Production method of medium-density fiberboard using waste and old wood

A production method and medium-density technology, which is applied in the direction of wood processing equipment, pretreatment and application of molding materials, etc., can solve the problems of unreasonable utilization, limited production scale, waste of raw materials, etc., to expand the source of raw materials and increase the scale of production. , the effect of reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

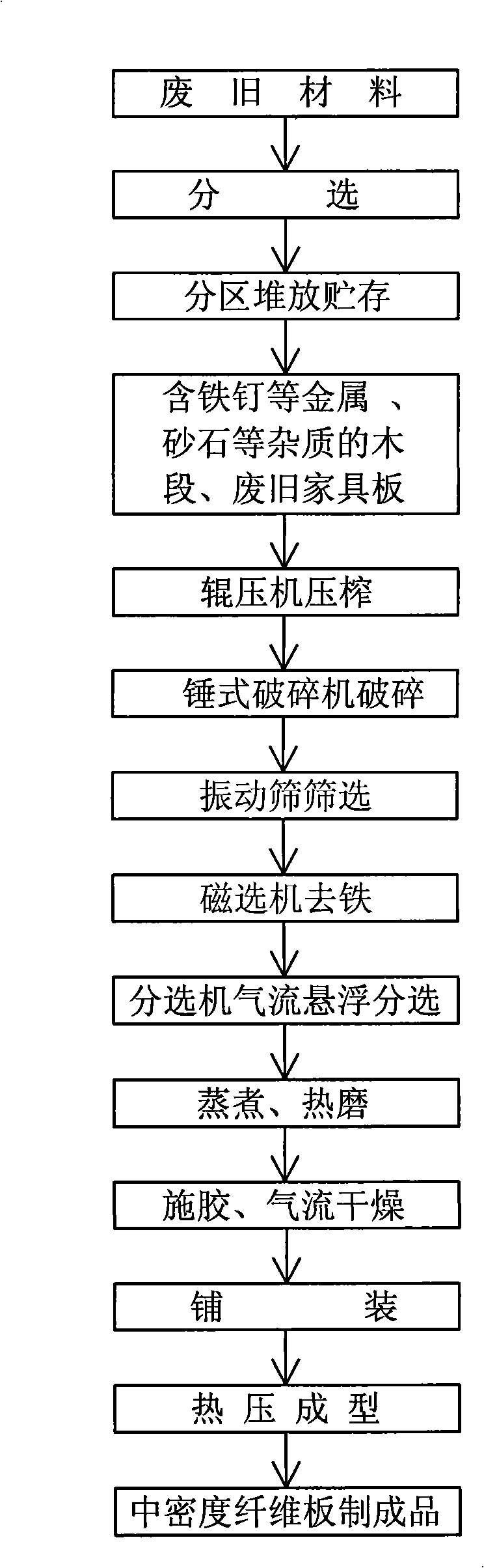

[0012] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] At present, the conventional production technology of medium density fiberboard at home and abroad is very mature. The production process of most manufacturers at home and abroad is: the logs (mainly small-diameter wood or branch wood) or scraps are used by chippers or planers. After grinding, sizing, drying, paving, hot pressing, trimming, sanding and other processes to produce MDF, the recovery of raw materials is limited to raw materials, scraps and other waste materials with less impurity content. The production technology of medium density fiberboard of the present invention is mostly the same as the conventional one, and the difference is mainly that the production technology before the fiber preparation process is different. Raw materials such as wood boards disassembled from old wood sections and old furniture have m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com