Method for producing laminated fiber body

A manufacturing method and technology of accumulating body, which can be used in clothing, underwear, baby underwear, etc., and can solve the problems of excessive supply of overlapping parts and inability to become a constant supply amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

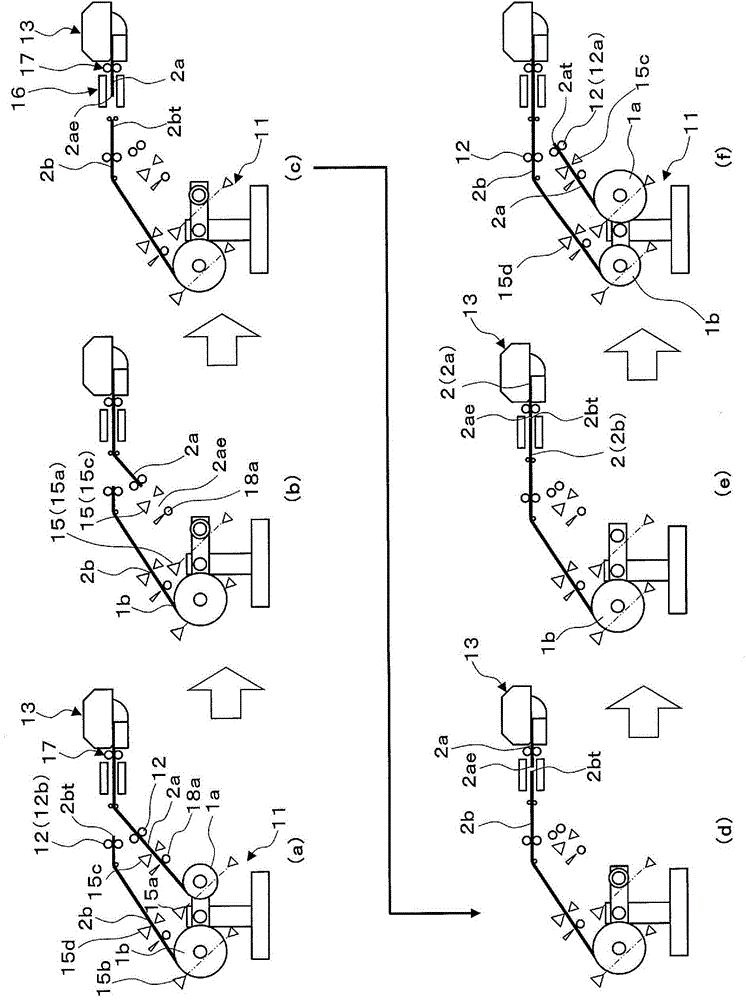

[0012] The present invention relates to a technique for solving the problem of continuously supplying new pulp sheets to the defibrator when the supply of the pulp sheets to the defibrator is exhausted when the pulp sheets extracted from the pulp base are supplied to the defibrator. The new and old sheets overlap and the interval between the old and new sheets is too large.

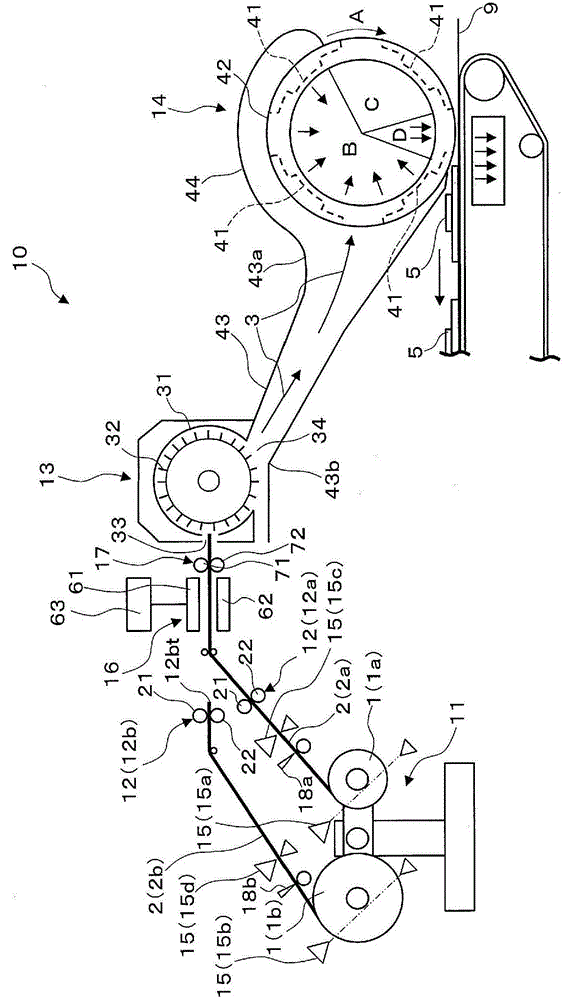

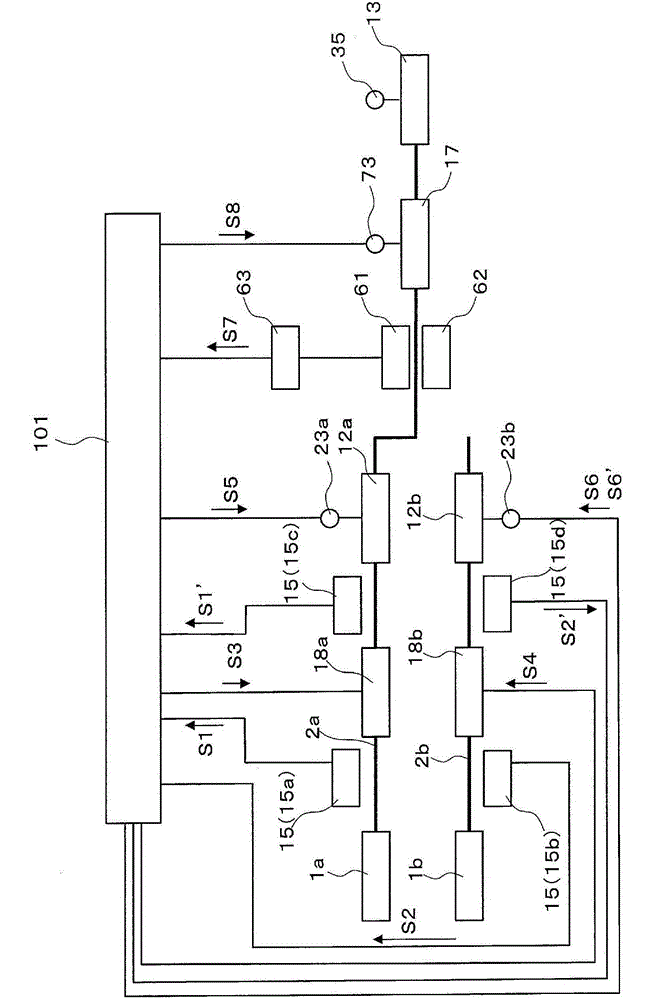

[0013] Below, while referring to figure 1 with figure 2 , a preferred embodiment of the manufacturing method of the fiber piling body of the present invention will be described.

[0014] First, refer to figure 1 The manufacturing apparatus of a fiber piling body suitable for carrying out the manufacturing method of a fiber piling body is demonstrated.

[0015] Such as figure 1 As shown, as a preferable example of the structure of the manufacturing apparatus 10 of a fibrous body, the pulp raw material unwinder 11, the pulp raw material conveyance mechanism 12, the defibrator 13, and the fiber stacker ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com