Patents

Literature

60results about "Beating/refining control devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for estimating relative proportion of wood chips species to be fed to a process for producing pulp

InactiveUS20060278353A1Effective monitoringBeating/refining control devicesDigestersLight reflectionImproved method

Improved methods and apparatus for estimating and controlling relative proportion of wood chips originating from a plurality of sources characterized by various wood species, in a mass of wood chips to be fed to a process for producing pulp, use light reflection-related and density-related properties as input in a model characterizing a relation between such wood chip properties and species information. This principle allows efficient monitoring of the variation in wood species composition characterizing the wood chips to be processed, for the purpose of stabilizing chip feeding control and optimizing process parameters adjustment.

Owner:CENT DE RES & DEV IND DU QUEBEC

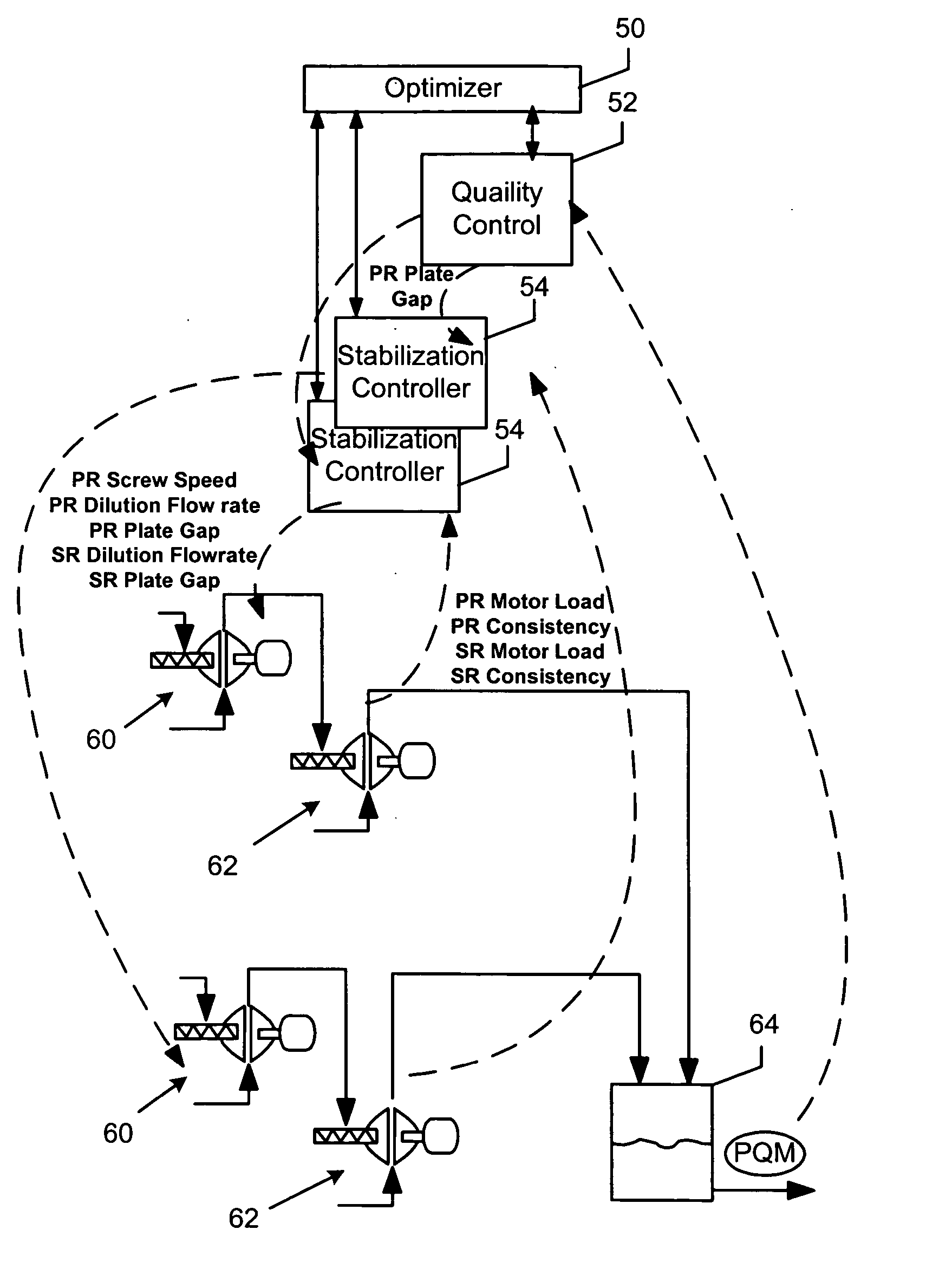

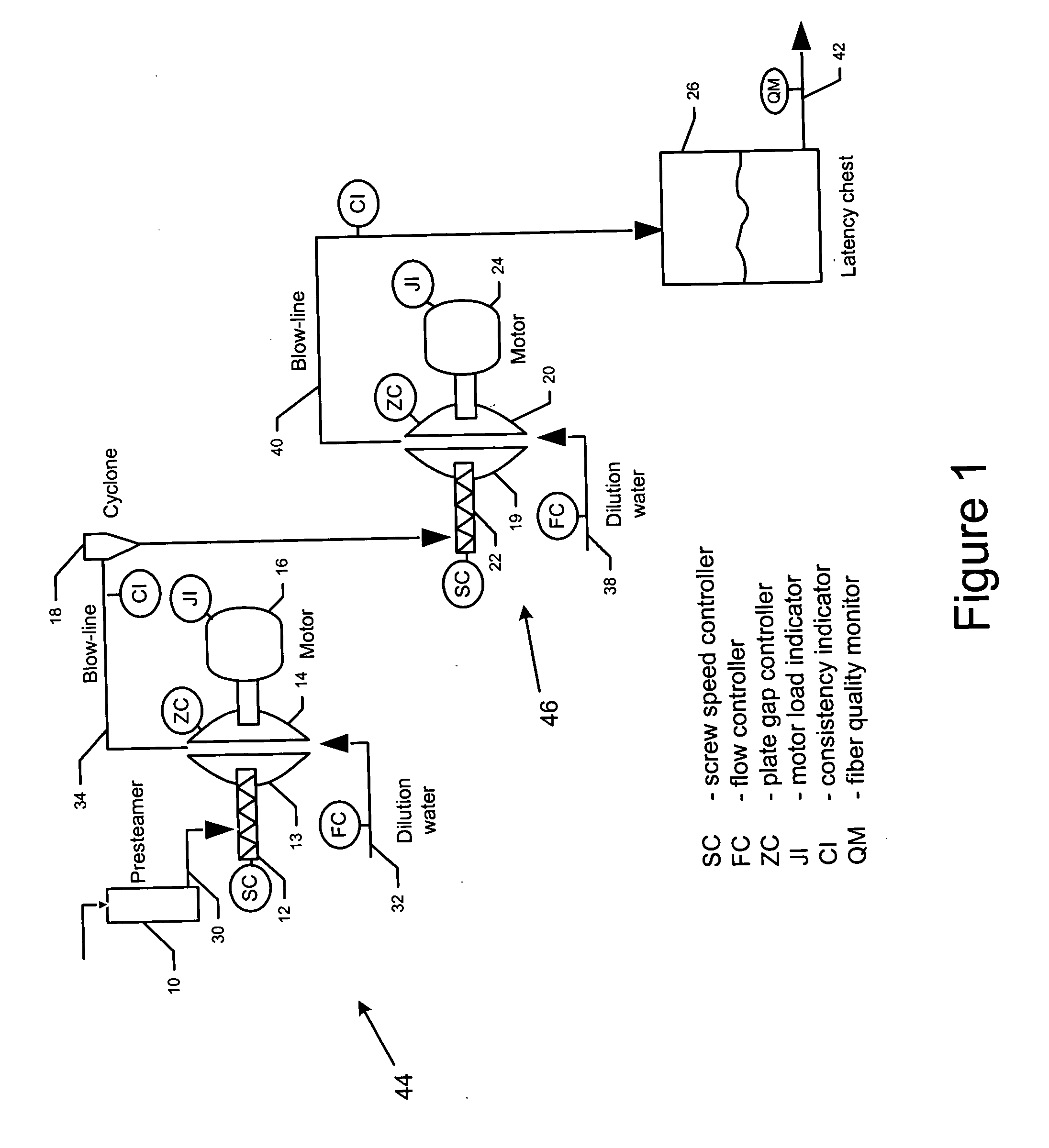

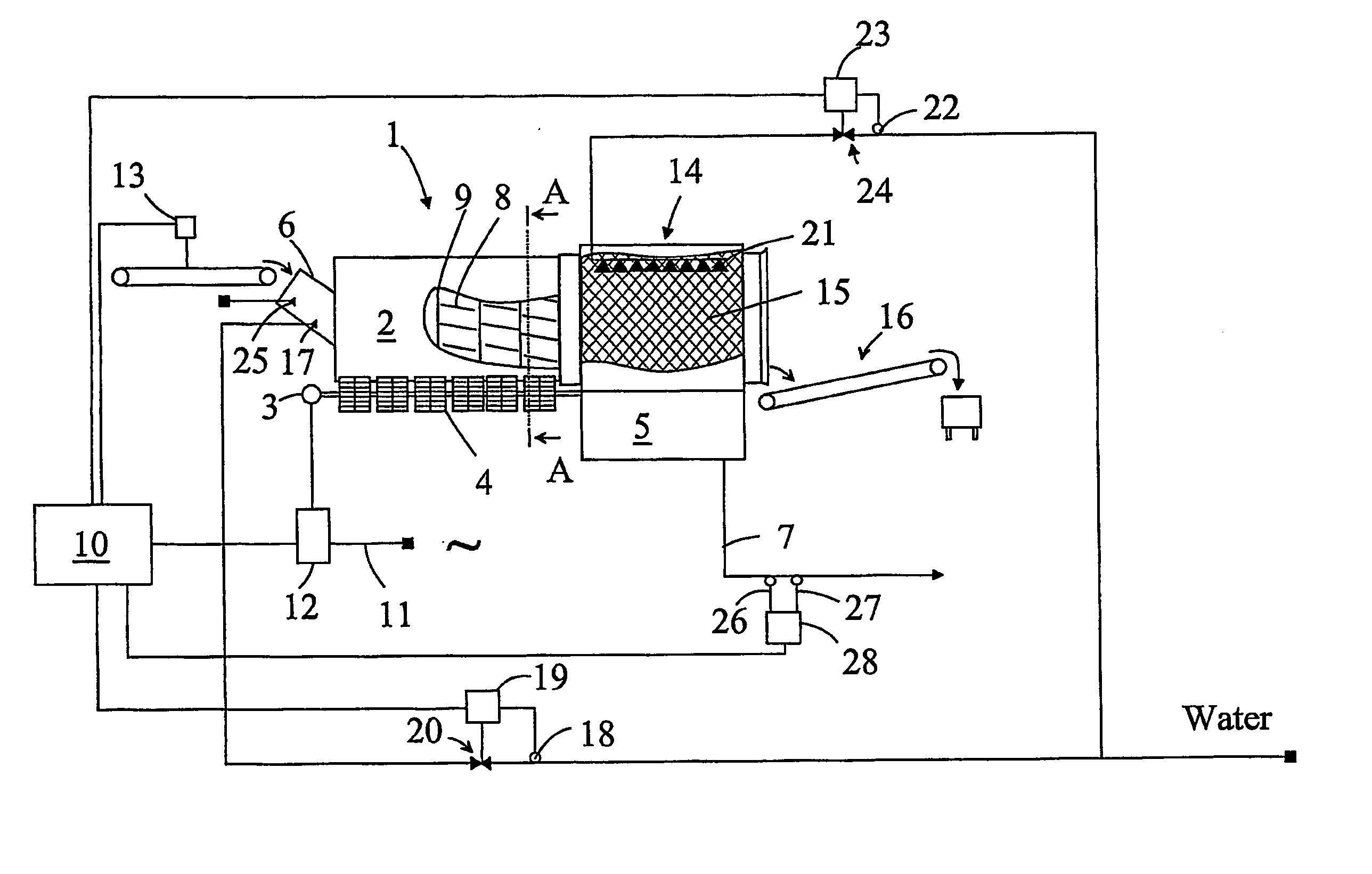

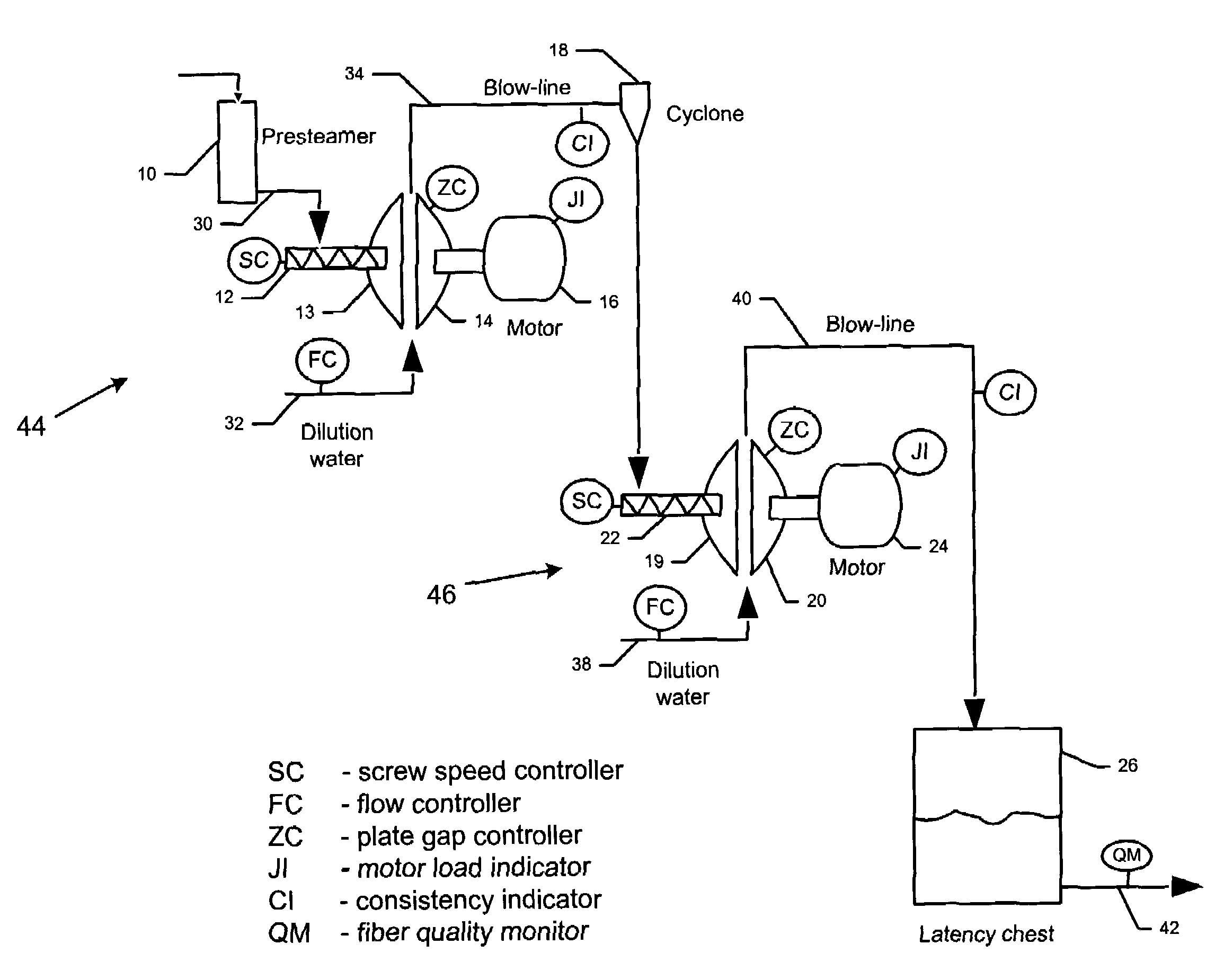

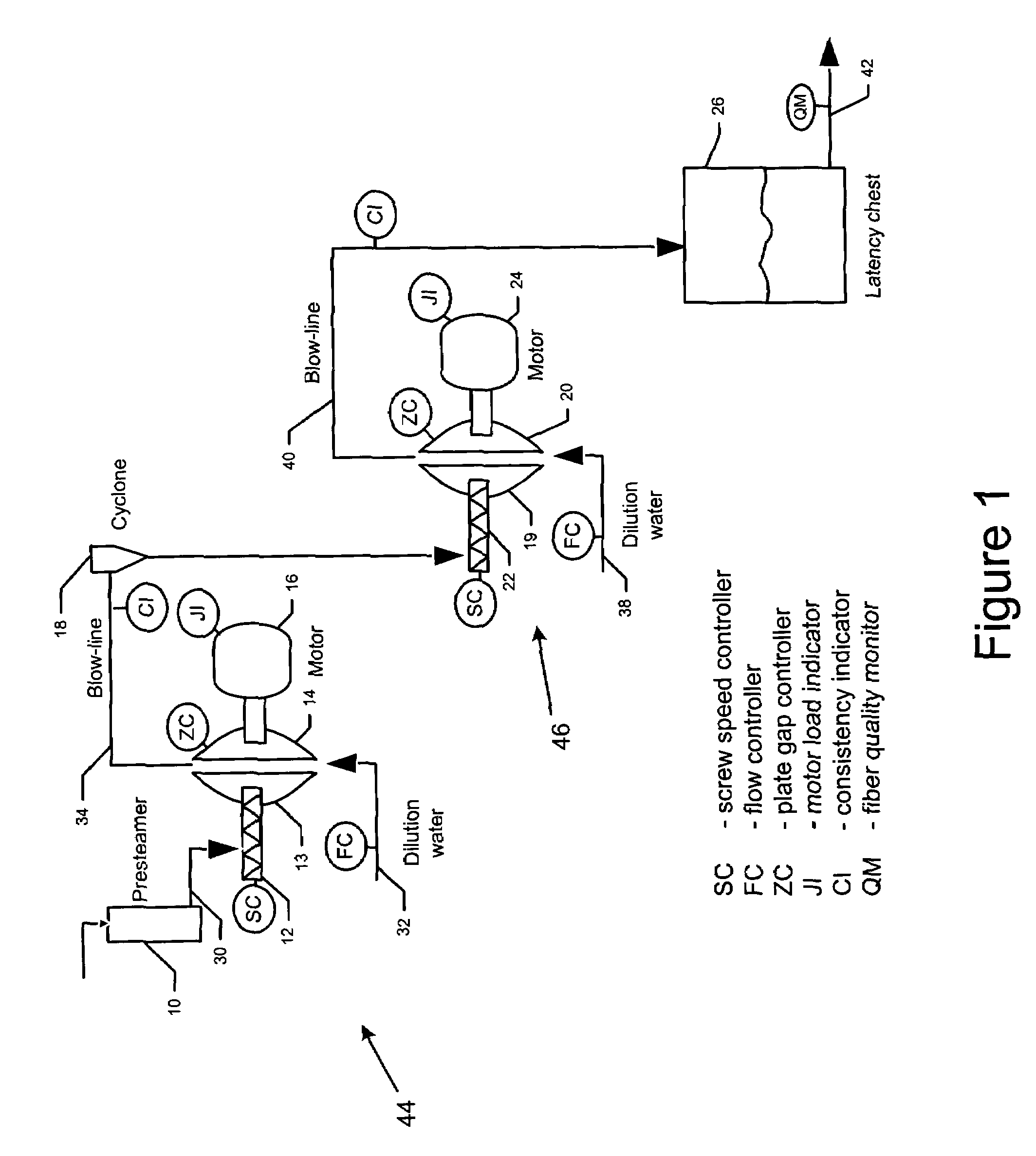

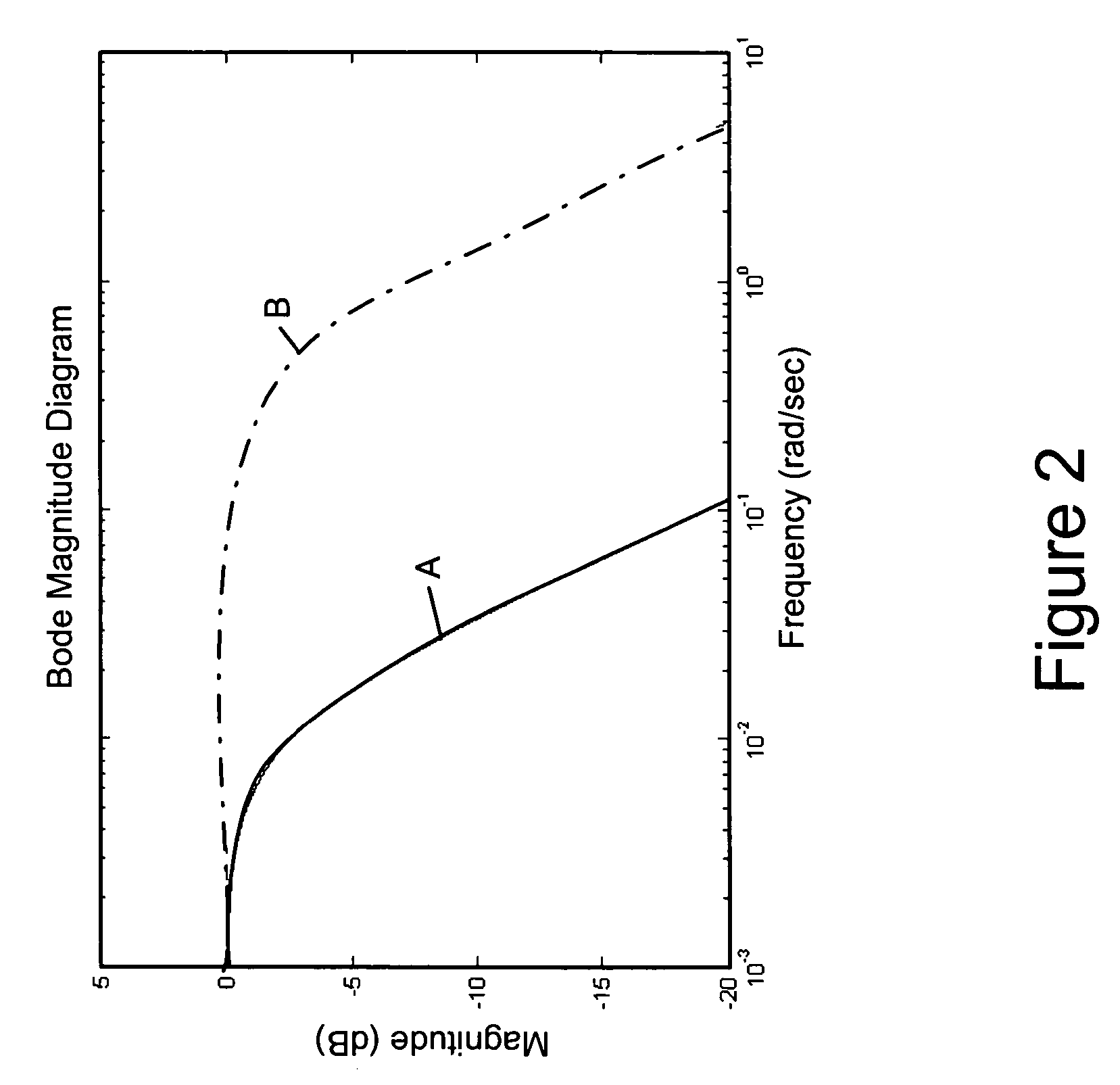

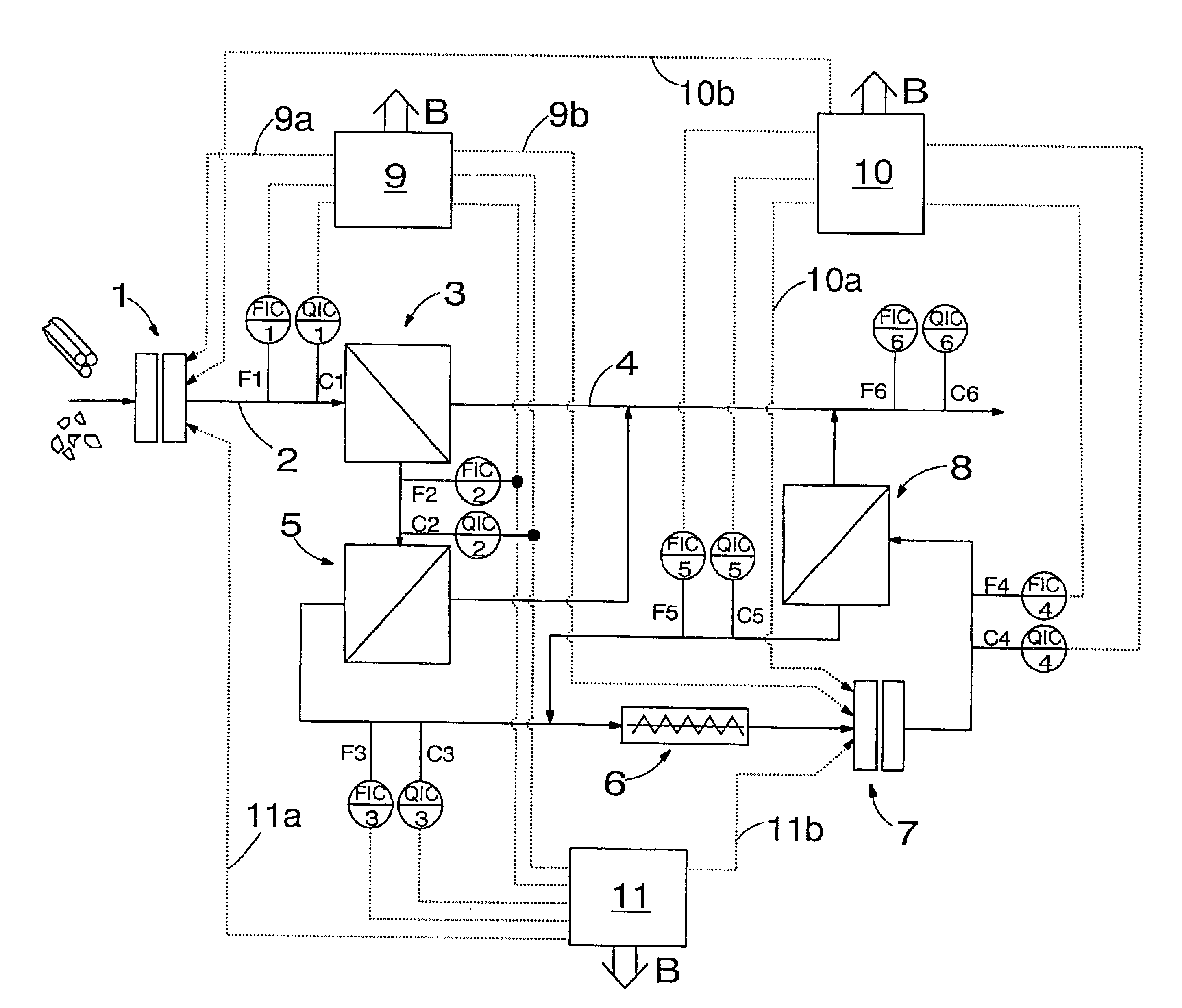

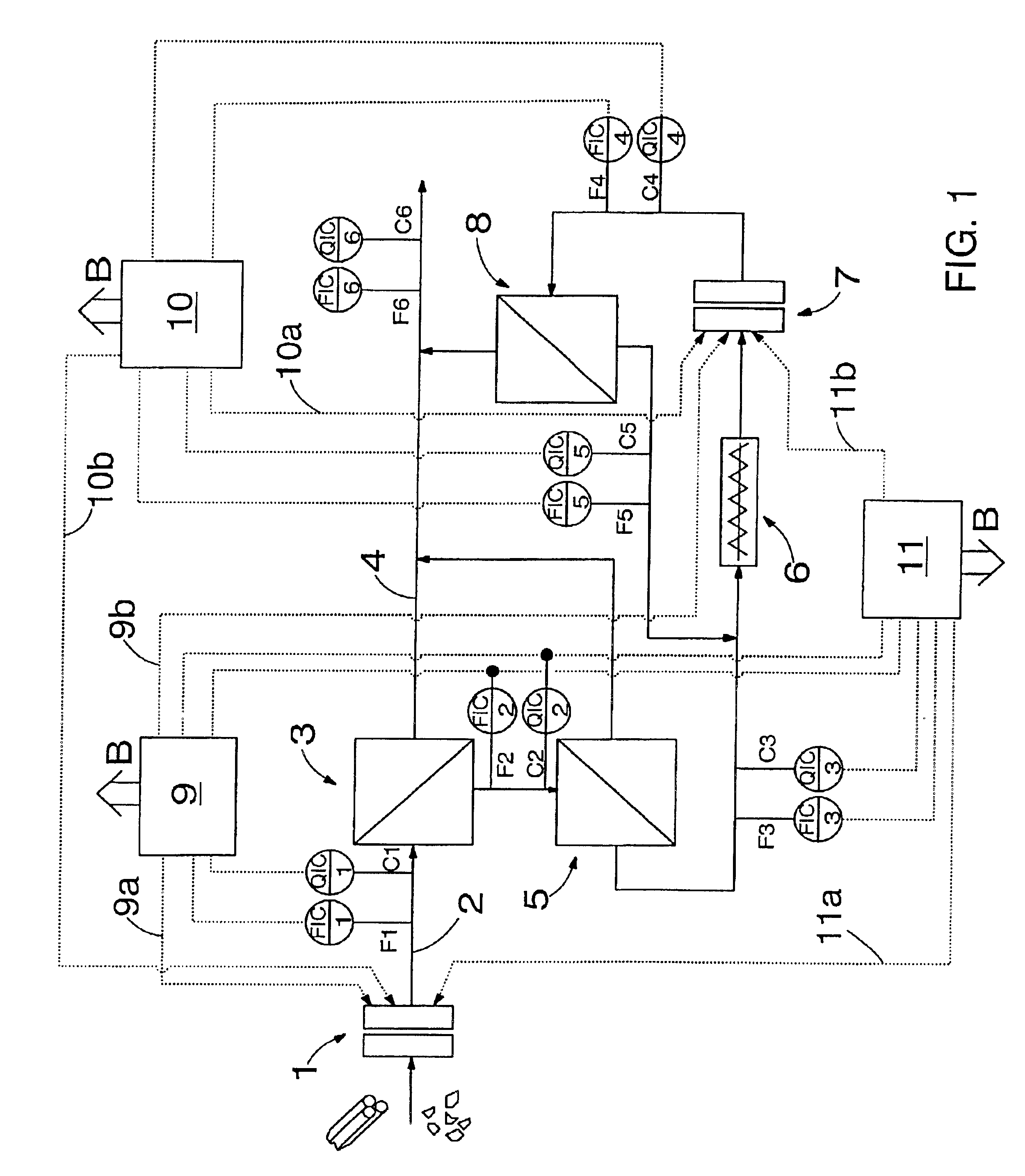

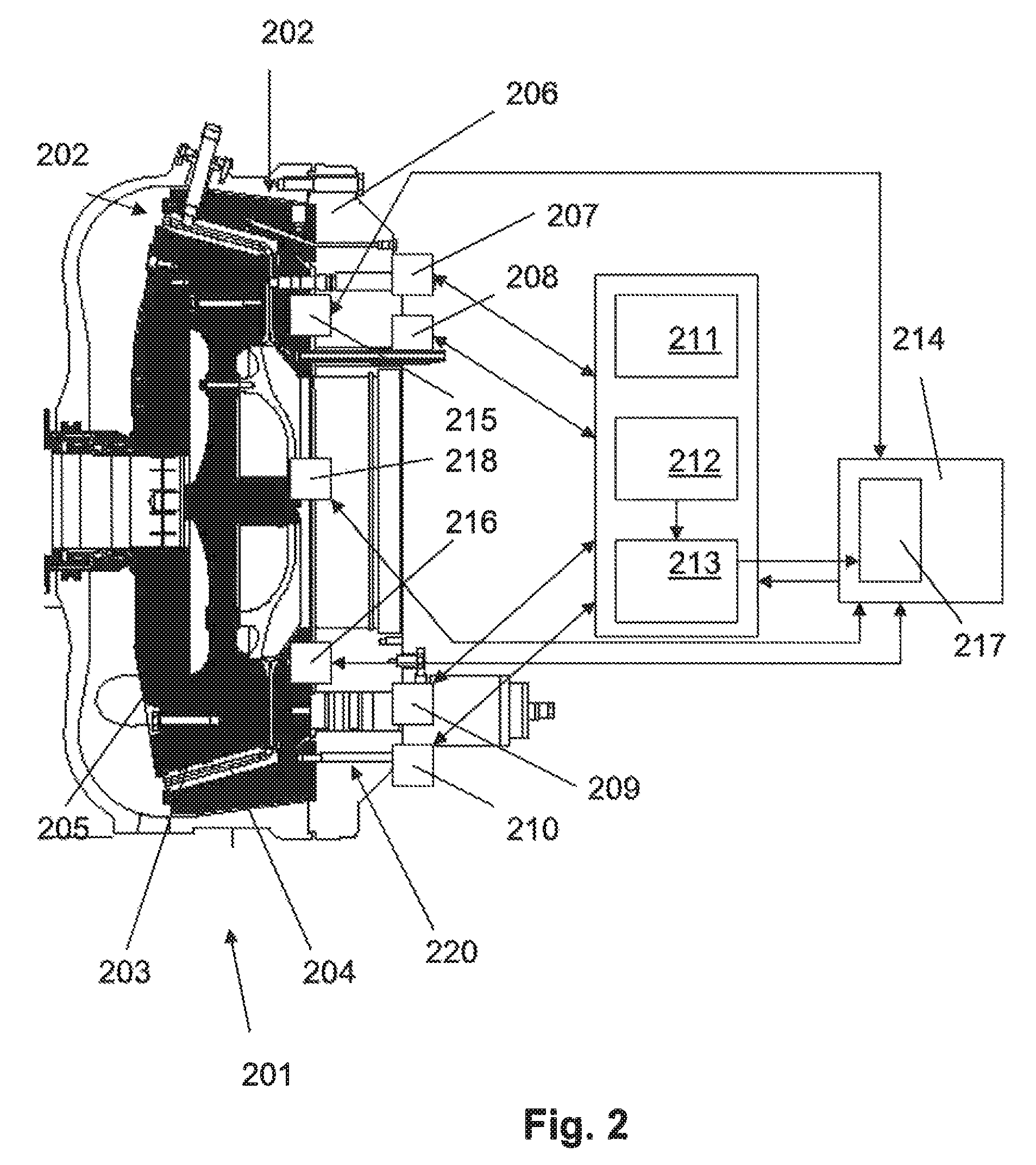

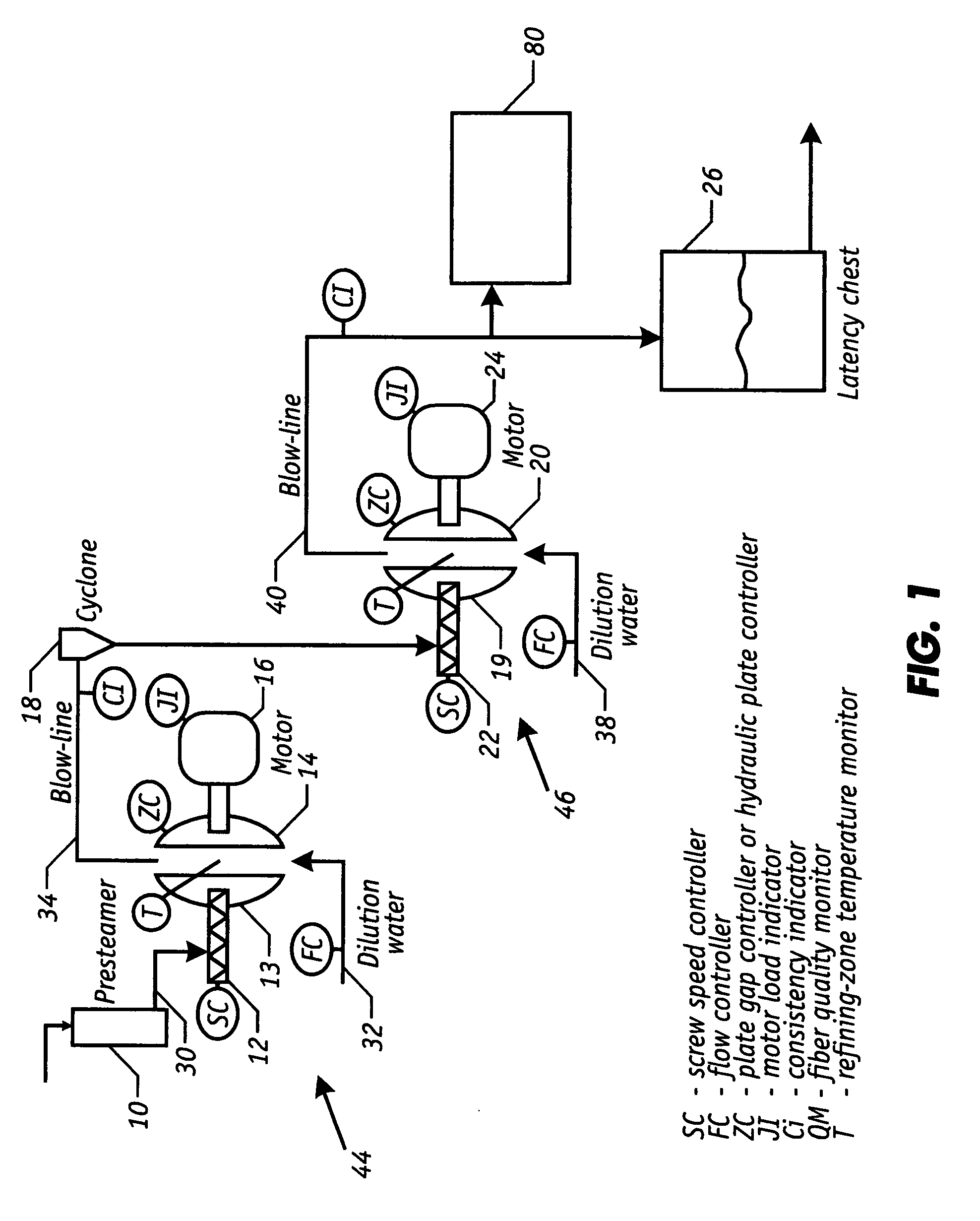

System and method for controlling a thermo-mechanical wood pulp refiner

ActiveUS20050263259A1Improve throughputReduce energy useBeating/refining control devicesComputer controlFiberQuality optimization

Thermomechanical pulp is an important process for producing fibrous mass used in papermaking. A two-level control strategy that stabilizes and optimizes the refining process has been developed. The Stabilization layer consists of a multivariable model predicative range controller that regulates the refiner line operations. The Quality Optimization layer provides the pulp quality control as measured by an online pulp quality (freeness, fibre length) sensor. This control startegy leverages the natural decoupling in the process. The modular design technique is able to handle multiple refiner lines that empty into a common latency chest. A global optimizer is also used to integrate and coordinate the two layers for enhanced constraint handling.

Owner:HONEYWELL INT INC

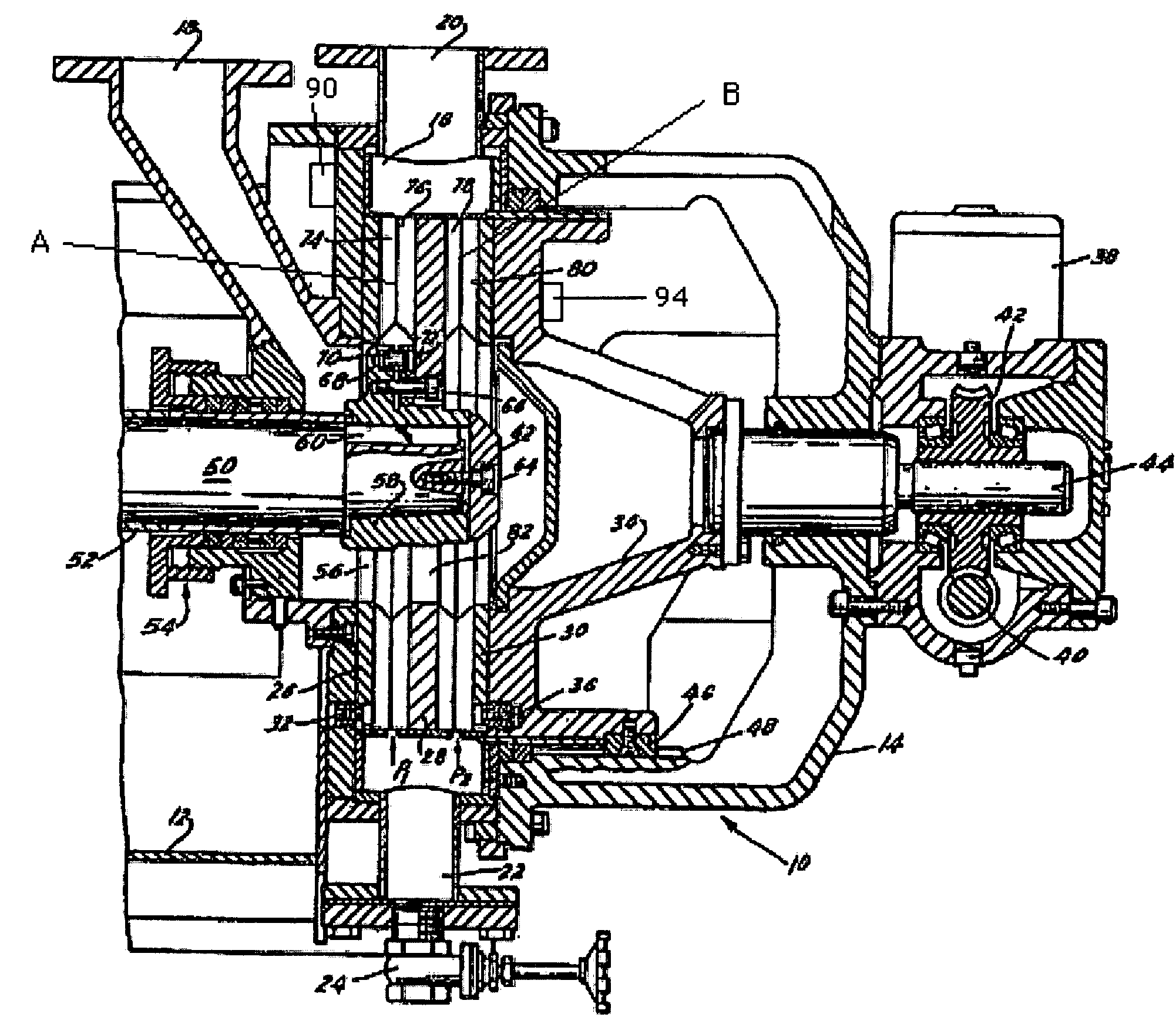

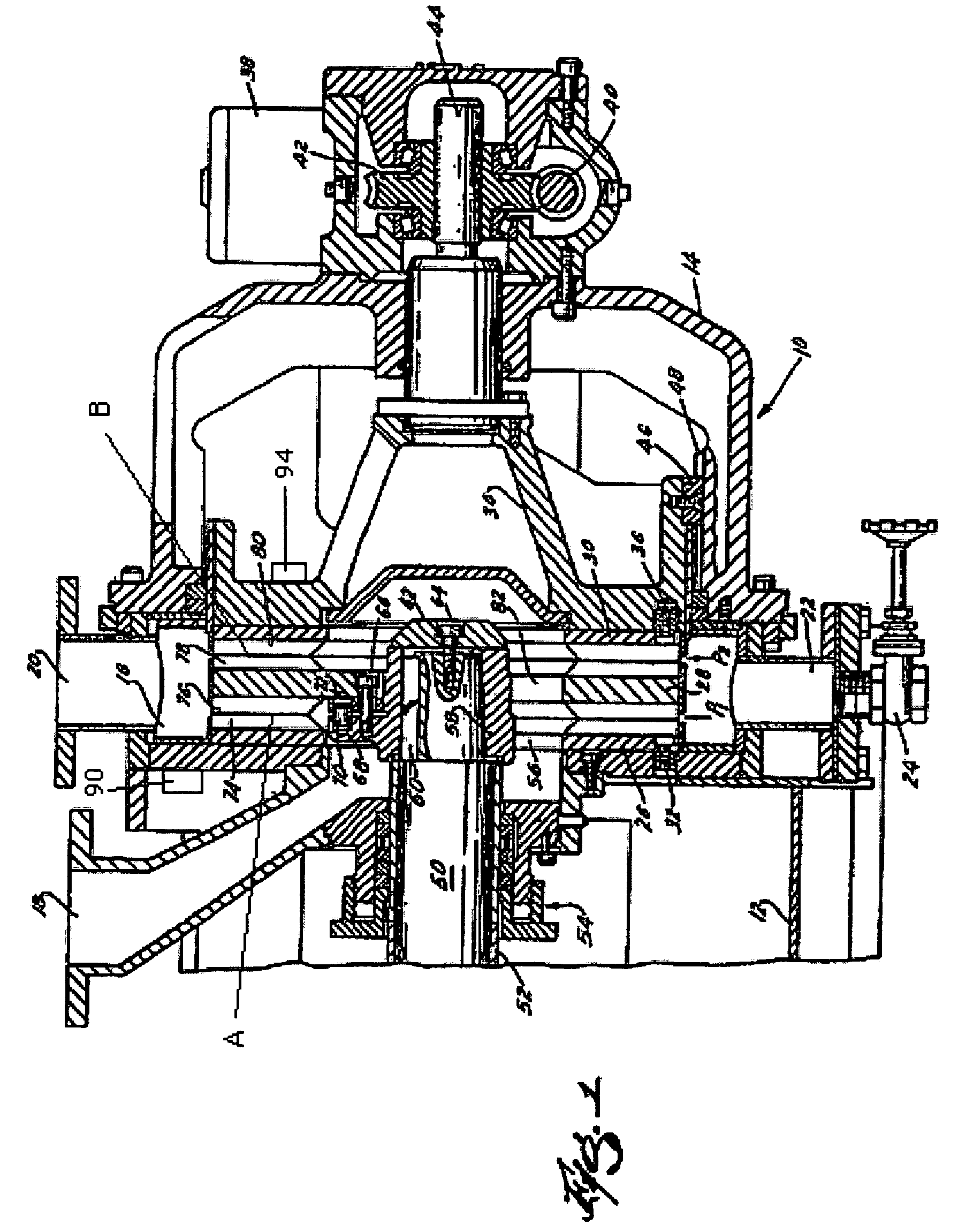

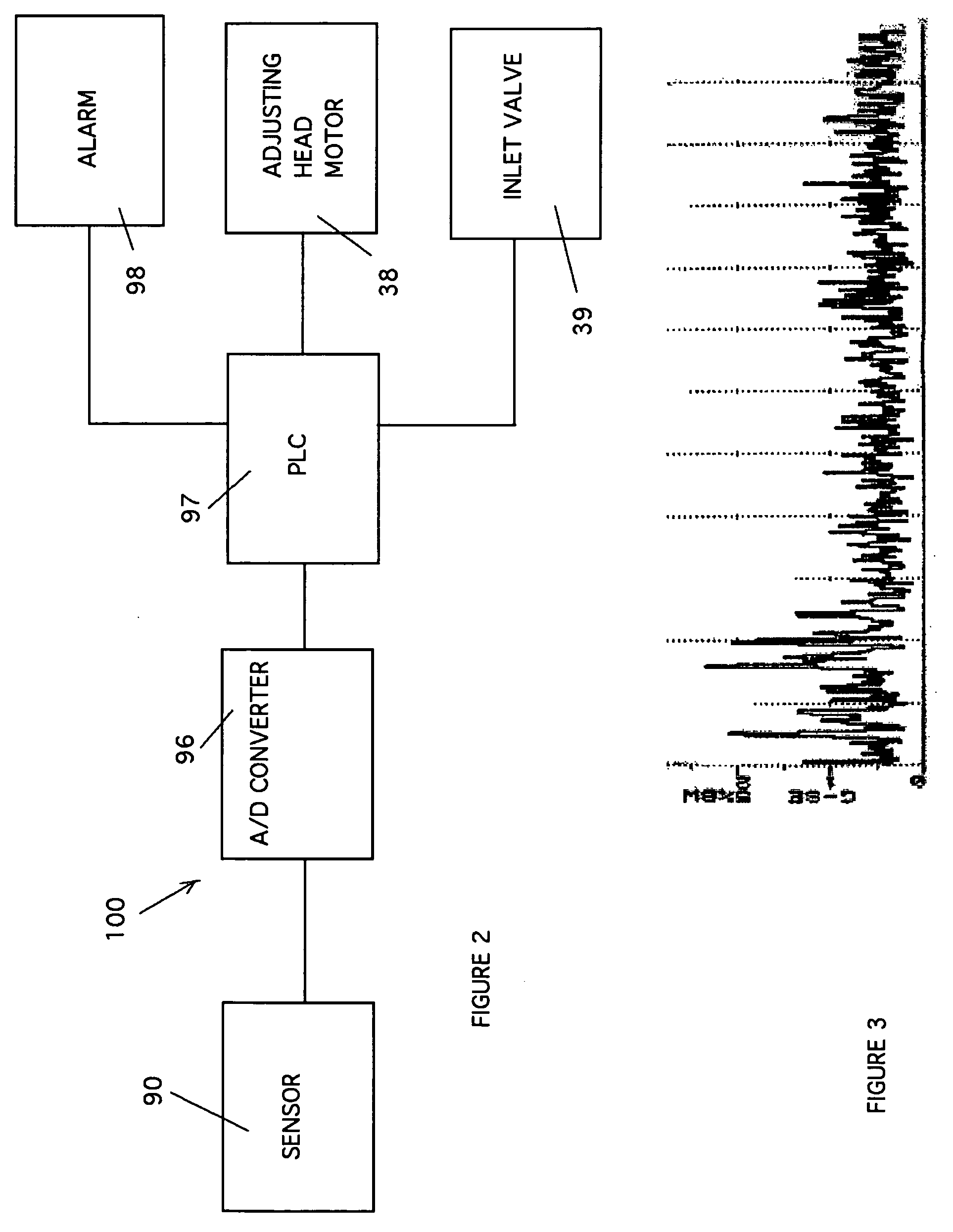

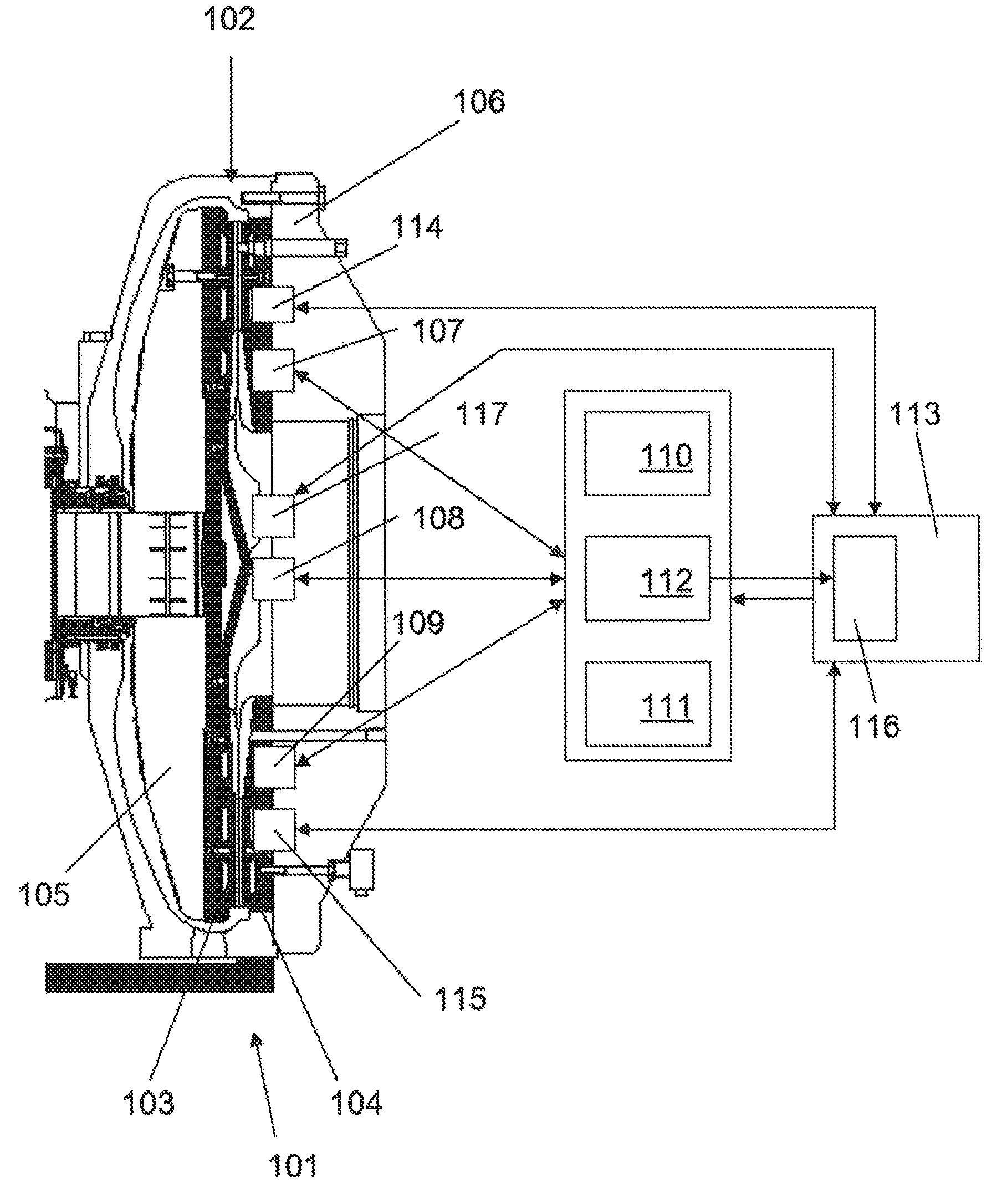

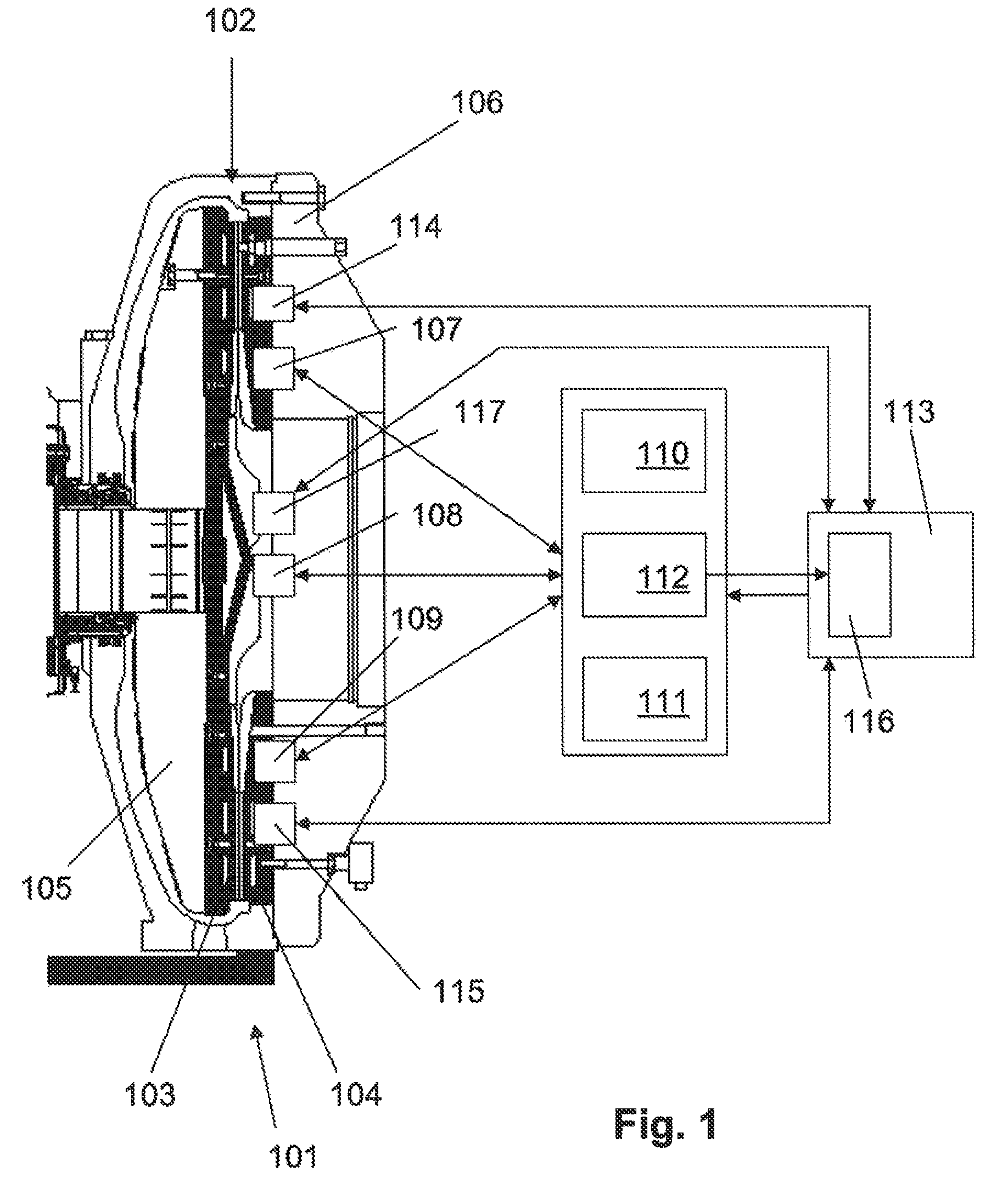

Refining member clash control method

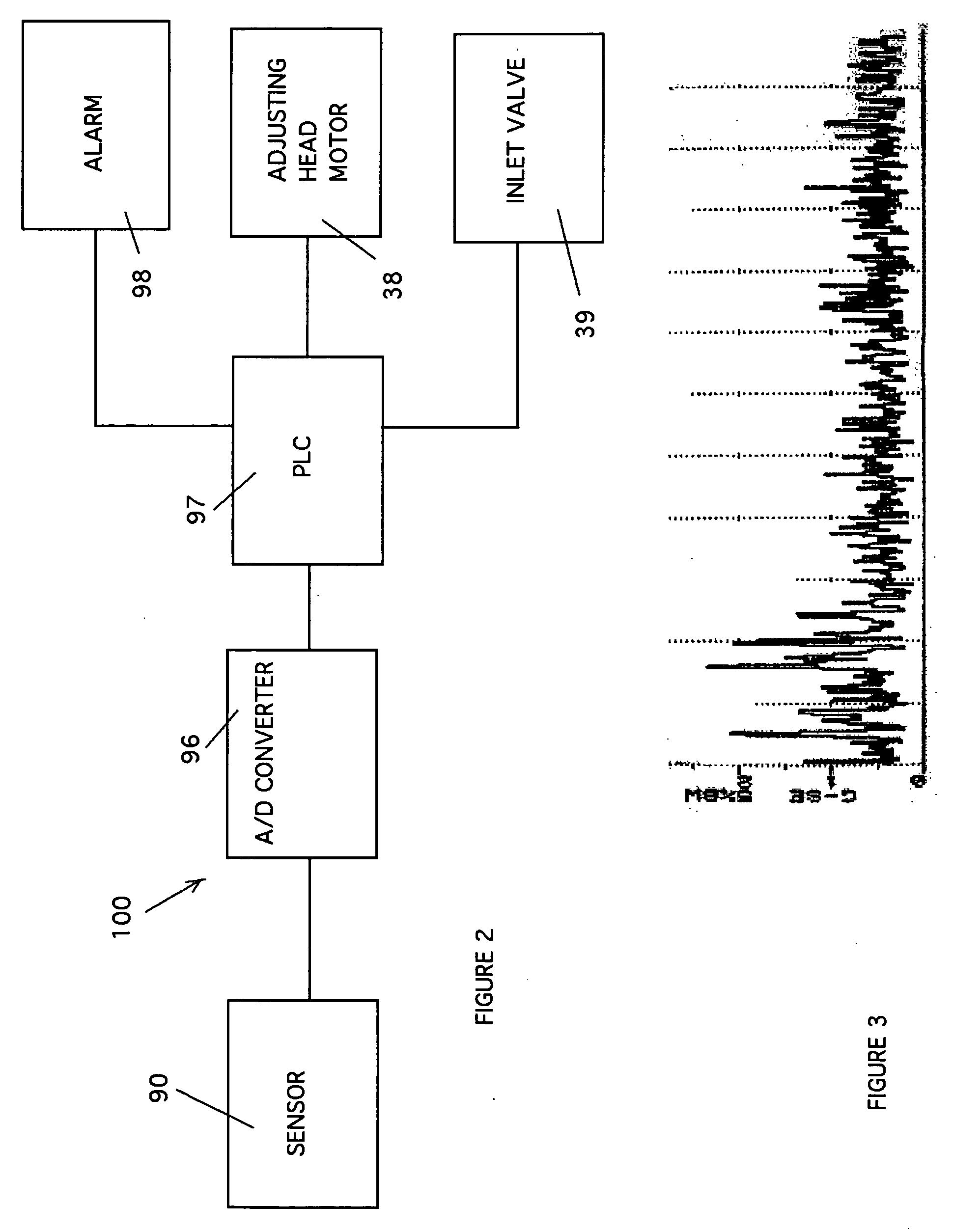

ActiveUS20070125891A1Alleviate plate clashingEasy constructionBeating/refining control devicesCocoaControl systemA d converter

A method and a control system for a refiner for pulp or like materials, the control system comprising a sensor mounted in direct mechanical connection to a non-rotating refining member so that the sensor is responsive to axial vibration movement of the support, and an analog to digital converter connected to the output of the sensor. The method and control system also include a controller connected to the analog to digital converter and responsive to the analog to digital converter to compare the amplitude of the output signal from the sensor to a baseline value based on the level of vibration associated with the pulp refiner when it is operating without plate clashing. When the signal exceeds the baseline value, an action is taken to help alleviate the plate clashing.

Owner:OVIVO LUXEMBOURG R L

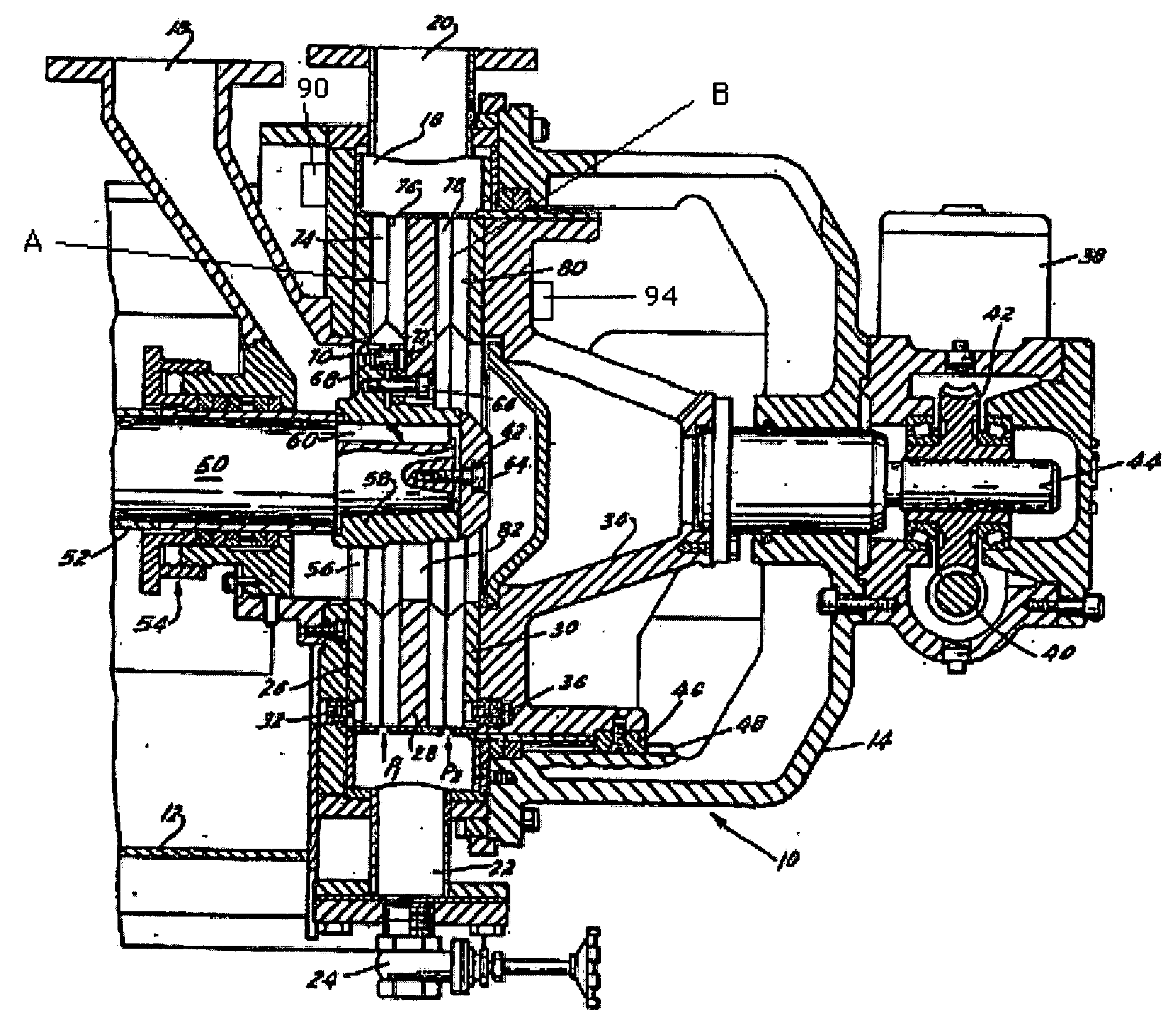

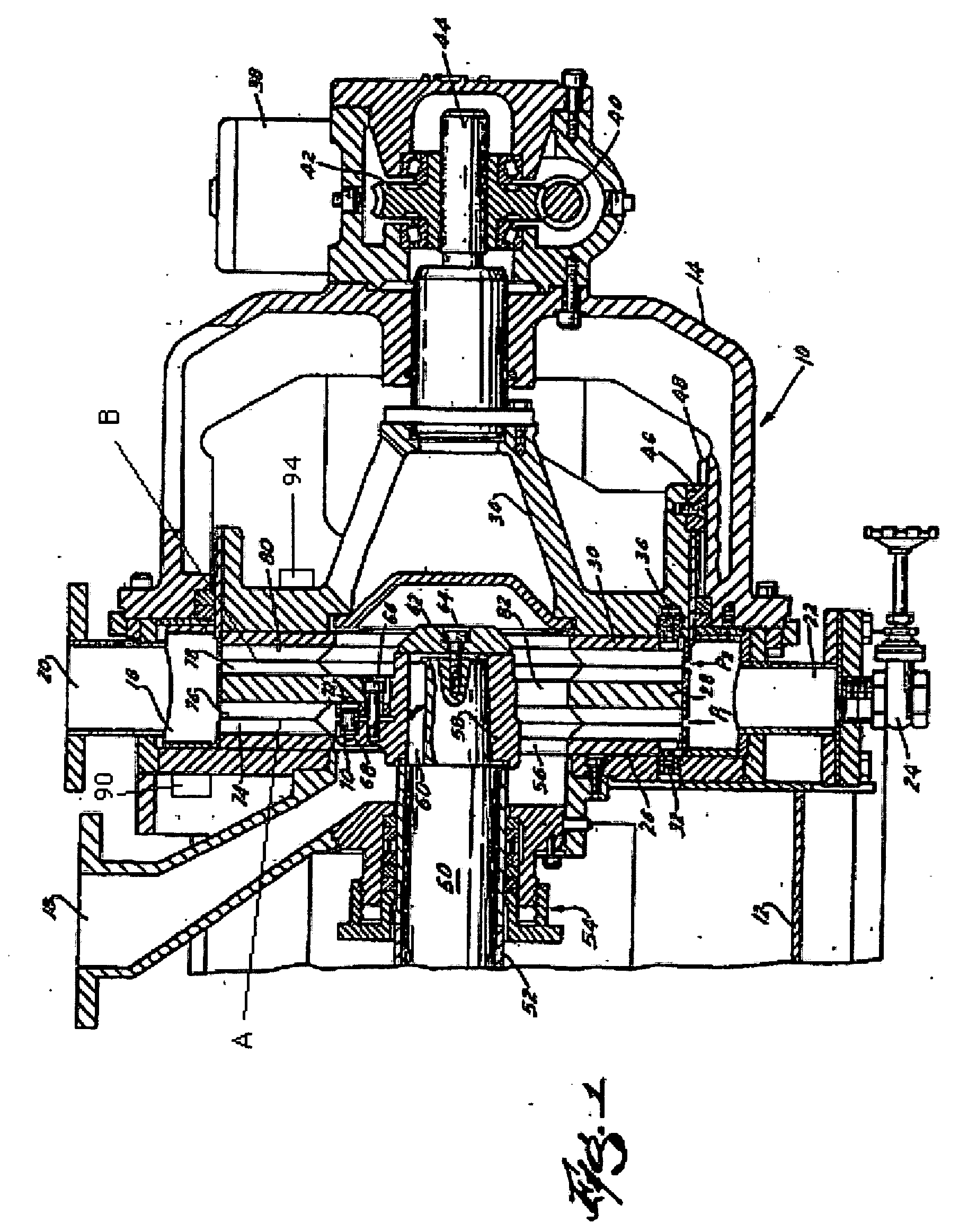

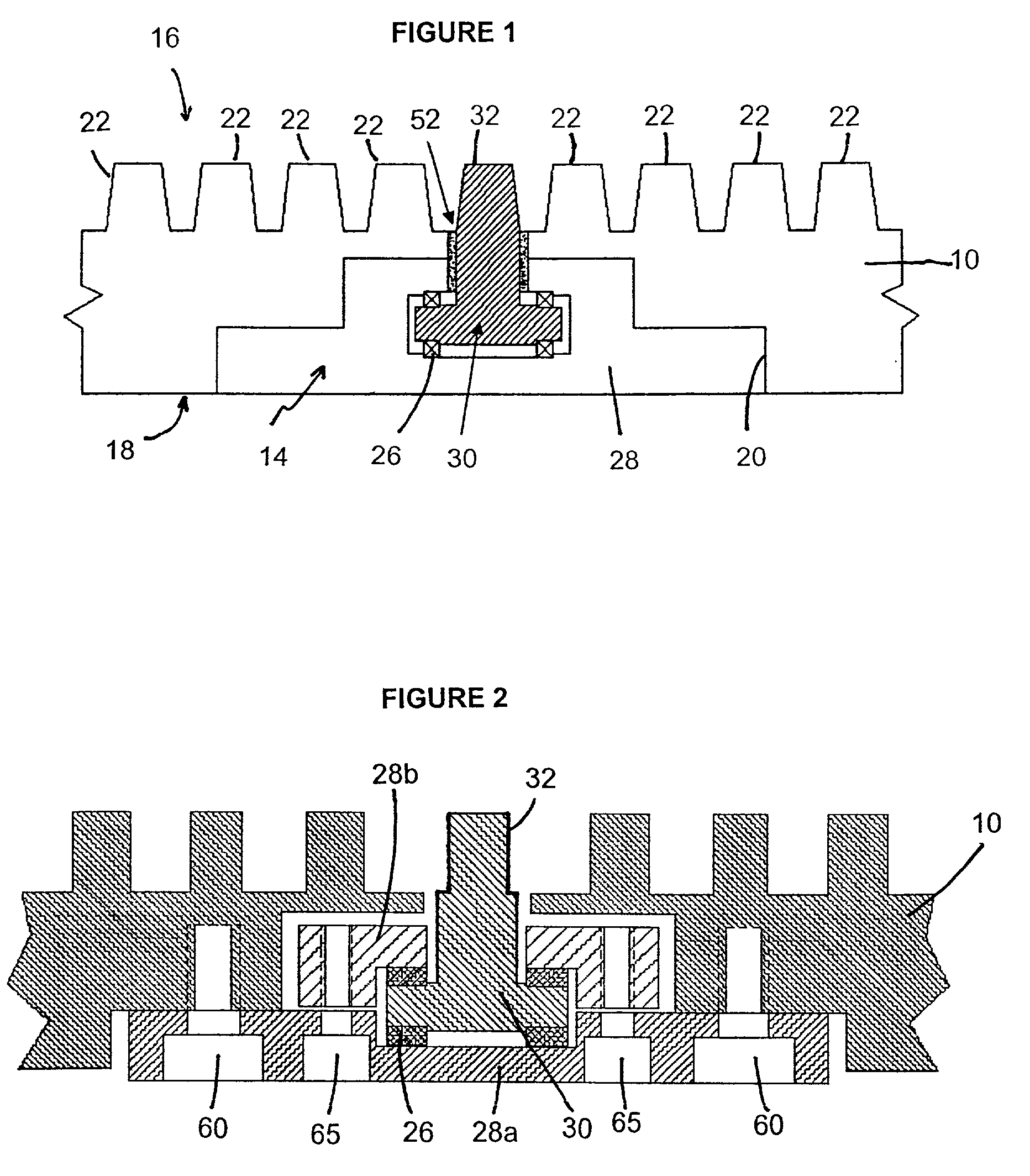

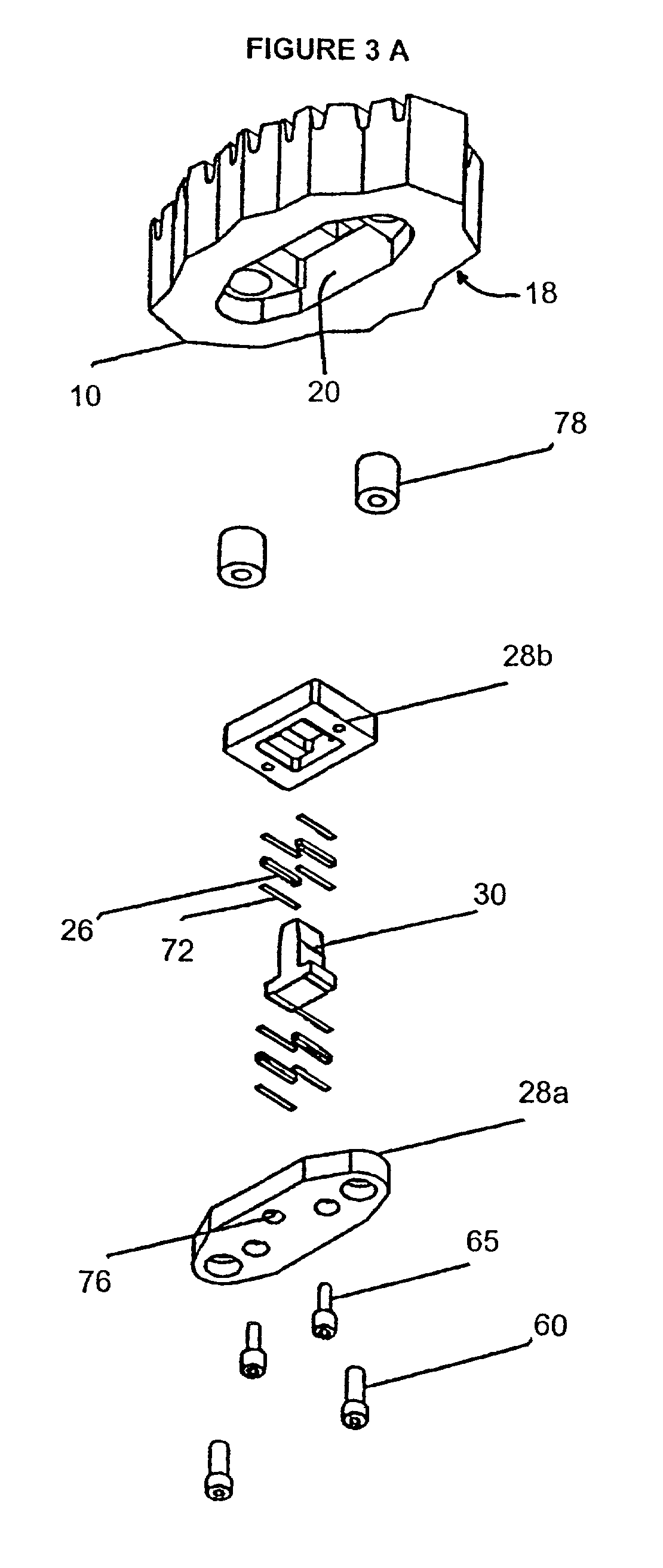

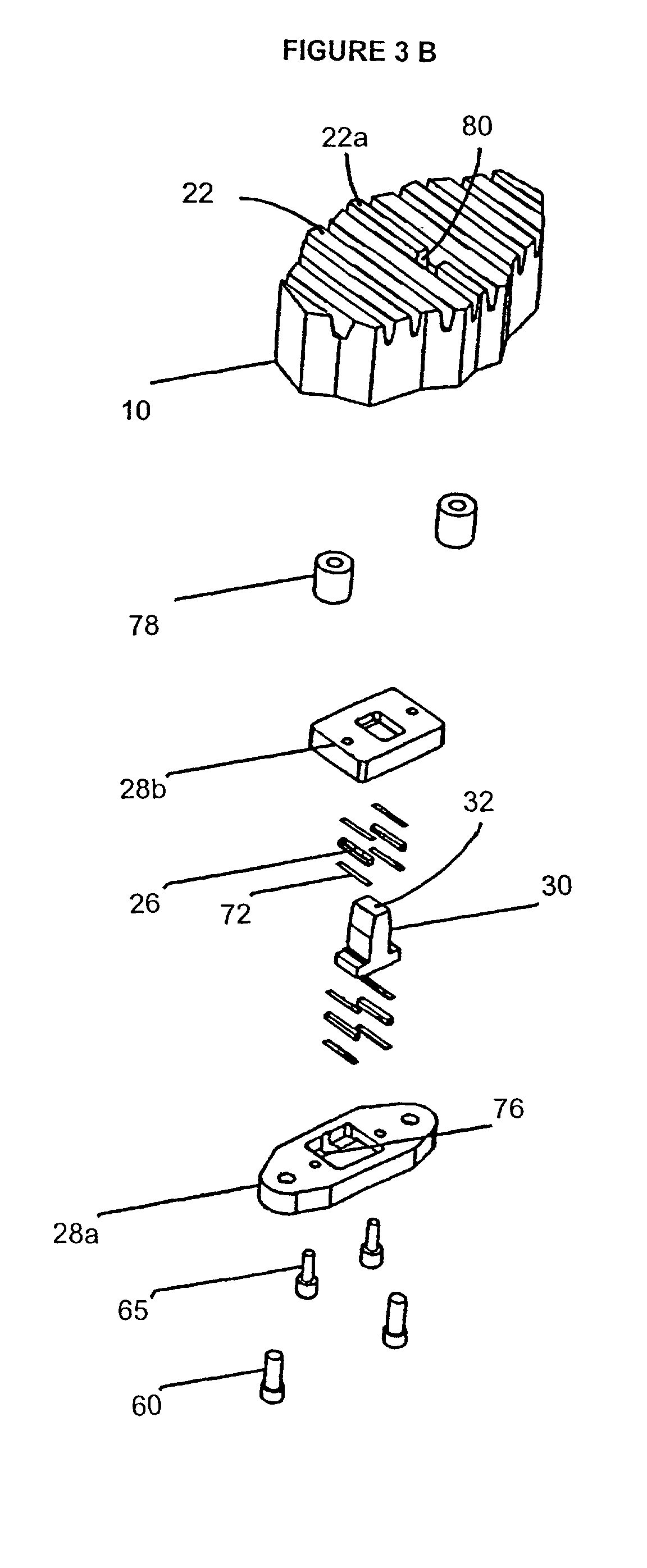

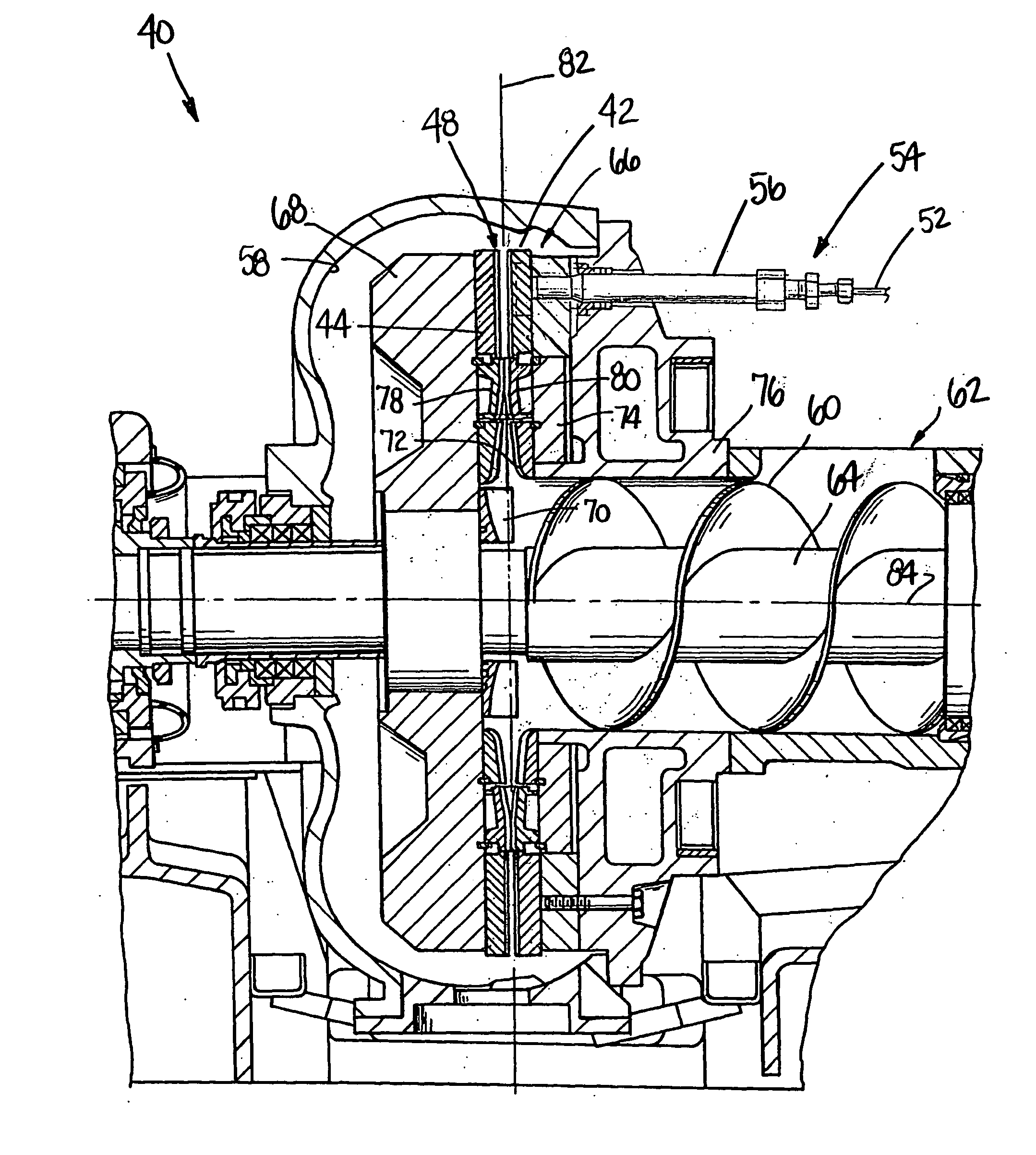

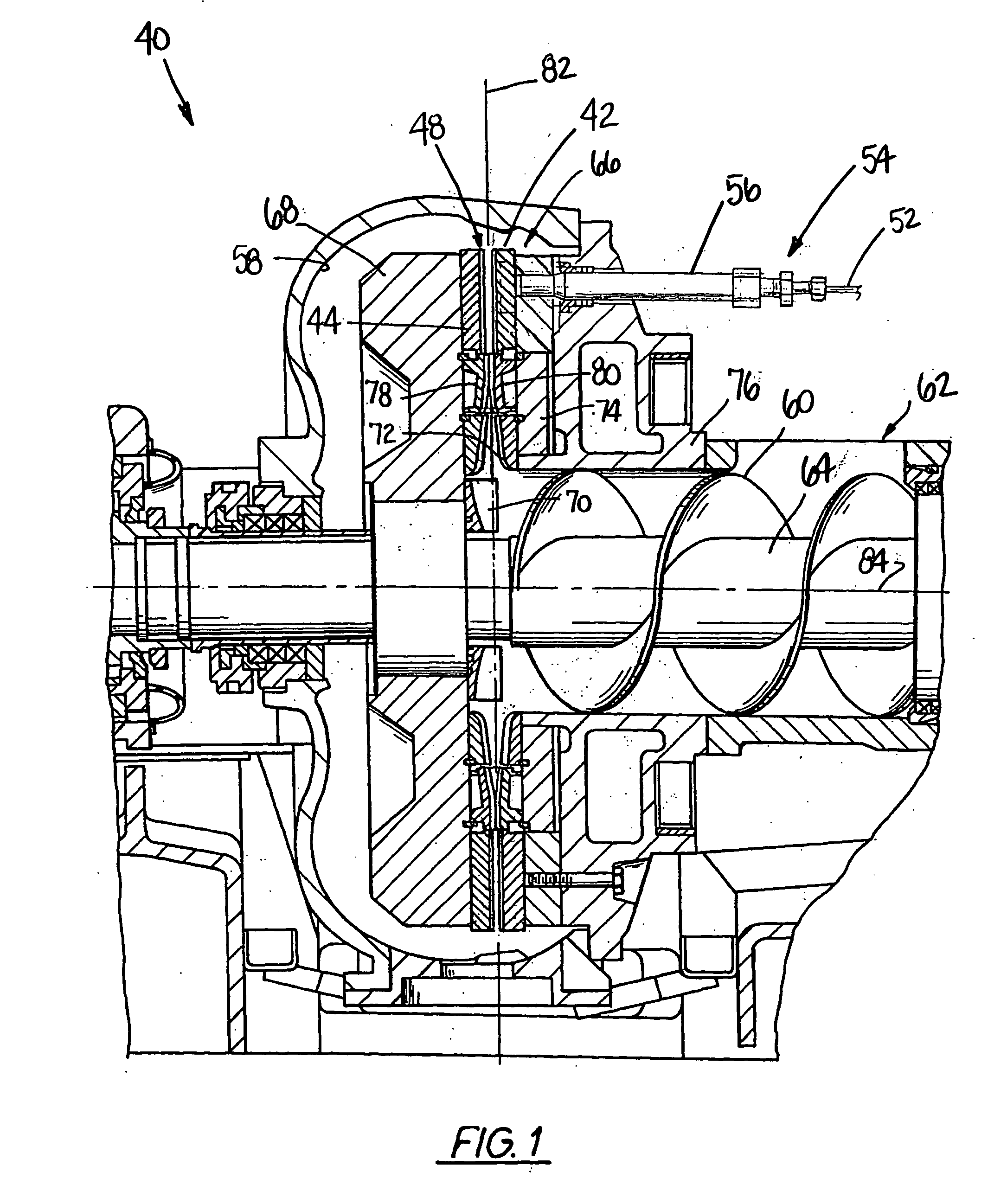

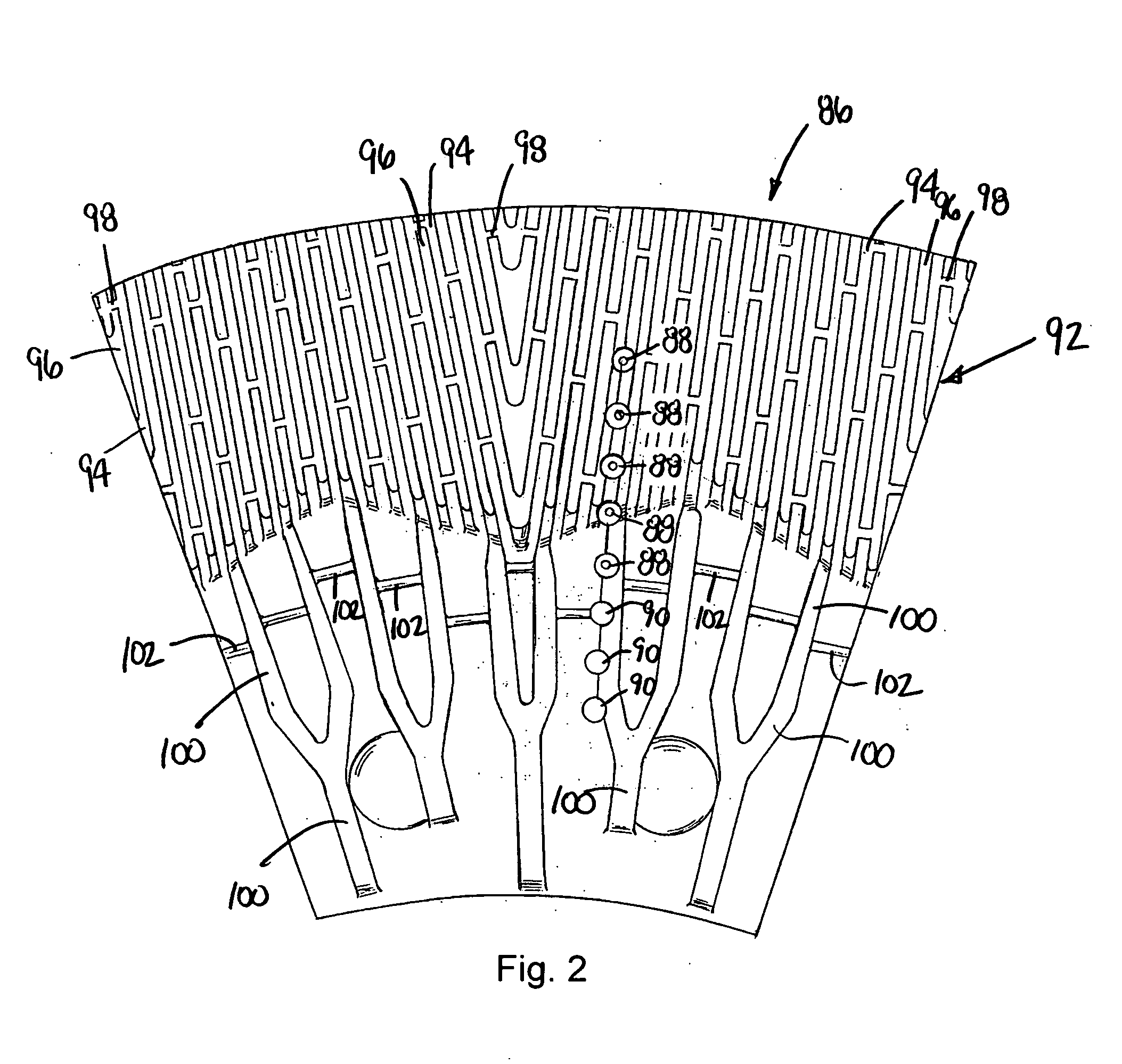

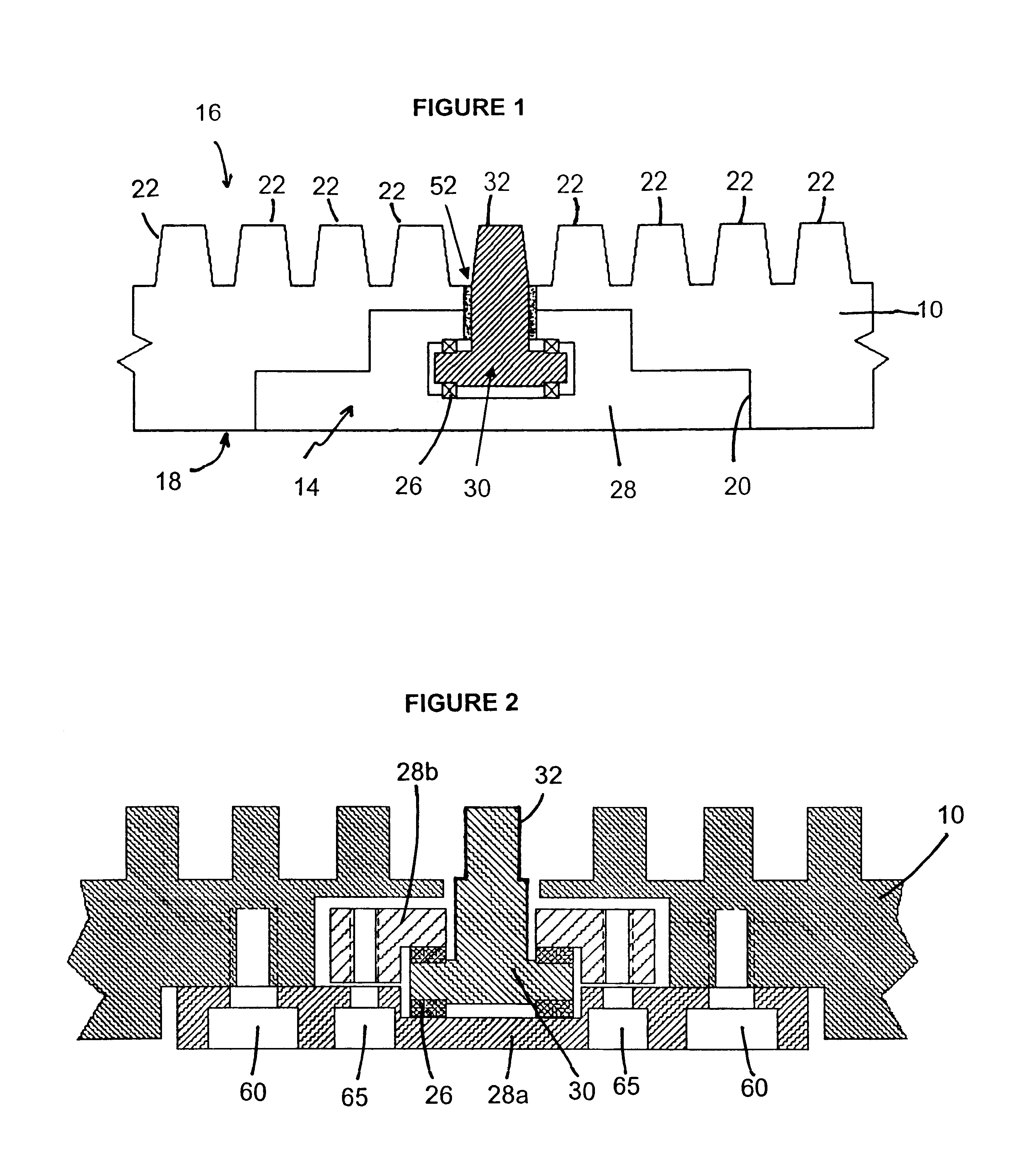

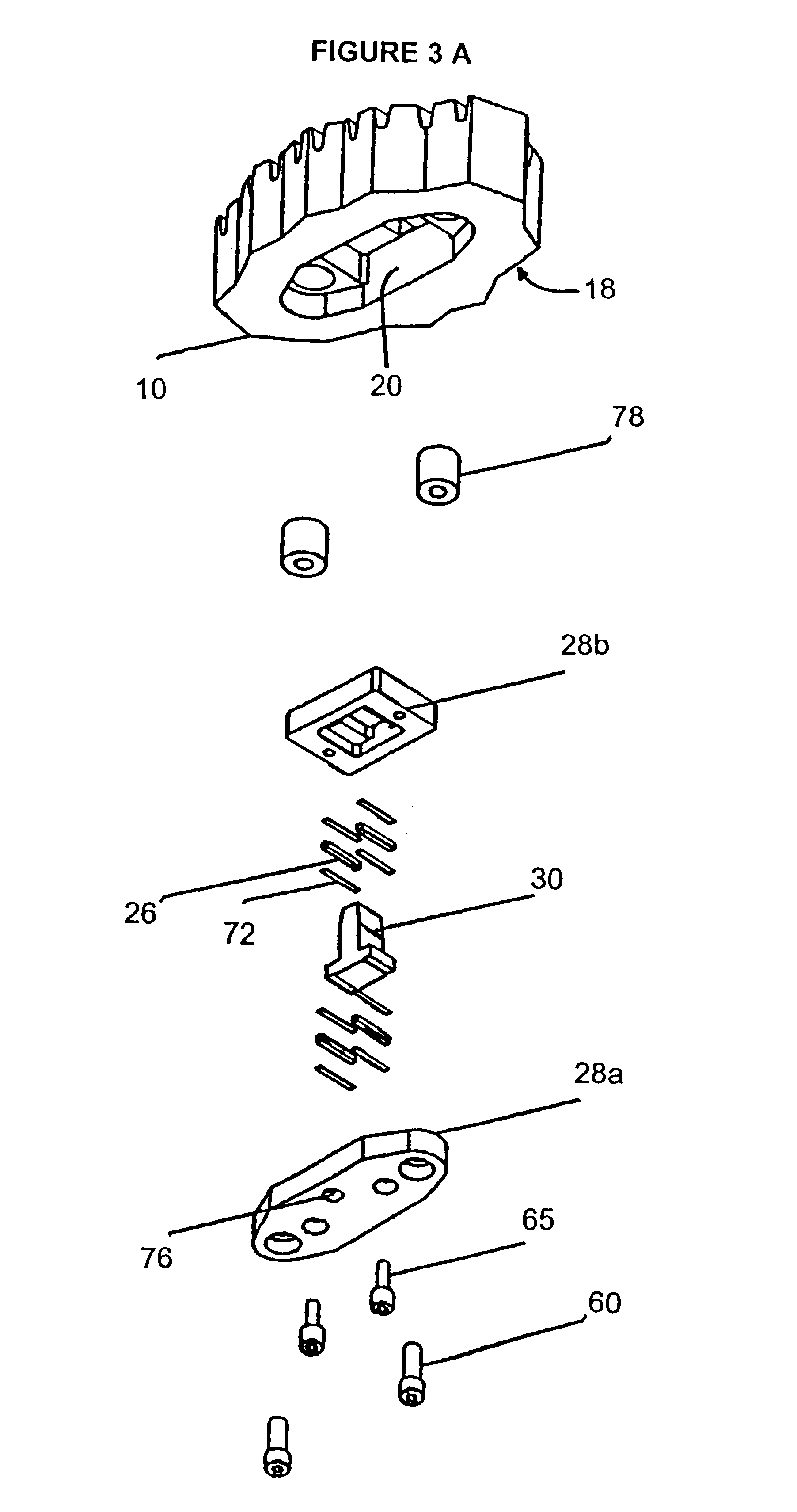

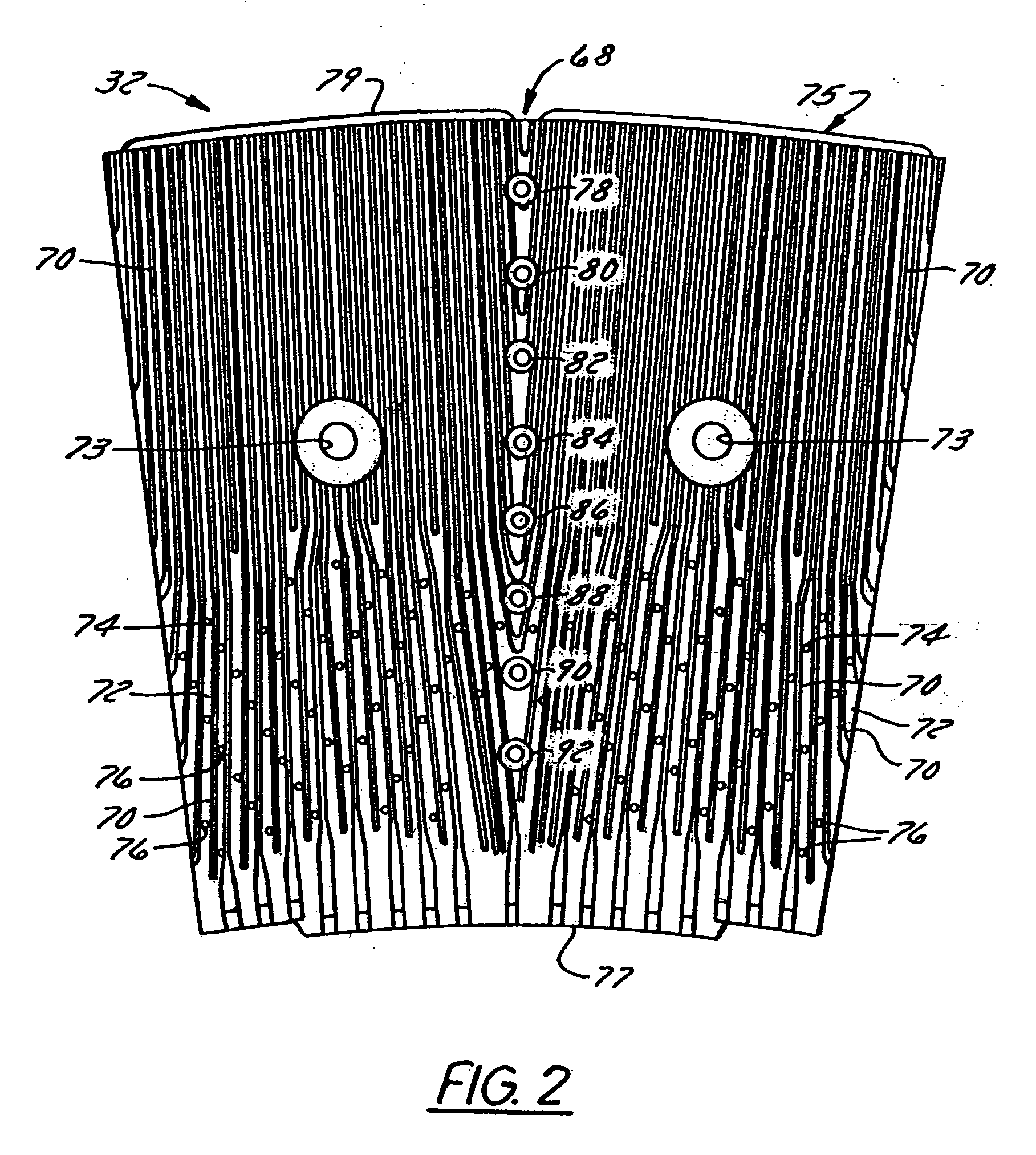

Refiner disk sensor and sensor refiner disk

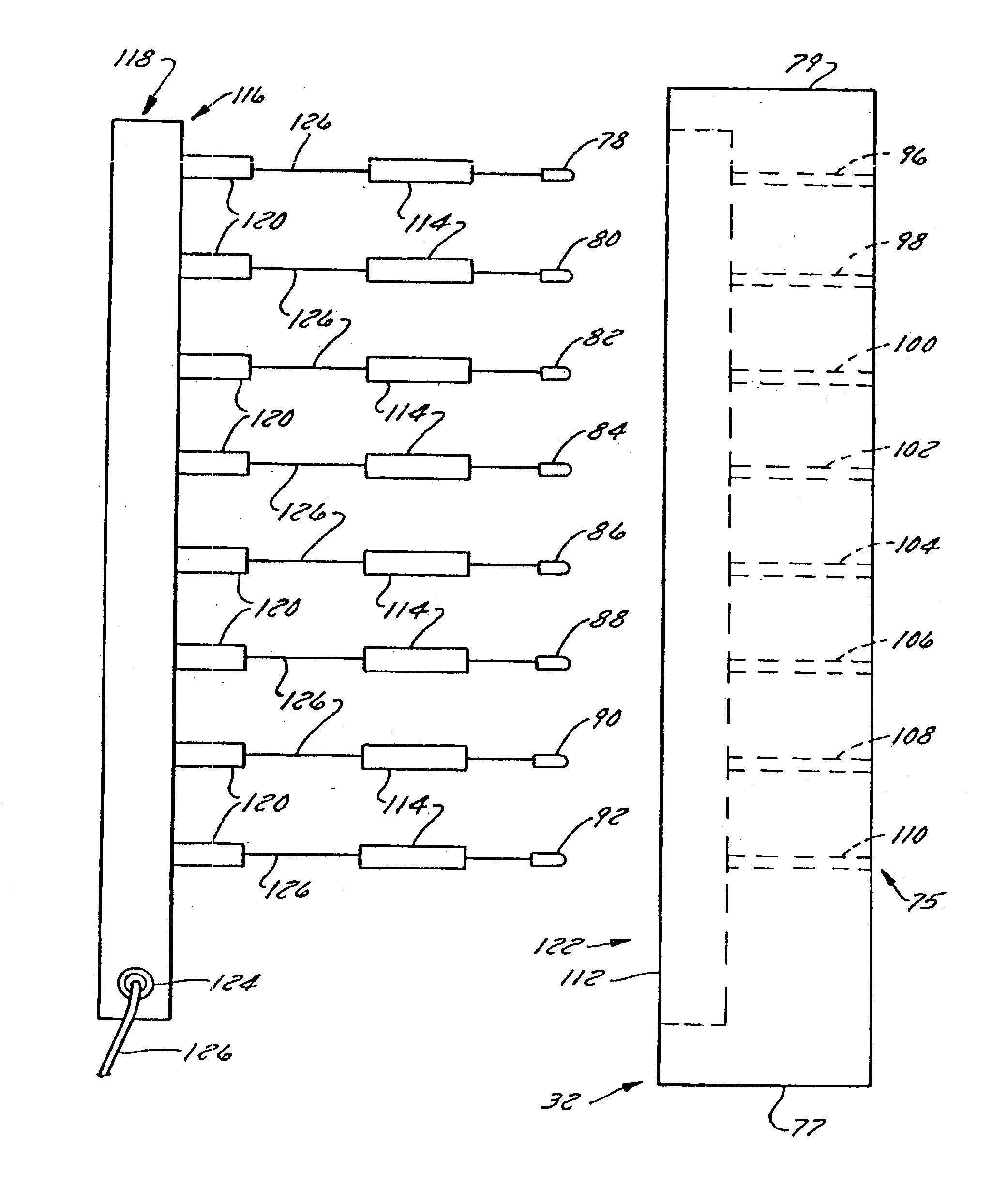

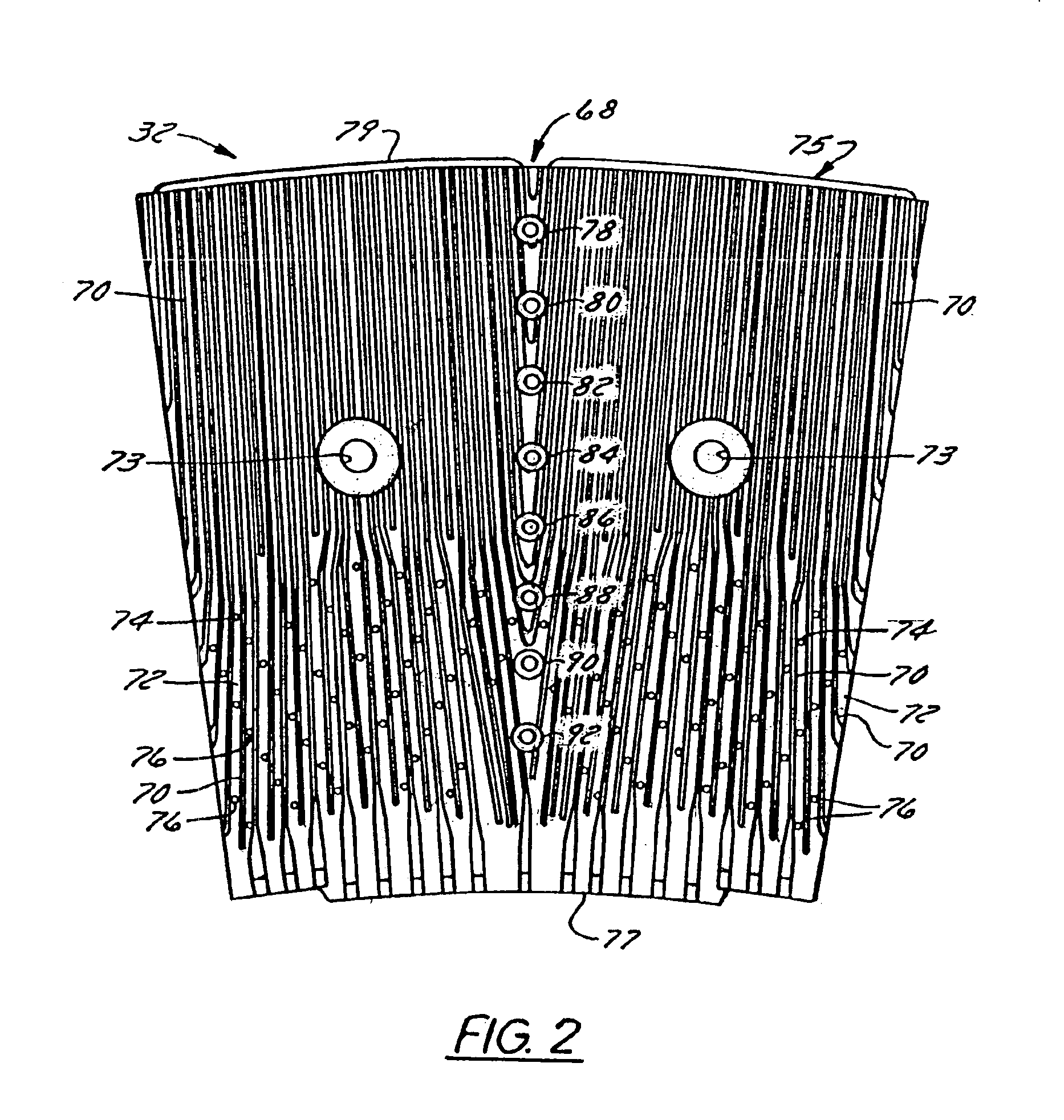

InactiveUS6892973B2Simple and flexible and reliable and long lastingReduce manufacturing costBeating/refining control devicesCocoaFiberEngineering

A sensor, sensor disk, sensor measurement correction system, and method used in measuring a parameter in the refining zone. The sensor includes a spacer that spaces its sensing element from the disk. In one preferred embodiment, the spacer is made of an insulating material that insulates the sensing element from the thermal mass of the disk to prevent the thermal mass from affecting sensor measurement. The sensor includes a housing carried by the spacer that, in turn, carries the sensing element. Where the sensing element is a temperature sensing element, the housing is thermally conductive and the housing and spacer enclose the sensing element. Each sensor is disposed in the refining surface, preferably in its own separate bore in the disk and flush with or below axial refiner bar height. Signals from one or more sensors are processed by a processing device linked to a module containing calibration data that is applied to make sensor measurements more accurate. The module holds calibration data from sensors that are precalibrated before the sensor disk in which they are assembled is shipped, along with the module, to a fiber processing plant where the disk is installed in a refiner and the module connected to the processing device. In one preferred embodiment the sensor or sensors are carried by a sensor module that can be a removable segment of a refiner disk.

Owner:J & L FIBER SERVICES

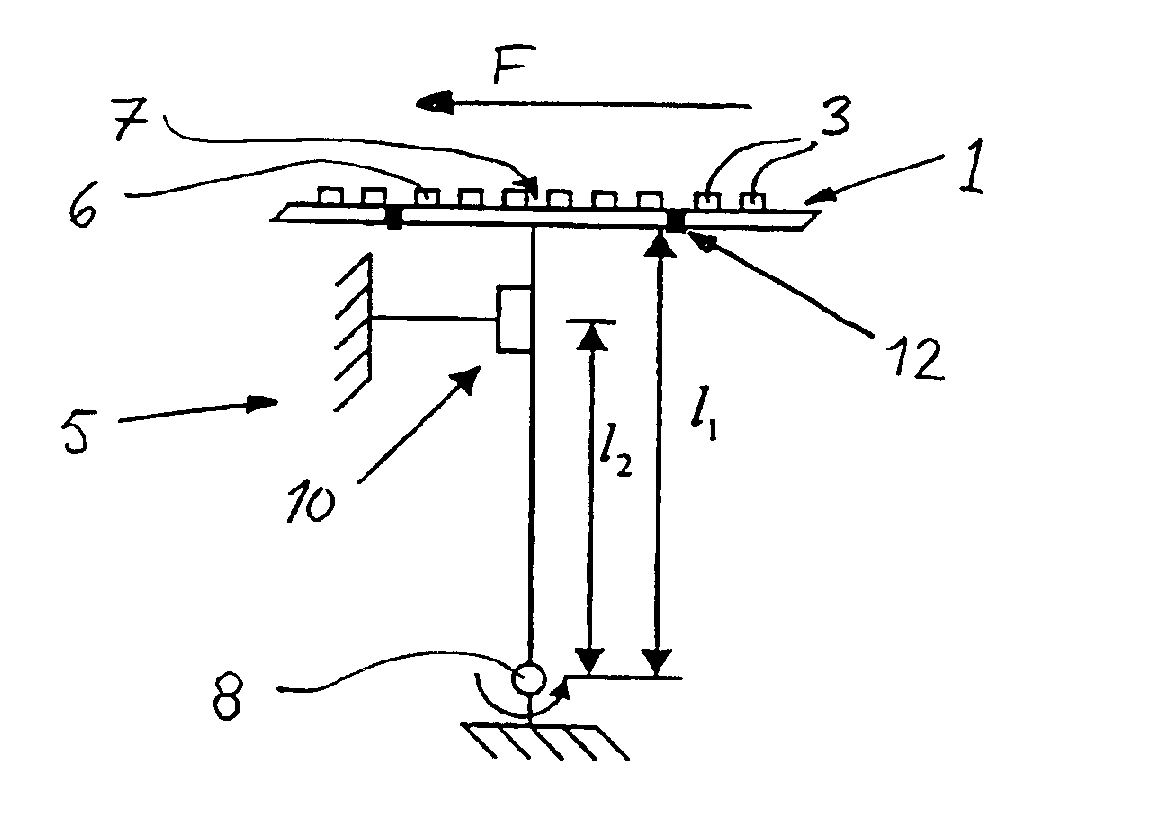

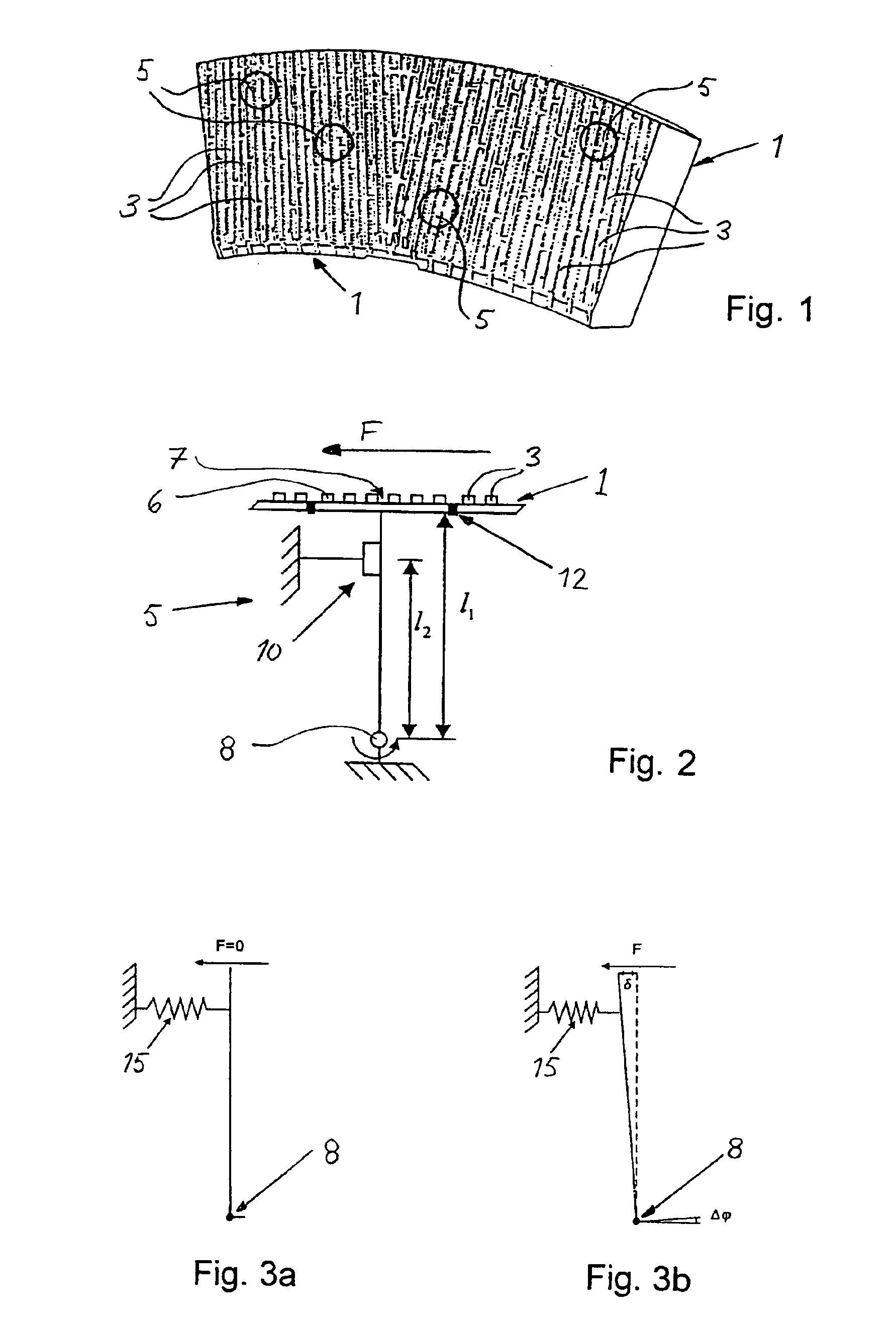

Refiner force sensor

This invention relates to a refiner force sensor for refiners used in the pulp and paper industry, to a refining apparatus, and to a method of measuring force acting on a refiner bar in a refiner.

Owner:QUEENS UNIV OF KINGSTON +3

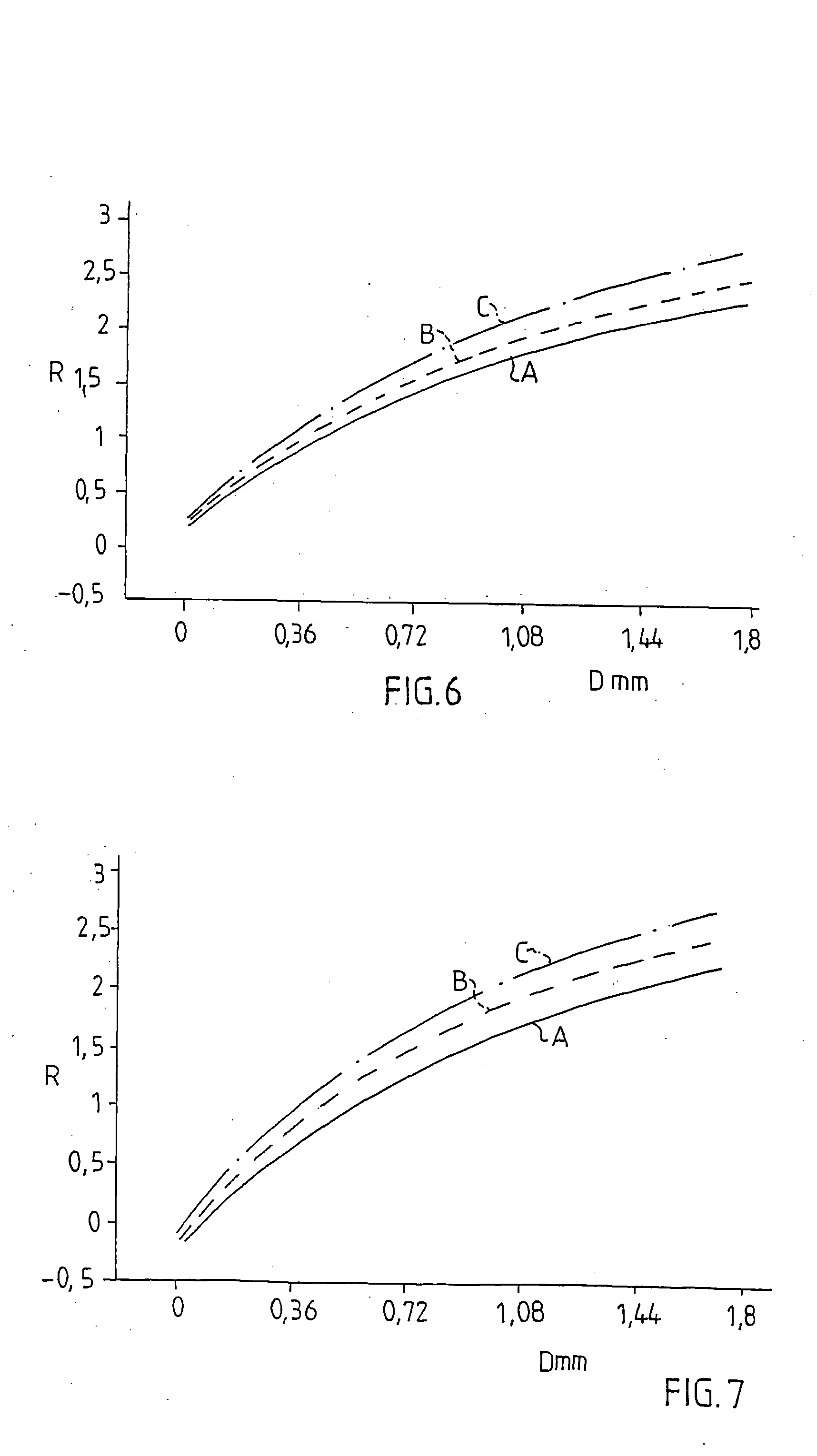

Method of diagnosing and controlling a grinding mill for paper and the like

InactiveUS6955309B2Simple designBroaden applicationBeating/refining control devicesCocoaFiberPulp and paper industry

This invention relates to a method of diagnosing or controlling a grinding mill for paper pulp, wood chips, or other fibrous materials, by measuring the incremental change in power related to an incremental change in the gap, and using the ratio of the two differences, together with the measure of applied power, as the diagnostic or control parameter.

Owner:AIKAWA FIBER TECH

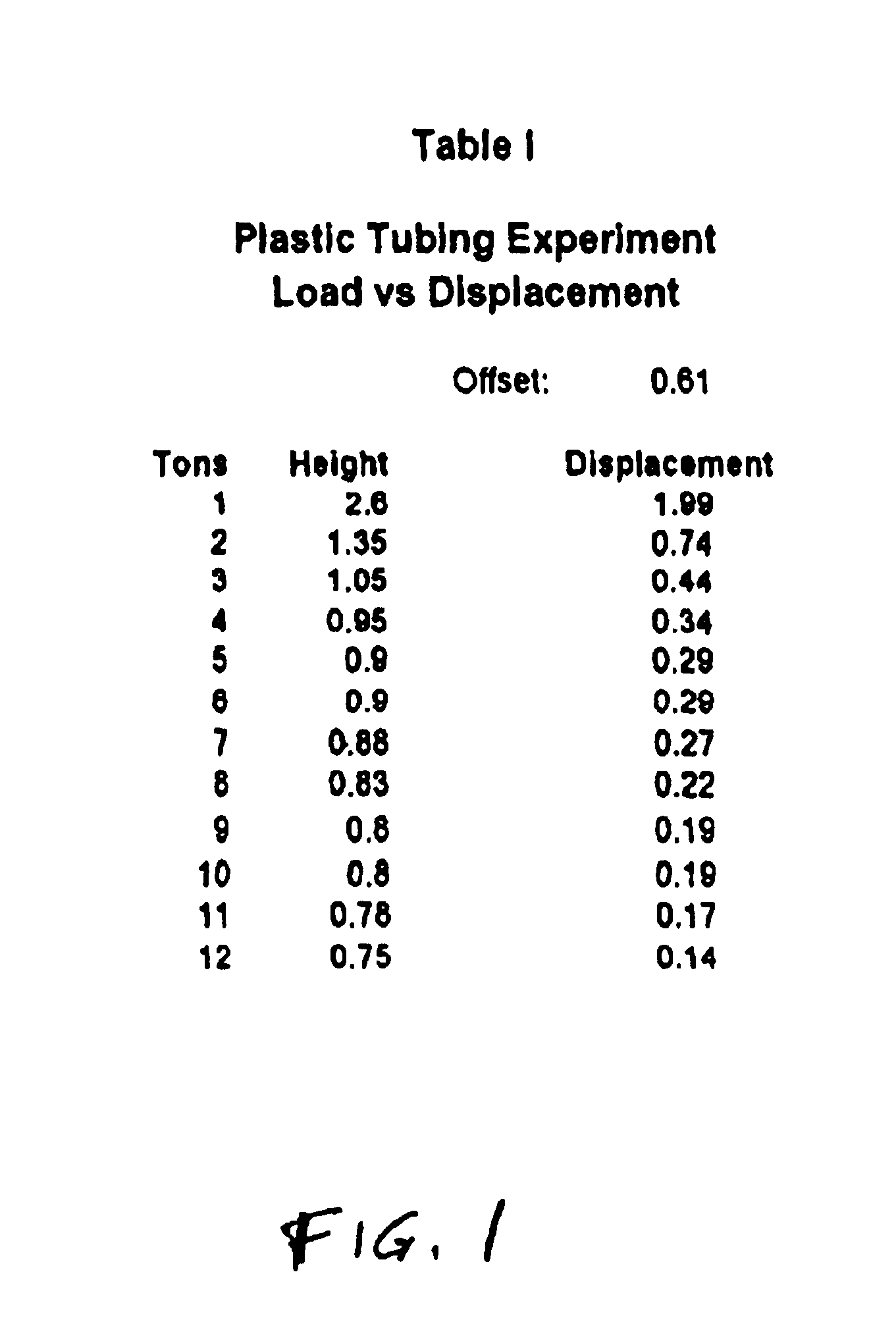

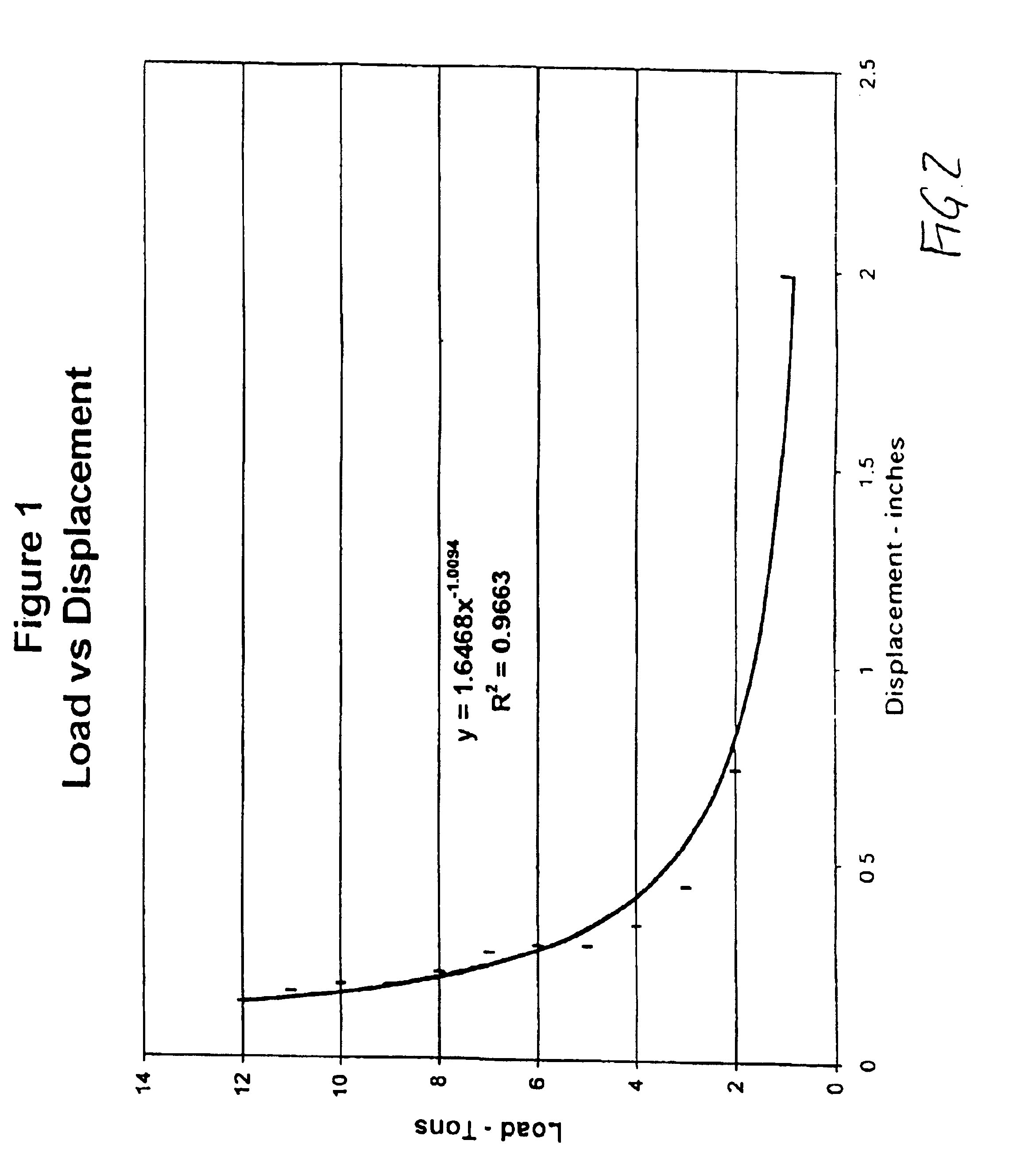

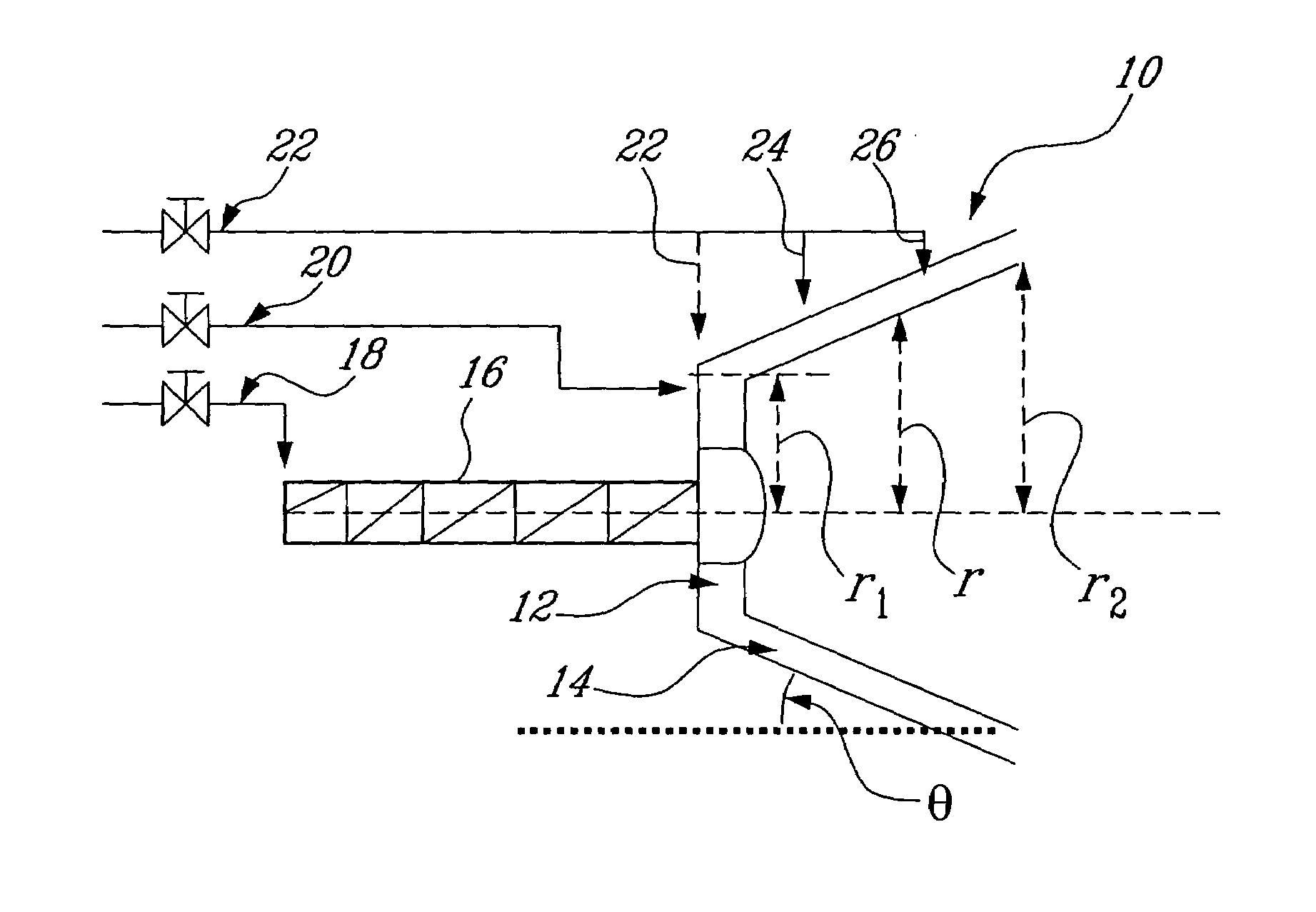

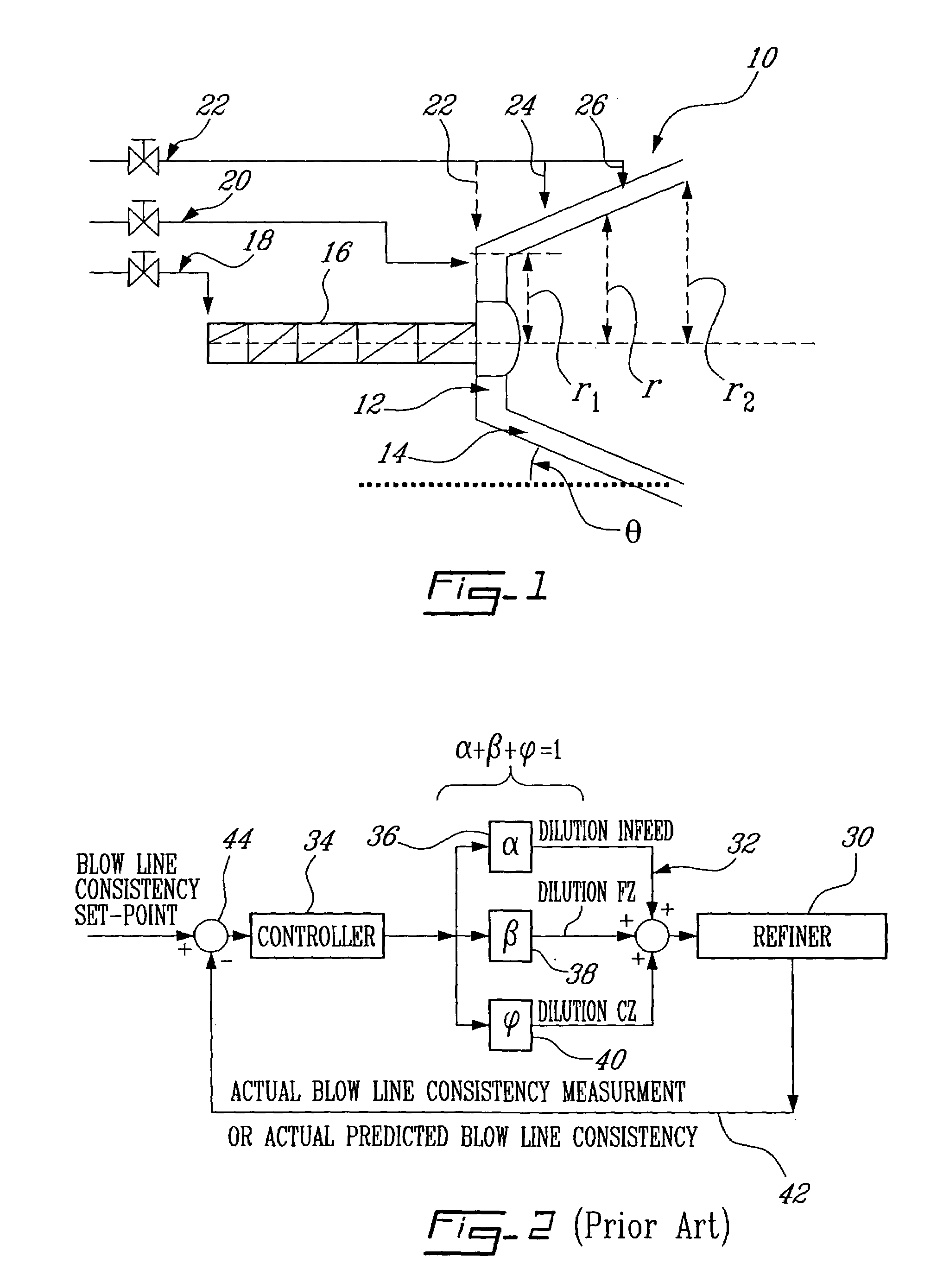

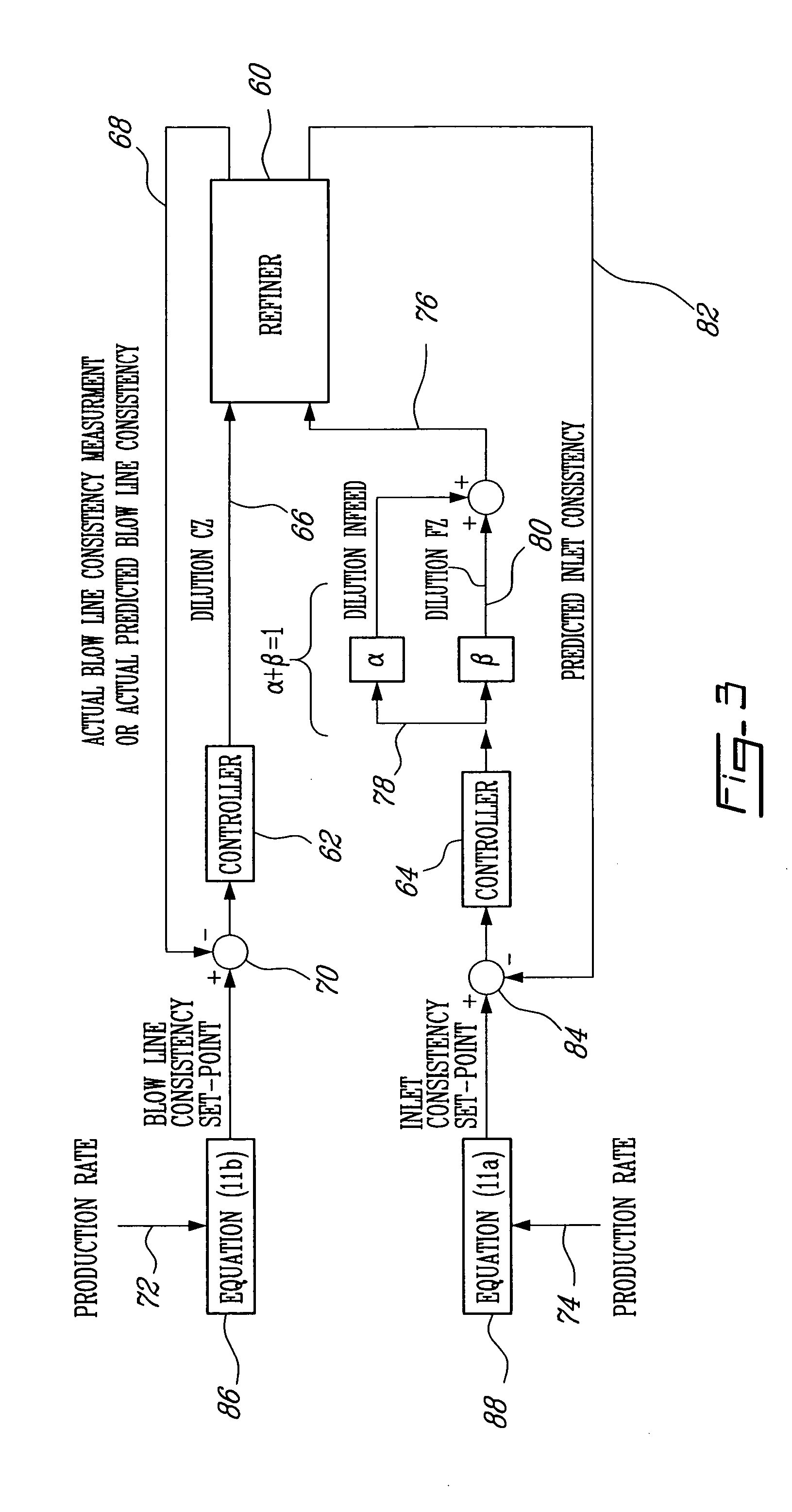

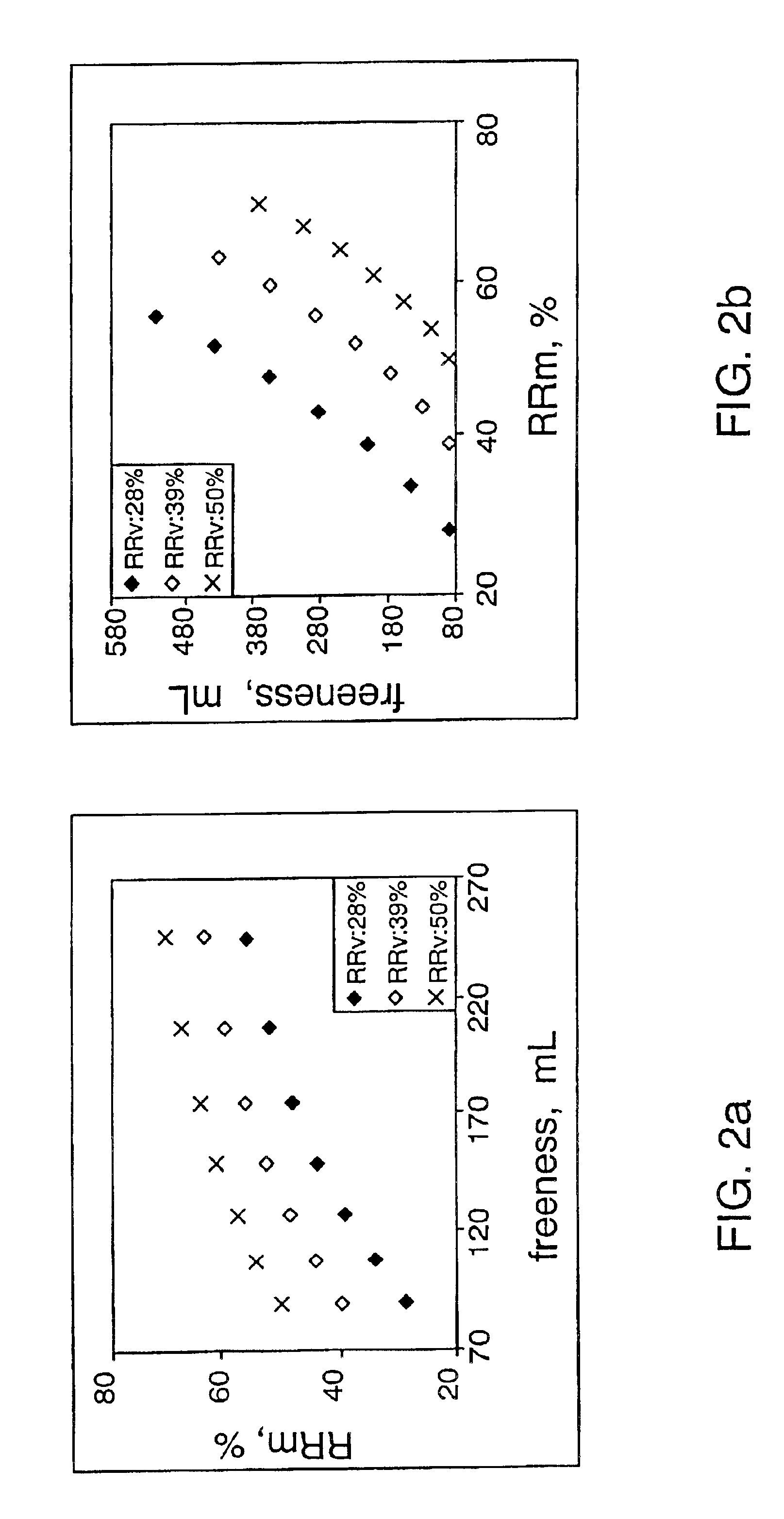

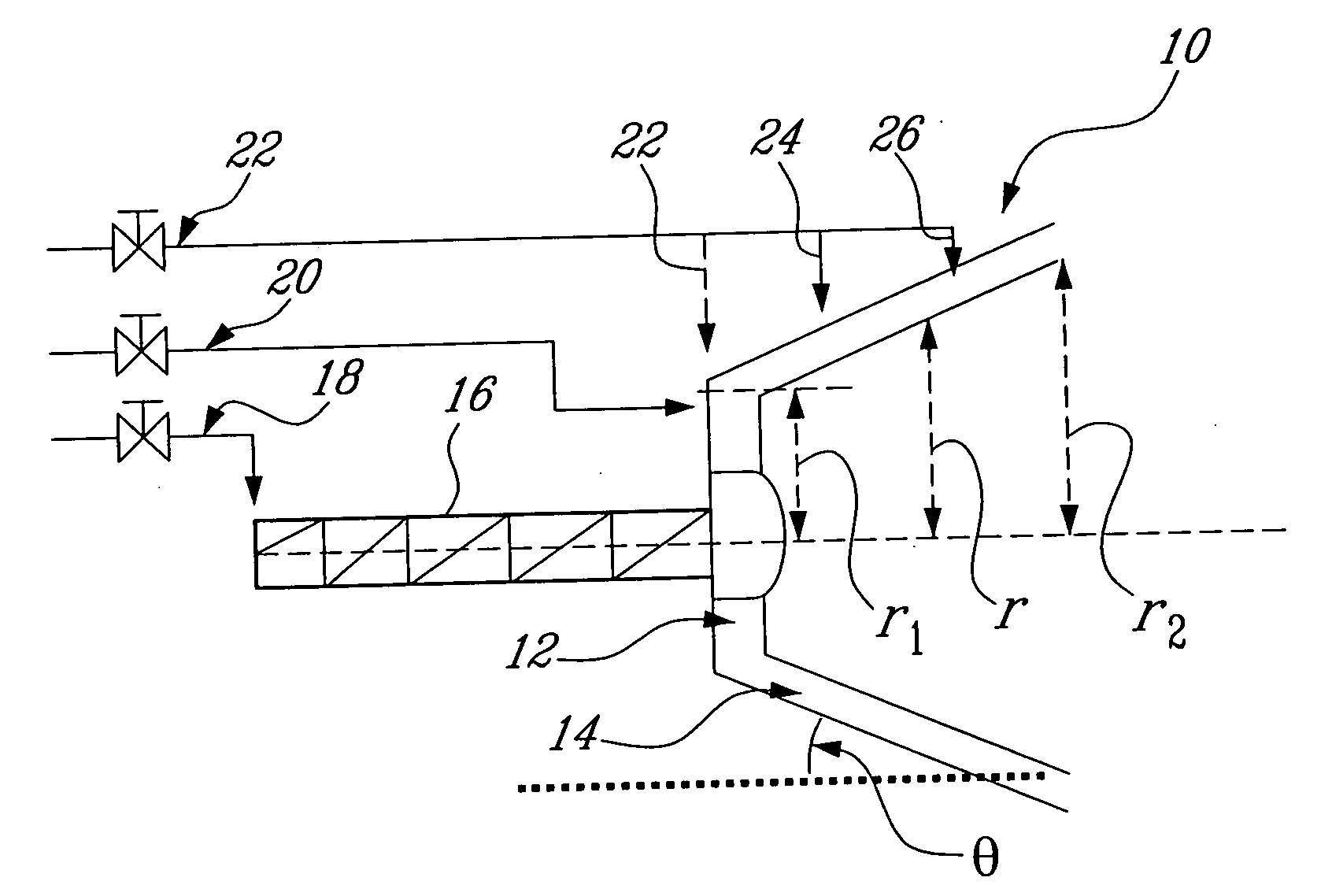

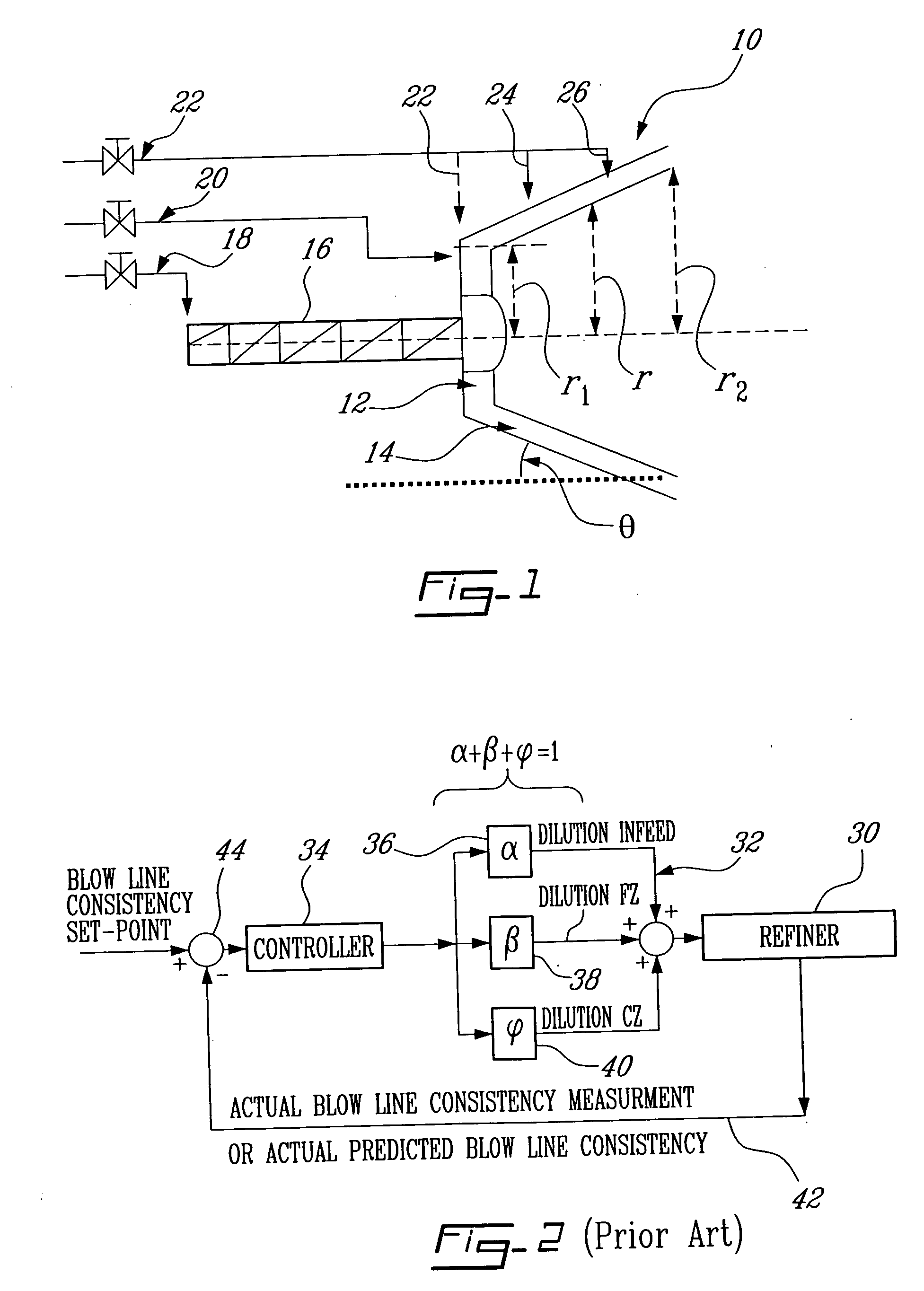

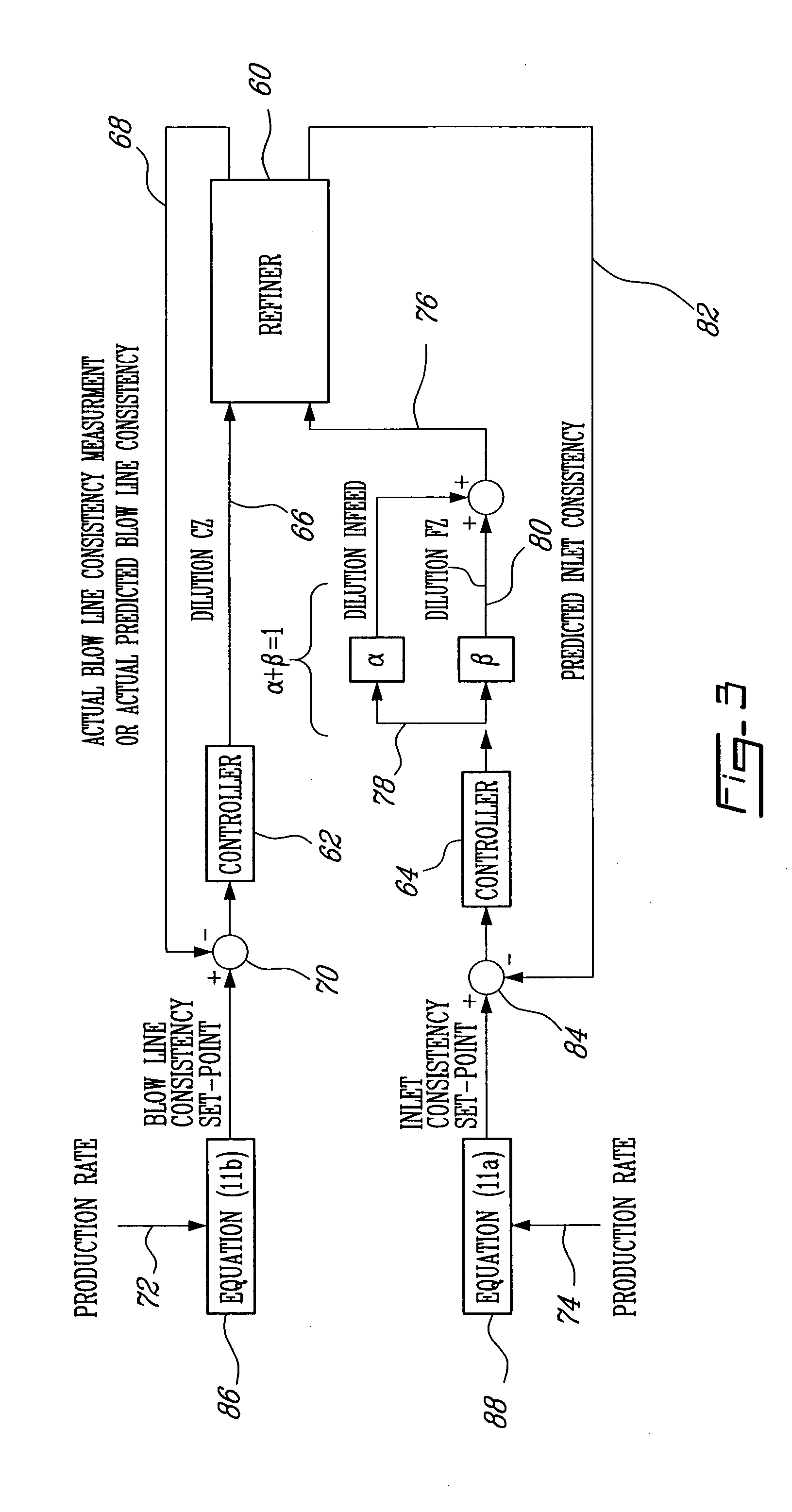

Method of refining wood chips or pulp in a high consistency conical disc refiner

ActiveUS7240863B2Avoid cloggingImprove consistencyBeating/refining control devicesReed/straw treatmentProduction rateFiber

A method is proposed for improving pulp quality at high production rates on conical disc refiners. It permits a reduction in refining intensity by enabling fibre residence time to increase by increasing consistency, while avoiding the problem of plate plugging normally associated with high discharge consistency. In practice, inlet consistency is increased by the in-feed dilution, flat zone dilution or both, but without allowing the discharge consistency to rise. Instead, the discharge consistency is controlled at a fixed optimum value by the addition of dilution water within the conical zone. The result is that residence time is increased, and refining intensity decreased, by raising the consistency in the inner region of the refining zone, while avoiding the plate plugging caused by excessive consistency in the outer region of the refining zone.

Owner:FPINNOVATIONS INC

Refiner sensor and coupling arrangement

InactiveUS20050211809A1Improve assembly reliabilityImprove robustnessBeating/refining control devicesCocoaCouplingEngineering

A sensor assembly and coupling arrangement for a rotary disk refiner. The sensor assembly includes a housing formed by a base and frustoconical cap that has a sensing element carrying bulb extending outwardly therefrom. The coupling arrangement includes a conduit arrangement that is received in one or more aligned preexisting instrument ports of the refiner and that releasably couples with a connector puck. The puck is carried by the backside of a refiner disk segment that lies next to the refiner disk segment that is equipped with one or more sensor assemblies. Preferably, a flexible hose communicates sensor wiring from a sensor manifold that holds a plurality of sensor assemblies to the connector puck. The sensor manifold preferably is carried by the backside of the sensor refiner disk.

Owner:J & L FIBER SERVICES

Method and means for measuring stress forces in refiners

InactiveUS6915711B1Reliable resultsMeasure directlyBeating/refining control devicesForce measurementEngineering

Owner:VALMET FIBERTECH AB

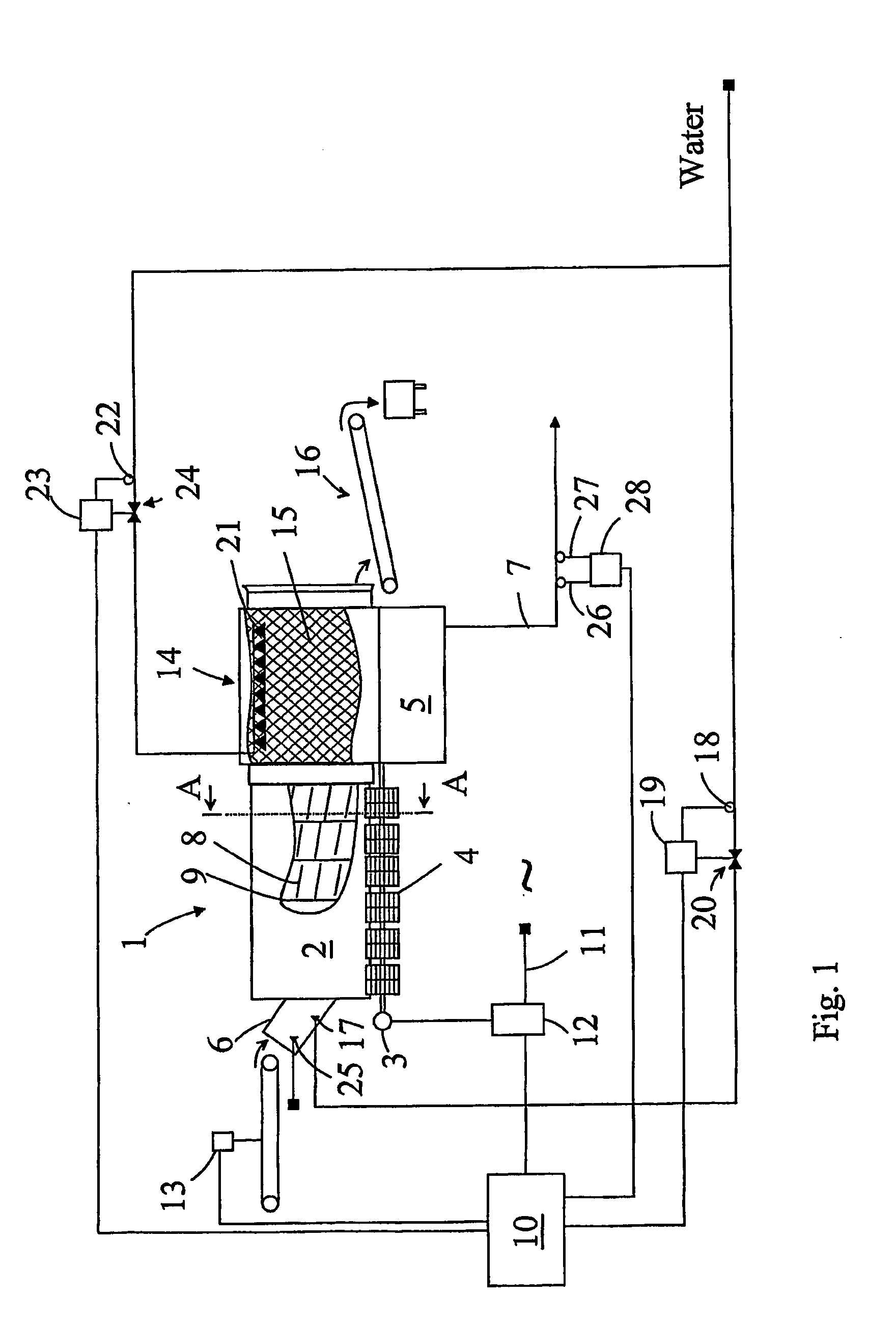

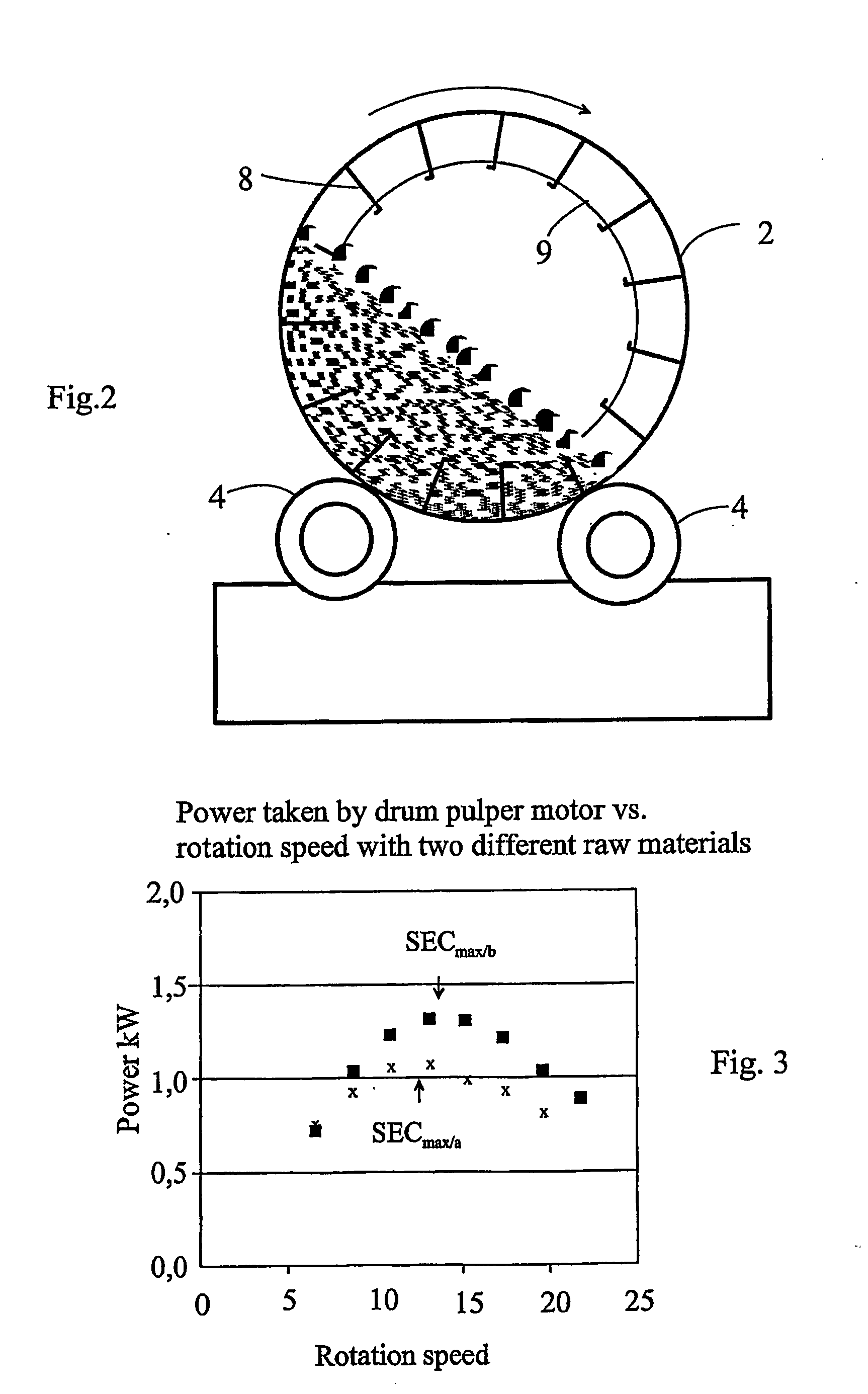

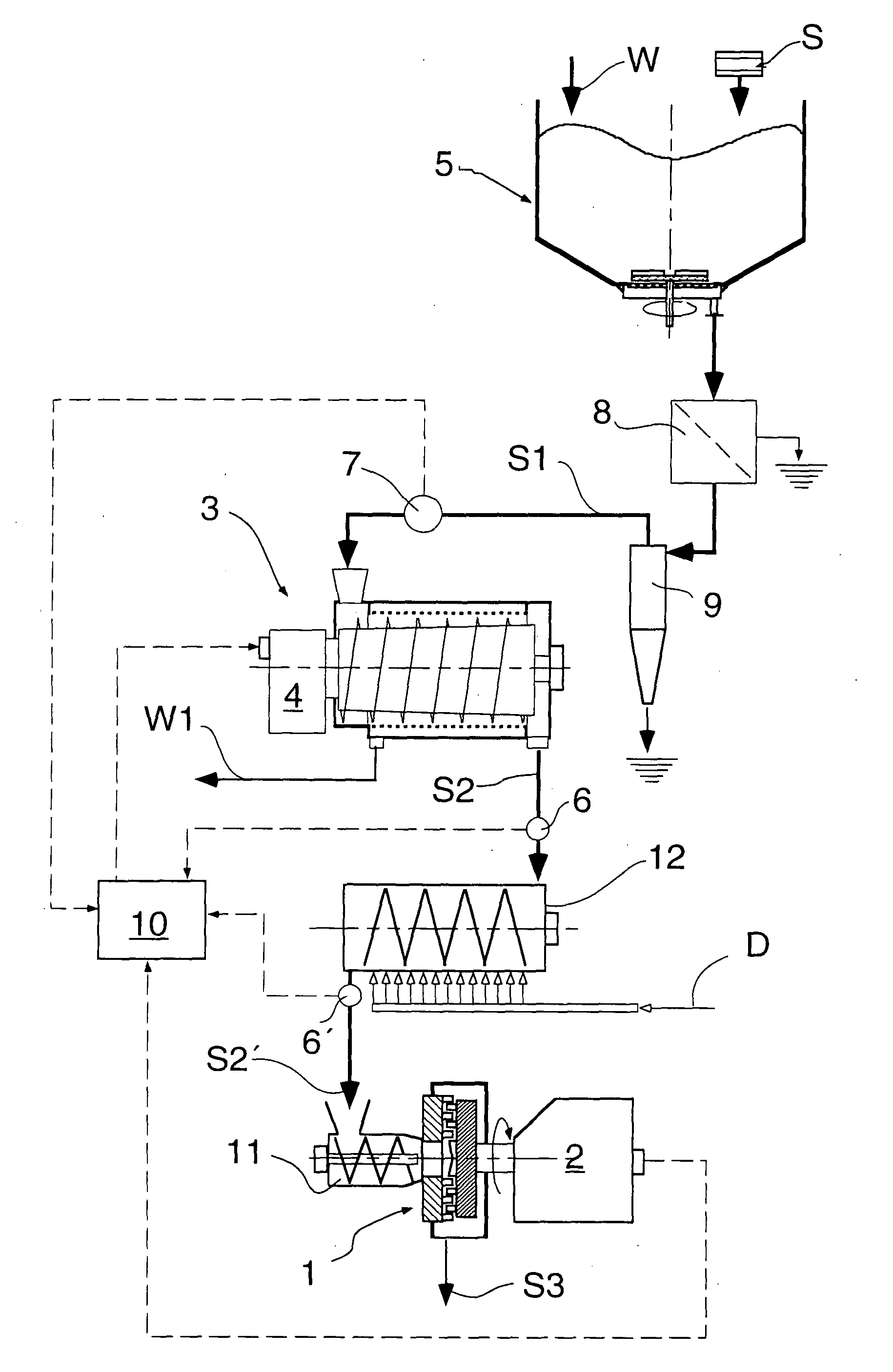

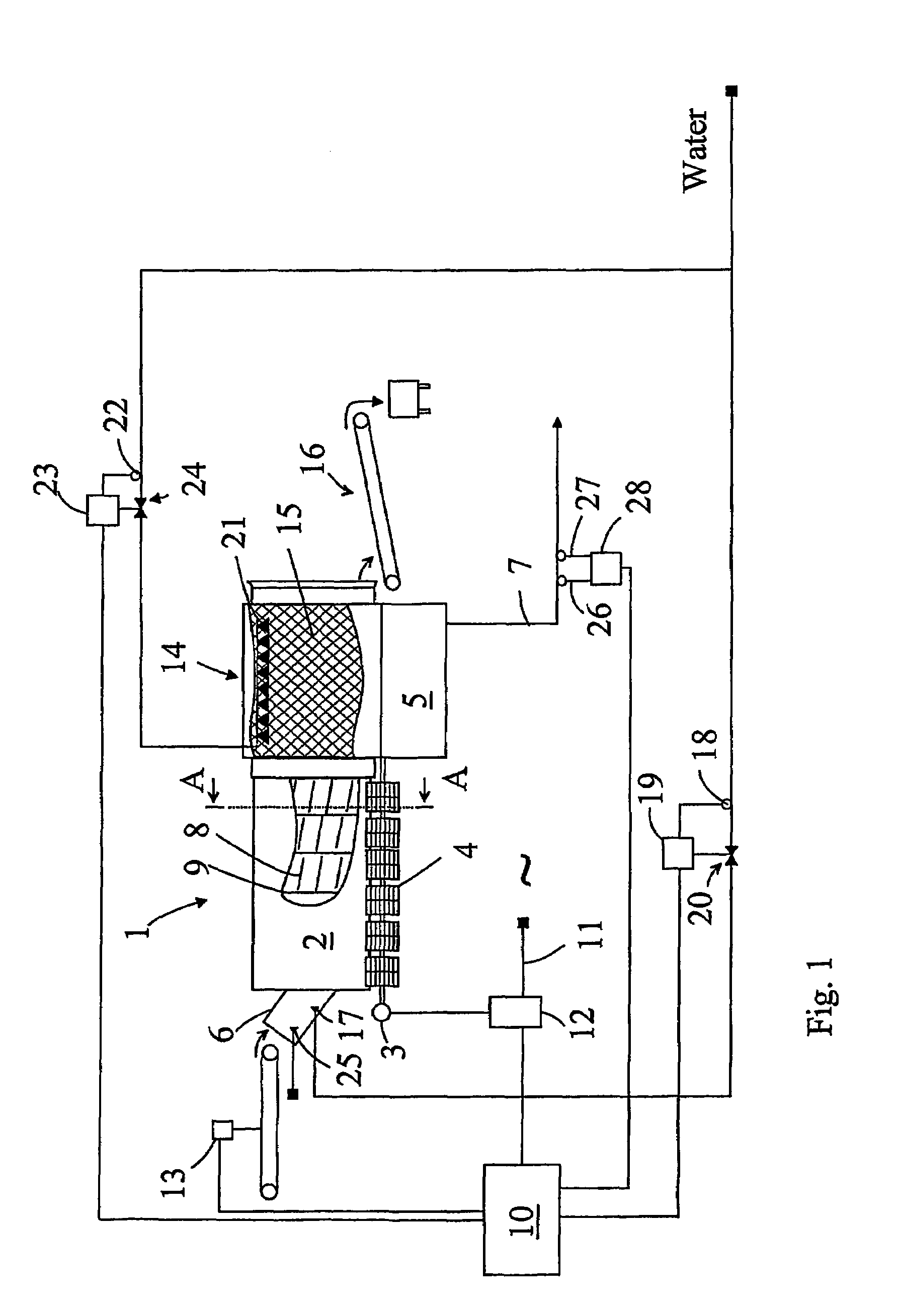

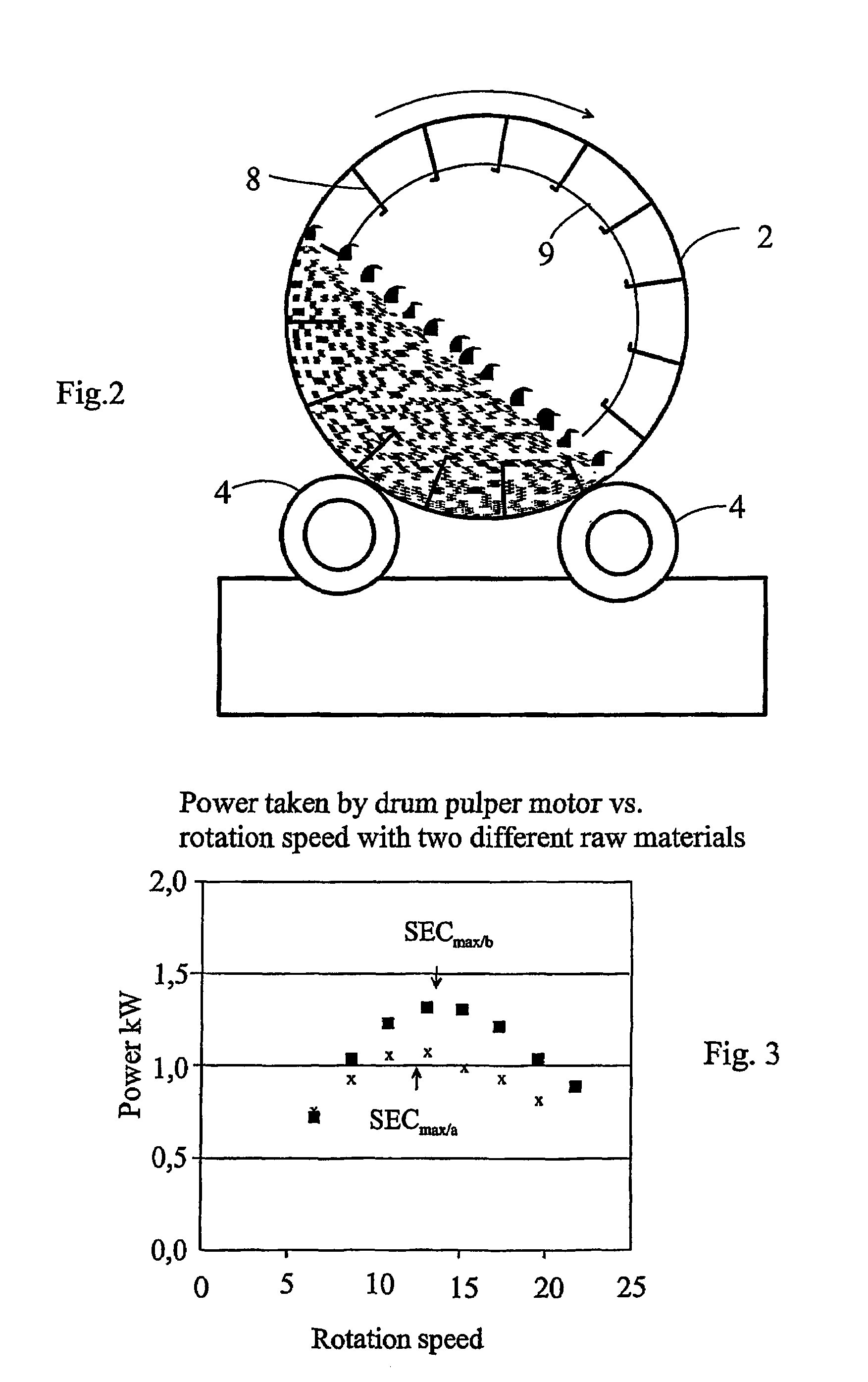

Method for defibring recycled fiber material in a drum pulper, and a drum pulper

InactiveUS20050103453A1Increase rotation speedReduce speedBeating/refining control devicesCork treatment detailsFiberPulp and paper industry

The invention relates to a method for defibering recycled fiber material in a drum pulper provided with a substantially horizontal drum. Recycled fiber material and water are fed to the drum pulper and the drum of the drum pulper is simultaneously rotated. When the drum rotates, the recycled fiber material rises up in the rotating drum and finally, due to gravitational force, falls back down. After falling and hitting to the bottom, the recycled fiber material is defibered, forming a fiber pulp mixture with water. A value of at least one parameter describing the defibration process or fiber pulp properties is measured on the basis of the drum pulper or the resultant fiber pulp mixture, and this value is used for controlling the rotation speed of the drum of the drum pulper. The invention also relates to a drum pulper implementing the method of the invention.

Owner:VALMET TECH INC

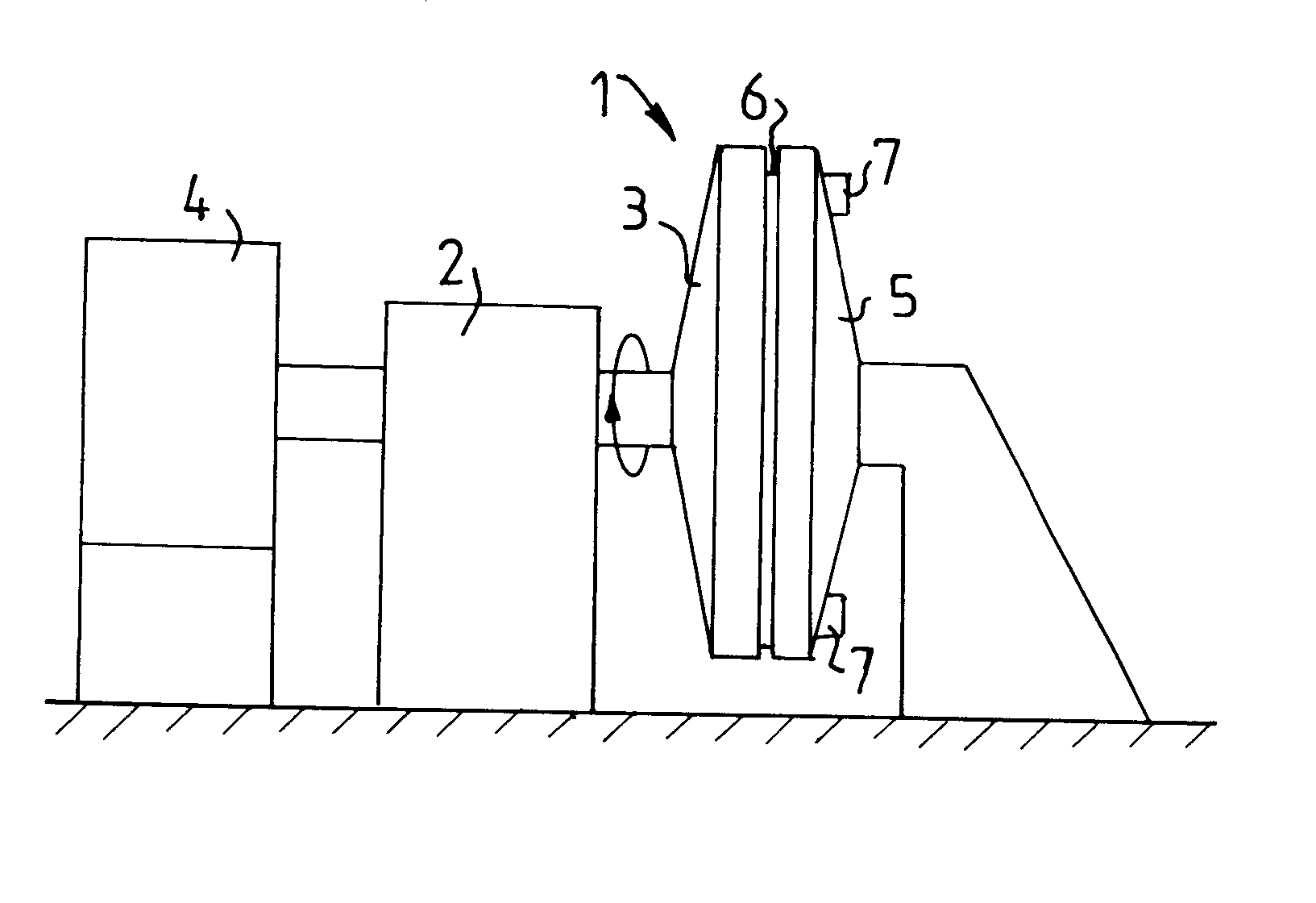

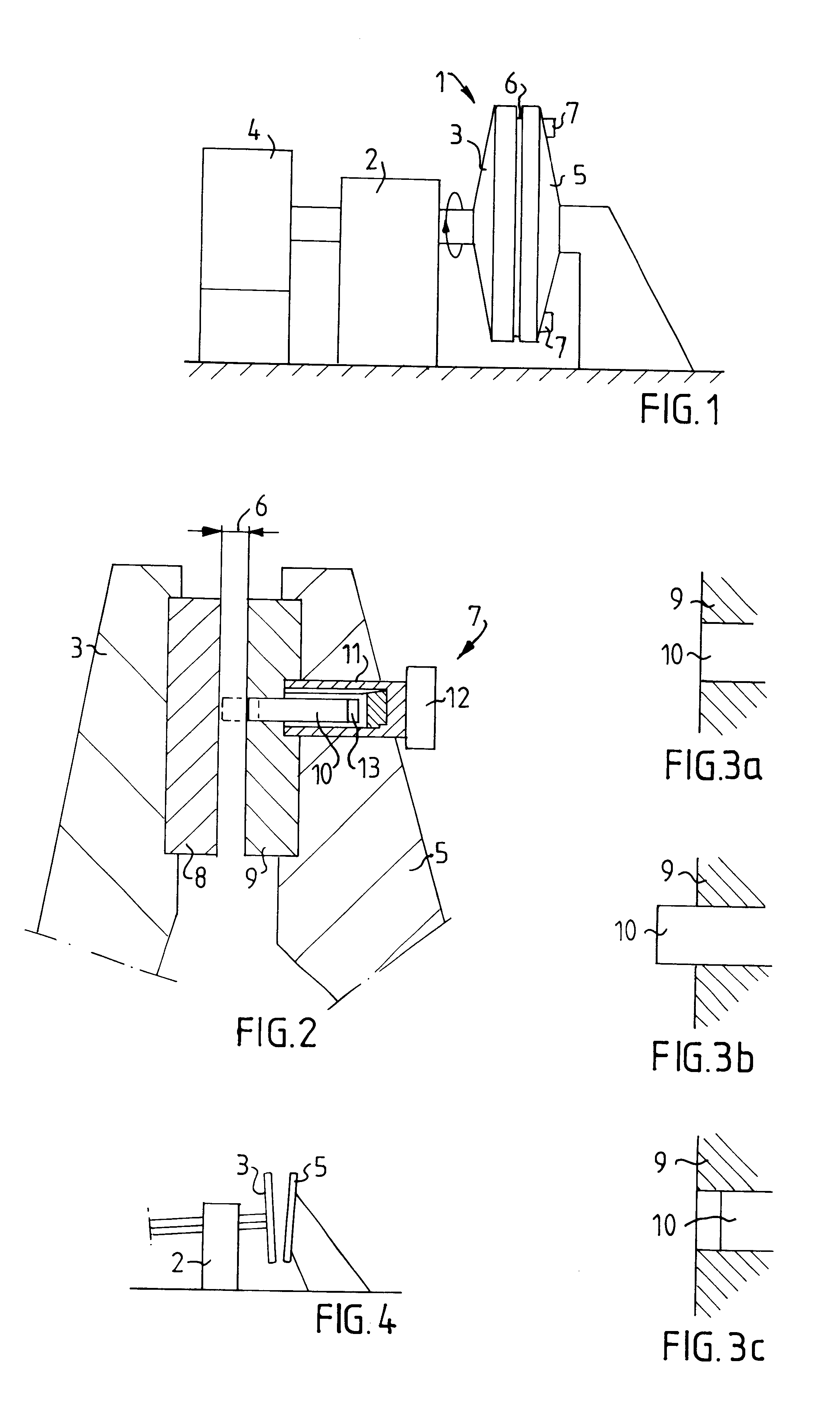

Method and device for measuring a distance between a stator and a rotor

InactiveUS6657427B2Easy and reliable determination of distanceEasy CalibrationBeating/refining control devicesUsing electrical meansPhysicsStator

In a machine which is provided with a stator and an opposite rotor, a sensor of magnetic type, arranged in the stator, for determining the distance between the stator and the rotor can be calibrated by the sensor first being moved relative to the stator into contact with the rotor for zeroing. The sensor is then reversed a predetermined distance, after which the sensor signal can be used for determining the distance between the stator and the rotor. In an arrangement suitable for the purpose, the stator has at least one sensor of magnetic type, which is intended to interact with an opposite surface on the rotor. The sensor is mounted displaceably in the axial direction of the rotor and can be brought into contact with the rotor.

Owner:CV PROD INC

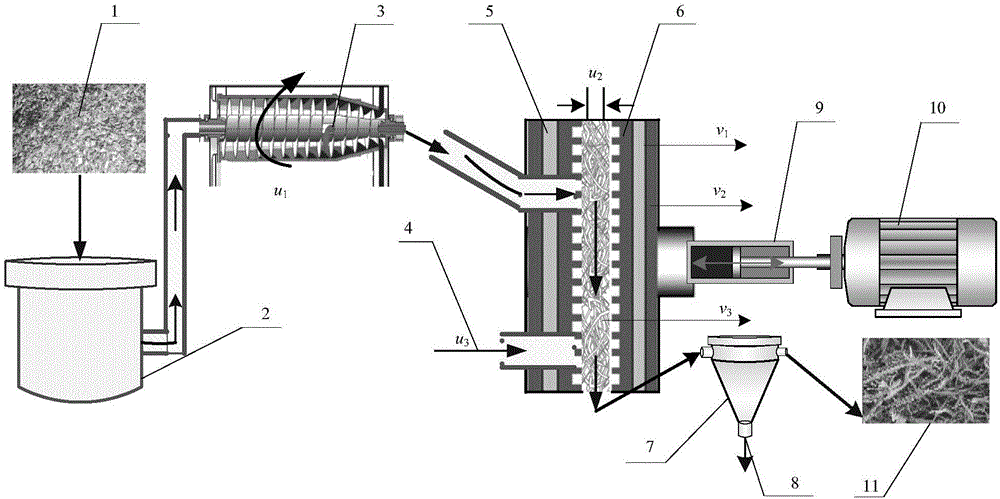

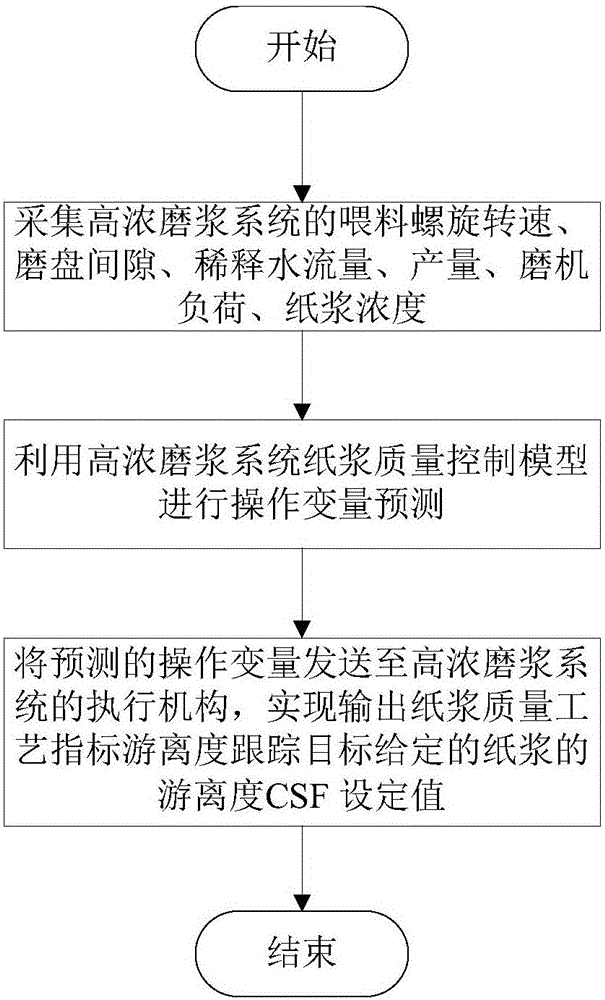

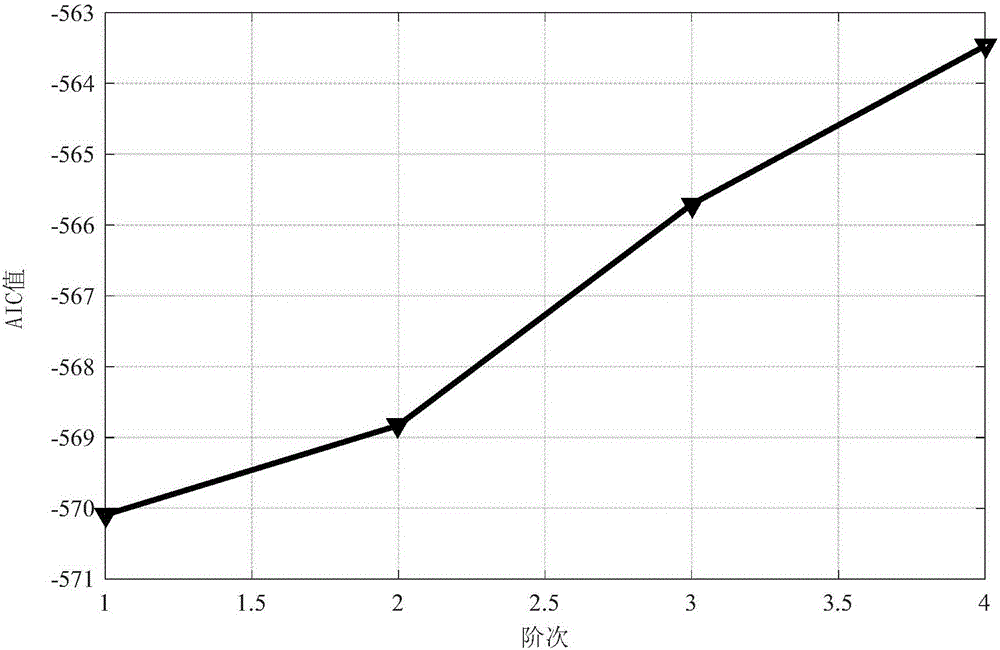

Paper pulp quality control method and system of high-concentration defibrination system

ActiveCN106283806AReduce energy consumptionBeating/refining control devicesDigestersHigh concentrationProduction line

The invention provides a paper pulp quality control method and system of a high-concentration defibrination system. The method comprises the steps that the feeding spiral rotating speed, abrasive wheel clearance, dilution water flow, yield, mill load and paper pulp concentration of the high-concentration defibrination system are collected; a high-concentration defibrination system paper pulp quality control model is used for operation variable prediction; predicated operation variables are sent to an executing mechanism of the high-concentration defibrination system. The system comprises a data collecting unit, an operation variable prediction unit and an output paper pulp quality control unit. Based on high-concentration disc mill input and output relevant data measured by a sensor on a chemical mechanical pulping production line, an AIC criterion is combined to determine the order of a submodel, a submodel parameter is obtained through a forgetting factor least square algorithm, a mechanism model of the paper pulp quality freeness index is combined to build a Wiener model structure of the a high-concentration defibrination system, the quadratic performance index is optimized through a sequential quadratic programming algorithm, and the pulping output paper pulp quality index-freeness is effectively controlled.

Owner:NORTHEASTERN UNIV

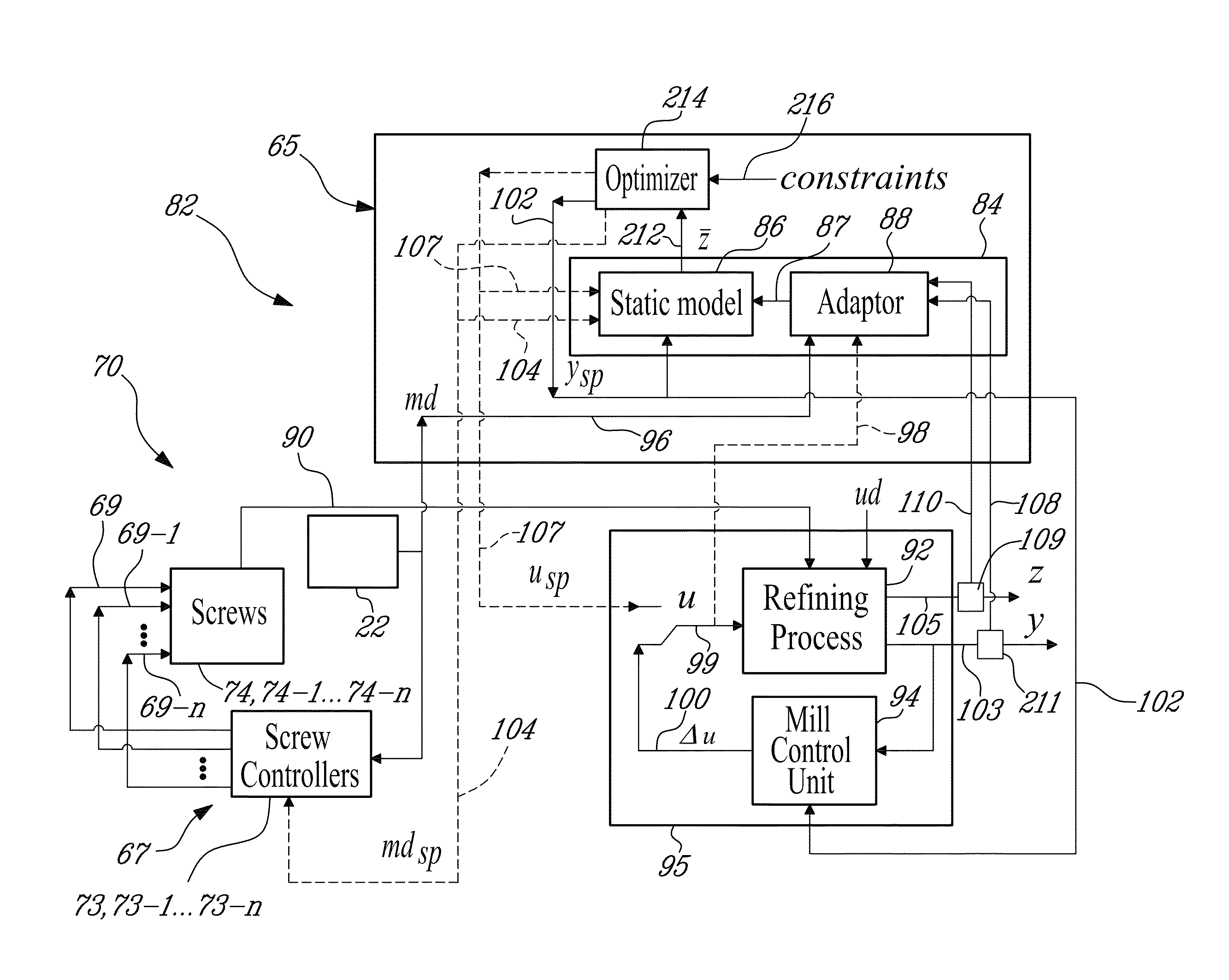

System and method for controlling a thermo-mechanical wood pulp refiner

ActiveUS7381303B2Improves overall constraint handling of control strategyImprove throughputBeating/refining control devicesComputer controlFiberProduction line

Thermomechanical pulp is an important process for producing fibrous mass used in papermaking. A two-level control strategy that stabilizes and optimizes the refining process has been developed. The Stabilization layer consists of a multivariable model predicative range controller that regulates the refiner line operations. The Quality Optimization layer provides the pulp quality control as measured by an online pulp quality (freeness, fibre length) sensor. This control startegy leverages the natural decoupling in the process. The modular design technique is able to handle multiple refiner lines that empty into a common latency chest. A global optimizer is also used to integrate and coordinate the two layers for enhanced constraint handling.

Owner:HONEYWELL INT INC

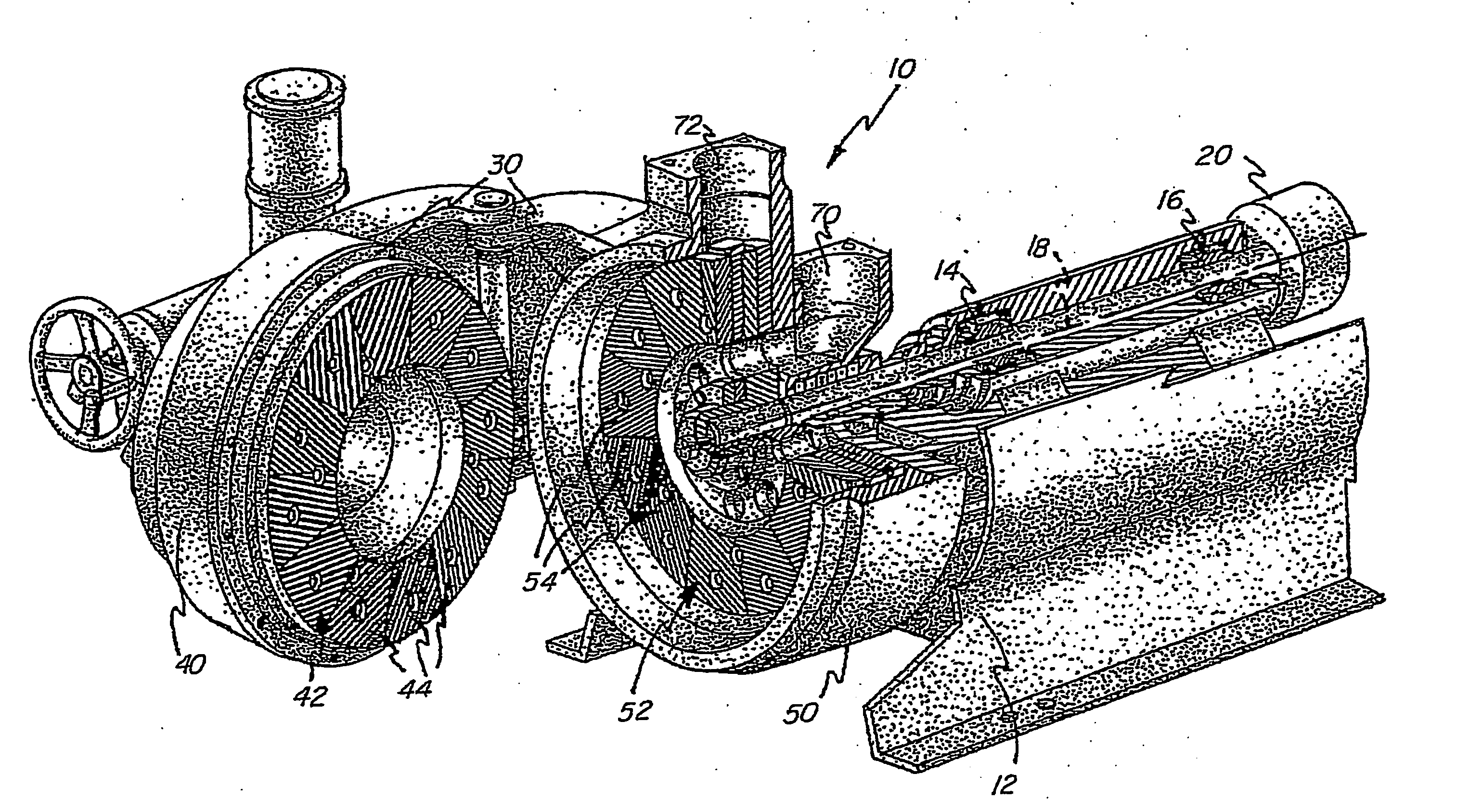

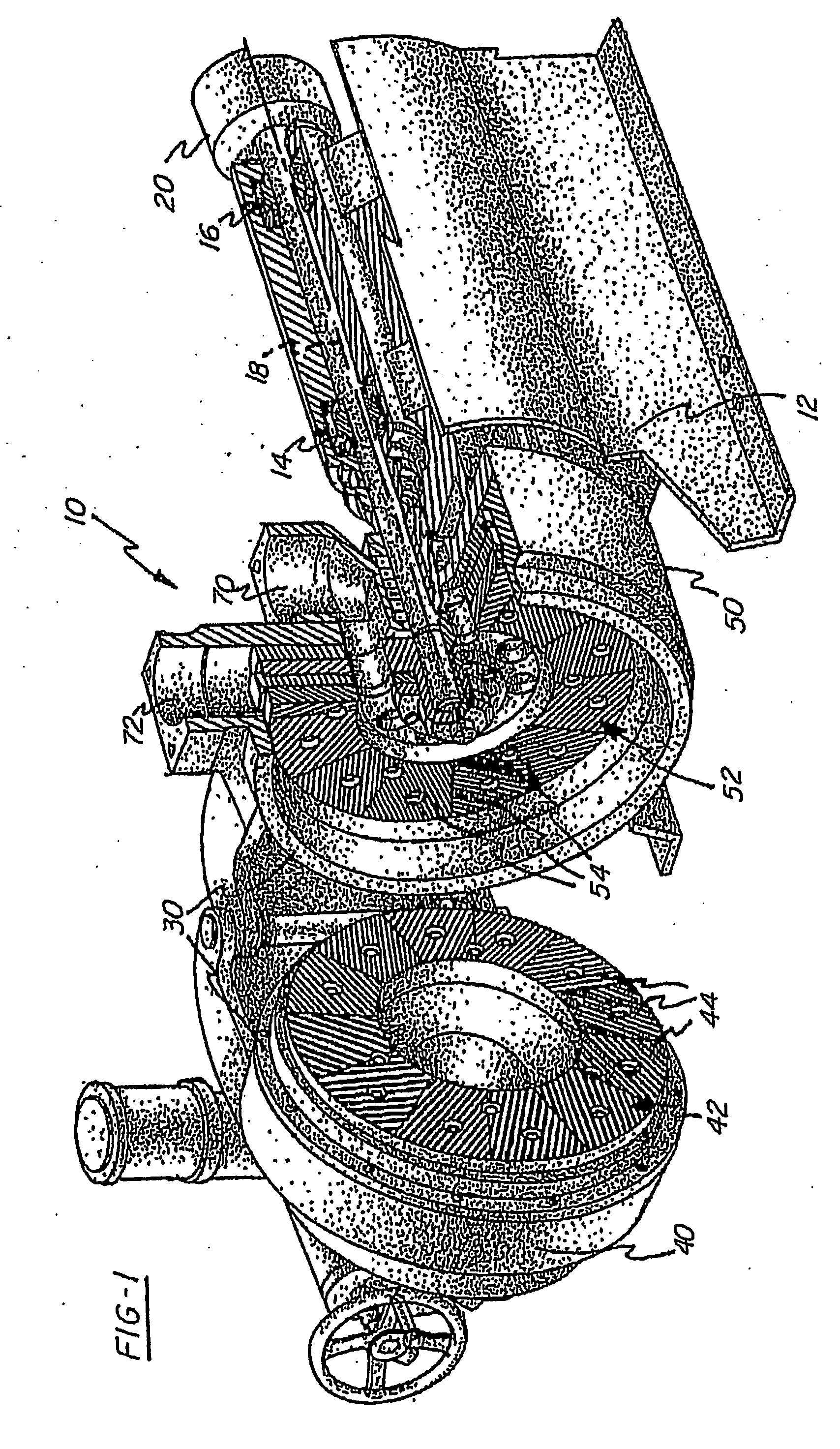

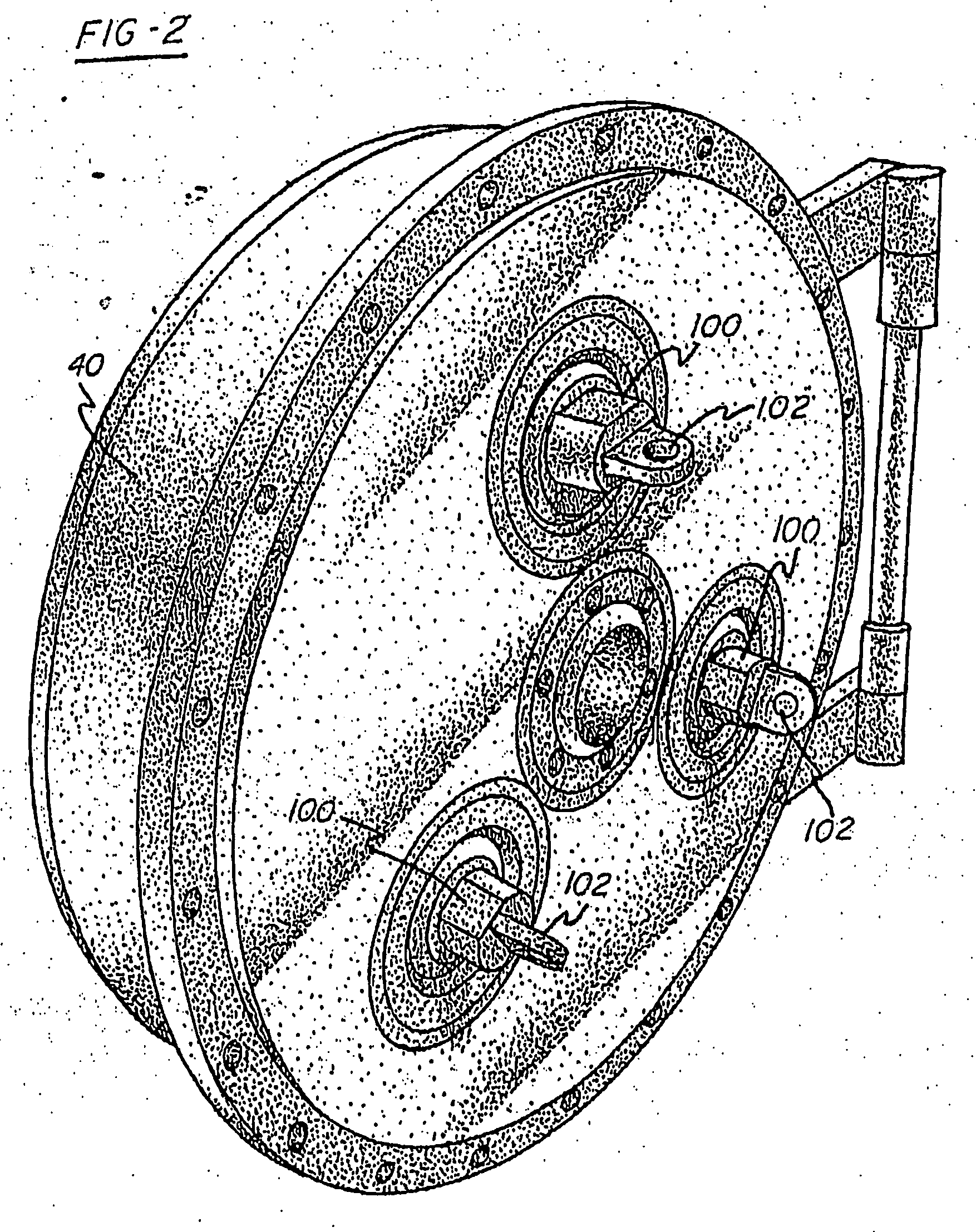

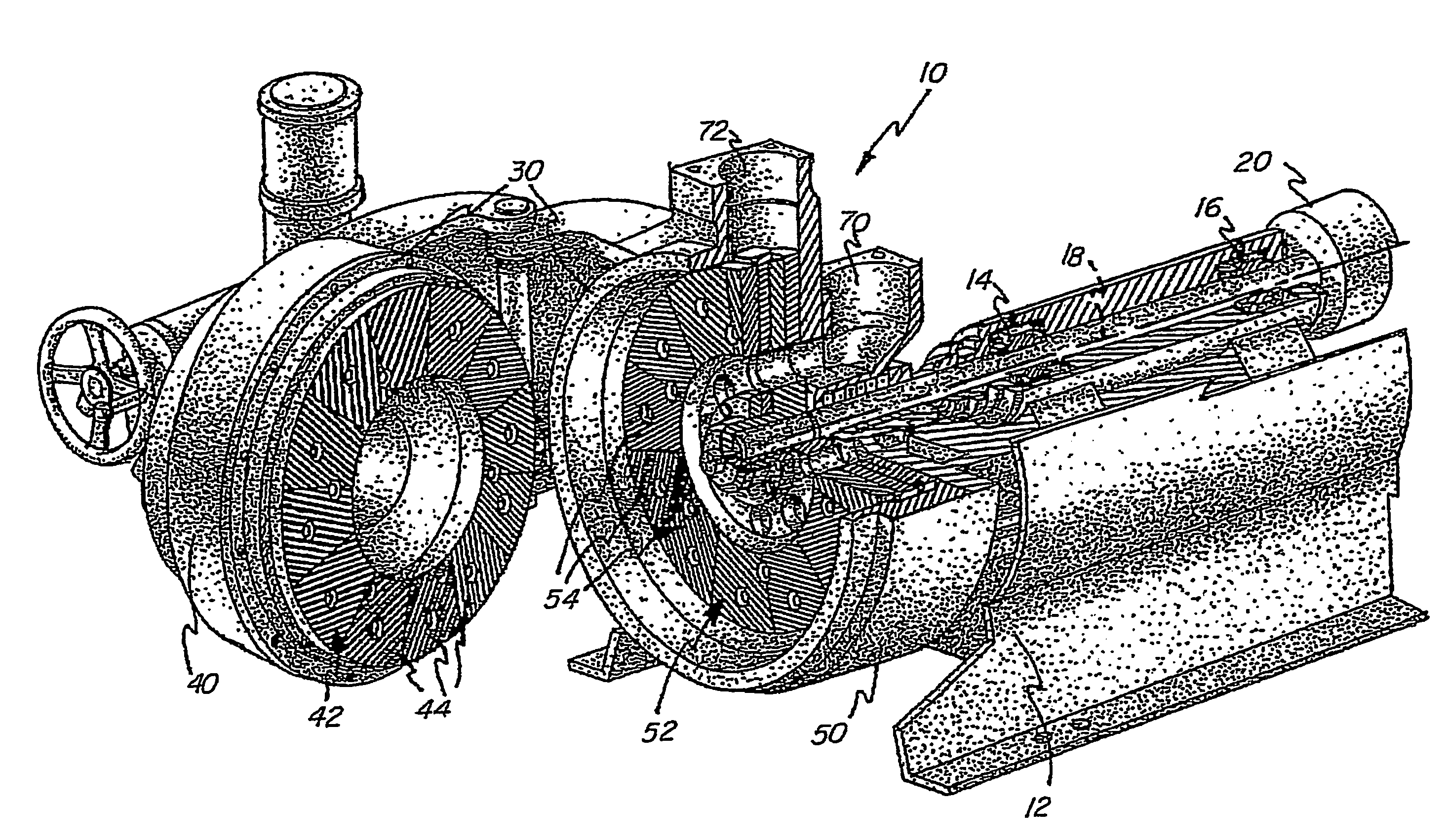

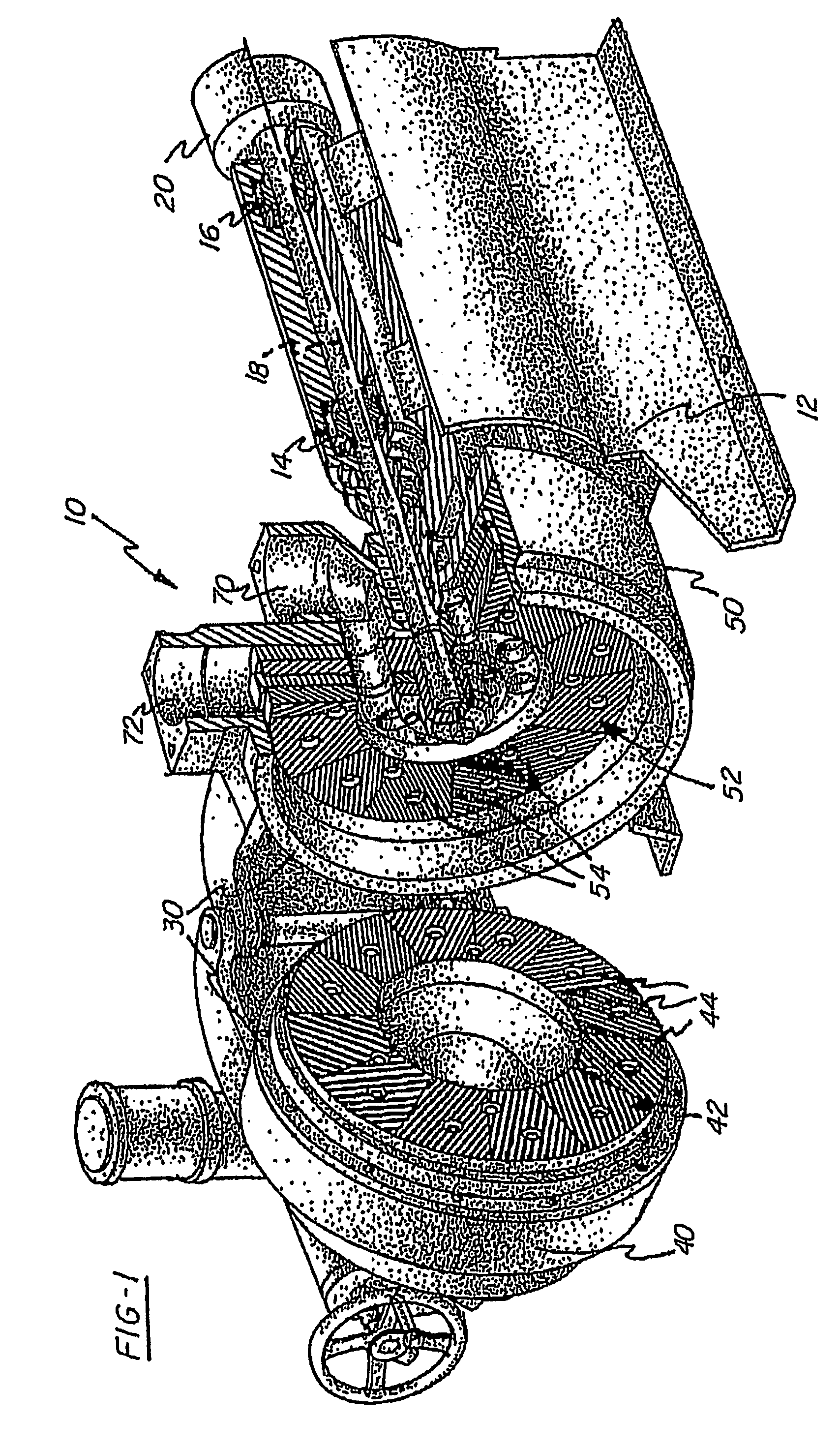

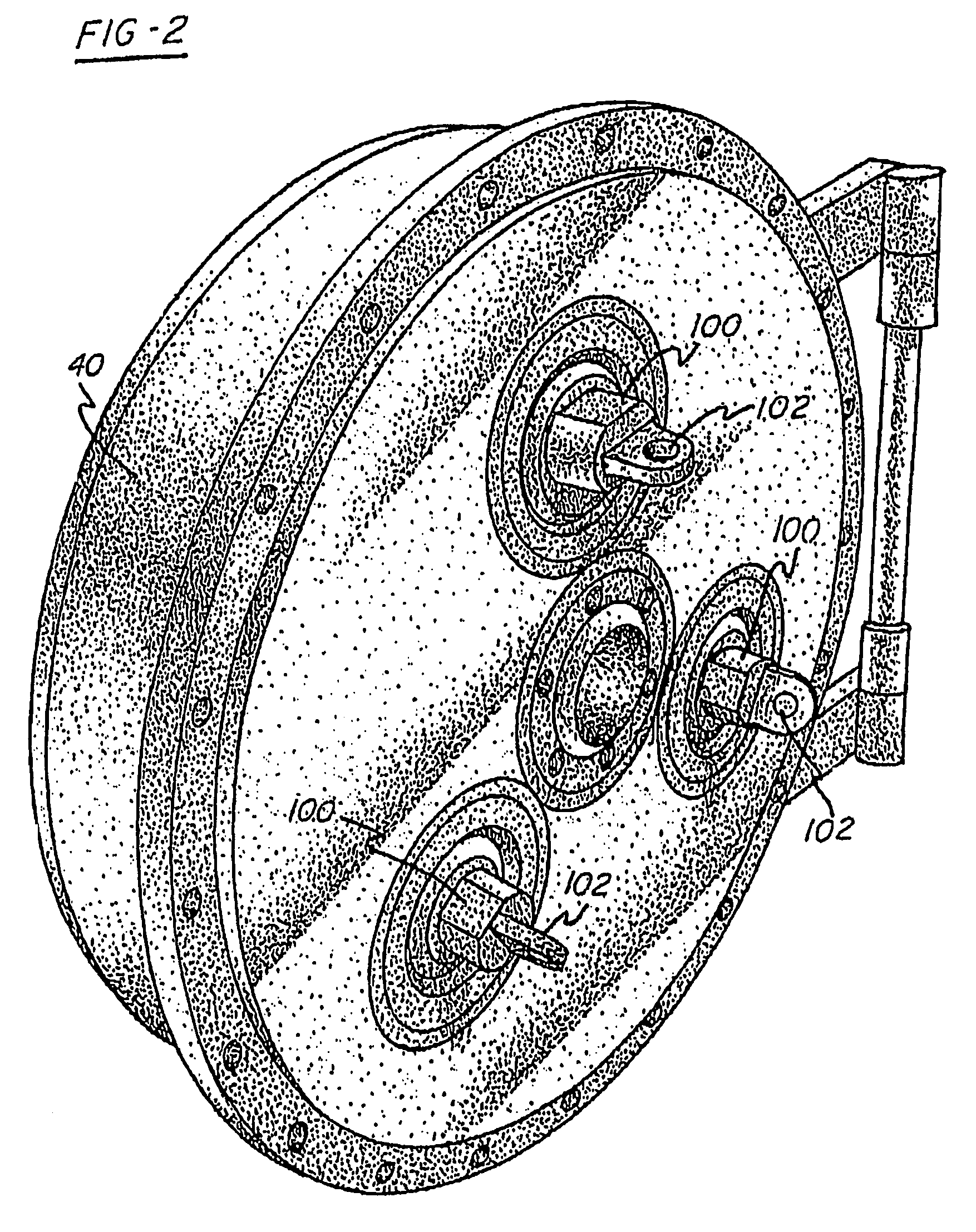

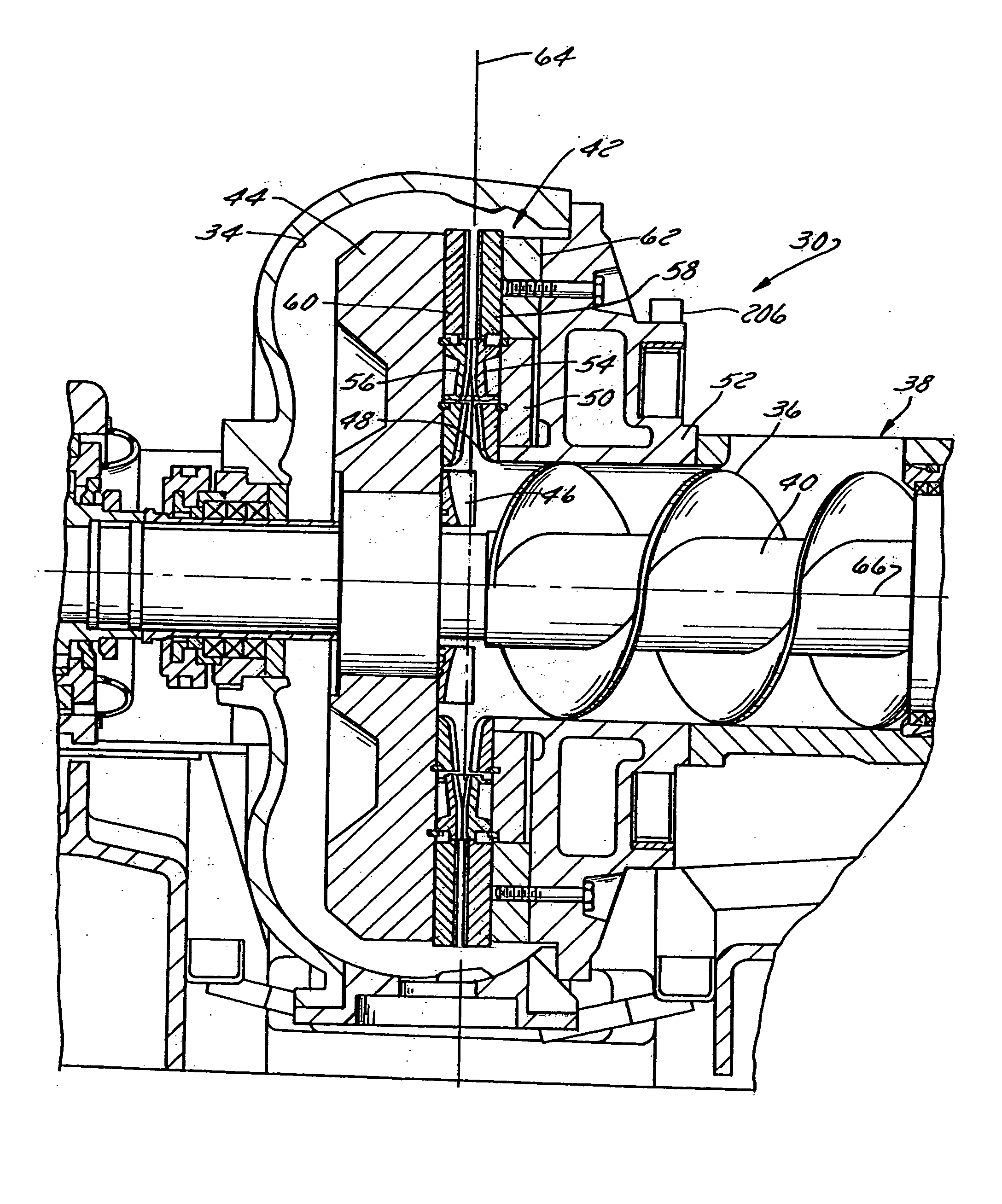

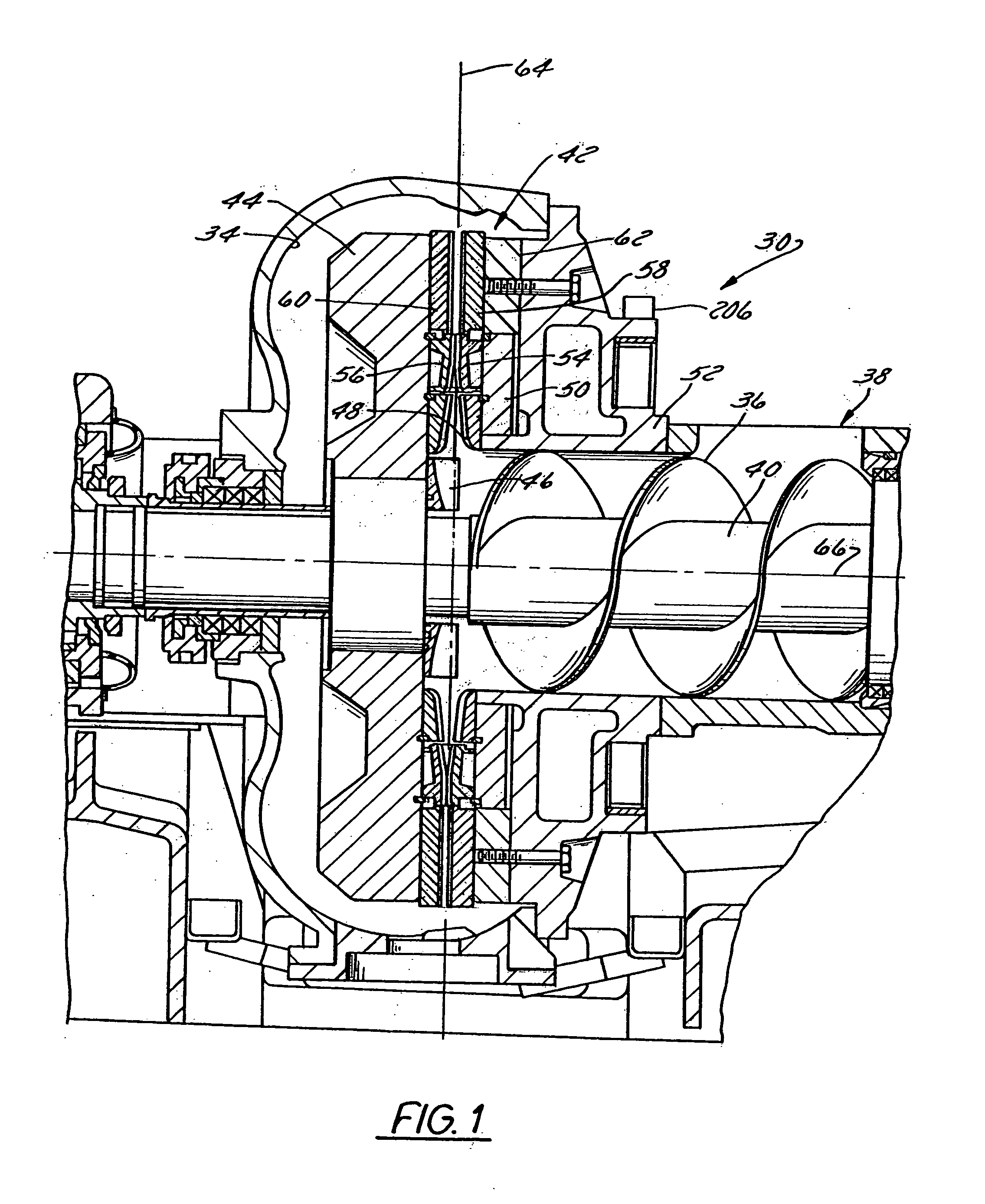

Self-aligning and actively compensating refiner stator plate system

InactiveUS20060231649A1Adjustable widthImproved degree controlBeating/refining control devicesGrinding machine componentsActuatorImproved method

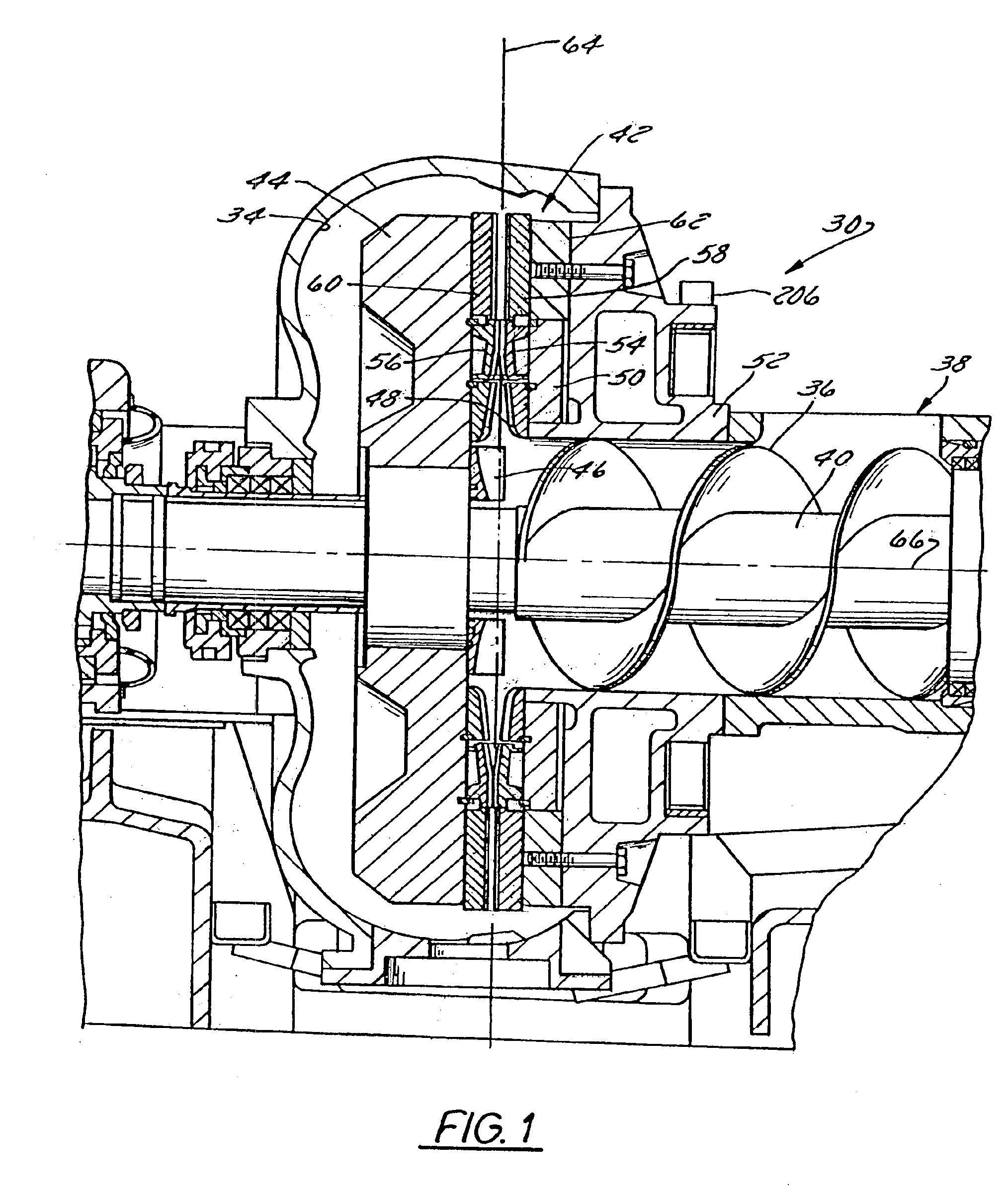

An improvement to a mechanical refining system relates to an apparatus including three or more actuators (100) coupled to a stator (42) of the refining system, and a controller for independently operating the actuators. An improved method of refining permits adjustment of the overall width of a refining gap between refining elements mounted by the stator and a rotor as well as the trim of the refining elements relative to each other

Owner:THERMO BLACK CLAWSON

Method for controlling quality of pulp

InactiveUS6846381B2Quality improvementBeating/refining control devicesFats/resins/pitch/waxes removal in pulpWaste productPulp and paper industry

A method for controlling the quality of pulp. Pulp produced by mechanical defibering of wood is screened to provide at least two fractions, of which the accept that has passed the screening phase is carried forward for use and the reject that has not passed the screening is removed from the screening phase. The consistency of the reject that is to be removed from the screening is measured and the consistency value thus obtained is used for controlling the defibrator to adjust the quality of the accept.

Owner:VALMET TECH INC

Refining member clash control method

ActiveUS7309036B2Simple designAlleviate the plate clashingBeating/refining control devicesCocoaControl systemEngineering

A control system with a sensor mounted in direct mechanical connection to a non-rotating refining member so that the sensor is responsive to axial vibration movement of the support, and an analog to digital converter directly connected to the output of the sensor without filtering. The control system also includes a controller connected to the analog to digital converter and responsive to the analog to digital converter to compare the amplitude of the output signal from the sensor to a baseline value based on the level of vibration associated with the pulp refiner when it is operating without plate clashing. When the signal exceeds the baseline value, an action is taken to help alleviate the plate clashing.

Owner:OVIVO LUXEMBOURG R L

Process for the hot dispersing of a paper fiber stock

InactiveUS20060102301A1Increase consumptionFalling consumptionBeating/refining control devicesConveyor partsFiberThermal energy

The present invention is directed to a process for the hot dispersing of a paper fiber stock that includes providing an aqueous paper fiber stock and pressing the aqueous fiber stock in a thickening device. In this manner, water is at least partially removed from the aqueous fiber stock to form a highly consistent paper fiber stock. The process further includes heating the highly consistent paper fiber stock, dispersing the heated highly consistent paper fiber stock with a disperser, determining a thermal energy consumed to heat the highly consistent paper fiber stock, and controlling a dewatering effect of the thickening device. The dewatering effect is increased with rising thermal energy consumption and is reduced with a falling thermal energy consumption. The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

Refiner force sensor

This invention relates to a refiner force sensor for refiners used in the pulp and paper industry, to a refining apparatus, and to a method of measuring force acting on a refiner bar in a refiner.

Owner:QUEENS UNIV OF KINGSTON +3

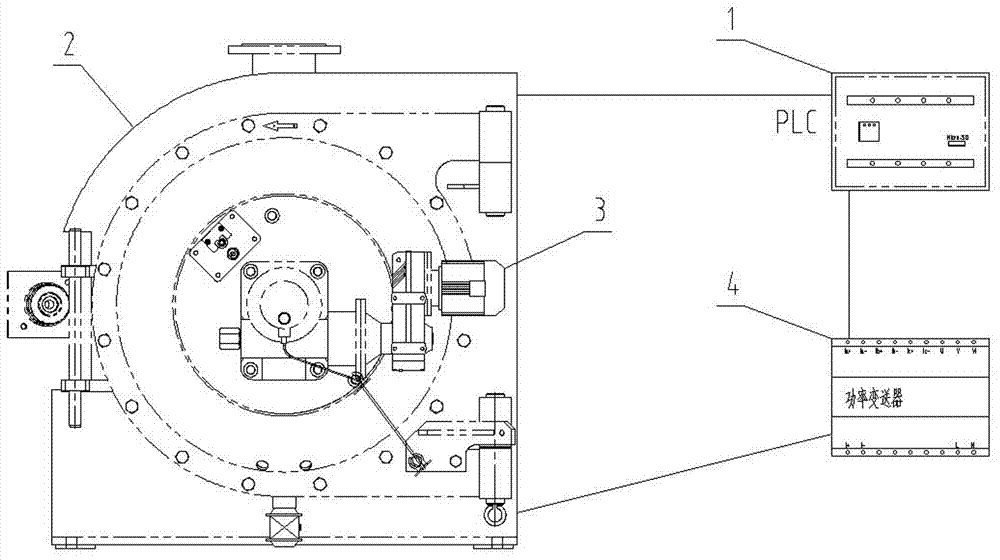

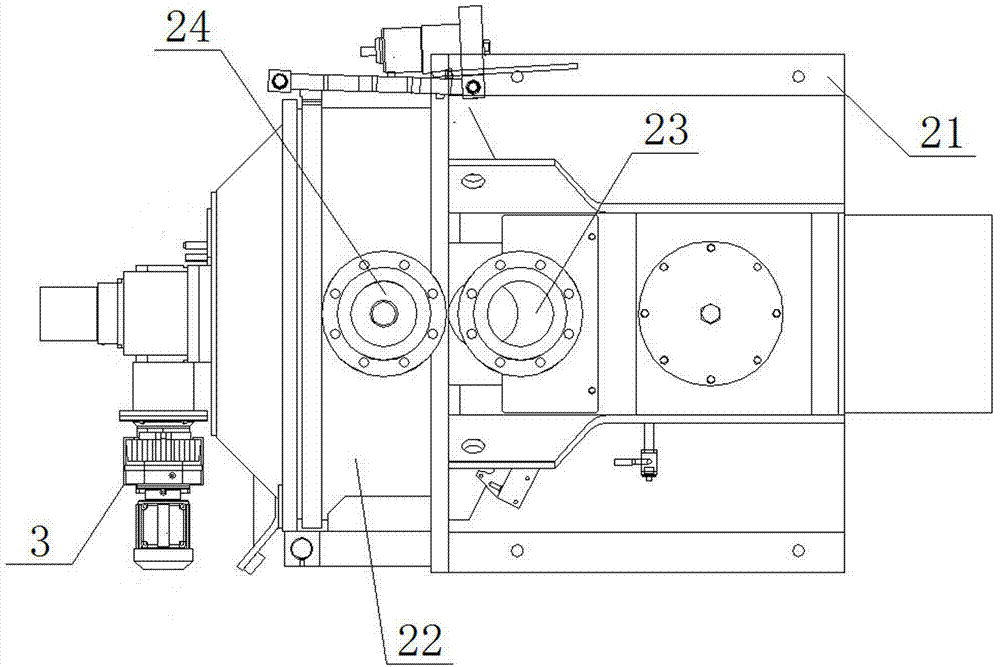

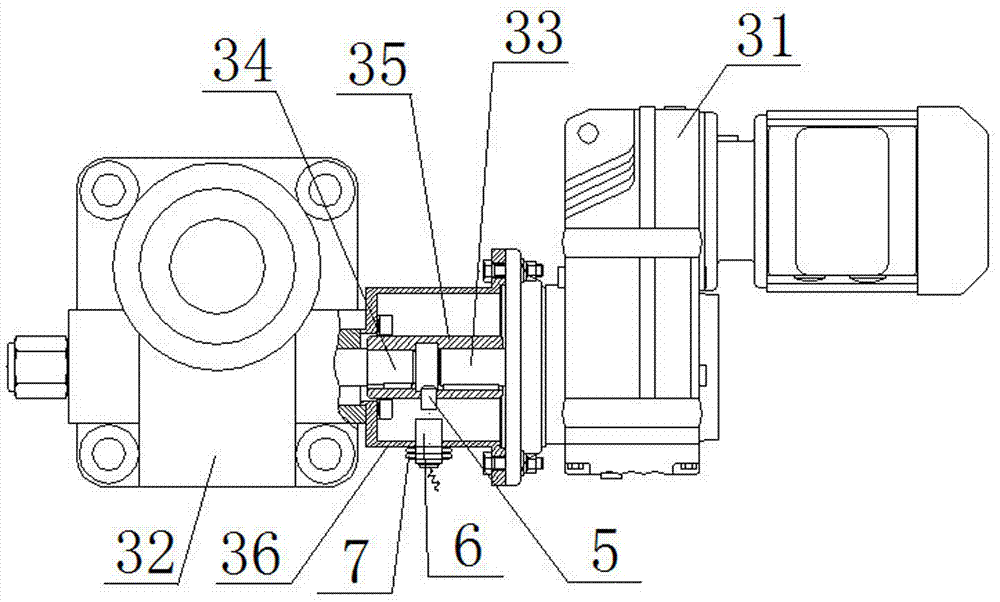

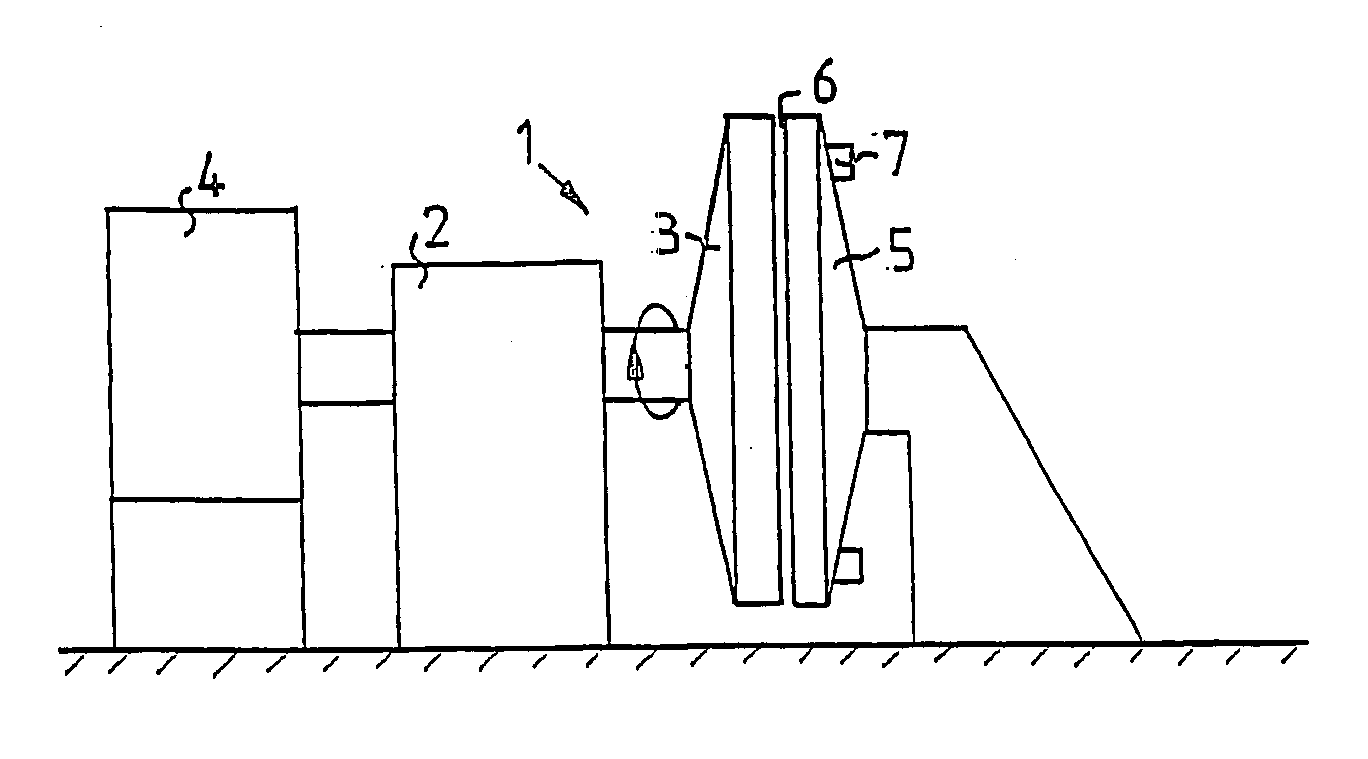

Automatic control system and method of knife feeding and retracting of dual-disc refiner

ActiveCN107974857AReduce wasteReduce feed timeBeating/refining control devicesAutomatic controlTime efficient

The invention provides an automatic control system and method of knife feeding and retracting of a dual-disc refiner. The dual-disc refiner comprises a knife feeding speed reduction motor and a worm wheel and worm box. An output shaft of the knife feeding speed reduction motor is connected with a worm through a coupler. A coupler protecting cover is arranged on the periphery of the coupler. A counting marker is fixed to the coupler. A sensor corresponding to the counting marker in position is fixed to the coupler protecting cover. When the knife feeding speed reduction motor conducts rapid knife retracting, the sensor detects and records the rotating revolution N of the counting marker; when the knife feeding speed reduction motor conducts knife feeding, rapid feeding is conducted according to the revolution N stored in the last time of knife retracting, and the feeding revolution is (N-1); when knife feeding is conducted by (N-1) revolutions, rapid knife feeding is stopped and changedinto slow knife feeding; when main motor actual power collected by a power transmitter is equal to set power, knife feeding is stopped. The dual-disc refiner can conduct rapid knife feeding after being turned on, time is saved, energy consumption is reduced, the work efficiency of the device is improved, and the collision of abrasive discs of the dual-disc refiner can be prevented.

Owner:ZHENGZHOU YUNDA PAPER EQUIP

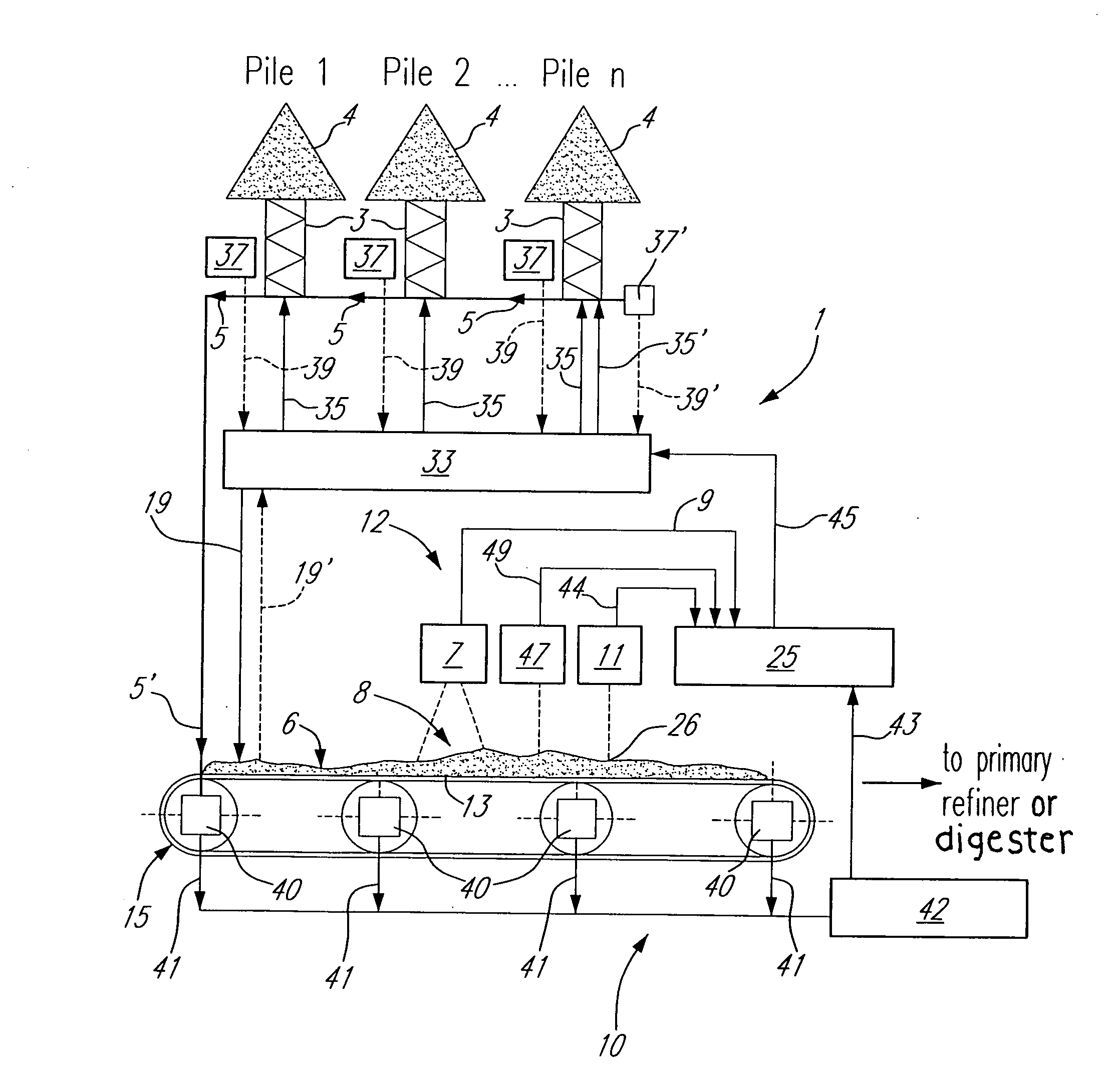

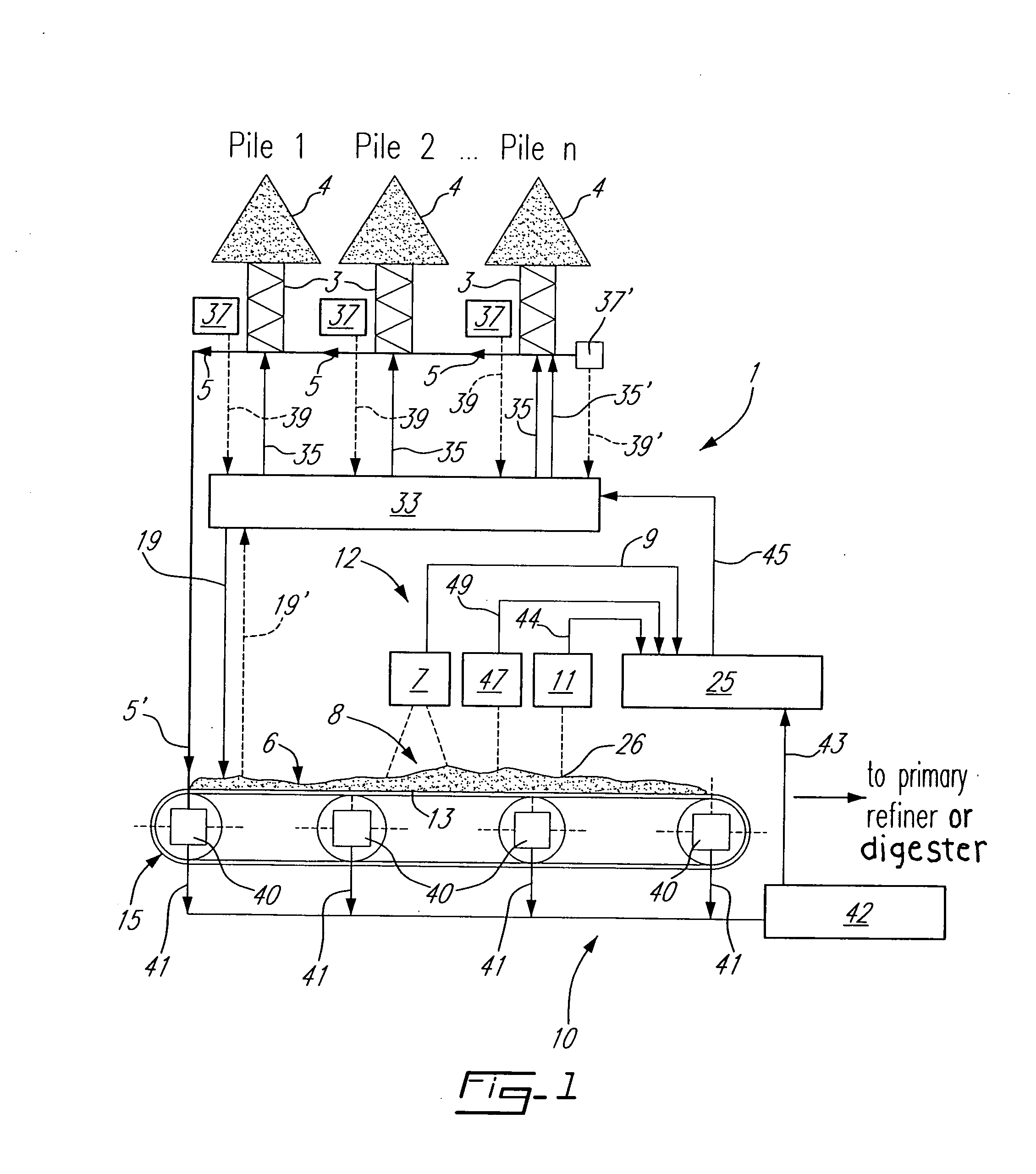

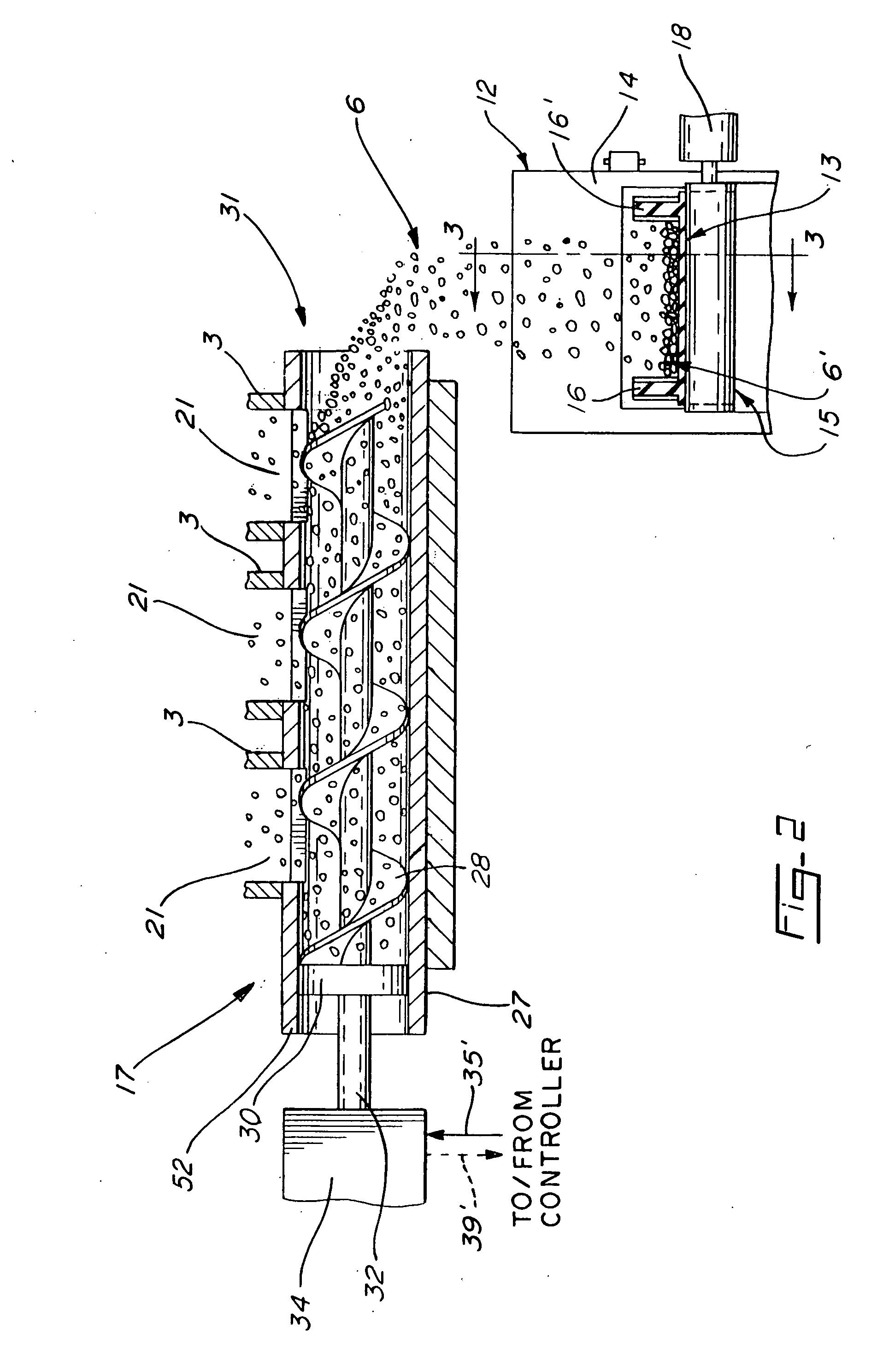

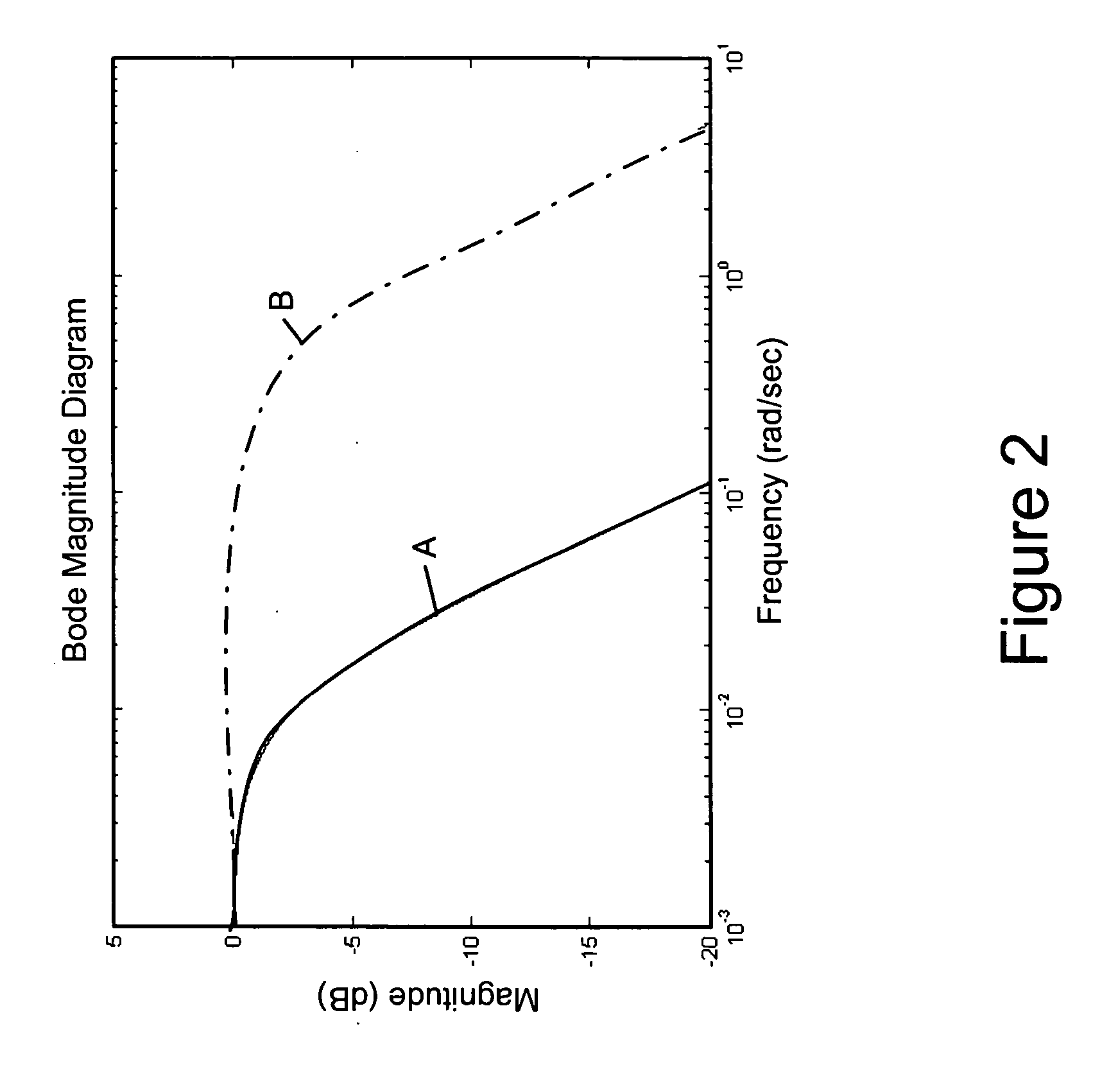

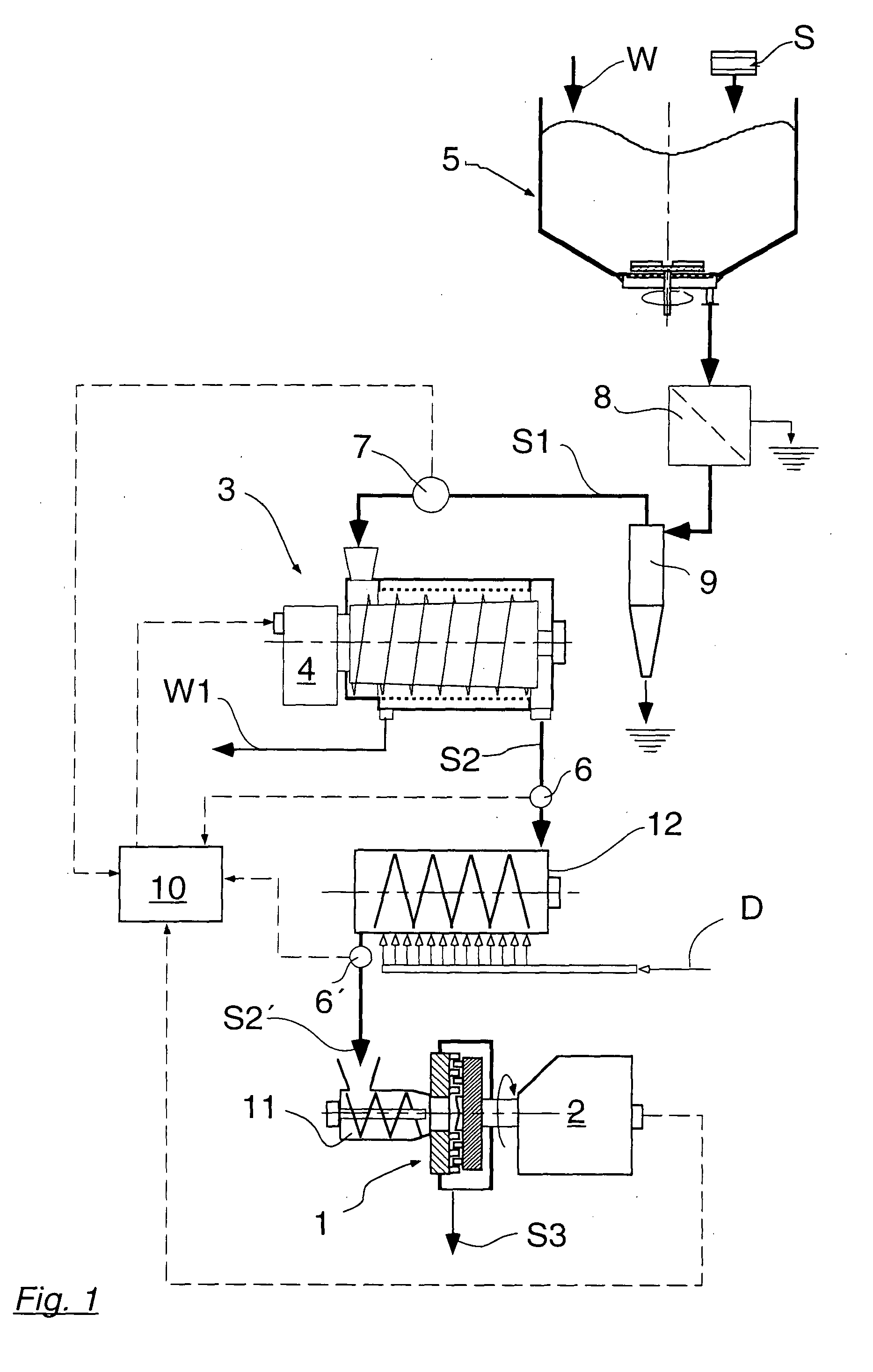

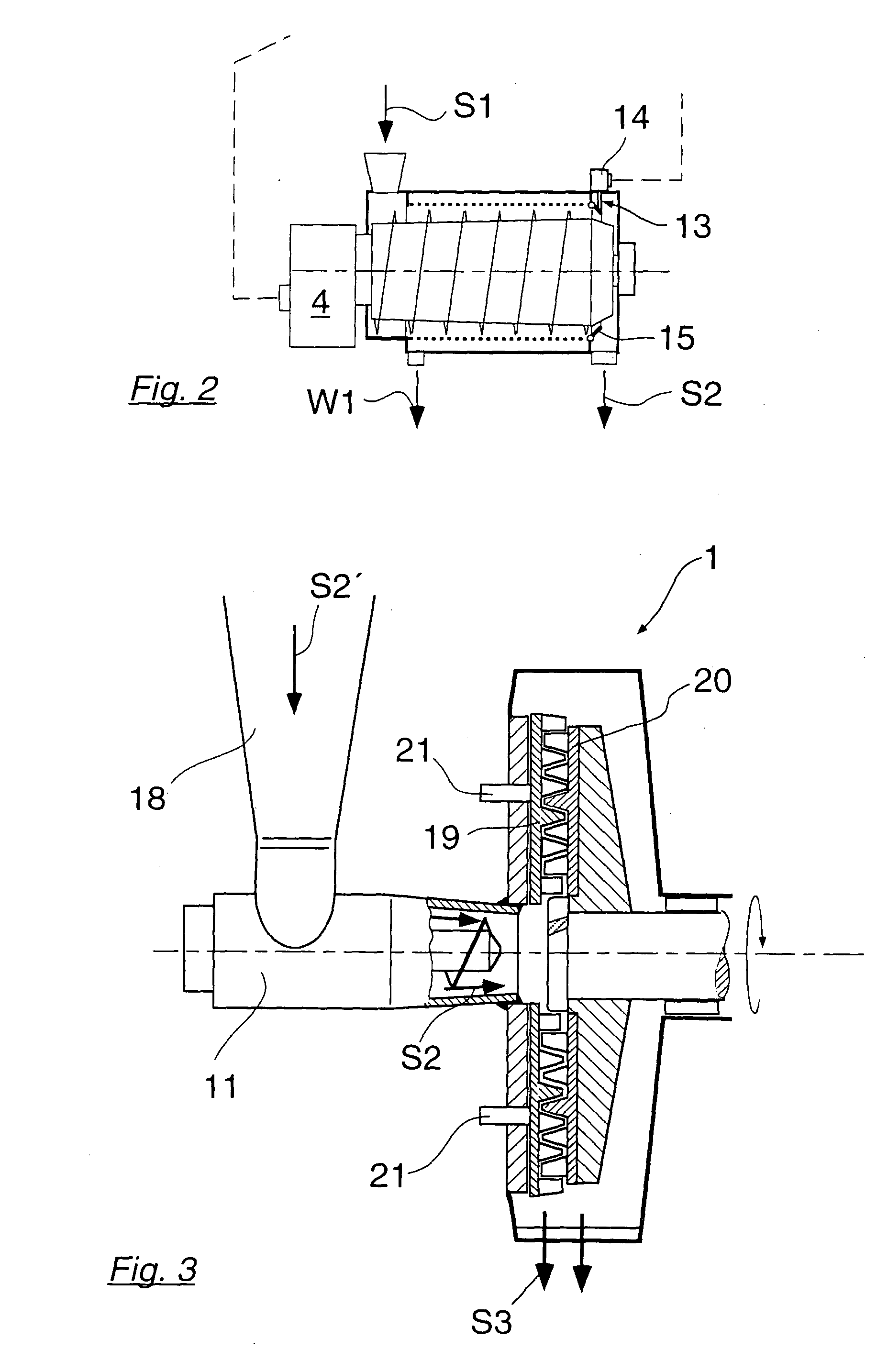

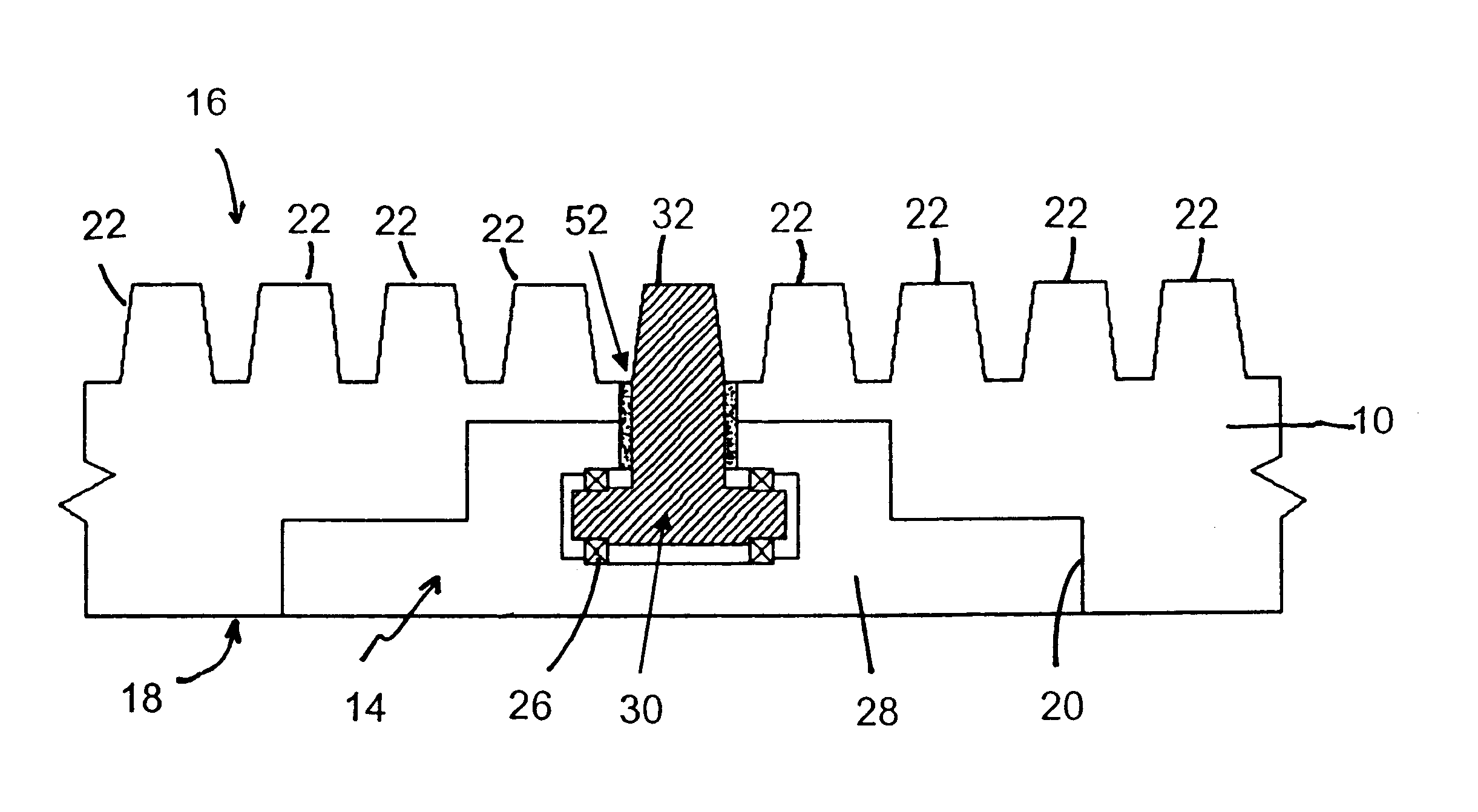

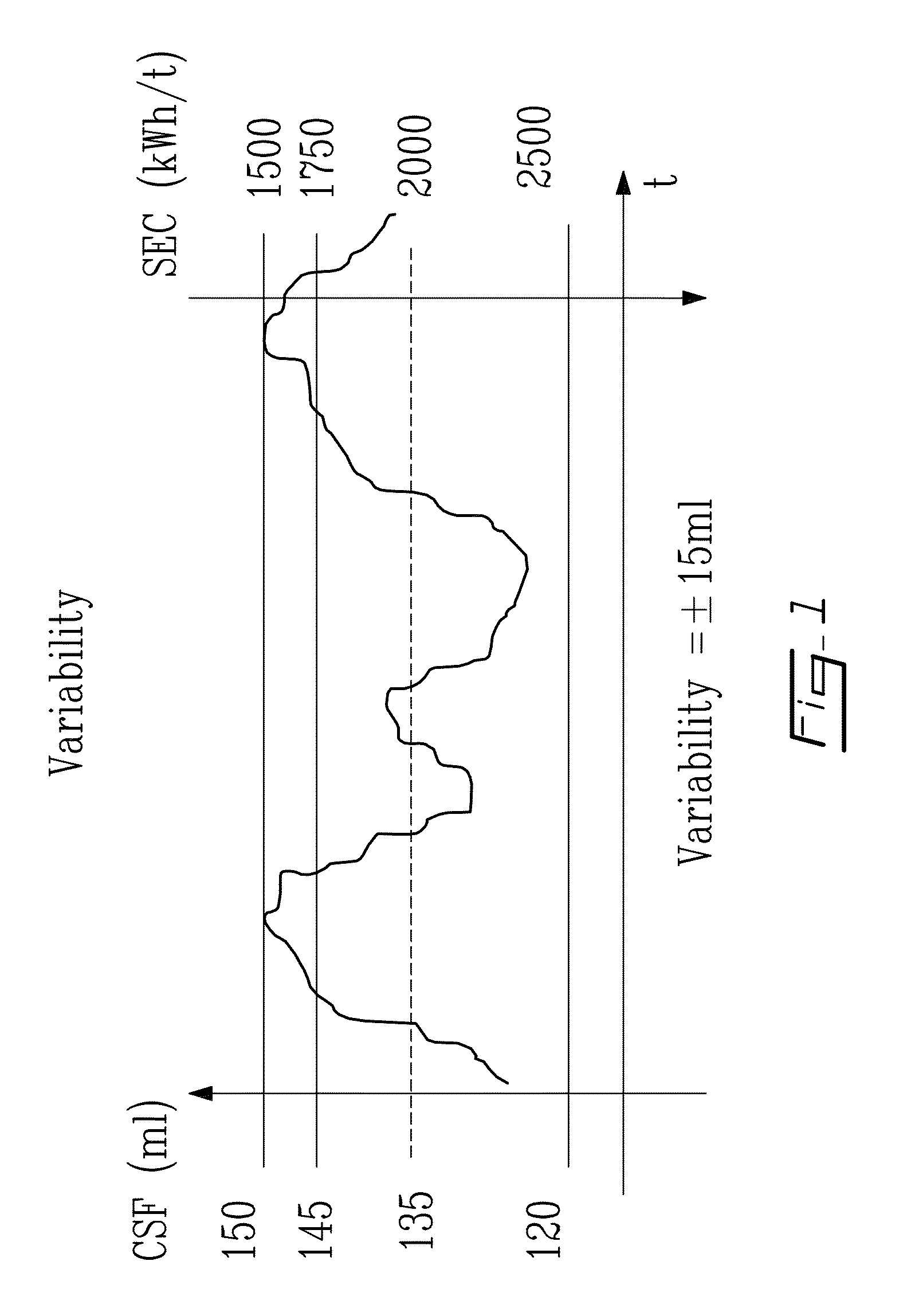

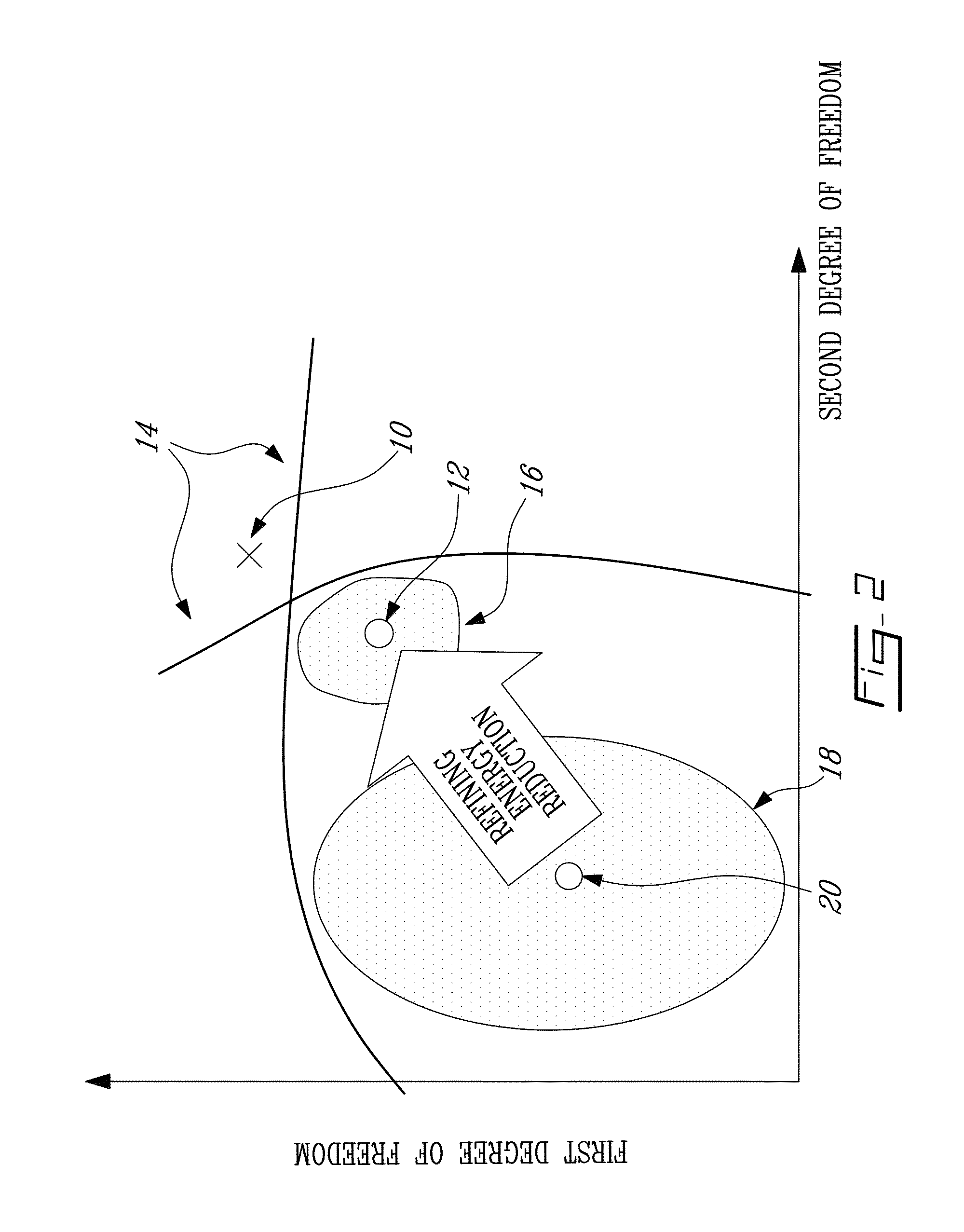

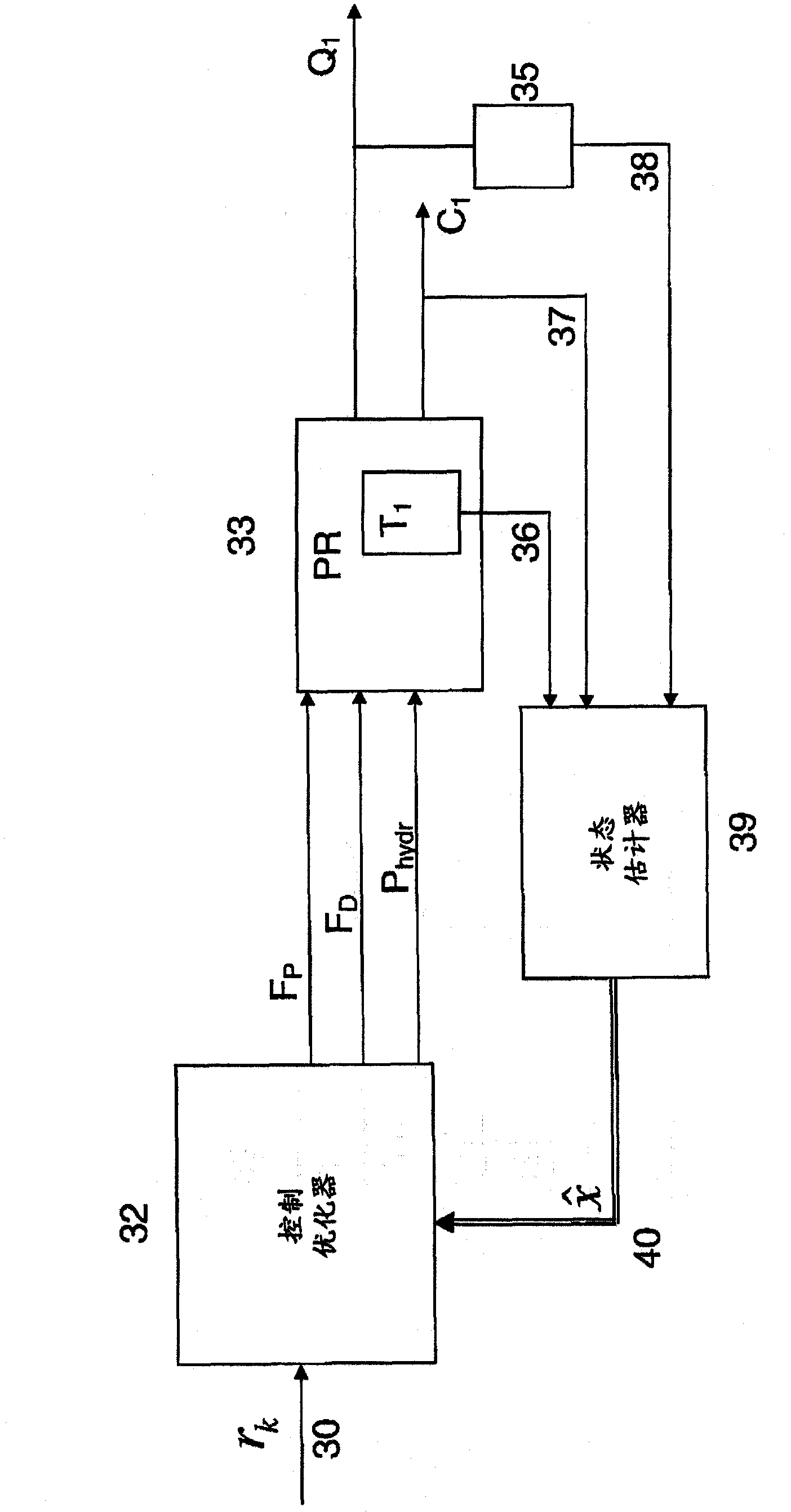

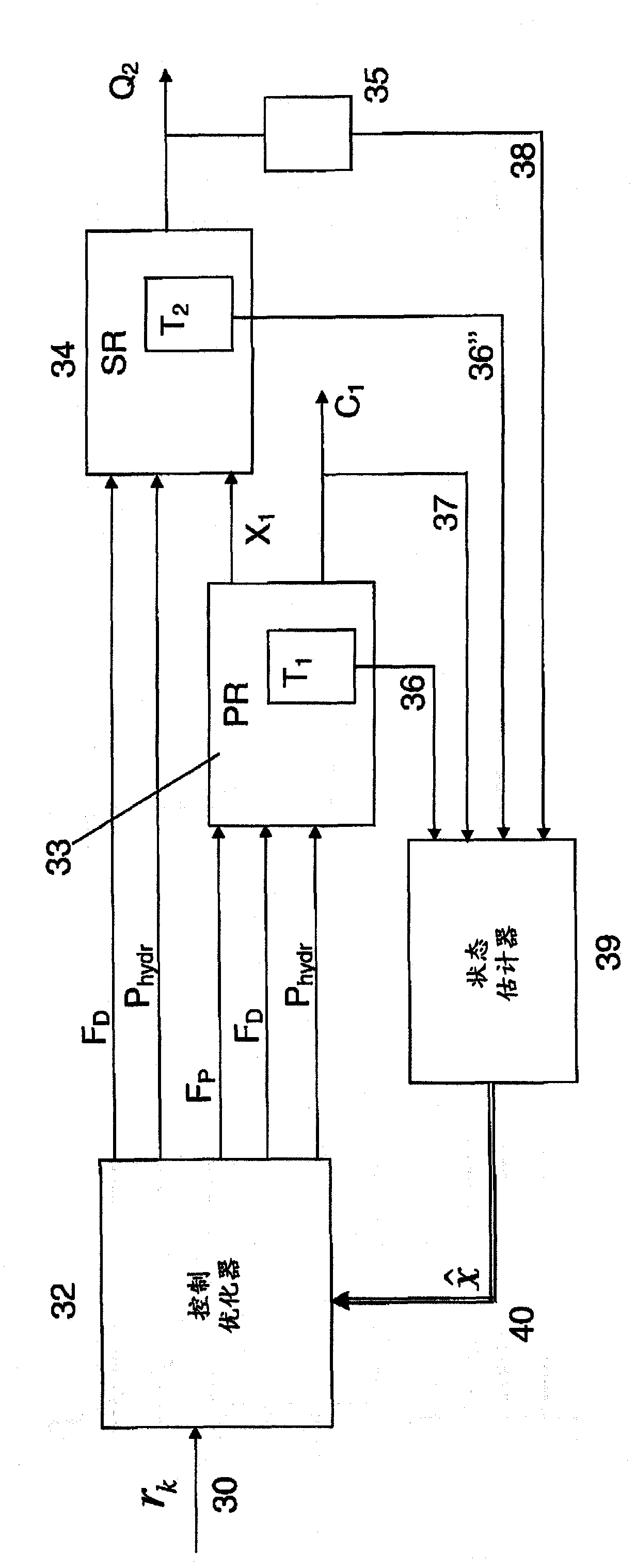

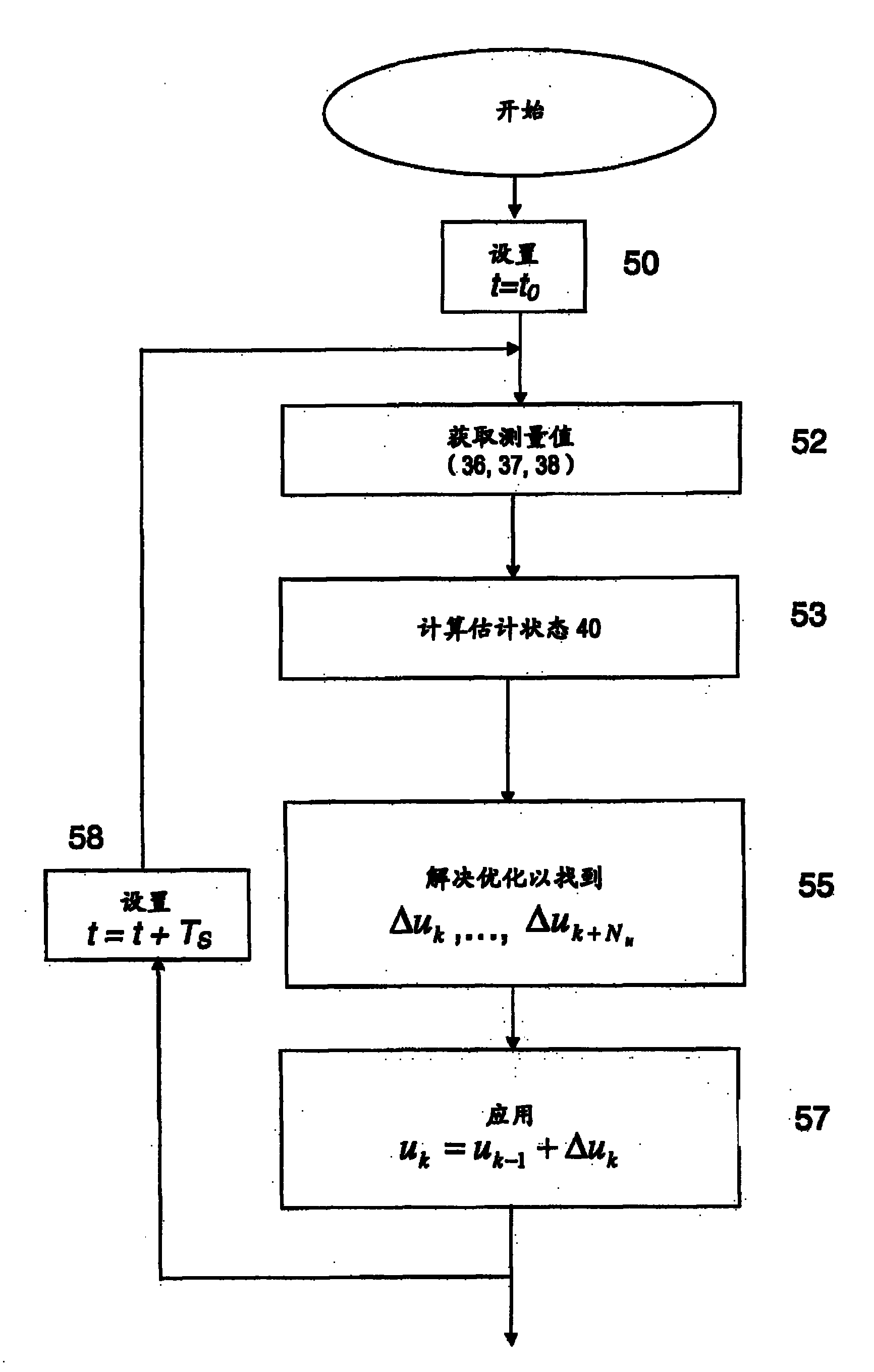

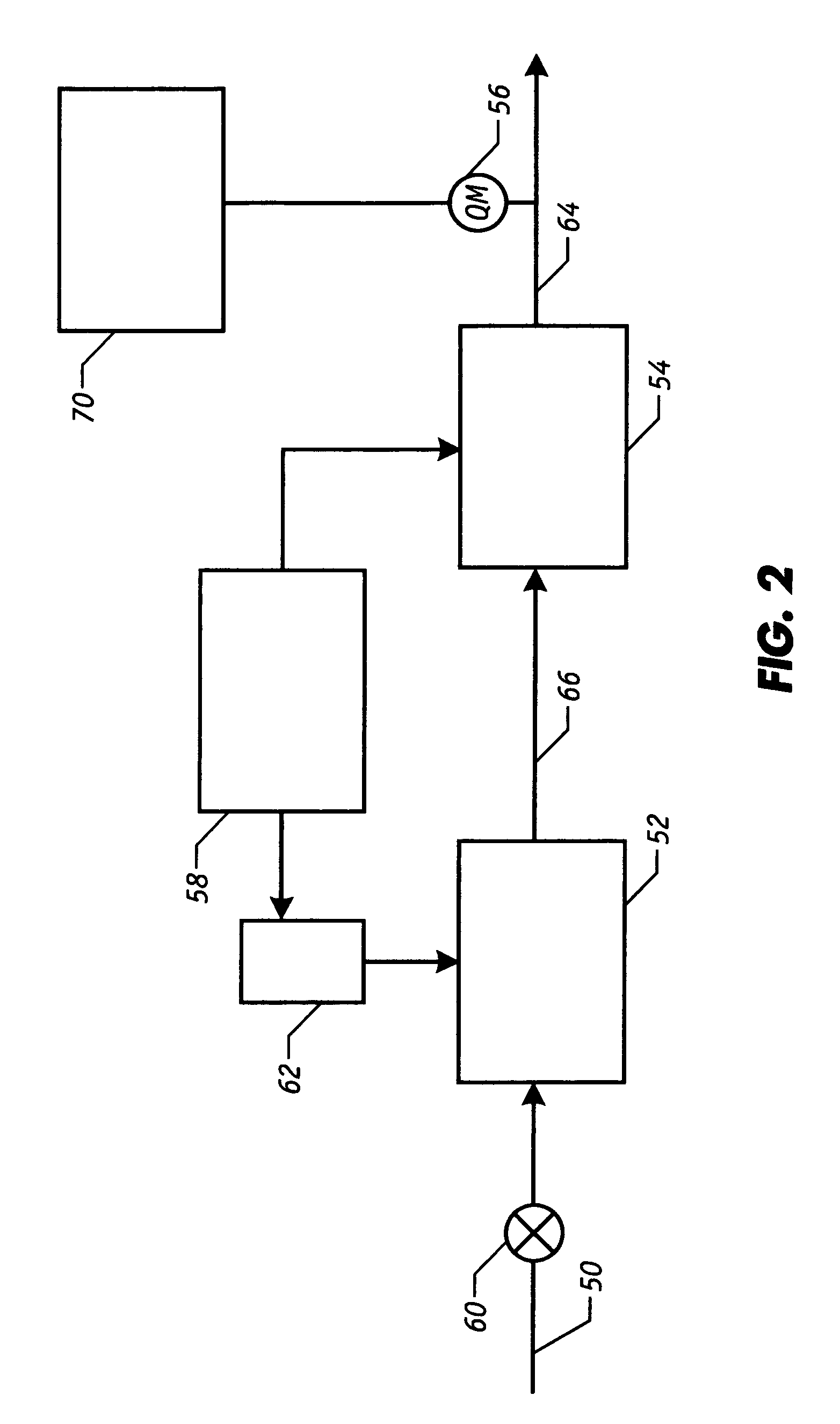

System and method for optimizing lignocellulosic granular matter refining

A system and method for optimizing a process for refining lignocellulosic granular matter such as wood chips use a predictive model including a simulation model based on relations involving a plurality of matter properties characterizing the matter such as moisture content, density, light reflection or granular matter size, refining process operating parameters such as transfer screw speed, dilution flow, hydraulic pressure, plate gaps, or retention delays, at least one output controlled to a target such as primary motor load or pulp freeness, and at least one uncontrolled output such as specific energy consumption, energy split, long fibers, fines and shives. An adaptor is fed with measured values of matter properties and measured values of controlled and uncontrolled outputs, to adapt the simulation model accordingly. An optimizer generates a value of the target according to a predetermined condition on a predicted uncontrolled output parameter and to one or more process constraints.

Owner:CENT DE RES & DEV IND DU QUEBEC

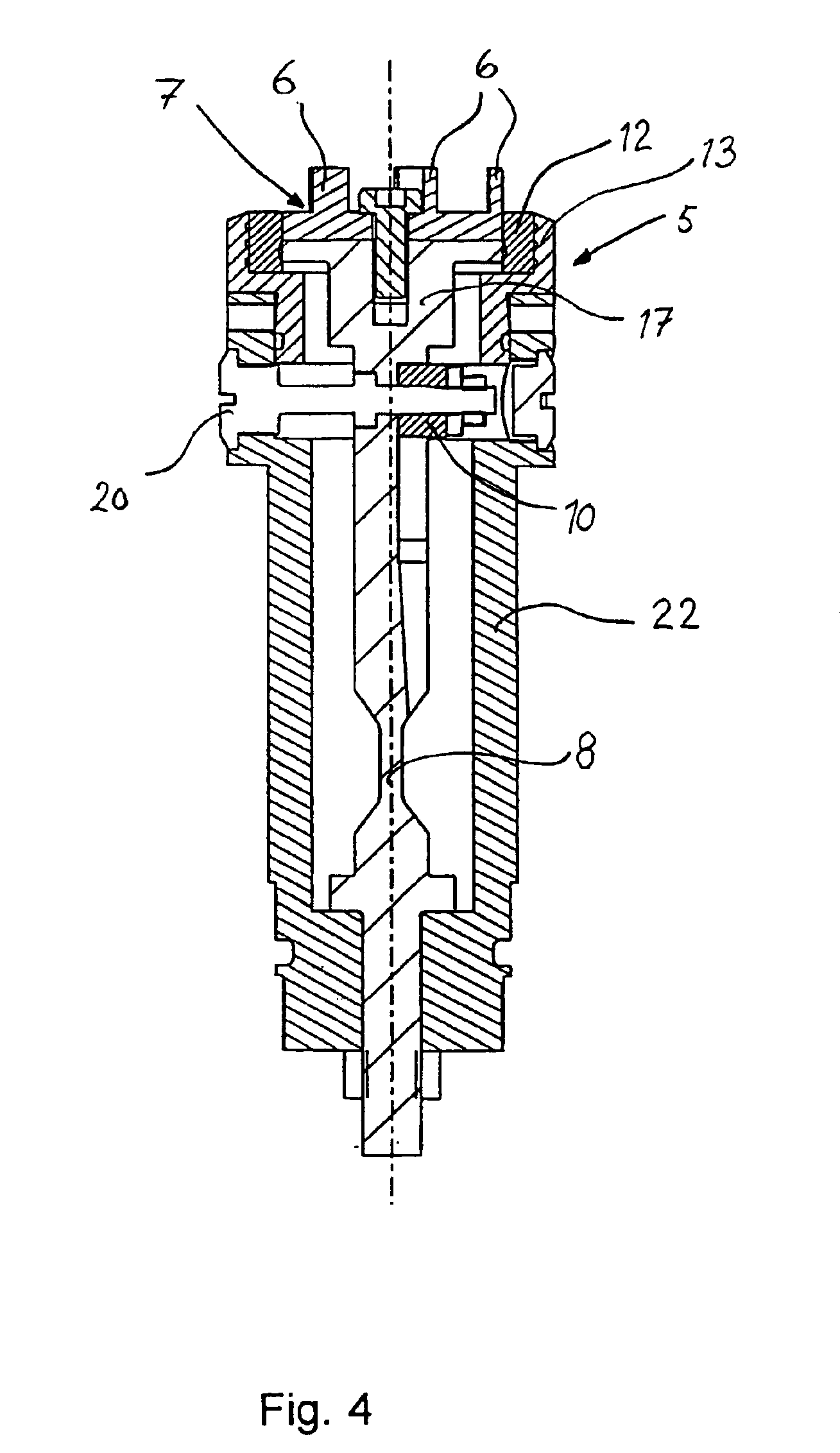

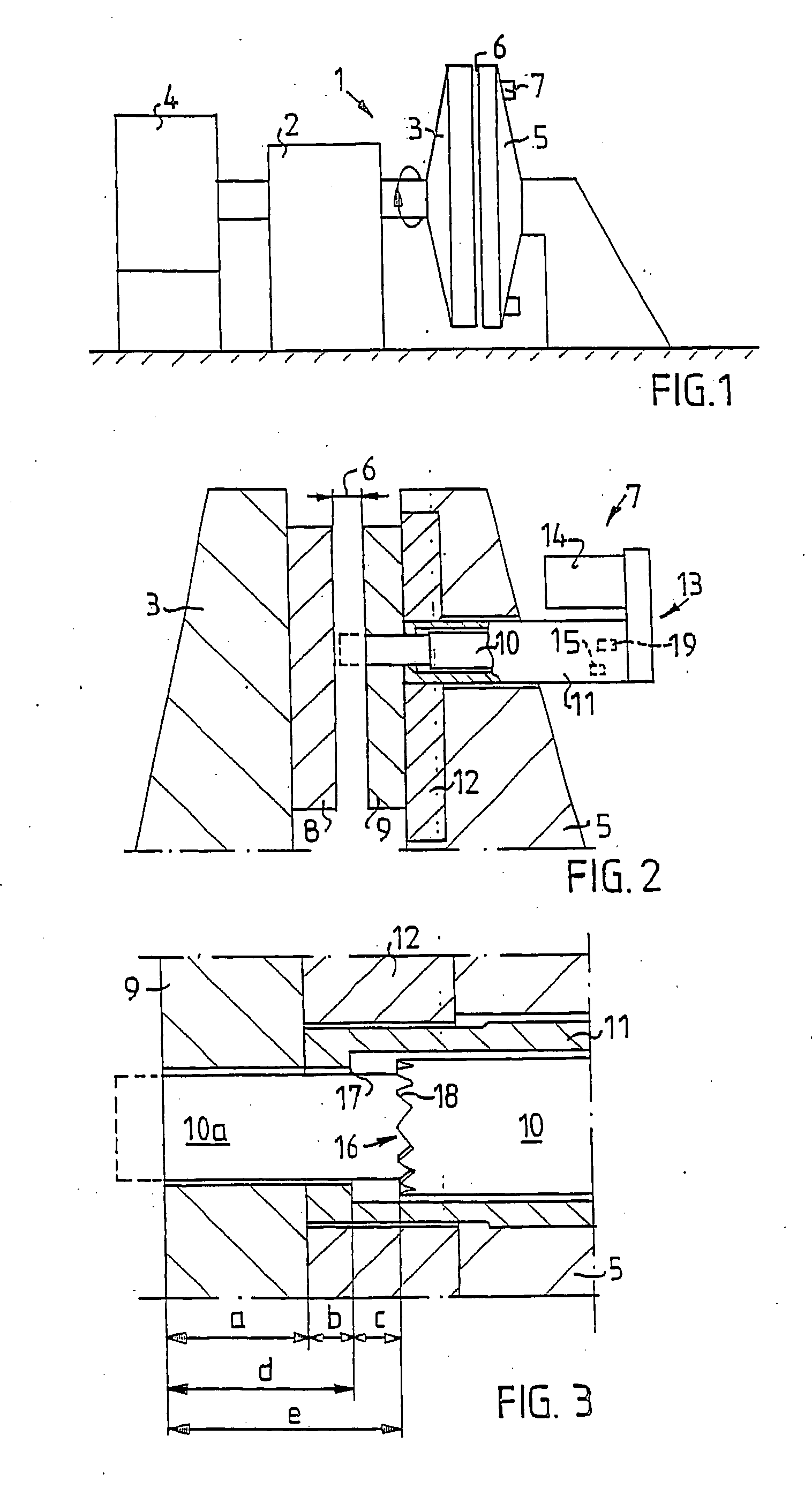

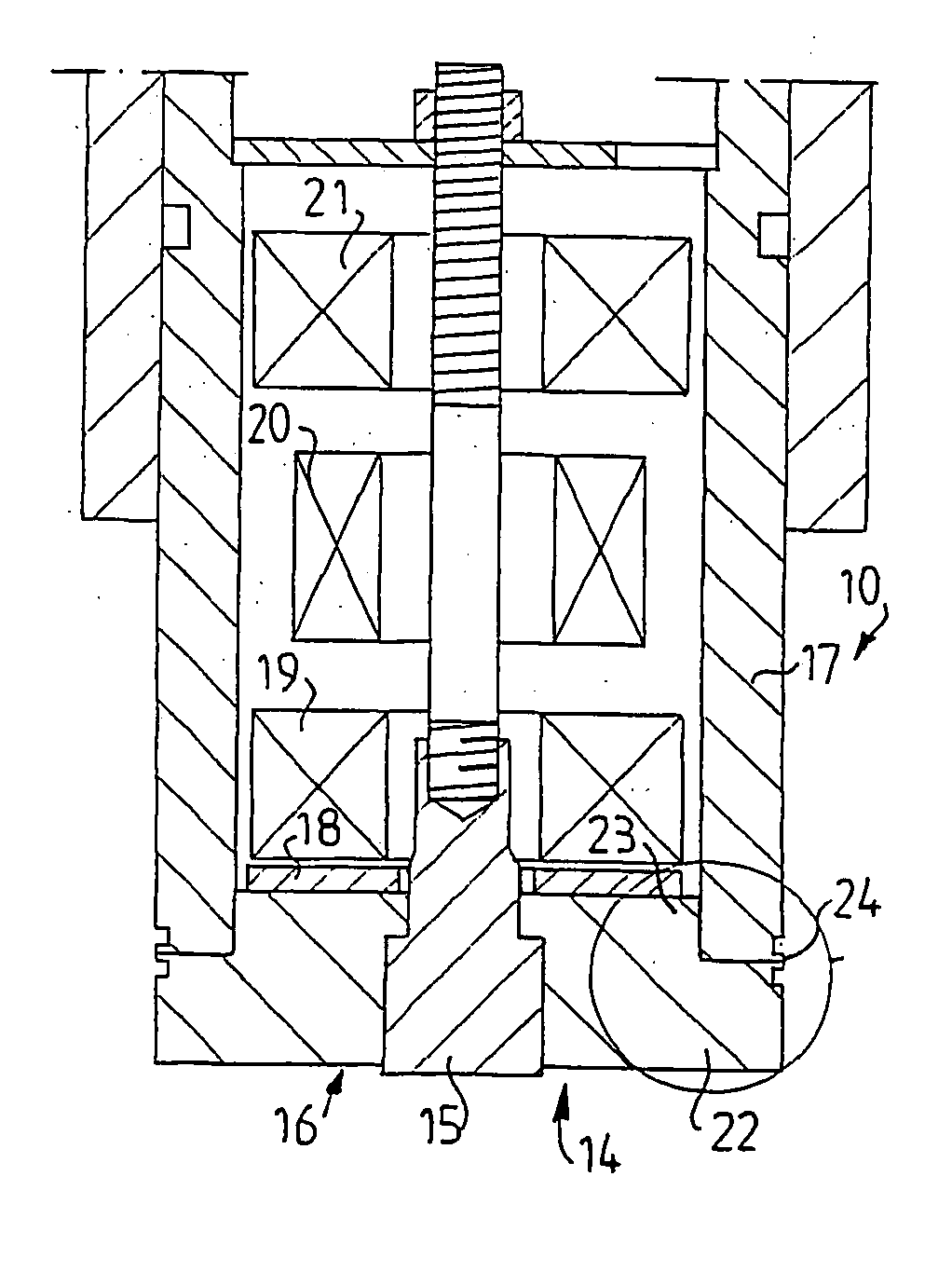

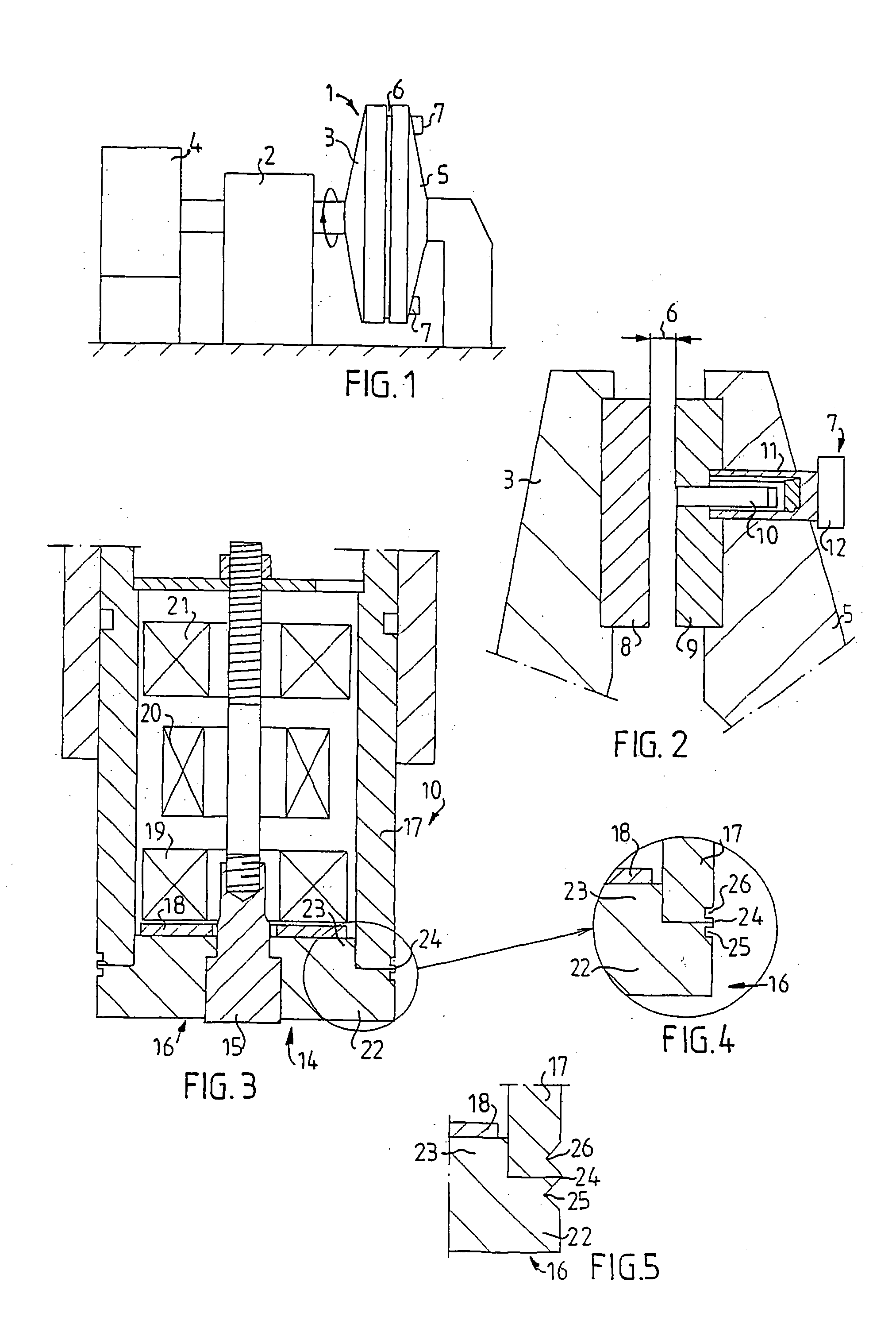

Method and a sensor device for measuring the distance between a stator and an opposing rotor

ActiveUS20070090828A1Accurate CalibrationHigh precisionBeating/refining control devicesUsing electrical meansElectrical and Electronics engineeringStator

A sensor device for measuring distance between a stator and a rotor in a machine is of the magnetic type and is intended to be mounted in the stator in order to interact with an opposing surface on the rotor. A sensor body (10) can be moved axially in a housing (11) mounted in the stator by means of an operating mechanism (13) and has a stop (16) at a predetermined distance (e) from its end surface designed to interact with a corresponding stop (17) inside the housing. This distance (e) exceeds the distance (d) between the stop (17) in the hosing and the end of the sensor body (10) by a predetermined distance (c) when the sensor body is in its normal measuring position. These stops (16, 17) make possible a particularly accurate calibration of the sensor device.

Owner:DAPROKS AB

Procedure and system for control of refiner to improve energy efficiency and pulp quality

InactiveCN102227532AFast control responseBeating/refining control devicesEngineeringMathematical process

Owner:A 卡尔斯托姆

Method and a device for controlling the alignment between refining surfaces

InactiveUS7845583B2Effective controlQuality improvementBeating/refining control devicesReed/straw treatmentEngineeringComparator

Methods and apparatus controlling the alignment between refining surfaces of opposite refining discs are disclosed which are relatively rotatable and which are incorporated in a refiner for disintegrating and refining lignocellulose-containing material in a refining gap between the refining surfaces. The disclosed method includes positioning at least three sensors at least three measurement positions, measuring the vibrations at each of the measurement positions during refiner operation, and comparing each of the measured vibrations at each of the measurement positions with each other. The apparatus disclosed includes at least three sensors disposed in at least three predetermined measurement positions, each of the sensors comprising a vibration sensor disposed on a refining disc for measuring the vibrations at the measurement positions whereby measuring can take place during operation of the refiner and a comparator for comparing the measurements of the measurement positions to provide a comparison therebetween.

Owner:VALMET TECH INC

Rapid sampling assembly for thermo-mechanical pulp control application

InactiveUS20070137806A1Easy to controlEliminate delaysBeating/refining control devicesDigestersLag timeFeedback control

Owner:HONEYWELL INT INC +1

Method of refining wood chips or pulp in a high consistency conical disc refiner

ActiveUS20060180684A1Avoid cloggingImprove consistencyBeating/refining control devicesReed/straw treatmentFiberProduction rate

A method is proposed for improving pulp quality at high production rates on conical disc refiners. It permits a reduction in refining intensity by enabling fibre residence time to increase by increasing consistency, while avoiding the problem of plate plugging normally associated with high discharge consistency. In practice, inlet consistency is increased by the in-feed dilution, flat zone dilution or both, but without allowing the discharge consistency to rise. Instead, the discharge consistency is controlled at a fixed optimum value by the addition of dilution water within the conical zone. The result is that residence time is increased, and refining intensity decreased, by raising the consistency in the inner region of the refining zone, while avoiding the plate plugging caused by excessive consistency in the outer region of the refining zone.

Owner:FPINNOVATIONS INC

Transducer for distance measurement

InactiveUS20040169506A1High measurement accuracyEasy to solveBeating/refining control devicesMagnetic measurementsMechanical engineeringDistance measurement

A transducer (10) for distance measurement, especially between a stator and a rotor in a refiner for paper pulp production, in which the transducer is of the magnetic type and has a tubular casing (17), the one end of which forms a measuring head (14), in which a measuring pole (15) is fitted in a holder (16) which is mounted in the end of the casing (17) and seals this. The holder (16), with a first portion (22) of its axial length, reaches beyond the end of the casing. This first portion (22) and the measuring pole (15) are intended to be able to be worn away to a smaller axial length during use of the transducer, whilst the length of the casing is maintained.

Owner:DAPROKS AB

Method for defibring recycled fiber material in a drum pulper, and a drum pulper

InactiveUS7318880B2Increase rotation speedReduce speedBeating/refining control devicesCork treatment detailsFiberGravitational force

The invention relates to a method for defibering recycled fiber material in a drum pulper provided with a substantially horizontal drum. Recycled fiber material and water are fed to the drum pulper and the drum of the drum pulper is simultaneously rotated. When the drum rotates, the recycled fiber material rises up in the rotating drum and finally, due to gravitational force, falls back down. After falling and hitting to the bottom, the recycled fiber material is defibered, forming a fiber pulp mixture with water. A value of at least one parameter describing the defibration process or fiber pulp properties is measured on the basis of the drum pulper or the resultant fiber pulp mixture, and this value is used for controlling the rotation speed of the drum of the drum pulper. The invention also relates to a drum pulper implementing the method of the invention.

Owner:VALMET TECH INC

Self-aligning and actively compensating refiner stator plate system

InactiveUS7694902B2Improved degree controlImprove performanceBeating/refining control devicesGrinding machine componentsImproved methodActuator

Owner:THERMO BLACK CLAWSON

Refiner disk sensor and sensor refiner disk

InactiveUS20050230511A1Minimize impactPrevent leakageBeating/refining control devicesCocoaFiberEngineering

A sensor, sensor disk, sensor measurement correction system, and method used in measuring a parameter in the refining zone. The sensor includes a spacer that spaces its sensing element from the disk. In one preferred embodiment, the spacer is made of an insulating material that insulates the sensing element from the thermal mass of the disk to prevent the thermal mass from affecting sensor measurement. The sensor includes a housing carried by the spacer that, in turn, carries the sensing element. Where the sensing element is a temperature sensing element, the housing is thermally conductive and the housing and spacer enclose the sensing element. Each sensor is disposed in the refining surface, preferably in its own separate bore in the disk and flush with or below axial refiner bar height. Signals from one or more sensors are processed by a processing device linked to a module containing calibration data that is applied to make sensor measurements more accurate. The module holds calibration data from sensors that are precalibrated before the sensor disk in which they are assembled is shipped, along with the module, to a fiber processing plant where the disk is installed in a refiner and the module connected to the processing device. In one preferred embodiment the sensor or sensors are carried by a sensor module that can be a removable segment of a refiner disk.

Owner:J & L FIBER SERVICES

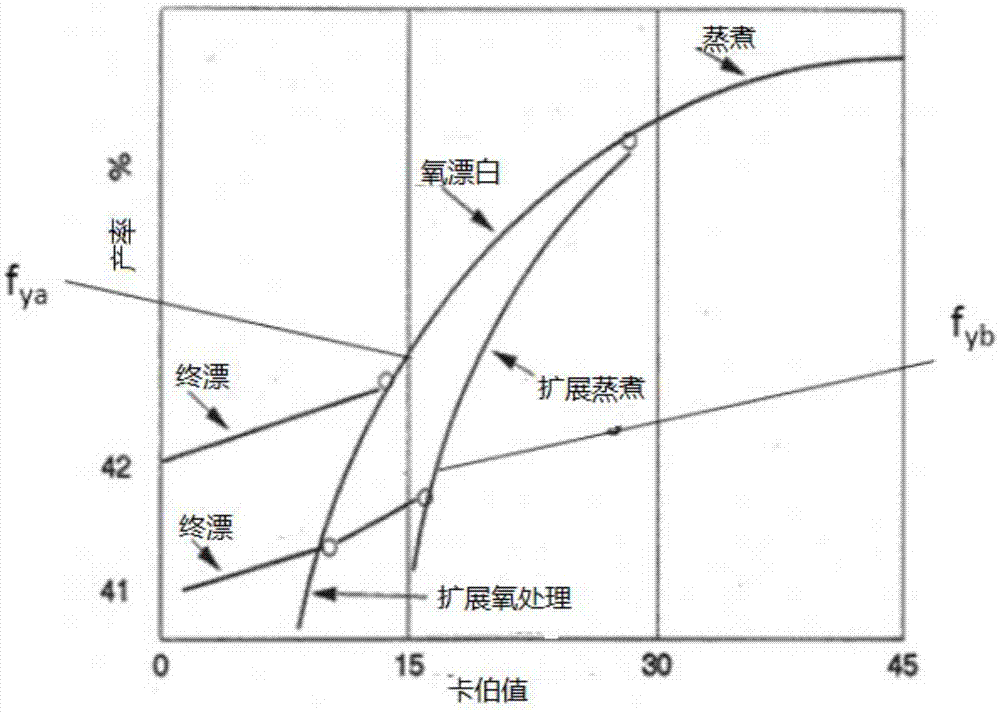

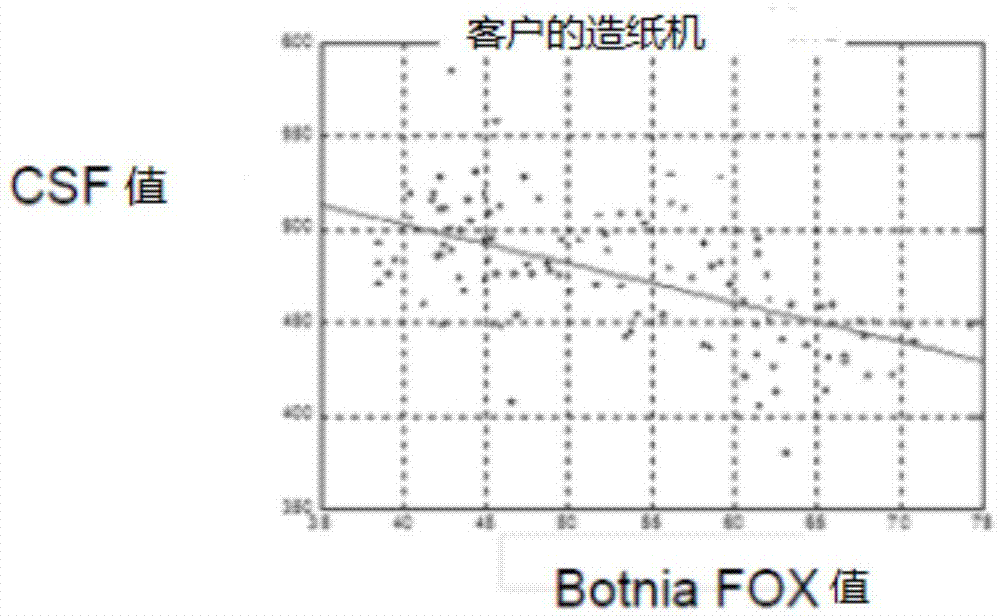

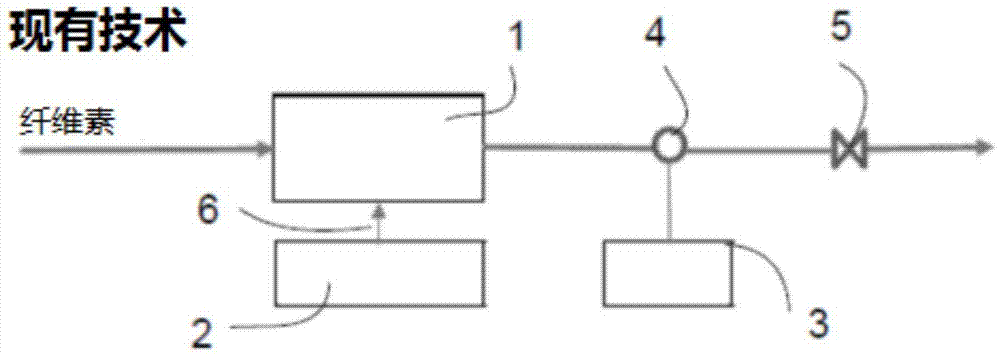

A method and a system for controlling a refiner, for refining a product containing cellulose, such as pulp, and an information of a quality index of the product

ActiveCN105452560AAccurate predictionProcess Control ImprovementBeating/refining control devicesPaper testingCelluloseControl signal

The present invention relates to a method and a system for controlling a refiner, grinder or the like for refining a product containing cellulose, such as pulp. A quality index specific to the product is provided and related to at least one predefined property of a slurry containing the cellulose product, or a finished product made of it. Control signals in response to the quality index is generated to achieve a desired value of the predetermined property, and at least one operating parameter of the refiner is set accordingly. The predefined property is either the tensile strength of said finished product or the Canadian Standard Freeness (CSF) of the slurry.

Owner:芬宝公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com