Physical method straw fibrosis

A physical method and straw technology, applied in fiber raw material treatment, raw material pretreatment, pulp beating/refining method, etc., can solve problems such as unsustainable, unscientific, and increasing farmland soil diseases and insect pests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation

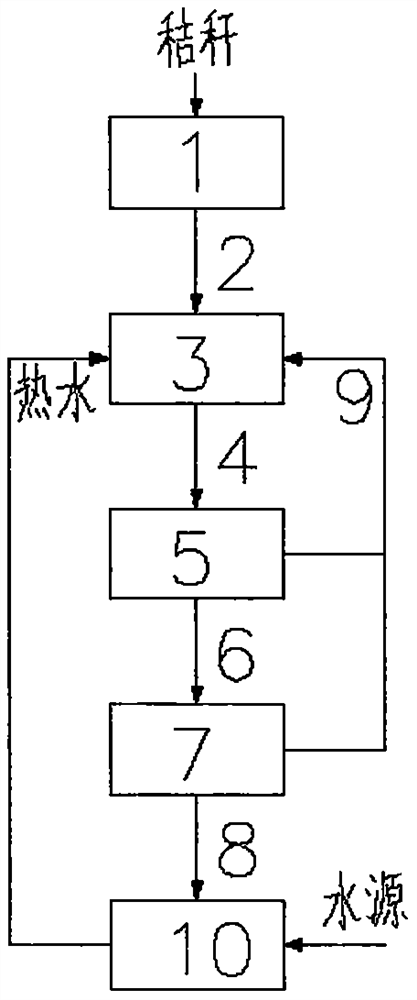

[0023] Attached below figure 1 The physical method of straw fibrosis of the present invention is further analyzed.

[0024] Such as figure 1 As shown, the physical method of straw fiberization in the present invention is mainly composed of wind power preparation raw material part 1, raw material forced input part 2, raw material drug-free cooking device and heating part 3, material unloading and pressure difference conveying part 4, initial high solid Thermal mill unit and solid-vapor separation part 5, several primary fiber unloading and pressure difference conveying parts 6, several high-solid thermal mill units and solid-vapor separation part 7, forced output fiber and waste heat recovery and utilization part 8, separation steam recovery and reuse The part 9 and the preheating water supply part 10 etc. constitute. Its implementation method is: plant resources and straw solid waste are processed into production raw materials by wind power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com