Automatic control system and method of knife feeding and retracting of dual-disc refiner

An automatic control system and double-disc refiner technology, applied in pulp beating/refining method, beating/refining control device, textile and papermaking, etc., can solve the problems of pulp waste, affecting beating degree, increasing power consumption, etc. Achieve the effect of simple power transmission, reduce feeding time, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical objectives, technical solutions, and beneficial effects of the present invention clearer, the technical solutions of the present invention will be further described below with reference to the drawings and specific embodiments.

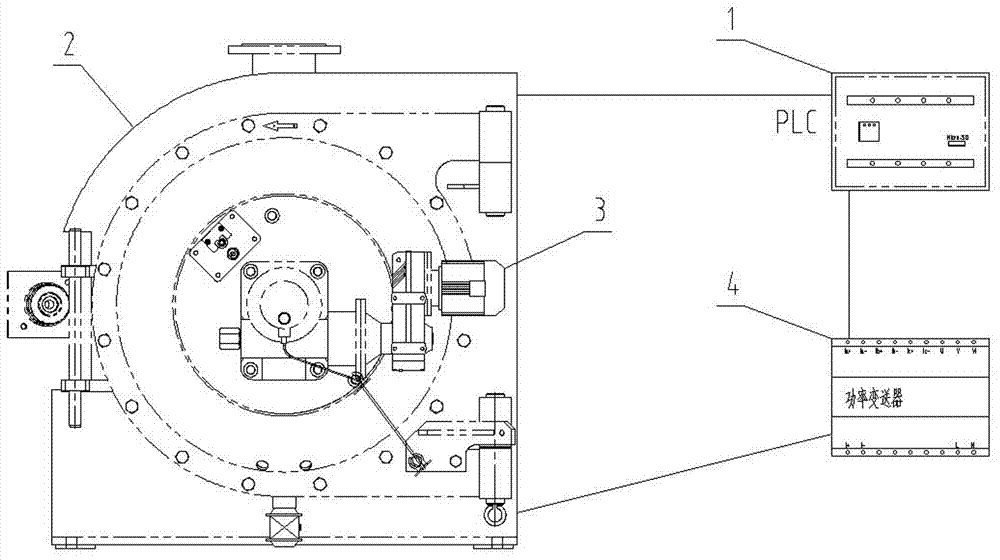

[0030] Such as figure 1 As shown, the present invention includes a control center unit 1, an actuator unit and a signal acquisition unit.

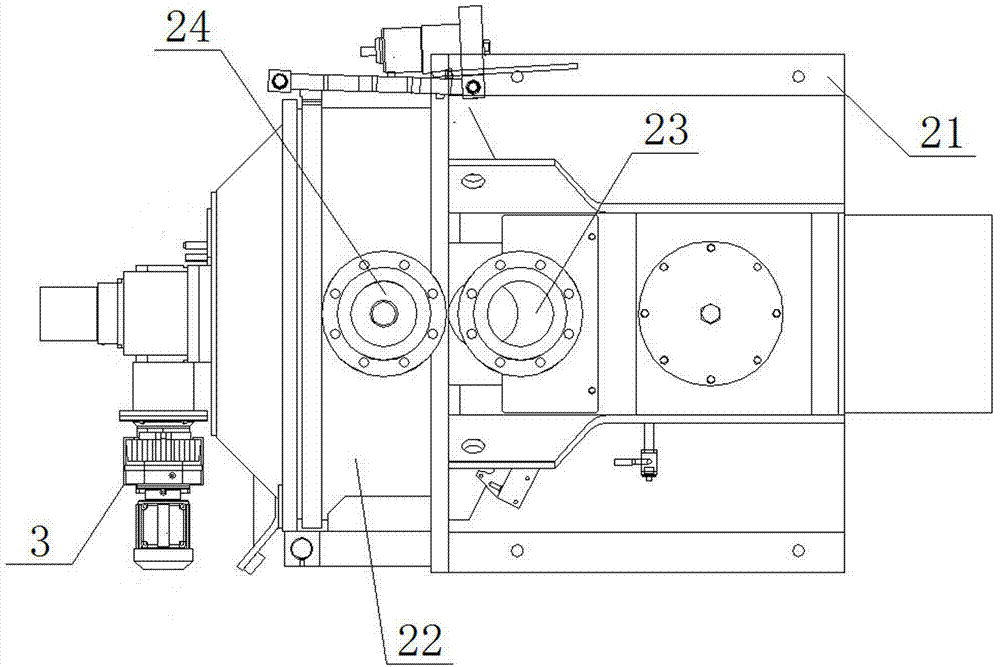

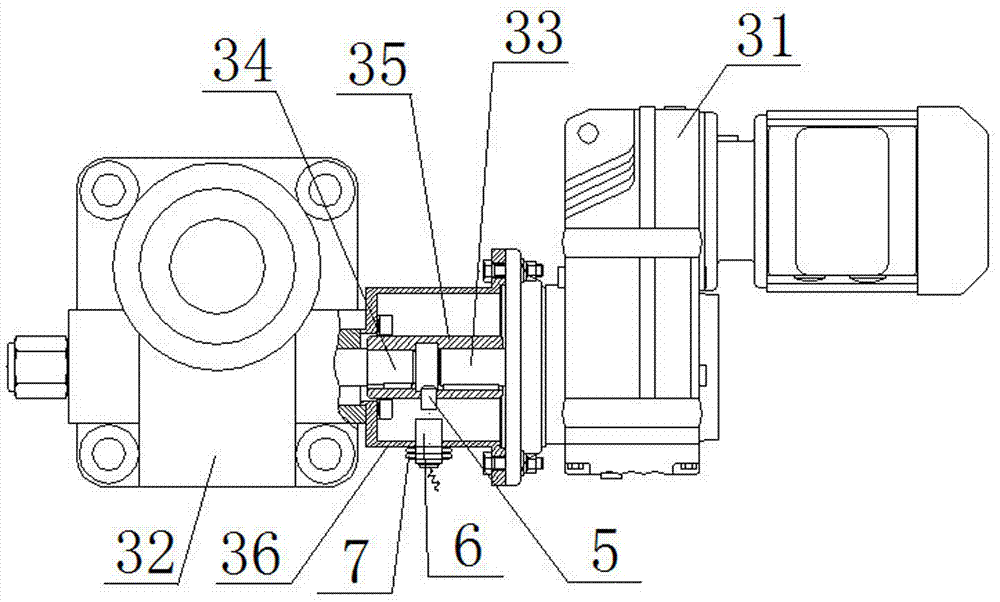

[0031] The actuator unit includes a double-disc refiner 2, which includes a frame 21, a main motor (not shown in the figure), a refining part 22, a pulp inlet 23, a pulp outlet 24 and an inlet For the transmission mechanism 3, the refining part 22 includes a moving seat, a turntable, and a fixed seat in turn from left to right. The space between the moving seat and the turntable constitutes a refining zone, and the space between the turntable and the fixed seat The space constitutes the second refining zone, the left grinding plate is fixed on the right surface of the movable seat,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com