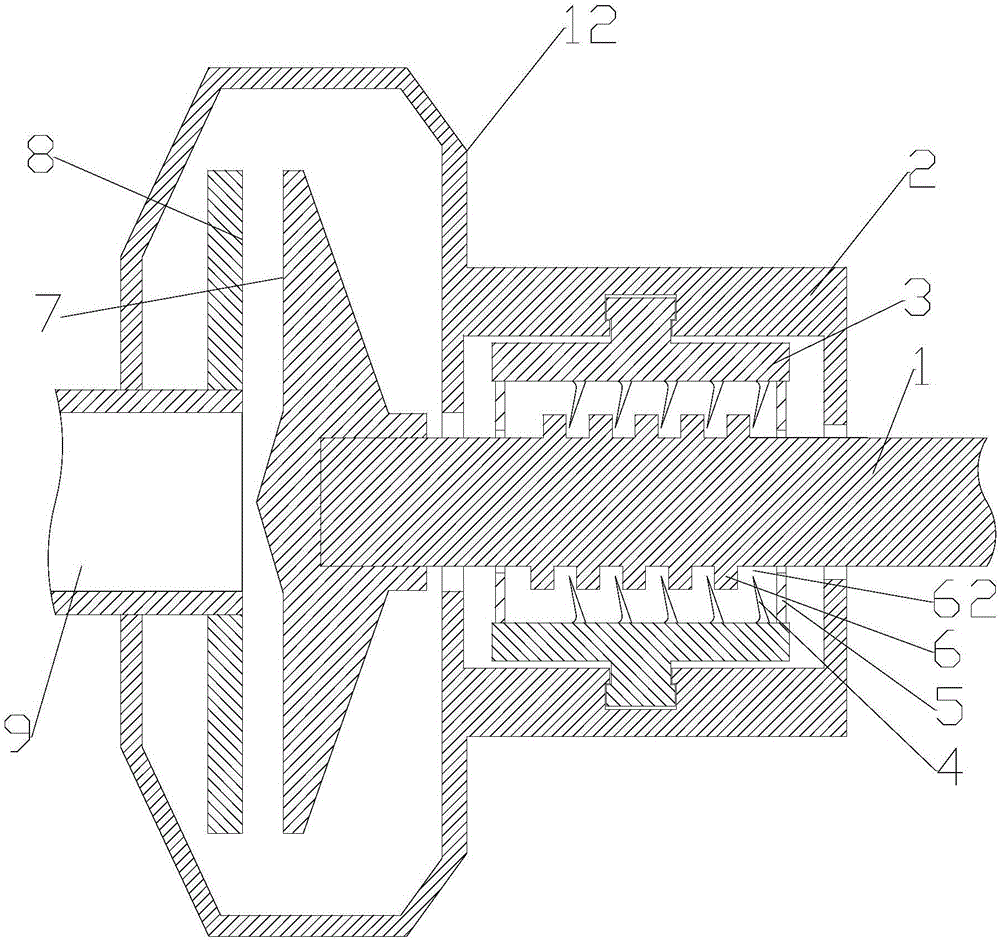

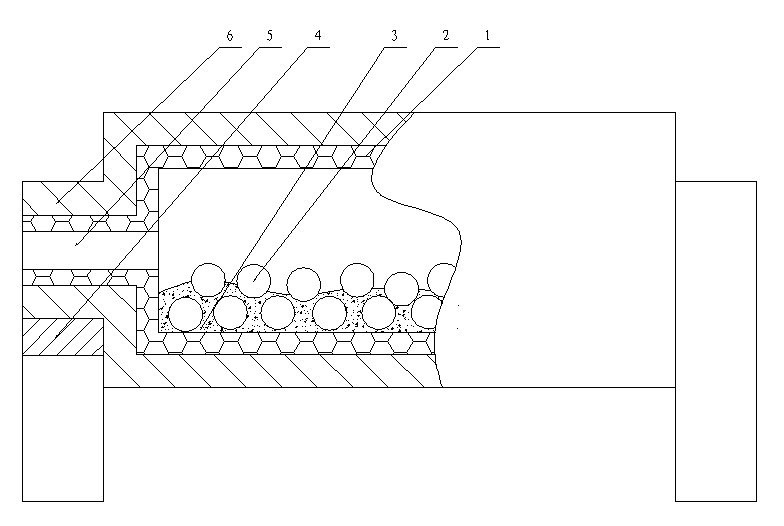

Papermaking defibrator

InactiveCN106400569AStop the leakReduce leakageEngine sealsPulp beating/refining methodsPapermakingDefibrator

The invention relates to the technical field of papermaking equipment, and particularly relates to a papermaking defibrator. The papermaking defibrator comprises a motor, a control part, a grinding device, a discharge device, a preheating and cooking device, a steam pipe and a feeder, wherein the grinding device comprises a grinding head and a sealing mechanism; the grinding head comprises a shell, and a static abrasive disc and a movable abrasive disc which is correspondingly matched with the static abrasive disc are installed in the shell; the static abrasive disc is fixed to the shell by a feed pipe; the sealing mechanism comprises a steam seal ring which is installed on the shell and thread teeth which are installed on a grinding shaft, the grinding shaft penetrates through the steam seal ring, one end of the grinding shaft extends into the shell, and the end of the grinding shaft is connected with the movable abrasive disc; the steam seal ring sleeves the thread teeth and corresponds to the thread teeth. The invention aims to provide the papermaking defibrator, which solves the problems of poor sealing effect and easiness in damage to the grinding shaft of an existing papermaking defibrator.

Owner:怀宁县天元纸业有限公司

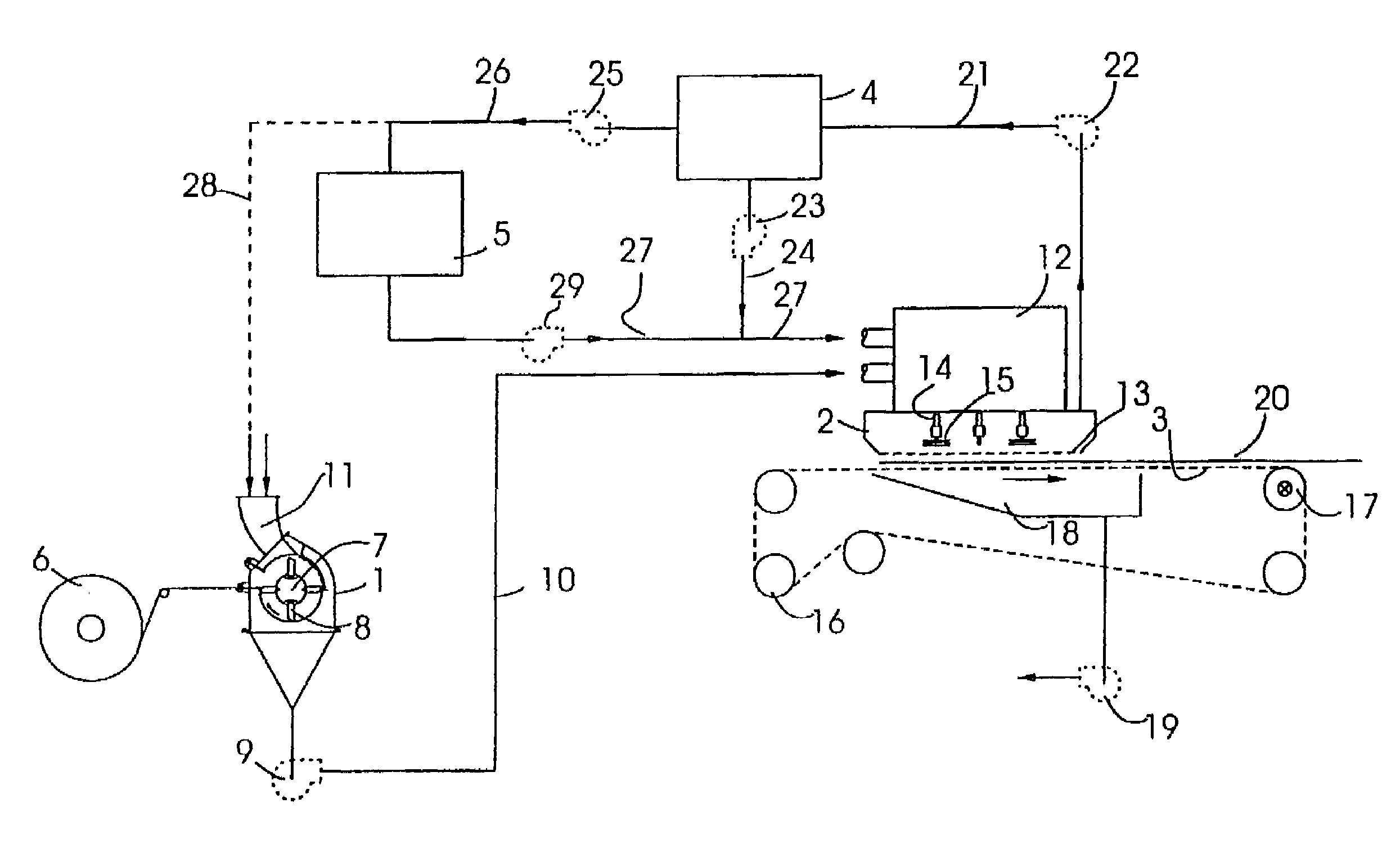

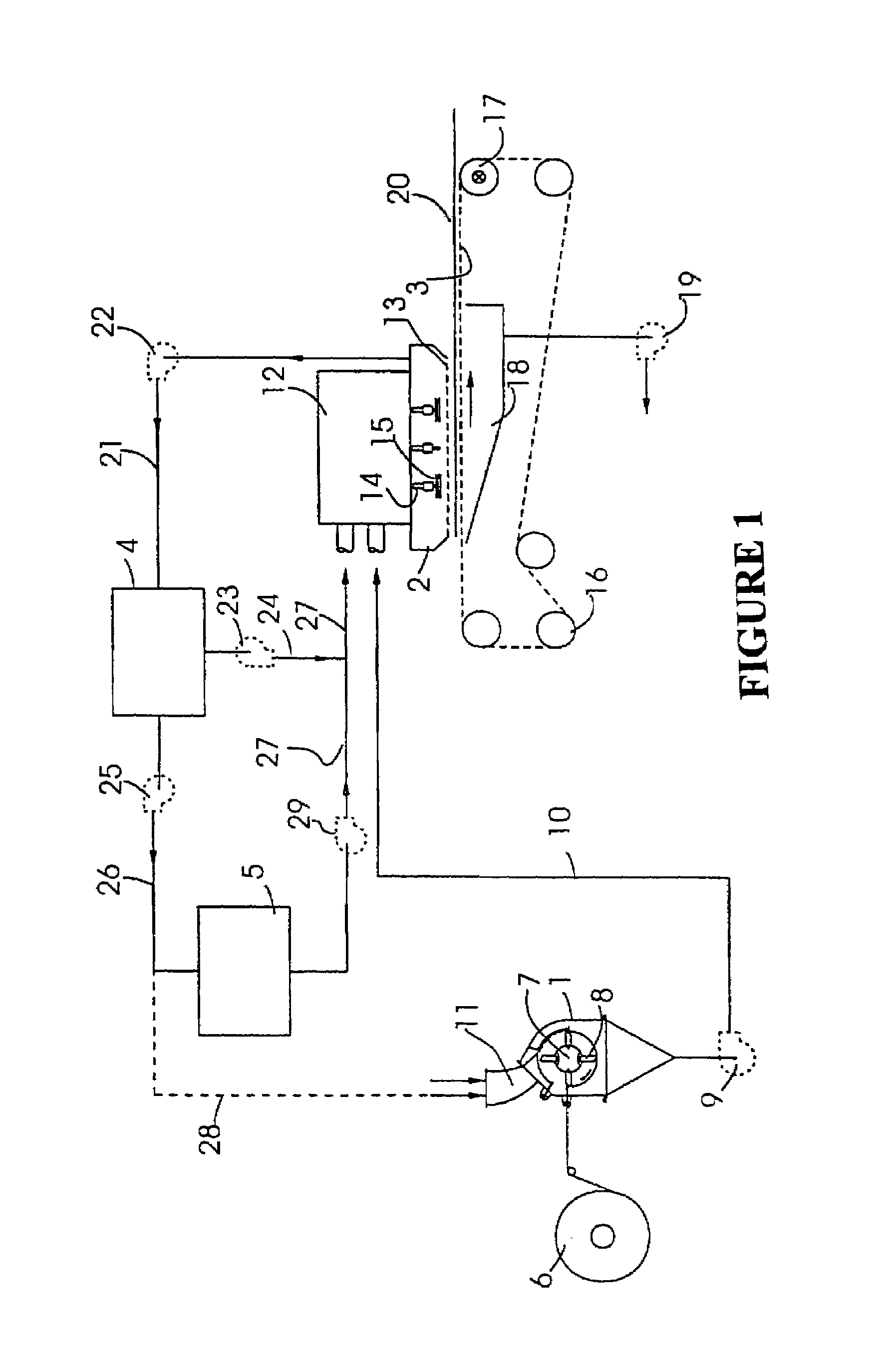

Nits separator

InactiveUS7134859B1Reduce energy consumptionWood working apparatusCeramic shaping apparatusEngineeringCellulose pulp

A plant which serves to produce a nonwoven web of fibers out of a fibrous material, such a cellulose pulp. The plant comprises a hammer mill for defibrating the fibrous material and a forming head for forming a web of fibers on an endless forming wire, which, during operation, runs mainly horizontally, a first transport fan for transporting defibrated fiber to the forming head via a first air duct and a second transport fan to extract nits from the forming head via a second air duct. Furthermore, the plant comprises a separator, which is connected to the second air duct and arranged for separating the nits and the well-opened fiber, a third transport fan for returning the separated, well-opened fibers to the forming head, and a nits-opener for converting the separated nits into well-opened fiber. The separated nits are transported from the nits separator to the nits-opener by means of a fourth transport fan via a fourth air duct. The defibrated fibers are returned to the forming head by means of a fifth transport fan via a fifth air duct. The plant is easy to control and is capable of producing optimally high quality fiber products. In addition, the plant allows the defibrator to defibrate new fiber material at full capacity so that the remainder of the plant is able to produce at an optimum output level. The plant is furthermore very energy-saving.

Owner:OERLIKON TEXTILE GMBH & CO KG

Sheet manufacturing apparatus

ActiveUS10100466B2Increased ease of installationWasted spacePaper recyclingPress sectionManufactured apparatusEngineering

Owner:SEIKO EPSON CORP

Straw fiber board manufacturing method and liquid ball mill with plastic lining boards

InactiveCN102431071ASmall grinding forceReduce contentDomestic articlesFlat articlesHydrofluoric acidHydrogen

The invention discloses a straw fiber board manufacturing method. The straw fiber board manufacturing method includes that 1, straws are cut into sections with lengths ranging from 5mm to 15mm, 2, the straws are inputted into a liquid ball mill with plastic lining boards, water is filled in the liquid ball mill, hydrofluoric acid is added into the liquid ball mill, after grinding, a pH (potential of hydrogen) value ranges from 5 to 6, the pH value is changed to range from 6 to 7 by means of washing, and then centrifugal separation is carried out, 3, straw blocks are subject to defibrator process in a defibrator so that straw fibers are produced, 4, the straw fibers are conveyed to a sizing system to realize sizing and then are dried, and 5, the straw fibers are in hot-pressing, edging and sanding after being laid, so that straw fiber boards are produced. By the aid of acidifying processing of the straws, the hydrofluoric acid is immersed into cells, SiO2 is further dissolved, SiO2 content in the straw fibers is greatly reduced, an adhesion performance of the straw fibers is improved, and the strength of the straw fiber boards is further increased. The straws are ground by the liquid ball mill with the plastic fining boards, particles are uniform after the straws are ground, a lining of a bin of the liquid ball mill with the plastic lining boards is an abrasion-resistant plastic layer, an outer layer of a grinding ball is an abrasion-resistant plastic layer, and the inner wall of the liquid ball mill cannot be corroded.

Owner:张文生

Method for producing medium-density fiberboard through branches and trunk of ricinus communis and stalks of miscanthus

ActiveCN104179054APromote incomePromote employmentFibrous raw materialsDomestic articlesRicinus sanguineusPolymer science

The invention provides a method for producing a medium-density fiberboard through branches and trunk of ricinus communis and stalks of miscanthus. The method comprises the following steps: 1, after the branches and trunk of ricinus communis and stalks of miscanthus are mixed, cutting the mixture into pieces; 2, humidifying and preheating the pieces, and performing fiber separation through a defibrator; 3, applying urea resin, an ammonium chloride curing agent and a paraffin waterproofing agent after fiber mixing, and uniformly mixing; 4, drying the fiber mixture; 5, screening the dried fibers, and manufacturing the fiber rough board through hot pressing of a hot press; 6, cooling the rough board, cutting edges and sanding, so as to obtain the finished product medium-density fiberboard. The medium-density fiberboard manufactured through the method provided by the invention is smooth in surface, uniform in fiber texture, moderate in density, good in dimensional stability, good in machining performance, high in bonding strength, static bending strength and plane tensile strength, good in elastic modulus, strong in bolt holding force, and low in moisture absorption and water absorption performance. According to the method, the branches and trunk of ricinus communis and stalks of miscanthus are used to produce the fiberboard, that branches and trunk of ricinus communis are cut down in successive years for updating is achieved and the forest fire caused by stalks of miscanthus is eliminated, and the method is suitable for areas, where ricinus communis and miscanthus grow.

Owner:亚丹生态家居(荆门)有限公司

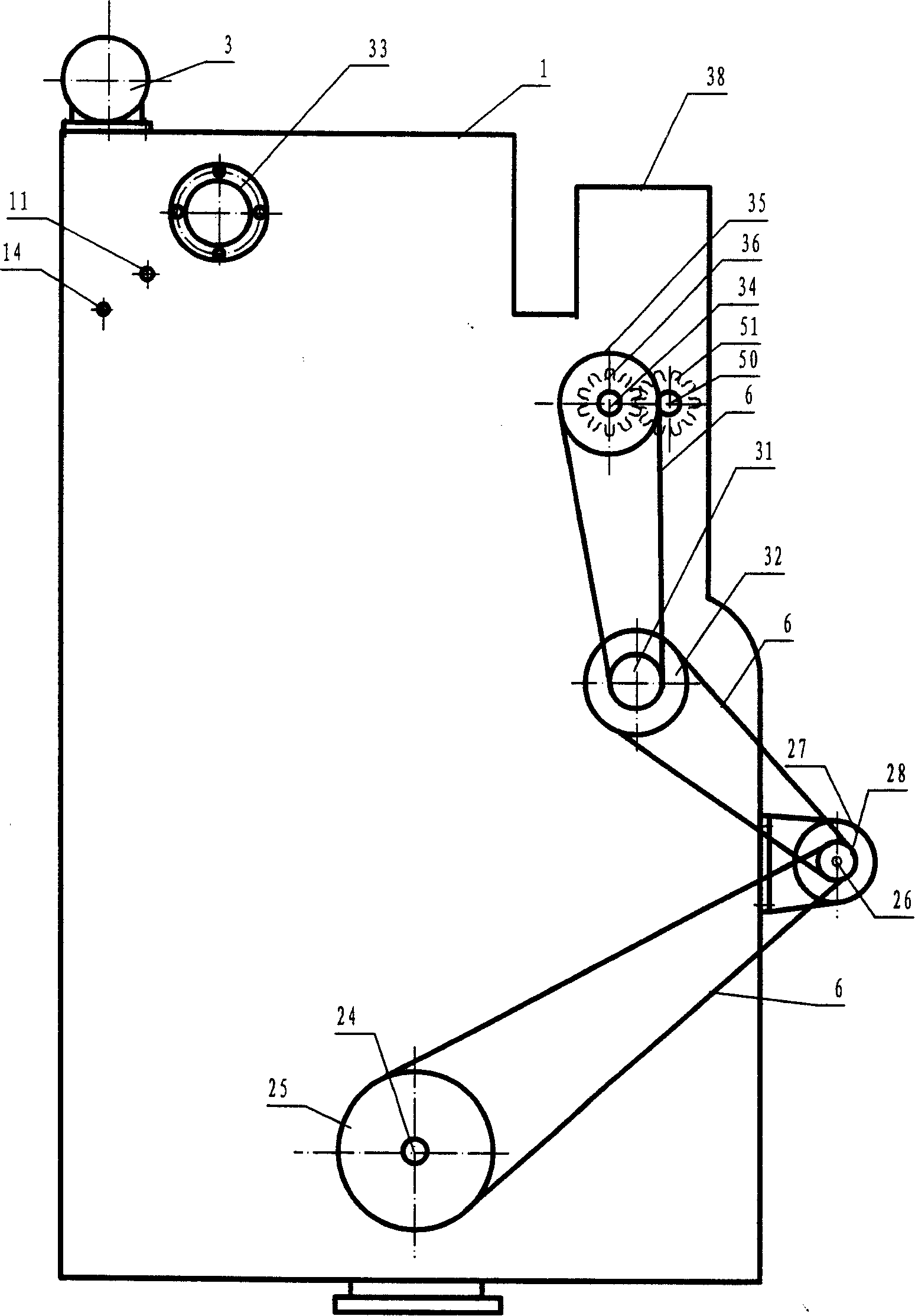

Method for producing laminated fiber body

Provided is a method for producing a laminated fiber body in which pulp fiber acquired by defibrating, using a defibrator, a pulp sheet drawn from pulp stock is supplied to a stacking machine together with an air flow so as to acquire a laminated fiber body in which the pulp fiber has been deposited. In this method, when a second pulp sheet drawn from new pulp stock is to be supplied to the defibrator after a first pulp sheet supplied to the defibrator, the second pulp sheet is drawn at a conveying speed faster than the conveying speed of the first pulp sheet supplied to the defibrator, the conveying speed of the second pulp sheet is decelerated so that the tip of the second pulp sheet follows the end of the first pulp sheet, the tip of the second pulp sheet is set to be in a state of contacting or approaching the end of the first pulp sheet, and the second pulp sheet is supplied following the first pulp sheet.

Owner:KAO CORP

Preparation system of compound type bamboo fiberboards and preparation method of compound type bamboo fiberboards

PendingCN108544630AIncrease production rateGuaranteed thermoforming effectCane mechanical workingReed/straw treatmentProduction rateEngineering

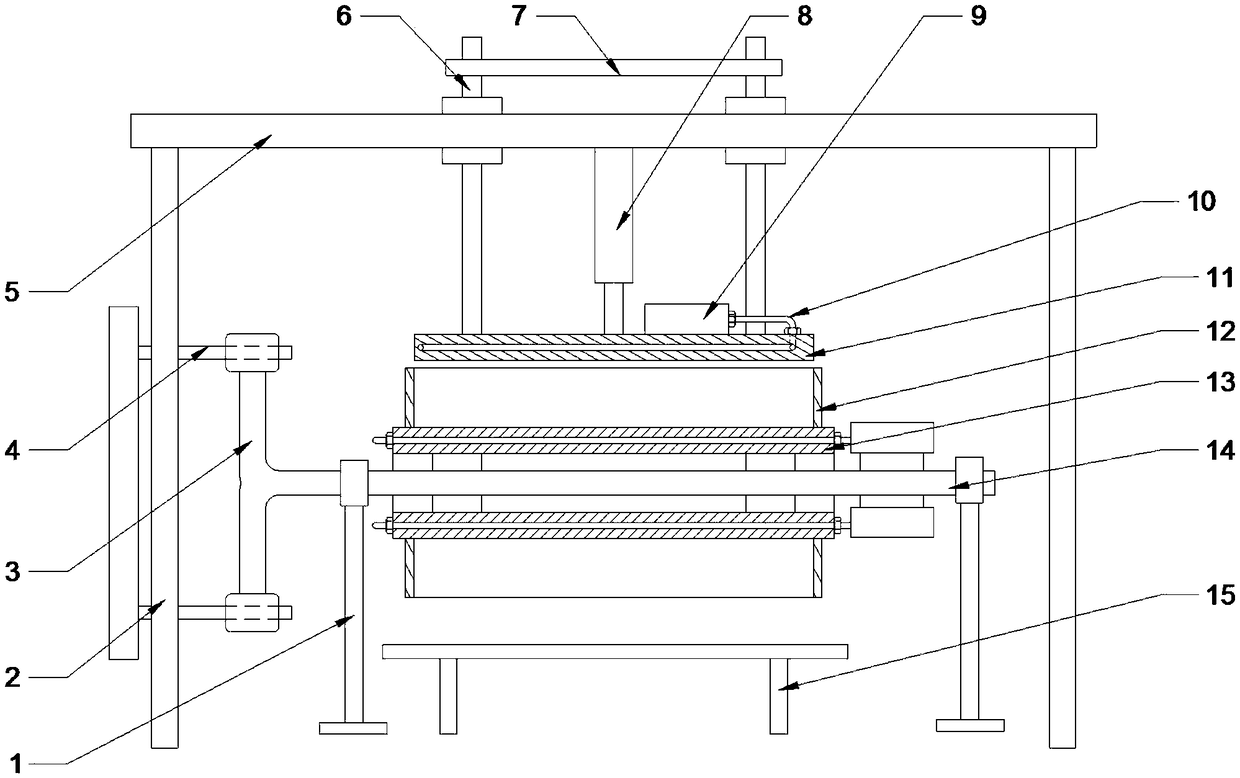

The invention relates to the field of processing devices for bamboo fiberboards, and specifically relates to a preparation system of compound type bamboo fiberboards and a preparation method of the compound type bamboo fiberboards. The preparation system comprises a chipping machine, a defibrator, a drying machine and a hot-press forming machine. The hot-press forming machine comprises a hydraulicrod, hot-press dies, a heat conduction oil heating device, a heat conduction oil guide pipe, a pressing plate and top plates. The hot-press forming machine further comprises shaft supports. A rotating shaft is further installed on the shaft supports. The top plates are annularly arrayed on the rotating shaft around the axis of the rotating shaft. The hot-press dies are installed on the top plates. Each hot-press die is a rectangular frame without a top cover and a bottom cover. The hydraulic rod is installed on a beam. The head portion of a telescopic rod of the hydraulic rod is connected with the pressing plate. Heat conduction oil through holes are formed in the pressing plate and a bottom plate. A loop for circularly heating heat conduction oil is composed of the heat conduction oil through holes, the heat conduction oil guide pipe and the heat conduction oil heating device. By means of the preparation system and the preparation method, the production rate is increased, and meanwhile the product hot-press forming effect is ensured and the product quality is good; and tests of different environments can be met while strength of the compound type bamboo fiberboards is ensured.

Owner:HONGYA BAMBOO ERA SCI & TECH

Prepn of paraffin emulsion with waste water from medium density fiber plate defibrator system

InactiveCN1974731AEmulsification process is easyWax physical treatmentMixing methodsParaffin waxStearic acid

The process of preparing paraffin emulsion with waste water from medium density fiber plate defibrator system features that paraffin emulsion is prepared with solid paraffin and the waste water from medium density fiber plate defibrator system as main material, stearic acid and triethanolamine as emulsifier, ammonia water as catalyst, and sodium carboxymethylcellulose as colloid protectant. The process is simple, and the paraffin emulsion is used for the production of medium density fiber plate. Reusing partial waste water can reduce the quantity of waste water to be treated.

Owner:福人集团有限责任公司

System and method for performing wind cleaning on wood chips

InactiveCN102247948AImprove cleaning qualityCompact structureGas current separationWood treatment detailsCyclonePositive pressure

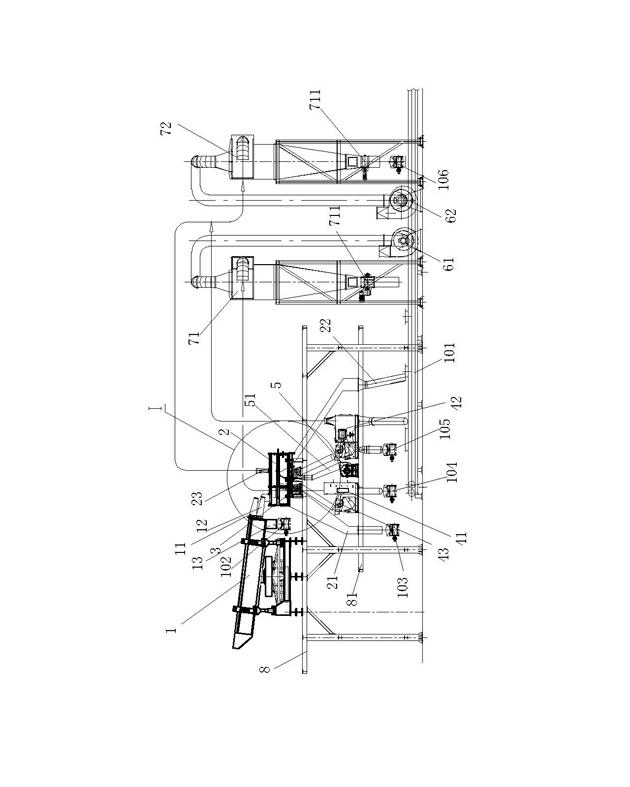

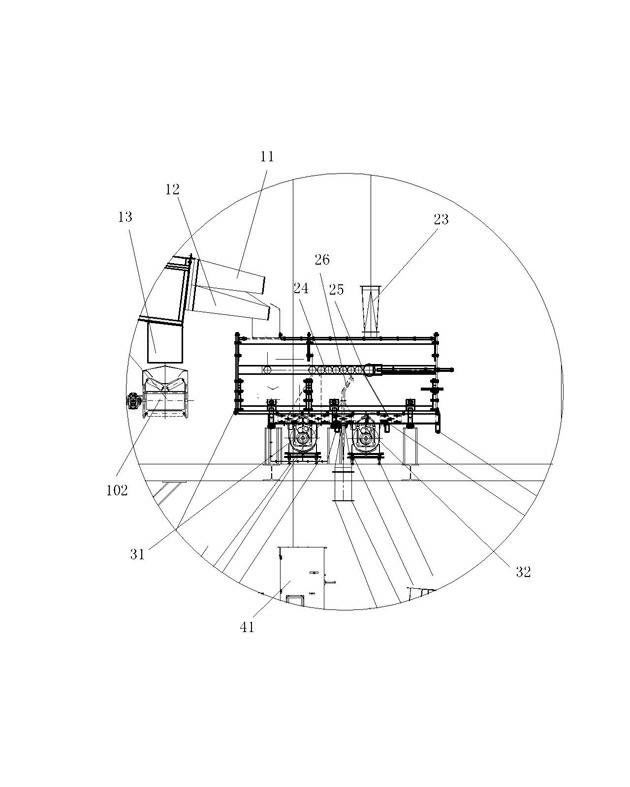

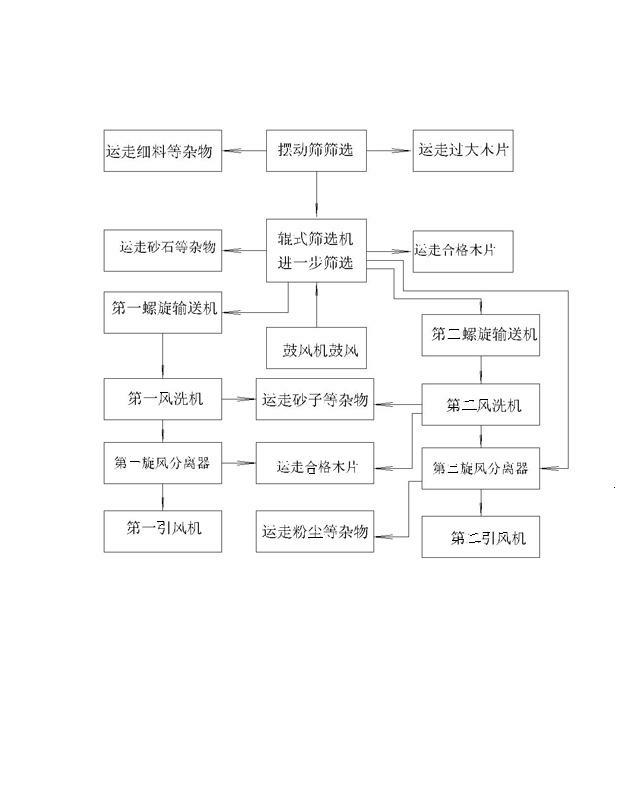

The invention discloses a system for performing wind cleaning on wood chips. The system for performing wind cleaning on the wood chips comprises a vibrating screen, a roll screening machine, a plurality of screw conveyors, a plurality of wind cleaning machines, a plurality of air blowers, a plurality of sundry conveyors, a qualified wood chip conveyor, a plurality of draught fans, and a pluralityof cyclone separators. A method for performing wind cleaning on the wood chips comprises the following steps of: 1) inputting mixed large and small wood chips into the vibrating screen and screening;2) inputting the wood chips screened by the vibrating screen into the roll screening machine and further screening; 3) screening by using positive pressure wind through gaps among conveying rolls of the roll screening machine, screening by the wind cleaning machines through negative pressure, and carrying away wood chips with the qualified sizes by the conveyor; and 4) carrying away sundries and dust which are separated by the cyclone separators by the conveyors. The system for performing wind cleaning on the wood chips has a compact structure, can continuously perform wind cleaning on wood chips in a centralized way for multiple times, and is high in efficiency and low in energy consumption; and impurities such as dust, heavy objects, iron blocks and the like can also be removed when thewood chips with qualified sizes are pneumatically separated, the cleaning quality of the wood chips can be improved more efficiently, and the damage to a defibrator is avoided.

Owner:SUZHOU SUFOMA MACHINERY

Method for producing anti-fatigue light gray paper

InactiveCN104863009AQuality improvementReduce deforestationInorganic compound additionPaper-making machinesPapermakingDefibrator

The invention relates to a method for producing anti-fatigue light gray paper, and belongs to the technical field of papermaking. Waste paper or wheat straw is smashed, then goes through a pressure screen, and is separated with a defibrator, then, size mixing and coloring are carried out on purified fiber, dehydration and forming are carried out, and the anti-fatigue paper can be obtained. According to the method for producing anti-fatigue light gray paper, the produced paper is warm gray, the saturation of the paper ranges from 70% to 90%, the lightness of the paper ranges from 20% to 45%, the paper can effectively relieve fatigue, the production process does little harm on the environment, and cost is low.

Owner:GUANGZHOU YADI STATIONERY CO LTD

Recycling method of leading waste water into grinding chamber body in MDF production

InactiveCN101798766ASolve processing problemsRelieve stressMultistage water/sewage treatmentFibrous raw materialsSocial benefitsWastewater

The invention relates to a recycling method of leading waste water into a grinding chamber body in a MDF production. The waste water extruded from a defibrator in the MDF hot grinding technology is filtered and deposited. The temperature of the waste water is controlled within 20 to 70 degrees centigrade. The waste water is transmitted to the grinding chamber body of the defibrator to be recycled. The method solves not only the difficult processing problem of the waste water extruded from the defibrator but also the water shortage problem of the hot grinding process, saves production water supply, recycles lignin, hemicellulose and other condensates in the waste water, makes the best use of energy resources, saves the cost of processing the waste water and has the obvious characteristic of saving energy, and environmental protection and good economic and social benefit.

Owner:FUJIAN AGRI & FORESTRY UNIV

Equipment for producing corrugated body paper through recycled pulp recycling

PendingCN108517705AReduce electricity consumptionEmission reductionDryer sectionPaper recyclingElectricityHigh volume manufacturing

The invention discloses equipment for producing corrugated body paper through recycled pulp recycling. The equipment comprises a pulper, a control switch is installed on one side of the outer wall ofthe pulper through screws, a desander is arranged on one side of the pulper, the discharge end of the pulper is connected with a feed end pipeline of the desander, and a defibrator is arranged on oneside of the desander. The equipment is simple in structure, low in manufacturing cost and convenient to operate, waste paper can be recycled to be made into waste paper pulp, then corrugated body paper is produced, papermaking is conducted by means of recycled fiber, and forest, water, power consumption and pollutant emission can be greatly reduced; meanwhile, the processing cost can be greatly lowered, and the equipment has a good market prospect; by means of an installed up-flow pressure screen, the multiple purification effect is achieved, and the cleanliness of slurry can be ensured; meanwhile, the production quality of the corrugated body paper is improved, and practicability is high; by means of an installed drying box, finished paper dryness is increased to be 92-95%, the strength of the paper is improved, the smoothness of the paper is increased, and the equipment is suitable for mass production.

Owner:浙江兴舟纸业有限公司

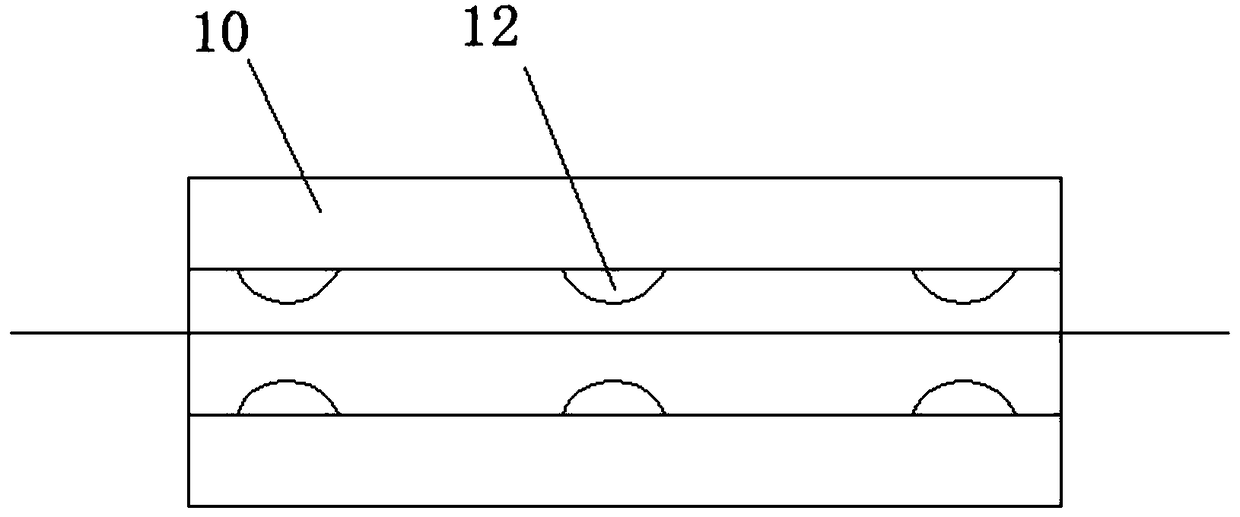

Preparation method of composite floor base material

ActiveCN106272867AFill in the gapsIncrease contact areaWood working apparatusFlat articlesWood fibrePre treatment

The invention discloses a preparation method of a composite floor base material. The preparation method comprises the following steps that firstly, early wood and late wood are selected, and a first raw material and a second raw material are obtained; secondly, the first raw material is subjected to fumigation treatment to obtain the pretreated first raw material; thirdly; the second raw material is pretreated according to the method in the second step to obtain the pretreated second raw material; fourthly, the pretreated first raw material and the pretreated second raw material are boiled and subjected to fiber separation through a defibrator, and a first wood fiber and a second wood fiber are obtained; fifthly, the first wood fiber and the second wood fiber are mixed to obtain a mixed fiber; sixthly, a floor base material is prepared through gluing and hot pressing; and seventhly, the floor base material is subjected to cooling hardening and tempering and sanding cutting to obtain the composite floor base material. The composite floor base material is high in strength, resistant to impacts, good in dampproof performance, good in stability, not prone to buckling deformation and low in formaldehyde emission.

Owner:宁波远志立方能源科技有限公司

Automatic steam control system of defibrator

InactiveCN1974920AEasy to operateReduce power consumptionPipeline systemsFibrous raw materialsAutomatic controlControl system

The present invention is automatic steam control system of large defibrator. The technological scheme of the present invention is that the automatic steam control system consists of pipeline, pneumatic regulating valve, pneumatic ball valve, platinum resistor, pressure transmitter, safety valve, cut-off valve, draining valve, etc. It used in controlling the steam replenishment, monitoring and maintaining during the defibrator operation. The present invention has the advantages of simple operation, reasonable and reliable steam supply, automatic balancing, capacity of reducing power consumption of the defibrator and raising production efficiency, etc.

Owner:SHANGHAI WOOD-BASED PANEL MASCH CO LTD

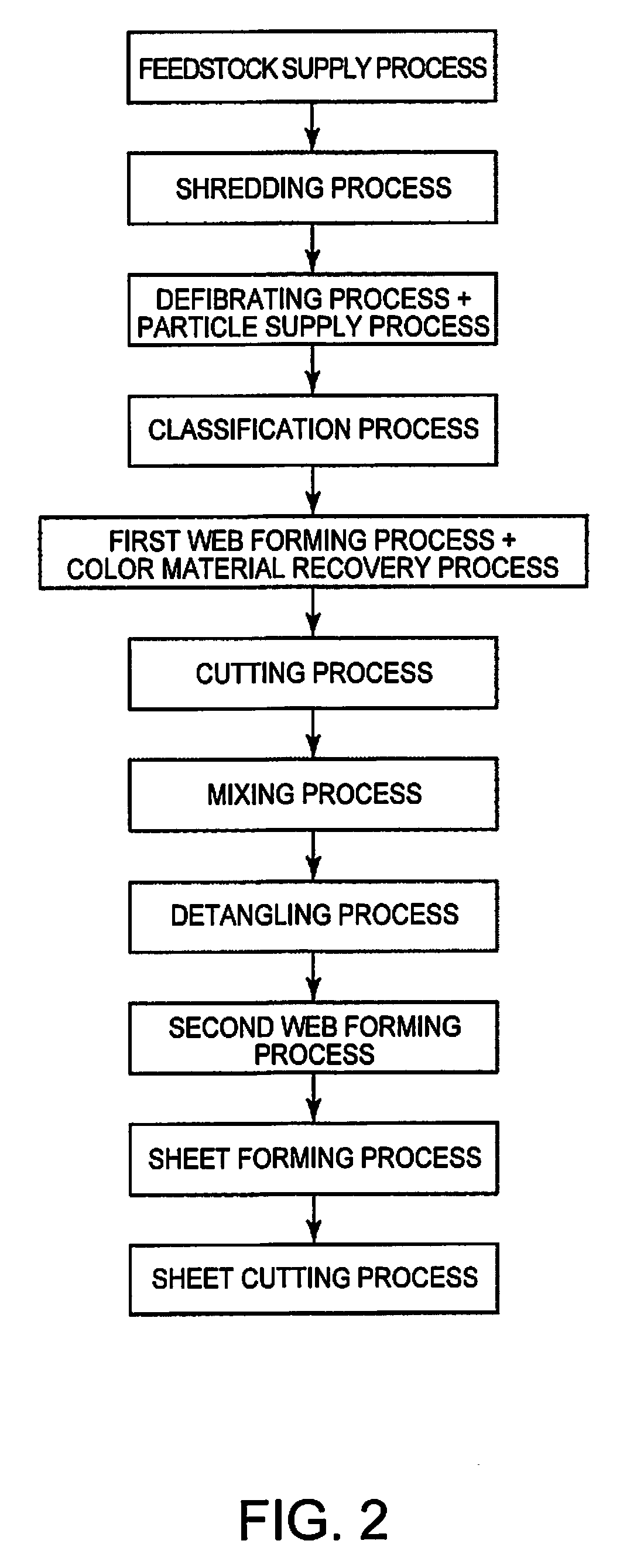

Processing device, sheet manufacturing apparatus, processing method, and sheet manufacturing method

ActiveUS20180305868A1Easy to removePaper recyclingElectrography/magnetographyDry iceManufactured apparatus

A processing device, a sheet manufacturing apparatus, a processing method, and a sheet manufacturing method enable quickly removing color material when color material is contained in a material containing fiber. A processing device has a defibrator configured to defibrate, in air, fibrous material containing fiber; and a particle supply device configured to supply particles of dry ice to the material containing fiber during defibration or after defibration. The material containing fiber contains color material; and the particles work to separate the color material for the fibers by colliding with the color material contained in the material containing fiber.

Owner:SEIKO EPSON CORP

Preparation method of antiseptic composited wood

InactiveCN109719810AMultiple permeation pathwaysImprove permeabilityWood veneer joiningWood impregnation detailsCopperResin adhesive

The invention discloses a preparation method of antiseptic composited wood. The preparation method comprises the following steps of 1, cutting wood into single boards in a rotary manner through a rotary cutter, conducting cutting, and then, defibering the single boards into network-state or bundle-state wood bundles through a defibrator; 2, putting the wood bundles into a copper azole antiseptic substance for soaking, and conducting air-drying after soaking; 3, putting the air bundles obtained after air-drying into phenolic resin adhesive for adhesive dipping, and conducting drying after adhesive dipping; and 4, conducting rift grain assembly on the dried wood bundles, putting the wood bundles into hot pressing equipment for hot pressing gluing, so that boards are formed and composited wood finished products are obtained. The antiseptic composited wood is excellent in corrosion resistance, size stability and mechanical performance; and in addition, the treatment mode of the copper azole antiseptic substance for soaking the composited wood and the composited wood hot pressing process are further optimized, and the corrosion resistance and mechanical performance of the composited wood are further improved.

Owner:国家林业和草原局竹子研究开发中心

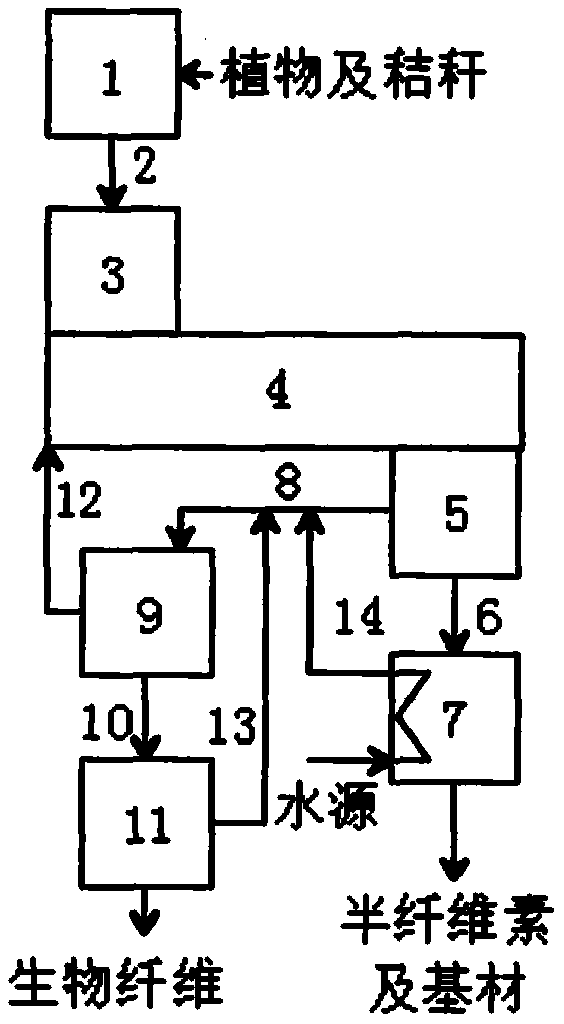

Straw raw material clean co-production technology and efficient hot-pressing device

The invention relates to a straw raw material clean co-production technology and an efficient hot-pressing device. The device is mainly composed of whole-system straw preparation raw material equipment, compression type raw material input equipment, a raw material cooking phase-change hydrolysis container, hydrolysate heat preservation, pressure maintaining, discharging and conveying equipment, ahydrolysate high-temperature high-pressure solid-liquid separation unit, liquid phase conveying equipment, liquid-phase hemicellulose and base material production equipment, solid-phase stirring and conveying equipment, a high-temperature and high-pressure defibrator unit, defibrated material heat preservation, pressure maintaining, discharging, steam exhausting, stirring and conveying equipment,a defibrated material high-temperature and high-pressure solid-liquid separation unit, defibration water-liquid circulation equipment, defibration steam purification, heat supply and heat source equipment, defibration vapour removal and recovery equipment and the like. The device has the beneficial effects that the textbook confinement of plant cooking, hydrolysate spraying and normal-state solid-liquid separation is broken through, and a clean co-production technology and efficient hot-pressing equipment taking plant cooking, defibration and heat and pressure preservation solid-liquid separation as cores are innovated, so that the last kilometer of efficient conversion between straw solid waste treatment and raw material utilization is broken through.

Owner:北京鑫泽清源植物秸秆技术有限公司

Physical method straw fibrosis

Physical method straw fibrosis is characterized in that a high-solid preparation technology based on heat and pressure for plant and straw fibrosis and an efficient mechanism of the high-solid preparation technology are conceived, and the physical method fibrosis taking whole-process sealing and temperature and pressure bearing as a cleaning mechanism is constructed. Main components are a wind power raw material preparation part, a forced raw material input part, a raw material medicine-free digester and heat supply part, a material discharging and differential pressure conveying part, a primary high-solid defibrator set and solid-steam separation part, a plurality of primary fiber discharging and differential pressure conveying parts, a plurality of high-solid defibrator sets and solid-steam separation parts, a forced fiber output and waste heat recycling part, a separation steam recycling and reusing part, a preheating water supply part and the like. The physical method straw fibrosis disclosed by the invention has the beneficial effects that a physical method is adopted to fibrillate plants and straw, so that the last kilometer of efficient and large-scale conversion between straw disposal and recycling can be promoted and broken through.

Owner:北京鑫泽清源植物秸秆技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com